BLACKHAWK! BH8075 User Manual

! ADVERTENCIA

• Leer, comprender, y seguir las instrucciónes antes de utilizar el aparato.

• El manual de instrucciónes y la información de seguridad deben estar comunicado en lengua del operador

antes del uso.

• No seguir estas indicaciónes puede causar daños personales o materiales.

Model Capacity

BH8075 1500 lb

SFA Companies

10939 N. Pomona Ave. Kansas City, MO 64153

sales@blackhawk-automotive.com

Wheel Dolly

Operating Instructions & Parts Manual

Made in PRC

BH8075-M0 rev 12/07

Blackhawk Automotive is a Licensed Trade Mark Made by SFA Companies, Kansas City, MO

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

!

Read this manual and follow all the Safety Rules and Operating Instructions before using this product.

2

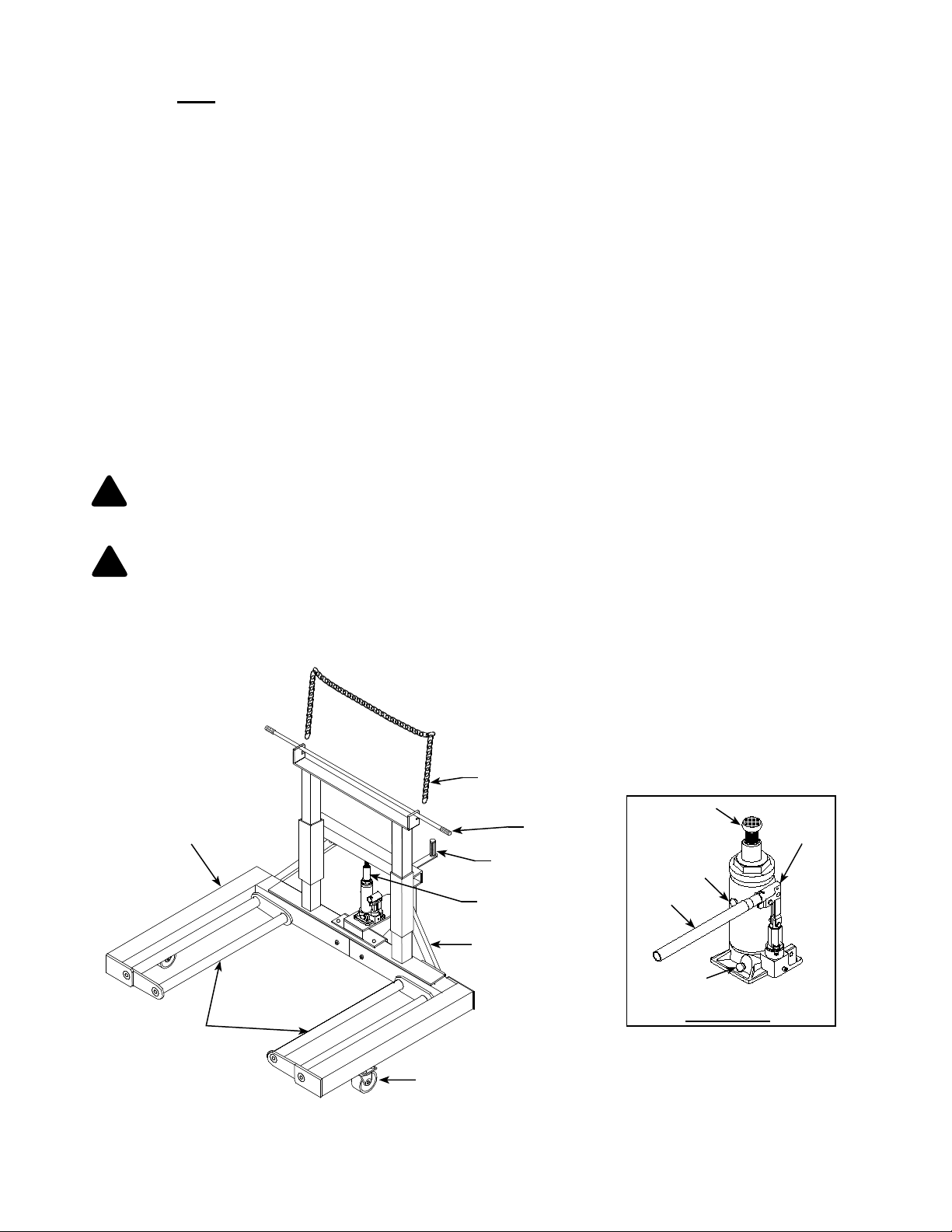

Main Frame

Front Caster

Load Leveler

Chain

Handle

Support Strap

Hydraulic Unit

Figure 1 - Wheel Dolly Components

SAFETY and GENERAL INFORMATION

Save these instructions. For your safety, read, understand, and follow the information provided with and on this wheel

dolly before using. The owner and/or operator of this equipment shall have an understanding of this equipment and

safe operating procedures before attempting to use. The owner and/or operator shall be aware that use and repair

of this product may require special skills and knowledge. Instructions and safety information shall be conveyed in

the operator’s native language before use of this product is authorized. If any doubt exists as to the safe and proper

use of this wheel dolly, remove from service immediately.

Inspect before each use. Do not use if broken, bent, cracked, or damaged parts (including labels) are noted. Any

wheel dolly that appears damaged in any way, operates abnormally or is missing parts, shall be removed from service

immediately and the manufacturer notified. If you suspect that the product was subjected to a shock load (a load

dropped suddenly, unexpectedly upon it), immediately discontinue use until it has been checked by a factory authorized

service center (contact distributor or manufacturer for list of Authorized Service Centers). It is recommended that an

annual inspection be done by qualified personnel. Labels and owner’s manuals are available from manufacturer.

PRODUCT DESCRIPTION

Hydraulic wheel dolly is designed to facilitate the removal and installation of pneumatic tires and wheel assemblies

found on many trucks, buses and trailers. This is NOT suitable for use as a wheel and tire puller. It is designed ONLY

for use in removing up to rated capacity tire and wheel assemblies which are not bound and/or seized up at the brake

drum or hub assemblies. This device is designed to be used in conjunction with jacks and jack stands

NEVER load this device with more than the weight of the wheel assembly to be removed! ENSURE that the

vehicle is securely positioned and supported by mechanical means such as a pair of appropriately rated

jack stands or cribbing and blocking.

NEVER use a wheel dolly as a wheel pulling device. Before transporting wheel assembly ensure that it is

free from the hub or drum assembly and that it is secured to the wheel dolly using the provided securing means.

NEVER load this device with more than the weight of the wheel assembly to be removed!

!

!

Lifting Arms

Saddle

Handle

Sleeve

Hydraulic Unit

Oil Filler

Plug

Handle

Release

Valve

3

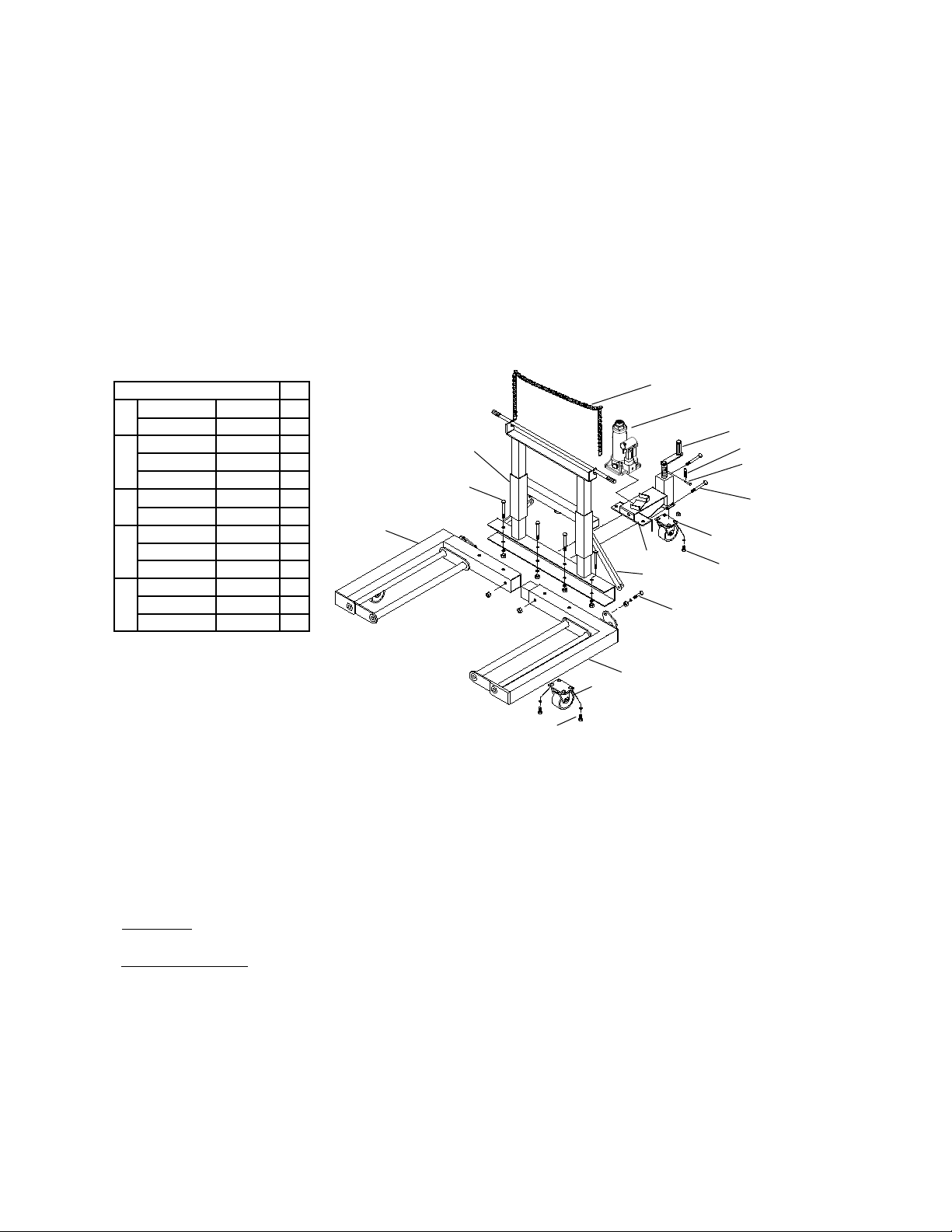

Figure 2 - Assembly Illustration for Model BH8075

PREPARATION

Assembly (refer to Fig. 1 & 2)

1. Attach 3 1/2" caster (1) to left and right main frame (2 & 3) with bolts & washers (4).

2. Attach 5" caster (5) to rear support (6), with bolts, washers & nuts (7).

3. Insert left main frame (2) into right main frame (3).

4. Attach upright (8) and rear support (6) into the main frame assembly (2 & 3) with two bolts &

nuts (9) and four bolts, washers & nuts (10).

5. Attach support straps (11) to the mouting ears of upright and main frame with bolts, washers

and nuts (12).

6. Attach hydraulic unit (13) onto the upright assembly (8).

7. Insert load leveler handle (14) to rear support (6) with pin and cotter pin (15 & 16).

8. Attach the chain (17) onto upright assembly.

BEFORE USE

1. Verify that the product and the application are compatible, if in doubt call Blackhawk tech. service (816) 891-

6390.

2. Before using this product, read the operator's manual completely and familiarize yourself thoroughly with the

product, its components and recognize the potential hazards associated with its use.

3. To familiarize yourself with basic operation; position the hydraulic unit upright as shown in Fig. 1, engage the

release valve with the slotted portion of the provided handle, then turn the release valve:

a. Clockwise until firm resistance is felt to further turning. This is the ‘CLOSED’ release valve position used to

raise the load.

b. Counter-clockwise, but no more than 1 turn from the closed position. This is the ‘OPEN’ release valve position

used to lower the load.

4. With saddle fully lowered, remove the oil filler plug. Insert the handle into the handle sleeve; then pump 6 to 8

full strokes. This will help release any pressurized air which may be trapped within the reservoir. Check oil level.

Proper oil level is level with the oil filler plug hole. Adjust as needed, reinstall the oil filler plug.

5. Place the hydraulic unit to the wheel dolly as shown in Fig. 1. Position the hydraulic unit such that the saddle

mates with the provided indentation.

6. Check to ensure that wheel dolly rolls freely, that the pump and release valve operate smoothly. Raise and lower

the unloaded wheel dolly throughout the lifting range before putting into service. Replace worn or damaged parts

and assemblies with

Factory Authorized Replacement Parts only.

13

17

14

16

9

15

6

5

7

1

2

4

Size of Hardware Kits Qty

3 bolt M8x16 8

lock washer

M8 8

7 bolt M8x16 4

lock washer M8 4

nut M8 4

9 bolt M12x100 2

nut M12 2

10 bolt M14x110 4

washer M14 4

nut M14 4

12 bolt M8x34 4

lock washer M8 4

nut M8 4

3

8

10

11

12

Loading...

Loading...