20V MAX* CORDLESSDRILL

iNSTRUCTiON MANUAL

CATALOG NUMBER

LDX220 (20V MAX*)

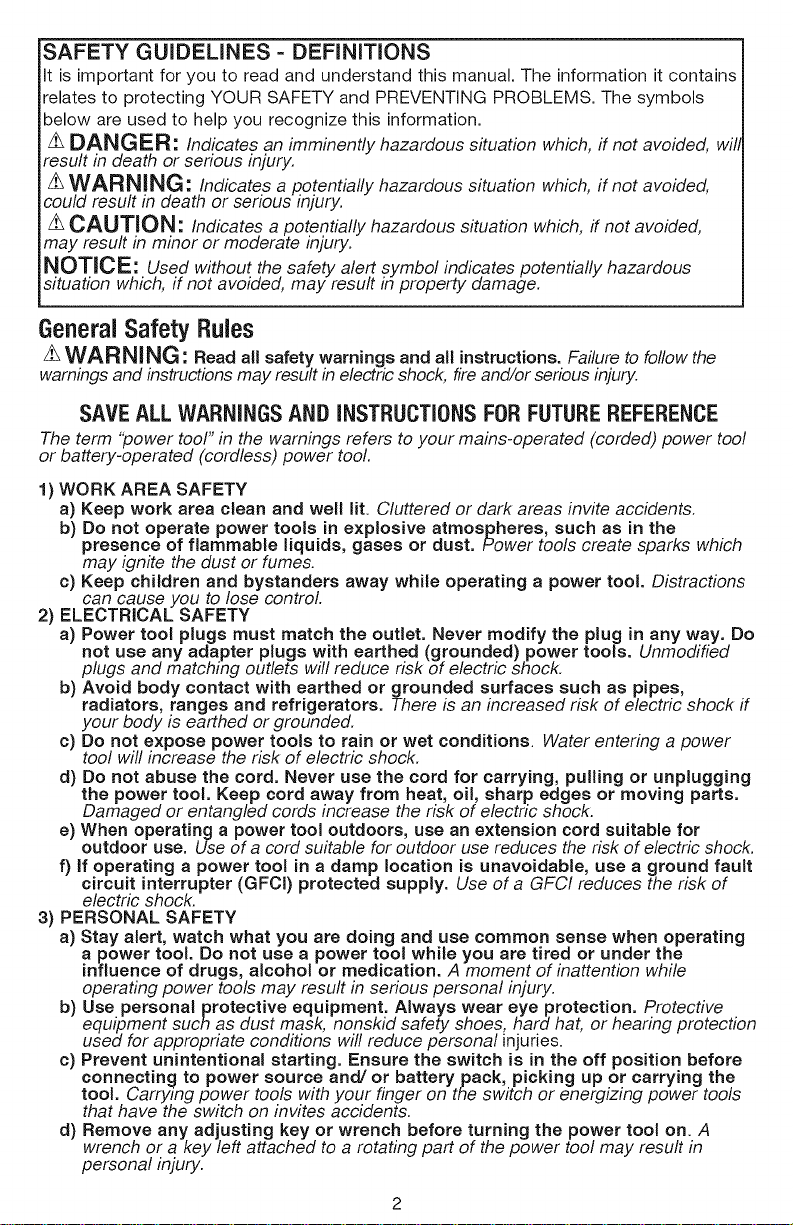

SAFETY GUiDELiNES - DEFiNiTiONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

z_ DANG E R: Indicates an imminently hazardous situation which, if not avoided, wil,

result in death or serious injury.

z_WARNING: Indicates a Rot.entially hazardous situation which, if not avoided,

could result in death or serious tnjury.

zLCAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates potentially hazardous

situation which, if not avoided, may result in property damage.

GeneralSafetyRules

WARNING: Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

SAVEALL WARNINGSANDiNSTRUCTiONSFORFUTUREREFERENCE

The term "power tool" in the warnings refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock:

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool wifl increase the risk of electric shock:

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) if operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCl) protected supply. Use of a GFCI reduces the risk of

electric shock:

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool's

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the manufacturer. A charger that

is suitable for one type of battery pack may create a risk of fire when used with

another battery pack:

b) Use power tools only with specifically designated battery packs. Use of any

other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects like

paper clips, coins, keys, nails, screws, or other smaJl metal objects that can

make a connection from one terminal to another. Shorting the battery terminals

together may cause bums or a fire.

d) Under abusive conditions, liquid may be ejected from the battery, avoid

contact, if contact accidentally occurs, flush with water, if liquid contacts

eyes, additionally seek medical help. Liquid ejected from the battery may cause

irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power toolis maintained.

Specific Safety Rules

• Hold power tool by insulated gripping surfaces, when performing an operation where the

cutting accessory may contact hidden wiring. Cutting accessory contacting a "live" wire may

make exposed metalparts of the power tool "live" and could give the operator an electric shock.

• Use auxiliary handle(s) if supplied with the tool. Loss of control can cause personal injury.

• Use clamps or another practical way to secure and support the work piece to a stable

platform. Holding the work by hand or against your body leaves it unstable and may lead to

loss of control.

• When not in use, place tool on its side on astable surface where it will not cause a

tripping or falling hazard. Some tools with large battery packs will stand upright but may be

easily knocked over.

• Keep your hair, clothing, and gloves away from air vents. Air vents often cover

moving parts in which these items can be caught.

. Hold tool firmly with two hands, one hand on thehandle, and the othergripping the bottom

around the battery area. Use auxiliary handle if provided. Lossof control can cause personal injury.

z_WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work ina well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

• arsenic and chromium from chemically-treated lumber.

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

z_WARNING: Use of this tool can generate and/or dispersedust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHAapproved respiratory

protection appropriatefor thedust exposure. Directparticles awayfrom faceand body.

• Wear appropriate hearing protection during use. Under some conditions and duration

of use, noise from this product may contribute to hearing loss.

z_WARNING: ALWAYS use safety glasses. Everyday eye glasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty.

ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/OPA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NOSH/OSHA respiratory protection.

SYMBOLS

The label on your tool may include the following symbols. The symbols and their definitions are as

follows:

V.................. volts

Hz................ hertz

min .............. minutes

- - -. ............ direct current

@ ................ Class I Construction

(grounded)

[] ................ Class II Construction

(double insulated)

_, ............ Readinstructionmanualbeforeuse

G ................ Use proper eye protection

A................... amperes

W.................. watts

,x,................ alternating current

no ................. no load speed

(_.................. earthing terminal

z_................ safety alert symbol

.../min or rpm...revolutions or

reciprocation per minute

.................. Use proper respiratory protection

0 .................. Use proper hearing protection

IMPORTANTSAFETYINSTRUCTIONSFORBATTERYCHARGERS

SAVE THESE iNSTRUCTiONS: This manual contains important safety instructions for

battery chargers.

• Before using charger, read all instructions and cautionary markings on charger, battery

pack, and product using battery pack.

z_WARNING: Shock hazard. Do not allow any liquid to get inside charger.

2_CAUTION: Burn hazard. To reduce the risk o! injury charge only designated Black

& Decker batteries. Other types of batter es may Durst caus ng personal njury and damage.

z_CAUTION: Under certain conditions, with the charger plugged in to the power supply,the

charger can be shorted by foreign material. Foreign materials of aconductive nature such as,

but not limited to, steel wool, aluminum foil, or any buildup of metallic particles should be kept

away from charger cavities. Always unplugthe charger from the power supply when there is no

battery pack in the cavity. Unplug chargerbefore attempting to clean.

z_WARNING: DO NOT attempt to charge the battery pack with any chargers other

than the ones in this manual. The charger and battery pack are specificall_ designed

to work together.

. These chargers are not intended for any uses other than charging designated Black

& Decker rechargeable batteries. Any other uses may result in ri_k ot fire, electric shock or

electrocution.

• Do not expose charger to rain or snow.

• pull by plug.rather than cord when disconnecting charger. This will reduce risk of

damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

• Do not use an extension cord unless it is absolutely necessary. Use of improper

extension cord could result in risk of fire, electric shock, or electrocution.

• An extension cord must have adequate wir e size (AWG or Ame.rican Wire Gauge )

for safety. The smafler the gauge number of the wire, the .qreater the capacitv ot the

cable, that is 16 gauge has more capacity than 18 gauge.q/t/hen using more fhan one

extension to make up, the total length, be sure each incfividual extension contains at

least the minimum wire size.

• Do not operate charger with damaged cord or plug -- have them replaced

immediately.

• Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damagedin any way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service center when service

or repair is required. Incorrect reassembly may result in a risk of electric shock,

electrocution or fire.

• Disconnect the charger from the outlet before attempting any cleaning. This will

reduce the risk of electric shock. Removing the battery pac_will-not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household electrical power

(120 Volts). Do not attempt to use it on any other voltage.

SAVE THESE iNSTRUCTiONS

FUNCTIONAL DESCRIPTION

1. Variable speed switch

2. Forward/reverse button

3. Torque adjustment collar

4. Keytess chuck

5. Dual range gearing

6. LED work bight

7. Battery

8. Battery release button

9. Charger

10. Screwdriver bit holder

iMPORTANT SAFETY iNSTRUCTiON FOR BATTERY PACKS

zLWARNING: For .safe operation, read this manual and manuals originally supplied

with tool before using the charger.

The battery pack is not fully charged out of the carton. Before using the battery pack and

charger, read the safety instructions below. Then follow charging procedures outlined•

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely damaged or is completely

worn out. The battery pack can explode in a fire. Toxic f(Jmes and materials are created

when battery packs are burned.

• Do not charge or use battery in explosive atmospheres,such as in thepresence of

flammable liquids, gases or dust. Inserting or removing the battery trom the charger

may ignite the dust or fumes.

• if battery contents come into contact with the skin. immediately wash area

with mild soap and water. If b.attery fiquid gets into the eye, rinse water over the.

open eye. for 15.minutes or until irritation ceases. If medical attention is needed, the

battery electrolyte for Lithium-Ion batteries is composed of a mixture of fiquid organic

carbonates and fithium salts.

• Contents of opened battery ceils may cause respiratory irritation. Provide fresh air.

If svmptomspersist, seek medical attention.

zLWARNING: Burn hazard. Battery liquid may be flammable if exposed to spark or flame.

• Charge the battery packs only in Black & Decker chargers.

• DO NOT splash or immerse in water or other liquids. Thismay cause premature cell failure.

• Do not store or use the tool and battery pack in locations where the temperature may

reach or exceed 105 F (40°C) (such as outside sheds or metal buildings in summer).

WARNING: Never attempt to open the battery pack for any reason. If battery pack

case is cracked or damaged, do not insert into charger. Do not crush, drop or damage

battery pack. Do not use a battery pack or charger that has received a sharp blow, Seen

dropped, run over or damaged in any way _i.e., pierced with a nail, hit with a hammer,

s_epped on). Damaged battery packs should be returned to service center for recycfing.

_W,WARNING: Fire hazard. Do not store or carry battery so that rnetal objects can

contact exposed battery terminals. For example, d-onot place battery in aprons, pockets,

tool boxes, pro.duct kit boxes, drawers, etc., w#h loose nails, screws, keys, etc. =

Transporting batteries can possibly cause fires if the battery terminals inadvertently

come in contact with conductive materials such as keys, coins, hand tools and the like.

The US Department of Transportation Hazardous Material Regulations _HMR) actually .

prohibit transportinq batteries in commerce or on airplanes (i.e., packed in suitcases and

carry-on luggage) UNLESS they are properly protected from short circuits. So when

transporting individual.batteries, make sure that the battery terminals are protected and well

insulated from materials that could contact them and cause a short circuiL NOTE: Lithium-

Ion batteries should not be put in checked baggage.

STORAGE RECOMMENDATIONS

. The best storage place is one that is coolanddry away from directsunlight and excess heat or cold.

• Long storage will not harm the battery pack or charger•

CHARGING PROCEDURE

Black & Decker chargers are designed to charge

Black & Decker battery packs in 3.5-4 hours depending

on the pack being charged.

1. Plug the charger into an appropriate outlet before

inserting the battery pack.

2. Insert the battery pack into the charger as shown in

figure A.

3. The green LED will flash indicating that the battery is

being charged.

4. The completion of charge is indicated by the green

LED remaining on continuously. The pack is fully

charged and may be used at this time or left on the

charger•

Recharge discharged batteries as soon as possible after use or battery life may_

be greatly diminished. For Ionqest battery life, do not discharge batteries full_ It is

recommended that the batteries be recharged after each use.

LEAVING THE BATTERY iN THE CHARGER

The charger and battery pack can be left connected with the green LED glowing

indefinitely• The charger will keep the battery pack fresh and fully charged•

IMPORTANTCHARGINGNOTES

1.Longestlifeandbestperformancecanbeobtainedifthebatterypackischargedwhen

theairtemperatureisbetween65°Fand75°F(18°-24°C).DONOTchargethebattery

packinanairtemperaturebelow+40°F(+4.5°C),orabove+105°F(+40.5°C).Thisis

importantandwillpreventseriousdamagetothebatterypack.

2.Thechargerandbatterypackmaybecomewarmtotouchwhilecharging.Thisisa

normalcondition,anddoesnotindicateaproblem.Tofacilitatethecoolingofthebattery

packafteruse,avoidplacingthechargerorbatterypackinawarmenvironment such as

in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or other appliance

b. Check to see if receptacle is connected to a light switch which turns power off

when you turn out the lights.

c. Move charger and battery pack to a location where the surrounding air

temperature is approximately 65°F - 75°F (18°- 24°C).

d. If charging problems persist, take the tool, battery pack and charger to your

local service center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs

which were easily done previously. DO NOT CONTINUE to use under these conditions.

Follow the charging procedure. You may also charge a partially used pack whenever you

desire with no adverse affect on the battery pack.

5. Foreign materials of a conductive nature such as, but not limited to, steel wool,

aluminum foil, or any buildup of metallic particles should be kept away from charger

cavities. Always unplug the charger from the power supply when there is no battery pack

in the cavity. Unplug charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

z_WARNING: Shock hazard. Do not allow any liquid to get inside charger. Never

attempt to open the battery pack for any reason. If the plastic housing of the battery pack

breaks or cracks, return to a service center for recycling.

SAFETY WARNINGS AND INSTRUCTIONS: DRILLS

1. Hold drill firmly with one hand on the grip andthe other hand on the bottom of the battery pack.

2. When attaching accessories in the drill chuck, hand tighten the keyless chuck firmly.

z_WARNING: Drill may stall (if overloaded or improperly used) causing a twist. Always

expect the stall. Grip the drill firmly with both hands to control the twisting action and

prevent toss of control which could cause personal injury. If a stall does occur, release

the trigger immediately and determine the reason for the stall before re-starting.

INSTALLING AND REMOVING THE

BATTERY PACK FROM THE TOOL

_WARNING: Make certain the lock-off button is

engaged to prevent switch actuation before removing

or installing battery.

TO INSTALL BATTERY PACK: Insert battery pack

into toot until an audible click is heard (figure B). Make

sure battery pack is fully seated and fully latched into

position.

TO REMOVE BATTERY PACK: Depress the battery

release button as shown in figure C and pull battery

pack out of tool.

®

OPERATING INSTRUCTIONS

TRIGGER SWITCH & REVERSING BUTTON

The drill is turned ON and OFF by pulling

and releasing the trigger switch (1). The

farther the trigger is depressed, the higher

the speed of the drill.

A forward/reverse control button (2)

determines the direction of the tool and

also serves as a lock off button.

To select forward rotation, release the

trigger switch and depress the forward/

reverse control button to the left.

To select reverse, depress the forward/

reverse control button the opposite

direction.

NOTE: The center position of the control

button locks the tool in the off position.

When changing the position of the control

button, be sure the trigger is released.

TORQUE CONTROL (FIGURE E)

This tool is fitted with a torque adjustment

collar (3) to select the operating mode and

to set the torque for tightening screws. Large

screws and hard workpiece materials require

a higher torque setting than small screws and

soft workpiece materials.

For drilling in wood, metal and plastics, set

the collar to the drilling position symbol

For screwdriving, set the collar to the

desired setting. If you do not yet know the

appropriate setting, proceed as follows:

Set the collar to the lowest torque setting.

Tighten the first screw.

Ifthe clutch ratchets before the desired result is achieved, increase the collar setting

and continue tightening the screw. Repeat until you reach the correct setting. Use this

setting for the remaining screws.

FIGURE D)

®

KEYLESS CHUCK (FIGURE F)

z_WARNING: Make certain the lock-off

button is engaged to prevent switch actuation

before installing or removing accessories.

To insert a drill bit or other accessory:

1. Grasp the rear half of the chuck (4)

with one hand and use your other

hand to rotate the front half (4a) in the

counterclockwise direction, as viewed from

the chuck end.

2. Insert the bit or other accessory fully into

the chuck, and tighten securely by holding

the rear half of the chuck and rotating the

front portion in the clockwise direction as

viewed from the chuck end.

z_WARNING: Do not attempt to tighten drill

bits (or any other accessory) by gripping the front part of the chuck and turning the tool

on. Damage to the chuck and personal injury may occur when changing accessories.

DUALRANGEGEARING(FIGUREG)

Thedualrangefeatureofyourdrillallowsyou

®

toshiftgearsforgreaterversatility.Toselect

lowspeed,hightorquesetting(position1),turn

tooloffandpermittostop.Slidegearshifter

button(5)awayfromthechuck.Toselectthe

highspeed,towtorquesetting(position2),turn

tooloffandpermittostop.Slidegearshifter

buttontowardsthechuck.

NOTE:Donotchangegearswhentoolis

running.Ifyouarehavingtroublechanging

gears,makesurethatthedualrangegear

buttoniseither completely pushed forward or

completely pushed back.

SCREW DRIVING

For driving fasteners, the reversing button should be pushed to the left. Use reverse

(button pushed to the right) for removing fasteners. When moving from forward to reverse,

or vice versa, always release the trigger switch first.

ON BOARD BIT STORAGE (FIGURE H)

A bit storage slot (10) is built-in to the area just above the

battery pack.

':4

LED Work Light (FIGURE I)

When drill is activated by pulling the trigger switch (1), the

integrated LED work light (6) will automatically illuminate

the work area. Do not use LED work light as flashlight.

@

DRILLING

• Use sharp drill bits only.

• Support and secure work properly, as instructed in the Safety Instructions.

• Use appropriate and required safety equipment, as instructed in the Safety Instructions.

• Secure and maintain work area, as instructed inthe Safety Instructions.

• Run the drill very slowly, using light pressure, until the hole is started enough to keep the

drill bit from slipping out of it.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting but

not so much as to stall the motor or deflect the bit.

• Hold the drill firmly with two hands to control its twisting action.

• DO NOT CLICK THE TRIGGER OF A STALLED DRILL OFF AND ON IN AN ATTEMPT

TO START IT. DAMAGE TO THE DRILL CAN RESULT.

• Minimize stalling on breakthrough by reducing pressure and slowly drilling through the last

part of the hole.

: Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

• Make sure switch turns drill on and off.

DRiLLiNG IN WOOD

Holes in wood can be made with the same twist drill bits used for metal or with spade bits.

These bits should be sharp and should be pulled out frequently when drilling to clear chips

from the flutes.

DRILLINGINMETAL

Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which

should be drilled dry. The cutting lubricants that work best are sulfurized cutting oil or lard oil.

DRiLLiNG IN MASONRY

Use carbide tipped masonry bits. Refer to Drilling section. Keep even force on the drill but

not so much that you crack the brittle material. A smooth, even flow of dust indicates the

proper drilling rate.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized service

centers or other qualified service personnel, always using identical replacement parts.

TROUBLESHOOTING

Problem

• Unitwill not start.

• Battery pack willnot

charge.

• Unit shutsoff abruptly.

For assistance with your product, visit our website www.blackanddecker.com for the

location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-8986.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986.

z_WARNING: The use of any accessory not recommended for use with this toot could be

hazardous.

The RBRC TM Seal

The RBRC TM (Rechargeable Battery Recycling Corporation) Seal on the

lithium-ion battery (or battery pack) indicates that the costs to recycle the

battery (or battery pack) at the end of its useful life have already been paid

by Black & Decker. In some areas, it is illegal to place spent lithium-ion

batteries in the trash or municipal solid waste stream and the RBRC program provides an

environmentally conscious alternative.

RBRC in cooperation with Black & Decker and other battery users, has established

programs in the United States and Canada to facilitate the collection of spent lithium-ion

batteries. Help protect our environment and conserve natural resources by returning the

tool to an authorized Black & Decker service center for recycling. You may also contact your

local recycling center for information on where to drop off the spent battery, or cal

1-800-8-BATTERY.

Possible Cause

• Battery pack not installed

properly

• Battery pack not charged

• Battery pack not insertedinto

charger.

• Charger not plugged in.

• Surrounding airtemperature

too hot or too cold.

• Battery pack has reached its

maximum thermal limit.

• Out ofcharge. (To

maximize the life ofthe

battery pack itis designed

to shutoff abruptly when

the charge is depleted.)

10

Possible Solution

• Check battery pack

installation.

• Check battery pack charging

requirements.

• Insertbattery pack into

charger untilgreen LED appears.

• Plugcharger intoa working

outlet. Refer to "ImportantCharging

Notes"for more details.

• Move charger and battery

packto a surrounding airtemperature of

above 40 degrees F(4.5°C)or below

105degrees F (+40.5°C).

•Allow batterypackto cool

down.

• Placeon charger and

allow tocharge.

ThisClassBdigitalapparatuscomplieswithCanadianICES-003.

Thisdevicecomplieswithpart15oftheFCCrules.Operationissubjecttothefollowing

twoconditions:(1)Thisdevicemaynotcauseharmfulinterference,and(2)thisdevice

mustacceptanyinterferencereceived,includinginterferencethatmaycauseundesired

operation.

NOTE:ThisequipmenthasbeentestedandfoundtocomplywiththelimitsforaClassB

digitaldevice,pursuanttoPart15oftheFCCRules.Theselimitsaredesignedtoprovide

reasonableprotectionagainstharmfulinterferenceinaresidentialinstallation.This

equipmentgenerates,usesandcanradiateradiofrequencyenergyand,ifnotinstalled

andusedinaccordancewiththeinstructions,maycauseharmfulinterferencetoradio

communications.However,thereisnoguaranteethatinterferencewillnotoccurina

particularinstallation.

Ifthisequipmentdoescauseharmfulinterferencetoradioortelevisionreception,which

canbedeterminedbyturningtheequipmentoffandon,theuserisencouragedtotryto

correcttheinterferencebyoneormoreofthefollowingmeasures:

• Reorientorrelocatethereceivingantenna.

• Increasetheseparationbetweentheequipmentandreceiver.

• Connecttheequipmentintoanoutletonacircuitdifferentfromthattowhichthereceiver

isconnected.

• Consultthedealeroranexperiencedradio/TVtechnicianforhelp.

Changesormodificationstothisunitnotexpresslyapprovedbythepartyresponsiblefor

compliancecouldvoidtheuser'sauthoritytooperatetheequipment.ThisClassBdigital

apparatuscomplieswithCanadianICES-003.

SERVICE iNFORMATiON

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair,

or genuine factory replacement parts, contact the Black & Decker location nearest you. To

find your local service location, refer to the yellow page directory under "Toots--Electric" or

call: 1-800-544-6986 or visit www.blackanddecker.com

LIMITED TWO=YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should be

made within the time period of the retailer's policy for exchanges (usually 30 to 90 days after

the sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required.Black & Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state or province to province. Should

you have any questions, contact the manager of your nearest Black & Decker Service

Center. This product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, check country specific warranty information contained in the

packaging, call the local company or see the website for warranty information.

Black & Decker (U.S.) Inc.,

Imported by

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

11

Electric'

See 'Tools= [_

- Yellow Pages -

for Service &

Sales

LAPERCEUSESANSFILDE20VMAX*

MANUELD' iNSTRUCTiONS

N° DECATALOGUE

LDX220 (20V MAX*)

12

LIGNES DIRECTRICES EN MATII_RE DE S_CURi'r_ _ D_FINmONS

IIestimportantquevouslisiezet compreniezcemoded'emploi.Le,sinformationsqu'ilcontient

concernentVOTRESECURITEetvisenta EVlTERTOUTPROBLEME.Lessymbolesci-dessous

serventavousaiderareconna;trecetteinformation.

zLDANGER • Indique une situation dangereuse imminente qui, si elle n'est pas evit6e,

causera la mort ou des graves blessures.

AVERTISSEMENT • Indiqueune situationpotentiellement dangereuse qui, si elle n'est

pas evit6e, pourrait causer la mort ou de graves blessures.

z_MISE EN GARDE • Indique une situation potentiellementdangereuse qui, si elle n'est

pas evit6e, pourrait causer des blessures mineuresou moder6es.

AVIS " Utilisesans le symbole d'alerte a.la securit& indique unesituation potentiel lement

dangereuse qui, si elle n'est pas evit6e, peut resulteren des dommages a la propriet&

AVERTISSEMENTSDESI CURITEGI NI RAUXPOURLESOUTILSI LECTRIQUES

zLAVERTISSEMENT• Life tousles avertissements de securit6 et routes

les directives. Le non-respect des avertissements et des directives pourrait

se solder par un choc electnque, un incendie et/ou une blessure grave.

Conserver tous les avertissements et toutes les directives pour un usage utt6rieur.

Le terme ,,outil electrique,, cite dans les avertissements se rapporte A votre

outil electrique A alimentation sur secteur (avec ill) ou par piles (sans ill).

1) S_curit_ du lieu de travail

a) Tenir la zone de travail propre et bien _clair_e. Les endroits sombres sont souvent des

causes d'accidents.

b) Nepas faire fonctionner d'outils 61ectriques dans un milieu d_flagrant, soit en presence

de liquides inflammables, de gaz ou de poussi_re. Les outils electriques produisent des

etincelles qui peuvent enfiammer lapoussiere ou les vapeurs.

c) Eloignerles enfants et les curieux au moment d'utiliser un outil _lectrique. Une

distraction pourrait vous en faire perdre la ma#rise.

2) S6curit6 en mati_re d'_lectricit_

a) Les fiches des outils 61ectriques doivent correspondre _ la prise. Nejamais modifier la

fiche en aucune fa£on. Ne jamais utiliser de fiche d'adaptation avec un outil electrique

mis a la terre. Le risque de choc electrique sera reduit par I'utilisation de fiches non

modifiees correspondant a la prise.

b) Eviter tout contact physique avec des surfaces raises _ la terre comme des tuyaux, des

radiateurs, des cuisini_res et des r_frig_rateurs. Le risque de choc electrique est plus

elev6 si votre corps est mis a la terre.

c) Ne pas exposer les outils _lectriques _ la pluie ou _ d'autres conditions o_ il pourrait

_tre mouill& La p6n6tration de I'eau clans un outil 61ectriqueaugmente le risque de choc

61ectrique.

d) Ne pas utiliser abusivement le cordon d'alimentation. Ne jamais utiliser le

cordon pour transporter, tirer ou d_brancher un outil 61ectrique. Tenir le cordon _loign6

de la chaleur, de I'huile, des bords tranchants ou des pi_ces mobiles. Les cordons

endommag#s ou emm#l#s augmentent les risques de choc #lectrique.

e) Pour I'utilisation d'un outil 61ectrique _ I'ext6rieur, se servir d'une rallonge

convenant _ une telle utilisation. L 'utilisation d'une rallonge concue pour I'ext#rieur

r#duit les risques de choc #lectrique.

f) S'il est impossible d'eviter I'utilisation d'un outil _lectrique darts un endroit humide, brancher

routil dans une prise ou sur un circuit d'alimentation dotes d'un disjoncteur de fuite a la

terre (GFCl). L'utilisation de ce type de disjoncteur r#duit les risques de choc #lectrique.

3) S6curit6 personnelle

a) Etre vigilant, surveiller le travail effectu6 et faire preuve de jugement Iorsqu'un outil

_lectrique est utilis& Ne pas utiliser d'outil 61ectrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de m_dicaments. Un simple moment d'inattention en

utilisant un outil e'lectrique peut entrainer des blessures corporelles graves.

b) Utiliser des _quipements de protection individuelle. Toujours porter une protection

oculaire. L 'utilisation d'#quipements de protection comme un masque antipoussi#re,

des chaussures antiderapantes, un casque de s#curit# ou des protecteurs auditifs

Iorsque la situation le requiert r#duira les risques de blessures corporelles.

13

c) Emp_cher les d6marrages intempestifs. S'assurer que I'interrupteur se trouve _ la

position d'arr_t avant de relierI'outil _ une source d'alimentation et/ou d'ins_rer un bloc-

Pdiles,de ramasser ou de transporter I'outil. Transporterun outil electrique alors que le

oigt repose sur I'interrupteur ou brancber un outil e/ectrique dont I'interrupteur est a/a

position de marche risque de provoquer un accident.

d) Retirer toute cl6 de r_glage ou cl6 standard avant de d6marrer I'outil. Une cle

standard ou une cle de reglage attachee a une partie pivotante peut causer des

blessures.

e) Ne pas trop tendre les bras. Conserver son 6quilibre en tout temps. Cela permet de

mieux maitriser I'outil electrique dans les situations imprevues.

f) S'habiller de mani_re appropri6e. Ne pas porterde v_tements amples ni de bijoux. Garder

lescheveux, les v6tements et les gants _1'6cartdes pi_ces mobiles. Les v6tements

amples, les bijoux ou les cheveux longs risquent de rester coinces clanslespi_ces

mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de d6poussi6rage

et de ramassage, s'assurer que ceux-ci sont bien raccord6s et utilis6s. L'utilisation o'un

dispositif de depoussierage peut reduire les dangers engendres par les poussieres.

4) Utilisation et entretien d'un outil 61ectrique

a) Ne pas forcer un outil 61ectrique. Utiliser I'outil 61ectrique appropri6 _ I'application.

L'outil electrique approprie effectuera un meilleur travail, de fa_on plus sore eta la

vitesse pour laquelle # a 6te con_u.

b) Ne pas utiliser un outil 61ectrique dont I'interrupteur est d6fectueux. Tout outil

electrique dont I'interrupteur est defectueux est dangereux et doit _tre repare.

c) D6brancher la fiche du secteur ou le bloc-piles de I'outil _lectrique avant de faire tout

r6glage ou changement d'accessoire, ou avant de ranger I'outil 61ectrique. Ces mesures

preventives reduisent les risques de demarrage accidentel de I'outil electrique.

d) Ranger les outils 61ectriques hors de la port6e des enfants, et ne permettre _ aucune

personne n'6tant pas famili_re avec un outil 61ectrique (ou son manuel d'instruction)

d'utiliser ce dernier. Les outils electriques deviennent dangereux entre les mains

d'utilisateurs inexperiment6s.

e) Entretenir les outils 61ectriques. V_rifier les pi_ces mobiles pour s'assurer qu'elles sont

bien align6es et tournent librement, qu'elles sont en bon 6tat e!,ne sont affect_es par

aucun trouble susceptible de nuire au bon fonctionnement de Ioutil 61ectrique. En cas

de dommage, faire re'parer I'outil 61ectriqueavant toute nouvelle utilisation. Beaucoup

d'accidents sont causes par des outils electriques mal entretenus.

f) S'assurer que les outils de coupe sont aiguis6s et propres. Les outils de coupe bien

entretenus et affOtes sont moins susceptibles de se coincer et sont plus faciles

contr61er.

g) Utiliserrouti] electrique, lesaccessoires, lesforets, etc. conformement aux presentes

directives en tenant compte des conditions de travail et du travail aeffectuer. L'utilisation

d'un outii _lectrique pour toute operation autre que celle pour laquelle il a et_ con_u est

dangereuse.

5) Utilisation et entretien du bloc-piles

a) Ne recharger I'outil qu'au moyen du chargeur pr6cis_ par lefabricant. L'utilisation d'un

chargeur qui convient a un type de bloc-piles risque de provoquer un incendie s'il est

utilis_ avec un autre type de bloc-piles.

b) Utiliser les outils _lectriques uniquement avec les blocs-piles con_us _ ceteffet.

L'uti/isation de toutautre bloc-piles risque de causer des blessures ou un incendie.

c) Lorsque le bloc-piles West pas utilis6, le tenir _loign6 des objets m_talliques, notamment

des trombones, de la monnaie, des cl6s, des clous, des vis, etc., qui peuvent _tablir une

connexion entre les deux bornes. Le court-circuit des bomes du bloc-piles risque de

provoquer des etincelles, des brOlures ou un incendie.

d) En cas d'utilisation abusive, le liquide peut gicler hors du bloc-piles, _viter tout contact.

Si un contact accidentel se produit, laver_ grande eau. Si le liquide entre en contact

avec les yeux, obtenir des soins m_dicaux. Le liquide qui gicle hors du bloc-piles peut

provoquer des irritations ou des brOlures.

6) R6paration

a) Faire r_parer I'outil_lectrique par un r_parateur professionnelen n'utilisant que des pi_ces

de rechange identiques.Cela permettra de maintenir une utilisation securitaire de I'outil

electrique.

Regles de s6curit sp cifiques

• Porter des protecteurs auditifs si une perceuse a percussion est utilisee. Une

exposition au bruit peut entrMner une perte auditive.

• Utiliser les poignees au×iliaires fournies avec I'outil. Une perte de mMtrise de I'outit

14

peutentrafnerdesblessurescorporeltes.

• SaisirI'outil electrique par ses surfaces de prises isolees Iorsque I'outil peut

entrer en contact avec des ills caches ou son cordon. En cas de contact avec un fit

sous tension, les pieces metalliques de I'outil seront sous tension et l'utilisateur subira des

secousses etectriques.

• Lorsqu'on est installe sur une echelle ou un echafaudage pour travailler, on dolt

deposer I'outil sur le cSte Iorsqu'on ne s'en sert plus. Bien que certains outils munis

d'un gros bloc-piles puissent _tre places &la verticale, dans cette position, its peuvent

facilement 6tre renverses.

• Utiliser des brides de fixation ou un autre dispositif de fixation permettant de fixer

solidement et de soutenir la piece sur une plateforme stable. Tenir la piece avec la main

ou contre son corps la rend instable et risque de provoquer une perte de maTtrisede I'outil.

• Tenir les cheveux, les v_tements et les gants loin des events. En effet, les events

cachent souvent des pieces mobiles qui risquent de happer ces articles.

• Tenir fermement I'outit a deux mains. Utitiser la poignee auxiliaire si l'outit en est

muni. Sinon, saisir t'outit par le bas du bloc-piles. Une perte de maTtrise de I'outit peut

entratner des btessures.

z_AVERTISSEMENT • certains outils electriques, tels que les sableuses, les

scies, les meules, les perceuses ou certains autres outits de construction,

peuvent produire de la poussiere contenant des produits chimiques reconnus par

I'Etat de la Californie comme etant susceptibles d'entrainer le cancer, des

malformations congenitales ou pouvant _tre nocifs pour le systeme reproductif.

Parmi ces produits chimiques, on retrouve :

•le ptomb dans les peintures &base de ptomb,

•la silice cristalline dans les briques et le ciment et autres produits de ma(;onnerie,

•I'arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique.

Le risque associe &de tetles expositions varie selon ta frequence avec laquelle on

effectue ces travaux. Pour reduire l'exposition & de tets produits, il faut travailler dans

un endroit bien aer6 et utitiser le materiel de securit6 approprie, tel un masque anti-

poussieres specialement congu pour filtrer les particules microscopiques.

• Eviter tout contact prolonge avec la poussiere soulevee par cet outil ou autres

outils etectriques. Porter des v6tements de protection et nettoyer les parties

exposees du corps avec de I'eau savonneuse. S'assurer de bien se proteger afin

d'eviter d'absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

2_AVERTISSEMENT " Cet outil peut produire et repandre de la poussiere

susceptible de causer des dommages serieux et permanents au systeme

respiratoire. Toujours utiliser un appareil respiratoire anti-poussieres approuve par le

NIOSH ou I'OSHA. Diriger les particutes dans le sens oppose du visage et du corps.

AVERTISSEMENT " TOUJOURS porter des lunettes de securit& Les

lunettes de vue ne constituent PAS des lunettes de securit& Utiliser egalement

un masque facial ou anti-poussiere si Fgperation de decoupe genere de

la poussiere. TOUJOURS PORTER UN EQUIPEMENT DE PROTECTION

HOMOLOGUE :

. protection oculaire conforme D la norme ANSI 787.1 (CAN/CSA 794.3);

. protection auditive ANSI S12.6 ($3. 19);

° protection des voles respiratoires conformes aux normes NIOSH/OSHA/MSHA.

SYMBOLES

L'6tiquette appos_e sur votre outil pourrait comprendre les symboles suivants. Les

symboles et leurs d_finitions sont indiqu_s ci-apres :

V .volts ......... amperes A

Hz ............. hertz 14/................ watts

min ........... minutes _ _ .............. courant altematif

- - -. ......... courant continue non ............. r6gime _ vide

[] .............. Construction classe II _ borne de terre

........... symbole d'alerte _ la .../minorrpm..r6volutions ou altemance par minute

s_curit_

15

DESCRIPTION

FONCTIONNELLE

1. Detente de vitesse variable

2. Bouton de marche avant/marche

arriere

3. Bague de reglage du couple

4. Mandrin auto-serrant

5. Engrenage & deux vitesses

6. Lampe de travail a. DEL

7. Bloc-piles

8. Bouton de degagement du bloc-piles

9. Chargeur

10. Porte-

embout de

vissage

DIRECTIVES DE SI_CURITi_ IMPORTANTES POUR LES

CHARGEURS DE PILES

CONSERVER CES DiRECTiVES : ce mode d'emploi comprend d'importantes directives

de s6curite pour les chargeurs de piles.

• Avant d'utitiser le chargeur, lire toutes les directives et tousles avertissements figurant sur

le chargeur, le bloc-piles et le produit utitise avec le bloc-piles.

z_AVERTISSEMENT : risque de choc electrique. Eviter la p6netration de tout liquide

darts le chargeur.

z_MISE EN GARDE : risque de brt31ure. Pour reduire le risque de blessures, charger

uniquement des piles Black & Decker conseillees. D'autres types de piles peuvent

exptoser et provoquer des blessures corporelles et des dommages.

z_MISE EN GARDE : darts certaines circonstances, Iorsque le chargeur est branche au

bloc d'alimentation, le chargeur peut etre court-circuite par des corps etrangers

conducteurs tels que, mais sans s'y limiter, la laine d'acier, le papier d'aluminium ou toute

accumulation de particules metalliques. Its doivent etre maintenus & distance des

ouvertures du chargeur. Debrancher systematiquement celui-ci si aucun bloc-piles n'y est

inser& Debrancher le chargeur avant tout nettoyage.

• NE PAS tenter de charger le bloc-piles avec autre chose qu'un chargeur de marque.

Les chargeurs et blocs-piles sont congus sp#cialement pour fonctionner ensemble.

• Ces chargeurs ne sont pas destines a _tre utilises a d'autres fins que celles de

charger les piles rechargeables conseillees Black & Decker. Toute autre utilisation

risque de provoquer un incendie, un choc _lectrique ou une _lectrocution.

• Proteger le chargeur de la pluie et de la neige.

• Tirer Is fiche plut6t que le cordon pour debrancher le chargeur ou pour debrancher

lea cordons a l'aide de la fonction de guirlande. Cela permet de r6duire le risque

d'endommager la fiche ou le cordon d'alimentation.

• S'assurer que le cordon eat situe en lieu sQr de maniere ace que personne ne

marche ni ne trebuche dessus ou ace qu'it ne soit pas endommage ni soumis a une

tension.

• Ne pas utiliser de rallonge a moins que cela ne soit absolument necessaire.

L'utilisation d'une rallonge inadequate risque d'entrafner un incendie, un choc _lectrique

ou une 61ectrocution.

• Pour la securit6 de I'utilisateur, utitiser une rallonge de calibre adequat (AWG,

American Wire Gauge [calibrage americain normatise des ills]). Plus le num6ro de

calibre de fil est petit et plus sa capacit6 est grande, par exemple un calibre 16 a plus de

capacit# qu'un calibre 18. Si plus d'une rallonge est utilis6e pour obtenir la Iongueur totale,

16

s'assurer que chaque rallonge pr6sente au moins le calibre de fil minimum.

Calibre de fil minimum recommande pour les rallonges

Longueur totale de la rallonge

25 pi 50 pi 75 pi 100 pi 125 pi 150 pi 175 pi

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Calibre AWG

18 18 16 16 14 14 12

• Ne pas mettre d'objet sur le chargeur ni mettre ce dernier sur une surface souple,

ce qui pourrait causer I'obstruction des fentes de ventilation et, du fait, provoquer

une chaleur interne excessive, leloigner le chargeur de toute source de chaleur. La

ventilation du chargeur se fait par les fentes pratiqu_es dans les parties sup_rieures et

inf_rieures du boftier.

• Ne pas installer le chargeur sur un tour nile fixer de maniere permanente sur

toute surface. Le chargeur est destin_ _ une utilisation sur une surface plane et stable

(c.-9-d. un dessus de table ou d'_tabli).

• Ne pas faire fonctionner le chargeur si la fiche ou le cordon est endommage; les

remplacer imm6diatement.

• Ne jamais se servir d'un chargeur qui a subi un choc violent, qui est tombe par

terre ou qui est endommage de quelque maniere que ce soit. Le faire v_rifier clans

un centre de r6paration autoris6.

• Ne pas demonter le chargeur; confier I'entretien ou la r6paration de I'appareil _ un

centre de r6paration autoris_. Le remontage non conforme du chargeur comporte des

risques de choc _lectrique, d'61ectrocution ou d'incendie.

• Debrancher le chargeur avant de le nettoyer. Cela r6duira le risque de choc _lectrique.

Le risque ne sera pas _limin_ en enlevant simplement le bloc-piles.

• NE JAMAIS relier deu× chargeurs ensemble.

• Le chargeur est con?u pour _tre alimente en courant domestique standard

(120 V). Ne pas utiliser une tension superieure pour le chargeur.

CONSERVER CES DIRECTIVES

DIRECTIVES DE SI_CURITI_ IMPORTANTES POUR LES BLOCS-PILES

z_AVERTiSSEMENT : pour un fonctionnement sOr, lire le pr6sent mode d'emploi et les

manuels foumis avec I'outil avant d'utiliser le chargeur.

Le bloc-piles n'est pas completement charge & la sortie de I'emballage. Avant d'utiliser

le bloc-piles et le chargeur, lire les directives de securit6 ci-apres. Respecter ensuite les

consignes de chargement decrites.

LIRE TOUTES LES DIRECTIVES.

• Ne pas incinerer le bloc-piles, re@me s'it est tres endommage ou completement use,

car il peut exploser au contact de flammes. Des vapeurs et des matieres toxiques sont

d_gag_es Iorsque les blocs-piles sont incin_r6s.

• Ne pas charger ou utiliser un bloc-piles darts un milieu defiagrant, en presence

de liquides, de gaz ou de poussiere inflammables. InsUrer ou retirer un bloc-piles du

chargeur peut enflammer de la poussiere ou des _manations.

• Si le contenu de la pile entre en contact avecla peau, laver immediatement ta zone

touchee au savon dou× eta I'eau. Si le liquide de la pile entre en contact avec les yeux,

rincer I'oeil ouvert & I'eau pendant 15 minutes ou jusqu'& ce que l'irritation cesse. Si des

soins medicaux sont necessaires, I'electrolyte des piles au Lithium-Ion est compose d'un

melange de carbonates organiques liquides et de sels de lithium.

• Le contenu des ceflules de pile ouvertes peut provoquer une irritation respiratoire.

Exposer la personne _ de I'air frais. Si les symptSmes persistent, obtenir des soins m6dicaux.

z_AVERTISSEMENT : risque de brQlure. Le liquide du bloc-piles peut s'enflammer s'il

est expos6 _ des _tincelles ou Dune flamme.

• Charger les blocs-piles uniquement au moyen de chargeurs Black & Decker.

• NE PAS eclabousser le bloc-piles ou I'immerger dans I'eau ou tout autre liquide.

Cela peut entrafner une d_faillance pr6matur6e de 1'61_ment.

• Ne pas ranger ni utiliser I'outil et te bloc-piles darts un endroit o_ la temperature

peut atteindre ou depasser les 40 °C (105 °F) (comme darts les remises e×terieures

ou les b_timents metalliques en ete).

17

z_AVERTISSEMENT: ne jamais ouvrir le bloc-piles pour quelque raison que ce soit. Si le

boffier du bloc-piles est fissur6 ou endommag_, ne pas I'ins_rer clans un chargeur. Ne

pas _craser, faire tomber ou endommager le bloc-piles. Ne pas utiliser un bloc-piles ou un

chargeur qui a regu un choc violent, qui est tomb_, a _t_ 6cras_ ou est endommag_ de

quelque maniere que ce soit (p. ex. perc_ par un clou, frapp6 d'un coup de marteau,

pitting). Les blocs-piles endommag_s doivent _tre envoy_s au centre de r6paration pour

_tre recycles.

z_AVERTISSEMENT : risque d'incendie. Ne pas ranger ou transporter les piles de

maniere ace que des objets metalliques puissent entrer en contact avec les

homes exposees des piles. Par exemple, ne pas mettre un bloc-piles dans un tabtier,

une poche, une bofte & outils, une bofte de necessaire de produit ou un tiroir contenant

des objets tels que des ctous, des vis ou des cles, car tout contact accidentel entre tes

bomes & decouvert et un objet metallique conducteur comme une cle, une piece de

monnaie, un outit & main, etc. risque de provoquer un incendie. La Hazardous Material

Regulations (regtementation sur les produits dangereux) du departement americain des

transports interdit en fait te transport des blocs-piles pour le commerce et dans les avions

(c.-&-d. dans des valises et tes bagages & main) A MOINS qu'ils ne soient bien proteg6s

contre les courts-circuits. Pour le transport de piles individueltes, on doit donc s'assurer

que les bomes sont proteg6es et bien isolees contre toute matiere pouvant entrer en

contact avec elles et provoquer un court-circuit. REMARQUE : it ne faut pas laisser de

piles au Lithium-ion darts les bagages enregistres.

RECOMMANDATIONS EN MATIERE DE RANGEMENT

1. Le meilteur endroit de rangement est celui qui est frais et sec, loin de toute lumiere

directe du soleil et proteg6 d'une temperature extreme (chaleur ou froid).

2. Un entreposage prolonge ne nuira pas au bloc-piles ou au chargeur.

PROCEDURE DE CHARGE

Les chargeurs Black & Decker sont con£us pour

charger les blocs-piles Black & Decker dans un delai

de 3 &4 heures seton le bloc-piles & charger.

1. Brancher le chargeur dans une prise appropriee

avant d'inserer le bloc-piles.

2. Inserer le bloc-piles dans le chargeur (fig. A). i _ ..;

3. Le voyant DEL vert clignotera indiquant ainsi que le ,_,_...... ._

bloc-piles est en cours de charge.

4. La fin de la charge est indiquee par le voyant DEL vert

qui demeure atlume. Le bloc-piles est charge & ptein et

peut etre utilise &ce moment-ci ou laisse sur le chargeur.

Recharger les piles epuis6es aussit6t que

possiMe apres leur utilisation pour prolonger leur duree de vie. Pour preserver

le plus possible la duree de vie du bloc=piles, ne pas le decharger tout a fait. It est

recommande de recharger le bloc-piles apres chaque utilisation.

BLOC=PILES LAISSI_ DANS LE CHARGEUR

Le chargeur et te bloc-piles peuvent etre laisses branches, le voyant DEL vert demeurant

allume. Le chargeur maintiendra le bloc-piles en bon etat et comptetement charge.

REMARQUES IMPORTANTES POUR LE CHARGEMENT

1. Pour augmenter la duree de vie du bloc-piles et optimiser son rendement, le charger

& une temperature entre 18 et 24 °C (65 et 75 °F). NE PAS charger le bloc-piles &

des temperatures inferieures & 4,5 °C (40 °F) ou superieures & 40,5 °C (105 °F). Ces

consignes sont importantes et permettent d'eviter d'endommager gravement le bloc-piles.

2. Le chargeur et le bloc-piles peuvent devenir chauds au toucher pendant la charge. It

s'agit d'un etat normal et cela n'indique pas un probteme. Pour facititer le refroidissement

du bloc-piles apres son utilisation, eviter de mettre le chargeur ou le bloc piles dans un

endroit chaud comme dans une remise metatlique ou une remorque non isolee.

3. Si le bloc-piles ne se charge pas adequatement, on doit :

a. verifier le courant & la prise en branchant une lampe ou un autre appareil electrique;

b. verifier si la prise est reliee &un interrupteur mural qui la met hors tension Iorsque

la lumiere sont eteinte;

c. deplacer le chargeur et le bloc-piles dans un endroit ou la temperature ambiante

est entre 18 et 24 °C (65 et 75 °F);

d. si le probleme persiste, apporter ou envoyer I'outit, le bloc-piles et le chargeur au

18

centredereparationdevotreregion.

4.Lebloc-pilesdoltetrerechargeIorsqu'iln'arrivepasaproduiresuffisammentdepuissance

pourdestravauxquietaientfacilementrealisesauparavant.NEPASCONTINUERautiliserle

bloc-pilesdanscesconditions.Suivrelesproceduresdecharge.Onpeutegalementrecharger

toutmomentunbloc-pilespartiellementdechargesansnuireasonfonctionnement.

5.Toutcorpsetrangerconducteur,telquenotammentlalained'acier,lepapier

d'aluminium,outouteaccumulationdeparticulesmetalliques,doltetremaintenuadistance

desouverturesduchargeur.Debranchersystematiquementcelui-cisiaucunbloc-pilesn'y

estinser&Debrancherlechargeuravanttoutnettoyage.

6.Nepascongelerlechargeur,I'immergeransl'eauoudanstoutautreliquide.

Z_AVERTISSEMENT: risquedechoc electrique, nejamais ouvrir le bloc-piles pour

quelque raison que ce soil Si le boffier en plastique du bloc-piles est bris6 ou fissur& le

retoumer _ un centre de reparation pour qu'il soit recycl&

z_AVERTISSEMENT : de securite et directives : perceuses

1. Tenir fermement ta perceuse en saisissant la poignee d'une main et en plagant I'autre

main sur la partie inferieure du bloc-piles.

2. Lots de I'insertion d'accessoires dans le mandrin de laperceuse, serrer fermement a la main le

mandrin sans cl&

Z_AVERTISSEMENT : la perceuse pourrait se btoquer (& cause d'une surcharge ou d'une

mauvaise utilisation), produisant ainsi une torsion brusque. Toujours s'attendre & un

btocage. Saisir fermement la perceuse avec les deux mains afin de maftriser le

mouvement de torsion et d'eviter d'en perdre la maTtrise ce qui pourrait entrafner des

blessures corporelles. En cas de btocage, rel&cher la detente immediatement et

determiner la raison du btocage avant de redemarrer.

INSERTION ET RETRAIT DU BLOC-PILES DE L'OUTIL

z_AVERTISSEMENT :S'assurer que le bouton de verrouillage est bien engag_ pour

emp_cher I'utilisation de I'interrupteur Iors de lapose et du retrait du bloc-piles.

INSERTION DU BLOC-PILES : Inserer le bloc-piles

dans I'outit de maniere & entendre un declic (figure B).

S'assurer que le bloc-piles est bien loge et enclenche

en place.

RETRAIT DU BLOC-PILES : Enfoncer le bouton de

degagement du bloc-piles, comme montre & la figure C,

puis retirer le bloc-piles de I'outit.

19

DiRECTiVES D'UTILISATION

DC;TENTE ET BOUTON INVERSEUR (FIGURE D)

• La perceuse est mise en positions de

MARCHE et d'ARRI_T en tirant et en _'_

rel&chant la detente (1). Plus on enfonce

la detente, plus la vitesse de la perceuse

augmente.

• Un bouton de commande marche avant/

marche arriere (2) determine le sens de

I'outil et sert aussi de bouton de verrouitlage.

• Pour choisir une rotation en marche avant,

rel&cher la detente et abaisser le bouton de

commande marche avant/marche arriere

vers la gauche.

• Pour choisir la marche arriere, abaisser le

bouton de commande marche avant/marche

arriere en direction opposee.

REMARQUE : la position du centre du

bouton de commande verrouilte I'outil en

position d'arr_t. Toujours ret&cher la detente

avant de changer la position du bouton de commande.

REGLAGE DU COUPLE (FIGURE E)

L'outit est muni d'une bague (3) de regtage du d'_

couple qui permet de selectionner le mode de

travail et de regler le couple de serrage pour le

serrage des vis. Les grosses vis et les pieces

en matiere dure exigent un couple de serrage

plus elev6 que les petites vis et les pieces de

matieres plus souptes.

Pour le per(_age du bois, du metal et des

plastiques, aligner la bague sur le symbote

de la perceuse.

Pour le vissage, aligner la bague sur la

configuration voulue. Si la configuration

n'est pas connue, proceder comme suit :

Regler la bague sur le couple le plus faible.

Serrer la premiere vis.

Si I'embrayage emet des _,cliquetis _>avant I'obtention du resultat voulu, augmenter le

regtage de la bague et poursuivre le vissage. Repeter la procedure jusqu'& I'obtention

du bon reglage. Utiliser la configuration obtenue pour les autres vis.

MANDRIN SANS CL¢: (FIGURE F)

zLAVERTISSEMENT : S assurer que le bouton de verrouillage est bien engag# pour

emp_cher /'activation de la d_tente /orsde la pose ou de la d_pose d'accessoires.

Pour inserer une meche ou autre accessoire :

1. Saisir la partie inferieure du mandrin (4a) avec une main et utiliser I'autre pour faire

toumer la partie superieure du mandrin en sens antihoraire, si vous regardez la

perceuse par le mandrin.

2. Inserer comptetement la meche ou tout q,D

autre accessoire dans le mandrin et

resserrer fermement en retenant la partie

inferieure du mandrin et en faisant tourner

sa pattie superieure en sens horaire, si

vous regardez la perceuse, par le mandrin.

z_AVERTISSEMENT : ne pas essayer

de resserrer les meches (ou tout autre

accessoire) en saisissant la partie avant du

mandrin et en mettant I'outil en marche. Lors

du changement d'accessoires, it y a risque

d'endommager le mandrin et d'entrafner des

blessures corporettes.

2O

Engrenage a deux vitesses (FIGURE G

La caracteristique de vitesse double de la

perceuse permet de changer d'engrenage de

vitesse, pour une polyvalence accrue. Pour

setectionner la basse vitesse, reglage de coupt_

elev6 (position 1), eteindre I'outit et le laisser

s'arr_ter. Coutisser le bouton de changement de

rapport (5) loin du mandrin. Pour selectionner

la vitesse 6levee, reglage de couple faible

(position 2), eteindre I'outil et le laisser s'arr_ter.

Coutisser le bouton de changement de rapport

en direction du mandrin.

REMARQUE : ne pas changer de rapport

Iorsque I'outil fonctionne. En cas de difficulte &

changer de rapport, s'assurer que le bouton soit

completement avance ou recute.

VlSSAGE

Pour visser des attaches, pousser le bouton de marche arriere vers la gauche. Utitiser ta

marche arriere (le bouton pousse a.droite) pour retirer les attaches. Lots de ta permutation

entre la marche avant et la marche arriere, ou vice versa, s'assurer de rel&cher d'abord la

detente.

RANGEMENT INTEGRE DES MI_CHES (FIGURE H)

IIexiste une rainure pour le rangement des meches (10)

juste au-dessus du bloc-piles.

Lampe de travail a DEL (FIGURE I)

Lorsque la perceuse est actionnee en tirant sur la detente

(1), la lampe de travail & DEL (6) integr6e s'itluminera O

automatiquement. Ne pas utitiser la lampe de travail & DEL

comme lampe de poche.

PER_AGE

N'utiliser que des forets bien aff0tes.

Veiller &ce que la piece & percer soit solidement

retenue ou fixee en place, selon les mesures de

securit6.

Porter t'equipement de securit6 approprie et requis,

seton tes mesures de securit6.

Rendre la zone de travail sQre et en assurer I'entretien, selon les mesures de securit6.

Actionner la perceuse a. basses vitesses en exergant une pression minimale jusqu'& ce

que le trou soit suffisamment perce afin d'emp_cher le glissement du foret hors du trou.

Toujours exercer la pression en ligne directe avec le foret. N'user que de la force

necessaire pour que le foret continue de percer; eviter de trop forcer, ce qui pourrait

faire etouffer le moteur ou devier le foret.

Bien saisir Is perceuse afin de maitrise son effet de torsion.

NE PAS ACTIONNER A PLUSIEURS REPRISES LA DE_TENTE D'UNE PERCEUSE

BLOQUEE DANS LE BUT DE LA DECOINCER AU RISQUE DE L'ENDOMMAGER.

Reduire la pression exercee sur I'outit et le foret vers la fin de la course afin d'eviter

que le moteur ne cale en traversant le materiau.

Laisser le moteur en marche Iorsqu'on retire le foret du trou afin d'en prevenir le

coincement.

S'assurer que I'interrupteur met I'outil en marche et qu'it I'arr_te.

21

PER(_AGEDU BOIS

On peut percer le bois au moyen des meches helicofdales qu'on utilise pour le metal ou de

meches &vrille. On dolt utiliser des meches bien aiguisees et les sortir frequemment pour

enlever les copeaux testes coinces dans les cannelures.

PER_AGE DU METAL

Utiliser une huile de coupe Iorsqu'on perce des metaux, & I'exception de la fonte et du

laiton, car ces demiers doivent _tre perces & sec. Pour cette t&che, les meilleurs lubrifiants

sont l'huile sulfuree et I'huile de bard.

PER(_AGE DE LA MA(_ONNERIE

Utiliser des meches a.pointe carburee (voir la section ,<Mode per£_age>>).Maintenir une

pression uniforme sur la perceuse, sans trop forcer pour eviter de fissurer les materiaux

plus cassants. La vitesse choisie est appropriee Iorsque la poussiere est soulevee

uniformement et regulierement.

ENTRETIEN

Nettoyer I'outil seutement a. I'aide d'un savon doux et d'un linge humide. Ne laisser aucun

liquide s'infiltrer darts l'outil et ne jamais immerger I'outil.

IMPORTANT : Pour assurer la SECURITE D'EMPLOI et la FIABILITE de I'outit, n'en

confier la reparation, I'entretien et les rajustements qu'& un centre de service ou & un atelier

d'entretien autorise n'utitisant que des pieces de rechange identiques.

DEPANNAGE

Probleme Cause possible

• L'appareil refuse de • Mauvaise installation du

demarrer, bloc-piles.

• Bloc-piles non chargee.

Le bloc-piles ne se • Bloc-piles non inser6e

charge pas. dans le chargeur.

• Chargeur non branch&

• Temperature ambiante

trop chaude ou froide.

• L'appareil s'eteint

soudainement.

Pour de I'aide avec I'outil, consulter notre site Web www.blackanddecker.com pour

I'emptacement du centre de reparation le plus pres ou communiquer avec I'assistance

BLACK & DECKER au 1-800-544-6986.

• Le bloc-pilesa atteint sa

limitethermique maximale.

•Bloc-pilesepuis& (Pour

maximiser la duree de vie du

bloc-piles, cetui-ci estcon£u

pour s'_eindre soudainement

Iorsqu'ilest epuis&)

• Verifier I'instaltation du

bloc-piles.

• Verifier les exigences de

charge pour le bloc-piles.

• Inserer le bloc-piles darts le

chargeur de sorte que le

voyant DEL vert apparaisse.

•Brancher lechargeur dans

une prise qui fonctionne. Se

reporter & la rubrique ,, Remarques

importantes de chargement >>pour

plus de renseignements.

• Deptacer le chargeur

et l'outit & une temperature ambiante

de plus de 4.5 °C (40 °F) ou sous les

40.5 °C (105 °F).

• Laisserlebloc-piles

refroidir.

• Placer darts lechargeur le

temps d'une charge.

Solution possible

22

Accessoires

Les detaiNants et le centre de service de la region vendent les accessoires recommandes

pour I'outil. Pour trouver un accessoire, composer le 1 800 544-6986.

z_AVERTISSEMENT : L'utiNsation de tout accessoire non recommande pour I'outit peut

etre dangereuse.

LE SCEAU RBRC Mc

Le sceau SRPRC Mc(Societ6 de Recyclage des Piles Rechargeables

au Canada) sur la pile Nthium-ion (ou sur le bloc-piles) indique que son

coQt de recyctage (ou celui du bloc-piles) & la fin de sa vie utile sera paye

par Black & Decker. Darts certaines regions, il est iNegal de jeter les piles

lithium-ion darts les poubeNes ou darts le systeme municipal d'evacuation

des residus sondes. Le programme RBRC represente doric une alternative sensibilisee &

I'environnement.

La SRPRC en collaboration avec Black & Decker et d'autres utitisateurs de piles ont

etabli aux t_tats-Unis et au Canada des programmes facilitant la cueillette des piles

lithium-ion epuis6es. Aidez-nous & proteger I'environnement et & conserver nos

ressources naturelles en retournant I'outil & un centre de reparation Black & Decker pour

qu'elles soient recyclees. Vous pouvez aussi communiquer avec votre centre local de

recyctage qui vous fera part du lieu de disposition de vos batteries epuis6es ou composer

le numero 1-800-8-BATTERY.

Cet appareit numerique de la classe Best conforme & la norme NMB-O03 du Canada.

Cet appareil est conforme aux dispositions du paragraphe 15 des reglements de la FCC.

Son fonctionnement est regi par les deux conditions suivantes : (1) Cet appareil ne peut

pas causer d'interference nuisible et (2) cet appareit doit accepter toutes les interferences

re£;ues, y compris celles qui risquent d'en g_ner te fonctionnement.

REMARQUE : ce materiel a ate testa et a ate declare conforme aux Nmites en vigueur

concernant les dispositifs numeriques de ctasse B, en vertu de la partie 15 de la

reglementation FCC. Ces Nmites visent & assurer une protection raisonnabte contre tout

brouillage nuisible darts une installation residentielte. Ce materiel produit, consomme

et peut emettre une energie de radiofrequence et, s'it n'est pas installe et utilise

conformement aux directives qui I'accompagnent, it peut entrafner un brouiltage nuisibte

des communications radio. Cependant, nous ne garantissons pas I'absence de brouiNage

darts tousles types d'environnement. Si, apres avoir effectue une verification en mettant

I'appareil hors tension puis sous tension, I'utiNsateur s'aper£oit que ce materiel provoque

un brouitlage nuisibte & la reception des signaux de radio ou de television, il lui faudra

essayer de corriger ce brouittage en prenant une ou plusieurs des mesures ci-dessous :

• Reorienter ou repositionner I'antenne de reception.

• Etoigner le plus possible le materiel du recepteur.

• Brancher le materiel darts une prise electrique situee sur un circuit different de celui du

recepteur.

• Consulter ledistributeur ou un technicien radio/television experimente pour obtenir de I'aide.

Tout changement ou toute modification & cet appareil qui n'est pas expressement

approuve par I'institution responsable de la conformite peut faire annuter le droit de

I'utiNsateur d'utitiser ce materiel. Cet appareit numerique de la classe Best conforme & la

norme NMB-O03 du Canada.

INFORMATION SUR LES REPARATIONS

Tousles centres de reparation Black & Decker sont dotes de personnel quaNfie en matiere

d'outittage electrique; ils sont doric en mesure d'offrir & leur clientele un service efficace

et liable. Que ce soit pour un avis technique, une reparation ou des pieces de rechange

authentiques installees en usine, communiquer avec I'etabNssement Black & Decker

le plus pres de chez vous. Pour trouver I'etabNssement de reparation de votre region,

consulter le repertoire des Pages jaunes & la rubrique ,, Outils electriques >>ou composer

le numero suivant : 1-800-544-6986 ou consulter le site www.blackanddecker.com

23

GARANTIECOMPLETEDEDEUXANS POUR UNE UTILISATION DOMESTIQUE

Black & Decker (E_.-U.)Inc. garantit ce produit pour une duree de deux ans contre tout

defaut de materiau ou de fabrication. Le produit defectueux sera remptace ou repar6 sans

frais de I'une des deux fagons suivantes :

La premiere fagon consiste en un simple echange chez le detaillant qui I'a vendu (pourvu

qu'il s'agisse d'un detaillant participant). Tout retour dolt se faire durant la periode

correspondant a la politique d'echange du detaillant (habituellement, de 30 a 90 jours apres

I'achat). Une preuve d'achat peut _tre requise. Verifier aupres du detaillant pour connaftre

sa politique concernant les retours hors de la periode definie pour les echanges.

La deuxieme option est d'apporter ou d'envoyer le produit (transport paye d'avance) a un

centre de reparation autorise ou a un centre de reparation de Black & Decker pour faire

reparer ou echanger le produit, a.notre discretion. Une preuve d'achat peut 6tre requise.

Les centres Black & Decker et les centres de service autorises sont r6pertories dans les

pages jaunes, sous la rubrique ,, Outils electriques ,.

Cette garantie ne s'apptique pas aux accessoires. Cette garantie vous accorde des droits

legaux specifiques et vous pourriez avoir d'autres droits qui varient d'un Etat ou d'une

province a I'autre. Pour toute question, communiquer avec le directeur du centre de

reparation Black & Decker le plus pres de chez vous. Ce produit n'est pas destine a un

usage commercial.

REMPLACEMENT GRATUIT DES I_TIQUETTES D'AVERTISSEMENT : si les etiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1=800=544-6986

pour en obtenir le remplacement gratuit.

Imported by / Importe par

Black & Decker Canada Inc.

100 Central Ave.

Brockvitle (Ontario) K6V 5W6

Voir la rubrique

"Outils electriques"

des Pages Jaunes

pour le service et les ventes.

24

IJ-,,M

TALADROINALAiVlBRICODE20VMAX*

MANUALDEiNSTRUCCIONES

CATALOGON°

LDX220 ( _V

25

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La informaci6n.que contiene se

relaciona con la protecci6n de SU SEGURIDAD y la PREVENClON DE PROBLEMAS.

Los sfmbolos que siguen se utilizan para ayudarlo a reconocer esta informaci6n.

z_PELIGRO: indica una situaci6n de peligro inminente que, si no se evita,

z_ provocara, la muerte o lesiones graves.

ADVERTENOIA: indica una situaci6n de peligro potencial que, si no se evita,

z_ provocara, la muerte o lesiones graves.

PRECAUCION: indica una situaci6n de petigro potencial que, si no se evita,

provocar& lesiones leves o moderadas.

PRECAUCION: utiNzadosin el simbolo de alerta de seguridad indica una situacion de