Page 1

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

11113333 AAAAmmmmpppp EEEElllleeeeccccttttrrrriiiicccc PPPPoooowwwweeeerrrr WWWWaaaasssshhhheeeerr

rr

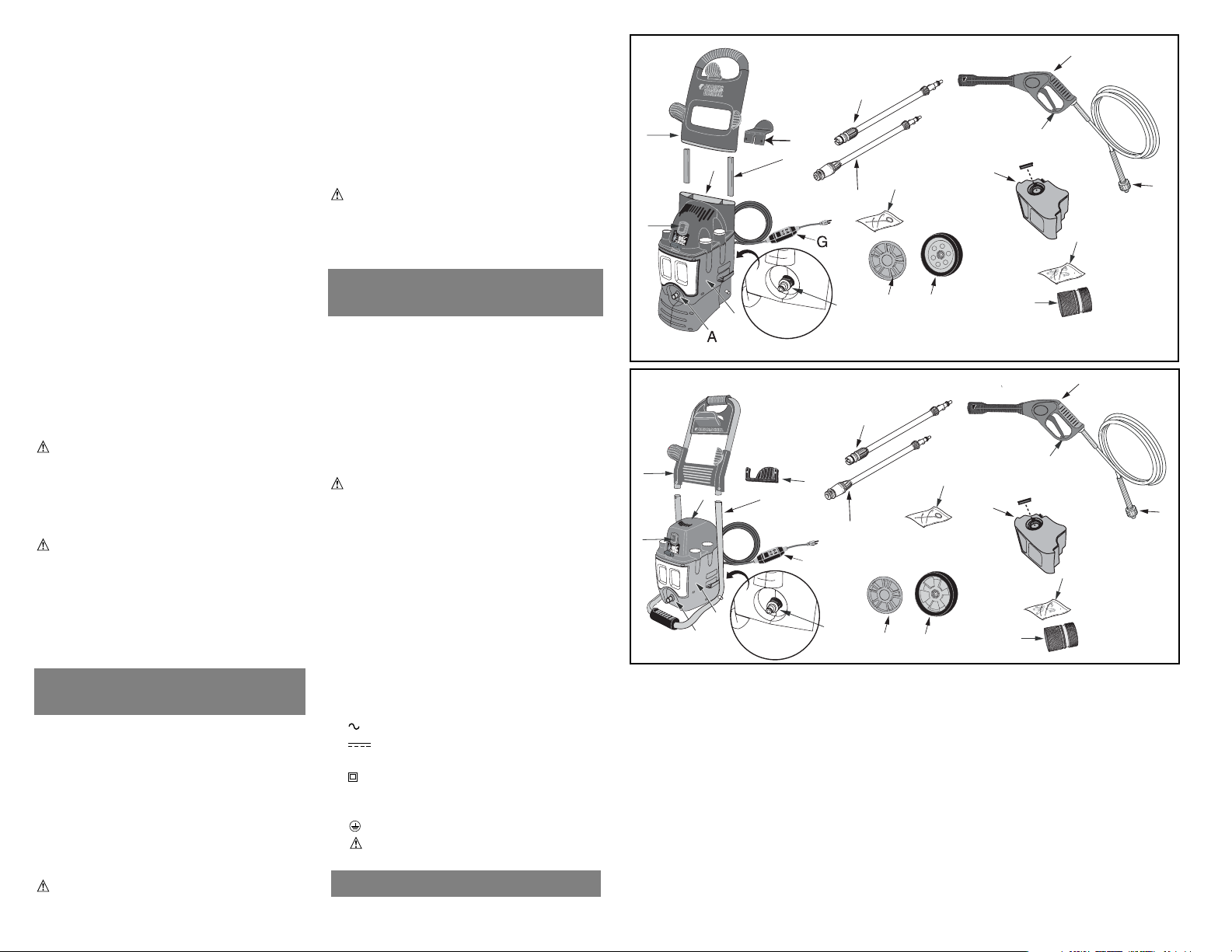

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PRODUCT,

CALL 1-800-544-6986

IN MOST CASES, ABLACK & DECKER REPRESENTATIVE CAN RESOLVE YOUR PROBLEM OVER

THE PHONE. IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS

VITALTO BLACK & DECKER.

Catalog Number PW1600, PW1750

O

I

O

I

Page 2

2

3

WARNING: When using this product,

basic precautions should always be

followed, including the following:

1. Read and understand all instructions

before using the product.

2. To reduce the risk of injury, close

supervision is necessary when a product is

used near children.

3. Know how to stop this product and bleed

pressure quickly. Be thoroughly familiar with

the controls.

4. Stay alert - watch what you are doing.

5. Do not operate this product when

fatigued or under the influence of alcohol or

drugs.

6. Keep operating area clear of all persons.

7. Do not use on ladder. Loss of balance

and serious injury could result. Do not

overreach or stand on unstable support.

Keep good footing and balance at all times.

8. Follow the maintenance instructions

specified in the manual.

9. This product is provided with a Ground

Fault Circuit Interrupter (GFCI) built into the

power cord. If replacement of the plug or

cord is needed, use only identical

replacement parts.

10. WARNING: Risk of Injection or Injury.

Do Not Direct Discharge Stream at

Persons.

GENERAL SAFETY RULES

WARNING: When using this product,

basic precautions should always be

followed, including the following:

1. Always follow detergent manufacturer’s

label recommendations for proper use of

detergents. Always protect eyes, skin and

respiratory system from detergent if used.

2. Never try to stop or deflect leaks with

any body part.

3. Never put hand or fingers over the spray

tip while operating the unit.

4. Always wear safety glasses or goggles,

hearing and respiratory protection and

protective clothing when operating or

performing maintenance.

5. Always engage the trigger safety latch in

the safe position when spraying is stopped

even if only for a few moments.

6. Keep clear of nozzle. Never direct high

pressure spray at any person, animal or

self.

7. Do not use pressure that exceeds the

operating pressure of any of the parts

(hoses, fittings, etc.) in the pressurized

system. Never use with any other

manufacturers accessories or components.

8. Never spray flammable liquids or use

pressure washer in areas containing

combustible dust, liquids or vapors.

9. Never operate this machine in or near an

explosive environment.

10. Do not spray electrical apparatus and

wiring.

11. Never disconnect the high pressure

discharge hose from the machine while the

system is pressurized. To depressurize

machine, turn power and water supply off,

then press gun trigger 2-3 times.

12. Never permanently engage the trigger

mechanism on the gun.

13. Never operate the machine without all

components properly connected to the

machine (handle, gun/wand assembly,

nozzle, etc.).

14. Always turn water supply “on” before

turning pressure washer “on” unless

draining for storage. Running pump dry

causes serious damage.

15. Do not operate the pressure washer

with the inlet water filter removed. Keep

filter clear of debris and sediment.

16. Never operate pressure washer with

broken or missing parts. Check equipment

regularly and repair or replace worn or

damaged parts immediately.

17. Use only the nozzles, parts and

accessories supplied with this machine.

18. Never leave the wand unattended while

the machine is running or switched on.

19. Always hold gun and wand firmly when

starting and operating the machine.

20. Discharge residual pressure by

pressing the trigger until no more water

comes out of the nozzle.

IMPORTANT SAFETY INSTRUCTIONS

CAUTION: Wear appropriate hearing

protection during use. Under some

conditions and duration of use, noise from

this product may contribute to hearing loss.

WARNING: This product contains

chemicals, including lead, known to the

state of California to cause cancer, and

birth defects or other reproductive harm.

Wash hands after handling.

GROUNDING INSTRUCTIONS

This product must be grounded. If it should

malfunction or break down, grounding

provides a path of least resistance for

electric current to reduce the risk of electric

shock. This product is equipped with a cord

having an equipment-grounding conductor

and a grounding plug. The plug must be

plugged into an appropriate outlet that is

properly installed and grounded in

accordance with all local codes and

ordinances.

DANGER: Improper connection of the

equipment-grounding conductor can result

in a risk of electrocution. Check with a

qualified electrician or service personnel if

you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug

provided with the product - if it will not fit

the outlet, have a proper outlet installed by

a qualified electrician. Do not use any type

of adapter with this product.

WARNING: To reduce the risk of

electrocution, keep all connections dry and

off the ground. Do not touch plug with wet

hands.

GROUND FAULT CIRCUIT

INTERRUPTER PROTECTION

This pressure washer is provided with a

Ground Fault Circuit Interrupter (GFCI) built

into the power supply cord. This device

provides additional protection from the risk

of electrical shock. Should replacement of

the plug or cord become necessary, use

only identical replacement parts that

include GFCI protection. See Figure 13 for

testing procedure.

WARNING: Connect directly to outlet.

Do not use with extension cord. The use

of an extension cord will override the

GFCI built into the plug of the power

supply cord resulting in the risk of

electrical shock.

• The label on your tool may include the

following symbols.

V..............volts

A..............amperes

Hz............hertz

W ............watts

min ..........minutes

............alternating current

........direct current

no ............no load speed

............Class II Construction

…/min......revolutions or reciprocation

per minute

............earthing terminal

............safety alert symbol

SAVE THESE INSTRUCTIONS

Page 3

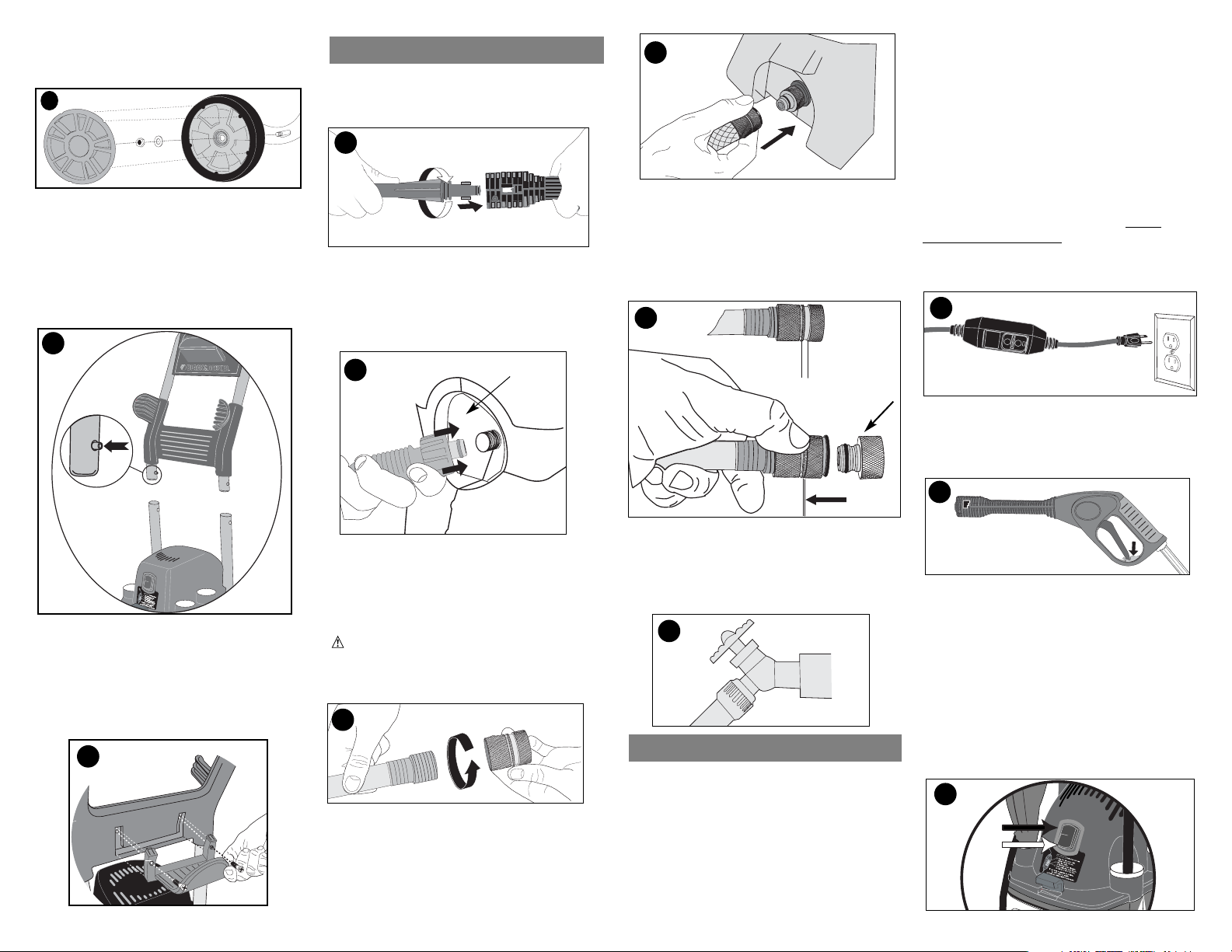

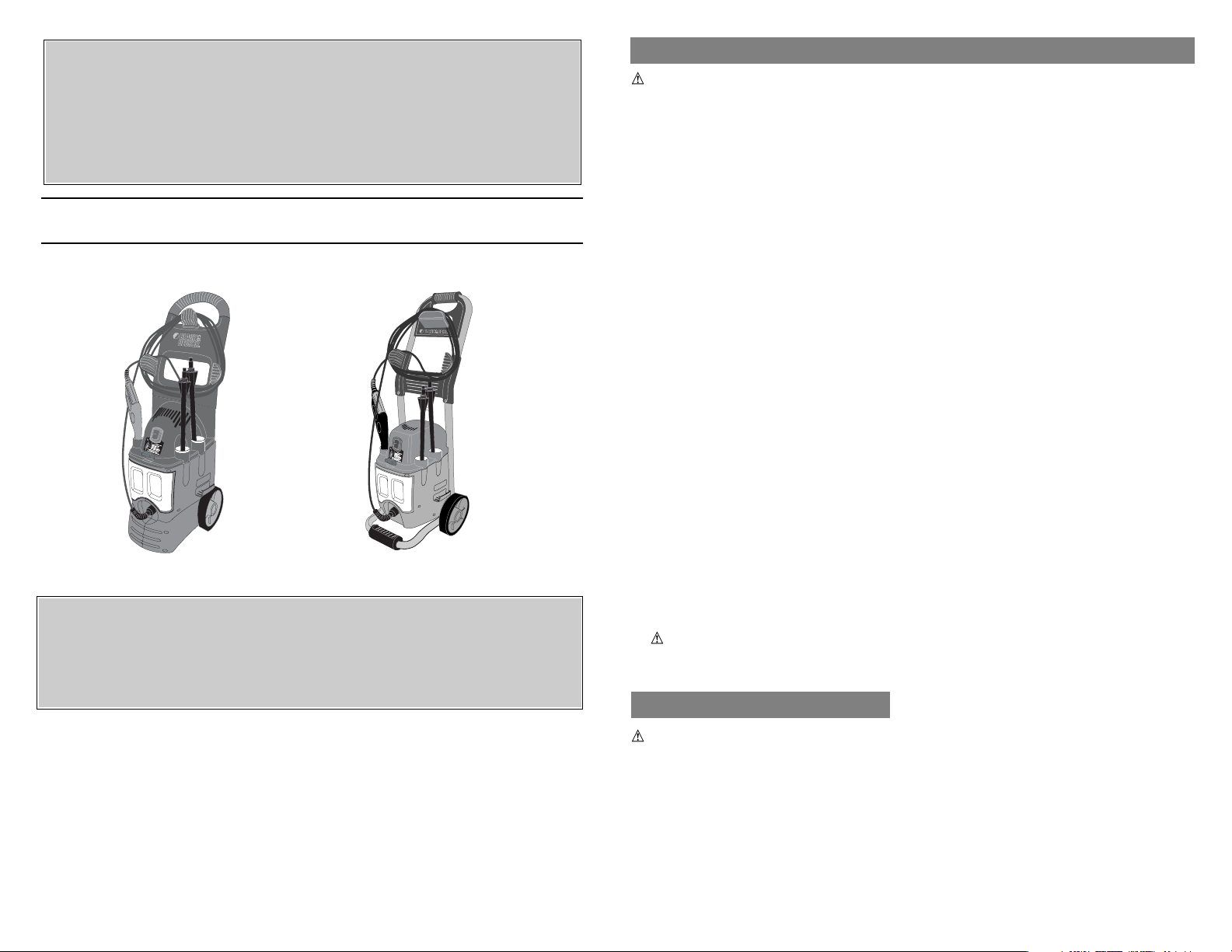

Upper Cord Wrap Hook Assembly - PW1600

Insert cord wrap top hook (M) into the rear

slot in handle (K), pushing down firmly until it

stops. Drive two 1 1/2” self tapping screws

included in cord hook bag through handle

holes into cord wrap hook as shown until

tight. DO NOT over tighten.

PW1750 ASSEMBLY:

Tools Required:

Philips screwdriver

Adjustable wrench

Hardware Bag Contents:

- 2 pcs. flat washers

- 2 pcs. hex locking nuts

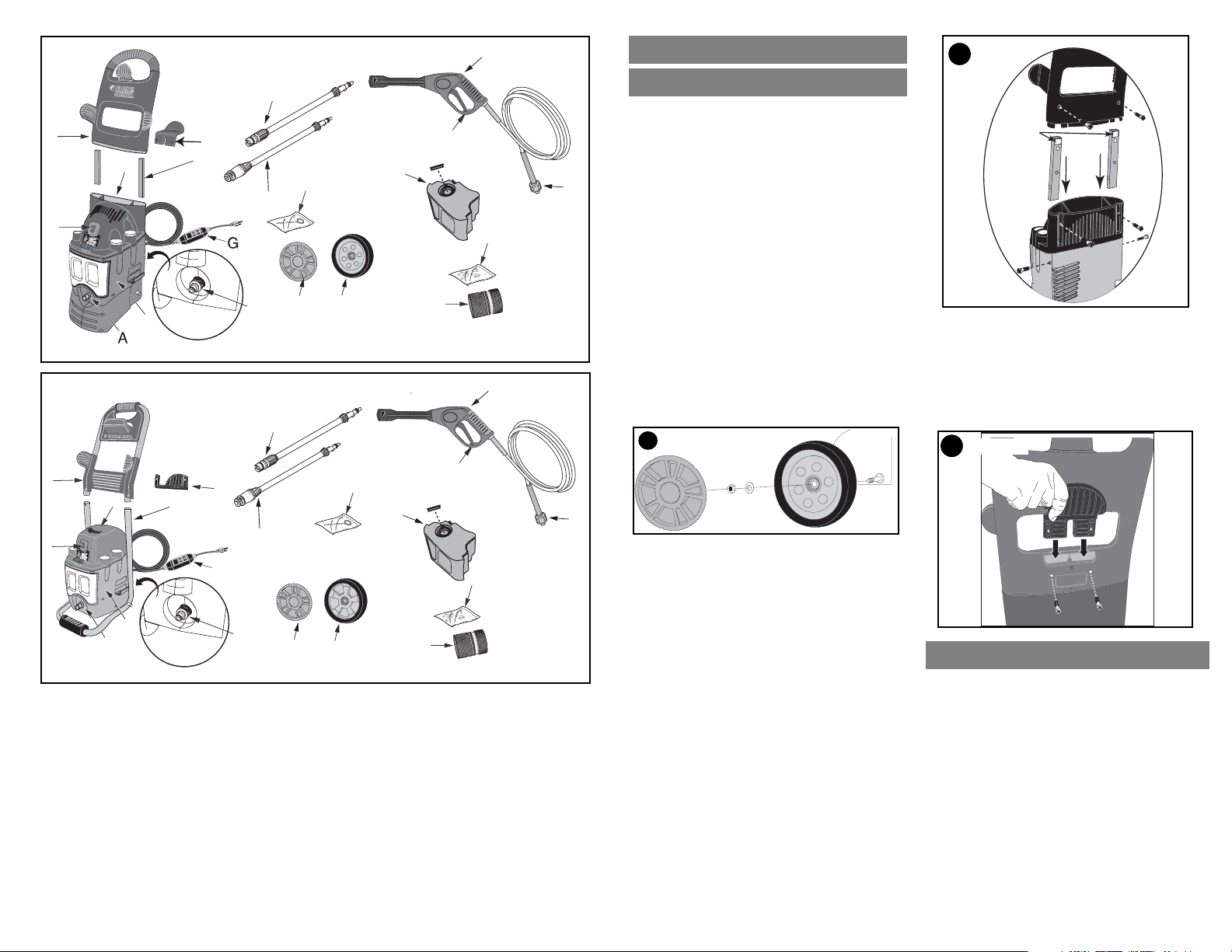

Wheel Assembly - PW1750

Remove the 2 protective plastic end caps

from axle and discard. Place wheel (E) with 5

raised square bumps facing outwards as

shown below over threaded axle end,

followed by flat washer, and hex locking nut.

Using wrench, tighten nut securely. Align 5

square knotches in wheel cap (E1) to raised

PW1600

1

3

4

2

“UP”

Label

UNIT ASSEMBLY

PW1600 ASSEMBLY:

Tools Required:

Philips screwdriver

Adjustable wrench

Hardware Bag Contents:

- 2 pcs. flat washers

- 2 pcs. hex locking nuts

- 6 pcs. 5/8” screws

Wheel Assembly - PW1600

Remove the 2 protective plastic end caps

from axle and discard. Place wheel (E), flat

washer, and hex locking nut over axle end

as shown with smooth face of wheel having

circular holes only facing outwards (side of

wheel with raised spokes faces inwards

toward pressure washer body). Using a

wrench, tighten nut securely. Align wheel

cap (E1) over wheel face as shown and

press center of wheel cap until it snaps

securely to wheel.

Handle Assembly - PW1600

1.) With rectangular steel tube (N) ends

pointing upwards as labeled, push tubes

down firmly into rectangular holes in black

top housing (P) until they hit bottom.

2.) Drive one 5/8” screw through the hole in

each side of the orange housing (Q) as

shown and into the tapped hole of the tube

until tight.

3.) Next drive one 5/8” screw through each

hole in the upper back side of the black top

housing (P) as shown into the tapped hole

of the tube until tight.

4.) You are now ready to align the

rectangular holes in bottom of handle (K)

over the tubes, pushing the handle down

until it’s bottom edge slides into black

housing (P) fully. Drive one 5/8” screw

through each hole in the back of the handle

(K) as shown into the tubes until tight to

complete handle assembly.

4

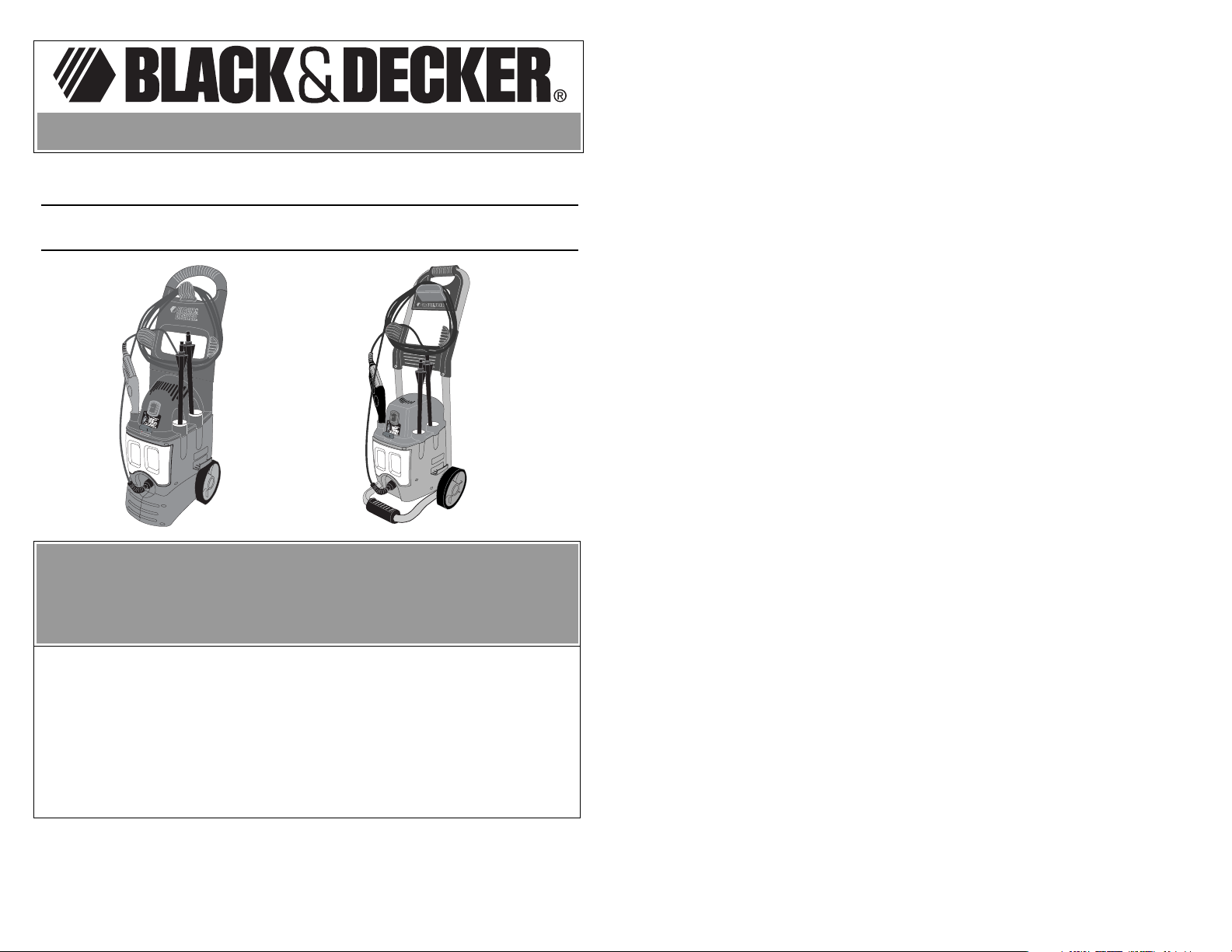

A. High pressure water outlet (OUTLET)

B. Pump Quick Connector

C. High pressure turbo wand

D. Adjustable fan wand

E. Wheels

E1. Wheel Cap

F. Gun

F1. High pressure hose connector

F2. Gun safety catch

G. Power supply cord with GFCI

H. Hardware bag

I. On/off switch

J. Garden hose Quick Connector

K. Handle

L. Removable detergent tank with cap

M. Cord wrap top hook

N. Steel Support tubes

O. Nozzle Cleaning tool

P. Black top housing

Q. Orange main housing

F

F1

F2

H

O

I

I

K

L

J

M

N

O

B

E1

E

D

P

Q

C

O

I

E1

F

F1

F2

I

K

L

J

H

M

O

D

C

E

G

N

Q

A

P

B

PW1600

PW1750

5

2

1

PW1600

3

PW1600

Page 4

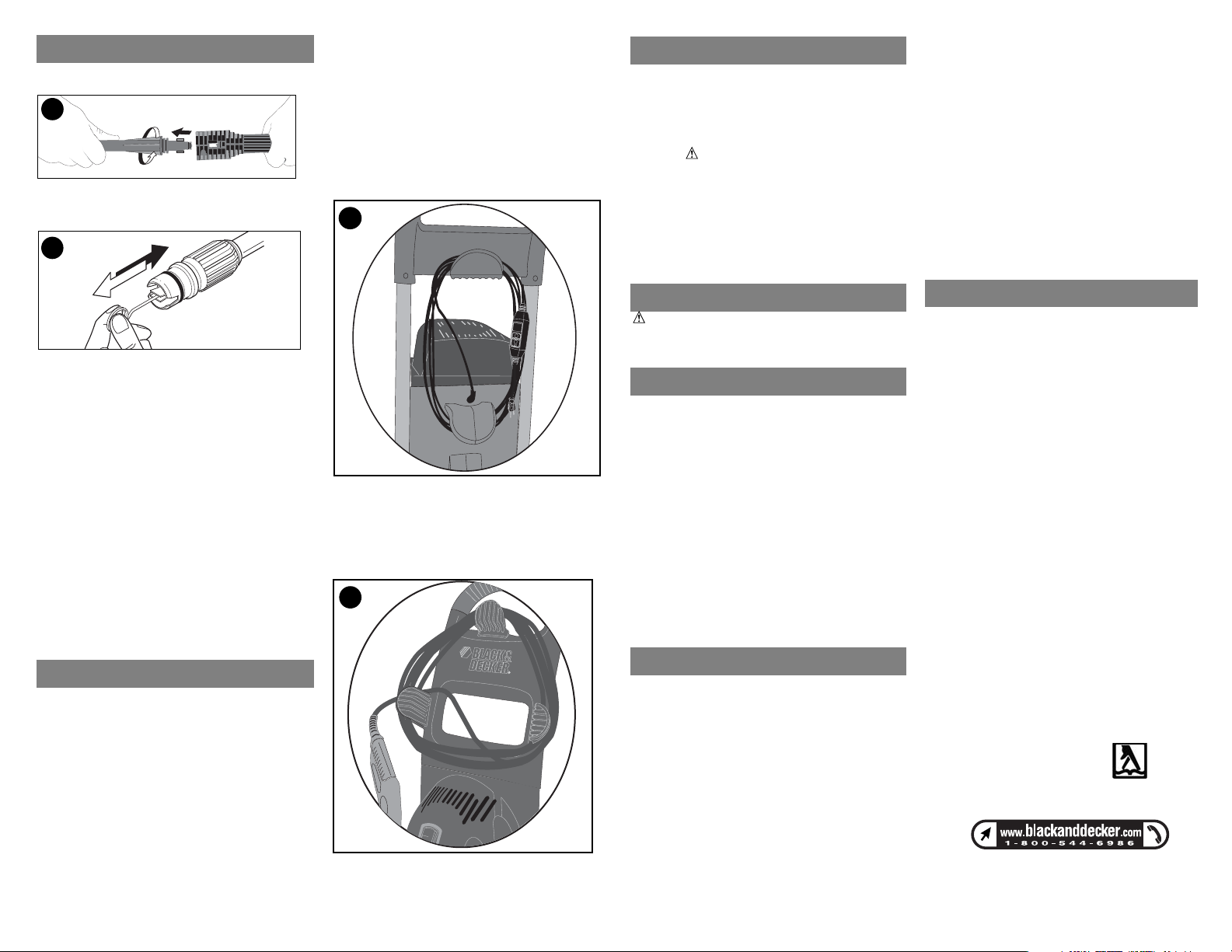

IMPORTANT: The outer brass ring on the

garden hose quick connector MUST be

pulled back fully as shown in Fig. 11b)

before pushing it over the pump quick

connector (B). Water will not flow through

to the pump if these 2 connectors are not

fully coupled.

Figure 12 - Connect other end of garden

hose to the cold water source and turn

water on full. This pressure washer is not

intended to pump hot water. Never connect

it to a hot water supply as it will significantly

reduce the life of the pump.

OPERATION

NOTE: Before cleaning any surface, an

inconspicuous area should be cleaned to

test spray pattern and distance for

maximum cleaning results. If painted

surfaces are peeling or chipping, use

extreme caution as pressure washer may

remove the loose paint from the surface.

This Pressure Washer is equipped with

automatic delivery flow cut-off:

When the trigger is released, the dynamic

pressure automatically stops the motor.

When the trigger is pressed, the internal

pressure drop automatically starts the

motor and the spray pressure is restored

with a very slight delay.

Figure 13 - Ensure the on/off switch (I) is in

the off position before plugging in the unit.

Depress the switch portion marked “O” to

ensure unit is off. Plug the Ground Fault

Circuit Interrupter (GFCI) (G) into a power

outlet. Indicator should turn red. T

EST

BEFORE EACH USE. Press the “TEST”

button. Red indicator should disappear.

Press “RESET” button again for use. Do

not use if above test fails.

Figure 14 - Before each use, ensure the

gun safety catch is released by pushing it

down as shown, then press the trigger for a

few seconds to allow air to escape and to

discharge residual pressure in the hoses.

Figure 15 - Turn on the pressure washer by

depressing the bottom half of the switch (I)

marked “I”. The unit will run for a few

seconds as it builds up pressure, then will

shut off. It will run on demand as the gun

trigger is depressed. Turn off the pressure

washer by depressing the upper half of the

switch marked “0”.

YOUR PRESSURE WASHER IS NOW

READY TO USE - PLEASE REVIEW THE

FOLLOWING FOR DETAILS ON

ACCESSORIES APPLICATION.

SET-UP / ADJUSTMENT

Figure 7 - Insert the fan wand (D) into the

gun wand (F) by pushing and rotating until

the two parts are locked as shown in

Figure 7.

Figure 8 - Connect the high pressure hose

(F1) to the water (OUTLET) (A) on the unit

by first inserting the brass end of the hose

into the threaded outlet on the front of the

unit, then snugly threading on the hose

coupling.

Figure 9 - Connect the garden hose quick

connector (J) to your garden hose as shown

in Fig. 9. The intake water temperature

must NOT exceed 50°C (122°F). The water

supply pressure must be between

20 and 80 psi.

CAUTION: The pressure washer must

only be used with clean water; use of

unfiltered water or corrosive chemicals will

damage the pressure washer.

Figure 10 - With the quick connector (J)

attached to your garden hose, pull back on

its outer ring and push firmly onto the

mating pump quick connector (B), (already

attached to the pressure washer inlet), then

release ring to engage.

bumps of wheel as shown and press center

of wheel cap until it snaps securely to

wheel.

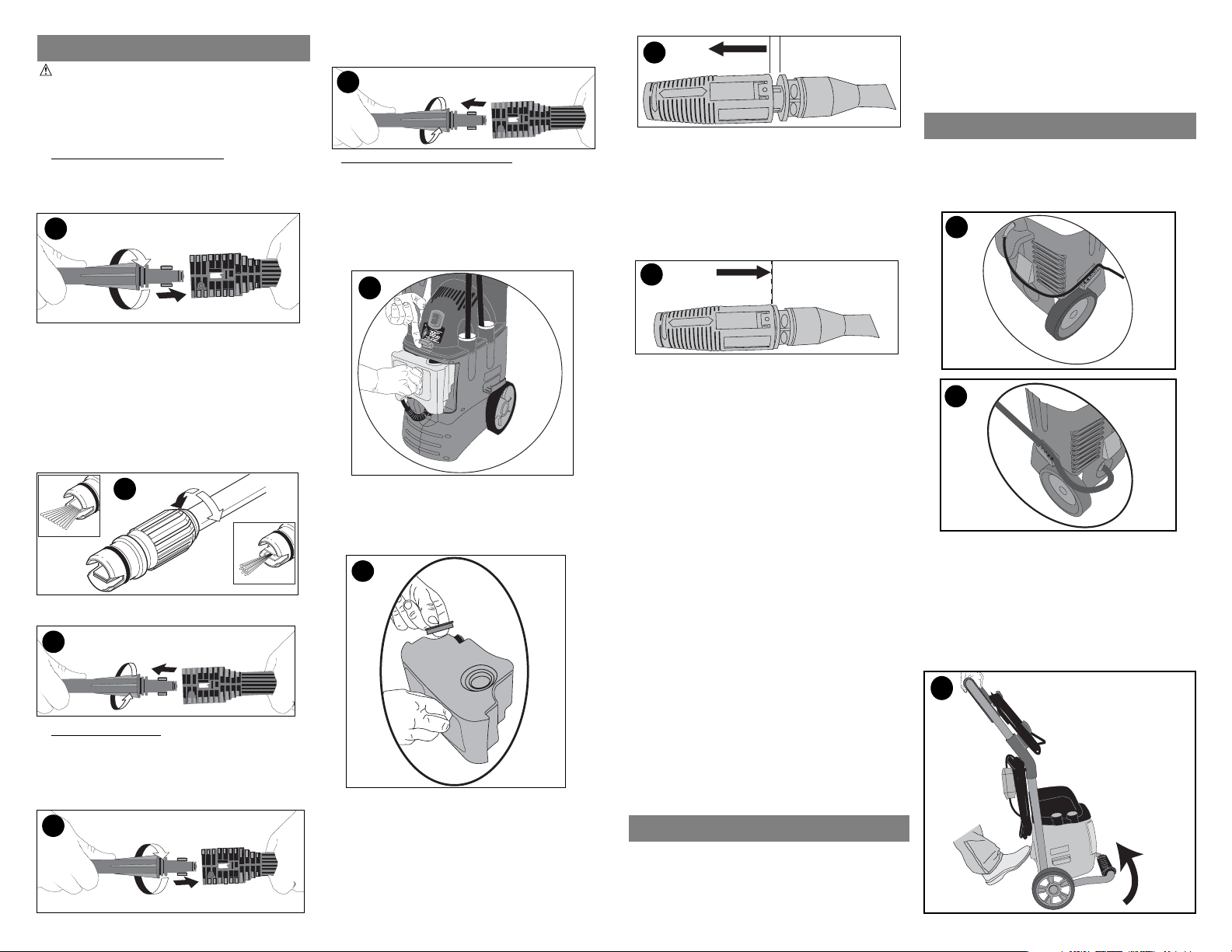

Handle Assembly - PW1750

Align and begin to push tubes of handle (K)

down inside lower tubes (N) as shown.

Press spring buttons (R) of handle (K)

inward as handle tubes are pushed down

fully into lower tubes (N), and both spring

buttons protrude out through holes in lower

tube (N) completing assembly.

Upper Cord Wrap Hook Assembly - PW1750

Insert cord wrap top hook (M) into the rear

slots in handle (K) by pushing upward and

inward to snap in place. Drive two 1/2” self

tapping screws included in cord hook bag

through cord wrap holes into handle as

shown until tight. DO NOT over tighten.

6

High pressure hose

7

O

I

6

7

8

9

10

12

15

13

14

11

a)

b)

Pump Quick

Connector

O

I

PW1750

R

4

PW1750

PW1750

5

Page 5

5.) Apply detergent as directed by the

detergent manufacturer.

6.) To rinse, put the on-off switch in the “off”

(0) position before pushing the adjustable

fan wand nozzle inwards as shown in

Figure 24. This will increase water pressure

and automatically stop detergent flow.

Return on-off switch to “on” (I) position.

7.) Rinse detergent from surface.

8.) When you have finished using the

detergent dispensing system, or when

changing from one detergent type to

another, you must ensure the entire system

has been rinsed clean. To do this, remove

tank to empty remaining detergent, and rinse

tank out several times with clean water.

Then fill detergent tank with clean water and

replace into pressure washer. Leaving the

nozzle in the outward detergent pick up

position as shown in figure 23, press the gun

trigger for 1 minute until only clean water is

sprayed. Remove tank and empty remaining

water. NOTE: Failure to follow the above

detergent rinsing procedure will cause the

dispensing system to become clogged.

NOTE: DO NOT USE:

• Bleach, chlorine products and other

corrosive chemicals.

• Liquids containing solvents (i.e., paint

thinners, gasoline, oils)

• Tri-sodium phosphate products

• Ammonia products

• Acid-based products

These chemicals will harm the unit and will

damage the surface being cleaned.

SURFACE PREPARATION

Before starting any cleaning task it is

important to inspect the area for objects

which could create a hazard. Remove

objects from the area which could be tripped

over such as children’s toys or outdoor

3.) To remove, push turbo wand into gun

wand and twist as shown in Figure 20.

• DETERGENT

DISPENSER

Follow detergent manufacturer’s label

directions for mixing correct concentrations

of soap and detergents.

To use the detergent dispenser:

1.) Pull locking tab upwards as shown in

Fig. 21 and pull tank out of unit.

2.) Lift up to remove cap as shown in

Figure 22, fill tank with detergent and

replace cap. Reinsert tank fully into unit

until locking tab snaps into place.

3.) Insert the adjustable fan wand into gun.

Detergent applicator will only work with

adjustable fan wand.

4.) With the on-off switch in “off” (O)

position, pull the adjustable fan wand

nozzle outwards as shown in Figure 23 to

allow detergent pick up. Put on-off switch in

“on” (I) position.

ACCESSORIES

CAUTION: Before changing

accessories, adjusting pressure, or

engaging detergent draw system, switch

the unit off, pull trigger to release

pressure, and activate gun safety catch.

• ADJUST

ABLE FAN WAND

1.) Insert the fan wand (D) into the gun

wand (F) by pushing and rotating until the

two parts are locked as shown in Figure 16.

2.) To obtain maximum pressure, rotate the

fan wand nozzle in a clockwise direction as

shown in Figure 17. This narrow stream

results in deeper cleaning in a concentrated

area. For a wider fan pattern rotate the fan

wand nozzle in the counterclockwise

direction. The wider fan pattern reduces

the risk of surface damage and allows for

cleaning large surface areas quickly.

3.) To remove, push fan wand into gun

wand and twist as shown in Figure 18.

• TURBO

NOZZLE

1.) Insert the turbo nozzle wand (C) into the

gun wand (F) by pushing and rotating until

the two parts are locked as shown in

Figure 19.

8

O

I

9

furniture. Insure that all doors and windows

are closed tight. Also make sure that all

plants and trees in the adjacent area are

protected by a drop cloth ensuring that they

will not be harmed by any over spray.

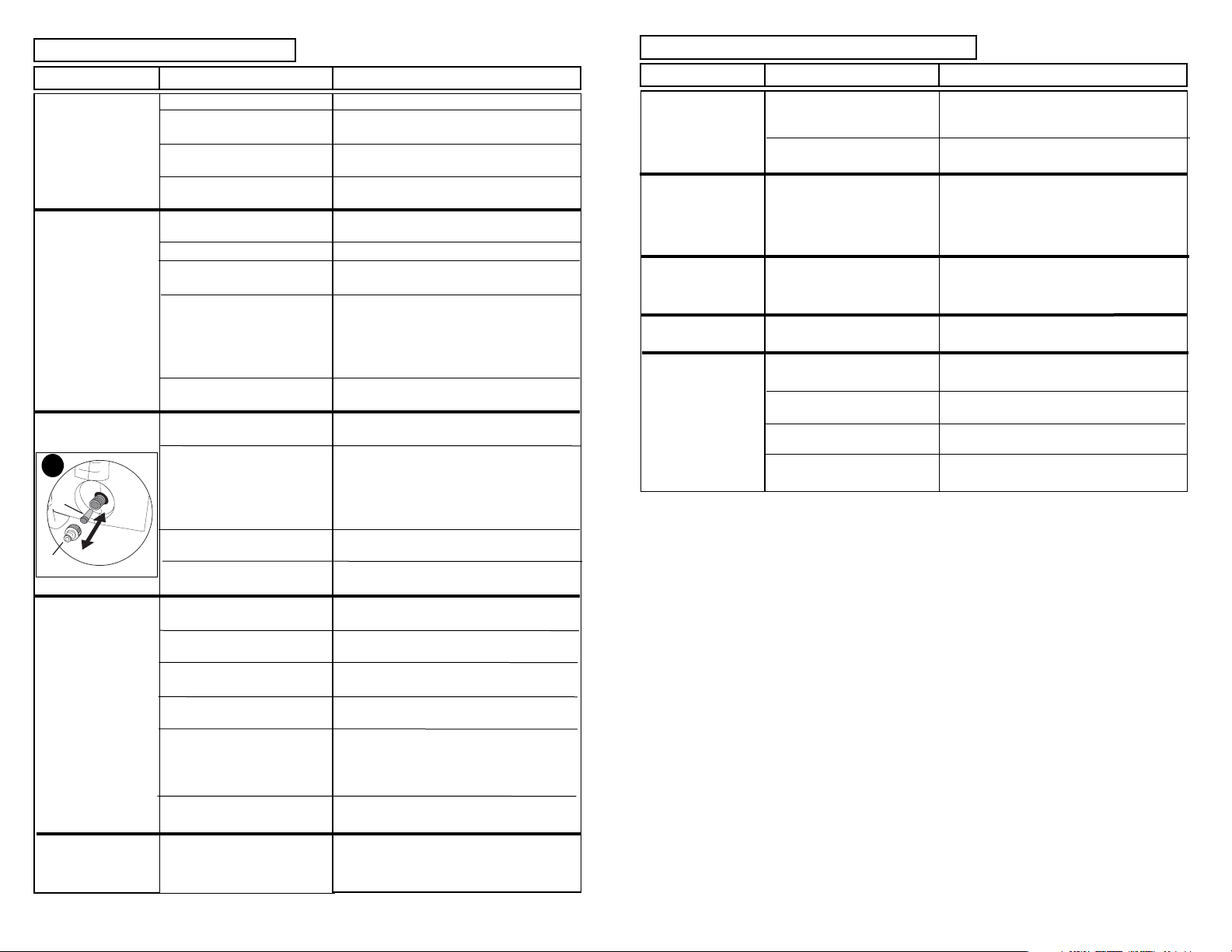

RELOCATING UNIT

1.) To move unit to another location during

cleaning, switch off unit before moving it.

2.) Place power cord and garden hose into

retaining clips as shown in Figures 25 & 26.

3.) Place hand on upper handle and prop

foot against base of unit as shown in

Fig. 27 and tilt the unit backwards.

4.) Pull unit to desired location.

5.) Remove garden hose and power cord

from retaining clips.

6.) Switch unit on to continue use.

25

16

20

23

19

17

18

21

22

24

26

27

Page 6

4. Disconnect the garden hose from the

water inlet.

5. Without garden hose connected to unit,

turn unit on for a few seconds and squeeze

gun trigger until water spray stops. Turn off

switch immediately.

6. Remove any remaining fluid from

detergent tank.

7. Wrap power cord on rear of unit, clipping

plug onto cord as shown in Figure 30.

8. Disconnect the high pressure hose from

the high pressure outlet and drain hose by

pressing gun trigger.

9. Engage the gun safety catch.

10. Wrap high pressure hose on front of

unit as shown in Fig. 31.

IMPORTANT: Store pressure washer

indoors away from areas that might freeze

to avoid seriously damaging the pump.

GENERAL CLEANING TIPS

• Remove the fan wand (D) from the gun

wand (F) as shown in Figure 28.

• Clean the nozzle with the cleaning tool (O).

Remove any dirt from the fan wand nozzle

hole as shown in Figure 29 and rinse.

• For cleaning tasks such as deck or brick

patio cleaning, limit your work area to

approximately 25 square feet at a time.

• Pre-rinse cleaning area with fresh water.

• Use only detergents formulated for

pressure washers.

• Always test detergent in an inconspicuous

area before use.

• Begin with a wide fan nozzle spray and

adjust the pressure to the desired spray

pattern.

• The best angle for spraying water against

a cleaning surface is 45 degrees. Spraying

head on tends to cause dirt particles to

imbed in the surface. When working on

vertical surfaces, it is best to apply

detergent starting at the bottom and working

upwards which will prevent the detergent

from sliding down and causing streaks.

SHUTDOWN / STORAGE

1. Ensure detergent tank and dispensing

system has been thoroughly rinsed as

described on page 9, and empty tank has

been replaced in unit. To empty remaining

water from detergent system put on-off

switch in “on” (I) position, and with nozzle in

outward detergent pick up position, press

gun trigger for 30 seconds. Water from the

pump will still be sprayed at low pressure

after 30 seconds, but detergent system will

be purged.

2. Put the on-off switch in “off” (O) position

and unplug the cord from the outlet.

3. Turn off water at the faucet.

O

I

31

30

11

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

TECHNICAL INFORMATION

Operating pressure – 1250/1300psi

Maximum pressure* - 1600/1700psi

1. Maximum Water Flow rate* - 1.6gpm

2. Electrical requirements – 120V,

15amps, 60hz

3. Electrical cord – 35ft

4. High pressure hose – 25ft

5. Minimum amperage source –

15amps

6. Pressure of inlet water –

20 to 80 psi

7. Inlet water – Cold water only

8. Chemical injection rate 0.1 gpm

*Water flow and Max. pressure ratings

determined in accordance with PWMA

standard PW101.

29

MAINTENANCE

Clean the nozzle with the tool provided.

Remove any dirt from the spray wand

nozzle hole as shown in Figure 29 and

rinse.

Use only mild soap and damp cloth to clean

the tool. CAUTION: Never use the

pressure washer to clean itself.

IMPORTANT: To assure product SAFETY

and RELIABILITY, repairs, maintenance and

adjustment should be performed by

authorized service centers or other qualified

service personnel, always using identical

replacement parts.

ACCESSORIES

WARNING: The use of any accessory

not recommended for use with this pressure

washer could be hazardous.

SERVICE INFORMATION

Do not return this product to your

retailer. Black & Decker offers a full

network of company-owned and authorized

service locations throughout North America.

All Black & Decker Service Centers are

staffed with trained personnel to provide

customers with efficient and reliable power

tool service.

Whether you need technical advice, repair,

or genuine factory replacement parts,

contact the Black & Decker location nearest

you.

To find your local service location, refer to

the yellow page directory under “Tools—

Electric” or call: 1-800-544-6986.

TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this

product for two years against any defects in

material or workmanship. The defective

product will be replaced or repaired at no

charge. Do not return this product to

your retailer.

Take or send the product (prepaid) to a

Black & Decker owned or authorized

Service Center for repair or replacement at

our option. Proof of purchase may be

required. Black & Decker owned and

authorized Service Centers are listed under

“Tools-Electric” in the yellow pages of the

phone directory.

This warranty does not apply to

accessories. This warranty gives you

specific legal rights and you may have

other rights which vary from state to state

and province to province. Should you have

any questions, contact the manager of your

nearest Black & Decker Service Center.

This product is not intended for commercial

use.

Free Warning Label Replacement: If your

warning labels become illegible or are

missing, call 1-800-544-6986 for a free

replacement.

28

10

Page 7

Unit not plugged in.

On/Off switch is in the Off

position.

Gun trigger not being

squeezed.

GFCI tripped.

Water faucet not fully

turned on.

Water inlet filter clogged.

Nozzle worn.

Pump is sucking air.

Water supply restricted.

Not enough inlet water

supply.

Pump is sucking air.

Water inlet filter clogged.

Discharge nozzle is

obstructed.

Adjustable fan wand nozzle

tip is not pulled forward.

Turbo wand is installed.

Detergent container is

empty.

Detergent is too thick.

Filter on detergent suction

tube is clogged.

Discharge nozzle is

obstructed.

Loose fittings.

Missing/worn rubber

washer.

Plug in power cord.

Turn switch to the “On” position.

Squeeze gun trigger with switch in

“ON” position.

Press reset button at GFCI on plug

end of cord.

Open water faucet fully.

Remove filter (B1) and rinse to clean. Fig. 32

Contact B&D Customer Service

Representative at 1-800-544-6986.

Check that hoses and fittings are air

tight. Turn off machine and purge

pump by squeezing gun trigger until a

steady flow of water emerges from the

nozzle.

Check garden hose for kinks, leaks

and blockage.

Turn water on full force - check garden

hose for leaks and kinks.

Check that hoses and fittings are air

tight. Turn off machine and purge

pump by squeezing gun trigger until a

steady flow of water emerges from the

nozzle.

Remove filter (B1) and rinse to clean.

Fig. 32

Remove debris as shown in Fig. 29

with tool provided.

Pull nozzle tip forward.

Remove turbo wand. Install adjustable

fan wand and pull nozzle tip forward.

Add more detergent.

Use detergent recommended for use

in pressure washers only.

Fill tank with warm water and allow

filter to soak. Empty and fill tank with

clean water several times to rinse out

filter.

Remove debris as shown in Fig. 29

with tool provided.

Tighten fittings.

Replace washer in hose adapter.

Motor does not start.

Unit does not reach

high pressure.

Output pressure

varies high/low.

No detergent.

.

Garden hose

connection leaks.

12

TROUBLESHOOTING GUIDE

Symptom Cause Solution

32

Spray wand not properly

attached.

Broken O-ring.

Pump is sucking air.

Loose fittings.

Water seals are damaged

or worn.

Oil seals are damaged or

worn.

Supply voltage below

minimum.

System has residual

pressure.

Voltage loss due to

extension cord.

Cleaner not used for long

periods.

Insert the spray wand into the wand

extension. Push in and turn to lock

spray wand into place.

Contact B&D Customer Service

Representative at 1-800-544-6986.

Check that hoses and fittings are air

tight. Turn off machine and purge

pump by squeezing trigger gun until a

steady flow of water emerges from the

nozzle.

Check that all fittings are tight.

Contact B&D Customer Service

Representative at 1-800-544-6986.

Contact B&D Customer Service

Representative at 1-800-544-6986.

Verify that ONLY the pressure washer

is running on this circuit.

Turn unit off, squeeze gun trigger to

release pressure, then turn unit on.

Do not use extension cord with this

unit - plug directly into outlet.

Contact B&D Customer Service

Representative at 1-800-544-6986.

Spray wand or

extension leaks.

Pump is

excessively noisy.

Water leaks from

pump.

Oil leak.

Motor buzzes but

fails to run.

TROUBLESHOOTING GUIDE - continued

Symptom Cause Solution

13

B

B1

Page 8

14

MANUEL D’UTILISATION

NNNNeeeettttttttooooyyyyeeeeuuuurrrr àààà pppprrrreeeessssssssiiiioooonnnn éééélllleeeeccccttttrrrriiiiqqqquuuuee

ee

ccccoooommmmppppaaaacccctt

tt

AVANT DE RETOURNER CE PRODUIT POUR

QUELQUE RAISON QUE CE SOIT, APPELEZ

BLACK & DECKER AU 1 800 544-6986

NNNNoooo ddddeeee ccccaaaattttaaaalllloooogggguuuueeee PPPPWWWW1111666600000000,,,, PPPPWWWW11117777555500

00

AVERTISSEMENT : Lorsqu’on utilise ce

produit, on doit s’assurer de suivre les

directives indiquées ci-dessous, y compris

les consignes de sécurité suivantes:

1. Lire et comprendre toutes les directives

avant d’utiliser ce produit.

2. Afin de réduire les risques de blessure,

surveiller attentivement les enfants

lorsqu’on utilise ce produit à proximité de

ces derniers.

3. S’assurer de savoir comment arrêter ce

produit et le purger rapidement et de bien

en connaître les commandes.

4. Rester vigilant en tout temps.

5. Ne pas utiliser ce produit lorsqu’on est

fatigué ou sous l’influence de drogues ou

d’alcool.

6. Tenir toute autre personne à l’écart de la

zone de travail.

7. Ne pas utiliser sur une échelle. Perte

d’équilibre et blessures graves pourraient

en résulter. Ne pas travailler hors de portée

ou sur un support instable. Maintenir son

équilibre et les pieds bien ancrés au sol en

tout temps.

8. Suivre les instructions d’entretien

spécifiées dans ce manuel.

9. Ce produit est pourvu d’un Disjoncteur

de fuites à la terre (DDFT) intégré au

cordon d’alimentation. Dans l’éventualité

où la fiche ou le cordon devrait être

remplacé, n’utiliser que des pièces de

rechange identiques.

10. AVERTISSEMENT : Afin d’éviter les

risques d’injection ou de blessure, ne pas

diriger le jet d’eau vers des personnes.

AVERTISSEMENT : Lorsqu’on utilise ce

produit, on doit s’assurer de suivre les

directives indiquées ci-dessous, y compris

les consignes de sécurité suivantes :

1. Toujours suivre les recommandations

précisées sur l’étiquette du fabricant de

détergent afin de s’assurer qu’on utilise

correctement les détergents. Toujours

protéger les yeux, la peau et le système

respiratoire lorsqu’on utilise un détergent.

2. Ne jamais tenter d’utiliser une partie du

IMPORTANTES CONSIGNES DE SÉCURITÉ

corps pour arrêter ou détourner une fuite.

3. Ne jamais placer les mains ou les doigts

sur l’embout de pulvérisation lorsque

l’appareil fonctionne.

4. Toujours porter des lunettes de sécurité,

des protecteurs auditifs, un appareil de

protection respiratoire et des vêtements de

protection lorsqu’on utilise l’appareil ou

qu’on en effectue l’entretien.

5. Toujours enclencher le verrou de sécurité

de la gâchette en position fermée chaque

fois qu’on cesse de pulvériser, même si ce

n’est que pour quelques minutes.

6. Se tenir éloignée de la buse; ne jamais

diriger le jet à haute pression vers une

autre personne, un animal ou soi-même.

7. N’utiliser qu’avec des accessoires ayant

une valeur nominale de 140 bars ou moins.

Ne jamais utiliser une pression supérieure à

la pression d’utilisation d’une pièce

quelconque (flexible, raccord, etc.) lorsque

le système est sous pression, ni un

accessoire ou un composant d’un autre

fabricant.

8. Ne jamais pulvériser de liquide

inflammable ni utiliser le nettoyeur à

pression en présence de poussières, de

liquides ou de vapeurs combustibles.

9. Ne jamais faire fonctionner cette machine

dans un environnement explosif ou à

proximité de celui-ci.

10. Ne jamais pulvériser d’appareils ou de

fils électriques.

11. Ne jamais débrancher le tuyau

d’évacuation haute pression de la machine

lorsque le système est sous pression. Pour

dépressuriser le système, mettre la

machine hors tension, puis fermer le

système d’approvisionnement en eau et

enfoncer la gâchette 2 ou 3 fois.

12. Ne jamais enclencher le mécanisme de

détente de façon permanente.

13. S’assurer que tous les composants

(poignée, ensemble pistolet/tube rallonge,

buse, etc.) sont raccordés correctement à la

machine avant de la faire fonctionner.

14. Toujours mettre le système

d’approvisionnement en eau à la position

de marche (« ON ») avant de mettre le

nettoyeur sous tension afin d’éviter de faire

fonctionner la pompe à sec et

RÈGLES DE SÉCURITÉ - GÉNÉRALITES

15

O

I

O

I

Page 9

16

d’endommager sérieusement la machine,

sauf lorsqu’on purge le système en vue de

le ranger.

15. Ne pas utiliser le nettoyeur à pression

lorsque la grille d’entrée d’eau n’y est pas

rattachée. Toujours s’assurer que la grille est

exempte de débris et de dépôts.

16. Ne jamais faire fonctionner le nettoyeur

lorsque certaines pièces sont manquantes

ou brisées. Vérifier régulièrement

l’équipement et faire réparer ou remplacer

immédiatement les pièces usées ou

endommagées, le cas échéant.

17. N’utiliser que les buses, les pièces et les

accessoires fournis avec la machine.

18. Ne jamais laisser le tube rallonge sans

surveillance lorsque la machine est en

marche ou sous tension.

19. Toujours tenir fermement le pistolet et le

tube rallonge lorsqu’on démarre et qu’on

utilise la machine.

20. Éliminer toute pression résiduelle en

appuyant sur la gâchette jusqu’à l’arrêt

complet de tout écoulement d’eau de l’embout.

MISE EN GARDE : Porter un dispositif de

protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions

et pendant toute la durée de l’utilisation, le

bruit émanant de ce produit pourrait

contribuer à la perte d’audition.

AVERTISSEMENT : Ce produit contient

des produits chimiques, y compris le plomb,

qui, dans l’État de la Californie, sont

reconnus comme étant susceptibles de

causer le cancer, d’entraîner des

malformations congénitales ou d’être nocifs

pour le système reproductif.

Se laver les mains après chaque utilisation.

Le nettoyeur à pression doit être mis à la

terre. En cas de défaillance ou de bris, la

mise à la terre procure un chemin de faible

résistance au courant afin de réduire les

risques de choc électrique. Cet outil est doté

d’un cordon à conducteur et broche de terre;

on doit en raccorder la fiche dans une prise

murale appropriée, bien installée et mise à la

terre, conformément à tous les codes et

règlements en vigueur.

DANGER : Si le conducteur de terre n’est

pas correctement relié à l’appareil, on

s’expose à des risques d’électrocution.

Communiquer avec un technicien ou un

électricien qualifié en cas de doute quant à

la directive de mise à la terre. On ne doit

jamais tenter de modifier cette fiche; si elle

ne s’adapte pas à la prise murale, on doit

faire appel à un électricien qualifié pour

l’installation de la prise appropriée. Ne

jamais utiliser d’adaptateur quelconque avec

ce produit.

AVERTISSEMENT : Afin de réduire les

risques d’électrocution, s’assurer que tous

les raccords sont secs et dégagés du sol.

Ne pas toucher à la fiche avec les mains

mouillées.

Ce nettoyeur à pression est pourvu d’un

Disjoncteur de fuites à la terre (DDFT)

intégré au cordon d’alimentation. Ce

dispositif fournit une protection additionnelle

contre tout risque de choc électrique. S’il est

nécessaire de changer la fiche ou le cordon,

n’utiliser que des pièces de rechange

identiques offrant une protection DDFT. Se

reporter en Figure 13 pour la procédure de

test.

AVERTISSEMENT : Brancher le cordon

directement dans la prise de courant; ne

pas utiliser de rallonge. L'utilisation

d'une rallonge aurait pour effet de

neutraliser le disjoncteur de fuite à la

terre intégré à la fiche du cordon

d'alimentation, ce qui entraînerait des

risques de choc électrique.

• L’étiquette apposée sur l’outil peut afficher

les symboles suivants :

V..............volts

A..............ampères

Hz............hertz

W ............watts

min ..........minutes

............courant alternatif

........courant continu

no ............fonctionnement à vide

............Construction de classe II

…/min......tours ou mouvements

alternatifs par minute

............borne de terre

............symbole d’avertissement

DIRECTIVES CONCERNANT LA MISE À

LA TERRE

CONSERVER CES DIRECTIVES

DISJONCTEUR DE FUITE

À LA TERRE (GFCI)

17

A. Sortie d’eau haute pression (SORTIE)

B. Raccord rapide de pompe

C. Turbo buse à haute pression

D. Buse soufflante réglable

E. Roues

E1. Enjoliveur

F. Pistolet

F1. Raccord de tuyau à haute pression

F2. Cran de sécurité

G. Cordon d’alimentation avec DDFT

H. Sac pour quincaillerie

I. Interrupteur Marche/Arrêt

J. Raccord rapide de tuyau d’arrosage

K. Poignée

L. Réservoir à détergent amovible avec

capuchon

M. Crochet supérieur du rembobineur de

cordon

N. Tubes-supports métalliques

O. Outil de nettoyage du pistolet

P. Boîtier noir

Q. Boîtier principal orange

F

F1

F2

H

O

I

I

K

L

J

M

N

O

B

E1

E

D

P

Q

C

O

I

E1

F

F1

F2

I

K

L

J

H

M

O

D

C

E

G

N

Q

A

P

B

PW1600

PW1750

Page 10

(1/2 po) (incluses dans le sachet du

rembobineur de cordon) au travers des

trous du rembobineur de cordon dans la

poignée comme illustré. Attention à NE PAS

trop serrer.

CONFIGURATION / REGLAGE

Figure 7 - Insérer la buse soufflante (D)

dans la buse du pistolet (F) en appuyant

tout en tournant jusqu’à ce que les deux

parties soient verrouillées ensemble comme

illustré en Figure 7.

Figure 8 - Connecter le tuyau à haute

pression (F1) à la (SORTIE) d’eau (A) sur

l’appareil en insérant tout d’abord le bout en

laiton du tuyau dans la sortie filetée à

l’avant de l’appareil, puis en serrant le

filetage du raccord de tuyau.

Figure 9 - Connecter le raccord rapide de

tuyau d’arrosage (J) au tuyau d’arrosage

comme illustré en Figure 9. La température

d’arrivée d’eau NE doit PAS excéder 50°C

(122°F). La pression d’eau doit être entre 20

et 80 psi.

MISE EN GARDE : Le nettoyeur à

pression ne doit être utilisé qu’avec de l’eau

claire. L’utilisation d’eau non filtrée ou de

produits chimiques corrosifs endommagera

le nettoyeur à pression.

18

19

(P). Pour terminer l’assemblage, visser à

fond l’une des vis de 15,9 mm (5/8 po)

dans chacun des trous à l’arrière de la

poignée (K) comme illustré puis dans le

tube.

Assemblage du crochet supérieur du

rembobineur de cordon - PW1600

Insérer le crochet supérieur (M) du

rembobineur de cordon dans l'orifice arrière

de la poignée (K), en poussant à fond

fermement. Serrer à fond deux vis

autotaraudeuses de 38,1 mm (1 1/2 po)

(incluses dans le sachet du rembobineur de

cordon) au travers les trous de la poignée

dans le crochet du rembobineur de cordon

comme illustré. Attention à NE PAS trop

serrer.

ASSEMBLAGE DU PW1750 :

Outils nécessaires :

Tournevis Philips

Clé réglable

Contenu du sac pour quincaillerie :

- 2 rondelles plates

- 2 écrous de blocage hexagonaux

ASSEMBLAGE

ASSEMBLAGE DU PW1600 :

Outils nécessaires :

Tournevis Philips

Clé réglable

Contenu du sac pour quincaillerie :

- 2 rondelles plates

- 2 écrous de blocage hexagonaux

- 6 vis de 15,9 mm (5/8 po)

Assemblage des roues - PW1600

Retirer et jeter les 2 caches de protection en

plastique des axes. Placer une roue (E), une

rondelle plate et un écrou de blocage

hexagonal de chaque côté de l'axe comme

illustré avec la surface lisse de la roue

pourvue seulement de trous circulaires

dirigée vers l'extérieur (le côté de la roue

pourvu d'embossures est dirigé vers

l'intérieur, vers le châssis du nettoyeur à

pression). À l'aide d'une clé, serrer l'écrou

fermement. Aligner un enjoliveur (E1) sur

chaque roue comme illustré puis appuyer sur

son centre pour l'enclencher à fond sur

chaque roue.

Assemblage de la poignée - PW1600

1.) Avec les bouts rectangulaires du tube

en acier (N) dirigés vers le haut suivant

l’inscription, pousser fermement et à fond

les tubes dans les trous rectangulaires du

boîtier noir (P).

2.) Visser à fond l’une des vis de 15,9 mm

(5/8 po) dans chacun des trous de chaque

côté du boîtier orange (Q) comme illustré et

dans le trou taraudé du tube.

3.) Visser ensuite à fond l’une des vis de

15,9 mm (5/8 po) dans chacun des trous à

l’arrière de la partie supérieure du boîtier noir

(P) comme illustré et dans le trou taraudé du

tube.

4.) Aligner maintenant les trous

rectangulaires sur la partie inférieure de la

poignée (K) sur les tubes, en appuyant sur la

poignée jusqu’à ce que le bord inférieur

s’encastre complètement dans le boîtier noir

PW1600

1

3

4

2

2

Étiquette

« UP »

Assemblage des roues - PW1750

Retirer et jeter les 2 caches de protection

en plastique des axes. Installer les roues

(E) (avec les 5 embossures carrées

dirigées vers l'extérieur comme illustré cidessous) au bout de l'axe fileté, mettre

ensuite une rondelle plate, et un écrou de

blocage hexagonal. À l'aide d'une clé,

serrer l'écrou fermement. Aligner les 5

encoches de l'enjoliveur (E1) sur les

embossures de la roue comme illustré

puis appuyer sur le centre de l'enjoliveur

pour l'enclencher à fond sur la roue.

Assemblage de la poignée - PW1750

Aligner et introduire les tubes de poignée

(K) dans les tubes inférieurs (N) comme

illustré. Pour terminer, appuyer sur les

boutons à ressort (R) de la poignée (K)

tout en poussant les tubes de poignée

complètement dans les tubes inférieurs

(N) jusqu’à ce que les boutons à ressort

s’enclenchent dans les trous du tube

inférieur (N).

Assemblage du crochet supérieur du

rembobineur de cordon - PW1750

Insérer le crochet supérieur (M) du

rembobineur de cordon dans les orifices

arrière de la poignée (K) en poussant vers

le haut pour l'enclencher à fond. Serrer à

fond deux vis autotaraudeuses de 13 mm

3

6

7

8

Tuyau à haute pression

O

I

PW1750

5

R

PW1600

PW1750

PW1600

PW1750

1

4

Page 11

Figure 10 - Une fois le raccord rapide (J)

rattaché au tuyau d’arrosage, repousser son

anneau externe puis pousser fermement sur

le raccord rapide de pompe concourant (B),

(déjà rattaché à l’arrivée du nettoyeur à

pression), relâcher ensuite l’anneau pour

l’encastrer.

IMPORTANT : L’anneau externe en laiton

du raccord rapide de tuyau d’arrosage DOIT

être repoussé à fond comme illustré en

Figure 11b avant de le pousser sur le

raccord rapide de la pompe. (B) L’eau ne

pourra traverser la pompe si ces 2 raccords

ne sont pas intimement assemblés.

Figure 12 - Connecter l’autre bout du tuyau

d’arrosage à la source d’eau froide puis

ouvrir le robinet à fond. Ce nettoyeur à

pression n’a pas été conçu pour pomper de

l’eau chaude. Ne jamais le connecter à une

arrivée d’eau chaude car cela réduirait

considérablement la durée de vie de la

pompe.

20

21

FONCTIONNEMENT

REMARQUE : Avant de nettoyer toute

surface, nettoyer un endroit caché pour

tester la forme de jet et la distance pour un

rendement optimal. Si les surfaces peintes

pèlent ou s’écaillent, prendre des

précautions supplémentaires car le

nettoyeur à pression pourrait enlever la

peinture qui se décolle.

Ce nettoyeur à pression est équipé d’un

système d’arrêt automatique.

Lorsque la gâchette est relâchée, la

pression dynamique arrête

automatiquement le moteur.

Lorsqu’on appuie sur la gâchette, la baisse

de pression interne met en marche

automatiquement le moteur et la pression

du jet est restaurée très rapidement.

Figure 13 – S’assurer que l’interrupteur (I)

est en position « Arrêt » avant de brancher

l’appareil. Appuyer sur la partie de

l’interrupteur marquée « 0 » pour s’assurer

que l’appareil est arrêté. Brancher le

disjoncteur de fuites à la terre (DDFT) (G)

sur le secteur. Le voyant rouge devrait

s’allumer. TESTER

AVANT CHAQUE

UTILISATION. Appuyer sur le bouton

«TEST». Le voyant rouge devrait

s’éteindre. Appuyer sur le bouton «RESET»

(Réinitialiser) pour utiliser l’appareil. Ne pas

utiliser l’appareil si ce test ne réussi pas.

Figure 14 - Avant chaque utilisation,

s’assurer que le cran de sécurité est bien

relâché en le poussant comme illustré, puis

en appuyant sur la gâchette quelques

secondes pour permettre à l’air de

s’échapper pour éliminer toute pression

résiduelle dans les tuyaux.

Figure 15 - Mettre le nettoyeur à pression

en marche en appuyant sur la partie

inférieure de l’interrupteur (I) marquée

d’un « I ». L’appareil fonctionnera

quelques secondes pour accumuler de la

pression, puis s’arrêtera. Il fonctionnera

sur demande en appuyant sur la gâchette

du pistolet. Arrêter le nettoyeur à pression

en appuyant sur la partie supérieure de

l’interrupteur marquée d’un « 0 ».

LE NETTOYEUR À PRESSION EST

MAINTENANT PRÊT À L’UTILISATION VEUILLEZ REVOIR LES ÉLÉMENTS

SUIVANTS RELATIFS À L’UTILISATION

DES ACCESSOIRES.

ACCESSOIRES

MISE EN GARDE : Avant tout

changement d'accessoire, réglage de

pression, ou toute utilisation du

système à détergent, arrêter l’appareil,

tirer sur la gâchette pour éliminer la

pression, et activer le cran de sécurité.

• BUSE SOUFFLANTE RÉGLABLE

1.) Insérer la buse soufflante (D) dans la

buse du pistolet (F) en appuyant tout en

tournant jusqu’à ce que les deux parties

soient verrouillées ensemble comme

illustré en Figure 16.

2.) Pour obtenir un maximum de pression,

faire tourner l’embout de la buse soufflante

vers la droite comme illustré en Figure 17.

Le jet effilé permet de nettoyer en

profondeur une surface restreinte. Pour un

jet plus large faire tourner l’embout de la

buse soufflante vers la gauche. Le jet plus

large réduit les risques d’endommager

certaines surfaces et permet de nettoyer

de larges surfaces rapidement.

3.) Pour la retirer, pousser la buse soufflante

dans la buse du pistolet puis tourner comme

illustré en Figure 18.

•

TURBO EMBOUT

1.) Insérer l’embout de la turbo buse (C)

dans la buse du pistolet (F) en appuyant tout

en tournant jusqu’à ce que les deux parties

soient verrouillées ensemble comme illustré

en Figure 19.

3.) Pour la retirer, pousser la turbo buse

dans la buse du pistolet puis tourner comme

illustré en Figure 20.

• DISTRIBUTEUR DE DÉTERGENT

Suivre les directions fournies par le

fabriquant du détergent pour déterminer le

degré de concentration de savon ou détergent.

Pour utiliser le distributeur de détergent :

1.) Tirer la languette vers le haut comme

illustré en Figure 21 et retirer le réservoir

de l’appareil.

11

a)

b)

Raccord

rapide de

pompe

O

I

15

16

13

20

17

18

14

O

I

21

9

10

19

12

Page 12

22

23

2.) Retirer le capuchon comme illustré en

Figure 22, remplir le réservoir avec le

détergent puis remettre le capuchon.

Pousser le réservoir dans l’appareil pour

l’enclencher à fond.

3.) Insérer la buse soufflante réglable dans

le pistolet. Le distributeur de détergent ne

fonctionnera qu’avec la buse soufflante

réglable.

4.) Avec l’interrupteur en position « Arrêt »

(O), tirer l’embout de la buse soufflante

réglable comme illustré en Figure 23 pour

amorcer le détergent. Mettre l’interrupteur

en position « Marche » (I),

5.) Administrer la quantité de détergent

recommandée par le fabriquant.

6.) Pour rincer, mettre l’interrupteur en

position « Arrêt »(0) avant de pousser sur

l’embout de la buse soufflante comme

illustré en Figure 24. Cela augmentera la

pression d’eau et arrêtera automatiquement

le flot de détergent. Remettre l’interrupteur

en position « Marche » (I).

7.) Rincer la surface de tout détergent.

8.) Une fois l’utilisation du dispensateur de

détergent terminée ou pour changer de type

de détergent, s’assurer de bien rincer

l’ensemble du système. Pour cela, retirer le

réservoir pour en vider tout résidu de

détergent, puis le rincer plusieurs fois à

l’eau claire. Remplir ensuite le réservoir

d’eau claire et le réinstaller sur le nettoyeur

à pression. En laissant l’embout en position

de prise de détergent dirigé vers l’extérieur

comme illustré en Figure 23, appuyer 1

minute sur le pistolet jusqu’à ce que seule

de l’eau claire soit projetée. Retirer le

réservoir et en vider tout résidu d’eau.

REMARQUE : Le fait de ne pas suivre

cette procédure de rinçage aura pour

conséquence de boucher le dispensateur

de détergent.

REMARQUE : NE JAMAIS UTILISER :

• Eau de Javel, produit à base de chlore ou

tout autre produit chimique corrosif.

• Liquides à base de solvants

(ex. : diluants, essence, huiles)

• Produits à base de triphosphate de sodium

• Produits ammoniaqués

• Produits à base d’acide

Ces produits chimiques endommageront

l’appareil ainsi que les surfaces nettoyées.

PREPARATION DES SURFACES

Avant de commencer tout projet de

nettoyage, il est important d’inspecter les

lieux de travail pour prévenir tout accident

potentiel. Retirer les objets sur lesquels on

pourrait trébucher comme jouets ou

meubles de jardin. S’assurer que porte et

fenêtre sont bien fermées. S’assurer aussi

que plantes et arbres sur la périphérie sont

protégés par une toile de protection pour

éviter qu’ils soient endommagés par des

éclaboussures.

DEPLACEMENT DE L’APPAREIL

1.) Pour déplacer l’appareil pendant le

nettoyage, arrêter tout d’abord ce dernier.

2.) Disposer cordon d’alimentation et tuyau

d’arrosage dans les serre-câbles comme

illustré en Figure 25 et 26.

3.) Attraper la poignée supérieure et

appliquer le pied contre la base de

l’appareil comme illustré en Figure 27 puis

incliner l’appareil vers l’arrière.

4.) Tirer l’appareil jusqu’à l’endroit désiré.

5.) Retirer cordon d’alimentation et tuyau

d’arrosage des serre-câbles.

6.) Remettre l’appareil en marche.

CONSEILS GENERAUX DE NETTOYAGE

• Retirer la buse soufflante (D) de la buse

du pistolet (F) comme illustré en Figure 28.

• Nettoyer l’embout à l’aide de l’outil de

nettoyage (O). Éliminer toute saleté de

l’embout de la buse soufflante comme

illustré en Figure 29 puis rincer.

• Pour tout projet de nettoyage tels

terrasses ou patios de brique, limiter la

surface de travail à environ 25 pieds carré à

la fois.

• Effectuer un pré rinçage de la surface à

l’eau claire.

• N’utiliser que des détergents formulés

pour des nettoyeurs à pression.

• Toujours tester le détergent sur un endroit

caché avant usage.

• Commencer par un jet large avec la buse

soufflante puis régler la pression à la forme

de jet désirée.

• Le meilleur angle de jet par rapport à une

surface à nettoyer est de 45 degrés. Le fait

d’arroser directement a tendance à

augmenter l’adhésion des particules de

saleté à la surface. Lors du travail sur des

surfaces verticales, il est conseillé

d’appliquer le détergent du bas vers le haut

pour prévenir toute coulée de détergent et

laisser des traces.

ARRET / RANGEMENT

1. Bien s’assurer que le réservoir et le

dispensateur de détergent ont été rincés à

fond comme décrit en page 21, et que le

réservoir vide à été réinstallé sur l’appareil.

Pour vider le dispensateur de détergent de

tout résidu, mettre l’interrupteur

marche/arrêt en position « ON » (I), puis

avec l’embout en position de prise de

25

24

26

27

29

28

23

22

Page 13

24

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

25

détergent dirigé vers l’extérieur, appuyer

sur le pistolet 30 secondes. L’eau de la

pompe continuera d’être projetée à basse

pression après 30 secondes, mais le

dispensateur de détergent sera purgé.

2. Mettre l’interrupteur en position d’arrêt

(O) puis débrancher le cordon du secteur.

3. Arrêter le robinet d’eau.

4. Déconnecter le tuyau d’arrosage de

l’arrivée d’eau.

5. Une fois le tuyau d’arrosage

déconnecté de l’appareil, mettre ce dernier

en marche quelques minutes et appuyer

sur le pistolet pour éliminer tout résidu

d’eau. Arrêter l’appareil immédiatement.

6. Vider complètement le réservoir de tout

détergent.

7. Enrouler le cordon d’alimentation à

l’arrière de l’appareil, en accrochant la

fiche à la corde comme illustré en Figure

30.

8. Déconnecter le tuyau à haute pression

de la sortie à haute pression et vider le

tuyau en appuyant sur la gâchette du

pistolet.

9. Mettre le cran de sécurité.

10. Enrouler le tuyau à haute pression à

l’avant de l’appareil comme illustré en

Figure 31.

O

I

31

30

INFORMATION SUR LES SERVICES

Ne pas retourner cet appareil chez

votre détaillant. Black & Decker dispose

d’un réseau complet composé de centres

de service et de centres autorisés situés

partout en Amérique du Nord. Tous les

centres de service Black & Decker sont

dotés de personnel qualifié en matière

d’outillage électrique; ils sont donc en

mesure d’offrir à leur clientèle un service

efficace et fiable.

Pour obtenir un conseil technique ou une

pièce d’origine ou pour faire réparer un

outil, on peut communiquer avec le centre

Black & Decker le plus près.

Pour obtenir le numéro de téléphone,

consulter les pages jaunes sous la

rubrique «Outils - électriques» ou

composer le 1 800 544-6986.

GARANTIE DE DEUX ANS POUR

USAGE RESIDENTIEL

Black & Decker (É.U.) Inc., garantit ce

produit pour une période de deux ans

contre tout défaut de matériel ou de

fabrication. Le produit défectueux sera

réparé ou remplacé gratuitement. Ne pas

retourner cet appareil chez votre détaillant.

Rapporter ou envoyer l’appareil (prépayé)

à un centre Black & Decker ou à un centre

de service autorisé aux fins de réparation

ou de remplacement, selon notre choix.

Une preuve d’achat peut être requise. Les

centres Black & Decker et les centres de

service autorisés sont répertoriés dans les

pages jaunes sous la rubrique «Outils électriques».

Cette garantie ne s’applique pas aux

accessoires. Elle confère des droits légaux

particuliers à l’acheteur, mais celui-ci

pourrait aussi bénéficier d’autres droits

variant d’un état à l’autre.

Toute question doit être adressée au

gérant du centre Black & Decker le plus

près. Ce produit n’est pas destiné à un

usage commercial.

IMPORTANT : Ranger le nettoyeur à

pression à l’intérieur, à l’abri du gel pour

éviter d’endommager sérieusement la

pompe.

ENTRETIEN

Nettoyer l’embout à l’aide de l’outil fourni à

cet effet. Éliminer toute saleté de l’embout

de la buse soufflante comme illustré en

Figure 29 puis rincer.

Nettoyer l'outil à l'aide d'un savon doux et

d’un linge humide.

MISE EN GARDE : Ne jamais utiliser le

nettoyeur à pression pour nettoyer ce

dernier.

IMPORTANT: pour assurer la SÉCURITÉ

et la FIABILITÉ de ce produit, toutes les

opérations de réparation, d’entretien et de

réglage doivent être effectuées dans un

centre de service autorisé ou par du

personnel qualifié; on ne doit utiliser que

des pièces de rechange identiques.

ACCESSOIRES

AVERTISSEMENT : L’usage de tout

accessoire non recommandé avec ce

nettoyeur à pression peut présenter un

danger.

REMPLACEMENT GRATUIT DE

L’ÉTIQUETTE D’AVERTISSEMENT :

En cas de perte ou d’endommagement des

étiquettes d’avertissement, composer le

1 800 544-6986 afin d’en obtenir de

nouvelles sans frais.

FICHE TECHNIQUE

Pression d’utilisation – 1250/1300psi

Pression maximum* - 1600/1700psi

1. Débit d’eau maximum*

– 6,06 l/min (1,6gpm)

2. Spécifications électriques

– 120V, 15amp, 60Hz

3. Cordon d’alimentation – 10m67 (35pi)

4. Tuyau à haute pression – 7m62 (25 pi)

5. Intensité minimale – 15 amp

6. Pression d’arrivée d’eau – 20 à 80 psi

7. Arrivée d’eau – Eau froide seulement

8. Débit d’injection de produits chimiques

– 0,38 l/min (0,1 gpm)

*Débit d’eau et pression maximum

déterminés conformément aux standards

PWMA, PW101.

Page 14

26

27

Brancher le cordon d’alimentation.

Mettre l’interrupteur en position

«Marche».

Appuyer sur la gâchette du pistolet

avec l’interrupteur en position «

Marche ».

Appuyer sur le bouton de

réinitialisation sur le dispositif DDFT.

Ouvrir le robinet d’eau à fond.

Retirer le filtre (B1) et le rincer pour le

nettoyer. Fig. 32

Contacter les services clientèle B&D

au 1-800-544-6986.

Vérifier que tuyaux et raccords sont

étanches à l’air. Arrêter l’appareil et

purger la pompe en appuyant sur la

gâchette du pistolet jusqu’à ce qu’un

flot régulier d’eau sorte de l’embout.

Vérifier l’absence de tout

enchevêtrement, fuite ou blocage

Ouvrir l’arrivée d’eau à fond. Vérifier

l’absence de toute fuite ou

enchevêtrement sur le tuyau

d’arrosage.

Vérifier que tuyaux et raccords sont

étanches à l’air. Arrêter l’appareil et

purger la pompe en appuyant sur la

gâchette du pistolet jusqu’à ce qu’un

flot régulier d’eau sorte de l’embout.

Retirer le filtre (B1) et le rincer pour le

nettoyer. Fig. 32

Retirer tout débris comme illustré en

Figure 29 avec l’outil fourni à cet effet.

Tirer l’embout vers l’avant.

Retirer la turbo buse. Installer la buse

soufflante réglable et tirer son embout

en avant.

Rajouter du détergent.

Utiliser un détergent recommandé pour

les nettoyeurs à pression.

L’appareil n’est pas

branché.

L’interrupteur est en

position d’arrêt.

La gâchette n’est pas

poussée.

Le DDFT a sauté.

Le robinet d’eau n’est pas

ouvert à fond.

Le filtre d’arrivée d’eau est

bouché.

L’embout est usé.

La pompe aspire de l’air.

La source d’eau est

restreinte.

Arrivée d’eau insuffisante.

La pompe aspire de l’air.

Le filtre d’arrivée d’eau est

bouché.

L’embout est bouché.

L’embout de la buse

soufflante réglable n’est

pas tiré en avant.

La turbo buse est

installée.

Le réservoir de détergent

est vide.

Le détergent est trop

épais.

Le moteur refuse de

démarrer.

L’appareil ne

fournit pas de

haute pression.

La pression de

sortie est

irrégulière.

Aucun détergent.

GUIDE DE DÉPANNAGE

Symptôme Cause Solution

Le filtre sur le tube

d’aspiration de détergent

est bouché.

L’embout est bouché.

Raccords lâches.

Joint caoutchouc

manquant ou usé.

La buse d’arrosage n’est

pas rattachée

correctement.

Joint torique endommagé.

La pompe aspire de l’air.

Raccords lâches.

Les joints d’étanchéité sont

endommagés ou usés.

Les joints d’étanchéité

d’huile sont endommagés

ou usés.

Le voltage minimum n’est

pas respecté.

Il reste de la pression

résiduelle dans le système.

Perte de voltage causée

par une rallonge.

Le nettoyeur n’a pas été

utilisé pendant une période

de temps prolongée.

Remplir le réservoir d’eau tiède et

laisser le filtre tremper. Vider le

réservoir puis le remplir d’eau claire

plusieurs fois pour rincer le filtre.

Retirer tout débris comme illustré en

Figure 29 avec l’outil fourni à cet effet.

Serrer les raccords.

Changer le joint du raccord de tuyau.

Insérer la buse d’arrosage dans la

buse d’allonge. Pousser en tournant

pour verrouiller la buse d’arrosage en

place.

Contacter les services clientèle B&D

au 1-800-544-6986.

Vérifier que tuyaux et raccords sont

étanches à l’air. Arrêter l’appareil et

purger la pompe en appuyant sur la

gâchette du pistolet jusqu’à ce qu’un

flot régulier d’eau sorte de l’embout.

Vérifier que les raccords sont bien

serrés.

Contacter les services clientèle B&D

au 1-800-544-6986.

Contacter les services clientèle B&D

au 1-800-544-6986.

Vérifier que SEUL le nettoyeur à

pression fonctionne sur ce circuit.

Arrêter l’appareil, appuyer sur la

gâchette pour éliminer toute pression,

puis remettre l’appareil en marche.

Ne pas utiliser de rallonge avec cet

appareil. Le brancher directement sur

le secteur.

Contacter les services clientèle B&D

au 1-800-544-6986.

Aucun détergent

Fuite au niveau de

la connexion au

tuyau d’arrosage.

Fuite au niveau de

la buse d’arrosage

ou de l’allonge.

La pompe est

excessivement

bruyante.

Fuite d’eau à la

pompe.

Fuite d’huile.

Le moteur

ronronne puis

s’arrête de

fonctionner.

GUIDE DE DÉPANNAGE

Symptôme Cause Solution

32

B

B1

Page 15

28

29

MANUAL DE INSTRUCCIONES

LLLLaaaavvvvaaaaddddoooorrrr aaaa pppprrrreeeessssiiiióóóónnnn ccccoooommmmppppaaaaccccttttoo

oo

NNNNúúúúmmmmeeeerrrroooo ddddeeee ccccaaaattttáááállllooooggggoooo PPPPWWWW1111666600000000,,,, PPPPWWWW11117777555500

00

ANTES DE DEVOLVER ESTE PRODUCTO

POR CUALQUIER MOTIVO POR FAVOR LLAME

(55)5326-7100

ADVERTENCIA: Tome siempre las

precauciones de rigor al usar este

producto, incluyendo lo siguiente:

1. Lea todas las instrucciones antes de

usar el producto.

2. A fin de reducir el riesgo de lesiones, se

debe supervisar el producto muy

atentamente cuando se utiliza cercano a

los niños.

3. Sepa cómo parar el producto y purgar la

presión rápidamente. Familiarícese muy

bien con los controles.

4. Manténgase alerta – esté atento a lo que

está haciendo.

5. No use este producto cuando usted está

fatigado o bajo la influencia del alcohol o

drogas.

6. Mantenga el área de operación

despejada de personas.

7. No se incline demasiado. Conserve

siempre los pies bien apoyados, al igual

que su equilibrio.

8. Siga las instrucciones de mantenimiento

especificados en el manual.

9. Este producto viene con un interruptor

accionado por corriente de pérdida a tierra

(GFCI – Ground Fault Circuit Interrupter)

integrado en el enchufe del cable de

corriente. De necesitarse reemplazar el

enchufe o cable, use únicamente piezas de

repuesto idénticas.

10. ADVERTENCIA: Riesgo de inyección

o lesión. No dirija el chorro de descarga a

las personas.

REGLAS GENERALES DE SEGURIDAD

ADVERTENCIA: Tome siempre las

precauciones de rigor al usar este

producto, incluyendo lo siguiente

1. Siga siempre las recomendaciones para

usar correctamente los detergentes que se

encuentran en la etiqueta del fabricante.

Proteja siempre los ojos, la piel y el

sistema respiratorio cuando usa el

detergente.

2. Nunca trate de parar o desviar escapes

de agua con una parte de su cuerpo.

3. No ponga nunca la mano o sus dedos

sobre la punta del rociador mientras opera

la unidad.

4. Siempre use gafas de seguridad,

protección auditiva y respiratoria así como

vestimenta protectora cuando utiliza el

producto o le hace mantenimiento.

5. Mantenga siempre el cerrojo de

seguridad del gatillo en la posición de

seguridad al parar el rociado, aun cuando

esto sea por algunos momentos.

6. Manténgase alejado de la boquilla de

rociado. Nunca dirija el chorro de alta

presión a otra persona, algún animal o

usted mismo.

7. Usar sólo con accesorios cuya potencia

nominal mínima es de 140 barias. No use

presión que exceda la presión de operación

de cualquiera de las piezas (mangueras,

accesorios, etc.) integrantes del sistema

presurizado. No use nunca con accesorios o

componentes de otro fabricante.

8. Nunca rocíe líquidos inflamables ni use

el lavador a presión en áreas que contengan

líquidos, gases o polvos inflamables.

9. Nunca use esta máquina en atmósferas

explosivas o cerca de ellas.

10. No rocíe aparatos y cableados

eléctricos.

11. Nunca desconecte la manguera de

descarga de alta presión de la máquina

mientras el sistema está presurizado. Para

despresurizar la máquina, apague el

suministro de corriente y agua, presione

luego el gatillo 2 ó 3 veces.

12. Nunca mantenga el mecanismo del

gatillo de la pistola permanentemente

enganchado.

13. Nunca opere la máquina sin todos los

componentes correctamente conectados a

la máquina (manija, unidad de

pistola/varilla, boquilla, etc.)

14. Abra siempre el suministro de agua

antes de activar el lavador a presión, a

menos que lo está drenando para

guardarlo. Dejar que la bomba opere en

seco puede causar daño grave.

15. No opere el lavador a presión sin el

filtro de entrada de agua. Mantenga el filtro

libre de residuos y sedimentos.

16. Nunca opere el lavador a presión con

piezas rotas o faltantes. Inspeccione el

equipo regularmente y repare o reemplace

toda parte desgastada o dañada

inmediatamente.

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

O

I

O

I

Page 16

17. Use las boquillas, partes y accesorios

suministrados con esta máquina solamente.

18. Nunca deje la varilla desatendida

mientras la máquina está prendida o

funcionando.

19. Siempre sujete la pistola y la varilla

firmemente cuando pone en marcha y

opere la máquina.

20. Descargue la presión residual

apretando el gatillo hasta que el agua ya

no sale más de la boquilla.

PRECAUCIÓN Use protección auditiva

adecuada al operar la máquina.

Dependiendo de ciertas condiciones y

duración de la operación, el ruido de este

producto podría contribuir a la pérdida de

la audición.

ADVERTENCIA: La utilización de este

producto lo expondrá a sustancias química

que en el Estado de California se

consideran causantes de cáncer, defectos

congénitos y otros daños reproductivos.

Lávese las manos después de

manipularlo.

Este producto debe estar puesto a tierra.

Si el producto funciona mal eléctricamente, o

falla, la puesta a tierra provee una vía de

resistencia baja de la corriente eléctrica que

reduce el riesgo de electrochoque. Este

producto viene equipado con un cable con

conducto a tierra del equipo y un enchufe

Ídem. El enchufe debe enchufarse a un

tomacorriente adecuado, correctamente

instalado y puesto a tierra de acuerdo con

los códigos y ordenanzas locales.

PELIGRO: Una conexión incorrecta del

conducto de puesta a tierra del equipo

puede resultar en riesgo de electrocución.

Contacte a un electricista o personal de

servicio competente si tiene dudas de si el

tomacorriente está debidamente puesto a

tierra. No modifique el enchufe

suministrado con el producto – si no

encaja en el tomacorriente, instale un

tomacorriente adecuado por un electricista

competente. No use ningún tipo de

adaptador con este producto.

ADVERTENCIA: A fin de reducir el

riesgo de electrocución, mantenga todas

las conexiones secas y por encima de la

tierra. No toque el enchufe con las manos

mojadas.

Este producto viene con un interruptor

accionado por corriente de pérdida a tierra

(GFCI –Ground Fault Circuit Interrupter)

integrado en el enchufe del cable de

corriente. Este dispositivo brinda

protección adicional contra el riesgo de

electrochoque. De ser necesario

reemplazar el enchufe o el cable, uso solo

piezas de repuesto idénticas que incluyan

protección GFCI. Vea la Figura 13 para el

procedimiento de prueba.

ADVERTENCIA: Conectar

directamente al tomacorriente. No usar

con cable de extensión. Usar un cable

de extensión invalidaría el GFCI

integrado en el enchufe del cable de

suministro eléctrico y ocasionar un

riesgo de electrochoque.

• La etiqueta puesta en su herramienta

podría incluir los símbolos siguientes.

V...................voltios

A...................amperios

Hz ................hertzios

W................. vatios

min............... minutos

................ corriente alterna

.............. corriente directa

no ............ velocidad sin carga

.................. Construcción Clase II

.../min ........revoluciones por minuto

.................. terminal a tierra

.................. símbolo de alerta de

seguridad

GUARDE ESTAS INSTRUCCIONES

PROTECCIÓN DE UN INTERRUPTOR

ACCIONADO POR CORRIENTE DE

PÉRDIDA A TIERRA (GFCI – GROUND

FAULT CIRCUIT INTERRUPTER)

INSTRUCCIONES DE PUESTA

A TIERRA

A. Salida de agua a alta presión (SALIDA)

B. Conector rápido para la bomba

C. Vara turbo de alta presión

D. Vara ajustable de rociado en abanico

E. Ruedas

E1. Tapa de la rueda

F. Pistola

F1. Conector de alta presión para la

manguera

F2. Seguro de la pistola

G. Cable de alimentación eléctrica con

GFCI

H. Bolsa de ferretería

I. Conmutador de encendido y apagado

J. Conector rápido para la manguera de

entrada

K. Mango

L. Depósito desmontable con tapa para el

detergente

M. Gancho superior para enrollado del

cable

N. Tubos de metal de soporte

O. Herramienta de limpieza de la boquilla

P. Caja externa superior negra

Q. Caja externa naranja

F

F1

F2

H

O

I

I

K

L

J

M

N

O

B

E1

E

D

P

Q

C

O

I

E1

F

F1

F2

I

K

L

J

H

M

O

D

C

E

G

N

Q

A

P

B

PW1600

PW1750

30 31

Page 17

Ensamblaje del gancho superior para

enrollado del cable - PW1750

Inserte el gancho superior para enrollado

del cable (M) en las ranuras posteriores del

mango (K) empujando hacia arriba y hacia

adentro hasta que entre en su lugar.

Atornille dos tornillos autoenroscables de

1/2” incluidos en la bolsa del gancho para

el cable por los orificios del dispositivo para

enrollado del cable al mango, como

aparece ilustrado, hasta que quede

ajustado. NO ajuste demasiado.

MONTAJE / AJUSTE

Figura 7 - Inserte la vara de rociado en

abanico (D) en la vara de la pistola (F)

empujándola y girándola hasta que las dos

piezas queden enganchadas, como

aparece en la Figura 7.

Figura 8 - Conecte la manguera de alta

presión (F1) al agua (SALIDA) (A) en la

unidad insertando primero el extremo de

latón de la manguera en la salida con hilo

para enroscado del frente de la unidad y

luego enroscando bien el acoplamiento de

la manguera.

rectangulares de la parte inferior del mango

(K) sobre los tubos, empujando el mango

hacia abajo hasta que su borde inferior se

deslice completamente dentro de la caja

externa negra (P). Atornille un tornillo de

15,9 mm (5/8 pulg.) en cada uno de los

orificios de la parte posterior del mango

(K), como lo muestra la figura, dentro de

los tubos hasta que quede ajustado para

completar la unidad del mango.

Ensamblaje del gancho superior para

enrollado del cable - PW1600

Inserte el gancho superior para enrollado

del cable (M) en la ranura posterior del

mango (K), empujando con firmeza hasta

que tope. Atornille dos tornillos autoenroscables

de 1 1/2” incluidos en la bolsa del gancho

para el cable por los orificios del mango al

gancho para enrollado del cable, como

aparece ilustrado, hasta que quede

ajustado. NO ajuste demasiado.

ENSAMBLAJE DE LA PW1750:

Herramientas necesarias: