Page 1

General Safety Rules

WARNING! Read all instructions. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury. The term “power tool” in all of

the warnings listed below refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

WARNING: To reduce the risk of injury, user must read instruction manual.

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock. Replace or repair

damaged cords. Make sure your extension cord is in good condition. Use only 3-wire

extension cords that have 3-prong grounding-type plugs and 3-pole receptacles that

accept the tool’s plug.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

When using an extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tool may

result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging

in. Carrying power tools with your finger on the switch or plugging in power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts. Air vents often cover moving parts and should also be avoided.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of these devices can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed. Use of

the power tool for operations different from those intended could result in a hazardous

situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

b) If the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products,

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate personal hearing protection during use. Under some

conditions and duration of use, noise from this product may contribute to hearing

loss.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min ........................minutes ......................alternating current

......................direct current

n

o ........................no load speed

..........................

Class II Construction

........................

earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

Motor

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your

tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A

rating of 120 volts AC/DC means that your tool will operate on standard 60 Hz AC or DC

power. This information is printed on the nameplate. Lower voltage will cause loss of power

and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does

not operate, check the power supply.

KEY INFORMATION YOU SHOULD KNOW:

• Regularly check wear on paper and replace worn paper.

• Do not push down—let the sander do the work.

• Extended drywall sanding is not recommended for this product.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZADE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR ELPRODUCTO.

INSTRUCTION

MANUAL

Catalog Number FS2200QS

Catalog No. FS2200QS Form No. 90501831 (MAR’06) Copyright © 2006 Black & Decker Printed in China

B

C

7

5

6

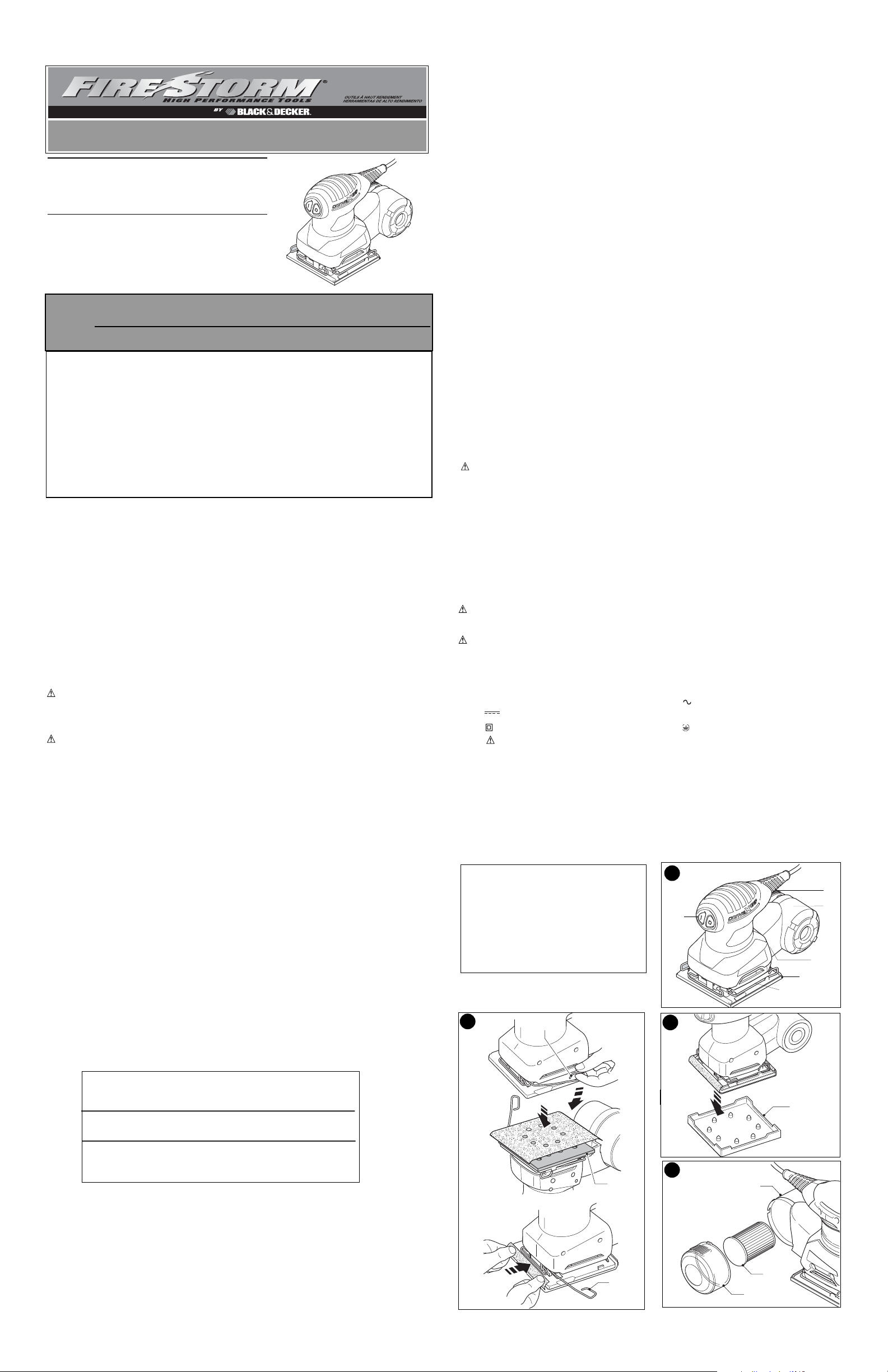

Features - Figure A

1. On/off switch

2. Dust canister cover

3. Dust canister

4. Dust extraction outlet

5. Sanding base

6. Paper clamp lever

1111////4444 SSSShhhheeeeeeeetttt FFFFiiiinnnniiiisssshhhh SSSSaaaannnnddddeeeerr

rr

T

T

HANK

HANK

YOU

YOU

FOR

FOR

CHOOSING

CHOOSING

F

F

IREST

IREST

ORM

ORM

!

!

G

G

OOTTOOWWW

WWW

.F

.F

IREST

IREST

ORMT

ORMT

OOLS

OOLS

.

.

COM

COM

/P

/P

RODUCT

RODUCT

R

R

EGISTRA

EGISTRA

TION

TION

TTOOREGISTER

REGISTER

YOUR

YOUR

NEW

NEW

PRODUCT

PRODUCT

.

.

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

BEFORE YOU CALL, HAVE THE CATALOG No. AND DATE CODE AVAILABLE. IN MOST CASES, A

BLACK & DECKER REPRESENTATIVE CAN RESOLVE THE PROBLEM OVER THE PHONE. IF YOU HAVE A

SUGGESTION OR COMMENT, GIVE US ACALL. YOUR FEEDBACK IS VITALTO BLACK & DECKER.

1

2

3

4

5

6

6

D

3

8

2

A

Page 2

Sanding

Lead based paint

Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the

contaminated dust. The greatest danger of lead poisoning is to children and pregnant

women.

Since it is difficult to identify whether or not a paint contains lead without a chemical

analysis, we recommend the following precautions when sanding any paint:

Personal safety

• No children or pregnant women should enter the work area where the paint sanding is

being done until all clean up is completed.

• A dust mask or respirator should be worn by all persons entering the work area. The filter

should be replaced daily or whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should

be used. Ordinary painting masks do not offer this protection. See your local hardware

dealer for the proper (NIOSH approved) mask.

• NO EATING, DRINKING or SMOKING should be done in the work area to prevent

ingesting contaminated paint particles. Workers should wash and clean up BEFORE

eating, drinking or smoking. Articles of food, drink, or smoking should not be left in the work

area where dust would settle on them.

Environmental safety

• Paint should be removed in such a manner as to minimize the amount of dust generated.

• Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils

thickness.

• Sanding should be done in a manner to reduce tracking of paint dust outside the work

area.

Cleaning and disposal

• All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the

duration of the sanding project. Vacuum filter bags should be changed frequently.

• Plastic drop cloths should be gathered up and disposed of along with any dust chips or

other removal debris. They should be placed in sealed refuse receptacles and disposed of

through regular trash pick-up procedures. During clean up, children and pregnant women

should be kept away from the immediate work area.

• All toys, washable furniture and utensils used by children should be washed thoroughly

before being used again.

ASSEMBLY

WARNING: To reduce the risk of injury, make sure that the tool is switched off and

unplugged before performing any of the following assembly.

Fitting sanding sheets (fig. B )

• Soften the sanding sheet by rubbing its non-abrasive side over the edge of a work table.

• Press the paper clamp levers (6) upwards to release them from the retaining grooves and

open the paper clamps by pressing them down.

• Place the sheet onto the sanding base.

• Insert the edge of the sanding sheet into the front paper clamp as shown.

• Press the front paper clamp lever (6) downwards and locate it in the retaining groove.

• While keeping a slight tension on the sheet, insert the rear edge of the sheet into the rear

paper clamp.

• Press the rear paper clamp lever (6) downwards and locate it in the retaining groove.

Punching sanding sheets (fig. C)

The paper punch (7) is used for punching dust extraction holes in sanding sheets without

pre-punched holes.

Fit a sanding sheet.

• Hold the tool in position right above the paper punch (7).

• Press the tool with the sanding base (5) down into the paper punch.

• Take the tool off the paper punch (7) and check whether the holes in the sanding sheet

have been fully pierced.

Fitting and removing the dust canister (fig. D)

• Fit the dust canister (3) over the dust extraction outlet (4).

• To remove the dust canister (3), pull the dust canister to the rear and off the outlet (4).

OPERATION

WARNING: To reduce the risk of injury, let the tool work at its own pace. Do not

overload.

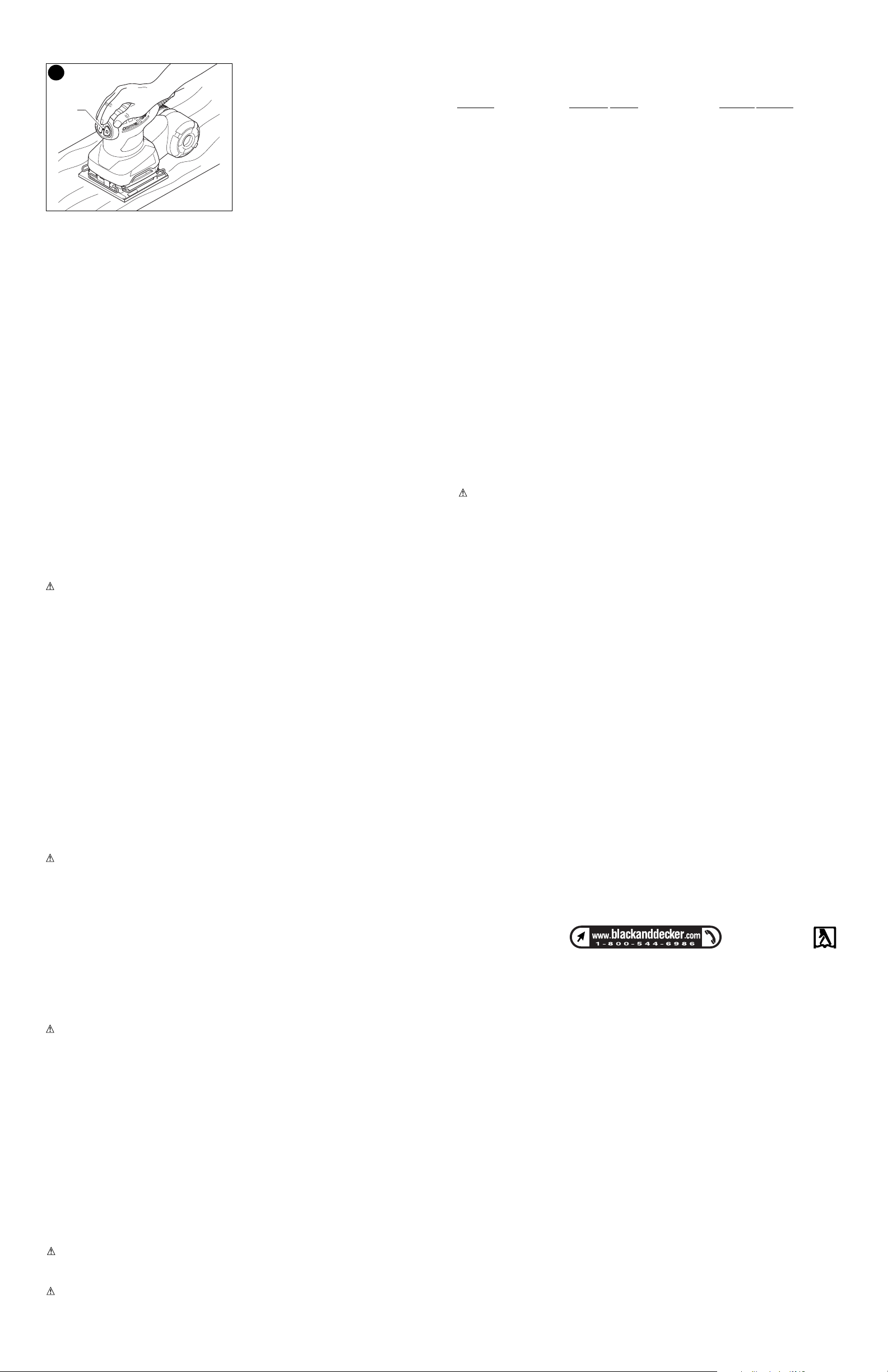

Switching on and off (fig. E)

• To switch the tool on, press the part of the on/off switch (1) marked 'I'.

• To switch the tool off, press the part of the on/off switch (1) marked '0'.

Emptying the dust canister (fig. D)

• The dust canister should be emptied every 10 minutes.

• Pull the dust canister (3) to the rear and off the tool .

• Remove the cover (2) by twisting it counterclockwise.

• Hold dust canister with the filter (8) facing down and shake the canister (3) to empty the

contents.

• Shake the cover (2) to empty the contents.

• Refit the cover (2) onto the dust canister (3), twisting it clockwise until it locks into place.

• Fit the dust canister (3) onto the tool.

Cleaning the dust canister filter

Warning: To reduce the risk of personal injury, do not use compressed air to clean the

filter.

NOTE: Do not use a brush or sharp objects to clean the filter as these items can reduce

the durability of the filter material. Do not wash the filter.

• The dust canister filter (8) is re-usable and should be cleaned regularly.

• Empty the dust canister (3) as described above.

• Pull the dust canister filter (8) off the dust canister (3).

• Shake off the excess dust by tapping the filter (8) into a trash can.

• Replace the dust canister filter (8).

• Fit the cover (2).

• Fit the dust canister (3) onto the tool.

Hints for optimum use

• Do not place your hands over the ventilation slots.

• Do not exert too much pressure on the tool.

• Regularly check the condition of the sanding sheet. Replace when necessary.

• Always sand with the grain of the wood.

• When sanding new layers of paint before applying another layer, use extra fine grit.

• On very uneven surfaces, or when removing layers of paint, start with a coarse grit. On

other surfaces, start with a medium grit. In both cases, gradually change to a fine grit for a

smooth finish.

Dust Collection

WARNING: Fire hazard. Collected sanding dust from sanding surface coatings

(polyurethane, linseed oil, etc.) can self-ignite in sander dust canister or elsewhere and cause

fire. To reduce risk, empty canister frequently and strictly follow sander manual and coating

manufacturer's instructions.

WARNING: Fire hazard. When working on metal surfaces, do not use the dust canister or

a vacuum cleaner because sparks are generated. Wear safety glasses and a dustmask. Due

to the danger of fire, do not use your sander to sand magnesium surfaces. Do not use for wet

sanding.

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unit will not start. • Cord not plugged in. • Plug tool into a working

outlet.

• Circuit fuse is blown. • Replace circuit fuse.

(If the product repeatedly

causes the circuit fuse to

blow, discontinue use

immediately and have it

serviced at a Black & Decker

service center or authorized

servicer.)

• Circuit breaker is tripped. • Reset circuit breaker.

(If the product repeatedly

causes the circuit breaker to

trip, discontinue use

immediately and have it

serviced at a Black & Decker

service center or authorized

servicer.)

• Cord or switch is damaged. • Have cord or switch

replaced at Black & Decker

Service Center or Authorized

Servicer.

For assistance with your product, visit our website www.blackanddecker.com for the loca-

tion of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

Maintenance

Your tool has been designed to operate over a long period of time with a minimum of

maintenance.

Continuous satisfactory operation depends upon proper tool care and regular cleaning.

• Clear the cooling vents and slots with a clean, dry paint brush.

• Clean the housing with a clean, damp cloth. Do not use solvents.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory for your

tool, please call 1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair, or

genuine factory replacement parts, contact the Black & Decker location nearest you. To find

your local service location, refer to the yellow page directory under "Tools—Electric" or call:

1-800-544-6986 or visit www.blackanddecker.com

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under "ToolsElectric" in the yellow pages of the phone directory and available on our website

www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state. Should you have any questions,

contact the manager of your nearest Black & Decker Service Center. This product is not

intended for commercial use.

Free warning label replacement: If your warning labels become illegible or are missing, call

1-800-544-6986 for a free replacement.

Special Warranty Note to Contractors:

FIRESTORMTMbranded products are offered as high end consumer home use tools and

carry a HOME USE WARRANTY. These tools are designed, manufactured and tested to

meet or exceed the needs of the do-it-yourselfer in the execution of projects and repairs in

and around the home. With proper use they will provide the home owner with step up power

and performance well beyond their two year warranty. However, if you use tools for a living

and use FIRESTORMTMbranded products or any of Black & Decker’s other Consumer

Home Use tools ON THE JOBSITE you should know that they CANNOT BE COVERED

UNDER OUR WARRANTY.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

E

1

Page 3

CONSERVER CE MODE D’EMPLOI POUR UN USAGE ULTÉRIEUR.

Règles de sécurité générales

AVERTISSEMENT! Lire toutes les directives. Tout manquement aux directives

suivantes pose des risques de choc électrique, d’incendie et/ou de blessure grave.

Le terme « outil électrique » dans tous les avertissements ci-après se rapporte à

votre outil électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

AVERTISSEMENT

::

Afin de réduire le risque de blessures, l’utilisateur doit lire

le mode d’emploi.

CONSERVER CES DIRECTIVES

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir la zone de travail propre et bien éclairée. Les endroits sombres sont souvent

des causes d'accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, soit en

présence de liquides inflammables, de gaz ou de poussière. Les outils électriques

produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les curieux au moment d’utiliser un outil électrique. Une

distraction pourrait vous en faire perdre la maîtrise.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais

modifier la fiche en aucune façon. Ne jamais utiliser de fiche d’adaptation avec un

outil électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation de

fiches non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des

tuyaux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc

électrique est plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à d'autres conditions où il

pourrait être mouillé. La pénétration de l’eau dans un outil électrique augmente le

risque de choc électrique.

d) Ne pas utiliser abusivement le cordon d’alimentation. Ne jamais utiliser le cordon

pour transporter, tirer ou débrancher un outil électrique. Tenir le cordon éloigné

de la chaleur, de l’huile, des bords tranchants ou des pièces mobiles. Les cordons

endommagés ou emmêlés augmentent les risques de choc électrique. Remplacer ou

réparer les cordons endommagés. S’assurer que la rallonge est en bon état. Utiliser

uniquement une rallonge à 3 fils pourvue d'une fiche de mise à la terre à 3 lames et une

prise à 3 fentes correspondant à la fiche.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à une telle utilisation. L’utilisation d’une rallonge conçue pour l’extérieur

réduit les risques de choc électrique. Lorsque qu’une rallonge électrique est utilisée,

s’assurer d’en utiliser une de calibre suffisamment élevé pour assurer le transport du

courant nécessaire au fonctionnement de votre appareil. Un cordon de calibre inférieur

causera une chute de tension de ligne et donc une perte de puissance et une

surchauffe. Le tableau suivant indique le calibre approprié à utiliser selon la longueur du

cordon et l’intensité nominale de la plaque signalétique. En cas de doute, utiliser le

calibre suivant le plus gros. Plus le numéro de calibre est petit, plus le cordon est lourd.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un

outil électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou

sous l’influence de drogues, d’alcool ou de médicaments. Un moment d’inattention,

durant l’utilisation d’un outil électrique, peut se solder par des blessures graves.

b) Utiliser un équipement de sécurité. Toujours porter une protection oculaire.

L’utilisation d’un équipement de sécurité comme un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la

situation le requiert réduira les risques de blessures corporelles.

c) Attention de ne pas mettre en marche l’outil accidentellement. S’assurer que

l’interrupteur est en position d’arrêt avant tout branchement. Transporter un outil

électrique alors que le doigt est sur l’interrupteur ou brancher un outil électrique alors

que l’interrupteur est en position de marche risque de causer un accident.

d) Retirer toute clé de réglage ou clé standard avant de démarrer l’outil. Une clé

standard ou une clé de réglage attachée à une partie pivotante peut causer des

blessures.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet de

mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de bijoux.

Maintenir cheveux, vêtements et gants éloignés des pièces mobiles. Les vêtements

amples, bijoux ou cheveux longs pourraient s'enchevêtrer dans les pièces mobiles. Se

tenir éloigné des évents puisque ces derniers pourraient camoufler des pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de

dépoussiérage et de ramassage, s’assurer que ceux-ci sont bien raccordés et

utilisés. L’utilisation de ces dispositifs peut réduire les risques engendrés par les

poussières.

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à

l’application. L’outil électrique approprié effectuera un meilleur travail, de façon plus

sûre et à la vitesse pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche du secteur ou le bloc-piles de l’outil électrique avant de faire

tout réglage ou changement d’accessoire, ou avant de ranger l’outil électrique.

Ces mesures préventives réduisent les risques de démarrage accidentel de l’outil

électrique.

d) Ranger les outils électriques hors de la portée des enfants, et ne permettre à

aucune personne n’étant pas familière avec un outil électrique (ou son manuel

d’instruction) d’utiliser ce dernier. Les outils électriques deviennent dangereux entre

les mains d’utilisateurs inexpérimentés.

e) Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer

qu’elles sont bien alignées et tournent librement, qu’elles sont en bon état et ne

sont affectées par aucun trouble susceptible de nuire au bon fonctionnement de

l’outil électrique. En cas de dommage, faire réparer l’outil électrique avant toute

nouvelle utilisation. Beaucoup d’accidents sont causés par des outils électriques mal

entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe

bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à

contrôler.

g) Utiliser l’outil électrique, les accessoires, les mèches, etc., conformément aux

présentes directives et suivant la manière prévue pour ce type particulier d’outil

électrique, en tenant compte des conditions de travail et du travail à effectuer.

L’utilisation d’un outil électrique pour toute opération autre que celle pour laquelle il a

été conçu est dangereuse.

5) RÉPARATION

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que

des pièces de rechange identiques. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

b) S’il faut remplacer le cordon d’alimentation, ceci doit être fait par le fabricant ou son

agent pour éviter tout risque d’accident.

AVERTISSEMENT : Certaines poussières produites par les activités de ponçage, de

sciage, de meulage, de perçage et autres activités de construction peuvent

contenir des produits chimiques pouvant causer le cancer, des anomalies

congénitales ou d'autres problèmes liés aux fonctions reproductrices. Voici

quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline provenant de la brique, du ciment et d'autres produits de

maçonnerie;

• l'arséniate de cuivre et de chrome provenant du bois traité chimiquement.

Les risques reliés à l'exposition à ces poussières varient selon la fréquence à laquelle

l’utilisateur travaille avec ce type de matériaux. Afin de réduire votre exposition à ces

produits chimiques : travailler dans un endroit bien ventilé et porter un équipement de

sécurité approuvé comme un masque anti-poussières conçu spécialement pour filtrer les

particules microscopiques.

• Éviter le contact prolongé avec les poussières produites par les activités de

ponçage, sciage, meulage, perçage et autres activités de construction. Porter des

vêtements de protection et laver les parties du corps exposées avec une solution

d'eau et de savon. Le fait de laisser la poussière pénétrer dans la bouche et les yeux ou

de la laisser reposer sur la peau, peut promouvoir l'absorption de produits chimiques

nocifs.

AVERTISSEMENT : L'utilisation de cet outil peut produire ou propulser des poussières

qui pourraient causer des problèmes respiratoires graves et permanents ou d'autres

problèmes médicaux. Toujours porter un appareil respiratoire approuvé par la

NIOSH/OSHA pour se protéger de la poussière. Diriger les particules loin du visage et du

corps.

MISE EN GARDE : Porter un pare-main anti-bruit pendant l’utilisation. Dans certaines conditions et selon la durée d’utilisation, le bruit causé par ce produit peut

contribuer à une perte auditive.

L’étiquette apposée sur votre outil peut comprendre les symboles suivants.

V ....................................volts A ..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o ........................vitesse à vide

....................................

Assemblage de classe II

........................borne de terre

..................................symbole d’alerte à la .../min ..................min ou

sécurité alternances par minute

Moteur

S’assurer que le bloc d’alimentation est compatible avec l’inscription de la plaque

signalétique. 120 volts c.a. signifie seulement que l’outil fonctionnera sur une alimentation

domestique standard de 60 Hz. Ne pas faire fonctionner des outils à courant alternatif (c.a.)

sur un courant continu (c.c.). Un régime nominal de 120 volts c.a./c.c. signifie que votre outil

fonctionnera avec une alimentation standard 60 Hz c.a. ou c.c. Ce renseignement figure sur

la plaque signalétique. Une plus faible tension entraînera une baisse de régime, ce qui peut

entraîner une surchauffe. Tous les outils Black & Decker sont testés en usine; si cet outil ne

fonctionne pas, vérifier le bloc d’alimentation.

Caractéristiques – Figure A

1. Interrupteur Marche/Arrêt

2. Couvercle du compartiment à poussière

3. Compartiment à poussière

4. Sortie de dispositif de dépoussiérage

5. Base de ponçage

6. Levier de pince à papier

Ponçage

Peinture à base de plomb

Le ponçage d’une peinture au plomb N’EST PAS RECOMMANDÉ en raison de la difficulté

entourant le contrôle de la poussière contaminée. Le danger le plus important

d’empoisonnement au plomb touche les enfants et les femmes enceintes.

Étant donné qu’il est difficile d’identifier si une peinture contient ou non du plomb sans une

analyse chimique, nous vous recommandons de suivre les précautions suivantes lors du

ponçage d’une peinture.

Sécurité personnelle

• Les enfants et les femmes enceintes ne devraient pas entrer dans une zone de travail où

se fait le ponçage de la peinture avant que la zone n’ait été entièrement nettoyée.

• Toutes les personnes entrant dans la zone de travail doivent porter un masque

antipoussières ou un respirateur. Le filtre doit être remplacé chaque jour ou dès que la

personne qui le porte éprouve de la difficulté à respirer.

REMARQUE : Seuls les masques qui conviennent pour le travail avec de la poussière et

des émanations de peinture au plomb doivent être utilisés. Les masques pour peinture

ordinaires n’offrent pas cette protection. Consulter la quincaillerie de votre région pour avoir

un masque adéquat (approuvé par la NIOSH).

• Il faut éviter de MANGER, BOIRE et FUMER dans la zone de travail pour empêcher toute

ingestion de particules de peinture contaminée. Les travailleurs doivent se laver les mains

AVANT de manger, de boire ou de fumer. Ne pas laisser de nourriture, de breuvages ou

d’articles de fumeur dans la zone de travail où ils risquent de recevoir de la poussière.

Respect de l'environnement

• La peinture doit être enlevée de façon à minimiser la quantité de poussière produite.

• Les zones où la peinture est enlevée doivent être scellées avec des feuilles de plastique

d’une épaisseur de 4 mils.

• Le ponçage doit se faire de façon à réduire le repérage de la poussière de peinture à

l’extérieur de la zone de travail.

Nettoyage et élimination

• Toutes les surfaces de la zone de travail doivent être nettoyées à fond à l’aide d’un

aspirateur, et ce, chaque jour, pour la durée du projet de ponçage. Il faut changer

régulièrement les sacs de filtre pour aspirateur.

• Les toiles de peinture en plastique doivent être rassemblées et mises au rebut avec les

particules de poussière ou tout autre débris d’enlèvement. Il faut les placer dans des

récipients à rebut étanches et les éliminer par la collecte des ordures ménagères. Pendant

VOICI DES RENSEIGNEMENTS IMPORTANTS QU’IL VOUS FAUT

SAVOIR :

• Vérifier régulièrement l’usure du papier et le remplacer lorsqu’il est usé.

• Ne pas pousser l’outil vers le bas, le laisser effectuer le travail.

• Il n’est pas recommandé d’utiliser ce produit pour un ponçage prolongé de

cloisons sèches.

Calibre minimum pour les rallonges

Volts Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité nominale

Plus Pas plus Calibrage américain normalisé des fils (AWG)

de de

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

MODE D’EMPLOI

PPPPOOOONNNNCCCCEEEEUUUUSSSSEEEE DDDDEEEE FFFFIIIINNNNIIIITTTTIIIIOOOONNNN 1111////4444 DDDDEEEE FFFFEEEEUUUUIIIILLLLLLLLEE

EE

Numéro de catalogue FS2200QS

AAAAVVVVAAAANNNNTTTT DDDDEEEE RRRREEEETTTTOOOOUUUURRRRNNNNEEEERRRR CCCCEEEE PPPPRRRROOOODDDDUUUUIIIITTTT PPPPOOOOUUUURRRR QQQQUUUUEEEELLLLQQQQUUUUEE

EE

RRRRAAAAIIIISSSSOOOONNNN QQQQUUUUEEEE CCCCEEEE SSSSOOOOIIIITTTT,,,, CCCCOOOOMMMMPPPPOOOOSSSSEEEERRRR LLLLEEEE NNNNUUUUMMMMÉÉÉÉRRRROOOO

SSSSUUUUIIIIVVVVAAAANNNNTTTT :::: 1111 888800000000 555544444444----66669999888866

66

MMMMEEEERRRRCCCCIIII DDDD’’’’AAAAVVVVOOOOIIIIRRRR CCCCHHHHOOOOIIIISSSSIIII FFFFIIIIRRRREEEESS

SSTTTTOOOORRRRMMMM!!!! VVVVIIIISSSSIIIITTTTEEEEZZZZ

WWWWWWWWWW

WW

....FFFFIIIIRRRREEEESSSSTTTTOOOORRRRMMMMTTTTOOOOOOOOLLLLSSSS....CCCCOOOOMMMM////PPPPRRRROOOODDDDUUUUCCCCTTTTRRRREEEEGGGGIIIISSSSTTTTRRRRAAAATTTTIIIIOOOONN

NN

PPPPOOOOUUUURRRR EEEENNNNRRRREEEEGGGGIIIISSSSTTTTRRRREEEERRRR VVVVOOOOTTTTRRRREEEE NNNNOOOOUUUUVVVVEEEEAAAAUUUU PPPPRRRROOOODDDDUUUUIIIITTTT..

..

Page 4

le nettoyage, les enfants et les femmes enceintes doivent éviter de se trouver dans la zone

immédiate de travail.

• Tous les jouets, meubles lavables et les ustensiles utilisés par les enfants doivent être

nettoyés à fond avant de les utiliser de nouveau.

Assemblage

AVERTISSEMENT : pour réduire les risques de blessures, vérifier que l’outil est

éteint et débranché avant d’effecteur l’assemblage suivant.

Ajustement des feuilles de papier abrasif (fig. B)

• Assouplir la feuille de papier abrasif en frottant le côté non abrasif sur le bord de la table de

travail.

• Appuyer sur les leviers des pinces à papier vers le haut (6) pour les dégager des rainures

de blocage et ouvrir les pinces à papier en appuyant dessus.

• Placer la feuille sur la base de ponçage.

• Insérer le bord de la feuille de papier dans la pince avant comme illustré.

• Appuyer sur le levier de la pince à papier avant (6) et le placer dans la rainure de blocage.

• Tout en maintenant une légère tension sur la feuille, insérer le bord arrière de la feuille

dans la pince à papier arrière.

• Appuyer sur le levier de la pince à papier arrière (6) et le placer dans la rainure de blocage.

Perforation des feuilles de papier abrasif (fig. C)

Le perforateur à papier (7) est utilisé pour percer les trous d’extraction de la poussière dans le

papier abrasif ne comportant pas de trous pré-percés.

Placer une feuille de papier abrasif.

• Tenir l’outil en position jusque au-dessus du perforateur à papier (7).

• Appuyer l’outil avec la base de ponçage (5) dans le perforateur à papier.

• Dégager l’outil du perforateur à papier (7) et vérifier si les trous dans la feuille de papier

abrasif ont été complètement perforés.

Mise en place et retrait du compartiment à poussière (fig. D)

• Ajuster le compartiment à poussière (3) sur la sortie du dispositif de dépoussiérage (4).

• Pour retirer le compartiment à poussière (3), le tirer vers l’arrière pour le dégager de la

sortie (4).

FONCTIONNEMENT

AVERTISSEMENT ::pour réduire les risques de blessures, laisser l’outil travailler à

sa propre vitesse. Ne pas le surcharger.

Mise en marche et arrêt (fig. E)

• Pour allumer l’outil, appuyer sur la partie de l’interrupteur marche/arrêt (1) marquée "I".

• Pour éteindre l’outil, appuyer sur la partie de l’interrupteur marche/arrêt (1) marquée "0".

Vidage du compartiment à poussière (fig. D)

• Le compartiment à poussière doit être vidé toutes les 10 minutes.

• Tirer le compartiment à poussière (3) vers l’arrière et le dégager de l’outil.

• Retirer le couvercle (2) en le tournant dans le sens antihoraire.

• Tenir le compartiment à poussière avec le filtre (8) orienté vers le bas et secouer le

compartiment à poussière (3) pour le vider.

• Secouer le couvercle (2) pour vider le contenu.

• Remettre le couvercle (2) sur le compartiment à poussière (3) et le tourner dans le sens

horaire de manière à le verrouiller en place.

• Placer le compartiment à poussière (3) sur l’outil.

Nettoyage du filtre du compartiment à poussière

AVERTISSEMENT ::pour réduire les risques de blessures, ne pas utiliser d’air

comprimé pour nettoyer le filtre.

REMARQUE : ne pas utiliser de brosse ou d’objets pointus pour nettoyer le filtre car ils

pourraient réduire la durée de vie du matériau du filtre. Ne pas laver le filtre.

• Le filtre du compartiment à poussière (8) est réutilisable et doit être nettoyé régulièrement.

• Vider du compartiment à poussière (3) comme décrit ci-dessus.

• Sortir le filtre (8) du compartiment à poussière (3).

• Secouer l’excès de poussière en tapant le filtre (8) au-dessus d’une poubelle.

• Remettre en place le filtre du compartiment à poussière (8).

• Remettre le couvercle en place (2).

• Fixer le compartiment à poussière (3) sur l’outil.

Conseils pour une utilisation optimale

• Ne pas mettre les mains sur les fentes d’évent.

• Ne pas appliquer trop de pression sur l’outil.

• Vérifier régulièrement l’état de la feuille de papier abrasif. Le remplacer au besoin.

• Toujours poncer dans le sens du grain de bois.

• Pour le ponçage de nouvelles couches de peinture avant d’appliquer une autre couche,

utiliser un grain extra fin.

• Sur des surfaces très inégales, ou pour enlever des couches de peinture, commencer

avec un grain grossier. Sur d’autres surfaces, commencer par un grain moyen. Dans les

deux cas, passer graduellement à un grain fin pour un fini lisse.

Dépoussiérage

AA

VERTISSEMENT : risque d’incendie. Les poussières de ponçage issues des couches

de protection (polyuréthanne, huile de lin, etc.) peuvent s’enflammer spontanément dans

le compartiment à poussière ou ailleurs et causer un incendie. Pour réduire les risques,

vider fréquemment le compartiment à poussière et suivre strictement le mode d’emploi de

la ponceuse ainsi que les directives du fabricant de l’enduit.

AVERTISSEMENT : risque d’incendie. Pour le travail effectué sur des surfaces

métalliques, ne pas utiliser le compartiment à poussière ou un aspirateur parce que des

étincelles peuvent se produire. Porter des lunettes de sécurité et un masque antipoussières. En raison du risque d’incendie, ne pas utiliser la ponceuse pour poncer des surfaces de magnésium. Ne pas utiliser pour poncer une surface mouillée.

Dépannage

Pr

oblème

Cause possible Solution possible

• L’appareil refuse de • Cordon d’alimentation • Brancher le chargeur dans une prise

démarrer. non branché. qui fonctionne.

• Le fusible du circuit est • Remplacer le fusible du circuit. (Si le

grillé. produit fait griller de façon répété le

fusible du circuit, arrêter

immédiatement d’utiliser le produit et

le faire réparer dans un centre de

réparation Black & Decker ou un

centre de réparation autorisé.)

• Le disjoncteur s’est • Remettez à zéro le disjoncteur. (Si le

déclenché. produit fait déclencher de façon

répétée le disjoncteur, arrêter

immédiatement d’utiliser le produit et

le faire réparer dans un centre de

réparation Black & Decker ou un

centre de réparation autorisé.)

• Cordon d’alimentation • Faire remplacer le cordon ou

ou interrupteur l’interrupteur au centre de réparation

endommagé. Black & Decker ou à un centre de

réparation autorisé.

Pour de l’aide sur l’outil, consulter notre site Web www.blackanddecker.com pour

l’emplacement du centre de réparation le plus près ou communiquer avec l’assistance

BLACK & DECKER au 1-800-544-6986.

Entretien

L’outil a été conçu pour fonctionner longtemps avec un minimum d’entretien.

Un fonctionnement satisfaisant continu dépend du bon entretien et du nettoyage régulier de

l’outil.

• Dégager les évents de refroidissement et les fentes au moyen d’un pinceau propre et sec.

• Nettoyer le boîtier avec un chiffon propre humecté. Ne pas utiliser de solvants.

Accessoires

Les accessoires recommandés pour être utilisés avec l’outil sont disponibles chez le

distributeur ou le centre de réparation autorisé de votre région. Pour toute assistance en

matière d'accessoire convenant à l’outil acheté, composer le numéro suivant :

1-800-544-6986.

AVERTISSEMENT : L'utilisation de tout accessoire non recommandé avec cet outil

pourrait s'avérer dangereuse.

Information sur les réparations

Black & Decker dispose d’un réseau complet de centres de réparation et de centres

autorisés situés partout en Amérique du Nord. Tous les centres de réparation Black &

Decker sont dotés de personnel qualifié en matière d’outillage électrique; ils sont donc en

mesure d’offrir à leur clientèle un service efficace et fiable.

Que ce soit pour un avis technique, une réparation ou des pièces de rechange authentiques

installées en usine, communiquer avec l’établissement Black & Decker le plus près de chez

vous.

Pour trouver l’établissement de réparation de votre région, consulter le répertoire des Pages

jaunes sous la rubrique « Outils électriques » ou composer le numéro suivant :

1-800-54-HOW TO (544-6986) ou consulter le site www.blackanddecker.com.

Garantie complète de deux ans pour une utilisation

domestique

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout défaut

de matériau ou de fabrication. Le produit défectueux sera remplacé ou réparé sans frais de

l’une des deux façons suivantes :

La première façon consiste en un échange chez le détaillant où le produit a été acheté (à la

condition que le magasin soit un détaillant participant). Tout retour doit se faire durant la période

correspondant à la politique d’échange du détaillant (habituellement, de 30 à 90 jours après

l’achat). Une preuve d’achat pourrait être requise. Vérifier auprès du détaillant pour connaître sa

politique concernant les retours hors de la période définie pour les échanges.

La deuxième option est d’apporter ou d’envoyer le produit (transport payé d’avance) à un

centre de réparation autorisé ou à un centre de réparation de Black & Decker pour faire réparer

ou échanger le produit, à notre discrétion. Une preuve d’achat pourrait être requise. Les

centres de réparation de Black & Decker et les centres de réparation autorisés sont répertoriés

dans les pages jaunes sous la rubrique « Outils électriques » de l'annuaire téléphonique et sont

disponibles sur notre site Web www.blackanddecker.com.

Cette garantie ne s’applique pas aux accessoires. Cette garantie vous accorde des droits

légaux spécifiques et vous pourriez avoir d’autres droits qui varient d’un État ou d’une province

à l’autre. Pour toute question, communiquer avec le directeur du centre de réparation

Black & Decker le plus près de chez vous. Ce produit n’est pas destiné à un usage commercial.

Remplacement gratuit des étiquettes d’avertissement : si les étiquettes d’avertissement

deviennent illisibles ou sont manquantes, composer le 1-800-544-6986 pour en obtenir le

remplacement gratuit.

Remarque à l’intention des entrepreneurs concernant la garantie

spéciale

Les produits de marque FIRESTORMMCsont des outils hauts de gamme destinés aux

consommateurs et comportent une GARANTIE POUR USAGE RÉSIDENTIEL. Ces

outils sont conçus, fabriqués et mis à l’essai en vue de répondre aux besoins du

bricoleur, ou de les dépasser, lorsque ce dernier réalise des projets ou effectue des

réparations à l’intérieur ou à l’extérieur de sa résidence. Utilisés correctement, ces

outils procurent à l’utilisateur un rendement et une puissance supérieurs qui excèdent de

loin la période de garantie de deux ans. Par contre, tout outil utilisé à des fins

commerciales ou tout produit de marque FIRESTORMMCou tout autre produit

Black & Decker destiné aux consommateurs et réservé à un usage résidentiel, utilisé dans

le cadre d’une ACTIVITÉ RELIÉE AU TRAVAIL, N’EST PAS COUVERT PAR LA PRÉSENTE

GARANTIE.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

INFORMACIÓN CLAVE QUE USTED DEBE CONOCER:

• Compruebe periódicamente el desgaste del papel de lija y reemplace el papel de

lija gastado.

• No presione hacia abajo, deje que la lijadora haga el trabajo.

• No se recomienda usar este producto para el lijado extendido en madera

contrachapada.

CONSERVE ESTE MANUAL PARA FUTURAS CONSULTAS.

Normas generales de seguridad

ADVERTENCIA: Lea todas las instrucciones. El incumplimiento de las instrucciones

enumeradas debajo puede provocar descarga eléctrica, incendio o lesiones graves. El

término “herramienta eléctrica” incluido en todas las advertencias enumeradas a

continuación hace referencia a su herramienta eléctrica operada con corriente (alámbrica)

o a su herramienta eléctrica operada con baterías (inalámbrica).

ADVERTENCIA: Para reducir el riesgo de lesiones, el usuario debe leer el manual de

instrucciones.

CONSERVE ESTAS INSTRUCCIONES

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y

oscuras propician accidentes.

b) No opere herramientas eléctricas en atmósferas explosivas, como ambientes

donde se encuentran líquidos, gases o polvo inflamables. Las herramientas eléc-

tricas

originan chispas que pueden encender el polvo o los vapores.

c) Mantenga a los niños y espectadores alejados de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente.

Nunca modifique el enchufe de ninguna manera. No utilice ningún enchufe

adaptador con herramientas eléctricas con conexión a tierra. Los enchufes no

modificados y que se adaptan a los tomacorrientes reducirán el riesgo de descarga

eléctrica.

b) Evite el contacto corporal con superficies puestas a tierra, como por ejemplo

tuberías, radiadores, rangos y refrigeradores. Existe mayor riesgo de descarga

eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad.

Si ingresa agua a una herramienta eléctrica, aumentará el riesgo de descarga

eléctrica.

d) No maltrate al cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta eléctrica. Mantenga el cable lejos del calor, aceite, bordes afilados o

piezas móviles. Los cables dañados o enredados aumentan el riesgo de descarga

eléctrica. Repare o reemplace los cables dañados. Asegúrese de que el cable

prolongador esté en buenas condiciones. Utilice solamente cables prolongadores de

3 conductores que tengan enchufes a tierra de 3 patas y receptáculos de tripolares

que se adapten al enchufe de la herramienta.

MANUAL DE INSTRUCCIONES

LLLLIIIIJJJJAAAADDDDOOOORRRRAAAA PPPPAAAARRRRAAAA AAAACCCCAAAABBBBAAAADDDDOOOOSSSS DDDDEEEE

HHHHOOOOJJJJAAAASSSS DDDDEEEE 1111////44

44

Número de catálogo FS2200QS

AAAANNNNTTTTEEEESSSS DDDDEEEE DDDDEEEEVVVVOOOOLLLLVVVVEEEERRRR EEEESSSSTTTTEEEE PPPPRRRROO

OODDDDUUUUCCCCTTTTOOOO PPPPOOOORRRR

CCCCUUUUAAAALLLLQQQQUUUUIIIIEEEERRRR MMMMOOOOTTTTIIIIVVVVOO

OO

,,,, LLLLLLLLAAAAMMMMEEEE AAAALLLL ((((55555555)))) 5555333322226666----77771111000000

00

¡¡¡¡GGGGRRRRAAAACCCCIIIIAAAASSSS PPPPOOOORRRR EEEELLLLEEEEGGGGIIIIRRRR FFFFIIIIRRRREEEESSSSTT

TTOOOORRRRMMMM!!!! VVVVAAAAYYYYAAAA AAAA

WWWWWWWWWWWW....FFFFIIIIRRRREEEESSSSTTTTOOOORRRRMMMMTTTTOOOOOOOOLLLLSSSS....CCCCOOOOMMMM////PPPPRRRROOOODDDDUUUUCC

CCTTTT RRRREEEEGGGGIIIISSSSTTTTRRRRAAAA

TTTTIIIIOOOONN

NN

PPPPAAAARRRRAAAA RRRREEEEGGGGIIIISSSSTTTTRRRRAAAARRRR SSSSUUUU NNNNUUUUEEEEVVVVOOOO PPPPRRRROOOODDDDUUUUCCCCTTTTOOOO..

..

Page 5

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a fin de

reducir el riesgo de descarga eléctrica. Cuando utilice un cable prolongador,

asegúrese de que tenga la capacidad para conducir la corriente que su producto

exige. Un cable de menor capacidad provocará una disminución en el voltaje de la

línea que producirá pérdida de potencia y sobrecalentamiento. La siguiente tabla

muestra la medida correcta que debe utilizar según la longitud del cable y la

capacidad nominal en amperios indicada en la placa. En caso de duda, utilice el

calibre inmediatamente superior. Cuanto menor es el número de calibre, más grueso

es el cable.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica

si está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un

momento de descuido mientras se opera una herramienta eléctrica podría provocar

daños personales graves.

b) Use equipo de seguridad. Siempre utilice protección para los ojos. El equipo de

seguridad, como las máscaras para polvo, el calzado de seguridad antideslizante, los

cascos o la protección auditiva utilizados para condiciones adecuadas reducirán las

lesiones personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de enchufar la herramienta. Transportar herramientas

eléctricas con su dedo apoyado sobre el interruptor o enchufar herramientas

eléctricas con el interruptor en posición de encendido puede propiciar accidentes.

d) Retire las clavijas de ajuste o llaves de tuercas antes de encender la

herramienta eléctrica. Una llave de tuercas o una clavija de ajuste que se deje

conectada a una pieza giratoria de la herramienta eléctrica pueden provocar lesiones

personales.

e) No se estire. Conserve el equilibrio adecuado y manténgase parado

correctamente en todo momento. Esto permite un mejor control de la herramienta

eléctrica en situaciones inesperadas.

f) Vístase apropiadamente. No use ropas holgadas ni joyas. Mantenga el cabello,

las ropas y los guantes alejados de las piezas móviles. Las ropas holgadas, las

joyas o el cabello largo pueden quedar atrapados en las piezas móviles. Los

orificios de ventilación suelen cubrir piezas móviles, por lo que también se deben evitar.

g) Si se suministran dispositivos para la conexión de accesorios para la

recolección y extracción de polvo, asegúrese de que estén conectados y se

utilicen correctamente. El uso de estos dispositivos puede reducir los peligros

relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta para

el trabajo que realizará. La herramienta eléctrica correcta hará el trabajo mejor y

más seguro a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta eléctrica que no puede ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

c) Desconecte el enchufe de la fuente de energía y/o el paquete de baterías de la

herramienta eléctrica antes de realizar ajustes, cambiar accesorios o almacenar

herramientas eléctricas. Estas medidas de seguridad preventivas reducen el riesgo

de encender la herramienta eléctrica en forma accidental.

d) Guarde las herramientas eléctricas que no están en uso fuera del alcance de

los niños y no permite que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta. Las herramientas eléctricas son peli-

grosas en las manos de usuarios no entrenados.

e) Mantenimiento de las herramientas eléctricas. Controle que no haya piezas

móviles mal alineadas o trabadas, piezas rotas y toda otra situación que pueda

afectar el funcionamiento de las herramientas eléctricas. Si encuentra daños,

haga reparar la herramienta eléctrica antes de utilizarla. Se producen muchos

accidentes a causa de las herramientas eléctricas que carecen de un mantenimiento

adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de corte

con mantenimiento adecuado, con los bordes de corte afilados son menos propensas

a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y de la forma prevista para el tipo de

herramienta eléctrica en particular, teniendo en cuanta las condiciones de

trabajo y el trabajo que debe realizarse. El uso de la herramienta eléctrica para

operaciones diferentes de aquéllas para las que fue diseñada puede provocar una

situación peligrosa.

5) MANTENIMIENTO

a) Haga que una persona de reparaciones calificada realice el mantenimiento de

su herramienta eléctrica y utilice piezas de repuesto idénticas solamente. Esto

garantizará la seguridad de la herramienta eléctrica.

b) Si necesita un cable de alimentación de repuesto, debe adquirirlo a través del fabri-

cante o su agente para evitar un riesgo de seguridad.

ADVERTENCIA: Algunas partículas originadas al lijar, aserrar, amolar, taladrar y

realizar otras actividades de construcción contienen productos químicos que producen cáncer, defectos de nacimiento y otros problemas reproductivos. Algunos

ejemplos de estos productos químicos son:

• el plomo de las pinturas de base plomo,

• la sílice cristalina de ladrillos, cemento y otros productos de mampostería,

• el arsénico y el cromo de la madera con tratamiento químico (CCA).

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice

este tipo de trabajo. Para reducir la exposición a estos productos químicos: se recomienda

trabajar en áreas bien ventiladas y usar equipos de seguridad aprobados, como las máscaras para polvo especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con las partículas de polvo originadas al lijar,

aserrar, esmerilar, taladrar y realizar demás actividades de la construcción. Use

indumentaria protectora y lave las áreas expuestas con agua y jabón. Evite que el

polvo entre en la boca y en los ojos o se deposite en la piel, para impedir la absorción

de productos químicos nocivos.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar partículas de

polvo, que pueden causar lesiones respiratorias permanentes y graves u otras lesiones.

Use siempre protección respiratoria aprobada por NIOSH/OSHA (Instituto Nacional de

Salud y Seguridad Ocupacional de EE.UU./Administración de la Salud y Seguridad

Ocupacional de EE.UU.) apropiada para la exposición al polvo. Aleje las partículas de la

cara y el cuerpo.

PRECAUCIÓN: Utilice la protección auditiva apropiada mientras usa la

herramienta. En ciertas condiciones y según el período de uso, el ruido provocado

por este producto puede llevar a la pérdida de audición.

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V....................voltios A .................amperios

Hz..................hertz W.................vatios

min.................minutos ................corriente alternante

............corriente directa no ................velocidad sin carga

.................Construcción Clase II ................terminal a tierra

................símbolo de alerta .../min ........ .revoluciones u

de seguridad oscilaciones por minuto

Motor

Asegúrese de que el suministro de energía concuerde con lo marcado en la placa. CA de

120 voltios solamente significa que su herramienta funcionará con la energía doméstica

estándar de 60 Hz. No haga funcionar herramientas para corriente alterna (CA) con

corriente directa (CD). Una capacidad nominal de 120 voltios CA/CD significa que su

herramienta funcionará con energía estándar de 60 Hz CA o CD. Esta información está

impresa en la placa. Un voltaje menor producirá pérdida de potencia y puede provocar

sobrecalentamiento. Todas las herramientas Black & Decker se prueban en fábrica. Si esta

herramienta no funciona, controle el suministro eléctrico.

Características - Figura A

1. Interruptor de Encendido/Apagado

2. Tapa del depósito de aserrín

3. Depósito de aserrín

4. Salida de extracción de polvo

5. Base lijadora

6. Palanca de la pieza para sujetar el papel

Lijado de pintura de base plomo

NO SE RECOMIENDA lijar pintura de base plomo debido a la dificultad para controlar el

polvo contaminado. El peligro mayor de envenenamiento por plomo es para los niños y las

mujeres embarazadas.

Como es difícil identificar si una pintura contiene o no plomo sin realizar análisis químicos,

recomendamos tomar las siguientes precauciones al lijar cualquier pintura:

Seguridad personal

• Ningún niño o mujer embarazada debe ingresar al área de trabajo donde se está lijando

la pintura hasta que se haya terminado la limpieza final.

• Todas las personas que ingresan al área de trabajo deben usar una máscara para polvo

o una mascarilla de respiración. El filtro se debe cambiar diariamente o toda vez que el

usuario tenga dificultad para respirar.

NOTA: Sólo se deben usar aquellas máscaras para polvo apropiadas para trabajar con

polvo y vapores de pintura de base plomo. Las máscaras comunes para pintar no ofrecen

esta protección. Consulte a su comerciante local sobre la máscara apropiada (aprobada

por NIOSH).

• NO SE DEBE COMER, BEBER O FUMAR en el área de trabajo para evitar ingerir

partículas de pintura contaminada. Los trabajadores se deben lavar y limpiar ANTES de

comer, beber o fumar. No se deben dejar artículos para comer, beber o fumar en el área

de trabajo donde se podría depositar polvo sobre ellos.

Seguridad ambiental

• La pintura debe ser retirada de forma tal de reducir al mínimo la cantidad de polvo

generado.

• Las áreas donde se realiza remoción de pintura deben estar selladas con hojas de

plástico de 4 milésimas de pulgada de espesor.

• El lijado se debería realizar de manera de reducir los vestigios de polvo de pintura fuera

del área de trabajo.

Limpieza y eliminación

• Todas las superficies del área de trabajo deben ser limpiadas cuidadosamente y

repasadas con aspiradora todos los días mientras dure el proyecto de lijado. Se deben

cambiar con frecuencia las bolsas de filtro de la aspiradora.

• Las telas plásticas del piso se deben recoger y eliminar junto con cualquier resto de polvo

u otros residuos del lijado. Deben colocarse en recipientes de desperdicios sellados y

eliminarse por medio de los procedimientos normales de recolección de residuos.

Durante la limpieza, los niños y las mujeres embarazadas deben mantenerse lejos del

área de trabajo inmediata.

• Todos los juguetes, muebles lavables y utensilios utilizados por los niños deben ser

lavados cuidadosamente antes de ser utilizados nuevamente.

Ensamblaje

Advertencia: Para reducir el riesgo de lesiones, asegúrese de que la herramienta

esté apagada y desenchufada antes de realizar cualquiera de los siguientes

ensamblajes.

Montaje de las hojas de lija (fig. B )

• Ablande el papel de lija rozando el lado no abrasivo sobre el borde de una mesa de

trabajo.

• Presione las palancas de la pieza para sujetar el papel (6) hacia arriba para liberarlas de

las ranuras de retención y abra las piezas de sujeción del papel presionándolas hacia

abajo.

• Coloque la hoja en la base para lijar.

• Inserte el borde de la hoja de lija en el frente de la pieza de sujeción del papel como se

muestra.

• Presione la palanca de la pieza para sujetar el papel frontal (6) hacia abajo y colóquela

en la ranura de retención.

• Mientras mantiene la hoja ligeramente tensionada, inserte el extremo posterior de la hoja

en la pieza de sujeción del papel trasera.

• Presione la palanca de la pieza de sujeción del papel trasera (6) hacia abajo y colóquela

en la ranura de retención.

Perforación de las hojas de lija (fig. C)

El punzón para papel (7) se utiliza para perforar orificios de extracción de polvo en las

hojas de lija que no tienen orificios perforados previamente.

Colocación de una hoja de lija

• Sostenga la herramienta en lugar justo sobre el punzón para papel (7).

• Presione la herramienta con la base lijadora (5) hacia abajo en el punzón para el papel.

• Retire la herramienta del punzón para papel (7) y verifique si los orificios en la hoja de lija

se perforaron por completo.

Colocación y retiro del depósito de aserrín (fig. D)

• Coloque el depósito de aserrín (3) sobre la salida de extracción de polvo (4).

• Para retirar el depósito de aserrín (3), tire el depósito hacia atrás y afuera de la salida (4).

OPERACIÓN

Advertencia: Para reducir el riesgo de lesiones, permita que la herramienta trabaje a

su propio ritmo. No la sobrecargue.

Encendido y apagado (fig. E)

• Para encender la herramienta, oprima la parte del interruptor de encendido/apagado (1)

marcada con la letra 'I'.

• Para apagar la herramienta, oprima la parte del interruptor de encendido/apagado (1)

marcada con la letra '0'.

Vaciado del depósito de aserrín (fig. D)

• El depósito de aserrín debe vaciarse cada 10 minutos.

• Tire el depósito de aserrín (3) hacia atrás y afuera de la herramienta.

• Retire la tapa (2) girándola en el sentido contrario a las agujas del reloj.

• Sostenga el depósito de aserrín con los filtros (8) hacia abajo y sacuda el depósito (3)

para vaciar su contenido.

• Sacuda la tapa (2) para vaciar el contenido.

• Vuelva a colocar la tapa (2) sobre el depósito de aserrín (3), gírela en el sentido de las

agujas del reloj hasta que se ajuste en su lugar.

• Coloque el depósito de aserrín (3) en la herramienta.

Limpieza del filtro del depósito de aserrín

Advertencia: Para reducir el riesgo de lesiones personales, no utilice aire

comprimido para limpiar el filtro.

NOTA: No utilice un cepillo u objetos filosos para limpiar el filtro ya que estos elementos

pueden reducir la durabilidad del material del filtro. No lave el filtro.

• El filtro del depósito de aserrín (8) es reutilizable y debe limpiarse periódicamente.

• Vacíe el depósito de aserrín (3) como se describió anteriormente.

• Quite el filtro del depósito de aserrín (8) del depósito (3).

• Sacuda el exceso de polvo al golpear suavemente el filtro (8) en un contenedor de

residuos.

• Reemplace del filtro del depósito de aserrín (8).

• Coloque la tapa (2).

• Coloque el depósito de aserrín (3) en la herramienta.

Consejos para un uso óptimo

• No coloque las manos sobre las ranuras de ventilación.

• No ejerza demasiada presión sobre la herramienta.

• Revise el estado del papel de lija periódicamente. Reemplácelo cuando sea necesario.

• Siempre lije con la veta de la madera.

Calibre mínimo para cables prolongadores

Voltios Largo total del cable en pies

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Capacidad nominal en amperios

Más de No más de Medida de conductor estadounidense

que que

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

Page 6

• Cuando lije capas nuevas de pintura antes de aplicar otra capa, utilice grano extra fino.

• Sobre superficies muy disparejas o cuando retira capas de pintura, comience con un

grano grueso. En otras superficies, comience con un grano mediano. En ambos casos,

cambie gradualmente a un grano fino para un acabado liso.

Recolección de aserrín

ADVERTENCIA: Riesgo de incendio. El polvo acumulado que se produce al lijar los

revestimientos de las superficies (poliuretano, aceite de lino, etc.) puede iniciar una

combustión espontánea dentro del depósito de aserrín de la lijadora o en algún otro lugar y

ocasionar un incendio. Para reducir este riesgo, vacíe el depósito regularmente y siga

estrictamente las instrucciones del manual de la lijadora y del fabricante del revestimiento.

ADVERTENCIA: Riesgo de incendio. Al trabajar sobre superficies de metal, no utilice el

depósito de aserrín ni una aspiradora debido a que se originan chispas. Utilice anteojos de

seguridad y una máscara para polvo. Debido al riesgo de incendio, no utilice la lijadora

para lijar superficies de magnesio. No utilice la herramienta para lijar superficies húmedas.

DETECCIÓN DE PROBLEMAS

Problema Causa posible Solución posible

•La unidad no enciende. • Cable desenchufado. • Enchufe la herramienta en un

tomacorriente que funcione.

• Fusible quemado. • Reemplace el fusible quemado.

(Si el producto provoca

que el fusible del circuito

salte en ocasiones repetidas,

interrumpa su uso de inmediato y

llévelo a un centro de mantenimiento

de Black & Decker o centro de

servicio autorizado para su

reparación).

• Disparo del interruptor • Reinicie el interruptor automático.

automático. (Si el producto provoca que el

interruptor automático se dispare,

interrumpa su uso de inmediato y

llévelo a un centro de mantenimiento

de Black & Decker o centro de

servicio autorizado para su

reparación).

• Interruptor o cable • Lleve el cable o el interruptor a un

dañado. centro de mantenimiento

Black & Decker o en un centro de

mantenimiento autorizado para que

su reemplazo.

Para recibir ayuda con su producto, visite nuestro sitio Web www.blackanddecker.com

y conozca la ubicación del centro de servicio más cercano a su domicilio o llame a la línea

de ayuda de BLACK & DECKER al al 1-800-544-6986.

Mantenimiento

Su herramienta ha sido diseñada para funcionar durante un largo período con un mínimo

mantenimiento.

El funcionamiento continuo satisfactorio depende del cuidado adecuado de la herramienta

y de una limpieza periódica.

• Despeje los conductos y las ranuras de ventilación con un pincel limpio y seco.

• Limpie la caja con un paño húmedo y limpio. No utilice solventes.

Accesorios

Los accesorios que se recomiendan para la herramienta están disponibles a un costo

adicional en su distribuidor local o en un centro de mantenimiento autorizado. Si necesita

ayuda para ubicar algún accesorio para su herramienta, llame al (55)5326-7100

ADVERTENCIA: El uso de accesorios no recomendados para utilizar con esta

herramienta puede resultar peligroso.

Información de servicio

Todos los Centros de mantenimiento de Black & Decker cuentan con personal altamente

capacitado dispuesto a brindar a todos los clientes un servicio eficiente y confiable en la

reparación de herramientas eléctricas. Si necesita consejo técnico, reparaciones o piezas

de repuesto originales de fábrica, póngase en contacto con el centro de mantenimiento de

Black & Decker más cercano a su domicilio. Para ubicar a su servicio local, consulte

“Herramientas eléctricas” (Tools-Electric) en la sección amarilla, o llame al:

(55)5326-7100 o visite www.blackanddecker.com

Garantía completa de dos años para uso en el hogar

Black & Decker (EE.UU.) Inc. ofrece una garantía de dos años por cualquier defecto del

material o de fabricación de este producto. El producto defectuoso se reparará o

reemplazará sin costo alguno de dos maneras.

La primera opción, el reemplazo, es devolver el producto al comercio donde se lo adquirió

(siempre y cuando se trate de un comercio participante). Las devoluciones deben

realizarse conforme a la política de devolución del comercio (generalmente, entre 30 y 90

días posteriores a la venta). Le pueden solicitar comprobante de compra. Consulte en el

comercio acerca de la política especial sobre devoluciones una vez excedido el plazo

establecido.

La segunda opción es llevar o enviar el producto (con flete pago) a un Centro de

mantenimiento propio o autorizado de Black & Decker para su reparación o reemplazo

según nuestro criterio. Le pueden solicitar comprobante de compra. Encontrará una lista de

los Centros de mantenimiento autorizados y de propiedad de Black & Decker bajo

"Herramientas eléctricas" (Tools-Electric) en las páginas amarillas de la guía telefónica; la

lista también está disponible en nuestro sitio web www.blackanddecker.com.

Esta garantía no se extiende a los accesorios. Esta garantía le concede derechos legales

específicos que pueden variar según el estado. Ante cualquier inquietud, comuníquese con

el Centro de mantenimiento de Black & Decker más cercano. Este producto no es para uso

comercial.

Reemplazo gratuito de las etiquetas de advertencia: Si sus etiquetas de advertencia se

vuelven ilegibles o faltan, llame al (55)5326-7100 para que se le reemplacen gratuitamente.

Nota especial de GARANTÍA para Contratistas:

Los productos de marca FIRESTORMMCse ofrecen como herramientas de calidad superior

para uso doméstico y llevan una GARANTÍA PARA USO DOMÉSTICO.

Estas herramientas son diseñadas, fabricadas y probadas para satisfacer o sobrepasar las

necesidades del bricolero en la ejecución de proyectos y reparaciones en su casa y sus

alrededores. El uso apropiado de esta herramienta le dará al dueño de casa una potencia

y un desempeño superiores que durarán mucho más que la garantía de dos años. Sin

embargo, si utiliza herramientas para su trabajo y usa productos de marca FIRESTORM

MC

o cualquiera de las herramientas para uso doméstico Black & Decker EN SU LUGAR DE

TRABAJO, debería saber que NO PODRÁ SER CUBIERTO BAJO

NUESTRA GARANTÍA.

ESPECIFICACIONES

Tensión de alimentación: 120 V~

Potencia nominal: 246 W

Frecuencia de operacion: 60 Hz

Consumo de corriente: 2,2 A

BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 55-5326-7100

Vea “Herramientas

eléctricas (Tools-Electric)”

– Páginas amarillas –

para Servicio y ventas

CULIACAN, SIN

Av. Nicolás Bravo #1063 Sur

(667) 7 12 42 11

Col. Industrial Bravo

GUADALAJARA, JAL

Av. La Paz #1779

(33) 3825 6978

Col. Americana Sector Juarez

MEXICO, D.F.

Eje Central Lázaro Cardenas

No. 18

(55) 5588 9377

Local D, Col. Obrera

MERIDA, YUC

Calle 63 #459-A

(999) 928 5038

Col. Centro

MONTERREY, N.L.

Av. Francisco I. Madero

No.831

(81) 8375 2313

Col. Centro

PUEBLA, PUE

17 Norte #205

(222) 246 3714

Col. Centro

QUERETARO, QRO

Av. Madero 139 Pte.

(442) 214 1660

Col. Centro

SAN LUIS POTOSI, SLP

Av. Universidad 1525

(444) 814 2383

Col. San Luis

TORREON, COAH

Blvd. Independencia, 96 Pte.

(871) 716 5265

Col. Centro

VERACRUZ, VER

Prolongación Díaz Mirón #4280

(229)921 7016

Col. Remes

VILLAHERMOSA, TAB

Constitución 516-A

(993) 312 5111

Col. Centro

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

Para reparación y servicio de sus herramientas eléctricas, favor de dirigirse

al Centro de Servicio más cercano:

Loading...

Loading...