Black & Decker DR450 Instruction Manual

GENERAL SAFETY RULES

WARNING! Read and understand all instructions.Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

• Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or modify the

plug in any way. Do not use any adaptor plugs. Check with a qualified electrician if you are in

doubt as to whether the outlet is properly grounded. If the tools should electrically malfunction

or break down, grounding provides a low resistance path to carry electricity away from the user.

Applicable only to Class I (Grounded) tools.

• Double insulated tools are equipped with a polarized plug (one blade is wider than the other.)

This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet.

Do not change the plug in any way.Double Insulation eliminates the need for the three wire

grounded power cord and grounded power supply system. Applicable only to Class ll tools.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords

immediately.Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.”

These cords are rated for outdoor use and reduce the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in serious personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat,

or hearing protection must be used for appropriate conditions.

Tool Use and Care

• Use clamps or other practical way to secure and support the workpiece to a stable platform.

Holding the work by hand or against your body is unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the

tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with

sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model. Accessories

that may be suitable for one tool, may become hazardous when used on another tool.

Service

• Tool service must be performed only by qualified repair personnel. Service or maintenance

performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

• Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with a "live" wire will make exposed metal parts of the tool

"live" and shock the operator.

WARNING:Some dust created by power sanding, sawing, grinding, drilling, and other construction activ-

ities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as

those dust masks that are specially designed to filter out microscopic particles.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

CAT. NO. DR450 FORM NO. 389782 (AUG00 CD-1) COPYRIGHT 1999 PRINTED IN USA

The label on your tool may include the following symbols.

V ..........................volts A ........................amperes

Hz ........................hertz W ......................watts

min ......................minutes ......................alternating current

....................direct current

n

o ......................no load speed

........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ................revolutions or

reciprocations

per minute

OPERATION

MOTOR

Your drill is powered by a Black & Decker built motor. Be sure your power supply agrees with the nameplate

marking. A marking of 120 volts, 50/60 Hz or 120 volts, AC only means that the tool is designed to operate on normal 120 volt house current. Voltage decrease of more than 10% will cause loss of power and overheating. All Black & Decker tools are factory tested. If this tool does not run, check the power supply.

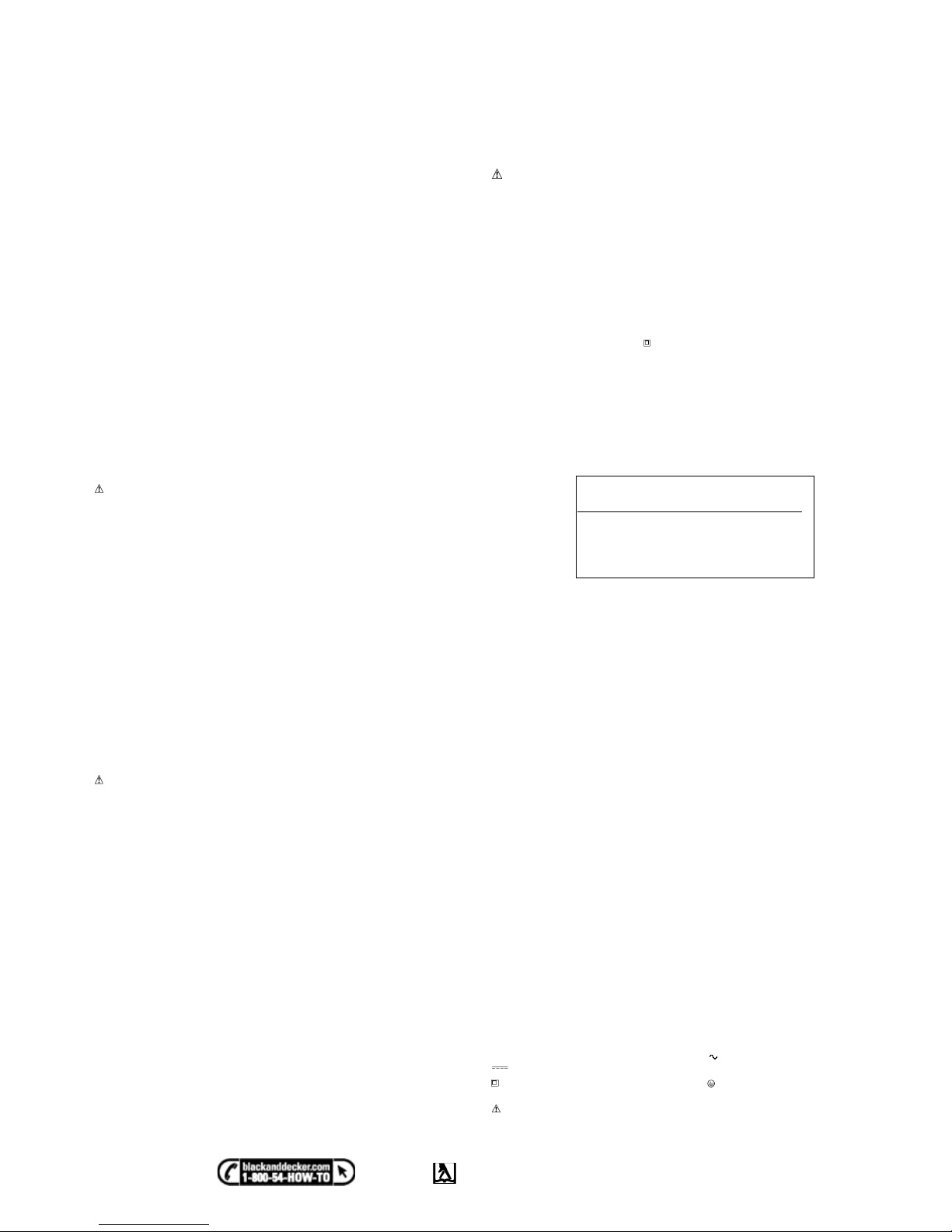

LOCK-ON BUTTON

To start drill, depress trigger switch; to stop drill, release trigger. To lock trigger in ON position for continuous

operation, depress trigger and push up lock-on button "A" shown in Figure 1, then gently release trigger. To

release locking mechanism, depress trigger fully, then release it. Before using the tool (each time) be sure that

the lock-on button release mechanism is working freely. Do not lock the switch ON when drilling by hand so

that you can instantly release then trigger switch if the bit binds in the hole. The lock-on button is for use only

when the drill is mounted in a drill press stand or otherwise held stationary. Be sure to release the lock-on button before disconnecting the plug from the power supply. Failure to do so will cause the tool to start immediately the next time it is plugged in. Damage or injury could result.

V ARIABLE SPEED SWITCH

This permits FREE HAND speed control—the further the trigger is depressed, the higher the R.P.M. Use lower

speeds for starting holes without a center punch, drilling in metal, plastics, and ceramics, or driving screws.

Higher speeds are better for drilling wood and composition boards, and for using abrasive and polishing

accessories.

REVERSING LEVER

The reversing lever is used for withdrawing bits from tight holes and removing screws. It is located above the

trigger switch (Fig. 2). To reverse the motor, release the trigger FIRST and then push the lever to the right. After

any reversing operations, return lever to forward position.

BUBBLE

BULLE

BURBUJA

BUILT-IN LEVEL

NIVEAU INCORPORÉ

NIVEL INTERCONSTRUIDO

Fig. 3A

Fig. 3B

BUBBLE

BULLE

BURBUJA

BUILT-IN LEVEL

NIVEAU INCORPORÉ

NIVEL INTERCONSTRUIDO

Fig. 4

Fig. 5

Fig. 6

Fig. 1

Fig. 2

REVERSING LEVER

INVERSEUR DE MARCHE

PALANCADE REVERSA

"A"

KEY INFORMATION YOU SHOULD KNOW:

•Reversing drills must be switched into forward or reverse in

order to operate. They will not run with the switch control

lever in the center position.

INSTRUCTION MANUAL

Catalog Number DR450

3333////8888"""" ((((11110000mmmmmmmm)))) KKKKEEEEYYYYLLLLEEEESSSSSSSSCCCCHHHHUUUUCCCCKKKKDDDDRRRRIIIILLLLLL

LL

DRILLING

1. Always unplug the drill when attaching or changing bits or accessories.

2. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits, power auger bits, or hole saws.

For METAL, use high-speed steel twist drill bits or hole saws. For MASONRY, such as brick, cement, cinder

block, etc., use carbide-tipped bits.

3. Be sure the material to be drilled is anchored or clamped firmly. If drilling thin material, use a wood

"back-up" block to prevent damage to the material.

4. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting, but do

not push hard enough to stall the motor or deflect the bit.

5. Hold drill firmly to control the twisting action of the drill.

6. If drill stalls, it is usually because it is being overloaded or improperly used. RELEASE TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO NOT CLICK TRIGGER OFF AND

ON IN AN ATTEMPT TO START A STALLED DRILL—THIS CAN DAMAGE THE DRILL.

7. To minimize stalling on breaking through the material, reduce pressure on drill and ease the bit through

the last fractional part of the hole.

8. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent jamming.

9. With variable speed drills there is no need to center punch the point to be drilled. Use a slow speed to

start the hole and accelerate by squeezing the trigger harder when the hole is deep enough to drill without

the bit skipping out.

DRILLING IN METAL

Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which should be drilled

dry. The cutting lubricants that work best are sulphurized cutting oil or lard oil; bacon-grease will also serve

the purpose. NOTE: Large (5/16" to 3/8") (7.9mm to 9.5mm) holes in steel can be made easier if a pilot hole

(5/32" to 3/16") (3.9mm to 4.8mm) is drilled first.

DRILLING IN WOOD

Holes in wood can be made with the same twist drills used for metal. These bits may overheat unless pulled

out frequently to clear chips from the flutes. For larger holes, use power drill wood bits. Work that is apt to

splinter should be backed up with a block of wood.

DRILLING IN MASONRY

Use carbide-tipped masonry bits at low speeds. Keep even force on the drill but not so much that you crack

the brittle materials. A smooth, even flow of dust indicates the proper drilling rate.

BUILT-IN 2-WAY LEVEL

Your drill is equipped with a 2-way bubble level that assists you in drilling level holes. For horizontal drilling,

tilt the drill up or down as required so the bubble floats in the center of the parallel lines drawn on the glass.

When the bubble is centered between the lines, as shown in Figure 3A, the drill is level. For vertical drilling,

align the drill so that the bubble in the level floats in the center of the bull’s-eye, as shown in Figure 3B. To

assure accuracy, first place a level on your workpiece and position it so that it is level. Then, when the drill

reads level, the two will be aligned. (Any bubble level can only indicate level relative to the earth.)

NOTE: The level is filled with mineral oil that may cause minor skin or eye irritation when contacted. If the

level breaks and this fluid gets on your skin, rinse thoroughly with water. If any liquid gets in your eyes, rinse

thoroughly with water and call a physician immediately.

KEYLESS CHUCK

Your tool features a keyless chuck for greater convenience. To insert a drill bit or other accessory, follow the

steps listed below.

1. TURN OFF AND UNPLUG. Make sure that the lock-on button is released.

2. Grasp the rear half of the chuck with one hand and use your other hand to rotate the front half in the

direction marked RELEASE on the nose of the chuck, as shown in Figure 4. Rotate far enough so that the chuck

opens sufficiently to accept the desired accessory.

3. Insert the bit or other accessory about 3/4" (19mm) into the chuck and tighten securely by holding the

rear half of the chuck and rotating the front portion in the GRIP direction. To release the accessory, repeat

step 2 listed above.

WARNING: Do not attempt to tighten drill bits (or any other accessory) by gripping the front part of the

chuck and turning the tool on. Damage to the chuck and personal injury may result. Always unplug unit and

turn off switch when changing accessories.

CHUCK REMOV AL

Place hex key in chuck as shown in Figure 5. Using a wooden mallet or similar object, strike key sharply in

the RELEASE direction. This will loosen the chuck so that it can be unscrewed by hand.

CHUCK INSTALLATION

Screw the chuck on by hand as far as it will go. Tighten the chuck around the shorter end of a 1/4" (6.4mm)

or larger hex key (not supplied) strike the longer end in the GRIP direction with a soft hammer, as shown in

Figure 6.

LUBRICATION

Your new drill uses self lubricating bearings and gears. Periodic relubrication is not required.

PROJECT TIPS

1. When drilling into metal, use a Bullet®Pilot®point drill bit to achieve a fast, clean hole without the bit

walking on the surface at start up.

2. For accurate horizontal and vertical drilling, use the built in level.

3. When using corded drills like the DR450, use the shortest practical extension cord or none at all.

Extension cords rob your drill of power and the longer they are, the more power they consume.

4. When driving screws into drywall, avoid driving them so deep that they tear the paper.

5. When driving screws in wood, pre-drill pilot holes to avoid splitting the wood.

Maintenance

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid. IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, mainte-

nance and adjustment should be performed by authorized service centers or other qualified service organizations, always using identical replacement parts.

Accessories

Recommended accessories for use with your tool are available from your local dealer or authorized service

center. If you need assistance regarding accessories, please call: 1-800-54-HOW TO.

WARNING: The use of any accessory not recommended for use with this tool could be hazardous. For

safety in use, the following accessories should be used only in sizes up to the maximum shown in the table

below. We recommend that your first purchase be safety glasses which should be used with all accessories.

MAXIMUM RECOMMENDED CAPACITIES

DRILL CAPACITY 3/8" (10mm)

R.P.M. 0–2,500

BITS, METAL DRILLING 3/8" (10mm)

WOOD, FLAT BORING 1" (25.4mm)

BITS, MASONRY DRILLING 1/2" (12.7mm)

ACCESSORY MUST BE RATED FOR USE AT SPEED EQUAL TO OR HIGHER THAN NAMEPLATE R.P.M. OF

TOOL WITH WHICH IT IS BEING USED.

WIRE WHEEL BRUSHES 4" (101.6mm) Diameter Maximum

WIRE CUP BRUSHES 3" (76.2mm) Diameter Maximum

BUFFING WHEELS 3" (76.2) Diameter Maximum

RUBBER BACKING PADS 4-5/8" (117.5mm) Diameter Maximum

Service Information

Black & Decker offers a full network of company-owned and authorized service locations throughout North

America. All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool service. Whether you need technical advice, repair, or genuine factory replacement parts, contact the Black & Decker location nearest you. To find your local service location, refer to the

yellow page directory under "Tools—Electric" or call: 1-800-54-HOW TO.

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the store is a participating retailer). Returns should be made within the time period of

the retailer’s policy for exchanges (usually 30 to 90 days after the sale). Proof of purchase may be required.

Please check with the retailer for their specific return policy regarding returns that are beyond the time set for

exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service

Center for repair or replacement at our option. Proof of purchase may be required. Black & Decker owned

and authorized Service Centers are listed under "Tools-Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have

other rights which vary from state to state. Should you have any questions, contact the manager of your nearest Black & Decker Service Center. This product is not intended for commercial use.

RENSEIGNEMENTS IMPORTANTS

•Bien serrer à la main le mandrin sans clé après chaque remplacement de foret.

CONSERVER LE PRÉSENT GUIDE À TITRE DE RÉFÉRENCE.

Mesures de sécurité

AVERTISSEMENT!

Lire et comprendre toutes les directives. Le non-respect de toutes les directives

suivantes présente des risques de secousses électriques, d’incendie ou de blessures

graves.

CONSERVER CES MESURES.

ZONE DE TRA VAIL

• S'assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et des endroits sombres

présentent des risques d'accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs explosives (comme celles dégagées par des

liquides, des gaz ou des poussières inflammables). Les étincelles générées par le moteur des outils

électriques peuvent enflammer les poussières ou les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu'on utilise un outil électrique.

Une distraction peut entraîner la perte de maîtrise de l'outil.

MESURES DE SÉCURITÉ RELATIVES À L'ÉLECTRICITÉ

• Les outils à double isolation comportent une fiche polarisée (une lame plus large que l'autre). La fiche

n'entre que d'une façon dans une prise polarisée. Lorsque la fiche n'entre pas à fond dans la prise,

essayer de nouveau après avoir inversé les broches de la fiche. Si la fiche n'entre toujours pas dans la

prise, communiquer avec un électricien certifié afin de faire installer une prise polarisée. Ne modifier en

aucune façon la fiche. La double isolation élimine le besoin d'un cordon trifilaire mis à la terre et d'un

système d'alimentation mis à la terre.

• Éviter de toucher à des surfaces mises à la terre comme des tuyaux, des radiateurs, des cuisinières et des

réfrigérateurs. Les risques de secousses électriques sont plus élevés si le corps de l'utilisateur est mis à la

terre.

• Protéger les outils électriques de la pluie ou des conditions mouillées. Une infiltration d'eau dans l'outil

augmente les risques de secousses électriques.

• Manipuler le cordon avec soin. Ne jamais se servir du cordon afin de transporter l'outil ni tirer sur le

cordon pour débrancher l'outil. Éloigner le cordon des sources de chaleur, des flaques d'huile, des arêtes

tranchantes et des pièces mobiles. Remplacer immédiatement les cordons endommagés. Les cordons

endommagés augmentent les risques de secousses électriques.

• Lorsqu'on utilise un outil électrique à l'extérieur, se servir d'un cordon de rallonge prévu pour l'extérieur,

portant la mention «W-A» ou «W». Ces cordons sont conçus pour servir à l'extérieur et minimisent les

risques de secousses électriques.

SÉCURITÉ PERSONNELLE

• Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu'on utilise un outil électrique. Ne pas

s'en servir lorsqu'on est fatigué ou affaibli par des drogues, de l'alcool ou des médicaments. De graves

blessures peuvent résulter d'un moment d'inattention lors de l'utilisation d'un outil électrique.

• Porter des vêtements appropriés. Éviter de porter des vêtements amples ou des bijoux. Recouvrir la

chevelure si elle est longue. Éloigner les cheveux, les vêtements et les gants des pièces en mouvement qui

peuvent les happer.

• Éviter les démarrages accidentels. S'assurer que l'interrupteur est en position hors tension avant de

brancher l'outil. Afin d'éviter les risques de blessures, ne pas transporter l'outil avec le doigt sur

l'interrupteur ni brancher un outil dont l'interrupteur est en position sous tension.

• Enlever les clés de réglage avant de mettre l'outil sous tension. Une clé qui est laissée sur une pièce rotative

de l'outil présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s'assure d'une meilleure maîtrise de

l'outil dans des situations imprévues grâce à une position stable et un bon équilibre.

• Porter de l'équipement de sécurité. Toujours porter des lunettes de sécurité. Dans certaines conditions, il

faut porter des masques respiratoires, des chaussures antidérapantes, un casque de sécurité ou des protègetympans.

UTILISATION ET ENTRETIEN DE L'OUTIL

• Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de soutenir la pièce à

ouvrer sur une plate-forme stable. La pièce est instable lorsqu'elle est retenue par la main ou le corps de

l'utilisateur. Cela présente des risques de perte de maîtrise de l'outil.

• Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche. L'outil approprié fonctionne mieux et sûrement

lorsqu'on s'en sert à son rendement nominal.

• Ne pas se servir de l'outil lorsque l'interrupteur est défectueux. Le cas échéant, l'outil est dangereux et il

faut le réparer.

• Débrancher l'outil de la source d'alimentation avant de le régler, d'en remplacer les accessoires ou de le

ranger. On minimise de la sorte le risque de démarrage accidentel de l'outil.

• Ranger l'outil hors de portée des enfants et de toute autre personne qui n'en connaît pas le

fonctionnement. L'outil est dangereux entre les mains de ces personnes.

• Prendre soin des outils. S'assurer que les outils de coupe sont tranchants et propres. Des outils bien

entretenus à arêtes tranchantes ont moins tendance à se coincer et ils se maîtrisent mieux.

• Vérifier l'alignement et les attaches des pièces mobiles, le degré d'usure des pièces ainsi que tout autre

facteur susceptible de nuire au bon fonctionnement de l'outil. Faire réparer un outil endommagé avant de

s'en servir. Des outils mal entretenus sont la cause de nombreux accidents.

• Utiliser seulement les accessoires recommandés par le fabricant. Des accessoires qui conviennent à un outil

peuvent présenter des risques avec un autre outil

ENTRETIEN

• Confier l'entretien de l'outil seulement à du personnel qualifié. Le non-respect de la présente directive

présente des risques de blessures.

• Lors de l'entretien de l'outil, utiliser seulement des pièces de rechange identiques. Respecter les consignes

relatives à l'entretien du présent guide d'utilisation. Il y a risque de secousses électriques ou de blessures

lorsqu'on utilise des pièces non autorisées ou lorsqu'on ne respecte pas les consignes relatives à l'entretien.

• Tenez l’outil par ses surfaces de prise isolées pendant toute opération où l’outil de coupe portrait venir en

contact avec un câblage dissimulé ou avec son propre cordon. En cas de contact avec un conducteur sous

tension, les pièces métalliques à découvert de l’outil transmettraient un choc électrique à l’utilisateur.

L’étiquette de l’outil peut comporter les symboles suivants.

V....................................volts A ........................ampères

Hz ..................................hertz W ......................watts

min ................................minutes ......................courant alternatif

..............................courant continu

n

o ......................sous vide

..................................

construction de classe II

........................borne de mise à la

minute

..................................symbole d´avertissement .../min ................tours ou courses

à la minute

FONCTIONNEMENT

MOTEUR

Un moteur Black & Decker entraîne l’outil . Veiller à ce que la tension d’alimentation soit conforme aux exigences

de la plaque signalétique de l’outil. La mention 120 volts, 50/60 Hz ou 120 volts c.a. seulement signifie que

l’outil fonctionne seulement sur une alimentation domestique standard de 120 volts. Une baisse de tension de plus

de 10 p. 100 entraîne une perte de puissance et la surchauffe. Tous les outils sont essayés avant de quitter l’usine.

Lorsque celui-ci refuse de fonctionner, vérifier la source de courant électrique.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

GUIDE D'UTILISATION

PERCEUSE DE 10 MM

(3/8

PO)

ET DE 5 A À MANDRIN SANS CLÉ - DR450

Loading...

Loading...