Page 1

WOODWORKSPti TOOLS BY

BIACK&DECKER

Instruction Manual

Plunge Cut Routers

3303,3304

Page 2

Thanks for

buying an ELU

Plunge Cut Router.

If you already own an ELU

power tool, you know the pleasures

of working with a real pro. Built to

ELU’s traditional standards for high

quality and durability and backed

by Black & Decker’s extensive

service network, you’ve got an

excellent value that will serve you

well for years to come.

im

WOODWORKING TOOLS BY

BIACK&DEGKEII

Please take the time to read

this informative manual and pay

particular attention to the safety

rules we've provided for your

protection.

Don’t forget to send in your

owner’s registration card.

Thanks again for buying Black

& Decker!

Page 3

Important Safety Instructions

WARN ING: When using Electric Tools, basic safety precautions should always be followed to

reduce risk of fire, shock, and personal injury, including the following:

READ ALL INSTRUCTIONS

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t expose power tools to rain. Don’t

use power tools in damp or wet locations. Keep work area well lit.

3. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces.

For example: pipes, radiators, ranges, refrigerator enclosures.

4. KEEP CHILDREN AWAY. All visitors should be kept away from work area. Do not let

visitors contact tool or extension cord.

5. STORE IDLE TOOLS. When not in use, tools should be stored in dry, and high or

locked-up place—out of reach of children.

6. DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was

intended.

7. USE RIGHT TOOL. Don’t force small tool or attachment to do the job of a heavy-duty

tool. Don’t use tool for purpose not intended, for example, don’t use circular sawfor cutting

tree limbs or logs.

8. DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be caught in

moving parts. Rubber gloves and non-skid footwear are recommended when working

outdoors. Wear protective hair covering to contain long hair.

9. USE SAFETY GLASSES. Also use face or dustmask if cutting operation is dusty.

10. DON’T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges,

11. SECURE WORK. Use clamps or a vise to hold work. It’s safer than using your hand and it

frees both hands to operate tool.

12. DON’T OVERREACH. Keep proper footing and balance at all times.

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and olean for better and safe

performance. Follow instructions for lubrioating and changing accessories. Inspect tool

cords periodically and if damaged have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep handles dry, clean, and free

from oil and grease.

14. DISCONNECT TOOLS. When not in use, before servicing, and when changing

accessories, such as blades, bits, cutters.

15. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from tool before turning it on.

16. AVOID UNINTENTIONAL STARTING. Don’t carry plugged-in tool with finger on

switch. Be sure switch is off when plugging in.

17. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

18. ST AY ALERT. Watch what you are doing. Use common sense. Do not operate tool when

you are tired.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate and perform its

intended function. Check for alignment of moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction manual. Have defective

switches replaced by authorized service center. Do not use tool if switch does not turn it

on and off.

20. DO NOT OPERATE portable electric tools near flammable liquids or in gaseous or

explosive atmospheres. Motors in these tools normally spark, and the sparks might ignite

fumes.

SAVE THESE INSTRUCTIONS

Page 4

Double Insulation

Your unit is DOUBLE-

INSULATED to give you added

safety. This means that it is

constructed throughout with TWO

separate "layers” of electrical

insulation or one DOUBLE thickness

of insulation between you and the

tool’s electrical system.

Tools built with this insulation

system are not intended to be

grounded. As a result your unit is

equipped with a two-prong plug which

permits you to use extension cords

without concern for maintaining a

ground connection.

NOTE: DOUBLE INSULATION

does not take the place of normal

safety precautions when operating

this tool. The insulation system is for

added protection against injury

resulting from a possible electrical

insulation failure within the tool.

CAUTION: When servicing all

tools. USE ONLY IDENTICAL

REPLACEMENT PARTS. Repair or

replace damaged cords.

Motor

Your ELU tool is powered by an

ELU-built motor. Be sure your power

supply agrees with the nameplate

marking.

Volts 50/60 Hz or "AC only”

means your tool must be operated

only with alternating current and never

with direct current.

Voltage decrease of more than

10% will cause loss of power and

overheating. All ELU toos are factory

tested; if this tool does not operate,

check the power supply.

Extension Cords

Double insulated tools have 2 wire cords, and can be used with 2 wire or 3

wire extension cords. Only round jacketed extension cords should be used, and

we recommend that they be listed by Underwriters Laboratories (U.L.). If the

extension will be used outside, the cord must be suitable for outdoor use. Any

cord marked as outdoor can also be used for indoor work. The letters "WA” on

the cord jacket indicate that the cord is suitable for outdoor use.

An extension cord must have adequate wire size (AWG or American Wire

Gauge) for safety, and to prevent loss of power and overheating. The smaller

the gauge number of the wire, the greater the capacity of the cable, that is 16

gauge has more capacity than 18 gauge. When using more than one extension

to make up the total length, be sure each individual extension contains at least

the minimum wire size.

To determine the minimum wire size required, refer to the chart below.

CHART FOR MINIMUM WIRE SIZE (AWG) OF EXTENSION CORDS

NAMEPLATE

RATING-AMPS

0-10.0 18

10.1 -13.0

13.1 - 15.0

Before using an extension cord, inspect it for loose or exposed wires,

damaged insulation, and defective fittings. Make any needed repairs or replace

the cord if necessary.

TOTAL EXTENSION CORD LENGTH-FEET

25 50 75 100 125 150 175 200

14

18 16 16

16 16

14

14

14 14 14 12 12

12 12

14

12

12

12 12

12

12

—

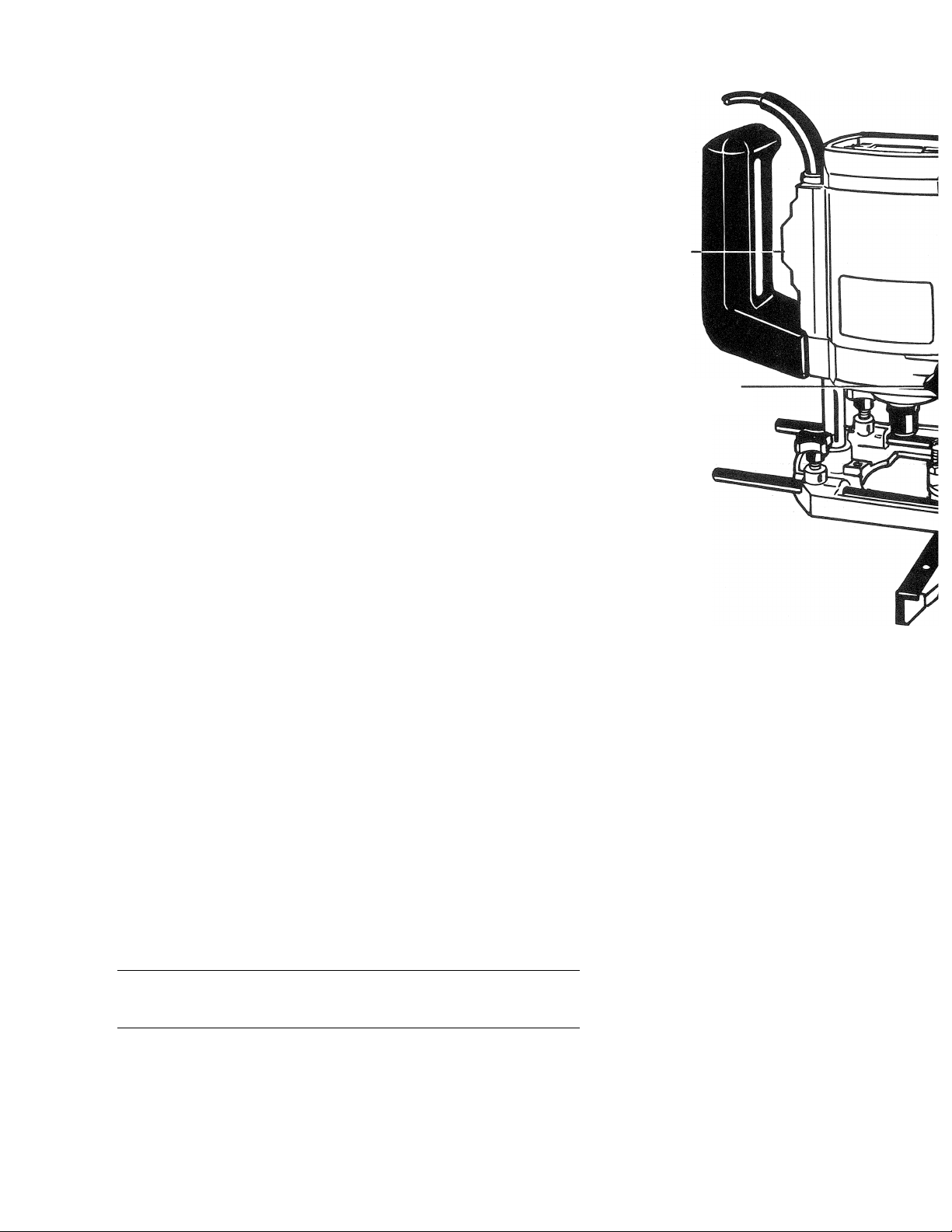

Switch

Depth Bar

Clamp Screw

Special

Instructions For

Electronic Router

Cat. #3304

You have just purchased a

portable router which incorporates a

state of the art electronic motor

control. The control system governs

the motor to give you easy start-up,

smooth cutting, and higher power

output. These unique capabilities give

you a router which is responsive to

your needs.

The electronic motor control

system has two basic features (Fig. 1 ).

A. Ramp start - when you turn on the

router, you will notice that it does

not have the jerk from the rapid

acceleration of the motor. This

router has a starting circuit which

accelerates the motor up to speed

smoothly, without jerking, and

allows you to maintain easier

control of the router during the

start-up period.

Page 5

> \G \

в. Constant speed cutting - as you

load the router, the selected cutting

speed does not slow down during

normal use. The electronic control

governs the motor and gives you a

consistent finish to your work. Only

under very heavy loading will the

speed of the unit fall below the

governed speed.

To set the router speed (from

8,000 RPM to 24,000 RPM) rotate the

speed control wheel shown in Figure

1. The higher the number the higher

the speed. The numbers on the wheel

are for reference only and do not

indicate any particular speed.

The lower the speed setting, the

slower the router runs. Lower speed

settings may be useful for making fine

cuts in softer materials, where control

of the unit may be of greater

importance.

Router bits larger than 1 /4"

diameter are not recommended when

routing soft woods on the lowest

speed setting.

Operating

Instructions For

The Router

PREPARATION FOR USE

The motor in this router is

relatively high-powered (750 Watts,

max.). Despite this, it is advisable to

cut deep grooves or remove large

amounts of material in two or more

passes.

TECHNICAL DATA

Model

Voltage

Speed

Insulation

Column

Plunging stroke

Routing depth

Cutter

mounting

Cutter cap

routing

Rotary depth

stop

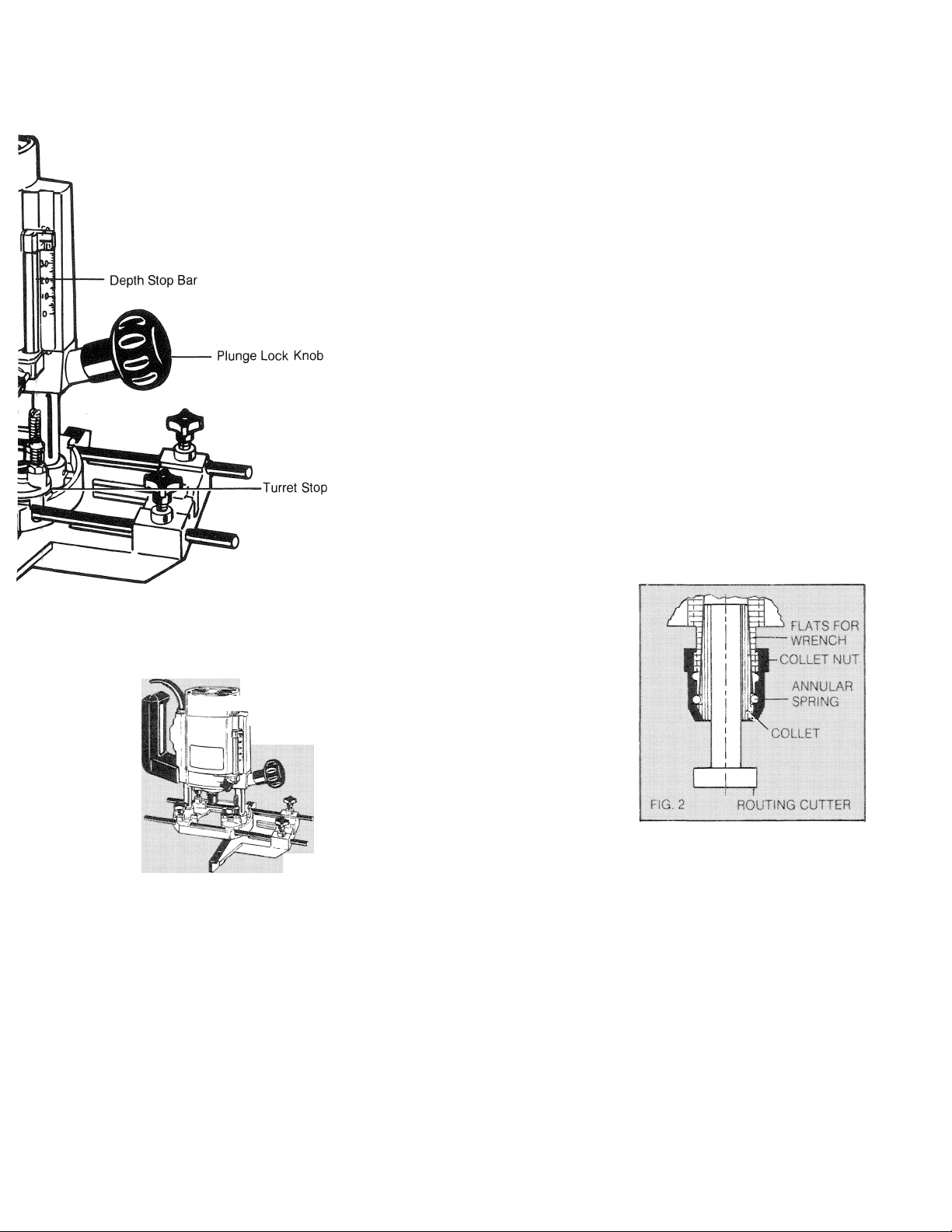

IMPORTANT NOTE

NEVER TIGHTEN COLLET

NUT IF THERE IS NO CUTTER IN

THE COLLET. COMPRESSING

COLLET TOO MUCH MIGHT

RESULT IN IT BEING DAMAGED.

TO CHANGE COLLET

THE COLLET IS SECURED IN

THE COLLET NUT BY MEANS OF

THE ANNULAR SPRING. A

STRONG PULL WILL RELEASE

THE COLLET FROM THE NUT

THE NEW COLLET SHOULD

THEN BE INSERTED IN THE NUT

AND BE PUSHED IN.

3303, 3304

120

24,000 r.p.m,

double

insulated

spring loaded

twin column

50 mm

(1-15/16")

0-50 mm

adjustable

precision collet,

size 1 /4"

max. 30 mm

(1-3/16")

(shallow)

3 stage depth

position

INSTALLING ROUTER BITS

(TURN OFF AND UNPLUG

ROUTER)

To install a router bit, first open

the collet by loosening

(counterclockwise) the collet nut, Use

the supplied wrenches if necessary.

Insert the shaft of the desired bit into

the collet as far as it will go and then

pull it out about 1 /16". Hold the router

shaft with one of the wrenches and

firmly tighten the collet nut with the

other.

Reverse the process to remove

bits. Always be sure to turn off and

unplug the router when installing or

removing bits.

CAUTION; Router Bits Are Sharp

... Use Care In Handling Them.

The front face of the collet must

always be flush with the face of the

nut. If this is not the case, remove the

assembly from the machine and press

the collet into the collet nut so that it is

held by the spring with the faces flush.

SETTING DEPTH OF CUT USING

DEPTH STOP (FIG. 3)

(TURN OFF AND UNPLUG

ROUTER)

Loosen the Depth Bar Clamp

Screw and the Plunge Lock Knob.

Push the router down until the cutter

contacts the workpiece and tighten

the Plunge Lock Knob.

Raise the Depth Stop Bar until the

distance between the lower end of the

bar and the selected screw in the

Turret Stop is equal to the desired

depth of cut. Tighten the Depth Bar

Clamp Screw and loosen the Plunge

Lock Knob. (The tool will spring up.)

The depth of cut will be equal to

the distance between the head of the

bolt on the turret stop and the end of

the depth stop bar. The depth of cut

can be gauged by using the

graduated scale.

Page 6

When several cuts are to be

made at different depths in the

material, the three bolts on the turret

stop are adjusted accordingly.

NOTE: The Turret Stop can be

adjusted so that the Depth Stop Bar

does not contact any screw head. To

adjust any screw in the Turret Stop,

use the wrench supplied and loosen

the lock nut. Turn the screw as

desired and retighten the lock nut.

The Depth Stop Bar can be

removed from the tool for free hand

cutting.

hJ

-------—KNOB

FIG. 3 TURRET STOP

LOCK

Switch

TO SWITCH ON THE MACHINE

The switch positions are

indicated by red markings on and off.

Note: Always pull the plug on the

cord set out of its receptacle when

changing a cutter or fitting the

accessories in order to avoid any

chance of an accident.

GENERAL (FIGS. 4, 5, 6. 7)

All common routing tasks can be

performed with ease with the Plunge

Cut Router; Grooving, rabbeting,

recessing, veining, and profiling on all

types of wood and plastic.

Always feed the router opposite

to the direction in which the cutter is

rotating.

The router should be moved in a

clockwise direction when working

round a template, or routing free-hand.

Only carbide-tipped cutters

should be used on panels faced with

plastic laminates.

ROUTER UPiN(. U.vr.. AMAND GUÍO:. sMiM: ;

S DUG NCI

Accessories

Black & Decker offers a wide

array of router bits and other

accessories to enhance the versatility

of your router. Visit your local Black &

Decker Service Center where

recommended accessories can be

purchased.

If you need assistance in locating

recommended accessories for your

tool, contact:

Black & Decker (U.S.) Inc.

User Services Department

10 North Park Drive

P.O. Box 857

Hunt Valley, MD 21030-0857

Recommended accessories for

your tool are available at extra cost

from your local Black & Decker

Service Center. The use of any other

accessories or attachments may be

hazardous. If you have any questions

concerning which accessories are

recommended, contact Black &

Decker at the above address.

Operation

After setting the cutting depth as

described on page 5, locate the router

such that the bit is directly over the

place you will be cutting. With the

router running, lower the unit smoothly

down into the workpiece. (DO NOT

JAM THE ROUTER DOWN) When

the tool reaches the pre-set depth,

tighten the Plunge Lock Knob. When

you have finished routing, loosen the

knob and let the spring lift the router

directly out of the workpiece.

Important

To assure product SAFETY and

RELIABILITY, repairs maintenance

and adjustment, (including brush

inspection and replacement) should

be performed by qualified service

organizations, always using ELU

replacement parts.

ELU products are serviced by

Black & Decker company owned

Service Centers.

Page 7

Page 8

Commercial/Industrial Use Warranty

ELL) warrants this product for one year from date of purchase. We will

repair without charge, any defects due to faulty material or workmanship. Please

return the complete unit, transportation prepaid, to any Black & Decker Service

Center or Authorized Service Station listed under 'Tools Electric” in the yellow

pages. This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others.

Like most Black & Decker products your tool is listed by Underwriters

Laboratories to ensure that it meets stringent safety requirements.

This symbol on the nameplate means the product is listed by Underwriters

Laboratories, Inc.

WOODWORKING TOOLS BY

B1ACKS.DECKER Form No, 741388

BLACK & DECKER (U.S.) INC., U.S. Power Tools Group, 10 North Park Drive, P.O. 798, Hunt Valley, MD 21030-0798 U.S.A.

(JULY87) ©1987 Printed in Switzerland

096 04 00 09

Loading...

Loading...