Page 1

WARNING: For your own safety read instruction manual before operating tool.

Grounding Instructions

In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances. Do not modify plug provided—if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

Repair or replace damaged or worn cords immediately.

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in

Figure A. The tool has a grounding plug that looks like the plug illustrated in Figure A. A

temporary adapter, which looks the adapter illustrated in Figures B and C, may be used to

connect this plug to a 2-pole receptacle as shown in Figure B if a properly grounded outlet is

not available. The temporary adapter should be used only until a properly grounded outlet

can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like,

extending from the adapter must be connected to a permanent ground such as a properly

grounded outlet box.

WARNING:Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

Important Safety Instructions

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys

and adjusting wrenches are removed from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet

locations, or expose them to rain. Keep work area well lighted.

• KEEP CHILDREN AWAY.All visitors should be kept safe distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter

keys.

• DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When using and extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

• OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets,

or other jewelry which may get caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

• ALWA YS USE SAFETYGLASSES.Also use face or dust mask if cutting operation is dusty .

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest per-

formance. Follow instructions for changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits,

cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position

before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON T OOL. Serious injury could occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function–check for alignment of moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that may affect its operation. Aguard or other

part that is damaged should be properly repaired or replaced.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool

until it comes to a complete stop.

ADDITIONAL SAFETY RULES FOR SCROLL SAWS

• MATERIALHOLD-DOWN must be properly set according to these instructions and remain

in position during use.

• NEVER reach under the table when operating or make any adjustments when it is running.

• SECURE saw to work bench or stand with clamps or mounting hardware. Secure work

bench or stand to floor.

• DO NOT use the upper arm as a lifting point.

• MAKE SURE blade tension is properly adjusted.

• AVOID awkward hand positions where a sudden slip could cause a hand to move into a saw

blade or cutting tool. DO NOT PLACE FINGERS OR HANDS IN PATH OF THE SAW

BLADE.

• WHEN REMOVING short workpieces, or cleaning up around the table, be sure the saw is in

the OFF position and blade has stopped moving.

• NEVER turn the saw ON before clearing the table of all tools, wood scraps, etc., except the

workpiece and related feed or support devices for the operation planned.

• CHECK for proper blade size and type.

• DO NOT attempt to saw stock that does not have a flat surface, unless a suitable support is

used.

• HOLD material firmly against table and feed into blade teeth at a moderate speed.

• TURN OFF motor if the material resists being backed out of an uncompleted cut. Use

appropriate speed for applications.

• MAKE “relief” cuts before cutting long curves.

• USE a dust mask and safety glasses when sawing.

• KEEP GUARDS in place and working order.

• MAKE SURE your fingers do not contact the terminals of the power cord when installing or

removing the plug to or from the line power source.

• NEVER overfeed or force work into the blade.

• WARNING: Do not allow familiarity (gained from frequent use of your saw) to replace

following safety rules. Always remember that a careless fraction of a second is sufficient to

inflict severe injury.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

KEY INFORMATION YOU SHOULD KNOW:

• For best performance, secure saw to work bench or stand with clamps or mounting

hardware. Secure work bench or stand to floor.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZADE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR ELPRODUCTO.

INSTRUCTION MANUAL

Catalog Number BT4000

Catalog No. BT4000 Form No. 398178-00 (JUL00-1) Copyright © 2000 Black & Decker Printed in Taiwan

R

11116666”””” VVVVAAAARRRRIIIIAAAABBBBLLLLEEEESSSSPPPPEEEEEEEEDDDDSSSSCCCCRRRROOOOLLLLLLLLSSSSAAAAWW

WW

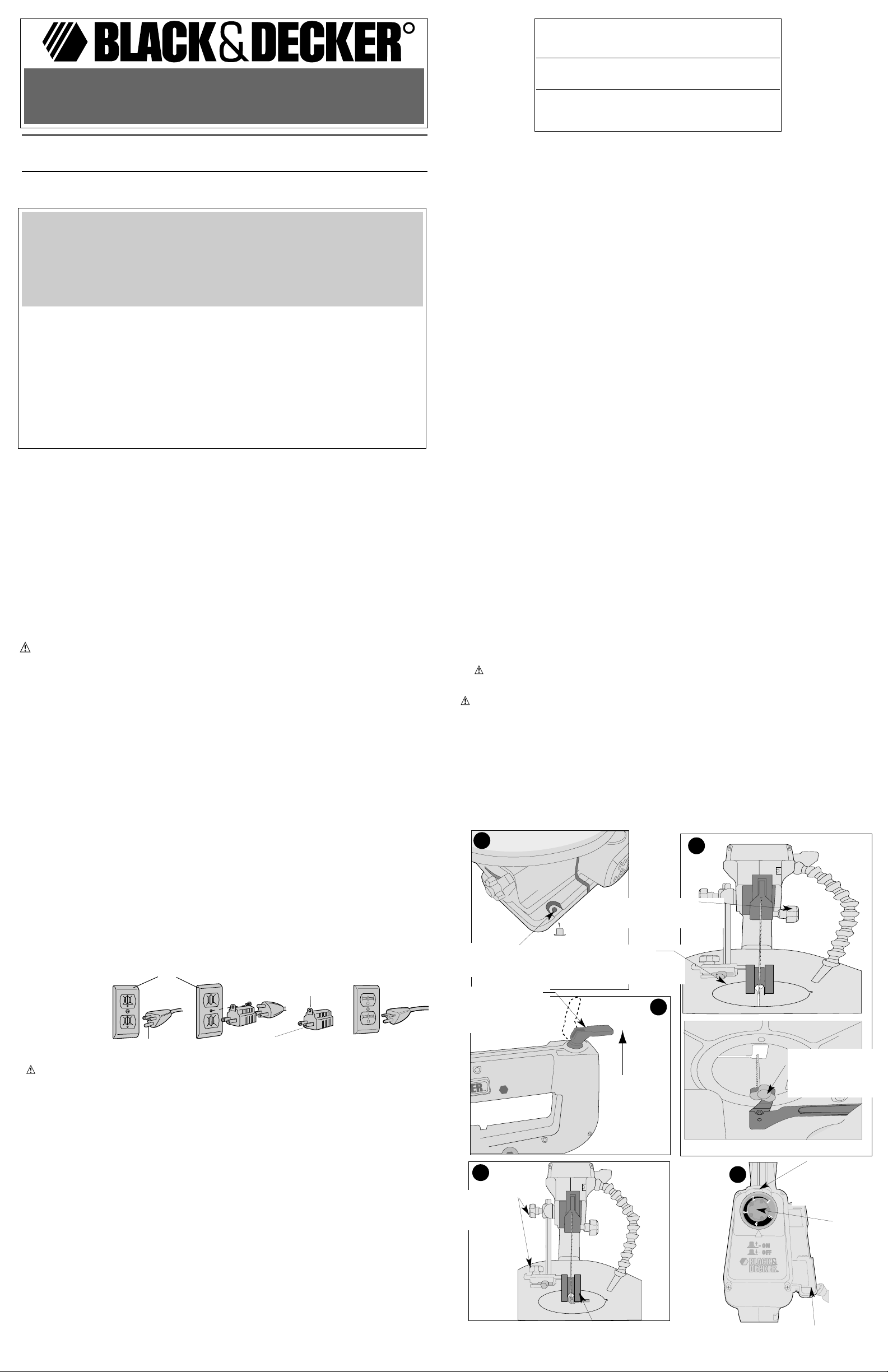

1

3

4

5

Mounting Hole

Orifice de montage

Perforación para montaje

2

Bottom Thumbscrew

Vis à oreilles

inférieure

Tornillo de mariposa

inferior

Top Thumbscrew

Vis à oreilles supérieure

Tornillo de mariposa superior

Blade Tension Lever

Levier de réglage de

tension de la lame

Palanca de tensión de

la sierra

Table Insert

Plaquette amovible du

plateau

Mesa amovible

Material Hold Down / Guard

Dispositif de fixation du matériau

Sujetador del material

Thumbscrews

Vis à oreilles

Tornillos de

mariposa

Pad Lock Slot

Orifice pour

cadenas

Ranura de bloqueo

de la placa

Blade Storage Tray

Bac de rangement des lames

Bandeja de almacenamiento de sierras

Switch

Interrupteur

Interruptor

AB C

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

ADAPTER-(NOT APPLICABLE IN CANADA)

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PURCHASE,

CALL 1-800-54-HOW-TO (1-800-544-6986).

IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT,

GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO THE SUCCESS OF BLACK & DECKER'S QUALITY

IMPROVEMENT PROGRAM.

(544-6986)

Page 2

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

Motor

Be sure the power supply agrees with nameplate marking. 120 Volts AC only means your tool

will operate on standard 60 Hz household power. Do not operate AC tools on DC. A rating of

120 volts AC/DC means that your tool will operate on standard 60 Hz AC or DC power. This

information is printed on the nameplate. Lower voltage will cause loss of power and can result

in over-heating. All Black & Decker tools are factory-tested; if this tool does not operate, check

the power supply.

Unpacking Y our Saw

Check the contents of your scroll saw carton to make sure that you have received all parts. In

addition to this instruction manual, the carton should contain one No. BT4000 scroll saw and

the following:

- (12) assorted blades (1 already installed on unit)

- (1) zero clearance table insert

- (1) pattern book / helpful hints

- (3) rubber mounting feet

Mounting

Three holes are provided in the base of the scroll saw to facilitate mounting to a table or

bench (Figure 1). Place three rubber mounting feet from hardware bag into the three mounting holes. Always mount your saw firmly to prevent movement. Do not over tighten mounting

bolts. Leave some cushion in the rubber feet for absorbing noise and vibration.

Aligning the Blade With the table Top

This is most easily accomplished with a carpenter’s tri-square. Begin by installing a blade in

the saw. Next, place the tri-square on the table top, close to the blade. Observe the alignment of the blade to the edge of the square. The blade should be vertically parallel to the trisquare edge. If it is not, you need to adjust the zero degree stop as described in the following paragraph.

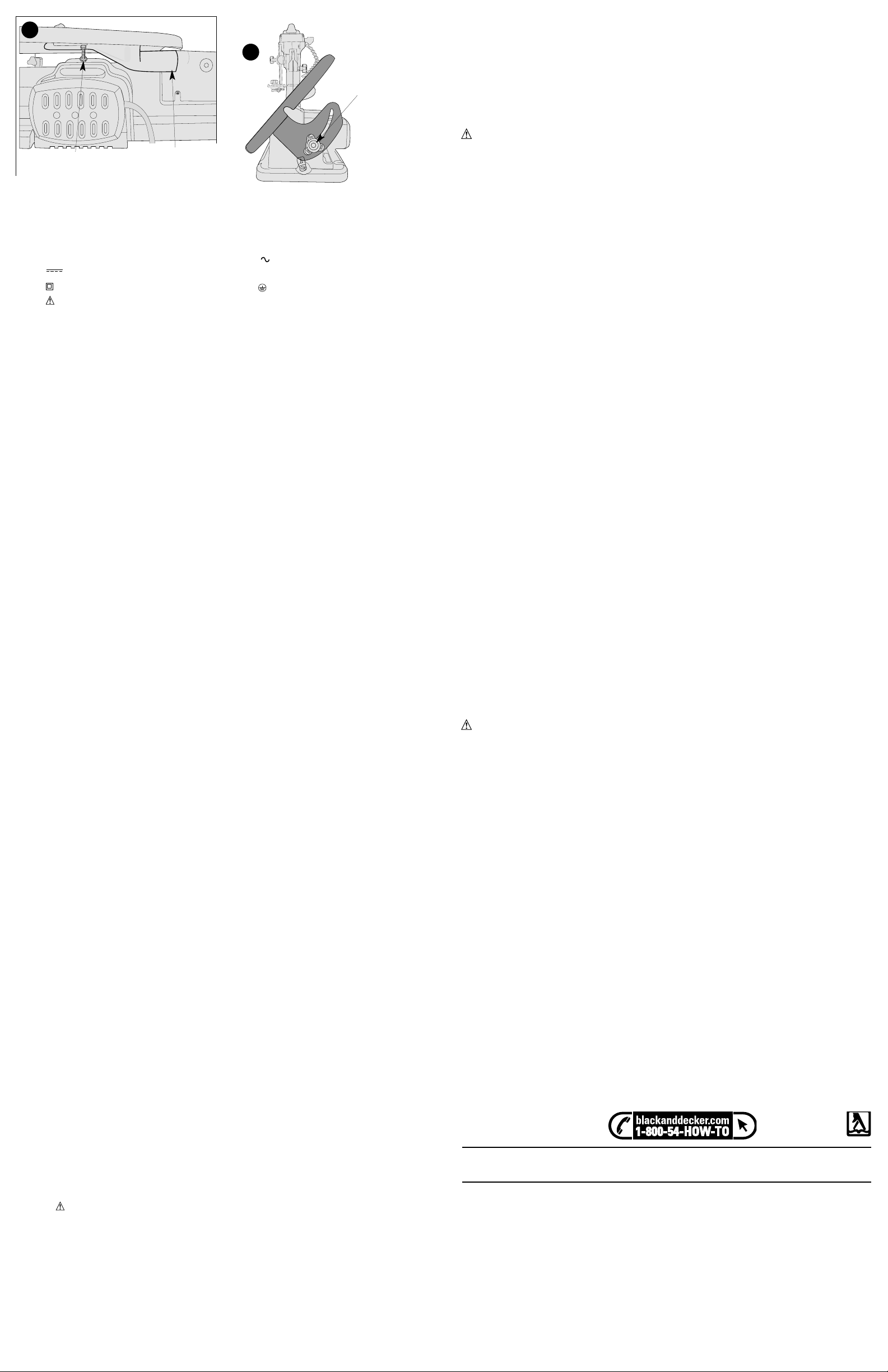

Adjusting the Zero Degree Stop

The zero degree stop is located on top of the motor housing on the right side of the saw

below the table (Figure 6). The stop is preset at the factory to have the table rest at 0˚. To

adjust the zero degree stop, tilt the table to 45˚. Loosen the nut, located at the bottom of the

bolt. The bolt can then be turned to correctly align the table at 0˚. Tilt the table to the right

until it stops on the bolt. Re-check the alignment of the blade with the table top. If the alignment is correct, tighten the nut finger tight.

To allow the table to tilt 1˚ or 2˚ to the right, turn the zero degree stop completely clockwise.

Installing the Blade

BEFORE INSTALLING A BLADE, UNPLUG THE SCROLL SAW.

The blade is held in place by the thumbscrew blade clamps attached to the top and bottom

arms of the scroll saw (Figure 2).

Before installing a blade, make sure the blade tension lever is rotated upward as shown in

Figure 3. Remove the table insert and loosen, but do not unscrew, the top and bottom thumbscrews (Figure 2). Thread the blade through the hole in table, with the teeth facing toward

the front of the saw. NOTE: Scroll saws cut on the downstroke, so it is essential that teeth

face forward and down.

Insert the blade into the bottom blade clamp and securely tighten the thumbscrew. Reinstall

table insert. Next, insert the top of the blade into the top blade clamp and securely tighten

the top thumbscrew.

Properly adjust the tension of the blade before operating your scroll saw. (See: Blade Tension

Lever section of this manual.)

Blade Tension Lever

Move the blade tension lever (Figure 3) downward to tension the blade.

NOTE: The lever should move downward with a steady even pressure. The blade is too tight

if excessive pressure is needed.

TO FINE ADJUST THE TENSION ON THE BLADE FOLLOW THE STEPS

BELOW.

1.) To decrease tension, rotate the tension lever counterclockwise 1 or 2 turns.

2.) If the blade is too loose the tension can be increased by leaving the lever in the down

position and turning it clockwise until you feel the tension increase on the blade.

The proper degree of tension varies with different blade sizes. If you are frequently breaking

blades, decrease tension on the blade.

As you become more accustomed to operating your scroll saw, you will become more proficient

in fine-tuning blade tension. Practice on scrap material when possible.

Remove the blade or release tension on the blade when not using your scroll saw for an

extended period. Blade tension can be removed by flipping the blade tension lever up. Be sure

to place the blade tension lever in its downward position again before turning saw on.

Material Hold-down / Guard

The material hold-down (Figure 4) should contact the surface of the workpiece. To adjust the

material hold-down / guard, loosen the thumbscrew (Figure 4) and move the rod up or down.

The material hold-down / guard must be beveled when the table is beveled. To bevel the

material hold-down / guard, loosen the thumbscrew shown in Figure 4 and bevel the material hold-down / guard until it is parallel to the table. Retighten the material hold-down / guard

before cutting.

Your scroll saw has a maximum thickness capacity of 2" at 0˚. Do not cut material thicker

than 2". CAUTION: NEVER remove the material hold-down since it also functions as a

barrier between fingers and blade. This is especially important when cutting metals; sharp

edges may be present

Air Hose

Your scroll saw features an adjustable air hose to keep your work area free from dust and

debris. Be sure to position the air hose properly: it should blow saw dust away from the operator.

On/Off Switch

To turn the scroll saw on, pull up on the switch shown in Figure 5. To turn the tool off, push

down on the switch. Aslot is provided for insertion of a padlock to lock the saw off (Figure 5).

NOTE: The pad lock shackle diameter should be between 3/16” and 7/32”.

GUIDE D’UTILISATION

Speed Control Knob

Your scroll saw features a variable speed control, from 400 to 1,700 strokes per minute. To

operate the variable speed feature, turn the speed control knob (Figure 5).

To increase the speed, turn the knob clockwise. The numbers on the speed control knob

represent speed ranges. 1 is the minimum speed, 5 is the maximum speed.

Slower speeds are recommended for metals, plastics, harder woods and very thin materials.

Sawing

Hold material firmly against table. Always feed material toward the blade. Feed the workpiece

fast enough to allow the blade to cut, but do not force material into the blade too quickly.

CAUTION: The scroll saw should be used to cut wood, wood-like products, plastics

and nonferrous metals (aluminum, copper, brass etc.) only. DO NOT use for cutting ferrous

metals such as iron and steel. Note that when cutting nonferrous metals, the hot metal

shavings can cause a fire when coming in contact with sawdust.

When sawing nonferrous metals:

• V acuum all sawdust from inside and under the saw before use.

• Vacuum all traces of metal dust (after it has completely cooled) from inside and under the

saw before using saw to cut wood, etc.

Sawdust Collection Port

A sawdust collection port is located on the side of the saw as shown in Figure 6. To use the

port, attach a 1-1/4” vac hose to the opening.

NOTE: Through normal use sawdust accumulates under the saw. Frequently clean sawdust

from under the unit to prevent the linkage from binding, which could overload and damage the

motor. A hole can also be cut in the bench or stand below the lower blade clamp in such a manner that will not allow sawdust to accumulate under the tool.

Beveling

The table of your scroll saw bevels 47° left and -2° right. Astop is set at 0°. To bevel the scroll

saw table, loosen the bevel lock knob (Figure 7), and bevel the table to the desired setting,

indicated by the bevel pointer.

Fretwork

INSIDE CUTS

Y our scroll saw is ideal for making inside cuts for detail work. To make an inside cut:

1. Drill a pilot hole in your workpiece.

2. Make sure the blade tension lever is rotated upward to remove tension.

3. Loosen the top blade clamp knob.

4. Leaving the blade held in place by the bottom blade clamp, thread the saw blade through

the pilot hole in your workpiece and reattach the blade by tightening the top blade clamp

knob.

5. Readjust the blade tension and begin the inside cut.

Zero Clearance Table Insert

A Zero Clearance Table Insert (solid orange plastic circular disk) is included with the scroll

saw. It is designed to give maximum support to the underside of the workpiece and to prevent

small workpieces from falling into the saw.

When working with small workpieces with the table set at 0˚, remove the standard insert and

replace with the Zero Clearance Table Insert.

Before using, drill a hole in the center of the disk for the blade. You should drill the smallest

hole possible that will allow the blade to move freely.

Table

Keep the table clean and free from oil, grease and pitch. Treat the table with paste wax to

help maintain its smooth finish.

Blade Storage Tray

A convenient storage tray for blades is built into the top of the saw (Figure 5).

Accessories

Use only 5" plain end and pin scroll saw blades. Recommended accessories for use with your

tool are available at extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, please call:

1-800-54-HOW-TO (544-6986).

CAUTION: The use of any other accessory not recommended for use with this tool

could be hazardous.

Maintenance

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid. Dry table thoroughly to prevent rust.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service personnel, always using identical replacement parts.

Service Information

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact the

Black & Decker location nearest you. To find your local service location, refer to the yellow

pages directory under "Tools—Electric" or call: 1-800-54-HOW-TO (544-6986).

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of two

ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the sale).

Proof of purchase may be required. Please check with the retailer for their specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for repair or replacement at our option. Proof of purchase may be required.

Black & Decker owned and authorized Service Centers are listed under "Tools-Electric" in the

yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state. Should you have any questions, contact the manager of your nearest Black & Decker Service Center. This product is not intended

for commercial use.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

6

7

Zero Degree Stop

Butée de zéro degré

Posición a cero grados

Dust Collection Port

Orifice d’évacuation

Salida para

recolección del aserrín

Bevel Lock Knob

Bouton de

verrouillage

d’angle de biseau

Perilla de

bloqueo para

biselado

Mise à la terre

En cas de mauvais fonctionnement ou de bris de l’outil, la mise à la terre procure un chemin

de moindre résistance au courant électrique afin de minimiser les risques de secousses élec-

triques. Le cordon de l’outil comporte un conducteur de terre et une fiche de mise à la terre.

La fiche doit être branchée dans une prise de machine bien installée et mise à la terre conformément aux lois et règlements locaux. Ne pas modifier la fiche fournie. Lorsque la fiche

n’entre pas dans la prise, demander à un électricien qualifié d’installer une prise appropriée.

La mauvaise connexion du conducteur de terre de l’outil présente des risques de secousses

électriques. Le conducteur dont l’isolant est vert ou vert avec des lignes jaunes constitue la

mise à la terre. En cas de réparation ou de remplacement du cordon ou de la fiche, ne pas

relier le conducteur de terre à une borne sous tension.

Consulter un électricien qualifié ou le personnel des centres de service an cas d’incompréhension des instructions relatives à la mise à la terre ou en cas de doute quant à la mise

à la terre de l’outil.

Page 3

AVERTISSEMENT : Certains outils, tels que les sableuses électriques, les scies, les meules,

les perceuses ou certains autres outils de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on

retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit

bien ventilé et utiliser l’équipement de sécurité approprié tel un masque anti-poussières spé-

cialement conçu pour filtrer les particules microscopiques.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

Construction de classe II

........................borne de mise à la

minute

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

Moteur

On doit s’assurer que l’intensité nominale du cordon d’alimentation corresponde à celle

indiquée sur la plaque signalétique; sur cette dernière, la mention «120 V c.a.» signifie que

l’outil ne doit être branché que dans une prise résidentielle standard de courant alternatif de 60

Hz et non pas dans une prise de courant continu, alors que «120 V c.a. / c.c.» signifie que l’outil

peut fonctionner sur une prise standard de 60 Hz de courant alternatif ou continu. Une tension

inférieure à celle indiquée pourrait entraîner une perte de puissance et une surchauf fe. Tous les

outils Black & Decker sont soumis à des essais en usine; si cet outil ne fonctionne pas, on doit

d’abord vérifier l’intensité nominale du cordon d’alimentation.

Déballage

Vérifier le contenu de la boîte afin de s’assurer d’avoir bien reçu toutes les pièces. En plus du

manuel d’utilisation, la boîte devrait contenir une scie à découper no BT4000 ainsi que les élé-

ments suivants :

- (12) lames variées (dont une est déjà installée sur la scie);

- (1) plaquette amovible sans jeu;

- (1) guide avec conseils pratiques.

Assemblage

La base de la scie à découper est dotée de trois orifices qui en facilite la fixation à un plateau

ou un établi (fig. 1); la scie doit toujours être fixée solidement afin d’en éviter tout mouvement.

On doit serrer les boulons sans trop exercer de force afin de laisser suffisamment de jeu et permettre aux supports en caoutchouc d’absorber le bruit et les vibrations.

Alignement de la lame avec la surface du plateau

Afin de faciliter la tâche, on recommande d’utiliser une équerre de menuisier. Insérer d’abord

une lame dans la scie, puis mettre l’équerre sur la surface du plateau, près de la lame. Vérifier

si la lame est bien alignée avec le bord de l’équerre, c’est-à-dire si la lame, placée à la verticale, est parallèle à ce dernier. Si ce n’est pas le cas, il faut régler la butée de zéro degré en

suivant les directives du paragraphe suivant.

Réglage de la butée de zéro degré

La butée de zéro degré est située sur le dessus du carter du moteur, du côté droit de la scie,

sous le plateau (fig. 6); le plateau est réglé en usine à un angle de 0∞. Pour régler la butée,

incliner le plateau à un angle de 45∞, puis desserrer l’écrou situé sur la partie inférieure du

boulon. Tourner ensuite ce dernier jusqu’à ce que le plateau soit placé correctement, soit à un

angle de 0∞, puis pencher ce dernier vers la droite jusqu’à ce qu’il s’appuie contre le boulon.

Vérifier de nouveau l’alignement de la lame par rapport à la surface du plateau; s’il l’alignement

est correct, serrer l’écrou manuellement.

Pour permettre l’inclinaison du plateau vers la droite de 1∞ ou 2∞, tourner la butée complètement vers la droite.

Installation de la lame

AVANT D’INSTALLER LA LAME, DÉBRANCHER LA SCIE À DÉCOUPER.

La lame est fixée à la scie au moyen de brides de serrage à vis à oreilles, lesquelles sont

ancrées aux leviers inférieur et supérieur de la scie (fig. 2).

Avant d’installer la lame, on doit s’assurer que le levier de réglage de tension de la lame soit

orienté vers le haut, tel qu’illustré à la figure 3. Retirer la plaquette amovible du plateau, puis

desserrer légèrement les vis à oreilles inférieure et supérieure sans les enlever (fig. 2). Insérer

la lame dans l’orifice du plateau, en s’assurant que les dents soient orientées vers l’avant de la

scie. REMARQUE: puisque les scies à découper ont un mouvement descendant, il est important de toujours orienter les dents vers l’avant et vers le bas.

Insérer la lame dans la bride de serrage inférieure prévue à cette fin et bien serrer la vis à

oreilles. Remettre la plaquette amovible en place, puis insérer la partie supérieure de la lame

dans la bride de serrage supérieure, et bien serrer la vis à oreilles supérieure.

Régler la tension de la lame avant de faire fonctionner la scie (consulter la section concernant

le levier de réglage de tension de la lame du présent manuel).

Levier de réglage de tension de la lame

Déplacer le levier (fig. 3) vers le bas afin d’augmenter la tension de la lame.

POUR RÉGLER LA TENSION DE LA LAME AVEC PRÉCISION, SUIVRE LES ÉTAPES

INDIQUÉES CI-DESSOUS.

REMARQUE: on doit pouvoir déplacer le levier vers le bas en exerçant une légère pression

uniforme; si le levier devient difficile à abaisser, cela signifie que la lame est déjà trop serrée.

1)Pour réduire la tension, tourner le levier vers la gauche de 1 ou 2 tours, puis le remettre vers

le bas.

2)Si la lame n’est pas assez serrée, on peut augmenter la tension en laissant le levier vers le

bas et en le tournant vers la droite jusqu’à ce qu’on sente la tension s’accroître sur la lame.

3)Une fois qu’on a senti la tension augmenter, on doit tourner le levier d’un tour complet vers

la droite. La tension ainsi réglée devrait convenir à la majorité des travaux de coupe.

La tension requise varie selon la dimension de la lame utilisée. Si les lames utilisées ont tendance à se briser, il faut en réduire la tension.

Mieux on connaît la scie et son fonctionnement, mieux on sera en mesure de régler la tension

de la lame avec précision; on recommande de pratiquer sur des retailles lorsque cela est possible.

Retirer la lame ou en relâcher la tension lorsqu’on range la scie pour une longue période

(soulever le levier de réglage de tension); s’assurer cependant d’abaisser le levier avant de

mettre la scie en marche.

Dispositif de fixation du matériau à couper

Le dispositif de fixation du matériau (fig. 4) doit entrer en contact avec l’ouvrage. Pour régler le

dispositif, desserrer le bouton (fig. 4) et déplacer la tige vers le haut ou vers le bas. Le dispositif doit être placé de biais lorsque le plateau est en biseau. Pour ce faire, desserrer le bouton

(fig. 4), puis déplacer le dispositif jusqu’à ce qu’il soit parallèle au plateau. Resserrer le bouton

avant d’amorcer la coupe.

La scie est conçue pour couper des matériaux ne dépassant pas 51 mm (2 po); vérifier l’é-

paisseur de l’ouvrage avant de procéder.

MISE EN GARDE : afin d’éviter tout contact entre la lame et les doigts, on ne doit JAMAIS

retirer le dispositif de fixation puisqu’il sert aussi de dispositif de protection. Ceci est particulièrement important lorsqu’on coupe des métaux en raison de la présence possible de bords

tranchants

Tuyau à air

La scie à découper est munie d’un tuyau à air réglable destiné à éliminer la poussière et les

débris de la zone de travail; l’utilisateur doit s’assurer de bien fixer le tuyau afin qu’il puisse

évacuer la poussière de façon efficace.

Interrupteur de marche / arrêt

Pour faire démarrer la scie, tirer l’interrupteur (fig. 5) vers le haut; l’enfoncer pour arrêter l’outil.

Ce dernier est muni d’un orifice dans lequel on peut insérer un cadenas et ainsi bloquer la scie

en position d’arrêt (fig. 5).

REMARQUE: le diamètre de l’arceau du cadenas utilisé doit mesurer entre 4,8 et 5,5 mm (3/16

et 7/32 po).

Utiliser seulement des cordons de rallonge trifilaires dotés de fiche mise à la terre à trois

broches, ainsi que des prises à 3 orifices acceptant la fiche de l’outil.

Réparer ou remplacer immédiatement les cordons endommagés ou usés.

L ‘outil est conçu pour être branché sur un circuit dont les prises ressemblent à celle illustrée

à la figure A. L’outil comporte une fiche de terre qui ressemble à celle illustrée à la figure A.

On peut se servir d’un adaptateur temporaire (comme celui des figures B et C) pour brancher la fiche dans une prise à 2 orifices (fig. B) lorsqu’il n’y a pas de prise mise à la terre. Il faut

seulement se servir de l’adaptateur temporaire jusqu’à ce qu’un électricien certifié puisse

installer une prise mise à la terre appropriée. Il faut alors relier l’oreille rigide, la cosse ou tout

autre objet du genre de couleur verte à une mise à la terre permanente (comme à la boîte

d’une prise bien mise à la terre).

Importantes mesures de sécurité

• S’ASSURER QUE LES PROTECTEURS sont en place et en bon état.

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et des établis encombrés

peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils électriques de la pluie. Ne

pas s’en servir dans des endroits humides ou mouillés. Bien éclairer la surface de travail.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus à l’écart de l’aire de tra-

vail.

• RENDRE L’ATELIER SÛR POUR LES ENFANTSà l’aide de cadenas, de disjoncteurs, ou

en retirant les clés de mise en tension.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr et efficace, utiliser l’outil

à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil ou d’un accessoire le

rendement d’un outil de fabrication plus robuste.

• UTILISER DES CORDONS DE RALLONGE APPROPRIÉS. S’assurer que le cordon de

rallonge est en bon état. Lorsqu’on se sert d’un cordon de rallonge, s’assurer qu’il est de

calibre approprié pour la tension nécessaire au fonctionnement de l’outil. L’utilisation d’un

cordon de calibre inférieur occasionne une baisse de tension entraînant une perte de puissance et la surchauffe. Le tableau suivant indique le calibre approprié selon la longueur du

cordon et les mentions de la plaque signalétique de l’outil. En cas de doute, utiliser un cordon de calibre supérieur. Le chiffre indiquant le calibre est inversement proportionnel au

calibre du cordon.

• CORDONS DE RALLONGE POUR L’EXTÉRIEUR. Lorsque l’outil sert à l’extérieur, utilis-

er seulement des cordons de rallonge prévus à cet effet et portant la mention appropriée.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des vêtements amples, des

gants, des cravates, des bagues, des bracelets ou d’autres bijoux qui peuvent être happés

par les pièces en mouvement. Le port des chaussures à semelle antidérapante est recommandé. Protéger la chevelure si elle est longue.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Porter également un masque

respiratoire si le travail de coupe produit de la poussière. Des lunettes de correction de la

vue standard comportent seulement des verres résistant aux chocs; ce NE sont PAS des

lunettes de sécurité.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une position stable et garder

son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et affûtés pour qu’ils donnent

un rendement supérieur et sûr. Suivre les directives relatives à la remplacement des accessoires.

• DÉBRANCHER L’OUTIL avant de le réparer ou d’en changer un accessoire (comme une

lame, un foret ou un couteau).

• MINIMISER LES RISQUES DE DÉMARRAGES ACCIDENTELS. S’assurer que l’interrupteur est en position hors tension avant de brancher l’outil.

• UTILISER LES ACCESSOIRES RECOMMANDÉS. Consulter le guide d’utilisation afin de

connaître les accessoires recommandés. L’utilisation d’accessoires inappropriés présente

des risques de blessures.

• NE JAMAIS SE TENIR SUR L’OUTIL. Cela présente des risques de blessures graves si

l’outil bascule ou si on touche à la lame par inadvertance.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à utiliser l’outil, il faut véri-

fier si le protecteur ou toute autre pièce endommagée remplit bien la fonction pour laquelle il a été prévu. Vérifier l’alignement et les attaches des pièces mobiles, le degré d’usure

des pièces et leur montage, ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l’outil. Il faut réparer ou remplacer tout protecteur ou autre composant

endommagé.

• NE JAMAIS LAISSER UN OUTIL EN MARCHE SANS SURVEILLANCE. LE METTRE

HORS TENSION. Ne pas laisser l’outil avant l’immobilisation complète de la lame.

Mesures de sécurité additionnelles relatives aux scies à

découper

• LE DISPOSITIF DE RETENUE DU MATÉRIAU doit être régler conformément aux

présentes directives et rester en place pendant l’utilisation.

• NE JAMAIS placer les mains sous l’outil en service ni régler l’outil qui fonctionne.

• FIXER la scie à un établi ou à un support à l’aide de brides ou de ferrures de montage. Fixer

l’établi ou le support au sol.

• NE PAS se servir du bras supérieur pour soulever la scie.

• S’ASSURER que la tension de la lame est bien réglée.

• ÉVITER les positions bizarres des mains car un soudain manque d’équilibre pourrait

projeter la main dans la trajectoire de la scie ou d’un autre outil de coupe. NE P AS PLACER

LES DOIGTS NI LES MAINS DANS LATRAJECTOIRE DE LALAME.

• LORSQU’ON RETIRE de petites pièces à ouvrer ou qu’on nettoie la table, s’assurer que la

scie est en position d’ARRÊT et que la lame est immobilisée.

• NE JAMAIS mettre la scie EN MARCHE avant d’avoir libéré la table de tous les outils,

bouts de bois inutiles, etc., à l’exception de la pièce à ouvrer et des dispositifs connexes

d’alimentation ou de soutien nécessaires à la tâche.

• VÉRIFIER la dimension et le type de la lame.

• NE PAS découper un matériau qui n’a pas de surface plane à moins de le soutenir

convenablement.

• SOUTENIR fermement le matériau contre la table et l’alimenter dans les dents de la lame à

une vitesse modérée.

• METTRE LE MOTEUR HORS TENSION si on n’arrive pas à retirer le matériau d’une

coupe incomplète. Couper à la vitesse appropriée à la tâche.

• EFFECTUER des coupes pour alléger le matériau avant de découper de longues courbes.

UTILISER un masque respiratoire et des lunettes de sécurité lors de la coupe.

• S’ASSURER QUE LES PROTECTEURS sont en place et en bon état.

• S’ASSURER que les doigts ne sont pas en contact avec les bornes du cordon d’alimenta-

tion lorsqu’on branche la fiche dans la prise ou qu’on l’en débranche.

• NE JAMAIS forcer le matériau dans la lame.

• AVERTISSEMENT : Ne pas laisser l’habitude (acquise avec l’utilisation fréquente de la

scie) remplacer les mesures de sécurité suivantes. Toujours se rappeler qu’une fraction de

seconde d’inattention suffit à infliger de graves blessures.

AB C

BROCHE DE PRISE

MISE À LA TERRE

PRISE MISE

À LA TERRE

DISPOSITIF DE

MISE À LA TERRE

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

ADAPTATEUR L’adaptateur (C) ne

peut être utilisé au Canada.

Page 4

MANUAL DE INSTRUCCIONES

Esta herramienta está diseñada para utilizarse en circuitos que tengan una toma de corriente

similar a la ilustrada en la figura A. Se puede utilizar un adaptador temporal, que se parece al

mostrado en las figuras B y C, para conectar esta clavija a una toma de corriente de dos

polos como se observa en la figura B si no dispone de una toma aterrizada. Solamente debe

utilizar el adaptador temporal hasta que un electricista le instale una toma apropiada.

La oreja, lengüeta, o similar de color verde que se extiende del adaptador debe conectarse a

tierra permanente, como una toma de corriente aterrizada.

Instrucciones importantes de seguridad

• CONSERVE LAS GUARDAS EN SU SITIO y listas para trabajar.

• CONSERVE LIMPIAEL AREA DE TRABAJO. Las áreas y bancos con objetos acumulados

en desorden propician los accidentes.

• NO SE EMPLEE EN AMBIENTES PELIGROSOS. No utilice herramientas eléctricas en

ligares inundados o mojados, ni las exponga a la lluvia. Conserve bien iluminada el área

de trabajo.

• CONSERVE AP ARTADOS A LOS NIÑOS. Todos los visitantes deben permanencer a dis-

tancia segura de la zona de trabajo.

• HAGA SU TALLER A PRUEBA DE NIÑOS con candados, interruptores maestros y reti-

rando las llaves de encendido.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá mejor con su trabajo y de manera más

segura bajo las especificaciones para las que se diseñó.

• EMPLEE LA HERRAMIENTAADECUADA. No fuerce una herramienta o sus dispositivos

en una tarea para los que no han sido diseñados.

• UTILICE UN CABLE DE EXTENSION ADECUADO. Asegúrese que su extensión esté en

buenas condiciones. Cuando utilice una extensión, asegúrese de emplear una que soporte

la corriente que su herramienta necesita. Una extensión con calibre insuficiente provocará

una caída en el voltaje de la línea, ocasionando pérdida de potencia y sobrecalentamiento. El cuadro siguiente muestra el calibre correcto a utilizarse de acuerdo con la longitud y

el amperaje indicado en la placa de identificación. Si tiene dudas, utilice el calibrte siguiente. Mientras más pequeño sea el número del calibre, mayor será su capacidad.

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando utilice la herramienta a la

intemperie, solamente utilice extensiones diseñadas para ello y así marcadas.

• VISTA LAS PRENDAS ADECUADAS. No utilice prendas de vestir flojas, guantes, cor-

batas, anillos, brazaletes ni otras piezas de joyería que pudiesen quedar atrapadas en las

partes móviles. Se recomienda el empleo de calzado antiderrapante. Cúbrase el cabello si

lo tiene largo.

• SIEMPRE UTILICE GAFAS DE SEGURIDAD. También utilice una máscara contra polvo

si la operación a efectuar lo produce. Los anteojos de uso diario solamente tienen lentes

resistentes al impacto, NO SON anteojos de seguridad.

• NO SE SOBREEXTIENDA. Conserve siempre bien apoyados los pies, lo mismo que el

equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas afiladas y limpias para que

funcionen mejor y de manera más segura. Siga las instrucciones de cambio de accesorios.

• DESCONECTE LA HERRAMIENTAS antes de efectuarles servicio y cuando les cambie

acesorios, como cuchillas, brocas y similares.

• REDUZCA EL RIESGO DE ENCENDIDO ACCIDENTAL. Asegúrese que el interruptor

esté en posición de apagado antes de conectar la herramienta.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Busque en el manual de instrucciones

los accesorios recomendados. El uso de accesorios inadecuados puede causar riesgos de

lesiones.

• NUNCA SE PARE EN LA HERRAMIENTA. Puede provocarse lesiones graves si la her-

ramienta se vuelca o si hace contacto accidental con la herramienta de corte.

• REVISE LAS PARTES DAÑADAS.Antes de seguir utilizando la herramienta, debe revis-

ar cuidadosamente una guarda o cualquier otra pieza que esté dañada para determinar si

cumplirá adecuadamente con su función; revise la alineación de las piezas móviles, sus

montajes, ruptura de partes y cualesquiera otras condiciones que pudiesen afectar su

operación. Repare o reemplace las piezas dañadas.

• NUNCA DEJE LA HERRAMIENTA EN FUNCIONAMIENTO Y DESATENDIDA.

APAGUELA. No deje la herramienta hasta que se haya detenido por completo.

Instrucciones adicionales de seguridad para sierras

caladoras

• EL SUJETADOR DE MATERIAL debe ajustarse correctamente de acuerdo a estas

instrucciones y debe permanecer en esta posición durante el uso.

• NUNCA coloque las manos por debajo de la mesa ni haga ajustes cuando la sierra este

en operación.

• ASEGURE la sierra a su mesa de trabajo con prensas u otros medios. Asegure la mesa

de trabajo al piso.

• NO utilice el brazo superior para levantar la sierra.

• ASEGURESE que la tensión de la segueta se ajustó correctamente.

• EVITE posiciones irregulares de las manos en las que un resbalón pudiese causar que se

muevan hacia la segueta. NO COLOQUE LOS DEDOS O LAS MANOS EN EL CAMINO

DE LA SEGUETA.

• CUANDO RETIRE piezas pequeñas o limpie la mesa, asegúrese que la sierra esté AP AGADA y que la segueta ha dejado de moverse.

• NUNCA ENCIENDA la sierra antes de limpiar la mesa con excepción de la pieza de trabajo y los instrumentos necesarios para la operación planeada.

• VERIFIQUE que la segueta sea del tipo y tamaño adecuados.

• NO intente cortar piezas que no tengan una superficie plana, a menos que utilice algún

medio de soporte.

• SUJETE el material con firmeza contra la mesa y aváncelo hacia los dientes de la segueta a velocidad moderada.

• APAGUE el motor si el material se resiste a salir después de un corte incompleto. Utilice

la velocidad adecuada para su aplicación.

• HAGA cortes de salida antes de cortar curvas pronunciadas..

• UTILICE una mascarilla contra el polvo y gafas de seguridad cuando corte.

• CONSERVE LAS GUARDAS en su sitio listas para funcionar.

• ASEGURESE que sus dedos no toquen las terminales del cable de alimentación cuando

conecte o desconecte la clavija a o de la linea de alimentación.

• NUNCA fuerce la pieza de trabajo hacia la segueta.

• ADVERTENCIA: no permita que la familiaridad (ganada con el uso frecuente de su

sierra) reemplace las reglas de seguridad. Recuerde siempre que un descuido de una fracción de segundo es suficiente para ocasionar una lesión de gravedad.

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar, moler o perforar con máquina,

así como al realizar otras actividades de la construcción, contiene substancias químicas que

se sabe producen cáncer, defectos congénitos u otras afecciones reproductivas. Algunos ejem-

plos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia en que se haga este tipo

de trabajo. Para reducir la exposición a esas substancias químicas: trabaje en un área bien

ventilada, y trabaje con equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

AB C

PATA DE

CONEXION A

TIERRA

TOMA DE

CORRIENTE

ATERRIZADA

MEDIO DE

ATERRIZAJE

Calibre mínimo para cordones de extensión

VOLTS Longitud total del cordón en metros

120V 0 - 7,62 7,63 - 15,24 15,25 - 30,48 30,49 - 45,72

240V 0 - 15,24 15,25 - 30,48 30,49 - 60,96 60,97 - 91,44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

Bouton de réglage de la vitesse

La scie est dotée d’une commande de vitesse variable pouvant être réglée entre 400 et 1 700

courses / minute. Pour régler la vitesse de l’outil, mettre la scie en marche, puis tourner le bouton de réglage de la vitesse (fig. 5); le tourner vers la droite pour augmenter la vitesse. Les

chiffres apparaissant sur le bouton représentent les plages de vitesses; le numéro 1 correspond

à la vitesse minimale et le numéro 5, à la vitesse maximale. On recommande d’utiliser les basses vitesses pour couper les métaux, les plastiques, les bois durs et les matériaux très minces.

Sciage

Tenir fermement le matériau à couper contre la surface du plateau. Toujours faire avancer le

matériau en direction de la lame, assez rapidement pour permettre à la lame de couper le

matériau sans toutefois le forcer contre celle-ci.

MISE EN GARDE : n’utiliser la scie à découper que pour couper le bois et les matériaux

semblables, le plastique ainsi que les métaux non ferreux comme l’aluminium, le cuivre, le

laiton, etc. NE PAS utiliser la scie pour couper les métaux ferreux comme le fer et l’acier. Il est

important de noter que lorsqu’on coupe des métaux non ferreux, les particules de métal

chaudes peuvent causer un incendie si elles entrent en contact avec de la sciure de bois.

Par conséquent, lorsqu’on scie ce type de métal, on doit:

• etirer la sciure qui se trouve à l’intérieur et sous la scie au moyen d’un aspirateur avant chaque

usage;

• éliminer complètement les fines particules métalliques (une fois complètement refroidies) qui

se trouvent à l’intérieur et sous la scie avant de réutiliser celle-ci.

Orifice d’évacuation

L’outil est doté d’un orifice d’évacuation, situé sur le côté de la scie (fig. 6), auquel on peut rac-

corder un tube d’aspiration de 3,18 cm (1-1/4 po).

REMARQUE: la sciure de bois s’accumule sous la scie pendant l’utilisation; on doit donc nettoyer l’outil fréquemment afin d’empêcher le blocage du mécanisme, ce qui pourrait surcharger le moteur et l’endommager. On peut aussi couper un orifice directement dans l’établi ou le

support, sous la bride de serrage inférieure de la lame, afin de permettre à la sciure de s’échap-

per.

Coupes en biseau

Le plateau de l’outil permet d’effectuer des coupes en biseau pouvant atteindre 47º (vers la

gauche) et -2º (vers la droite); une butée, réglée à un angle de zéro degré, est également

fournie. Pour effectuer de telles coupes, desserrer le bouton de verrouillage d’angle de biseau

(fig. 7) et incliner le plateau à l’angle voulu (un pointeur indique l’angle choisi).

Chantournage

COUPES INTERNES

La scie à découper est idéale pour réaliser des coupes internes de précision. Pour effectuer

ce type de coupe, on doit:

1.percer un trou de guidage dans l’ouvrage;

2.s’assurer que le levier de réglage de tension de la lame soit orienté vers le haut afin de

relâcher la tension;

3.desserrer le bouton de la bride de serrage supérieure de la lame;

4.maintenir la lame en place au moyen de la bride de serrage inférieure, puis insérer la lame

dans le trou de guidage. Fixer de nouveau la lame en serrant le bouton de la bride

supérieure.

5.régler la tension et amorcer la coupe interne.

Plateau

On doit garder le plateau propre et exempt d’huile, de graisse ou de tout résidu; en traiter la

surface au moyen d’une cire en pâte afin d’en conserver le fini lisse.

Bac de rangement des lames

Un bac de rangement pratique est intégré à la partie supérieure de la scie pour ranger les

lames (fig. 5).

Entretien

Nettoyer l'outil à l'aide d'un savon doux et d'un chiffon humide. Ne laisser aucun liquide s'infiltrer dans l'outil et ne jamais l'immerger.

IMPORTANT : Pour assurer la SÉCURITÉ D'EMPLOI et la FIABILITÉ de l'outil, n'en confier la

réparation, l'entretien et les rajustements qu'au personnel d'un centre de service ou à un atelier d'entretien autorisé n'utilisant que des pièces de rechange identiques.

Accessoires

Les détaillants ou le centre de service autorisé de la région vendent des accessoires recommandés pour l'outil. Pour trouver un accessoire, il suffit de composer le

1 (800) 544-6986.

AVERTISSEMENT : L'utilisation de tout accessoire non recommandé pour l'outil peut être

dangereuse.

Renseignements relatifs au service

Black & Decker exploite un réseau complet de centres de service et d'ateliers d'entretien

autorisés par toute l'Amérique du Nord. Le personnel de tous les centres de service Black &

Decker a reçu la formation voulue pour assurer l'entretien efficace et fiable des outils électriques.

Pour obtenir des renseignements d'ordre technique, des conseils relatifs aux réparations ou

des pièces de rechange d'origine, communiquer avec le centre de service Black & Decker de

la région. On peut trouver l'adresse du centre de service de la région dans l'annuaire des

Pages Jaunes à la rubrique «Outils électriques» ou en composant le numéro suivant :

1 (800) 544-6986.

Garantie compléte de deux ans pour utilisation

domestique

Black & Decker garantit le produit pour une période de deux ans contre les vices de matière ou

de fabrication. Le produit défectueux sera réparé ou remplacé sans frais conformément à l'une

des conditions suivantes.

Pour échanger l'outil, il suffit de le retourner au détaillant (si le d étaillant participe au programme

d'échange rapide Black & Decker). Le retour doit être effectuer dans les délais impartis par la

politique de retour du détaillant (habituellement entre 30 et 90 jours suivant la date d'achat). Le

détaillant peut exiger une preuve d'achat. Prière de vérifier la politique de retour du détaillant

au-delà des délais impartis.

On peut également retourner l'outil (port payé) à un centre de service Black & Decker ou à tout

autre atelier d'entretien accrédité pour y être remplacé ou réparé, à notre gré. On peut exiger

une preuve d'achat. Les adresses des centres de service Black & Decker se trouvent à la

rubrique «Outils électriques» des Pages Jaunes.

La présente garantie ne vaut pas pour les accessoires. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L'utilisateur peut également se prévaloir d'autres droits

selon l'état ou la province qu'il habite. Pour obtenir de plus amples renseignements, communiquer avec le directeur du centre de service Black & Decker de la région. Le produit n'est pas

conçu pour un usage commercial.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

ADVERTENCIA: Por su propia seguridad lea el manual de instrucciones antes de operar

la herramienta.

Instrucciones de conexión a tierra

En el caso de mal funcionamiento, la tierra proporciona una vía de menor resistencia a la

corriente eléctrica para reducir el riesgo de choque eléctrico. Esta herramienta está equipada

con un cable eléctrico con un conductor a tierra y pata de aterrizaje. La clavija debe

conectarse a una toma de corriente instalada correctamente y aterrizada de conformidad con

todos los reglamentos locales. No modifique la clavija, si no se ajusta a la toma de corriente,

haga que un electricista calificado le instale una toma adecuada.

La conexión incorrecta del conductor a tierra del equipo puede originar riesgos de choque

eléctrico. El conductor cuyo aislamiento es de color verde con o sin franjas amarillas es el

conductor a tierra del equipo. Si se requiere reparación o cambio del cable eléctrico o la

clavija, no conecte el conductor a tierra a una terminal viva.

Consulte con un electricista si no comprende perfectamente las instrucciones de aterrizaje, o

si tiene dudas acerca de la conexión a tierra de su equipo.

Utilice solamente extensiones de tres cables que tengan clavijas de tres patas y tomas de

corriente de tres polos que acepten la clavija de la herramienta.

Repare o reemplace inmediatamente los cables dañados o desgastados.

ADAPTADOR -

El adapta-

dor (C) no debe usarse

en Canadá.

Page 5

La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..........................volts SPM ....................Golpes por minuto

A ..........................amperes Hz........................hertz

W ..........................watts min ......................minutos

........................corriente alterna ....................corriente directa

n

o ..........................velocidad sin carga

........................construcción clase

II

............................

erminales de conexión a tierre

........................símbolo de alerta seguridad .../min ..................revoluciones o

reciprocaciones

por minuto

CONSERVE ESTAS INSTRUCCIONES

Motor

Asegúrese de que el suministro de corriente coincida con el de la placa de especificaciones.

“120 voltios AC solamente”, significa que su herramienta funciona con corriente alterna de 60

Hz. No haga funcionar herramientas de corriente alterna (AC) con corriente continua (DC). Una

especificación de 120 voltios AC/DC significa que su herramienta funcionará con corriente

alterna o continua a 60 Hz. Esta información se encuentra impresa en la placa de especificaciones. Un voltaje inferior causará la pérdida de potencia y un eventual recalentamiento. Todas

las herramientas Black & Decker son verificadas en fábrica; si esta herramienta no funciona,

verifique el suministro de corriente.

Desempaque de su sierra

Verifique el contenido de la caja de su sierra para recortar, con el fin de verificar si usted ha

recibido todos los componentes. Además de este manual de instrucciones, la caja debe contener una sierra para recortar N° BT4000 y los siguientes elementos:

- (12) sierras de corte diferentes (1 ya instalada en su herramienta)

- (1) Mesa amovible sin juego

- (1) libro de modelos e indicaciones útiles

Montaje

La base de la sierra para recortar tiene 3 orificios para su montaje en una mesa o banco de

trabajo (Fig. 1). Instale firmemente su sierra para evitar su movimiento. No apriete demasiado

los pernos de montaje. Deje cierto margen en las patas de caucho con el fin de absorber el

ruido y la vibración.

Alineación de la sierra con la parte superior de la mesa

Esta tarea resulta más fácil de realizar con una escuadra de carpintero. Para empezar, instale

una cuchilla en la sierra. Instale luego la escuadra en la parte superior de la mesa, cerca de la

sierra. Observe la alineación de la sierra con relación al borde de la escuadra. La sierra debe

estar alineada verticalmente con el borde de la escuadra. De lo contrario, usted debe ajustar

la posición a cero grados, tal como se describe en el siguiente párrafo.

Ajuste de la posición a cero grados

La posición a cero grados se localiza en la parte superior de la tapa del motor, al lado derecho

de la sierra, bajo la mesa (Fig. 6). La posición es ajustada previamente en fábrica con el fin de

colocar la superficie de la mesa a 0°. Con el fin de ajustar la posición a cero grados, incline la

mesa a 45°. Afloje la tuerca localizada en la parte inferior del perno. El perno puede entonces

girarse para alinear correctamente la mesa en la posición 0°. Incline la mesa a la derecha

hasta que el perno la detenga. Verifique de nuevo la alineación de la sierra con relación a la

parte superior de la mesa. Si la alineación es correcta, apriete fuertemente la tuerca.

Para permitir la inclinación de la mesa 1°ó 2° a la derecha, gire completamente la posición a

cero grados en el sentido de las manecillas de reloj.

Instalación de la sierra

DESCONECTE LA SIERRA ANTES DE INSTALARLA.

La sierra es sostenida en su lugar por las abrazaderas con tornillos de mariposa sujetas en los

brazos superior e inferior de la sierra para recortar (Fig. 2).

Antes de instalar la cuchilla, gire hacia arriba la palanca de tensión tal como se muestra en la

Fig. 3. Retire la mesa amovible y afloje, pero no destornille completamente los tornillos de

mariposa superior e inferior (Fig. 2). Pase la sierra a través de los orificios de la mesa, con la

parte dentada hacia el frente de la sierra. NOTA: La sierra para recortar corta en sentido

descendente, por lo cual es esencial que la zona dentada se encuentre hacia adelante y hacia

abajo.

Inserte la sierra en la abrazadera inferior y apriete firmemente el tornillo de mariposa. Instale

nuevamente la mesa amovible. Luego, inserte la parte superior de la sierra en la abrazadera

superior y apriete firmemente la mariposa superior.

Ajuste adecuadamente la tensión de la sierra antes de utilizar su sierra para recortar (consulte

la sección Palanca de tensión de la sierra, de este manual).

Palanca de tensión de la sierra

Mueva la palanca de tensión (Fig. 3) hacia abajo con el fin de tensar la sierra.

PARA LOGRAR UN BUEN AJUSTE DE LA SIERRA, SIGA LOS SIGUIENTES

PASOS.

NOTA: la palanca debe ser movida hacia abajo con una presión continua. Si usted requiere

hacer demasiada presión, la sierra quedaría demasiado apretada.

1) Para disminuir la tensión, gire la palanca de tensión en dirección opuesta a las manecillas

del reloj 1 ó 2 vueltas, y coloque luego la palanca hacia abajo.

2) Si la cuchilla está demasiado floja, la tensión debe ser aumentada, dejando para ello la

palanca hacia abajo y girándola en el sentido de las manecillas del reloj hasta que usted

sienta que aumenta la tensión de la sierra.

3) Después de sentir el aumento de la tensión de la sierra, gire la palanca una vuelta completa

en el sentido de las manecillas del reloj. Este nivel de presión es deseable para la mayor

parte de los cortes.

El nivel adecuado de tensión varía según el tamaño de las sierras. Si se quiebran las sierras

con frecuencia disminuya la tensión.

En la medida en que se acostumbre a utilizar la sierra para recortar, usted podrá realizar más

fácilmente una ajuste preciso de la tensión de la sierra. Si es posible, practique con un material de desecho. Retire la sierra o afloje su tensión cuando no la vaya a utilizar durante un largo

periodo de tiempo. La tensión de la sierra puede ser retirada levantando la palanca de tensión

hacia arriba. Asegúrese de colocar la palanca de tensión de la sierra hacia abajo antes de

encender su sierra para recortar.

Sujetador del material

El sujetador del material (Fig. 4) debe estar en contacto con la superficie de la pieza de trabajo. Para ajustar el sujetador del material, afloje la perilla (Fig. 4) y mueva la barra hacia arriba

o hacia abajo. El sujetador debe estar a falsa escuadra cuando la mesa se encuentre a falsa

escuadra. Para inclinar el sujetador, afloje la perilla como se muestra en la Fig. 4, e incline el

material hasta que se encuentre paralelo con la mesa. Apriete de nuevo el sujetador antes de

proceder a cortar.

Su sierra para recortar tiene una capacidad mínima de 2”. No corte material más delgado de

2”.

ADVERTENCIA: NUNCA retire el sujetador dado que este funciona como una barrera

entre los dedos del usuario y la sierra. Esto es especialmente importante al cortar metales;

pueden haber filos cortantes

Manguera de aire

Su sierra para recortar cuenta con una manguera de aire ajustable con el fin de mantener el

área de trabajo libre de polvo y de desechos. Asegúrese de colocar la manguera de aire adecuadamente, de manera que ésta aleje el polvo del operador.

Interruptor de encendido y apagado

Para encender su sierra para recortar, empuje hacia arriba el interruptor tal como se muestra

en la Fig. 5. Para apagar la herramienta, empuje hacia abajo el interruptor. Su herramienta está

provista con una ranura que permite la inserción de un candado, con el fin de asegurarla en la

posición de apagado (Fig. 5).

NOTA: La argolla del candado debe tener entre 3/16” y 7/32” de diámetro.

Perilla de control de velocidad

Su sierra para recortar cuenta con un sistema de control de velocidad que varía de 400 a 1.700

golpes por minuto. Para utilizar esta función, gire la perilla de control de velocidad (Fig. 5) con

la sierra en funcionamiento. Para aumentar la velocidad, gire la perilla en el sentido de las

manecillas el reloj. Los números que se encuentran en la perilla de control de velocidad representan distintos rangos de velocidad. La velocidad mínima es 1 y la máxima es 5. Las velocidades más bajas son recomendadas para metales, plásticos, maderas duras y materiales muy

delgados.

Corte

Sujete el material firmemente contra la mesa. Empuje siempre el material que va a cortar

hacia la mesa. Empuje el material suficientemente rápido para permitir que la sierra corte,

pero no fuerce el material dentro de la sierra demasiado rápido.

ADVERTENCIA: La sierra para recortar debe ser utilizada para cortar tan sólo madera o

productos que imiten la madera, plásticos y materiales no ferrosos (aluminio, cobre, bronce,

etc.). NO CORTE materiales ferrosos tales como el hierro y el acero. Cuando corte materiales

no ferrosos, la viruta caliente puede prender fuego cuando entre en contacto con el aserrín.

Cuando corte materiales no ferrosos:

• Aspire todo el aserrín que se encuentre dentro y bajo la sierra antes de utilizarla.

• Aspire todo el polvo de metal (después de que éste se haya enfriado completamente) al

interior y bajo la sierra antes de utilizar la sierra para cortar madera, etc.

Salida para recolección del aserrín

La salida para recolección del aserrín está colocada al lado de la sierra, tal como se muestra

en la Fig. 6. Para utilizar esta salida, fije una manguera de 1-1/4” a la abertura.

NOTA:Con una utilización normal de la sierra, el aserrín se acumula bajo aquella. Limpie con

frecuencia el polvo bajo la unidad para prevenir la aglutinación, la cual podrá sobrecargar y

averiar el motor. Se recomienda la realización de un orificio en el banco o bajo la abrazadera

inferior de la sierra, de manera que no permita la acumulación de aserrín bajo la herramienta.

Biselado

La mesa de su sierra para recortar se inclina a 47° hacia la izquierda y a –2° a la derecha. La

posición de parada se ha calibrado a 0°. Para inclinar la sierra para recortar, afloje la perilla

de bloqueo para biselado (Fig. 7), e incline la mesa al ángulo deseado, por medio del indicador de ángulo.

Calado

CORTES INTERIORES

Su sierra para recortar es ideal para realizar cortes interiores para hacer trabajos de

detalles. Para realizar un corte interior:

1.Realice una perforación-guía en la pieza de trabajo.

2.Asegúrese de que la palanca de tensión se encuentre hacia arriba con el fin de eliminar la

tensión.

3.Afloje la perilla superior de la abrazadera de la sierra.

4.Deje la sierra sujeta en su lugar por medio de la abrazadera inferior, deslice la sierra a

través de la perforación-guía de su pieza de trabajo y sujete nuevamente la sierra

apretando firmemente la perilla superior de la abrazadera de la sierra.

5.Reajuste la tensión de la sierra e inicie el corte interior.

Mesa

Mantenga la mesa limpia, libre de aceite y grasa, y nivelada. Trate la mesa con cera para ayudar a mantener su acabado liso.

Bandeja de almacenamiento de sierras

En la parte superior de la herramienta se encuentra una bandeja para el almacenamiento adecuado de las sierras (Fig. 5).

Accesorios

Los accesorios recomendados para emplearse con su herramienta se encuentran a su disposición con su distribuidor local o en los centros de servicio autorizado. Si necesita ayuda en

relación con los accesorios, por favor llame: 326-7100

ADVERTENCIA: El uso de cualquier accesorio no recomendado para emplearse con esta

herramienta puede ser peligroso.

Mantenimiento

Solamente utilice jabón suave y un trapo húmedo para limpiar la herramienta. Nunca permita

que ningún líquido se introduzca en la herramienta; nunca sumerja ninguna parte de la herramienta en ningún líquido.

IMPORTANTE: Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto, las

reparaciones, el mantenimiento y los ajustes deben ser realizados por centros de servicio

autorizados u otras personal de servicio calificadas, que siempre utilicen partes de repuesto

idénticas. Este producto no está destinado a uso comercial.

PARAREPARACION Y SERVICIO DE SUS HERRAMIENTAS ELECTRICAS FAVOR DE

DIRIGIRSE AL CENTRO DE SERVICIO MAS CERCANO

CULIACAN

Av . Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av . La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av . Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av . Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: 326 7100

Información de servicio

Black & Decker ofrece una red completa de centros de servicio propiedad de la compañía y

franquiciados a través de toda Norteamérica. Todos los centros de servicio Black & Decker

cuentan con personal capacitado para proporcionar el servicio a herramientas más eficiente

y confiable.

Siempre que necesite consejo técnico, reparaciones o partes de repuesto genuinas,

comuníquese con el centro Black & Decker más cercano a usted.

Para encontrar su centro de servicio local, consulte la sección amarilla bajo "Herramientas

eléctricas", o llame al: 326-7100

Garantía para uso doméstico por dos años completos

Black & Decker (U.S.) garantiza este producto por dos años completos contra cualquier falla

originada por materiales o mano de obra defectuosos. El producto defectuoso será reemplazado o reparado sin cargo alguno en cualquiera de las siguientes dos maneras:

La primera, que resulta únicamente en cambios, es regresar el producto al vendedor al que

se compró (en la suposición que es un distribuidor participante). Las devoluciones deberán

hacerse dentro del tiempo estipulado por la política de cambios del distribuidor (usualmente

de 30 a 90 días después de la venta). Se puede requerir prueba de compra. Por favor verifique con el vendedor las políticas específicas de devolución relacionadas a las devoluciones

en tiempo posterior al estipulado para cambios.

La segunda opción es llevar o enviar el producto (con porte pagado) a los centros de servicio

Black & Decker propios o autorizados, para que la reparemos o reemplacemos a nuestra

opción. Se puede requerir prueba de compra. Los centros de servicio Black & Decker propios

y autorizados están enlistados bajo “Herramientas eléctricas” en la sección amarilla del directorio telefónico.

Esta garantía no se aplica a los accesorios. Esta garantía le otorga derechos legales especí-

ficos, y usted puede tener otros que varíen de estado a estado. Si tiene usted cualquier pregunta, comuníquese con el gerente del centro de servicio Black & Decker más cercano.

ESPECIFICACIONES BT4000

Tensión de alimentación: 120 V~ Potencia nominal: 145 W

Frecuencia de operacion: 60 Hz Consumo de corriente: 1.3A

IMPORTADO: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 3-26-71-00

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Loading...

Loading...