Page 1

BPSM1510

www.blackanddecker.ae

Page 2

ENGLISH

2

31.6

2

2.5

2

2

.

5

31.6

15

15

30

30

0

4

5

45

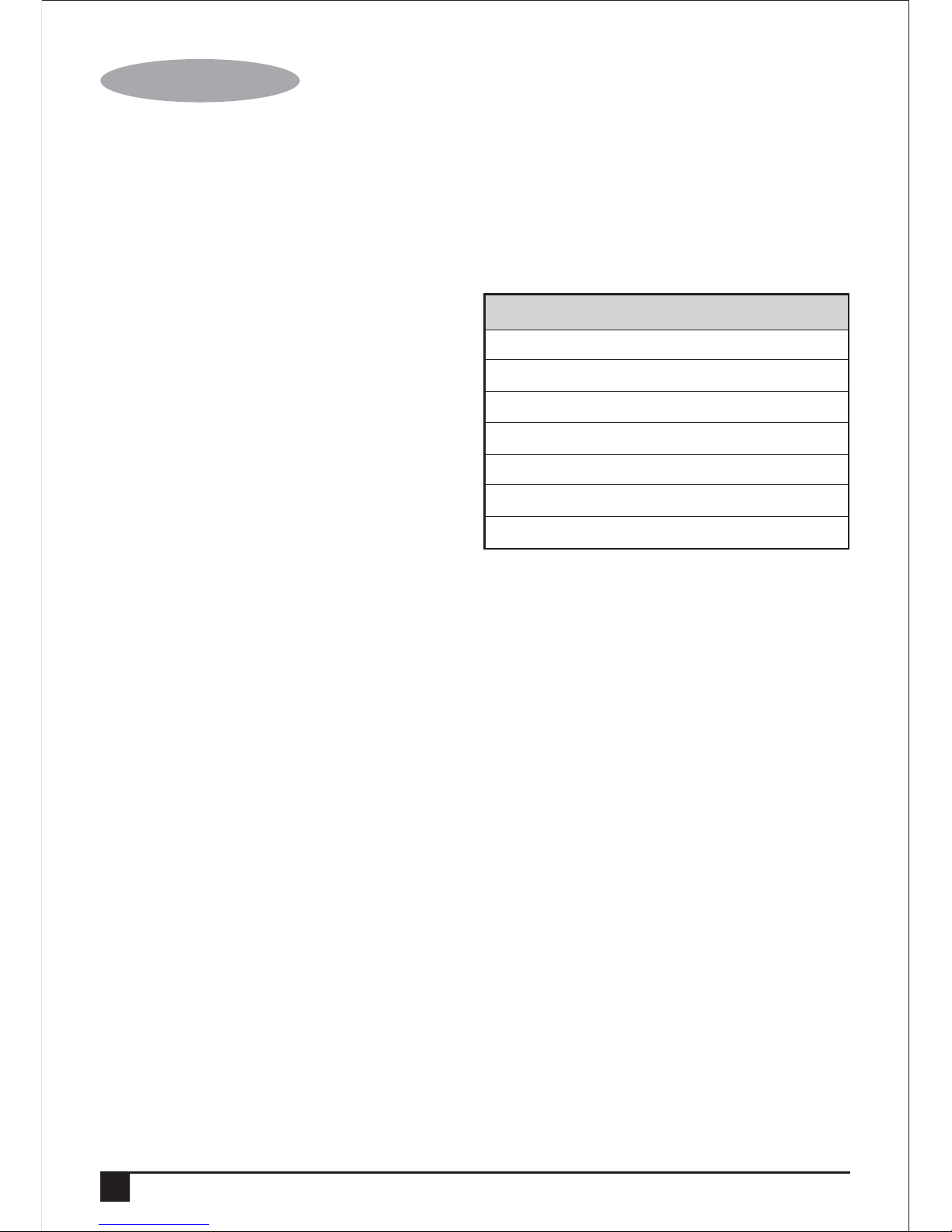

1

2

3

6

5

4

8

7

9

13

14

16

15

Page 3

3

ENGLISH

31.6

22.5

2

2

.5

3

1.6

15

15

30

30

0

4

5

45

31.6

22.5

2

2

.

5

3

1

.

6

15

15

30

30

0

45

45

A

B

C

Page 4

4

ENGLISH

Intended use

Your Black & Decker Mitre Saw has been designed for fast

cutting in wood, fine finishing or aluminum cutting .

General safety rules

Warning! Read and understand all instructions.

Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious

personal injury.

Save these instructions

Safety instructions

General power tool safety warnings

Warning! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

Note: The term "Residual Curent Device (RCD)" can be

replaced by "Ground Fault Circuit Interrupter (GFCI)" or by

"Earth Leakage Circuit Breaker (ELCB)".

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear

eye, ear and respiratory protection. Protective

equipment such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

Page 5

5

ENGLISH

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Use the power tool, accessories and tool bits etc., in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

6. Electrical safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main

voltage corresponds to the voltage on the rating

plate.

Warning! If the power cord is damaged, it must

be replaced by the manufacturer, authorized

Black & Decker Service Center or an equally qualified

person in order to avoid damage or injury. If the power cord

is replaced by an equally qualified person, but not

authorized by Black & Decker, the warranty will not be valid.

7. Labels on tool

The label on your tool may include the following symbols:

Important safety instructions

Key information you should know:

• Cut only with sharp blades. Dull blades cut poorly and

overload the motor.

Hz ....... Hertz

W ....... Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

...... Class II

Construction

...... Earthing

Terminal

...... Safety

Alert Symbol

.../min.. Revolutions

or Recipro cation per

minute

V ........ Volts

A ........ Amperes n

0

....... No-Load

Speed

Page 6

6

ENGLISH

• If the saw does not cut accurately, refer to the trouble

shooting chart in this manual.

Warning! When using electric tools, basic

safety precautions should always be followed to

reduce risk of fire, electric shock, and personal

injury, including the following:

Safety warnings: double insulation

Double insulated tools are constructed throughout with two

separate layers of electrical insulation or one double

thickness of insulation between you and the tool’s electrical

system. Tools built with this insulation system are not

intended to be grounded. As a result, your tool is equipped

with a two prong plug which permits you to use extension

cords without concern for maintaining a ground connection.

Note: Double insulation does not take the place of normal

safety precautions when operating this tool. The insulation

system is for added protection against injury resulting from a

possible electrical insulation failure within the tool.

Warning: When servicing all tools, use

identical replacement parts. repair or replace

damaged cords.

Safety instructions: polarized plugs

To reduce the risk of electric shock, this equipment has a

polarized plug (one blade is wider than the other). This plug

will fit in a polarized outlet only one way. If the plug does not

fit fully into the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the proper utlet. Do

not change the plug in any way.

Warning: Failure to heed these warnings may

result in personal injury and serious damage to

the saw.

Additional safety rules for mitre saws

• Do not use saw blades which are damaged or

deformed.

• Do-Protect electric supply line with at least a 15 ampere

time-delay fuse or a circuit breaker.

• Do-Make certain the blade rotates in the correct

direction and that the teeth at the bottom of the blade

are pointing to the rear of the mitre saw.

• Do-Be sure all clamp handles are tight before starting

any operation.

• Do-Be sure all blade and clamp washers are clean and

recessed sides of collars are against blade. Tighten

arbor screw securely.

• Do-Keep saw blade sharp.

• Do-Keep motor air slots free of chips and dirt.

• Do-Use blade guards at all times.

• Do-Keep hands out of path of saw blade.

• Do-Shut off power, disconnect cord from power source

and wait for saw blade to stop before servicing or

adjusting tool.

• Do-Support long work with an outboard tool rest.

• Do-Use only 10 inch diameter blades.

• Don’t-Attempt to operate on anything but designated

voltage.

• Don’t-Operate unless all clamp handles are tight.

• Don’t-Use blades larger or smaller than those which are

recommended.

• Don’t-Wedge anything against fan to hold motor shaft.

• Don’t-Force cutting action. (Stalling or partial stalling of

motor can cause major damage. Allow motor to reach full

speed before cutting.)

• Don’t-Cut ferrous metals (Those with any iron or steel

content) or any masonry.

• Don’t-Use abrasive wheels. The excessive heat and

abrasive particles generated by them will damage saw.

• Don’t-Allow anyone to stand behind saw.

• Don’t-Apply lubricants to the blade when it’s running.

• Don’t-Place either hand in the blade area when the saw

is connected to the power source.

• Don’t-Use blades rated less than 5500 R.P.M.

• Don’t-Attempt to cut small pieces (hand within 6" of

blade) without clamping.

• Don’t-Operate saw without guards in place.

Page 7

7

ENGLISH

• Don’t-Perform any operation freehand.

• Don’t-Reach around or behind saw blade.

• Don’t-Place hands closer than 6 inches from the saw

blade.

• Don’t-Reach underneath the saw unless it is turned off

and unplugged. The saw blade is exposed on the

underside of the saw.

• Don’t-Move either hand from saw or workpiece or raise

arm until blade has stopped.

• Don’t-Use without Kerf Plate or when kerf slot is wider

than 3/8"

• Don’t- Carry saw by work extension or other accessory.

Caution: Some wood contains preservatives

such as copper chromium arsenate (CCA)

which can be toxic. When cutting these

materials extra care should be taken to avoid inhalation and

minimize skin contact.

Caution: Use of this tool can generate dust

containing chemicals known to cause cancer,

birth defects or other reproductive harm. Use

appropriate respiratory protection.

Caution: Do not connect unit to electrical power

source until complete instructions are read and

understood.

For your convenience and safety, the following warning

labels are on your mitre saw.

On motor housing:

Warning: For your own safety, read instruction

manual before operating saw. When servicing,

use only identical replacement parts. always

wear eye protection.

On fence: Clamp small pieces before cutting. see manual.

On guard:

Danger: Keep away from blade.

On guard retainer plate: “properly secure bracket with both

screws before use.” on table: (2 sitios)

Always tighten adjustment knobs before

use. Keep hands 6" from path of saw

blade. Never perform any operation

freehand. Never cross arms in front of

blade. Think! You can prevent accidents.

Do not operate saw without guards in place. Never reach in

back of saw blade. always wear eye protection. Shut off

power and wait for blade to stop before servicing, adjusting

tool, or moving hands.

Electrical connection

Be sure your power supply agrees with the nameplate

marking. A voltage decrease of 10 percent or more will

cause a loss of power and overheating. All B&D tools are

factory tested. If this tool does not operate, check the power

supply.

Familiarization

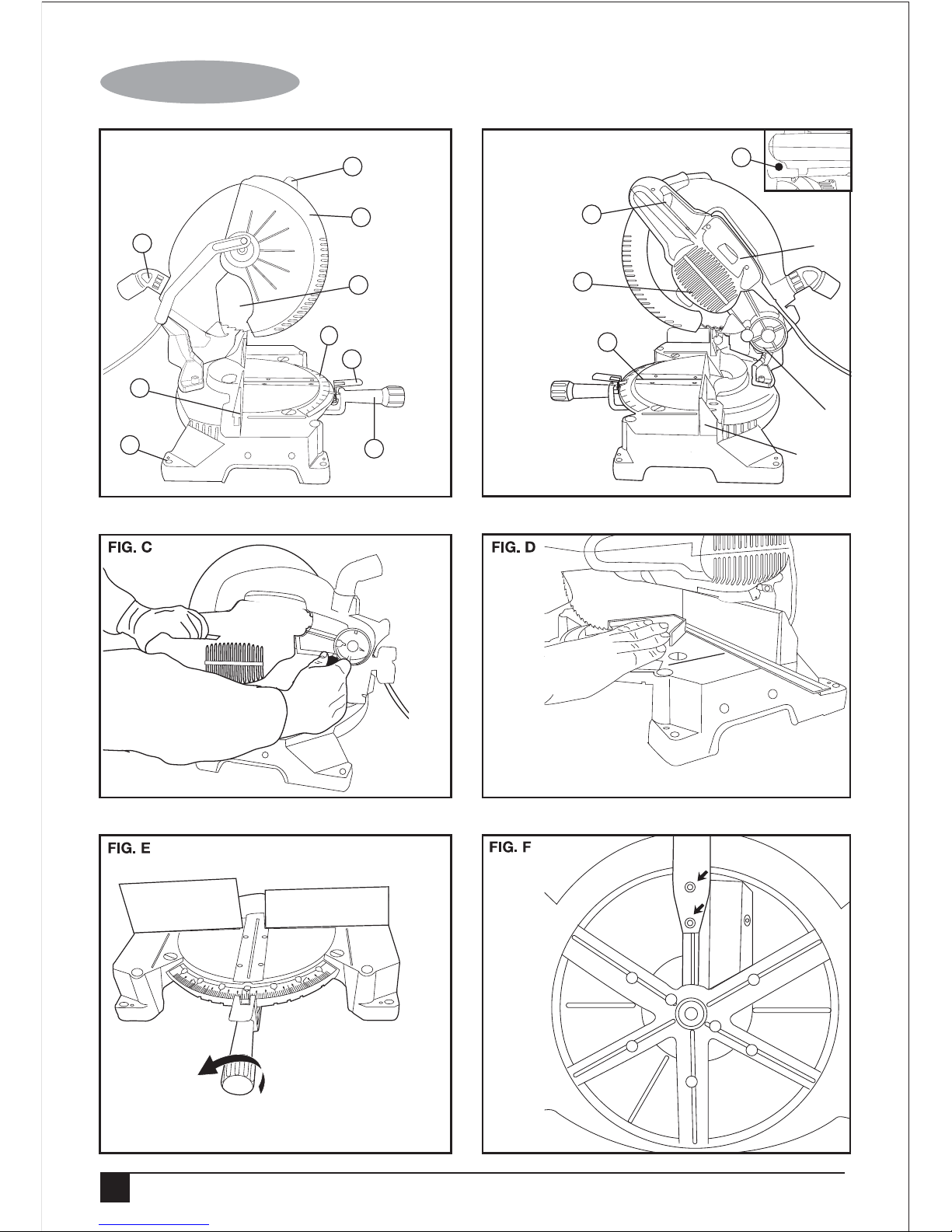

Place the saw on a smooth, flat surface such as a

workbench or strong table. Examine Fig. A & B and refer to

the parts description to become familiar with the saw and its

various parts. The following section on adjustments will refer

to these terms and you must know what and where the parts

are. The part name is followed by the corresponding part

number Example - lock down pin (10). Press down lightly on

the operating handle and pull out the lock down pin (10), as

shown in Fig. C. Gently release the downward pressure and

allow the arm to rise to its full height. Use the lock down pin

when carrying the saw from one place to another. Use the

operating handle (1) to transport the saw or the hand

indentations (11) shown in Fig. B after unplugging.

Bench mounting

Bench mounting holes (8) are provided in all four feet to

facilitate bench mounting, as shown in FIG. A. (Two different

sized holes are provided to accommodate different sizes of

screws. Use either hole, it is not necessary to use both.)

Always mount your saw firmly to prevent movement. To

enhance the tool’s portability, it can be mounted to a piece of

1/2" or thicker plywood which can then be clamped to your

work support or moved to other job sites and reclamped.

Page 8

8

ENGLISH

Note: If you elect to mount your saw to a piece of plywood,

make sure that the mounting screws don’t protrude from the

bottom of the wood. The plywood must sit flush on the work

support. When clamping the saw to any work surface, clamp

only on the clamping bosses where the mounting screw

holes are located. Clamping at any other point will interfere

with the proper operation of the saw.

Caution: To prevent binding and inaccuracy, be sure the

mounting surface is not warped or otherwise uneven. If the

saw rocks on the surface, place a thin piece of material

under one saw foot until the saw sits firmly on the mounting

surface.

Installing a new saw blade

(Unplug the mitre saw) do not use ferrous metal or masonry

cutting blades in this saw

• Loosen hex bolt on center cover counter clockwise with

box wrench.

• Lift up the safe cover and center cover.

• Press down the lock to lock spindle.

• Loosen hex bolt clockwise with box wrench, then

dismount the bolt and flange.

• Mount the blade of saw on spindle. Make sure that the

arrow direction on surface of saw blade is same as one

of the cover.

Note: There are two different internal diameters of cutter in

inner plate which have steel stamp marked 25.4mm 16mm.

When mounting, the outer diameter of inner plate must be

correspondent with the internal diameter of saw blade.

• Mount flange and hex bolt.

• Press axle lock and tighten hex bolt counter clock wise

with box wrench firmly, then tighten hex bolt clockwise to

fix centre cover.

Note: Only use attached wrench when mounting or

dismounting saw blade. When dismounting saw blade, lift up

safe cover and centre cover. Loosen hex bolt with box

wrench and disassemble hex bolt, flange and saw blade.

Never depress the spindle lock pin while the blade is

rotating. Be sure to hold the guard bracket down and firmly

tighten the guard bracket screw when you finish installing the

saw blade. Failure to do so will cause serious damage to the

saw.

Assembling and adjusting your saw

Perform all assembly with saw unplugged. attach mitre

clamp handle.

Remove the mitre clamp handle (4) from the plastic parts

bag and carefully thread it into the bracket in the front of the

saw.

Attaching dust bag

A zippered cloth dust bag is included with your saw. To

attach the bag, fit the plastic opening firmly over the dust

spout (9).

Note: The saw can also be used with a vacuum cleaner

hose attached to the dust spout or without any attachment.

Adjustments

Perform all adjustments with the mitre saw unplugged.

Note: Your mitre saw is fully and accurately adjusted at the

factory at the time of manufacture. If readjustment due to

shipping and handling or any other reason is required, follow

the steps below to adjust your saw:

• mitre scale adjustment. place a square against the saw’s

fence and blade, as shown in Fig. D. (Do not touch the

tips of the blade teeth with the square. To do so will

cause an inaccurate measurement.) Loosen the mitre

clamp handle (4) as shown in Fig. E and swing the mitre

arm until the mitre latch (5) locks it at the 0 mitre position.

Do not tighten the clamp handle. If the saw blade is not

exactly perpendicular to the fence, loosen the two screws

that hold the handle to the base (shown in Fig. 6) and

move the arm of the saw left or right until the blade is

perpendicular to the fence, as measured with the square.

Retighten the two screws. Pay no attention to the reading

of the mitre pointer at this point.

Page 9

9

ENGLISH

• Guard actuation and visibility. the blade guard on your

saw has been designed to automatically raise when the

arm is brought down and to lower over the blade when

the arm is raised. The guard can be raised by hand

when installing or removing saw blades or for inspection

of the saw. Never raise the blade guard manually unless

the saw is turned off.

Note: Certain special cuts will require that you manually

raise the guard. To do this, simply place your right thumb on

the upper side of the guard and roll the guard up just

enough to clear the workpiece.Never tie up or otherwise

prevent the guard from operating normally.

Operation

Plug the saw into any power source. Refer to the nameplate

for voltage. Be sure the cord will not interfere with your

work.

Switch

To turn the saw on, depress the trigger switch (16). To turn

the tool off, release the switch. There is no provision for

locking the switch on.

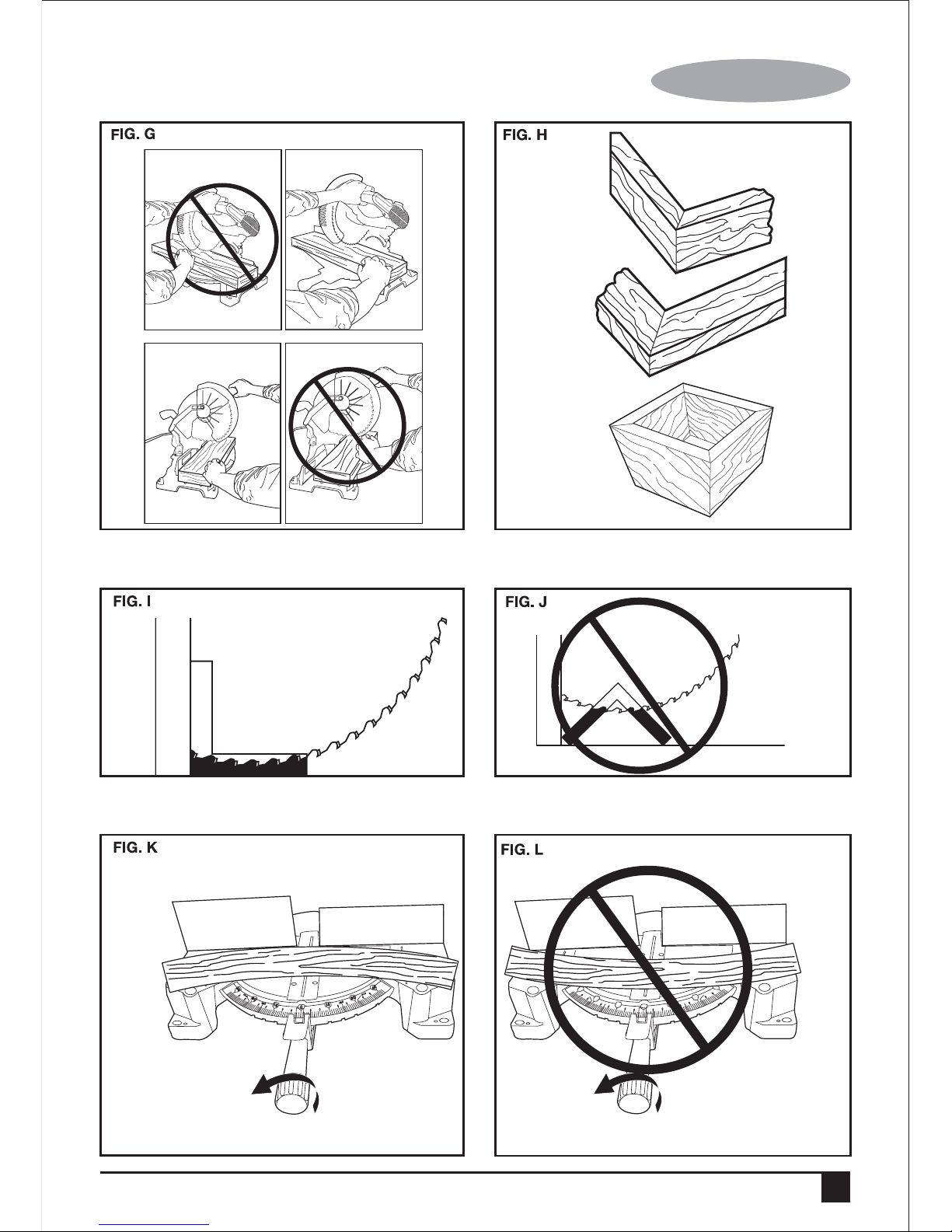

Body and hand position (see fig. G)

Proper positioning of your body and hands when operating

the mitre saw will make cutting easier, more accurate and

safer. Never place hands near cutting area. Place hands no

closer than 6" from the blade. Hold the workpiece tightly to

the table and the fence when cutting. Keep hands in position

until the trigger has been released and the blade has

completely stopped. Always make dry runs (unpowered)

before finish cuts so that you can check the path of the

blade. do not cross hands, as shown in Fig. G.

Cutting with your saw

Note: Although this saw will cut wood and many nonferrous

materials, we will limit our discussion to the cutting of wood

only. The same guidelines apply to the other materials. Do

not cut ferrous (iron and steel) materials or masonry with

this saw. Do not use any abrasive blades.

Crosscuts

Note: Cutting of multiple pieces is not recommended, but

can be done safely by ensuring that each piece is held firmly

against the table and fence. A crosscut is made by cutting

wood across the grain at any angle.

• A straight crosscut is made with the mitre arm at the zero

degree position. Set the mitre arm at zero, hold the wood

on the table and firmly against the fence. Turn on the

saw by squeezing the trigger switch.

• When the saw comes up to speed (about 1 second)

lower the arm smoothly and slowly to cut through the

wood. Let the blade come to a full stop before raising

arm.

• Mitre crosscuts are made with the mitre arm at some

angle other than zero. This angle is often 45º degrees for

making corners, but can be set anywhere from zero to

degrees left or right. After selecting the desired mitre

angle, be sure to tighten the mitre clamp handle (4).

Make the cut as described above.

Bevel cuts

A bevel cut is a crosscut made with the saw blade at a bevel

to the wood. In order to set the bevel, loosen the bevel

clamp knob (17) and move the saw to the left as desired.

Once the desired bevel angle has been set, tighten the bevel

clamp knob firmly. Bevel angles can be set up to 45º

degrees left and can be cut with the mitre arm set between

zero and 47º degrees right or left.

Quality of cut

• The smoothness of any cut depends on a number of

variables. Things like material being cut, blade type,

blade sharpness and rate of cut all contribute to the

quality of the cut.

• When smoothest cuts are desired for molding and other

precision work, a sharp (60 tooth carbide) blade and a

slower, even cutting rate will produce the desired results.

• Ensure that material does not creep while cutting, clamp

it securely in place. Always let the blade come to a full

stop before raising arm.

Page 10

• If small fibers of wood still split out at the rear of the

workpiece, stick a piece of masking tape on the wood

where the cut will be made. Saw through the tape and

carefully remove tape when finished.

• Keep both feet firmly on the floor and maintain proper

balance. As you move the mitre arm left and right, follow

it and stand slightly to the side of the saw blade. Sight

through the guard louvers when following a pencil line.

Clamping the workpiece

Turn off and unplug saw.

• If you cannot secure the workpiece on the table and

against the fence by hand (irregular shape, etc.) or your

hand will be within 6” of the blade, a clamp or fixture

must be used.

• Other convenient clamps such as spring, bar or C

clamps may be appropriate for certain sizes and shapes

of workpieces. Use care in selecting and placing these

clamps and make a dry run before making the cut.

Support for long pieces

Turn off and unplug saw. Always support long pieces. For

best results, use an extension work support to extend the

table width of your saw. Support long workpieces using any

convenient means such as sawhorses or similar devices to

keep the ends from dropping.

Cutting picture frames, and other four sided projects

• To best understand how to make the items listed here,

we suggest that you try a few simple projects using

scrap wood until you develop a “FEEL” for your saw.

• Your saw is the perfect tool for mitering corners like the

ones shown in FIG. H, which shows a joint made by

setting the mitre arm at 45º degrees to to mitre the two

boards to form a 90º degree corner. To make this type of

joint, set the mitre arm to 45º degrees. The wood was

positioned with the broad flat side against the table and

the narrow edge against the fence.

• As the number of sides changes, so do the mitre angles.

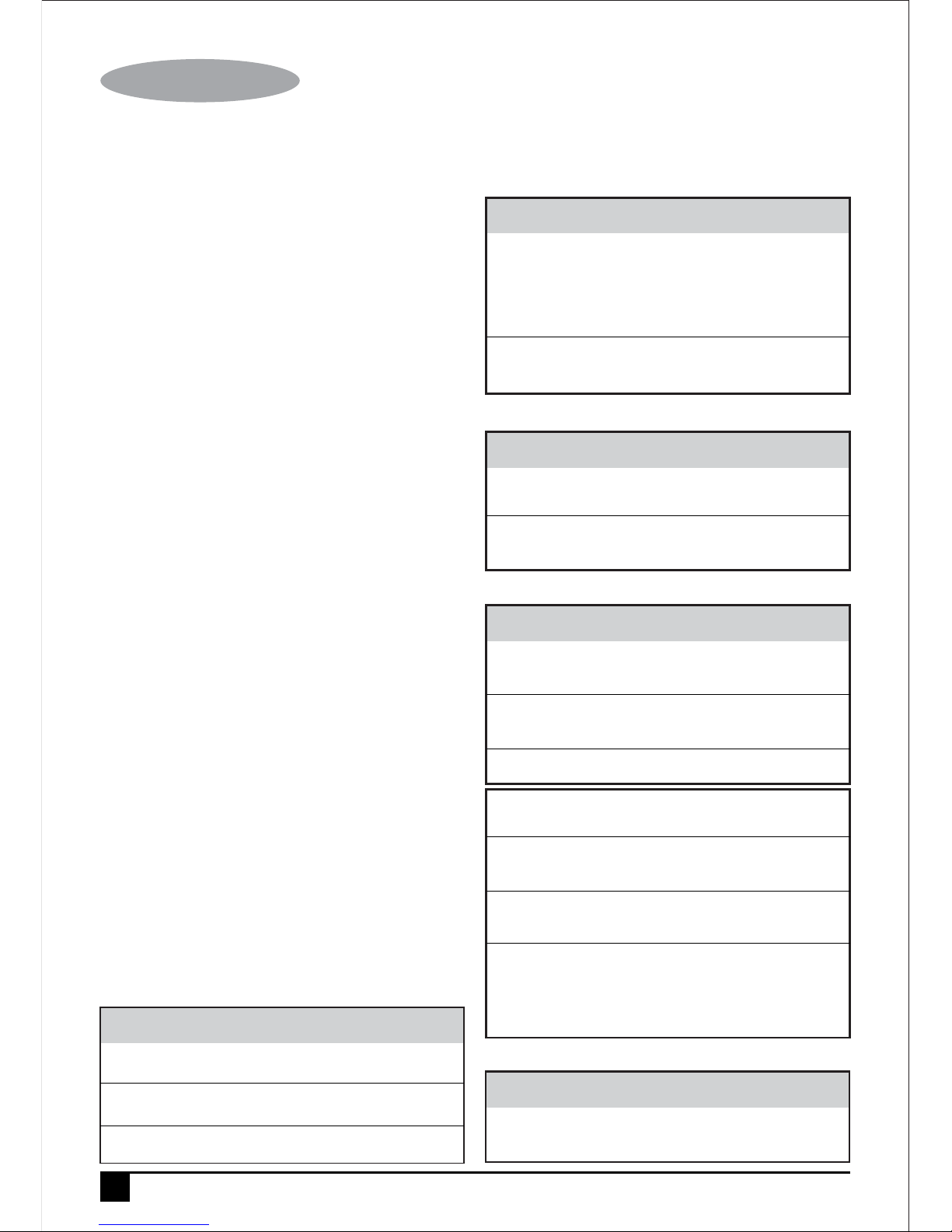

The chart below gives the proper angles for

a variety of shapes. (The chart assumes that all sides

are of equal length.)

• For a shape that is not shown in the chart, use the

following formula. 180º degrees divided by the number of

sides equals the mitre.

Examples

Cutting compound mitres

The A compound mitre is a cut made using a mitre angle and

a bevel angle at the same time. This is the type of cut used

to make frames or boxes with slanting sides like the one

shown in Fig. H.

Note: If the cutting angle varies from cut to cut, check that

the bevel clamp knob (10) and the mitre clamp handle (4)

are securely tightened. These knobs must be tightened after

making any changes in bevel or mitre.

Cutting crown molding

• In order to fit properly, crown molding must be mitreed

with extreme accuracy. The two flat surfaces on a given

piece of crown molding are at angles that, when added

together, equal exactly 90º degrees. Most, but not all,

crown molding has a top rear angle (the section that fits

flat against the ceiling) of 52º degrees and a bottom rear

angle (the part that fits flat against the wall) of 38º

degrees.

• Pretesting with scrap material is extremely important!

Place the bottom side (the side that will be against the

wall) against the mitre saw fence. Place the top (that part

that will be against the ceiling) against the saw table and

the crown molding fence.

10

ENGLISH

NO. SIDES ANGLE MITRE

4 45º

5 36º

6 30º

7 25.7º

8 22.5º

9 20º

10 18º

Page 11

11

ENGLISH

Instructions for cutting crown molding angled between

the fence and the table of the saw for all cuts:

• Angle the molding so the bottom of the molding (part

which goes against the wall when installed) is against

the fence and the top of the molding is resting on the

table of the saw.

• The angled “flats” on the back of the molding must rest

squarely on the fence and table of the saw.

Inside corner:

Left side Right side

• Mitre right at 45° • Mitre left at 45°

• Save the right side of cut • Save left side of cut

Outside corner:

Left side Right side

• Mitre left at 45° • Mitre right at 45°

• Save the right side of cut • Save left side of cut

Always make dry runs to check for clearance and

correctness of cuts.

Never make any cuts unless the material is secured on the

table and against the fence.

Special cuts

Aluminum cutting

(Carbide tipped blade only)

• Aluminum extrusions such as those used when making

aluminum screens and storm windows can easily be cut

with your saw using the proper blade designed for

non-ferrous metal cutting. Position the material so that

you will be cutting the thinnest cross section, as shown

in Fig. I.

• Fig. J illustrates the wrong way to cut these extrusions.

Use a wax lubricant when cutting aluminum such as

Johnson’s Stick Wax No.140. Apply the stick wax directly

to the saw blade before cutting.

• Never apply stick wax to a moving blade. The wax,

available at most hardware stores and industrial mill

supply houses, provides proper lubrication and keeps

chips from adhering to the blade.

• Be sure to properly secure work. Certain workpieces,

due to their size, shape or surface finish, may require

the use of a clamp, jig or fixture to prevent movement

during the cut.

Bowed material

The When cutting bowed material always position it as

shown in Fig. K and never like that shown in Fig. L.

Positioning the material incorrectly will cause it to pinch the

blade near the completion of the cut.

Cutting plastic pipe and other round cross-sectional

material

Plastic pipe can be easily cut with your saw. It should be cut

just like wood and clamped or held firmly to the fence to

keep it from rolling particularly when making angle cuts.

Accessories

The performance of your tool depends on the accessory

used. Black & Decker and Piranha accessories are

engineered to high quality standards and designed to

enhance the performance of your tool. By using these

accessories you will get the very best from your tool.

Maintenance

Perform all maintenance with mitre saw unplugged.

1. All bearings are sealed. They are lubricated for life and

need no further maintenance.

2. Periodically clean all dust and wood chips from around

and under the base and the rotary table. Even though

slots are provided to allow debris to pass through, some

dust will accumulate.

3. The brushes are designed to give you several years of

use. If they ever need replacement follow the instructions

in this manual or return the tool to the nearest service

center for repair.

Your tool has been designed to operate over a long period of

time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

Warning: Before performing any maintenance, switch off

and unplug the tool.

• Regularly clean the ventilation slots in your tool using a

soft brush or dry cloth.

• Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

• If the table insert / slot is worn, please take this tool to

authorized Black & Decker Service Center to replace it in

order to avoid damage or injury.

Page 12

12

ENGLISH

Power 1500W

No-Load speed 5500/min

Max Depth 70mm

Installing a New Saw Blade

(UNPLUG THE MITRE SAW)

• DO NOT USE FERROUS METAL or masonry cutting

blades in this saw

• Loosen hex bolt on center cover counter clockwise with

box wrench.

• Lift up the safe cover and center cover.

• Press down the lock to lock spindle.

• Loosen hex bolt clockwise with box wrench, then

dismount the bolt and flange.

• Mount the blade of saw on spindle. Make sure that the

arrow direction on surface of saw blade is same as one

of the cover.

Note: There are two different internal diameters of cutter in

inner plate which have steel stamp marked 25.4mm 16mm.

When mounting, the outer diameter of inner plate must be

correspondent with the internal diameter of saw blade.

• Mount flange and hex bolt.

• Press axle lock and tighten hex bolt counter clock wise

with box wrench firmly, then tighten hex bolt clockwise to

fix centre cover.

Note: Only use attached wrench when mounting or

dismounting saw blade. When dismounting saw blade, lift up

safe cover and centre cover. Loosen hex bolt with box

wrench and disassemble hex bolt, flange and saw blade.

NEVER DEPRESS THE SPINDLE LOCK PIN WHILE THE

BLADE IS ROTATING.

• Be sure to hold the guard bracket down and firmly

tighten the guard bracket screw when you finish

installing the saw blade. Failure to do so will cause

serious damage to the saw.

Specifications

Troubleshooting

Trouble! Saw makes unsatisfactory cuts

What’s wrong? What to do

3. Gum or pitch on blade. 3 Remove blade and

clean with turpentine

and coarse steel wool

or household oven

cleaner.

4. Incorrect blade for work 4. Change the blade.

being done.

Trouble! blade does not come up to speed

What’s wrong? What to do

1. Extension cord is too light 1. Replace with adequate

or too long. size cord.

2. Low house current. 2. Contact your electric

company.

Trouble! Machine vibrates excessively

What’s wrong? What to do

1. Saw not mounted securely. 1. Tighten all mounting

hardware.

2. Stand or bench on 2. Reposition on flat level

uneven floor. surface.

3. Damaged saw blade. 3. Replace blade.

1. mitre scale not adjusted 1. Check and adjust.

correctly.

2. Blade is not square to 2. Check and adjust.

fence.

3. The disc is perpendicular 3. Check and adjust the

to the table. guide.

4. Workpiece moving. 4. Clamp workpiece to

fence or glue 120 grit

sandpaper to fence

with rubber cement.

Trouble! Material pinches blade

What’s wrong? What to do

1. Cutting bowed material. 1. Position bowed material

as shown in Fig. K.

Page 13

13

ENGLISH

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Black & Decker

product needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and

packaging allows materials to be recycled and used

again. Reuse of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Black & Decker provides a facility for the collection and

recycling of Black & Decker products once they have

reached the end of their working life. To take advantage of

this service please return your product to any authorised

repair agent who will collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Black & Decker office at the

address indicated in this manual. Alternatively, a list of

authorised Black & Decker repair agents and full details of

our after-sales service and contacts are available on the

Internet at: www.2helpU.com.

Service information

Black & Decker offers a full network of company-owned and

authorized service locations. All Black & Decker Service

Centers are staffed with trained personnel to provide

customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine

factory replacement parts, contact the Black & Decker

location nearest you.

Guarantee

Black & Decker is confident of the quality of its products and

offers an outstanding guarantee. This guarantee statement is

in addition to and in no way prejudices your statutory rights.

The guarantee is valid within the territories of the Member

States of the European Union and the European Free Trade

Area.

If a Black & Decker product becomes defective due to faulty

materials, workmanship or lack of conformity, within 12

months from the date of purchase, Black & Decker

guarantees to replace defective parts, repair products

subjected to fair wear and tear or replace such products to

make sure of the minimum inconvenience to the customer

unless:

• The product has been used for trade, professional or hire

purposes.

• The product has been subjected to misuse or neglect.

• The product has sustained damage through foreign

objects, substances or accidents.

• Repairs have been attempted by persons other than

authorised repair agents or Black & Decker service staff.

To claim on the guarantee, you will need to submit proof of

purchase to the seller or an authorised repair agent. You can

check the location of your nearest authorised repair agent by

contacting your local Black & Decker office at the address

indicated in this manual. Alternatively, a list of authorised

Black & Decker repair agents and full details of our aftersales

service and contacts are available on the Internet at:

www.2helpU.com

Please visit our website www.blackanddecker.co.uk to

register your new Black & Decker product and to be kept up

to date on new products and special offers. Further

information on the Black & Decker brand and our range of

products is available at www.blackanddecker.co.uk.

Page 14

14

FRANÇAIS

31.6

2

2.5

2

2

.

5

31.6

15

15

30

30

0

4

5

45

10

1

2

3

6

5

4

8

7

9

1

12

13

14

16

11

15

Page 15

15

FRANÇAIS

31.6

22.5

2

2

.5

3

1.6

15

15

30

30

0

4

5

45

31.6

22.5

2

2

.

5

3

1

.

6

15

15

30

30

0

45

45

A

B

C

Page 16

16

FRANÇAIS

Utilisation prévue

Votre souffleur Black & Decker a été conçu pour souffler et

nettoyer et possède la capacité d’une aspiration de niveau

léger.

Consignes générales de sécurité

Attention! Lisez toutes les instructions. Le

non-respect des instructions indiquées

ci-dessous peut entraîner un choc électrique,

un incendie et/ou des blessures graves.

Conservez ces consignes de sécurité

Consignes de sécurité concernant les outils

électroportatifs

Attention ! Lisez avec attention tous les

avertissements et toutes les instructions. Le

non-respect de cette consigne peut entraîner

une électrocution, un incendie et/ou de graves blessures.

Conservez tous les avertissements et instructions pour

référence ultérieure.

La notion d'« outil électroportatif » mentionnée par la suite

se rapporte à des outils électriques raccordés au secteur

(avec câble de raccordement) ou fonctionnant avec batterie

(sans fil).

1. Sécurité de la zone de travail

a. Maintenez la zone de travail propre et bien éclairée.

Un lieu de travail en désordre ou mal éclairé augmente

le risque d'accidents.

b. N'utilisez pas les outils électroportatifs dans un

environnement présentant des risques d'explosion

ni en présence de liquides, gaz ou poussières

inflammables. Les outils électroportatifs génèrent des

étincelles risquant d'enflammer les poussières ou les

vapeurs.

c. Pendant l’utilisation d’un outil électroportatif, les

enfants et autres personnes doivent rester éloignés.

En cas d'inattention, vous risquez de perdre le contrôle

de l'outil.

2. Sécurité électrique

a. La prise de l'outil électroportatif doit convenir à la

prise de courant. Ne modifiez en aucun cas la prise.

N'utilisez pas de prises d'adaptateur avec des

appareils ayant une prise de terre. Le respect de ces

consignes réduit le risque de choc électrique.

b. Évitez le contact physique avec des surfaces mises

à la terre telles que tuyaux, radiateurs, fours et

réfrigérateurs. Le risque de choc électrique augmente si

votre corps est relié à la terre.

c. N'exposez pas l'outil électroportatif à la pluie ni à

l'humidité. La pénétration d'eau dans un outil

électroportatif augmente le risque de choc électrique.

d. Préservez le câble d'alimentation. N'utilisez pas le

câble pour porter l'outil, pour l'accrocher ou encore

pour le débrancher. Maintenez le câble éloigné des

sources de chaleurs, des parties huilées, des bords

tranchants ou des parties de l'appareil en rotation.

Le risque de choc électrique augmente si les câbles sont

endommagés ou emmêlés.

e. Si vous utilisez l'outil électroportatif à l'extérieur,

utilisez une rallonge homologuée pour utilisation à

l'air libre. L'utilisation d'une rallonge électrique

homologuée pour les travaux à l’extérieur réduit le risque

de choc électrique.

f. Si l’outil doit être utilisé dans un endroit humide,

prenez les précautions nécessaires en utilisant un

dispositif à courant résiduel (RCD). L’utilisation d’un

tel dispositif réduit les risques d’électrocution.

Remarque: Le terme “dispositif à courant résiduel (RCD)”

peut être remplacé par “disjoncteur de fuite à la terre (GFCI)”

ou par “interrupteur différentiel de sécurité (ELCB)".

3. Sécurité personnelle

a. Restez vigilant, surveillez ce que vous faites. Faites

preuve de bon sens quand vous utilisez un outil

électroportatif. N’utilisez pas l’outil lorsque vous

êtes fatigué ou après avoir consommé de l’alcool

ainsi que des médicaments. Un moment d'inattention

lors de l'utilisation de l'outil peut entraîner de graves

blessures.

b. Portez un équipement de protection. Portez toujours

des lunettes de protection. Selon le travail à effectuer,

le port d'équipement de protection tels que masque

anti-poussières, chaussures de sécurité antidérapantes,

casque ou protection auditive, réduit le risque de

blessures.

c. Évitez un démarrage imprévu. L’appareil doit être en

position OFF (arrêt) avant d'effectuer le branchement

à l'alimentation et/ou au bloc-batterie, de le ramasser

ou de le porter. Ne laissez pas votre doigt sur le bouton

de commande, ceci peut être à l’origine d’accident.

Page 17

17

FRANÇAIS

d. Retirez tout outil ou clé de réglage avant de mettre

l’outil en marche. Une clé ou un outil se trouvant sur

une partie en rotation peut causer des blessures.

e. Adoptez une position confortable. Adoptez une

position stable et gardez votre équilibre en

permanence. Vous contrôlerez ainsi mieux l'outil dans

des situations inattendues.

f. Portez des vêtements appropriés. Ne pas porter de

vêtements flottants ou de bijoux. N’approchez pas

les cheveux, vêtements ou gants des parties des

pièces mobiles. Les vêtements amples, les bijoux ou

les cheveux longs peuvent être attrapés dans les pièces

en mouvement.

g. En cas d’utilisation d’appareils servant à aspirer ou

à recueillir les poussières, assurez-vous qu’ils sont

correctement raccordés et utilisés. L'utilisation de tels

appareils permet de réduire les dangers liés aux

poussières.

4. Utilisation des outils électroportatifs et

précautions

a. Respectez la capacité de l'outil. Utilisez l'outil

électroportatif approprié pour le travail à effectuer.

Avec un outil approprié, vous travaillerez mieux et en

toute sécurité.

b. N’utilisez pas un outil électroportatif dont

l’interrupteur marche/arrêt est défectueux. Un outil

électroportatif qui ne peut plus être mis en marche ou

arrêter est dangereux et doit être réparé.

c. Retirez la prise de courant et/ou débranchez le

blocbatterie avant d'effectuer des réglages, de

changer les accessoires ou de ranger l'outil. Cette

mesure de précaution empêche de mettre l’outil en

marche accidentellement.

d. Rangez les outils électroportatifs hors de portée des

enfants. Les personnes ne connaissant pas l’outil ou

n’ayant pas lu ces instructions ne doivent en aucun

cas l’utiliser. Les outils électroportatifs sont dangereux

lorsqu'ils sont utilisés par des personnes non initiées.

e. Prenez soin des outils électroportatifs. Vérifiez que

les parties en mouvement fonctionnent correctement

et qu'elles ne sont pas coincées. Vérifiez qu'il n’y a

pas de pièces cassées ou endommagées

susceptibles de nuire au bon fonctionnement de

l'outil. S’il est endommagé, faites réparer l’outil

avant de l’utiliser. De nombreux accidents sont la

conséquence d’outils mal entretenus.

f. Utilisez les outils électroportatifs, les accessoires,

etc. en suivant ces instructions et en tenant compte

des conditions de travail, ainsi que du travail à

effectuer. L'utilisation des outils électroportatifs à

d'autres fins que celles prévues peut vous mettre en

situation dangereuse.

5. Réparations

a. Faites réparer votre outil électroportatif uniquement

par du personnel qualifié et seulement avec des

pièces de rechange appropriées. La fiabilité de l’outil

sera ainsi maintenue.

6. Sécurité électrique

Cet outil est doublement isolé; par conséquent,

aucun câble de mise à la terre n’est nécessaire.

Vérifiez toujours que la tension secteur

correspond à celle indiquée sur la plaque signalétique.

Attention! Si le câble d’alimentation est

endommagé, il doit être remplacé par le

fabricant, par un centre de réparation Black &

Decker agréé ou par un technicien qualifié, de façon à éviter

les dommages matériels et corporels. En cas de

remplacement du câble d’alimentation par un technicien

qualifié mais non agréé par Black & Decker, la garantie ne

sera pas valable.

7. Etiquettes apposées sur les outils

L’étiquette apposée sur votre outil peut afficher les symboles

suivants:

Consignes de sécurité importantes

Informations clés que vous devez connaître:

• Scier uniquement avec des lames bien affûtées. Les

lames émoussées scient difficilement et surchargent le

moteur.

Hz ....... Hertz

W ....... Watts

min ..... minutes

..... Courant

alternatif

..... Courant

continu

Lire le

manuel

d’instructions

Utiliser une

protection

oculaire

Utiliser des

protections

auditives

...... Construction

de classe II

...... Borne

de terre

...... Symbole

d’alerte de

sécurité

.../min.. Rotations

par minute

V ........ Volts

A ........ Ampères n

0

....... Vitesse

à vide

Page 18

18

FRANÇAIS

• Si la scie ne coupe pas avec précision, reportez-vous à

la section Dépannage dans ce manuel.

Attention! Pendant l’utilisation d’outils

électriques, des précautions de base doivent

être prises pour réduire tout risque d’incendie,

de choc électrique et de blessures corporelles, y compris les

suivantes:

Consignes de sécurité: double isolation

Les outils à double isolation sont conçus de façon à offrir

sur toute leur surface deux couches séparées d’isolation

électrique ou une double épaisseur d’isolation entre

l’utilisateur et le système électrique de l’outil. Les outils

fabriqués avec ce type d’isolation ne requièrent pas de mise

à la terre. Par conséquent, cet outil est muni d’une fiche à

deux broches qui permet d’utiliser une rallonge sans se

soucier de maintenir une connexion à la terre.

Remarque: L’isolation double ne remplace pas les mesures

de sécurité normales à observer durant l’utilisation de l’outil.

Le système d’isolation assure plutôt une protection

supplémentaire contre les blessures causées par un

éventuel défaut d’isolement dans l’outil.

Attention: Pendant le service d’entretien, et en

cas de réparation des outils ou du

remplacement de câbles endommagés,

utilisez toujours des pièces de rechange

identiques.

Consignes de sécurité: fiches polarisées

Afin de réduire le risque de choc électrique, cet appareil est

pourvu d’une fiche polarisée (une lame est plus large que

l’autre). Cette fiche ne peut être branchée dans une prise

polarisée que dans un seul sens. Si la fiche ne peut être

insérée complètement dans la prise, inversez-la. Si malgré

cette inversion la fiche ne peut toujours pas être insérée

complètement, prenez contact avec un électricien qualifié

pour qu’il installe une prise polarisée. Ne modifier la fiche

d’aucune façon.

Attention: Le non-respect de ces consignes

peut entraîner des blessures corporelles et des

dommages importants à la scie.

Consignes de sécurité supplémentaires pour scies à

onglet

• Protéger le câble d’alimentation électrique avec un

fusible de 15 ampères minimum ou un disjoncteur.

• S’assurer que la lame tourne dans le sens correct et

que les dents du bas de la lame sont dirigées vers

l’arrière de la scie à onglet.

• S’assurer que les poignées de serrage sont fermement

serrées avant toute opération.

• S’assurer que toutes les lames et les rondelles de

serrage soient propres et que les parties incurvées des

colliers font face à la lame. Serrez fermement les écrous.

• Maintenir les lames de scie correctement affûtées.

• S’assurer que les orifices de ventilation de l’outil sont

propres et exempts de copeaux.

• S’assurer que les carters de protection sont en place à

tout moment.

• Eloigner les mains de la trajectoire de la lame.

• Mettre l’outil hors tension, débrancher le câble

d’alimentation du secteur et attendre que la lame se soit

arrêtée complètement avant d’effectuer tout entretien ou

de procéder à des réglages de l’outil.

• Toujours soutenir les pièces longues avec un support

porte-outils.

• N’utiliser que des lames de 10 pouces (25,4 cm) de

diamètre.

• Ne pas essayer de faire fonctionner l’outil sur toute autre

tension que celle désignée.

• Ne pas mettre en fonctionnement avant de s’assurer que

toutes les poignées de serrage sont correctement

serrées.

• Ne pas utiliser de lame d’un diamètre supérieur ou

inférieur à celui recommandé.

• Ne pas caler d’objet contre le ventilateur pour bloquer

l’arbre du moteur.

• Ne pas forcer l’action de coupe. (Le calage du moteur

même partiel peut causer des dommages importants.

Laisser le moteur atteindre sa pleine vitesse avant de

commencer le sciage.)

• Ne pas scier des métaux ferreux (Ceux qui contiennent

du fer ou de l’acier) ni la maçonnerie.

• Ne pas utiliser de disques abrasifs. La chaleur excessive

et les particules qu’ils génèrent peuvent endommager la

scie.

• Ne permettre à personne de se tenir derrière la scie.

• Ne jamais lubrifier une lame en mouvement.

• Ne jamais avancer les mains à proximité de la scie

lorsqu’elle est sous tension.

• Ne pas utiliser des lames de puissance inférieure à 5500

tr/mn.

• Ne pas essayer de scier des petites pièces (main à 6

pouces (15 cm) de la lame) sans les fixer avec une

pince.

Page 19

19

FRANÇAIS

• Ne pas faire fonctionner la scie sans les carters de

protection bien en place.

• Ne jamais travailler à main levée.

• Ne jamais passer la main autour ou derrière la lame de

scie.

• Ne jamais placer les mains à moins de 6 pouces (15

cm) de la lame de scie.

• Ne pas placer les mains en-dessous de la scie, sauf si

elle est éteinte et débranchée. En-dessous de la scie la

lame n’est pas protégée.

• Ne pas enlever les mains de la scie ou de la pièce et ne

pas lever les bras avant l’arrêt complet de la lame.

• Ne pas utiliser sans guide de coupe ou lorsque la fente

de coupe est supérieure à 3/8 pouces (9,52 mm)

• Ne pas transporter l’outil par une extension ou un autre

accessoire.

Avertissement: Certains bois contiennent des

agents de traitements tels que l’arséniate de

cuivre chromé (CCA) qui peuvent être toxiques.

Lors de la coupe de ces matériaux, prendre des

précautions supplémentaires pour éviter toute inhalation et

minimiser le contact avec la peau.

Avertissement: L’utilisation de cet outil peut

produire de la poussière contenant des produits

chimiques connus pour causer le cancer, des

malformations congénitales ou des lésions de l’appareil

reproducteur. Utiliser une protection respiratoire adaptée.

Avertissement: Ne pas brancher l’outil à une

source d’alimentation électrique avant d’avoir lu

et bien compris toutes les instructions.

Pour votre confort et votre sécurité, les symboles

d’avertissement suivants sont apposés sur cette scie à

onglet.

Sur le boîtier du moteur:

Attention: Pour votre propre sécurité, lire ce

manuel d’instructions avant d’utiliser la scie. Lors

de l’entretien, utiliser uniquement des pièces de

rechange identiques. Portez toujours des

lunettes de protection.

Sur le guide: Fixer les petites pièces avant de les scier.

Voir instructions sur le manuel.

Sur le carter de protection:

Danger: Rester à l’écart de la lame.

Sur la plaque de retenue du carter de protection: “fixer

correctement le support à l’aide des deux vis avant

utilisation.” Sur tableau: (2)

Serrez bien les boutons de réglage avant

l’utilisation. Tenir les mains à une distance

de 6 pouces (15 cm) de la trajectoire de la

lame de scie. Ne jamais travailler à

mainlevée. Ne jamais croiser les bras

devant la lame. Restez vigilant! Vous

pouvez prévenir les accidents. Ne pas faire fonctionner la

scie sans les carters de protection bien en place. Ne jamais

toucher l’arrière de la lame. Toujours porter des lunettes de

protection. Eteindre l’outil et attendre l’arrêt complet de la

lame avant d’effectuer toute opération d’entretien, de

réglages et avant de déplacer les mains.

Branchement électrique

Assurez-vous que la tension de votre alimentation électrique

correspond à celle qui est indiquée sur l’étiquette

signalétique de l’outil. Une baisse de tension de 10 pour cent

ou plus entraîne une baisse de puissance et une surchauffe.

Tous les outils B&D sont testés en usine. Si cet outil ne

fonctionne pas, vérifiez l’alimentation électrique.

Familiarisation

Posez la scie sur une surface lisse et plane, comme un

établi ou une table robuste. Examinez les Fig. A et B et

reportez-vous à la description des pièces pour vous

familiariser avec la scie et ses différentes parties. La section

suivante sur les réglages se réfère a ces termes et vous

devez savoir de quelle pièce il s’agit et l’endroit où elle est

placée. Le nom de la pièce est suivi de son numéro de

référence ; par exemple – broche de verrouillage (10).

Appuyez légèrement sur la poignée d’actionnement et tirez

la broche de verrouillage (10), comme le montre la Fig. C.

Relâchez doucement la pression et laissez le bras s’élever

sur toute sa hauteur. Utilisez la broche de verrouillage

lorsque vous transportez la scie d’un endroit à un autre.

Utilisez la poignée d’actionnement (1) pour transporter la

scie ou les encoches à main (11), comme le montre la Fig.

B, après avoir débranché l’outil.

Installation sur établi

Des trous de montage (8) ont été établi sur les quatre pieds

pour faciliter l’installation sur un établi, comme le montre la

FIG. A. (Deux différentes tailles de trous sont prévues pour

recevoir différentes tailles de vis. Optez pour l’une des

dimensions proposées, l’utilisation des deux est superflue.)

Arrimez solidement la scie pour en prévenir tout mouvement.

Pour faciliter son transport, l’outil peut être fixé sur une

planche de contreplaqué de 1/2 pouce (1,27 cm) ou plus, qui

pourra par la suite être arrimée à votre support de travail ou

transportée sur d’autres lieux de travail puis arrimée.

Page 20

20

FRANÇAIS

Remarque: Si vous choisissez de monter la scie sur une

planche de contreplaqué, assurez-vous que les vis de

montage ne dépassent pas de la surface du bois. Le

contreplaqué doit être posé bien à plat sur l’établi. Pour fixer

la scie à une surface de travail, utilisez seulement les

saillies de fixation au niveau des trous de vis. Le fait

d’utiliser tout autre point pourrait interférer avec le bon

fonctionnement de la scie.

Avertissement: Pour prévenir tout grippage ou imprécision,

assurez-vous que la surface de montage n’est pas

déformée ou inégale. Si la scie est bancale, placez une cale

sous l’un des pieds pour la stabiliser.

Installation d’une nouvelle lame

(Débranchez la scie à onglet) Pour cette scie n’utilisez pas

de lame de coupe en métal ferreux ou pour le sciage de

maçonnerie.

• Desserrez le boulon hexagonal du carter central en

tournant dans le sens antihoraire à l’aide de la clé

polygonale.

• Soulevez le carter de protection et le carter central.

• Appuyez sur le dispositif de blocage pour verrouiller

l’arbre.

• Desserrez le boulon hexagonal en tournant dans le sens

horaire à l’aide de la clé polygonale, puis démontez le

boulon et la bride.

• Installez la lame de scie sur l’arbre. Assurez-vous que la

flèche figurant sur la lame de scie est orientée dans le

même sens que la flèche du carter.

Remarque: Sur la plaque interne il y a deux diamètres

internes différents qui sont estampillés : 25,4mm 16mm

dans l’acier. Lors du montage, le diamètre extérieur de la

plaque interne doit correspondre au diamètre intérieur de la

lame de scie.

• Montez la bride et le boulon hexagonal.

• Appuyez sur le dispositif de blocage de l’arbre et serrez

le boulon hexagonal dans le sens antihoraire à l’aide de

la clé polygonale pour fixer le carter central.

Remarque: Utilisez la clé fournie pour le montage et le

démontage de la lame de scie. Lorsque vous démontez la

lame de scie, levez le carter de protection et le carter

central. Desserrez le boulon hexagonal à l’aide de la clé

polygonale et enlevez le boulon hexagonal, la bride et la

lame de scie.

Ne jamais appuyer sur le dispositif de blocage de l’arbre

pendant que la lame est en rotation. Assurez-vous de tenir le

support du carter de protection abaissé et serrez fermement

la vis du support du carter de protection lorsque vous avez

terminé l’installation de la lame de scie. Si vous ne le faites

pas, ceci risque d’endommager sérieusement la scie.

Assemblage et réglage de la scie

Avant l’assemblage, assurez-vous que la scie est éteinte

et débranchée. Attachez la poignée de serrage d’onglet.

Retirez la poignée de serrage d’onglet (4) du sac plastique

et vissez-la avec précaution dans le support à l’avant de la

scie.

Installation du sac à poussière

Un sac à poussière à fermeture zippée est fourni avec votre

scie. Pour installer ce sac, passez l’ouverture en plastique

fermement autour de la buse d’extraction de la poussière

(9).

Remarque: La scie peut également être utilisée avec le

tuyau d’un aspirateur fixé à la buse d’extraction de poussière

ou sans accessoire rattaché.

Réglages

Avant de procéder aux réglages, assurez-vous que la scie à

onglet est débranchée.

Remarque: Le réglage de cette scie à onglet est effectué

avec précision en usine au moment de la fabrication. Si un

nouveau réglage s’avère nécessaire à cause du transport ou

pour toute autre raison, suivez les étapes énoncées

ci-dessous pour régler votre scie :

• Réglage de l’échelle d’onglet. Placez un carré contre le

guide de la scie et la lame, comme le montre la Fig. D.

(Ne pas mettre les pointes des dents de la lame en

contact avec le carré. Si vous le faites, cela fausserait la

mesure).Desserrez la poignée de serrage d’onglet (4)

comme le montre la Fig. E et faites pivoter le bras

d’onglet jusqu’a ce que le verrou (5) se trouve en

position d’onglet 0. Ne serrez pas la poignée de serrage.

Si la lame de scie n’est pas exactement perpendiculaire

au guide, desserrez les deux vis qui maintiennent la

poignée au socle (illustré sur Fig. 6) et déplacez le bras

de la scie à gauche et à droite jusqu’à ce que la lame

soit perpendiculaire au guide, comme mesuré par le

carré. Resserrez les deux vis. A ce stade ne prêtez pas

attention à la lecture de la graduation d’onglet.

Page 21

21

FRANÇAIS

• Actionnement du carter de protection et visibilité. Le

carter de protection de lame de cette scie a été conçu

pour se lever automatiquement lorsque le bras de la scie

est abaissé et pour s’abaisser sur la lame de scie

lorsque le bras est levé. Il est possible de lever le carter

de protection manuellement lors de l’installation ou du

retrait de la lame de scie ou pour en vérifier l’état.

Assurez-vous que la scie est éteinte avant de lever

manuellement le carter de protection de lame.

Remarque: Pour certaines coupes spéciales il est

nécessaire de lever le carter de protection manuellement.

Pour ce faire, il suffit de placer votre pouce droit sur la face

supérieure du carter de protection et de soulever le carter

de protection juste assez pour dégager la pièce à travailler.

Ne jamais attacher le carter de protection ou l’empêcher de

fonctionner normalement.

Fonctionnement

Branchez la scie à une source d’alimentation.

Reportez-vous à l’étiquette signalétique pour la tension

requise. Assurez-vous que le câble ne peut pas interférer

avec votre travail.

Interrupteur

Pour mettre la scie en marche, appuyez sur l’interrupteur à

gâchette (16). Pour éteindre l’outil, relâchez la gâchette. Il

n’est pas prévu de bloquer l’interrupteur en position de

marche.

Position du corps et des mains (voir fig. G)

Une position correcte de votre corps et de vos mains

lorsque vous utilisez la scie à onglet permet un travail plus

précis et plus sûr. Ne placez jamais vos mains près de la

zone de coupe. Eloignez vos mains d’au moins de 15 cm (6

pouces) de la lame. Pour la découpe, serrez fermement la

pièce à couper sur le socle ainsi que le guide. Maintenez

vos mains en place jusqu’à ce que la gâchette soit relâchée

et que la lame soit complètement arrêtée. Avant les coupes

de finition, faites passer la lame en laissant la scie éteinte.

Ne croisez pas vos mains, voir Fig. G.

Travaux de coupe avec la scie

Remarque: Bien que cette scie coupe du bois et de

nombreux matériaux non ferreux, nous limiterons nos

propos seulement à la coupe du bois. Les mêmes conseils

s’appliquent aux autres matériaux. Ne sciez pas des

matériaux ferreux (fer et acier) ou la maçonnerie avec cette

scie. N’utilisez pas de lames abrasives.

Coupes transversales

Remarque: Scier plusieurs pièces à la suite n’est pas

recommandé, mais cela peut être fait en toute sécurité en

veillant à ce que chaque pièce soit maintenue fermement

contre l’établi et le guide. On parle de coupe transversale

lorsque la coupe est effectuée en travers du grain de la

pièce en bois et à n’importe quel angle.

• Pour effectuer une coupe transversale droite, le bras

d’onglet doit être réglé sur la position 0°. Réglez le bras

d’onglet sur 0°. Maintenez la pièce en bois sur l’établi

fermement contre le guide. Mettez la scie en marche en

appuyant sur la gâchette.

• Lorsque la scie atteint sa pleine vitesse (après 1

seconde environ) abaissez le bras de la scie doucement

et lentement pour couper le bois. Attendez l’arrêt complet

de la lame avant de relever le bras de la scie.

• Les coupes transversales d’onglet sont réalisées en

réglant le bras d’onglet sur tout angle autre que 0°.

L’angle utilisé est souvent 45º degrés lorsque l’on veut

réaliser des coins, mais il peut se situer entre 0° et plus

à gauche ou à droite. Après avoir sélectionné l’angle

d’onglet voulu, veillez à serrer la poignée de serrage

d’onglet (4). Réalisez la coupe comme décrit ci-dessus.

Coupe en biseau

Une coupe en biseau est une coupe transversale réalisée

dans le bois avec la lame de scie en biais. Afin de régler le

biseau, desserrez le bouton de blocage de biseau (17) et

inclinez la scie vers la gauche comme souhaité. Une fois

que l’angle souhaité est réglé, serrez fermement le bouton

de blocage de biseau. Les angles de biseau peuvent être

réglés jusqu’à 45º degrés et peuvent être coupés avec le

bras d’onglet réglé entre 0°et 47º à droite ou à gauche.

Qualité de la coupe

• La régularité d’une coupe dépend de nombreuses

variables. Le matériau à couper, le type de lame,

l’affûtage de la lame et sa capacité sont tous des

éléments qui contribuent à la qualité de la coupe.

• orsque l’on souhaite des coupes régulières pour des

moulures ou autres travaux précis, une lame tranchante

(60 dents au carbure) et un travail de coupe lent et

régulier produisent les meilleurs résultats.

• Assurez-vous que le matériau ne glisse pas pendant la

coupe, serrez-le solidement en position. Attendez

toujours l’arrêt complet de la lame avant de lever le bras

de la scie.

Page 22

22

FRANÇAIS

• Si de petites fibres de bois continuent à être projetées à

l’arrière de la pièce, collez un morceau de ruban cache à

l’endroit où la coupe sera faite. Scier à travers l’adhésif

et enlevez-le soigneusement une fois la coupe terminée.

• Gardez vos pieds bien ancrés au sol et maintenez votre

équilibre. Lorsque vous déplacez le bras d’onglet à

gauche et à droite, suivez-le et tenez-vous légèrement

sur le côté de la lame de scie. Lorsque vous devez

suivre une ligne tracée au crayon, suivez-la en

regardant à travers les ailettes du carter de protection.

Serrage de la pièce à couper

Eteignez et débranchez la scie.

• Si vous ne pouvez pas sécuriser la pièce à couper sur

l’établi et contre le guide en la tenant par la main (forme

irrégulière, etc.) ou si votre main doit être à moins de (15

cm) 6 pouces de la lame, vous devez utiliser une pince

de fixation ou tout autre moyen de serrage.

• D’autres dispositifs de serrage comme les pinces de

serrage à ressort ou en C, ou les tasseaux de serrage

peuvent convenir à certaines tailles ou formes de pièces

à couper. Faites attention lorsque vous choisissez et

placez ces pinces de serrage et faites des essais avant

de réaliser la coupe.

Soutenir les longues pièces

Eteignez et débranchez la scie. Les longues pièces

nécessitent un support additionnel. Pour de meilleurs

résultats, utilisez des rallonges de support pour agrandir la

largeur de la table de la scie. Pour soutenir les longues

pièces à couper, utilisez tout moyen adéquat, comme un

chevalet de construction ou autres dispositifs similaires pour

éviter aux extrémités libres de la pièce de s’affaisser.

Coupe de cadres et autres projets à quatre pans

• Pour mieux comprendre comment réaliser ces articles,

nous vous suggérons de réaliser quelques projets

simples en utilisant des chutes de bois afin de vous faire

une idée du sciage. Pratiquez toujours sur des chutes

de bois avant de tenter de couper la pièce finale.

• Votre scie est l’outil idéal pour faire des coins en onglet,

comme ceux illustré sur la FIG. H, qui montre un joint

réalisé avec un réglage d’onglet à 45º avec deux

planches pour former un coin à 90º. Pour faire ce type

de joint, réglez le bras d’onglet à 45º. Le côté large plat

du bois a été posé contre l’établi et le bord étroit contre

le guide.

• Au fur et à mesure que les nombres de côtés changent,

les angles d’onglet aussi. Le tableau ci-dessous donne

les angles appropriés pour une variété de formes. (Le

tableau suppose que tous les côtés sont d’égale

longueur.)

• Pour une forme non indiquée sur le tableau, utilisez la

formule suivante. 180º divisé par le nombre de côtés est

égal à l’onglet.

Coupes mixtes

Une coupe mixte est un mélange de coupe en biseau et de

coupe d’onglet. C’est le type de coupe utilisée pour fabriquer

des cadres ou des boîtes avec des côtés obliques, comme

celle représentée en Fig. H.

Remarque: Si l’angle de coupe varie de coupe en coupe,

vérifiez que le bouton de blocage de biseau (10) et la

poignée de blocage d’onglet (4) sont bien serrés. Ces

boutons doivent être resserrés après chaque changement

de biseau et d’onglet.

Coupe d’une moulure couronnée

• Pour un ajustage adéquat, les moulures couronnées

doivent être coupées avec une précision extrême. Les

deux surfaces de contact d’une section de moulure

couronnée sont à des angles qui, lorsqu’ils sont

additionnés, totalisent 90º. La plupart des moulures

couronnées, mais pas toutes, présentent un angle

supérieur arrière (partie reposant à plat contre le plafond)

de 52º et un angle inférieur arrière (partie reposant à plat

sur le mur) de 38º.

• Faire des essais au préalable avec des chutes de bois

est très important! Placez la partie inférieure (partie qui

reposera contre le mur) contre le guide de la scie à

onglet. Placez la partie supérieure (partie qui reposera

contre le plafond) contre l’établi et le guide de moulure

couronnée.

NO. COTES ANGLE D’ONGLET

4 45º

5 36º

6 30º

7 25.7º

8 22.5º

9 20º

10 18º

Page 23

23

FRANÇAIS

Instructions pour la coupe de moulures couronnées

posées à un angle entre le guide et la table de la scie et

pour tous les types de coupe:

• Inclinez la moulure de façon à placer le bord inférieur de

la moulure (partie reposant sur le mur une fois installée)

contre le guide et le bord supérieur de la moulure sur la

table de la scie.

• Les “plats” inclinés au dos de la moulure doivent

reposer directement sur le guide et la table de la scie.

Coin intérieur:

Côté gauche Côté droit

• Angle d’onglet droit à 45° • Angle d’onglet

gauche à 45°

• Côté droit de coupe maintenu • Côté gauche de

coupe maintenu

Coin extérieur:

• Côté gauche • Côté droit

• Angle d’onglet gauche à 45° • Angle d’onglet droit

à 45°

• Côté droit de coupe maintenu • Côté gauche de

coupe maintenu

Effectuez toujours une coupe d’essai pour confirmer

l’exactitude des angles.

Ne jamais commencer à scier avant d’avoir fixé le matériau

sur l’établi et contre le guide.

Coupes spéciales

Sciage de l’aluminium

(Lames à pointes de carbure uniquement)

• Les extrusions d’aluminium, comme celles utilisées pour

fabriquer des moustiquaires et des contre-fenêtres,

peuvent facilement être découpées avec cette scie

équipée d’une lame appropriée conçue pour scier les

métaux non-ferreux. Placez le matériau de façon à scier

la section la plus mince, comme illustré en Fig. I.

• La Fig. J illustre ce qu’il ne faut pas faire pour scier ces

extrusions. Utilisez un lubrifiant à base de cire lorsque

vous coupez de l’aluminium, comme un bâton de cire

No.140 de Johnson. Appliquez la cire directement sur la

lame de scie avant de couper.

• N’appliquez jamais la cire sur une lame en mouvement.

La cire, disponible dans la plupart des quincailleries et

magasins d’approvisionnement industriel, offre une

bonne lubrification et empêche les copeaux d’adhérer à

la lame.

• Veillez à bien sécuriser le travail. Certaines pièces à

couper, en raison de leur taille, de leur forme ou de leur

surface, peuvent nécessiter l’utilisation d ‘une bride de

serrage, d’un gabarit ou d’un autre dispositif de fixation

pour l’empêcher de bouger pendant la coupe.

Pièces voilées

Lors de la coupe d’une pièce voilée, placez-la comme le

montre la Fig. K et jamais comme le montre la Fig. L. Si une

pièce voilée est placée dans le mauvais sens, elle pincera la

lame vers la fin de la coupe.

Coupe de tuyaux en plastique et autres tubes

Les tuyaux en plastique peuvent facilement être coupés

avec cette scie. Le plastique doit être coupé tout comme le

bois et les pièces doivent être maintenues fermement contre

le guide pour les empêcher de rouler, en particulier lors de

coupes d’angles.

Accessoires

La performance de votre outil dépend des accessoires que

vous utilisez. Les accessoires Black & Decker et Piranha

sont conçus selon des normes de qualité supérieure pour

améliorer les performances de votre outil. En utilisant ces

accessoires, vous obtiendrez le meilleur de votre outil.

Entretien

La scie à onglet doit être débranchée avant toute

intervention d’entretien.

1. Tous les roulements sont scellés. Ils sont lubrifiés à vie

et ne nécessitent aucun entretien supplémentaire.

2. Nettoyez fréquemment autour et sous le socle et la table

rotative et enlevez la poussière et les copeaux de bois.

Bien que des fentes soient prévues pour laisser passer

les débris, la poussière peut s’y accumuler.

3. Les balais sont conçus pour vous donner des années

d’usage. S’il est besoin de les remplacer, suivez les

instructions de ce manuel ou faites réparer votre outil

dans le centre de service le plus proche.

Page 24

24

FRANÇAIS

Puissance 1500W

Vitesse à vide 5500/min

Votre outil a été conçu pour fonctionner sur une longue

période de temps avec un minimum d’entretien. Un

fonctionnement continu satisfaisant dépend d’un nettoyage

et d’un entretien soigneux et régulier.

Attention: Avant d’effectuer un nettoyage ou un entretien,

assurez-vous que l’outil est éteint et débranché.

• Nettoyez régulièrement les fentes de ventilation de votre

outil et du chargeur à l’aide d’une brosse souple ou d’un

chiffon sec.

• Nettoyez régulièrement le boîtier du moteur avec un

chiffon humide. N’utilisez pas de produits abrasifs ou à

base de solvants.

Spécifications

Dépannage

Problème! Les coupes de la scie sont mauvaises

Cause possible Solution possible

3. Colle ou résine sur la 3 Enlevez la lame et

lame.. nettoyez-la à l’aide de

laine d’acier et de

térébenthine ou avec

un nettoyant à four.

4. Lame non adaptée 4. Changez la lame.

pour le travail à effectuer.

Problème! La lame n’atteint pas sa pleine vitesse

Cause possible Solution possible

1. Le câble d’extension est 1. Remplacez le câble par

trop léger ou trop long un autre de la taille

correcte.

2. La tension de l’alimentation 2. Contactez votre

électrique est trop faible. fournisseur d’électricité.

Problème!

L’outil vibre excessivement

Cause possible Solution possible

1. La scie n’est pas fermement 1. Resserrez toute la visserie

arrimée. de montage.

2. L’établi ou le poste de travail 2. Repositionnez-les sur un

reposent sur un sol inégal. sol plat.

3. La lame de la scie est 3. Changez la lame.

endommagée.

1. L’échelle à onglet n’est pas 1. Vérifiez et réglez.

correctement réglée.

2. La lame n’est pas 2. Vérifiez et réglez.

perpendiculaire au guide.

3. Le disque est perpendiculaire 3. Le disque est

à l’établi. perpendiculaire à l’établi.

4. La pièce à couper bouge. 4. Sécurisez la pièce à

couper contre le guide ou

collez du papier abrasif

120 avec de la colle

caoutchouc sur le guide.

Problème!

Le matériau pince la lame

Cause possible Solution possible

1. Le matériau à couper 1. Placez le matériau voilé

est voilé. comme le montre la Fig. K

Page 25

25

FRANÇAIS

Garantie