Black & Decker LP1000 User Manual

1

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

POUR LE FRANÇAIS, VOIR LA COUVERTURE ARRIÈRE.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

IF YOU SHOULD HAVE A QUESTION OR

EXPERIENCE A PROBLEM WITH YOUR

BLACK & DECKER PRODUCT,

CALL 1-800-544-6986

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION

AVAILABLE, CATALOG No., TYPE No., AND DATE CODE (e.g. 0130M). IN

MOST CASES, A BLACK & DECKER REPRESENTATIVE CAN

RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE A

SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS

VITAL TO BLACK & DECKER.

KEY INFORMATION YOU SHOULD KNOW:

• DO NOT OVER-TENSION CHAIN. Refer to “CHAIN

TENSION ADJUSTMENT" for proper method of

tensioning chain.

• Retighten chain frequently during first two hours of use as

chain breaks in.

RLLIGATOR

RLLIGATOR

A

R

AA

LLLLPPPP11110000000000

00

479970-00 LP1000 9/14/05 1:00 PM Page 1

LLIGATO

A

LLIGATO

A

LLIGATO

TM

2

Intended use

Your Black & Decker Alligator LopperTMhas been designed for

pruning trees and cutting small logs up to 4 inches (100mm) in

diameter. This tool is intended for consumer use only.

General Safety Rules

WARNING: Read all instructions. Failure to follow all instructions

listed below may result in electric shock, fire and/or serious injury.

WARNING: To reduce the risk of injury, user must read

instruction manual.

SAVE THESE INSTRUCTIONS.

1. Work area

a. Keep work area clean and well lit. Cluttered and dark areas

invite accidents.

b. Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces such

as pipes, radiators, ranges, refrigerators and wire fences. There

is an increased risk of electric shock if your body is earthed or

grounded.

c. Do not expose power tools to rain, damp or wet conditions.

Water entering a power tool will increase the risk of electric shock.

Don’t use in rain.

d. Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away from

heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

f. Ground Fault Circuit Interrupter (GFCI) protection should be

provided on the circuit(s) or outlet(s) to be used for the

gardening appliance. Receptacles are available having built-in

GFCI protection and may be used for this measure of safety.

3. Personal safety

a. Before you start the saw, make sure the saw chain is not

contacting anything. Stay alert, watch what you are doing and

use common sense when operating a power tool. Do not use a

power tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

b. Use safety equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hard hat,

rubber gloves, snug-fitting clothing or hearing protection used for

appropriate conditions will reduce personal injuries.

c. Avoid accidental starting. Ensure the switch is in the off

position before plugging in. Carrying power tools with your finger

on the switch or plugging in power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all

times. This enables better control of the power tool in unexpected

situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep

479970-00 LP1000 9/14/05 1:00 PM Page 2

3

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g. If devices are provided for the connection of dust extraction

and collection facilities, ensure these are connected and

properly used. Use of these devices can reduce dust related

hazards.

h. Maintain Appliance With Care - Keep cutting edge sharp and

clean for best performance and to reduce the risk of injury.

Follow instructions for lubricating and changing accessories. Inspect

appliance cord periodically, and if damaged, have it repaired by an

authorized service facility. Inspect extension cords periodically and

replace if damaged. Keep handles dry, clean, and free from oil and

grease.

i. Grip Saw Firmly - Hold the chain saw firmly with both hands

when the motor is running. Use a firm grip with thumbs and

fingers encircling the chain saw handles.

j. Power Supply - Connect chain saw to correct voltage, that is,

be sure that the voltage supplied is the same as that specified

on the nameplate of the tool.

4. Power tool use and care

a. Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better and

safer at the rate for which it was designed.

b. Do not use the power tool if the switch does not turn it on

and off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

c. Disconnect the plug from the power source when not in use,

before servicing, before making any adjustments, changing

accessories and attachments such as saw chain and guard or

storing power tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

d. When not in use, appliances should be stored indoors in a

dry, and high or locked-up place, out of the reach of children

and do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Check Damaged Parts - Before further use of the appliance, a

guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting, and any other

condition that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced by an authorized

service center unless indicated elsewhere in this manual.

f. Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier

to control.

g. Use the power tool, accessories and tool bits etc., in

accordance with these instructions and in the manner intended

for the particular type of power tool, taking into account the

working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result

in a hazardous situation.

h. Do not operate a chain saw that is damaged, improperly

adjusted, or is not completely and securely assembled. Be sure that

the saw chain stops moving when the trigger is released.

i. Use extreme caution when cutting small size brush and

saplings because the slender material may catch the saw chain

and be whipped toward you or pull you off balance.

j. Carry the chain saw by the front handle with the saw stopped,

finger off the switch, the guide bar and saw chain to the rear.

k. Maintain Chain Saw With Care - Inspect chain saw cords

periodically and if damaged, have repaired by authorized

service facility. Keep cord clear of the chain and operator at all

479970-00 LP1000 9/14/05 1:00 PM Page 3

4

times. Never carry saw by the cord or pull it to disconnect from

receptacle. Keep cord from oil and sharp edges. Inspect extension

cords periodically and replace if damaged. Keep tools sharp and

clean for better and safer performance. Follow instructions for

lubricating and changing accessories. Keep handles dry, clean, and

free from oil and grease.

5. Service

a. Have your power tool serviced by a qualified repair person

using only identical replacement parts. This will ensure that the

safety of the power tool is maintained.

b. If the replacement of the supply cord is necessary, this has to

be done by the manufacturer or his agent in order to avoid a safety

hazard.

Additional safety instructions for the

Alligator

TM

Lopper

WARNING: Never use the tool above shoulder height. Always

position yourself out of the path of falling branches and debris.

WARNING: Do not use this tool to fell trees.

- Pre-plan a safe exit from falling branches and debris. Ensure the

exit route is clear of obstacles that would prevent or hinder

movement. Remember wet grass and freshly cut bark is slippery.

- Be aware of the direction that a branch may fall. Consider all

conditions that may affect the direction of fall, including:

- The intended direction of fall.

- The natural lean of the branch.

- Any unusual heavy limb structure or decay.

- Surrounding trees and obstacles including overhead lines.

- The wind speed and direction.

- The safe distance between a branch and debris to be felled and

bystanders, buildings and other objects is at least 2 1/2 times the

length of the branch. Any bystander, building or object within this

distance is at risk from being struck by the falling branch.

- When cutting a limb that is under tension be aware of spring back.

When the tension in the wood fibres are released the spring loaded

limb may strike the operator and/or throw the tool out of control.

- Always wear suitable safety equipment such as non-skid

heavy-duty shoes, goggles, ear protection and gloves when

operating the tool.

- Ensure someone is nearby (at a safe distance) in case of an

accident.

- Do not attempt to operate the tool when in a tree, on a ladder or

standing on any other unstable support.

- Keep proper footing and balance at all times.

- Hold the tool firmly with both hands when the motor is running.

- Keep handles dry, clean and free from oil and grease. Greasy oily

handles are slippery causing loss of control.

- Do not let the moving chain contact any object at the tip of the

guide bar.

- Keep your saw chain properly tensioned. Check tension at regular

intervals with the motor stopped and cord disconnected.

- Begin and continue cutting only with the chain moving at full

speed.

- Watch for shifting branches or other forces that could close a cut

and pinch or fall into the chain.

- Use extreme caution when re-entering a previous cut. Engage

spikes on lower jaw into wood and allow the chain to reach full

speed before proceeding with cut.

- Use of this tool for operation different to those intended could

result in hazardous situations. Cut wood only. Don't use this tool for

purposes not intended - for example - Don't use tool for cutting

plastic, masonry or non-wood building materials.

- If any debris gets caught with the guard or tool discontinue use,

disconnect power cord and clear debris.

479970-00 LP1000 9/14/05 1:00 PM Page 4

5

- Worn chains and chain guide bars should be replaced.

- Only use replacement bars and chains specified by the

manufacturer.

- This electrically powered saw is classified by CSA as a Class 2C

saw. It is intended for infrequent use by homeowners, cottagers,

and campers, and for such general applications as clearing,

pruning, cutting firewood, etc. It is not intended for prolonged use.

Prolonged periods of operation can cause circulatory problems in

the user's hands due to vibration. For such use, it may be

appropriate to use a saw having an anti-vibration feature.

Kickback Safety Features

Guard against kickback. Kickback is the upward motion of the guide

bar that occurs when the saw chain, at the nose of the guide bar,

contacts an object. Kickback can lead to dangerous loss of control of

the chain saw.

WARNING: The following features are included on your Alligator

Lopper

TM

to help reduce the hazard of kickback; however such

features will not totally eliminate this dangerous reaction. As a chain

saw user do not rely only on safety devices. You must follow all

safety precautions, instructions, and maintenance in this manual to

help avoid kickback and other forces which can result in serious

injury.

Top Jaw - This has been designed specifically to cover the tip of the

chain bar where the danger zone for kickback occurs. In the event

of any kickback the guard also helps prevent the chain coming into

contact with the operator.

Reduced Kickback Guide Bar - This has been designed with a

small radius tip which reduces the size of the kickback zone on the

bar tip.

Reduced Kickback Chain - Designed with a contoured depth gauge

and guard link which deflect kickback force and allows wood to

gradually ride into the cutter.

Electrical safety

This tool is double insulated; therefore no grounding wire is

required. Always check that the power supply corresponds to the

voltage on the rating plate.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse

dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away

from face and body.

CAUTION: Wear appropriate personal hearing protection during use.

479970-00 LP1000 9/14/05 1:00 PM Page 5

6

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

Extension Cord

Make sure your extension cord is in good condition. When using an

extension cord be sure it is heavy enough to carry the current your

product will draw. An undersized extension cord will cause a drop in

line voltage resulting in loss of power and overheating. The following

table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

Double Insulation

Double insulated tools are constructed throughout with two

separate layers of electrical insulation or one double thickness

of insulation between you and the toolÅfs electrical system.

Tools built with this insulation system are not intended to be

grounded. As a result, your tool is equipped with a two prong

plug which permits you to use extension cords without concern

for maintaining a ground connection. NOTE: Double insulation does

not take the place of normal safety precautions when operating this

tool. The insulation system is for added protection against injury

resulting from a possible electrical insulation failure within the tool.

REPLACEMENT PARTS: When servicing all tools, USE IDENTICAL

REPLACEMENT PARTS. Repair or replace damaged cords.

Polarized Plugs

To reduce the risk of electric shock, this equipment has a polarized

plug (one blade is wider than the other). This equipment must be

used with a suitable polarized 2 wire or 3 wire extension cord.

Polarized connections will fit together only one way. Make sure that

the receptacle end of the extension cord has large and small blade

slot widths. If the plug does not fit fully into the extension cord,

reverse the plug. If it still does not fit, obtain a suitable extension cord.

If the extension cord does not fit fully into the outlet, contact a

qualified electrician to install the proper outlet. Do not change the tool

plug or extension cord in any way.

The label on your tool may include the following symbols.

V................volts A ....................amperes

Hz..............hertz W ..................watts

min ............minutes ..................alternating current

..........direct current

n

o ..................no load speed

..............

Class II Construction

....................earthing terminal

............safety alert symbol .../min ............revolutions

per minute

SAVE THESE INSTRUCTIONS

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

479970-00 LP1000 9/14/05 1:00 PM Page 6

7

CHAIN SAW NAMES AND TERMS

• Bucking - The process of cross cutting a felled tree or log into

lengths.

• Chain Brake - A device used to stop the chain saw.

• Chain Saw Powerhead - A chain saw without the saw chain and

guide bar.

• Clutch - A mechanism for connecting and disconnecting a driven

member to and from a rotating source of power.

• Drive Sprocket or Sprocket - The toothed part that drives the

saw chain.

• Felling - The process of cutting down a tree.

• Felling Back Cut - The final cut in a tree felling operation made

on the opposite side of the tree from the notching cut.

• Guide Bar - A solid railed structure that supports and guides the

saw chain.

• Kickback - The backward or upward motion, or both of the guide

bar occurring when the saw chain near the nose of the top area of

the guide bar contacts any object such as a log or branch, or when

the wood closes in and pinches the saw chain in the cut.

• Kickback, Pinch - The rapid pushback of the saw which can

occur when the wood closes in and pinches the moving saw chain

in the cut along the top of the guide bar.

• Kickback, Rotational - The rapid upward and backward motion

of the saw which can occur when the moving saw chain near the

upper portion of the tip of the guide bar contacts an object, such as

a log or branch.

• Low-Kickback Chain - A chain that complies with the kickback

performance requirements of ANSI B175.1-1991 (when tested ona

representative sample of chain saws.)

• Normal Cutting Position - Those positions assumed in

performing the bucking and felling cuts.

• Reduced Kickback Guide Bar - A guide bar which has been

demonstrated to reduce kickback significantly.

• Replacement Saw Chain - A chain that complies with kickback

performance requirements of ANSI B175.1-1991 when tested

with specific chain saws. It may not meet the ANSI performance

requirements when used with other saws.

• Saw Chain - A loop of chain having cutting teeth, that cut the

wood and that is driven by the motor and is supported by the guide

bar.

• Switch - A device that when operated will complete or interrupt an

electrical power circuit to the motor of the chain saw.

• Switch Linkage - The mechanism that transmits motion from a

trigger to the switch.

479970-00 LP1000 9/14/05 1:00 PM Page 7

8

A

B

C

D

F

E

479970-00 LP1000 9/14/05 1:00 PM Page 8

15

9

G

H

Contents

1. Oil Bottle

2. Wrench

3. Instruction Manual

4. Alligator Lopper

TM

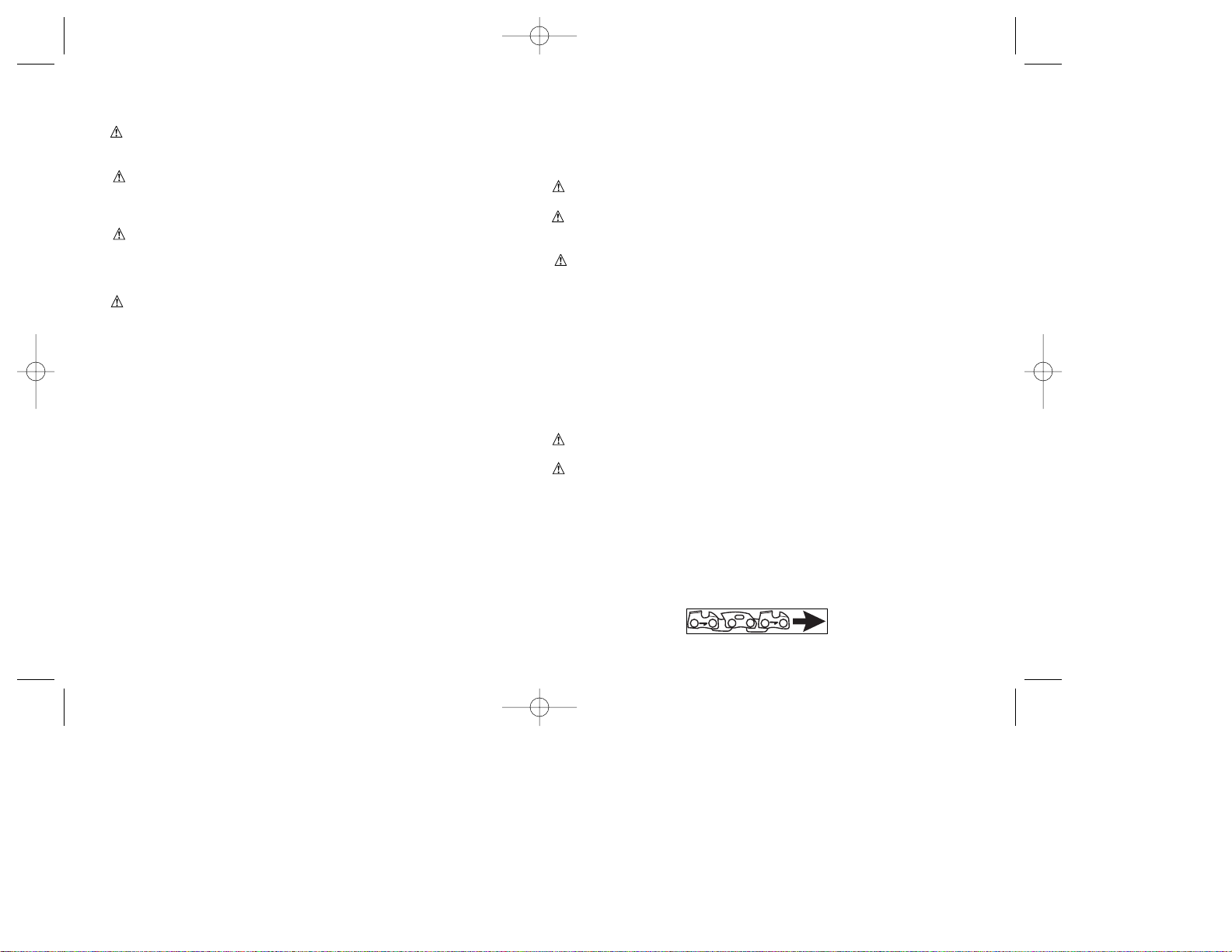

Overview

5. On/off switch actuators

6. Top jaw

7. Lower jaw

8. Chain guide bar

9. Chipping ejection point

10. Oiling cover

479970-00 LP1000 9/14/05 1:00 PM Page 9

10

Preparing Your AlligatorLopperTMFor Use

WARNING: Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury

WARNING: Sharp moving blade. To prevent accidental

operation, ensure that the tool is disconnected from the power

source before performing the following operations. Failure to do

this could result in serious personal injury.

CAUTION: Sharp moving blade. Always wear protective

gloves when installing or removing the chain. The chain is sharp

and can cut you when it is not running.

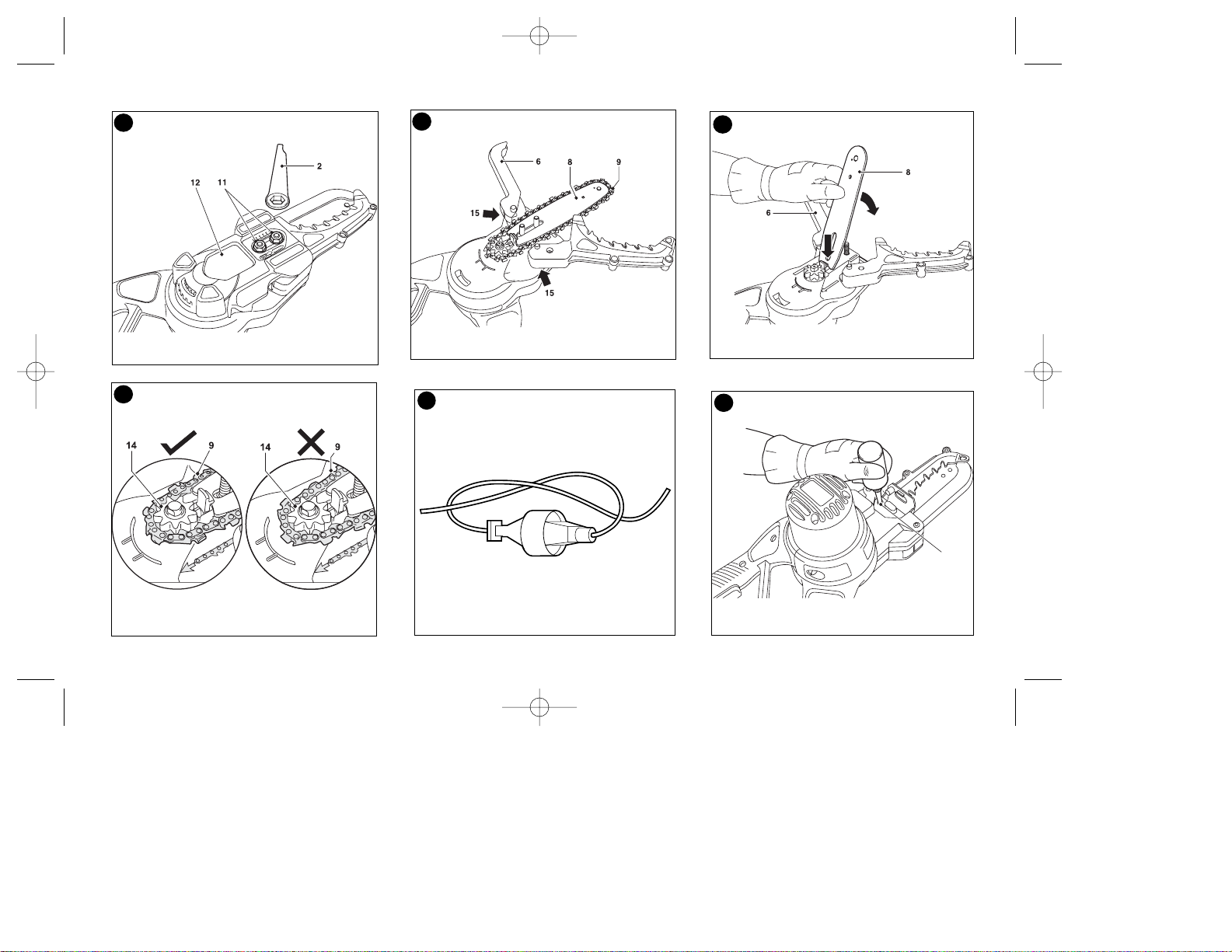

Chain tension adjustment (fig. A)

WARNING: Before chain or other adjustments, make sure

that the tool is switched off and unplugged.

If the chain can not be correctly tensioned, it may need to be

replaced. Contact your nearest service center.

The product comes ready assembled. However we recommend that

you check the tension of the chain, and chain retention nuts before

use and if required adjust.

Checking and adjusting the chain tension (fig. A)

To tension the chain slacken the two chain cover retention nuts (11)

with the wrench (2) and the chain tensioning device will push the

chain bar out, setting the correct tension. Retighten the two

retention nuts (11) securely.

Check that the correct tension has been set by lightly pulling on the

chain. The tension is correct when the chain snaps back after being

pulled 1/8” inch (3 mm) away from the guide bar. There should be

no "sag" between the guide bar and chain on the underside.

Note: Do not over tension the chain as this will lead to excessive

wear and reduce the life of the bar and chain. It will also lead to

reduced product performance.

Note: With first use and when the chain is new, check tension

frequently as a new chain stretches slightly.

Replacing the chain and chain bar

After prolonged use the chain and / or chain bar may need

replacing. Use Black & Decker replacement chain RC600 only.

Low-Kickback saw chain is a chain which has met the kickback

performance requirements of ANSI B175.1 when tested on the

representative sample of chain saws.

Removing the saw chain & chain bar (figs. A & B)

WARNING: Before chain or other adjustments, make sure

that the tool is switched off and unplugged.

WARNING: Laceration hazard. Always wear protective gloves

when installing or removing the saw chain. The saw chain is sharp

and can cut you when it is not running.

WARNING: Burn hazard. The chain guide bar and chain may

become hot during use. Allow to cool before adjustment or removal.

- Place the tool on a firm surface.

- Rotate the two retention nuts (11) counter clockwise with wrench

(2) provided and remove completely.

- Remove the chain access cover (12).

- Open the handles and pull back the top chain cover (6).

- Pull back chain bar (8) and then lift the saw chain (9) out of the

groove in the guide bar. The chain can then be removed from the

unit.

- The chain bar can then be angled up and over the bolts.

Assembling the chain bar and chain (figs. C&D)

WARNING: Before chain or other adjustments, make sure

that the tool is switched off and unplugged.

WARNING: Always wear protective gloves when installing or

removing the saw chain. The saw chain is sharp and can cut you

when it is not running.

- Ensure the operation is carried out on a firm surface.

- Open the handles and pull back the top jaw (6).

- Insert the chain bar (8) into the space between the chain

tensioner and the first bolt, angle the chain bar down over the bolts.

- Place the chain (9) around the front of the chain bar and engage

in the nose sprocket of the chain bar. Make sure chain is installed

properly, with the cutting teeth facing forward as shown here.

479970-00 LP1000 9/14/05 1:00 PM Page 10

11

Pull the chain bar and chain back, engaging it in the groove in the

chain bar and then over the sprocket (14) positioning teeth in the

correct position on the sprocket.

- Replace the chain access cover (12) and retention nuts (11)

tightening securely.

Operation

Never operate a chain saw that is damaged or improperly adjusted or

that is not completely and securely assembled. Be sure that the saw

chain stops moving when the power control system triggers are

released. Never adjust the guide bar or saw chain when the engine is

operating.

WARNING: Let the tool work at its own pace. Do not overload.

- Carry out regular cleaning of the unit as described in the

maintenance section and in particular cleaning inside the chain

access cover.

- The lower guard (7) and top jaw (6) are designed to close when

one of the handles is released or when the piece of branch being

cut has been cut. If this does not occur, discontinue use of the tool

and remove the power cord. Check if any debris is blocking

movement. To help in this process it may be necessary to remove

chain access cover(12). If on assembly the problem is still present

take the unit to a service center.

Extension Cord (fig. E)

To reduce the risk of disconnection of appliance cord from the

extension cord during operation make a knot as shown in Figure E on

page 8.

NOTE: Always keep the cord away from the cutting area and position

the cord so that it will not be caught on branches, and other material,

during cutting.

Oiling (fig. F)

A high quality bar and chain oil or SAE30 weight motor oil should be

used for chain and bar lubrication. The use of a vegetable based bar

and chain oil is recommended when pruning trees. Never use waste

oil or very thick oil. These may damage your chain saw.

- Before first use and every ten minutes of use you must oil the

product with the recommended chain oil. Open the oiling cover (10)

and insert the bottle into the oil filling hole (15) apply pressure to the

bottle once to dispense oil.

- This should be adequate for about 10 minutes of cutting

depending upon cutting speed and type of wood.

- The hole feeds the oil through to the chain onto the chain bar and

an excessive amount of oil applied to the unit could mean the oil

drips from the unit around the jaw area. This is normal and is

nothing to be concerned about.

Switching on and off (fig. G)

For your safety, this tool is equipped with a double switching

system. This system prevents starting the tool inadvertently.

A chain saw is intended for two-handed use. Serious injury to the

operator, helpers, and/or bystanders can result from one-handed

operation.

Switching on

Ensure a firm grip on the handles and then squeeze both switch

actuators to switch the unit on.

Note: Both switches must be activated for the product to be used.

Do not force the tool - allow it to do the work. It will do a better and

safer job at the speed for which it is designed. Excessive force will

stretch the chain.

If the saw chain or bar becomes jammed:

- Switch the tool off.

- Disconnect the tool from the power supply.

- Open the cut with wedges to relieve the strain on the guide bar.

Do not try to wrench the saw free. Start a fresh cut.

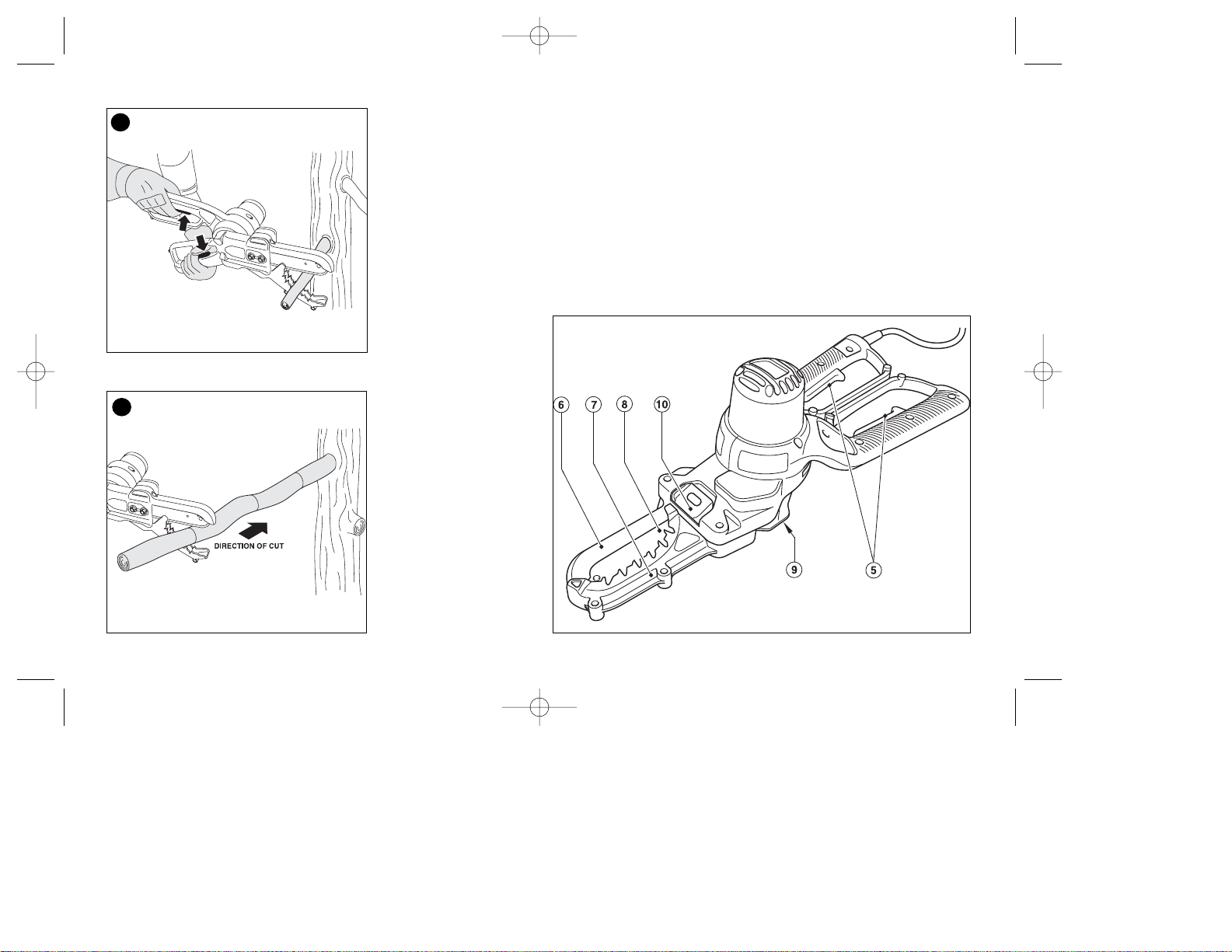

Trimming branches

- Make sure the tool is running at full speed before making a cut.

- Hold the tool firmly in place to avoid possible bouncing or

sideways movement of the tool.

- Guide the tool using light pressure.

- Always cut down from the top. This way you will avoid pinching

the saw chain.

479970-00 LP1000 9/14/05 1:00 PM Page 11

12

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment should be performed by authorized

service centers or other qualified service organizations, always using

identical replacement parts.

Accessories

Replacement chain and bar are available from your nearest Black &

Decker service center.

Replacement chain catalog number RC600

The use of accessories not recommended in this manual may be

hazardous.

Service Information

Whether you need technical advice, repair, or genuine factory

replacement parts, contact the Black & Decker location nearest you.

To find your local service location, refer to the yellow page directory

under "Tools–Electric" or call: 1-800-54-HOW TO (544-6986).

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against

any defects in material or workmanship. The defective product will be

replaced or repaired at no charge in either of two ways:

The first, which will result in exchanges only, is to return the product

to the retailer from whom it was purchased (provided that the store is

a participating retailer). Returns should be made within the time

period of the retailer’s policy for exchanges (usually 30 to 90 days

after the sale). Proof of purchase may be required. Please check

with the retailer for their specific return policy regarding returns that

are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black

& Decker owned or authorized Service Center for repair or

replacement at our option. Proof of purchase may be required. Black

& Decker owned and authorized service centers are listed under

"Tools–Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you

specific legal rights and you may have other rights which vary from

state to state. Should you have any questions, contact the manager

of your nearest Black & Decker Service Center. This product is not

intended for commercial use.

- Remove branches as shown in Fig H. Starting from branch tip

reduce the branch in logical steps cutting off small sections. “When

cutting a limb that is under tension be aware of spring back.

- When the tension in the wood fibres are released the spring

loaded limb may strike the operator and /or throw the tool out of

control”

- Remove the tool from the cut while it is running at full speed.

Maintenance

Your Black & Decker tool has been designed to operate over a long

period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular

cleaning.

If the replacement of the supply cord is necessary, this has to be

done by the manufacturer or his agent in order to avoid a safety

hazard.

WARNING: Before performing any maintenance or cleaning of

the tool, unplug the unit from the power supply.

Cleaning

- Regularly remove the chain access cover and remove any debris

that has become trapped.

- Regularly clean the ventilation slots with a clean, dry paint brush.

- To clean the tool, use only mild soap and a damp cloth. Never let

any liquid get inside the tool and never immerse any part of the tool

into liquid.

Oiling

- Regularly oil the oiling points (15) as indicated in figure F.

Transporting

- Always transport the tool with the jaws closed.

Storage

- When the tool will not be used for several months, wipe any metal

components with oil.

- Store the tool in a secure and dry location. The storage

temperature must always remain in the range of 41°F (+5 °C) to

104°F (+40 °C). Place the product on a level safe location.

479970-00 LP1000 9/14/05 1:00 PM Page 12

Loading...

Loading...