Page 1

WARNING! Read and understand all instructions. Failure to follow all instructions listed below may result

n electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids,

gases, or dust. Power tools create sparks which may ignite the dust or fumes.

Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause you

to lose control.

LECTRICAL SAFETY

Double insulated tools are equipped with a polarized plug (one blade is wider than the other .) This plug

will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in

any way. Double insulation eliminates the need for the three wire grounded power cord and

grounded power supply system.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is

• Do not force tool. Use the correct tool for your applicatio

safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any to

dangerous and must be repaired.

• Disconnect the plug from the power source before makin

storing the tool. Such preventative safety measures reduce

• Store idle tools out of reach of children and other untrain

untrained users.

• Maintain tools with care. Keep cutting tools sharp and cl

cutting edges are less likely to bind and are easier to cont

• Check for misalignment or binding of moving parts, brea

may affect the tools operation. If damaged, have the too

caused by poorly maintained tools.

• Use only accessories that are recommended by the manu

be suitable for one tool, may become hazardous when use

SERVICE

• T ool service must be performed only by qualified repair

by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement pa

section of this manual. Use of unauthorized parts or failu

a risk of electric shock or injury.

W ARNING! Read and und

instructions listed below, may result in electric shock, fire and

SAVE THESE INST

ADDITIONAL SAFETY RULES

• Hold tool by insulated gripping surfaces when perfor ming

hidden wiring or its own cord. Contact with a "live" wire will

shock the operator.

• KEEP HANDS AWAY from cutting area. Never reach undern

saw by grasping the contoured gripping area. Do not insert fi

ing blade and blade clamp. Do not stabilize the saw by gripp

• KEEP BLADES SHARP. Dull blades may cause the saw to swe

CAUTION: Some wood contains preservatives such as cop

toxic. When cutting these materials extra care should be taken

The label on your tool may include the following symb

V ..........................volts

Hz ........................hertz

min ......................minutes

....................direct current

........................

Class II Construction

........................safety alert symbol

.../min ..................revolutions or

reciprocations

per minute

Fig. 1

TRIGGER SWIT

INTERRUPTEUR À D

GATILLO INTERRU

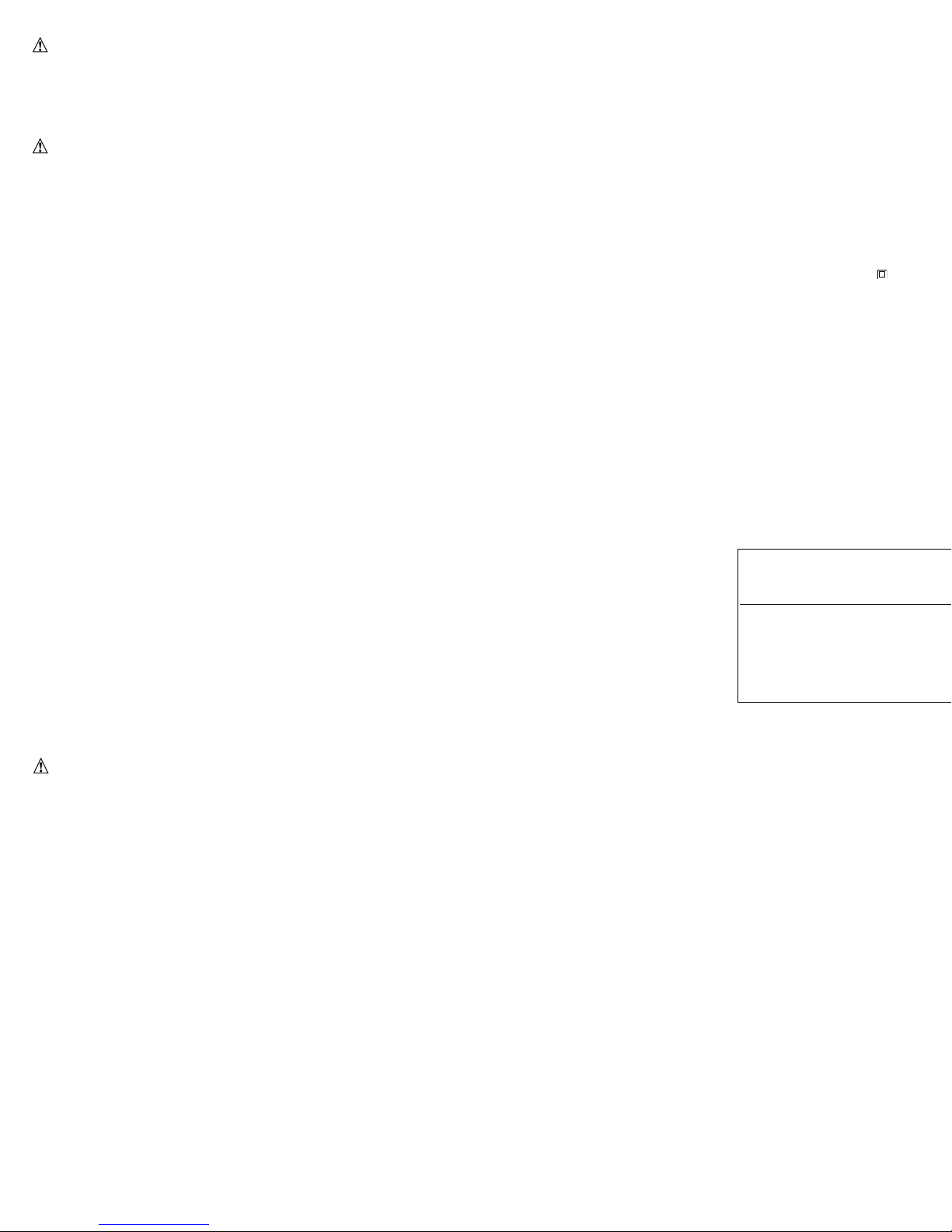

Fig. 2

BLADE GUARD

PROTÈGE-LAME

GUARDA DE LA SEGUETA

LOCKING BUTTO

BOUTON DE VERROU

BOTON DE SEGUR

RECIPROCATING SHAFT

ARBRE À MOUVEMENT ALTERN

EJE ALTERNATIVO

(BLADE GUARD CUT A

CLARITY)

(PROTÈGE-LAME DÉCOU

MIEUX VOIR)

(GUARDA DE LA SEGUE

PARA MAYOR VISIB

BLADE

LAME

CUCHILLA

Q450

INSTRUCTION MANUAL

VARIABLE SPEED RECIPROCATING SAW

INFORMATION YOU SHOULD KNOW

•Securely tighten blade.

•Keep shoe firmly against work surface.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

CAT. NO. Q450 FORM NO. 386870 Copyright © 1998 Black & Decker (FEB98-CD1) Printed in U.S.A.

Page 2

CAUTION! Always wear eye protection while operating this power tool.

LUSH-TO CUTTING

he exclusive, compact design of the motor housing and spindle housing permits extremely close cutting to floors,

orners and other difficult areas. When using an off-set shank blade for flush cutting reverse the blade as shown in

gure 3.

CAUTION: When sawing into walls, floors or wherever "live" electrical wires may be encountered, DO NOT

OUCH ANY METAL PARTS OF THE TOOL! Hold the saw only by its plastic handle to prevent electric shock if

ou saw into a "live" wire.

WOOD CUTTING

efore cutting any type of wood, be sure it is firmly anchored or clamped to prevent slippage. Check blade chart for

pe and length of blade necessary for best results. Place blade lightly against work to be cut, switch on saw motor

nd allow it to obtain maximum speed before applying pressure (see Figure 4). Always hold saw firmly with both

ands while cutting. Whenever possible, the saw shoe must be held firmly against the material being cut. This will

revent the saw from jumping or vibrating and minimize blade breakage.

OCKET CUTTING

he initial step in pocket cutting is to measure the surface area to be cut and mark clearly with a pencil, chalk or

criber. Insert pocket cutting blade in blade clamp, and tighten blade clamp securely. Next, tip the saw backward

ntil the back edge of the shoe is resting on the work surface and the blade is not touching the surface. Now switch

otor on, always permitting blade to attain maximum speed. Grip handle steadily and begin a slow, deliberate

pward swing with the handle of the saw, as shown in Figure 5. Blade will begin to feed into material. Always be

ure blade is completely through material before continuing with pocket cut.

OTE: In areas where blade visibility is limited, use the edge of the saw shoe as a guide. Lines for any given cut should

e extended beyond edge of cut to be made.

METAL CUTTING

his unit has different metal cutting capacities depending upon the type of blade used and the metal to be cut. Use

finer blade for ferrous metals (metals containing iron or steel) and a coarse blade for non-ferrous materials. In thin

auge sheet metals it is best to clamp wood to both sides of metal sheet. This will ensure a clean cut without excesve vibration or tearing of metal. Always remember not to force the saw as this reduces blade life and causes cost-

blade breakage.

OTE: When cutting metals you should spread a thin film of oil or other coolant along the line ahead of the saw cut

or easier operation and longer blade life. For cutting aluminum, kerosene is preferred.

UBRICATION

our tool was properly lubricated before leaving the factory. Once every year take or send your tool to a Black &

ecker service center, or authorized service station, for a complete cleaning, inspection and lubrication. Tools used

ontinuously on production jobs will need relubrication more often. Tools "out of service" for long periods should be

elubricated before being put back to work.When these tools are used on sports cars, boats etc., it has been found

at they are subject to accelerated wear and possible premature failure, as the fiberglass chips are highly abrasive

bearings, brushes, commutators and other parts.

onsequently it is not recommended that this tool be used for continuous production work on any fiberglass materi-

. During any use on fiberglass it is extremely important that the tool is cleaned frequently by blowing through with

n air jet.

CCESSORIES

he accessories listed in this manual are available at extra cost from your local dealer or Black & Decker service

enter.

CAUTION: The use of any accessory or attachment other than those recommended in this manual may be

azardous.

ROJECT TIPS

1. Cut only with sharp blades; they cut cleaner, faster and put less strain on the motor while cutting.

2. When cutting, always ensure that the shoe is resting against the workpiece. This will improve operator con-

ol and minimize vibration.

3. Blades available include both straight and slightly angled shanks. If you are using a straight shanked

lade in wood, hold the saw at a slight angle to the cutting plane to improve cutting performance.

4. For longer blade life, use bi-metal blades. These utilize a carbon steel back welded to high speed steel

eth making the blade more flexible and less prone to breaking.

MPORTANT

T o assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments should be performed by

Black & Decker service centers or other qualified service organizations, always using Black & Decker

replacement parts.

Service Information

Black & Decker offers a full network of company-owned and authorized service locations throughout North

America. All Black & Decker Service Centers are staffed with trained personnel to provide customers with

efficient and reliable power tool service.

Whether you need technical advice, repair , or genuine factory replacement parts, contact the Black &

Decker location nearest you. T o find your local service location, refer to the yellow page directory under

"T ools—Electric" or call: 1-800-54-HOW TO.

ULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or

workmanship. The defective product will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom it was

purchased (provided that the store is a participating retailer). Returns should be made within the time

period of the retailer’ s policy for exchanges (usually 30 to 90 days after the sale). Proof of purchase may

be required. Please check with the retailer for their specific return policy regarding returns that are beyond

AVERTISSEMENT! Lire et comprendre toutes les directives

suivantes présente des risques de secousses électriques, d

CONSERVER CES

ZONE DE TRAVAIL

•S'assurer que la zone de travail est propre et bien éclai

sombres présentent des risques d'accidents.

•Ne pas utiliser des outils électriques en présence de vap

des liquides, des gaz ou des poussières inflammables). L

électriques peuvent enflammer les poussières ou les vapeu

• Éloigner les curieux, les enfants et les visiteurs de la zo

électrique. Une distraction peut entraîner la perte de maît

MESURES DE SÉCURITÉ RELATIVES À L'ÉLECTRICIT

•Les outils à double isolation comportent une fiche polari

n'entre que d'une façon dans une prise polarisée. Lorsqu

essayer de nouveau après avoir inversé les broches de la

prise, communiquer avec un électricien certifié afin de fa

aucune façon la fiche. La double isolation élimine le be

système d'alimentation mis à la terre.

•Éviter de toucher à des surfaces mises à la terre comme

des réfrigérateurs. Les risques de secousses électriques so

la terre.

•Protéger les outils électriques de la pluie ou des conditio

augmente les risques de secousses électriques.

•Manipuler le cordon avec soin. Ne jamais se servir du c

cordon pour débrancher l'outil. Éloigner le cordon des so

arêtes tranchantes et des pièces mobiles. Remplacer imm

cordons endommagés augmentent les risques de secousses

•Lorsqu'on utilise un outil électrique à l'extérieur , se serv

l'extérieur , portant la mention “W-A” ou “W”. Ces cordo

minimisent les risques de secousses électriques. Lorsqu'on

est de calibre approprié pour la tension nécessaire au fonc

de calibre inférieur occasionne une baisse de tension entra

Le tableau suivant indique le calibre approprié selon la lon

signalétique de l'outil. En cas de doute, utiliser un cordon

calibre est inversement proportionnel au calibre du cordon

SÉCURITÉ PERSONNELLE

•Demeurer vigilant, prendre soin et faire preuve de juge

pas s'en servir lorsqu'on est fatigué ou affaibli par des d

graves blessures peuvent résulter d'un moment d'inattentio

•Porter des vêtements appropriés. Éviter de porter des v

chevelure si elle est longue. Éloigner les cheveux, les vête

peuvent les happer .

•Éviter les démarrages accidentels. S'assurer que l'inter

brancher l'outil. Afin d'éviter les risques de blessures, ne p

l'interrupteur ni brancher un outil dont l'interrupteur est en

•Enlever les clés de réglage avant de mettre l'outil sous te

rotative de l'outil présente des risques de blessures.

•Ne pas dépasser sa portée. Garder son équilibre en to

de l'outil dans des situations imprévues grâce à une positio

•Porter de l'équipement de sécurité. Toujours porter des

il faut porter des masques respiratoires, des chaussures an

protège-tympans.

UTILISATION ET ENTRETIEN DE L'OUTIL

•Utiliser des pinces de serrage ou de tout autre moyen p

ouvrer sur une plate-forme stable. La pièce est instable lo

l'utilisateur . Cela présente des risques de perte de maîtrise

•Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche

lorsqu'on s'en sert à son rendement nominal.

•Ne pas se servir de l'outil lorsque l'interrupteur est défe

il faut le réparer .

•Débrancher l'outil de la source d'alimentation avant de

le ranger . On minimise de la sorte le risque de démarrage

•Ranger l'outil hors de portée des enfants et de toute aut

fonctionnement. L'outil est dangereux entre les mains de c

•Prendre soin des outils. S'assurer que les outils de coup

entretenus à arêtes tranchantes ont moins tendance à se co

•Vérifier l'alignement et les attaches des pièces mobiles,

facteur susceptible de nuire au bon fonctionnement de l'o

de s'en servir. Des outils mal entretenus sont la cause de n

•Utiliser seulement les accessoires recommandés par le f

Calibre minimal des cordo

Tension Longueur totale d

120 V De 0 à 25 De 26 à 50

240 V De 0 à 50 De 51à 100

Intensité (A)

Au Au Calibre m

moins plus

0-6 18 16

6 - 10 18 16

10 - 12 16 16

12 - 16 14 12

Page 3

P ATIN FIXE - Optimisation de la visibilité pendant la coupe.

REBORD DE P ATIN À RAYON - Coupe plongeante facilitée.

VITESSE : De 0 à 2 400 courses/min.

CORDON : 2,4 m (8 pi), 120 V c.a. seulement.

ACCESSOIRES COMPRIS - UNE LAME DE QUALITÉ SUPÉRIEURE, UNE CLÉ

HEXAGONALE ET UN PORTE-CLÉ.

MOTEUR

n moteur Black & Decker entraîne l’outil. Veiller à ce que la tension d'alimentation soit conforme aux exigences de

plaque signalétique de l'outil. La mention “120 volts, 50/60 Hz” ou “120 volts c.a.” seulement signifie que l'outil

onctionne seulement sur une alimentation domestique standard de 120 volts. Une baisse de tension de plus de 10

. 100 entraîne une perte de puissance et la surchauffe. Tous les outils sont essayés avant de quitter l'usine. Lorsque

elui-ci refuse de fonctionner, vérifier la source de courant électrique.

NTERRUPTEUR

a scie alternative, modèle Q450, comporte un régulateur de vitesse (fig. 1) qui permet de choisir la vitesse appro-

riée à la tâche à exécuter. Enfoncer l’interrupteur à détente pour mettre l'outil en marche. Pour l'arrêter, il suffit de

elâcher l'interrupteur. Plus on enfonce la détente de l’interrupteur, plus la vitesse de l’outil augmente (de 0 à 2 400

ourses/min). Pour assurer le fonctionnement continu de l'outil à plein régime, il suffit d'enfoncer à fond la détente

d’appuyer sur le bouton de verrouillage situé sur le côté, puis de relâcher doucement l'interrupteur (fig. 1). Pour

rrêter l'outil lorsqu'il est en mode de fonctionnement continu, enfoncer l'interrupteur à fond et le relâcher.

ERRAGE DE LA LAME

OTE : Il n'est pas nécessaire d'enlever le protège-lame pour installer la lame. Pour fixer la lame sur la scie, voir la

gure 2.

1. Débrancher l'outil.

2. Desserrer la vis de fixation.

3. Insérer la queue de la lame à l'avant de l'outil entre l'arbre à mouvement alternatif et le serre-lame.

acer le trou de la lame sur l'ergot de l'arbre à mouvement alternatif.

4. Resserrer la vis de fixation.

ans l'éventualité où la lame se briserait et où la queue resterait coincée dans le serre-lame, s'assurer que la vis de

xation est desserrée, puis dégager la queue de la lame à l'aide d'un clou ou d'un objet pointu.

NOTE : Un ergot spécial retient le serre-lame sur l'arbre à mouvement alternatif afin de l'empêcher de se dégager

rsqu'on desserre la vis de fixation. NE JAMAIS UTILISER LA SCIE SANS LE PROTÈGE-LAME EN PLACE.

MISE EN GARDE : Toujours porter des lunettes de sécurité lorsqu'on utilise l’outil électrique.

OUPE À RAS

a conception compacte exclusive du carter du moteur et de celui de l'axe de la scie alternative permet de couper

u ras des planchers, des coins et d'autres endroits d'accès difficile. Lorsqu'on utilise une lame à arbre décentré

our la coupe à ras, placer la lame en position inversée de la façon illustrée à la figure 3.

MISE EN GARDE : Lorsqu'on scie dans les murs, les planchers ou tout autre endroit où peuvent se trouver des fils sous

nsion, NE PAS TOUCHER À TOUT COMPOSANT MÉTALLIQUE DE L'OUTIL. Ne le saisir que par sa poignée en

astique afin de se protéger des secousses électriques que provoquerait le contact de la lame avec un fil sous ten-

on.

OUPE DU BOIS

vant de couper une pièce de bois quelconque, s'assurer qu'elle est solidement assujettie ou immobilisée afin d'emêcher qu'elle ne glisse. Consulter le tableau de sélection des lames afin de choisir la longueur et le type appropriés

e lame dans le but d'optimiser les résultats. Appuyer légèrement la lame contre la pièce à couper, mettre le moteur

e la scie en marche et attendre qu'il ait atteint sa vitesse maximale avant d'exercer de la pression (fig. 4). Toujours

aisir la scie fermement des deux mains pendant le travail. Dans la mesure du possible, appuyer fermement le patin

e la scie contre la pièce pendant la coupe. Cette mesure empêche la scie de sauter ou de vibrer , et réduit les risques

e bris de la lame.

OUPE EN RETRAIT

a première étape de la coupe en retrait consiste à mesurer la superficie de la pièce à couper et à la marquer à

aide d'un trait de crayon ou de craie, ou d'un traçoir. Insérer ensuite la lame de coupe en retrait dans le serre-

me et bien la fixer. Incliner alors la scie vers l'arrière jusqu'à ce que le bord postérieur du patin repose contre la

urface de travail. Mettre le moteur en marche et attendre que la lame ait atteint la vitesse maximale de coupe. Saisir

rmement la poignée, puis redresser lentement et avec prudence la poignée de la scie (fig. 5). La scie commence

ors à s'avancer dans la pièce à couper. Toujours s'assurer que la scie transperce le matériau avant de poursuivre

coupe.

OTE : Dans les endroits où il est difficile de voir la lame pendant la coupe, utiliser le bord du patin de la scie comme

uide. On conseille de prolonger les lignes tracées au crayon au-delà de la limite de la coupe à exécuter.

OUPE DE MÉTAUX

e rendement de la scie dépend du type de lame utilisé et du métal à couper. Se servir d'une lame à dents fines pour

ouper les métaux ferreux, et d'une lame à dents plus grosses pour couper les métaux non ferreux. Lorsqu'on coupe

ne feuille de tôle mince, il est préférable d'immobiliser la feuille de métal entre deux pièces de bois. On élimine

insi les vibrations et les risques de déchirement de la tôle. Il ne faut jamais forcer l'outil en le poussant trop

nergiquement car on réduirait la durée de la lame tout en risquant de l'endommager.

NOTE : Il est généralement conseillé, pour la coupe des métaux, d'enduire la ligne de coupe d'une mince pellicule

'huile ou d'une substance semblable afin de faciliter la manoeuvre de l'outil et de prolonger la durée de la lame.

est conseillé d'utiliser du kérosène pour la coupe de l'aluminium.

UBRIFICATION

outil a été lubrifié en usine. Il faut le retourner chaque année à un centre de service Black & Decker ou à un ate-

er d'entretien autorisé afin d'en effectuer une inspection, une lubrification et un nettoyage complets. Les outils con-

amment utilisés doivent être lubrifiés plus souvent. De plus, les outils rangés pendant de longues périodes doivent

re relubrifiés avant de s'en servir de nouveau. Il est prouvé que les outils électriques utilisés pour effectuer des

avaux sur des embarcations, des véhicules ou tout autre objet en fibre de verre s'usent rapidement et risquent d'être

ndommagés car les éclats de fibre de verre sont très abrasifs et peuvent endommager les roulements, les balais, les

ommutateurs et autres composantes semblables. Il n'est donc pas recommandé d'utiliser la scie pour effectuer des

avaux sur de la fibre de verre. Le cas échéant, nettoyer fréquemment l'outil à l'aide d'un jet d'air.

CCESSOIRES

ESPAÑOL

MANUAL DE INS

Q450

ANTES DE DEVOLVER ESTE PRO

RAZON POR FAVO

326-71

INFORMACION QUE

• Apriete la segueta de manera segura.

• Conserve la zapata apoyada firmemente con

CONSERVE ESTE MANUAL PARA

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERV

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DUDAS, POR FA VOR LLAME. 326-7100

ADVERTENCIA: Lea y comprenda todas las instruccio

choque eléctrico, incendio y lesio

CONSERVE ESTAS IN

AREA DE TRABAJO

•Conserve su área de trabajo limpia y bien iluminada. Las b

cian los accidentes.

•No opere herramientas eléctricas en atmósferas explosivas,

inflamables. Las herramientas eléctricas producen chispas que

vapores.

•Conserve a observadores, niños y visitantes alejados mient

ciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

•Las herramientas con doble aislamiento están equipadas co

ancha que la otra.) Esta clavija se acoplará únicamente en u

Si la clavija no se acopla al contacto, inviértala. Si aún así n

ficado para que le instalen una toma de corriente polarizada

necesidad de cables con tres hilos y sistemas de alimentación

•Evite el contacto corporal con superficies aterrizadas tales c

adores. Hay un gran riesgo de choque eléctrico si su cuerpo h

•No exponga las herramientas eléctricas a la lluvia o a cond

introduce en las herramientas aumenta el riesgo de descargas

•No maltrate el cable. Nunca tome el cable para transporta

toma de corriente. Consérvelo alejado de calor aceite, borde

mente los cables dañados. Los cables dañados aumentan el r

•Cuando opere una herramienta eléctrica a la intemperie, ut

Estas extensiones están clasificadas para uso a la intemperie y

Cuando utilice una extensión, asegúrese de emplear una con e

necesaria para su herramienta. Una extensión con calibre ina

línea resultando en pérdida de potencia y sobrecalentamiento

para usarse, relativo a la longitud de la extensión y el ampera

tiene dudas, utilice el calibre siguiente. Mientras más pequeño

dad.

SEGURIDAD PERSONAL

•Esté alerta concéntrese en lo que está haciendo. Recurra al

Calibre mínimo para cordo

Volts Longitud total

120V 0 - 7.62 7.63 - 15.24

240V 0 - 15.24 15.25 - 30.48

AMPERAJE

Más No más Calbre

de de

0-6 18 16

6 - 10 18 16

10 - 12 16 16

12 - 16 14 12

Page 4

EGLAS DE SEGURIDAD ADICIONALES

Tome la herramienta por las superficies aislantes de sujecin cuando realice una operacin en que la her-

amienta de corte pueda hacer contacto con cables ocultos o con su propia extensin. El contacto con un cable

vo har que las partes metlicas de la herramienta queden vivas y descarguen hacia el operador.

CONSERVE LAS MANOS ALEJADAS del rea de corte. Nunca las coloque por debajo del material por ningn

otivo. Sujete el frente de la sierra por la zona de agarre. No inserte los dedos en la zona contigua a la

gueta y al porta seguetas. No estabilice la sierra sujetando la zapata.

CONSERVE AFILADAS LAS SEGUETAS. Las seguetas sin filo pueden causar que la sierra se atore o se atasque

ajo presin.

PRECAUCION: algunos tipos de madera contienen conservadores como el arsenato cprico de cromo (CCA)

ue pueden ser txicos. Cuando lije, perfore o corte estos materiales, debe tener precaucin para evitar la

halacin y para minimizar el contacto de estas sustancias con la piel.

a etiqueta de su herramienta puede incluir los siguientes smbolos.

a etiqueta de su herramienta puede incluir los siguientes símbolos.

V..............................volts SPM........................Golpes por minuto

A..............................amperes Hz ..........................hertz

W ............................watts min ........................minutos

..........................corriente alterna ......................corriente directa

n

o ............................velocidad sin carga

..........................construcción clase II

............................erminales de conexión a tierre

..........................símbolo de alerta seguridad .../min ....................revoluciones o

reciprocaciones

por minuto

CARACTERSTICAS Y BENEFICIOS

OTENTE MOTOR DE 6,0 AMPERES - Para larga duracin y proteccin contra sobrecargas.

00% BALEROS DE BOLAS Y DE RODILLOS - Larga vida y durabilidad.

OLPE DE CORTE DE 28,5 mm (1-1/8")

NGRANE CONTRAPESADO - Minimiza la vibracin.

NTERRUPTOR DE ENCENDIDO PERMANENTE - Para uso ms cmodo en periodos prolongados.

ISEO DE ZAPATA FIJA - Proporciona mxima visibilidad en el corte.

APATA DE BORDE RADIAL - Para penetracin de corte ms sencilla.

ELOCIDAD - 02,400 gpm (golpes por minuto)

ORDON ELECTRICO - 2,4 m (8 ft.) 120 V~

QUIPO ESTANDAR - SEGUETA DE ALTA CALIDAD, LLAVE HEXAGONAL, PORTA LLAVE

OTOR

u herramienta funciona con un motor Black & Decker integrado. Asegrese que su alimentacin de corriente conuerde con la marcada en la placa de identificacin. 120 volts, 50/60 Hz o 120 volts CA significa que la heramienta est diseada para funcionar con corriente domstica de 120 volts. Disminuciones en el voltaje mayores

10% causarn prdida de potencia y sobrecalentamiento. Todas las herramientas Black & Decker se prueban en

fbrica. Si la herramienta no funciona, verifique la alimentacin de corriente.

NTERRUPTOR

u sierra reciprocante Q450 est equipada con velocidad variable (Figura 1)que le permite seleccionar la veloci-

ad apropiada para cualquier operacin. Oprima el gatillo interruptor para ENCENDER la herramienta. Libere

gatillo para APAGARLA. Mientras ms oprima el gatillo, mayor ser la velocidad. (0-2400 golpes por minuto)

ara asegurar el gatillo en posicin de operacin continua, oprmalo, empuje el botn de encendido permanente

ue se encuentra del lado izquierdo del mango, y a continuacin, libere el gatillo (Figura 1). Para desactivar el

ecanismo de encendido permanente, oprima el gatillo hasta el fondo y sultelo a continuacin.

ONTAJE DE LAS SEGUETAS

OTA: No es necesario quitar la guarda de la segueta para instalar una segueta nueva. Para instalar una

gueta en la sierra consulte la figura 2.

1. Desconecte la herramienta

2. Afloje el tornillo prisionero.

3. Introduzca la espiga de la segueta desde el frente entre el eje reciprocante y el sujetador de seguetas.

oloque el agujero de la segueta sobre el perno en el eje reciprocante.

4. Apriete el prisionero.

la segueta se rompiera y el eje no sale del sujetador, asegrese de que el prisionero est flojo, y expulse el eje

on la ua o con un objeto puntiagudo.

OTA: un perno especial fija el sujetador de la segueta al eje reciprocante para evitar que el sujetador se salga

uando el tornillo de sujecin se afloja.

UNCA OPERE LA SIERRA SIN LA GUARDA DE LA SEGUETA EN SU POSICION.

PRECAUCION!: Utilice siempre proteccin para los ojos cuando opere herramientas elctricas.

ORTES AL PAO

exclusivo diseo compacto de la cubierta del motor de la sierra y de la cubierta del eje, permite hacer cortes

xtremadamente cercanos al piso, esquinas y otras reas difciles. Cuando emplee una segueta con vstago no

aralelo para cortes al pao, invierta la segueta como se ilustra en la figura 3.

PRECAUCION: Cuando corte en paredes, pisos o dondequiera que se puedan encontrar cables elctricos

ivos", NO TOQUE NINGUNA PARTE METALICA FRONTAL DE LA HERRAMIENTA. Sujete la sierra solamente

el mango de plstico y de la cubierta para prevenir descargas elctricas si corta un cable "vivo".

ACCESORIOS

Dispone usted de los accesorios enlistados para su herramient

izado Black & Decker.

PRECAUCION: Es peligroso emplear cualquier accesorio no

RECOMENDACIONES PARA SUS PROYECTOS

1. Solamente use seguetas afiladas; hacen cortes ms limpio

corte.

2. Cuando corte, asegrese siempre que la zapata est apoya

control del operador y minimiza la vibracin.

3. Las seguetas disponibles incluyen vstago recto y ligerame

recto en madera, sujete la sierra ligeramente inclinada con rel

to en el corte.

4. Para aumentar la duracin de las seguetas, utilice aquella

acero al carbn soldado a los dientes de acero de alta velocida

ceptible a fracturas.

PARA REPARACION Y SERVICIO DE SUS HERRAM

DIRIGIRSE AL CENTRO DE SERVICIO MAS CERCA

CULIACAN

Av . Nicolas Bravo #1063 Sur (91 6

GAUDALAJARA

Av . La Paz #1779 (91 3

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-

MERIDA

Calle 63 #459-A (91 9

MONTERREY

Av . Francisco I. Madero Pte. 1820-A (91 8

PUEBLA

17 Norte #205 (91 2

QUERETARO

Av . Madero 139 Pte. (91 4

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 4

TORREON

Blvd. Independencia, 96 pte. (91 1

VERACRUZ

Prolongación Diaz Miron #4280 (91 2

VILLAHERMOSA

Constitucion 516-A (91 9

PARAOTRAS LOCALIDADES

INFORMACIÓN DE SERVICIO

Black & Decker ofrece una red completa de centros de serv

a través de toda Norteamérica. Todos los centros de servic

capacitado para proporcionar el servicio a herramientas

Siempre que necesite consejo técnico, reparaciones o part

centro Black & Decker más cercano a usted.

Para encontrar su centro de servicio local, consulte la secc

llame al: 326-7100.

POLIZA DE GARANTIA

IDENTIFICACION DEL PRODUCTO:

Sello firma del Distribuidor .

Nombre del producto:_____________ Mod/Cat.: ____

Marca: _________________________ Núm. de serie:_

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: ____________

Nombre y domicilio del distribuidor donde se adquirió el p

_________________________________________________

Este producto esta garantizado por dos años a partir de la

su funcionamento, así como en materiales y mano de obra

garantía incluye la reparación o reposición del producto y

cliente, incluyendo mano de obra, así como los gastos de t

derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su her

sellada por el establecimiento comercial donde se adquirió

factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condicione

• Cuando el producto no hubiese sido operado de acue

paña;

• Cuando el producto hubiese sido alterado o reparado

de este certificado.

Anexo encontrará una relación de sucursales de servicio d

Page 5

Loading...

Loading...