Page 1

BUGIC&DEeKER

PROFESSIONAL

WM2000 FOLDfiWAY WORKBENCH

OPERATING INSTRUCTIONS

743190

Page 2

FOLDfiWAY PROCEDURE

Fig. 10

V-.*- ' ■

The WM2000 folds flat for storage,

carrying or taking to the workplace.

To fold away it is important that the

following procedure is followed.

Ensure that the centreboard is securely

clamped between the two vice jaws fig. 10

or removed altogether.

Place WM2000 flat on its work top fig. 2

and release the metal struts on the front

pair of legs and fold away.

Repeat liiis exercise for the rear legs

ensuring that the retaining latches are

engaged to hold the rear legs securely.

SAFETY INSTRUCTIONS

Do not use crossmembers as a stepladder or stand on top of the WM2000.

Never drop heavy loads onto your WM2000 always ensure that they are gently placed into

position.

Although your WM2000 can be used to provide a secure and safe mount for power tools and

attachments (use vice pegs to secure units), it is important to always disconnect the power tool

from the mains supply when setting up or making adjustments.

Check all moving parts, pivots etc for wear, damage or looseness.

Please note:

“Do not carry your WM2000 by the vice jaws. We recommend the use of the front crossmember

as a suitable carrying point. Ensure the centre board is either removed or secure before

transporting”.

Always ensure the WM2000 is used on a flat level surface.

Always locate safety locks by pressing firmly on each vice jaw before use.

Page 3

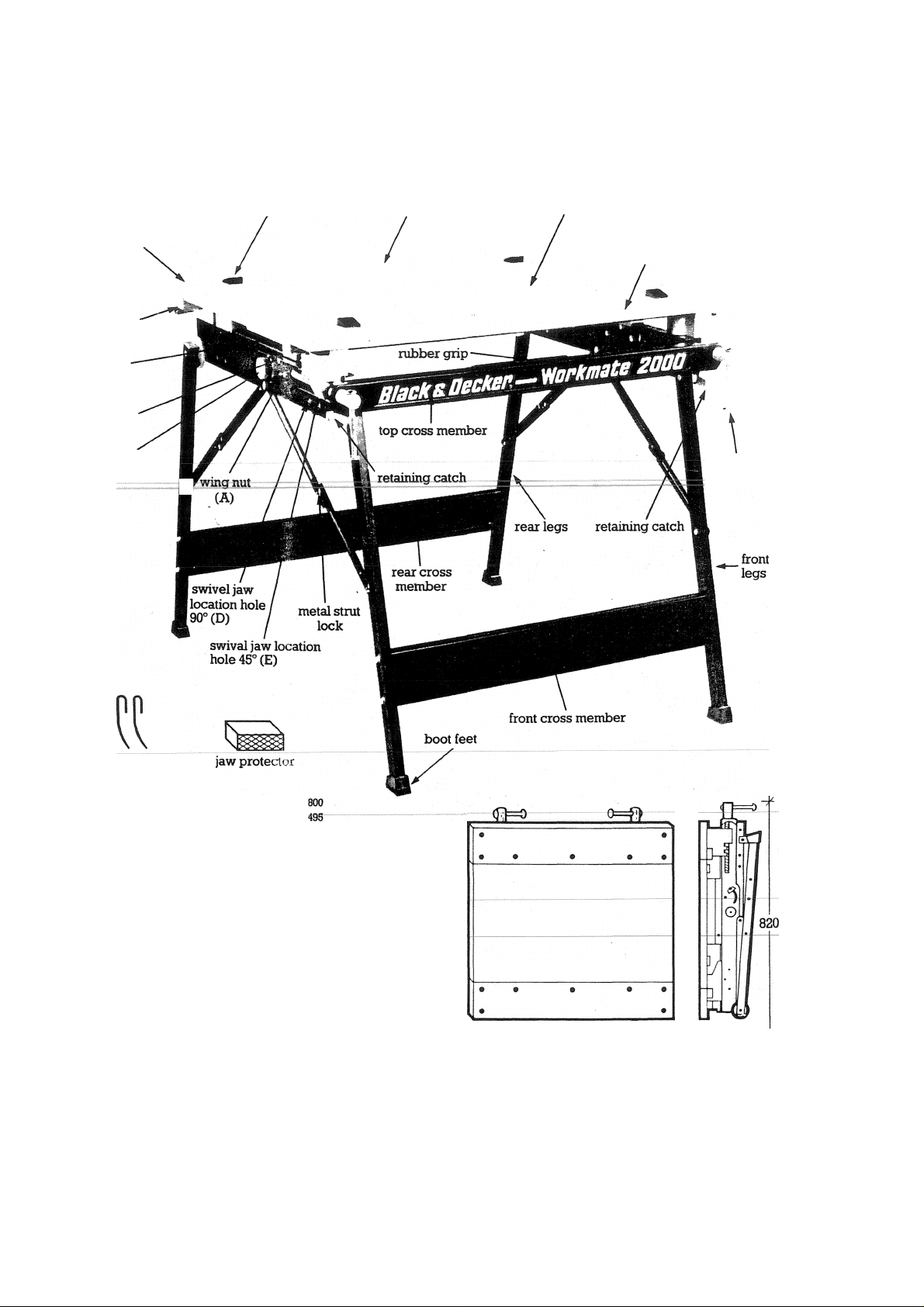

WM 2000 FOLDHWAY WORKBENCH

vice boles

snap l^k

mechanisiii

parallel

rails

hexagonal

nut (C)

cam lock

mechanism (B)

vice pe^

removable rear vice jaw

centre board

swivelling vice jaw

tommy bar

handles

metal drawing

board brackets

Working height

Max. vice jaw opening (mm)

(Centre board removed WM2000)

Work surface dimensions (mm) (L x W x II)

Vice jaw dimensions (nun) (L x W x H)

Centre board dimensions (mm) (L x W x II)

Max. vice jaw opening (mm)

(Centre board in workbench position)

Max. vice jaw opening 45° (mm)

Max. vice jaw opening ^° (mm)

(Centre board between lower cross members)

Folded dimensions (mm) (L x W x H)

Weight (Kg)

Standard equipment

ACCESSORIES Vice pegs (set of 4)

Fig.l

900 X 730 x 20

900 X 115 X 20

900 X 490 X 20

85

135

625

mxmK$m

■m

4 X vice pegs

2 X drawing board brackets

2 X jaw protectors

A»26

4- ^230-^7=

Page 4

ASSEMBLY INSTRUCTIONS

I vviiji me legs iii the

7cr:icm pcGiticr; lock

ihe meia.1 strats as sho'v/n

Fig. 2

Remove the WM2000 from packaging

ensuring that the centreboard is clamped

securely between the vice jaws.

Place the WM2000 on floor as shown in

fig. 2 and release the two retaining

catches and open the first pair of legs,

with the legs in vertical position lock &e

metal struts as shown.

Release the remaining set of legs and

foUow above procedure.

Note: Before placing the WM2000 in the

upright position ensuring all four metal

struts are locked securely.

STANDARD EQUIPMENT

Each WM2000 is supplied with:

(A) Four vice pegs - ideal for clamping

irregular shaped work pieces safely fig. 3.

(B) Two jaw protectors - ideal for

gripping pipes etc, securely either

vertically or horizontally.

(C) Two metal drawing board brackets

as shown in fig. 9.

Page 5

VICE JAWS AND CEOTRE BOARD OPERATION

By loosening the two tommy bar handles

the centreboard can be removed

converting the WM2000 into a large

capacity vice. Each tcxnmy bar works

independently so that the front vice jaw

can be adjusted into a tapered position

when required (fig. 4). The rear vice jaw is

adjusted by a snap lock mechanism

(pressure upwards releases the jaw, and

downwards pressure locks the jaw) and

can be repositioned into a series of

parallel holes (fig. 4).

The centre board can be used between

the two bottom crossframe members

when greater capacity is required fig. 4 &

fig. 7.

rig. 4

VICE JAW AND WOPJtBENCH COMBINED

Slide the centre board base supports (B)

into the rear holes of the appropriate

parallel frame.

Mote; Wiiei; correctly positioned a slight

gap remains between the rear vice jaw

and the centre board (A) (fig. 5).

Page 6

LARGE CAPACITY CLAMPING PRESS AND

90° VICE ADJUSTMENT

The swivel vice jaw can be locked in six

different 90° positions 3 front facing and 3

rear facing.

To position the swivelling vice jaw at 90°

remove the wing nuts (A) and hexagonal

nuts (C) and rotate cam lock (B) clockwise

through 45°.

Remove swivel vice jaw and reposition in

one of the above 6 positions. Secure the

swivel vice jaw following the above

procedure in reverse order.

Note: remember to use the swivel jaw

clamping press location holes (D) fig. 1.

Fig. 7

Fig. 7 shows the centre board between the

two bottom cross frames as described in

fig. 4. Allowing for greater clamping

capacity.

NOTE: The adjustable vice jaw should

be removed or placed at the end of the

parallel rails.

Page 7

' : • • .' >; - ■ *1».

■S'r .■■vi--

■&■’-; ■ ■ •■ --■

Fig. 8

The swivel jaw can be locked in six

different 45° positions 3 front facing and 3

rear facing.

Follow the procedure shown in 90°

clamping fig. 6 ensuring that the metal

pins of the cam locks are released into the

holes provided for 45° angles. (E) fig. 1.

Fig. 9

The WM2000 can be converted into a

drawing board with the aid of the two

metal brackets provided. Follow the set

up procedure in fig. 6.90° vice adjustment.

Set the swivelling vice jaw as shown in fig.

9. The removable vice jaw should be

either removed as shown in fig. 9. or

positioned at the front end of the parallel

rails.

Lock the metal brackets into the plastic

base supports (rectangtdar supports) of

the centre board and clip over the front

top cross member. As shown, fig. 9.

Page 8

TOOL SERVICING OR REPAIR

For maximum life and safe, efficient operation, we advise that your tool be returned to your nearest

Black & Decker Service Centre for re^ar cleaning, inspection and service, particularly when being

used in extremely arduous conditions. If your tool shows obvious signs of malfunction, damage or

fails to operate, return it to yoiu nearest Service Centre whose address is given in your local Yellow

Pages Directory.

Black & Decker also have Professional Repairing Distributors and Service Agents located in major

towns and cities offering the same high standard of service.

Contact a Black & Decker Service Centre for further details.

THE BLACK AND DECKER GUARANTEE

If your Black & Decker Professional product becomes defective due to faulty materials or

workmanship within 6 months from the date of purchase, we guarantee to replace all defective parts

free of charge or, at our discretion, relace the unit free of charge, provided that:

1. The product has not been misused.

2. Repairs have not been attempted by persons other than our own service staff or the staff of

authorised repairers.

3. Proof of purchase date is produced.

The guarantee is offered as an extra benefit and is additional to consumers statutory rights.

Loading...

Loading...