Page 1

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

POUR LE FRANÇAIS, VOIR LA COUVERTURE ARRIÈRE.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

FFFFSSSS222211110000LLLLSSSS 11110000”””” TTTTAAAABBBBLLLLEEEE SSSSAAAAWW

WW

Cat.No. FS210LS Form No. 90520749 Rev. 1 AUG. ‘07 Copyright©2007 Black & Decker Printed in China

BEFORE RETURNING THIS PRODUCT FOR ANY

REASON PLEASE CALL 1-800-544-6986

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION AVAILABLE, CATALOG NO., TYPE NO., AND DATE CODE . IN MOST

CASES, A BLACK & DECKER REPRESENTATIVE CAN RESOLVE THE PROBLEM OVER THE PHONE. IF YOU HAVE A

SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL TO BLACK & DECKER.

THANK YOU FOR CHOOSING FIRESTORM! GOTO

WWW

.FIRESTORMTOOLS.COM/PRODUCTREGISTRATION

TO REGISTER YOUR NEW PRODUCT

.

Page 2

2

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols to the right. Please read the manual and pay attention to these sections.

SAFETY GUIDELINES - DEFINITIONS

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock,

fire, and/or serious personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there

are certain hazards involved with the operation of the product. Using the machine with respect and caution will

considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or ignored,

personal injury to the operator may result. Safety equipment such as guards, push sticks, hold-downs, featherboards,

goggles, dust masks and hearing protection can reduce your potential for injury. But even the best guard won’t make

up for poor judgment, carelessness or inattention. Always use common sense

and exercise caution

in the workshop.

If a procedure feels dangerous, don’t try it. Figure out an alternative procedure that feels safer. REMEMBER: Your

personal safety is your responsibility.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective

clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct

particles away from face and body.

Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

Page 3

3

GENERAL SAFETY RULES

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE.

Learning the machine’s application, limitations, and

specific hazards will greatly minimize the possibility of

accidents and injury.

2. WEAR EYE PROTECTION. ALWAYS USE SAFETY

GLASSES. Also use face or dust mask if cutting

operation is dusty. Everyday eyeglasses are NOT safety

glasses. USE CERTIFIED SAFETY EQUIPMENT. Eye

protection equipment should comply with ANSI Z87.1

standards, hearing equipment should comply with

ANSI S3.19 standards, and dust mask protection

should comply with MSHA/NIOSH certified respirator

standards. Splinters, air-borne debris, and dust can

cause irritation, injury, and/or illness.

3. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslip

footwear is recommended. Wear protective hair

covering to contain long hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or

wet locations or in rain can cause shock or

electrocution. Keep your work area well-lit to prevent

tripping or placing arms, hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the

machine, check for any damaged parts. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, and any other conditions that may

affect its operation. A guard or any other part that is

damaged should be properly repaired or replaced.

Damaged parts can cause further damage to the

machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can

be injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure that the switch is in the “OFF” position

before plugging in the power cord. In the event of a

power failure, move the switch to the “OFF” position.

An accidental start-up can cause injury.

10. USE THE GUARDS. Check to see that all guards are in

place, secured, and working correctly to prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES

BEFORE STARTING THE MACHINE. Tools, scrap

pieces, and other debris can be thrown at high speed,

causing injury.

12. USE THE RIGHT MACHINE. Don’t force a machine or

an attachment to do a job for which it was not

designed. Damage to the machine and/or injury may

result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by

Delta may cause damage to the machine or injury to the

user.

14. USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage, resulting in loss of

power and overheating. See the Extension Cord Chart

for the correct size depending on the cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold

the workpiece when practical. Loss of control of a

workpiece can cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause

the workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you

fall into a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the

tool tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFF. Don’t leave the machine until it

comes to a complete stop. A child or visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing

or removing accessories, before adjusting or changing

set-ups, or when making repairs. An accidental start-up

can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY

REMOVING STARTER KEYS. The accidental start-up

of a machine by a child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND

USE COMMON SENSE. DO NOT USE THE

MACHINE WHEN YOU ARE TIRED OR UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR MEDICATION. A moment of inattention while operating power

tools may result in injury.

24. TAKE PRECAUTIONS AGAINST DUST INHALATION.

The dust generated by certain woods and wood

products can be injurious to your health. Always

operate machinery in well-ventilated areas, and provide

for proper dust removal. Use wood dust collection

systems whenever possible.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

Page 4

4

ADDITIONAL SAFETY RULES FOR

TABLE SAWS

1. DO NOT OPERATE THIS MACHINE until it is

assembled and installed according to the

instructions.

2. OBTAIN ADVICE FROM YOUR SUPERVISOR,

instructor, or another qualified person if you are not

familiar with the operation of this machine.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections.

4. USE THE GUARDS WHENEVER POSSIBLE. Check

to see that they are in place, secured, and working

correctly.

5. KICKBACK IS THE NATURAL TENDENCY OF THE

WORKPIECE TO BE THROWN BACK AT THE

OPERATOR when the workpiece initially contacts the

blade or if the workpiece pinches the blade. Kickback

is dangerous and can result in serious injury.

AVOID KICKBACK by:

A. keeping blade sharp and free of rust and pitch.

B. keeping rip fence parallel to the saw blade.

C. using saw blade guard and spreader for every

possible operation, including all through sawing.

D. pushing the workpiece past the saw blade prior to

release.

E. never ripping a workpiece that is twisted or

warped, or does not have a straight edge to guide

along the fence.

F. using featherboards when the anti-kickback device

cannot be used.

G. never sawing a large workpiece that cannot be

controlled.

H. never using the fence as a guide when

crosscutting.

I. never sawing a workpiece with loose knots or other

flaws.

6. ALWAYS USE GUARDS, SPLITTER, AND ANTI-

KICKBACK FINGERS whenever possible.

7. REMOVE CUT-OFF PIECES AND SCRAPS from the

table before starting the saw. The vibration of the

machine may cause them to move into the saw blade

and be thrown out. After cutting, turn the machine off.

After the blade has come to a complete stop, remove

all debris.

8. NEVER START THE MACHINE with the workpiece

against the blade.

9. NEVER run the workpiece between the fence and a

moulding cutterhead.

10. CUTTING THE WORKPIECE WITHOUT THE USE OF

A FENCE OR MITER GAUGE IS KNOWN AS

“FREEHAND” CUTTING. NEVER perform “free-hand”

operations. Use either the fence or miter gauge to

position and guide the workpiece.

11. HOLD THE WORKPIECE FIRMLY against the miter

gauge or fence.

12. CUTTING COMPLETELY THROUGH THE WORK-

PIECE IS KNOWN AS “THROUGH-SAWING”.

Ripping and cross-cutting are through-sawing

operations. Cutting with the grain (or down the length

of the workpiece) is ripping. Cutting across the grain (or

across the workpiece) is cross-cutting. Use a fence or

fence system for ripping. DO NOT use a fence or fence

system for cross-cutting. Instead, use a miter gauge.

USE PUSH STICK(S) for ripping a narrow workpiece.

13. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause a hand

to move into the blade.

14. KEEP ARMS, HANDS, AND FINGERS away from the

blade.

15. NEVER have any part of your body in line with the path

of the saw blade.

16. NEVER REACH AROUND or over the saw blade.

17. NEVER attempt to free a stalled saw blade without first

turning the machine “OFF”.

18. PROPERLY SUPPORT LONG OR WIDE workpieces.

19. NEVER PERFORM LAYOUT, assembly or set-up work

on the table/work area when the machine is running.

20. TURN THE MACHINE “OFF” AND DISCONNECT

THE MACHINE from the power source before

installing or removing accessories, before adjusting or

changing set-ups, or when making repairs.

21. TURN THE MACHINE “OFF”, disconnect the machine

from the power source, and clean the table/work area

before leaving the machine. LOCK THE SWITCH IN

THE “OFF” POSITION to prevent unauthorized use.

22. ADDITIONAL INFORMATION regarding the safe

and proper operation of power tools (i.e. a safety

video) is available from the Power Tool Institute,

1300 Sumner Avenue, Cleveland, OH 44115-2851

(www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121 Spring

Lake Drive, Itasca, IL 60143-3201. Please refer to the

American National Standards Institute ANSI 01.1

Safety Requirements for Woodworking Machines and

the U.S. Department of Labor OSHA 1910.213

Regulations.

SAVE THESE INSTRUCTIONS.

Refer to them often

and use them to instruct others.

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING

THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock, fire,

and/or serious personal injury or property damage.

Page 5

5

A separate electrical circuit should be used for your machine. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have 3prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch is in the “OFF” position and be sure that the electric current is of the

same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

SHOCK HAZARD. DO NOT EXPOSE MACHINE TO RAIN OR OPERATE MACHINE IN DAMP

LOCATIONS.

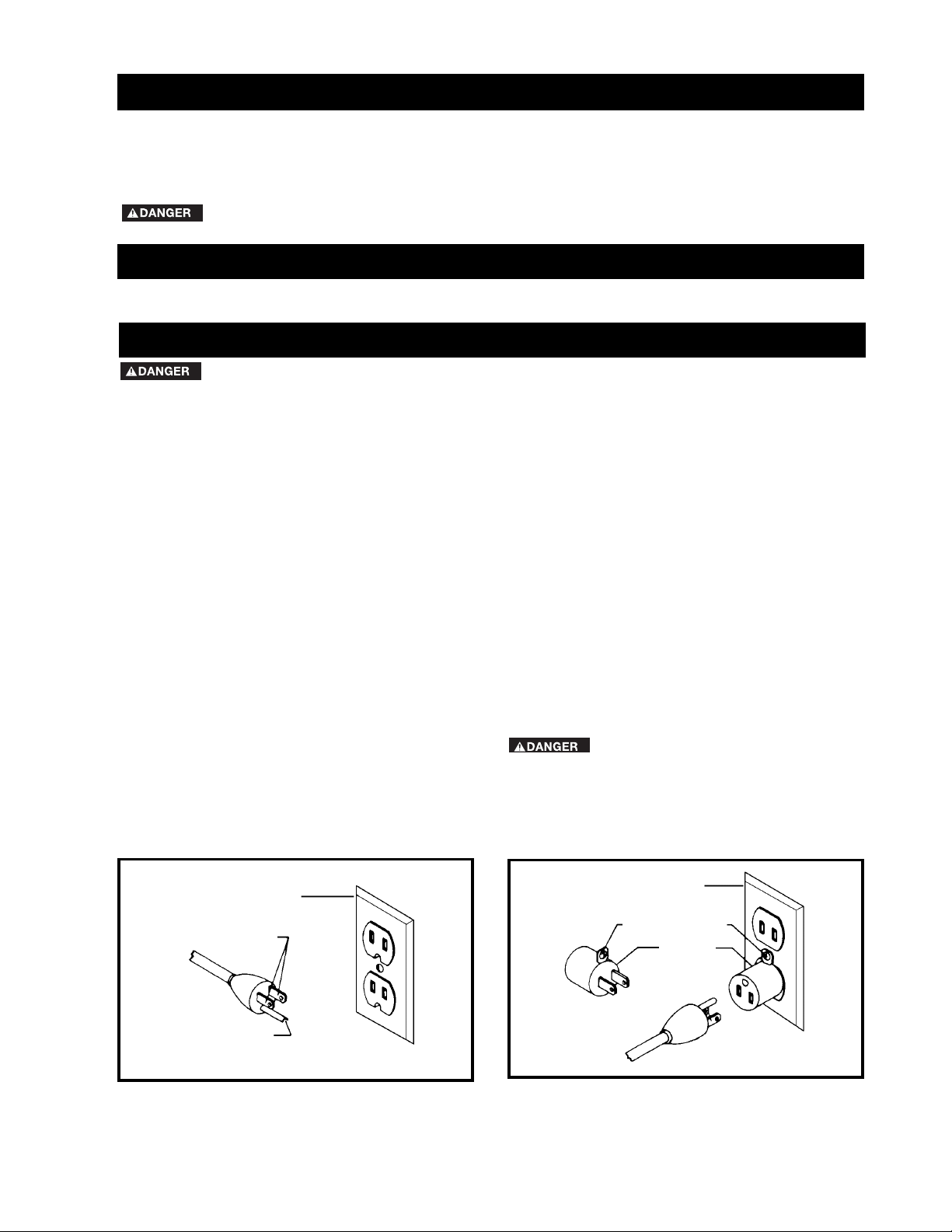

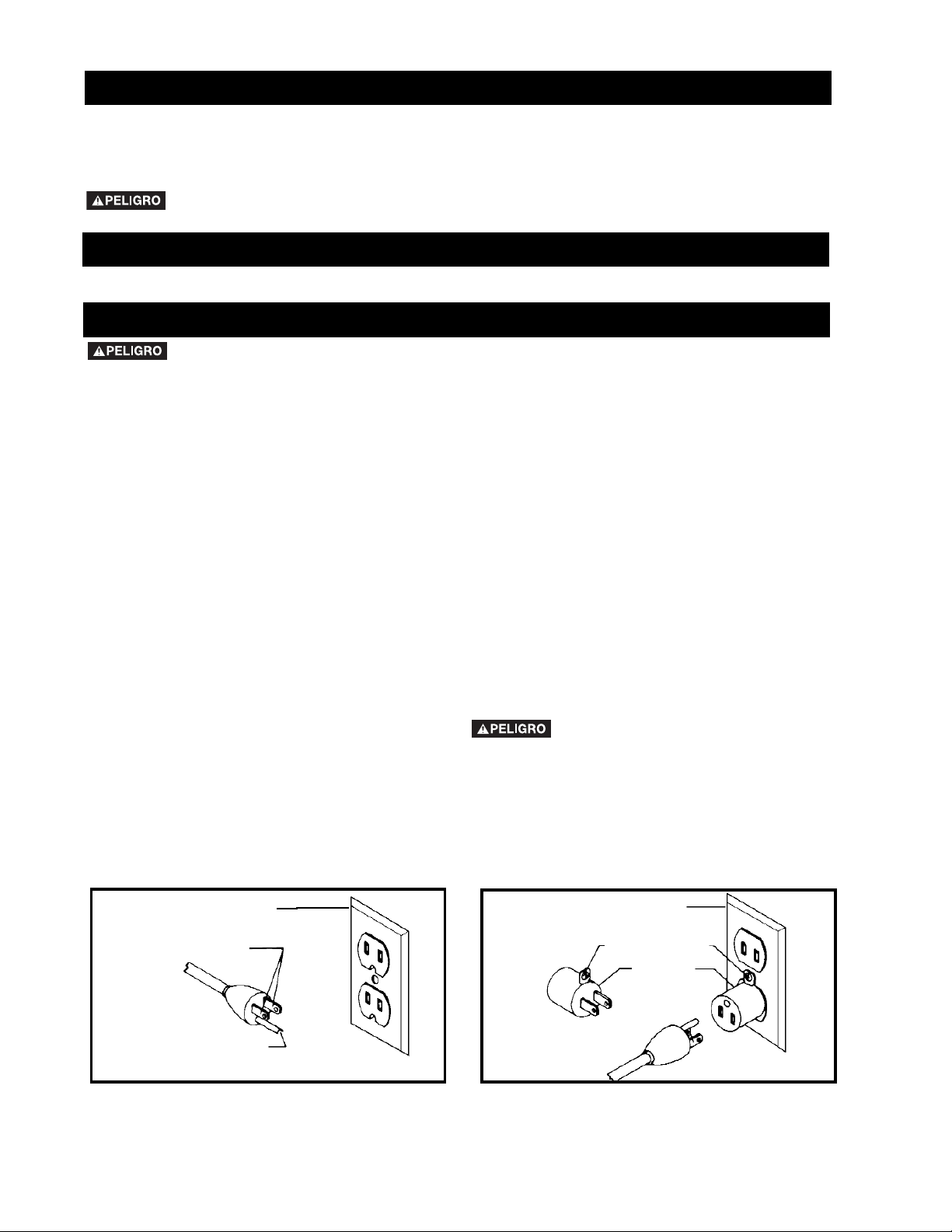

Fig. A Fig. B

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

2. Grounded, cord-connected machines intended for use

on a supply circuit having a nominal rating less than 150

volts:

If the machine is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug

illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect

this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box. Whenever

the adapter is used, it must be held in place with a metal

screw.

NOTE: In Canada, the use of a temporary adapter is not

permitted by the Canadian Electric Code.

IN ALL CASES, MAKE CERTAIN THE

RECEPTACLE IN QUESTION IS PROPERLY

GROUNDED. IF YOU ARE NOT SURE HAVE A

QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is

equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely

understood, or if in doubt as to whether the machine is

properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown in

Fig. A.

Repair or replace damaged or worn cord immediately.

POWER CONNECTIONS

MOTOR SPECIFICATIONS

Your machine is wired for 120 volt, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

SHOCK HAZARD. THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE

OPERATOR FROM ELECTRIC SHOCK.

Page 6

FOREWORD

Model FS210LS has big saw capacity at an economical price. It has an extra large, 17 in. x 34 in. aluminum table with

extension and is powered by a heavy-duty 15 amp. motor with a floating jackshaft gear - the most powerful in its class.

This saw is designed to give high quality performance with depth of cut capacity up to 3 in. (76mm) at 90° and 2.5 in.

(63.5mm) at 45° for clean cutting of standard stock sizes. This package includes the saw, a metal stand, rip fence, miter

gage, see-through blade guard with splitter and anti-kickback fingers, table extensions a 10 in. carbide-tipped saw

blade, table insert and blade wrenches.

6

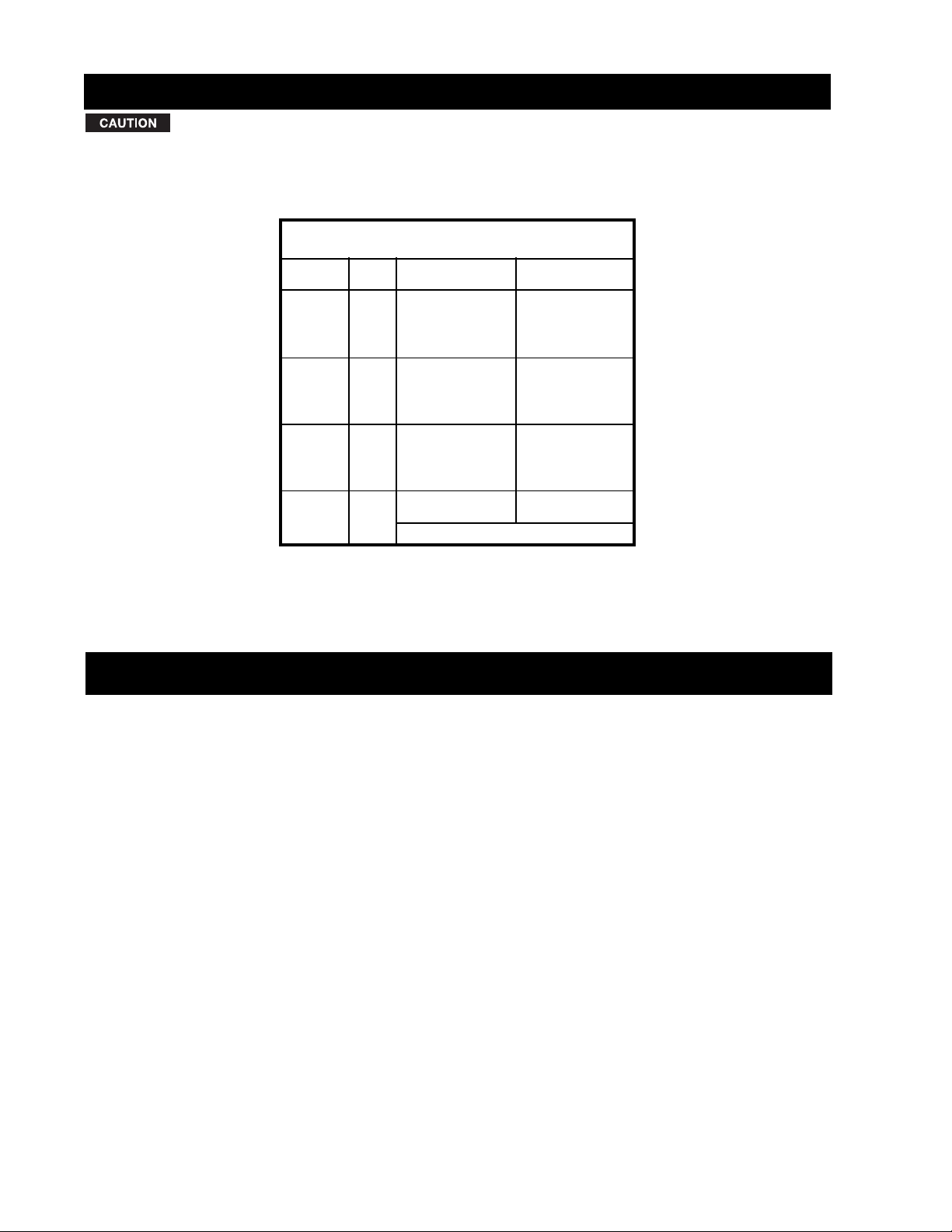

EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s

plug. When using an extension cord, be sure to use one heavy enough to carry the current of the machine. An

undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig. C, shows the correct

gauge to use depending on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Fig. C

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 120

up to

25 18 AWG

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

up to

25 18 AWG

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

up to

25 16 AWG

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

up to

25 14 AWG

12-16 120 25-50 12 AWG

12-16 120

GREATER THAN 50 FEET NOT RECOMMENDED

FUNCTIONAL DESCRIPTION

Page 7

7

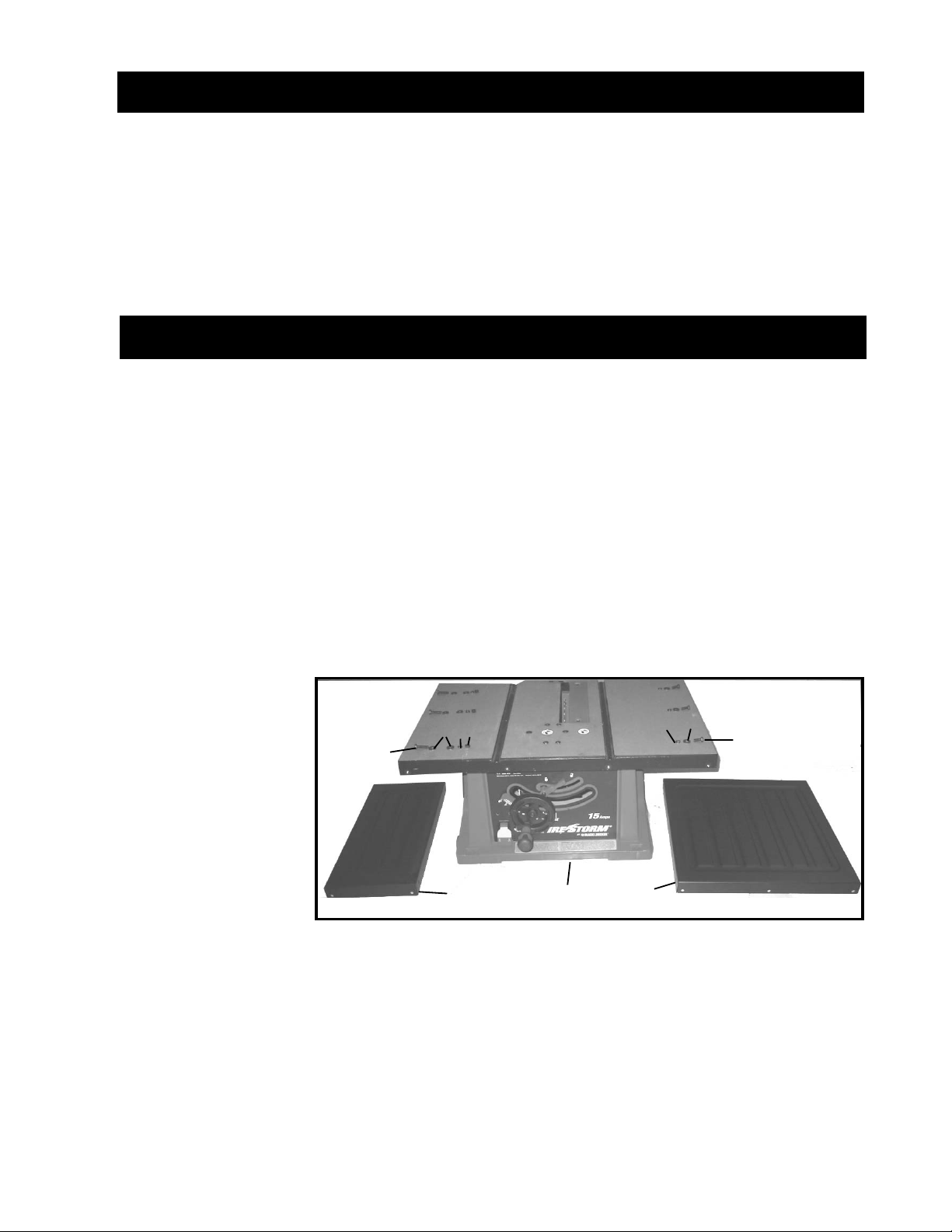

Fig. 1

TABLE SAW PARTS

9

2

3

4

5

1- Saw

2- Left Extension Wing

3- 1/4 in.-20X1 in.Hex Head

Screw for Left Extension

Wing (3)

4- 1/4 in. Flat Washer for

Left Extension Wing (6)

5- 1/4 in. Lockwasher for

Left Extension Wing (3)

6- 1/4 in.-20 Hex Nut for Left

Extension Wing (3)

7- Right Extension Wing

8- 1/4 in.-20X5/8 in.Hex

Head Screw for Right

Extension Wing (3)

9- 1/4 in. Flat Washer for

Right Extension Wing (3)

10- 1/4 in. Lockwasher for

Right Extension Wing (3)

7

ASSEMBLY

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from

all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone,

gasoline or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household

floor paste wax.

NOTICE: THE PHOTO ON THE MANUAL COVER ILLUSTRATES THE

CURRENT PRODUCTION MODEL. ALL OTHER ILLUSTRATIONS CONTAINED

IN THE MANUAL ARE REPRESENTATIVE ONLY AND MAY NOT DEPICT THE

ACTUAL COLOR, LABELING OR ACCESSORIES AND ARE INTENDED TO

ILLUSTRATE TECHNIQUE ONLY.

6

ASSEMBLY TOOLS REQUIRED

ASSEMBLY TIME ESTIMATE

1). Adjustable wrench

2.) 13mm wrench for stand bolts.

3.) 10mm wrench for splitter assembly bolts, rear supports assembly and extension wings assembly.

4.) Slotted screwdriver.

6.) Phillips screwdriver.

5.) Straight edge and/or framing square for adjustments.

2 Hours

7

8

10

1

Page 8

8

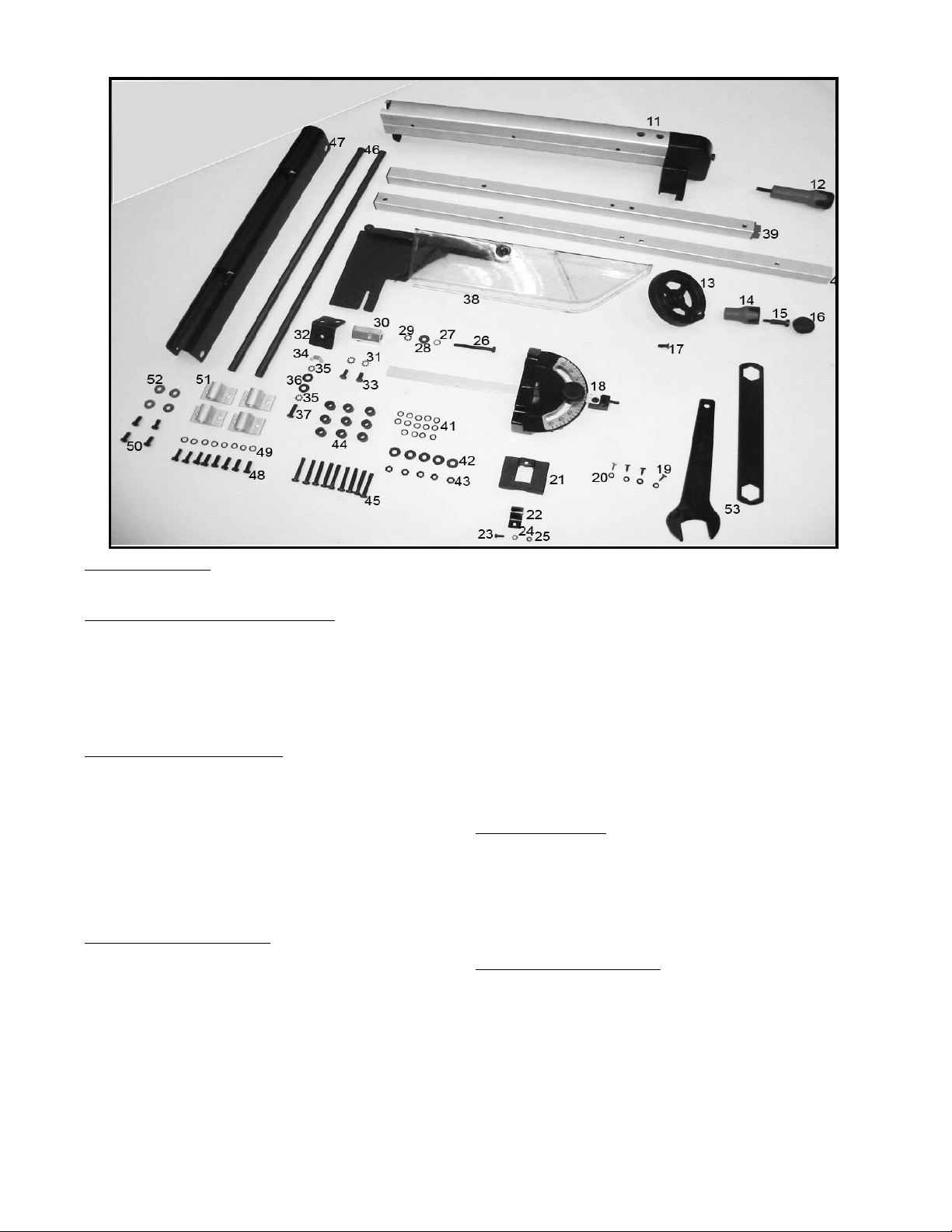

Fig. 2

RIP FENCE

P

ARTS

(11,12)

11-Rip Fence

12-Locking Handle for Rip Fence

BLADE RAISING HANDWHEEL P

ARTS

(13,14,15,16,17)

13-Blade Raising and Lowering Handwheel

14-Handle for Blade Raising and Lowering handwheel

15-Screw for Mounting Handwheel Handle

16-Cap for Handle

17-M6X1X12mm Flat Head Screw for Mounting Blade

Raising and Lowering Handwheel

18-Miter Gage

MITER

GAGE

HOLDER

PARTS

(19,20,21,22,23,24,25)

19-M4.2X10mm Pan Head Tap Screws for Mounting

Miter Gage Holder(4)

20-Lockwasher for Mounting Miter Gage Holder(4)

21-Miter Gage Holder

22-Spring Clip for Miter Gage Holder

23-M4X0.7X10mm Pan Head Screw for Miter Gage

Holder

24-3/16 in.External Tooth Lockwasher for Miter Gage

Holder

25-M4X0.7mm Hex Nut for Miter Gage Holder

SPLITTER BRACKET PARTS (26,27,28,29,30,31,32,33,

34,35,36,37)

26-1/4-20X2-1/4 in.Long Hex Head Screw for Mounting

Splitter Bracket

27-1/4 in.Internal Tooth Lockwasher for Mounting

Splitter Bracket

28-1/4 in.Flat Washer for Mounting Splitter Bracket

29-1/4 in.External Tooth Lockwasher for Mounting

Splitter Bracket

30-Splitter Bracket

31-1/4 in.External Tooth Lockwasher for Splitter

Bracket(2)

32-Splitter Support Bracket

33-1/4-20X1/2 in.Hex Head Screws for Splitter

Bracket(2)

34-Wing Nut for Mounting Splitter Support Bracket

35-1/4 in.External Tooth lockwasher for Splitter

Bracket(2)

36-1/4 in.Flat washer for Mounting Splitter Support

Bracket(2)

37-M6X1X20mmHex Head Screw for Mounting Splitter

Support Bracket

38-Splitter and Guard Assembly

39-Fence Left Rail

40-Fence Right Rail

FENCE RAIL

PAR

TS

(41,42,43,44,45)

41-M6 Lockwasher for Mounting Fence Rail(14)

42-1/4 in. Flat washer for Mounting Fence Rail(5)

43-1/4 in.-20 Hex Nut for Mounting Rail and Extension

Wings(5)

44-Spacers for Mounting Fence(9)

45-1/4 in.-20X1-1/4 Round Head Screws for Mounting

Fence Rail (9)

OUTFEED SUPPORT

P

ART

S

(46,47,48,49,50,51,52)

46-Rod for Rear Support (2)

47-Rear Support

48-M6X1X15mm Hex Cross Screw for Bracket(8)

49-M6 Lockwasher for Mounting Bracket(8)

50-1/4 in.-20X1/2 in. Hex Head Screw for Rod(4)

51-Bracket(4)

52-1/4 in.Flat Washers for Mounting Rod(4)

53-Wrenches for Blade Changing

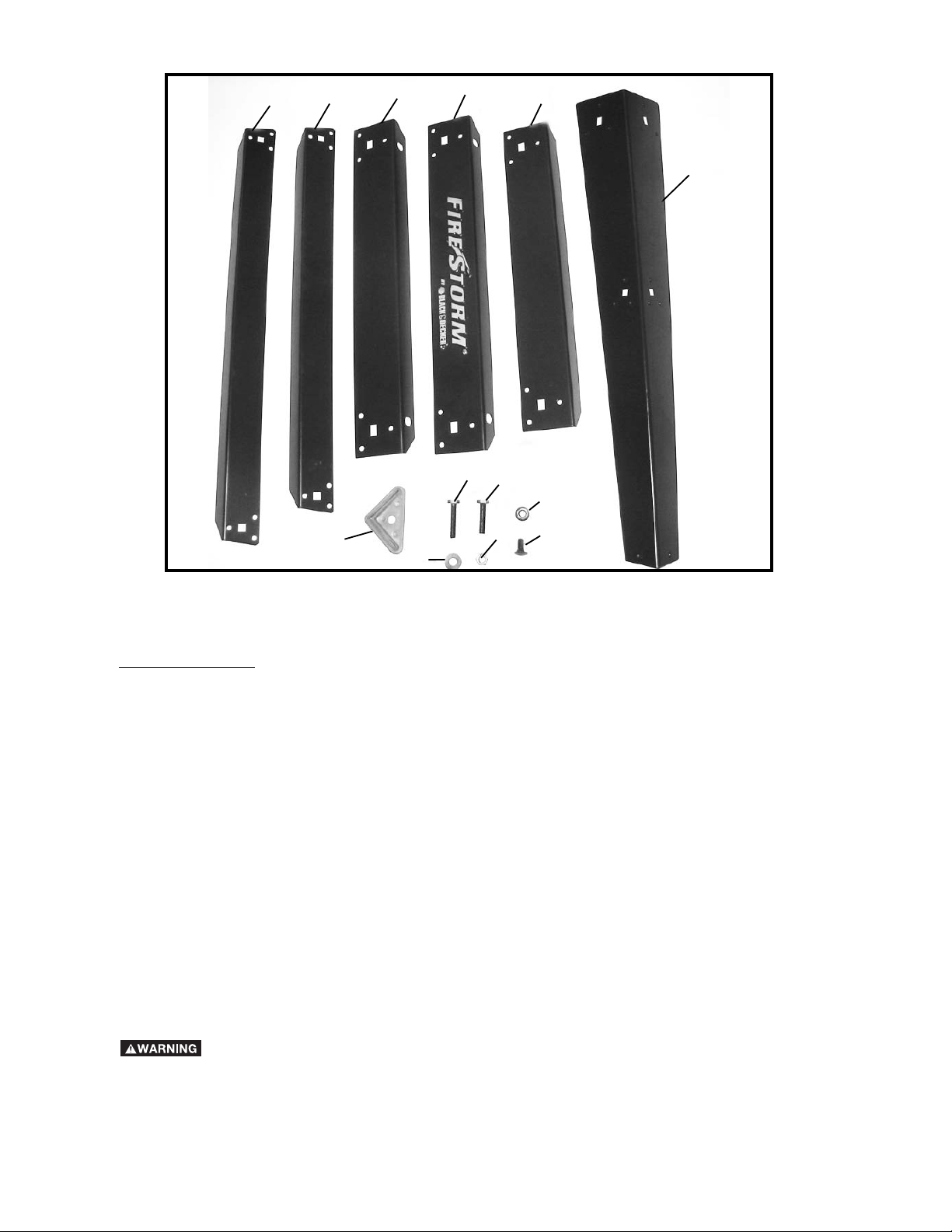

Page 9

9

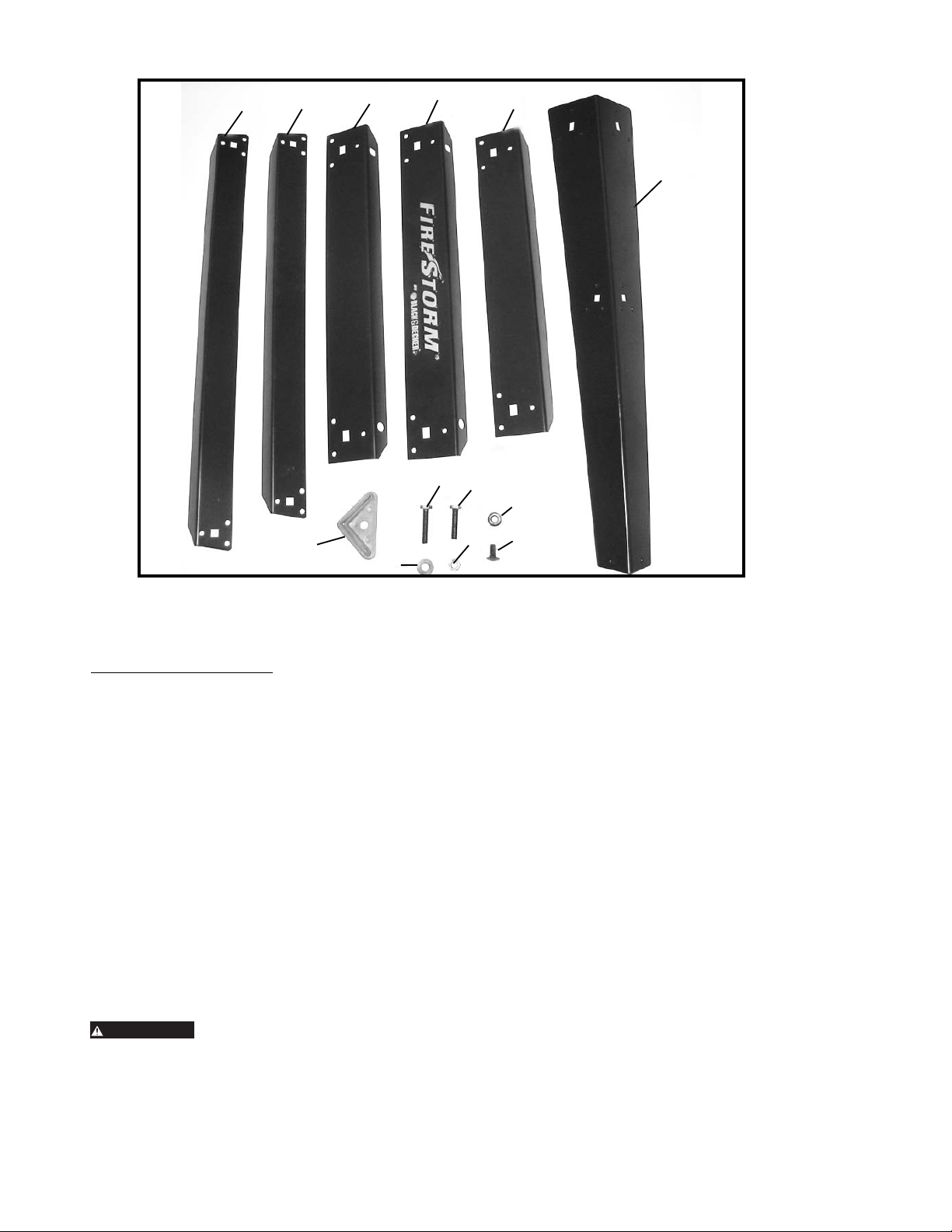

Fig. 3

STAND PARTS

53-Leg(4)

54-Top side Bracket(2)

55-Top Front Bracket

56-Top Rear Bracket

57-Bottom side Brackets(2)

58-Bottom Front Brackets(2)

59-Foot(4)

FOR YOUR OWN SAFETY, DO NOT CONNECT THE MACHINE TO THE POWER SOURCE UNTIL

THE MACHINE IS COMPLETELY ASSEMBLED. DO NOT OPERATE THIS MACHINE UNTIL YOU READ AND

UNDERSTAND THE ENTIRE INSTRUCTION MANUAL

53

54

55

56

57

58

60

61

62

63

59

64

65

60-M8X1.25X45mm Hex Head Screw for Leg and

Base(2)

61-M8X1.25X30mm Hex Head Screw for Leg and

Base(2)

62-5/16 in.Hex lock Nut(16)

63-5/16 in.Carriage Bolt(16)

64-M8 Hex Nut(4)

65- M8 Flat washer(8)

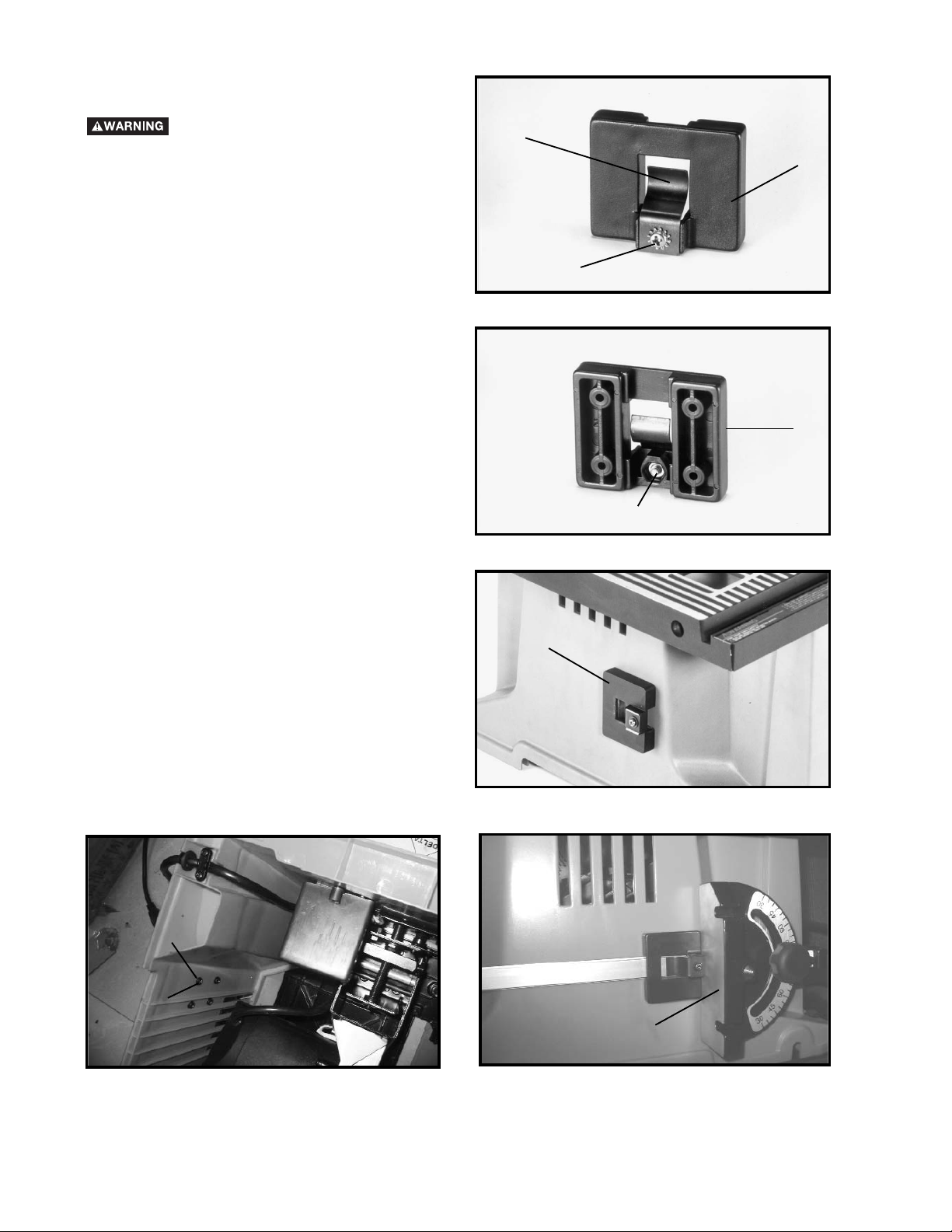

Page 10

10

MITER GAGE HOLDER

DISCONNECT MACHINE FROM

POWER SOURCE.

1. Assemble spring clip (E) Fig. 4, to the miter gage

holder (A) as shown using a M4x.7x10mm pan head

screw (F), 3/16 in. lockwasher and M4x.7 hex nut.

NOTE: Hex nut (G) Fig. 5, will fit into the recess at the

back of the miter gage holder (A) to keep spring clip (E)

Fig. 4, secured to the miter gage holder.

2. Assemble the miter gage holder (A) Fig. 6, to the left

side of the saw cabinet using the four M4.2x10mm pan

head screws (B) Fig. 7, and 3/16 in. washers (C) from

inside saw cabinet.

3. Fig. 8, illustrates the miter gage (D) inserted into the

miter gage holder when not in use.

Fig. 7

Fig. 4

Fig. 5

Fig. 6

Fig. 8

E

A

F

A

G

A

C

B

D

Page 11

11

STAND ASSEMBLY

1. The stand legs have protrusions which align with the

holes in the top and bottom brackets. Assemble the

stand as shown in Fig. 9A, using 16 carriage bolts and

hex lock nuts. Do not completely tighten the hardware at

this time.

A-Top front bracket (with logo)

B-Top rear bracket

C-Bottom side brackets

D-Bottom front and rear brackets

E-Top side brackets

F-Foot

IMPORTANT: THE TOP, FRONT, AND REAR

BRACKETS (A&B) FIG. 9A, ARE LONGER THAN THE

TOP SIDE BRACKETS (E) FIG. 9A. THE BOTTOM

FRONT AND REAR BRACKETS (D) FIG. 9A, ARE

LONGER THAN THE BOTTOM SIDE BRACKETS (C).

2. Assemble the rubber feet (F) Fig. 9A. NOTE: Each

rubber foot is provided with holes for mounting the

stand to the floor surface if required.

ATTACHING DUST BAG

1. Attach the dust bag to the bag frame and place the

frame of the dust bag inside the saw stand as shown in

Fig. 9B. Refer to the section below to attach this

assembly to the saw.

SAW TO STAND

1. Turn saw table face down on a piece of cardboard to

protect the table surface. Place stand upside down onto

saw and align the four holes in the stand with the

mounting holes in the saw.

2. Using the 2 longer screws for the front, place a M8 flat

washer on a M8X1.25X45mm hex head screw. Insert the

hex head screw through the mounting hole in the saw

and the mounting hole in the stand. Place another M8

flat washer on the hex screw and thread a M8X1.25 hex

nut on the screw and loosely tighten. Repeat this

process to complete another hole in the saw front.

Using the 2 shorter screws for the back, place a M8 flat

washer on a M8X1.25X30mm hex head screw in the

back of saw. Insert the hex head screw through the

mounting hole in the saw and the mounting hole in the

stand. Place another M8 flat washer on the hex screw

and thread a M8X1.25 hex nut on the screw and loosely

tighten. Repeat this process to complete another hole in

the saw back.

3. Then, turn saw table face up, as shown in Fig. 9C

(Saw is shown fully assembled here).

4. Push down on top of the saw so the legs of the stand

adjust to the surface of the floor and tighten all stand

hardware and hardware which secures saw to stand.

Fig. 9A

Fig. 9C

Fig. 9B

C

E

B

D

E

A

C

D

F

Page 12

12

ASSEMBLING BLADE

RAISING AND LOWERING

HANDWHEEL

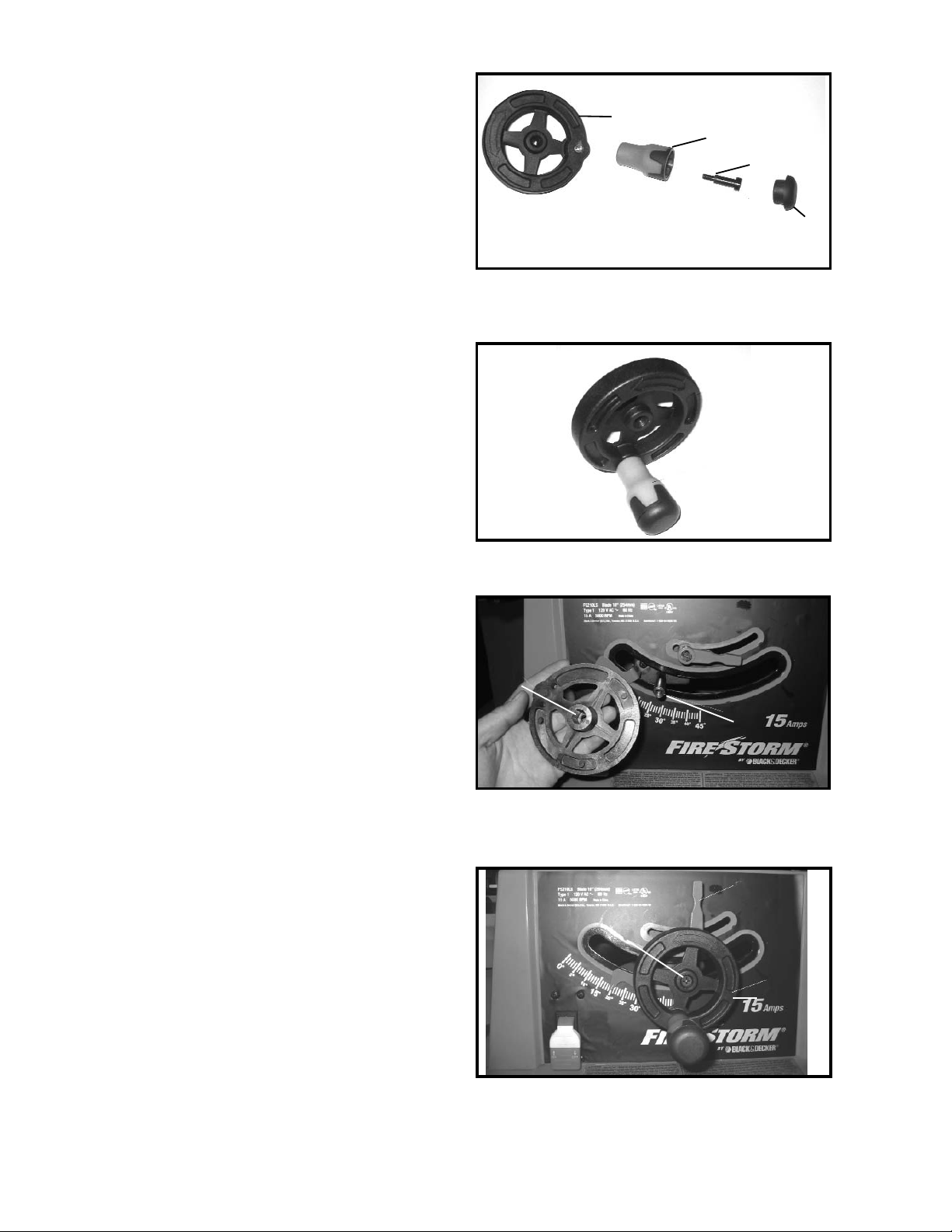

1. Insert special screw (C) through handle (B) Fig.10 and

assembly handle to handwheel (A) by threading screw

clockwise into handwheel. Then push on handle cover

(D).

2. Fig. 11, illustrates the handle (B) assembled to

handwheel (A).

3. Assemble handwheel (A) Fig. 12, to shaft (B) making

sure the flat on inside of handwheel lines up with flat on

shaft.

4. Fasten handwheel (A) Fig. 13, to shaft (B) Fig. 12,

using a M6x1x12mm flat head screw (C) Fig. 13.

Fig. 10

Fig. 11

Fig. 12

Fig. 13

A

B

A

C

A

B

C

D

Page 13

13

BLADE GUARD AND

SPLITTER ASSEMBLY

DISCONNECT MACHINE FROM

POWER SOURCE.

1. IMPORTANT: THE BLADE GUARD AND SPLITTER

ASSEMBLY MUST BE PROPERLY ALIGNED TO THE

SAW BLADE IN ORDER TO PREVENT KICKBACK.

2. Position the blade 90 degrees to the table and lock in

place. Refer to page 18 “Blade Raising and Lowering

Control” and page 19 “Blade Tilting Control”.

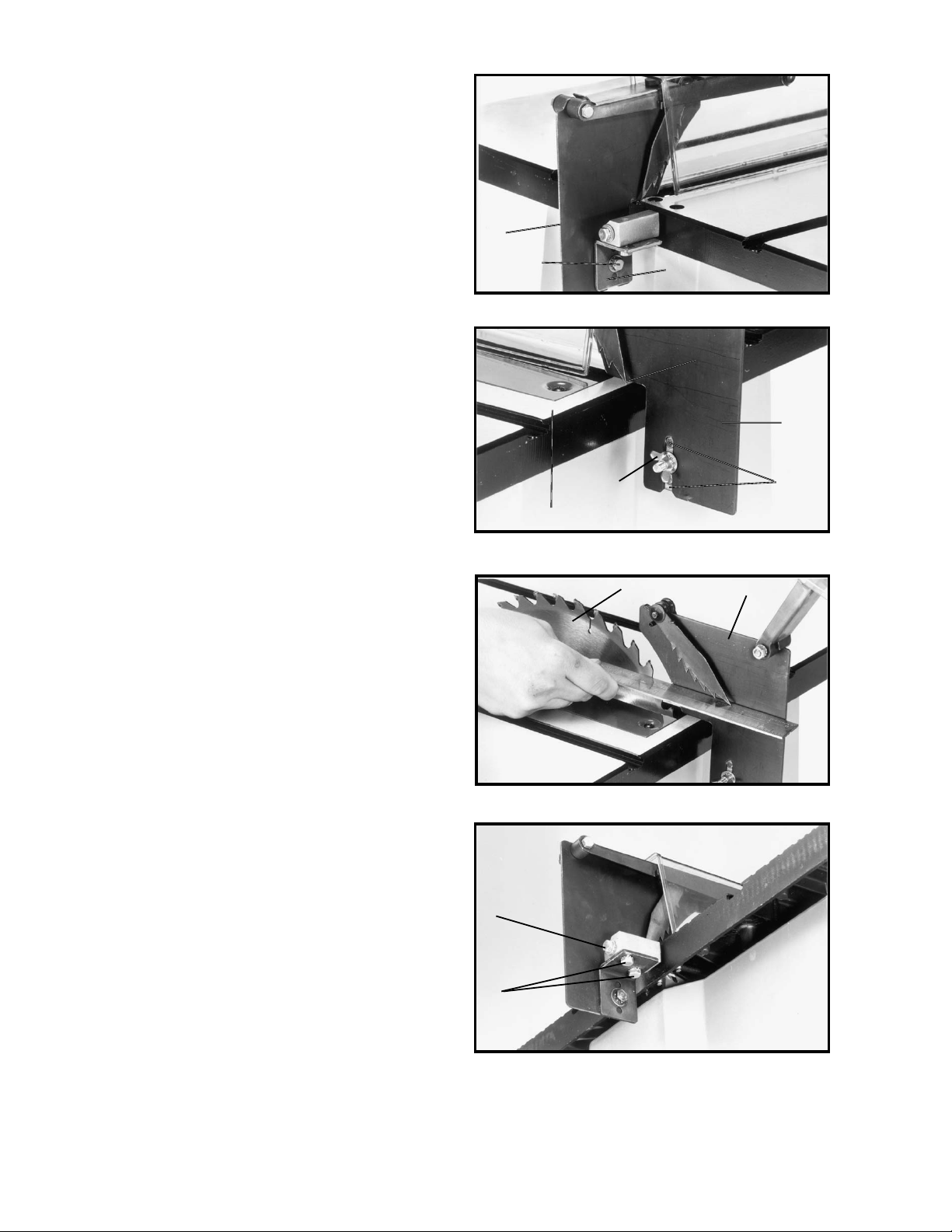

3. Fasten the splitter support bracket (A) Fig. 14, to

splitter bracket (B) using two 1/4-20 x 1/2 in. Hex Head

Screws (C), and two 1/4 in. external tooth lockwashers

as shown. NOTE: Do not completely tighten screws

(C) at this time.

4. Locate the 1/4-20 x 2-1/4 in. hex head screw (G) Fig.

15, and assemble the 1/4 in. internal tooth lockwasher

(O), 1/4 in. flat washer (P) and 1/4 in. external tooth

lockwasher (R) onto screw (G).

5. Position recessed end (E) Fig. 16, of splitter bracket

(B) against end of pivot rod (F) and fasten in place using

assembly from STEP 4 above. NOTE: Do not

completely tighten screw (G) at this time. Assembly

shown in Fig. 17.

6. Position the splitter (H) Fig. 18, on the splitter support

bracket as shown, making certain the two protrusions

(K) on the splitter support bracket are inside the slot of

splitter (H).

Fig. 14

Fig. 15

Fig. 16

Fig. 18Fig. 17

K

H

G

F

E

B

R

P

O

G

A

B

C

Page 14

14

7. Assemble splitter (H) Fig. 19, to splitter support

bracket (B) as shown using M6x1x20mm hex head

screw (L), 1/4 in. external tooth washer, and 1/4 in. flat

washer.

8. Fasten splitter (H) Fig. 20, to splitter support bracket

using 1/4 in. flat washer, 1/4 in. external tooth

lockwasher and M6 wing nut (M). NOTE: Before

tightening wing nut (M) make certain there is at least a

1/8 in. gap between the bottom edge of splitter (N) and

top surface of table (P) and that protrusion “pins” (K) Fig.

20, are inside the slot of splitter assembly (H).

9. Using a straight edge, check to see if the splitter (H)

Fig. 21, is aligned with the saw blade (R). If an

adjustment is necessary, the splitter (H) can be moved

left or right and rotated.

10. When you are certain the splitter is properly aligned

with the saw blade, tighten the two screws (C) Fig. 22,

that fasten the splitter support bracket to the splitter

bracket and tighten screw (G) that fastens the splitter

bracket to the pivot rod.

Fig. 19

Fig. 20

Fig. 21

Fig. 22

C

G

R

H

P

M

K

H

N

H

L

B

Page 15

15

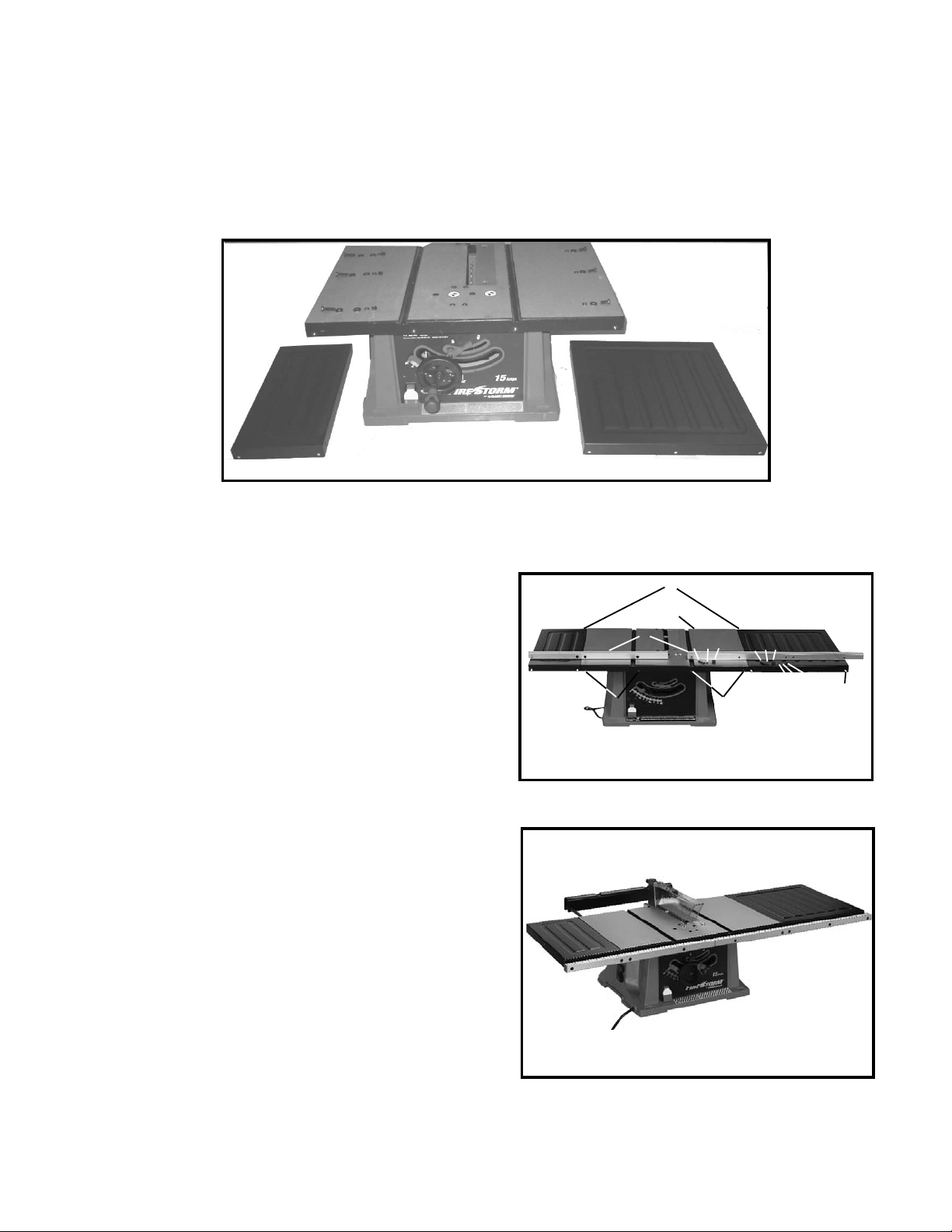

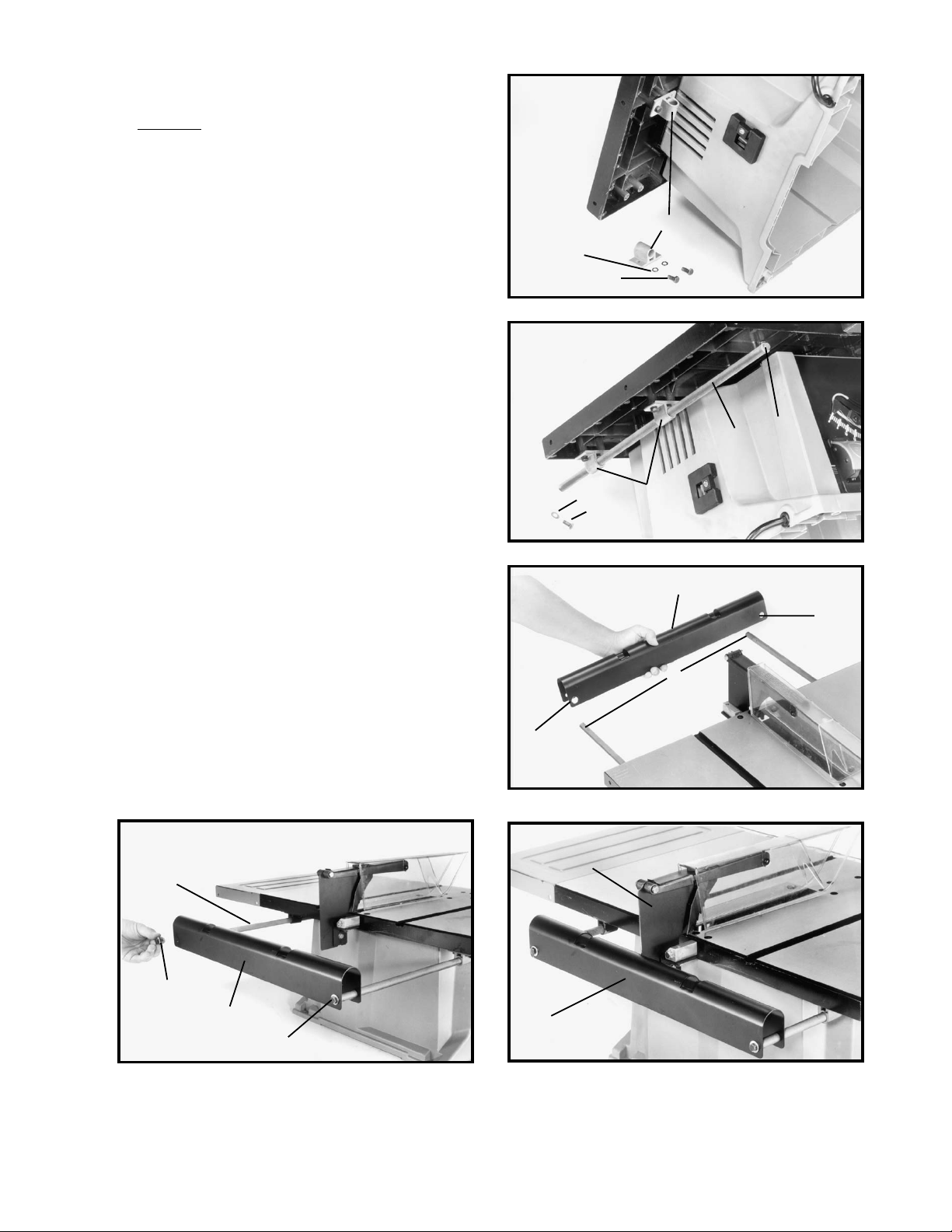

EXTENSION WINGS

1. Assemble left extension wing (Fig.23), to the saw table using 1/4-20X1 in.hex head screws (3), 1/4 in.flat washers (6),

1/4 in.lockwashers (3),1/4 in.hex nuts (3).

2. Assemble right extension wing into the threaded holes of the saw using 1/4 in.-20X5/8 in. hex head screws (3),

1/4 in. flat washers (3) 1/4 in. lockwashers (3).

3. With a straight edge, make certain the top, front and rear edges of the extension wings are level with the saw table

before tightening three screws which secure extension wing to table.

Fig. 23

GUIDE RAIL TO SAW

1. Holding the guide rail with the larger holes facing you,

loosely fasten guide rails (A) Fig. 24, to the four

threaded holes (B) in saw table (C) using two 1/4-20

x 1-1/4 in. long screws (D), 1/4 in. lockwashers (E), and

spacers (F).

IMPORTANT: Spacers (F) Fig. 24, are positioned

between guide rails (A) and saw table (C).

2. Fasten guide rails (A) Fig. 24, to extension wings

(G) through hole (K) using the 1/4-20 x 1-1/4 in. long

screw (D), 1/4 in. lockwasher (E), spacer (F), 1/4 in. flat

washer (H), 1/4 in. lockwasher (E), and 1/4-20 hex nut

(J). Then tighten all guide rail mounting hardware.

IMPORTANT: Spacer (F) Fig. 24, is positioned

between guide rails (A) and extension wings (G).

3. Fig. 25, illustrates the guide rails properly assembled

to saw table and extension wings.

Fig. 24

Fig. 25

C

A

G

J

E

H

D

E

K

F

B

D

E

F

B

Page 16

16

RIP FENCE

1. Thread the M8x1.25 hex nut (A) Fig. 26,

approximately halfway on the stud of the handle (B).

2. Thread the handle (B) Fig. 26 into the tapped hole

(C) in the fence cam (D). Tighten the hex nut (A) Fig. 26

against the cam (D).

3. Lower rip fence onto table as shown in Fig. 27,

making certain rear clamp hooks over back edge of

table.

4. The rip fence is usually operated on the right hand

side of the saw table. Lift lock handle (B), and position

fence on table. Push downward on handle (B), to lock

fence in place on saw table.

MITER GAGE

The miter gage is shipped completely assembled and is

supplied with a T-slot miter gage bar (A) Fig. 28, that is

inserted into either one of the two T-slotted miter gage

grooves located in the table top, as shown. The T-slot

miter gage prevents the miter gage from falling when it

is extended out beyond the front of the table when

cross-cutting extra wide workpieces.

Fig. 26

Fig. 27

Fig. 28

A

B

B

A

C

D

Page 17

17

OUTFEED SUPPORT

1. LOOSELY fasten both brackets (A) Fig. 29, to the

bottom left side of the saw table as shown, using two

M6x1x15mm phillips hex head screws (B) and M6.1

lockwashers (C). Assemble two remaining brackets to

the bottom right side of saw table in the same manner.

2. Insert rod (D) Fig. 30, through holes in brackets (A) as

shown. Then thread and tighten one 1/4-20x1/2 in. hex

head screw (E) and 1/4 in. flat washer (F) into the front

end of rod (D) as shown at (G). Assemble remaining rod

to the opposite side of saw in the same manner.

3. Insert rods (D) Fig. 31, into larger holes (H) in outfeed

support (J) as shown.

4. Secure outfeed support (J) Fig. 32, to rods (D) using

two 1/4-20x1/2 in. hex head screws and 1/4 in. flat

washers (K) as shown.

5. Push entire outfeed support assembly (J) Fig. 33, in

until it contacts splitter/guard assembly (L) as shown.

Then tighten all outfeed support mounting hardware.

6. Place washer on 1/4-20x1/2 in. hex screw and thread

into the other end of the rods tp prevent them from

coming out of outfeed support brackets.

Fig. 32

Fig. 29

Fig. 30

Fig. 31

Fig. 33

A

B

C

F

E

D

G

A

J

H

H

D

D

K

J

K

L

J

Page 18

1818

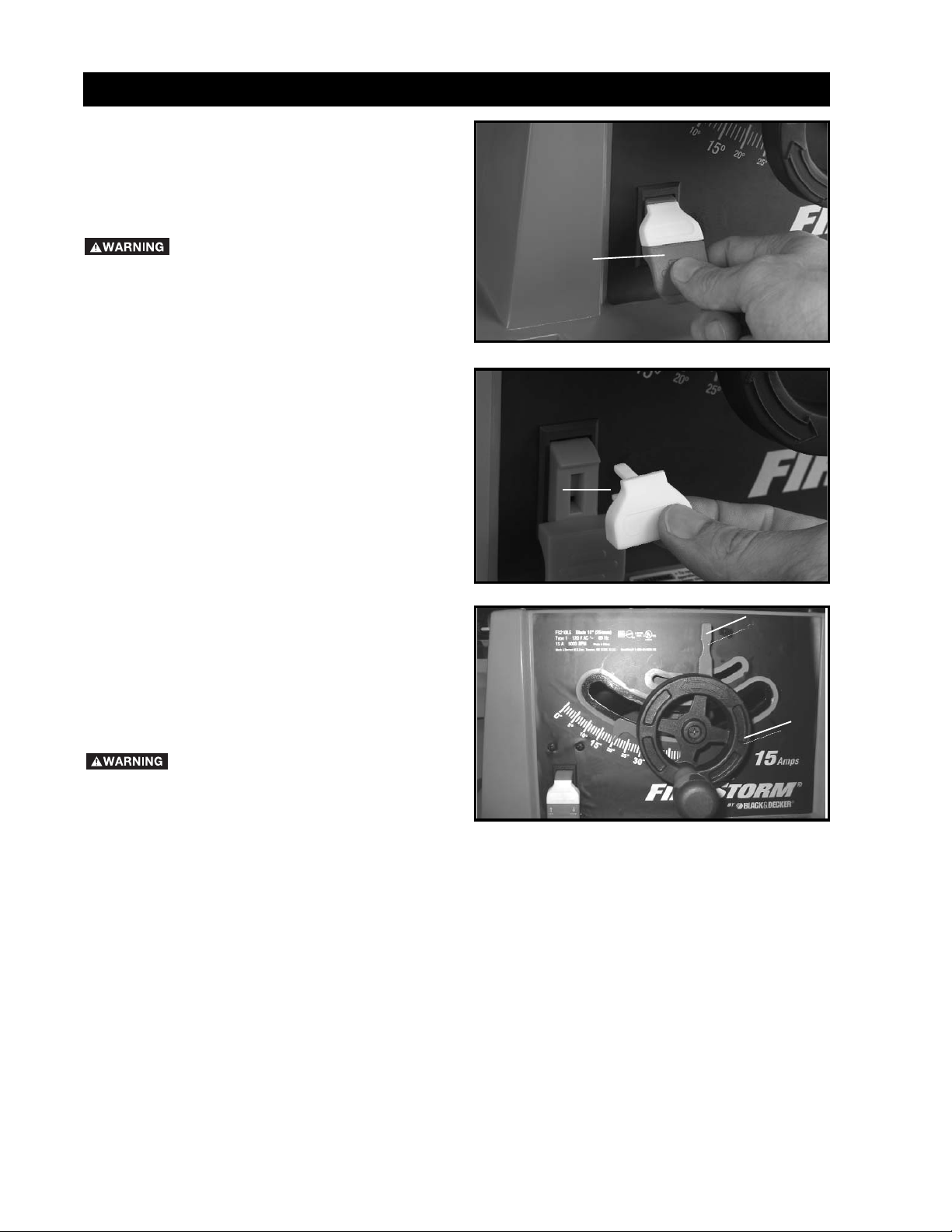

STARTING AND STOPPING SAW

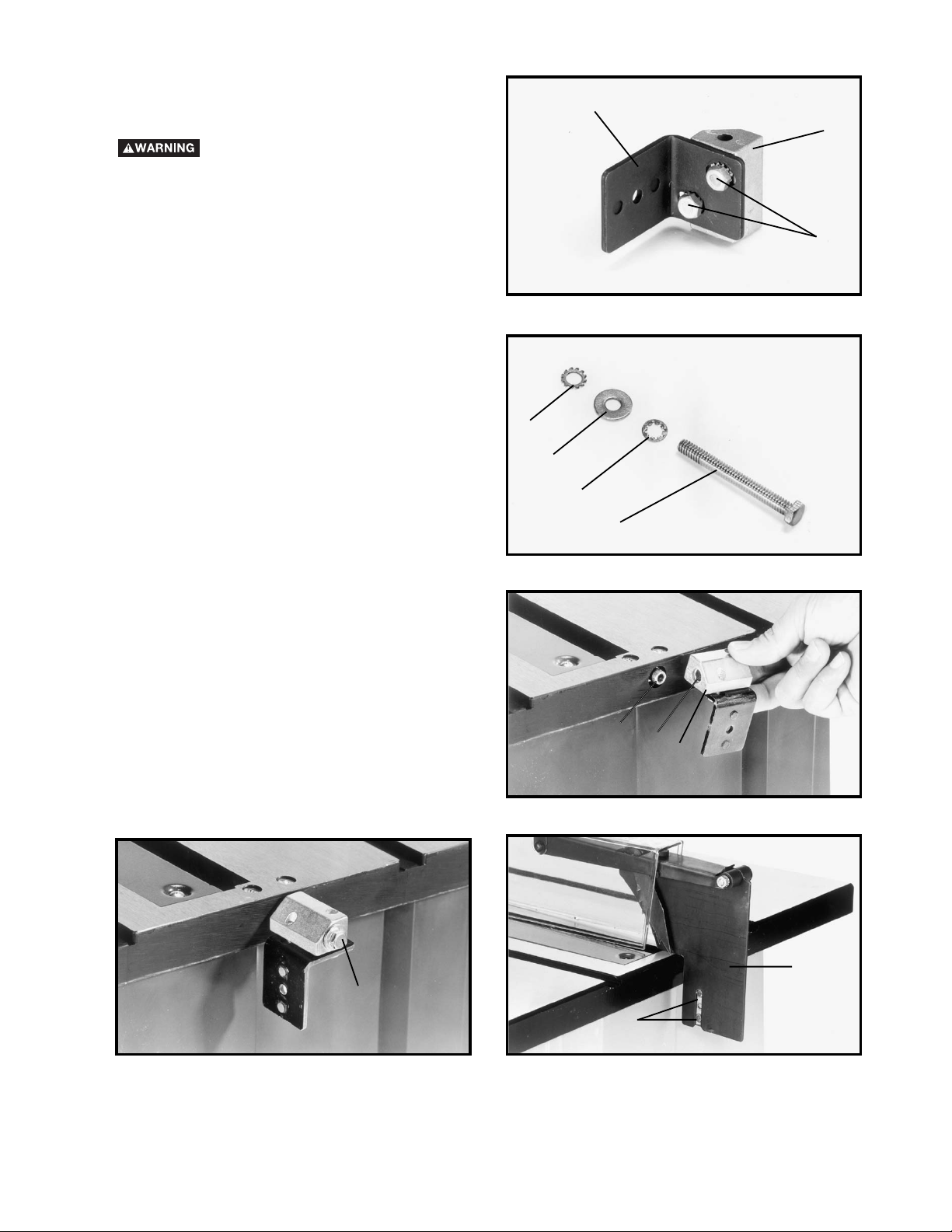

The on/off switch (A) Fig. 34 is located on the front of the

saw cabinet. To turn the saw “ON”, move the switch (A)

up to the “ON” position. To turn the saw “OFF”, move the

switch (A) down to the “OFF” position.

MAKE SURE THAT THE SWITCH IS IN

THE “OFF” POSITION BEFORE PLUGGING IN THE

POWER CORD. IN THE EVENT OF A POWER FAILURE,

MOVE THE SWITCH TO THE “OFF” POSITION. AN

ACCIDENTAL START-UP CAN CAUSE INJURY.

LOCKING SWITCH IN THE “OFF”

POSITION

IMPORTANT: When the tool is not in use, the switch

should be locked in the “OFF” position to prevent

unauthorized use. To lock the tool, grasp the switch

toggle (B) and pull it out of the switch (Fig. 35). With the

switch toggle (B) removed, the switch will not operate.

However, should the switch toggle be removed while the

saw is running, the machine can be turned “OFF,” but

cannot be restarted without re-inserting the switch toggle

(B).

BLADE RAISING AND

LOWERING CONTROL

To raise or lower the saw blade, turn handwheel (A) Fig.

36. Turning the handwheel clockwise lowers the blade

and turning the handwheel counterclockwise raises the

blade.

THE BLADE TILTING LOCK HANDLE

(B) FIG. 36, MUST BE LOCKED DURING ALL

CUTTING OPERATIONS.

Fig. 34

Fig. 35

Fig. 36

A

B

A

B

OPERATING CONTROLS AND ADJUSTMENTS

Page 19

19

BLADE TILTING CONTROL

To tilt the saw blade, loosen blade tilting lock handle (A)

Fig. 37, move handwheel (B) until the blade is at the

desired angle and tighten lock handle (A). NOTE: The

lock handle (A) is spring-loaded and can be repositioned

by pulling out on the handle (A) and repositioning it on

the serrated stud located underneath the handle.

THE BLADE TILTING LOCK HANDLE

(A) MUST BE LOCKED DURING ALL CUTTING

OPERATIONS.

Fig. 37

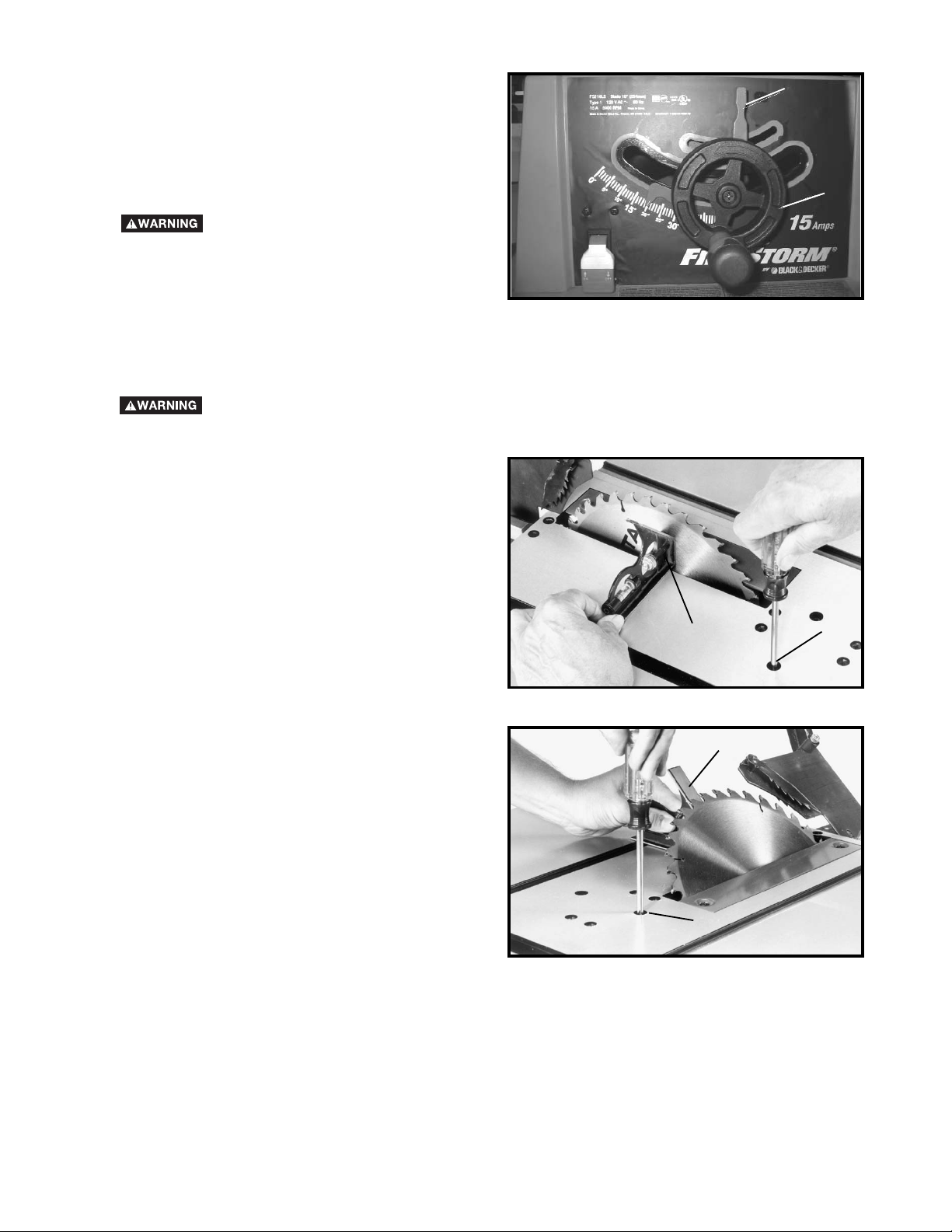

ADJUSTING 90 AND 45 DEGREE POSITIVE STOPS

Your saw is equipped with positive stops for rapid and accurate positioning of the saw blade at 90 and 45 degrees to

the table. To adjust the positive stops, proceed as follows:

DISCONNECT MACHINE FROM POWER SOURCE.

1. Raise the saw blade to its maximum height.

Fig. 38

Fig. 39

TO ADJUST POSITIVE STOP AT 90

DEGREES

2. Loosen the blade tilting lock handle, move the blade

tilting mechanism as far as possible to the left and

tighten the blade tilting lock handle.

3. Place a square (A) Fig. 38, on the table with one end

of the square against the blade, as shown, and check to

see if the blade is at 90 degrees to the table. If it is not,

loosen screw (B) a few turns and move the blade tilting

mechanism until the blade is at 90 degrees to the table.

Then tighten blade tilting lock handle and tighten screw

(B) until it bottoms.

TO ADJUST POSITIVE STOP AT 45

DEGREES

4. Loosen the blade tilting lock handle, move the blade

tilting mechanism as far as possible to the right and

tighten the blade tilting lock handle.

5. Place a square (A) Fig. 39, on the table with one end

of the square against the blade as shown, and check to

see if the blade is at 45 degrees to the table. If it is not,

loosen screw (C) a few turns and move the blade tilting

mechanism until the blade is at 45 degrees to the table.

Then tighten blade tilting lock handle and tighten screw

(C) until it bottoms.

A

B

A

C

A

B

Page 20

2020

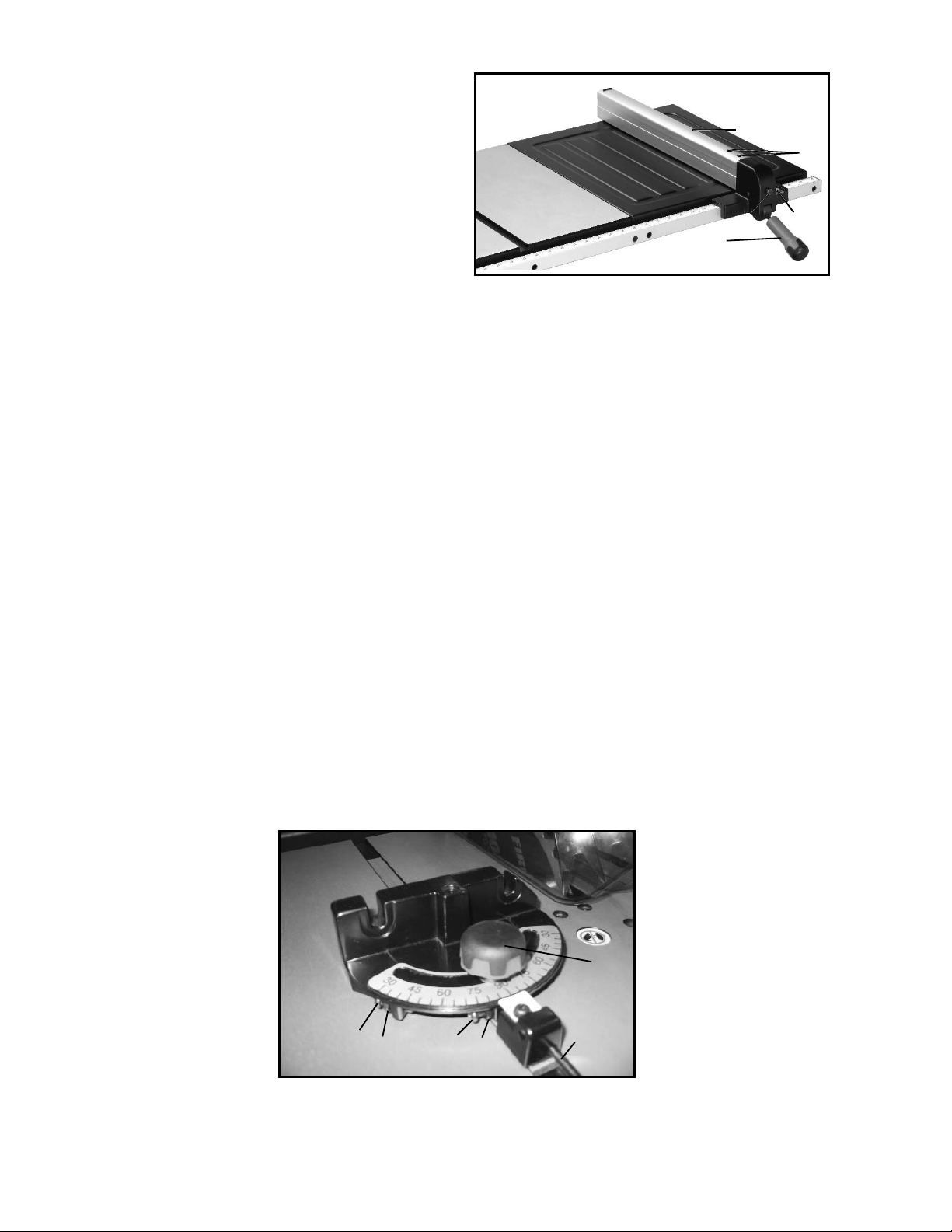

RIP FENCE OPERATION

AND ADJUSTMENTS

1. To move the rip fence (A) Fig. 40, along the table, lift

up fence locking lever (B), slide the fence to the desired

location on the table and push down fence locking lever

(B) to lock the fence in position.

2. A pointer is supplied to indicate the distance the fence

is positioned away from the saw blade. If an adjustment

to the pointer is required, loosen the screw (C) Fig. 40,

that fastens the pointer to the fence bracket and adjust

the pointer accordingly. Then, tighten screw (C).

3.IMPORTANT: THE RIP FENCE MUST BE PROPERLY

ALIGNED TO THE MITER GAGE SLOT IN ORDER TO

HELP PREVENT KICKBACK WHEN RIPPING.

4. The saw blade is set parallel to the miter gage slot at

the factory and the fence must be parallel to the miter

gage slot in order to do accurate work and prevent

kickback when ripping. To check the alignment:

5. Position the fence at one end of the miter gage slot.

Clamp the fence to the table by pushing down the

locking lever. The edge of the fence should then line up

parallel with the miter gage slot.

6. If an adjustment is necessary, proceed as follows:

Fig. 40

MITER GAGE OPERATION AND ADJUSTMENTS

When straight cross-cutting (blade set 90 degrees to the table) the miter gage can be used in either table slot. When

bevel cross-cutting (blade tilted) only use the miter gage in the right table slot where the blade is tilted away from the

miter gage and your hands.

This miter gage is equipped with individually adjustable index stops at 90 degrees and 45 degrees right and left.

Adjustment to the index stops can be made by loosening lock nuts (B) Fig. 41, and tightening or loosening the three

adjusting screws (C) until they contact the other end of stop pin (D) when the miter gage is at 90 and 45 degrees to the

saw blade. Then, tighten lock nuts (B).

To operate the miter gage, simply loosen lock knob (E) Fig. 41, and move the body of the miter gage to the desired

angle. When the stop pin (D) is pushed in, the miter gage body will stop at 90 degrees and 45 degrees right and left.

To rotate the miter gage body past these points, pull out stop pin (D).

Fig. 41

7. Loosen the two 3/16 in. allen head screws (D) Fig. 40,

and lift up locking lever (B). Then while holding the fence

bracket firmly toward the front of the saw, move the rear

end of the fence (A) until it is parallel with the miter gage

slot. Then tighten two screws (D) and push down locking

lever (B).

8. The clamping action of the fence (A) Fig. 40, can be

adjusted by lifting up locking lever (B) and turning screw

(E) clockwise to increase or counterclockwise to

decrease the clamping action of the fence.

C

B

C

B

D

E

C

B

A

D

E

Page 21

21

ADJUSTING BLADE PARALLEL TO

MITER GAGE SLOTS

The blade was adjusted parallel to the miter gage slots

at the factory. In order to insure accurate cuts and help

prevent kickback when cutting, this adjustment should

be rechecked and if necessary, readjusted as follows:

1. DISCONNECT MACHINE FROM POWER SOURCE.

2. Raise the blade to its highest position and adjust the

blade so it is 90 degrees to the table.

3. Select a tooth on the saw blade that is set to the left.

Mark this tooth with a pencil or marker.

4. Using a combination square, place the body (A)

Fig. 42, of the square against the miter gage slot and

adjust the blade (B) of the square until it just touches the

marked tooth, as shown.

5. Rotate the blade and check the same marked blade

tooth at the rear of the saw table in the same manner, as

shown in Fig. 43.

6. If the front and back measurements (Figs. 42 and 43)

are not identical, you can adjust the blade. Start by

loosening the nuts below the four screws (C) Fig. 44 on

the table. Then loosen the screws (C). Carefully move

the saw blade until the blade is parallel to the miter

gauge slot. When done, tighten four nuts under the table

and the four screws (C) Fig. 44 securely.

NOTE: If sufficient adjustment cannot be achieved by

loosening screws (C), screws (D) may also be loosened

if absolutely necessary to make the adjustment.

NOTE: Guard has been removed for illustrative

purposes only.

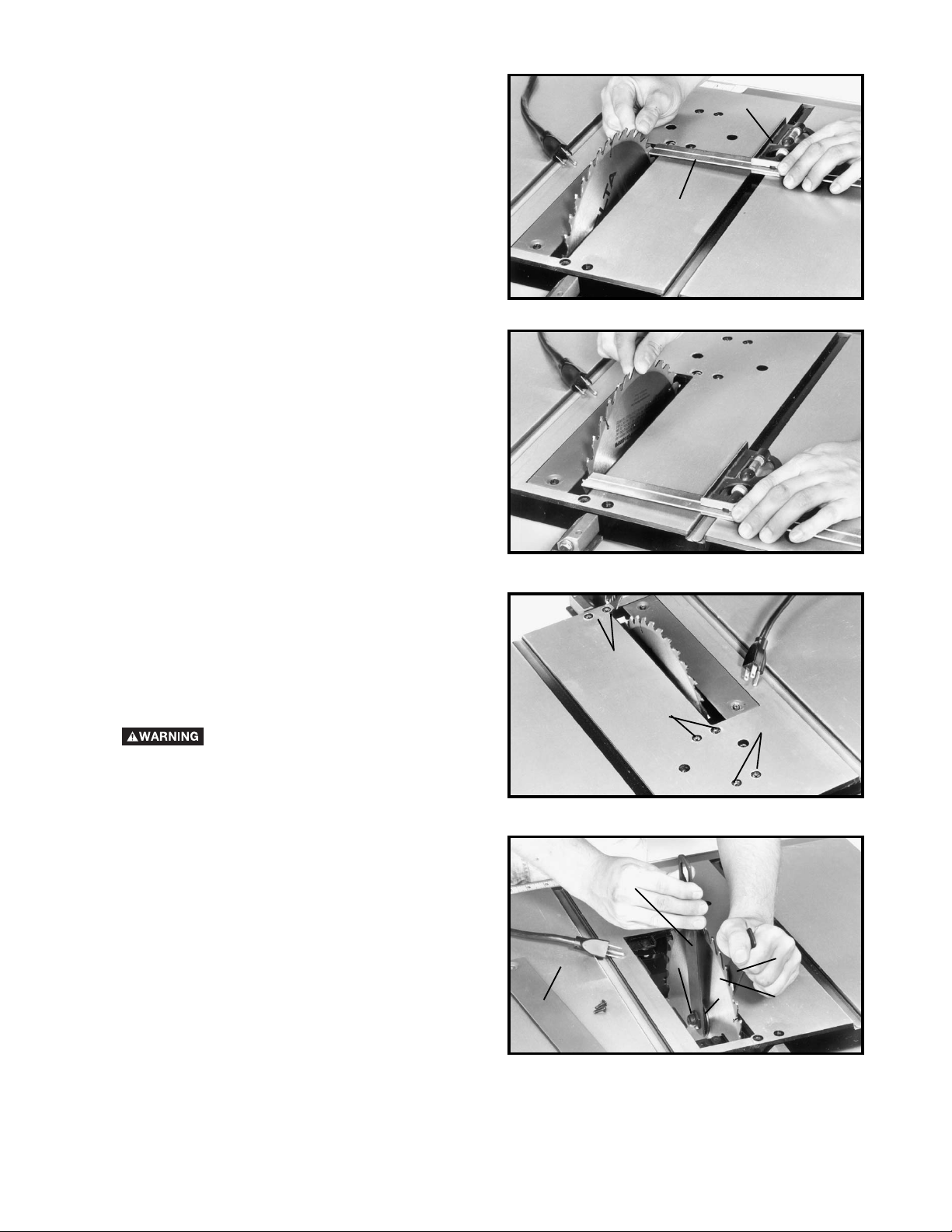

CHANGING THE BLADE

DISCONNECT MACHINE FROM POWER

SOURCE. USE ONLY 10 in. DIAMETER

SAW BLADES RATED FOR 5000 RPM OR HIGHER

WITH 5/8 in. ARBOR HOLES.

1. Raise the saw blade to its maximum height and

remove the table insert (A) Fig. 45.

2. Using the open end wrench (B) Fig. 45, place open

end of wrench on flats on inside blade flange to keep the

saw arbor from rotating and remove arbor nut (C) with

wrench (D). Turn nut (C) counterclockwise to remove.

Remove outside blade flange (E) and saw blade (F).

3. Assemble new blade, making certain teeth of blade

are pointing down at the front of the saw table and

assemble the outside blade flange (E) Fig. 45, and arbor

nut (C). Tighten nut (C) with wrench (D) by turning nut

clockwise while holding arbor steady with other wrench

(B).

4. Replace table insert.

Fig. 42

Fig. 43

Fig. 44

Fig. 45

A

B

C

C

D

A

D

C

E

F

B

Page 22

2222

COMMON SAWING OPERATIONS

CROSS-CUTTING

Cross-cutting requires the use of the miter gage to

position and guide the work. Place the work against the

miter gage and advance both the gage and work toward

the saw blade, as shown in Fig. 46. The miter gage may

be used in either table slot. When bevel cutting (blade

tilted), use the table groove that does not cause

interference of your hand or miter gage with the saw

blade guard.

Start the cut slowly and hold the work firmly against the

miter gage and the table. One of the rules in running a

saw is that you never hang onto or touch a free piece of

work. Hold the supported piece, not the free piece that

is cut off. The feed in cross-cutting continues until the

work is cut in two, and the miter gage and work are

pulled back to the starting point. Before pulling the work

back, it is good practice to give the work a little

sideways shift to move the work slightly away from the

saw blade. Never pick up any short length of free work

from the table while the saw is running. Never touch a

cut-off piece unless it is at least a foot long.

For added safety and convenience the miter gage can

be fitted with an auxiliary wood-facing. This auxiliary

wood-facing can be fastened to the front of the miter

gage by using two wood screws through the slots (A)

Fig. 45, provided in the miter gage body and into the

wood-facing.

NEVER USE THE FENCE AS A CUT-OFF

GAGE WHEN CROSS-CUTTING.

When cross-cutting a number of pieces to the same length,

a block of wood (B) Fig. 46A can be clamped to the fence

and used as a cut-off gage. It is important that this block of

wood always be positioned in front of the saw blade as

shown. Once the cut-off length is determined, secure the

fence and use the miter gage to feed the work into the cut.

This block of wood allows the cut-off piece to move freely

along the table surface without binding between the fence

and the saw blade, thereby lessening the possibility of

kickback and injury to the operator.

WHEN USING THE BLOCK (B) FIG. 46A,

AS A CUT-OFF GAGE, IT IS VERY

IMPORTANT THAT THE REAR END OF THE BLOCK

BE POSITIONED SO THE WORK PIECE IS CLEAR OF

THE BLOCK BEFORE IT CONTACTS THE BLADE.

Common sawing operations include ripping and crosscutting plus a few other standard operations of a fundamental

nature. As with all power machines, there is a certain amount of hazard involved with the operation and use of the

machine. Using the machine with the respect and caution demanded as far as safety precautions are concerned, will

considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or

completely ignored, personal injury to the operator can result. The following information describes the safe and proper

method for performing the most common sawing operations.

THE USE OF ATTACHMENTS AND ACCESSORIES NOT RECOMMENDED MAY RESULT IN THE

RISK OF INJURY TO THE USER OR OTHERS.

Fig. 46

Fig. 46A

A

B

Page 23

23

Ripping is cutting lengthwise through a board. The rip

fence (A) Fig. 47 is used to position and guide the work.

One edge of the work rides against the rip fence while

the flat side of the board rests on the table. Since the

work is pushed along the fence, it must have a straight

edge and make solid contact with the table. The saw

blade guard must be used. The guard has anti-kickback

fingers to prevent kickback and a splitter to prevent the

wood kerf from closing and binding the blade.

RIPPING

1. Start the motor and advance the work holding it down

and against the fence. Never stand in the line of the saw

cut when ripping. Hold the work with both hands and

push it along the fence and into the saw blade (Fig. 48).

The work can then be fed through the saw blade with

one or two hands. After the work is beyond the saw

blade and anti-kickback fingers, the hand is removed

from the work. When this is done the work will either

stay on the table, tilt up slightly and be caught by the

end of the rear guard, or slide off the table to the floor.

Alternately, the feed can continue to the end of the table,

after which the work is lifted and brought along the

outside edge of the fence. The cut-off stock remains on

the table and is not touched until the saw blade has

stopped, unless it is a large piece allowing safe removal.

When ripping boards longer than three feet, it is

recommended that outfeed support (B) Fig. 47, should

be extended as far out as possible to keep workpiece

from falling off the saw table.

2. If the ripped work is less than 4 inches wide, a push

stick should always be used to complete the feed, as

shown in Fig. 49. The push stick can easily be made from

scrap material as explained in the section

“CONSTRUCTING A PUSH STICK.”

3. Ripping narrow pieces can be dangerous if not done

carefully. Narrow pieces usually cannot be cut with the

guard in position. If the workpiece is short enough, use a

pushboard. When ripping material under 2 inches in

width, a flat pushboard is a valuable accessory since

ordinary type sticks may interfere with the blade guard.

When using a pushboard, the width of the pushboard

must be added to the width of the rip fence position

setting. A flat pushboard can be constructed as shown in

Fig. 50 and should be used as shown in Fig. 48

NOTE: Some special operations require the addition of

an auxiliary wood facing to the fence, as explained in the

section “USING AUXILIARY WOOD FACING ON THE

RIP FENCE” and use of a push stick.

Fig. 49

Fig. 47

A

Fig. 48

B

Fig. 50

Page 24

24

USING AUXILIARY WOODFACING ON

RIP FENCE

Wood facings (A) Fig. 51 are necessary on some special

operations to one or both sides of the rip fence. The wood

facing is attached to the fence with screws through the

holes in the fence. Most work will require a 3/4 in. stock,

although an occasional job may require 1in. facing.

Fig. 54 Fig. 55

Fig. 53

1. Dadoing is cutting a rabbet or wide groove into the

work. Most dado head sets are made up of two outside

saws and four or five inside cutters, (Fig. 53). Various

combinations of saws and cutters are used to cut

grooves from 1/8 in. to 13/16 in. for use in shelving,

making joints, tenoning, grooving, etc. The cutters are

heavily swaged and must be arranged so that this heavy

portion falls in the gullets of the outside saws, as shown

in Fig. 54. The saw and cutter overlap is shown in Fig. 55,

(A) being the outside saw, (B) an inside cutter, and (C) a

paper washer or washers, used as needed to control the

exact width of groove. A 1/4 in. groove is cut by using

the two outside saws. The teeth of the saws should be

positioned so that the raker on one saw is beside the

cutting teeth on the other saw.

A

B

C

THE BLADE GUARD AND SPLITTER

ASSEMBLY CANNOT BE USED WHEN

DADOING. IT MUST BE REMOVED.

ACCESSORY DADO CUTTERHEAD

Fig. 52

A

Before dadoing, loosen wing nut (A) Fig. 52 and take

off the blade guard and splitter assembly (B). Keep

assembly handy to replace it after dadoing.

B

Fig. 51

A

NOTE: THE MAXIMUM WIDTH DADO CUT FOR THIS

SAW IS 1/2 INCH.

Page 25

25

Fig. 56

Fig. 57

D

E

2. Attach the dado head set (D) Fig. 56, to the saw arbor.

NOTE: THE OUTSIDE ARBOR FLANGE CAN NOT BE

USED WITH THE DADO HEAD SET, TIGHTEN THE

ARBOR NUT AGAINST THE DADO HEAD SET BODY.

DO NOT LOSE THE OUTSIDE ARBOR FLANGE. IT

WILL BE NEEDED WHEN REATTACHING A BLADE TO

THE ARBOR.

THE ACCESSORY DADO HEAD SET

TABLE INSERT (E) FIG. 56, MUST BE

USED IN PLACE OF THE STANDARD TABLE INSERT.

THE BLADE GUARD AND SPLITTER

ASSEMBLY CANNOT BE USED WHEN

DADOING AND MUST BE REMOVED OR SWUNG TO

THE REAR OF THE SAW. AUXILIARY JIGS,

FIXTURES, PUSH STICKS AND FEATHER BOARDS

CAN AND SHOULD BE USED.

3. Fig. 57, shows a typical dado operation using the miter

gage as a guide.

NEVER USE THE DADO HEAD IN A

BEVEL POSITION.

ALWAYS INSTALL BLADE GUARD

AFTER OPERATION IS COMPLETED.

Page 26

2626

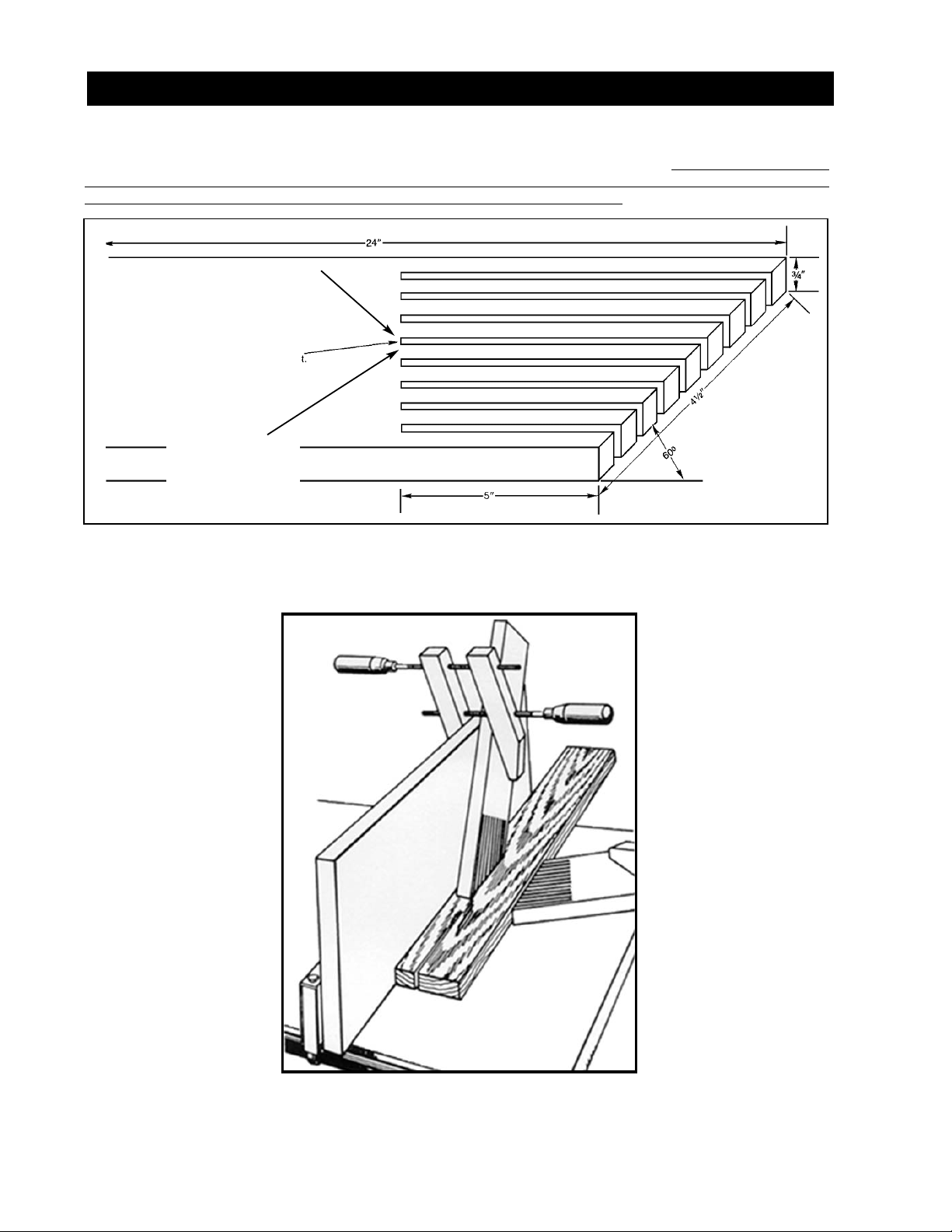

CONSTRUCTING A FEATHERBOARD

Fig. 58, illustrates dimensions for making a typical featherboard. The material which the featherboard is constructed

of, should be a straight piece of wood that is free of knots and cracks. Featherboards are used to keep the work in

contact with the fence and table and help prevent kickbacks. Clamp the featherboards to the fence and table so that

the leading edge of the featherboards will support the workpiece until the cut is completed. Use featherboar

ds for all

non “thru-sawing” operations where the guard and spreader assembly must be removed (see Fig. 59). Always replace

the guard and spreader assembly when the non thru-sawing operation is completed.

Fig. 58

Fig. 59

Kerf should be

about 1/4in.

apart.

LA DISTANCE

ENTRE LES TRAITS

DE SCIE DOIT ÊTRE

D’ENVIRON 6,4 MM

(1/4 PO)

EL CORTE DEBE

ESTAR SEPARADO

POR 6,35 mm (1/4in.)

APROXIMADAMENTE

Page 27

27

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE! SAW WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1.Saw not plugged in. 1.Plug in saw.

2.Fuse blown or circuit breaker tripped. 2.Replace fuse or reset

circuit breaker.

3.Cord damaged. 3.Have cord replaced by

authorized service center.

4.Brushes worn out. 4.Have brushes replaced

by authorized service center.

TROUBLE! SAW MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1.Dull blade. 1.Replace blade.

2.Blade mounted backwards. 2.Turn blade around.

3.Gum or pitch on blade. 3.Remove blade and

clean with turpentine.

4.Incorrect blade for work being done. 4.Change the blade.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1.Extension cord too light or too long. 1.Replace with adequate

size cord.

2.Low house current. 2.Contact your electric

company.

TROUBLE! MACHINE VIBRATES EXCESSIVELY

WHAT’S WRONG? WHAT TO DO…

1.Stand on uneven floor. 1.Reposition on flat level

surface.

2.Damaged saw blade. 2.Replace blade.

TROUBLE! DOES NOT MAKE ACCURATE MITER CUTS

WHAT’S WRONG? WHAT TO DO…

1.Miter scale not adjusted correctly. 1.Check and adjust.

2.Blade is not square to fence. 2.Check and adjust.

3.Blade is not perpendicular to table. 3.Check and adjust fence.

4.Workpiece moving. 4.Clamp workpiece to

fence or glue 120 grit

sandpaper to fence with

rubber cement.

TROUBLE! MATERIAL PINCHES BLADE

WHAT’S WRONG? WHAT TO DO…

1.Cutting bowed material. 1. Position bowed material

with concave or hollow side down.

2.Rip fence not parallel to blade. 2. Realign rip fence.

TROUBLE! CANNOT LOCK BLADE INTO BEVEL POSITION

WHAT’S WRONG? WHAT TO DO…

1.Blade tilting lock handle too loose. 1.Remove blade raising and lowering with

handwheel.

2. Remove flat head screw from lock handle.

3. Tighten blade tilting lock handle. The lock

handle (A) is spring-loaded and can be

repositioned by pulling out on the handle (A)

and repositioning it on the serrated stud

located underneath the handle. NOTE: After

tightening, place the handle at the one o’clock

position.

4. Replace the flat head screw.

TROUBLESHOOTING GUIDE

Page 28

28

When ripping work less than 4 inches wide, a push stick should be used to complete the feed and could easily be

made from scrap material by following the pattern shown in Fig. 60.

PUSH STICK

MAKE FROM 1/2in. OR 3/4in.

WOOD OR THICKNESS

LESS THAN WIDTH OF

MAT’L. TO BE CUT

CUT OFF HERE TO

PUSH 1/4in. WOOD

CUT OFF HERE TO

PUSH 1/2in. WOOD

NOTCH TO HELP

PREVENT HAND

FROM SLIPPING

1/2in. SQUARES

CONSTRUCTING A PUSH STICK

Fig. 60

Page 29

29

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or authorized service center. If you need

assistance regarding accessories, please call:1-800-544-6986.

The use of any accessory not recommended for use with this tool could be hazardous..

Maintenance

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a

liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (other than those listed in this

manual) should be performed by authorized service centers or other qualified service organizations, always using identical

replacement parts.

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool

service. Whether you need technical advice, repair, or genuine factory replacement parts, contact the Black & Decker location

nearest you. To find your local service location, refer to the yellow page directory under "Tools—Electric" or call:

1-800-544-6986 or visit www.blackanddecker.com

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product

will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the

store is a participating retailer). Returns should be made within the time period of the retailer’s policy for exchanges (usually 30 to 90

days after the sale). Proof of purchase may be required. Please check with the retailer for their specific return policy regarding

returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for repair or

replacement at our option. Proof of purchase may be required. Black & Decker owned and authorized Service Centers are listed

under "Tools-Electric" in the yellow pages of the phone directory and on our website www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other rights which vary

from state to state or province to province. Should you have any questions, contact the manager of your nearest Black & Decker

Service Center. This product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-544-6986 for a free

replacement.

Special Warranty Note to Contractors:

FIRESTORMTMbranded products are offered as high end consumer home use tools and carry a HOME USE WARRANTY. These

tools are designed, manufactured and tested to meet or exceed the needs of the do-it-yourselfer in the execution of projects and

repairs in and around the home. With proper use they will provide the home owner with step up power and performance well beyond

their two year warranty. However, if you use tools for a living and use FIRESTORM

TM

branded products or any of Black & Decker’s

other Consumer Home Use tools ON THE JOBSITE you should know that they CANNOT BE COVERED UNDER OUR

WARRANTY.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

www.FireStormTools.com

1-800-544-6986

Page 30

30

SSSSCCCCIIIIEEEE ÀÀÀÀ TTTTAAAABBBBLLLLEEEE DD

DDEEEE 222255554444

MM

MM

MM

MM

((((11110000

PPPPOO

OO)))) FFFFSSSS222211110000LLLLSSSS

CONSERVER CE MODE D’EMPLOI POUR UN USAGE ULTÉRIEUR.

AVANT DE RETOURNER CE PRODUIT POUR QUELQUE RAISON QUE CE SOIT,

COMPOSER LE NUMÉRO

SUIVANT : 1 800 544-6986

MERCI D’A

MERCI D’A

VOIR CHOISI FIREST

VOIR CHOISI FIREST

ORM ! VISITEZ

ORM ! VISITEZ

WWW

WWW

.FIREST

.FIREST

ORMT

ORMT

OOLS.COM/PRODUCTREGISTRA

OOLS.COM/PRODUCTREGISTRA

TION

TION

POUR ENREGISTRER VOTRE NOUVEAU PRODUIT

POUR ENREGISTRER VOTRE NOUVEAU PRODUIT..

MODE D’EMPLOI

Page 31

31

Indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des graves

blessures.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer la mort ou de

graves blessures.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer des

blessures mineures ou modérées.

Utilisé sans le symbole d’alerte à la sécurité, indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, peut se solder par des dommages à la propriété

Ce mode d’emploi contient de l’information qu’il est important de connaître et de comprendre. Cette information

concerne VOTRE SÉCURITÉ et vise à ÉVITER TOUT PROBLÈME D’ÉQUIPEMENT. Pour vous aider à reconnaître ces

informations, nous utilisons les symboles à droite. Veuille lire le mode d’emploi et porter une attention accrue à ces

sections.

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ —

DÉFINITIONS

ATTENTION

ATTENTION

AVERTISSEMENT

Certaines poussières produites par les activités de ponçage, de sciage, de meulage, de perçage et

autres activités de construction peuvent contenir des produits chimiques pouvant causer le cancer,

des anomalies congénitales ou d’autres problèmes liés aux fonctions reproductrices. Voici quelques exemples de ces

produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline de la brique, du ciment et d’autres produits de maçonnerie; et

• l’arsenic et le chrome provenant du bois traité chimiquement.

Les risques reliés à l’exposition à ces poussières varient selon la fréquence à laquelle l’utilisateur travaille avec ce type de

matériaux. Pour réduire l’exposition à ces produits chimiques, travailler dans un endroit bien ventilé et porter un équipement

de sécurité approuvé comme un masque antipoussières conçu spécialement pour filtrer les particules microscopiques.

• Éviter le contact prolongé avec les poussières produites par les activités de ponçage, sciage, meulage, perçage et autres

activités de construction. Porter des vêtements de protection et laver les parties du corps exposées avec une solution d’eau et

de savon. Le fait de laisser la poussière pénétrer dans la bouche et les yeux ou de la laisser reposer sur la peau, peut

promouvoir l’absorption de produits chimiques nocifs.

l’utilisation de cet outil peut produire et/ou propulser des poussières qui pourraient causer des

problèmes respiratoires graves et permanents, ou d’autres problèmes médicaux. Toujours porter un

appareil respiratoire approuvé par la NIOSH/OSHA pour se protéger de la poussière. Diriger les particules loin du visage et du

corps.

porter une protection auditive appropriée pour utiliser l’appareil. Dans certaines conditions et selon la durée

d’utilisation, le bruit provoqué par ce produit peut contribuer à une perte auditive.

AVERTISSEMENT

AVERTISSEMENT

ATTENTION

RÈGLES GÉNÉRALES DE SÉCURITÉ

LIRE ATTENTIVEMENT TOUTES LES MISES EN GARDE ET DIRECTIVES

D’UTILISATION AVANT D’UTILISER CET ÉQUIPEMENT. À défaut de suivre les directives

sous-mentionnées, un choc électrique, un incendie, des dommages ou une blessure corporelle grave

pourraient survenir.

AVERTISSEMENT

DIRECTIVES DE SÉCURITÉ IMPORTANTES

Le travail du bois peut être dangereux si des procédures de sécurité et d’utilisation ne sont pas suivies. Comme avec

tout équipement, l’utilisation du produit comporte certains dangers. En utilisant cette machine avec toute la prudence

requise, le risque de blessures corporelles en sera considérablement réduit. Au contraire, si les mesures de sécurité

normales ne sont pas respectées ou sont ignorées, l’opérateur de l’outil peut être blessé. L’utilisation d’équipement de

sécurité comme des pare-mains, des poussoirs, des dispositifs d’ancrage, des planches en éventail, des lunettes de

sécurité, des masques antipoussières, des protecteurs auditifs peut réduire le risque de blessure. Cependant, même

la meilleure des protections ne compense pas pour un faible jugement, une imprudence ou de l’inattention. T

oujours

fair

e pr

euve de jugement et être prudent dans l’atelier. Si une procédure semble dangereuse, ne pas l’essayer.

Rechercher une procédure alternative qui semble plus sécuritaire. RAPPEL : votre sécurité personnelle est de votre

responsabilité.

Page 32

32

1. POUR SA PROPRE SÉCURITÉ, LIRE LE MODE

D’EMPLOI AVANT D’UTILISER L’OUTIL. L’apprentissage

de l’utilisation de cet outil, des restrictions, et des risques

qui lui sont propres réduit grandement la possibilité

d'accidents et de blessures.

2. PORTER UNE PROTECTION OCULAIRE. TOUJOURS

PORTER DES LUNETTES DE SÉCURITÉ. Utiliser

également un masque facial ou anti-poussière si

l’opération de découpe génère de la poussière. Les

lunettes de vue ne constituent PAS des lunettes de

sécurité. UTILISER UN ÉQUIPEMENT DE SÉCURITÉ

HOMOLOGUÉ. Votre protection oculaire doit être

conforme aux normes ANSI Z87.1, vos protecteurs auditifs

aux normes ANSI S3.19, et votre masque anti-poussières

aux normes homologuées MSHA/NIOSH. Les éclats de

bois, débris en suspension dans l’air, et poussières

peuvent provoquer des irritations, blessures et/ou

maladies.

3. PORTER LES VÊTEMENTS APPROPRIÉS. Ne pas

porter de vêtement ample, ni gant, ni cravates, ni bague,

ni bracelet, ni autre bijou, car ces derniers pourraient

s’enchevêtrer dans des pièces mobiles. Le port de

chaussures antidérapantes est recommandé. Se couvrir

les cheveux s’ils sont longs.

4. NE PAS UTILISER CET OUTIL DANS UN

ENVIRONNEMENT DANGEREUX. L'utilisation d'outils

électriques dans des endroits humides ou mouillés ou

sous la pluie peut provoquer un choc électrique ou

l'électrocution. Tenir la zone de travail bien éclairée pour

éviter de trébucher ou de mettre vos bras, mains et doigts

en danger.

5. CONSERVER TOUS LES OUTILS ET MACHINES DANS

LE MEILLEUR ÉTAT POSSIBLE. S’assurer que vos outils

sont aiguisés et propres afin d’optimiser sécurité et

performance. Suivre les consignes de graissage et de

changement d’accessoires. Les outils et machines mal

entretenus peuvent s'endommager davantage et/ou

provoquer des blessures.

6. VÉRIFIER QUE LES PIÈCES NE SONT PAS

ENDOMMAGÉES. Avant d’utiliser la machine, vérifier

qu'aucune pièce n'est endommagée. Vérifier l’alignement

des pièces mobiles, la présence de grippage des pièces

mobiles, de bris de pièces et tout autre problème pouvant

nuire au fonctionnement de l’outil. Un dispositif de

protection ou toute autre pièce qui pourrait être

endommagé(e) doit être réparé(e) ou remplacé(e)

correctement. Les pièces endommagées peuvent

contribuer à endommager davantage l'appareil et/ou

provoquer des blessures.

7. GARDER LA ZONE DE TRAVAIL PROPRE. Les zones et

établis encombrés sont souvent des causes d’accidents.

8. ÉLOIGNER LES ENFANTS ET LES VISITEURS. L'atelier

représente un environnement potentiellement dangereux.

Les enfants et les visiteurs peuvent être blessés.

9. RÉDUIRE LE RISQUE DE DÉMARRAGE ACCIDENTEL.

S’assurer que l’interrupteur se trouve sur la position d’arrêt

avant de brancher le cordon d’alimentation. En cas de

panne de courant, mettre l’interrupteur sur la position

d’arrêt. Un démarrage accidentel peut provoquer des

blessures.

10. UTILISATION DES DISPOSITIFS DE PROTECTION.

Vérifier que tous les dispositifs de protection sont en

place, fixés, et qu’ils fonctionnent correctement afin de

réduire tout risque de blessure.

11. RETIRER LES CLÉS ET LES CLÉS DE RÉGLAGE.

AVANT LE DÉMARRAGE DE L'APPAREIL. Des outils,

chutes, et autres débris peuvent être projetés à grande

vitesse, provoquant des blessures.

12. UTILISATION DE L’OUTIL APPROPRIÉ. Ne pas forcer un

appareil ou un accessoire pour accomplir un travail pour

lequel il n'est pas conçu. Cela pourrait endommager

l'appareil et/ou causer des blessures.

13. UTILISATION DES ACCESSOIRES RECOMMANDÉS.

L'utilisation d'accessoires non recommandés par Delta

pourrait endommager l'appareil ou blesser l'utilisateur.

14. UTILISER LA RALLONGE APPROPRIÉE. S'assurer que

la rallonge est en bon état. En utilisant une rallonge,

s'assurer d'utiliser une rallonge assez lourde pour le

transport du courant nécessaire au fonctionnement du

produit. Une rallonge sousdimensionnée provoquera une

chute de tension menant ainsi à une perte de courant et

une surchauffe. Se reporter au tableau des rallonges

électriques pour connaître le calibre approprié à utiliser

selon la longueur de la rallonge et l’intensité nominale de

la plaque signalétique. En cas de doute, utiliser le calibre

suivant le plus gros. Plus le numéro de calibre est petit,

plus la rallonge est lourde.

15. FIXER LA PIÈCE. Utiliser des pinces ou un étau pour

maintenir la pièce lorsque c’est possible. La perte de

contrôle d'une pièce peut provoquer des blessures.

16. ACHEMINER LA PIÈCE À CONTRE-COURANT DU

SENS DE ROTATION DE LA LAME, DE LA FRAISE, OU

DE LA SURFACE ABRASIVE. En l'acheminant à

contresens, la pièce sera projetée à grande vitesse.

17. NE PAS FORCER LA PIÈCE SUR L'APPAREIL.Cela

pourrait endommager l'appareil et/ou causer des

blessures.

18. NE PAS TROP TENDRE LES BRAS. Une perte

d’équilibre peut vous faire tomber sur une machine en

fonctionnement provoquant ainsi des blessures.

19. NE JAMAIS SE TENIR DEBOUT SUR L'APPAREIL. Si

l’outil bascule, ou si vous touchez accidentellement l’outil

de coupe, vous pouvez être blessé.

20. NE JAMAIS LAISSER LA MACHINE FONCTIONNER

SANS SURVEILLANCE. ÉTEINDRE L’APPAREIL. Ne

pas laisser l'appareil tant qu’il ne soit pas complètement

arrêté. Un enfant ou un visiteur pourrait être blessé.

21. ÉTEINDRE L'APPAREIL ET COUPER LE COURANT

avant d'installer ou de retirer des accessoires, avant tout

réglages ou modifications de celles-ci ou lors de

réparation. Un démarrage accidentel peut provoquer des

blessures.

22. METTRE L'ATELIER À L'ÉPREUVE DES ENFANTS

AVEC DES CADENAS, DES INTERRUPTEURS

PRINCIPAUX OU EN RETIRANT LES CLÉS DE

DÉMARRAGE. Le démarrage accidentel d'un appareil par

un enfant ou par un visiteur peut causer des blessures.

23. DEMEURER VIGILANT, SURVEILLER LE TRAVAIL

EFFECTUÉ, ET FAIRE PREUVE DE JUGEMENT. NE

PAS UTILISER L'APPAREIL EN CAS DE FATIGUE OU

SOUS L’INFLUENCE DE DROGUES, D'ALCOOL, OU

DE MÉDICAMENTS. Un moment d'inattention, en utilisant

des outils électriques, peut se solder par des blessures.

24. PRENDRE DES MESURES PRÉVENTIVES CONTRE

L’INHALATION DE POUSSIÈRES. La poussière produite

par certains bois et produits en bois peut nuire à votre

santé. Toujours utiliser l’équipement dans des endroits

bien aérés et veiller à le dépoussiérer correctement.

Utiliser des systèmes de dépoussiérage lorsque c’est

possible.

RÈGLES GÉNÉRALES DE SÉCURITÉ

NÉGLIGER DE SUIVRE CES RÈGLES RISQUE D’ENTRAÎNER DES BLESSURES GRAVES.

AVERTISSEMENT

Page 33

33

CONSERVER CES DIRECTIVES.

Les consulter souvent et les utiliser pour donner des directives aux autres.

1. NE PAS UTILISER CET OUTIL AVANT qu'il ne soit

assemblé et installé conformément aux instructions.

2. CONSULTER LE SUPERVISEUR, instructeur, ou autre

personne qualifiée si vous n'êtes pas familiarisé avec le

fonctionnement de cet outil.

3. SUIVRE TOUS LES CODES DE CÂBLAGE et les

connexions électriques recommandées.

4. UTILISER LES DISPOSITIFS DE PROTECTION

CHAQUE FOIS QUE POSSIBLE. Vérifier qu’ils sont

bien en place et fixés et fonctionnent correctement.

5. LE REBOND EST LA TENDANCE NATURELLE DE LA

PIÈCE DE REVENIR VERS L'OPÉRATEUR lorsque la

pièce entre en contact pour la première fois avec la lame

ou si la pièce pince la lame. L'effet de rebond est

dangereux et peut se solder par de graves blessures.

POUR ÉVITER L’EFFET DE REBOND :

A. maintenir la lame affûtée et libre de rouille et de résine.

B. garder le guide longitudinal parallèle à la lame de la scie.

C. utiliser le dispositif de protection de lame et dispositif

d'écartement pour toutes les opérations possibles, y

compris pour tous les débitages complets.

D. pousser la pièce au-delà de la lame de scie avant de

dégager.

E. ne jamais scier en long une pièce qui est tordue ou

voilée, ou qui n'a pas de bord droit pour glisser le long du

guide.

F. utiliser des planches en éventail lorsqu'on ne peut pas

utiliser les dispositifs anti-effet de rebond.

G. ne jamais scier une grande pièce qui ne peut pas être

contrôlée.

H. ne jamais utiliser le guide comme guide longitudinal pour

le tronçonnage.

I. ne jamais scier une pièce avec des n?uds détachés ou

autres défauts.

6. TOUJOURS UTILISER DES PARE-MAINS, UN

COUTEAU SÉPARATEUR ET DES DOIGTS ANTIEFFET DE REBOND si possible.

7. DÉGAGER LA TABLE DES PIÈCES COUPÉES ET

CHUTE avant de démarrer la scie. La vibration de

l'appareil pourrait les entraîner vers la lame de scie et les

projeter Après la coupe, éteindre la machine. Une fois la

lame complètement immobilisée, enlever tous les débris.

8. NE JAMAIS DÉMARRER L'APPAREIL avec la pièce

contre la lame.

9. NE JAMAIS acheminer la pièce entre le guide et la fraise

à moulurer.

10. LA COUPE DE PIÈCE SANS GUIDE OU DE JAUGE À

ONGLET EST CONNUE SOUS LE NOME DE COUPE