Page 1

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

BBBBrrrraaaadddd NNNNaaaaiiiilllleeeerrrr //// SSSSttttaaaapppplllleeeerr

rr

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PRODUCT,

CALL 1-800-544-6986

IN MOST CASES, ABLACK & DECKER REPRESENTATIVE CAN RESOLVE YOUR PROBLEM OVER

THE PHONE. IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS

VITALTO BLACK & DECKER.

Catalog Number

FS2NC

Catalog Number FSBN125 Shown

635549-00,FS2NC 7/13/05 10:10 AM Page 1

Page 2

2

WARNING: Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury. The

symbols below are used to help you recognize this information.

indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

used without the safety alert symbol indicates potentially

hazardous situation which, if not avoided, may result in property

damage.

SAVE THESE INSTRUCTIONS

Read and understand all warnings and operating instructions before

using any tool or equipment. When using tools or equipment, basic safety precautions

should always be followed to reduce the risk of personal injury. Improper operation,

maintenance or modification of tools or equipment could result in serious injury and

property damage. There are certain applications for which tools and equipment are

designed. Black & Decker strongly recommends that this product NOT be modified

and/or used for any application other than for which it was designed.

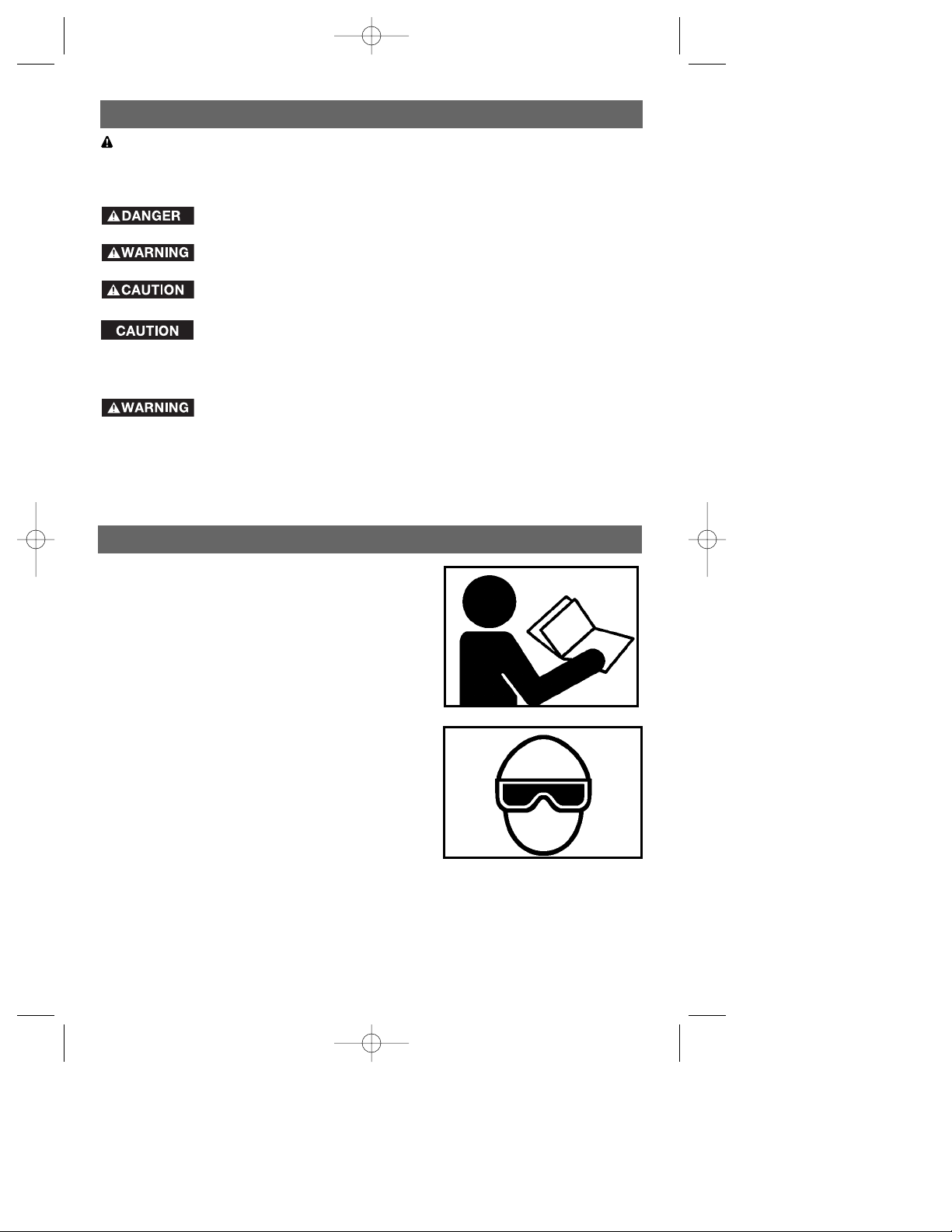

SAFETY GUIDELINES / DEFINITIONS

• Read and understand tool labels and manual.

Failure to follow warnings could result in DEATH or

SERIOUS INJURY. (Fig. 1)

• Operator and others in work area MUST wear

safety glasses with side shields. These safety

glasses must conform to ANSI Z87.1 requirements

(approved glasses have “Z87” printed or stamped on

them). (Fig. 2)

• Keep fingers AWAY from trigger when not

driving fasteners to avoid accidental firing.

Never carry tool with finger on trigger. In "contact

actuation mode", tool will fire a fastener if tool is

bumped.

• Choice of triggering method is important.

Check manual for triggering options. See “Using

the Tool“ section of this manual.

Fig. 2

Fig. 1

GENERAL SAFETY RULES

635549-00,FS2NC 7/13/05 10:10 AM Page 2

Page 3

3

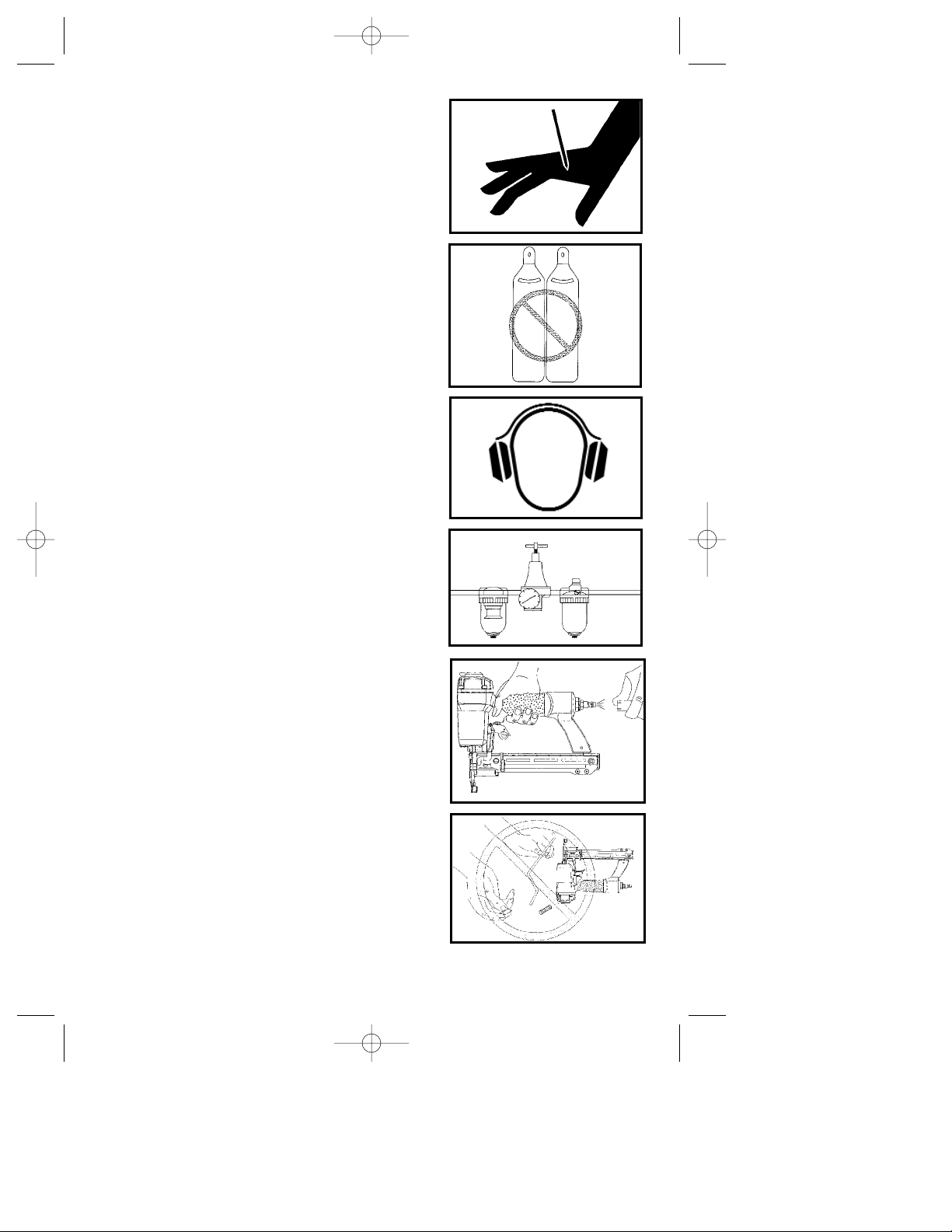

• Never point tool at yourself or others in work

area. Serious injury or death may occur if the tool

is activated. (Fig. 3)

• Never use oxygen or other bottled gasses.

Explosion will occur. Never use combustible

gases or any other reactive gas as a power

source for this tool: explosion and serious

personal injury will result. (Fig. 4)

• Wear ear protection to safe-guard against

possible hearing loss. Ear protection equipment

must conform to ANSI S3.19 requirements. (Fig. 5)

• Use clean, dry, regulated, compressed air at 70

to 120 PSI, (4.8 to 8.3 BAR). (Fig. 6)

• Do not connect tool to pressure which

potentially exceeds 200 PSI (13.7 BAR).

• All air line components (hoses, connectors,

filters, regulators, etc.) must be rated for a

maximum working pressure of at least 150 PSI

(10.3 BAR) or 150% of the maximum system

pressure, which ever is greater.

• Connect tool to air supply hose with a coupling

that automatically removes all pressure from the

tool when the coupling is disconnected. (Fig. 7).

• Disconnect tool from air supply hose before

doing tool maintenance, clearing a jammed

fastener, leaving work area, moving tool to another

location, or handing the tool to another person.

(Fig. 7)

• Never use a tool that is leaking air, has missing

or damaged parts, or requires repair. Make sure

all screws and caps are securely tightened.

(Fig. 8).

• Never use tool if safety, trigger or springs are

inoperable, missing or damaged. Do not alter or

remove safety, trigger, or springs. Make daily

inspections for free movement of trigger and

safety mechanism. (Fig. 8)

Fig. 6

Fig. 5

Fig. 3

Fig. 4

Fig. 8

Fig. 7

635549-00,FS2NC 7/13/05 10:10 AM Page 3

Page 4

4

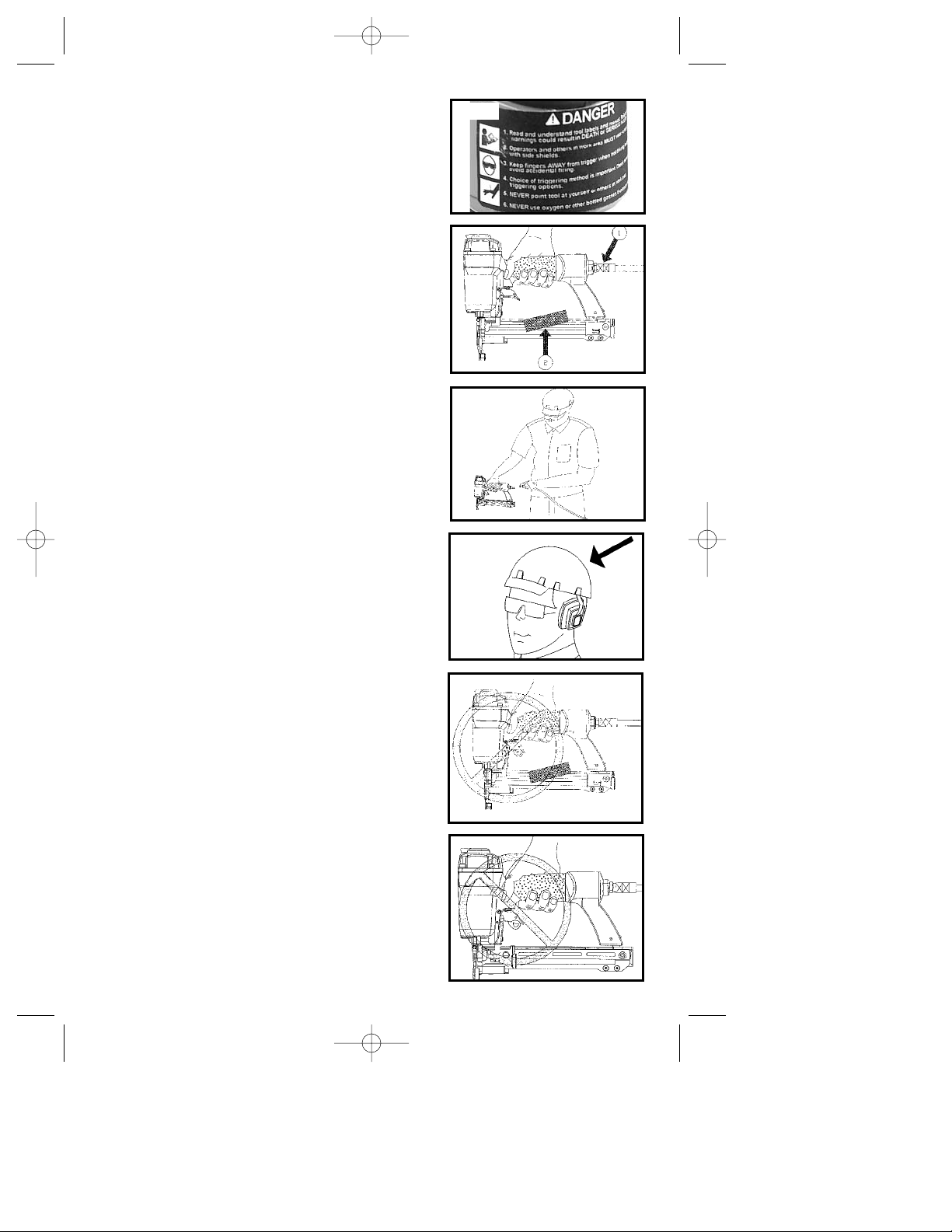

• Do not use tool without safety warning label. If

label is missing, damaged or unreadable, contact

1-800-544-6986 for a replacement. (Fig. 9)

• Only use parts, fasteners and accessories

approved by Black and Decker.

• Connect tool to air supply before loading

fasteners, to prevent a fastener from being fired

during connection. The tool driving mechanism may

cycle when tool is connected to the air supply.

(Fig. 10)

• Always assume the tool contains fasteners. No

horseplay. Respect the tool as a working

implement. (Fig. 11)

• Operator and bystanders should wear hard hats

to safeguard against possible injuries. (Fig. 12)

• Do not load fasteners with trigger or safety

depressed, to prevent unintentional firing of a

fastener. (Fig. 13

)

• Remove finger from trigger when not driving

fasteners. Never carry tool with finger on trigger. In

“Contact Actuation Mode” tool will fire a fastener if

safety is bumped while trigger is depressed.

(Fig. 14)

Fig. 9

Fig. 11

Fig. 10

Fig. 12

Fig. 13

Fig. 14

635549-00,FS2NC 7/13/05 10:10 AM Page 4

Page 5

5

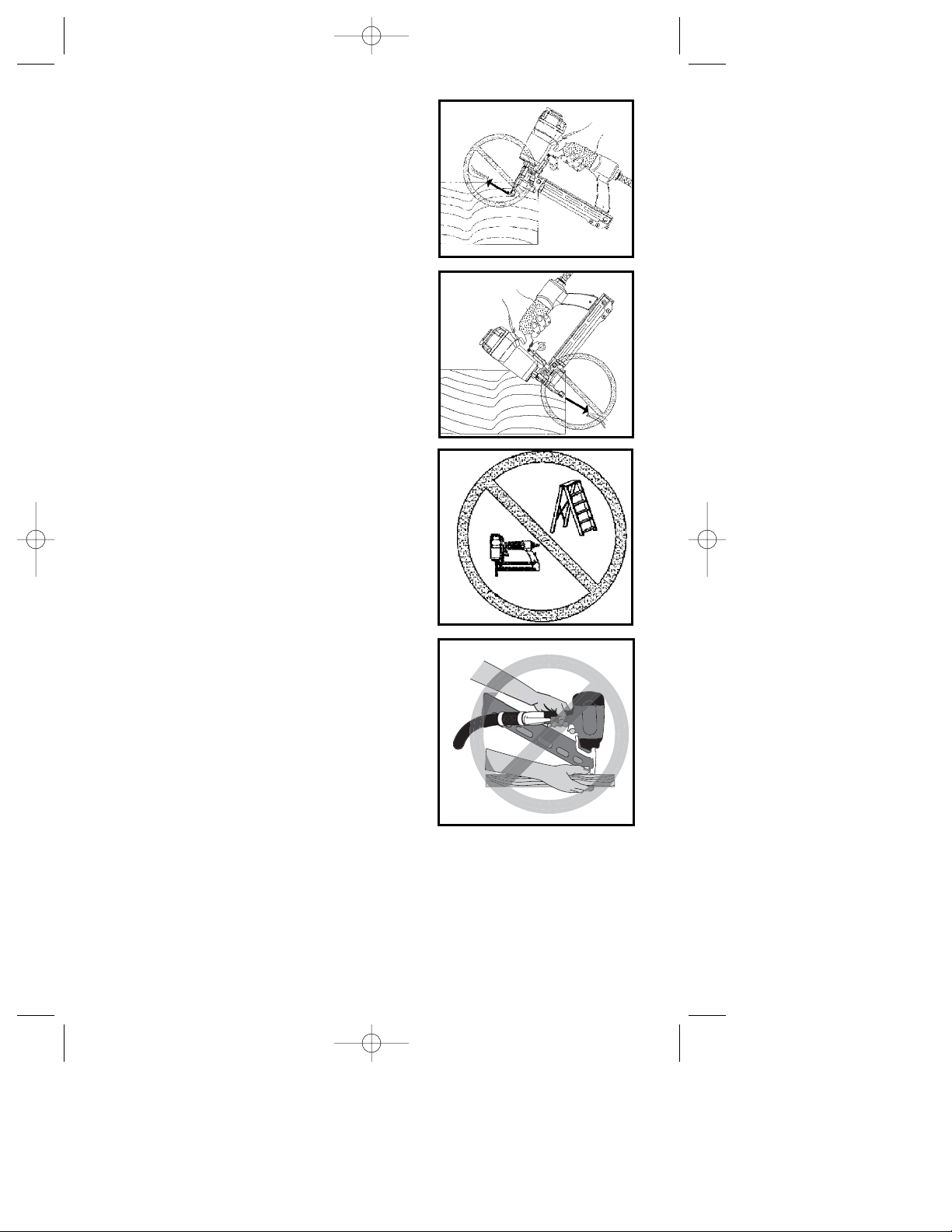

• Do not overreach. Keep proper footing and

balance at all times when using or handling the

tool.

• Fire fasteners into work surface only: never

into materials too hard to penetrate. (Fig. 15)

• Grip tool firmly to maintain control while

allowing tool to recoil away from work surface

as fastener is driven. In “Contact Actuation

Mode” if safety element is allowed to re-contact

work surface before trigger is released an

unwanted fastener will be fired.

• Do not drive fasteners on top of other

fasteners, or with the tool at too steep an angle:

the fasteners can ricochet causing personal injury.

(Fig. 15)

• Do not drive fasteners close to the edge of the

workpiece. The workpiece is likely to split

allowing the fastener to fly free or ricochet causing

personal injury. (Fig. 16)

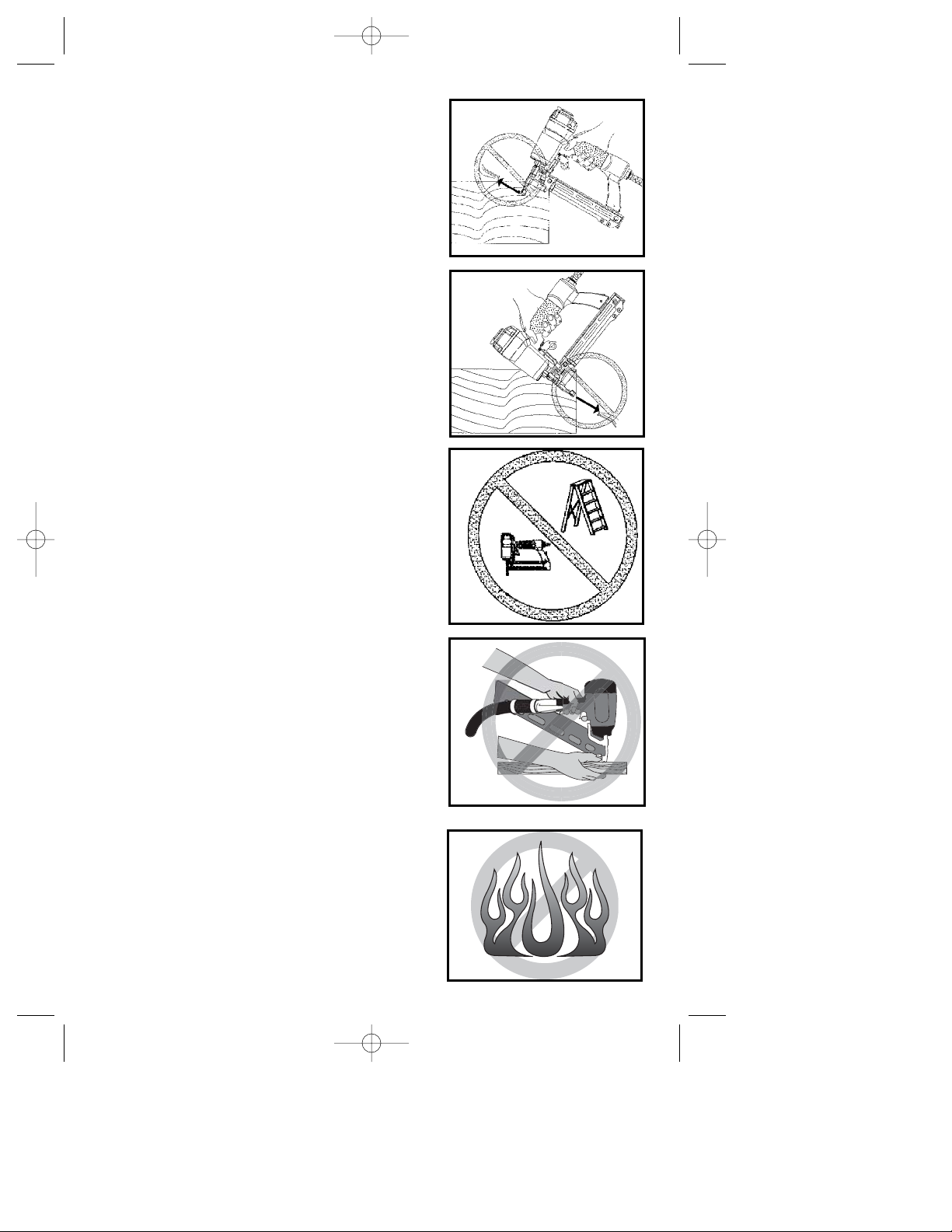

• FOR TOOLS USED IN CONTACT ACTUATION

MODE, Do not use on scaffoldings or ladders

or for tasks in which changing location involves

the use of scaffoldings, stairs, ladders, and the

like. Do not use for specific tasks such as closing

boxes or crates or fitting transportation safety

systems on vehicles and wagons. (Fig. 17)

• Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

• Make sure hose is free of obstructions or

snags. Entangled or snarled hoses can cause

loss of balance or footing.

• Always keep fingers clear of fastener track of

magazine to prevent injury from inadvertent

release of the pusher. (Fig. 18)

• Refer to the Maintenance section for detailed

information on the proper maintenance of the

tool.

• Always operate the tool in a clean, lighted

area. Be sure the work surface is clear of any

debris and be careful not to lose footing when

working in elevated environments such as

rooftops.

• Do not use tool in the presence of flammable

dust, gases or fumes. The tool may produce a

spark that could ignite gases causing a fire.

Driving a fastener into another fastener may also

cause a spark. (Fig. 19)

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

635549-00,FS2NC 7/13/05 10:10 AM Page 5

Page 6

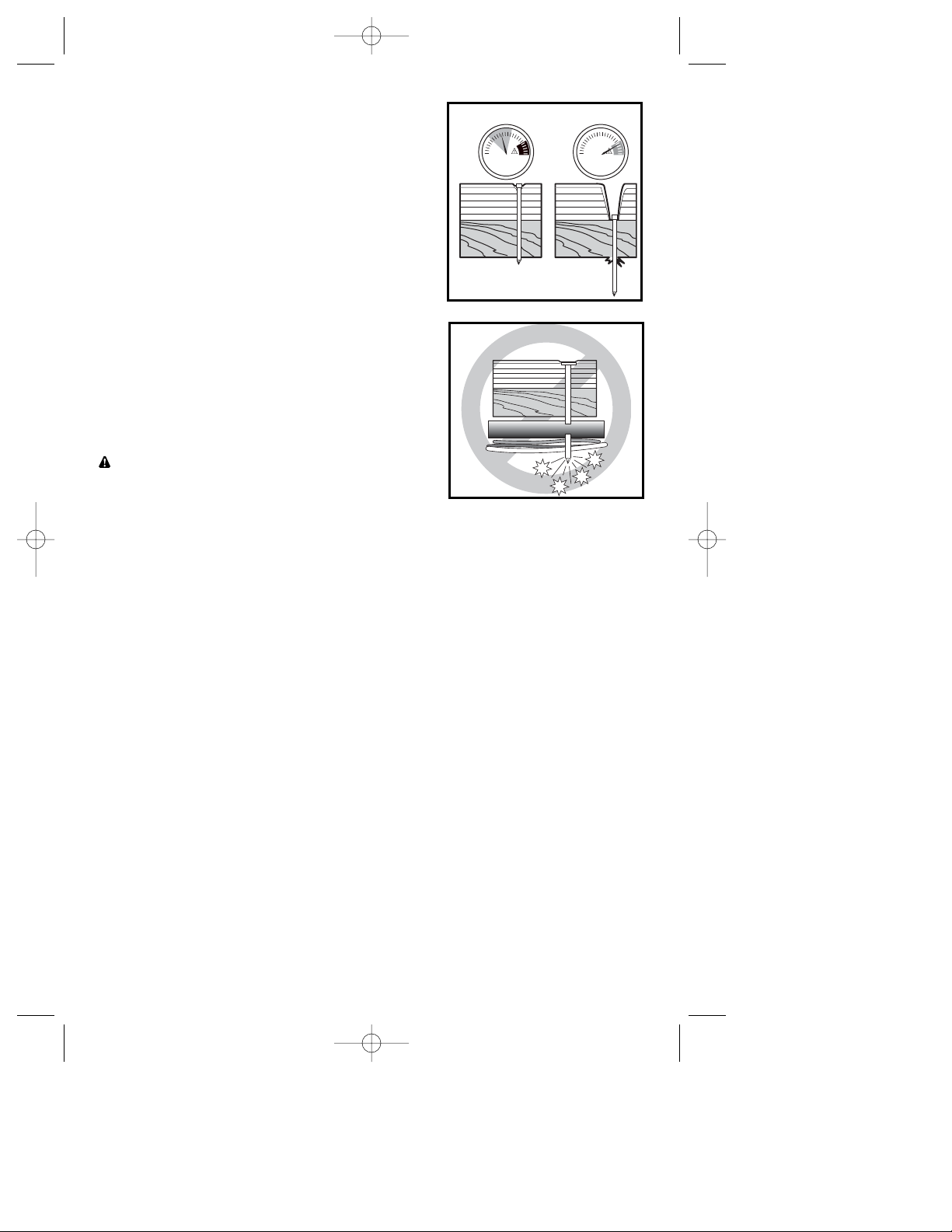

• Be aware of material thickness when

using the fastener. A protruding fastener

may cause injury.

• Be aware that when the tool is being

utilized at pressures on the high end of its

operating range, fasteners can be driven

completely through thin or very soft work

material. Make sure the pressure in the

compressor is set so that fasteners are set

into the material and not pushed completely

through. (Fig. 20)

• Do not drive fasteners blindly into walls,

floors or other work areas. Fasteners

driven into live electrical wires, plumbing, or

other types of obstructions can result in

injury. (Fig. 21)

• Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

WARNING: Use of this product will expose

you to chemicals known to the State of

California to cause cancer, birth defects and

other reproductive harm. Avoid inhaling

vapors and dust, and wash hands after

using.

6

Fig. 20

Fig. 21

635549-00,FS2NC 7/13/05 10:10 AM Page 6

Page 7

7

The FSBN125 Nailer is designed to install 18 ga. brad nails of various lengths from 3/8"

to 1

1

/4" long. Brad nails are loaded into the magazine from the side.

The FSNS100 Stapler is designed to install 18 ga. narrow crown staples of various

lengths from

3

/8" to 1" long. Narrow crown staples are loaded into the magazine from

the top.

POWER SOURCE

This tool is designed to operate on clean, dry, compressed air at regulated pressures

between 70 and 120 PSI (Pounds per Square Inch)

(4.8 to 8.3 BAR)

. The preferred

system would include a filter, a pressure regulator, and an automatic oiler located as close

to the tool as possible, within 15 ft/4.6 m is ideal.

All compressed air contains moisture and other contaminates that are detrimental to

internal components of the tool. An air line filter will remove most of these contaminates

and significantly prolong the life of the tool. If an in-line oiler is not available: place five or

six drops of air tool oil into the tool’s air inlet on a daily basis.

The tool is equipped with a 1/4" male “quick connector”. The tool must always be

connected to the air supply with a coupling such that all pressure is removed from the tool

when the coupling is disconnected.

PREPARING THE TOOL

Keep tool pointed in a safe direction when loading nails.

Never load fasteners with the contact trip or trigger activated.

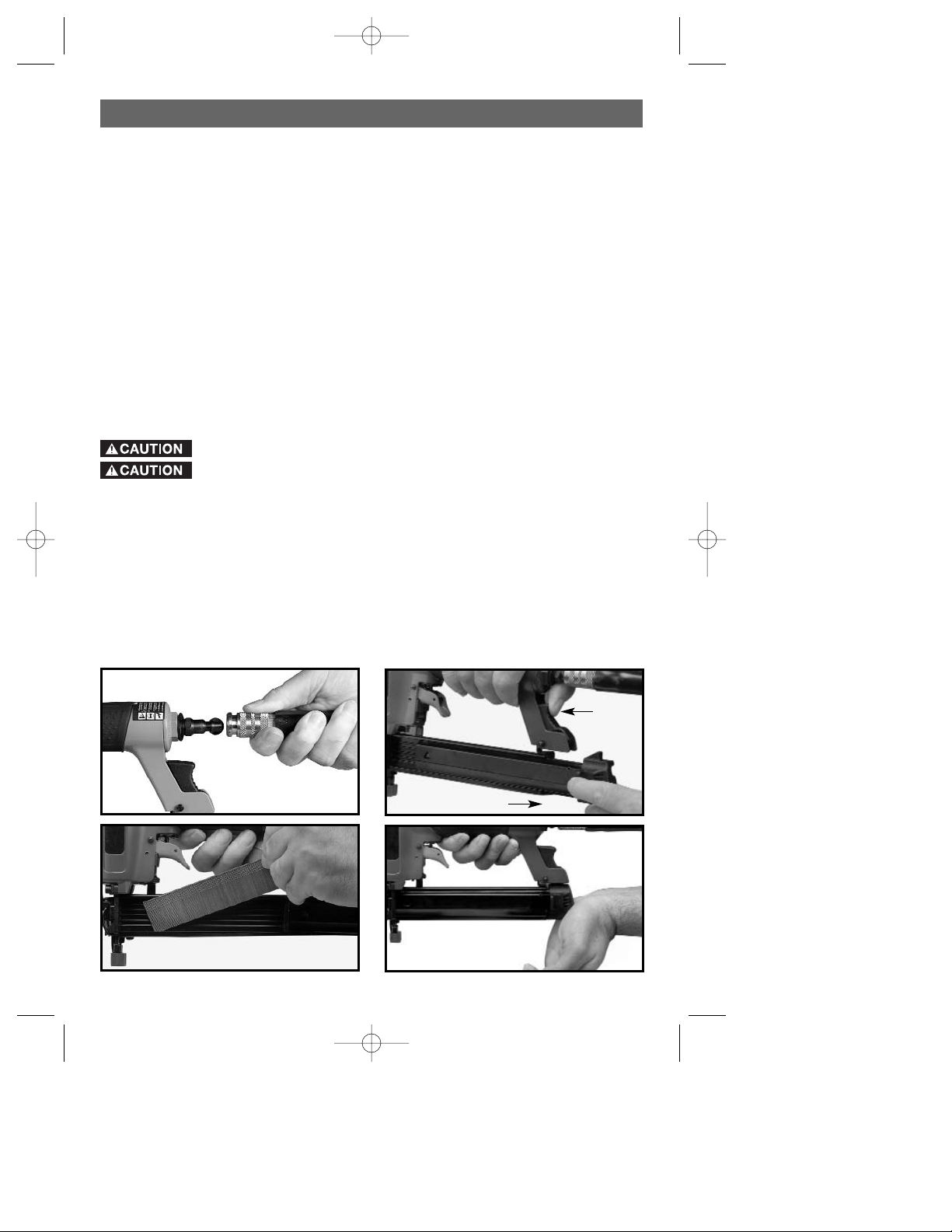

1. After reading and understanding this entire manual, connect tool to

air supply. (Fig. 22)

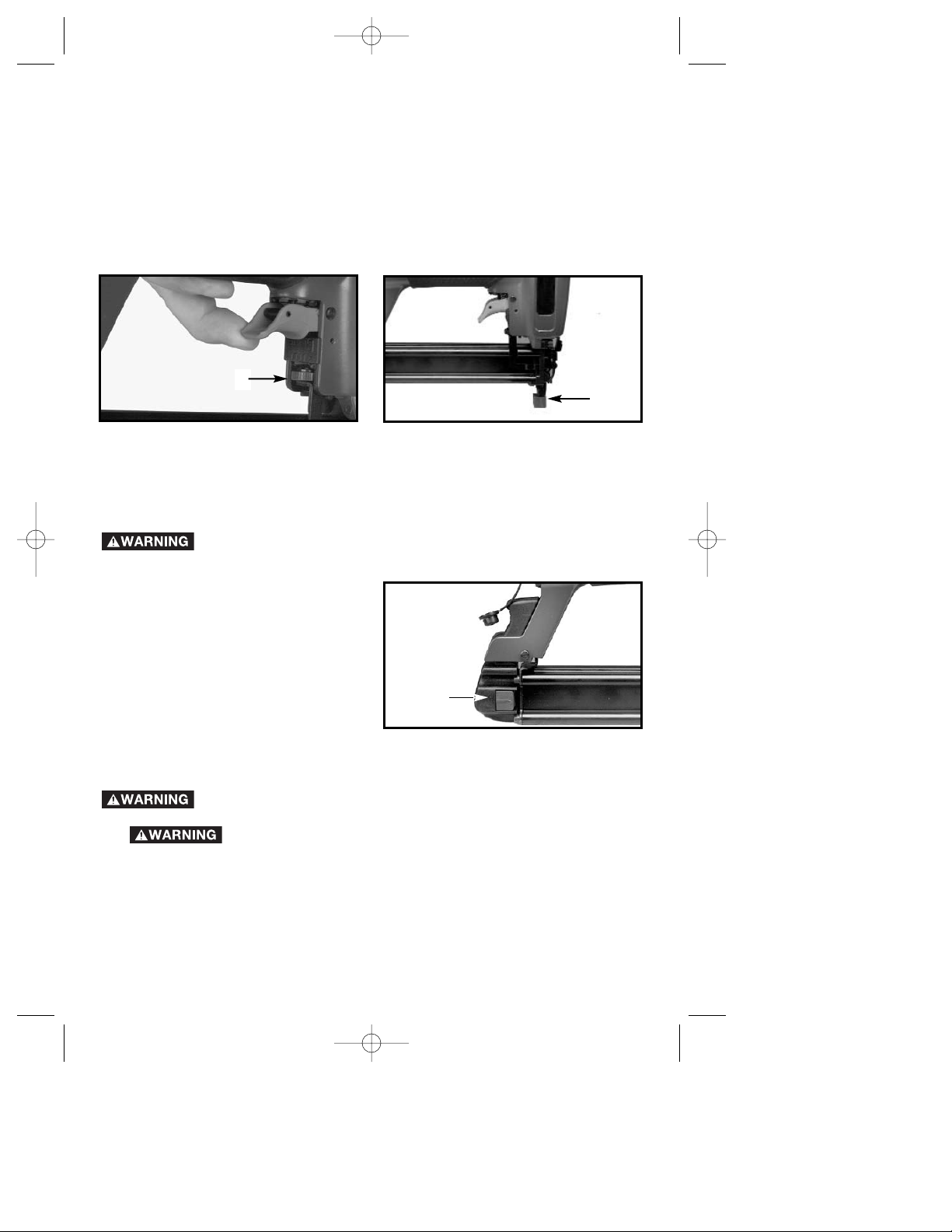

2. Depress latch and slide magazine cover open. (Fig. 23)

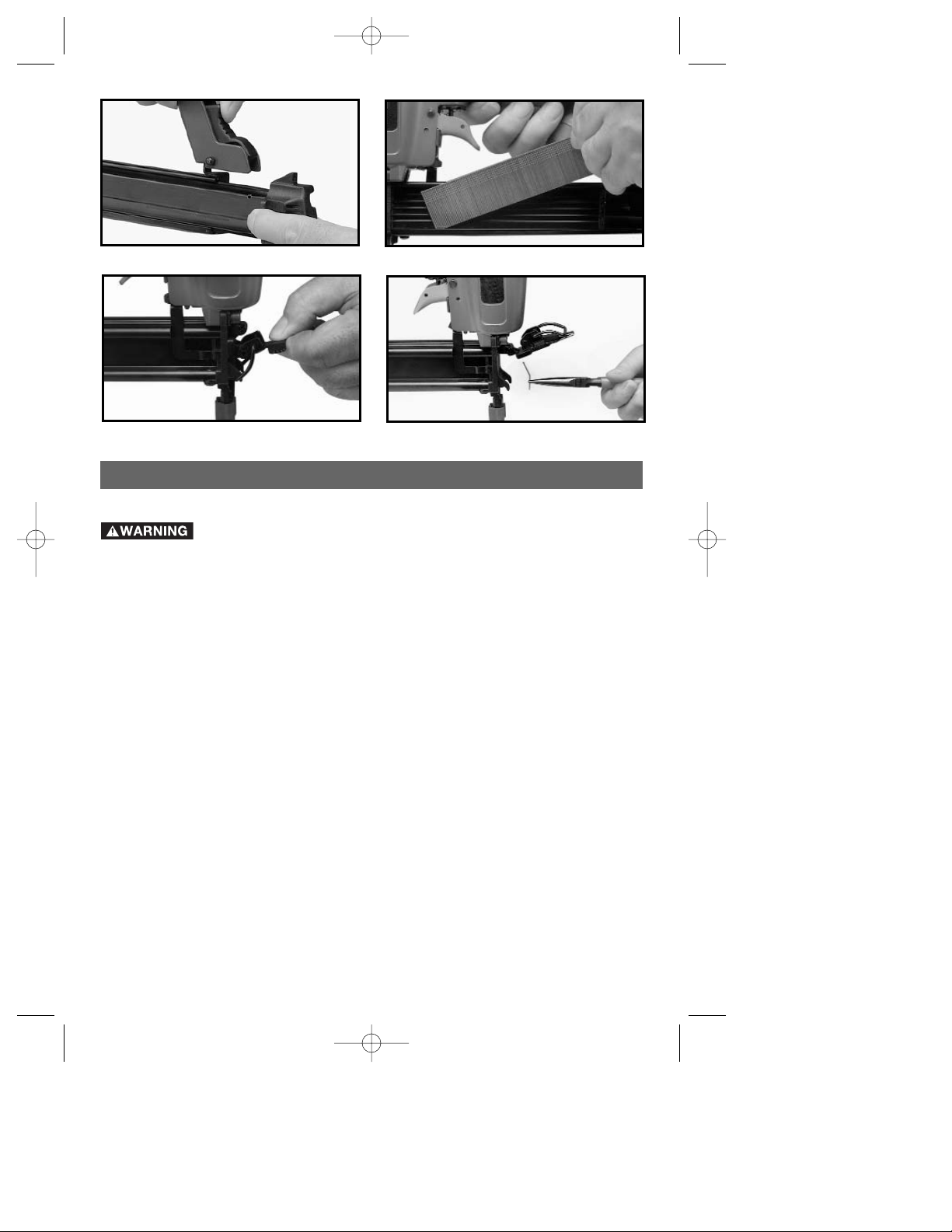

3. Insert a strip of approved fasteners. (Fig. 24) Orient fasteners with points down

in the magazine. NOTE: Brad nails are side loaded and staples are top loaded.

4. Push magazine cover closed. (Fig. 25)

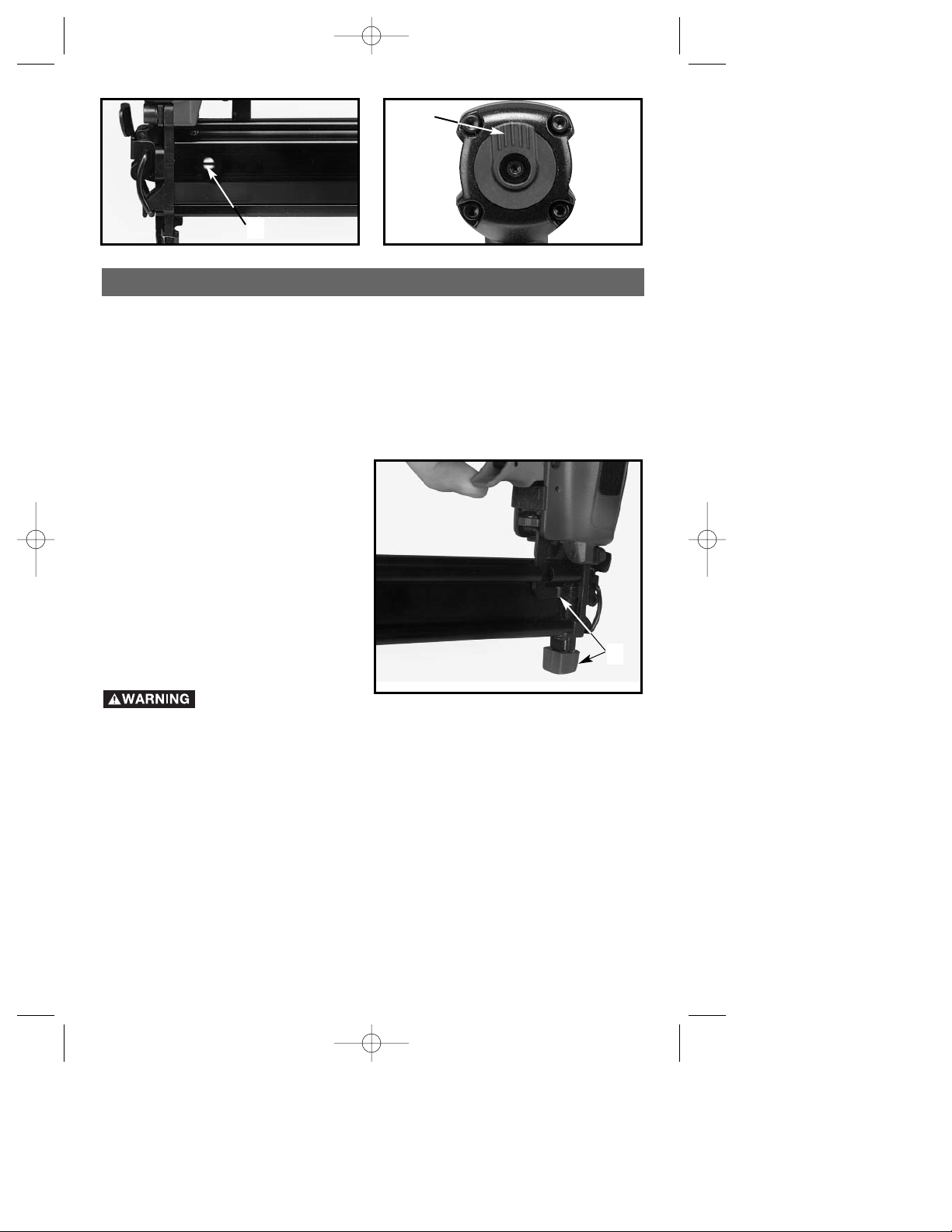

5. Observe the low fastener indicator (A) Fig. 26 and reload as needed.

6. Adjust directional exhaust deflector (A) Fig. 27, so that the exhaust air

or debris will be directed away from the operator. Grasp the deflector

and rotate it to the desired position for the current application.

FUNCTIONAL DESCRIPTION

Fig. 22

Fig. 23

Fig. 24 Fig. 25

635549-00,FS2NC 7/13/05 10:10 AM Page 7

Page 8

8

USING THE TOOL

Complete all steps of PREPARING THE TOOL before using the tool.

This tool is shipped from the factory with a “single sequential actuation” trigger. To

fire, grip the tool firmly to maintain control, position nose of tool onto work

surface, push the tool firmly against work surface to depress safety (S) Fig. 28,

and squeeze trigger to fire a fastener. Allow tool to recoil away from work surface as

fastener is driven. This “single sequential actuation” method provides the most

accurate fastener placement.

Disconnect tool from air supply before performing

maintenance, clearing a jammed fastener, leaving work area, moving tool to

another location, or handing the tool to another person.

Clean and inspect tool daily. Carefully check for proper operation of trigger and

safety mechanism. Do Not use the tool unless both the trigger and the safety

mechanism are functional, or if the tool is leaking air or needs any other repair.

Fig. 26

Fig. 27

A

A

OPERATING INSTRUCTIONS

Fig. 28

S

635549-00,FS2NC 7/13/05 10:10 AM Page 8

Page 9

9

The depth to which a fastener is driven is controlled by the depth adjustment knob (A)

Fig. 29. The depth of drive is factory adjusted to a nominal setting. Test fire a fastener

and check depth. If a change is desired, rotate the adjustment knob (A) Fig. 29. The

adjustment knob has detents every 1/4 turn. Rotate the knob (A) Fig. 29 clockwise to

increase the depth of drive, rotate the knob counterclockwise to decrease the depth of

drive. Test fire another fastener and check depth. Repeat as necessary to achieve

desired results. The amount of air pressure required will vary depending on the size of

the fastener and the material being fastened. Experiment with the air pressure setting to

determine the lowest setting that will consistently perform the job at hand. Air pressure

in excess of that required can cause premature wear and/or damage to the tool.

Fig. 29

Fig. 30

A

A

RUBBER NOSE CUSHION

A rubber nose cushion (A) Fig. 30 is provided to reduce marring of the work surface.

The rubber cushion can be removed, and stored inside the magazine (B) Fig. 31 when

it is not required.

Disconnect tool from air supply before removing or re- installing rubber

cushion.

CLEARING A JAMMED FASTENER

Disconnect tool from air supply.

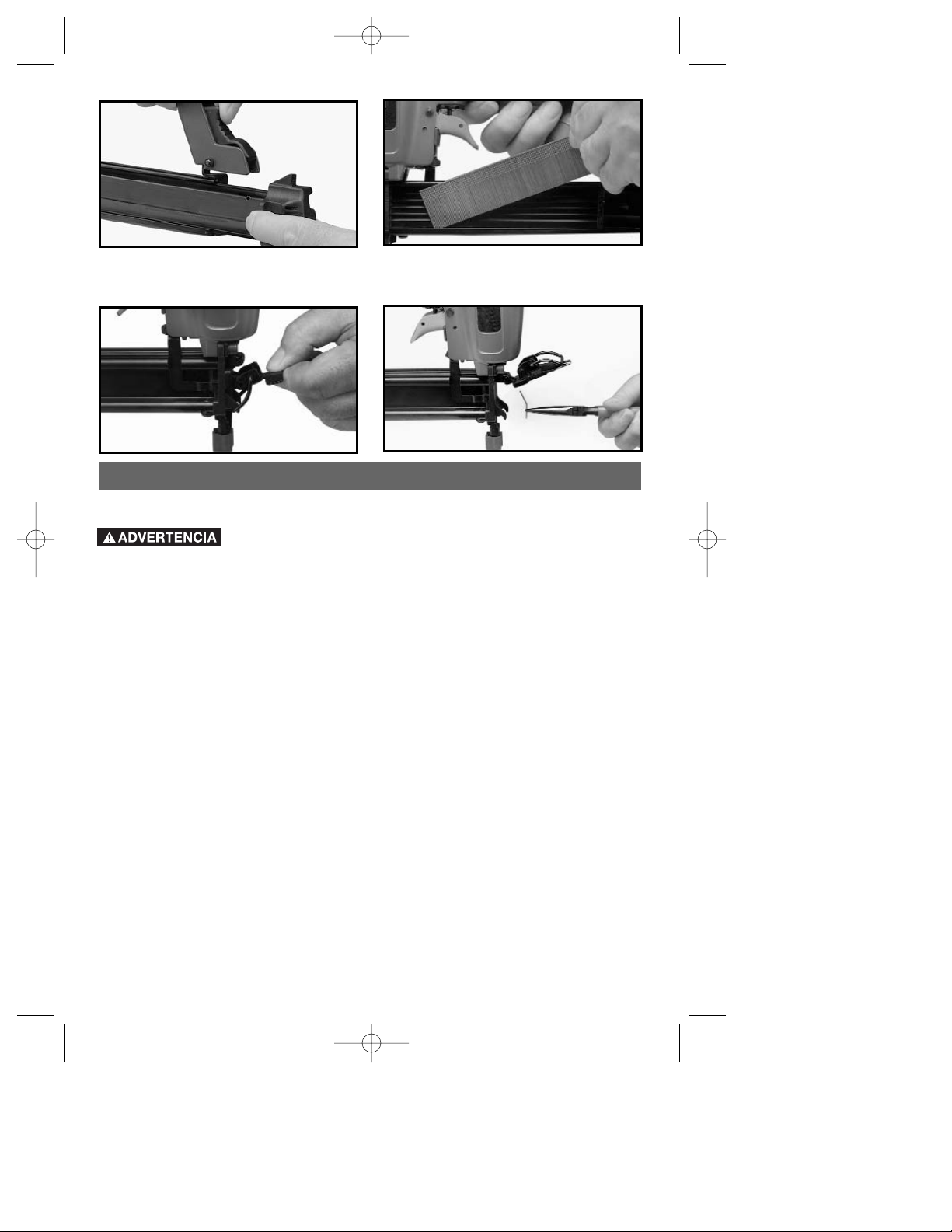

1. Open magazine and remove remaining fasteners. (Fig. 32 and Fig. 33)

Remove fasteners from tool before opening the fastener guide

plate. Fasteners are under pressure and may shoot out of magazine which could

cause injury.

2. Open the quick release latch and the fastener guide plate. (Fig. 34)

3. Remove the jammed fastener. (Fig. 35)

4. Close the fastener guide plate, and the quick release latch.

Fig. 31

B

635549-00,FS2NC 7/13/05 10:10 AM Page 9

Page 10

10

Fig. 32

Fig. 33

Fig. 34

Fig. 35

MAINTENANCE

CLEAN AND INSPECT DAILY

Disconnect tool from air supply before cleaning and inspection. Correct

all problems before placing the tool back in use.

Wipe tool clean and inspect for wear or damage. Use non-flammable cleaning solutions

to wipe exterior of tool only if necessary. DO NOT SOAK tool with cleaning solutions.

Such solutions can damage internal parts.

Inspect trigger and safety mechanism to assure system is complete and functional: no

loose or missing parts, no binding or sticking parts.

Keep all screws tight. Loose screws can cause personal injury or damage tool.

If tool is used without an in-line oiler: place five or six drops of air tool oil into the tool’s

air inlet on a daily basis.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized

service centers or other qualified service organizations, always using identical

replacement parts.

635549-00,FS2NC 7/13/05 10:10 AM Page 10

Page 11

11

Disconnect tool from air supply before performing any Service

Procedure.

SYMPTOM PROBLEMS SOLUTIONS

1. Air leak near top of Loose screws. Tighten screws.

tool or in trigger area. Worn or damaged B&D service for overhaul.

o-rings or seals.

2. Tool does nothing or Inadequate air supply. Verify adequate air supply.

operates sluggishly. Inadequate lubrication. Put 5 or 6 drops of oil into air inlet.

Worn or damaged B&D service for overhaul.

o-rings or seals.

3. Air leak near bottom Loose screws. Tighten screws.

of tool. Worn or damaged B&D service for overhaul.

o-rings or bumper.

4. Tool jams frequently. Incorrect fasteners. Verify approved fasteners of

correct size.

Damaged fasteners. Replace w/undamaged fasteners.

Magazine or nose Tighten screws.

screws loose.

Magazine is dirty. Clean magazine.

Driver is worn or damaged. B&D service for driver maintenance.

5. Other. Contact a Black & Decker

Service Facility.

ACCESSORIES

Recommended accessories for use with your tool are available from your local retailer.

The use of any accessory not recommended for use with this tool could

be hazardous.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service

locations throughout North America. All Black & Decker Service Centers are staffed

with trained personnel to provide customers with efficient and reliable power tool

service.

Whether you need technical advice, repair, or genuine factory replacement parts,

contact the Black & Decker location nearest you.

To find your local service location, refer to the yellow page directory under “Tools—

Electric” or call: 1-800-544-6986.

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in

material or workmanship. The defective product will be replaced or repaired at no

charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns

should be made within the time period of the retailer’s policy for exchanges (usually 30

to 90 days after the sale). Proof of purchase may be required. Please check with the

retailer for their specific return policy regarding returns that are beyond the time set for

exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned

or authorized Service Center for repair or replacement at our option. Proof of purchase

TROUBLESHOOTING

635549-00,FS2NC 7/13/05 10:10 AM Page 11

Page 12

12

may be required. Black & Decker owned and authorized Service Centers are listed

under “Tools-Electric” in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal

rights and you may have

other rights which vary from state to state and province to province. Should you have

any questions, contact the manager of your nearest Black & Decker Service Center.

This product is not intended for commercial use.

Free Warning Label Replacement: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

635549-00,FS2NC 7/13/05 10:10 AM Page 12

Page 13

13

AVANT DE RETOURNER CE PRODUIT POUR QUELQUE

RAISON QUI SOIT, VEUILLEZ APPELER AU 1 800 544-6986

AVERTISSEMENT : Assurez-vous de lire et de comprendre toutes les directives.

Négliger de suivre les instructions énumérées ci-dessous pourrait être la cause d'un

choc électrique, d'un incendie ou d'une blessure corporelle grave. Les symboles cidessous servent à vous aider à reconnaître cette information. .

indique une situation dangereuse imminente qui, si elle n’est pas évitée,

causera la mort ou des graves blessures.

indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait causer la mort ou de graves blessures.

indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait causer des blessures mineures ou modérées.

utilisé sans le symbole d’alerte à la sécurité indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée, peut résulter en des dommages à

la propriété.

CONSERVEZ CES DIRECTIVES

Lisez et comprenez tous les avertissements et directives

d’utilisation avant d’utiliser un outil ou un équipement. Lorsque vous utilisez des outils

ou un équipement, des précautions de base en matière de sécurité doivent être

suivies afin de réduire le risque de blessure personnelle. Un fonctionnement, un

entretien ou une modification inappropriés des outils ou de l’équipement pourraient

résulter en de graves blessures ou en des dommages à la propriété. Certaines

applications sont conçues pour des outils et de l’équipement spécifiques. Black &

Decker recommande fortement NE PAS modifier ce produit ou de NE PAS l’utiliser

pour une application autre que celle pour laquelle il a été conçu.

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ / DÉFINITIONS

• Lisez et comprenez les étiquettes sur l’outil ainsi

que son manuel. La non-observation des

avertissements pourrait résulter en la MORT ou en

de SÉRIEUSES BLESSURES. (Fig. 1)

• L’opérateur et les autres personnes oeuvrant

dans la zone de travail DOIVENT porter des

lunettes de sécurité munies de protecteurs

latéraux. Ces lunettes de sécurité doivent être

conformes à la norme ANSI Z87.1 (les lunettes

approuvées portent l’inscription imprimée ou

estampillée « Z87 »). (Fig. 2)

• Gardez vos doigts ÉLOIGNÉS du déclencheur

lorsque vous n’utilisez pas les attaches afin

d’éviter un allumage accidentel. Ne portez jamais

un outil en ayant un doigt sur le déclencheur. En «

mode d’activation », un outil tire une attache si l’outil

est frappé.

• Le choix de la méthode de déclenchement est

important. Consultez le manuel pour connaître les

options de déclenchement. Voir la section «

Utilisation de l’outil » dans le présent manuel.

RÈGLES GÉNÉRALES DE SÉCURITÉ

Fig. 2

Fig. 1

635549-00,FS2NC 7/13/05 10:10 AM Page 13

AVERTISSEMENT

ATTENTION

ATTENTION

AVERTISSEMENT

Page 14

14

• Ne pointez jamais l’outil sur vousmême ou sur d’autres personnes

dans la zone de travail. De graves

blessures, voire la mort peuvent survenir

si l’outil est activé. (Fig. 3)

• N’utilisez jamais d’oxygène ou

d’autres gaz en bouteille. Une explosion

risque de se produire. N’utilisez jamais

de gaz combustible ou tout autre type

de gaz réactif comme source d’énergie

pour cet outil : une explosion et de

graves blessures corporelles risquent de

se produire. (Fig. 4)

• Portez un dispositif de protection des

oreilles pour vous protéger contre une

perte auditive. Le dispositif de protection

des oreilles doit être conforme aux

normes ANSI S3.19. (Fig. 5)

• Utilisez de l’air comprimé propre, sec,

contrôlé à 4,8 à 8,3 bar (70 à 120 psi).

(Fig. 6)

• Ne branchez pas l’outil à une pression

pouvant dépasser 13,7 bar (200 psi).

• Tous les composants de conduited’air

(tuyaux, connecteurs, filtres,

régulateurs, etc.) doivent être classés

par valeur nominale pour obtenir une

pression de fonctionnement maximale

d’au moins 10,3 bar (150 psi) ou 150 %

de la pression maximale du système,

selon la plus élevée des deux.

• Branchez l’outil au tuyau d’alimentation

d’air avec un accouplement qui élimine

automatiquement toute la pression de

l’outil lorsque l’accouplement est

débranché. (Fig. 7)

• Débranchez l’outil du tuyau

d’alimentation d’air avant d’effectuer

l’entretien de l’outil ou de résoudre un

problème de blocage d’attache, de laisser

la zone de travail, de déplacer l’outil dans

un autre endroit ou de donner l’outil à une

autre personne. (Fig. 7)

• N’utilisez jamais un outil qui laisse

échapper de l’air, a des pièces

manquantes ou endommagées ou qui a

besoin d’être réparé. Assurez-vous que

toutes les vis et tous les bouchons sont

bien serrés. (Fig. 8)

• N’utilisez jamais l’outil si le dispositif

de sécurité, le déclencheur ou les

ressorts ne fonctionnent pas, sont

manquants ou endommagés. Ne modifiez

pas ou n’enlevez pas le dispositif de

sécurité, le déclencheur ou les ressorts.

Faites des inspections quotidiennes pour

vous assurer qu’il y a libre mouvement du

déclencheur et du mécanisme de sécurité.

(Fig. 8)

Fig. 6

Fig. 5

Fig. 3

Fig. 4

Fig. 8

Fig. 7

635549-00,FS2NC 7/13/05 10:10 AM Page 14

Page 15

15

• N’utilisez pas l’outil s’il n’a pas

d’étiquette de sécurité. Si l’étiquette est

manquante, endommagée ou illisible,

appelez au 1 800 544-6986 pour en

recevoir une de remplacement. (Fig. 9)

• N’utilisez que les pièces, les attaches

et les accessoires approuvés par

Black & Decker.

• Branchez l’outil à l’alimentation d’air

avant de charger les attaches afin de

prévenir qu’une attache soit tirée au cours

du branchement. Le mécanisme

d’entraînement de l’outil peut être mis en

cycle lorsque l’outil est branché à

l’alimentation d’air. (Fig. 10)

• Prenez toujours pour acquis que l’outil

contient des attaches. Pas de

bousculades. Traitez l’outil comme un

outil de travail. (Fig. 11)

• L’opérateur et les personnes

avoisinantes doivent porter un casque

de protection pour se protéger contre

des blessures possibles. (Fig. 12)

• Ne chargez pas les attaches en

enfonçant le déclencheur ou le

mécanisme de sécurité pour empêcher

qu’une attache soit tirée par inadvertance.

(Fig. 13)

• Enlevez votre doigt du déclencheur

lorsque les attaches ne sont pas utilisées.

Ne portez jamais un outil en ayant un

doigt sur le déclencheur.

En « mode d’activation », l’outil tire une

attache si le mécanisme de sécurité est

frappé pendant que le déclencheur est

enfoncé. (Fig. 14)

Fig. 9

Fig. 11

Fig. 10

Fig. 12

Fig. 13

Fig. 14

635549-00,FS2NC 7/13/05 10:10 AM Page 15

Page 16

16

Fig. 15

Fig. 16

Fig. 17

Fig. 18

• Ne tendez pas trop les bras. Soyez en

équilibre en tout temps lorsque vous

utilisez ou manipulez l’outil.

• Tirez les attaches dans la surface de

travail seulement : jamais dans des

matériaux trop durs à pénétrer. (Fig. 15)

• Agrippez l’outil fermement pour garder

le contrôle tout en lui permettant de

reculer hors de la surface de travail

lorsque l’attache est utilisée. En « mode

d’activation », si l’élément de sécurité peut

entrer à nouveau en contact avec la

surface de travail avant que le déclencheur

soit relâché, une attache non désirée sera

tirée.

• Ne mettez pas d’attaches par-dessus

d’autres attaches, ou ne mettez pas l’outil

dans un angle trop penché : les attaches

peuvent faire un ricochet causant des

blessures personnelles. (Fig. 15)

• N’utilisez pas d’attaches près du bord

de la pièce à travailler. La pièce risque de

se fendre, ce qui permettrait à l’attache

d’être lancée ou de faire un ricochet et de

causer des blessures personnelles. (Fig. 16)

• POUR LES OUTILS UTILISÉS EN MODE

D’ACTIVATION, ne les utilisez pas sur

des échafaudages ou des échelles ou

pour des tâches pour lesquelles un

changement d’emplacement implique

l’utilisation d’échafaudages, d’escaliers,

d’échelles et autres. Ne les utilisez pas

pour des tâches spécifiques comme la

fermeture de boîtes ou de caisses ou pour

mettre les systèmes de sécurité de

transport sur des véhicules ou des

remorques. (Fig. 17)

• Éloignez les curieux, les enfants et les

visiteurs lorsque vous utilisez un outil

électrique. Une distraction pourrait vous en

faire perdre la maîtrise.

• Assurez-vous que le tuyau n’est pas

obstrué ou décroché. Des tuyaux

enchevêtrés ou bouclés peuvent vous faire

perdre l’équilibre.

• Gardez toujours vos doigts loin de

l’alignement du chargeur pour empêcher

un déclenchement par inadvertance du

poussoir. (Fig. 18)

• Reportez-vous à la section Entretien

pour obtenir de plus amples

renseignements sur l’entretien approprié

de l’outil.

• Faites toujours fonctionner l’outil dans

un endroit propre et éclairé. Assurez-

vous que la surface de travail ne présente

aucun débris et assurez-vous de rester en

équilibre lorsque vous travaillez en hauteur

comme sur des toits.

635549-00,FS2NC 7/13/05 10:10 AM Page 16

Page 17

17

Fig. 20

Fig. 21

Fig. 19

• N’utilisez pas d’outil en présence de

poussière, de gaz ou d’émanations

inflammables. L’outil peut produire une

étincelle qui pourrait allumer les gaz et

causer un incendie. Placer une fixation

dans une autre fixation peut aussi

causer une étincelle. (Fig. 19)

• Informez-vous de l’épaisseur du

matériau lorsque vous utilisez un

marteau cloueur. Une fixation en saillie

peut causer des blessures.

• Soyez conscient que lorsque l’outil

est utilisé à des pressions du côté

élevé de sa gamme de

fonctionnement, les fixations peuvent

passer complètement à travers un

matériau mince ou très souple.

Assurez-vous que la pression dans le

compresseur est réglée de façon à ce

que les fixations soient fixées dans le

matériau et non poussés entièrement

dans celui-ci. (Fig. 20)

• N’insérez pas les fixations n’importe

où dans les murs, les planchers et

autres zones de travail. Les attaches

insérées dans des lignes sous tension,

de la plomberie ou autres types

d’obstructions peuvent causer des

blessures. (Fig. 21)

• Soyez vigilant, faites attention à ce

que vous faites et faites preuve de

jugement lorsque vous utilisez un

outil électrique. N’utilisez pas un outil

lorsque vous êtes fatigué ou lorsque

vous avez pris de la drogue, de

l’alcool ou des médicaments. Un

moment d’inattention, lorsque vous

utilisez un outil électrique, peut se solder

par des blessures sérieuses.

AVERTISSEMENT : L’utilisation de ce

produit vous expose à des substances

chimiques reconnues dans l’État de

Californie pour causer le cancer, des

anomalies congénitales et d’autres

troubles des systèmes reproductifs.

N’inhalez pas les vapeurs et la

poussière, et lavez-vous les mains

après l’utilisation.

635549-00,FS2NC 7/13/05 10:10 AM Page 17

Page 18

18

Fig. 22

Fig. 23

DESCRIPTION FONCTIONNELLE

Le marteau cloueur FSBN125 a été conçu pour installer des clous à tête de diamant

cal. 18 de diverses longueur allant de 3/8 po à 1-1/4 po. Les clous à tête de diamant

sont chargés dans le chargeur,depuis la partie latérale.

L'agrafeuse FSNS100 est conçue pour poser des agrafes étroites de calibre 18 de

diverses longueurs variant de 9,5 mm à 25,4 mm (3/8 po à 1 po). Les agrafes étroites

sont insérées dans le chargeur par le haut.

SOURCE D’ALIMENTATION

Cet outil a été conçu pour fonctionner avec de l’air propre, sec et comprimé à des

pressions contrôlées entre 4,8 et 8,3 bar (70 et 120 psi [livre par pouce carré]). Le

système adéquat doit inclure un filtre, un régulateur de pression et une burette à huile

qui se trouvent le plus près possible de l’outil que possible, préférablement à une

distance de moins de 4,6 m (15 pi).

L’air comprimé contient de l’humidité et d’autres contaminants qui sont nuisibles pour

les composants internes de l’outil. Un filtre de canalisation d’air enlève la plupart des

contaminants et prolonge de façon significative la durée de vie de l’outil. Si une burette

à huile en ligne n’est pas disponible : placez chaque jour cinq ou six gouttes d’huile

pour outil pneumatique dans l’admission d’air de l’outil.

L’outil est équipé d’un « raccord rapide » mâle 1/4 po. L’outil doit toujours être branché

à l’alimentation d’air avec un accouplement pour que toute la pression soit enlevée de

l’outil lorsque l’accouplement est débranché.

PRÉPARATION DE L’OUTIL

Dirigez l’outil dans une direction sûre lorsque vous chargez les clous.

Ne chargez jamais les fixations lorsque le dispositif de contact ou le

déclencheur est activé.

1. Après avoir lu et compris le présent manuel, branchez l’outil à l’alimentation d’air.

(Fig. 22)

2. Enfoncez le taquet et faites glisser la couverture du chargeur pour l’ouvrir. (Fig. 23)

3. Insérez une bande d’attaches approuvées.(Fig. 24) Dirigez les attaches en les

pointant vers le bas dans le chargeur. REMARQUE : Les clous à tête de diamant

sont chargés par le côté et les agrafes, par le haut.

4. Poussez sur le couvercle du chargeur pour le fermer. (Fig. 25)

5. Observez le témoin de bas niveau d’attaches (A) Fig. 26 et rechargez au besoin.

6. Réglez le déflecteur d’échappement directionnel (A) Fig. 27, de façon à ce que l’air

d’échappement ou les débris soient éloignés de l’opérateur. Empoignez le déflecteur

et faites-le tourner à la position désirée pour l’application nécessaire.

635549-00,FS2NC 7/13/05 10:10 AM Page 18

ATTENTION

ATTENTION

Page 19

UTILISATION DE L’OUTIL

Complétez toutes les étapes de la section PRÉPARATION DE L’OUTIL avant d’utiliser

ce dernier.

Cet outil est expédié de l’usine avec un déclencheur « à activation séquentielle

unique ». Pour tirer, empoignez fermement l’outil pour garder le contrôle,

positionnez le nez de l’outil sur la surface de travail, poussez l’outil fermement

contre la surface de travail pour enfoncer le mécanisme de sécurité (S) Fig. 28, et

resserrez le déclencheur pour tirer une fixation. Laissez l’outil reculer pour

s’éloigner de la surface de travail lorsque la fixation est envoyé. Cette méthode «

d’activation séquentielle unique » fournit la mise en place de l’organe d’assemblage

la plus précise.

Débranchez l’outil de l’alimentation d’air avant d’effectuer l’entretien,

de dégager une attache bloquée, de laisser la zone de travail, de déplacer l’outil dans

un autre endroit ou de donner l’outil à une autre personne.

Nettoyez et inspectez l’outil chaque jour. Assurez-vous que le déclencheur et le

mécanisme de sécurité fonctionnent correctement. N’utilisez pas l’outil à moins que le

déclencheur et le mécanisme de sécurité soient fonctionnels, ou ne l’utilisez pas si

l’outil laisse échapper l’air ou a besoin d’être réparé.

19

DIRECTIVES D’UTILISATION

Fig. 28

S

Fig. 24

Fig. 25

Fig. 27

A

Fig. 26

A

635549-00,FS2NC 7/13/05 10:10 AM Page 19

AVERTISSEMENT

Page 20

20

La profondeur à laquelle une fixation est enfoncée est contrôlée par la poignée de

réglage de profondeur (A) Fig. 29. La profondeur de l’entraînement est réglée en usine

en fonction d’un réglage nominal. Faites un essai de tire avec une attache et vérifiez la

profondeur. Si un changement est requis, tournez la poignée de réglage (A) Fig. 29. La

poignée de réglage a une résistance d’encliquetage tous les quarts de tour. Tournez la

poignée (A) Fig. 29 vers la droite pour accroître la profondeur de l’entraînement,

tournez la poignée vers la gauche pour diminuer cette même profondeur. Faites un

essai de tire d’attache et vérifiez la profondeur. Répétez au besoin pour obtenir les

résultats désirés. La quantité de pression d’air varie selon la dimension de l’attache et

le matériau qui est attaché. Faites des essais avec le réglage de la pression d’air afin

de déterminer le réglage le plus bas qui puisse faire le travail nécessaire. La pression

d’air en surplus de celle requise peut causer une usure prématurée ou des dommages

à l’outil.

COUSSIN DE NEZ EN CAOUTCHOUC

Un coussin de nez en caoutchouc (A) Fig. 30 est fourni pour réduire le tachage de la

surface de travail. Il est possible d’enlever le coussin en caoutchouc et de le garder

dans le chargeur (B) Fig. 31 lorsqu’il n’est pas utilisé.

Débranchez l’outil de l’alimentation d’air avant d’enlever ou de

remettre en place le coussin en caoutchouc.

DÉGAGEMENT D’UNE ATTACHE BLOQUÉE

Débranchez l’outil de l’alimentation d’air.

1. Ouvrez le chargeur et enlevez les attaches qui restent. (Fig. 32 et Fig. 33)

Enlevez les attaches de l’outil avant d’ouvrir la plaque de guidage

d’attaches. Les attaches sont sous pression et elles pourraient être tirées hors du

chargeur, ce qui risque de causer des blessures.

2. Ouvrez le système de verrouillage rapide et la plaque de guidage d’attaches.

(Fig. 34)

3. Enlevez l’attache bloquée. (Fig. 35)

4. Fermez la plaque de guidage d’attaches et le système de verrouillage rapide.

Fig. 29

Fig. 30

A

A

Fig. 31

B

635549-00,FS2NC 7/13/05 10:10 AM Page 20

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

Page 21

21

Fig. 32

Fig. 33

Fig. 34

Fig. 35

INSPECTION ET NETTOYAGE QUOTIDIENS

Débranchez l’outil de l’alimentation d’air avant son nettoyage et son

inspection.

Corrigez tous les problèmes avant de remettre l’outil en service.

Essuyez l’outil et inspectez-le pour déceler toute trace d’usure ou de dommages.

Utilisez des solutions nettoyantes ininflammables pour essuyer l’extérieur de l’outil

seulement, au besoin. NE TREMPEZ PAS l’outil dans du détergent liquide. De tels

produits peuvent endommager les pièces internes. Inspectez le déclencheur et le

mécanisme de sécurité afin de vous assurer que le système est complet et

fonctionnel : aucune pièce desserrée ou manquante, aucune pièce coincée ou collée.

Serrez toutes les vis. Les vis desserrées risquent de causer des blessures

personnelles ou des dommages à l’outil.

Si l’outil est utilisé sans une burette à huile en ligne : placez chaque jour cinq ou six

gouttes d’huile pour outil pneumatique dans l’admission d’air de l’outil.

IMPORTANT : Pour garantir la SÉCURITÉ et la FIABILITÉ du produit, les réparations,

l’entretien et le réglage (autre que ceux énumérés dans ce manuel) doivent être

réalisés par un centre de réparation autorisé ou tout autre centre de réparation

professionnel, et les des pièces de rechange identiques doivent être utilisées.

ENTRETIEN

635549-00,FS2NC 7/13/05 10:10 AM Page 21

AVERTISSEMENT

Page 22

DÉPANNAGE

22

SYMPTÔME

1. Fuite d’air près de la partie

supérieure de l’outil ou

dans la zone du

déclencheur.

2. L’outil ne fonctionne pas

ou fonctionne lentement.

3. Fuite d’air près du fond de

l’outil.

4. L’outil se bloque souvent.

5. Autre.

SOLUTIONS

Serrez les vis.

Réparation B&D pour

remise en état.

Vérifiez si l’alimentation

d’air est adéquate.

Ajoutez 5 ou 6 gouttes

d’huile dans l’admission

d’air.

Réparation B&D pour

remise en état.

Serrez les vis. Réparation

B&D pour remise en état.

Vérifiez si les attaches sont

appropriées et de bonne

dimension.

Remplacez par des

attaches intactes.

Serrez les vis.

Nettoyez le chargeur.

Réparation B&D pour

l’entretien de l’organe

moteur.

Communiquez avec le

service d’entretien

Black & Decker.

PROBLÈMES

Vis desserrées.

Joints toriques ou joints

d’étanchéité usés ou

endommagés.

Alimentation d’air inadéquate.

Graissage inadéquat.

Joints toriques ou joints

d’étanchéité usés ou

endommagés.

Vis desserrées.

Joints toriques ou amortisseur

usés ou endommagés.

Mauvaises attaches.

Attaches endommagées.

Chargeur ou vis de nez

desserrés.

Chargeur sale.

Entraînement usé ou

endommagé.

Débranchez l’outil de l’alimentation d’air avant d’effectuer une

procédure de réparation.

635549-00,FS2NC 7/13/05 10:10 AM Page 22

AVERTISSEMENT

Page 23

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir ‘Outils électriques’

– Pages Jaunes –

pour Service et ventes

23

ACCESSOIRES

Les accessoires recommandés pour être utilisés avec votre outil sont disponibles chez

votre détaillant local.

L'utilisation de tout accessoire non recommandé avec cet outil

pourrait s'avérer dangereuse.

INFORMATION SUR LES RÉPARATIONS

Black & Decker dispose d’un réseau complet de centres de service et de centres

autorisés situés partout en Amérique du Nord. Tous les centres de service

Black & Decker sont dotés de personnel qualifié en matière d’outillage électrique; ils

sont donc en mesure d'offrir à leur clientèle un service efficace et fiable.

Que vous ayez besoin d’un avis technique, d’une réparation ou de pièces de rechange

authentiques installées en usine, communiquez avec l’établissement Black & Decker le

plus près de chez vous.

Pour trouver l’établissement de réparation de votre région, consultez le répertoire des

pages jaunes à la rubrique « Outils électriques » ou composez le 1-800-544-6986.

GARANTIE COMPLÈTE DE DEUX ANS POUR USAGE RÉSIDENTIEL

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout

défaut de matériau ou de fabrication. Le produit défectueux sera remplacé ou réparé

sans frais de l’une des deux façons suivantes :

La première façon consiste en un échange chez le détaillant où le produit a été acheté

(à la condition que le magasin soit un détaillant participant).

Tout retour doit se faire durant la période correspondant à la politique d'échange du

détaillant (habituellement, entre 30 et 90 jours après l’achat). Une preuve d’achat peut

être requise. Vérifiez auprès du détaillant pour connaître sa politique concernant les

retours hors de la période définie pour les échanges.

La deuxième option est d’apporter ou d’envoyer le produit (transport payé d'avance) à

un centre de réparation autorisé ou à un centre de service de Black & Decker pour faire

réparer ou échanger le produit, à notre discrétion. Une preuve d’achat peut être requise.

Les centres de réparation autorisés et appartenant à Black & Decker se trouvent sous la

rubrique « Outils électriques » des pages jaunes de l’annuaire téléphonique.

Cette garantie ne s’applique pas aux accessoires. Cette garantie vous accorde des

droits légaux spécifiques et vous pourriez avoir d’autres droits qui varient d’un État ou

d'une province à l'autre. Si vous avez des questions, communiquez avec le directeur du

centre de réparation Black & Decker le plus près de chez vous. Ce produit n’est pas

destiné à un usage commercial.

Remplacement gratuit des étiquettes d’avertissement Si vos étiquettes

d’avertissement sont illisibles ou manquantes, appelez au 1 800 544-6986 pour en

obtenir une de remplacement.

635549-00,FS2NC 7/13/05 10:10 AM Page 23

AVERTISSEMENT

Page 24

24

ANTES DE DEVOLVER ESTE PRODUCTO POR

CUALQUIER RAZÓN,

POR FAVOR LLAME AL 1-800-544-6986

ADVERTENCIA: Lea y comprenda todas las instrucciones. El incumplimiento de

todas y cada una de las instrucciones enumeradas debajo puede provocar descarga

eléctrica, incendio o lesiones personales graves. Los símbolos que siguen se utilizan

para ayudarlo a reconocer esta información.

indica una situación de peligro inminente, que si no se evita, provocará

la muerte o lesiones graves.

indica una situación de peligro potencial, que si no se evita,

provocará la muerte o lesiones graves.

indica una situación de peligro potencial, que si no se evita,

provocará lesiones leves o moderadas.

utilizado sin el símbolo de alerta de seguridad indica una situación

de peligro potencial, que si no se evita, puede provocar daños en la propiedad.

CONSERVE ESTAS INSTRUCCIONES

Lea y comprenda todas las instrucciones operativas y las

advertencias antes de utilizar cualquier herramienta o equipo. Cuando se utilizan

herramientas o equipos, siempre se deben respetar las precauciones de seguridad

para reducir el riesgo de lesiones personales. La operación, el mantenimiento o la

modificación incorrectos de herramientas o equipos pueden provocar lesiones graves

y daños a la propiedad. Las herramientas y los equipos están diseñados para

determinados usos. Black & Decker recomienda enfáticamente que NO se modifique

este producto y que NO se utilice para ningún otro uso que aquel para el que fue

diseñado.

NORMAS DE SEGURIDAD: DEFINICIONES

• Lea y comprenda las etiquetas de la

herramienta y el manual. La falta de

cumplimiento de las advertencias puede provocar

la MUERTE o LESIONES GRAVES. (Fig.1)

• El operador y toda otra persona que se

encuentre en el área de trabajo DEBEN usar

anteojos de seguridad con protección lateral.

Estos anteojos de seguridad deben cumplir con los

requisitos ANSI Z87.1 (los anteojos aprobados

tienen impreso o estampado “Z87”). (Fig. 2)

• Mantenga los dedos ALEJADOS del disparador

cuando no esté colocando elementos de

fijación para evitar disparos accidentales.

Nunca transporte la herramienta con el dedo en el

disparador. En el “modo accionamiento por

contacto”, la herramienta disparará un elemento de

fijación si se la golpea.

• La elección del método de disparo es

importante. Verifique las opciones de disparo en

el manual. Consulte la sección “Uso de la

herramienta” en este manual.

NORMAS GENERALES DE SEGURIDAD

Fig. 2

Fig. 1

635549-00,FS2NC 7/13/05 10:10 AM Page 24

Page 25

25

Fig. 6

Fig. 5

Fig. 3

Fig. 4

Fig. 8

Fig. 7

• Nunca apunte la herramienta a usted

mismo o a otras personas en el área

de trabajo. Si la herramienta se activa

puede provocar lesiones graves o la

muerte. (Fig. 3)

• Nunca utilice oxígeno u otros gases

envasados. Se producirá una explosión.

Nunca utilice gases combustibles o

cualquier otro gas reactivo como fuente

de energía para esta herramienta: se

producirán una explosión y lesiones

personales graves. (Fig. 4)

• Utilice protección auditiva para evitar

la posible pérdida de audición. El equipo

de protección auditiva debe cumplir los

requisitos ANSI S3.19. (Fig. 5)

• Utilice aire comprimido limpio, seco y

regulado de 4,8 a 8,3 bar (70 a 120

PSI). (Fig. 6)

• No conecte la herramienta a una

presión que exceda potencialmente los

13,7 BAR (200 PSI).

• Todos los componentes de la línea de

aire (mangueras, conectores, filtros,

reguladores, etc.) deben estar

indicados para una presión máxima de

trabajo de al menos 10,3 BAR (150 PSI)

o 150% de la presión máxima del

sistema, la que resulte mayor.

• Conecte la herramienta a la manguera

de suministro de aire con un acople que

retire automáticamente toda la presión

de la herramienta cuando se desconecta

el acople. (Fig. 7)

• Desconecte la herramienta de la

manguera de suministro de aire antes

de realizarle mantenimiento a la

herramienta, retirar un elemento de

fijación atascado, dejar el área de

trabajo, trasladar la herramienta a otra

ubicación o entregarle la herramienta a

otra persona. (Fig. 7)

• Nunca utilice una herramienta que

está perdiendo aire, que tiene partes

faltantes o dañadas, o que necesita

reparación. Asegúrese de que todos los

tornillos y las tapas estén bien ajustados.

(Fig. 8)

• Nunca utilice la herramienta si el

seguro, el disparador o los resortes no

funcionan, faltan o están dañados. No

modifique o retire el seguro, el

disparador o los resortes. Inspeccione

diariamente que los movimientos del

disparador y del mecanismo de

seguridad estén libres. (Fig. 8)

635549-00,FS2NC 7/13/05 10:10 AM Page 25

Page 26

26

Fig. 9

Fig. 11

Fig. 10

Fig. 12

Fig. 13

Fig. 14

• No utilice la herramienta sin la etiqueta

de advertencia de seguridad. Si la

etiqueta falta, está dañada o ilegible,

llame al 1-800-544-6986 para recibir un

reemplazo. (Fig. 9)

• Utilice únicamente piezas, elementos

de fijación y accesorios aprobados por

Black y Decker.

• Conecte la herramienta al suministro

de aire antes de cargar los elementos

de fijación, para evitar que un elemento

de fijación se dispare durante la

conexión. El mecanismo impulsor de la

herramienta puede presentar ciclos

cuando se conecta la herramienta al

suministro de aire. (Fig. 10)

• Siempre dé por sentado que la

herramienta contiene elementos de

fijación. No juegue. Respete la

herramienta como un elemento de

trabajo. (Fig. 11)

• El operador y las personas que estén

cerca deben utilizar cascos para

protegerse de posibles lesiones.

(Fig. 12)

• No cargue elementos de fijación con

el disparador o el seguro oprimidos para

evitar disparar un elemento de fijación

involuntariamente. (Fig. 13)

• Quite el dedo del disparador cuando

no está colocando elementos de fijación.

Nunca transporte la herramienta con el

dedo en el disparador. En el “Modo

accionamiento por contacto” la

herramienta disparará un elemento de

fijación si se golpea el seguro mientras

el disparador está oprimido. (Fig. 14)

635549-00,FS2NC 7/13/05 10:10 AM Page 26

Page 27

27

• No se estire. Manténgase

correctamente parado y equilibrado en

todo momento mientras utiliza o

manipula la herramienta.

• Dispare elementos de fijación

solamente en la superficie de trabajo:

nunca en materiales que sean

demasiado duros como para penetrarlos.

(Fig. 15)

• Agarre la herramienta con firmeza

para mantener el control pero

permitiendo que la herramienta

retroceda de la superficie de trabajo

cuando se clava el elemento de

fijación. En el “Modo accionamiento por

contacto” si se permite que el elemento

de seguridad vuelva a tomar contacto

con la superficie de trabajo antes de que

se suelte el disparador, se disparará un

elemento de fijación innecesario.

• No clave elementos de fijación sobre

otros elementos de fijación, o con la

herramienta en un ángulo demasiado

pronunciado: los elementos de fijación

pueden rebotar y causar lesiones

personales. (Fig. 15)

• No clave elementos de fijación cerca

de los bordes del trabajo. El trabajo

puede rajarse dejando que el elemento

de fijación vuele libre o rebote

provocando lesiones personales. (Fig.16)

• PARA LAS HERRAMIENTAS QUE SE

USAN EN MODO ACCCIONAMIENTO

POR CONTACTO. No las utilice sobre

andamios o escaleras o para tareas

en las que el cambio de ubicación

involucre el uso de andamios,

escalones, escaleras y elementos

similares. No las utilice para tareas

específicas como cerrar cajas o cajones

de embalaje o para fijar sistemas de

seguridad para el transporte en

vehículos y furgonetas.

• Mantenga alejados a espectadores,

niños y visitantes lejos de la

herramienta eléctrica o neumática en

funcionamiento. Las distracciones

pueden provocar pérdida del control.

• Asegúrese de que la manguera está

libre de obstrucciones o dobleces.

Las mangueras enredadas o

enmarañadas pueden provocar la

pérdida del equilibrio o del punto de

apoyo de los pies.

• Siempre mantenga los dedos fuera

del trayecto de los sujetadores de la

fuente para evitar las lesiones

producidas por la liberación

inadvertida del impulsor. (Fig. 18)

Fig. 15

Fig. 16

Fig. 17

Fig. 18

635549-00,FS2NC 7/13/05 10:10 AM Page 27

Page 28

28

• Consulte la sección Mantenimiento

para obtener información detallada

sobre el mantenimiento correcto de

la herramienta.

• Opere siempre la herramienta en un

área limpia e iluminada. Asegúrese de

que la superficie de trabajo está libre de

cualquier residuo y tenga cuidado de no

perder el equilibrio cuando trabaja en

lugares altos, como techos.

• No utilice la herramienta en

presencia de polvo, gases o vapores

inflamables. La herramienta puede

producir una chispa que le prenda

fuego a los gases y provoque un

incendio. Operar un sujetador hacia otro

sujetador también puede provocar

chispas. (Figura 19).

• Tenga en cuenta el grosor del

material al utilizar el sujetador. Un

sujetador que sobresale puede

ocasionar lesiones.

• Tenga en cuenta que cuando se

utiliza la herramienta en presiones

extremas de su rango de operación,

los sujetadores pueden perforar

materiales delgados o muy blandos.

Asegúrese de que la presión en el

compresor esté configurada de modo tal

que los sujetadores se coloquen

adecuadamente en el material y no lo

perforen. (Fig. 20)

• No coloque sujetadores a ciegas en

paredes, pisos u otras áreas de

trabajo. Los elementos de fijación

clavados en cables eléctricos con

corriente, cañerías de agua u otros

tipos de obstrucciones pueden provocar

lesiones. (Fig. 21)

• Permanezca alerta, controle lo que

está haciendo y utilice el sentido

común cuando emplee una

herramienta eléctrica o neumática.

No utilice herramientas si está

cansado o bajo el efecto de drogas,

alcohol o medicamentos. Un momento

de descuido mientras se opera una

herramienta eléctrica o neumática

podría provocar daños personales

graves.

ADVERTENCIA: El uso de este

producto lo expondrá a productos

químicos que el Estado de California

reconoce que producen cáncer, defectos

de nacimiento y otros daños

reproductivos. EVITE LA INHALACIÓN

DE LOS VAPORES Y EL POLVO, Y

LÁVESE LAS MANOS DESPUÉS DE SU

USO.

Fig. 20

Fig. 21

Fig. 19

635549-00,FS2NC 7/13/05 10:10 AM Page 28

Page 29

29

La Clavadora FSBN125 está diseñada para instalar clavos de terminación calibre 18

de largos que varían entre 0,95 y 3,17 cm (3/8" y 1-1/4"). Los clavos de terminación se

cargan en el cargador desde el costado.

La engrapadora FSNS100 está diseñada para instalar grapas de corona angostas calibre

18 de varias longitudes, desde 9,5 mm (3/8") a 25 mm (1") en la fuente desde la parte

superior.

FUENTE DE ENERGÍA

Esta herramienta está diseñada para funcionar mediante aire comprimido limpio y seco

a presiones reguladas entre 4,8 y 8,3 BAR (70 y 120 PSI [libras por pulgada cuadrada]).

El sistema preferido debería incluir un filtro, un regulador de presión y un engrasador

automático ubicado tan cerca de la herramienta como sea posible, lo ideal sería dentro

de los 4,6 m/15 pies.

Todo aire comprimido contiene humedad y otros contaminantes que son perjudiciales

para los componentes internos de la herramienta. Un filtro en la tubería neumática

retendrá la mayoría de estos contaminantes y prolongará significativamente la vida de

la herramienta. Si no se dispone de un engrasador en línea: coloque cinco o seis gotas

de aceite para herramienta neumática en la entrada de aire de la herramienta diariamente.

La herramienta está equipada con un “conector rápido” macho de 0,63 cm (1/4”). La

herramienta siempre debe estar conectada al suministro de aire mediante un acople que

permita que salga toda la presión de la herramienta cuando se desconecta el acople.

PREPARACIÓN DE LA HERRAMIENTA

Mantenga la herramienta apuntando hacia una dirección segura

mientras carga los clavos.

Nunca cargue los sujetadores con el interruptor de contacto y el

disparador activado.

1. Después de leer y comprender todo este manual, conecte la herramienta al suministro

de aire. (Fig. 22)

2. Oprima el cerrojo y abra la cubierta deslizable del depósito. (Fig. 23)

3. Inserte una tira de elementos de fijación aprobados. (Fig. 24) Oriente los elementos de

fijación con las puntas hacia abajo en el depósito. NOTA: Los clavos de terminación se

cargan desde el costado y las grapas desde la parte superior.

4. Empuje la cubierta del deposito a la posición de cerrado. (Fig. 25)

5. Observe el indicador de baja existencia de elementos de fijación (A) Fig. 26 y vuelva a

cargar según sea necesario.

6. Ajuste el deflector de dirección del escape (A) Fig. 27 para que los gases de escape o

los residuos se alejen del operador. Tome el deflector y gírelo a la posición deseada para

el uso actual.

DESCRIPCIÓN DE LAS FUNCIONES

Fig. 22

Fig. 23

635549-00,FS2NC 7/13/05 10:10 AM Page 29

Page 30

30

USO DE LA HERRAMIENTA

Complete todos los pasos de PREPARACIÓN DE LA HERRAMIENTA antes de usar la

herramienta.

Esta herramienta se despacha de fábrica con un disparador de “accionamiento

secuencial simple”. Para disparar, sostenga la herramienta con firmeza para

mantener el control, ubique la boca de la herramienta contra la superficie de

trabajo para oprimir el seguro (S) Fig. 28, y oprima el disparador para disparar

un sujetador. Permita que la herramienta se repliegue de la superficie de trabajo

cuando se clava el clavo. Este método de “accionamiento secuencial simple”

brinda la ubicación más exacta del elemento de fijación.

Desconecte la herramienta del suministro de aire antes de realizar

tareas de mantenimiento, retirar un elemento de fijación atascado, abandonar el área

de trabajo, transportar la herramienta a otra ubicación o entregarle la herramienta a

otra persona.

Limpie e inspeccione la herramienta diariamente. Controle cuidadosamente la correcta

operación del disparador y del mecanismo de seguridad. NO utilice la herramienta a

menos que tanto el disparador como el mecanismo de seguridad funcionen

correctamente, o si la herramienta pierde aire o requiere cualquier otra reparación.

INSTRUCCIONES DE OPERACIÓN

Fig. 28

S

Fig. 27

A

Fig. 26

A

Fig. 24 Fig. 25

635549-00,FS2NC 7/13/05 10:10 AM Page 30

Page 31

31

La profundidad a la que se coloca un sujetador se controla mediante la perilla de ajuste

de profundidad (A) Fig. 29. La profundidad de penetración se ajusta en fábrica a un

valor nominal. Realice un disparo de prueba y verifique la profundidad. Si se desea un

cambio, gire la perilla de ajuste (A) Fig. 29. La perilla de ajuste tiene retenes cada

cuarto de giro. Gire la perilla (A) Fig. 29 en el sentido de las agujas del reloj para

aumentar la profundidad de penetración y gire la perilla en el sentido inverso a las

agujas del reloj para disminuir la profundidad de penetración. Realice otro disparo de

prueba y verifique la profundidad. Repita estos pasos tantas veces como sea necesario

para obtener los resultados deseados. La cantidad de presión de aire requerida variará

de acuerdo con el tamaño del elemento de fijación y el material sobre el que se clava.

Experimente con el valor de la presión de aire para determinar el valor menor que

realice correctamente el trabajo en curso. La presión de aire que exceda la requerida

puede provocar desgaste prematuro o daños a la herramienta.

Fig. 29

Fig. 30

A

A

PROTECTOR DE GOMA DE LA BOCA

Se provee un protector de goma para la boca (A) Fig. 30 para reducir daños a la

superficie de trabajo. El protector de goma se puede retirar y guardar dentro del

cargador (B) Fig. 31 cuando no se lo necesita.

Desconecte la herramienta del suministro de aire antes de retirar o

volver a instalar el protector de goma.

REMOCIÓN DE UN ELEMENTO DE FIJACIÓN ATASCADO

Desconecte la herramienta del suministro de aire.

1. Abra el depósito y retire los elementos de fijación que quedan. (Fig. 32 y Fig. 33)

Retire los elementos de fijación de la herramienta antes de abrir

la placa guía de los elementos de fijación. Los elementos de fijación están bajo

presión y pueden dispararse del depósito lo que podría provocar lesiones.

2. Abra el cerrojo de liberación rápida y la placa guía de los elementos de fijación.

(Fig. 34)

3. Retire el elemento de fijación atascado. (Fig. 35)

4. Cierre la placa guía de los elementos de fijación, y el cerrojo de liberación rápida.

Fig. 31

B

635549-00,FS2NC 7/13/05 10:10 AM Page 31

Page 32

32

Fig. 32

Fig. 34

MANTENIMIENTO

LIMPIE E INSPECCIONE DIARIAMENTE

Desconecte la herramienta del suministro de aire antes de limpiar

e inspeccionar. Subsane todos los problemas antes de volver a poner en uso la

herramienta.

Limpie la herramienta con un paño e inspeccione si hay desgaste o daños. Use

soluciones limpiadoras no inflamables para limpiar la parte exterior de la herramienta

sólo de ser necesario. NO EMPAPE la herramienta con soluciones limpiadoras. Esas

soluciones pueden provocar daños a las piezas internas. Inspeccione el disparador y el

mecanismo de seguridad para asegurarse de que el sistema está completo y en

buenas condiciones de funcionamiento: sin piezas flojas ni faltantes, sin piezas que se

traben o se atasquen.

Mantenga ajustados todos los tornillos. Los tornillos flojos pueden provocar lesiones

personales o daños a la herramienta.

Si la herramienta se utiliza sin un engrasador en línea: coloque cinco o seis gotas de

aceite para herramienta neumática en la entrada de aire de la herramienta diariamente.

IMPORTANTE: Para asegurar la SEGURIDAD y la CONFIABILIDAD del producto, las

reparaciones, el mantenimiento y los ajustes (los que no estén enumerados en este

manual) se deben realizar en los centros de mantenimiento autorizados o en otras

organizaciones de mantenimiento calificadas, utilizando siempre piezas de repuesto

idénticas.

Fig. 33

Fig. 35

635549-00,FS2NC 7/13/05 10:10 AM Page 32

Page 33

33

Desconecte la herramienta del suministro de aire antes de realizar

cualquier procedimiento de mantenimiento.

SÍNTOMA PROBLEMAS SOLUCIONES

DETECCIÓN DE PROBLEMAS

1. Pérdida de aire cerca de

la parte superior de la

herramienta o en el área

del disparador.

2. La herramienta no

funciona o funciona con

lentitud.

3. Pérdida de aire cerca de

la parte inferior de la

herramienta.

4. La herramienta se atasca

con frecuencia.

5. Otros

Tornillos flojos

Juntas tóricas (O-rings) o sellos

gastados o dañados.

Suministro de aire inadecuado.

Lubricación inadecuada.

Juntas tóricas (O-rings) o sellos

gastados o dañados.

Tornillos flojos

Juntas tóricas (O-rings) o

amortiguador gastados o

dañados.

Elementos de fijación incorrectos.

Elementos de fijación dañados.

Tornillos del cargador o de la

boca flojos.

El depósito está sucio.

El impulsor está gastado o

dañado.

Ajustar tornillos

Servicio de reparaciones de B&D.

Verificar el suministro de aire

adecuado.

Colocar 5 o 6 gotas de aceite en

la entrada de aire.

Servicio de reparaciones de B&D.

Ajustar tornillos Servicio de

reparaciones de B&D.

Verificar si los elementos de

fijación son aprobados y del

tamaño correcto.

Reemplazar con elementos de

fijación en buen estado.

Ajustar tornillos.

Limpiar el depósito.

Servicio B&D para mantenimiento

del impulsor.

Comuníquese con un centro de

servicios de Black & Decker.

635549-00,FS2NC 7/13/05 10:10 AM Page 33

Page 34

34

ACCESORIOS

Los accesorios que se recomiendan para utilizar con su herramienta están disponibles

en su comercio minorista local.

El uso de accesorios no recomendados para utilizar con esta

herramienta puede resultar peligroso.

INFORMACIÓN DE SERVICIO

Black & Decker ofrece una amplia red de puntos de servicio propios y autorizados en

toda Norteamérica. Todos los Centros de servicio Black & Decker cuentan con personal

altamente capacitado dispuesto a brindar a todos los clientes un servicio eficiente y

confiable en la reparación de herramientas eléctricas.

Si necesita consejo técnico, reparaciones o piezas de repuesto originales de fábrica,

póngase en contacto con el centro de servicios de Black & Decker más cercano a su

domicilio. Para ubicar a su servicio local, consulte “Herramientas eléctricas” en la

sección amarilla, o llame al: 1-800-544-6986.

GARANTÍA COMPLETA DE DOS AÑOS PARA USO EN EL HOGAR

Black & Decker (U.S.) Inc. ofrece una garantía de dos años por cualquier defecto del

material o de fabricación de este producto. El producto defectuoso se reparará o

reemplazará sin costo alguno de dos maneras.

La primera opción, el reemplazo, es devolver el producto al comercio donde se lo

adquirió (siempre y cuando se trate de un comercio participante).

Las devoluciones deben realizarse conforme a la política de devolución del comercio

(generalmente, entre 30 y 90 días posteriores a la venta). Le pueden solicitar

comprobante de compra. Consulte en el comercio acerca de la política especial sobre

devoluciones una vez superado el plazo establecido.

La segunda opción es llevar o enviar el producto (con flete pago) a un Centro de

servicio autorizado propio de Black & Decker para su reparación o reemplazo según

nuestro criterio. Le pueden solicitar comprobante de compra. Los Centros de Servicio

propios y autorizados de Black & Decker se enumeran bajo "Herramientas eléctricas

(Tools-Electric)" en las páginas amarillas de la guía telefónica.

Esta garantía no se extiende a los accesorios. Esta garantía le concede derechos

legales específicos, usted puede tener otros derechos que pueden variar según el

estado y la provincia. Ante cualquier inquietud, comuníquese con el gerente del Centro

de servicio de Black & Decker más cercano. Este producto no es para uso comercial.

Reemplazo gratuito de la etiqueta de advertencias: Si sus etiquetas de advertencia

están ilegibles o faltan, llame al (55) 5326-7100 para que se le reemplacen

gratuitamente.

635549-00,FS2NC 7/13/05 10:10 AM Page 34

Page 35

35

CULIACAN, SIN

Av. Nicolás Bravo #1063 Sur

(667) 7 12 42 11

Col. Industrial Bravo

GUADALAJARA, JAL

Av. La Paz #1779

(33) 3825 6978

Col. Americana Sector Juarez

MEXICO, D.F.

Eje Central Lázaro Cardenas

No. 18

(55) 5588 9377

Local D, Col. Obrera

MERIDA, YUC

Calle 63 #459-A

(999) 928 5038

Col. Centro

MONTERREY, N.L.

Av. Francisco I. Madero

No.831

(81) 8375 2313

Col. Centro

PUEBLA, PUE

17 Norte #205

(222) 246 3714

Col. Centro

QUERETARO, QRO

Av. Madero 139 Pte.

(442) 214 1660

Col. Centro

SAN LUIS POTOSI, SLP

Av. Universidad 1525

(444) 814 2383

Col. San Luis

TORREON, COAH

Blvd. Independencia, 96 Pte.

(871) 716 5265

Col. Centro

VERACRUZ, VER

Prolongación Díaz Mirón #4280

(229)921 7016

Col. Remes

VILLAHERMOSA, TAB

Constitución 516-A

(993) 312 5111

Col. Centro

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

Para reparación y servicio de sus herramientas eléctricas, favor de dirigirse

al Centro de Servicio más cercano:

BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 55-5326-7100

Vea “Herramientas

eléctricas (Tools-Electric)”

– Páginas amarillas –

para Servicio y ventas

635549-00,FS2NC 7/13/05 10:10 AM Page 35

Page 36

36

Cat. # FS2NC (FSBN125 / FSNS100) Form # 635549-00

JULY ‘05 Copyright © 2005 Black & Decker Printed in China

635549-00,FS2NC 7/13/05 10:10 AM Page 36

Loading...

Loading...