Page 1

www.blackanddecker.ae

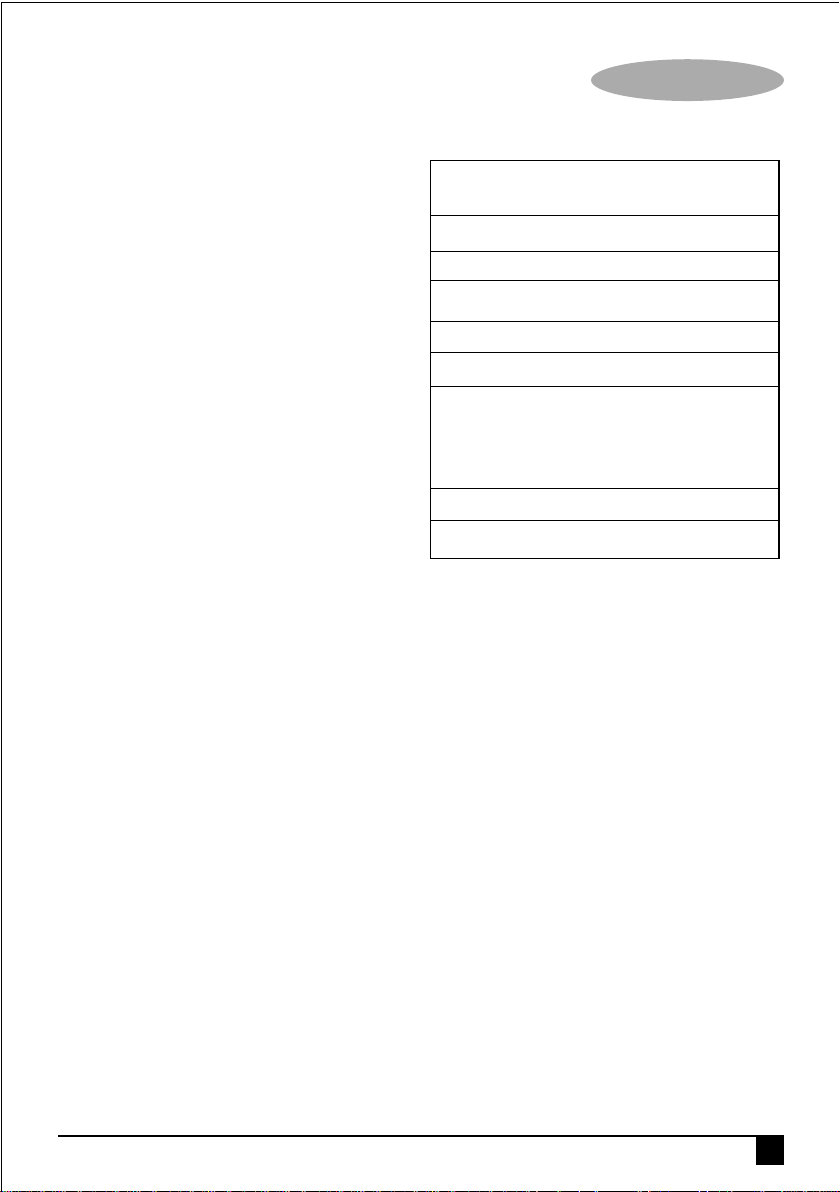

KG2300

Page 2

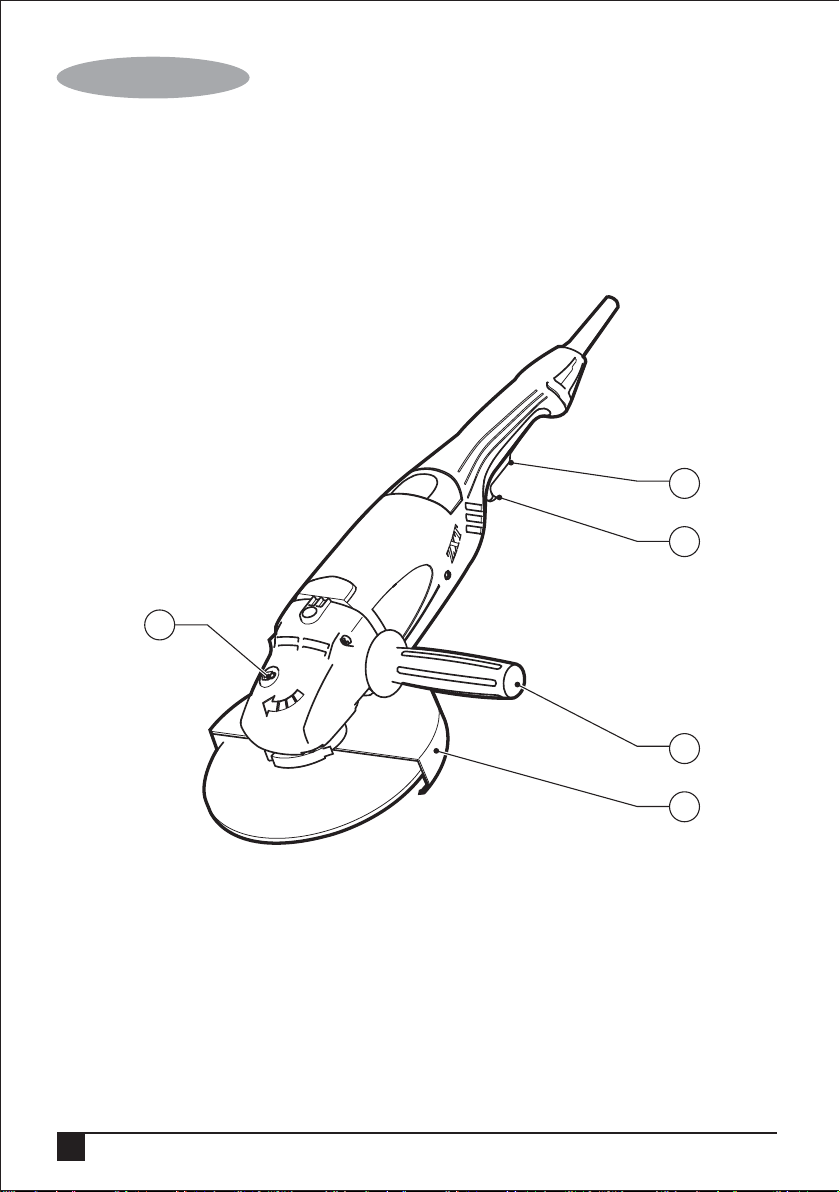

ENGLISH

4

1

2

3

5

2

Page 3

ENGLISH

5

8

14

A

10

6

9

7

9

12

13

11

6

B

14

12

11

6

14

15 14 12

C

12

11

6

4

D

3

Page 4

ENGLISH

Intended use

Your Black & Decker angle grinder has been

designed for grinding and cutting metal and

masonry using the appropriate type of cutting or

grinding disc. When fitted with the appropriate

guard, this tool is intended for consumer use

only.

Safety instructions

General power tool safety warnings

Warning! Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

The term "power tool" in all of the warnings

listed below refers to your mains operated

(corded) power tool or battery operated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

4

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

power tools that have the switch on invites

accidents.

Page 5

ENGLISH

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power

tool may result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes,

jewellery or long hair can be caught in

moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b. Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk

of starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g. Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

5. Service

a. Have your power tool serviced by a qualified

repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Additional power tool safety

warnings

Warning! Additional safety warnings for

grinding, sanding, wire brushing,

polishing or abrasive cutting-off operations

• This power tool is intended to function as a

grinder, sander, wire brush, polisher or cut-off

tool. Read all safety warnings, instructions,

illustrations and specifications provided with

this power tool. Failure to follow all

instructions listed below may result in electric

shock, fire and/or serious injury.

• Operations for which the power tool was not

designed may create a hazard and cause

personal injury.

5

Page 6

ENGLISH

• Do not use accessories which are not

specifically designed and recommended by

the tool manufacturer. Just because the

accessory can be attached to your power

tool, it does not assure safe operation.

• The rated speed of the accessory must be at

least equal to the maximum speed marked

on the power tool. Accessories running faster

than their rated speed can break and fly

apart.

• The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded

or controlled.

• The arbour size of wheels, flanges, backing

pads or any other accessory must properly fit

the spindle of the power tool. Accessories

with arbour holes that do not match the

mounting hardware of the power tool will run

out of balance, vibrate excessively and may

cause loss of control.

• Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheels for chips and cracks,

backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If

power tool or accessory is dropped, inspect

for damage or install an undamaged

accessory. After inspecting and installing an

accessory and run the power tool at

maximum no-load speed for one minute.

Damaged accessories will normally break

apart during this test time.

• Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As

appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection

must be capable of stopping flying debris

6

generated by various operations. The dust

mask or respirator must be capable of filtering

particles generated by your operation.

Prolonged exposure to high intensity noise

may cause hearing loss.

• Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken

accessory may fly away and cause injury

beyond immediate area of operation.

• Hold power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. Cutting

accessory contacting a "live" wire may make

exposed metal parts of the power tool "live"

and shock the operator.

• Position the cord clear of the spinning

accessory. If you lose control, the cord may

be cut or snagged and your hand or arm may

be pulled into the spinning accessory.

• Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and

pull the power tool out of your control.

• Do not run the power tool while carrying it at

your side. Accidental contact with the

spinning accessory could snag your clothing,

pulling the accessory into your body.

• Regularly clean the power tool's air vents.

The motor's fan will draw the dust inside the

housing and excessive accumulation of

powdered metal may cause electrical

hazards.

• Do not operate the power tool near flammable

materials. Sparks could ignite these

materials.

• Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Page 7

ENGLISH

Note: The above warning does not apply for

power tools specifically designed for use with a

liquid system.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power tool

to be forced in the direction opposite of the

accessory's rotation at the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel's movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking proper

precautions as given below.

• Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or

kickback forces, if proper precautions are

taken.

• Never place your hand near the rotating

accessory. Accessory may kickback over

your hand.

• Do not position your body in the area where

power tool will move if kickback occurs.

Kickback will propel the tool in direction

opposite to the wheel's movement at the

point of snagging.

• Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag

the rotating accessory and cause loss of

control or kickback.

• Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create

frequent kickback and loss of control.

Additional safety warnings

specific for abrasive cutting-off

operations

• Do not "jam" the cut-off wheel or apply

excessive pressure. Do not attempt to make

an excessive depth of cut. Over stressing the

wheel increases the loading and susceptibility

to twisting or binding of the wheel in the cut

and the possibility of kickback or wheel

breakage.

• Do not position your body in line with and

behind the rotating wheel. When the wheel, at

the point of operation, is moving away from

your body, the possible kickback may propel

the spinning wheel and the power tool directly

at you.

• When wheel is binding or when interrupting a

cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never

attempt to remove the cut-off wheel from the

cut while the wheel is in motion otherwise

kickback may occur. Investigate and take

corrective action to eliminate the cause of

wheel binding.

• Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully re-enter the cut. The wheel may

bind, walk up or kickback if the power tool is

restarted in the workpiece.

7

Page 8

ENGLISH

• Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag

under their own weight. Supports must be

placed under the workpiece near the line of

cut and near the edge of the workpiece on

both sides of the wheel.

• Use extra caution when making a "pocket

cut" into existing walls or other blind areas.

The protruding wheel may cut gas or water

pipes, electrical wiring or objects that can

cause kickback.

Safety warnings specific for sanding

operations

• Do not use excessively oversized sanding

disc paper. Follow manufacturers

recommendations, when selecting sanding

paper. Larger sanding paper extending

beyond the sanding pad presents a

laceration hazard and may cause snagging,

tearing of the disc or kickback.

Safety warnings specific for polishing

operations

• Do not allow any loose portion of the

polishing bonnet or its attachment strings to

spin freely. Tuck away or trim any loose

attachment strings. Loose and spinning

attachment strings can entangle your fingers

or snag on the workpiece.

Safety warnings specific for wire brushing

operations

• Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

• If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire

wheel or brush may expand in diameter due

to work load and centrifugal forces.

Safety of others

• This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervision or

instruction concerning use of the appliance by

a person responsible for their safety.

• Children should be supervised to ensure that

they do not play with the appliance.

Vibration

The declared vibration emission values stated in

the technical data and the declaration of

conformity have been measured in accordance

with a standard test method provided by EN

60745 and may be used for comparing one tool

with another. The declared vibration emission

value may also be used in a preliminary

assessment of exposure.

Warning! The vibration emission value during

actual use of the power tool can differ from the

declared value depending on the ways in which

the tool is used. The vibration level may increase

above the level stated.

When assessing vibration exposure to determine

safety measures required by 2002/44/EC to

protect persons regularly using power tools in

employment, an estimation of vibration exposure

should consider, the actual conditions of use and

the way the tool is used, including taking account

of all parts of the operating cycle such as the

times when the tool is switched off and when it is

running idle in addition to the trigger time.

8

Page 9

ENGLISH

Labels on tool

The following pictograms are shown on the tool:

Warning! To reduce the risk of injury,

the user must read the instruction

manual.

Wear safety glasses or goggles when

operating this tool.

Wear ear protection when operating

this tool.

Electrical safety

This tool is double insulated; therefore

no earth wire is required. Always check

that the power supply corresponds to

the voltage on the rating plate.

• If the supply cord is damaged, it must be

replaced by the manufacturer or an

authorised Black & Decker Service Centre in

order to avoid a hazard.

Features

This tool includes some or all of the following

features.

1. On/off switch

2. Lock-off button

3. Side handle

4. Spindle lock

5. Guard

Assembly

Warning! Before assembly, make sure that the

tool is switched off and unplugged.

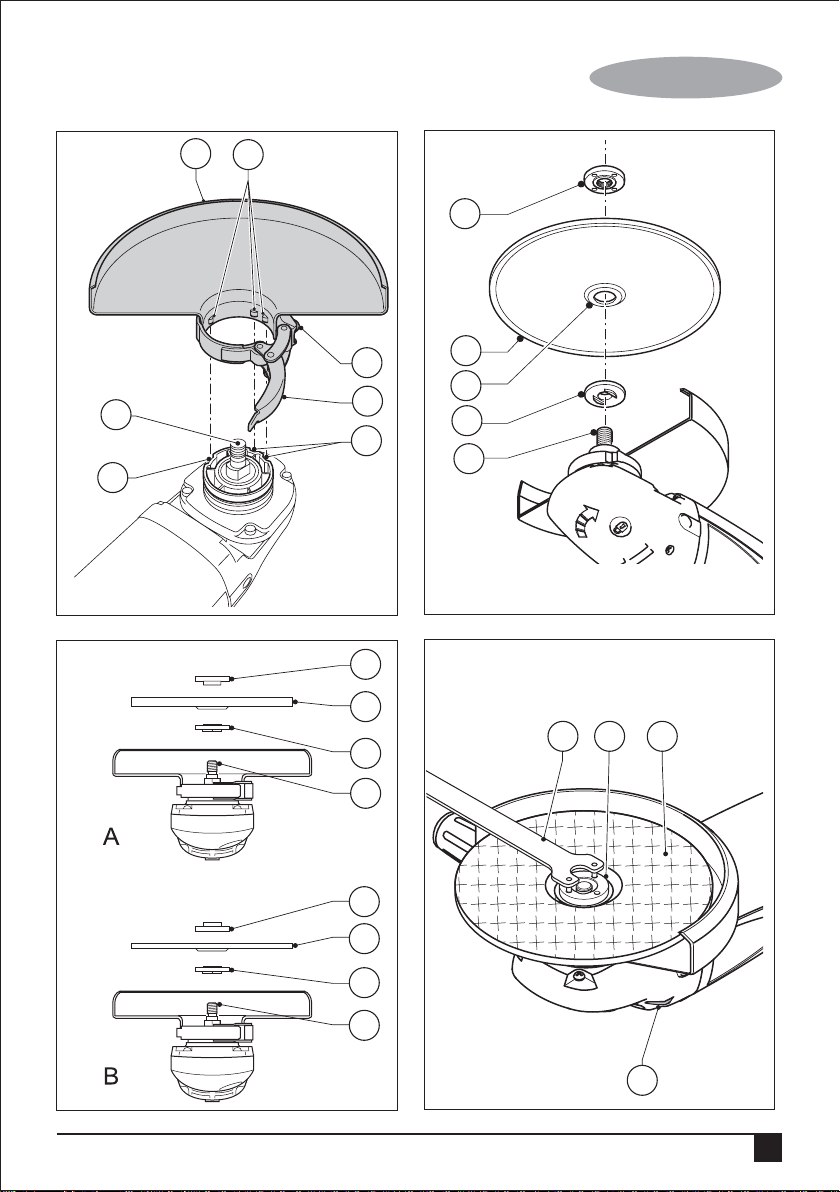

Fitting and removing the guard

(fig. A)

The tool is supplied with a guard intended for

grinding purposes only. If the unit is intended to

perform cutting off operations, a guard specific

for this operation must be fitted. A suitable guard

for cutting off operations part number

1004484-02 is available and can be obtained

from Black & Decker service centres.

Fitting

• Place the tool on a table, with the spindle (6)

facing up.

• Release the clamping lock (7) and hold the

guard (5) over the tool as shown.

• Align the lugs (8) with the notches (9).

• Press the guard down and rotate it

counterclockwise to the required position.

• Fasten the clamping lock to secure the guard

to the tool.

• If required, tighten the screw (10) to increase

the clamping force.

Removing

• Release the clamping lock (7).

• Rotate the guard clockwise to align the lugs

(8) with the notches (9).

• Remove the guard from the tool.

Adjusting the guard (fig. A)

The guard can be rotated 90°.

• Rotate the guard as required.

Fitting the side handle (fig. B)

• Screw the side handle (3) into one of the

mounting holes in the tool.

Warning! Always use the side handle.

Fitting and removing grinding or

cutting discs (fig. B - D)

Always use the correct type of disc for your

application. Always use discs with the correct

diameter and bore size (see technical data).

9

Page 10

ENGLISH

Fitting

•

Fit the guard as described above.

• Place the inner flange (11) onto the spindle

(6) as shown (fig. B). Make sure that the

flange is correctly located on the flat sides of

the spindle.

• Place the disc (12) onto the spindle (6) as

shown (fig. B). If the disc has a raised centre

(13), make sure that the raised centre faces

the inner flange.

• Make sure that the disc locates correctly on

the inner flange.

• Place the outer flange (14) onto the spindle.

When fitting a grinding disc, the raised centre

on the outer flange must face towards the

disc (A in fig. C). When fitting a cutting disc,

the raised centre on the outer flange must

face away from the disc (B in fig. C).

• Keep the spindle lock (4) depressed and

tighten the outer flange using the two-pin

spanner (15) (fig. D).

Removing

•

Keep the spindle lock (4) depressed and

loosen the outer flange (14) using the

two-pin spanner (15) (fig. D).

• Remove the outer flange (14) and the disc

(12).

Use

• Warning! Let the tool work at its own pace.

Do not overload.

• Carefully guide the cable in order to avoid

accidentally cutting it.

• Be prepared for a stream of sparks when the

grinding or cutting disc touches the

workpiece.

• Always position the tool in such a way that

the guard provides optimum protection from

the grinding or cutting disc.

Switching on and off

• To switch the tool on, move the lock-off button

(2) into the unlock position and squeeze the

on/off switch (1).

• To switch the tool off, release the on/off

switch.

Warning! Do not switch the tool off while under

load.

Hints for optimum use

• Firmly hold the tool with one hand around the

side handle and the other hand around the

main handle.

• When grinding, always maintain an angle of

approx. 15° between the disc and the

workpiece surface.

Maintenance

Your Black & Decker corded/cordless

appliance/tool has been designed to operate

over a long period of time with a minimum of

maintenance. Continuous satisfactory operation

depends upon proper tool care and regular

cleaning.

Warning! Before performing any maintenance

on corded/cordless power tools:

• Switch off and unplug the appliance/tool.

• Or switch off and remove the battery from the

appliance/tool if the appliance/tool has a

separate battery pack.

• Or run the battery down completely if it is

integral and then switch off.

10

Page 11

ENGLISH

• Unplug the charger before cleaning it. Your

charger does not require any maintenance

apart from regular cleaning.

• Regularly clean the ventilation slots in your

appliance/tool/charger using a soft brush or

dry cloth.

• Regularly clean the motor housing using a

damp cloth. Do not use any abrasive or

solvent-based cleaner.

• Regularly open the chuck and tap it to

remove any dust from the interior (when

fitted).

Mains Plug Replacement

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal of

the new plug.

Technical Data

KG2300

Type 2

Input voltage Vac 220-240

Power input W 2,300

No-load speed min

Disc diameter mm 230

Disc bore mm 22

Max. disc thickness

Grinding discs mm 6

Cutting discs mm 3

Spindle size M14

Weight kg 6.4

-1

6,000

• Connect the blue lead to the neutral terminal.

• If the product is class l (earthed), connect the

green / yellow lead to the earth terminal.

Warning! If your product is class ll double

insulated (only 2 wires in the cord set), no

connection is to be made to the earth terminal.

Follow the fitting instructions supplied with good

quality plugs.

Any replacement fuse must be of the same

rating as the original fuse supplied with the

product.

11

Page 12

ENGLISH

Protecting the environment

Separate collection. This product must not

be disposed of with normal household

waste.

Should you find one day that your Black &

Decker product needs replacement, or if it is of

no further use to you, do not dispose of it with

other household waste. Make this product

available for separate collection.

• Black & Decker provides a facility for

recycling Black & Decker products once they

have reached the end of their working life.

This service is provided free of charge. To

take advantage of this service please return

your product to any authorised repair agent

who will collect them on our behalf.

• You can check the location of your nearest

authorised repair agent by contacting your

local Black & Decker office at the address

indicated in this manual. Alternatively, a list of

authorized Black & Decker repair agents and

full details of our after-sales service and

contact are available on the Internet at:

www.2helpU.com.

Warranty

If a Black & Decker product becomes defective

due to a material or manufacturing defect , within

12 months from the date of purchase, Black &

Decker guarantees to replace defective parts or

replace such products to ensure minimum

inconvenience to the customer unless:

• The product has been subjected to misuse or

neglect.

• The product has sustained damage through

foreign objects, substances or accidents.

• Repairs have been attempted by persons

other than authorised repair agents or Black

& Decker service staff.

To claim on the warranty, you will need to submit

proof of purchase to the seller or an authorised

repair agent. You can check the location of your

nearest authorised repair agent by contacting

your local Black & Decker office at the address

indicated in this manual. Alternatively, a list of

authorised Black & Decker repair agents and full

details of our after-sales service and contacts are

available on the Internet at: www.2helpU.com.

Please visit our website www.blackanddecker.ae

to register your new Black & Decker product and

to be kept up to date on new products and

special offers. Further information on the Black &

Decker brand and our range of products is

available at www.blackanddecker.ae.

12

Page 13

ARABIC

1

2

4

3

5

13

Page 14

ARABIC

5

8

14

A

10

6

9

7

9

12

13

11

6

B

14

12

11

6

14

15 14 12

C

14

12

11

6

4

D

Page 15

ARABIC

Ö«HÉfC’G πãe á°VQDƒŸG í£°SCÓd ∂ª°ùL á°ùeÓe ÖæŒ .Ü

ôWÉfl OGOõJ å«M ,äÉLÓãdGh óbGƒŸGh áÄaóàdG Iõ¡LC

.Ék°VQDƒe ∂ª°ùL ¿Éc GPEG á«FÉHô¡c áeó°üH ∂àHÉ°UEG

,áÑWôdG AGƒLC’G hCG ô£ª∏d á«FÉHô¡μdG Iõ¡LC’G ¢Vô©J ’ .ê

¤EG »FÉHô¡μdG RÉ¡÷G πNGO AÉŸG ∫ƒNO …ODƒj ±ƒ°ùa

.á«FÉHô¡c áeó°üH áHÉ°UE’G ôWÉfl IOÉjR

.ÅWÉN πμ°ûH »FÉHô¡μdG QÉ«àdG ∂∏°S ΩGóîà°SG ΩóY Öéj .O

RÉ¡÷G πª◊ »FÉHô¡μdG QÉ«àdG ∂∏°S Ék≤∏£e Ωóîà°ùJ ’

ɪc .»FÉHô¡μdG QÉ«àdG øY ¬∏°üa hCG ¬Ñë°S hCG »FÉHô¡μdG

IQGô◊G øY Gkó«©H »FÉHô¡μdG QÉ«àdG ∂∏°ùH ®ÉØàM’G Öéj

kɪ∏Y .ácôëàŸG AGõLC’G hCG IOÉ◊G ±Gƒ◊G hCG âjõdG hCG

ôWÉfl øe ójõJ áμHÉ°ûàŸG hCG áØdÉàdG ∑Ó°SC’G ¿CÉH

.á«FÉHô¡c áeó°üH áHÉ°UE’G

Öéj ,êQÉÿG ‘ »FÉHô¡μdG RÉ¡÷G 𫨰ûJ óæY .`g

,»LQÉÿG ΩGóîà°SÓd Ö°SÉæŸG π«°UƒàdG ∂∏°S ΩGóîà°SG

Ö°SÉæŸG »FÉHô¡μdG QÉ«àdG ∂∏°S ΩGóîà°SG ¿C’ kGô¶f

áeó°üd ¢Vô©àdG ôWÉfl øe π∏≤j »LQÉÿG ΩGóîà°SÓd

Öéj ,ÖWQ ¿Éμe ‘ »FÉHô¡μdG RÉ¡÷G 𫨰ûJ ºà– GPEG .h

¿C’ kGô¶f ,»≤ÑàŸG QÉ«àdG øe ájÉbh RÉ¡L ΩGóîà°SG

øe π∏≤j »≤ÑàŸG QÉ«àdG øe ájÉbh RÉ¡L ΩGóîà°SG

.á«FÉHô¡c áeó°üH áHÉ°UE’G ôWÉfl

á«°üî°ûdG áeÓ°ùdG .3

óæY º«∏°ùdG ¢ù◊G Ωóîà°SGh ¬∏©ØJ ÉŸ ¬ÑàfGh kGQòM øc .CG

»FÉHô¡μdG RÉ¡÷G Ωóîà°ùJ ’ .»FÉHô¡μdG RÉ¡÷G 𫨰ûJ

äÉHhöûŸG hCG ÒbÉ≤©dG ÒKCÉJ â– hCG É

AÉæKCG á∏بdG øe á¶◊ ÖÑ°ùàJ ó≤a ,ájhOC’G hCG á«dƒëμdG

á«°üî°T áHÉ°UEG çhóM ‘ á«FÉHô¡μdG Iõ¡LC’G 𫨰ûJ

m¥Gh ÉkehO …óJQG .á«°üî°ûdG ájÉbƒdG äGó©e Ωóîà°SG .Ü

äÉeɪc πãe ,ájÉbƒdG äGó©e ΩGóîà°SG ¿C’ ,Úæ«©∏d

áÑ∏°üdG äGPƒÿGh ¥’õfÓd á©fÉŸG ájòMC’Gh áHôJC’G

äÉHÉ°UEG çhóM ôWÉfl øe π∏≤j ,™ª°ùdG ájÉbh äGhOCGh

¿hO ∫ƒë∏d áeRÓdG äÉWÉ«àM’G áaÉc PÉîJG Öéj .ê

óY ™°Vh ‘ ìÉàØŸG ¿CG ócCÉJ .ó°üb ¿hO RÉ¡÷G 𫨰ûJ

hCG/h »FÉHô¡μdG QÉ«àdG Qó°üà π«°UƒàdG πÑb 𫨰ûàdG

πªM ¿CG PE

™°Vh ‘ ìÉàØŸGh ábÉ£dÉH á«FÉHô¡μdG Iõ¡LC’G ójhõJ

G .¬∏ªM hCG RÉ¡÷G ™aQ hCG ,äÉjQÉ£ÑdG Ö«côJ

hCG ìÉàت∏d á°ùeÓe ™HÉ°UC’Gh á«FÉHô¡μdG Iõ¡LC’G

.çOGƒM ´ƒbh ¤EG …ODƒj 𫨰ûàdG

μ¡æe âæc GPEG

k

Gh

.á«FÉHô¡c

.á¨dÉH

.á«°üî°T

ΩGóîà°S’G ¢VôZ

ï∏÷ ôμjO ófBG ∑ÓH á«fGƒ£°S’G ï∏÷G áæ«cÉe º«ª°üJ ”

Ö°SÉæŸG ´ƒædG ΩGóîà°SÉH AÉæÑdG OGƒeh ¿OÉ©ŸG ™«£≤Jh

ºª°üe RÉ¡÷G Gòg ¿CÉH kɪ∏Y ,™«£≤àdG hCG ï∏÷G ¢UGôbCG øe

äGhOCÉH √ójhõJ á£jöT ;§≤a ∂∏¡à°ùŸG ᣰSGƒH ¬eGóîà°S’

.áeRÓdG ájÉbƒdG

áeÓ°ùdG äGOÉ°TQEG

á«FÉHô¡μdG Iõ¡LC’G ¢Uƒ°üîH áeÉ©dG áeÓ°ùdG äGôjò–

äGOÉ°TQEGh äGôjò– áaÉc IAGôb »¨Ñæj !ôjò–

äGôjòëàdG áaÉc ´ÉÑJEG ΩóY ÖÑ°ùàj ó≤a .áeÓ°ùdG

hCG á«FÉHô¡c áeó°U çhóM ‘ √ÉfOCG IQƒcòŸG äGOÉ°TQE’Gh

.kÉ©e AÉ«°TC’G √òg ™«ªL hCG IÒ£N áHÉ°UEG hCG ≥jôM

´ƒLô∏d äGOÉ°TQE’Gh äGôjòëàdG áaÉμH ®ÉØàM’G ≈Lôj

.kÓÑ≤à°ùe É¡«dEG

áaÉc ‘ OQGƒdG "»FÉHô¡c RÉ¡L" í∏£°üŸG Ò°ûj

…òdG »FÉHô¡μdG RÉ¡÷G ¤EG √ÉfOCG IQƒcòŸG äGôjòëàdG

»FÉHô¡μdG RÉ¡÷G hCG (É

É¡JAÉ°VEGh πª©dG á≤£æe áaɶf ≈∏Y ®ÉØ◊G »¨Ñæj .CG

ΩÉcôdÉH á¶àμŸG hCG áª∏¶ŸG ≥WÉæŸG ÖÑ°ùàJ PEG ,Gkó«L

á∏HÉb AGƒLCG ‘ á«FÉHô¡μdG Iõ¡LC’G 𫨰ûàH º≤J ’ .Ü

hCG äGRÉZ hCG πFGƒ°S OƒLh ‘ É¡∏«¨°ûJ πãe ;QÉéØfÓd

á«FÉHô¡μdG Iõ¡LC’G ¿C’ kGô¶f ,∫É©à°TÓd πHÉb QÉÑZ

hCG QÉѨdG ∫É©à°TG ¤EG …ODƒJ ób äGQGöT É¡æY èàæj

RÉ¡÷G 𫨰ûJ AÉæKCG IQÉŸGh ∫ÉØWC’G OÉ©HEG »¨Ñæj .ê

Iô£«°ù∏d ∂fGó≤a ‘ AÉ¡dE’G ÖÑ°ùàj ó≤a ,»FÉHô¡μdG

™e á≤aGƒàe »FÉHô¡μdG RÉ¡÷G ¢ùHGƒb ¿ƒμJ ¿CG Öéj .CG

¢ùHÉ≤dG πjó©J Ék≤∏£e ÖæŒ .»FÉHô¡μdG QÉ«àdG òNCÉe

™e ä’ƒfi ¢ùHGƒb ájCG Ωóîà°ùJ ’h ,á≤jôW ájCÉH

ádó©ŸG ÒZ ¢ùHGƒ≤dG ΩGóîà°SG ¿C’ ,á°VQDƒŸG Iõ¡LC’G

π«∏≤J ¤EG …ODƒj á≤aGƒàŸG »FÉHô¡μdG QÉ«àdG òNBÉeh

«μ∏°S) »FÉHô¡μdG QÉ«àdÉH πª©j

k

.(Ék«μ∏°S’) ájQÉ£ÑdÉH πª©j …òdG

πª©dG á≤£æe áeÓ°S .1

.çOGƒ◊G ´ƒbh ‘

.áæNOC’G

.RÉ¡÷G ≈∏Y

á«FÉHô¡μdG áeÓ°ùdG .2

.á«FÉHô¡c áeó°üd ¢Vô©àdG ôWÉfl

15

Page 16

ARABIC

¢üëaG .á«FÉHô¡µdG Iõ¡LCÓd ájQhO áfÉ«°U AGôLEG Öéj .`g

¥ƒ©J »àdG hCG ¬«a áÑ«©ŸG AGõLC’G ≈∏Y ±ô©à∏d RÉ¡÷G

AGõLC’G øe √ƒ∏N øe ócCÉàdGh ácôëàŸG AGõLC’G ácôM

IAÉØc ≈∏Y ôKDƒj ób ôNBG A»°T …CG øeh IQƒ°ùµŸG

RÉ¡÷G ìÓ°UEG Öéj ,∞∏J …CG ±É°ûàcG ” GPEGh .¬∏«¨°ûJ

øe ójó©dG ¿CÉH kɪ∏Y ,¬eGóîà°SG πÑb »FÉHô¡µdG

.á«FÉHô¡µdG Iõ¡LC’G áfÉ«°U Aƒ°S ÖÑ°ùH ™≤J çOGƒ◊G

¿C’ ,áØ«¶fh

Ö°SÉæŸG πµ°ûdÉH É¡«∏Y ®ÉØ◊G ºàj »àdG ™£≤dG äGhOCG

∫É£YCÓd á°VôY πbCG IOÉM á©WÉb äGôØ°ûH IOhõŸGh

¬FGõLCGh ¬JÉ≤ë∏eh »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG Öéj .R

±hôX òNCG ™e ,äGOÉ°TQE’G √ò¡d Ék≤ah ∂dP ¤EG Éeh

ó≤a ,QÉÑàY’G ‘ √ò«ØæJ OGôŸG πª©dGh ᣫëŸG πª©dG

äÉ«∏ªY πLCG øe »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG ÖÑ°ùàj

çhóM ‘ É¡∏LCG øe ºª°üŸG ¢VGôZC’G iƒ°S 𫨰ûJ

ᣰSGƒH »FÉHô¡µdG RÉ¡÷G ìÓ°UEGh áfÉ«°U Öéj .CG

∂dP ¿C’ ,á≤HÉ£e QÉ«Z ™£b ΩGóîà°SÉH πgDƒe ¢üî°T

IOÉM ™£≤dG äGhOCG ≈∏Y ®ÉØ◊G »¨Ñæj .h

k

.ºµëàdG ‘ π¡°SCGh

.ôWÉfl

áfÉ«°üdG .5

.»FÉHô¡µdG RÉ¡÷G áeÓ°S øª°†j

RÉ¡÷G ¢Uƒ°üîH á«aÉ°VEG áeÓ°S äGôjò–

»FÉHô¡µdG

¢Uƒ°üîH á«aÉ°VEG áeÓ°S äGôjò– !ôjò–

¢TôØdÉH ∞«¶æàdG hCG IôØæ°üdG hCG ï∏÷G äÉ«∏ªY

.»î«∏éàdG ™«£≤àdG hCG ™«ª∏àdG hCG ᫵∏°ùdG

ï∏L áæ«cɪc ¬eGóîà°S’ »FÉHô¡µdG RÉ¡÷G Gòg ºª°U

Öéj .᫵∏°S IÉ°TôØc hCG ™«£≤J hCG ™«ª∏J hCG IôØæ°U hCG

Ωƒ°SôdGh äGOÉ°TQE’Gh ¿ÉeC’G äGôjò– áaÉc IAGôb

RÉ¡÷G Gòg ™e IOhõŸG äÉØ°UGƒŸGh á«ë«°VƒàdG

äGOÉ°TQE’G ™«ªL ´ÉÑJG ΩóY ¿CÉH kɪ∏Y ,»FÉHô¡µdG

hCG á«FÉHô¡c áeó°U çhóM ¤EG …ODƒj ób √ÉfOCG IOQGƒdG

.kÉ©e AÉ«°TC’G √òg ™«ªL hCG IÒ£N äÉHÉ°UEG hCG ≥FGôM

ºàj ⁄ ¢VGôZCG ‘ »FÉHô¡µdG RÉ¡÷G Gòg ΩGóîà°SG

ÖÑ°ùàjh ôWÉîŸG øe ójó©dG ódƒj ób É¡∏LCG øe ¬ª«ª°üJ

.á«°üî°T äÉHÉ°UEG çhóM ‘

16

𫨰ûJ πÑb §HQ ìÉàØe hCG πjó©J ìÉàØe …CG ádGREÉH ºb .O

kÉ`≤∏©e ìÉàØŸG ∑ôJ ÖÑ°ùàj ó≤a ,»FÉHô¡µdG RÉ¡÷G

áHÉ°UEG çhóM ‘ »FÉHô¡µdG RÉ¡÷G øe QGhódG Aõ÷ÉH

Öéj ɪc ,•ôØe πµ°ûH RÉ¡÷G øe ÜGÎb’G ΩóY Öéj .`g

¿C’ ,πª©dG AÉæKCG ¿RGƒàdGh Úeó≤dG äÉÑK ≈∏Y ®ÉØ◊G

RÉ¡÷G ≈∏Y ó«L πµ°ûH Iô£«°ùdG ∂d í«àj ∂dP

.á©bƒàŸG ÒZ ∞bGƒŸG ‘ »FÉHô¡µdG

¢ùHÓŸG AGóJQG ΩóYh ,áÑ°SÉæŸG ¢ùHÓŸG AGóJQG Öéj .h

∂°ùHÓeh ∑ô©°T AÉ≤HEG Öéj ɪc ,»∏◊G hCG á°VÉØ°†ØdG

¢ùHÓŸG ¿C’ ,ácôëàŸG AGõLC’G øY Gkó«©H ∂jRÉØbh

™e ∂HÉ°ûàj ób ‹óàŸG ô©°ûdG hCG »∏◊G hCG á°VÉØ°†ØdG

.ácôëàŸG AGõLC’G

hCG QÉѨdG êGôîà°S’ äGhOCÉH

É¡eGóîà°SGh äGhOC’G ∂∏J π«°UƒJ øe ócCÉJ ,¬©«ªŒ

øe π∏≤j äGhOC’G √òg ΩGóîà°SG ¿C’ ,Ö°SÉæe πµ°ûH

¬H ájÉæ©dGh »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG .4

ÒZ ¢VôZ ‘ »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG ΩóY Öéj .CG

»FÉHô¡µdG RÉ¡÷G Ωóîà°SG Öéj πH ,¬d ¢ü°üfl

»FÉHô¡µdG RÉ¡÷G ¿C’ ,√ójôJ …òdG ¢Vô¨dÉH ¢UÉÿG

ÉkfÉeCG ÌcCGh π°†aCG πµ°ûH πª©dG …ODƒj ±ƒ°S Ö°SÉæŸG

.¬∏LCG øe ¬ª«ª°üJ ” …òdG ∫ó©ŸÉHh

‘ ºµëàdG ™£à°ùJ ⁄

…CG ¿C’ ,ìÉàØŸG ᣰSGƒH ¬∏«¨°ûJ ±É≤jEGh ¬∏«¨°ûJ

ìÉàØŸG ΩGóîà°SÉH ¬«a ºµëàdG øµÁ ’ »FÉHô¡c RÉ¡L

QÉ«àdG Qó°üe øY »FÉHô¡µdG RÉ¡÷G ¢ùHÉb π°üa Öéj .ê

•

hCG äÓjó©J ájCG AGôLEG πÑb äÉjQÉ£ÑdG hCG/h »FÉHô¡µdG

Iõ¡LC’G ‘ äÉ≤ë∏e ájCG Ö«côJ hCG äGÒ«¨J

á«FÉbƒdG áeÓ°ùdG äGAGôLEG ¿C’ ,É¡æjõîJ hCG á«FÉHô¡µdG

»FÉHô¡µdG RÉ¡÷G 𫨰ûJ AóH ôWÉfl øe π∏≤J √òg

áeóîà°ùŸG ÒZ á«FÉHô¡µdG Iõ¡LC’G øjõîJ Öéj .O

ÒZ ¢UÉî°TCÓd íª°ùJ ’h ∫ÉØWC’G ∫hÉæàe øY Gkó«©H

•

ÒZ hCG »FÉHô¡µdG RÉ¡÷G ΩGóîà°SG ≈∏Y øjOÉà©ŸG

RÉ¡÷G 𫨰ûàH äGOÉ°TQE’G √òg ≈∏Y Ú©∏£ŸG

Gô£N πµ°ûJ á«FÉHô¡µdG Iõ¡LC’Éa ,»FÉHô¡µdG

ÉeóæY

k

GPEG »FÉHô¡µdG RÉ¡÷G Ωóîà°ùJ ’ .Ü

k

.¬MÓ°UEG Öéjh ôWÉîŸÉH kÉaƒØfi ¿ƒµj

.ÚHQóe ÒZ ¢UÉî°TCG É¡eóîà°ùj

GOhõe RÉ¡÷G ¿Éc GPEG .R

k

.QÉѨdÉH á£ÑJôŸG ôWÉîŸG

.ó°üb ¿hO ICÉéa

.á«°üî°T

Page 17

ARABIC

¿ƒμJ ¿CG Öéj ,∂dP ¤EG áaÉ°VEG .áØ∏àîŸG äÉ«∏ª©dG

í«°TôJ ≈∏Y IQOÉb ¢ùØæàdG áeɪc hCG áHôJC’G áeɪc

¢Vô©àdG …ODƒj óbh .πª©dG AÉæKCG áŒÉædG äÉÄjõ÷G

.™ª°ùdG ¿Gó≤a ¤EG á∏jƒW IóŸ Ió°ûdG á«dÉY AÉ°Vƒ°†d

ɪc ,πª©dG á≤£æe øe kGóL ÜGÎb’ÉH IQɪ∏d íª°ùJ ’

πª©dG á≤£æe ¤EG ΩOÉb ¢üî°T …CG …óJôj ¿CG Öéj

á©£b Éjɶ°T ôjÉ£àJ ó≤a ,á«°üî°ûdG ájÉbƒdG äGó©e

áHÉ°UEG çhóM ‘ ÖÑ°ùàJh IQƒ°ùμŸG äÉ≤ë∏ŸG hCG πª©dG

.πª©dG á≤£æà kIöTÉÑe ᣫëŸG á≤£æŸG ‘

äGP ∑É°ùeEG äGhOCG ᣰSGƒH »FÉHô¡μdG RÉ¡÷G ∂°ùeG

ób ™«£≤àdG ≥ë∏e ¿C’ ,Ée á«∏ªY AGOCG óæY ádhõ©e í£°SCG

,É¡H ¢UÉÿG ∂∏°ùdG hCG »Øfl »FÉHô¡c QÉ«J ∂∏°S ¢ùeÓj

¬«a …öùj ∂∏°ùd ™«£≤àdG ≥ë∏e á°ùeÓe …ODƒJ óbh

RÉ¡÷G ‘ á«fó©ŸG AGõLC’G ájô©J ¤EG "»FÉHô¡c QÉ«J"

¢Vô©Jh ¬«a »Hô¡μdG QÉ«àdG ¿ÉjöSh »FÉHô¡μdG

.á«FÉHô¡c áeó°üd Ωóîà°ùŸG

≥ë∏ŸG øY kÉeÉ“ »FÉHô¡μdG QÉ«àdG ∂∏°S OÉ©HEG Öéj

ób ,RÉ¡÷G ≈∏Y Iô£«°ùdG ¿Gó≤a ádÉM ‘ ¬fC’ ,QGhódG

∂YGQP hCG ∑ój ¬©e Öë°ùjh ≥∏©j hCG ∂∏°ùdG ™£≤æj

.QGhódG ≥∏ëŸG √ÉŒÉH

∞bƒàj ⁄ Ée í£°S …CG ≈∏Y »FÉHô¡μdG RÉ¡÷G ∑ÎJ ’

QGhódG ≥ë∏ŸG Ωƒ≤j ó≤a ,kÉeÉ“ ¿GQhódG øY ¬≤ë∏e

.»FÉHô¡μdG RÉ¡÷G ≈∏Y Iô£«°ù∏d ∑OÉ≤aEGh í£°ùdG ÜòéH

QGƒéH ¬∏ªM óæY »FÉHô¡μdG RÉ¡÷G 𫨰ûàH º≤J ’

∂°ùHÓà káaó°U ¢ùeÓàj ób QGhódG ≥ë∏ŸG ¿C’ ,∂ÑfÉL

.∂ª°ùL √ÉŒ ≥ë∏ŸG ÜòéH Ωƒ≤jh É¡H ≥∏©jh

»FÉHô¡μdG RÉ¡÷G ‘ ájƒ¡àdG äÉëàa ∞«¶æJ Öéj

πNGO QÉѨdG Öë°ùJ ∑ôëŸG áMhôe ¿C’ ,ΩɶàfÉH

QÉѨd •ôØŸG ºcGÎdG …ODƒj óbh ∑ôëŸG ¥hóæ°U

.á«FÉHô¡c ôWÉfl çhóM ¤EG ¿OÉ©ŸG

á∏HÉ≤dG OGƒŸG øe Üô≤dÉH »FÉHô¡μdG RÉ¡÷G Ωóîà°ùJ ’

‘ ÖÑ°ùàJ ¿CG øμÁ áŒÉædG IQGöûdG ¿C’ ,∫É©à°TÓd

.OGƒŸG √òg ∫É©à°TG

,á∏FÉ°S äGOÈe ¤EG êÉà– »àdG äÉ≤ë∏ŸG Ωóîà°ùJ ’

¤EG iôNC’G ójÈàdG πFGƒ°S hCG √É«ŸG ΩGóîà°SG …ODƒj ó≤a

.á«FÉHô¡μdG äÉeó°üdG hCG AÉHô¡μdÉH ≥©°üdG

á©æ°üŸG ácöûdG É¡ªª°üJ ⁄ äÉ≤ë∏e Ωóîà°ùJ ’ •

»æ©j ’h .É¡eGóîà°SÉH â°UhCGh RÉ¡÷G Gò¡d kÉ°ü«°üN

¿CG ,»FÉHô¡μdG RÉ¡÷ÉH ≥ë∏e …CG Ö«côJ øμÁ ¬fCG

.¿ÉeCÉH 𪩫°S RÉ¡÷G

•

≈∏Y ájhÉ°ùe ≥ë∏ª∏d áØæ°üŸG áYöùdG ¿ƒμJ ¿CG Öéj

RÉ¡÷G ≈∏Y IOóëŸG iƒ°ü≤dG áYöù∏d πbC’G

áYöùH É¡∏«¨°ûJ ºàj »àdG äÉ≤ë∏ŸG ¿C’ ,»FÉHô¡μdG

.kGó«©H ôjÉ£àJh öùμæJ ób áØæ°üŸG É¡àYöS RhÉéàJ

¬μª°Sh ≥ë∏ª∏d »LQÉÿG ô£≤dG ¿ƒμj ¿CG Öéj

•

¿C’ ,»FÉHô¡μdG RÉ¡é∏d IQó≤dG ∞«æ°üJ ™e Ú≤aGƒàe

hCG É¡àjÉbh øμÁ ’ áÑ°SÉæŸG ÒZ äÉ≤ë∏ŸG ΩÉéMCG

.É¡«∏Y Iô£«°ùdG

hCG äÉéæ∏ØdG hCG äÓé©dG ´òL ºéM ¿ƒμj ¿CG Öéj

Oƒª©d kÉeÉ“ kÉÑ°SÉæe ôNBG ≥ë∏e …CG hCG ºYódG íFÉØ°U

»àdG äÉ≤ë∏ŸG ¿C’ ,»FÉHô¡μdG RÉ¡÷G ‘ ¿GQhódG

äGó©e ™e á≤HÉ£àe ÒZ ´hòL äÉëàa ≈∏Y …ƒà–

•

ÒZ IQƒ°üH πª©J ób »FÉHô¡μdG RÉ¡÷G ‘ Ö«cÎdG

¿Gó≤a ‘ ÖÑ°ùàj ób Ée ,•ôØe πμ°ûH õà¡Jh áfRGƒàe

.RÉ¡÷G ≈∏Y Iô£«°ùdG

πc πÑb Öéjh .kÉ≤∏£e kÉHƒ£©e kÉ≤ë∏e Ωóîà°ùJ ’

•

kÉãëH ï∏÷G äÓéY πãe äÉ≤ë∏ŸG ¢üëa ΩGóîà°SG

øY kÉãëH ºYódG íFÉØ°Uh ,¥ƒ≤°ûdGh Éjɶ°ûdG øY

IÉ°TôØdGh ,ó◊G øY óFGõdG πcBÉàdG hCG ≥≤°ûàdGh ,¥ƒ≤°ûdG

GPEGh .á≤≤°ûàŸG hCG áÑFÉ°ùdG ∑Ó°SC’G øY kÉãëH á«μ∏°ùdG

•

¬°üëa Öéj ,¬JÉ≤ë∏e hCG »FÉHô¡μdG RÉ¡÷G §≤°S

äÉ≤ë∏e Ö«côJ hCG QöV …CÉH ¬àHÉ°UEG ΩóY øe ócCÉà∏d

Öéj ,äÉ≤ë∏e …CG Ö«côJh ¢üëa ó©Hh .᪫∏°S iôNCG

•

™°Vh ‘ áYöS ≈°übCÉH »FÉHô¡μdG RÉ¡÷G 𫨰ûJ

öùμæJ Ée kIOÉ©a ,á∏eÉc á≤«bO IóŸ π«ªëàdG ΩóY

.√òg QÉÑàN’G Ióe ∫ÓN áØdÉàdG äÉ≤ë∏ŸG

≈∏Y kGOɪàYGh .á«°üî°ûdG ájÉbƒdG äGó©e AGóJQG Öéj

•

¬Lƒ∏d ájɪM IGOCG Ωóîà°SG ,¬H Ωƒ≤J …òdG πª©dG ´ƒf

áHôJCG áeɪc …óJQG ,IQhö†dG óæYh .á«bGh äGQɶfh

≈∏Y QOÉb πªY á°TQh AGOQh äGRÉØbh ™ª°ù∏d äÉ«bGhh

ï∏÷G AÉæKCG ôjÉ£àJ »àdG IÒ¨°üdG Éjɶ°ûdG øe ∂àjɪM

•

äGQɶædG ¿ƒμJ ¿CG Öéj ɪc ,πª©dG á©£b øe hCG

øY Å°TÉædG ôjÉ£àŸG ΩÉcôdG ó°U ≈∏Y IQOÉb á«bGƒdG

•

•

•

•

•

17

Page 18

ARABIC

RÉ¡÷G ¬«a ∑ôëà«°S …òdG õ«◊G øY kGó«©H ∂ª°ùL ≥HG

±ƒ°ùa ,áØ«æY äGOGóJQG çhóM ádÉM ‘ »FÉHô¡μdG

√ÉŒ’G ‘ RÉ¡÷G ™aO ¤EG áØ«æ©dG äGOGóJQ’G …ODƒJ

.QÉ°ûëf’G á£≤f óæY äÓé©dG ácô◊ ¢ùcÉ©ŸG

IOÉ◊G ±Gƒ◊Gh ÉjGhõdG ™e πª©dG óæY kÉeÉ“ ¢SÎMG

hCG ÉjGhõdÉa ,≥ë∏ŸG QÉ°ûëfGh OGóJQG ÖæŒ .ÉgÒZh

QÉ°ûëfG ‘ ÖÑ°ùàJ ób OGóJQ’G hCG IOÉ◊G ±Gƒ◊G

äGOGóJQG çhóM hCG Iô£«°ùdG ¿Gó≤ah QGhódG ≥ë∏ŸG

.áØ«æY

hCG Ö°ûÿG âëæd QÉ°ûæe ôjõæL IôØ°T Ö«cÎH º≤J ’

çhóM ¤EG …ODƒJ äGôØ°ûdG √ò¡a ,áææ°ùe QÉ°ûæe IôØ°T

.Qôμàe πμ°ûH Iô£«°ùdG ¿Gó≤ah áØ«æY äGOGóJQG

™«£≤àdG äÉ«∏ª©H á°UÉÿG áeÓ°ùdG äGôjò–

»î«∏éàdG

§¨°†d É¡°†jô©J hCG ™«£≤àdG á∏éY "á∏bôY" ΩóY Öéj •

øY IóFGR ¥ƒ≤°T AGôLEG ádhÉfi ΩóY Öéj ɪc ,•ôØe

ójõj á∏é©dG ≈∏Y •ôØŸG §¨°†dG ¿C’ ,샪°ùŸG ó◊G

AÉæKCG AÉæãf’Gh AGƒàdÓd É¡°Vô©jh É¡«∏Y AÖ©dG

hCG áØ«æY äGOGóJQG çhóM á«dɪàMG ∂dòch ,™«£≤àdG

.á∏é©dG º£–

ÉeóæY ¬fC’ ,É¡Ø∏N hCG IQGhódG á∏é©dG IGPÉëà ∞≤J ’

ób ,™«£≤àdG á£≤f ‘ ,∑ó°ùL øY kGó«©H á∏é©dG ∑ôëàJ

IQGhódG á∏é©dG ´ÉaófG ¤EG …ODƒJ áØ«æY äGOGóJQG çó–

.∂gÉŒÉH »FÉHô¡μdG RÉ¡÷Gh

ÖÑ°S …C’ ™«£≤àdG á«∏ªY á©WÉ≤e hCG á∏é©dG ∞bƒJ óæY

¬à«ÑãJh »FÉHô¡μdG RÉ¡÷G ±É≤jEG Öéj ,ÜÉÑ°SC’G øe

¿GQhódG øY á∏é©dG ∞bƒàJ ≈àM kÉ≤∏£e ¬μjô– ¿hO

≥°ûdG øe ™«£≤àdG á∏éY ádGREG kÉ≤∏£e ∫hÉ– ’h .kÉeÉ“

.∞«æY OGóJQG çóëj ób ’EGh ,á∏é©dG ¿GQhO AÉæKCG

áÑ°SÉæŸG á«ë«ë°üàdG äGAGôLE’G òîJGh á∏é©dG ¢üëaG

.á∏é©dG á∏bôY ÖÑ°S øe ¢ü∏îà∏d

∑ôJG πH ,πª©dG á©£b ™«£≤J ‘ iôNCG Iôe CGóÑJ ’

‘ É¡∏NOCG ºK É¡àYöS πeÉc ¤EG π°üJ ≈àM á∏é©dG

∞æ©H óJôJ hCG õØ≤J hCG á∏é©dG ∞bƒàJ ó≤a ,QòëH ≥°ûdG

á©£b πNGO »FÉHô¡μdG RÉ¡÷G 𫨰ûJ IOÉYEG ádÉM ‘

.πª©dG

•

Iõ¡LC’G ≈∏Y √ÓYCG OQGƒdG ôjòëàdG ≥Ñ£æj ’ :á¶MÓe

º¶ædG ™e ΩGóîà°SÓd kÉ°ü«°üN ᪪°üŸG á«FÉHô¡μdG

á∏°üdG äGP äGôjòëàdGh áØ«æ©dG äGOGóJQ’G

•

çó– áÄLÉØe áØ«æY π©a OhOQ »g áØ«æ©dG äGOGóJQ’G

,ºYódG áë«Ø°U hCG ,IQGhódG á∏é©dG QÉ°ûëfG hCG πbô©J áé«àf

ÖÑ°ùàJ å«M ,iôNC’G äÉ≤ë∏ŸG øe …CG hCG IÉ°TôØdG hCG

ƒgh ;ICÉéa QGhódG ≥ë∏ŸG ∞bƒJ ‘ QÉ°ûëf’G hCG á∏bô©dG

•

•

•

•

RÉ¡÷G ≈∏Y Iô£«°ùdG ¿Gó≤a ¿CG ¤EG √QhóH …ODƒj Ée

≥ë∏ŸG ¿GQhód ¢ùcÉ©ŸG √ÉŒ’G ¤EG ¬YÉaófGh »FÉHô¡μdG

.πbô©àdG á£≤f óæY

ï∏÷G á∏éY πbô©J hCG QÉ°ûëfG ádÉM ‘ ,∫ÉãŸG π«Ñ°S ≈∏Y

á°ùeÓŸG á∏é©dG áaÉM …ODƒJ ób ,πª©dG á©£b ᣰSGƒH

‘ ÖÑ°ùàj ɇ IOÉŸG í£°S ‘ ôØ◊G ¤EG QÉ°ûëf’G á£≤æd

√ÉŒÉH ÉeEG á∏é©dG õØ≤J óbh .êQÉÿG ¤EG á∏é©dG ´ÉaófG

‘ á∏é©dG ácôM √ÉŒ’ kÉ©ÑJ ,¬æY kGó«©H hCG Ωóîà°ùŸG

√òg πX ‘ kÉ°†jCG ï∏÷G äÓéY öùμæJ óbh .πbô©àdG á£≤f

RÉ¡÷G ΩGóîà°SG Aƒ°ùd káé«àf áØ«æ©dG äGOGóJQ’G çó–

,𫨰ûàdG äGOÉ°TQEG hCG äɪ«∏©J ´ÉÑJG ΩóY hCG/h »FÉHô¡μdG

≈∏Y áÑ°SÉæŸG äÉWÉ«àM’G PÉîJG ∫ÓN øe É¡ÑæŒ øμÁh

.√ÉfOCG ÚÑŸG ƒëædG

º°ù÷G AÉ≤HEGh ΩÉμMEÉH »FÉHô¡μdG RÉ¡÷G ∑É°ùeEG Öéj

äGOGóJQ’G áehÉ≤Ã íª°ùJ á«©°Vh ‘ ÚYGQòdGh

GPEG ,‘É°VE’G ¢†Ñ≤ŸG ΩGóîà°SG kÉehO Öéjh .áØ«æ©dG

≈°übCÉH ≈∏Y Iô£«°ùdG πLCG øe ,RÉ¡÷G ™e kGôaƒàe ¿Éc

hCG ¿GQhódG Ωõ©d IOÉ°†ŸG π©ØdG OhOQ ≈∏Y øμ‡ Qób

™«£à°ùjh .RÉ¡÷G 𫨰ûJ AóH óæY áØ«æ©dG äGOGóJQ’G

Ωõ©d IOÉ°†ŸG π©ØdG OhOQ ≈∏Y Iô£«°ùdG Ωóîà°ùŸG

äòîJG Ée GPEG áØ«æ©dG äGOGóJQ’G hCG ¿GQhódG

.áÑ°SÉæŸG äÉWÉ«àM’G

óJôJ ó≤a ,IQGhódG äÉ≤∏ëŸG øe Üô≤dÉH ∑ój ™°†J ’

.∑ój √ÉŒÉH áÄLÉØe IQƒ°üH äÉ≤ë∏ŸG

.á∏FÉ°ùdG

.±hô¶dG

•

•

18

Page 19

ARABIC

™e ájÉbh IGOCG ΩGóîà°SÉH äÉ«°UƒJ ∑Éæg âfÉc GPEG

IÉ°Tôa hCG á∏éY ∂HÉ°ûàH íª°ùJ Óa ,á«μ∏°ùdG IÉ°TôØdG

IÉ°Tôa hCG á∏éY ô£b ™°ùàj ó≤a ,ájÉbƒdG IGOCG ™e ∑Ó°SC’G

.…õcôŸG Oô£dG iƒbh πª©dG πªM ÖÑ°ùH ∑Ó°SC’G

øjôNB’G áeÓ°S

ᣰSGƒH ¬eGóîà°S’ ¢ü°üfl ÒZ RÉ¡÷G Gòg •

ájó°ù÷G äGQó≤dG …hP (∫ÉØWC’G ∂dP ‘ ÉÃ) ¢UÉî°TC’G

º¡jód øjòdG hCG ,á«fóàŸG á«∏≤©dGh á«°ù◊Gh á«ægòdGh

πX ‘ ’EG ,ΩGóîà°S’G »MGƒæH á∏«∏b áaô©e hCG IÈN

á≤∏©àŸG äɪ«∏©àdG º¡FÉ£YEG hCG º¡«∏Y ±GöTE’G

øY ∫hDƒ°ùŸG ¢üî°ûdG πÑpb øe RÉ¡÷G ΩGóîà°SÉH

.º¡àeÓ°S

º¡ãÑY ΩóY ¿Éª°†d ∫ÉØWC’G ≈∏Y ±GöTE’G Öéj

.RÉ¡÷ÉH

RGõàg’G

‘ IQƒcòŸG áæ∏©ŸG äGRGõàg’G çÉ©ÑfG º«b ¢SÉ«b ”

QÉÑàNG á≤jô£d Ék≤ah á≤HÉ£ŸG ¿ÓYEGh á«æØdG äÉfÉ«ÑdG

EN 60745 QÉ«©ŸG ÖLƒÃ É¡«∏Y ¢Uƒ°üæe á«°SÉ«b

øμÁh .ôNBG ™e Ée RÉ¡L áfQÉ≤Ÿ É¡eGóîà°SG øμÁh

‹hCG º««≤J AGôLE’ áæ∏©ŸG äGRGõàg’G çÉ©ÑfG ᪫b ΩGóîà°SG

.äGRGõàgÓd ¢Vô©àdG áÑ°ùæd

ºé◊G IÒÑc πªY á©£b …CG hCG ìGƒdC’G º«YóàH ºb •

•

äGOGóJQG çhóMh äÓé©dG QÉ°ûëfG ôWÉfl π«∏≤àd

πØ°SC’ ¤óàJ ºé◊G IÒÑc πª©dG ™£b ¿C’ ,áØ«æY

â– äÉeÉYO ™°Vh Öéj Gòd ,óFGõdG É¡fRh áé«àf

áaÉM øe Üô≤dÉHh ≥°ûdG §N øe Üô≤dÉH πª©dG á©£b

.á∏é©dG »ÑfÉL Óc ≈∏Y πª©dG á©£b

≥°T" AGôLEG óæY á≤FÉØdG äÉWÉ«àM’G PÉîJG Öéj

,iôNCG AÉ«ªY ≥WÉæe …CG hCG á«æÑe §FGƒM ‘ "»Ñ«L

hCG √É«ŸG hCG RɨdG Ö«HÉfCG ™£≤J ób IQGhódG á∏é©dG ¿C’

‘ ÖÑ°ùàJ ób »àdG ΩÉ°ùLC’G hCG á«Hô¡μdG ∑Ó°SC’G

.áØ«æY äGOGóJQG çhóM

•

.¥QƒdG QÉ«àNG óæY á©æ°üŸG äÉcöûdG äÉ«°UƒJ ™ÑJG

¬ªéM RhÉéàj …òdG ÒÑμdG IôØæ°üdG ¥Qh ¿CÉH kɪ∏Y

çhóM hCG ,¢Uô≤dG ¥õ“ hCG QÉ°ûëfG çhóM ‘ ÖÑ°ùàj

IôØæ°üdG äÉ«∏ª©H á°UÉÿG áeÓ°ùdG äGôjò–

.•ôØe πμ°ûH ºé◊G ÒÑc IôØæ°U ábQh Ωóîà°ùJ ’

óbh ¥õªàdG ôWÉfl øe ójõj IôØæ°üdG IóYÉb ºéM

.áØ«æY äGOGóJQG

™«ª∏àdG äÉ«∏ª©H á°UÉÿG áeÓ°ùdG äGôjò–

•

•

AÉæKCG äGRGõàg’G çÉ©ÑfG ᪫b ∞∏àîJ ¿CG øμÁ !ôjò–

áæ∏©ŸG ᪫≤dG øY »FÉHô¡μdG RÉ¡é∏d »∏©ØdG ΩGóîà°S’G

OGOõj óbh ,RÉ¡÷G ΩGóîà°SG ¥ôW ≈∏Y ∂dP ∞bƒàj å«M

.QƒcòŸG iƒà°ùŸG øY RGõàg’G iƒà°ùe

áeÓ°ùdG äGAGôLEG ójóëàd RGõàgÓd ¢Vô©àdG º««≤J óæY

ájɪ◊ EC/2002/44 QÉ«©ŸG ÖLƒÃ áHƒ∏£ŸG

πμ°ûH á«FÉHô¡μdG Iõ¡LC’G ¿ƒeóîà°ùj øjòdG ¢UÉî°TC’G

º««≤J á«∏ªY ‘ »∏j Ée IÉYGôe Ωõ∏j ,º¡∏ªY ‘ º¶àæe

á≤jô£dGh ΩGóîà°SÓd á«∏©ØdG ±hô¶dG :RGõàgÓd ¢Vô©àdG

AGõLCG áaÉc òNCG ∂dP ‘ Éà ,É¡H RÉ¡÷G ΩGóîà°SG ºàj »àdG

É¡«a ºàj »àdG äÉbhC’G πãe ;QÉÑàY’G ‘ 𫨰ûàdG IQhO

™°Vh ‘ RÉ¡÷G ¿ƒμj ÉeóæY hCG RÉ¡÷G 𫨰ûJ ±É≤jEG

.𫨰ûàdG äÉbhCG ¤EG áaÉ°VE’ÉH ,¿ƒμ°ùdG

AÉ£Z ‘ ÖFÉ°S AõL …CG ¿GQhóH ìɪ°ùdG ΩóY Öéj

¢üb hCG §HQ Öéj Gòd ,ájôëH §HôdG ∫ÉÑM hCG ™«ª∏àdG

hCG áÑFÉ°ùdG §HôdG ∫ÉÑM ¿C’ kGô¶f ,áÑFÉ°S §HQ ∫ÉÑM …CG

.πª©dG á©£≤H ≥∏©J hCG ∂©HÉ°UCG ∫ƒM ∞à∏J ób IQGhódG

¢TôØdÉH ∞«¶æàdG äÉ«∏ª©H á°UÉÿG áeÓ°ùdG äGôjò–

á«μ∏°ùdG

≈àM IÉ°TôØdG øe IôjÉ£àŸG ∑Ó°SC’G äGÒ©°T øe QòMG

≈∏Y §¨°†dG ‘ •ôØJ ’ .…OÉ©dG 𫨰ûàdG AÉæKCG

,IÉ°TôØdG ≈∏Y •GôaEÉH π«ªëàdG ≥jôW øY ∑Ó°SC’G

áØ«ØÿG ¢ùHÓŸG ¥ÎîJ ¿CG øμÁ ∑Ó°SC’G äGÒ©°ûa

.ádƒ¡°ùH ó∏÷G hCG/h

•

•

19

Page 20

ARABIC

Ö«cÎdG

OƒªY ¬Lh ¿ƒμj å«ëH ,ádhÉW ≈∏Y RÉ¡÷G ™°V •

.≈∏YC’ (6) ¿GQhódG

¥ƒa (5) ájÉbƒdG IGOCG âÑKh (7) â«ÑãàdG πØb ∂ØH ºb

.πμ°ûdÉH ÚÑe ƒg ɪc RÉ¡÷G

.(9) ¿Éæ°SC’G ™e (8) äGhô©dG IGPÉëà ºb

¢ùμY ÉgôjhóàH ºb ºK πØ°SC’ ájÉbƒdG IGOCG ≈∏Y §¨°VG •

.܃∏£ŸG ¿ÉμŸG ¤EG π°üJ ≈àM áYÉ°ùdG ÜQÉ≤Y

‘ ájÉbƒdG IGOCG â«Ñãàd (7) â«ÑãàdG πØb §HQ óYCG

.RÉ¡÷G

IOÉjõd ΩÉμMEÉH (10) »ZÈdG §HQG ,ôeC’G ≈°†àbG GPEG

.â«ÑãàdG Iƒb

ádGRE’G

.(7) â«ÑãàdG πØb ∂ØH ºb •

áYÉ°ùdG ÜQÉ≤Y √ÉŒG ‘ ájÉbƒdG IGOCG ôjhóàH ºb •

.(9) ¿Éæ°SC’G ™e (8) äGhô©dG IGPÉëŸ

.RÉ¡÷G øe ájÉbƒdG IGOCG ádGREÉH ºb

Iõ¡LC’G ≈∏Y äÉ≤°ü∏ŸG

:RÉ¡÷G ≈∏Y á«dÉàdG á«ë«°VƒàdG Qƒ°üdG ô¡¶J

≈∏Y Öéj ,áHÉ°UE’G ôWÉfl π«∏≤àd !ôjò–

•

•

.äGOÉ°TQE’G π«dO IAGôb Ωóîà°ùŸG

Gòg 𫨰ûJ óæY á«bGh äGQɶf AGóJQG Öéj

.RÉ¡÷G

Gòg 𫨰ûJ óæY ÚfPCÓd m¥Gh AGóJQG Öéj

.RÉ¡÷G

á«FÉHô¡μdG áeÓ°ùdG

•

’ ,∂dòdh ;ÉkLhOõe k’õY ∫hõ©e RÉ¡÷G Gòg

ÉkªFGO ócCÉàdG »¨Ñæjh .»°VQCG ∂∏°S ¤EG áLÉM

ó¡÷G ™e »FÉHô¡μdG QÉ«àdG Qó°üe ≥aGƒJ øe

•

¬dGóÑà°SG Öéj ,»FÉHô¡μdG QÉ«àdG ∂∏°S ∞∏J ádÉM ‘

iód óªà©e áfÉ«°U õcôe hCG á©æ°üŸG ácöûdG πÑpb øe

.É¡©«ªL hCG á«dÉàdG ÉjGõŸG ¢†©H ≈∏Y RÉ¡÷G Gòg πªà°ûj

•

.∞«æ°üàdG áMƒd ≈∏Y í°VƒŸG

.ôWÉîŸG Öæéàd ôμjO ófBG ∑ÓH

±É≤jEG / 𫨰ûJ ìÉàØe .1

•

ÉjGõŸG

(CG πμ°ûdG) ájɪ◊G IGOCG πjó©J

.áLQO 90 ájhGõH ájÉbƒdG IGOCG ôjhóJ øμÁ

.܃∏£ŸG ™°VƒdG ¤EG ájÉbƒdG IGOCG ôjhóàH ºb

(Ü πμ°ûdG) »ÑfÉ÷G ¢†Ñ≤ŸG Ö«côJ

Ö«cÎdG äÉëàa ióMEG ‘ (3) »ÑfÉ÷G ¢†Ñ≤ŸG §HQG •

.RÉ¡÷G ‘ IOƒLƒŸG

.kÉehO »ÑfÉ÷G ¢†Ñ≤ŸG Ωóîà°SG !ôjò–

É¡àdGREGh ™«£≤àdG hCG ï∏÷G ¢UGôbCG Ö«côJ

(O - Ü πμ°ûdG)

,¬H Ωƒ≤J …òdG πª©∏d Ö°SÉæŸG ¢Uô≤dG ´ƒf kÉehO Ωóîà°SG

á«∏NGódG QÉ£bC’Gh äÉ£«ëŸG äGP ¢UGôbC’G kÉehO Ωóîà°SGh

.(á«æØdG äÉfÉ«ÑdG ™LGQ) áÑ°SÉæŸG

20

»ÑfÉL ¢†Ñ≤e .3

•

ó«b ¢ù«d RÉ¡÷G ¿CG ócCÉJ ,äÉ≤ë∏e …CG Ö«côJ πÑb !ôjò–

.»Hô¡μdG QÉ«àdG Qó°üà π°Uƒe ÒZh 𫨰ûàdG

¿GQhódG OƒªY πØb ìÉàØe .4

ájÉbh IGOCG .5

(CG πμ°ûdG) É¡àdGREGh ájÉbƒdG IGOCG Ö«côJ

ï∏÷G ¢VGôZC’ á°ü°üfl ájÉbh IGOCG RÉ¡÷G Gòg ™e »JCÉj

,™«£≤àdG äÉ«∏ªY AGôLE’ IóMƒdG ΩGóîà°SG ádÉM ‘h .§≤a

IGOCG AõL ºbQ ¿CÉH kɪ∏Y .áÑ°SÉæŸG ájÉbƒdG IGOCG Ö«côJ Öéj

1004484-02 ƒg ™«£≤àdG äÉ«∏ª©d Ö°SÉæŸG ájÉbƒdG

ófBG ∑ÓÑd á©HÉàdG áfÉ«°üdG õcGôe øe ¬«∏Y ∫ƒ°ü◊G øμÁh

πØb QR .2

Ö«cÎdG

.ôμjO

Page 21

ARABIC

¢ùeÓj ÉeóæY IQGöûdG øe QÉ«J Qhó°üd kGó©à°ùe øc •

.πª©dG á©£b ™«£≤àdG hCG ï∏÷G ¢Uôb

ájɪM ≈°übCG ∂d ôaƒJ á«©°Vh ‘ kÉehO RÉ¡÷G âÑK

.™«£≤àdG hCG ï∏÷G ¢Uôb ó°V

±É≤jE’Gh 𫨰ûàdG

AɨdEG ™°Vh ¤EG (2) πØ≤dG QR ∑ôM ,RÉ¡÷G 𫨰ûàd •

.±É≤jE’G/𫨰ûàdG ìÉàØe ≈∏Y §¨°VG ºK ,πØ≤dG

.±É≤jE’G/𫨰ûàdG ìÉàØe ≈∏Y §¨°VG ,RÉ¡÷G ±É≤jE’

.¬eGóîà°SG AÉæKCG RÉ¡÷G ±É≤jEÉH º≤J ’ !ôjò–

πãeC’G ΩGóîà°SÓd íFÉ°üf

∑É°ùeE’ øjó«dG ióMEG kÉeóîà°ùe ΩÉμMEÉH RÉ¡÷G ∂°ùeG •

.»°SÉ°SC’G ¢†Ñ≤ª∏d iôNC’Gh »ÑfÉ÷G ¢†Ñ≤ŸG

á©£b í£°Sh ¢Uô≤dG ÚH áaÉ°ùe ∑ôJ Öéj ,ï∏÷G óæY

.áLQO 15 ÉgQób ájhGõH πª©dG

áfÉ«°üdG

𪩫d »μ∏°SÓdG hCG »μ∏°ùdG ôμjO ófBG ∑ÓH RÉ¡L ºª°U

∫ƒ°ü◊G óªà©jh .áfÉ«°üdG øe øμ‡ óM πbCÉH á∏jƒW äGÎØd

RÉ¡÷ÉH áÑ°SÉæŸG ájÉæ©dG ≈∏Y ôªà°ùeh

:á«μ∏°SÓdG hCG á«μ∏°ùdG Iõ¡LCÓd áfÉ«°U …CG AGôLEG πÑb !ôjò–

.»FÉHô¡μdG QÉ«àdG øY ¬∏°üah RÉ¡÷G ±É≤jEÉH ºb

¢Vôe AGOCG ≈∏Y

m

.ΩɶàfÉH ¬Ø«¶æJh

.√ÓYCG í°Vƒe ƒg ɪc ájÉbƒdG IGOCG Ö«cÎH ºb •

•

ɪc (6) ¿GQhódG OƒªY ‘ (11) á«∏NGódG áéæ∏ØdG ™°V •

πμ°ûH áàÑãe áéæ∏ØdG ¿CG ócCÉJ .(Ü πμ°ûdG) ÚÑe ƒg

.¿GQhódG Oƒª©d á룰ùŸG ÖfGƒ÷G ≈∏Y í«ë°U

ƒg ɪc (6) ¿GQhódG OƒªY ≈∏Y (12) ¢Uô≤dG ™°V

õcôe ≈∏Y …ƒàëj ¢Uô≤dG ¿Éc GPEG .(Ü πμ°ûdG) ÚÑe

áéæ∏Ø∏d kÉ¡LGƒe ÅJÉædG õcôŸG ¿CG ócCÉJ ,(13) ÅJÉf

•

áéæ∏ØdG ≈∏Y í«ë°U πμ°ûH ´ƒ°Vƒe ¢Uô≤dG ¿CG ócCÉJ

óæY .¿GQhódG Qƒfi ≈∏Y (14) á«LQÉÿG áéæ∏ØdG ™°V •

ÅJÉædG õcôŸG ¿ƒμj ¿CG Öéj ,ï∏L ¢Uôb Ö«côJ

.(ê πμ°ûdG ‘ CG) ¢Uô≤∏d kÉ¡LGƒe á«LQÉÿG áéæ∏Ø∏d

õcôŸG ¿ƒμj ¿CG Öéj ,™«£≤J ¢Uôb Ö«côJ óæYh

•

‘ Ü) ¢Uô≤∏d ¬LGƒe ÒZ á«LQÉÿG áéæ∏Ø∏d ÅJÉædG

á«LQÉÿG áéæ∏ØdG §HQGh (4) ¿GQhódG OƒªY πØb âÑK

πμ°ûdG) (15) ¿Éæ°SC’G »FÉæK §HôdG ìÉàØe ΩGóîà°SÉH

áéæ∏ØdG ∂ØH ºbh (4) ¿GQhódG OƒªY πØb âÑK •

»FÉæK §HôdG ìÉàØe ΩGóîà°SÉH (14) á«LQÉÿG

.(O πμ°ûdG) (15) ¿Éæ°SC’G

•

.(12) ¢Uô≤dGh (14) á«LQÉÿG áéæ∏ØdG ádGREÉH ºb

.á«∏NGódG

.á«∏NGódG

.(ê πμ°ûdG

Ö«cÎdG

•

•

•

.(O

ádGRE’G

•

¿Éc PEG RÉ¡÷G øe ájQÉ£ÑdG ádGREGh RÉ¡÷G ±É≤jEÉH ºb hCG •

.á∏°üØæe äÉjQÉ£H IóMh ≈∏Y πªà°ûj RÉ¡÷G

GPEG kÉeÉ“ ájQÉ£ÑdG ÆôØJ ¿CG ¤EG RÉ¡÷G 𫨰ûàH ºb hCG

.¬aÉ≤jEÉH ºb ºK RÉ¡÷ÉH á›óe ájQÉ£ÑdG âfÉc

ΩGóîà°S’G

¬∏ª– ’h ,ájOÉ©dG ¬àYöùH πª©j RÉ¡÷G ∑ôJG !ôjò– •

•

.¬©£b Öæéàd ¢UôëH »FÉHô¡μdG QÉ«àdG ∂∏°S ÖbGQ •

.¬àbÉW ¥ƒa

21

Page 22

ARABIC

á«æØdG äÉfÉ«ÑdG

KG2300

Type 2

220-240 OOΟG QÉ«àdG Ió°T »Hô¡µdG ó¡÷G

2300 äGh πNGódG »Hô¡µdG QÉ«àdG

6000

230 º∏e ¢Uô≤dG §«fi

22 º∏e ¢Uô≤∏d »∏NGódG ô£≤dG

6 º∏e ï∏÷G ¢UGôbCG

3 º∏e ™«£≤àdG ¢UGôbCG

M14 ¿GQhódG OƒªY ºéM

6.4 ºéc ¿RƒdG

-1

á≤«bO πªM ¿hóH áYöùdG

¢Uô≤∏d ∂ª°S ≈°übCG

’ øMÉ°ûdG ¿CÉH kɪ∏Y ,¬Ø«¶æJ πÑb øMÉ°ûdG π°üØH ºb •

.ΩɶàfÉH ¬Ø«¶æJ iƒ°S áfÉ«°U …CG ¤EG êÉàëj

ΩɶàfÉH RÉ¡÷G øMÉ°T ‘ ájƒ¡àdG äÉëàa ∞¶f

.áaÉL ¢Tɪb á©£b hCG áªYÉf IÉ°Tôa kÉeóîà°ùe

á©£b ΩGóîà°SÉH ΩɶàfÉH ∑ôëŸG ¥hóæ°U ∞¶f

hCG ᣰTÉc ∞«¶æJ IOÉe …CG Ωóîà°ùJ ’ .áÑWQ ¢Tɪb

QÉÑZ …CG ádGRE’ ≥aôH ¬°†ØfGh º≤∏dG ¢†HÉb íàaG

,»°ù«FôdG òNCɪ∏d ójóL ¢ùHÉb Ö«cÎd áLÉ◊G ádÉM ‘

.øeBG πµ°ûH Ëó≤dG ¢ùHÉ≤dG øe ¢ü∏îJ

π°UƒŸG ±ô£dÉH ¿ƒ∏dG »æÑdG π«°UƒàdG ∂∏°S π°U •

•

•

.áÑjòe

•

.(¬Ñ«côJ ” GPEG) ¬∏NGóH

»°ù«FôdG òNCÉŸG ¢ùHÉb ∫GóÑà°SG

:»∏j Ée ™ÑJG

•

.ójó÷G ¢ùHÉ≤dG øe QÉ«àdÉH

22

.ójÉëŸG ±ô£dÉH ¿ƒ∏dG ¥QRC’G π«°UƒàdG ∂∏°S π°U

∂∏°ùdG π°U ,(¢VQDƒe) 1 áÄØdG øe èàæŸG ¿Éc GPEG •

.»°VQC’G ±ô£dÉH ¿ƒ∏dG ôØ°UC’G/ö†NC’G

ÉkLhOõe k’õY ádhõ©ŸG 2 áÄØdG øe èàæŸG ¿Éc GPEG !ôjò–

π«°UƒJ …C’

òFóæY áLÉM Óa (πѵdG ‘ §≤a ¿Éµ∏°S)

m

.»°VQC’G ±ô£dÉH

.IOƒ÷G á«dÉY ¢ùHGƒ≤dG ™e á≤aôŸG Ö«cÎdG äɪ«∏©J ™ÑJG

ô¡°üŸG ≤e ¢ùØf ∫óÑà°ùe ô¡°üe …C’ ¿ƒµj ¿CG »¨Ñæj

.èàæŸG ™e ≥aôŸG »∏°UC’G

•

Page 23

ARABIC

¿Éª°†dG

OGƒŸG ‘ Ö«Y ÖÑ°ùH ôμjO ófBG ∑ÓH èàæe ‘ π∏N ô¡X GPEG

¿EÉa ,AGöûdG ïjQÉJ øe

∫GóÑà°SG hCG áÑ«©ŸG AGõLC’G ∫GóÑà°SG øª°†J ôμjO ófBG ∑ÓH

:GPEG ’EG ,𫪩∏d бMGфdG шe Qуb ≈°ьbCG Тaƒаd дЙйажŸG √тg

.∫ɪgE’G hCG ΩGóîà°S’G IAÉ°SE’ èàæŸG ¢Vô©J

OGƒe hCG ΩÉ°ùLCG ÖÑ°ùH èàæŸÉH ᪫°ùL QGöVCG â≤◊ •

hCG øjóªà©ŸG áfÉ«°üdG AÓch iƒ°S ôNBG ¢üî°T ∫hÉM

ìÓ°UEG ôμjO ófBG ∑ÓÑd Ú©HÉàdG áfÉ«°üdG »∏eÉY

AGöûdG IQƒJÉa Ëó≤J Öéj ,¿Éª°†dG äÉeóN ≈∏Y ∫ƒ°üë∏d

ÜôbCG ™bƒe áaô©e ∂æμÁ .óªà©ŸG áfÉ«°üdG π«ch hCG ™FÉÑ∏d

ófBG ∑ÓH Öàμà ∫É°üJ’G ≥jôW øY óªà©e áfÉ«°U π«ch

øe k’óHh .π«dódG Gòg ‘ ÚÑŸG ¿Gƒæ©dG ‘ »∏ëŸG ôμjO

ófBG ∑ÓH iód øjóªà©ŸG áfÉ«°üdG AÓcƒH áªFÉb ôaƒàJ ,∂dP

äÉ¡Lh ™«ÑdG ó©H Ée áeóÿ á∏eÉμdG π«°UÉØàdGh ôμjO

Gô¡°T 12 ¿ƒ°†Z ‘ ,™«æ°üàdG hCG

k

.çOGƒM hCG áÑjôZ

.èàæŸG

:âfÎfE’G ≈∏Y Éæ©bƒe ≈∏Y ∫É°üJ’G

.www.2helpU.com

áÄ«ÑdG ájɪM

Gòg øe ¢ü∏îàdG ΩóY Ωõ∏j .π°üØæŸG ™ª÷G

.ájOÉ©dG á«dõæŸG áeɪ≤dG ™e èàæŸG

ôμjO ófBG ∑ÓH èàæe ∫GóÑà°SG ΩÉjC’G øe Ωƒj ‘ Ωõd GPEG

™e ¬æe ¢ü∏îàJ Óa ,¬eóîà°ùJ ó©J ⁄ GPEG hCG ,∂H ¢UÉÿG

•

èàæŸG Gòg áMÉJEG øe ócCÉJ πH ,iôNC’G á«dõæŸG áeɪ≤dG

.π°üØæŸG ™ªé∏d

ôjhóJ IOÉYE’ ≥aôe ôμjO ófBG ∑ÓH ácöT ôaƒJ

бjЙ¡f ¤EG Й¡dƒ°Uh OфйГ фμjO уfBG ∑УH дЙйажe

•

√òg Ëó≤J ºàjh .πª©∏d É¡à«MÓ°U ΩóYh ÉgôªY

≈Lôj ,áeóÿG √òg øe IOÉØà°SÓd .É

±ƒ°S …òdGh óªà©e áfÉ«°U π«ch …CG ¤EG èàæŸG IOÉYEG

.ЙжY бHЙ«f дЙйажŸG ™ªL √QhуH ¤ƒаj

óªà©e áfÉ«°U π«ch ÜôbCG ™bƒe ≈∏Y ±ô©àdG ∂æμÁ

»∏ëŸG ôμjO ófBG ∑ÓH Öàμe ≈∏Y ∫É°üJ’G ∫ÓN øe

,∂dP øe k’óHh .π«dódG Gòg ‘ í°VƒŸG ¿Gƒæ©dG ‘

Ú©HÉàdG øjóªà©ŸG áfÉ«°üdG AÓcƒH áªFÉb óLƒJ

Ée äÉeóÿ á∏eÉμdG π«°UÉØàdGh ôμjO ófBG ∑ÓH ácöûd

âfÎfE’G ≈∏Y ÉæH á°UÉÿG ∫É°üJ’G πFÉ°Shh ™«ÑdG ó©H

.www.2helpU.com :ÊhÎμdE’G ™bƒŸG ≈∏Y

fÉ› áeóÿG

k

•

•

π«é°ùàd www.blackanddecker.ae IQÉjõH π°†ØJ

дЙйажŸG ≈∏Y ´УW’Gh фμjO уfBG ∑УH шe уjучG ∂йажe

äÉeƒ∏©ŸG øe ójõŸG ôaƒàJ .á°UÉÿG ¢Vhô©dGh Iójó÷G

≈∏Y ÉæJÉéàæe áYƒª›h ôμjO ófBG ∑ÓH ácöT ∫ƒM

.www.blackanddecker.ae

23

Page 24

FRENCH

4

1

2

24

3

5

Page 25

FRENCH

5

8

14

A

10

6

9

7

9

12

13

11

6

B

14

12

11

6

14

15 14 12

C

12

11

6

4

D

25

Page 26

FRENCH

Utilisation prévue

Votre meuleuse d'angle Black & Decker a été

conçue pour meuler et découper le métal et le

béton avec des disques de tronçonnage ou de

meulage spécifiques. Équipé du carter de

protection approprié, cet outil est réservé à un

usage domestique.

Instructions de sécurité

Consignes de sécurité générales pour les outils

électriques

Attention ! Prenez connaissance de

tous les avertissements de sécurité et

de toutes les instructions. Le non-respect des

avertissements et des instructions indiqués

ci-dessous peut entraîner une électrocution, un

incendie ou de graves blessures.

Conservez tous les avertissements et

instructions pour référence future.

La notion d'« outil électroportatif » mentionnée par

la suite se rapporte à des outils électriques

raccordés au secteur (avec câble de

raccordement) ou fonctionnant sur piles (sans fil).

1. Sécurité de la zone de travail

a. Maintenez la zone de travail propre et bien

éclairée. Un lieu de travail en désordre ou mal

éclairé augmente le risque d'accidents.

b. N'utilisez pas les outils électroportatifs dans un

environnement présentant des risques

d'explosion ni en présence de liquides, gaz ou

poussières inflammables. Les outils

électroportatifs génèrent des étincelles risquant

d'enflammer les poussières ou les vapeurs.

c. Tenez les enfants et autres personnes éloignés

durant l'utilisation de l'outil électroportatif. En

cas d'inattention, vous risquez de perdre le

contrôle sur l'outil.

2. Sécurité électrique

a. La fiche de secteur de l'outil électroportatif doit

convenir à la prise de courant. Ne modifiez en

aucun cas la fiche. N'utilisez pas de fiches

d'adaptateur avec des outils ayant une prise de

terre. Les fiches non modifiées et les prises de

courant appropriées réduisent le risque

d'électrocution.

b. Évitez le contact physique avec des surfaces

mises à la terre telles que tuyaux, radiateurs,

fours et réfrigérateurs. Il y a un risque élevé

d'électrocution si votre corps est relié à la terre.

26

c. N'exp

d. Préservez le câble d'alimentation. N'utilisez

e. Si vous utilisez l'outil électroportatif à

f. Si l'usage d'un outil dans un emplacement

3. Sécurité personnelle

a. Restez vigilant, surveillez ce que vous faites.

b. Utilisez un équipement de protection

c. Évitez toute mise en marche involontaire.

osez pas l'outil électroportatif à la pluie

ni à l'humidité. La pénétration d'eau dans un

outil électroportatif augmente le risque

d'électrocution.

pas le câble à d'autres fins que celles

prévues, notamment pour porter l'outil,

l'accrocher voire le débrancher de la prise de

courant. Maintenez le câble éloigné des

sources de chaleur, des parties grasses, des

bords tranchants ou des parties de l'outil en

rotation. Un câble endommagé ou enchevêtré

augmente le risque d'électrocution.

l'extérieur, utilisez une rallonge homologuée

pour utilisation à l'air libre. L'utilisation d'une

rallonge électrique homologuée pour les

applications extérieures réduit le risque

d'électrocution.

humide est inévitable, utilisez une

alimentation protégée par un dispositif à

courant différentiel résiduel (RCD). L'usage

d'un RCD réduit le risque de choc électrique.

Faites preuve de bon sens quand vous

utilisez l'outil électroportatif. N'utilisez pas

l'outil lorsque vous êtes fatigué ou après avoir

consommé de l'alcool, des drogues voire des

médicaments. Un moment d'inattention lors

de l'utilisation de l'outil peut entraîner de

graves blessures.

personnelle. Portez toujours une protection

pour les yeux. Les équipements de protection

personnelle tels que les masques

anti-poussières, chaussures de sécurité

antidérapantes, casques ou protections

acoustiques utilisés dans des conditions

appropriées réduisent les blessures.

Vérifiez que l'interrupteur est en position arrêt

avant de brancher l'outil au secteur ou au

bloc de batteries, de le prendre ou de le

porter. Transporter les outils en avec le doigt

sur l'interrupteur ou les brancher avec

l'interrupteur en position de marche est une

source d'accidents.

Page 27

FRENCH

d. Enlevez tout outil ou clé de réglage avant de

mettre l'outil en marche. Une clé ou un outil

se trouvant sur une partie en rotation peut

causer des blessures.

e. Adoptez une position confortable. Adoptez

une position stable et gardez votre équilibre

à tout moment. Vous contrôlerez mieux l'outil

dans des situations inattendues.

f. Portez des vêtements appropriés. Ne portez

pas de vêtements flottants ou de bijoux.

N'approchez pas les cheveux, vêtements ou

gants des parties des pièces mobiles. Les

vêtements amples, les bijoux ou les cheveux

longs peuvent être attrapés dans les pièces

en mouvement.

g. Si des dispositifs servant à aspirer ou à

recueillir les poussières doivent être utilisés,

vérifiez qu'ils sont correctement raccordés et

utilisés. Le fait d'aspirer la poussière permet

de réduire les risques inhérents à la

poussière.

4. Utilisation des outils électroportatifs et

précautions

a. Ne surchargez pas l'outil. Utilisez l'outil

électroportatif approprié pour le travail à

effectuer. Avec l'outil électroportatif

approprié, vous travaillerez mieux et avec

plus de sécurité à la vitesse pour laquelle il a

été conçu.

b. N'utilisez pas un outil électroportatif dont

l'interrupteur est défectueux. Un outil

électroportatif qui ne peut plus être mis en ou

hors fonctionnement est dangereux et doit

être réparé.

c. Déconnectez la prise de la source

d'alimentation ou le pack-batterie de l'outil

électrique avant tout réglage, changement

d'accessoire voire rangement des outils

électriques. Cette mesure de précaution

empêche une mise en marche par mégarde.

d. Rangez les outils électroportatifs hors de

portée des enfants. Ne laissez pas les

personnes n'étant pas familiarisées avec

l'outil ou n'ayant pas lu ces instructions

l'utiliser. Les outils électroportatifs sont

dangereux lorsqu'ils sont utilisés par des

personnes non initiées.

e. Prenez soin des outils électroportatifs.

Vérifiez que les parties en mouvement

fonctionnent correctement et qu'elles ne sont

pas coincées ; vérifiez qu'il n'y a pas de

pièces cassées ou endommagées

susceptibles de nuire au bon fonctionnement

de l'outil. S'il est endommagé, faites réparer

l'outil avant de l'utiliser. De nombreux

accidents sont dus à des outils

électroportatifs mal entretenus.

f. Maintenez les outils de coupe aiguisés et

propres. Des outils soigneusement

entretenus avec des bords tranchants bien

aiguisés se coincent moins souvent et

peuvent être guidés plus facilement.

g. Utilisez l'outil électrique, les accessoires et

forets, etc. conformément à ces instructions,

en tenant compte des conditions de travail et

des tâches à effectuer. L'utilisation des outils

électroportatifs à d'autres fins que celles

prévues peut entraîner des situations

dangereuses.

5. Réparations

a. Faites réparer votre outil électroportatif

uniquement par du personnel qualifié et

seulement avec des pièces de rechange

d'origine. Cela garantira le maintien de la

sécurité de votre outil.

Avertissements de sécurité

additionnels pour les outils

électriques

Attention ! Avertissements de sécurité

additionnels pour les opérations de

meulage, de ponçage, de brossage, de

polissage ou de tronçonnage par abrasion.

• Cet outil électrique est conçu pour être utilisé

comme une meuleuse, une ponceuse, une

brosse métallique, une polisseuse et une

tronçonneuse. Lisez tous les avertissements

de sécurité, instructions, illustrations et

spécifications fournis avec cet outil électrique.

Le non-respect des instructions indiquées

ci-dessous peut entraîner une électrocution,

un incendie ou de graves blessures.

• Les opérations pour lesquelles cet outil

électrique n'a pas été conçu sont des sources

de dangers et de blessures.

27

Page 28

FRENCH

• Utilisez uniquement les accessoires

spécifiquement conçus et recommandés par

le fabricant de l'outil. Il ne suffit pas qu'un

accessoire soit adaptable sur votre outil

électrique pour assurer son utilisation en

toute sécurité.

• La vitesse nominale de l'accessoire doit être

au moins égale à la vitesse maximum

mentionnée sur l'outil électrique. Les

accessoires dépassant leur vitesse nominale

peuvent se rompre et être projetés.

• Le diamètre extérieur et l'épaisseur de votre

accessoire doivent respecter la capacité

nominale de votre outil électrique. Des

accessoires d'une taille incorrecte ne

peuvent bénéficier d'une protection et d'un

contrôle adéquats.

• L'alésage des roues, brides, tampons de

support ou autres accessoires doit s'adapter

correctement à l'axe de l'outil électrique. Les

accessoires dont l'alésage ne correspond

pas au système de fixation de l'outil

électrique sont déséquilibrés, vibrent

excessivement et peuvent causer une perte

de contrôle.

• N’utilisez pas un accessoire endommagé.

Avant chaque utilisation, vérifiez l'état de

l'accessoire : disque abrasif ébréché ou

fissuré, tampon de support fissuré, usure ou

dégâts excessifs, brosse métallique aux fils

libres ou cassés. Si l'outil électrique ou

l'accessoire tombe, vérifiez son état ou

installez un accessoire en parfait état. Après

l'inspection et l'installation d'un accessoire,

faites marcher l'outil électrique à la vitesse

maximum à vide pendant une minute. Un

accessoire endommagé casse normalement

après ce délai de test.

• Portez un équipement de protection

personnelle. Selon l'application, utilisez un

écran facial, un masque de sécurité ou des

lunettes de sécurité. Selon les besoins,

portez un masque anti-poussière, une

protection auditive, des gants et un tablier

d'atelier capable de stopper de petits

fragments générés par l'abrasion ou de la

pièce à ouvrer. La protection oculaire doit

pouvoir arrêter les débris projetés par les

diverses opérations. Le masque

anti-poussière ou le respirateur doit pouvoir

28

filtrer les particules générées par l'opération.

Une exposition prolongée à des bruits d'une

intensité élevée peut engendrer une perte de

l'audition.

• Maintenez les passants à distance de

sécurité de la zone de travail. Quiconque

pénétrant dans la zone de travail doit porter

un équipement de protection personnelle.

Des fragments de pièce à ouvrer ou un

accessoire cassé peuvent être projetés et

blesser au-delà de la zone de travail

immédiate.

• Tenez l’outil électrique uniquement par les

surfaces isolées des poignées si l’opération

effectuée peut mettre la lame en contact avec

des câbles électriques cachés ou son propre

cordon électrique. Le contact de l’accessoire

de coupe avec un câble sous tension met les

parties métalliques de l’outil électrique sous

tension et peut provoquer une électrocution

de l’utilisateur.

• Positionnez le cordon à l'écart de l'accessoire

en rotation. Si vous perdez le contrôle, le

cordon peut être coupé ou attrapé et votre

main ou votre bras être attiré dans

l'accessoire en rotation.

• Ne posez jamais l'outil électrique tant que

l'accessoire ne s'est pas arrêté

complètement. L'accessoire en rotation peut

toucher la surface et faire échapper l'outil

électrique à votre contrôle.

• N'utilisez pas l'outil électrique en le tenant à

vos côtés. Un contact accidentel avec

l'accessoire en rotation pourrait attraper vos

vêtements et attirer l'accessoire vers votre

corps.

• Nettoyez régulièrement les fentes de

ventilation de l'outil électrique. Le ventilateur

du moteur attire la poussière à l'intérieur du

carter et une accumulation excessive de

poudre métallique est une source de dangers

électriques.

• N'utilisez pas l'outil électrique près de

matériaux inflammables. Des étincelles

pourraient enflammer ces matériaux.

• N'utilisez aucun accessoire nécessitant un

liquide de refroidissement. L'emploi d'eau ou

d'autres liquides de refroidissement peut

occasionner une électrocution ou un choc.

Page 29

FRENCH

Remarque : l'avertissement précédent ne

concerne pas les outils électriques spécialement

conçus pour être utilisés avec un système

liquide.

Contrecoup et avertissements

associés

Le contrecoup est une réaction soudaine d'un

disque, d'un tampon de support, d'une brosse

ou de tout autre accessoire en rotation pincé ou

attrapé. Le pincement ou le blocage entraîne un

calage rapide de l'accessoire en rotation ce qui

provoque une perte de contrôle de l'outil

électrique qui est forcé dans le sens opposé à la

rotation de l'accessoire à l'endroit du blocage.

Par exemple, si un disque abrasif est attrapé ou

pincé par la pièce à ouvrer, le bord du disque

inséré dans le point de pincement peut

s'enfoncer dans la surface du matériau, faisant

sauter ou remonter le disque. Le disque peut

être soit projeté en avant, soit s'éloigner de

l'opérateur, selon le sens de rotation du disque à

l'endroit du pincement. Dans ces conditions, un

disque abrasif peut même se casser.

Le contrecoup est le résultat d'une utilisation

inappropriée de l'outil électrique voire de

procédures ou de conditions d’utilisation

incorrectes. Il peut être évité en appliquant les

précautions adéquates, décrites ci-dessous:

• Maintenez une prise ferme sur l'outil

électrique et positionnez votre corps et votre

bras afin de disposer d'une force suffisante

pour résister aux contrecoups. Utilisez

toujours la poignée auxiliaire, le cas échéant,

pour disposer d'un contrôle maximum sur le

contrecoup ou sur la réaction du couple au

démarrage. L'opérateur peut contrôler les

réactions du couple et les forces de

contrecoup si les précautions adaptées sont

respectées.

• Ne placez jamais votre main à proximité de

l'accessoire rotation. Le contrecoup de

l'accessoire peut toucher votre main.

• Ne positionnez jamais votre corps dans la

zone où l'outil électrique peut se déplacer en

cas de contrecoup. Le contrecoup propulse

l'outil dans le sens opposé à la rotation du

disque au point de blocage.

• Faites spécialement attention en travaillant

dans les angles, les arêtes, etc. Évitez toute

secousse et tout blocage de l'accessoire. Les

angles, les arêtes et les secousses ont

tendance à bloquer l'accessoire en rotation et

peuvent vous faire perdre le contrôle ou

générer un contrecoup.

• Ne montez pas une chaîne de coupe, une

lame à sculpter le bois ou une lame de scie

dentée. Ce type de lames génère

fréquemment des contrecoups et des pertes

de contrôle.

Avertissements de sécurité

additionnels spécifiques aux

opérations de tronçonnage par

abrasion

• Ne bloquez pas le disque de tronçonnage et

n'appliquez pas de pression excessive.

N'essayez pas d'effectuer une coupe d'une

profondeur excessive. Une pression

excessive sur le disque augmente la charge,

donc le risque de torsion ou de blocage du

disque dans la coupe et, par conséquent, la

possibilité de contrecoup ou de rupture du

disque.

• Ne positionnez pas votre corps aligné ou

derrière le disque en rotation. Lorsque le

disque, au point d'opération, s'écarte de votre

corps, le contrecoup potentiel peut propulser

le disque en rotation avec l'outil électrique

directement vers vous.

• Lorsque le disque bloqué ou en cas

d'interruption d'une coupe pour une raison

quelconque, arrêtez l'outil électrique et

maintenez-le immobile jusqu'à l'arrêt complet

du disque. N'essayez jamais de retirer un

disque tronçonnage de la coupe alors qu'il est

encore en rotation sinon un contrecoup est

possible. Déterminez pourquoi le disque s’est

coincé et corrigez le problème.

• Ne recommencez pas à l'opération de coupe

dans la pièce à ouvrer. Laissez le disque

atteindre sa vitesse maximum puis entrez à

nouveau dans la coupe avec précaution. Le

disque peut se pincer, remonter ou générer

un contrecoup si l'outil électrique est

redémarré dans la pièce à ouvrer.

29

Page 30

FRENCH

• Soutenez les panneaux ou les pièces à

ouvrer de grande taille afin de minimiser le

risque de pincement et de contrecoup du

disque. Les grandes pièces à ouvrer ont

tendance à s’arquer sous leur propre poids.

La pièce à ouvrer doit être soutenue des

deux côtés par des supports près de la fente

de scie ainsi qu'aux bords, de chaque côté

du disque.

• Faites preuve d’une prudence particulière

pour effectuer une « découpe en poche »

dans les murs préexistants ou autres parties

non apparentes. Le disque saillant peut

couper les conduites de gaz ou d'eau, le

câblage électrique ou d'autres objets

susceptibles de générer un contrecoup.

Avertissements de sécurité spécifiques aux

opérations de ponçage

• N'utilisez pas un papier de ponçage

surdimensionné. Suivez les

recommandations du fabricant pour le choix

du papier de ponçage. Un papier de

ponçage plus grand, dépassant du patin de

ponçage, présente un risque de lacération et

peut attraper ou casser le disque voire

engendrer un contrecoup.

Avertissements de sécurité spécifiques aux

opérations de polissage

• Ne laissez aucune partie libre du chapeau de

polissage ou ses cordons de fixation tourner

librement. Écartez ou coupez tout cordon de

fixation libre. Un cordon de fixation libre en

rotation peut s'enchevêtrer avec vos doigts

ou attraper la pièce à ouvrer.

Avertissements de sécurité spécifiques aux

opérations de brossage

• Notez que des brins métalliques sont

projetés par la brosse même pendant le

fonctionnement normal. Ne forcez pas les fils

en appliquant une pression excessive sur la

brosse. Les brins métalliques peuvent

facilement pénétrer sous les vêtements ou la

peau.

• Si l'emploi d'une protection est recommandé

avec la brosse métallique, aucun élément du

disque ou de la brosse ne doit interférer avec

la protection. Le disque ou la brosse

métallique peut voir son diamètre s'agrandir

en raison de la charge de travail et des forces

centrifuges.

Sécurité des tiers

• Cet appareil n'est pas destiné à être utilisé

par des personnes (notamment des enfants)

présentant des capacités physiques,

sensorielles ou mentales limitées voire

dépourvues de connaissance et d'expérience,

sauf si elles sont supervisées ou ont reçu des

instructions pour l'usage de l'appareil par une

personne responsable de leur sécurité.

• Les enfants ne doivent pas jouer avec

l’appareil.

Vibration

Les valeurs des émissions de vibrations

mentionnées dans les données techniques et la

déclaration de conformité ont été mesurées

conformément à la méthode de test normalisée

indiquée par EN 60745 et permettent les

comparaisons entre outils. Les valeurs des

émissions de vibrations peuvent également

servir à une évaluation préliminaire de

l'exposition.

Attention ! Les valeurs des émissions de

vibrations en utilisant réellement l'outil peuvent

différer des valeurs déclarées en fonction du

mode d'usage de l'outil. Le niveau de vibration

peut dépasser le niveau indiqué.

Pour évaluer l'exposition aux vibrations afin de

déterminer les mesures de sécurité imposées

par 2002/44/CE pour protéger les personnes

utilisant régulièrement des outils électriques, une

estimation de l'exposition aux vibrations devrait

prendre en compte les conditions réelles et le

mode d'utilisation de l'outil, notamment

l'ensemble du cycle de fonctionnement ainsi

l'arrêt de l'outil et son fonctionnement au ralenti,

outre le démarrage.

30

Page 31

FRENCH

Étiquettes apposées sur l'outil

Les pictogrammes suivants sont présents sur

l'outil :

Attention ! Afin de réduire les risques

de blessures, l'utilisateur doit lire le

manuel d'instructions.

Portez des lunettes de sécurité lorsque

vous utilisez cet outil.

Portez des protections auditives

lorsque vous utilisez cet outil.

Sécurité électrique

L'outil est doublement isolé ; par

conséquent, aucun câble de masse

n'est nécessaire. Vérifiez si le voltage

mentionné sur la plaque signalétique de la

machine correspond bien à la tension de

secteur présente sur lieu.

• Si le câble d'alimentation est endommagé, il

doit être remplacé par le fabricant ou par un

centre de réparation agréé Black & Decker

afin d'éviter tout accident.

Caractéristiques

Cet outil comprend toutes ou certaines des

caractéristiques suivantes.

1. Interrupteur marche/arrêt

2. Bouton de blocage

3. Poignée latérale

4. Verrouillage de l’arbre

5. Carter de protection

Assemblage

Attention ! Avant l'assemblage, assurez-vous

que l'outil est éteint et débranché.

Installation et retrait du carter

de protection (fig. A)

L'outil est fourni avec un carter de protection

réservé à des fins de meulage. Si l'unité doit

être employée pour des opérations de découpe,

un carter de protection spécifique doit être

installé. Un carter de protection pour les

opérations de découpe référence 1004484-02

est disponible et peut être obtenu auprès des

centres d'entretien Black & Decker.

Installation

• Placez l'outil sur une table, arbre (6) tourné

vers le haut.

• Dévissez le système de blocage (7) et placez

le carter de protection (5) sur l'outil selon le

schéma.

• Alignez les œillets (8) avec les encoches (9).

• Enfoncez le carter de protection et faites-le

tourner dans le sens inverse des aiguilles

d'une montre jusqu'à la position souhaitée.

• Serrez le système de blocage pour bloquer le

carter de protection sur l'outil.

• Si nécessaire, serrez la vis (10) pour

augmenter la force de serrage.

Retrait

• Relâchez le système de blocage (7).

• Faites tourner le carter de protection dans le

sens horaire pour aligner les œillets (8) avec

les encoches (9).

• Déposez le carter de protection.