Page 1

B

C

GENERAL SAFETY RULES

WARNING! Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury. The term “power tool” in all of the

warnings listed below refers to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can

cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication.

A moment of inattention while operating power tool may

result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging

in.

Carrying power tools with your finger on the switch or plugging in power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts.

Loose clothes, jewelry or long hair can be caught in

moving parts. Air vents often cover moving parts and should also be avoided.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used.

Use of these devices can

reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools.

Such preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use.

Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

SAVE THIS MANUAL FOR FUTURE

REFERENCE.

INSTRUCTION MANUAL

Catalog Number CSD300T

Cat No. CSD300T Form #90530144 JAN. ‘08

Copyright © 2008 Black & Decker Printed in China

taking into account the working conditions and the work to be performed.

Use of

the power tool for operations different from those intended could result in a hazardous

situation.

5) Battery tool use and care

a) Ensure the switch is in the off position before inserting battery pack.

Inserting the

battery pack into power tools that have the switch on invites accidents.

b) Recharge only with the charger specified by the manufacturer.

A charger that is

suitable for one type of battery pack may create a risk of fire when used with another

battery pack.

c) Use power tools only with specifically designated battery packs.

Use of any other

battery packs may create a risk of injury and fire.

d) When battery pack is not in use, keep it away from other metal objects like paper

clips, coins, keys, nails, screws, or other small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

e) Under abusive conditions, liquid may be ejected from the battery, avoid contact. If

contact accidentally occurs, flush with water. If liquid contacts eyes, additionally

seek medical help.

Liquid ejected from the battery may cause irritation or burns.

6) Service

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts.

This will ensure that the safety of the power tool is maintained.

b) If the replacement of the supply cord is necessary,

this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

Specific Safety Rules

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

• Use clamps or another practical way to secure and support the work piece to a stable

platform. Holding the work by hand or against your body leaves it unstable and may lead to

loss of control.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA

approved respiratory protection appropriate for the dust exposure. Direct particles

away from face and body.

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

The label on your tool may include the following symbols. The symbols and their

definitions are as follows:

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating

current

......................direct current

n

o ........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

T

T

HANK

HANK

YOU

YOU

FOR

FOR

CHOOSING

CHOOSING

B

B

LACK

LACK

&&D

D

ECKER

ECKER

!

!

G

G

OOTTOOWWW

WWW

.B

.B

LACKAND

LACKAND

D

D

ECKER

ECKER

.

.

COM

COM

/N

/N

EW

EW

O

O

WNER

WNER

TTOOREGISTER

REGISTER

YOUR

YOUR

NEW

NEW

PRODUCT

PRODUCT

.

.

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-544-6986

BEFORE YOU CALL, HAVE THE CATALOG No. AND DATE CODE AVAILABLE. IN MOST CASES, A

BLACK & DECKER REPRESENTATIVE CAN RESOLVE THE PROBLEM OVER THE PHONE. IF YOU HAVE A

SUGGESTION OR COMMENT, GIVE US ACALL. YOUR FEEDBACK IS VITAL TO BLACK & DECKER.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE

SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

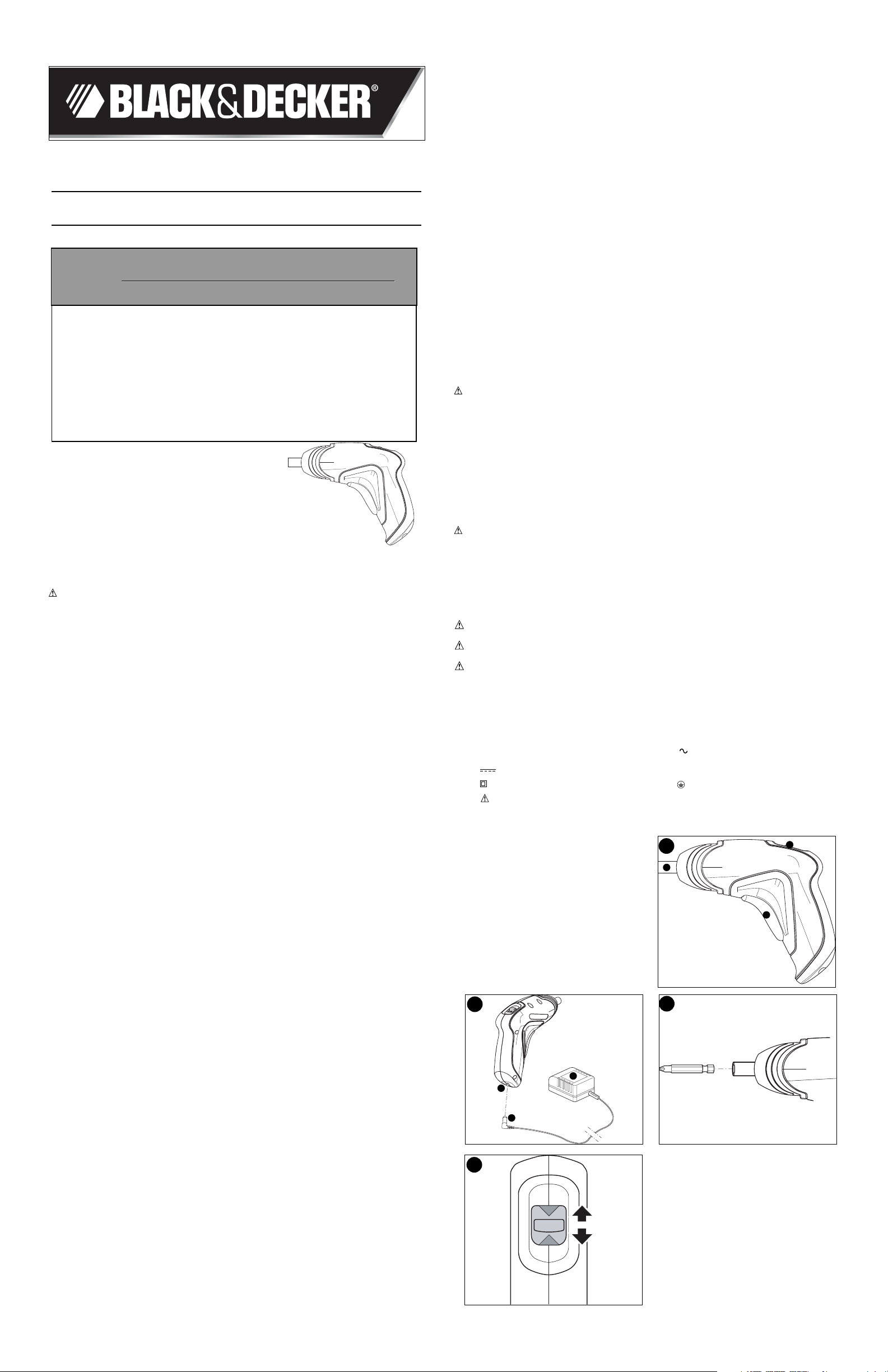

Functional Description

1. Spindle

2. On / off switch

3. Forward / reverse slider

A

1

6

5

4

3

2

D

CORDLESS SCREWDRIVER

Page 2

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Tool will not start. • Battery not charged. • Check battery charging

requirements.

• Battery will not charge. • Charger not plugged in. • Plug charger into a

working outlet. Refer to

“Important Charging

Notes” for more details.

• Check current at

receptacle by plugging in

a lamp or other appliance.

• Check to see if

receptacle is connected to

a light switch which turns

power off when you turn

out the lights.

• Surrounding air temperature • Move charger and tool

too hot or too cold. to a surrounding air

temperature of above 40

degrees F (4,5°C) or

below 105 degrees F

(+40,5°C).

For assistance with your product, visit our website www.blackanddecker.com for the

location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

Accessories

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

BATTERY REMOVAL

Before attempting to disassemble this tool, turn it on and run it in either direction until it stops

to ensure a complete discharge of the batteries. Using a phillips screwdriver, remove the

screws in the product housing and lift the housing half from the tool. Disconnect the terminal

clips from the batteries and lift the batteries out. See “Service Information” for battery

replacement.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corporation) Seal on the nickelcadmium battery (or battery pack) indicates that the costs to recycle the battery

(or battery pack) at the end of its useful life have already been paid by Black &

Decker. In some areas, it is illegal to place spent nickel-cadmium batteries in the trash or

municipal solid waste stream and the RBRC program provides an environmentally

conscious alternative.

RBRC in cooperation with Black & Decker and other battery users, has established

programs in the United States and Canada to facilitate the collection of spent nickelcadmium batteries. Help protect our environment and conserve natural resources by

returning the spent nickel-cadmium battery to an authorized Black & Decker service center

or to your local retailer for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery, or call 1-800-8-BATTERY.

SERVICE INFORMATION

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair, or

genuine factory replacement parts, contact the Black & Decker location nearest you. To find

your local service location, refer to the yellow page directory under "Tools—Electric" or call:

1-800-544-6986 or visit www.blackanddecker.com

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should be

made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after

the sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under "ToolsElectric" in the yellow pages of the phone directory and on our website

www.blackanddecker.com.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center. This

product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-544-6986 for a free replacement.

SAFETY WARNINGS AND INSTRUCTIONS: CHARGING

1. This manual contains important safety and operating instructions.

2. Before using battery charger, read all instructions and cautionary markings on

battery charger, battery pack, and product using battery pack.

3. CAUTION: To reduce the risk of injury, charge only Black & Decker Batteries. Other

types of batteries may burst causing personal injury and damage.

4. Do not expose charger to rain or snow.

5. Use of an attachment not recommended or sold by Black & Decker may result in a risk

of fire, electric shock, or injury to persons.

6. To reduce risk of damage to electric plug and cord, pull by plug rather than cord when

disconnecting charger.

7. Make sure cord is located so that it will not be stepped on, tripped over, or otherwise

subjected to damage or stress.

8. An extension cord should not be used unless absolutely necessary. Use of improper

extension cord could result in a risk of fire, electric shock or electrocution.

a. Two-wire cords can be used with 2-wire or 3-wire extension cords. Only round

jacketed extension cords should be used, and we recommend that they be listed by

Underwriters Laboratories (U.L.). If the extension is to be used outside, the cord must

be suitable for outdoor use. Any cord marked for outdoor use can also be used for

indoor work. The letters "W" or "WA" on the cord jacket indicate that the cord is

suitable for outdoor use.

b. An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety, and to prevent loss of power and overheating. The smaller the gauge number of

the wire, the greater the capacity of the cable; that is, 16 gauge has more capacity than

18 gauge. When using more than one extension to make up the total length, be sure

each extension contains at least the minimum wire size.

9. Use only the supplied charger when charging your tool. The use of any other charger

could damage the tool or create a hazardous condition.

10. Use only one charger when charging.

11. Do not attempt to open the charger. There are no customer serviceable parts inside.

Return to any authorized Black & Decker service center.

12. DO NOT incinerate the battery pack even if they are severely damaged or completely

worn out. The battery can explode in a fire.

13. A small leakage of liquid from the battery pack cells may occur under extreme usage,

charging or temperature conditions. This does not indicate a failure. However, if the

outer seal is broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If the battery liquid gets in your eyes, flush them with clean water for a minimum of 10

minutes and seek immediate medical attention. MEDICAL NOTE: The liquid is a

25-35% solution of potassium hydroxide.

CHARGING PROCEDURE

IMPORTANT: The batteries in your tool are not fully charged at the factory. Before

attempting to charge them, thoroughly read all of the safety instructions. To charge the tool,

follow the steps below:

1. Insert the jack plug (5) of the charger (4) into the charging port (6) in the bottom of the

tool handle as shown in figure B.

2. Plug the charger into any standard 120 Volt 60 Hz electrical outlet.

3. Let the tool charge initially for 17 hours.

WARNING: When disconnecting the tool from the charger, be sure to unplug the charger

(6) from the outlet first, then disconnect the jack plug (5) from the tool.

IMPORTANT CHARGING NOTES

1. Charger will work best at normal room temperature.

2. The charger plug and the tool handle may become warm while charging. This is normal

and does not indicate a problem.

3. A minimum charge time of 17 hours is required to recharge a completely discharged tool.

4. For most fix up jobs a shorter charge time may be adequate.

SAFETY WARNINGS AND INSTRUCTIONS: DRILLING

• Hold tool firmly to control its twisting action.

WARNING: Tool may stall (if overloaded or improperly used) causing a twist. To

reduce the risk of injury always expect the stall. Grip the tool firmly to control the twisting

action and prevent loss of control which could cause personal injury. If a stall does occur,

release the trigger immediately and determine the reason for the stall before re-starting.

OPERATING INSTRUCTIONS

REMOVING AND INSTALLING BITS

• Insert power hex bit or bit tip with bit tip holder into the cavity in the spindle (1) until it snaps

into place.

• To remove the bit pull it straight out. If bit does not fit into spindle, rotate the bit and re-insert

it. Do not insert a bit tip without a bit tip holder.

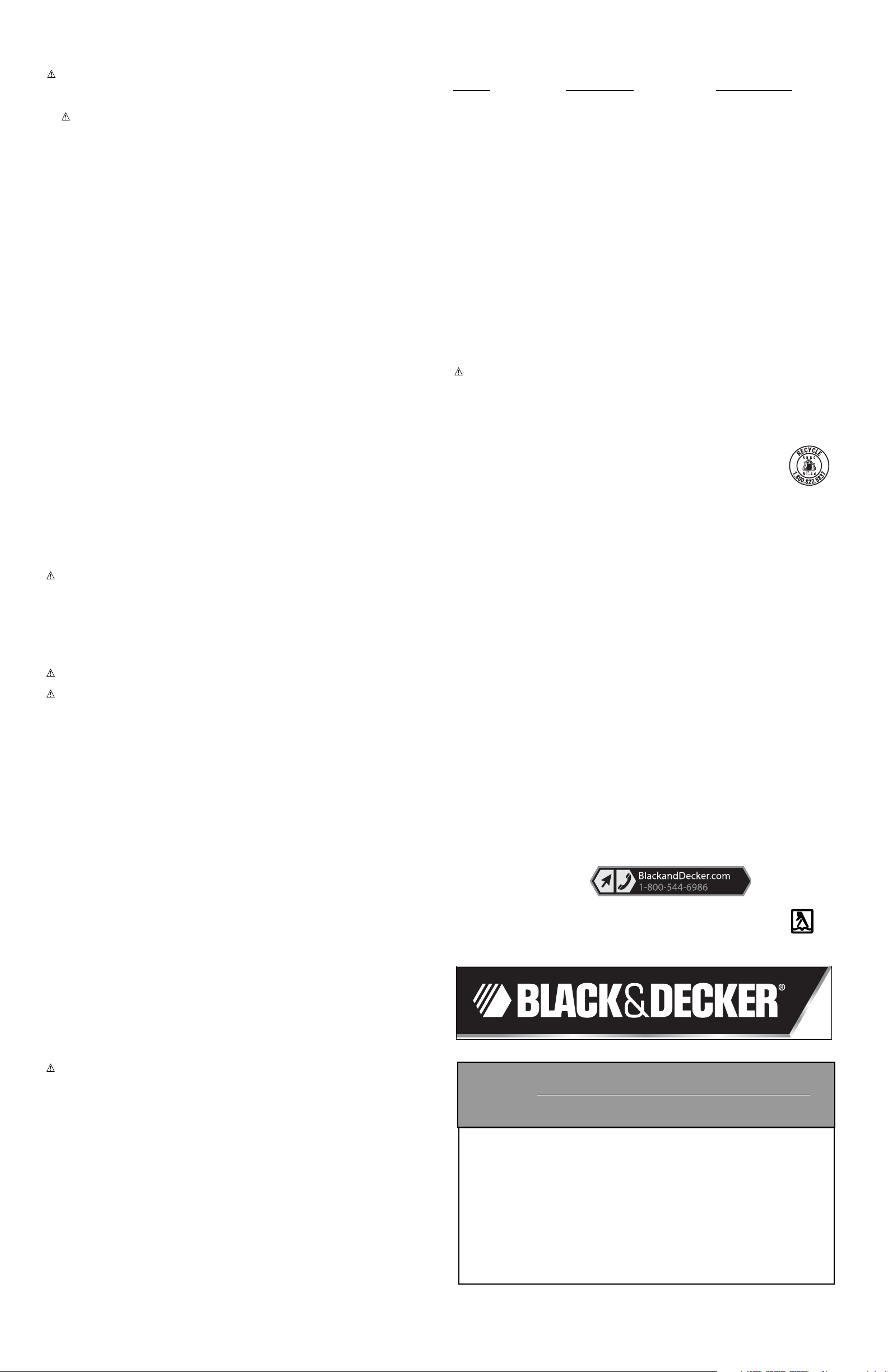

TRIGGER SWITCH & FORWARD/REVERSE SLIDER

The tool is turned ON and OFF by pulling and releasing the trigger switch (2). A

forward/reverse control button (3) determines the direction of the tool and also serves as a

lock off button.

• To select forward rotation, release the trigger switch and push the forward/reverse button

forward as shown in figure D.

• To select reverse, release the trigger switch and pull the forward/reverse button backward

as shown in figure D.

• The neutral (no run) position of the button locks the tool in the off position. When changing

the position of the button, be sure the trigger is released.

DRILLING

• Use sharp drill bits only.

• Drill bits for metal can be used for drilling holes in wood. These bits must be sharp and

should be pulled out frequently when drilling to clear chips from the flutes.

• Support and secure work properly, as instructed in the safety Instructions.

• Use appropriate and required safety equipment, as instructed in the safety instructions.

• Secure and maintain work area, as instructed in the safety instructions.

• Use light pressure until the hole is started enough to keep the drill bit from slipping out of it.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting but

not so much as to stall the motor or deflect the bit

• Minimize stalling on breakthrough by reducing pressure and slowly drilling through last part

of hole.

• Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

• Make sure switch turns tool on and off.

WARNING: It is important to support work properly and to hold the tool firmly to prevent

loss of control which could cause personal injury.

HINTS FOR OPTIMUM USE

• Always use the correct type of screwdriver bit. Never use a screwdriver bit tip without a bit tip

holder

• If screws are difficult to tighten, try applying a small amount of washing liquid or soap as a

lubricant.

• Always hold the tool and screwdriver bit in a straight line with the screw.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized service

centers or other qualified service personnel, always using identical replacement parts.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

Numéros de catalogue CSD300T

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

AVANT DE RETOURNER CE PRODUIT POUR QUELQUE

RAISON QUE CE SOIT, COMPOSER LE

1-800-544-6986

AVANT D’APPELER, AYEZ EN MAIN LE N° DE CATALOGUE ET LE CODE DE DATE. DANS LAPLUPART

DES CAS, UN REPRÉSENTANT DE BLACK & DECKER PEUT RÉSOUDRE LE PROBLÈME PAR

TÉLÉPHONE. SI VOUS AVEZ UNE SUGGESTION OU UN COMMENTAIRE, APPELEZ-NOUS. VOS

IMPRESSIONS SONT CRUCIALES POUR BLACK & DECKER.

M

M

ERCI

ERCIDD

’

’

AAVOIR

VOIR

CHOISI

CHOISI

B

B

LACK

LACK

& D

& D

ECKER

ECKER

!

!

V

V

ISITEZ

ISITEZ

WWW

WWW

.B

.B

LACKAND

LACKAND

D

D

ECKER

ECKER

.

.

COM

COM

/N

/N

EW

EW

O

O

WNER

WNER

POUR

POUR

ENREGISTRER

ENREGISTRER

VOTRE

VOTRE

NOUVEAU

NOUVEAU

PRODUIT

PRODUIT

.

.

Page 3

mettre les pièces métalliques de l’outil sous tension, engendrant des risques de choc

électrique.

• Utiliser des brides de fixation ou un autre dispositif de fixation permettant de fixer

solidement et de soutenir la pièce sur une plateforme stable. Tenir la pièce avec la

main ou contre son corps la rend instable et risque de provoquer une perte de maîtrise

de l’outil.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies,

les meules, les perceuses ou certains autres outils de construction, peuvent

produire de la poussière contenant des produits chimiques susceptibles

d’entraîner le cancer, des malformations congénitales ou pouvant être nocifs pour

le système reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de

maçonnerie,

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique

(comme l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un

endroit bien aéré et utiliser le matériel de sécurité approprié, tel un masque

anti-poussières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres

outils électriques. Porter des vêtements de protection et nettoyer les parties

exposées du corps à l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible

de causer des dommages sérieux et permanents au système respiratoire. Toujours

utiliser un appareil respiratoire anti-poussières approprié approuvé par le NIOSH ou

l’OSHA. Diriger les particules dans le sens opposé du visage et du corps.

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode d’emploi. Les informations qu’il

contient concernent VOTRE SÉCURITÉ et visent à ÉVITER TOUT PROBLÈME. Les

symboles ci-dessous servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle n’est pas évitée,

causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait causer la mort ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, pourrait causer des blessures mineures ou modérées.

MISE EN GARDE : Utilisé sans le symbole d’alerte à la sécurité, indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée, peut résulter en des dommages à la

propriété.

L’étiquette apposée sur votre outil pourrait comprendre les symboles suivants. Les

symboles et leurs définitions sont indiqués ci-après :

V ..............volts A ................ampères

Hz ............hertz W................watts

min............minutes ..............courant alternatif

..........courant continue non ............régime à vide

..............Construction classe II

............

borne de terre

............

symbole d’alerte à la .../min ........révolutions ou alternance par minute

sécurité

Description fonctionnelle

1. Broche

2. Interrupteur Marche/Arrêt

3. Bouton de marche avant/marche arrière

Directives et consignes de sécurité concernant le chargement

1. Le présent guide comprend d’importantes directives, dont un mode d’emploi et des

consignes de sécurité.

2. Avant d’utiliser le chargeur de pile, lire toutes les directives et les indications

d’avertissement apposées sur le chargeur, le bloc-piles et le produit qui utilise le blocpiles.

3. MISE EN GARDE : pour réduire le risque de blessure, charger seulement les piles

Black & Decker. D’autres types de piles peuvent exploser et provoquer des blessures

corporelles et des dommages.

4. Ne pas exposer le chargeur à la pluie ou à la neige.

5. L’utilisation d’un accessoire n’étant ni recommandé ni vendu par Black & Decker peut

entraîner des risques d’incendie, de choc électrique ou de blessure.

6. Afin de réduire les risques de dommage à la fiche ou au cordon électrique,

débranche le chargeur en saisissant la fiche, non le cordon.

7. S’assurer que le cordon est placé de manière à éviter qu’il ne subisse des

dommages ou des contraintes ou que les personnes s’y prennent les pieds et

trébuchent.

8. Ne pas utiliser de rallonge à moins que cela ne soit absolument nécessaire, car

l’usage d’une rallonge ayant une puissance inadéquate pourrait causer des risques

d’incendie, de choc électrique ou d’électrocution.

a. Bien qu’on puisse utiliser un cordon bifilaire avec une rallonge bifilaire ou trifilaire, on

ne doit utiliser qu’une rallonge à cordon; on recommande que celle-ci soit approuvée

par l’organisme américain Underwriters Laboratories (UL). Lorsqu’on utilise un outil

électrique à l’extérieur, on ne doit utiliser que des rallonges conçues pour cet usage,

comme celles de type W-A ou W. Toute rallonge conçue pour un usage extérieur peut

aussi être employée à l’intérieur.

b. Afin d’éviter une perte de puissance ou une surchauffe et d’assurer la sécurité de

l’utilisateur, la rallonge doit être de calibre AWG approprié. Plus le calibre est petit,

plus la capacité est grande; autrement dit, une rallonge de calibre 16 est plus

puissante qu’une rallonge de calibre 18. Lorsqu’on utilise plusieurs rallonges pour

obtenir la longueur voulue, s’assurer que chacune d’elles présente les valeurs

minimales requises.

9. Utiliser seulement le chargeur fourni pour charger l’outil. L’utilisation de tout autre

chargeur risque d’endommager l’outil ou de créer une situation dangereuse.

10.N’utiliser qu’un seul chargeur durant le chargement.

11.Ne pas ouvrir le chargeur; ces derniers ne contiennent aucune pièce pouvant être

réparée par le client et doivent être retournés à un centre de service Black & Decker,

le cas échéant.

12.NE PAS incinérer le bloc-piles même s’il est très endommagé ou complètement usé.

La pile peut exploser dans un incendie.

13.Une petite fuite de liquide peut se produire dans les cellules du bloc-piles en cas

d’utilisation, de charge ou de conditions de température extrêmes, cela n’indique pas de

défaillance. Toutefois, si le joint d’étanchéité extérieur est rompu et que le liquide entre

en contact avec la peau :

a. se laver rapidement la partie du corps touchée avec de l’eau savonneuse;

b. neutraliser l’effet au moyen d’un acide doux tel que du jus de citron ou du vinaigre;

c. si les yeux sont touchés, les rincer à fond avec de l’eau propre pendant au moins 10

minutes et consulter immédiatement un médecin.

REMARQUE AUX FINS MÉDICALES :

ce liquide contient une solution composée de 25 à 35 % d’hydroxyde de potassium.

PROCÉDURE DE CHARGE

IMPORTANT : les piles de l’outil ne sont pas complètement chargées à l’usine. Avant

de les charger, lire attentivement toutes les consignes de sécurité. Pour charger l’outil,

suivre les étapes suivantes :

1. Insérer le connecteur mâle (5) du chargeur (4) dans le port de charge (6) logé à

l’extrémité de la poignée de l’outil comme l’indique la figure B.

Règles de sécurité générales

AVERTISSEMENT! Lire toutes les directives. Tout manquement aux directives

suivantes pose des risques de choc électrique, d’incendie et/ou de blessure grave.

Le terme « outil électrique » dans tous les avertissements ci-après se rapporte à

votre outil électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

CONSERVER CES DIRECTIVES

1) Sécurité du lieu de travail

a) Tenir la zone de travail propre et bien éclairée.

Les endroits sombres sont souvent

des causes d'accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, soit en

présence de liquides inflammables, de gaz ou de poussière.

Les outils électriques

produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les curieux au moment d’utiliser un outil électrique.

Une

distraction pourrait vous en faire perdre la maîtrise.

2) Sécurité en matière d’électricité

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais

modifier la fiche en aucune façon.

Ne jamais utiliser de fiche d’adaptation avec un

outil électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation

de fiches non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des

tuyaux, des radiateurs, des cuisinières et des réfrigérateurs.

Le risque de choc

électrique est plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à d'autres conditions où il

pourrait être mouillé.

La pénétration de l’eau dans un outil électrique augmente le

risque de choc électrique.

d) Ne pas utiliser abusivement le cordon d’alimentation. Ne jamais utiliser le

cordon pour transporter, tirer ou débrancher un outil électrique. Tenir le cordon

éloigné de la chaleur, de l’huile, des bords tranchants ou des pièces mobiles.

Les

cordons endommagés ou emmêlés augmentent les risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à une telle utilisation.

L’utilisation d’une rallonge conçue pour l’extérieur

réduit les risques de choc électrique.

3) Sécurité personnelle

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un

outil électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou

sous l’influence de drogues, d’alcool ou de médicaments.

Un moment d’inatten-

tion, durant l’utilisation d’un outil électrique, peut se solder par des blessures graves.

b) Utiliser un équipement de sécurité. Toujours porter une protection oculaire.

L’utilisation d’un équipement de sécurité comme un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque

la situation le requiert réduira les risques de blessures corporelles.

c) Attention de ne pas mettre en marche l’outil accidentellement. S’assurer que

l’interrupteur est en position d’arrêt avant tout branchement.

Transporter un outil

électrique alors que le doigt est sur l’interrupteur ou brancher un outil électrique alors

que l’interrupteur est en position de marche risque de causer un accident.

d) Retirer toute clé de réglage ou clé standard avant de démarrer l’outil.

Une clé

standard ou une clé de réglage attachée à une partie pivotante peut causer des

blessures.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps.

Cela permet

de mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de

bijoux. Maintenir cheveux, vêtements et gants éloignés des pièces mobiles.

Les

vêtements amples, bijoux ou cheveux longs pourraient s'enchevêtrer dans les pièces

mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de

dépoussiérage et de ramassage, s’assurer que ceux-ci sont bien raccordés et

utilisés.

L’utilisation de ces dispositifs peut réduire les risques engendrés par les

poussières.

4) Utilisation et entretien d’un outil électrique

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à

l’application.

L’outil électrique approprié effectuera un meilleur travail, de façon plus

sûre et à la vitesse pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux.

Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche du secteur ou le bloc-piles de l’outil électrique avant de faire

tout réglage ou changement d’accessoire, ou avant de ranger l’outil électrique.

Ces mesures préventives réduisent les risques de démarrage accidentel de l’outil

électrique.

d) Ranger les outils électriques hors de la portée des enfants, et ne permettre à

aucune personne n’étant pas familière avec un outil électrique (ou son manuel

d’instruction) d’utiliser ce dernier

. Les outils électriques deviennent dangereux entre

les mains d’utilisateurs inexpérimentés.

e) Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer

qu’elles sont bien alignées et tournent librement, qu’elles sont en bon état et ne

sont affectées par aucun trouble susceptible de nuire au bon fonctionnement de

l’outil électrique

.

En cas de dommage, faire réparer l’outil électrique avant toute

nouvelle utilisation.

Beaucoup d’accidents sont causés par des outils électriques mal

entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres.

Les outils de coupe

bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à

contrôler.

g) Utiliser l’outil électrique, les accessoires, les mèches, etc., conformément aux

présentes directives et suivant la manière prévue pour ce type particulier d’outil

électrique, en tenant compte des conditions de travail et du travail à effectuer.

L’utilisation d’un outil électrique pour toute opération autre que celle pour laquelle il a

été conçu est dangereuse.

5) Utilisation et entretien du bloc-piles

a) S’assurer que l’interrupteur se trouve à la position d’arrêt avant d’insérer le

bloc-piles. Insérer un bloc-piles dans un outil électrique dont l’interrupteur est à

la position de marche risque de provoquer un accident.

b) Ne recharger l’outil qu’au moyen du chargeur précisé par le fabricant.

L’utilisation

d’un chargeur qui convient à un type de bloc-piles risque de provoquer un incendie s’il

est utilisé avec un autre type de bloc-piles.

c) Utiliser les outils électriques uniquement avec les blocs-piles conçus à cet effet.

L’utilisation de tout autre bloc-piles risque de causer des blessures ou un incendie.

d) Lorsque le bloc-piles n’est pas utilisé, le tenir éloigné des objets métalliques,

notamment des trombones, de la monnaie, des clés, des clous, des vis, etc., qui

peuvent établir une connexion entre les deux bornes.

Le court-circuit des bornes du

bloc-piles risque de provoquer des étincelles, des brûlures ou un incendie.

e) En cas d’utilisation abusive, le liquide peut gicler hors du bloc-piles, éviter tout

contact. Si un contact accidentel se produit, laver à grande eau. Si le liquide

entre en contact avec les yeux, obtenir des soins médicaux.

Le liquide qui gicle

hors du bloc-piles peut provoquer des irritations ou des brûlures.

6) Réparation

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que

des pièces de rechange identiques

. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

b) S’il faut remplacer le cordon d’alimentation,

ceci doit être fait par le fabricant ou

son agent pour éviter tout risque d’accident.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en

contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent

Page 4

RETRAIT DES PILES

Avant de démonter cet appareil, le faire fonctionner en marche avant ou arrière jusqu’à

arrêt complet pour décharger complètement les piles. À l’aide d’un petit tournevis Phillips,

retirer les vis du boîtier de l’appareil et séparer ces derniers de moitié. Déconnecter les

cosses des piles puis retirer les piles du boîtier. Se reporter à la section « Informations sur

les services » pour remplacer les piles.

Le sceau RBRC™

RBRC™ (Société de recyclage des piles rechargeables)

Ce sceau apposé sur la pile au nickel-cadmium (ou sur le bloc-piles) indique

que les coûts de recyclage de cette pile (ou de ce bloc-piles) à la fin de sa vie utile ont déjà

été payés par Black & Decker. Dans certaines régions, il est illégal de jeter les piles au

nickel-cadmium déchargées dans les poubelles ou dans le système municipal de cueillette

des résidus solides. Le programme de la RBRC représente donc une alternative

écologique.

La RBRC, en collaboration avec Black & Decker et d’autres utilisateurs de piles, a établi

aux États-Unis et au Canada des programmes facilitant la cueillette des piles au nickelcadmium déchargées. Black & Decker encourage ses clients à protéger l’environnement et

à conserver les ressources naturelles, et ce, en retournant les piles au nickel-cadmium

déchargées à un centre de réparation Black & Decker autorisé ou à un détaillant local pour

qu’elles soient recyclées. On peut aussi communiquer avec le centre local de recyclage

pour savoir où déposer les piles déchargées ou composer le numéro

1-800-8-BATTERY.

INFORMATION SUR LES RÉPARATIONS

Tous les centres de réparation Black & Decker sont dotés de personnel qualifié en matière

d’outillage électrique; ils sont donc en mesure d’offrir à leur clientèle un service efficace et

fiable. Que ce soit pour un avis technique, une réparation ou des pièces de rechange

authentiques installées en usine, communiquer avec l’établissement Black & Decker le

plus près de chez vous. Pour trouver l’établissement de réparation de votre région,

consulter le répertoire des Pages jaunes à la rubrique « Outils électriques » ou composer

le numéro suivant : 1-800-544-6986 ou consulter le site www.blackanddecker.com

GARANTIE COMPLÈTE DE DEUX ANS POUR UNE UTILISATION DOMESTIQUE

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout

défaut de matériau ou de fabrication. Le produit défectueux sera remplacé ou réparé sans

frais de l’une des deux façons suivantes :

La première façon consiste en un simple échange chez le détaillant qui l’a vendu (pourvu

qu’il s’agisse d’un détaillant participant). Tout retour doit se faire durant la période

correspondant à la politique d’échange du détaillant (habituellement, de 30 à 90 jours

après l’achat). Une preuve d’achat peut être requise. Vérifier auprès du détaillant pour

connaître sa politique concernant les retours hors de la période définie pour les échanges.

La deuxième option est d’apporter ou d’envoyer le produit (transport payé d’avance) à un

centre de réparation autorisé ou à un centre de réparation de Black & Decker pour faire

réparer ou échanger le produit, à notre discrétion. Une preuve d’achat peut être requise.

Les centres Black & Decker et les centres de service autorisés sont répertoriés dans les

pages jaunes, sous la rubrique « Outils électriques ».

Cette garantie ne s’applique pas aux accessoires. Cette garantie vous accorde des droits

légaux spécifiques et vous pourriez avoir d’autres droits qui varient d’un État ou d’une

province à l’autre. Pour toute question, communiquer avec le directeur du centre de

réparation Black & Decker le plus près de chez vous. Ce produit n’est pas destiné à un

usage commercial.

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : si les étiquettes

d’avertissement deviennent illisibles ou sont manquantes, composer le 1-800-544-6986

pour en obtenir le remplacement gratuit.

2. Brancher le chargeur dans une prise électrique standard de 120 volts, 60 Hz.

3. Lors de la première charge, laisser l’outil se charger durant 17 heures.

AVERTISSEMENT : avant de retirer l’outil du chargeur, débrancher d’abord le chargeur

(6) de la prise murale, puis retirer le connecteur mâle (5) de l’outil.

REMARQUES IMPORTANTES POUR LE CHARGEMENT

1. Le fonctionnement du chargeur sera optimisé à température ambiante normale.

2. En cours de charge, il est possible que la fiche du chargeur et la poignée de l’outil

deviennent chaudes au toucher. C’est un état normal et cela n’indique pas un

problème.

3. Au moins 17 heures sont nécessaires pour recharger un outil dont le bloc-piles est

complètement épuisé.

4. Pour la plupart des travaux de réparation, un temps de charge plus court pourrait être

adéquat.

AVERTISSEMENTS DE SÉCURITÉ ET DIRECTIVES : PERÇAGE

• Tenir fermement l’outil afin de maîtriser son mouvement de torsion.

AVERTISSEMENT : l’outil pourrait se bloquer (à cause d’une surcharge ou d’une

mauvaise utilisation), produisant ainsi une torsion brusque. Pour réduire le risque de

blessure, toujours s’attendre à un blocage soudain. Empoigner fermement l’outil pour

maîtriser son mouvement de torsion et éviter d’en perdre la maîtrise, ce qui pourrait causer

des blessures corporelles. En cas de blocage, relâcher la détente immédiatement et

déterminer la raison du blocage avant de redémarrer.

FONCTIONNEMENT

RETRAIT ET INSERTION DES EMBOUTS

• Insérer la mèche à queue hexagonale pour outil électrique ou la pointe de tournevis avec

le porte-pointe dans la cavité de la broche (1) jusqu’à ce qu’il ou elle s’enclenche en

position.

• Pour retirer la mèche, tirer en ligne droite sur celle-ci. Si la mèche ne s’insère pas dans la

broche, tourner la mèche puis la réinsérer. Ne pas insérer de pointe de tournevis

directement sans le porte-pointe.

DÉTENTE ET BOUTON DE MARCHE AVANT/MARCHE ARRIÈRE

L’outil est mis en position de MARCHE et d’ARRÊT en tirant et en relâchant la détente (2).

Un bouton de commande marche avant/marche arrière (3) détermine le sens de rotation

de l’outil et sert également de bouton de verrouillage.

• Pour sélectionner la rotation en marche avant, relâcher la détente et pousser le bouton

marche avant/marche arrière vers l’avant, comme indiqué à la figure D.

• Pour sélectionner la marche arrière, relâcher la détente et tirer le bouton marche

avant/marche arrière vers l’arrière, comme indiqué à la figure D.

• La position neutre (sans fonctionnement) du bouton verrouille l’outil en position d’arrêt.

Toujours relâcher la détente avant de changer la position du bouton.

PERÇAGE

• N’utiliser que des mèches bien aiguisées.

• Des mèches de perçage de métaux peuvent être utilisées pour percer des trous dans le

bois. Ces mèches doivent être bien aiguisées et doivent être fréquemment retirées pour

nettoyer les cannelures.

• S’assurer que la pièce est bien appuyée et stable comme indiqué dans les consignes de

sécurité.

• Utiliser l’équipement de sécurité nécessaire et approprié comme indiqué dans les

consignes de sécurité.

• Sécuriser et entretenir la surface de travail comme indiqué dans les consignes de sécurité.

• Utiliser peu de pression jusqu’à ce que le trou soit suffisamment grand pour que la mèche

ne glisse pas.

• Exercer une pression en ligne droite avec la mèche. Exercer suffisamment de pression

pour faire mordre la mèche, mais ne pas trop appuyer pour éviter de faire caler le moteur

ou de faire dévier la mèche.

• Éviter les blocages en réduisant la pression lors du perçage et percer lentement dans la

dernière portion du trou.

• Faire tourner la perceuse pour retirer la mèche du trou percé. Cette pratique réduira ainsi

les blocages.

• S’assurer que l’interrupteur met l’outil sous tension et hors tension.

AVERTISSEMENT : il est important de bien appuyer la pièce et de tenir l’outil fermement

afin d’en conserver la maîtrise et ainsi d’éviter des blessures corporelles.

Conseils pour une utilisation optimale

• Toujours utiliser le bon type de pointe de tournevis. Ne jamais utiliser de pointe de tournevis

sans le porte-pointe.

• Si les vis sont difficiles à serrer, appliquer une petite quantité de détergent à vaisselle ou de

savon comme lubrifiant.

• Utiliser la broche en position verrouillée pour desserrer des vis très serrées ou pour visser

fermement des vis.

• Toujours tenir l’outil et la pointe de tournevis en ligne droite avec la vis.

ENTRETIEN

Nettoyer l’outil au moyen d’un savon doux et d’un linge humide seulement. Ne jamais

laisser de liquide s’infiltrer à l’intérieur de l’outil ni tremper ce dernier dans un liquide

quelconque.

IMPORTANT : pour assurer la SÉCURITÉ et la FIABILITÉ de ce produit, toutes les

opérations de réparation, d’entretien et de réglage (autres que celles décrites aux

présentes) doivent être effectuées dans un centre de service autorisé ou par du

personnel qualifié; on ne doit utiliser que des pièces de rechange identiques.

DÉPANNAGE

Problème

Cause possible

Solution possible

• L’appareil refuse de • Pile non chargée. • Vérifier les exigences de

démarrer. charge pour la pile.

• La pile ne se charge pas. • Chargeur non branché. •Brancher le chargeur dans

une prise qui fonctionne. Se

reporter à la rubrique

« Remarques importantes

de chargement » pour plus

de renseignements.

•Vérifier le courant à la

prise en branchant une

lampe ou un autre appareil

électrique.

•Vérifier si la prise est reliée

à un interrupteur qui coupe

le courant au moment

d’éteindre la lumière

• Température ambiante • Déplacer le chargeur

trop chaude ou froide. et l’outil à une température

ambiante de plus de 4,5 °C

(40 °F) ou sous les 40,5 °C

(105 °F) 105 degree F

(+40,5°C).

Pour de l’aide avec l’outil, consulter notre site Web www.blackanddecker.com pour

l’emplacement du centre de réparation le plus près ou communiquer avec l’assistance

BLACK & DECKER au 1-800-544-6986.

ACCESSOIRES

Les accessoires recommandés pouvant être utilisés avec l’outil sont disponibles auprès de

votre distributeur local ou centre de réparation autorisé. Pour tout renseignement

concernant les accessoires, composer le : 1 800 544-6986.

AVERTISSEMENT : l’utilisation de tout accessoire non recommandé avec cet outil

pourrait s’avérer dangereuse.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

CONSERVE ESTE MANUAL PARA FUTURAS CONSULTAS.

ANTES DE DEVOLVER ESTE PRODUCTO POR

CUALQUIER MOTIVO, LLAME AL

(55)5326-7100

ANTES DE LLAMAR, TENGA ELNÚMERO DE CATÁLOGO Y ELCÓDIGO DE FECHA PREPARADOS. EN

LA MAYORÍA DE LOS CASOS, UN REPRESENTANTE DE BLACK & DECKER PUEDE RESOLVER EL

PROBLEMA POR TELÉFONO. SI DESEAREALIZAR UNA SUGERENCIA O COMENTARIO, LLÁMENOS.

SU OPINIÓN ES FUNDAMENTALPARA BLACK & DECKER.

¡G

¡G

RACIAS

RACIAS

POR

POR

ELEGIR

ELEGIR

B

B

LACK

LACK

& D

& D

ECKER

ECKER

!

!

V

V

AAYYAAAAWWW

WWW

.B

.B

LACKAND

LACKAND

D

D

ECKER

ECKER

.

.

COM

COM

/N

/N

EW

EW

O

O

WNER

WNER

PPARA

ARA

REGISTRAR

REGISTRARSUSU

NUEVO

NUEVO

PRODUCT

PRODUCTOO

.

.

Números de catálogo CSD300T

Normas generales de seguridad

ADVERTENCIA: Lea todas las instrucciones. El incumplimiento de las instrucciones

enumeradas debajo puede provocar descarga eléctrica, incendio o lesiones graves. El

término “herramienta eléctrica” incluido en todas las advertencias enumeradas a

continuación hace referencia a su herramienta eléctrica operada con corriente (alámbrica) o a su herramienta eléctrica operada con baterías (inalámbrica).

CONSERVE ESTAS INSTRUCCIONES

1) Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada.

Las áreas abarrotadas y

oscuras propician accidentes.

b) No opere herramientas eléctricas en atmósferas explosivas, como ambientes

donde se encuentran líquidos, gases o polvo inflamables.

Las herramientas

eléctricas originan chispas que pueden encender el polvo o los vapores.

c) Mantenga a los niños y espectadores alejados de la herramienta eléctrica en

funcionamiento.

Las distracciones pueden provocar la pérdida de control.

2) Seguridad eléctrica

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente.

Nunca modifique el enchufe de ninguna manera. No utilice ningún enchufe

adaptador con herramientas eléctricas con conexión a tierra.

Los enchufes no

modificados y que se adaptan a los tomacorrientes reducirán el riesgo de descarga

eléctrica.

Page 5

aserrar, esmerilar, taladrar y realizar demás actividades de la construcción. Use

indumentaria protectora y lave las áreas expuestas con agua y jabón. Evite que el

polvo entre en la boca y en los ojos o se deposite en la piel, para impedir la absorción

de productos químicos nocivos.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar partículas

de polvo, que pueden causar lesiones respiratorias permanentes y graves u otras

lesiones. Use siempre protección respiratoria aprobada por NIOSH/OSHA (Instituto

Nacional de Salud y Seguridad Ocupacional de EE.UU./Administración de la Salud y

Seguridad Ocupacional de EE.UU.) apropiada para la exposición al polvo. Aleje las

partículas de la cara y el cuerpo.

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La información que contiene se relaciona con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS. Los

símbolos que siguen se utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará la muerte

o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita, provocará la

muerte o lesiones graves.

PRECAUCIÓN: indica una situación de peligro potencial que, si no se evita, provocará

lesiones leves o moderadas.

PRECAUCIÓN: utilizado sin el símbolo de alerta de seguridad indica una situación de peligro

potencial que, si no se evita, puede provocar daños en la propiedad.

La etiqueta de su herramienta puede incluir los siguientes símbolos. Los símbolos y sus

definiciones son los siguientes:

V ..............voltios A ............amperios

Hz ............hertz W ............vatios

min............minutos ..........corriente alterna

..........corriente continua

n

o............no velocidad sin carga

..............

Construcción de clase II

........

terminal a tierra

............

símbolo de alerta de .../min ......revoluciones o reciprocidad por minuto

seguridad

Descripción de las funciones

1. Eje

2. Interruptor de encendido/apagado

3. Botón de avance/reversa

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD:

CÓMO CARGAR

1. Este manual contiene instrucciones de seguridad y operación importantes.

2. Antes de utilizar el cargador de la batería, lea todas las instrucciones y las

indicaciones de precaución en el cargador de la batería, el paquete de baterías, y el

producto que utiliza el paquete de baterías.

3. PRECAUCIÓN: para reducir el riesgo de daños personales, cargue sólo baterías

Black & Decker. Otros tipos de baterías pueden estallar y provocar daños

personales y materiales.

4. No exponga el cargador a lluvia o nieve.

5. El uso de un accesorio no recomendado o vendido por Black & Decker podría

resultar en riesgo de incendio, descarga eléctrica o lesiones corporales.

6. Para reducir el riesgo de daño al enchufe y cable de alimentación, jale del enchufe

y no del cable cuando desconecte el cargador.

7. Asegúrese que el cable no sea ubicado de manera que podría ser pisado, causar

que alguien tropiece con él o ser expuesto a otro tipo de daños.

8. No se debería usar un alargador a no ser que sea absolutamente necesario. El uso

de un alargador incorrecto podría resultar en riesgo de incendio, descarga eléctrica

o electrocución.

a. Cables de dos hilos pueden ser usados con alargadores de 2 ó 3 hilos. Sólo se

deben usar alargadores con revestimiento redondo y recomendamos que además se

encuentren en la lista de Underwriters Laboratories (U.L.). Si el alargador será

utilizado en la intemperie, el cable debe ser adecuado para uso exterior. Cualquier

cable marcado para uso exterior es también adecuado para uso interior. Las letras

"W" o "WA" en el revestimiento del cable indican que el cable puede ser usado en

la intemperie.

b. Los hilos del alargador deben ser de un calibre apropiado (AWG o American Wire

Gauge) para su seguridad y para evitar la pérdida de potencia y sobrecalentamiento.

Mientras menor sea el calibre del hilo, mayor la capacidad del cable. Es decir, un

hilo calibre 16 tiene mayor capacidad que uno de 18. Cuando se utilice más de un

alargador para completar el largo total, asegúrese que los hilos de cada alargador

tengan el calibre mínimo.

9. Utilice únicamente el cargador provisto cuando carga su herramienta. El uso de

cualquier otro cargador puede dañar la herramienta o provocar una condición de riesgo.

10. Sólo use un cargador cuando la cargue.

11. No intente abrir el cargador. No contienen piezas que puedan ser reparadas por el

usuario. Devuelva a cualquier centro de servicio Black & Decker autorizado.

12. NO incinere el paquete de baterías aunque esté muy averiado o completamente

gastado. La batería puede explotar en el fuego.

13. En condiciones de uso, de carga o de temperaturas extremas, podría producirse una

pequeña pérdida de líquido en las celdas del paquete de baterías. Esto no indica una

falla. Sin embargo, si el sello externo está roto y esta pérdida toca su piel:

a. Lave rápidamente con jabón y agua.

b. Neutralice con un ácido suave como jugo de limón o vinagre.

c. Si el líquido de la batería le entra a los ojos, lávelos con agua limpia por al menos

10 minutos y hágase ver por un médico de inmediato. NOTA MÉDICA: El líquido es

una solución de 25-35% de hidróxido de potasio.

PROCEDIMIENTO DE CARGA

IMPORTANTE: Las baterías en la herramienta no vienen completamente cargadas de

fábrica. Antes de intentar cargarlas, lea atentamente todas las instrucciones de seguridad.

Para cargar la herramienta, siga los pasos a continuación:

1. Inserte un enchufe hembra (5) del cargador (4) en el puerto de carga (6) en la parte

inferior del mango de la herramienta como se muestra en la figura B.

2. Enchufe el cargador en cualquier tomacorriente eléctrico estándar de 120 voltios, 60 Hz.

3. Permita que, para la primera vez, la herramienta se cargue durante 17 horas.

ADVERTENCIA: Cuando desconecte la herramienta del cargador, primero asegúrese de

desenchufar el cargador (6) del tomacorriente y luego desconecte el enchufe hembra (5)

de la herramienta.

NOTAS IMPORTANTES SOBRE LA CARGA

1. El cargador funcionará mejor a temperatura ambiental normal.

2. El enchufe del cargador y el mango de la herramienta pueden estar calientes durante

la carga. Esto es normal y no indica un problema.

3. Se requiere un tiempo mínimo de carga de 17 horas para recargar una herramienta

descargada por completo.

4. Para la mayoría de los trabajos de reparación un tiempo de carga más corto puede ser

adecuado.

INSTRUCCIONES Y ADVERTENCIAS DE SEGURIDAD: TALADRADO

• Sostenga la herramienta con firmeza para controlar la torsión.

ADVERTENCIA: la herramienta puede atascarse (si se sobrecarga o se usa

inadecuadamente) y provocar una torsión. Para reducir el riesgo de lesiones espere

siempre el atascamiento. Sujete la herramienta con firmeza para controlar la torsión y

evitar la pérdida de control que podría ocasionar lesiones personales. En caso de que la

herramienta se atasque, suelte el disparador inmediatamente y determine la causa del

atascamiento antes de encenderla nuevamente.

b) Evite el contacto corporal con superficies puestas a tierra, como por ejemplo

tuberías, radiadores, rangos y refrigeradores.

Existe mayor riesgo de descarga

eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de

humedad.

Si ingresa agua a una herramienta eléctrica, aumentará el riesgo de

descarga eléctrica.

d) No maltrate al cable. Nunca utilice el cable para transportar, tirar o

desenchufar la herramienta eléctrica. Mantenga el cable lejos del calor, aceite,

bordes afilados o piezas móviles.

Los cables dañados o enredados aumentan el

riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador

adecuado para tal uso.

Utilice un cable adecuado para uso en exteriores a fin de

reducir el riesgo de descarga eléctrica.

3) Seguridad personal

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica

si está cansado o bajo el efecto de drogas, alcohol o medicamentos.

Un

momento de descuido mientras se opera una herramienta eléctrica podría provocar

daños personales graves.

b) Use equipo de seguridad. Siempre utilice protección para los ojos.

El equipo de

seguridad, como las máscaras para polvo, el calzado de seguridad

antideslizante, los cascos o la protección auditiva utilizados para condiciones

adecuadas reducirán las lesiones personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de enchufar la herramienta.

Transportar

herramientas eléctricas con su dedo apoyado sobre el interruptor o enchufar

herramientas eléctricas con el interruptor en posición de encendido puede propiciar

accidentes.

d) Retire las clavijas de ajuste o llaves de tuercas antes de encender la

herramienta eléctrica

. Una llave de tuercas o una clavija de ajuste que se deje

conectada a una pieza giratoria de la herramienta eléctrica pueden provocar

lesiones personales.

e) No se estire. Conserve el equilibrio adecuado y manténgase parado

correctamente en todo momento.

Esto permite un mejor control de la herramienta

eléctrica en situaciones inesperadas.

f) Vístase apropiadamente. No use ropas holgadas ni joyas. Mantenga el cabello,

las ropas y los guantes alejados de las piezas móviles. Las ropas holgadas, las

joyas o el cabello largo pueden quedar atrapados en las piezas móviles.

Los

orificios de ventilación suelen cubrir piezas móviles, por lo que también se deben evitar.

g) Si se suministran dispositivos para la conexión de accesorios para la

recolección y extracción de polvo, asegúrese de que estén conectados y se

utilicen correctamente.

El uso de estos dispositivos puede reducir los peligros

relacionados con el polvo.

4) Uso y mantenimiento de la herramienta eléctrica

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta

para el trabajo que realizará.

La herramienta eléctrica correcta hará el trabajo

mejor y más seguro a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el

interruptor.

Toda herramienta eléctrica que no puede ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

c) Desconecte el enchufe de la fuente de energía y/o el paquete de baterías de la

herramienta eléctrica antes de realizar ajustes, cambiar accesorios o

almacenar herramientas eléctricas.

Estas medidas de seguridad preventivas

reducen el riesgo de encender la herramienta eléctrica en forma accidental.

d) Guarde las herramientas eléctricas que no están en uso fuera del alcance de

los niños y no permite que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta.

Las herramientas eléctricas son

peligrosas en las manos de usuarios no entrenados.

e) Mantenimiento de las herramientas eléctricas. Controle que no haya piezas

móviles mal alineadas o trabadas, piezas rotas y toda otra situación que

pueda afectar el funcionamiento de las herramientas eléctricas. Si encuentra

daños, haga reparar la herramienta eléctrica antes de utilizarla.

Se producen

muchos accidentes a causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias.

Las herramientas de

corte con mantenimiento adecuado, con los bordes de corte afilados son menos

propensas a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y de la forma prevista para el tipo de

herramienta eléctrica en particular, teniendo en cuanta las condiciones de

trabajo y el trabajo que debe realizarse.

El uso de la herramienta eléctrica para

operaciones diferentes de aquéllas para las que fue diseñada puede provocar una

situación peligrosa.

5) Uso y mantenimiento de la herramienta con baterías

a) Asegúrese de que el interruptor esté en la posición de apagado antes de

insertar el paquete de baterías.

Insertar el paquete de baterías en las herramientas

eléctricas con el interruptor encendido puede provocar accidentes.

b) Recargue solamente con el cargador especificado por el fabricante.

Un cargador

adecuado para un tipo de paquete de baterías puede originar riesgo de incendio si se

utiliza con otro paquete de baterías.

c) Utilice herramientas eléctricas sólo con paquetes de baterías específicamente

diseñados.

El uso de cualquier otro paquete de baterías puede producir riesgo de

incendio y lesiones.

d) Cuando no utilice el paquete de baterías, manténgalo lejos de otros objetos

metálicos como sujetapapeles, monedas, llaves, clavos, tornillos u otros objetos

metálicos pequeños que puedan realizar una conexión desde un terminal al otro.

Los cortocircuitos en los terminales de la batería pueden provocar quemaduras o

incendio.

e) En condiciones abusivas, el líquido puede ser expulsado de la batería. Evite su

contacto. Si entra en contacto accidentalmente, enjuague con agua. Si el líquido

entra en contacto con sus ojos, busque atención médica.

El líquido expulsado de

la batería puede provocar irritación o quemaduras.

6) Mantenimiento

a) Haga que una persona de reparaciones calificada realice el mantenimiento de

su herramienta eléctrica y utilice piezas de repuesto idénticas solamente.

Esto

garantizará la seguridad de la herramienta eléctrica.

b) Si necesita un cable de alimentación de repuesto,

debe adquirirlo a través del

fabricante o su agente para evitar un riesgo de seguridad.

Normas de seguridad específicas

• Sujete la herramienta por sus empuñaduras aisladas si lleva a cabo una

operación en que la herramienta pueda tocar cables eléctricos ocultos o su

propio cable.

El contacto con un cable activo provocará que las piezas metálicas de

la herramienta se carguen y que el operador reciba una descarga eléctrica.

• Use abrazaderas u otra manera práctica de fijar y sujetar la pieza de trabajo a

una plataforma estable.

No sujete su trabajo en forma manual o contra su cuerpo

pues no quedará estable y podrá perder el control.

ADVERTENCIA: Algunas partículas originadas al lijar, aserrar, amolar, taladrar y

realizar otras actividades de construcción contienen productos químicos que

producen cáncer, defectos de nacimiento y otros problemas reproductivos. Algunos

ejemplos de estos productos químicos son:

• el plomo de las pinturas de base plomo,

• la sílice cristalina de ladrillos, cemento y otros productos de mampostería,

• el arsénico y el cromo de la madera con tratamiento químico (CCA).

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice

este tipo de trabajo. Para reducir la exposición a estos productos químicos: se recomienda trabajar en áreas bien ventiladas y usar equipos de seguridad aprobados, como las

máscaras para polvo especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con las partículas de polvo originadas al lijar,

Page 6

EL SELLO RBRC™

El sello RBRC™ (Corporación de reciclado de baterías recargables)

que se encuentra sobre la batería de níquel-cadmio (o paquete de batería)

indica que los costos para reciclar la batería (o el paquete de batería) al final

de su vida útil ya han sido pagados por Black & Decker. En algunas zonas,

es ilegal tirar las baterías usadas de níquel-cadmio en la basura o en el flujo de desechos sólidos del municipio. El programa RBRC proporciona una alternativa de conciencia sobre el cuidado del medio ambiente.

RBRC en cooperación con Black & Decker y otros usuarios de baterías, estableció programas en los Estados Unidos y Canadá para facilitar la recolección de baterías de

níquel-cadmio ya usadas. Ayude a proteger nuestro medio ambiente y a conservar los

recursos naturales devolviendo las baterías de níquel-cadmio ya usadas a un centro de

mantenimiento autorizado Black & Decker o a un comerciante minorista para que sean

recicladas. También puede comunicarse con el centro de reciclado para obtener información o dónde dejar las baterías, o llame al 1-800-8-BATTERY.

INFORMACIÓN DE MANTENIMIENTO

Todos los Centros de mantenimiento de Black & Decker cuentan con personal altamente

capacitado dispuesto a brindar a todos los clientes un servicio eficiente y confiable en la

reparación de herramientas eléctricas. Si necesita consejo técnico, reparaciones o piezas

de repuesto originales de fábrica, póngase en contacto con el centro de mantenimiento

de Black & Decker más cercano a su domicilio. Para ubicar su centro de servicio local,

consulte la sección “Herramientas eléctricas” (Tools-Electric) de las páginas amarillas,

llame al (55)5326-7100 o visite nuestro sitio www.blackanddecker.com.

GARANTÍA COMPLETA DE DOS AÑOS PARA USO EN EL HOGAR

Black & Decker (Estados Unidos) Inc. ofrece una garantía de dos años por cualquier

defecto del material o de fabricación de este producto. El producto defectuoso se

reparará o reemplazará sin costo alguno de dos maneras.

La primera opción, el reemplazo, es devolver el producto al comercio donde se lo adquirió

(siempre y cuando se trate de un comercio participante). Las devoluciones deben realizarse

conforme a la política de devolución del comercio (generalmente, entre 30 y 90 días

posteriores a la venta). Le pueden solicitar comprobante de compra. Consulte en el

comercio acerca de la política especial sobre devoluciones una vez excedido el plazo

establecido.

La segunda opción es llevar o enviar el producto (con flete pago) a un Centro de

mantenimiento propio o autorizado de Black & Decker para su reparación o reemplazo

según nuestro criterio. Le pueden solicitar el comprobante de compra. Los Centros de

mantenimiento autorizados y de propiedad de Black & Decker se detallan en la sección

“Herramientas eléctricas” (Tools-Electric) de las páginas amarillas de la guía telefónica.

Esta garantía no se extiende a los accesorios. Esta garantía le concede derechos legales

específicos; usted puede tener otros derechos que pueden variar según el estado o la

provincia. Si tiene alguna pregunta, comuníquese con el gerente del Centro de

mantenimiento de Black & Decker de su zona. Este producto no está diseñado para uso

comercial.

REEMPLAZO GRATUITO DE LAS ETIQUETAS DE ADVERTENCIAS: si sus etiquetas

de advertencia se tornan ilegibles o faltan, llame al (55)5326-7100 para que se le

reemplacen gratuitamente.

IMPORTADO: BLACK & DECKER

S.A. DE C.V.

BOSQUES DE CIDROS ACCESO

RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. (55)53-26-71-00

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Especificaciones

Cargador: 120V AC ~ 60Hz 5W

Salida: 4,2V AC 100mA

CULIACAN, SIN

Av. Nicolás Bravo #1063 Sur

(667) 7 12 42 11

Col. Industrial Bravo

GUADALAJARA, JAL

Av. La Paz #1779

(33) 3825 6978

Col. Americana Sector Juarez

MEXICO, D.F.

Eje Central Lázaro Cardenas

No. 18

(55) 5588 9377

Local D, Col. Obrera

MERIDA, YUC

Calle 63 #459-A

(999) 928 5038

Col. Centro

MONTERREY, N.L.

Av. Francisco I. Madero

No.831

(81) 8375 2313

Col. Centro

PUEBLA, PUE

17 Norte #205

(222) 246 3714

Col. Centro

QUERETARO, QRO

Av. Madero 139 Pte.

(442) 214 1660

Col. Centro

SAN LUIS POTOSI, SLP

Av. Universidad 1525

(444) 814 2383

Col. San Luis

TORREON, COAH

Blvd. Independencia, 96 Pte.

(871) 716 5265

Col. Centro

VERACRUZ, VER

Prolongación Díaz Mirón #4280

(229)921 7016

Col. Remes

VILLAHERMOSA, TAB

Constitución 516-A

(993) 312 5111

Col. Centro

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

Para reparación y servicio de sus herramientas eléctricas, favor de dirigirse

al Centro de Servicio más cercano:

INSTRUCCIONES DE OPERACIÓN

INSTALACIÓN Y RETIRO DE PUNTAS

• Inserte la broca eléctrica hexagonal o punta de broca con el sujetador de brocas en la

cavidad del eje (1) hasta que se fije en su lugar.

• Para retirar la broca, hale de ella hacia afuera. Si la broca no se adapta al eje, gire la broca y

vuelva a insertarla. No inserte una punta de broca sin un sujetador de puntas de broca.

INTERRUPTOR DISPARADOR Y BOTÓN DE AVANCE/REVERSA

La herramienta se ENCIENDE (ON) y se APAGA (OFF) tirando de y liberando el interruptor

disparador (2). El botón de control de avance/reversa (3) determina la dirección de la

herramienta y también sirve como botón de bloqueo.

• Para seleccionar la rotación de avance, libere el interruptor disparador y presione el botón

de avance/reversa hacia adelante, como se muestra en la figura D.

• Para seleccionar la rotación en reversa, libere el interruptor disparador y tire del botón de

avance/reversa hacia atrás, como se muestra en la figura D.

• La posición neutral (sin funcionamiento) del botón bloquea la herramienta en la posición de

apagado. Al cambiar la posición del botón, asegúrese de que el disparador esté liberado.

TALADRADO

• Use solamente brocas para taladro afiladas.

• Las brocas de taladro para metal se pueden usar para perforar orificios en madera. Estas

brocas deben estar afiladas y se deben retirar con frecuencia mientras se taladra para

limpiar las virutas de las ranuras.

• Sostenga y asegure el trabajo adecuadamente, según se indica en las instrucciones de

seguridad.

• Utilice equipos de seguridad adecuados y necesarios, como se indica en las instrucciones

de seguridad.