Page 1

General Safety Rules

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes. Use in well ventilated areas only.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

• Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install a polarized outlet. Do not change the plug in any way. Double insulation

eliminates the need for the three wire grounded power cord and grounded power supply

system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately.Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use and reduce the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in serious

personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair

can be caught in moving parts. Air vents cover moving parts and should be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or key that is

left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off.Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventative safety measures reduce

the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

Service

• Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Specific Safety Rules

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

• Keep hands away from cutting area. Never reach underneath the material for any reason.

Hold front of saw by grasping the contoured gripping area. Do not insert fingers or thumb into

the vicinity of the reciprocating blade and blade clamp. Do not stabilize the saw by gripping

the shoe.

• Keep blades sharp. Dull blades may cause the saw to swerve or stall under pressure.

• When cutting pipe or conduit ensure that they are free from water, electrical wiring, etc.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHAapproved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

The label on your tool may include the following symbols.

V..............volts

A..............amperes

Hz............hertz

W ............watts

min ..........minutes

............alternating current

........direct current

no............no load speed

............Class II Construction

SPM ........strokes per minute

............earthing terminal

............safety alert symbol

INSTRUCTION MANUAL

Cat. No. QP400

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

CAT. NO. QP400 FORM NO. 584825-00 Copyright © 2003 Black & Decker (APR-03) Printed in Czech Republic

VVVVaaaarrrriiiiaaaabbbblllleeee SSSSppppeeeeeeeedddd JJJJiiiigggg SSSSaaaaww

ww

Features

4-POSITION ORBITAL ACTION - For fast smooth cutting in various materials.

DUST COLLECTION SYSTEM - For a cleaner work environment.

ELECTRONIC VARIABLE SPEED - Precise cutting control maintains constant speed

under load.

3/4” (20MM) CUTTING STROKE - Faster cutting and longer blade life.

ROLLER SUPPORT GUIDE - Longer blade life and improved accuracy.

ADJUSTABLE SHOE - Can be tilted at angles up to 45 degrees for bevel cutting.

ANTI-SPLINTERING DEVICE - Reduces splintering of workpiece.

CHIP SHIELD - Retractable see-through chip shield deflects wood chips when lowered for

dust extraction.

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

IF YOU SHOULD HAVE A QUESTION OR

EXPERIENCE A PROBLEM WITH YOUR

BLACK & DECKER PRODUCT,

CALL 1-800-544-6986

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION AV AILABLE, CATALOG No.,

TYPE No., AND DATE CODE (e.g. 0130M). IN MOSTCASES, ABLACK & DECKER REPRE-

SENTA TIVE CAN RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE ASUGGES-

TION OR COMMENT, GIVE US ACALL. YOUR FEEDBACK IS VITALTO BLACK & DECKER.

Page 2

PROJECT TIPS

1.) Jigsaws cut on the upward stroke. T o minimize chipping of the finished workpiece, turn

the workpiece over with the “good” side down.

2.) Use plastic shoe cover provided to prevent marring surfaces.

3.) T o make more accurate circles and straight cuts, utilize a straight and circle cutting guide.

(Sold separately.)

4.) To optimize cutting performance, select the appropriate speed and orbital action setting

to match the material you are cutting.

5.) For best performance, use sharp, high quality blades.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service

personnel, always using identical replacement parts.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could be haz-

ardous.

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair, or

genuine factory replacement parts, contact the Black & Decker location nearest you. To find

your local service location, refer to the yellow page directory under "Tools—Electric", call:

1-800-544-6986 or visit www.blackanddecker.com

Limited Three Year Warranty

Black & Decker (U.S.) Inc. warrants this product for three years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge in

either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under "ToolsElectric" in the yellow pages of the phone directory and available on our website

www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state. Should you have any questions,

contact the manager of your nearest Black & Decker Service Center.

USE OF EXTENSION CORDS

Make sure the extension cord is in good condition before using. Always use the proper size

extension cords with the tool – that is, proper wire size for various lengths of cord and heavy

enough to carry the current the tool will draw. Use of an undersized cord will cause a drop in

line voltage resulting in loss of power and overheating. For proper size cords see chart

below.

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your

tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. Arating

of 120 volts AC/DC means that your tool will operate on standard 60 Hz AC or DC power . This

information is printed on the nameplate. Lower voltage will cause loss of power and can

result in over-heating. All Black& Decker tools are factory-tested; if this tool does not operate,

check the power supply.

SAVE THESE INSTRUCTIONS

OPERATION

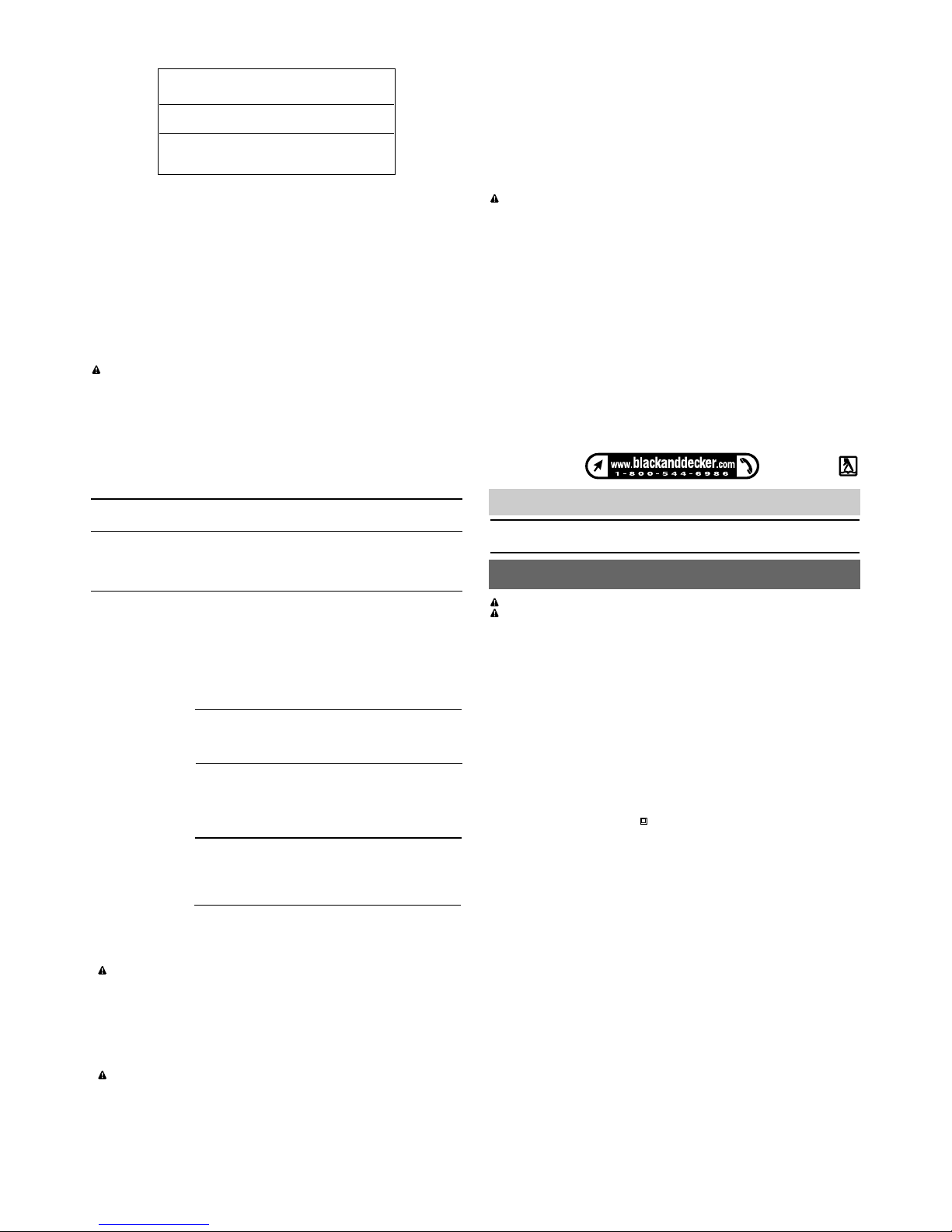

OFF/ON SWITCH

To turn the tool “ON” squeeze the switch trigger, as shown in Figure 1. To turn the tool “OFF”

release the switch trigger. To lock the tool “ON” for continuous use, squeeze the trigger and

hold it while you depress the switch lock located as shown in Figure 2. Hold the switch lock

button in while you release the trigger. Release the switch lock button and the tool will

continue to run. To turn the tool “OFF” from a locked “ON” condition, squeeze and release

trigger once.

INSTALLING A SAW BLADE

WARNING: Make sure that the tool is switched off and unplugged and that the saw blade

has stopped. Used saw blades can be hot.

Slide the clear plastic chip shield up all the way. Using the hex wrench supplied, loosen

(counterclockwise) the two blade clamping screws shown in Figure 3. Select a blade and

insert the blade shank as far as possible into the blade holder. Make sure that the back edge

of the blade rests in the center of the support roller, as shown in Figure 4. With the blade thus

installed, tighten the two blade clamping screws firmly.

ELECTRONIC SPEED CONTROL

Your jigsaw is equipped with electronic speed control that enables you to maintain a selected

speed even as the cutting load increases. Rotate the Variable Speed Dial on top of the tool to

the desired number, as shown in Figure 5. The setting on the wheel can be adjusted at any

time whether the jigsaw is running or not. Consult T able 1 to find the recommended speed for

a particular job.

TABLE 1

Material Suggested Speed Setting

Wood ...............................................6-Max.

Metal ...............................................2-3

Aluminum...........................................3-5

PVC....................................................3-4

Ceramic..............................................3-5

ORBITAL ACTION

Your saw is equipped with an orbital action feature that adjusts the aggressiveness of the

blade angle. As the blade comes up on its cutting stroke, the blade teeth can be thrust

forward for a more aggressive cut or drawn up in a conventional manner to give a standard

cut.

Refer to T able 2 to determine the proper setting of this feature. To adjust for a particular cut,

slide the indicator bar to align with the desired number (0,1, 2, 3) as shown in Figure 6.

TILTING SHOE

WARNING:Make sure that the tool is switched off and unplugged and that the saw blade

has stopped.

For making bevel cuts, your saw has a tilting shoe that tilts as far as 45° left and right. To

adjust the shoe, use the hex wrench to loosen the two screws in the bottom of the shoe, as

shown in Figure 7.

With the screws loosened, pull the shoe slightly forward and tilt it to the desired angle, as

shown in Figure 8. Alternately you can push the shoe slightly backward and lock it into any of

the fixed lock points at 0, 15, 30, and 45°. After setting the shoe angle, tighten the two

screws securely. NOTE: When making any angled cut (other than 0°) the plastic chip shield

must be pushed up all the way. Failure to do so will cause serious damage to the chip shield.

DUST EXTRACTION SYSTEM

CAUTION: Do not use vacuum adapter when cutting metal. Metal filings will be hot and

may cause a fire.

Your saw can be fitted for dust extraction by inserting the included dust extraction adaptor

into the hole in the rear of the tool, as shown in Figure 9. Align the arrows, insert and turn

clockwise to lock in place, as shown in the figure.

Your own standard vacuum hose will fit either over or inside the adaptor.

Lower the chip shield and the vacuum cleaner will automatically remove debris.

NOTE: It is recommended that the chip shield is only lowered for dust extraction purposes.

ANTI-SPLINTER DEVICE

To fit the anti-splinter device, insert it from the bottom of the shoe, as shown in Figure 10.

NOTE: The anti-splinter device can be used only when the shoe is set at 0° of angle.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

TABLE 2

WOOD METAL PLASTICS

Fast Cuts ____ Plastics

Thick Workpieces ____ Fiberglass,

Acrylic

Plywood, Chipboard Aluminum, Non-ferrous _____

Thin Workpieces Sheet Metal _____

Fine Cuts

SETTING # 3

SETTING # 2

SETTING # 1

SETTING # 0

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

GUIDE D’UTILISATION

SSSScccciiiieeee ssssaaaauuuutttteeeeuuuusssseeee àààà vvvviiiitttteeeesssssssseeee vvvvaaaarrrriiiiaaaabbbbllllee

ee

Règles de sécurité – Généralités

AVERTISSEMENT : Lire, comprendre et suivre toutes les directives précisées ci-dessous,

y compris les consignes de sécurité, afin d’éviter les risques de choc électrique, d’incendie ou

de blessure grave.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

• S'assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et

des endroits sombres présentent des risques d'accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs explosives (comme

celles dégagées par des liquides, des gaz ou des poussières inflammables). Les

étincelles générées par le moteur des outils électriques peuvent enflammer les poussières

ou les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu'on utilise

un outil électrique. Une distraction peut entraîner la perte de maîtrise de l'outil.

MESURES DE SÉCURITÉ RELATIVES À L'ÉLECTRICITÉ

• Les outils à double isolation comportent une fiche polarisée (une lame plus large que

l'autre). La fiche n'entre que d'une façon dans une prise polarisée. Lorsque la fiche

n'entre pas à fond dans la prise, essayer de nouveau après avoir inversé les broches

de la fiche. Si la fiche n'entre toujours pas dans la prise, communiquer avec un

électricien certifié afin de faire installer une prise polarisée. Ne modifier en aucune

façon la fiche. La double isolation élimine le besoin d'un cordon trifilaire mis à la terre et

d'un système d'alimentation mis à la terre.

• Éviter de toucher à des surfaces mises à la terre comme des tuyaux, des radiateurs,

des cuisinières et des réfrigérateurs. Les risques de secousses électriques sont plus

élevés si le corps de l'utilisateur est mis à la terre.

• Protéger les outils électriques de la pluie ou des conditions mouillées. Une infiltration

d'eau dans l'outil augmente les risques de secousses électriques.

• Manipuler le cordon avec soin. Ne jamais se servir du cordon afin de transporter

l'outil ni tirer sur le cordon pour débrancher l'outil. Éloigner le cordon des sources de

chaleur, des flaques d'huile, des arêtes tranchantes et des pièces mobiles.

Remplacer immédiatement les cordons endommagés. Les cordons endommagés

augmentent les risques de secousses électriques.

• Lorsqu'on utilise un outil électrique à l'extérieur, se servir d'un cordon de rallonge

prévu pour l'extérieur, portant la mention "W-A" ou "W". Ces cordons sont conçus pour

servir à l'extérieur et minimisent les risques de secousses électriques.

SÉCURITÉ PERSONNELLE

• Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu'on utilise un outil

électrique. Ne pas s'en servir lorsqu'on est fatigué ou affaibli par des drogues, de

l'alcool ou des médicaments. De graves blessures peuvent résulter d'un moment

d'inattention lors de l'utilisation d'un outil électrique.

• Porter des vêtements appropriés. Éviter de porter des vêtements amples ou des

bijoux. Recouvrir la chevelure si elle est longue. Éloigner les cheveux, les vêtements

et les gants des pièces en mouvement qui peuvent les happer.

• Éviter les démarrages accidentels. S'assurer que l'interrupteur est en position hors

tension avant de brancher l'outil. Afin d'éviter les risques de blessures, ne pas transporter

l'outil avec le doigt sur l'interrupteur ni brancher un outil dont l'interrupteur est en position

sous tension.

• Enlever les clés de réglage avant de mettre l'outil sous tension. Une clé qui est laissée

sur une pièce rotative de l'outil présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s'assure d'une

meilleure maîtrise de l'outil dans des situations imprévues grâce à une position stable et un

bon équilibre.

• Porter de l'équipement de sécurité. Toujours porter des lunettes de sécurité. Dans

certaines conditions, il faut porter des masques respiratoires, des chaussures

antidérapantes, un casque de sécurité ou des protège-tympans.

UTILISATION ET ENTRETIEN DE L'OUTIL

• Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de

soutenir la pièce à ouvrer sur une plate-forme stable. La pièce est instable lorsqu'elle

est retenue par la main ou le corps de l'utilisateur. Cela présente des risques de perte de

maîtrise de l'outil.

• Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche. L'outil approprié fonctionne

mieux et sûrement lorsqu'on s'en sert à son rendement nominal.

AVANTDE RETOURNER LE PRODUIT, PEUIMPORTE

LA RAISON PRIÈRE DE COMPOSER 1 800 544-6986

Page 3

• Ne pas se servir de l'outil lorsque l'interrupteur est défectueux. Le cas échéant, l'outil

est dangereux et il faut le réparer.

• Débrancher l'outil de la source d'alimentation avant de le régler, d'en remplacer les

accessoires ou de le ranger. On minimise de la sorte le risque de démarrage accidentel de

l'outil.

• Ranger l'outil hors de portée des enfants et de toute autre personne qui n'en connaît

pas le fonctionnement. L'outil est dangereux entre les mains de ces personnes.

• Prendre soin des outils. S'assurer que les outils de coupe sont tranchants et propres.

Des outils bien entretenus à arêtes tranchantes ont moins tendance à se coincer et ils se

maîtrisent mieux.

• Vérifier l'alignement et les attaches des pièces mobiles, le degré d'usure des pièces

ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l'outil.

Faire réparer un outil endommagé avant de s'en servir. Des outils mal entretenus sont la

cause de nombreux accidents.

• Utiliser seulement les accessoires recommandés par le fabricant. Des accessoires qui

conviennent à un outil peuvent présenter des risques avec un autre outil.

ENTRETIEN

• Confier l'entretien de l'outil seulement à du personnel qualifié. Le non-respect de la

présente directive présente des risques de blessures.

• Lors de l'entretien de l'outil, utiliser seulement des pièces de rechange identiques.

Respecter les consignes relatives à l'entretien du présent guide d'utilisation. Il y a

risque de secousses électriques ou de blessures lorsqu'on utilise des pièces non autorisées

ou lorsqu'on ne respecte pas les consignes relatives à l'entretien.

Consignes de sécurité particulières

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en

contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre

les pièces métalliques de l’outil sous tension, engendrant des risques de choc électrique.

• Garder les mains éloignées des zones de coupe. Ne pas mettre les mains sous la pièce

pour quelque raison que ce soit. Saisir la section profilée à l’avant de l’outil. Ne pas mettre

les doigts ou le pouce près de la lame à va-et-vient ni de sa bride de serrage. Ne pas

stabiliser la scie en saisissant le patin.

• Maintenir les lames bien aiguisées en tout temps; les lames usées peuvent faire dévier

la scie ou faire caler le moteur lorsqu’on exerce une pression sur l’outil.

• Lorsqu’on coupe des tuyaux ou des conduits, on doit s’assurer qu’ils ne renferment pas

d’eau ni de fil électrique, etc.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent produire de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique

(comme l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on effectue

ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien

aéré et utiliser le matériel de sécurité approprié, tel un masque anti-poussières spécialement

conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber

par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire anti-poussières approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps.

AVERTISSEMENT : Porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation,

le bruit émanant de ce produit pourrait contribuer à la perte d’audition.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min ..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

construction de classe II

........................borne de terre

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

Caractéristiques et composants

MOUVEMENT ORBITALÀ 4 POSITIONS permettant la coupe rapide et précise de

divers matériaux.

SYSTÈME DE DÉPOUSSIÉRAGE et de ramassage automatique des débris,

assurant un environnement de travail moins polluant.

COMMANDE DE VITESSE VARIABLE ÉLECTRONIQUE permettant de bien

maîtriser l’outil afin d’obtenir une coupe précise tout en maintenant la vitesse

constante sous charge.

COURSE UTILE DE 20 mm (3/4 po) assurant une coupe plus rapide et prologeant la

durée de vie de la lame

DISPOSITIF DE GUIDAGE DU GALET DE SUPPORT qui prolonge la durée de vie

de la lame et rehausse la précision de la coupe.

PATIN RÉGLABLE pouvant être incliné à des angles allant jusqu’à 45 º pour des

coupes en biseau.

DISPOSITIF ANTI-ÉCLATSréduisant l’éclatement du matériau.

DÉFLECTEUR DE COPEAUX escamotable transparent qui fait dévier les copeaux de

bois lorsqu’on l’abaisse en vue du dépoussiérage.

RALLONGES

S’assurer que la rallonge est en bon état avant de l’utiliser. Toujours utiliser une rallonge qui

convient à l’outil, c’est-à-dire dont le calibre des fils, la longueur du cordon et les valeurs nominales correspondent à l‘outil alimenté. L’usage d’une rallonge de calibre insuffisant pourrait

causer une chute de tension entraînant une perte de puissance et une surchauffe. Pour s’assurer qu’on utilise le calibre approprié, consulter le tableau indiqué ci-dessous.

MOTEUR

S’assurer que l’intensité nominale du cordon d’alimentation corresponde à celle indiquée sur la

plaque signalétique; sur cette dernière, la mention «120 V c.a.» signifie que l’outil ne doit être

branché que dans une prise résidentielle standard de courant alternatif de 60 Hz et non pas

dans une prise de courant continu, alors que «120 V c.a. / c.c.» signifie que l’outil peut fonctionner sur une prise standard de 60 Hz de courant alternatif ou continu. Une tension inférieure

à celle indiquée pourrait entraîner une perte de puissance et une surchauffe. Tous les outils

Black & Decker sont soumis à des essais en usine; si cet outil ne fonctionne pas, on doit

d’abord vérifier l’intensité nominale du cordon d’alimentation.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

CONSERVER CES DIRECTIVES

FONCTIONNEMENT

INTERRUPTEUR DE MARCHE-ARRÊT

Enfoncer l’interrupteur à gâchette pour mettre l’outil en marche; le relâcher pour arrêter l’outil.

Pour verrouiller l’outil en position de marche en fonctionnement continu, tel qu’illustré à la figure 1, enfoncer sans relâcher la gâchette et appuyer sur le bouton de verrouillage de l’interrupteur (voir son emplacement à la figure 2). Continuer à enfoncer le bouton de verrouillage en

relâchant la gâchette. Relâcher le bouton de verrouillage de l’interrupteur et l’outil continuera à

fonctionner. Pour arrêter l’outil lorsqu’il est verrouillé en position de marche, enfoncer puis

relâcher la gâchette une seule fois.

INSTALLATION DE LA LAME DE SCIE

AVERTISSEMENT : s’assurer que l’outil est mis hors tension et débranché et que la lame

est complètement immobilisée. Les lames usées peuvent être chaudes.

Glisser le déflecteur de copeaux en plastique transparent jusqu’au fond. Au moyen de la clé à

six pans fournie, desserrer les deux vis de serrage de la lame illustrée à la figure 3, en les tournant vers la gauche. Insérer la tige de la lame choisie aussi loin que possible dans le portelame, en s’assurant que le bord arrière de la lame repose au centre du galet de support (voir

la figure 4). Une fois la lame installée, serrer fermement ses deux vis de fixation.

COMMANDE DE VITESSE VARIABLE ÉLECTRONIQUE

La scie sauteuse est munie d’une commande de vitesse électronique qui permet de maintenir

la vitesse sélectionnée même lorsque la charge de coupe augmente. Tourner le bouton de

réglage de la vitesse situé sur le dessus de l’outil jusqu’au numéro voulu, tel qu’illustré à la figure 5. On peut régler la position indiquée sur la commande, que l’outil fonctionne ou non.

Consulter le tableau 1 pour connaître la vitesse recommandée pour un travail particulier.

TABLE 1

Matériel Réglage de vitesse suggéré

Bois .......................................6 ou max.

Métal .......................................2 ou 3

Aluminium ........................................3 à 5

PVC ........................................3 ou 4

Céramique .......................................3 à 5

MOUVEMENT ORBITAL

La scie est dotée d’une commande de mouvement orbital qui règle l’angle prononcé de la lame.

À mesure que la lame se déplace lors de la coupe, les dents de la lame peuvent être poussées

vers l’avant pour obtenir une coupe plus prononcée ou soulevées normalement en vue

d’obtenir une coupe ordinaire.

Se reporter au tableau 2 afin de déterminer le réglage approprié de ce dispositif. Pour le régler

en vue de réaliser une coupe particulière, glisser la barre indicatrice de manière à l’aligner avec

la position voulue (no 0, 1, 2 ou 3), tel qu’illustré à la figure 6.

PATIN OSCILLANT

AVERTISSEMENT : S’assurer que l’outil est mis hors tension et débranché et que la lame

est complètement immobilisée.

La scie est dotée d’un patin oscillant qui s’incline jusqu’à 45 º vers la gauche ou vers la droite

afin de permettre les coupes en biseau. Pour régler le patin, desserrer les deux vis de fixation

située sur le bas du patin au moyen de la clé à six pans fournie, tel qu’illustré à la figure 7.

Une fois les vis desserrées, tirer le patin légèrement vers l’avant et l’incliner jusqu’à l’angle

voulu (figure 8) ou encore, le pousser légèrement vers l’arrière et le verrouiller dans un des

points de verrouillage fixes à un angle de 0, de 15, de 30 ou de 45 º. Une fois l’angle du patin

réglé, serrer fermement les deux vis. REMARQUE : pousser complètement le déflecteur de

copeaux en plastique vers le haut avant d’effectuer une coupe angulaire (autre que 0 º) afin

d’éviter de l’endommager sérieusement.

SYSTÈME DE DÉPOUSSIÉRAGE

MISE EN GARDE : Ne pas utiliser l’adaptateur du tube d’aspiration pour couper le métal; les

débris métalliques sont chauds et peuvent causer un incendie.

La scie peut être utilisée pour le dépoussiérage; pour ce faire, insérer l’adaptateur fourni à cette

fin dans l’orifice situé à l’arrière de l’outil (figure 9) en alignant les flèches et en le tournant vers

la droite afin de bien l’enclencher (voir la figure).

On peut fixer n’importe quel tube d’aspiration standard sur le dessus ou à l’intérieur de l’adaptateur.

Baisser le déflecteur de copeaux afin de permettre à l’aspirateur de retirer les débris automatiquement.

REMARQUE : On recommande d’abaisser le déflecteur seulement pour extraire la poussière.

DISPOSITIF ANTI-ÉCLATS

Pour fixer le dispositif anti-éclats, on doit l’introduire par le bas du patin, tel qu’illustré à la figure 10.

REMARQUE : On doit toujours régler le patin à un angle de 0 º avant d’utiliser ce dispositif.

CONSEILS

1.) La lame effectue la coupe lorsqu’on remonte la scie. Afin de minimiser l’éclatement de la

pièce terminée, on doit la tourner de manière à orienter le « bon » côté vers le bas.

2.) Utiliser le couvre-patin en plastique fourni afin d’éviter d’endommager les surfaces.

3.) Afin d’obtenir une coupe circulaire ou une coupe droite plus précise, utiliser un guide de

coupe droite ou de coupe circulaire (vendus séparément).

4.) Afin d’optimiser l’efficacité de la coupe, sélectionner la vitesse et la position de la commande

de mouvement orbital qui conviennent le mieux au matériau à couper.

5.) Afin d’obtenir un rendement optimal, utiliser des lames aiguisées de haute qualité.

ENTRETIEN

Nettoyer l’outil au moyen d’un savon doux et d’un linge humide seulement. Ne jamais laisser

de liquide s’infiltrer à l’intérieur de l’outil ni tremper ce dernier dans un liquide quelconque.

IMPORTANT : pour assurer la SÉCURITÉ et la FIABILITÉ de ce produit, toutes les opérations

de réparation, d’entretien et de réglage doivent être effectuées dans un centre de service

autorisé ou par du personnel qualifié; on ne doit utiliser que des pièces de rechange identiques.

ACCESSOIRES

Les accessoires recommandés pour l’outil sont vendus chez les dépositaires locaux ou dans

les centres de service autorisés. Pour obtenir de l’aide concernant un accessoire, composer

le 1 800 544-6986.

AVERTISSEMENT :l’usage d’un accessoire non recommandé peut présenter un danger.

INFORMATION SUR LES SERVICES

Black & Decker dispose d’un réseau complet composé de centres de service et de centres

autorisés situés partout en Amérique du Nord. Tous les centres de service Black & Decker sont

dotés de personnel qualifié en matière d’outillage électrique; ils sont donc en mesure d’offrir à

leur clientèle un service efficace et fiable. Pour obtenir un conseil technique ou une pièce d’origine ou pour faire réparer un outil, on peut communiquer avec le centre Black & Decker le plus

près. Pour obtenir le numéro de téléphone, consulter les pages jaunes sous la rubrique «Outils

- électriques» ou composer le 1 800 544-6986.

TABLEAU 2

BOIS MÉTAL PLASTIQUE

Coupes rapides ____ Plastiques

Matériaux épais ____ Fibres de

verre,

acryliques

Contreplaqué, aggloméré Aluminium, _____

matériaux non ferreux

Matériaux minces, Feuilles de métal (tôles) _____

coupes fines

POSITION no 3

POSITION no 2

POSITION no 1

POSITION no 0

Page 4

GARANTIE LIMITÉE DE TROIS ANS

Black & Decker (U.S.) Inc. garantit ce produit pour une période de deux ans contre tout défaut

de matériel ou de fabrication. Le produit défectueux sera remplacé ou réparé sans frais,

suivant l’une des deux méthodes suivantes.

La première méthode consiste en un échange seulement. On doit retourner le produit au

détaillant qui l’a vendu (pourvu qu’il s’agisse d’un détaillant participant), en respectant les

délais stipulés dans sa politique relative aux échanges (normalement de 30 à 90 jours après

la vente). Une preuve d’achat peut être requise. On doit vérifier la politique de retour du

détaillant pour tout produit retourné après le délai prescrit pour les échanges.

La deuxième méthode consiste à apporter ou à envoyer le produit (prépayé) à un centre

Black & Decker ou à un centre de service autorisé aux fins de réparation ou de

remplacement, selon notre choix. Une preuve d’achat peut être requise. Les centres Black &

Decker et les centres de service autorisés sont répertoriés dans les pages jaunes sous la

rubrique «Outils - électriques».

Cette garantie ne s’applique pas aux accessoires. Elle confère des droits légaux particuliers à

l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un territoire à l’autre.

Toute question doit être adressée au gérant du centre Black & Decker le plus près.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

MANUAL DE INSTRUCCIONES

REGLAS GENERALES DE SEGURIDAD

ADVERTENCIA: Lea y comprenda todas las instrucciones. No seguir todas las

instrucciones enlistadas a continuación puede resultar en choque eléctrico, incendio y(o)

lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las bancas amontonadas y las

zonas oscuras propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados mientras opera una

herramienta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(con una pata más ancha que la otra.) Esta clavija se acoplará únicamente en una

toma de corriente polarizada de una manera. Si la clavija no se acopla al contacto,

inviértala. Si aún así no se ajusta, comuníquese con un electricista calificado para

que le instalen una toma de corriente polarizada apropiada. El doble aislamiento elimina

la necesidad de cables con tres hilos y sistemas de alimentación con conexión a tierra.

• Evite el contacto corporal con superficies aterrizadas tales como tuberías,

radiadores, hornos y refrigeradores. Hay un gran riesgo de choque eléctrico si su cuerpo

hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha

humedad. El agua que se introduce en las herramientas aumenta el riesgo de descargas

eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar una herramienta ni para

desconectarla de la toma de corriente. Consérvelo alejado de calor aceite, bordes

afilados o piezas móviles. Cambie inmediatamente los cables dañados. Los cables

dañados aumentan el riesgo de choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión

marcada "W-A" o "W". Estas extensiones están clasificadas para uso a la intemperie y

para reducir el riesgo de choques eléctricos.

SEGURIDAD PERSONAL

• Esté alerta, concéntrese en lo que está haciendo. Recurra al sentido común cuando

opere una herramienta eléctrica. No opere ninguna herramienta si se encuentra

fatigado o bajo la influencia de drogas, alcohol o medicamentos. Un momento de

desatención mientras se operan herramientas eléctricas puede ocasionar lesiones graves.

• Vístase de manera adecuada. No tenga puestas ropas o artículos de joyería flojos.

Cubra su cabello si lo tiene largo. Conserve su cabello, sus ropas y guantes alejados

de las piezas móviles. Las piezas de vestir flojas, las joyas y el cabello largo pueden

resultar atrapados por las piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor esté en posición de

apagado antes de conectar. Sostener una herramienta con el dedo en el interruptor o

conectarla sin fijarse si el interruptor está en posición de encendido propicia los accidentes.

• Retire las llaves de ajuste antes de encender la herramienta. Una llave que se deja en

una pieza giratoria puede ocasionar lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien apoyados, al igual que el

equilibrio. La posición correcta de los pies y el equilibrio permiten controlar mejor la

herramienta en situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en los ojos. Se deben utilizar

mascarillas contra polvo, zapatos antiderrapantes, casco o protectores para los oídos para

tener las condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice prensas u otros medios prácticos para asegurar y apoyar la pieza de trabajo en

una plataforma estable. Sujetar las piezas con la mano o contra su cuerpo es inestable y

puede originar la pérdida de control.

• No fuerce la herramienta. utilice la herramienta apropiada para su aplicación. La

herramienta apropiada hará el trabajo mejor y de manera más segura bajo las

especificaciones para las que se diseñó.

• No utilice la herramienta si el interruptor no enciende y apaga. Cualquier herramienta

que no pueda controlarse por medio del interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer cualquier ajuste, cambio

de accesorios o de guardar la herramienta. Tales medidas de seguridad preventivas

reducirán el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de otras personas no

capacitadas. Las herramientas son peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de corte afiladas y limpias. Las

herramientas que reciben un mantenimiento adecuado, con piezas de corte afiladas,

difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque fracturas en las piezas y

cualesquiera otras condiciones que puedan afectar la operación de las herramientas.

Si está dañada, lleve su herramienta a servicio antes de usarla de nuevo. Muchos

accidentes se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para su modelo de

herramienta. Los accesorios que estén diseñados para una herramienta, pueden volverse

peligrosos cuando se emplean con otra.

SERVICIO

• El servicio a las herramientas lo debe efectuar únicamente personal calificado. El

servicio o mantenimiento realizado por personal no calificado puede originar riesgos de

lesiones.

• Cuando efectúe servicio a una herramienta, utilice únicamente refacciones idénticas.

Siga las instrucciones de la sección de Mantenimiento de este manual. El empleo de

piezas no autorizadas o no seguir las instrucciones de mantenimiento puede originar riegos

de choque eléctrico o lesiones.

Reglas de Seguridad Específicas

• Cuando realice una operación en la cual la herramienta pueda hacer contacto con

cables escondidos, sujétela por las partes con aislamiento antideslizante. El contacto

con un cable con corriente hará que las partes metálicas de la herramienta puedan

transmitir una descarga eléctrica al operario.

• Mantenga sus manos fuera del área de corte. Nunca se incline por debajo del material

por ningún motivo. Sujete la parte frontal de la sierra asiéndola por el área contorneada de

agarre. No inserte los dedos o el pulgar cerca de la hoja de vaivén o el sujetador de la hoja.

No estabilice la sierra asiéndola por la platina.

• Mantenga las hojas afiladas. Las hojas sin filo pueden hacer que la sierra se desvíe o se

atasque al estar bajo presión.

• Al cortar un tubo o conducto portacables, asegúrese de que estos no contienen agua o

cables, etc.

AVERTISSEMENT : El polvo creado al lijar, aserrar, pulir, taladrar o realizar otras activi-

dades de la construcción, contiene substancias químicas que se sabe producen cáncer,

defectos de nacimiento u otros defectos del sistema reproductor. Algunos ejemplos de esos

productos químicos son:

• El plomo de las pinturas a base de plomo,

• La sílice cristalina de los ladrillos, del cemento y de otros productos de albañilería, y

• El arsénico y el cromo de la madera tratada químicamente (CCA).

El riesgo que se corre a causa del contacto con esos productos varía según la frecuencia

con que usted realice este tipo de trabajos. Con el fin de reducir su exposición a esas substancias químicas, trabaje en un área bien ventilada y utilice un equipo de seguridad

reglamentario, tal como una máscara contra el polvo especialmente diseñada para filtrar

partículas microscópicas.

• Evite el contacto prolongado con el polvo proveniente del lijado, aserrado, amolado y

taladrado eléctrico y otras actividades de construcción. Use vestimenta protectora y

lave todas las áreas expuestas con agua y jabón. De entrar polvo en sus ojos, boca, o

que este permanezca sobre su piel puede promover la absorción de químicos dañinos.

AVERTISSEMENT :El uso de esta herramienta puede generar y/o dispersar el polvo, el cual

puede ocasionar lesión respiratoria u otro tipo de lesión grave y permanente. Utilice siempre

protección respiratoria NIOSH/OSHAapropiada para la exposición al polvo. Dirija las partículas lejos de su cara o su cuerpo.

ATENCIÓN: Use protección auditiva apropiada cuando usa la herramienta. Bajo cier-

tas condiciones y el tiempo que se usa la herramienta, el ruido proveniente de este producto podría contribuir a pérdida auditiva.

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min ........................minutos ......................corriente alterna

......................corriente directa

n

o........................velocidad sin carga

..........................construcción clase II

........................terminales de

conexión a tierre

........................símbolo de alerta seguridad .../min ..................revoluciones o

reciprocaciones por

minuto

Características

ACCIÓN ORBITAL DE 4 POSICIONES – Para cortes rápidos y suaves en varios tipos de

materiales.

SISTEMA DE COLECCIÓN DE POLVO – Recoge desechos automáticamente para mantener

un entorno de trabajo más limpio.

VELOCIDAD ELECTRÓNICA VARIABLE – Control preciso de corte mantiene una velocidad

constante con carga.

PASADA DE CORTE DE _ PULGADA (20MM) – Un corte más rápido y una hoja de mayor

duración.

GUÍA DE SOPORTE DE RODILLOS – Mayor duración de la hoja y mayor precisión.

BASE METÁLICA AJUSTABLE – Puede ser inclinada para cortes biselados de hasta 45 gra-

dos.

DISPOSITIVO DE PROTECCIÓN CONTRA ASTILLADO – Reduce el astillado de la pieza de

trabajo.

REVESTIMIENTO CONTRA ASTILLAS – Revestimiento replegable contra astillas desvía

astillas de madera cuando se despliega para la extracción del polvo.

USO DE CABLES DE EXTENSIÓN

Asegúrese que el cable de extensión esté en buenas condiciones antes de usar. Al utilizar un

cable de extensión, asegúrese de que sea del tamaño correspondiente a la herramienta, o sea,

lo suficientemente “pesado” como para transportar la corriente que la herramienta va a extraer.

Un cable de tamaño insuficiente causará una caída en la línea de voltaje resultando en pérdida de energía y recalentamiento. Vea la tabla siguiente para el tamaño apropiado de cable.

Calibre mínimo para juegos de cables

Voltios Largo total del cable en pies

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Amperaje Nominal

Más No más American Wire Gage

de de

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No recomendado

MOTOR

Verifique que su suministro de corriente concuerde con el marcaje de la placa de datos. 120

Voltios de corriente alterna (AC) solo indica que su herramienta operará con corriente casera

estándar de 60 Hz. No opere herramientas de corriente alterna (AC) con corriente directa (DC).

Una potencia de régimen de 120 voltios AC/DC significa que su herramienta operará con corriente estándar de 60 Hz AC o DC. Esta información está impresa en la placa de datos. Un

voltaje menor ocasionará pérdida de corriente y puede resultar en recalentamiento. Todas las

herramientas Black & Decker se prueban en fábrica; si esta herramienta no funciona, verifique

el suministro de corriente.

GUARDE ESTAS INSTRUCCIONES

OPERACIÓN

CONMUTADOR OFF/ON (DE APAGADO Y ENCENDIDO)

Para encender la herramienta, presione el gatillo conmutador, como lo muestra la Figura 1.

Para apagar la herramienta, suelte el gatillo conmutador. Para su uso continuo, bloquee el conmutador en la posición “ON” apretando el gatillo y sujetándolo mientras presiona el bloqueador

del conmutador ubicado como lo muestra la Figura 2. Mantenga el botón bloqueador del conmutador presionado mientras suelta el gatillo. Suelte el botón bloqueador del conmutador y la

herramienta seguirá funcionando. Para apagar la herramienta cuando el conmutador está bloqueado en “ON”, apriete y suelte el gatillo una vez.

INSTALACIÓN DE UNA HOJA DE SIERRA

ADVERTENCIA: Asegúrese que la herramienta esté apagada y desenchufada y que la hoja

de la sierra se haya detenido. La hoja de sierra usada puede estar caliente.

Deslice completamente el revestimiento de plástico transparente contra astillas. Con la llave

hexagonal incluida, suelte (en dirección contraria a las manillas del reloj) los dos tornillos de

sujeción de la hoja como lo muestra la Figura 3. Seleccione una hoja e inserte su base completamente en el sujetador de la hoja. Asegúrese que el borde posterior de la hoja descanse

en el centro del rodillo de soporte, como lo muestra la Figura 4. Con la hoja instalada de esta

manera, ajuste bien los dos tornillos de sujeción de la hoja.

CONTROL ELECTRÓNICO DE VELOCIDAD

Su sierra de vaivén está equipada con un control electrónico de velocidad que le permite mantener la velocidad seleccionada aun cuando la carga del corte aumente. Rote el cuadrante de

velocidad variable que se encuentra en la parte superior de la herramienta hasta que esté en

el número deseado, como lo muestra la Figura 5. La posición del cuadrante puede ser ajustada en cualquier momento, sin dejar de operar la sierra de vaivén. Consulte el Cuadro 1 para

encontrar la velocidad recomendada para un trabajo en particular.

SS

SS

IIIIEEEERRRRRRRRAAAADDDDEEEEVVVVAAAAIIIIVVVVÉÉÉÉNNNNCCCCOOOONNNNVVVVEEEELLLLOOOOCCCCIIIIDDDDAAAADDDDVVVVAAAARRRRIIIIAAAABBBBLLLLEE

EE

Page 5

IMPORTADO: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 3-26-71-00

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

ACCIÓN ORBITAL

Su sierra está equipada con acción orbital para ajustar la agresividad del ángulo de la hoja. A

medida que la hoja sube después de una pasada, los dientes de la hoja pueden ser fijados

hacia adelante para un corte más agresivo, o de la manera convencional para un corte estándar.

Consulte el Cuadro 2 para determinar la posición apropiada de esta característica. Para ajustarla para realizar un corte específico, deslice la barra del indicador para alinearla con el

número deseado (0, 1, 2, 3), como lo muestra la Figura 6.

BASE METÁLICA INCLINABLE

ADVERTENCIA: Asegúrese que la herramienta esté apagada y desenchufada y que la hoja

de la sierra se haya detenido.

Para hacer cortes biselados, su sierra tiene una base metálica inclinable que se puede inclinar

hasta en 45°, a la izquierda o derecha. Para ajustarla, use la llave hexagonal para soltar los

dos tornillos en la parte inferior de la base, como lo muestra la Figura 7. Una vez sueltos, jale

la base ligeramente hacia adelante e inclínela al ángulo deseado, como lo muestra la Figura 8.

También puede empujarla ligeramente hacia atrás y fijarla en cualquiera de las posiciones fijas

a 0, 15, 30, y 45°. Luego de fijar el ángulo de la base, ajuste bien ambos tornillos. NOTA:

Cuando esté haciendo cualquier tipo de corte angulado (es decir, de un ángulo diferente a 0°),

el revestimiento de plástico contra astillas debe estar completamente replegado. De lo contrario, el revestimiento contra astillas será seriamente dañado.

SISTEMA DE EXTRACCIÓN DE POLVO

ATENCIÓN: No use el adaptador de aspiración cuando corte metal. Las limaduras metálicas

estarán calientes y pueden causar un incendio.

Su sierra puede extraer polvo si inserta el adaptador de extracción de polvo incluido, en el orificio que se encuentra en la parte posterior de la herramienta, como lo muestra la Figura 9.

Alinee las flechas, inserte y gire en dirección a las manillas del reloj para fijarlo en posición,

como lo muestra la figura. Puede usar la manguera estándar de su aspiradora ya sea encima

o dentro del adaptador. Despliegue el revestimiento contra astillas y la aspiradora podrá

automáticamente recoger el desecho.

NOTA: Se recomienda que el revestimiento contra astillas sólo sea desplegado para la extracción de polvo.

DISPOSITIVO DE PROTECCIÓN CONTRA ASTILLADO

Para instalar el dispositivo de protección contra astillado, insértelo desde la parte inferior de la

base metálica, como lo muestra la Figura 10.

NOTA:El dispositivo contra astillado sólo puede ser usado cuando la base metálica esté en un

ángulo de 0°.

SUGERENCIAS PARA SU PROYECTO

1.) Las sierras de vaivén cortan en la pasada ascendente. Para minimizar el astillado de la

pieza de trabajo terminada, voltee la pieza de trabajo para que el revés quede hacia arriba.

2.) Use el revestimiento de plástico incluido para la base metálica para evitar estropear la

superficie de trabajo.

3.) Para hacer círculos y cortes rectos más precisos, use una guía de corte recta o circular (se

vende por separado.)

4.) Para optimizar el desempeño del corte, seleccione la velocidad apropiada y la posición de

acción orbital para que vaya con el material que está cortando.

5.) Para un mejor desempeño, use hojas afiladas y de alta calidad.

MANTENIMIENTO

Utilice solamente jabón suave y agua para limpiar la herramienta. Nunca permita que ningún

líquido se introduzca dentro de la misma; nunca sumerja ninguna parte de la herramienta dentro de algún líquido.

IMPORTANTE: Para garantizar la SEGURIDAD y la FIABILIDAD del producto, toda

reparación, mantenimiento y ajuste, deberán ser realizados en los centros autorizados de servicio u otras organizaciones de servicio calificadas, utilizando siempre para ello accesorios

originales.

ACCESORIOS

Los accesorios que se recomiendan usar con su herramienta están disponibles donde su distribuidor o centro de servicio local. De necesitar asistencia para obtener un accesorio, favor

llamar a: (55) 5326-7100.

ADVERTENCIA: Puede ser peligroso usar cualquier accesorio no recomendado.

INFORMATION ACERCA DE NUESTROS CENTROS DE SERVICIO

Black & Decker ofrece una red completa de centros de servicio y centros autorizados en toda

Norteamérica. Todos los centros de servicio Black & Decker disponen de personal entrenado

para dar un servicio eficiente y confiable a las herramientas eléctricas de sus clientes. De

necesitar orientación técnica, reparación o repuestos originales de fábrica, diríjase al centro

Black & Decker local. Para hallar la ubicación del centro de servicio más cercano, busque en

las páginas amarillas de la guía telefónica bajo "Herramientas—Eléctricas" o llame a:

(55) 5326-7100.

GARANTÍA LIMITADA DE TRES AÑOS.

Black & Decker (U.S.) Inc. garantiza este producto por dos años contra todo defecto de material y fabricación. El producto defectuoso será reemplazado o reparado sin costo en una de

las dos formas siguientes.

La primera opción, que resultará en intercambio solamente, será devolviendo el producto al

minorista donde fue comprado (siempre que la tienda sea un minorista participante). Las

devoluciones deberán hacerse dentro del período de intercambio que el minorista tiene por

política (generalmente de 30 a 90 días después de la venta). La prueba de compra podrá ser

requerida. Favor informarse con el minorista sobre la política específica de devolución en

cuanto a devoluciones hechas en fecha posterior a la fijada para intercambios.

La segunda opción es llevar o enviar el producto (pre-pagado) a un centro de servicio Black

& Decker o un centro autorizado para reparaciones o reemplazo, a nuestra discreción. La

prueba de compra podrá ser requerida. Los centros de servicio Black & Decker o centros

autorizados se anuncian bajo "Herramientas - Eléctricas" en las páginas amarillas de la guía

telefónica.

Esta garantía no aplica a los accesorios. Esta garantía le otorga a usted derechos legales

específicos y otros derechos que pueden variar de estado en estado. Si tiene alguna pregunta, comuníquese con el gerente de su centro de servicio Black & Decker más cercano.

CUADRO 1

Material Posición sugerida de velocidad

Madera ........................................... 6-Máx.

Metal ...............................................2-3

Aluminio...........................................3-5

Policloruro de vinilo..........................3-4

Cerámica..........................................3-5

TCUADRO 2

MADERA METAL PLÁSTICOS

Cortes rápidos ____ Plásticos

Piezas de trabajo gruesas ____ Fibra de vidrio,

acrílico

Contrachapado, madera prensada Aluminio, no-férreo _____

Piezas de trabajo delgadas Metal en planchas _____

Cortes finos

POSICIÓN # 3

POSICIÓN # 2

POSICIÓN # 1

POSICIÓN # 0

ARA REPARACION YSERVICIO DE SUS HERRAMIENTAS ELECTRICAS FAVOR DE

DIRIGIRSE ALCENTRO DE SERVICIO MAS CERCANO

CULIACAN Av. Nicolas Bravo #1063 Sur (56 77) 12 42 10

GAUDALAJARA Av . La Paz #1770 (33 38) 26 69 78

LEON Polara #32 (47 77) 13 14 56

MEXICO Sonora #134 Hiprodromo Condesa (55 55) 53 99 79

MERIDA Calle 63 #459 (99 99) 23 54 90

MONTERREY Av. Francisco I. Madero Pte. 1820-A (81 83) 72 11 25

PUEBLA 17 Norte #2057 (22 22) 46 90 20

QUERETARO Av. Madero 139 Pte. (44 22) 14 60 60

SAN LOUIS POTOSI Pedro Moreno #408 Fracc. la Victoria (44 48) 14 25 67

TORREON Blvd. Independencia, 96 pte. (87 17) 16 52 65

VERACRUZ Prolongación Diaz Miron #4280 (29 99) 21 70 18

VILLAHERMOSA Zaragoza #105 (99 33) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: (55) 5326-7100 INFORMACIÓN DE SERVICIO

ESPECIFICACIONES

QP400

Tensión de alimentación: 120 V~ Potencia nominal: 508 W

Frecuencia de operacion: 60 Hz Consumo de corriente: 4,6A

Loading...

Loading...