Page 1

GENERAL SAFETY RULES

WARNING! Read and understand all instructions. Failure to follow all instructions list-

ed below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install a polarized outlet. Do not change the plug in any way. Double insulation

eliminates the need for the three wire grounded power cord and grounded power supply

system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair and clothing away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. Awrench or key that is

left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to a loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off.Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventative safety measures reduce the

risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

SERVICE

•Tool service must be performed only by qualified repair personnel. Service or mainte-

nance performed by unqualified personnel could result in a risk of injury.

•When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

• Always use proper guard with grinding wheel. A guard protects operator from broken

wheel fragments. Always position the guard so that as much of the exposed disc as possible is pointing away from you.

• Accessories must be rated for at least the speed recommended on the tool warning

label. Wheels and other accessories running over rated speed can fly apart and cause injury .

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

ADDITIONAL SAFETY RULES

• ALWAYS WEAR EYE PROTECTION.

• WEAR EAR PROTECTION. NOISE LEVEL MAY BE AMPLIFIED WHEN GRINDING IN

ENCLOSED SPACES.

• KEEP GUARDS IN PLACE.

• Use only accessories having a maximum operating speed at least as high as the speed

specified in the warning on the tool’s label.

• Before using, inspect recommended accessory for cracks or flaws. If such a crack or flaw

is evident, discard the accessory. The accessory should also be inspected whenever you

think the tool may have been dropped.

• When starting the tool (with a new or replacement wheel or brush installed) hold the tool in

a well protected area and let it run for one minute. If the wheel or brush has an undetected

crack or flaw, it should burst or separate in less than one minute. Never start the tool with a

person in line with the accessory. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment. If this occurs, stop the

tool and inspect the wheel.

• ALWAYS USE GUARDS with grinding wheels and wire brushes. Always position the

guard so that as much of the exposed wheel or wire brush as possible is pointing away from

you.

• Clean your tool out periodically.

• Do not use Type 1 abrasive or diamond wheels without proper guard. (Guard not included

with unit.)

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING:Use of this tool can generate and/or disperse dust, which may cause seri-

ous and permanent respiratory or other injury.Always use NIOSH/OSHAapproved respi-

ratory protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

• Do not operate this tool for long periods of time. Vibration caused by the operating

action of this tool may cause permanent injury to fingers, hands, and arms. Use gloves to

provide extra cushion, take frequent rest periods, and limit daily time of use.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol

SPM..................strokes per minute

.../min....................revolutions or

reciprocations

per minute

INFORMATION YOU SHOULD KNOW

• Wait until grinding wheel reaches full speed before applying work.

• Hold grinder at proper angle, as shown in Figure 1 1 and 12.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

CAT. NOS. FS6500AG FORM NO. 587811-00 Copyright © 2004 Black & Decker (FEB-04) Printed in China

1.) TRIGGER SWITCH / INTERRUPTEUR

COULISSANT / INTERRUPTOR DESLIZABLE

2.) LOCK-ON BUTTON / BOUTON DE

VERROUILLAGE / BOTON DE ENCENDIDO

PERMANENTE

3.) SPINDLE LOCK BUTTON / BOUTON DE

VERROUILLAGE D'ARBRE / BOTON DE

SEGURO DE LA FLECHA

4.) ACCESSORYWHEEL / MEULE ACCESSOIRE

/ DISCO ACCESORIO

5.) AUXILIARYHANDLE / POIGNÉE AUXILIAIRE /

MANGO AUXILIAR

6.) WHEEL GUARD / CARTER DE MEULE /

GUARDA DEL DISCO

3

4

5

6

7

4444--

--

11

11

////

22

22

”””” AAAANNNNGGGGLLLLEEEEGGGGRRRRIIIINNNNDDDDEEEERR

RR

1

2

3

4

5

6

2

Locking pin slot

Fente de la goupille

de sécurité

Catalog # FS6500AG

1

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

IF YOU SHOULD HAVE A QUESTION OR

EXPERIENCE A PROBLEM WITH YOUR

BLACK & DECKER PRODUCT,

CALL 1-800-544-6986

BEFORE YOU CALL, HA VE THE FOLLOWING INFORMATION AVAILABLE, CAT ALOG No.,

TYPE No., AND DATE CODE (e.g. 0130M). IN MOSTCASES, ABLACK & DECKER REPRE-

SENTATIVE CAN RESOL VE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE ASUGGES-

TION OR COMMENT, GIVE US ACALL. YOUR FEEDBACK IS VITALTO BLACK & DECKER.

INSTRUCTION MANUAL

A

FRONT

B

Page 2

AVERTISSEMENT! Lire et comprendre toutes les directives. Le non-respect de toutes

les directives suivantes présente des risques de secousses électriques, d'incendie ou de

blessures graves.

CONSERVER CES MESURES

ZONE DE TRAVAIL

•S'assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et

des endroits sombres présentent des risques d'accidents.

•Ne pas utiliser des outils électriques en présence de vapeurs explosives (comme

celles dégagées par des liquides, des gaz ou des poussières inflammables). Les

étincelles générées par le moteur des outils électriques peuvent enflammer les poussières

ou les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu'on utilise

un outil électrique. Une distraction peut entraîner la perte de maîtrise de l'outil.

MESURES DE SÉCURITÉ RELATIVES À L'ÉLECTRICITÉ

•Les outils à double isolation comportent une fiche polarisée (une lame plus large que

l'autre). La fiche n'entre que d'une façon dans une prise polarisée. Lorsque la fiche

n'entre pas à fond dans la prise, essayer de nouveau après avoir inversé les broches

de la fiche. Si la fiche n'entre toujours pas dans la prise, communiquer avec un

électricien certifié afin de faire installer une prise polarisée. Ne modifier en aucune

GUIDE D’UTILISATION

EXTENSION CORD

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The table below shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the

gage number, the heavier the cord.

MOTOR

Your tool is powered by a Black & Decker specified motor. Be sure your power supply agrees

with the nameplate marking. Amarking of 120 volts, 50/60 Hz or 120 volts, AC only means that

the tool is designed to operate on normal 120 volt house current. Voltage decrease of more that

10% will cause loss of power and overheating. All Black & Decker tools are factory tested. If

this tool does not run, check the power supply.

AUXILIARY HANDLE (FIG. 1)

A three position auxiliary handle (5) is furnished with your grinder and can be screwed into

either side of the grinder housing as well as into the top. This handle SHOULD BE USED AT

ALL TIMES to maintain complete control of the tool.

STARTING THE TOOL

To switch your angle grinder on, depress the trigger switch (1). The angle grinder will stop

when the trigger switch is released. For continuous operation depress the lock-on button (2)

while the trigger switch is depressed. Release the trigger switch prior to releasing the lockon button. To stop your angle grinder when operation is continuous depress the trigger switch

again and release.

OVERLOAD

Overloading will cause damage to the motor of your angle grinder. This can happen if your

angle grinder is subjected to heavy use for prolonged periods of time. Do not in any circumstances, attempt to exert too much pressure on your angle grinder to speed up your work.

The abrasive discs operate more efficiently when light pressure is exerted, thus avoiding a

drop in the speed of your angle grinder.

GRINDING AND WIRE BRUSHING

A TTACHING THE WHEEL GUARD (FIG.2)

TURN OFF AND UNPLUG THE TOOL. NEVER GRIND OR BRUSH WITHOUT GUARD IN

PLACE.

Place the angle grinder on a table, spindle up. Align the lug with the slot in the bracket. Press

the guard down and turn it in the direction of the arrow. NOTE: The guard locking pin prevents the guard from coming loose.

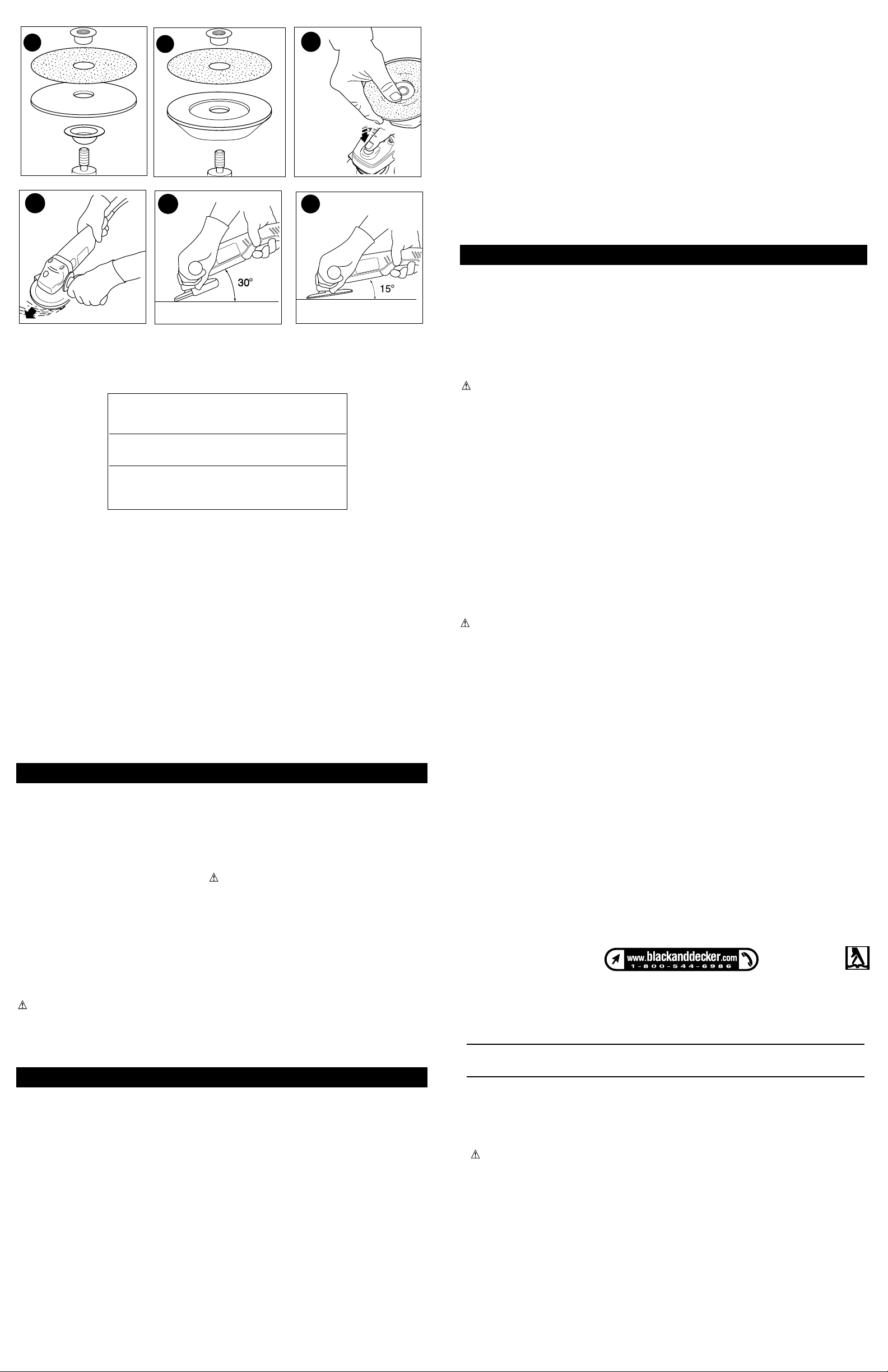

FITTING DEPRESSED CENTER WHEELS (FIGS. 3,4,5,6)

TURN OFF AND UNPLUG THE TOOL. CAUTION: Never use any depressed-center

wheels without the proper guard.

1. Ensure that the guard is fitted properly. Place the inner flange (a) in Fig. 3 on the spindle.

Ensure that it is located on the two flats.

2. Place the grinding wheel on the spindle and inner flange (a) in Fig. 4.

3. Fit the threaded outer flange (b) Fig. 5, making sure it is facing in the correct direction for

the type of wheel fitted. For thick grinding wheels, the flange ( b) is fitted with the raised portion facing towards the wheel. For thin grinding wheels, the flange (b) is fitted with the inner

portion facing away from the wheel.

4. Press in the spindle lock button and rotate the spindle until it locks. Keeping the lock button pressed in, tighten the outer flange with the spanner wrench provided as shown in Fig. 6.

5. When using a depressed-center wheel, hold the tool so that an angle of approximately

30° exists between the wheel and the work.

WARNING: Check rated speed on depressed-center wheel. Never use a wheel with rated

speed lower than the speed on the nameplate of the tool.

FITTING WIRE CUP BRUSHES

Wire cup brushes screw directly on the spindle of the machine without the use of flanges.

When using wire brushes, thread firmly on spindle by hand.

SANDING

REMOVING THE WHEEL GUARD (FIG. 7 SANDING ONLY)

TURN OFF AND UNPLUG THE TOOL.

NOTE: TO PREVENT LOSS OF CONTROL, DO NOT SET TOOL DOWN UNTIL ACCESSORY HAS COMPLETELY STOPPED TURNING.

As shown in Fig. 7, place the grinder on a table, spindle up. Rotate the guard in the direction

of the arrow until it stops. Use a small screwdriver to depress the locking pin in the slot. While

holding the locking pin down with the screwdriver, turn the guard slightly in the direction of

the arrow to keep the locking pin depressed. Remove the screwdriver and continue to turn

the guard until it is released.

PRECAUTIONS TO TAKE WHEN SANDING PAINT

1. Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling

the contaminated dust. The greatest danger of lead poisoning is to children and pregnant

women.

2. Since it is difficult to identify whether or not a paint contains lead without a chemical analysis,

we recommend the following precautions when sanding any paint:

PERSONAL SAFETY

1. No children or pregnant women should enter the work area where the paint sanding is being

done until all cleanup is completed.

2. A dustmask or respirator should be worn by all persons entering the work area. The filter

should be replaced daily or whenever the wearer has difficulty breathing.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

NOTE: ONLY THOSE DUSTMASKS SUITABLE FOR WORKING WITH LEAD PAINT

DUST AND FUMES SHOULD BE USED. ORDINARY PAINTING MASKS DO NOT

OFFER THIS PROTECTION. SEE YOUR LOCAL HARDWARE DEALER FOR THE

NIOSH APPROVED PROPER MASK.

ENVIRONMENTAL SAFETY

1. Paint should be removed in such a manner as to minimize the amount of dust gener-

ated.

2. Areas where paint removal is occurring should be sealed with plastic sheeting of 4

mils thickness.

3. Sanding should be done in a manner to reduce tracking of paint dust outside the work

area.

FITTING ABRASIVE DISCS

TURN OFF AND UNPLUG THE TOOL.

Use an abrasive disc with a backing pad for sanding with your angle grinder.

1. Remove the guard.

2. Place the flange, (backing pad and abrasive disc sold separately) and outer flange on

the spindle as shown in Figure 8. Figure 8A shows how to attach an abrasive disc with a

rubber backing pad.

3. Tighten the abrasive disc as shown in Figure 9 by depressing the spindle lock button

and turning the abrasive disc by hand.

GENERAL INFORMATION

HELPFUL HINTS

• Hold your angle grinder with one hand on the body and the other hand firmly around the

side handle as shown in Figure 10.

• Always position the guard so that as much of the exposed disc as possible is pointing away

from you.

• Be prepared for a stream of sparks when the disc touches the metal.

• Maintain an angle between the disc and work surface (Fig. 11) of approximately 30° when

grinding and 10°-15° when sanding ( Fig. 12) for best tool control, material removal, and

minimal loading.

WARNING: Always wear eye protection while operating this power tool.

TOOL MAINTENANCE

CLEANING: Blowing dust and grit out of the motor housing using compressed air is a

necessary maintenance procedure. Dust and grit containing particles from metal grinding

often accumulate on interior surfaces and could create an electrical shock hazard if not

cleaned out.

LUBRICATION

Black & Decker tools are properly lubricated at the factory and are ready for use. Tools

should be lubricated regularly every year depending on usage. (Tools used on heavy duty

jobs and tools exposed to heat may require more frequent lubrication.) This lubrication

should be attempted only by trained power tool repairperson's such as those at Black &

Decker service centers or in other qualified service personnel.

IMPORTANT

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments

should be performed by Black & Decker service centers or other qualified service personnel,

always using Black & Decker replacement parts.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call: 1-80054-HOW-TO (544-6986).

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact

the Black & Decker location nearest you. To find your local service location, refer to the

yellow page directory under "Tools—Electric" or call: 1-800-54-HOW TO.

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should be

made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after

the sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under "ToolsElectric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from province to province. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center. This

product is not intended for commercial use. FREE WARNING LABEL REPLACEMENT: If

your warning labels become illegible or are missing, call 1-800-544-6986 for a free

replacement.

RENSEIGNEMENTS À RETENIR

• Attendre que la meule atteigne sa vitesse maximale avant de la poser sur l'ouvrage.

• Tenir la meuleuse à l'angle approprié, tel qu'illustré à la fig.11, fig. 12.

10

11

12

8

9

8A

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

Page 3

façon la fiche. La double isolation élimine le besoin d'un cordon trifilaire mis à la terre et

d'un système d'alimentation mis à la terre.

•Éviter de toucher à des surfaces mises à la terre comme des tuyaux, des radiateurs,

des cuisinières et des réfrigérateurs. Les risques de secousses électriques sont plus

élevés si le corps de l'utilisateur est mis à la terre.

•Protéger les outils électriques de la pluie ou des conditions mouillées. Une infiltration

d'eau dans l'outil augmente les risques de secousses électriques.

•Manipuler le cordon avec soin. Ne jamais se servir du cordon afin de transporter

l'outil ni tirer sur le cordon pour débrancher l'outil. Éloigner le cordon des sources de

chaleur, des flaques d'huile, des arêtes tranchantes et des pièces mobiles. Remplacer

immédiatement les cordons endommagés. Les cordons endommagés augmentent les

risques de secousses électriques.

•Lorsqu'on utilise un outil électrique à l'extérieur, se servir d'un cordon de rallonge

prévu pour l'extérieur, portant la mention “W -A” ou “W”. Ces cordons sont conçus pour

servir à l'extérieur et minimisent les risques de secousses électriques. Lorsqu'on se sert d'un

cordon de rallonge, s'assurer qu'il est de calibre approprié pour la tension nécessaire au

fonctionnement de l'outil. L'utilisation d'un cordon de calibre inférieur occasionne une baisse

de tension entraînant une perte de puissance et la surchauffe. Le tableau suivant indique le

calibre approprié selon la longueur du cordon et les mentions de la plaque signalétique de

l'outil. En cas de doute, utiliser un cordon de calibre supérieur. Le chif fre indiquant le calibre

est inversement proportionnel au calibre du cordon.

SÉCURITÉ PERSONNELLE

•Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu'on utilise un outil

électrique. Ne pas s'en servir lorsqu'on est fatigué ou affaibli par des drogues, de

l'alcool ou des médicaments. De graves blessures peuvent résulter d'un moment

d'inattention lors de l'utilisation d'un outil électrique.

•Porter des vêtements appropriés. Éviter de porter des vêtements amples ou des

bijoux. Recouvrir la chevelure si elle est longue. Éloigner les cheveux, les vêtements et

les gants des pièces en mouvement qui peuvent les happer.

•Éviter les démarrages accidentels. S'assurer que l'interrupteur est en position hors

tension avant de brancher l'outil. Afin d'éviter les risques de blessures, ne pas transporter

l'outil avec le doigt sur l'interrupteur ni brancher un outil dont l'interrupteur est en position

sous tension.

•Enlever les clés de réglage avant de mettre l'outil sous tension. Une clé qui est laissée

sur une pièce rotative de l'outil présente des risques de blessures.

•Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s'assure d'une

meilleure maîtrise de l'outil dans des situations imprévues grâce à une position stable et un

bon équilibre.

•Porter de l'équipement de sécurité. Toujours porter des lunettes de sécurité. Dans

certaines conditions, il faut porter des masques respiratoires, des chaussures

antidérapantes, un casque de sécurité ou des protège-tympans.

UTILISATION ET ENTRETIEN DE L'OUTIL

•Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de

soutenir la pièce à ouvrer sur une plate-forme stable. La pièce est instable lorsqu'elle est

retenue par la main ou le corps de l'utilisateur. Cela présente des risques de perte de

maîtrise de l'outil.

•Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche. L'outil approprié fonctionne

mieux et sûrement lorsqu'on s'en sert à son rendement nominal.

•Ne pas se servir de l'outil lorsque l'interrupteur est défectueux. Le cas échéant, l'outil

est dangereux et il faut le réparer.

•Débrancher l'outil de la source d'alimentation avant de le régler, d'en remplacer les

accessoires ou de le ranger. On minimise de la sorte le risque de démarrage accidentel de

l'outil.

•Ranger l'outil hors de portée des enfants et de toute autre personne qui n'en connaît

pas le fonctionnement. L'outil est dangereux entre les mains de ces personnes.

•Prendre soin des outils. S'assurer que les outils de coupe sont tranchants et

propres. Des outils bien entretenus à arêtes tranchantes ont moins tendance à se coincer et

ils se maîtrisent mieux.

•Vérifier l'alignement et les attaches des pièces mobiles, le degré d'usure des pièces

ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l'outil.

Faire réparer un outil endommagé avant de s'en servir. Des outils mal entretenus sont la

cause de nombreux accidents.

•Utiliser seulement les accessoires recommandés par le fabricant. Des accessoires qui

conviennent à un outil peuvent présenter des risques avec un autre outil.

ENTRETIEN

•Confier l'entretien de l'outil seulement à du personnel qualifié. Le non-respect de la

présente directive présente des risques de blessures.

•Lors de l'entretien de l'outil, utiliser seulement des pièces de rechange identiques.

Respecter les consignes relatives à l'entretien du présent guide d'utilisation. Il y a

risque de secousses électriques ou de blessures lorsqu'on utilise des pièces non autorisées

ou lorsqu'on ne respecte pas les consignes relatives à l'entretien

CONSERVER CES DIRECTIVES

RÈGLES DE SÉCURITÉ PARTICULIÈRES

•Toujours utiliser le dispositif de protection qui convient à la meule afin de protéger

l’opérateur des fragments pouvant être projetés par une meule brisée.

•La vitesse des accessoires doit correspondre à la vitesse minimale recommandée indiquée

sur l’étiquette d’avertissement de l’outil, car les meules et les accessoires qui sont réglées à

une vitesse trop élevée peuvent se briser et occasionner des blessures lorsque des

fragments de métal sont projetés en l’air.

•Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en contact

avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre les pièces

métalliques de l’outil sous tension, engendrant des risques de choc électrique.

RÈGLES DE SÉCURITÉ ADDITIONNELLES

•TOUJOURS PORTER DES LUNETTES DE PROTECTION.

•TOUJOURS LAISSER LE DISPOSITIF DE PROTECTION EN PLACE.

•N'utiliser que des meules ayant une vitesse de fonctionnement maximale équivalant au

moins à la vitesse de rotation à vide (No Load RPM) marquée sur la plaque signalétique de

l'outil.

•Avant d’utiliser un accessoire recommandé, le vérifier afin de s’assurer qu’il n’y ait ni bris ni

fissure. Si on y trouve de tels défauts, mettre l’accessoire au rebut. Inspecter également

l’accessoire chaque fois qu’il subit une chute.

• Lorsqu’on démarre l’outil (après y avoir installé une meule neuve ou de rechange), se tenir

dans un endroit bien protégé et le faire fonctionner pendant une minute, car si l’outil est

fissuré ou brisé, il devrait éclater en moins d’une minute. Ne jamais démarrer un outil lorsque

quelqu’un, y compris l’opérateur, se tient directement devant lui.

•Éviter de faire rebondir la meule durant son fonctionnement ou de l’utiliser de manière

abusive. Si la meule subit de tels traitements, arrêter l’outil et inspecter cette dernière.

• TOUJOURS UTILISER UN DISPOSITIF DE PROTECTION lorsqu'on se sert de meules à

moyeu déporté ou de meules boisseaux coniques.

•Nettoyer l'outil périodiquement.

AVERTISSEMENT : Certains bois renferment des agents de conservation (comme de

l'arséniate de cuivre et de chrome) qui peuvent être toxiques. Lorsqu'on ponce de tels

matériaux, on doit prendre des précautions supplémentaires afin d'éviter d'inhaler les

vapeurs toxiques et de minimiser les contacts avec la peau.

AVERTISSEMENT :Puisque cet outil peut soulever de la poussière contenant des produits

chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant

être nocifs sur le plan reproductif, on recommande le port d’un appareil de protection

respiratoire approprié.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

Construction de classe II

........................borne de mise à la

minute

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

SPM.....................courses/min

RALLONGES

Lorsqu'on doit se servir d'une rallonge, il faut s'assurer qu'elle puisse transporter le courant

requis; si la rallonge est trop petite, la tension de ligne diminuera, provoquant une perte de

puissance et la surchauffe de l'outil. Le tableau ci-dessous indique le calibre à utiliser selon

la longueur du cordon et l'intensité nominale apparaissant sur la plaque signalétique. En cas

de doute, utiliser le calibre supérieur (il est à noter que plus le chiffre est petit, plus le calibre

du cordon est grand).

MOTEUR

Le moteur de cet outil a été conçu par Black & Decker. On doit s'assurer que l'alimentation

corresponde aux valeurs nominales de la plaque signalétique. La marque «120 volts, 50/60

Hz» ou «120 volts, AC only» (120 volts c.a. seulement) signifie que l'outil peut être alimenté

par un courant résidentiel standard. Les baisses de tension de plus de 10 % engendrent des

pertes de puissance et une surchauffe de l'outil. Tous les outils Black & Decker sont testés

en usine; si celui-ci ne fonctionne pas, on doit d'abord vérifier l'alimentation.

POIGNÉE AUXILIAIRE (FIG. 1)

Une poignée auxiliaire à trois positions (5), livrée avec la meuleuse, peut être vissée d'un

côté ou de l'autre ou sur le dessus du boîtier de l'outil. Cette poignée DOITÊTRE UTILISÉE

EN TOUTTEMPS afin de garder la maîtrise totale de l'outil.

DÉMARRAGE DE L'OUTIL

Pour faire démarrer la meuleuse, enfoncer l'interrupteur à gâchette (1); pour l'arrêter,

relâcher. Pour un fonctionnement continu, appuyer sur le bouton de verrouillage en position

«marche» (2) lorsque l'interrupteur est enfoncé; relâcher ce dernier avant de relâcher le

bouton de verrouillage. Pour arrêter la meuleuse en fonctionnement continu, appuyer

momentanément sur l'interrupteur.

SURCHARGES

Les surcharges peuvent endommager le moteur des meuleuses d'angle. Elles se produisent

généralement quand l'outil est utilisé à plein rendement pendant de longues périodes de

temps. On ne doit jamais, sous aucun prétexte, exercer trop de pression sur l'outil dans le

but d'accélérer le travail. Les disques abrasifs sont plus efficaces quand on n'appuie que

légèrement sur la meuleuse, ce qui permet d’éviter de ralentir l'outil.

MEULAGE ET BROSSAGE

FIXATION DU DISPOSITIF DE PROTECTION (FIG. 2)

ARRÊTER ET DÉBRANCHER L'OUTIL. NE JAMAIS FAIRE FONCTIONNER LA

MEULEUSE SANS LE DISPOSITIF DE PROTECTION.

Mettre la meuleuse sur une surface plane, broche vers le haut. Aligner la cosse avec la fente

du support. Enfoncer le dispositif et le tourner dans le sens indiqué par la flèche.

REMARQUE : La goupille de sécurité du dispositif de protection empêche ce dernier de se

desserrer.

INSTALLATION DE MEULES À MOYEU DÉPORTÉ (FIGS. 3, 4, 5, 6)

ARRÊTER ET DÉBRANCHER L'OUTIL. MISE EN GARDE : Ne jamais utiliser la

meuleuse à moyeu déporté sans le dispositif de protection approprié.

1. S'assurer que le dispositif de protection est bien installé. Insérer la bride interne (a) sur la

broche Fig. 3, en vérifiant qu'elle est bien appuyée sur les deux partie plates.

2. Insérer le disque abrasif sur la broche et la bride interne (a) Fig. 4.

3. Installer le flasque externe fileté (b) Fig. 5, en s'assurant qu'il est orienté dans le sens

requis pour le type de disque utilisé. Pour les disques à meuler, le flasque (b) doit être

installé de manière à ce que la face en saillie soit tournée vers le disque; pour les disques à

couper, il (b) doit être placé de manière à ce que la saillie soit vers l'extérieur Fig.5.

4. Enfoncer le bouton de verrouillage de l’axe et faire tourner ce dernier jusqu'à ce qu'il se

bloque. En maintenant le bouton de verrouillage enfoncé, serrer le flasque externe au

moyen de la clé à ergots fournie Fig. 6.

5. Lorsqu'on utilise une meuleuse à moyeu déporté, il faut tenir l'outil de manière à obtenir un

angle d'environ 30° entre la meuleuse et l'ouvrage.

MISE EN GARDE : On doit vérifier les caractéristiques de la meuleuse à moyeu déporté

afin d'éviter d'en utiliser une dont la vitesse nominale est inférieure à celle qui est indiquée

sur la plaque signalétique de l'outil.

INSTALLATION DE BROSSES EN FORME DE COUPELLES

La brosse en forme de coupelle se visse directement au moyeu de l’appareil sans utiliser de

flasques.

PONÇAGE

RETRAIT DU DISPOSITIF DE PROTECTION (FIG. 7 – PONÇAGE SEULEMENT)

ARRÊTER ET DÉBRANCHER L'OUTIL.

NOTA: POUR PRÉVENIR LES PERTES DE CONTRÔLE, NE PAS DÉPOSER L'OUTIL

AVANTQUE L'ACCESSOIRE AITCOMPLÈTEMENTCESSÉ DE TOURNER.

Tel qu'illustré à la Fig. 7, mettre la meuleuse sur une surface plane, broche vers le haut.

Faire tourner le dispositif de protection dans le sens indiqué par la flèche jusqu'à ce qu'il

bloque. En utilisant un petit tournevis, appuyer sur la goupille de sécurité située dans la

fente. En maintenant la goupille enfoncée, faire tourner le dispositif légèrement dans le sens

indiqué par la flèche afin d'empêcher la goupille de remonter. Retirer le tournevis et

continuer de faire tourner le dispositif jusqu'à ce qu'il se dégage.

MESURES DE PRÉCAUTION - PONÇAGE DE LA PEINTURE

1. Le ponçage de peinture à base de plomb n’est P AS RECOMMANDÉ car il est trop dif ficile

de maîtriser la poussière contaminée. Les enfants et les femmes enceintes courent le plus

grand risque d’intoxication par le plomb.

2. Puisqu’il est difficile de savoir, sans une analyse chimique, si une peinture contient du

plomb, on recommande de suivre les mesures de précaution décrites ci-après.

SÉCURITÉ PERSONNELLE

1. S’assurer qu’aucun enfant ni femme enceinte n’entre dans la zone de travail avant qu’elle

ait été nettoyée à fond.

2. Toute personne qui entre dans la zone de travail doit porter un masque antipoussière ou

un appareil respiratoire; le filtre doit être remplacé chaque jour ou lorsque la respiration

devient difficile.

REMARQUE : SEULS LES MASQUES QUI PROTÈGENT CONTRE LES POUSSIÈRES

ET LES ÉMANATIONS DE PLOMB DOIVENT ÊTRE UTILISÉS, CAR LES MASQUES

ORDINAIRES N’OFFRENT PAS LA PROTECTION VOULUE. CONSULTER LE

QUINCAILLIER POUR OBTENIR UN MASQUE APPROUVÉ PAR LE NIOSH.

SÉCURITÉ ENVIRONNEMENTALE

1. Enlever la peinture de manière à réduire au minimum la quantité de poussière produite.

2. Sceller les zones où on enlève la peinture au moyen de grandes feuilles de plastique

d’une épaisseur de 4 mm.

3. Poncer ponçage de manière à éviter autant que possible de traîner de la poussière à

l’extérieur de la zone de travail.

FIXATION DES DISQUES ABRASIFS

ARRÊTER ET DÉBRANCHER L'OUTIL.

Utiliser un plateau porte-disque pour poncer au moyen d'une meuleuse d'angle.

1. Retirer le dispositif de protection.

2. Insérer la bride interne, le plateau porte-disque, le disque (tous deux vendus séparément)

et la bride externe sur la broche, de la manière illustrée Fig. 8. La Figure 8A illustre la

manière de fixer un disque abrasif muni d’un tampon de caoutchouc.

3. Serrer le disque abrasif tel qu'illustré Fig. 9 en appuyant sur le bouton de verrouillage tout

en faisant tourner à la main le disque.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Page 4

gado antes de conectar. Sostener una herramienta con el dedo en el interruptor o conectarla sin fijarse si el interruptor está en posición de encendido propicia los accidentes.

•Retire las llaves de ajuste antes de encender la herramienta. Una llave que se deja en

una pieza giratoria puede ocasionar lesiones personales.

•No se sobreextienda. Conserve siempre los pies bien apoyados, al igual que el equilibrio. La posición correcta de los pies y el equilibrio permiten controlar mejor la herramienta

en situaciones inesperadas.

•Utilice equipo de seguridad. Siempre utilice protección en los ojos. Se deben utilizar

mascarillas contra polvo, zapatos antiderrapantes, casco o protectores para los oídos para

tener las condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

•Conserve los mangos secos, limpios y libres de aceite y grasa. Es recomendable uti-

lizar guantes de goma, esto le permitirá controlar mejor la herramienta.

•Utilice prensas u otros medios prácticos para asegurar y apoyar la pieza de trabajo

en una plataforma estable. Sujetar las piezas con la mano o contra su cuerpo es inestable

y puede originar la pérdida de control.

•No utilice la herramienta si el interruptor no enciende y apaga. Cualquier herramienta

que no pueda controlarse por medio del interruptores peligrosa y debe reemplazarse.

•Desconecte la clavija de la toma de corriente antes de hacer cualquier ajuste, cambio de accesorios o de guardar la herramienta. Tales medidas de seguridad preventivas

reducirán el riesgo de que la herramienta se encienda accidentalmente.

•Guarde las herramientas fuera del alcance de los niños y de otras personas no

capacitadas. Las herramientas son peligrosas en manos de personas no capacitadas.

•Cuide sus herramientas. Conserve las herramientas de corte afiladas y limpias. Las

herramientas que reciben un mantenimiento adecuado, con piezas de corte afiladas, difícilmente se atascan y son más fáciles de controlar.

•Verifique la alineación de las piezas móviles, busque fracturas en las piezas y cualesquiera otras condiciones que puedan afectar la operación de las herramientas. Si

está dañada, lleve su herramienta a servicio antes de usarla de nuevo. Muchos acci-

dentes se deben a herramientas con mantenimiento pobre.

•Solamente use accesorios que el fabricante recomiende para su modelo de herramienta.

Los accesorios que estén diseñados para una herramienta, pueden volverse peligrosos

cuando se emplean con otra.

SERVICIO

•El servicio a las herramientas lo debe efectuar únicamente personal calificado. El

servicio o mantenimiento realizado por personal no calificado puede originar riesgos de

lesiones.

•Cuando efectúe servicio a una herramienta, utilice únicamente refacciones idénticas. Siga las instrucciones de la sección de Mantenimiento de este manual. El empleo

de piezas no autorizadas o no seguir las instrucciones de mantenimiento puede originar riegos de choque eléctrico o lesiones.

REGLAS DE SEGURIDAD ESPECIFICAS

•Siempre utilice la guarda apropiada con una piedra de esmeril. La guarda protege al operador de fragmentos de la piedra.

•Los accesorios deben estar clasificados para al menos la velocidad recomendada en

la etiqueta de advertencia de la herramienta. Las piedras y otros accesorios que funcio-

nan a una velocidad mayor a la de su clasificación pueden salir despedidos y ocasionar

lesiones.

•Sujete la herramienta por las superficies de agarre aislantes cuando efectúe una

operación en la que la herramienta de corte pudiese hacer contacto con cableado

oculto o con su propio cable. El contacto con un cable “vivo” hará que las partes metáli-

cas de la herramienta que estén expuestas “vivan” y descarguen al operador.

REGLAS DE SEGURIDAD ADICIONALES

•UTILICE SIEMPRE PROTECCION PARALOS OJOS

•CONSERVE LAS GUARDAS EN SU SITIO

•Utilice exclusivamente ruedas de esmeril que tengan indicada en la etiqueta una velocidad

máxima de operación de por lo menos las “RPM sin carga” (no load RPM) indicadas en la

placa de identificación de la herramienta.

•Antes de usar la herramienta, revise siempre todos los accesorios en busca de cuarteaduras o defectos. ¡Descarte de inmediato la pieza si tiene un desperfecto de esta clase!

Deberá revisar, del mismo modo, la rueda cuando sospeche que la unidad ha caído o se ha

golpeado.

•Al accionar la herramienta (con una rueda nueva o de reemplazo instalada), sujétela bien

dentro de una zona protegida adecuadamente y déjela funcionar durante un minuto. Si la

rueda tiene una cuarteadura o una hendidura inadvertidas, deberá romperse en pedazos en

menos de un minuto. Nunca accione una herramienta cuando haya una persona alineada

con la rueda: esto incluye al propio operador.

•Evite que la rueda opere a saltos o se maltrate mientras funciona. Si sucediera así, apague

y desconecte la herramienta y revise la rueda.

•EMPLEE SIEMPRE GUARDAS cuando utilice discos con centro hendido o piedras de

copa.

•Limpie la herramienta periódicamente.

PRECAUCION: algunos tipos de madera contienen conservadores como el arsenato

cúprico de cromo (CCA) que pueden ser tóxicos. Cuando lije estos materiales, necesita

tener precaución para evitar la inhalación y para minimizar el contacto de estas sustancias

con la piel.

PRECAUCION: El uso de esta herramienta puede generar polvos con contenido de pro-

ductos químicos que se sabe pueden causar cáncer, defectos de nacimiento u otros daños

reproductivos. Utilice la protección respiratoria adecuada.

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..............................volts SPM........................Golpes por minuto

A ..............................amperes Hz ..........................hertz

W..............................watts min..........................minutos

............................corriente alterna ......................corriente directa

n

o..............................velocidad sin carga

............................construcción clase II

..............................erminales de conexión a tierre

............................símbolo de alerta seguridad .../min......................revoluciones o

reciprocaciones

por minuto

CABLE DE EXTENSION

Cuando utilice un cordón de extensión, asegúrese de emplear uno con el calibre suficiente

para soportar la corriente necesaria para su producto. Una extensión con calibre menor al

necesario causará una caída en el voltaje de la línea, resultando en pérdida de potencia y

sobrecalentamiento. El cuadro siguiente muestra los calibres correctos para usarse de

acuerdo con la longitud de la extensión y el amperaje especificado. Si tiene dudas, utilice el

calibre siguiente, más pesado. Cuanto más pequeño el número de calibre del alambre,

mayor la capacidad del cable.

MOTOR

Su herramienta funciona con un motor Black & Decker específico. Asegure que su

alimentación de corriente corresponda a la indicada en la placa de identificación. Una

indicación de 120 voltios, 50/60 Hz o 120 voltios, sólo corriente alterna (AC only), significa

que la herramienta está diseñada para operar con corriente doméstica normal de 120

voltios. Si el voltaje sufre disminuciones de más de 10%, se producirá una pérdida de poder

y el sobrecalentamiento de la herramienta. Todas las herramientas Black & Decker se

prueban en fábrica. Si su herramienta no funciona, verifique la alimentación de corriente.

MANGO AUXILIAR (FIG. 1)

Su esmeriladora viene acompañada de un mango auxiliar (5) de tres posiciones que puede

atornillarse a cualquier lado de la caja de la esmeriladora, así como a la parte superior. Este

mango DEBE USARSE SIEMPRE para mantener la herramienta completamente

controlada.

ADVERTENCIA: Lea y comprenda todas las instrucciones. No hacerlo puede originar ries-

gos de choque eléctrico, incendio y lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

•Conserve su área de trabajo limpia y bien iluminada. Las bancas amontonadas y las

zonas oscuras propician los accidentes.

•No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición de los polvos o los vapores.

•Conserve a observadores, niños y visitantes alejados mientras opera una herramienta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

•Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(con una pata más ancha que la otra.) Esta clavija se acoplará únicamente en una toma

de corriente polarizada de una manera. Si la clavija no se acopla al contacto, inviértala. Si aún así no se ajusta, comuníquese con un electricista calificado para que le

instalen una toma de corriente polarizada apropiada. El doble aislamiento elimina la

necesidad de cables con tres hilos y sistemas de alimentación con conexión a tierra.

•Evite el contacto corporal con superficies aterrizadas tales como tuberías, radiadores, hornos y refrigeradores. Hay un gran riesgo de choque eléctrico si su cuerpo hace

tierra.

•No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha

humedad. El agua que se introduce en las herramientas aumenta el riesgo de descargas

eléctricas.

•No maltrate el cable. Nunca tome el cable para transportar una herramienta ni para

desconectarla de la toma de corriente. Consérvelo alejado de calor aceite, bordes afilados o piezas móviles. Cambie inmediatamente los cables dañados. Los cables daña-

dos aumentan el riego de choque eléctrico.

•Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión marcada "W-A" o "W". Estas extensiones están clasificadas para uso a la intemperie y para

reducir el riesgo de choques eléctricos.Cuando utilice una extensión, asegúrese de emplear

una con el calibre uficiente para soportar la corriente necesaria para su herramienta. Una

extensión con calibre inadecuado causará una caída en el voltaje de la línea resultando en

pérdida de potencia y sobrecalentamiento. La tabla siguiente muestra el calibre correcto

para usarse, relativo a la longitud de la extensión y el amperaje mencionado en la placa de

identificación. Si tiene dudas, utilice el calibre siguiente. Mientras más pequeño sea el

número del calibre, mayor será su capacidad.

SEGURIDAD PERSONAL

•Esté alerta concéntrese en lo que está haciendo. Recurra al sentido común cuando

opere una herramienta eléctrica. No opere ninguna herramienta si se encuentra fatigado o bajo la influencia de drogas, alcohol o medicamentos. Un momento de desa-

tención mientras se operan herramientas eléctricas puede ocasionar lesiones graves.

•Vístase de manera adecuada. No tenga puestas ropas o artículos de joyería flojos.

Cubra su cabello si lo tiene largo. Conserve su cabello, sus ropas y guantes alejados

de las piezas móviles. Las piezas de vestir flojas, las joyas y el cabello largo pueden resul-

tar atrapados por las piezas móviles.

•Evite el encendido accidental. Asegúrese que el interruptor esté en posición de apa-

INFORMACION QUE DEBE SABER

• Espere hasta que la piedra de esmeril alcance su velocidad completa antes de

aplicarla a la pieza de trabajo.

• Sujete la esmeriladora en el ángulo apropiado, como se muestra en la Fig.

11,12.

MANUAL DE INSTRUCCIONES

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7.62 7.63-15.24 15.25-30.48 30.49-45.72

240V 0-15.24 15.25-30.48 30.49-60.96 60.97-91.44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

RENSEIGNEMENTS GÉNÉRAUX

CONSEILS PRATIQUES

• Tenir la meuleuse en saisissant le boîtier d'une main et en agrippant fermement la poignée

auxiliaire de l'autre, tel qu'illustré à la Fig. 10.

• Toujours placer le dispositif de protection de manière à ce que la partie visible du disque

soit le moins possible orientée vers l'utilisateur.

• S'attendre à voir surgir une gerbe d'étincelles quand le disque entre en contact avec une

surface métallique.

• Maintenir entre le disque et la surface de travail Fig. 11 un angle d'environ 30° pour le

meulage et de 10 à 15° pour le ponçage Fig. 12, ce qui assurera une meilleure maîtrise de

l'outil et un retrait optimal de matériau, tout en réduisant au minimum les risques de

surcharge.

MISE EN GARDE : On doit toujours porter des lunettes de protection quand on utilise

cet outil.

ENTRETIEN DE L'OUTIL

NETTOYAGE : L’entretien périodique doit comprendre le nettoyage à l’air comprimé du

carter du moteur pour éliminer la poussière et les particules métalliques ou abrasives

logées à l’intérieur de celui-ci. Ces dernières tendent en effet à s’accumuler sur les surfaces

internes et peuvent engendrer des risques de choc électrique si elles ne sont pas souvent

nettoyées.

LUBRIFICATION

Les outils Black & Decker sont adéquatement lubrifiés en usine et sont donc prêts à utiliser ,

mais ils doivent être lubrifiés tous les ans, selon l'usage qu'on en fait (les outils utilisés pour

des gros travaux ou qui sont exposés à la chaleur doivent être lubrifiés plus souvent). La

lubrification devrait être confiée à des techniciens qualifiés, comme ceux des centres de

service Black & Decker autorisés.

IMPORTANT

Pour garantir la SÉCURITÉ et la FIABILITÉ de ce produit, l’outil doit être réparé, entretenu

et réglé par un centre de service Black & Decker autorisé ou qualifié; seules des pièces de

rechange identiques doivent être utilisées.

ACCESSOIRES

Les accessoires recommandés pour l’outil sont vendus chez les dépositaires locaux ou les

centres de service autorisés. Pour obtenir de l’aide concernant l’achat d’un accessoire,

composer le 1 800-544-6986.

AVERTISSEMENT : L’usage d’un accessoire non recommandé peut présenter un

danger.

RENSEIGNEMENTS RELATIFS AU SERVICE

Black & Decker offre un réseau complet de centres de service autorisés ou lui appartenant

d'un bout à l'autre de l'Amérique du Nord. Tous les centres de service Black & Decker

emploient du personnel formé pour assurer un service fiable et efficace aux utilisateurs

d'outils électriques. Qu'on ait besoin de conseils techniques, de réparations ou de pièces de

rechange sorties tout droit de l'usine, il suffit de communiquer avec le centre Black & Decker

le plus proche. Pour le trouver, consulter les pages jaunes sous la rubrique « Outils » ou

composer le 1-800-544-6986.

GARANTIE COMPLÈTE DE DEUX ANS POUR USAGE RÉSIDENTIEL

Black & Decker (U.S.) Inc. garantit ce produit pour une période de deux ans contre tout

défaut de matériel ou de fabrication. Le produit défectueux sera réparé sans frais, suivant

l’un des deux modes suivants.

Le premier mode consiste en un échange seulement. On doit retourner le produit au

détaillant qui l’a vendu (pourvu qu’il s’agisse d’un détaillant participant), en respectant les

délais stipulés dans sa politique d'échange (normalement de 30 à 90 jours après la vente).

Une preuve d’achat peut être requise. On doit vérifier la politique de retour du détaillant pour

tout produit retourné après le délai prescrit pour les échanges.

Le deuxième mode consiste à emporter ou à envoyer le produit (prépayé) à un centre Black

& Decker ou à un centre de service autorisé, pour réparation ou remplacement, selon notre

choix. Une preuve d’achat peut être requise. Les centres Black & Decker et les centres de

service autorisés figurent dans les pages jaunes sous la rubrique « Outils ».

Cette garantie ne s’applique pas aux accessoires. Elle confère des droits légaux particuliers

à l’acheteur, en sus des autres droits provinciaux dont il pourrait bénéficier. Pour tout

renseignement, s'adresser au gérant du centre Black & Decker le plus proche. Ce produit

n’est pas destiné à un usage commercial

Imported by / Importé par Black & Decker Canada Inc.

100 Central Ave. Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

Page 5

ENCENDIDO DE LA HERRAMIENTA

Para encender su esmeriladora angular, oprima el interruptor de gatillo (1). La

esmeriladora angular se apagará al soltar el gatillo. Para operar la herramienta en modo

continuo, oprima el botón de encendido permanente (2) al mismo tiempo que el gatillo.

Suelte el gatillo antes de liberar el botón de encendido permanente. Para apagar su

esmeriladora angular desde el modo de operación continua, oprima el interruptor de gatillo

una vez y suéltelo.

SOBRECARGA

Las sobrecargas dañan el motor de su esmeriladora angular. Esto puede ocurrir si la

esmeriladora angular se somete a usos pesados durante periodos prolongados. No ejerza

nunca presión excesiva sobre su esmeriladora para acelerar su tarea. Los discos

abrasivos operan de manera más eficiente con presión ligera, lo cual evita que la

esmeriladora angular pierda velocidad.

ESMERILADO Y LIMPIEZA CON CEPILLO METÁLICO

COLOCACIÓN DE LA GUARDA PROTECTORA (FIG. 2)

APAGUE Y DESCONECTE LA HERRAMIENTA. NUNCAPULA NI LIMPIE CON EL

CEPILLO METÁLICO SIN HABER COLOCADO ANTES LAGUARDA PROTECTORA.

Coloque la esmeriladora angular sobre una mesa, con la mecha hacia arriba. Haga

coincidir la

arandela con la ranura en la cartela. Presione la guarda hacia abajo y gírela en el mismo

sentido que la flecha. NOTA: ELperno de seguridad de la guarda impide que la guarda se

afloje.

COLOCACIÓN DE LOS DISCOS CON CENTRO HUNDIDO (FIGS. 3, 4, 5, 6)

APAGUE Y DESCONECTE LA HERRAMIENTA. [symbol] ADVERTENCIA: nunca utilice

ninguno de los discos con centro hundido sin colocar antes la guarda protectora.

1. Asegure que la guarda esté bien colocada. Coloque sobre la mecha la arandela interna

(a)

indicada en la Fig. 3. Asegure que quede colocada sobre las dos cubiertas planas.

2. Coloque el disco abrasivo en la mecha y la arandela interior (a) indicada en la Fig. 4.

3. Haga entrar en su sitio la arandela exterior de rosca (b) de la Fig. 5, asegurando que su

cara está en la dirección correcta para el tipo de disco colocado. Cuando se utilizan los

discos de pulido, la arandela (b) se coloca dejando la parte elevada con la cara volteada

hacia el disco. Cuando se utilizan los discos de corte, la arandela (b) se coloca con la parte

interna con la cara volteada en dirección contraria al disco.

4. Presione el botón de sujeción de la mecha y gire la mecha hasta que quede fija en su

sitio. Manteniendo presionado el botón de sujeción de la mecha, ajuste la arandela externa

con la llave provista como se muestra en la Fig. 6.

5. Cuando utilice un disco con centro hundido, sostenga la herramienta formando un

ángulo de 30º entre el disco y la superficie de trabajo.

ADVERTENCIA: verifique la velocidad estipulada sobre el disco de centro hundido.

Nunca utilice un disco de velocidad menor a la velocidad indicada sobre la placa de

fabricante de la herramienta.

COLOCACIÓN DEL CEPILLO METÁLICO ACAMPANADO

El cepillo metálico acampanado se atornilla directamente a la mecha de la herramienta, sin

arandelas.

ESMERILADO

RETIRADO DE LA GUARDA PROTECTORA (FIG. 7, SÓLO PARAESMERILADO)

APAGUE YDESCONECTE LAHERRAMIENT A.

NOTA: PARANO PERDER EL CONTROL DE LA HERRAMIENTA, NO LADEJE SOBRE

NINGUNA SUPERFICIE ANTES DE QUE EL ACCESORIO SE HAYA DETENIDO

COMPLETAMENTE.

Como se indica en la Fig. 7, coloque la pulidora sobre una mesa, con la mecha hacia

arriba. Gire la guarda en la dirección de la flecha hasta que llegue a su tope. Utilice un

pequeño destornillador para aflojar el perno de seguridad en la ranura. Manteniendo

presionado hacia abajo el perno con el destornillador, gire ligeramente la guarda en

dirección de la flecha para mantener el perno de seguridad aflojado. Retire el destornillador

y continúe girando la guarda hasta que quede libre.

PRECAUCIONES DURANTE EL LIJADO DE PINTURA

1. NO ES RECOMENDABLE lijar pinturas con base de plomo debido a la dificultad para

controlar el polvo contaminado. El envenenamiento por plomo es sobre todo peligroso para

los niños y las mujeres embarazadas.

2. Ya que es difícil determinar si una pintura contiene plomo sin efectuar un análisis

químico, recomendamos tomar las siguientes precauciones al lijar cualquier tipo de

pintura:

SEGURIDAD PERSONAL

1. Los niños y las mujeres embarazadas no deben entrar al área de trabajo antes de que

esta última se encuentre perfectamente limpia.

2. Todas las personas que ingresen al área de trabajo deben utilizar una mascarilla contra

polvo o un respirador. El filtro debe ser reemplazado a diario o siempre que el usuario

tenga dificultad para respirar a través del dispositivo.

NOTA: SÓLO DEBEN UTILIZARSE MASCARILLAS ESPECÍFICAMENTE DISEÑADAS

PARA PARTÍCULAS Y EMANACIONES ORIGINADAS POR PINTURAS QUE

CONTIENEN PLOMO. LAS MASCARILLAS CONTRA EL POLVO DE PINTURAS

CORRIENTES NO PROPORCIONAN ESE TIPO DE PROTECCIÓN. CONSULTE AL

DISTRIBUIDOR DE SU LOCALIDAD PARAOBTENER UNA MÁSCARA ADECUADA.

SEGURIDAD AMBIENTAL

1. Quitar la pintura tratando de generar la menor cantidad de polvo posible.

2. Sellar con hojas de plástico gruesas (mínimo 0,1 mm) los accesos a las áreas donde se

esté quitando la pintura.

3. Lijar tratando de reducir la salida de polvo de pintura fuera del área de trabajo.

INSTALACIÓN DE DISCOS ABRASIVOS

APAGUE YDESCONECTE LAHERRAMIENT A.

Utilice un disco abrasivo con almohadilla de respaldo para lijar con su esmeriladora

angular.

1. Retire la guarda.

2. Coloque la arandela (la almohadilla de respaldo y el disco abrasivo se venden por

separado) y la arandela exterior en la mecha como se indica en la Fig. 8. La Fig. 8A

muestra cómo fijar un disco abrasivo con un almohadilla de respaldo de caucho.

3. Apriete el disco abrasivo como se muestra en la Fig. 9, soltando el botón de seguridad

de la mecha y girando con la mano el disco abrasivo.

INFORMACIÓN GENERAL

CONSEJOS PRÁCTICOS

• Sujete su esmeriladora angular con una mano en el cuerpo y la otra mano alrededor del

mango lateral con firmeza como se muestra en la Figura 10.

• Coloque siempre la guarda de manera que la mayor parte expuesta del disco apunte

hacia el lado opuesto a usted.

• Prepárese para las chispas que saltarán cuando el disco haga contacto con el metal.

• Para trabajos de esmerilado, mantenga un ángulo aproximado (Fig. 11) de 30° entre el

disco y la superficie de trabajo, y entre 10º y 15º para lijar (Fig. 12) para mejor control de la

herramienta, eliminación de materiales y mínima sobrecarga.

ADVERTENCIA: Utilice siempre protección para los ojos cuando opere esta

herramienta.

MANTENIMIENTO DE LA HERRAMIENTA

LIMPIEZA: Un procedimiento indispensable para el mantenimiento de su unidad es

eliminar a intervalos regulares el polvo y rebabas acumulados en la coraza de la

herramienta, mediante sopleteado con aire comprimido. Amenudo se acumulan en la

superficie interior de la herramienta polvo y partículas metálicas que pueden causar

choques eléctricos, razón por la cual deben eliminarse con frecuencia.

LUBRICACIÓN

Las herramientas Black & Decker vienen lubricadas de fábrica y están listas para

emplearse. Deben lubricarse cada año, según la frecuencia con que se utilicen (las

unidades utilizadas en trabajos pesados y expuestas al calor pueden requerir una

lubricación más frecuente). Dicha lubricación debe ser realizada por el personal

especializado de los centros de servicio Black & Decker u otro servicio autorizado.

IMPORTANTE

Para garantizar la SEGURIDAD y la FIABILIDAD del producto, las reparaciones,

mantenimiento y calibraciones deben efectuarse en centros de servicio autorizado Black &

Decker u otro servicio autorizado que utilice repuestos originales Black & Decker.

ACCESORIOS

Los accesorios recomendados para su herramienta están disponibles en el distribuidor o

centro de servicio autorizados de su localidad. Para consultas sobre accesorios, favor de

llamar al

(55) 5326-7100.

ADVERTENCIA: la utilización de accesorios no recomendados por el fabricante para

esta herramienta puede ser peligrosa.

ARA REPARACION YSERVICIO DE SUS HERRAMIENTAS ELECTRICAS FAVOR DE

DIRIGIRSE ALCENTRO DE SERVICIO MAS CERCANO

CULIACAN Av. Nicolas Bravo #1063 Sur (56 77) 12 42 10

GAUDALAJARA Av . La Paz #1770 (33 38) 26 69 78

LEON Polara #32 (47 77) 13 14 56

MEXICO Sonora #134 Hiprodromo Condesa (55 55) 53 99 79

MERIDA Calle 63 #459 (99 99) 23 54 90

MONTERREY Av . Francisco I. Madero Pte. 1820-A (81 83) 72 11 25

PUEBLA 17 Norte #2057 (22 22) 46 90 20

QUERETARO Av. Madero 139 Pte. (44 22) 14 60 60

SAN LOUIS POTOSI Pedro Moreno #408 Fracc. la Victoria (44 48) 14 25 67

TORREON Blvd. Independencia, 96 pte. (87 17) 16 52 65

VERACRUZ Prolongación Diaz Miron #4280 (29 99) 21 70 18

VILLAHERMOSA Zaragoza #105 (99 33) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: (55) 5326-7100 INFORMACIÓN DE SERVICIO

SERVICIO

Black & Decker le ofrece una red propia y completa de centros de servicio autorizados en

toda Norteamérica. Todos los centros de servicio Black & Decker cuentan con personal

capacitado para proporcionarle eficaces y fiables servicios de reparación y mantenimiento

de herramientas.

Para consultas técnicas, reparaciones o repuestos originales, comuníquese con el centro

Black & Decker más cercano. Para identificar al centro de servicio de su localidad, consulte

la sección amarilla bajo "Herramientas eléctricas", o llame al

(55) 5326-7100

.

DOS AÑOS DE GARANTÍA TOTAL PARAUSO DOMÉSTICO

Black & Decker (U.S.) Inc. garantiza este producto por dos años contra cualquier falla

originada por materiales o mano de obra defectuosos. El producto defectuoso será

reemplazado o reparado sin cargo alguno en cualquiera de las dos maneras siguientes:

La primera opción (únicamente para cambios), es devolver el producto al vendedor del

cual compró la herramienta (siempre que sea un distribuidor participante). Las

devoluciones deberán hacerse dentro del plazo estipulado por la política de cambios del

distribuidor (usualmente entre 30 y 90 días después de la compra). Es posible que se le

pida el comprobante de pago o factura. Sírvase verificar con el vendedor las políticas

específicas para devoluciones posteriores al plazo límite estipulado para cambios de

mercancía.

La segunda opción es llevar o enviar el producto (con porte de retorno pagado) a un centro

de servicio Black & Decker u otro autorizado para que la herramienta sea reparada o

reemplazada por otra (según decida el centro de servicio). Es posible que se le pida el

comprobante de pago o factura.. Los centros de servicio Black & Decker y agentes

autorizados aparecen indicados bajo “Herramientas eléctricas” en la sección amarilla del

directorio telefónico.

Esta garantía no incluye los accesorios. Esta garantía le otorga derechos legales

específicos y es posible que tenga otros derechos según la legislación de su localidad.

Para cualquier consulta, sírvase comunicarse con el gerente del centro de servicio Black &

Decker más cercano. Este producto no está destinado para uso comercial.

ESPECIFICACIONES

FS6500AG

Tensión de alimentación: 120 V~ Potencia nominal: 725 W

Frecuencia de operacion: 60 Hz Consumo de corriente: 6,5

BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 3-26-71-00

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Loading...

Loading...