Page 1

• OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets,

or other jewelry which may get caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

• ALW AYS USE SAFETYGLASSES.Also use face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest per-

formance. Follow instructions for changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits,

cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position

before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting

tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function–check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that may affect its operation. Aguard

or other part that is damaged should be properly repaired or replaced.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool

until it comes to a complete stop.

ADDITIONAL SAFETY RULES FOR BENCH GRINDERS

• Always use proper guard with grinding wheel. Aguard protects operator from broken

wheel fragments.

• Accessories must be rated for at least the speed recommended on the tool warning

label. Wheels and other accessories running over the rated speed can fly apart and cause

injury.

• Before using, inspect recommended accessory for cracks or flaws. If such a crack or flaw is

evident, discard the accessory. DO NOT USE A GRINDING WHEELTHAT IS CRACKED

OR FLAWED IN ANYWAY.

• When starting the tool, let it run for one minute. Never start the tool with a person in line with

the wheel. This includes the operator.

• Do not grind on the sides of grinding wheels unless they are specifically designed for that

purpose.

• Do not overtighten wheel clamp nut. This may crack the grinding wheel.

• Clean the cavity around the grinding wheel periodically.

• Secure grinder to work bench or stand with clamps or mounting hardware. Secure work

bench or stand to floor.

• Make sure your fingers do not contact the terminals of the power cord when installing or

removing the plug to or from the line power source.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE LIQUIDS, GASES OR DUST.

Sparks or hot chips from grinding may ignite combustible materials.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

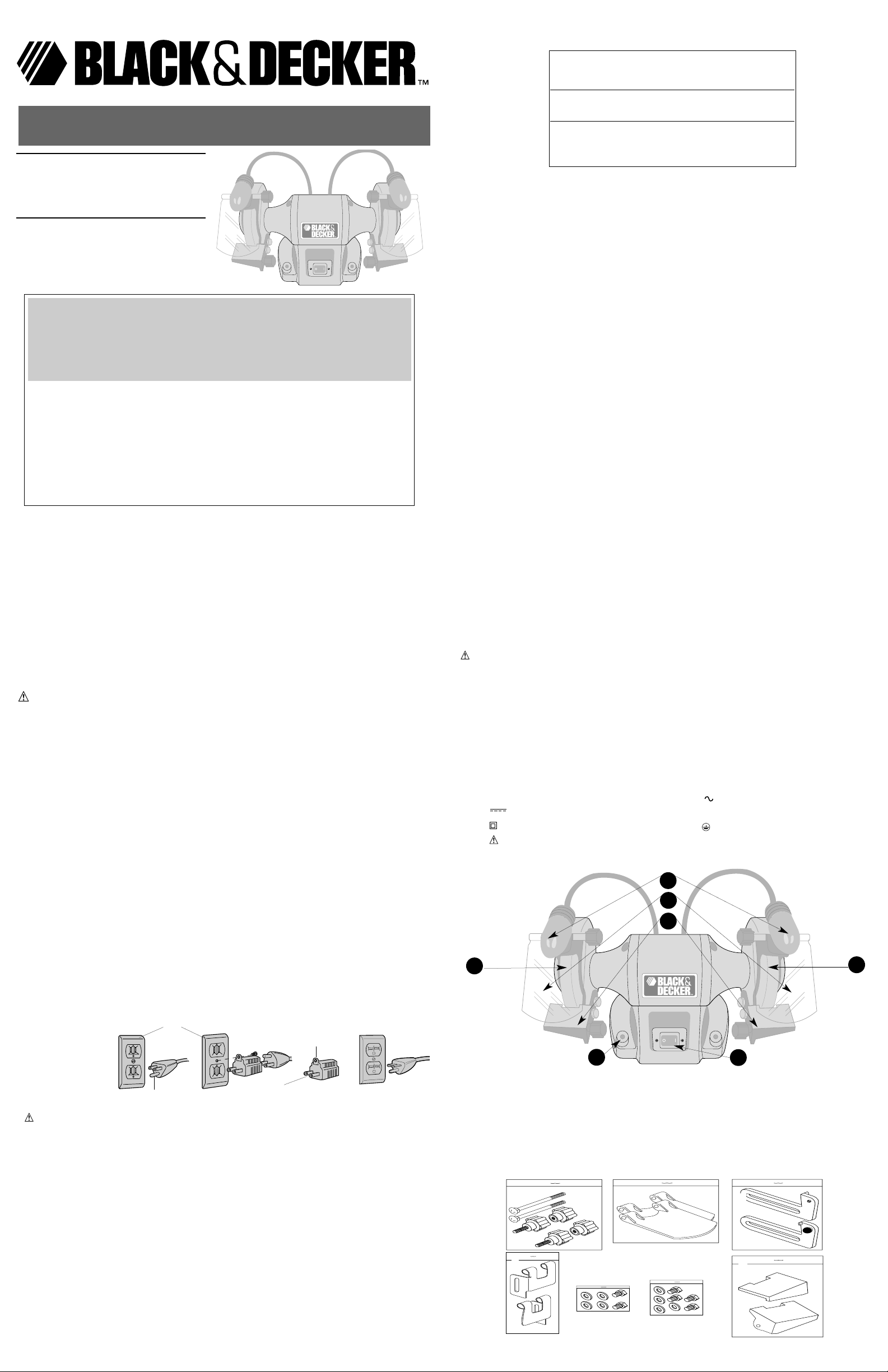

1. MEDIUM GRINDING WHEEL (60 GRIT) /MEULE À GRAINS MOYENS (NO 60) / RUEDA DE

ESMERIL, MEDIA (GRANO 60)

2. COARSE GRINDING WHEEL (36 GRIT) / MEULE À GROS GRAINS (NO 36) / RUEDA DE

ESMERIL, GRUESA (GRANO 36)

3. INTEGRATED LIGHTS / LAMPES INTÉGRÉES / LUCES INTEGRADAS

4. EYE SHIELDS / PROTÈGE-YEUX / PANTALLAS PROTECTORAS DE OJOS

5. TOOL RESTS / APPUIS / SOPORTES DE LA HERRAMIENTA

6. SWITCH (ON-OFF) / INTERRUPTEUR DE MARCHE / ARRÊT / INTERRUPTOR

ARRANQUE/PARADA(ON-OFF)

7. MOUNTING HOLES / ORIFICES DE MONTAGE / HUECOS DE MONTAJE

CAT. NOS. BT3500 FORM NO. 398203-00 Printed in Taiwan Copyright©2000 Black & Decker (SEP-00-01)

KEY INFORMA TION YOU SHOULD KNOW :

• Always wear eye protection.

• Make sure tool rests, spark guards, and eye shields are firmly secured before tool

is engaged.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZADE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR ELPRODUCTO.

CATALOG NUMBER

BT3500

INSTRUCTION

MANUAL

WARNING: For your own safety read instruction manual before operating tool.

Grounding Instructions

In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances. Do not modify plug provided—if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

Repair or replace damaged or worn cords immediately.

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in

Figure A. The tool has a grounding plug that looks like the plug illustrated in Figure A. A

temporary adapter, which looks the adapter illustrated in Figures B and C, may be used to

connect this plug to a 2-pole receptacle as shown in Figure B if a properly grounded outlet is

not available. The temporary adapter should be used only until a properly grounded outlet can

be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent ground such as a properly grounded

outlet box.

WARNING:Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

Important Safety Instructions

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys

and adjusting wrenches are removed from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet

locations, or expose them to rain. Keep work area well lighted.

• KEEP CHILDREN AWA Y.All visitors should be kept safe distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter

keys.

• DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When using and extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

6666”””” BBBBEEEENNNNCCCCHHHHGGGGRRRRIIIINNNNDDDDEEEERR

RR

FIG. 1

1

2

4

7

6

3

5

FIG. 2

1

2

3

4

5

6

7

AB C

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

ADAPTER-(NOT APPLICABLE IN CANADA)

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PURCHASE,

CALL 1-800-54-HOW-TO (1-800-544-6986).

IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT,

GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO THE SUCCESS OF BLACK & DECKER’S QUALITY

IMPROVEMENT PROGRAM.

(544-6986)

Page 2

Motor

Be sure your power supply agrees with the nameplate marking. 120 Volts, 60Hz means alternating current only should be used to operate this tool.A power decrease of more than 10%

will cause loss of power and overheating. All Black and Decker tools are factory tested; if this

tool does not operate, check the power supply.

Bench Mounting

1. The grinder should be unplugged.

2. Position grinder on workbench. Check for the availability of power for the grinder. Mark

location of holes for drilling.

3. Drill appropriate sized holes.

4. Insert 1/4” (6mm) Hex head bolts through washers and the holes. You may want to use

washers on the underside of the bench as well.

5. Tighten the nuts. Do not overtighten. Allow the rubber feet to absorb the vibration when

the grinder is running.

Installing Spark Guards, Light Fixtures, Eye Shields and

Quench Tray

TURN OFF TOOLAND DISCONNECT FROM POWER SUPPLY

There are seven seperate hardware bags and a quench tray packed with your bench grinder.

Hardware bag #’s 1,2, 3 and 4 shown in Figure 2 are used to assemble the spark guard, light

fixture and eye shield assemblies shown in Figure 3.

To begin assembly insert the 1/2” long machine screw with washer through the slot of the left

side spark guard and into the threaded hole located at the top of the inner metal wheel guard.

Adjust the edge of the spark guard to within 1/16” of the grinding wheel or other accessory.

Tighten the screw securely. Continue to adjust spark guard to be within 1/16” of grinding

wheel or other accessory as wear occurs.

Align the left side spark guard with the opening below the left side light fixture. Next, align the

clear plastic eye shield (rib side up per Figure 3) with the left side spark guard. With the three

items aligned, insert the 3-1/2” bolt through them from the left side insuring that the square

portion of the bolt head is seated fully into the square eye shield recess. Place a knob and

washer onto the threaded end of the bolt and hand tighten.

Adjust the eye shields so they are between the wheels and your eyes. Tighten the shields in

place by tightening the plastic knob in the assembly by hand. NOTE: EYE SHIELDS ARE

NOT DESIGNED TO REPLACE SAFETY GLASSES.

Repeat the procedure for the right side assembly inserting the 3-1/2” bolt from the right side.

Aquench tray is included for use in cooling the workpiece after the grinding process. The tray

can be filled with water (only use water) and attached to either side of the grinder by aligning

the tabs on the side of the tray with the slots on the outer sides of the wheel guards.

Installing Tool Rests

TURN OFF POWER AND DISCONNECT FROM POWER SUPPLY.

Hardware bags 5, 6, 7, and the remaining two knobs from bag #1 are used to assemble the

tool rests.

First install the left side tool rest brackets, as shown in Fig. 4. Next attach the tool rests. Use

the bolts, washers, spacers and lock nuts from the plastic bag to secure the brackets and tool

rests in place.

NOTE: There is a left and right tool rest. When in actual use, the tool rests should be adjusted to within 1/8” of the grinding wheel or other accessory being used.

CAUTION: Use the washers and screws supplied. Longer screws may interfere with the

movement of the grinding wheel.

Operation

NEVER USE ABENCH GRINDER IF IT IS NOT FIRMLY FASTENED TO A WORK BENCH

OR RIGID FRAME. Before turning the grinder on, put on safety glasses. Turn on the grinder

and allow it to reach full speed (3500 RPM ). Hold the workpiece firmly and against the tool

rest. Hold very small pieces with pliers or other suitable clamps. Feed the work smoothly and

evenly into the grinding wheel. Move the work slowly and avoid jamming the work against the

wheel. As the wheel tends to slow down you should occasionally release the pressure to let

the wheel return to full speed.

Grind only on the face of the grinding wheel and never on the side. (Some wheels are

designed for side grinding and will say so on their instruction sheets).

CAUTION: Prolonged grinding will cause most materials to become hot. Handle them with

pliers.

Switch

The switch is located on the front of the grinder, on the base. (Figure 1) To turn the tool on

depress the side of the rocker switch on the right side, marked “I”. To turn off the grinder,

depress the left side of the rocker switch, marked “O”.

Maintenance

CLEANING

Blowing dust and grit out of the wheel guards using compressed air is a necessary regular

maintenance procedure. Dust and grit containing metal particles often accumulate on interior surfaces and could create an electrical shock hazard if not frequently cleaned out.

ALWAYS WEAR SAFETY GLASSES.

CAUTION: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. Use clean, dry rag only.

Accessories

Recommended accessories for use with your tool are available at extra cost from your distributor or local service center.

Grinding wheels must fit within the confines of the guard and must be rated higher than the

recommended speed as marked on the nameplate.

CAUTION: Strands of wire brushes may break and fly off while in use. Users and others

in the area should wear adequate eye, face and body protection. Use only wire brushes that

are rated at or greater than the RPM shown on the tool’s nameplate.

The use of wire brushes is only recommended with the use of a spacer, Black & Decker part

no. 791695-00. The spacer should be positioned behind the inner clamp washer toward the

motor. To order the spacer call 1-800-54-HOW-TO (544-6986).

Do not use the spacer with grinding wheels.

WARNING: T o reduce the risk of injury, always use proper guards when grinding and wear

eye protection.

CAUTION: The use of any non-recommended accessory may be hazardous.

Changing Accessories

TURN OFF THE TOOL AND DISCONNECT FROM POWER SUPPLY.

CHANGE ACCESSORIES WHEN THE SPARK GUARD CAN NO LONGER BE ADJUSTED

TO 1/16” FROM THE WHEEL.

USE ONLY WHEELS THAT MEASURE 6” IN DIAMETER. THIS TOOL HAS 1/2” ARBORS

ON BOTH SIDES.

Follow the steps below to remove and replace an accessory.

1.Raise the eye shield up, and out of the way.

2.Loosen and pull the tool rest out as far as possible. Do not remove it.

3.Loosen and pull the spark guard out as far as possible, Do not remove it.

4.Remove the five screws from the side of the wheel cover and remove the cover.

5.Insert a flat bladed screwdriver into the slot in the left end of the grinder’s rotor shaft. Hold the

screwdriver firmly to keep the shaft from turning as you loosen and remove the hex nut in the

center of the grinding wheel or other accessory.

NOTE: If you are changing only the right side accessory, you need not remove the left wheel

cover. Ahole in the center of the cover permits screwdriver insertion into the slotted shaft.

Unscrew the nut in the center of the grinding wheel. It may be necessary to strike the wrench

sharply in the loosening direction with the heel of your hand to loosen the nut.

NOTE: The nut on the right side of the grinder has a standard right hand thread (turn

counterclockwise to loosen). The one on the left side has a left hand thread (turn clockwise to

loosen).

6.Remove the wheel washer and the wheel.

7. Inspect the wheel for cracks, chips or any other visible damage (other than normal wear)

and discard if such damage is found. Inspect the blotters for damage. If the blotters are

missing or severely damaged, replace them with pieces of thin cardboard or blotter paper cut

in the same shape. NEVER USE AGRINDING WHEEL WITHOUTA BLOTTER ON EACH

SIDE OF THE WHEEL.

8.Install the new wheel or other accessory. Be sure that both wheel washers are in place

(concave sides toward wheel). Use only flanges furnished with the grinder.

9. Hold as before and tighten the nut firmly but do not overtighten. OVERTIGHTENING CAN

CRACK AGRINDING WHEEL.

10. Replace the wheel cover and its five screws.

11. Adjust the spark guard to 1/16" (1.6mm) from the accessory and tighten it securely .

12. Adjust the tool rest to 1/8" (3.2mm) from the accessory and tighten securely.

13. Adjust the eye shield to a point between your eyes and the accessory.

Light

To replace the bulb, remove the screw and bulb housing shown in Figure 3 and unscrew the

bulb.

CAUTION: To reduce the risk of fire, use 10 watt max. appliance bulb.

Service Information

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact the

Black & Decker location nearest you. To find your local service location, refer to the yellow

pages directory under "Tools—Electric" or call: 1-800-54-HOW-TO (544-6986).

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service personnel, always using identical replacement parts.

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or repaired at no charge in either

of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under "ToolsElectric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state. Should you have any questions,

contact the manager of your nearest Black & Decker Service Center.

This product is not intended for commercial use.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

Mise à la terre

En cas de mauvais fonctionnement ou de bris de l’outil, la mise à la terre procure un chemin

de moindre résistance au courant électrique afin de minimiser les risques de secousses

électriques. Le cordon de l’outil comporte un conducteur de terre et une fiche de mise à la

terre. La fiche doit être branchée dans une prise de machine bien installée et mise à la terre

conformément aux lois et règlements locaux. Ne pas modifier la fiche fournie. Lorsque la

fiche n’entre pas dans la prise, demander à un électricien qualifié d’installer une prise appropriée.

La mauvaise connexion du conducteur de terre de l’outil présente des risques de secousses électriques. Le conducteur dont l’isolant est vert ou vert avec des lignes jaunes constitue

la mise à la terre. En cas de réparation ou de remplacement du cordon ou de la fiche, ne

pas relier le conducteur de terre à une borne sous tension.

Consulter un électricien qualifié ou le personnel des centres de service an cas d’incompréhension des instructions relatives à la mise à la terre ou en cas de doute quant à la mise

à la terre de l’outil.

Utiliser seulement des cordons de rallonge trifilaires dotés de fiche mise à la terre à trois

broches, ainsi que des prises à 3 orifices acceptant la fiche de l’outil.

Réparer ou remplacer immédiatement les cordons endommagés ou usés.

L ‘outil est conçu pour être branché sur un circuit dont les prises ressemblent à celle illus-

trée à la figure A. L’outil comporte une fiche de terre qui ressemble à celle illustrée à la fig-

AVANT DE RETOURNER LE PRODUIT, PEU IMPORTE LA RAI-

SON PRIÈRE DE COMPOSER

1 800 544-6986

IMPORT ANTS RENSEIGNEMENTS:

• Toujours porter des lunettes de protection.

• S’assurer que les appuis, les pare-étincelles et les protège-yeux soient

solidement fixés avant de faire fonctionner l’outil.

FIG. 3

SPARK GUARD

PARE-

ÉTINCELLES

GUARDACHIS-

PAS

EYE SHIELD

PROTÈGE-

YEUX

PANTALLA PRO-

TECTORA DE

OJOS

FIG. 4

TOOL REST

FERRURE DE

L’APPUI

RECEPTACULO

PARAEL

SOPORTE DE LA

HERRAMIENTA

TOOL REST BRACKET

APPUI DE L’OUTIL

SOPORTE DE LA HER-

RAMIENTA

MEULEUSE D’ÉTABLI DE 152 mm (6 po)

Page 3

ure A. On peut se servir d’un adaptateur temporaire (comme celui des figures B et C) pour

brancher la fiche dans une prise à 2 orifices (fig.B) lorsqu’il n’y a pas de prise mise à la terre.

Il faut seulement se servir de l’adaptateur temporaire jusqu’à ce qu’un électricien certifié

puisse installer une prise mise à la terre appropriée. Il faut alors relier l’oreille rigide, la cosse

ou tout autre objet du genre de couleur verte à une mise à la terre permanente (comme à la

boîte d’une prise bien mise à la terre).

Importantes mesures de sécurité

• S’ASSURER QUE LES PROTECTEURS sont en place et en bon état.

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et des établis encombrés

peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils électriques de la pluie. Ne

pas s’en servir dans des endroits humides ou mouillés. Bien éclairer la surface de travail.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus à l’écart de l’aire de tra-

vail.

• RENDRE L’ATELIER SÛR POUR LES ENFANTS à l’aide de cadenas, de disjoncteurs, ou

en retirant les clés de mise en tension.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr et efficace, utiliser l’outil

à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil ou d’un accessoire le

rendement d’un outil de fabrication plus robuste.

• UTILISER DES CORDONS DE RALLONGE APPROPRIÉS. S’assurer que le cordon de

rallonge est en bon état. Lorsqu’on se sert d’un cordon de rallonge, s’assurer qu’il est de

calibre approprié pour la tension nécessaire au fonctionnement de l’outil. L’utilisation d’un

cordon de calibre inférieur occasionne une baisse de tension entraînant une perte de puissance et la surchauffe. Le tableau suivant indique le calibre approprié selon la longueur du

cordon et les mentions de la plaque signalétique de l’outil. En cas de doute, utiliser un cordon de calibre supérieur. Le chiffre indiquant le calibre est inversement proportionnel au

calibre du cordon.

• CORDONS DE RALLONGE POUR L’EXTÉRIEUR. Lorsque l’outil sert à l’extérieur, utilis-

er seulement des cordons de rallonge prévus à cet effet et portant la mention appropriée.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des vêtements amples, des

gants, des cravates, des bagues, des bracelets ou d’autres bijoux qui peuvent être happés

par les pièces en mouvement. Le port des chaussures à semelle antidérapante est recommandé. Protéger la chevelure si elle est longue.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Porter également un masque

respiratoire si le travail de coupe produit de la poussière. Des lunettes de correction de la

vue standard comportent seulement des verres résistant aux chocs; ce NE sont PAS des

lunettes de sécurité.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une position stable et garder

son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et affûtés pour qu’ils donnent

un rendement supérieur et sûr. Suivre les directives relatives à la remplacement des accessoires.

• DÉBRANCHER L’OUTIL avant de le réparer ou d’en changer un accessoire (comme une

lame, un foret ou un couteau).

• MINIMISER LES RISQUES DE DÉMARRAGES ACCIDENTELS. S’assurer que l’interrupteur est en position hors tension avant de brancher l’outil.

• UTILISER LES ACCESSOIRES RECOMMANDÉS. Consulter le guide d ’utilisation afin de

connaître les accessoires recommandés. L’utilisation d’accessoires inappropriés présente

des risques de blessures.

• NE JAMAIS SE TENIR SUR L’OUTIL. Cela présente des risques de blessures graves si

l’outil bascule ou si on touche à la lame par inadvertance.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à utiliser l’outil, il faut véri-

fier si le protecteur ou toute autre pièce endommagée remplit bien la fonction pour laquelle il a été prévu. Vérifier l’alignement et les attaches des pièces mobiles, le degré d’usure

des pièces et leur montage, ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l’outil. Il faut réparer ou remplacer tout protecteur ou autre composant

endommagé.

• NE JAMAIS LAISSER UN OUTIL EN MARCHE SANS SURVEILLANCE. LE METTRE

HORS TENSION. Ne pas laisser l’outil avant l’immobilisation complète de la lame.

• FIXER l’outil à un établi ou à un support à l’aide de brides ou de ferrures de montage.

• S’ASSURER que les doigts ne sont pas en contact avec les bornes du cordon d’alimenta-

tion lorsqu’on branche la fiche dans la prise ou qu’on l’en débranche.

· NE PAS FAIRE FONCTIONNER CET OUTIL DANS LE VOISINAGE DE LIQUIDES, DE GAZ

OU DE POUSSIÈRES INFLAMMABLES. Les étincelles ou des copeaux brûlants provenant de

la coupe ou de l’amorçage du moteur risquent d’enflammer les matériaux combustibles.

AVERTISSEMENT : Certains outils, tels que les sableuses électriques, les scies, les meules,

les perceuses ou certains autres outils de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on

retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit

bien ventilé et utiliser l’équipement de sécurité approprié tel un masque anti-poussières spé-

cialement conçu pour filtrer les particules microscopiques.

MESURES DE SÉCURITÉ SPÉCIFIQUES

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

Construction de classe II

........................borne de mise à la

minute

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

RÈGLES DE SÉCURITÉ ADDITIONNELLES CONCERNANT LES MEULEUSES D’ÉTABLI

• Toujours utiliser le dispositif de protection qui convient à la meule afin de protéger

l’opérateur contre les fragments pouvant être projetés par une meule brisée.

• La vitesse des accessoires doit correspondre à la vitesse minimale recommandée

indiquée sur l’étiquette d’avertissement de l’outil; les meules et les accessoires qui

sont réglés à une vitesse trop élevée peuvent se briser et occasionner des blessures

lorsque des fragments de métal sont projetés.

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en

contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent met-

tre les pièces métalliques de l’outil sous tension, engendrant des risques de choc élec-

trique.

• Avant d’utiliser un accessoire recommandé, le vérifier afin de s’assurer qu’il n’y ait ni bris

ni fissure. Si on y trouve de tels défauts, mettre l’accessoire au rebut. NE JAMAIS UTILISER UNE MEULE BRISÉE OU FISSURÉE.

• Lorsqu’on démarre l’outil, le faire fonctionner pendant une minute; ne jamais démarrer un

outil lorsque quelqu’un, y compris l’opérateur, se tient directement devant lui.

• Ne pas utiliser l’outil en se servant des côtés de la meule, sauf si cette dernière est conçue

spécialement pour ce type de travaux.

• Ne pas trop serrer l’écrou de blocage de la meule afin d’éviter que cette dernière ne se

fissure.

• Nettoyer régulièrement la cavité entourant la meule.

MOTEUR

On doit s’assurer que l’intensité nominale du cordon d’alimentation corresponde à celle

indiquée sur la plaque signalétique; sur cette dernière, la mention «120 V , 60 Hz» signifie que

l’outil ne doit être branché que dans une prise de courant alternatif. L’utilisation d’une tension moindre de 10 % que celle indiquée entraînera une perte de puissance et une surchauffe. Tous les outils Black & Decker sont soumis à des essais en usine; si cet outil ne

fonctionne pas, on doit d’abord vérifier l’intensité nominale du cordon d’alimentation.

FIXATION DE LAMEULEUSE SUR UN ÉTABLI

1. Débrancher la meuleuse.

2. Placer cette dernière sur l’établi, en s’assurant qu’une prise murale se trouve à proximité.

Marquer l’endroit où les orifices de montage doivent être percés.

3. Percer des orifices, de la dimension appropriée.

4. Insérer les boulons à tête hexagonale de 6 mm (1/4 po) dans les rondelles, puis dans les

orifices; le cas échéant, mettre des rondelles additionnelles sous l’établi.

5. Serrer les écrous sans trop exercer de force afin de laisser suffisamment de jeu pour permettre aux supports en caoutchouc d’absorber les vibrations.

INSTALLATION DES PARE-ÉTINCELLES, DES LAMPES ET DES PROTÈGE-YEUX

ARRÊTER L’OUTIL ET LE DÉBRANCHER DE L’ALIMENTATION ÉLECTRIQUE.

Sept sacs de ferrure sont fournis avec la meuleuse d’établi; les sacs nos 1, 2, 3 et 4, illus-

trés à la figure 2, contiennent les ferrures nécessaires pour assembler le pare-étincelles, la

lampe et le protège-yeux (fig. 3).

Insérer d’abord la longue vis à métaux de 13 mm (1/2 po), munie d’une rondelle, dans la

fente du pare-étincelles gauche, puis dans l’orifice fileté situé sur le dessus du dispositif de

protection interne de la meule. Placer le bord du pare-étincelles afin qu’il soit à environ 1,5

mm (1/16 po) de la meule ou de l’accessoire utilisé. Serrer fermement la vis.

Aligner le pare-étincelles gauche avec l’ouverture qui se trouve sous la lampe gauche; aligner ensuite le protège-yeux en plastique transparent (le côté rainuré orienté vers le haut, conformément à la figure 3) avec le pare-étincelles gauche. Insérer le boulon de 8,9 cm (3-1/2

po) dans ces trois éléments, à partir du côté gauche, en s’assurant que la section carrée de

la tête du boulon soit bien enfoncée dans la cavité carrée du protège-yeux. Mettre un bouton sur la partie filetée du boulon et serrer manuellement.

Fixer cet assemblage sur le côté gauche de la meuleuse d’établi, en réglant les protège-yeux

de manière à ce qu’ils soient situés entre la meule et l’utilisateur, puis en en serrant solidement le bouton en plastique. REMARQUE: LES PROTÈGE-YEUX NE SONT PAS

DESTINÉS À REMPLACER LES LUNETTES DE PROTECTION.

Assembler les éléments du côté droit en reprenant les étapes ci-dessus, mais en insérant

cette fois-ci le boulon de 89 mm (3-1/2 po) à partir du côté droit.

INSTALLATION DES APPUIS DE L’OUTIL

COUPER LE COURANT ET DÉBRANCHER L’OUTIL DE L’ALIMENTATION ÉLECTRIQUE.

Installer d’abord les ferrures de l’appui gauche, tel qu’illustré à la figure 4, puis les appuis.

Serrer fermement les ferrures et les appuis au moyen des boulons, des rondelles, des cales

d’espacement et des écrous de blocage fournis.

REMARQUE: un appui se trouve de chacun des deux côtés de l’outil; ces derniers devront

être réglés à une distance de 3,2 mm (1/8 po) de la meule ou de l’accessoire utilisé.

Fonctionnement

NE JAMAIS UTILISER LA MEULEUSE AVANT DE L’AVOIR D’ABORD BIEN FIXÉE À

L’ÉTABLI OU À UNE SURFACE FERME. Mettre des lunettes de protection, puis faire

démarrer l’outil et attendre qu’il atteigne sa vitesse maximale (3 600 tr / min). Tenir fermement l’ouvrage contre les appuis de l’outil (utiliser une pince ou un outil semblable pour les

petits ouvrages). Faire avancer le matériau lentement et uniformément vers la meule, en évi-

tant de le forcer contre celle-ci. Puisque la meule a tendance à ralentir lorsqu’elle entre en

contact avec l’ouvrage, on recommande de relâcher la pression de temps à autre et de permettre à la meule de tourner momentanément à la vitesse maximale.

N’utiliser que la surface avant de la meule et non ses côtés (certaines meules sont conçues

pour ce type d’utilisation; consulter le feuillet de directives fourni).

MISE EN GARDE : puisque le matériau devient chaud lorsqu’on le meule pendant une

période prolongée, on recommande de le manipuler au moyen de pinces ou de porter des

gants épais.

INTERRUPTEUR

L’interrupteur est situé sur la base de la meuleuse, sur la partie avant (fig. 1). Pour mettre

l’outil en marche, enfoncer le côté droit de l’interrupteur à bascule (position «I»); appuyer sur

le côté gauche pour l’arrêter (position «O»).

ENTRETIEN

NETTOYAGE

On doit entretenir régulièrement le carter du moteur en y enlevant la poussière et la saleté

au moyen d’air comprimé. Les particules de métal ont tendance à s’accumuler sur les surfaces intérieures de l’outil et peuvent causer des risques de choc électrique si elles ne sont

pas éliminées régulièrement. TOUJOURS PORTER DES LUNETTES DE PROTECTION.

MISE EN GARDE : ne jamais nettoyer les parties non métalliques de l’outil au moyen de

solvants ou de produits semblables; n’utiliser qu’un chiffon propre et sec.

LUBRIFICATION

Les outils Black & Decker sont lubrifiés en usine et sont donc prêt à utiliser; ces derniers

doivent être lubrifiés régulièrement une fois par année, selon l’usage (les outils destinés aux

travaux importants et ceux exposés à la chaleur peuvent devoir être lubrifiés plus fréquemment). Seul le personnel qualifié des centres de service Black & Decker ou d’autres centres

autorisés ne doit effectuer ce travail.

ACCESSOIRES

Les accessoires recommandés pour cet outil sont vendus séparément chez tous les distributeurs ou dans tous les centres de service autorisés.

Les meules de rechange doivent être complètement recouvertes par le dispositif de protection et leur vitesse nominale doit être supérieure à celle indiquée sur la plaque signalétique

de l’outil.

Les accessoires recommandés pour cet outil sont vendus séparément chez tous les distributeurs ou dans tous les centres de service autorisés.

MISE EN GARDE : des brins de brosse métallique peuvent se détacher et être projetés

durant l’usage. Par conséquent, toute personne se trouvant à proximité de l’outil, y compris

l’utilisateur, doit porter l’équipement nécessaire pour se protéger les yeux, le visage et le

corps. N’utiliser que des brosses dont la vitesse de rotation nominale est égale ou supérieure

à celle indiquée sur la plaque signalétique de l’outil.

AVERTISSEMENT : afin de réduire les risques de blessure, toujours utiliser les disposi-

tifs de protection appropriés et porter des lunettes de protection.

MISE EN GARDE : l’usage d’un accessoire non recommandé peut présenter un danger.

CHANGEMENT D’ACCESSOIRES

ARRÊTER L’OUTIL ET LE DÉBRANCHER DE L’ALIMENTATION ÉLECTRIQUE.

ON DOIT CHANGER LES ACCESSOIRES LORSQU’IL DEVIENT IMPOSSIBLE DE

RÉGLER LE PARE-ÉTINCELLES À UNE DISTANCE DE 1,5 mm (1/16 po) DE LA MEULE.

N’UTILISER QUE DES MEULES DE 15,2 cm (6 po) DE DIAMÈTRE. CET OUTIL ESTDOTÉ

D’AXES DE 12,7 mm (1/2 po) SITUÉS DE CHACUN DE SES CÔTÉS.

Suivre les étapes énumérées ci-dessous pour retirer et remplacer un accessoire :

1. Soulever et repousser le protège-yeux.

AB C

BROCHE DE PRISE

MISE À LA TERRE

PRISE MISE

À LA

TERRE

DISPOSITIF DE

MISE À LA TERRE

ADAPTATEUR L’adaptateur (C) ne peut être utilisé au

Canada.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V De 0 à 25 De 26 à 50 De 51 à 100 De 101 à 150

240 V De 0 à 50 De 51à 100 De 101 à 200 De 201 à 300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Page 4

2. Desserrer l’appui de l’outil et l’éloigner le plus possible sans le retirer.

3. Desserrer le pare-étincelles et l’éloigner le plus possible sans le retirer.

4. Enlever les cinq vis fixées sur le côté du couvercle de la meule, puis retirer le couvercle.

5. Insérer un tournevis à lame plate dans la fente située à l’extrémité gauche de l’arbre rotor

de la meuleuse. Tenir fermement le tournevis afin d’empêcher l’arbre de tourner, puis dévisser et retirer l’écrou hexagonal se trouvant au centre de la meule ou de l’accessoire utilisé.

REMARQUE: si on ne change que la meule ou l’accessoire de droite, il n’est pas nécessaire

de retirer le couvercle gauche. Un orifice situé au centre du couvercle permet d’insérer un

tournevis pour bloquer l’arbre.

Dévisser l’écrou fixé au centre de la meule; il peut s’avérer nécessaire de frapper la clé d’un

coup sec de la paume vers la gauche (ou vers la droite, selon le cas), afin de pouvoir desserrer l’écrou.

REMARQUE: on doit desserrer l’écrou situé du côté droit de la meuleuse en le tournant vers la

gauche (filetage droit standard), et en tournant celui du côté gauche vers la droite (filetage

gauche).

6. Retirer la rondelle fixée à la meule ainsi que cette dernière.

7. Inspecter la meule afin de s’assurer qu’il n’y ait aucun signe d’endommagement autre que

l’usure normale, tel qu’une fissure, des éclats, etc.; le cas échéant, mettre la meule au rebut.

Vérifier également les buvards afin de s’assurer qu’ils ne soient pas endommagés. S’il c’est

le cas, ou si l’outil n’est pas doté des buvards requis, utiliser des morceaux de carton mince

ou de papier buvard coupés selon la même forme. NE JAMAIS UTILISER L’OUTIL S’IL

N’EST PAS POURVU DE BUVARDS DE CHAQUE CÔTÉ DE LAMEULE.

8. Installer la nouvelle meule ou l’accessoire voulu, en s’assurant d’avoir bien placé les deux

rondelles (les côtés concaves orientés vers la meule).

9. Bien tenir la meule et serrer fermement l’écrou sans exercer trop de force. ON PEUT FISSURER LA MEULE SI ON SERRE TROP LA VIS.

10.Remettre le couvercle de la meule en place et le fixer au moyen des cinq vis.

11.Régler le pare-étincelles à 1,5 mm (1/16 po) de la meule ou de l’accessoire utilisé, puis le

fixer solidement.

12.Régler l’appui à 3,2 mm (1/8 po) de l’accessoire, puis le fixer solidement.

13.Régler le protège-yeux afin qu’il soit situé entre l’utilisateur et l’accessoire.

LAMPE

Pour remplacer l’ampoule de la lampe, retirer la vis et le couvercle (fig. 3), puis retirer l’ampoule.

MISE EN GARDE : afin de réduire les risques d’incendie, utiliser une ampoule pour lampe

d’appareil électroménager de 40 watts; ne jamais utiliser une ampoule pour lampe résidentielle standard.

RENSEIGNEMENTS RELATIFS AU SERVICE

Black & Decker exploite un réseau complet de centres de service et d'ateliers d'entretien

autorisés par toute l'Amérique du Nord. Le personnel de tous les centres de service Black &

Decker a reçu la formation voulue pour assurer l'entretien efficace et fiable des outils

électriques.

Pour obtenir des renseignements d'ordre technique, des conseils relatifs aux réparations ou

des pièces de rechange d'origine, communiquer avec le centre de service Black & Decker de

la région. On peut trouver l'adresse du centre de service de la région dans l'annuaire des

Pages Jaunes à la rubrique «Outils électriques» ou en composant le numéro suivant :

1 (800) 544-6986.

GARANTIE COMPLÈTE DE DEUX ANS POUR UTILISATION DOMESTIQUE

Black & Decker garantit le produit pour une période de deux ans contre les vices de matière

ou de fabrication. Le produit défectueux sera réparé ou remplacé sans frais conformément à

l'une des conditions suivantes.

Pour échanger l'outil, il suffit de le retourner au détaillant (si le détaillant participe au

programme d'échange rapide Black & Decker). Le retour doit être effectuer dans les délais

impartis par la politique de retour du détaillant (habituellement entre 30 et 90 jours suivant la

date d'achat). Le détaillant peut exiger une preuve d'achat. Prière de vérifier la politique de

retour du détaillant au-delà des délais impartis.

On peut également retourner l'outil (port payé) à un centre de service Black & Decker ou à

tout autre atelier d'entretien accrédité pour y être remplacé ou réparé, à notre gré. On peut

exiger une preuve d'achat. Les adresses des centres de service Black & Decker se trouvent

à la rubrique «Outils électriques» des Pages Jaunes.

La présente garantie ne vaut pas pour les accessoires. Les modalités de la présente

garantie donnent des droits légaux spécifiques. L'utilisateur peut également se prévaloir

d'autres droits selon l'état ou la province qu'il habite. Pour obtenir de plus amples

renseignements, communiquer avec le directeur du centre de service Black & Decker de la

région. Le produit n'est pas conçu pour un usage commercial.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

ANTES DE DEVOLVER ESTE PRODUCTO POR CUALQUIER RAZON POR

FAVOR LLAME

326-7100

INFORMACION IMPORT ANTE QUE USTED DEBE SABER:

• Utilice siempre protección para los ojos.

• Verifique que los soportes de la herramienta, los guardachispas y pantallas

protectoras de ojos estén asegurados firmemente antes de accionar la

herramienta.

ADVERTENCIA: Por su propia seguridad lea el manual de instrucciones antes de operar

la herramienta.

Instrucciones de conexión a tierra

En el caso de mal funcionamiento, la tierra proporciona una vía de menor resistencia a la

corriente eléctrica para reducir el riesgo de choque eléctrico. Esta herramienta está equipada

con un cable eléctrico con un conductor a tierra y pata de aterrizaje. La clavija debe

conectarse a una toma de corriente instalada correctamente y aterrizada de conformidad con

todos los reglamentos locales. No modifique la clavija, si no se ajusta a la toma de corriente,

haga que un electricista calificado le instale una toma adecuada.

La conexión incorrecta del conductor a tierra del equipo puede originar riesgos de choque

eléctrico. El conductor cuyo aislamiento es de color verde con o sin franjas amarillas es el

conductor a tierra del equipo. Si se requiere reparación o cambio del cable eléctrico o la

clavija, no conecte el conductor a tierra a una terminal viva.

Consulte con un electricista si no comprende perfectamente las instrucciones de aterrizaje, o

si tiene dudas acerca de la conexión a tierra de su equipo.

Utilice solamente extensiones de tres cables que tengan clavijas de tres patas y tomas de

corriente de tres polos que acepten la clavija de la herramienta.

Repare o reemplace inmediatamente los cables dañados o desgastados.

Esta herramienta está diseñada para utilizarse en circuitos que tengan una toma de corriente

similar a la ilustrada en la figura A. Se puede utilizar un adaptador temporal, que se parece al

mostrado en las figuras B y C, para conectar esta clavija a una toma de corriente de dos

polos como se observa en la figura B si no dispone de una toma aterrizada. Solamente debe

utilizar el adaptador temporal hasta que un electricista le instale una toma apropiada.

La oreja, lengüeta, o similar de color verde que se extiende del adaptador debe conectarse a

tierra permanente, como una toma de corriente aterrizada.

ABC

PATA DE CONEX-

ION A TIERRA

TOMA DE COR-

RIENTE ATER-

RIZADA

MEDIO DE

ATERRIZAJE

ADAPTADOR - El adaptador (C) no debe

usarse en Canadá.

ESMERILADORA DE BANCO DE 6”

Instrucciones importantes de seguridad

• CONSERVE LAS GUARDAS EN SU SITIO y listas para trabajar.

• CONSERVE LIMPIA ELAREA DE TRABAJO. Las áreas y bancos con objetos

acumulados en desorden propician los accidentes.

• NO SE EMPLEE EN AMBIENTES PELIGROSOS. No utilice herramientas eléctricas en

ligares inundados o mojados, ni las exponga a la lluvia. Conserve bien iluminada el área

de trabajo.

• CONSERVE AP ART ADOS ALOS NIÑOS. Todos los visitantes deben permanencer a dis-

tancia segura de la zona de trabajo.

• HAGA SU TALLER A PRUEBA DE NIÑOS con candados, interruptores maestros y reti-

rando las llaves de encendido.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá mejor con su trabajo y de manera más

segura bajo las especificaciones para las que se diseñó.

• EMPLEE LA HERRAMIENTAADECUADA. No fuerce una herramienta o sus dispositivos

en una tarea para los que no han sido diseñados.

• UTILICE UN CABLE DE EXTENSION ADECUADO. Asegúrese que su extensión esté en

buenas condiciones. Cuando utilice una extensión, asegúrese de emplear una que soporte

la corriente que su herramienta necesita. Una extensión con calibre insuficiente provocará

una caída en el voltaje de la línea, ocasionando pérdida de potencia y sobrecalentamiento. El cuadro siguiente muestra el calibre correcto a utilizarse de acuerdo con la longitud y

el amperaje indicado en la placa de identificación. Si tiene dudas, utilice el calibrte siguiente. Mientras más pequeño sea el número del calibre, mayor será su capacidad.

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando utilice la herramienta a la

intemperie, solamente utilice extensiones diseñadas para ello y así marcadas.

• VISTA LAS PRENDAS ADECUADAS. No utilice prendas de vestir flojas, guantes, cor-

batas, anillos, brazaletes ni otras piezas de joyería que pudiesen quedar atrapadas en las

partes móviles. Se recomienda el empleo de calzado antiderrapante. Cúbrase el cabello si

lo tiene largo.

• SIEMPRE UTILICE GAFAS DE SEGURIDAD. También utilice una máscara contra polvo

si la operación a efectuar lo produce. Los anteojos de uso diario solamente tienen lentes

resistentes al impacto, NO SON anteojos de seguridad.

• NO SE SOBREEXTIENDA. Conserve siempre bien apoyados los pies, lo mismo que el

equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas afiladas y limpias para que

funcionen mejor y de manera más segura. Siga las instrucciones de cambio de accesorios.

• DESCONECTE LA HERRAMIENTAS antes de efectuarles servicio y cuando les cambie

acesorios, como cuchillas, brocas y similares.

• REDUZCA EL RIESGO DE ENCENDIDO ACCIDENTAL. Asegúrese que el interruptor

esté en posición de apagado antes de conectar la herramienta.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Busque en el manual de instrucciones

los accesorios recomendados. El uso de accesorios inadecuados puede causar riesgos de

lesiones.

• NUNCA SE PARE EN LA HERRAMIENTA. Puede provocarse lesiones graves si la her-

ramienta se vuelca o si hace contacto accidental con la herramienta de corte.

• REVISE LAS PARTES DAÑADAS. Antes de seguir utilizando la herramienta, debe revis-

ar cuidadosamente una guarda o cualquier otra pieza que esté dañada para determinar si

cumplirá adecuadamente con su función; revise la alineación de las piezas móviles, sus

montajes, ruptura de partes y cualesquiera otras condiciones que pudiesen afectar su

operación. Repare o reemplace las piezas dañadas.

• NUNCA DEJE LA HERRAMIENTA EN FUNCIONAMIENTO Y DESATENDIDA.

APAGUELA. No deje la herramienta hasta que se haya detenido por completo.

• ASEGURE la herrramienta a su mesa de trabajo con prensas u otros medios.

• ASEGURESE que sus dedos no toquen las terminales del cable de alimentación cuando

conecte o desconecte la clavija a o de la linea de alimentación.

• NO TRABAJE CON ESTA HERRAMIENTA CERCA DE LÍQUIDOS, GASES, O POLVO

INFLAMABLE. Las chispas o las astillas calientes producidas por el corte y chispas producidas por las escobillas del motor pueden encender los materiales inflamables.

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar, moler o perforar con máquina,

así como al realizar otras actividades de la construcción, contiene substancias químicas que

se sabe producen cáncer, defectos congénitos u otras afecciones reproductivas. Algunos

ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia en que se haga este tipo

de trabajo. Para reducir la exposición a esas substancias químicas: trabaje en un área bien

ventilada, y trabaje con equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

• La etiqueta de su herramienta puede incluir los siguientes símbolos.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutos ......................corriente alterna

......................corriente directa

n

o........................velocidad sin carga

..........................construcción clase II

........................erminales de

conexión a tierre

........................símbolo de alerta seguridad .../min ..................revoluciones o

reciprocaciones por

minuto

REGLAS DE SEGURIDAD ADICIONALES PARA ESMERILADORAS DE BANCO

· Utilice siempre la protección que corresponda con la rueda de esmeril. La protección

protege al operador de fragmentos de una rueda partida.

· Los accesorios deben tener como mínimo la velocidad nominal recomendada en la etiqueta

de advertencias de la herramienta. Las ruedas y otros accesorios que trabajan a mayor

velocidad que la nominal podrían volar en pedazos y producir lesiones.

· Sujete la herramienta por las superficies aisladas de agarre mientras ejecuta una operación

en la cual la herramienta cortante puede hacer contacto con cables escondidos o el cable

de la herramienta. El contacto con un cable con corriente hará que las partes metálicas

expuestas de la herramienta tengan corriente y le producirá una sacudida eléctrica al

operador.

· Antes de usar, revise si los accesorios recomendados tienen grietas o defectos. Si hay

evidencia de tal grieta o defecto, descarte el accesorio. NO UTILICE UNA RUEDADE

ESMERILQUE ESTË AGRIET ADAO TENGACUALQUIER TIPO DE DEFECTO.

· Al poner en marcha la herramienta, déjela funcionar por un minuto. Nunca ponga en marcha

la herramienta si hay una persona en línea con la rueda. Esto incluye al operador.

· No esmerile por los costados de las ruedas de esmeril a menos que hayan sido dise ñadas

específicamente para ese propósito.

· No apriete demasiado la tuerca de fijación de la rueda. Esto puede partir la rueda de

esmeril.

· Limpie periódicamente la cavidad alrededor de la rueda de esmeril.

MOTOR

Asegúrese de que su fuente de energía coincide con el marcaje de la placa del fabricante.

120 Voltios, 60Hz significa que sólo debe utilizarse corriente alterna para operar esta herramienta. Una baja de energía de más de 10% ocasionará pérdida de poder o recalen-

tamiento. Todas las herramientas Black and Decker han sido probadas en la fábrica: si esta

herramienta no funciona, revise la fuente de energía.

MONTAJE SOBRE EL BANCO

1.La esmeriladora debe estar desconectada.

2.Sitúe la esmeriladora sobre el banco de trabajo. Revise si la esmeriladora tiene acceso a

energía eléctrica. Marque los lugares de los huecos a ser taladrados.

Calibre mínimo para cordones de extensión

VOLTS Longitud total del cordón en metros

120V 0 - 7,62 7,63 - 15,24 15,25 - 30,48 30,49 - 45,72

240V 0 - 15,24 15,25 - 30,48 30,49 - 60,96 60,97 - 91,44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

Page 5

3.Taladre huecos de tamaño adecuado.

4.Inserte tornillos de cabeza hexagonal de 1/4” (6mm) a través de las arandelas y los huecos.

Puede poner arandelas en la parte inferior del banco también.

5.Apriete las tuercas. No las apriete demasiado. Deje que las patas de goma absorban la

vibración cuando la esmeriladora esté funcionando.

INSTALACIÓN DE GUARDACHISPAS, PORTALÁMPARA Y PANTALLAS

PROTECTORAS DE OJOS

APAGUE LAHERRAMIENTAY DESCONÉCTELADE LAFUENTE DE ENERGIA.

Hay siete bolsas de artículos de ferretería empacadas con su esmeriladora de banco. Las

bolsas Nos. 1,2, 3 y 4 que se muestran en la Figura 2 se usan para ensamblar el guardachispas, el portalámpara y la pantalla protectora de ojos como lo muestra la Figura 3.

Para comenzar el ensamblaje, introduzca el tornillo de máquina de 1/2” de largo con la arandela, a través de la abertura del guardachispas del lado izquierdo y dentro del hueco roscado situado en la parte de arriba de la parte interna del protector de metal de la rueda.

Ajuste el borde del guardachispas a un máximo de 1/16” de la rueda de esmeril u otro acce-

sorio. Apriete bien el tornillo.

Alinear el guardachispas del lado izquierdo con la abertura debajo del portalámpara del lado

izquierdo. Seguidamente, alinear la pantalla protectora de ojos de plástico transparente (los

listones hacia arriba como en la Figura 3) con el guardachispas del lado izquierdo. Con estos

tres elementos alineados, introducir el tornillo de 3-1/2” a través de ellos desde el lado

izquierdo, asegurándose de que la porción cuadrada de la cabeza del tornillo esté completamente asentada en el cuadrado ahuecado de la pantalla protectora de ojos. Coloque una

perilla sobre el final de la rosca del tornillo y atorníllela manualmente.

La unidad puede unirse ahora al lado izquierdo de la esmeriladora de banco mediante el

ajuste de las pantallas protectoras de ojos, de forma que queden entre las ruedas y sus ojos.

Fije las pantallas en su sitio apretando la perilla plástica de la unidad con la mano. NOTA:

LAS PANTALLAS PROTECTORAS DE OJOS NO ESTAN DISEÑADAS PARA REEMPLAZAR LOS ANTEOJOS DE SEGURIDAD.

Repita el procedimiento para el ensamblaje del lado derecho introduciendo el tornillo de 31/2” desde el lado derecho.

INSTALACIÓN DE LOS SOPORTES DE LA HERRAMIENTA

APAGUE Y DESCONECTE LA FUENTE DE ENERG ÍAELÉCTRICA.

Instale los receptáculos de los soportes, primero del lado izquierdo, como se muestra en la

Fig. 4. Seguidamente agregue los soportes de la herramienta. Utilice los tornillos, arandelas,

espaciadores y tuercas de seguridad contenidos en la bolsa plástica para fijar los receptáculos y soportes en su sitio.

NOTA: Hay un soporte para el lado izquierdo y uno para el lado derecho de la herramienta.

Durante su funcionamiento, los soportes de la herramienta deben estar ajustados dentro de

1/8” desde la rueda de esmeril u otro accesorio en uso.

Operación

NUNCAUTILIZAR UNA ESMERILADORADE BANCO QUE NO ESTË FIRMEMENTE FIJADAA UN BANCO DE TRABAJO O AUN ARMAZÓN RÍGIDO. Colóquese anteojos de seguridad antes de prender la esmeriladora. Prenda la esmeriladora y deje que llegue a velocidad

de plena marcha (3600 R.P.M. ). Sostenga la pieza de trabajo firmemente contra el soporte

de la herramienta. Sostenga piezas muy pequeñas con pinzas u otros sujetadores apropiados. Avance la pieza suave y uniformemente hacia la rueda de esmeril. Mueva la pieza lentamente y evite apretarla contra la rueda. Como la rueda tiende a bajar de velocidad, se debe

soltar la presión ocasionalmente para dejar que la rueda regrese a su velocidad de plena

marcha.

Esmerile sólo sobre el frente de la rueda de esmeril y nunca sobre el costado. (Algunas

ruedas están diseñadas para esmerilar de lado y esto se informará en las hojas de instrucciones respectivas.)

ATENCIÓN : Un esmerilado prolongado hará que la mayoría de los materiales se calien-

ten. Manéjelos con pinzas o guantes gruesos.

INTERRUPTOR

El interruptor está situado en la parte delantera de la esmeriladora, sobre la base (Figura 1).

Para poner en marcha la herramienta oprima el interruptor de vaivén en el lado derecho,

marcado “I”. Para apagar la esmeriladora, oprima el lado izquierdo del interruptor de vaivén,

marcado “O”.

INSTALACIÓN DE LOS SOPORTES DE LA HERRAMIENTA

APAGUE YDESENCHUFE LAESMERILADORA DE BANCO

Desempaque los soportes de la herramienta e instálelos como se muestra en la Figura 2.

ATENCIÓN : Utilice las arandelas y los tornillos suministrados. Tornillos más largos

pueden interferir con el movimiento de la rueda de esmeril.

MANTENIMIENTO

LIMPIEZA

Es necesaria la eliminación del polvo y las limaduras de la cubierta del motor mediante el

uso de aire comprimido como un procedimiento de mantenimiento regular. El polvo y las

limaduras que contienen partículas de metal, se acumulan a menudo sobre las superficies

interiores y podría producir riesgo de sacudida eléctrica si no se limpian frecuentemente.

UTILICE SIEMPRE ANTEOJOS DE SEGURIDAD.

ATENCIÓN : No utilice nunca solventes u otros productos químicos fuertes para limpiar

las partes no metálicas de la herramienta. Utilice sólo un trapo limpio y seco.

LUBRICACIÓN

Las herramientas Black & Decker vienen con lubricación adecuada desde la fábrica y están

listas para ser utilizadas. Las herramientas deben lubricarse regularmente cada año dependiendo de su uso. (Las herramientas utilizadas para trabajo fuerte y las herramientas

expuestas al calor pueden requerir lubricación más frecuente.) Esta lubricación sólo debe

realizarse por personas entrenadas en la reparación de herramientas eléctricas, como las de

los centros de servicio de Black & Decker o de otras organizaciones de servicio calificado.

ACCESORIOS

Los accesorios que se recomiendan usar con su herramienta, se pueden obtener a un costo

extra donde su distribuidor o centro de servicio local. Las ruedas de esmeril deben caber

dentro de los confines del protector y debe tener una velocidad nominal mayor que la

recomendada en la placa de marcaje e identificación.

Los accesorios que se recomiendan usar con su herramienta, se pueden obtener a un costo

extra donde su distribuidor o centro de servicio local.

ATENCIÓN : Al usar cepillos de alambre en copa puede suceder que se partan hebras

que salen despedidas. Los usuarios y otras personas en el área deben utilizar protección

adecuada para los ojos, cara y cuerpo. Utilice sólo cepillos de alambre en copa que tengan

una velocidad nominal igual o mayor que las R.P.M. que muestra la placa de identificación

de la herramienta.

ADVERTENCIA : Para reducir el riesgo de accidentes, usar siempre protectores apropiados durante el esmerilado así como protección para los ojos.

ATENCIÓN : La utilización de cualquier accesorio no recomendado puede ser peligrosa.

CAMBIO DE ACCESORIOS

APAGUE LAHERRAMIENTA Y DESCONÉCTELA DE LA FUENTE DE ENERGIA.

CAMBIE LOS ACCESORIOS CUANDO EL GUARDACHISPAS YA NO SE PUEDE AJUSTAR A 1/16” DE LA RUEDA.

SOLO UTILICE RUEDAS QUE MIDEN 6” DE DIAMETRO. ESTA HERRAMIENTA TIENE

EJES DE 1/2” DE CADA LADO.

Para quitar y reemplazar un accesorio, proceda como sigue:

1. Levante la pantalla protectora de ojos hacia arriba, despejando el área.

2. Afloje el soporte de la herramienta y hálelo hacia afuera lo más posible. No lo quite.

3. Afloje y hale el guardachispas hacia afuera lo más posible. No lo quite.

4. Saque los cinco tornillos del costado de la cubierta de la rueda y quite la cubierta.

5. Introduzca un destornillador plano dentro de la abertura en el extremo izquierdo del eje

del rotor de la esmeriladora. Sostenga el destornillador firmemente para evitar la rotación del

eje mientras afloja y quita el tornillo de cabeza hexagonal en el centro de la rueda de esmeril u otro accesorio.

NOTA: Si está cambiando solamente el accesorio del lado derecho, no necesita quitar la

cubierta de la rueda izquierda. Hay un hueco en el centro de la cubierta que permite la inserción del destornillador en la abertura del eje. Desenrosque la tuerca en el centro de la rueda

de esmeril. Puede que sea necesario dar un golpe fuerte a la llave en la dirección de afloje

con el canto de su mano para aflojar la tuerca.

NOTA: La tuerca del lado derecho de la esmeriladora tiene una rosca estándar de izquierda

a derecha (gire en contra del reloj para aflojar). La del lado izquierdo tiene una rosca de

IMPORTADO: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 3-26-71-00

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

derecha a izquierda (gire con el reloj para aflojar).

6. Quite la arandela de la rueda y la rueda.

7. Revise si la rueda está agrietada, astillada o si tiene otros daños visibles (fuera del desgaste normal) y descártela si encuentra tales daños. Revise si las arandelas de papel

secante están dañadas. Si faltan o están severamente dañadas, reemplácelas con piezas

de cartón delgado o papel secante cortadas de la misma forma. NO UTILICE NUNCA UNA

RUEDA DE ESMERIL SIN UNA ARANDELA DE PAPEL SECANTE A CADA LADO DE LA

RUEDA.

8. Instale la nueva rueda (u otro accesorio). Asegúrese de que ambas arandelas de la rueda

están en su sitio (los lados cóncavos hacia la rueda).

9. Sosténgala como antes y ajuste la tuerca firmemente pero sin apretar demasiado. UN

AJUSTE DEMASIADO APRETADO PUEDE RESQUEBRAJAR UNA RUEDADE ESMERIL.

10. Coloque de nuevo la cubierta de la rueda y sus cinco tornillos.

11. Ajuste el guardachispas a 1/16" (1.6mm) del accesorio y asegúrelo firmemente.

12. Ajuste el soporte de la herramienta a 1/8" (3.2mm) del accesorio y asegúrelo firmemente.

13. Ajuste la pantalla protectora de ojos en un punto entre sus ojos y el accesorio.

LUZ

Para reemplazar la bombilla/lámpara, quite el tornillo y portalámpara que se muestra en la

Figura 3 y desenrosque la bombilla.

ATENCIÓN : Para reducir el riesgo de fuego, utilice una bombilla de 40 vatios de tipo

electrodoméstico. No utilice una bombilla corriente de tipo casero.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS ELECTRICAS

FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS CERCANO

CULIACAN

Av . Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av . La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av . Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av . Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARAOTRAS LOCALIDADES LLAME AL: 326 7100

INFORMACIÓN DE SERVICIO

Black & Decker ofrece una red completa de centros de servicio propiedad de la compañía y

franquiciados a través de toda Norteamérica. Todos los centros de servicio Black & Decker

cuentan con personal capacitado para proporcionar el servicio a herramientas más eficiente

y confiable.

Siempre que necesite consejo técnico, reparaciones o partes de repuesto genuinas,

comuníquese con el centro Black & Decker más cercano a usted.

Para encontrar su centro de servicio local, consulte la sección amarilla bajo “Herramientas

eléctricas”, o llame al: 326-7100.

GARANTÍA PARAUSO DOMÉSTICO POR DOS AÑOS COMPLETOS

Black & Decker (U.S.) garantiza este producto por dos años completos contra cualquier falla

originada por materiales o mano de obra defectuosos. El producto defectuoso será reemplazado o reparado sin cargo alguno en cualquiera de las siguientes dos maneras:

La primera, que resulta únicamente en cambios, es regresar el producto al vendedor al que

se compró (en la suposición que es un distribuidor participante). Las devoluciones deberán

hacerse dentro del tiempo estipulado por la política de cambios del distribuidor (usualmente

de 30 a 90 días después de la venta). Se puede requerir prueba de compra. Por favor verifique con el vendedor las políticas específicas de devolución relacionadas a las devoluciones en tiempo posterior al estipulado para cambios.

La segunda opción es llevar o enviar el producto (con porte pagado) a los centros de servicio Black & Decker propios o autorizados, para que la reparemos o reemplacemos a nuestra opción. Se puede requerir prueba de compra. Los centros de servicio Black & Decker

propios y autorizados están enlistados bajo “Herramientas eléctricas” en la sección amarilla

del directorio telefónico.

Esta garantía no se aplica a los accesorios. Esta garantía le otorga derechos legales especí-

ficos, y usted puede tener otros que varíen de estado a estado. Si tiene usted cualquier pregunta, comuníquese con el gerente del centro de servicio Black & Decker más cercano. Este

producto no está destinado a uso comercial.

ESPECIFICACIONES

BT3500

Tensión de alimentación: 120 V~

Potencia nominal: 391 W

Frecuencia de operacion: 60 Hz

Consumo de corriente: 3.5A

Loading...

Loading...