Page 1

®

BPHR272

ENGLISH 3

Page 2

5

A

C

5

3

B

7

1

6

5

4

7

6

D E

2

XXXX XX JN

12

3

2

1

8

* The picture above may differ slightly to actual unit.

9

10

8

11

11

Page 3

ENGLISH

BPHR272

ROTARY HAMMER

Technical data

Rotary Hammer BPHR272

Voltage V 220-240

Frequency Hz 50/60

Power input W 850

No-load speed /min 700

Impact rate BPM 3400

Impact energy (EPTA) J 4.1

Modes 2

Max capacity mm

- Concrete 26

- Steel -

-Wood -

Weight kg 5.1

Intended use

Your Black & Decker hammer has been designed

for drilling in concrete and masonry as well as for

light chiselling applications.

Safety instructions

General power tool safety warnings

WARNING! Read all safety warnings

and all instructions. Failure to follow the

warnings and instructions listed below may

result in electric shock, re and/or serious

injury.

Save all warnings and instructions for future

reference. The term "power tool" in all of the warn-

ings listed below refers to your mains operated

(corded) power tool or battery operated (cordless)

power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Power

tools create sparks which may ignite the dust or

fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodied plugs

and matching outlets will reduce risk of electric

shock.

b. Avoid body contact with earthed or

grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your body is

earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

e. When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f. If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the inuence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the

switch is in the off-position before

3

Page 4

ENGLISH

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your nger on the

switch or energising power tools that have the

switch on invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

f. Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b. Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tools operation. If

damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g. Use the power tool, accessories and tool

bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

5. Service

a. Have your power tool serviced by a qualied

repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Hammer safety warnings

u Wear ear protectors. Exposure to noise can

cause hearing loss.

u Use auxiliary handle(s), if supplied with the

tool. Loss of control can cause personal injury.

u Hold power tool by insulated gripping sur-

faces, when performing an operation where

the cutting accessory may contact hidden

wiring or its own cord. Cutting accessory con-

tacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the

operator an electric shock.

u Never use a chisel accessory in rotary mode.

The acces-sory will bind in the material and

rotate the drill.

u Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body

leaves it unstable and may lead to loss of control.

u Before drilling into walls, oors or ceilings,

check for the location of wiring and pipes.

u Avoid touching the tip of a drill bit just after drill-

ing, as it may be hot.

u The intended use is described in this instruction

manual. The use of any accessory or attachment or performance of any operation with this

tool other than those recom-mended in this instruction manual may present a risk of personal

injury and/or damage to property.

4

Page 5

ENGLISH

Safety of others

u This appliance is not intended for use by per-

sons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use

of the appliance by a person responsible for

their safety.

u Children should be supervised to ensure that

they do not play with the appliance.

Residual risks

Additional residual risks may arise when using the

tool which may not be included in the enclosed

safety warnings. These risks can arise from misuse, prolonged use etc. Even with the application

of the relevant safety regulations and the implementation of safety devices, certain residual risks

can not be avoided. These include:

u Injuries caused by touching any rotating/moving

parts.

u Injuries caused when changing any parts,

blades or accessories.

u Injuries caused by prolonged use of a tool.

When using any tool for prolonged periods

ensure you take regular breaks.

u Impairment of hearing.

u Health hazards caused by breathing dust devel-

oped when using your tool (example:- working

with wood, especially oak, beech and MDF.)

Label on the tool

The following symbols are shown on the tool:

u If the wire is damaged, it should be replaced by

the manufacturer or a service center authorized

by Black & Decker, to avoid danger.

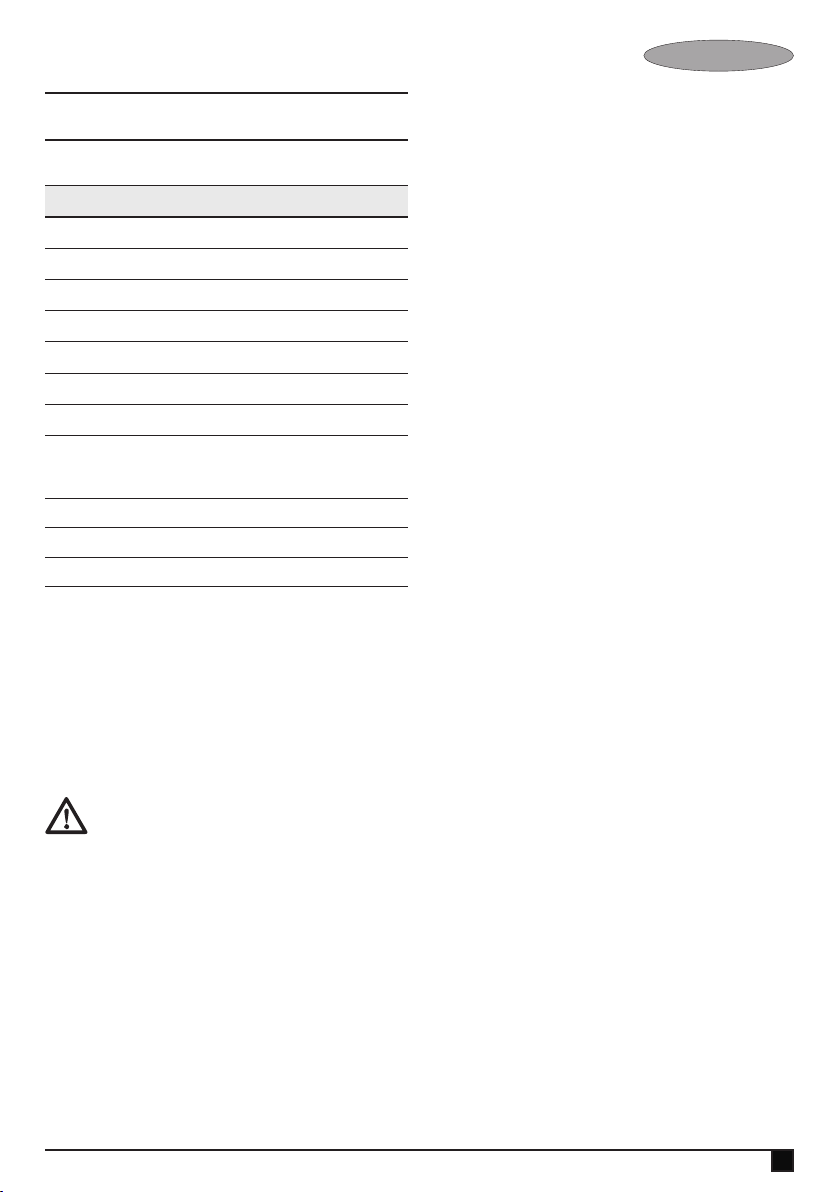

Part name

The power tool includes some or all of the following

parts:

1. Switch

2. Oil-injection inlet cap

3. Modes selector

4. Tool chuck (tool holder)

5. Sleeve

6. Side handle

7. Depth stop

8. Bottom cover

Assembly

Warning! Before assembly, please ensure that the

power tool is powered off and the power plug of the

tool is unplugged from the power source.

Install the side handle

Warning! When holes are drilled in the concrete,

bricks and other surfaces, please grip the side handle to ensure safe operation.

u The side handle (6) can be rotated to any side,

which can facilitate the use of the power tool in

any position.

u Rotate the side handle (6) counterclockwise, to

unlock and release the power tool, rotate it to

the desired position.

u Rotate the side handle clockwise to tighten it

adequately.

Warning! In order to reduce the risk of

injury, the user must read the manual.

Date code position (Fig. D)

The date code (12) is printed on the housing of the

tool, which also contains the year of manufacture.

For example: 2013 XX JN

Year of manufacture

Electrical safety

Double insulation measures are taken in

this power tool, so no grounding is needed.

Please check whether the voltage of power

supplied is consistent with the voltage on

the nameplate or not.

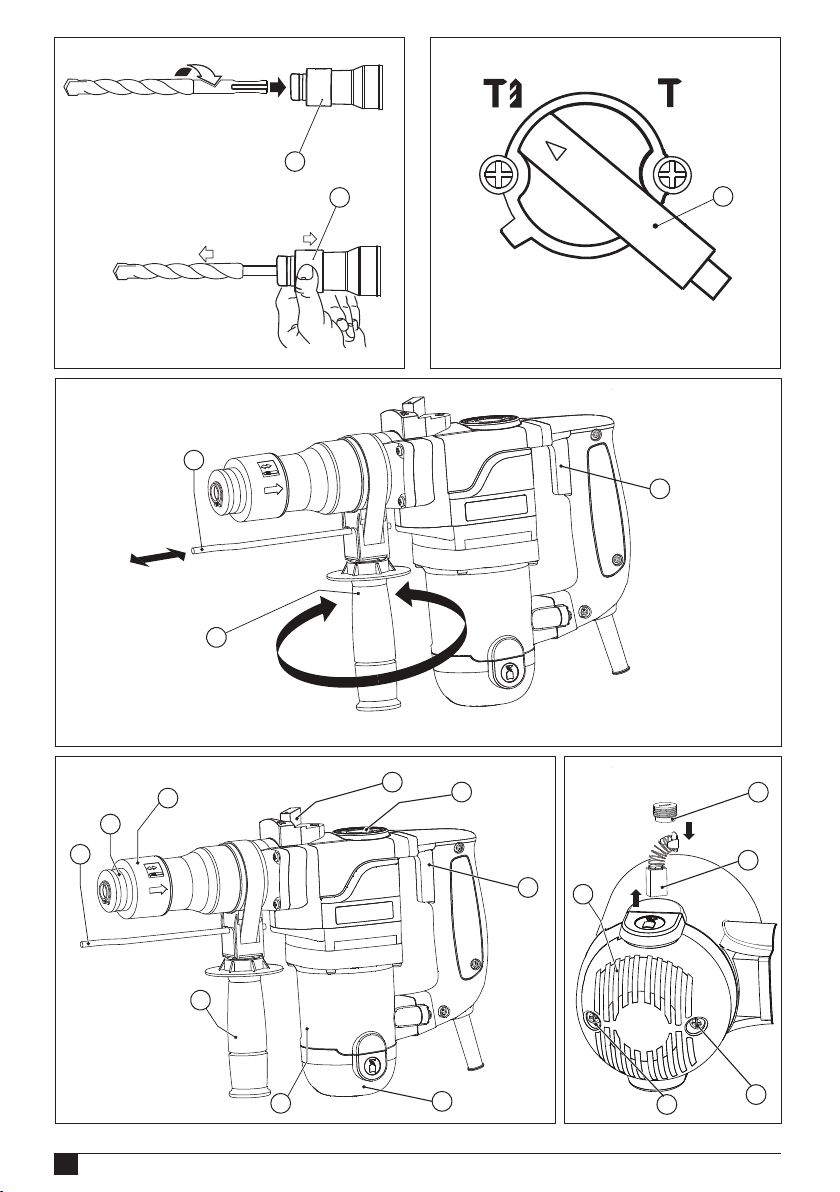

Fitting an accessory (Fig. A)

u Please clean the drill shank and lubricate the

drill bit before installing it.

u Pull back and hold the slide-sleeve(5), and

then screw the drill bit into the chuck, press it

internally until it is fastened, the drilling bit can

be automatically locked in situ. Pull the drill bit

outwards to test whether it has been adequately

locked in the correct position or not.

u Pull back and hold the drill sleeve(5) clamp, you

can remove the drill bit.

Use

Warning! Please use the power tool under normal

load; no overloading is permitted.

Warning! Before drilling holes in the wall, oor or

ceiling, please check the positions of the wire and

5

Page 6

ENGLISH

steel tube.

Chipping/Chiseling (Fig. B)

u When the cutting / stripping / removing opera-

tion is conducted, please put the operation

modes selector (3) to position , the drilling

bit, cold chisel and scaling chisel etc. should be

properly used.

Warning! Do not rotate the knob when the power

tool is rotating under the load, otherwise it will be

damaged.

Hammer drilling (Fig. B)

u When using the hammer driller to drill holes on

the masonry and concrete surfaces, the opera-

tion mode selector (3) should be set to position

.

u The drilling bit should be aligned to the drilling

position, and then press the switch button to

achieve the best effect. Keep the power tool be

positioned correctly, prevent it from deviating

the hole.

u When the fragments plug the borehole or

powders, please do not apply further pressure,

and make the tool rotate in an idling state, then

gradually take out the drilling bit from the hole.

Repeat the said steps for several times, the

plugged hole can be clean, and then resume

the normal drilling.

Warning! When the drilling bit begins to break

down the reinforced concrete or hit the steel bar

inside the concrete, the power tool may have

dangerous reaction force. Please always keep

balance, stable posture and tightly grip the tool, to

prevent from generating the dangerous reaction

force. When the concrete is chiseled, the distance

between the two points of one chiseling shall not

be too much away from the edge, which shall be

about 8cm or so, dene the distance through nding the cracking strength of the concrete.

Overload coupling device

If the drilling bit is clamped or hooked up, the driving force transmitted to the drill shaft will be cut off.

A huge force will occur, so two hands must tightly

grip the power tool when it is in operation, and

ensure that the operator is standing in a stable and

xed position.

6

Select the depth of holes to be drilled (Fig.

C)

A depth gauge is an easy to use ruler to ensure

that the drilling depth is consistent. Unlock the side

handle, adjust the depth gauge according to the

required depth, and then tighten the side handle.

u Unfasten the side handle (6) by turning counter-

clockwise the grip.

u Set the depth stop (7) to the desired position.

The maximum depth of the drilled hole shall

equal to the distance between the tip of drilling

bit and the front end of the depth stop.

u Tighten the side handle by turning the grip

clockwise.

Switch on and off

Warning! Before inserting the plug, please con-

rm whether the switch can trigger freely or not,

whether it can return to the original position after

releasing.

u Press the switch button (1), the power tool can

be started immediately.

u Release the button (1), the tool stops rotating.

Accessories

The performance of an electric tool depends on

its accessories. Black & Decker accessories are

designed according to high quality standards, to

enhance the performance of electric tool. The use

of these accessories can help you conveniently

operate the tool.

Maintenance

The Black & Decker cord / cordless appliance /

tools are of sophisticated design, can be used for

a long time, and only little maintenance is needed.

To obtain consistent satisfactory use, proper

maintenance and regular cleaning of the tools are

necessary.

Warning! Before performing any maintenance

work on the cord / cordless electric tools, the following points must be implemented:

u Switch off the power of the equipment / tools

and pull off the plug;

u If the equipment / tools are equipped with inde-

pendent battery pack, please turn off the power

and remove the battery pack from the equip-

ment / tools.

u If the equipment / tools are equipped with an

integrated battery, please run out the battery,

before turning off its power.

u Before the cleaning, unplug the charger plug

Page 7

ENGLISH

from the power source. In addition, except

the regular cleaning on your charger, no other

maintenance is needed.

u Regularly use the soft brush or dry cloth to

clean the ventilation slot of the equipment /

tools / charger.

u Regularly use a damp cloth to clean the motor

housing. Please do not use any abrasive clean-

ing agents or solvent-based cleansing agents.

u Regularly open the clamping chuck and tap it

gently to remove any internal dust (after instal-

lation).

Replace the carbon brushes (Fig. E)

Lubrication

u Regularly replace and check the carbon

brushes. Replace it in time when it is worn to

the abrasive boundary line. Keep the carbon

brush clean and make it freely slide in the

brushing range. Two brushes shall be replaced

at the same time.

u Use the cross screwdriver to counterclockwise

unscrew the screws, open the bottom cover(8)

with a at screwdriver to counterclockwise

open the brush cover(9), you can remove the

brush(10)as shown in the gure E, and put

the new brush, and then clockwise fasten the

brush cover(9), nally put the bottom cover(8),

and then use the cross screwdriver to tighten it

properly.

u Open the cap of the lube oil-injection inlet(2),

check the lube oil in the gearbox, if the lube

oil is dirty or insufcient, replace or add the

adequate amount of lube oil provided by the

company.

solvents or other irritant chemicals. These

chemicals may weaken the materials of

these components. Use a cloth moistened

with a mild soapy water to clean it. Do not

let any substance permeate into the tool

and.do not immerse any part of the tool

into a liquid.

Protect the environment

Separate collection. This product may not

be disposed together with the ordinary

household waste.

If you nd that your Black & Decker products are

needed to be replaced or you will no longer need

to use these products, please do not put them

together with the household waste. Please place

them separately to recycle.

Separate collection of the used products

and packaging materials allow the

materials to be recycled and reused.

Reuse of the recycled materials helps to prevent

the pollution of the environment, and reduces the

demand for raw materials. Local regulations may

provide separate collection of the electrical

products from the household, at the municipal

waste sites or by the retailer when you purchase a

new product.

Cleaning

Warning! Once the visible dust build-up

is found at and/or around the ventilating ports, immediately ush the dust and

powder within the host shell with clean dry

air. To perform this procedure, wear the

approved safety equipment and dust mask.

Warning! It is strictly forbidden to clean

the non-metallic parts of the tool with the

7

Page 8

N385514 03/2014

Loading...

Loading...