Page 1

ENRUUATR

www.blackanddecker.ru

G850

Page 2

ENGLISH

(Original instructions)

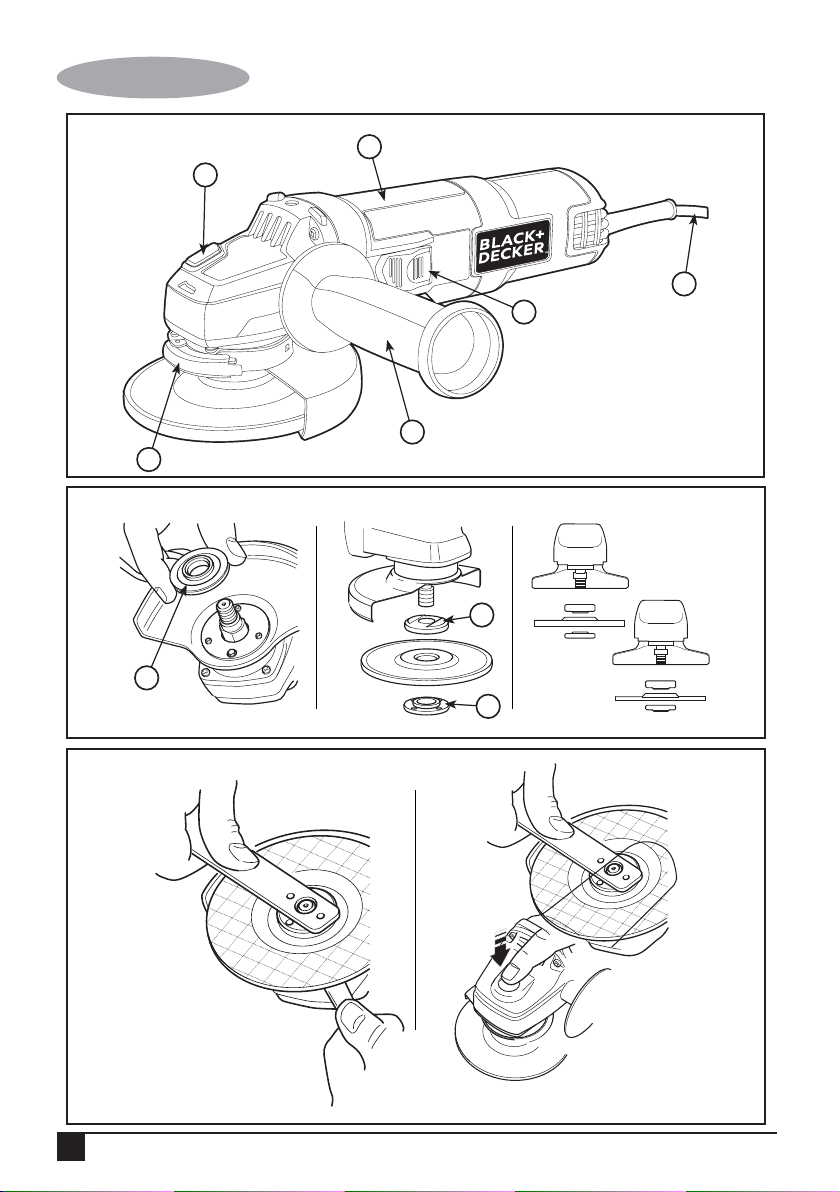

FIG. A

FIG. B

4

6

2

1

5

3

8

7

9

2

FIG. C

Page 3

FIG. D

FIG. E

(Original instructions)

ENGLISH

3

Page 4

ENGLISH

(Original instructions)

Intended use

Your BLACK+DECKER™ G850 angle grinder

has been designed for cutting metal and

masonry using the appropriate type of

cutting or grinding disc. This tool is

intended for consumer use only.

Safety instructions

General power tool safety warnings

Warning! Read all safety

warnings and all instructions.

Failure to follow the warnings and

instructions listed below may

result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in all of the warnings

listed below refers to your mains operated

(corded) power tool or battery operated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

b. Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

d. Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e. When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3. Personal safety

a. Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool

while you are tired or under the

influence of drugs, alcohol or

medication. A moment of inattention

while operating power tools may result in

serious personal injury.

b. Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure

the switch is in the o-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your

finger on the switch or energising power

tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

4

Page 5

(Original instructions)

ENGLISH

e. Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f. Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

4. Power tool use and care

a. Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b. Do not use the power tool if the switch

does not turn it on and o. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

c. Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive

safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e. Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may aect the power

tools operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g. Use the power tool, accessories and tool

bits etc., in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations dierent from those intended

could result in a hazardous situation.

5. Service

a. Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

Additional power tool safety

warnings

Warning! Additional safety

warnings for grinding, sanding, wire

brushing, polishing or abrasive

cutting-o operations

• This power tool is intended to function

as a grinder, sander, wire brush, polisher

or cut-o tool. Read all safety warnings,

instructions, illustrations and

specifications provided with this power

tool. Failure to follow all instructions

listed below may result in electric shock,

fire and/or serious injury.

• Operations for which the power tool was

not designed may create a hazard and

cause personal injury.

• Do not use accessories which are not

specifically designed and recommended

by the tool manufacturer. Just because

the accessory can be attached to your

power tool, it does not assure safe

operation.

• The rated speed of the accessory must

be at least equal to the maximum speed

marked on the power tool. Accessories

running faster than their rated speed can

break and fly apart.

• The outside diameter and the thickness

of your accessory must be within the

capacity rating of your power tool.

Incorrectly sized accessories cannot be

adequately guarded or controlled.

5

Page 6

ENGLISH

(Original instructions)

• The arbour size of wheels, flanges,

backing pads or any other accessory

must properly fit the spindle of the

power tool. Accessories with arbour

holes that do not match the mounting

hardware of the power tool will run out

of balance, vibrate excessively and may

cause loss of control.

• Do not use a damaged accessory.

Before each use inspect the accessory

such as abrasive wheels for chips and

cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or

cracked wires. If power tool or

accessory is dropped, inspect for

damage or install an undamaged

accessory. After inspecting and

installing an accessory and run the

power tool at maximum no-load speed

for one minute. Damaged accessories

will normally break apart during this test

time.

• Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye

protection must be capable of stopping

flying debris generated by various

operations. The dust mask or respirator

must be capable of filtering particles

generated by your operation. Prolonged

exposure to high intensity noise may

cause hearing loss.

• Keep bystanders a safe distance away

from work area. Anyone entering the

work area must wear personal

protective equipment. Fragments of

workpiece or of a broken accessory may

fly away and cause injury beyond

immediate area of operation.

• Hold power tool by insulated gripping

surfaces only, when performing an

operation where the cutting accessory

may contact hidden wiring or its own

cord. Cutting accessory contacting a

"live" wire may make exposed metal

parts of the power tool "live" and shock

the operator.

• Position the cord clear of the spinning

accessory. If you lose control, the cord

may be cut or snagged and your hand or

arm may be pulled into the spinning

accessory.

• Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the

surface and pull the power tool out of

your control.

• Do not run the power tool while carrying

it at your side. Accidental contact with

the spinning accessory could snag your

clothing, pulling the accessory into your

body.

• Regularly clean the power tool's air

vents. The motor's fan will draw the dust

inside the housing and excessive

accumulation of powdered metal may

cause electrical hazards.

• Do not operate the power tool near

flammable materials. Sparks could ignite

these materials.

• Do not use accessories that require

liquid coolants. Using water or other

liquid coolants may result in electrocution

or shock.

Note: The above warning does not apply for

power tools specifically designed for use

with a liquid system.

Kickback and related warnings

Kickback is a sudden reaction to a pinched

or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching or

snagging causes rapid stalling of the

rotating accessory which in turn causes the

uncontrolled power tool to be forced in the

direction opposite of the accessory's

rotation at the point of the binding.

For example, if an abrasive wheel is snagged

or pinched by the workpiece, the edge of

the wheel that is entering into the pinch

point can dig into the surface of the material

causing the wheel to climb out or kick out.

The wheel may either jump toward or away

from the operator, depending on direction of

the wheel's movement at the point of

pinching. Abrasive wheels may also break

under these conditions.

6

Page 7

(Original instructions)

ENGLISH

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

• Maintain a firm grip on the power tool

and position your body and arm to

allow you to resist kickback forces.

Always use auxiliary handle, if provided,

for maximum control over kickback or

torque reaction during start-up. The

operator can control torque reactions or

kickback forces, if proper precautions are

taken.

• Never place your hand near the rotating

accessory. Accessory may kickback over

your hand.

• Do not position your body in the area

where power tool will move if kickback

occurs. Kickback will propel the tool in

direction opposite to the wheel's

movement at the point of snagging.

• Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to

snag the rotating accessory and cause

loss of control or kickback.

• Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of

control.

Safety warnings specific for

grinding and abrasive cutting-o

operations

• Use only wheel types that are

recommended for your power tool and

the specific guard designed for the

selected wheel. Wheels for which the

power tool was not designed cannot be

adequately guarded and are unsafe.

• The grinding surface of centre

depressed wheels must be mounted

below the plane of the guard lip. An

improperly mounted wheel that projects

through the plane of the guard lip cannot

be adequately protected.

• The guard must be securely attached to

the power tool and positioned for

maximum safety, so the least amount of

wheel is exposed towards the operator.

The guard helps to protect operator from

broken wheel fragments and accidental

contact with wheel.

• Wheels must be used only for

recommended applications. For

example: do not grind with the side of

cut-o wheel. Abrasive cut-o wheels

are intended for peripheral grinding, side

forces applied to these wheels may cause

them to shatter.

• Always use undamaged wheel flanges

that are of correct size and shape for

your selected wheel. Proper wheel

flanges support the wheel thus reducing

the possibility of wheel breakage. Flanges

for cut-o wheels may be dierent from

grinding wheel flanges.

• Do not use worn down wheels from

larger power tools. Wheel intended for

larger power tool is not suitable for the

higher speed of a smaller tool and may

burst.

Additional safety warnings specific

for abrasive cutting-o operations

• Do not "jam" the cut-off wheel or apply

excessive pressure. Do not attempt to

make an excessive depth of cut. Over

stressing the wheel increases the loading

and susceptibility to twisting or binding

of the wheel in the cut and the possibility

of kickback or wheel breakage.

• Do not position your body in line with

and behind the rotating wheel. When the

wheel, at the point of operation, is

moving away from your body, the

possible kickback may propel the

spinning wheel and the power tool

directly at you.

• When wheel is binding or when

interrupting a cut for any reason, switch

o the power tool and hold the power

tool motionless until the wheel comes to

a complete stop. Never attempt to

remove the cut-o wheel from the cut

while the wheel is in motion otherwise

kickback may occur. Investigate and take

corrective action to eliminate the cause of

wheel binding.

7

Page 8

ENGLISH

(Original instructions)

• Do not restart the cutting operation in

the workpiece. Let the wheel reach full

speed and carefully re-enter the cut.

The wheel may bind, walk up or kickback

if the power tool is restarted in the

workpiece

• Support panels or any oversized

workpiece to minimize the risk of wheel

pinching and kickback. Large

workpieces tend to sag under their own

weight. Supports must be placed under

the workpiece near the line of cut and

near the edge of the workpiece on both

sides of the wheel..

• Use extra caution when making a

"pocket cut" into existing walls or other

blind areas. The protruding wheel may

cut gas or water pipes, electrical wiring

or objects that can cause kickback.

Safety warnings specific for

sanding operations

• Do not use excessively oversized

sanding disc paper. Follow

manufacturers recommendations, when

selecting sanding paper. Larger sanding

paper extending beyond the sanding pad

presents a laceration hazard and may

cause snagging, tearing of the disc or

kickback.

Safety warnings specific for

polishing operations

• Do not allow any loose portion of the

polishing bonnet or its attachment

strings to spin freely. Tuck away or trim

any loose attachment strings. Loose and

spinning attachment strings can entangle

your fingers or snag on the workpiece.

Safety of others

• This appliance is not intended for use by

persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use

of the appliance by a person responsible

for their safety.

• Children should be supervised to ensure

that they do not play with the appliance.

Residual risks.

Additional residual risks may arise when

using the tool which may not be included in

the enclosed safety warnings. These risks

can arise from misuse, prolonged use etc.

Even with the application of the relevant

safety regulations and the implementation of

safety devices, certain residual risks can not

be avoided. These include:

• Injuries caused by touching any

rotating/ moving parts.

• Injuries caused when changing any parts,

blades or accessories.

• Injuries caused by prolonged use of a

tool. When using any tool for prolonged

periods ensure you take regular breaks.

• Impairment of hearing.

• Health hazards caused by breathing dust

developed when using your tool

(example:- working with wood,

especially oak, beech and MDF.)

Vibration

The declared vibration emission values

stated in the technical data and the

declaration of conformity have been

measured in accordance with a standard test

method provided by EN 60745 and may be

used for comparing one tool with another.

The declared vibration emission value may

also be used in a preliminary assessment of

exposure.

Warning! The vibration emission value during

actual use of the power tool can dier from

the declared value depending on the ways in

which the tool is used. The vibration level

may increase above the level stated.

When assessing vibration exposure to

determine safety measures required by

2002/44/EC to protect persons regularly

using power tools in employment, an

estimation of vibration exposure should

consider, the actual conditions of use and

the way the tool is used, including taking

account of all parts of the operating cycle

such as the times when the tool is switched

o and when it is running idle in addition to

the trigger time.

8

Page 9

(Original instructions)

ENGLISH

Labels on tool

The following pictograms are shown on the

tool:

Warning! To reduce the risk of

injury, the user must read the

instruction manual.

Wear safety glasses or goggles

when operating this tool.

Wear ear protection when operating

this tool.

Electrical safety

This tool is double insulated;

therefore no earth wire is required.

Always check that the power supply

corresponds to the voltage on the

rating plate.

• If the supply cord is damaged, it must be

replaced by the manufacturer or an

authorised BLACK+DECKER Service

Centre in order to avoid a hazard.

Features (Fig. A)

1. Slider switch

2. Cable

3. Tool free guard

4. Body grip

5. Side handle (2 positions)

6. Spindle lock button

Operation

Operating your angle grinder (Fig. A)

To switch on, push the slider switch forward

(1). To switch o, press the rear of the slider

switch.

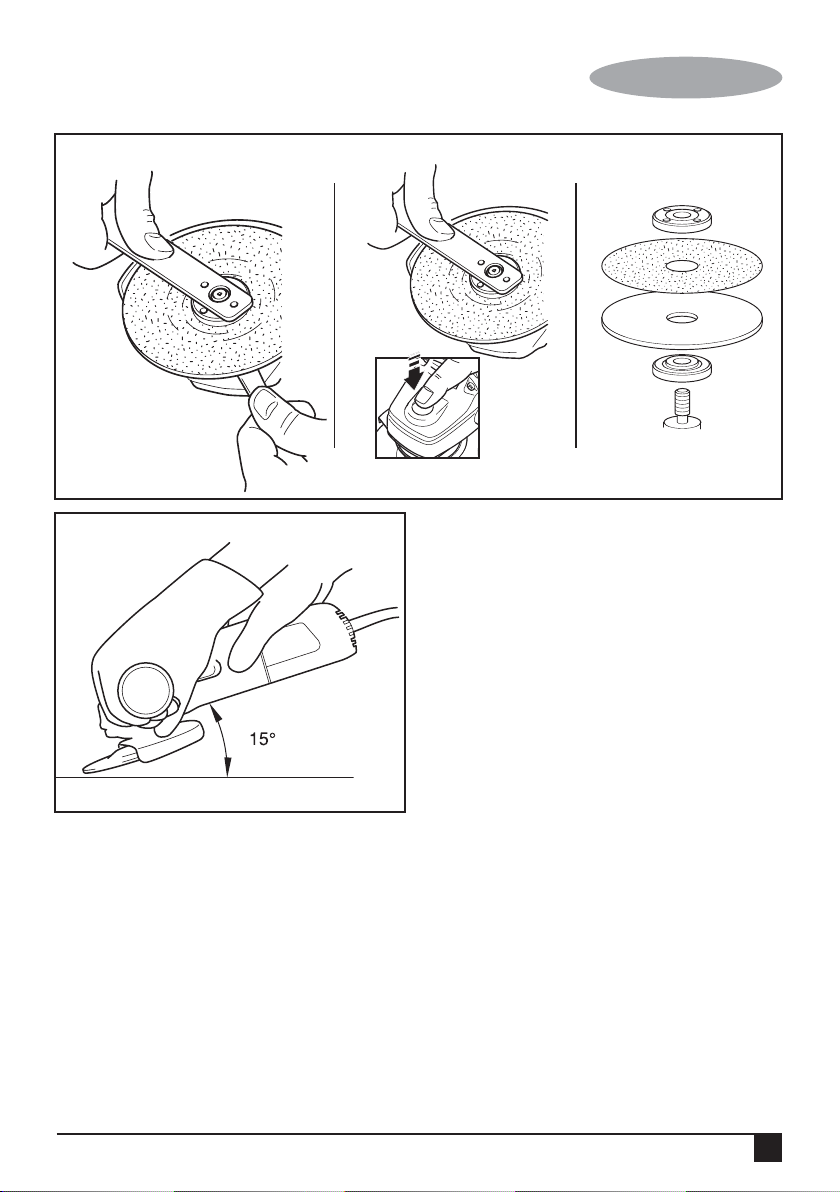

Fittingthe discs (Fig. B and C)

Proceed as follows:

• Disconnect the plug from the electricity

supply.

• Ensure the guard is fitted. Place the inner

flange (7) on the spindle. Ensure it is

located on the two flats.

• Place the abrasive disc on the spindle and

inner flange (8). Ensure it is correctly

located.

• Fit the threaded outer flange (9), making

sure it is facing in the correct direction for

the type of disc fitted. For grinding discs,

the flange (9) is fitted with the raised

portion facing towards the disc. For

cutting discs, the flange (9) is fitted with

the inner portion facing away from the

disc.

• Hold the spanner on the flats of the

spindle to prevent rotation of the disc

and tighten the outer flange with the

spanner provided.

• Press in the spindle lock button and

rotate the spindle until it locks (Fig. C).

Keeping the lock button pressed in,

tighten the outer flange with the spanner

provided.

Fitting sanding discs (fig. D)

• Use a sanding disc with the backing pad

for sanding with your angle grinder.

• Disconnect the plug from the electricity

supply.

• Remove the guard.

• Place the flange on the spindle. Place the

backing pad on the spindle and inner

flange, ensuring it is correctly located.

• Mount the fibre backed abrasive disc on

the backing pad.

• Fit the threaded outer flange and tighten

as explained in ‘Fitting the discs’.

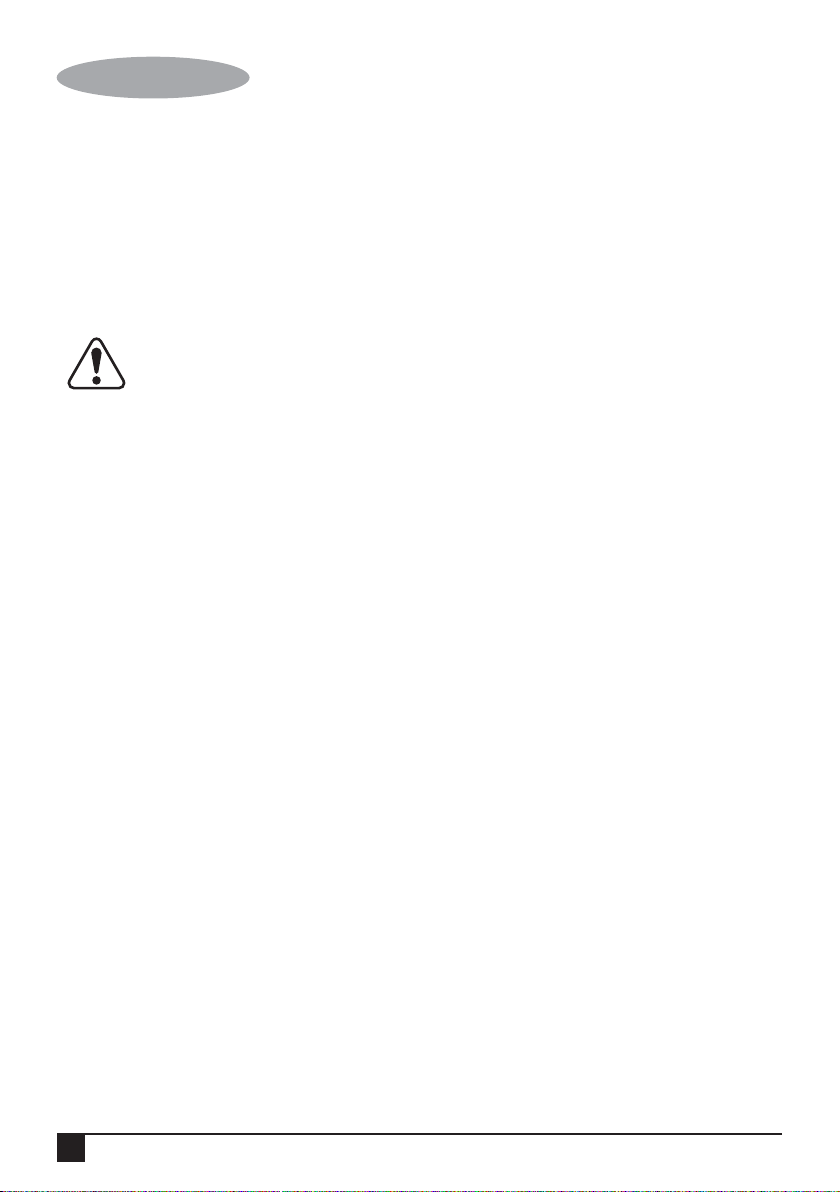

Handy hints (Fig. E)

Hold your angle grinder firmly with one hand

around the side handle and the other around

the body of your angle grinder.

• Always position the guard so that as

much of the exposed disc as possible is

pointing away from you.

• Be prepared for a stream of sparks when

the disc touches the metal.

9

Page 10

ENGLISH

(Original instructions)

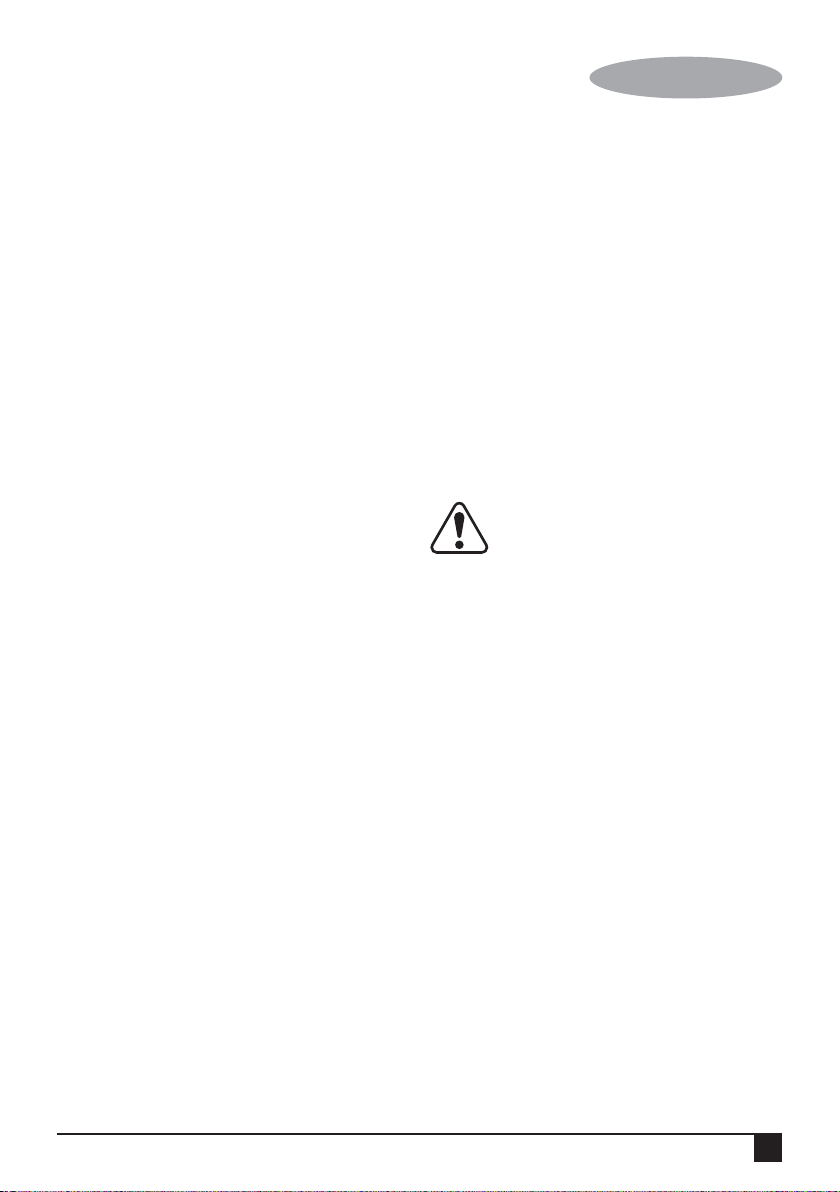

When grinding, always maintain the correct

angle between the disc and the work

surface (15°)(Fig. D). This increases the

removal capacity of the disc and avoids

unnecessary overloading.

Overload

Overloading will cause damage to the

motor of your angle grinder. This can

happen if your angle grinder is subjected to

heavy duty use for prolonged periods of

use. Do not in any circumstances, attempt

to exert too much pressure on your angle

grinder to speed up your work. The abrasive

discs operate more eciently when a light

pressure is exerted, thus avoiding a drop in

the speed of your angle grinder.

Maintenance

Keep guards, air vents and the motor

housing as clear as possible of dust and dirt.

Wipe with a clean cloth and blow through

with a low-pressure air supply. Excessive

build-up of metal dust can cause tracking of

electrical current from the internal parts to

exposed metal parts. Do not overload your

angle grinder. Overloading causes a

reduction in speed and eciency, causing

your angle grinder to become too hot. If this

happens, operate your angle grinder under

no load for one or two minutes until it has

cooled to normal operating temperature.

Switching your angle grinder o under load

will reduce the life of the switch.

Protecting the environment

Separate collection. This product

must not be disposed of with normal

household waste.

Should you find one day that your

BLACK+DECKER product needs replacement, or if it is of no further use to you, do

not dispose of it with household waste.

Make this product available for separate

collection.

Separate collection of used products

and packaging allows materials to be

recycled and used again. Reuse of

recycled materials helps prevent environmental pollution and reduces the demand

for raw materials.

Local regulations may provide for separate

collection of electrical products from the

household, at municipal waste sites or by

the retailer when you purchase a new

product.

BLACK+DECKER provides a facility for the

collection and recycling of BLACK+DECKER

products once they have reached the end of

their working life. To take advantage of this

service please return your product to any

authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your

local BLACK+DECKER oce at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair

agents and full details of our after-sales

service and contacts are available on the

Internet at: www.2helpU.com.

Cleaning

Use only mild soap and a slightly damp

cloth to clean your angle grinder. Many

household cleaners contain chemicals which

could seriously damage the plastic. Also, do

not use petrol, turpentine, lacquer or paint

thinners or similar products. Never let any

liquid get inside the tool and never immerse

any part of the tool into liquid.

Important! To assure product SAFETY and

RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this

manual) should be performed by authorized

service centers or other qualified service

personnel, always using identical

replacement parts.

TECHNICAL DATA

G850

Power W 850

Voltage V 220-240

Frequency Hz 50/60

Disc diameter mm 125

No load speed min

Spindle size M14

Cable length m 2

-1

12000 (RPM)

10

Page 11

Guarantee

BLACK+DECKER is confident of the quality

of its products and oers an outstanding

guarantee. This guarantee statement is in

addition to and in no way prejudices your

statutory rights.

If a BLACK+DECKER product becomes

defective due to faulty materials,

workmanship or lack of conformity, within

24 months from the date of purchase,

BLACK+DECKER guarantees to replace

defective parts, repair products subjected

to fair wear and tear or replace such

products to make sure of the minimum

inconvenience to the customer unless:

• The product has been used for trade,

professional or hire purposes.

• The product has been subjected to

misuse or neglect.

• The product has sustained damage

through foreign objects, substances or

accidents.

• Repairs have been attempted by persons

other than authorised repair agents or

BLACK+DECKER service sta.

(Original instructions)

ENGLISH

To claim on the guarantee, you will need to

submit proof of purchase to the seller or an

authorised repair agent. You can check the

location of your nearest authorised repair

agent by contacting your local

BLACK+DECKER oce at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair

agents and full details of our aftersales

service and contacts are available on the

Internet at: www.2helpU.com

11

Page 12

РУССКИЙ

(Перевод с оригинала инструкции)

Назначение

Эти угловые шлифовальные машины производства

BLACK+DECKER™ G850 были разработаны для

шлифования, резки металла и камня.

Перед тем как вернуть это изделие,

сначала свяжитесь с региональным

представительством BLACK+DECKER или в ближайший

авторизованный сервисный центр.

Общие правила техники безопасности

Внимание! Внимательно изучите все

указания по технике безопасности.

Несоблюдение указаний по безопасной

работе может привести к поражению

электрическим током, пожару и/или

серьезным травмам персонала.

Сохраните эти инструкции

Указания по технике безопасности

Общие указания по безопасной работе с

электрическим инструментом.

Внимание! Внимательно прочитайте все

предупреждающие надписи и указания по

безопасной работе. Несоблюдение предупреждающих

надписей и указаний по безопасной работе может

привести к поражению электрическим током, пожару

и/или серьезным травмам персонала.

Храните все предупреждающие надписи и указания

по безопасной работе для использования в

будущем.

Термин «электрический инструмент», используемый во

всех предупреждающих надписях и указаниях по

технике безопасности, представленных ниже,

относится к электрическому инструменту,

работающему от сети (со шнуром электропитания) или

от аккумуляторной батареи (без шнура питания).

1. Указания по безопасности на рабочем месте

a. Рабочее место должно содержаться в чистоте и

должно быть оборудовано надлежащим

освещением. Беспорядок или плохое освещение

на рабочем месте может привести к несчастному

случаю.

b. Запрещается использование электрического

инструмента во взрывоопасной среде,

например, в условиях наличия

легковоспламеняющихся жидкостей, газов или

пыли. Искры, возникающие при работе

электрического инструмента, могут воспламенить

пыль, пары и газы.

c. Запрещается нахождение детей и посторонних

лиц вблизи работающего электрического

инструмента. Отвлекающие факторы могут

привести к потере контроля за работой

инструмента.

2. Электрическая безопасность

a. Вилка шнура электрического инструмента

должна соответствовать сетевой розетке.

Запрещается вносить какие-либо изменения в

вилку электрического шнура. Запрещается

использование каких-либо штепсельных

переходников при работе заземленного

электрического инструмента. Отсутствие

изменений в вилках электрических шнуров и

соответствие электрических вилок и розеток

снижает риск поражения электрическим током.

b. Не допускайте контакта тела с заземленными

поверхностями таких объектов, как трубы,

радиаторы, электроплиты и холодильники. Если

ваше тело заземлено, риск его поражения

электрическим током повышается.

c. Электрические инструменты не должны

подвергаться воздействию дождя и находится в

условиях повышенной влажности. При попадании

влаги внутрь электрического инструмента

повышается риск поражения электрическим током.

d. Запрещается использовать электрический шнур

не по назначению. Никогда не берите, не тяните

и не вынимайте электрический инструмент за

шнур. Электрический шнур не должен

находиться вблизи источников тепла, масла,

острых краев и движущихся деталей.

Поврежденные и закрученные электрические

шнуры повышают риск поражения электрическим

током.

e. При работе электрического инструмента на

открытом воздухе используйте

соответствующий удлинитель. Использование

удлинителя, предназначенного для работы на

открытом воздухе, снижает риск поражения

электрическим током.

f. Если работы с помощью электрического

инструмента внутри влажного помещения

должны быть выполнены обязательно, в таком

случае необходимо использовать устройство

защитного отключения (УЗО) электрической

сети. Использование УЗО снижает риск поражения

электрическим током. Примечание: Термин

«устройство защитного отключения (УЗО)» может

быть заменен термином «выключатель короткого

замыкания на землю (ВКЗЗ)» или термином

«автоматический выключатель утечки на землю

(АВУЗ)».

12

Page 13

(Перевод с оригинала инструкции)

РУССКИЙ

3. Безопасность персонала

a. При работе с электрическим инструментом

необходимо быть осмотрительным, видеть

выполняемую работу и руководствоваться

здравым смыслом. Запрещается работать с

электрическим инструментом в состоянии

усталости и под воздействием наркотиков,

алкоголя и лекарственных препаратов.

Ослабление внимания даже на мгновение может

привести к серьезной травме.

b. Используйте средства индивидуальной защиты.

Всегда надевайте средства защиты глаз.

Используемые в соответствующих условиях

средства индивидуальной защиты, такие как

пылезащитная маска, нескользящая защитная

обувь, защитная каска или средства защиты

органов слуха. всегда снижают риск

травмирования.

c. Не допускайте непреднамеренного включения

инструмента. Перед тем, так подключить

источник питания или аккумулятор, поднимая

или неся инструмент, проверьте, чтобы его

выключатель находился в выключенном

положении. Переноска инструмента пальцем,

расположенном на его выключателе, или

включенного инструмента повышает риск

несчастного случая.

d. Перед включением инструмента всегда

снимайте с него регулировочный и гаечный

ключ. Оставленный на вращающейся детали

инструмента ключ может привести к

травмированию.

e. Не прикладывайте к инструменту чрезмерное

усилие во время работы. Всегда прочно

держитесь на ногах и сохраняйте равновесие во

время работы. Это позволяет лучше

контролировать электрический инструмент в

непредвиденных ситуациях.

f. Надевайте соответствующую одежду.

Запрещается надевать свободную одежду и

украшения. Волосы, одежда и перчатки должны

находиться на расстоянии от движущихся

деталей инструмента. Свободная одежда,

украшения или длинные волосы могут быть

захвачены движущимися деталями.

g. Если установлены устройства подключения

средств пылеулавливания и пылесборников,

необходимо проверять, чтобы они были

подключены и использовались надлежащим

образом. Использование средств

пылеулавливания снижает уровень риска,

связанного с наличием пыли в воздухе.

4. Использование и уход за электрическим

инструментом

a. Не прикладывайте чрезмерное усилие к

электрическому инструменту. Используйте

электрический инструмент, соответствующий

выполняемой задаче. При использовании

надлежащего инструмента вы выполните работу

лучше, с меньшим риском и со скоростью, на

которую рассчитан ваш инструмент.

b. Запрещается использовать инструмент, если его

выключатель не включается и не выключается.

Любой электрический инструмент, работой которого

нельзя управлять с помощью его выключателя,

представляет собой опасность и подлежит

обязательному ремонту.

c. Перед выполнением регулировки

электрического инструмента, заменой его

принадлежностей и постановкой на хранение

необходимо вынуть вилку его электрического

шнура из розетки и/или достать из него

аккумулятор. Такая превентивная мера

безопасности снижает риск случайного включения

инструмента.

d. Храните электрический инструмент, который в

данный момент не используется, в недоступном

для детей месте и разрешайте работать с

инструментом лицам, которые не знакомы с ним

или с этими указаниями. Электрический

инструмент является опасным в руках необученного

человека.

e. Поддерживайте инструмент в рабочем

состоянии. Проверяйте центровку и соединение

движущихся деталей, наличие поврежденных

деталей и любые факторы, которые могут

отрицательно сказаться на работе

электрического инструмента. В случае

обнаружения повреждения электрический

инструмент необходимо отремонтировать.

Много несчастных случае происходит вследствие

того, что инструмент находится в ненадлежащем

состоянии.

f. Режущие инструменты должны быть остро

заточенными и чистыми. Поддерживаемый в

надлежащем рабочем состоянии режущий

инструмент с острыми режущими кромками меньше

застревает и легче управляется.

g. Используйте электрический инструмент,

принадлежности, вставные резцы и т.д. в

соответствии с данными указаниями, учитывая

условия эксплуатации и работу, которая должна

быть выполнена. Использование электрического

инструмента с целью, отличной от

предусмотренного назначения, может привести к

опасной ситуации.

13

Page 14

РУССКИЙ

(Перевод с оригинала инструкции)

5. Обслуживание

a. Обслуживать электрический инструмент

должен только квалифицированный ремонтный

персонал, при этом должны использоваться

только оригинальные запасные детали.

Благодаря этому будет поддерживаться безопасное

рабочее состояние электрического инструмента.

Дополнительные специальные правила

техники безопасности

Указания по безопасному выполнению всех

операций

Меры предосторожности, общие для всех операций

шлифовки

a) Это электрический инструмент предназначен

для использования в качестве шлифовальной

машины. Внимательно изучите все

предупреждающие знаки, указания по

безопасной работе, графические материалы и

технические описания, прилагаемые к данному

электрическому инструменту. Несоблюдение

указаний по безопасной работе может привести к

поражению электрическим током, пожару и/или

серьезным травмам персонала.

b) С помощью этого электрического инструмента

не рекомендуется выполнять такие операции,

как резка, пескоструйная обработка, обработка

проволочной щеткой и полировка. Операции, на

которые не рассчитана конструкция этого

электрического инструмента, могут привести к

возникновению аварийной ситуации и травмам

персонала.

c) Не используйте принадлежности, которые не

были разработаны и не рекомендованы

производителем инструмента. Если

принадлежность можно установить на ваш

инструмент, это еще не является гарантией

безопасной работы.

d) Номинальная скорость принадлежности должна

быть по меньшей мере равной максимальной

скорости, указанной на электрическом

инструменте. Принадлежность, работающая со

скоростью, превышающей свою номинальную

скорость, может разрушиться и разлететься в

стороны.

e) Внешний диаметр и толщина принадлежности

должны лежать в пределах характеристик

вашего электрического инструмента.

Принадлежности неправильного размера не могут

быть надлежащим образом защищены

предохранительным щитком, и их работу

невозможно нормально контролировать.

f) Осевой размер колес, фланцев, подошв дисков и

других принадлежностей должен точно

совпадать с размером шпинделя электрического

инструмента. Принадлежности с осевыми

отверстиями, не совпадающими с элементами

крепления электрического инструмента, будут

разбалансированными, будут испытывать

чрезмерные вибрации и могут стать причиной

потери контроля за инструментом.

g) Запрещается использовать поврежденные

принадлежности. Перед началом работы всегда

проверяйте принадлежность, такую как

шлифовальный круг, на наличие сколов и

трещин, подошву на наличие трещин, дыр и

чрезмерного износа и проволочную щетку на

наличие обломанной проволоки. В случае

падения электрического инструмента или

принадлежности проверьте их на наличие

повреждений или замените поврежденную

принадлежность. После проверки и установки

принадлежности весь персонал должен уйти в

сторону от плоскости вращения

принадлежности, а затем необходимо включить

электрический инструмент на максимальную

скорость холостого хода без нагрузки.

Поврежденные принадлежности за это время

обычно разлетаются.

h) Используйте средства индивидуальной защиты.

В зависимости от способа использования,

используйте лицевой щиток, открытие или

закрытые защитные очки. В случае

необходимости надевайте пылезащитную маску,

средства защиты органов слуха, защитные

перчатки и рабочий фартук, способные

остановить мелкие абразивные частицы или

осколки рабочей детали. Средство защиты глаз

должно останавливать разлетающиеся частицы,

которые появляются во время работы.

Пылезащитная маска или респиратор должны

отфильтровывать частицы, которые появляются во

время работы. Продолжительное воздействие шума

высокого уровня может привести к ухудшению

слуха.

i) Другие лица должны находиться на безопасном

расстоянии от рабочей зоны. Любые лица,

входящие в рабочую зону, должны использовать

средства индивидуальной защиты. Осколки

рабочей детали или разрушенной принадлежности

могут разлетаться и стать причиной травмирования

персонала за пределами непосредственной зоны

работы.

14

Page 15

(Перевод с оригинала инструкции)

РУССКИЙ

j) Во время выполнения работ, когда режущая

деталь электрического инструмента может

соприкасаться со скрытой электропроводкой

или со своим шнуром, инструмент необходимо

держать только за диэлектрическую

поверхность. При контакте режущей детали с

проводом, находящимся под напряжением, под

напряжение могут попасть металлические детали

электрического инструмента, вследствие чего

возникает опасность поражения оператора

электрическим током.

k) Шнур электропитания должен находиться на

максимальном удалении от вращающейся

принадлежности. В случае потери контроля шнур

может быть перерезан, или с него может быть

ободрана изоляция, и ваша рука или ладонь может

быть втянута во вращающуюся принадлежность.

l) Запрещается ложить инструмент до тех пор,

пока полностью не остановится

принадлежность. Вращающаяся принадлежность

может захватить часть поверхности, в результате

чего инструмент выйдет из-под вашего контроля.

m) Инструмент не должен работать, если вы

держите его сбоку. При случайном контакте

вращающейся принадлежности может порваться

ваша одежда, и принадлежность может быть

втянута в тело.

n) Выполняйте регулярную очистку

вентиляционных отверстий электрического

инструмента. Вентилятор двигателя может

втягивать пыль внутрь его корпуса, и чрезмерное

скопление металлической пыли может возникнуть

опасность поражения электрическим током.

o) Запрещается работа электрического

инструмента вблизи легковоспламеняющихся

материалов. Такие материалы могут

воспламеняться от искр.

p) Не используйте принадлежности, которым

требуются жидкие охладители. Использование

воды или других жидких охладителей может

привести к поражению или даже смертельному

поражению электрическим током.

Дополнительные указания по

безопасному выполнению всех операций

Отдача и связанные с ней указания по безопасной

работе

Отдача - это мгновенная реакция на зажатое или

застопоренное вращающийся круг, подошву, щетку и

другие принадлежности. Зажатие или стопорение

приводит к быстрой остановке вращающейся

принадлежности, что, в свою очередь, привод к тому,

что неуправляемый электрический инструмент

начинает вращаться в направлении, противоположном

направлению вращения принадлежности, в точке

сцепления.

Например, если шлифовальный круг застопорился или

был зажат рабочей деталью, край круга, который

заходит в место стопорения, может углубиться в

поверхность материала, что приведет к выталкиванию

или отдаче круга. В зависимости от направления

вращения круга в точке стопорения, круг может

прыгнуть в направлении оператора или от него. В таких

условиях шлифовальные круги могут также

разрушаться.

Отдача является результатом неправильного

использования инструмента и/или неправильной

последовательности выполнения действий и

неправильных условий работы, и может быть устранена

при соблюдении мер предосторожности, указанных

ниже:

a) Не ослабляйте захват инструмента и установите

такое положение корпуса вашего тела, чтобы он

оказывал сопротивление силам отдачи. Всегда

используйте дополнительную рукоятку, если она

входит в комплект, чтобы в максимальной

степени контролировать отдачу или реакцию от

крутящего момента во время пуска. Оператор

может контролировать реакцию от крутящего

момента или отдачу, если были предприняты

надлежащие меры предосторожности.

b) Ваши руки никогда не должны находиться

вблизи вращающейся принадлежности.

Принадлежность может отскочить обратно на вашу

руку.

c) Не стойте в зоне, куда ваш инструмент может

уйти при отдаче. Отдача будет толкать инструмент

в направлении, противоположном направлению

движения круга в месте стопорения.

d) Будьте особенно внимательными при работе с

углами, острыми краями и т.д. Не допускайте

прыжков и стопорения принадлежности. Углы,

острые края и подпрыгивания приводят к

стопорению вращающейся принадлежности и

потере контроля или отдаче.

e) Запрещается прикреплять к инструменту нож

цепной пилы для дерева или зубчатый пильный

диск. Такие ножи быстро часто создают отдачу и

потерю управления инструментом.

15

Page 16

РУССКИЙ

(Перевод с оригинала инструкции)

Специальные указания по безопасному

выполнению шлифовки

a) Используйте только те типы кругов, которые

рекомендованы для вашего электрического

инструмента, и конкретные предохранительные

щитки, разработанные для данного круга. Для

кругов, которые не соответствуют конструкции

вашего инструмента, не может быть установлен

надлежащий предохранительный щиток, и поэтому

использование таких кругов является опасным.

b) Предохранительный щиток должен быть

надежно прикреплен к электрическому

инструменту и установлен в положение

максимального обеспечения безопасности, при

котором к оператору будет обращена

наименьшая открытая часть круга.

Предохранительный щиток помогает защищать

оператора от частиц круга, от случайного контакта с

кругом и от искр, от которых может загореться

одежда.

c) Круги должны использоваться только в тех

случаях, когда они рекомендованы к

применению. Например: нельзя выполнять

шлифовку стороной отрезного круга. Абразивные

отрезные круги предназначены для шлифования

периферией круга и поперечные силы,

приложенные к такому кругу, могут привести к

разрушению круга.

d) Всегда используйте только исправные фланцы

для кругов, размер и форма которых

соответствуют выбранному кругу. Правильно

выбранный фланец является опорой для круга,

благодаря чему уменьшается вероятность

разрушения круга. Фланцы для отрезных кругов

могут отличаться от фланцев для шлифовальных

кругов.

e) Запрещается использовать изношенные круги

от электрических инструментов большего

размера. Круг, предназначенный для инструмента

большего размера, не подходит для большей

скорости инструмента меньшего размера и может

разрушиться.

Электрическая безопасность

Этот инструмент имеет двойную изоляцию, и поэтому

провод заземления ему не нужен. Всегда проверяйте,

чтобы сетевое напряжение соответствовало значению,

указанному в табличке с паспортными данными.

Внимание! В случае повреждения шнура питания,

чтобы избежать несчастных случаев с персоналом и

повреждения оборудования, его замену должен

выполнить производитель, авторизованный сервисный

центр BLACK+DECKER или другое лицо, обладающее

надлежащей квалификацией. Если замену шнура

питания выполнило квалифицированное лицо, которое

не является уполномоченным лицом BLACK+DECKER,

гарантийные обязательства будут аннулированы.

Наклейки на инструменте

Наклейка на вашем инструменте вместе с кодом даты

может содержать следующие символы:

Прочитайте

инструкцию по

эксплуатации

Используйте

средства защиты

глаз

Используйте

средства защиты

органов слуха

В ........ Вольты

A ........ Амперы n0 ....... Скорость

холостого хода

Гц ....... Герцы

Вт ....... Ватты

мин ..... минуты

..... Переменный

ток

..... Постоянный

ток

...... Конструкция

Класс II

...... Клемма

заземления

...... Предупреж

дающий

.../мин.. Количес тво

оборотов или

возвратно поступательных

движений в

минуту

Место положения кода даты

Код даты, который также включает в себя год

изготовления, отштампован на поверхности корпуса

инструмента.

Пример:

2016 XX JN

Год изготовления

Функции (Рис. A)

1. Подвижный переключатель

2. Кабель

3. Подвижный предохранительный щиток

4. Захват корпуса

5. Боковая рукоятка (2 положения)

6. Кнопка фиксации шпинделя

Работа

Работа с вашей угловой шлифовальной машиной

(Рис. A)

Чтобы включить машину, сдвиньте подвижный

переключатель вперед (1). Чтобы выключить машину,

нажмите на заднюю часть подвижного переключателя.

16

Page 17

(Перевод с оригинала инструкции)

РУССКИЙ

Установка кругов (Рис. B и C)

Выполните следующее:

• Отсоедините штепсельную вилку от источника

электрического питания.

• Проверьте, чтобы был установлен защитный щиток.

Установите внутренний фланец (7) на шпиндель.

Проверьте, расположен ли он на двух гранях.

• Установите абразивный круг на шпиндель и

внутренний фланец (8). Проверьте, установлен ли

он правильно.

• Установите внешний фланец с резьбой (9), обращая

внимание на то, чтобы его ориентация

соответствовала типу установленного круга. Для

шлифовальных кругов фланец (9) должен быть

установлен выступом к кругу. Для отрезных кругов

фланец (9) должен быть установлен внутренней

частью от круга.

• Зафиксируйте гаечным ключом грани шпинделя для

предотвращения вращения круга и затяните

внешний фланец ключом, входящим в комплект

машины.

• Нажмите кнопку фиксации шпинделя и

поворачивайте шпиндель, пока он не

зафиксируется по месту (Рис. C). Удерживая кнопку

фиксации нажатой, затяните внешний фланец

ключом, входящим в комплект машины.

Установка наждачных кругов (Рис. D)

• Для работы с вашей угловой шлифовальной

машиной используйте наждачные круги с

подошвой для шлифовки.

• Отсоедините штепсельную вилку от источника

электрического питания.

• Снимите защитный щиток.

• Установите фланец на шпиндель. Установите

подошву на шпиндель и внутренний фланец,

проверяя, чтобы она точно стала по месту.

• Установите шлифовальный круг с волокном на

подложку.

• Закрутите внешний фланец с резьбой и затяните его

до упора, как указано в п. «Установка кругов».

Советы для удобного обращения (Рис. E)

Держите крепко шлифовальную машину одной рукой

за боковую рукоятку и второй рукой за корпус.

• Всегда устанавливайте предохранительный щиток

таким образом, чтобы открытая часть круга была

направлена максимально от вас.

• Будьте готовы к ливню искр, когда круг будет

касаться металла.

При шлифовке всегда выдерживайте надлежащий угол

между кругом и рабочей поверхностью (15°)(Рис. D).

Благодаря этому увеличивается шлифовальная

способность круга и предотвращается необязательная

перегрузка.

Перегрузка

Перегрузка приведет к повреждению двигателя вашей

угловой шлифовальной машины. Это может произойти в

том случае, если ваша угловая шлифовальная машина

работала в тяжелом режиме нагрузки на протяжении

длительного периода времени. Ни при каких

обстоятельствах не пытайтесь прикладывать слишком

большое усилие к угловой шлифовальной машине для

увеличения скорости ее работы. Абразивные диски

работают более эффективно, когда прикладывается

небольшое усилие, благодаря чему устраняется падение

оборотов вашей угловой шлифовальной машины.

Техническое обслуживание

Предохранительные щитки, вентиляционные отверстия

и корпус двигателя должны быть свободными от пыли и

грязи. Вытирайте пыль и грязь чистой тканью и

выдувайте пыль струей воздуха под низким давлением.

Чрезмерное накопление металлической пыли может

привести к появлению токопроводящих путей между

внутренними деталями инструмента и внешними

металлическими деталями. Не перегружайте вашу

угловую шлифовальную машину. Перегрузка приведет к

снижению скорости и эффективности работы машины,

вследствие чего она начнет сильно нагреваться. В таком

случае машина должна пару минут поработать без

нагрузки, пока ее температура не опустится до

нормального рабочего значения. Выключение угловой

шлифовальной машины в режиме работы под нагрузкой

приведет к сокращению срока службы переключателя.

Защита окружающей среды

Раздельный сбор отходов. Запрещается

утилизировать этот продукт вместе с

обычными бытовыми отходами.

Если вы решите, что ваше изделие BLACK+DECKER

необходимо заменить, или если вы не будете его больше

использовать¬, не утилизируйте его вместе с бытовыми

отходами. Этот продукт подлежит раздельному сбору

отходов.

17

Page 18

РУССКИЙ

(Перевод с оригинала инструкции)

Раздельный сбор использованных

продуктов и упаковочных материалов

позволяет производить их вторичную

переработку с дальнейшим повторным

использованием. Повторное использование

материалов, прошедших вторичную переработку,

снижает загрязнение окружающей среды¬ и

уменьшает потребность в сырьевых материалах.

Нормативные акты местных органов власти могут

предусматривать сбор использованных

электрических изделий отдельно от бытовых

отходов, в муниципальных пунктах сбора отходов

или в магазине при покупке нового изделия.

BLACK+DECKER предоставляет возможность для

сбора и повторной переработки продуктов

BLACK+DECKER после окончания срока их службы.

Чтобы воспользоваться преимуществом этого

сервиса, пожалуйста, отправьте ваш продукт

любому уполномоченному представителю по

ремонту, который собирает такие изделия от

нашего имени.

Вы можете узнать адрес нашего ближайшего

уполномоченного представителя по ремонту,

позвонив в региональное представительство

BLACK+DECKER, указанное в этой инструкции.

Кроме того, список уполномоченных

представителей по ремонту BLACK+DECKER,

подробная информация о послепродажном

обслуживании и контактные данные можно найти

на сайте www.2helpU.com.

Технические характеристики

G850

Мощность Вт 850

Напряжение В 220-240

Частота Гц 50/60

Диаметр диска мм 125

Скорость холостого

хода мин-1

Размер шпинделя M14

Длина кабеля м 2

12000 (ОБ/МИН)

Очистка

Для очистки угловой шлифовальной машины

пользуйтесь только мягким мыльным раствором и

слегка влажной тканью. Многие бытовые

чистящие средства содержат химические

вещества, которые могут серьезно повредить

пластмассовые детали машины. Также не

разрешается использовать бензин, терпентин,

лак, растворители красок и другие аналогичные

продукты. Ни в коем случае не допускайте

попадания жидкости внутрь инструмента и не

погружайте инструмент какой-либо частью в

жидкость. Важно! Чтобы гарантировать

БЕЗОПАСНОСТЬ и НАДЕЖНОСТЬ инструмента,

ремонт, обслуживание и настройка (кроме тех,

которые описаны в данной инструкции) должны

производиться в авторизованных сервисных

центрах или прочими квалифицированными

работниками, всегда с использованием

идентичных запчастей.

18

Page 19

(Перевод с оригинала инструкции)

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного

изделия Black+Decker и выражаем признательность за

Ваш выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель,

дата продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно

заполненного гарантийного талона мы будем вынуждены

отклонить Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации.

Правовой основой настоящих гарантийных условий

является действующее Законодательство.

Гарантийный срок на данное изделие составляет 24

месяца и исчисляется со дня продажи. В случае

устранения недостатков изделия, гарантийный срок

продлевается на период его нахождения в ремонте.

Срок службы изделия - 5 лет со дня продажи.

4. В случае возникновения каких-либо проблем в процессе

эксплуатации изделия рекомендуем Вам обращаться

только в уполномоченные сервисные центры

BLACK+DECKER, адреса и телефоны которых Вы

сможете найти в гарантийном талоне, на сайте

www.2helpU.com или узнать в магазине. Наши сервисные

станции - это не только квалифицированный ремонт, но и

широкий ассортимент запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

РУССКИЙ

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение

гарантийного срока и вызванные дефектами производства

и \ или материалов.

7. Гарантийные обязательства не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и

разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого

электрического кабеля, вызванного внешним ударным или

любым иным воздействием.

7.3. Попадания в вентиляционные отверстия и проникновение

внутрь изделия посторонних предметов, материалов или

веществ, не являющихся отходами, сопровождающими

применение изделия по назначению, такими как: стружка,

опилки, песок, и пр.

7.4. Воздействие на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанным на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов

напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченной сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как: приводные ремни и колеса, угольные щетки,

смазка, подшипники, зубчатое зацепление редукторов,

резиновые уплотнения, сальники, направляющие ролики,

муфты, выключатели, бойки, толкатели, стволы и т.п.

8.3. на сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и

абразивные диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни редуктора

и других узлов и деталей. К безусловным признакам

перегрузки изделия относятся, помимо прочих: появление

цветов побежалости, деформация или оплавление

деталей и узлов изделия, потемнение или обугливание

изоляции проводов электродвигателя под воздействием

высокой температуры.

19

Page 20

РУССКИЙ

(Перевод с оригинала инструкции)

Приложение к руководству по эксплуатации электроинструмента

Пилы дисковые

Модели: SGM146*, SGV115*, KS8215*, G650*, FME821*, FME822*, G850*, KG751*, SGV1* - Сделано в Китае.

Где символ “*” - различные варианты исполнения изделия.

Сертификат №: RU C-DE.АЯ46.B.78174

Действителен до: 12 января 2019 г.

Выдан: Орган по сертификации "РОСТЕСТ- Москва" , Адрес:

119049,г. Москва, улица Житная, д. 14, стр. 1; 117418, Москва,

Нахимовский просп., 31 (фактический), Телефон: (499)

1292311, (495) 6682893, Факс: (495) 6682893, E-mail:

office@rostest.ru

Изготовитель: Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

Хранение.

Необходимо хранить в сухом месте, вдали от источников

повышенных температур и воздействия солнечных лучей. При

хранении необходимо избегать резкого перепада температур.

Хранение без упаковки не допускается

Срок службы.

Срок службы изделия составляет 5 лет. Не рекомендуется к

эксплуатации по истечении 5 лет хранения с даты

изготовления без предварительной проверки.

Дата изготовления (код даты) указана на корпусе инструмента.

Код даты, который также включает год изготовления,

отштампован на поверхности корпуса изделия.

Пример:

2014 46 XX, где 2014 –год изготовления, 46-неделя

изготовления.

Определить месяц изготовления по указанной неделе

изготовления можно согласно приведенной ниже таблице.

Месяц Январь Февраль Март Апрель Май Июнь Июль Август Сентябрь Октябрь Ноябрь Декабрь Год производства

01 05 09 14 18 22 27 31 36 40 44 49

02 06 10 15 19 23 28 32 37 41 45 50

03 07 11 16 20 24 29 33 38 42 46 51 2014

04 08 12 17 21 25 30 34 39 43 47 52

Неделя

05 09 13 18 22 26 31 35 40 44 48

14 27

01 05 09 14 18 23 27 31 36 40 44 49

02 06 10 15 19 24 28 32 37 41 45 50

03 07 11 16 20 25 29 33 38 42 46 51 2015

04 08 12 17 21 26 30 34 39 43 47 52

Неделя

09 13 18 22 27 31 35 40 44 48 53

14 36 49

01 05 09 13 17 22 26 31 35 39 44 48

02 06 10 14 18 23 27 32 36 40 45 49

03 07 11 15 19 24 28 33 37 41 46 50 2016

04 08 12 16 20 25 29 34 38 42 47 51

Неделя

09 13 17 21 26 30 35 39 43 48 52

22 44

01 05 09 13 18 22 26 31 35 39 44 48

02 06 10 14 19 23 27 32 36 40 45 49

03 07 11 15 20 24 28 33 37 41 46 50 2017

Неделя

04 08 12 16 21 25 29 34 38 42 47 51

05 09 13 17 22 26 30 35 39 43 48 52

31 44

Уполномоченное изготовителем юр.лицо:

ООО "Стэнли Блэк энд Деккер",117485, город Москва, улица

Обручева, дом 30/1, строение 2

Телефон: + 7 (495) 258-3981, факс: + 7 (495) 258-3984, E-mail:

inbox@dewalt.com

Сведения о импортере указаны в сопроводительной

документации и/или на упаковке

Транспортировка.

Категорически не допускается падение и любые механические

воздействия на упаковку при транспортировке.

При разгрузке/погрузке не допускается использование любого

вида техники, работающей по принципу зажима упаковки.

Перечень критических отказов, возможные ошибочные

действия персонала.

Не допускается эксплуатация изделия:

-При появлении дыма из корпуса изделия

-При поврежденном и/ или оголенном сетевом кабеле

-при повреждении корпуса изделия, защитного кожуха, рукоятки

-при попадании жидкости в корпус

-при возникновении сильной вибрации

-при возникновении сильного искрения внутри корпуса

Критерии предельных состояний

При поврежденном и/или оголенном сетевом кабеле

-при повреждении корпуса изделия

20

Page 21

(Переклад оригінальних інструкцій)

УКРАЇНСЬКА

Призначення

Кутова шліфувальна машина BLACK+DECKER™ G850 була

розроблена для різання металу і цегляного мурування

за допомогою відрізного та шліфувального кола

відповідного типу. Цей інструмент призначений

виключно для використання споживачем.

Вказівки з техніки безпеки

Загальні вказівки щодо безпечної роботи з

електричним інструментом

Увага! Уважно прочитайте всі

попереджувальні написи та вказівки

щодо безпечної роботи. Порушення

наведених нижче попереджувальних

написів і вказівок може призвести до

ураження електричним струмом, пожежі та/або

серйозних травм.

Збережіть усі застереження та вказівки з техніки

безпеки для подальшого використання.

Термін «електричний інструмент», що використовується

у всіх застережливих написах та вказівках щодо техніки

безпеки, представлених нижче, відноситься до

електричного інструменту, що працює від мережі (зі

шнуром електроживлення) або від акумуляторної

батареї (без шнура живлення).

1. Вказівки з техніки безпеки на робочому місці

a. Утримуйте робоче місце в чистоті і добре

освітленим. Безлад або погане освітлення на

робочому місці можуть призвести до нещасного

випадку.

b. Не працюйте з електроінструментом в місці

зберігання вибухонебезпечних матеріалів,

наприклад, у присутності легкозаймистих рідин,

газів або пилу. Електричні інструменти створюють

іскри, що можуть запалити пил або пари.

c. Забороняється перебування дітей та сторонніх

осіб поблизу працюючого електричного

інструменту. Відволікання може призвести до

втрати контролю за роботою інструмента.

2. Електрична безпека

a. Вилка шнура живлення інструмента повинна

відповідати мережевій розетці. Забороняється

вносити будь-які зміни у вилку шнура живлення.

Не використовуйте жодних вилок-перехідників

із заземленими (зануленими)

електроінструментами. Відсутність змін у вилках

шнурів живлення та відповідність електричних

вилок і розеток знижує ризик ураження

електричним струмом.

b. Не торкайтеся поверхонь заземлених чи

занулених предметів, наприклад труб,

радіаторів, електроплит або холодильників.

Заземлення чи занулення тіла підвищує ризик

ураження електричним струмом.

c. Забороняється піддавати електричні

інструменти впливу дощу чи підвищеної

вологості. При попаданні вологи всередину

електричного інструмента підвищується ризик

ураження електричним струмом.

d. Обережно поводьтеся зі шнуром живлення. У

жодному разі не використовуйте шнур живлення

для перенесення чи зміни положення

інструмента; не тягніть за шнур, виймаючи вилку

з розетки. Не прокладайте шнур живлення поруч

із гарячими предметами, мастилом, гострими

краями і рухомими деталями. Пошкодження й

заплутування шнурів живлення підвищує ризик

ураження електричним струмом.

e. Під час роботи з електричним інструментом за

межами приміщень використовуйте відповідний

подовжувач. Використання подовжувача,

призначеного для роботи поза приміщеннями,

знижує ризик ураження електричним струмом.

f. Якщо електричним інструментом необхідно

користуватись у вологому місці, слід

використовувати пристрій захисного

відключення (ПЗВ) електричної мережі.

Використання ПЗВ знижує ризик ураження

електричним струмом.

3. Безпека персоналу

a. Під час роботи з електричним інструментом

необхідно бути обачним, слідкувати за

виконуваною роботою та керуватися здоровим

глуздом. Забороняється працювати з

електричним інструментом у стані втоми чи під

впливом наркотиків, алкоголю й лікарських

препаратів. Ослаблення уваги навіть на мить може

призвести до серйозної травми.

b. Використовуйте засоби індивідуального захисту.

Завжди користуйтеся засобами захисту очей.

Використання у відповідних умовах засобів

індивідуального захисту, наприклад пилозахисної

маски, протиковзного захисного взуття, захисної

каски або засобів захисту органів слуху, завжди

знижує ризик отримання травми.

c. Не допускайте ненавмисного вмикання

інструмента. Перш ніж підключити джерело

живлення та/або акумулятор, піднімаючи або

несучи інструмент, перевірте, щоб його вимикач

знаходився у вимкненому положенні. Якщо

тримати палець на вимикачі під час перенесення

інструмента чи підключення увімкненого

інструмента до мережі, це підвищує ризик

нещасного випадку.

21

Page 22

УКРАЇНСЬКА

(Переклад оригінальних інструкцій)

d. Перш ніж увімкнути електричний інструмент,

обов’язково вийміть із нього регулювальний чи

гайковий ключ. Ключ, залишений ключ на

обертальній деталі інструмента, може призвести до

травмування.

e. Не намагайтеся дотягнутися до важкодоступних

місць. Завжди міцно тримайтеся на ногах і

зберігайте рівновагу під час роботи. Це дозволяє

краще контролювати електричний інструмент у

непередбачуваних ситуаціях.

f. Одягайте відповідний одяг. Забороняється

одягати вільний одяг або прикраси. Волосся,

одяг та рукавиці повинні знаходитися на

максимальній відстані від рухомих деталей

інструмента. Вільний одяг, прикраси або довге

волосся можуть бути захоплені рухомими деталями.

g. Якщо встановлені пристрої підключення засобів

пиловловлювання та пилозбірників, необхідно

перевіряти, щоб вони були підключені та

використовувалися належним чином.

Використання цих пристроїв знижує рівень ризику,

пов’язаного з пилом.

4. Використання та догляд за електричним

інструментом

a. Не застосовуйте надмірне зусилля до

електричного інструмента. Використовуйте

електричний інструмент тільки за

призначенням. Правильно підібраний

електроінструмент дозволить виконати роботу

краще і безпечніше при швидкості, на яку він

розрахований.

b. Забороняється використовувати цей

електричний інструмент, якщо не вдається

ввімкнути чи вимкнути його вимикачем.

Будь-який електричний інструмент, роботою якого

неможливо керувати за допомогою вимикача, є

небезпечним, і його обов’язково потрібно

відремонтувати.

c. Перш ніж регулювати електричний інструмент,

замінювати на ньому приладдя чи класти на

зберігання, необхідно витягти вилку живлення з

розетки та/або зняти з нього акумулятор. Такий

превентивний захід безпеки знижує ризик

випадкового увімкнення інструмента.

d. Зберігайте електричний інструмент, який в

даний момент не використовується, в

недоступному для дітей місці та не дозволяйте

працювати з інструментом особам, які не

знайомі з ним або з цими вказівками.

Електричний інструмент є небезпечним в руках

ненавченої людини.

e. Підтримуйте інструмент в робочому стані.

Перевіряйте центрування та з’єднання рухомих

деталей, наявність пошкоджених деталей та

будь-які фактори, які можуть негативно

позначитися на роботі електричного

інструмента. У разі виявлення пошкодження

електричний інструмент необхідно відремонтувати

перед використанням. Багато нещасних випадків

трапляється через неналежне технічне

обслуговування електричних інструментів.

f. Ріжучі інструменти мають бути загостреними й

чистими. Підтримуваний у належному робочому

стані ріжучий інструмент з гострими лезами менше

застряє, ним легше керувати.

g. Використовуйте електричний інструмент,

приладдя, вставні різці тощо відповідно до

даних вказівок, враховуючи умови експлуатації

та роботу, яка повинна бути виконана.

Використання електричного інструмента всупереч

призначенню може призвести до виникнення

небезпечної ситуації.

5. Обслуговування

a. Обслуговувати електричний інструмент повинен

тільки кваліфікований ремонтний персонал, і

при цьому повинні використовуватися тільки

оригінальні запасні деталі. Це забезпечить

утримання електричного інструмента у безпечному

стані.

Додаткові спеціальні правила техніки

безпеки

Увага! Додаткові вказівки з безпечного

виконання шліфування, очищення

наждачним папером, полірування і

абразивного різання

• Цей електричний інструмент призначений для

використання в якості шліфувальної машини.

Уважно вивчіть всі попереджувальні знаки,

вказівки щодо безпечної роботи, графічні

матеріали та технічні описи, що додаються до

даного електричного інструменту. Недотримання

вказівок щодо безпечної роботи може призвести до

ураження електричним струмом, пожежі та/або

серйозних травм персоналу.

• Операції, на які не розрахована конструкція

цього електричного інструменту, можуть

призвести до виникнення аварійної ситуації та

травм персоналу.

• Не використовуйте приладдя, що не були

розроблені та не рекомендовані виробником

інструменту. Якщо приладдя можна встановити на

ваш інструмент, це ще не є гарантією безпечної

роботи.

22

Page 23

(Переклад оригінальних інструкцій)

УКРАЇНСЬКА

• Номінальна швидкість приладдя повинна

щонайменше дорівнювати максимальній

швидкості, зазначеній на електричному

інструменті. Приладдя, що працює зі швидкістю,

яка перевищує свою номінальну швидкість, може

зруйнуватися та розлетітися в сторони.

• Зовнішній діаметр та товщина приладдя

повинні лежати в межах характеристик вашого

електричного інструменту. Приладдя

неправильного розміру не можуть бути належним

чином захищені запобіжним щитком, і їх роботу

неможливо нормально контролювати.

• Осьовий розмір коліс, фланців, підошов дисків

та іншого приладдя повинен точно збігатися з

розміром шпинделя електричного інструменту.

Приладдя з осьовими отворами, що не збігаються з

елементами кріплення електричного інструмента,

будуть розбалансованими, будуть відчувати

надмірні вібрації та можуть стати причиною втрати

контролю за інструментом.

• Забороняється використовувати пошкоджене

приладдя. Перед початком роботи завжди

перевіряйте приладдя, таке як шліфувальні

кола, на наявність сколів та тріщин, підошву на

наявність тріщин, дір та надмірного зносу, і

дротяну щітку на наявність обламаного дроту. У

випадку падіння електричного інструменту та

приладдя перевірте їх на наявність пошкоджень

або замініть пошкоджене приладдя. Після

перевірки та установки приладдя весь персонал

повинен відійти у бік від площини обертання

приладдя, після чого необхідно ввімкнути

електричний інструмент на максимальну

швидкість холостого ходу без навантаження.

Пошкоджене приладдя за цей час зазвичай

розлітається.

• Використовуйте засоби індивідуального

захисту. Залежно від способу використання,

використовуйте лицьовий щиток, відкриті або

закриті захисні окуляри. У разі необхідності

надягайте пилозахисну маску, засоби захисту

органів слуху, захисні рукавички та робочий

фартух, що здатні зупинити дрібні абразивні

частки або осколки робочої деталі. Засіб захисту

очей повинен зупиняти частинки, що розлітаються,