Page 1

ENRUUA

www.blackanddecker.ru

HD555

HD555K

HD565K

Page 2

ENGLISH

(Original instructions)

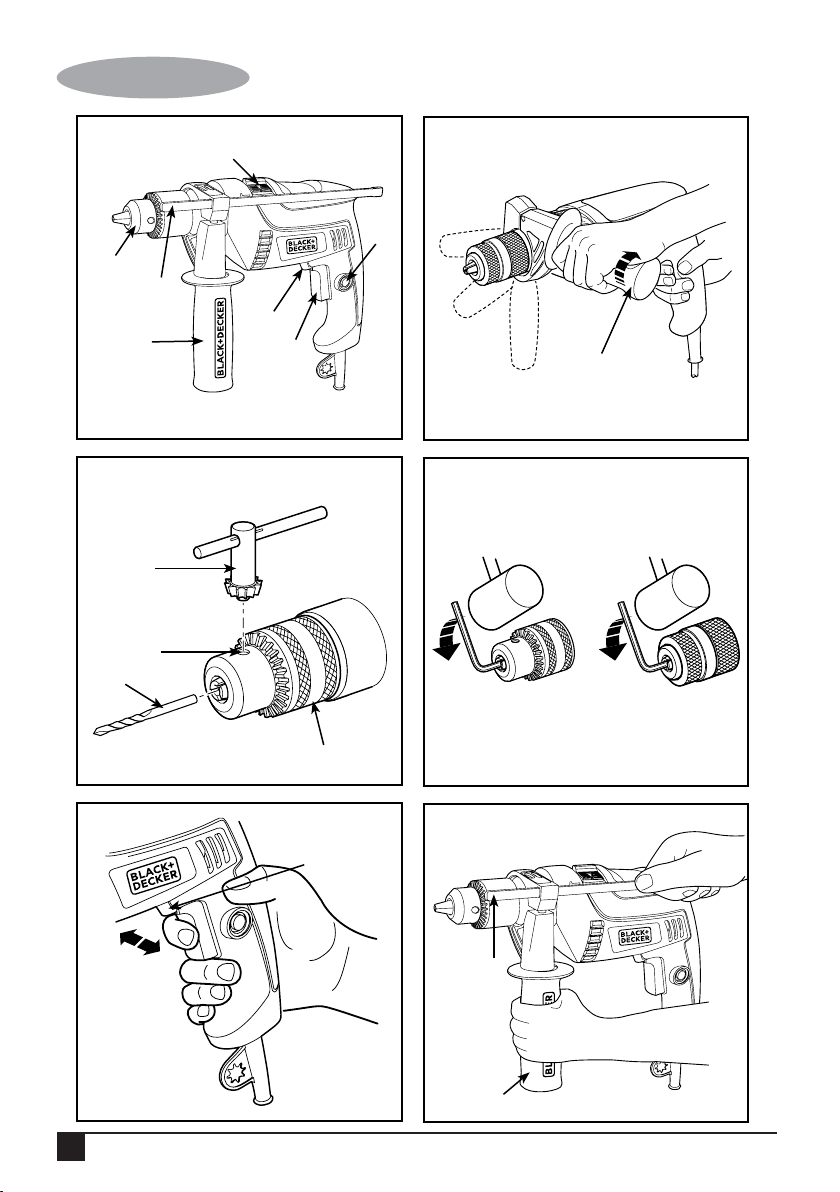

FIG. A

5

FIG. C

8

10

7

11

FIG. B

4

2

6

3

1

7

FIG. D

FIG. E

2

9

FIG. F

3

6

7

Page 3

(Original instructions)

ENGLISH

DO NOT RETURN THIS PRODUCT TO THE

STORE, first contact your local

BLACK+DECKER office or nearest

authorized service center.

General safety rules

Warning! Read and understand all

instructions. Failure to follow all instructions

listed below, may result in electric shock,

fire and/or serious personal injury.

Save these instructions

Safety instructions

General power tool safety warnings.

Warning! Read all safety warnings

and all instructions. Failure to

follow the warnings and instructions

listed below may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for

future reference. The term “power tool” in

all of the warnings listed below refers to

your mains operated (corded) power tool or

battery operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

b. Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

d. Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e. When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3. Personal safety

a. Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool

while you are tired or under the

influence of drugs, alcohol or

medication. A moment of inattention

while operating power tools may result in

serious personal injury.

b. Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your

finger on the switch or energising power

tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

3

Page 4

ENGLISH

(Original instructions)

e. Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f. Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

4. Power tool use and care

a. Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b. Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

c. Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive

safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e. Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g. Use the power tool, accessories and tool

bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5. Service

a. Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

6. Electrical safety

Your tool is double insulated;

therefore no earth wire is required.

Always check that the main voltage

corresponds to the voltage on the

rating plate.

Warning! If the power cord is

damaged, it must be replaced by the

manufacturer, authorized

BLACK+DECKER Service Center or

an equally qualified person in order

to avoid damage or injury. If the

power cord is replaced by an equally

qualified person, but not authorized

by BLACK+DECKER, the warranty

will not be valid.

7. Labels on tool

The label on your tool may include the

following symbols along with the date code:

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n0 ....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Hz .......

Position of date barcode

The Date Code, which also includes the year

of manufacture, is printed into the housing.

Example:

2017 XX JN

Year of manufacturing

4

Page 5

(Original instructions)

ENGLISH

Features (Fig. A)

1. Variable speed switch

2. Lock-on button

3. Forward/reverse slider

4. Drilling mode selector

5. Chuck

6. Depth stop

7. Side handle

Additional safety instructions for

hammer drill

• Wear ear protectors with impact drills.

Exposure to noise can cause hearing

loss.

• Use auxiliary handles supplied with the

tool. Loss of control can cause personal

injury.

• Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact

hidden wiring or its own cord. Contact

with a “live” wire will also make exposed

metal parts of the power tool “live” and

shock the operator.

• Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by

hand or against your body leaves it

unstable and may lead to loss of control.

• Before drilling into walls, floors or

ceilings check for the location of wiring

and pipes.

• Avoid touching the tip of a drill bit just

after drilling, as it may be hot

Assambly

Warning! Before assembly, make sure that

the tool is switched off and unplugged.

Fitting the side handle and depth

stop (Fig. B)

Turn the grip counterclockwise until you can

slide the side handle (7) onto the front of

the tool as shown.

• Rotate the side handle into the desired

position.

• Insert the depth stop (6) into the

mounting hole as shown.

• Set the drilling depth as described below.

• Tighten the side handle by turning the

grip clockwise.

Fitting a drill bit or screwdriver bit

Keyed chuck (Fig. C)

• Open the chuck by turning the sleeve (9)

counterclockwise.

• Insert the bit shaft (8) into the chuck.

• Insert the chuck key (10) into each hole

(11) in the side of the chuck and turn

clockwise until tight.

Removing and refitting the chuck

(Fig. D)

• Open the chuck as far as possible.

• Remove the chuck retaining screw,

located in the chuck, by turning it

clockwise using a screwdriver.

• Tighten an Allen key into the chuck and

strike it with a hammer as shown.

• Remove the Allen key.

• Remove the chuck by turning it

counterclockwise.

• To refit the chuck, screw it onto the

spindle and secure it with the chuck

retaining screw.

Use

Warning! Let the tool work at its own pace.

Do not overload.

Warning! Before drilling into walls, floors or

ceilings, check for the location of wiring and

pipes.

Selecting the direction of rotation

(Fig. E)

For drilling and for tightening screws, use

forward (clockwise) rotation. For loosening

screws or removing a jammed drill bit, use

reverse (counterclockwise) rotation.

• To select forward rotation, push the

forward/reverse slider (3) to the centre

position.

5

Page 6

ENGLISH

(Original instructions)

• To select reverse rotation, push the

forward/reverse slider to the left.

Warning! Never change the direction of

rotation while the motor is running.

Selecting the drilling mode

• For drilling in masonry, set the drilling

mode selector (3) to the position.

• For drilling in other materials and for

screwdriving, set the drilling mode

selector to the position.

Setting the drilling depth (Fig. F)

• Slacken the side handle (7) by turning

the grip counterclockwise.

• Set the depth stop (6) to the desired

position. The maximum drilling depth is

equal to the distance between the tip of

the drill bit and the front end of the

depth stop.

• Tighten the side handle by turning the

grip clockwise.

Switching on and off

• To switch the tool on, press the speed

switch (1). For tools with variable speed

switch, the tool speed depends on how

far you press the switch. As a general

rule, use low speeds for large diameter

drill bits and high speeds for smaller

diameter drill bits.

• For continuous operation, press the

lock-on button (2) and release the speed

switch. This option is available only at full

speed. This option does not work in

reverse rotation. Reverse rotation

available only for HD500.

• To switch the tool off, release the speed

switch. To switch the tool off when in

continuous operation, press the speed

switch once more and release it.

Maintenance

Keep guards, air vents and the motor

housing as clear as possible of dust and dirt.

Wipe with a clean cloth and blow through

with a low-pressure air supply. Excessive

build-up of metal dust can cause tracking of

electrical current from the internal parts to

exposed metal parts.

Important! To assure product SAFETY and

RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this

manual) should be performed by authorized

service centers or other qualified service

personnel, always using identical

replacement parts.

Protecting the environment

Separate collection. This product

must not be disposed of with normal

household waste.

Should you find one day that your

BLACK+DECKER product needs replacement, or if it is of no further use to you, do

not dispose of it with household waste. Make

this product available for separate collection.

Separate collection of used products

and packaging allows materials to be

recycled and used again. Reuse of

recycled materials helps prevent environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate

collection of electrical products from the

household, at municipal waste sites or by the

retailer when you purchase a new product.

BLACK+DECKER provides a facility for the

collection and recycling of BLACK+DECKER

products once they have reached the end of

their working life. To take advantage of this

service please return your product to any

authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your

local BLACK+DECKER office at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair agents

and full details of our after-sales service and

contacts are available on the Internet at:

www.2helpU.com.

Accessories

Recommended accessories for use with your

product are available from your local dealer

or authorized service center.

6

Page 7

(Original instructions)

ENGLISH

Service information

BLACK+DECKER offers a full network of

company-owned and authorized service

locations. All BLACK+DECKER Service

Centers are staffed with trained personnel

to provide customers with efficient and

reliable power tool service. For more

information about our authorized service

centers and if you need technical advice,

repair, or genuine factory replacement

parts, contact the BLACK+DECKER location

nearest you, or visit us at

www.blackanddecker.com

Specifications

HD555 / HD565

Power 550W

Voltage 220-240

50-60Hz

No-load speed 0 - 2800/min (rpm)

IPM - Blows per minute 45000 ipm (gpm)

Max drill capacity

Steel 1/2” (13mm)

Concrete 1/2” (13mm)

Wood 25/32” (20mm)

• The product has sustained damage

through foreign objects, substances or

accidents.

• Repairs have been attempted by persons

other than authorised repair agents or

BLACK+DECKER service staff.

To claim on the guarantee, you will need to

submit proof of purchase to the seller or an

authorised repair agent. You can check the

location of your nearest authorised repair

agent by contacting your local

BLACK+DECKER office at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair agents

and full details of our aftersales service and

contacts are available on the Internet at:

www.2helpU.com

Guarantee

BLACK+DECKER is confident of the quality

of its products and offers an outstanding

guarantee. This guarantee statement is in

addition to and in no way prejudices your

statutory rights.

If a BLACK+DECKER product becomes

defective due to faulty materials,

workmanship or lack of conformity, within

24 months from the date of purchase,

BLACK+DECKER guarantees to replace

defective parts, repair products subjected

to fair wear and tear or replace such

products to make sure of the minimum

inconvenience to the customer unless:

• The product has been used for trade,

professional or hire purposes.

• The product has been subjected to

misuse or neglect.

7

Page 8

РУССКИЙ

(Перевод с оригинала инструкции)

ПРЕЖДЕ ЧЕМ ВЕРНУТЬ ПРОДУКТ В МАГАЗИН,

обратитесь сначала в ваше региональное

представительство BLACK+DECKER или в ближайший

уполномоченный сервисный центр.

Общие правила техники безопасности

Внимание! Внимательно изучите все указания по

технике безопасности. Несоблюдение указаний по

безопасной работе может привести к поражению

электрическим током, пожару и/или серьезным травмам

персонала.

Сохраните эти инструкции

Указания по технике безопасности

Общие указания по безопасной работе с

электрическим инструментом.

Внимание! Внимательно прочитайте все

предупреждающие надписи и указания по

безопасной работе. Несоблюдение

предупреждающих надписей и указаний по безопасной

работе может привести к поражению электрическим

током, пожару и/или серьезным травмам персонала.

Храните все предупреждающие надписи и указания

по безопасной работе для использования в

будущем. Термин «электрический инструмент»,

используемый во всех предупреждающих надписях и

указаниях по технике безопасности, представленных

ниже, относится к электрическому инструменту,

работающему от сети (со шнуром электропитания) или

от аккумуляторной батареи (без шнура питания).

1. Указания по безопасности на рабочем месте

a. Рабочее место должно содержаться в чистоте и

должно быть оборудовано надлежащим

освещением. Беспорядок или плохое освещение на

рабочем месте может привести к несчастному

случаю.

b. Запрещается использование электрического

инструмента во взрывоопасной среде,

например, в условиях наличия

легковоспламеняющихся жидкостей, газов или

пыли. Искры, возникающие при работе

электрического инструмента, могут воспламенить

пыль, пары и газы.

c. Запрещается нахождение детей и посторонних

лиц вблизи работающего электрического

инструмента. Отвлекающие факторы могут

привести к потере контроля за работой

инструмента.

2. Электрическая безопасность

8

a. Вилка шнура электрического инструмента

должна соответствовать сетевой розетке.

Запрещается вносить какие-либо изменения в

вилку электрического шнура. Запрещается

использование каких-либо штепсельных

переходников при работе заземленного

электрического инструмента. Отсутствие

изменений в вилках электрических шнуров и

соответствие электрических вилок и розеток

снижает риск поражения электрическим током.

b. Не допускайте контакта тела с заземленными

поверхностями таких объектов, как трубы,

радиаторы, электроплиты и холодильники. Если

ваше тело заземлено, риск его поражения

электрическим током повышается.

c. Электрические инструменты не должны

подвергаться воздействию дождя и находится в

условиях повышенной влажности. При попадании

влаги внутрь электрического инструмента

повышается риск поражения электрическим током.

d. Запрещается использовать электрический шнур

не по назначению. Никогда не берите, не тяните и

не вынимайте электрический инструмент за

шнур. Электрический шнур не должен находиться

вблизи источников тепла, масла, острых краев и

движущихся деталей. Поврежденные и

закрученные электрические шнуры повышают риск

поражения электрическим током.

e. При работе электрического инструмента на

открытом воздухе используйте соответствующий

удлинитель. Использование удлинителя,

предназначенного для работы на открытом воздухе,

снижает риск поражения электрическим током.

f. Если работы с помощью электрического

инструмента внутри влажного помещения

должны быть выполнены обязательно, в таком

случае необходимо использовать устройство

защитного отключения (УЗО) электрической сети.

Использование УЗО снижает риск поражения

электрическим током.

3. Безопасность персонала

a. При работе с электрическим инструментом

необходимо быть осмотрительным, видеть

выполняемую работу и руководствоваться

здравым смыслом. Запрещается работать с

электрическим инструментом в состоянии

усталости и под воздействием наркотиков,

алкоголя и лекарственных препаратов.

Ослабление внимания даже на мгновение может

привести к серьезной травме.

Page 9

(Перевод с оригинала инструкции)

РУССКИЙ

b. Используйте средства индивидуальной защиты.

Всегда надевайте средства защиты глаз.

Используемые в соответствующих условиях

средства индивидуальной защиты, такие как

пылезащитная маска, нескользящая защитная

обувь, защитная каска или средства защиты

органов слуха. всегда снижают риск

травмирования.

c. Не допускайте непреднамеренного включения

инструмента. Перед тем, так подключить

источник питания или аккумулятор, поднимая

или неся инструмент, проверьте, чтобы его

выключатель находился в выключенном

положении. Переноска инструмента пальцем,

расположенном на его выключателе, или

включенного инструмента повышает риск

несчастного случая.

d. Перед включением инструмента всегда

снимайте с него регулировочный и гаечный

ключ. Оставленный на вращающейся детали

инструмента ключ может привести к

травмированию.

e. Не прикладывайте к инструменту чрезмерное

усилие во время работы. Всегда прочно

держитесь на ногах и сохраняйте равновесие во

время работы. Это позволяет лучше

контролировать электрический инструмент в

непредвиденных ситуациях.

f. Надевайте соответствующую одежду.

Запрещается надевать свободную одежду и

украшения. Волосы, одежда и перчатки должны

находиться на расстоянии от движущихся

деталей инструмента. Свободная одежда,

украшения или длинные волосы могут быть

захвачены движущимися деталями.

g. Если установлены устройства подключения

средств пылеулавливания и пылесборников,

необходимо проверять, чтобы они были

подключены и использовались надлежащим

образом. Использование средств

пылеулавливания снижает уровень риска,

связанного с наличием пыли в воздухе.

4. Использование и уход за электрическим

инструментом

a. Не прикладывайте чрезмерное усилие к

электрическому инструменту. Используйте

электрический инструмент, соответствующий

выполняемой задаче. При использовании

надлежащего инструмента вы выполните работу

лучше, с меньшим риском и со скоростью, на

которую рассчитан ваш инструмент.

b. Запрещается использовать инструмент, если его

выключатель не включается и не выключается.

Любой электрический инструмент, работой которого

нельзя управлять с помощью его выключателя,

представляет собой опасность и подлежит

обязательному ремонту.

c. Перед выполнением регулировки

электрического инструмента, заменой его

принадлежностей и постановкой на хранение

необходимо вынуть вилку его электрического

шнура из розетки и/или достать из него

аккумулятор. Такая превентивная мера

безопасности снижает риск случайного включения

инструмента.

d. Храните электрический инструмент, который в

данный момент не используется, в недоступном

для детей месте и разрешайте работать с

инструментом лицам, которые не знакомы с ним

или с этими указаниями. Электрический

инструмент является опасным в руках необученного

человека.

e. Поддерживайте инструмент в рабочем

состоянии. Проверяйте центровку и соединение

движущихся деталей, наличие поврежденных

деталей и любые факторы, которые могут

отрицательно сказаться на работе

электрического инструмента. В случае

обнаружения повреждения электрический

инструмент необходимо отремонтировать.

Много несчастных случае происходит вследствие

того, что инструмент находится в ненадлежащем

состоянии.

f. Режущие инструменты должны быть остро

заточенными и чистыми. Поддерживаемый в

надлежащем рабочем состоянии режущий

инструмент с острыми режущими кромками меньше

застревает и легче управляется.

g. Используйте электрический инструмент,

принадлежности, вставные резцы и т.д. в

соответствии с данными указаниями, учитывая

условия эксплуатации и работу, которая должна

быть выполнена. Использование электрического

инструмента с целью, отличной от

предусмотренного назначения, может привести к

опасной ситуации.

5. Обслуживание

a. Обслуживать электрический инструмент должен

только квалифицированный ремонтный

персонал, при этом должны использоваться

только оригинальные запасные детали.

Благодаря этому будет поддерживаться безопасное

рабочее состояние электрического инструмента.

9

Page 10

РУССКИЙ

(Перевод с оригинала инструкции)

6. Электрическая безопасность

Этот инструмент имеет двойную изоляцию, и

поэтому провод заземления ему не нужен.

Всегда проверяйте, чтобы сетевое

напряжение соответствовало значению,

указанному в табличке с паспортными

данными.

Внимание! В случае повреждения шнура

питания, чтобы избежать несчастных случаев

с персоналом и повреждения оборудования,

его замену должен выполнить

производитель, авторизованный сервисный

центр BLACK+DECKER или другое лицо,

обладающее надлежащей квалификацией.

Если замену шнура питания выполнило

квалифицированное лицо, которое не

является уполномоченным лицом

BLACK+DECKER, гарантийные обязательства

будут аннулированы.

7. Наклейки на инструменте

Наклейка на вашем инструменте вместе с кодом даты

может содержать следующие символы:

Прочитайте

инструкцию по

эксплуатации

Используйте

средства защиты

глаз

Используйте

средства защиты

органов слуха

В ........ Вольты

A ........ Амперы n0 ....... Скорость

холостого хода

Гц ....... Герцы

Вт ....... Ватты

мин ..... минуты

..... Переменный

ток

..... Постоянный

ток

...... Конструкция

Класс II

...... Клемма

заземления

...... Предупреж

дающий

.../мин.. Количество

оборотов или

возвратно поступательных

движений в

минуту

Положение штрих-кода с датой

Штрих-код с датой, который также включает год

изготовления, напечатан на корпусе.

Пример:

2017 XX JN

Год изготовления

Функции (Рис. A)

1. Переключатель количества оборотов

2. Кнопка фиксации

3. Подвижный переключатель прямого/обратного

направления вращения

4. Переключатель режима сверления

5. Зажимной патрон

6. Ограничитель глубины

7. Боковая рукоятка

Дополнительные указания по безопасной

работе ударной дрели

• При работе с ударными дрелями надевайте

средства защиты органов слуха. Воздействие

шума может привести к нарушению слуха.

• Используйте вспомогательные рукоятки,

которые поставляются вместе с инструментом.

Потеря управления инструментом может привести к

травмированию.

• Во время выполнения работ, когда режущая

деталь электрического инструмента может

соприкасаться со скрытой электропроводкой

или со своим шнуром, инструмент необходимо

держать за диэлектрическую поверхность. При

контакте режущей детали с проводом, находящимся

под напряжением, под напряжение могут попасть

металлические детали электрического инструмента,

вследствие чего возникает опасность поражения

оператора электрическим током.

• Для фиксации положения обрабатываемой детали

на устойчивом основании используйте зажимы или

другой удобный и практический способ. Если

держать деталь руками или прижимать ее к телу, она

будет находиться в незакрепленном положении, что

может привести к потере контроля за работой

инструмента.

• Перед выполнением сверления стен, полов и

потолков проверяйте расположение

электропроводки и труб.

• Не касайтесь наконечника сверла дрели после

сверления, поскольку он может быть горячим.

Сборка

Внимание! Перед выполнением сборки убедитесь, что

инструмент выключен, а вилка шнура вынута из сетевой

розетки.

Установка боковой рукоятки и

ограничителя глубины (Рис. B)

Поворачивайте зажим против часовой стрелки до тех

пор, пока вы не сможете перемещать боковую рукоятку

(7) на передней части инструмента, как показано на

рисунке.

10

Page 11

(Перевод с оригинала инструкции)

РУССКИЙ

• Поверните боковую рукоятку в требуемое

положение.

• Вставьте ограничитель глубины (6) в монтажное

отверстие, как показано на рисунке.

• Установите глубину сверления, как описано ниже.

• Затяните боковую рукоятку, поворачивая зажим по

часовой стрелке.

Установка сверла дрели или наконечника

шуруповерта в зажимной патрон под

ключ (Рис. C)

• Раскройте зажимной патрон, поворачивая втулку

(9) против часовой стрелки.

• Вставьте хвостовик сверла (8) в зажимной патрон.

• Вставляйте ключ (10) в каждое из боковых

отверстий (11) зажимного патрона и поворачивайте

по часовой до тех пор, пока патрон не дойдет до

упора.

Снятие и повторная установка

зажимного патрона (Рис. D)

• Максимально раскройте зажимной патрон.

• Выкрутите отверткой винт фиксации в зажимном

патроне, поворачивая ее по часовой стрелке.

• Вставьте плотно в патрон торцовый шестигранный

ключ и постучите по нему молотком, как показано

на рисунке.

• Выньте из зажимного патрона торцовый

шестигранный ключ.

• Снимите зажимной патрон с дрели, поворачивая

его против часовой стрелки.

• Чтобы снова установить зажимной патрон,

закрутите его на шпинделе и закрепите его

положение винтом фиксации.

Работа бытового прибора

Внимание! Дайте возможность инструменту работать с

естественной скоростью. Не перегружайте его.

Внимание! Перед выполнением сверления стен, полов

и потолков проверяйте расположение

электропроводки и труб.

Выбор направления вращения (Рис. E)

Для сверления и закручивания шурупов используйте

прямое (по часовой стрелке) направление вращения.

Для выкручивания шурупов и удаления застрявшего

сверла дрели используйте обратное (против часовой

стрелки) направление вращения.

• Чтобы выбрать прямое направление вращения,

установите подвижный переключатель

прямого/обратного направления вращения (3) в

центральное положение.

• Чтобы выбрать обратное направление вращения,

установите подвижный переключатель

прямого/обратного направления вращения в левое

положение.

Внимание! Запрещается изменять направление

вращения дрели при работающем двигателе.

Выбор режима сверления

• Для сверления кирпичной кладки установите

переключатель режима сверления (3) в положение

.

• Для сверления других материалов и закручивания

шурупов установите переключатель режима

сверления в положение .

Задание глубины сверления (Рис. F)

• Ослабьте боковую рукоятку (7), поворачивая зажим

против часовой стрелки.

• Установите необходимое значение ограничителя

глубины (6). Максимальная глубина сверления равна

расстоянию между наконечником сверла дрели и

передним концом ограничителя глубины.

• Затяните боковую рукоятку, поворачивая зажим по

часовой стрелке.

Включение и выключение

• Чтобы включить инструмент, нажмите

переключатель количества оборотов (1). В

инструментах с переключателем количества

оборотов скорость вращения инструмента зависит

от того, в какой степени вы нажали (утопили) этот

переключатель. В качестве общего правила, при

использовании сверла большого диаметра надо

работать на небольших оборотах, а при

использовании сверла меньшего диаметра надо

повышать обороты.

• Для продолжительной работы нажмите кнопку

фиксации (2) и отпустите переключатель количества

оборотов. Эта функция доступна только на полной

скорости вращения. Эта функция не работает в

режиме обратного вращения. Функция обратного

направления вращения доступна только для модели

HD500.

11

Page 12

РУССКИЙ

(Перевод с оригинала инструкции)

• Чтобы выключить инструмент, отпустите

переключатель количества оборотов. Чтобы

выключить инструмент после продолжительной

работы, еще раз нажмите и отпустите

переключатель количества оборотов.

Техническое обслуживание

Предохранительные щитки, вентиляционные отверстия

и корпус двигателя должны быть свободными от пыли и

грязи. Вытирайте пыль и грязь чистой тканью и

выдувайте пыль струей воздуха под низким давлением.

Чрезмерное накопление металлической пыли может

привести к появлению токопроводящих путей между

внутренними деталями инструмента и внешними

металлическими деталями.

Важно! Чтобы гарантировать БЕЗОПАСНОСТЬ и

НАДЕЖНОСТЬ инструмента, ремонт, обслуживание и

настройка (кроме описанных в данной инструкции)

должны производиться в авторизованных сервисных

центрах или прочими квалифицированными

работниками, всегда с использованием идентичных

запчастей.

Защита окружающей среды

Раздельный сбор отходов. Запрещается

утилизировать этот продукт вместе с

обычными бытовыми отходами.

Если вы решите, что ваше изделие BLACK+DECKER

необходимо заменить, или если вы не будете его

больше использовать¬, не утилизируйте его вместе с

бытовыми отходами. Этот продукт подлежит

раздельному сбору отходов.

Раздельный сбор использованных

продуктов и упаковочных материалов

позволяет производить их вторичную

переработку с дальнейшим повторным

использованием. Повторное использование

материалов, прошедших вторичную переработку,

снижает загрязнение окружающей среды¬ и

уменьшает потребность в сырьевых материалах.

Нормативные акты местных органов власти могут

предусматривать сбор использованных

электрических изделий отдельно от бытовых

отходов, в муниципальных пунктах сбора отходов

или в магазине при покупке нового изделия.

BLACK+DECKER предоставляет возможность для

сбора и повторной переработки продуктов

BLACK+DECKER после окончания срока их службы.

Чтобы воспользоваться преимуществом этого

сервиса, пожалуйста, отправьте ваш продукт

любому уполномоченному представителю по

ремонту, который собирает такие изделия от

нашего имени.

Вы можете узнать адрес нашего ближайшего

уполномоченного представителя по ремонту,

позвонив в региональное представительство

BLACK+DECKER, указанное в этой инструкции.

Кроме того, список уполномоченных

представителей по ремонту BLACK+DECKER,

подробная информация о послепродажном

обслуживании и контактные данные можно найти

на сайте www.2helpU.com.

Принадлежности

Приобретение аксессуаров для вашего инструмента

возможно у вашего местного дилера или в

авторизованном сервисном центре.

Информация по обслуживанию

BLACK+DECKER предлагает обширную сеть

принадлежащих компании и авторизованных сервисных

центров. Все сервисные центры BLACK+DECKER

укомплектованы обученным персоналом, который

выполняет эффективное и надежное сервисное

обслуживание владельцев электрических инструментов.

Для получения более подробной информации об

авторизованных сервисных центрах, чтобы получить

технический совет и выяснить вопросы ремонта и

оригинальных запасных деталей, обратитесь в

ближайшее представительство BLACK+DECKER или

зайдите на наш сайт www.blackanddecker.com

Технические характеристики

HD555 / HD565

Мощность 550 Вт

Напряжение 220-240

50-60 Гц

Скорость холостого хода 0 – 2800 об./мин.

Ударов в минуту 45 000

Наибольший диаметр сверления

Сталь 1/2” (13 мм)

Бетон 1/2” (13 мм)

Дерево 25/32” (20 мм)

12

Page 13

(Перевод с оригинала инструкции)

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного

изделия Black+Decker и выражаем признательность за

Ваш выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель,

дата продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно

заполненного гарантийного талона мы будем вынуждены

отклонить Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации.

Правовой основой настоящих гарантийных условий

является действующее Законодательство.

Гарантийный срок на данное изделие составляет 24

месяца и исчисляется со дня продажи. В случае

устранения недостатков изделия, гарантийный срок

продлевается на период его нахождения в ремонте.

Срок службы изделия - 5 лет со дня продажи.

4. В случае возникновения каких-либо проблем в процессе

эксплуатации изделия рекомендуем Вам обращаться

только в уполномоченные сервисные центры

BLACK+DECKER, адреса и телефоны которых Вы

сможете найти в гарантийном талоне, на сайте

www.2helpU.com или узнать в магазине. Наши сервисные

станции - это не только квалифицированный ремонт, но и

широкий ассортимент запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

РУССКИЙ

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение

гарантийного срока и вызванные дефектами производства

и \ или материалов.

7. Гарантийные обязательства не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и

разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого

электрического кабеля, вызванного внешним ударным или

любым иным воздействием.

7.3. Попадания в вентиляционные отверстия и проникновение

внутрь изделия посторонних предметов, материалов или

веществ, не являющихся отходами, сопровождающими

применение изделия по назначению, такими как: стружка,

опилки, песок, и пр.

7.4. Воздействие на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанным на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов

напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченной сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как: приводные ремни и колеса, угольные щетки,

смазка, подшипники, зубчатое зацепление редукторов,

резиновые уплотнения, сальники, направляющие ролики,

муфты, выключатели, бойки, толкатели, стволы и т.п.

8.3. на сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и

абразивные диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни редуктора

и других узлов и деталей. К безусловным признакам

перегрузки изделия относятся, помимо прочих: появление

цветов побежалости, деформация или оплавление

деталей и узлов изделия, потемнение или обугливание

изоляции проводов электродвигателя под воздействием

высокой температуры.

13

Page 14

УКРАЇНСЬКА

(Переклад оригінальних інструкцій)

ПЕРШ НІЖ ПОВЕРНУТИ ПРОДУКТ В МАГАЗИН,

зверніться спочатку до вашого регіонального

представництва BLACK + DECKER або до найближчого

авторизованого сервісного центру.

Загальні правила техніки безпеки

Обережно! Уважно вивчіть всі вказівки з техніки

безпеки. Недотримання вказівок щодо безпечної роботи

може призвести до ураження електричним струмом,

пожежі та/або серйозних травм персоналу.

Збережіть ці інструкції

Вказівки з техніки безпеки

Загальні вказівки щодо безпечної роботи з

електричним інструментом.

Обережно! Уважно прочитайте всі

попереджувальні написи та вказівки з

техніки безпеки. Порушення наведених

нижче попереджувальних написів і вказівок може

призвести до ураження електричним струмом, пожежі

та/або серйозних травм.

Збережіть усі застереження та вказівки з техніки

безпеки для подальшого використання. Термін

«електричний інструмент», що використовується у всіх

застережливих написах та вказівках щодо техніки

безпеки, представлених нижче, відноситься до

електричного інструменту, що працює від мережі (зі

шнуром електроживлення) або від акумуляторної

батареї (без шнура живлення).

1. Вказівки з техніки безпеки на робочому місці

a. Утримуйте робоче місце в чистоті і добре

освітленим. Безлад або погане освітлення на

робочому місці можуть призвести до нещасного

випадку.

b. Не працюйте з електроінструментом в місці

зберігання вибухонебезпечних матеріалів,

наприклад, у присутності легкозаймистих рідин,

газів або пилу. Електричні інструменти створюють

іскри, що можуть запалити пил або пари.

c. Забороняється перебування дітей та сторонніх

осіб поблизу працюючого електричного

інструменту. Відволікання може призвести до

втрати контролю за роботою інструмента.

2. Електрична безпека

a. Вилка шнура живлення інструмента повинна

відповідати мережевій розетці. Забороняється

вносити будь-які зміни у вилку шнура живлення.

Не використовуйте жодних вилок-перехідників із

заземленими (зануленими)

електроінструментами. Відсутність змін у вилках

шнурів живлення та відповідність електричних

вилок і розеток знижує ризик ураження

електричним струмом.

b. Не торкайтеся поверхонь заземлених чи

занулених предметів, наприклад труб,

радіаторів, електроплит або холодильників.

Заземлення чи занулення тіла підвищує ризик

ураження електричним струмом.

c. Забороняється піддавати електричні

інструменти впливу дощу чи підвищеної

вологості. При попаданні вологи всередину

електричного інструмента підвищується ризик

ураження електричним струмом.

d. Обережно поводьтеся зі шнуром живлення. У

жодному разі не використовуйте шнур живлення

для перенесення чи зміни положення

інструмента; не тягніть за шнур, виймаючи вилку

з розетки. Не прокладайте шнур живлення поруч

із гарячими предметами, мастилом, гострими

краями і рухомими деталями. Пошкодження й

заплутування шнурів живлення підвищує ризик

ураження електричним струмом.

e. Під час роботи з електричним інструментом за

межами приміщень використовуйте відповідний

подовжувач. Використання подовжувача,

призначеного для роботи поза приміщеннями,

знижує ризик ураження електричним струмом.

f. Якщо електричним інструментом необхідно

користуватись у вологому місці, слід

використовувати пристрій захисного

відключення (ПЗВ) електричної мережі.

Використання ПЗВ знижує ризик ураження

електричним струмом.

3. Безпека персоналу

a. Під час роботи з електричним інструментом

необхідно бути обачним, слідкувати за

виконуваною роботою та керуватися здоровим

глуздом. Забороняється працювати з

електричним інструментом у стані втоми чи під

впливом наркотиків, алкоголю й лікарських

препаратів. Ослаблення уваги навіть на мить може

призвести до серйозної травми.

14

Page 15

(Переклад оригінальних інструкцій)

УКРАЇНСЬКА

b. Використовуйте засоби індивідуального

захисту. Завжди користуйтеся засобами захисту

очей. Використання у відповідних умовах засобів

індивідуального захисту, наприклад пилозахисної

маски, протиковзного захисного взуття, захисної

каски або засобів захисту органів слуху, завжди

знижує ризик отримання травми.

c. Не допускайте ненавмисного вмикання

інструмента. Перш ніж підключити джерело

живлення та/або акумулятор, піднімаючи або

несучи інструмент, перевірте, щоб його вимикач

знаходився у вимкненому положенні. Якщо

тримати палець на вимикачі під час перенесення

інструмента чи підключення увімкненого

інструмента до мережі, це підвищує ризик

нещасного випадку.

d. Перш ніж увімкнути електричний інструмент,

обов’язково вийміть із нього регулювальний чи

гайковий ключ. Ключ, залишений ключ на

обертальній деталі інструмента, може призвести до

травмування.

e. Не намагайтеся дотягнутися до важкодоступних

місць. Завжди міцно тримайтеся на ногах і

зберігайте рівновагу під час роботи. Це дозволяє

краще контролювати електричний інструмент у

непередбачуваних ситуаціях.

f. Одягайте відповідний одяг. Забороняється

одягати вільний одяг або прикраси. Волосся,

одяг та рукавиці повинні знаходитися на

максимальній відстані від рухомих деталей

інструмента. Вільний одяг, прикраси або довге

волосся можуть бути захоплені рухомими деталями.

g. Якщо встановлені пристрої підключення засобів

пиловловлювання та пилозбірників, необхідно

перевіряти, щоб вони були підключені та

використовувалися належним чином.

Використання цих пристроїв знижує рівень ризику,

пов’язаного з пилом.

4. Використання та догляд за електричним

інструментом

a. Не застосовуйте надмірне зусилля до

електричного інструмента. Використовуйте

електричний інструмент тільки за

призначенням. Правильно підібраний

електроінструмент дозволить виконати роботу

краще і безпечніше при швидкості, на яку він

розрахований.

b. Забороняється використовувати цей

електричний інструмент, якщо не вдається

ввімкнути чи вимкнути його вимикачем.

Будь-який електричний інструмент, роботою якого

неможливо керувати за допомогою вимикача, є

небезпечним, і його обов’язково потрібно

відремонтувати.

c. Перш ніж регулювати електричний інструмент,

замінювати на ньому приладдя чи класти на

зберігання, необхідно витягти вилку живлення з

розетки та/або зняти з нього акумулятор. Такий

превентивний захід безпеки знижує ризик

випадкового увімкнення інструмента.

d. Зберігайте електричний інструмент, який в даний

момент не використовується, в недоступному

для дітей місці та не дозволяйте працювати з

інструментом особам, які не знайомі з ним або з

цими вказівками. Електричний інструмент є

небезпечним в руках ненавченої людини.

e. Підтримуйте інструмент в робочому стані.

Перевіряйте центрування та з’єднання рухомих

деталей, наявність пошкоджених деталей та

будь-які фактори, які можуть негативно

позначитися на роботі електричного

інструмента. У разі виявлення пошкодження

електричний інструмент необхідно відремонтувати

перед використанням. Багато нещасних випадків

трапляється через неналежне технічне

обслуговування електричних інструментів.

f. Ріжучі інструменти мають бути загостреними й

чистими. Підтримуваний у належному робочому

стані ріжучий інструмент з гострими лезами менше

застряє, ним легше керувати.

g. Використовуйте електричний інструмент,

приладдя, вставні різці тощо відповідно до

даних вказівок, враховуючи умови експлуатації

та роботу, яка повинна бути виконана.

Використання електричного інструмента всупереч

призначенню може призвести до виникнення

небезпечної ситуації.

5. Обслуговування

a. Обслуговувати електричний інструмент повинен

тільки кваліфікований ремонтний персонал, і

при цьому повинні використовуватися тільки

оригінальні запасні деталі. Це забезпечить

утримання електричного інструмента у безпечному

стані.

15

Page 16

УКРАЇНСЬКА

(Переклад оригінальних інструкцій)

6. Електрична безпека

Цей інструмент має подвійну ізоляцію, тому

дріт заземлення для нього не потрібен.

Завжди перевіряйте, чи мережева напруга

відповідає значенню, вказаному в таблиці з

паспортними даними.

Обережно! У разі пошкодження кабелю

живлення, щоб уникнути нещасних випадків з

персоналом та пошкодження обладнання,

його заміну повинен виконати виробник,

авторизований сервісний центр

BLACK+DECKER або інша особа, яка володіє

належною кваліфікацією. Якщо заміну шнура

живлення виконала кваліфікована особа, яка

не є уповноваженою особою BLACK+DECKER,

гарантійні зобов’язання будуть анульовані.

7. Наклейки на інструменті

Наклейка на вашому інструменті разом з кодом дати

може містити наступні символи:

Прочитайте

інструкцію з

експлуатації.

Використовуйте

засоби захисту

очей

Використовуйте

засоби захисту

органів слуху

Захист

V ........ Вольти

A ........ Ампери

Hz ....... Hertz

W ........ Watts

dak ..... хвилин

Змінне

.....

Струм

. Постійний

.....

струм

Швидкість

n0 .......

холостого

ходу

.../min..

......

....

....

Конструкції

класу II

Клема

заземлення

Попереджув

альний знак

Обороти або

цикли зворотно

поступального

руху за

Положення штрих-коду з датою

Штрих-код з датою, який також включає рік

виготовлення, надрукований на корпусі.

Приклад:

2017 XX JN

Рік виготовлення

Функції (Рис. A)

1. Перемикач кількості обертів

2. Кнопка фіксації

3. Рухомий перемикач прямого/зворотного напрямку

обертання

4. Перемикач режиму дриля

5. Затискний патрон

6. Обмежувач глибини

7. Бічна рукоятка

Додаткові вказівки щодо безпечної

експлуатації ударного дриля

• При роботі з ударними дрилями надягайте

засоби захисту органів слуху. Вплив шуму може

призвести до порушення слуху.

• Використовуйте допоміжні рукоятки, які

поставляються разом з інструментом. Втрата

управління інструментом може призвести до

травмування.

• Під час виконання робіт, коли ріжуча деталь

електричного інструмента може контактувати з

прихованою електропроводкою або зі своїм

шнуром, інструмент необхідно тримати за

діелектричну поверхню. При контакті ріжучої

деталі з проводом, що під напругою, під напругу

можуть потрапити металеві деталі електричного

інструменту, внаслідок чого виникає небезпека

ураження оператора електричним струмом.

• Закріпіть робочу деталь на стійкій основі

затискачами або іншим зручним і практичним

способом. Якщо тримати деталь руками або

притискати її до себе, вона буде незакріпленою, що

може призвести до втрати контролю за роботою

інструмента.

• Перед виконанням свердління стін, підлог і стель

перевіряйте розташування електропроводки і труб.

• Не торкайтеся наконечника свердла дрилю після

свердління, оскільки він може бути гарячим.

Монтаж

Обережно! Перед монтажем перевірте, щоб інструмент

був вимкнений, а вилка шнура була вийнята з розетки.

Установка бічного руків’я та обмежувача

глибини (Рис. В)

Повертайте затиск проти годинникової стрілки до тих

пір, поки ви не зможете переміщати бічну рукоятку (7) на

передній частині інструменту, як показано на рисунку.

• Поверніть бокову ручку в необхідне положення.

• Вставте обмежувач глибини (6) в монтажний отвір, як

показано на малюнку.

• Встановіть глибину свердління, як описано нижче.

16

Page 17

(Переклад оригінальних інструкцій)

УКРАЇНСЬКА

• Затягніть бічну рукоятку, повертаючи затиск за

годинниковою стрілкою.

Установка свердла дрилю або

наконечника шуруповерта в патрон під

ключ (Рис. C)

• Розкрийте затискний патрон, повертаючи втулку (9)

проти годинникової стрілки.

• Вставте хвостовик свердла (8) в патрон.

• Вставляйте ключ (10) в кожен з бічних отворів (11)

затискного патрона і повертайте за годинниковою

стрілкою доти, поки патрон не дійде до упору.

Зняття та повторне встановлення

затискного патрона (Рис. D)

• Максимально розкрийте затискний патрон.

• Викрутіть викруткою гвинт фіксації в затискному

патроні, повертаючи її за годинниковою стрілкою.

• Вставте щільно в патрон торцевий шестигранний

ключ і постукайте по ньому молотком, як показано

на рисунку.

• Вийміть із затискного патрона торцевий

шестигранний ключ.

• Зніміть затискний патрон з дрилю, повертаючи його

проти годинникової стрілки.

• Щоб знову встановити затискний патрон, закрутіть

його на шпинделі та закріпіть його положення

гвинтом фіксації.

Використання

Обережно! Інструмент має працювати зі швидкістю, яка

відповідає його технічним характеристикам. Не

перевантажуйте його.

Обережно! Перед виконанням свердління стін, підлог і

стель перевіряйте розташування електропроводки і

труб.

Вибір напрямку обертання (Рис. E)

Для свердління та закручування шурупів

використовуйте прямий (за годинниковою стрілкою)

напрямок обертання. Для викручування шурупів і

видалення застряглого свердла дрилі використовуйте

зворотний (проти годинникової стрілки) напрямок

обертання.

• Щоб вибрати прямий напрямок обертання,

встановіть рухливий перемикач

прямого/зворотного напрямку обертання (3) в

центральне положення.

• Щоб вибрати зворотний напрямок обертання,

встановіть рухливий перемикач

прямого/зворотного напрямку обертання в ліве

положення.

Обережно! Забороняється змінювати напрямок

обертання дрилі при працюючому двигуні.

Вибір режиму свердління

• Для свердління цегляної кладки встановіть

перемикач режиму свердління (3) в положення .

• Для свердління інших матеріалів та закручування

шурупів встановіть перемикач режиму свердління в

положення .

Задання глибини свердління (Рис. F)

• Послабте бокову ручку (7), повертаючи затиск проти

годинникової стрілки.

• Встановіть необхідне призначення обмежувача

глибини (6). Максимальна глибина свердління

дорівнює відстані між наконечником свердла дрилі і

переднім кінцем обмежувач глибини.

• Затягніть бічну рукоятку, повертаючи затиск за

годинниковою стрілкою.

Вмикання та вимикання

• Щоб ввімкнути інструмент, натисніть перемикач

кількості обертів (1). В інструментах з перемикачем

кількості оборотів швидкість обертання інструменту

залежить від того, якою мірою ви натиснули

(втопили) цей перемикач. В якості загального

правила, при використанні свердла великого

діаметру треба працювати на невеликих оборотах, а

при використанні свердла меншого діаметру треба

підвищувати обороти.

• Для тривалої роботи натисніть кнопку фіксації (2) та

відпустіть перемикач кількості обертів. Ця функція

доступна тільки на повній швидкості обертання. Ця

функція не працює в режимі зворотного обертання.

Функція зворотного напрямку обертання доступна

тільки для моделі HD500.

• Щоб вимкнути інструмент, відпустіть перемикач

кількості обертів. Щоб вимкнути інструмент після

тривалої роботи, ще раз натисніть та відпустіть

перемикач кількості обертів.

17

Page 18

УКРАЇНСЬКА

(Переклад оригінальних інструкцій)

Технічне обслуговування

Запобіжні щитки, вентиляційні отвори і корпус двигуна

повинні бути вільними від пилу і бруду. Витирайте пил і

бруд чистою тканиною та видувайте пил струменем

повітря під низьким тиском. Надмірне накопичення

металевого пилу може призвести до появи

струмопровідних шляхів між внутрішніми деталями

інструменту і зовнішніми металевими деталями.

Важливо! Щоб гарантувати БЕЗПЕКУ та НАДІЙНІСТЬ

інструмента, ремонт, обслуговування та налаштування

(окрім описаних в цій інструкції) повинні проводитись в

авторизованих сервісних центрах або кваліфікованими

працівниками, завжди з використанням ідентичних

запчастин.

Захист навколишнього середовища

Роздільний збір відходів. Забороняється

утилізувати цей продукт разом зі

звичайними побутовими відходами.

Якщо ви вирішите, що ваш виріб BLACK+DECKER

необхідно замінити, або якщо ви не будете його

більше використовувати, не утилізуйте його разом

із побутовими відходами. Цей продукт підлягає

роздільному збору відходів.

Роздільний збір використаних продуктів

та пакувальних матеріалів дозволяє

здійснювати їх вторинну переробку з

подальшим повторним використанням.

Використання матеріалів, що пройшли вторинну

переробку, знижує забруднення навколишнього

середовища та зменшує потребу в сировинних

матеріалах.

Нормативні акти місцевих органів влади можуть

передбачати збір використаних електричних

виробів окремо від побутових відходів, в

муніципальних пунктах збору відходів або в

магазині при покупці нового обладнання.

Компанія BLACK+DECKER надає можливість для

збору та повторної переробки продуктів

BLACK+DECKER після закінчення терміну їх

служби. Щоб скористатися перевагою цього

сервісу, будь ласка, надішліть ваш продукт

будь-якому уповноваженому представнику з

ремонту, який збирає такі вироби від нашого

імені.

Ви можете дізнатися адресу нашого найближчого

уповноваженого представника з ремонту,

зателефонувавши в регіональне представництво

BLACK+DECKER, вказане в цій інструкції. Крім того,

список уповноважених представників з ремонту

BLACK+DECKER, детальну інформацію про

обслуговування після продажу та контактні дані

можна знайти на сайті: www.2helpU.com.

Приладдя

Придбання аксесуарів для вашого інструменту можливе

у вашого місцевого дилера або в авторизованому

сервісному центрі.

Інформація з обслуговування

BLACK+DECKER пропонує широку мережу

авторизованих сервісних центрів, якими володіє

компанія. Всі сервісні центри BLACK+DECKER

укомплектовані навченим персоналом, який виконує

ефективне і надійне сервісне обслуговування власників

електричних інструментів. Для отримання більш

докладної інформації про авторизовані сервісні центри,

щоб отримати технічну пораду та з'ясувати питання

ремонту й оригінальних запасних частин, зверніться до

найближчого представництва BLACK+DECKER або

завітайте на наш сайт www.blackanddecker.com

Технічні характеристики

HD555 / HD565

Потужність 550 Вт

Напруга 220-240

50-60 Гц

Швидкість холостого ходу 0 – 2800 об./хв.

Ударів за хвилину 45 000

Найбільший діаметр свердління

Сталь 1/2” (13 мм)

Бетон 1/2” (13 мм)

Дерево 25/32” (20 мм)

18

Page 19

(Переклад оригінальних інструкцій)

Гарантійні умови

Шановний покупець!

1. Вітаємо Вас з покупкою високоякісного виробу

BLACK + DECKER і висловлюємо вдячність за Ваш

вибір.

2. При покупці виробу вимагайте перевірки його

комплектності і справності у Вашій присутності,

інструкцію з експлуатації та заповнений гарантійний

талон українською мовою

В гарантійному талоні повинні бути внесені: модель,

дата продажу, серійний номер, дата виробництва

інструменту; назва, печатка і підпис торгової

організації. За відсутності у Вас правильно

заповненого гарантійного талону, а також при

невідповідності зазначених у ньому даних ми

будемо змушені відхилити Ваші претензії щодо

якості даного виробу.

3. Щоб уникнути непорозумінь, переконливо просимо

Вас перед початком роботи з виробом уважно

ознайомитися з інструкцією з його експлуатації.

Правовою основою справжніх гарантійних умов є

чинне Законодавство. Гарантійний термін на даний

виріб складає 24 місяці і обчислюється з дня

продажу. У разі усунення недоліків виробу,

гарантійний строк продовжується на період його

перебування в ремонті. Термін служби виробу

становить 5 років з дня продажу.

4. У разі виникнення будь-яких проблем у процесі

експлуатації виробу рекомендуємо Вам звертатися

тільки в уповноважені сервісні центри BLACK +

DECKER, адреси та телефони яких Ви зможете

знайти в гарантійному талоні, на сайті

www.2helpU.com або дізнатися в магазині. Наші

сервісні станції - це не тільки кваліфікований

ремонт, але і широкий асортимент запчастин і

аксесуарів.

5. Виробник рекомендує проводити періодичну

перевірку і технічне обслуговування виробу в

уповноважених сервісних центрах.

6. Наші гарантійні зобов'язання поширюються тільки

на несправності, виявлені протягом гарантійного

терміну і викликані дефектами виробництва та \ або

матеріалів.

7. Гарантійні умови не поширюються на несправності

виробу, що виникли в результаті:

7.1 Недотримання користувачем приписів інструкції з

експлуатації виробу, застосування виробу не за

призначенням, неправильного зберігання,

використання приладдя, витратних матеріалів і

запчастин, що не передбачені виробником.

УКРАЇНСЬКА

7.2 Механічного пошкодження (відколи, тріщини і

руйнування) внутрішніх і зовнішніх деталей виробу,

основних і допоміжних рукояток, мережевого

кабелю, що викликані зовнішнім ударним або

будь-яким іншим впливом

7.3 Потрапляння у вентиляційні отвори та проникнення

всередину виробу сторонніх предметів, матеріалів

або речовин, що не є відходами, які супроводжують

застосування виробу за призначенням, такими як:

стружка, тирса, пісок, та ін.

7.4 Впливу на виріб несприятливих атмосферних і

інших зовнішніх факторів, таких як дощ, сніг,

підвищена вологість, нагрівання, агресивні

середовища, невідповідність параметрів

електромережі, що зазначені на інструменті.

7.5 Стихійного лиха. Пошкодження або втрати виробу,

що пов'язані з непередбаченими лихами,

стихійними явищами, у тому числі внаслідок дії

непереборної сили (пожежа, блискавка, потоп і інші

природні явища), а також внаслідок перепадів

напруги в електромережі та іншими причинами, які

знаходяться поза контролем виробника.

8. Гарантійні умови не поширюються:

8.1. На інструменти, що піддавались розкриттю, ремонту

або модифікації поза уповноваженим сервісним

центром.

8.2. На деталі, вузли та матеріали, що мають сліди

природного зносу, такі як: приводні ремені і колеса,

вугільні щітки, мастило, підшипники, зубчасті

зчеплення редукторів, гумові ущільнення, сальники,

направляючі ролики, муфти, вимикачі, бойки,

штовхачі, стволи тощо.

8.3. На змінні частини: патрони, цанги, затискні гайки і

фланці, фільтри, акумуляторні батареї, ножі,

шліфувальні підошви, ланцюги, зірочки, пильні

шини, захисні кожухи, пилки, абразиви, пильні і

абразивні диски, фрези, свердла, бури тощо

8.4. На несправності, що виникли в результаті

перевантаження інструменту (як механічного, так і

електричного), що спричинили вихід з ладу

одночасно двох і більше деталей і вузлів, таких як:

ротора і статора, обох обмоток статора, веденої і

ведучої шестерень редуктора або інших вузлів і

деталей. До безумовних ознак перевантаження

виробу відносяться, крім інших: поява кольорів

мінливості, деформація або оплавлення деталей і

вузлів виробу, потемніння або обвуглювання

ізоляції проводів електродвигуна під впливом

високої температури.

Виробник:

"Stanley BLACK+DECKER Deutschland

GmbH" Black-&-Decker Str.40, D-65510

Idstein, Німеччина

19

Page 20

09.2017

Loading...

Loading...