Page 1

BPGP1518

Page 2

2

English (Original instructions) 4

Türkçe (Çevirisi orijinal talimatlardan yapılmıştır) 11

Page 3

3

Page 4

4

ENGLISH

Do not return this product to the

store,

fi rst contact your local Black & Decker offi ce or

nearest authorized service center.

Intended use

Your BPGP1518 heavy-duty polisher has been

designed for polishing painted or unfi nished metal,

fi berglass, and composite surfaces in professional

applications. Common examles of use include

but are not limited to: auto/marine/RV/motorcycle

detailing and fi nish correction, boat construction

and repair, and metal or concrete fi nishing.

DO NOT use under wet conditions or in the

presence of fl ammable liquids or gases.

General safety rules

Warning! Read and understand

all instructions. Failure to follow all

instructions listed below, may result

in electric shock, fi re and/or serious

personal injury.

Save these instructions

Safety instructions

General power tool safety warnings.

Warning! Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions listed below

may result in electric shock, fi re and/or

serious injury.

Save all warnings and instructions for future

reference. The term “power tool” in all of the

warnings listed below refers to your mains

operated (corded) power tool or battery operated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered

and dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodifi ed plugs

and matching outlets will reduce risk of electric

shock.

b. Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body

is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

e. When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f. If operating a power tool in a damp location

is unavoidable, use a residual current

device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

Note: The term “Residual Curent Device

(RCD)” can be replaced by “Ground Fault

Circuit Interrupter (GFCI)” or by “Earth

Leakage Circuit Breaker (ELCB)”.

3. Personal safety

a. Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool while

you are tired or under the infl uence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your fi nger on the

switch or energising power tools that have the

switch on invites accidents.

d. Remove any adjusting key or wrench

before turning the power tool on. A wrench

Page 5

5

ENGLISH

or a key left attached to a rotating part of the

power tool may result in personal injury.

e. Do not overreach. Keep proper footing

and balance at at all times. This enables

better control of the power tool in unexpected

situations.

f. Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

g. If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can can reduce

dust related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b. Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e. Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tools operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

5. Service

a. Have your power tool serviced by

a qualifi ed repair person using only

identical replacement parts. This will ensure

that the safety of the power tool is maintained.

6. Electrical safety

Your tool is double insulated; therefore

no earth wire is required. Always check

that the main voltage corresponds to the

voltage on the rating plate.

Warning! If the power cord is damaged,

it must be replaced by the manufacturer,

authorized Black & Decker Service

Center or an equally qualifi ed person in

order to avoid damage or injury. If the

power cord is replaced by an equally

qualifi ed person, but not authorized by

Black & Decker, the warranty will not be

valid.

7. Labels on tool

The label on your tool may include the following

symbols:

Read Instructions

Manual

Hz Hertz Class II

Construction

Use Eye

Protection

W Watts Earthing

Terminal

Use Ear

Protection

min minutes Safety Alert

Symbol

V Volts

Alternating

Current

../min Revolu-

tions or

Reciprocation per

minute

A Amperes

Direct

Current

n

0

No-Load

Speed

Additional Specifi c Safety Rules

Safety Instructions for All Operations

• This power tool is intended to function

as a polisher. Read all safety warnings,

instructions, illustrations and specifi cations

provided with this power tool. Failure to

follow all instructions listed below may result in

electric shock, fi re and/or serious injury.

• Operations such as grinding, sanding,

wire brushing, or cutting-off are not

recommended to be performed with this

power tool. Operations for which the power

tool was not designed may create a hazard

and cause personal injury.

• Do not use accessories which are not

specifi cally designed and recommended

by the tool manufacturer. Just because the

Page 6

6

ENGLISH

accessory can be attached to your power tool,

it does not assure safe operation.

• The rated speed of the accessory must

be at least equal to the maximum speed

marked on the power tool. Accessories

running faster than their rated speed can break

and fl y apart.

• The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or

controlled.

• Threaded mounting of accessories must

match the grinder spindle thread. For

accessories mounted by fl anges, the

arbour hole of the accessory must fi t the

locating diameter of the fl ange. Accessories

that do not match the mounting hardware of

the power tool will run out of balance, vibrate

excessively and may cause loss of control.

• Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheels for chips and cracks,

backing pad for cracks, tear or excess

wear, wire brush for loose or cracked

wires. If power tool or accessory is

dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory and run the power

tool at maximum no-load speed for one

minute. Damaged accessories will normally

break apart during this test time.

• Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection

must be capable of stopping fl ying debris

generated by various operations. The dust

mask or respirator must be capable of fi ltering

particles generated by your operation.

Prolonged exposure to high intensity noise

may cause hearing loss.

• Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken

accessory may fl y away and cause injury

beyond immediate area of operation.

• Hold power tool by insulated gripping

surfaces only, when performing an

operation where the cutting accessory

may contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool

“live” and shock the operator.

• Use clamps or another practical way to

secure and support the workpiece to

a stable platform. Holding the work by hand

or against your body leaves it unstable and

may lead to loss of control.

• Position the cord clear of the spinning

accessory. If you lose control, the cord may

be cut or snagged and your hand or arm may

be pulled into the spinning accessory.

• Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the surface

and pull the power tool out of your control.

• Do not run the power tool while carrying

it at your side. Accidental contact with the

spinning accessory could snag your clothing,

pulling the accessory into your body.

• Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside

the housing and excessive accumulation of

powdered metal may cause electrical hazards.

• Do not operate the power tool near

fl ammable materials. Sparks could ignite

these materials.

• Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or

snagged polisher pad or any other accessory.

Pinching or snagging causes rapid stalling of

the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction

opposite of the accessory’s rotation at the point of

the binding.

For example, if an polisher pad is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material causing the wheel to climb

out or kick out. The wheel may either jump toward

or away from the operator, depending on direction

of the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

Page 7

7

ENGLISH

• Maintain a fi rm grip on the power tool

and position your body and arm to allow

you to resist kickback forces. Always use

auxiliary handle, if provided, for maximum

control over kickback or torque reaction

during start-up. The operator can control

torque reactions or kickback forces, if proper

precautions are taken.

• Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

• Do not position your body in the area where

power tool will move if kickback occurs.

Kickback will propel the tool in direction

opposite to the wheel’s movement at the point

of snagging.

• Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag

the rotating accessory and cause loss of

control or kickback.

• Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

Safety warnings specifi c for polishing

operations

• Do not allow any loose portion of the

polishing bonnet or its attachment strings

to spin freely. Tuck away or trim any loose

attachment strings. Loose and spinning

attachment strings can entangle your fi ngers or

snag on the workpiece.

Specifi c safety rules

Accessories must be rated for at least the

speed recommended on the tool warning label.

Wheels and other accessories running over rated

speed can fl y apart and cause injury.

Hold tool by insulated gripping surfaces when

performing an operation where the polishing

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

• Avoid prolonged contact with dust from

power sanding, sawing, grinding, drilling,

and other construction activities. Wear

protective clothing and wash exposed

areas with soap and water. Allowing dust to

get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

• Always wear eye protection.

• Be sure bonnet is snugly installed on pad.

• Keep hands and fi ngers away from rotating

bonnet.

• Before turning the switch to the ON position,

be sure the pad is free to revolve harmlessly.

• Inspect the bonnet frequently for wear, dirt or

imbedded debris.

Caution! Do not allow the power cord

to contact the rotating bonnet as it may

become quickly tangled around it. If this

occurs, turn tool OFF and unplug the

power cord before attempting to untangle

the cord. If the cord is damaged, have

it repaired or replaced at your local tool

repair station:

• Never use a damaged or torn bonnet.

• Wear proper clothing, short sleeves, nothing

loose or bulky, such as shop coat, etc.

• Do not turn tool on unless the polishing bonnet

is against surface being polished.

• Be extremely careful when polishing around

sharp or protruding objects on the car body.

Caution! Do not use abrasive or rubbing

compounds. The abrasive nature of these

products can damage painted surfaces.

Caution! Wear appropriate hearing

protection during use. Under some

conditions and duration of use, noise

from this product may contribute to

hearing loss.

Vibration

The declared vibration emission values stated in

the technical data and the declaration of conformity

have been measured in accordance with

a standard test method provided by EN 60745 and

may be used for comparing one tool with another.

The declared vibration emission value may also be

used in a preliminary assessment of exposure.

Warning! The vibration emission value during

actual use of the power tool can differ from the

declared value depending on the ways in which

the tool is used. The vibration level may increase

above the level stated.

When assessing vibration exposure to determine

safety measures required by 2002/44/EC to

protect persons regularly using power tools in

employment, an estimation of vibration exposure

should consider, the actual conditions of use and

the way the tool is used, including taking account

of all parts of the operating cycle such as the times

Page 8

8

ENGLISH

when the tool is switched off and when it is running

idle in addition to the trigger time.

Use of extension cords

Make sure the extension cord is in good condition

before using. Always use the proper size extension

cords with the tool – that is, proper wire size for

various lengths of cord and heavy enough to carry

the current the tool will draw. Use of an undersized

cord will cause a drop in line voltage resulting in

loss of power and overheating. For proper size

cords see chart below.

Minimum gage for cord sets

Volts Total length of cord in feet

120 V~ 0-25 26-50 51-100 101-150

220 V~ 0-50 51-100 101-200 201-300

Ampere rating

More than No more than American wire gage

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not recommended

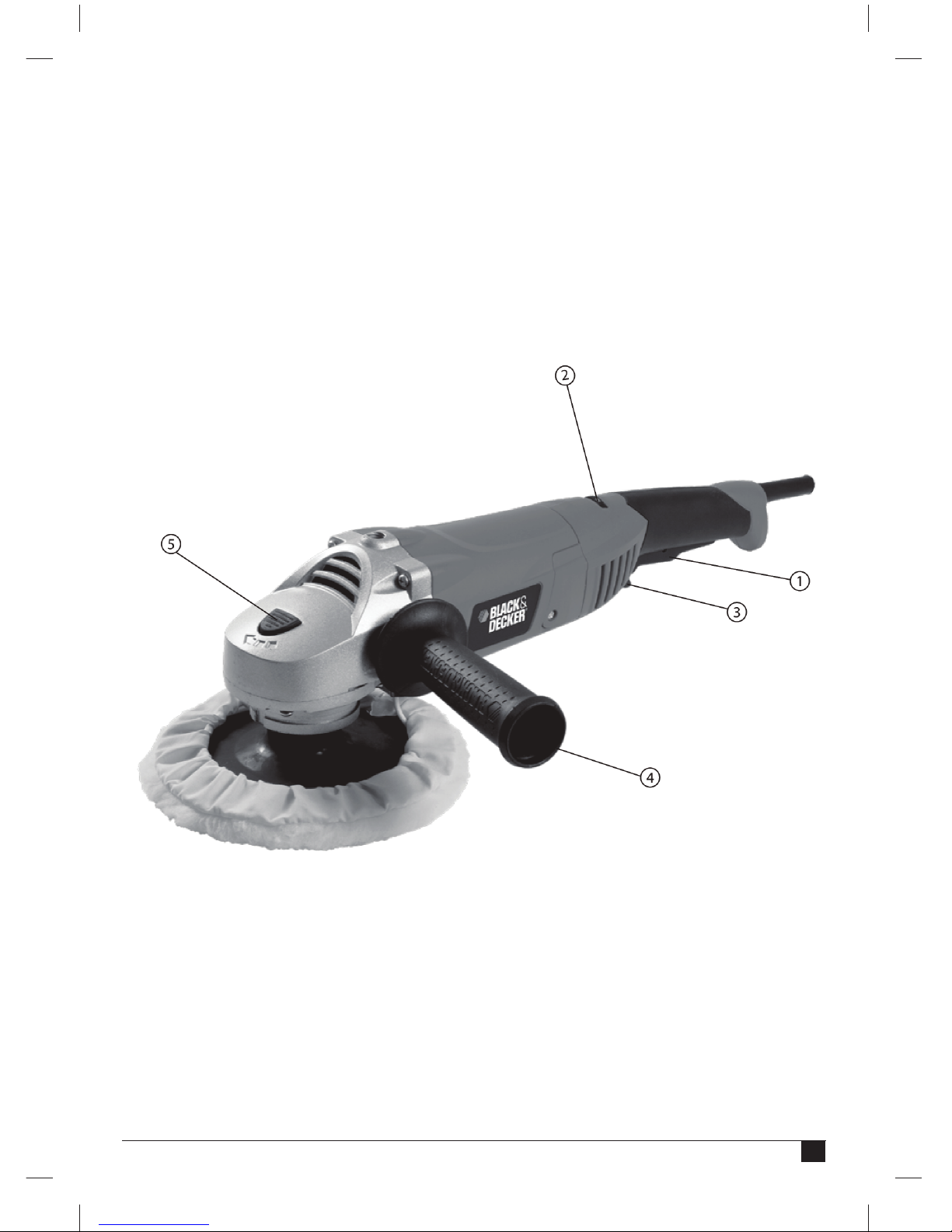

Features

1. On/off switch

2. Variable speed switch

3. Lock-on button

4. Side handle

5. Spindle lock

Motor

Warning! Be sure your power supply

agrees with nameplate marking.

Instalation

Assembly and adjustment

• Place the polisher disk on the spindle, mount

the concave recess side of the locking nut over

the spindle, and tighten with the two –hole

spanner.

• Mount the outside spindle over the spindle,

Install the woolen fabrics cover by simply

stretching the elastic and slipping the woolen

fabrics cover over the outside spindle. And

let it operate for more than three minutes for

checking it up without load.

Caution! Turn off and unplug from power

supply.

Before operating

Note: Although this discussion deals with polishing

a car, your polisher is capable of polishing a wide

array of fl at surfaces such as hardwood fl oors,

furniture, boats and other surfaces that could use

an occasional shine. Before you begin, make sure

the car is clean and dry. The work area should

be dry also. If necessary, remove road tar with

a general cleaner before polishing. Also remove

excess grease spots, bug stains, etc.

Selecting the correct operating speed

The work speed of the rotating part is controlled by

the timing. Switch indicated in fi gures. The further

the switch is moved away from its off position, such

as from 1 to 2, the faster the work part rotates.

Operation

• Make sure the polisher is in the “OFF”

position before plugging the polisher into an

appropriate power outlet.

• To switch your polisher on, press the on/off

switch. To switch it off press the on/off switch.

ALWAYS START AND STOP THE POLISHER

ON OR AGAINST THE SURFACE. Place the

cord over your shoulder and do fl at surfaces fi rst

- hood, trunk and roof. Cover areas quickly with

broad, sweeping strokes in a criss-cross pattern.

DO NOT press down on the polisher. The

machine’s action, not pressure, does the best

job.

• After fl at surfaces are covered with wax, do

sides of the car. Let the cord hang free. It is not

necessary to use a criss-cross motion on doors

and fenders.

• Put a clean polishing bonnet on the polisher

• Polish the wax. Use long, sweeping strokes in

a criss-cross pattern. Do not press hard. Let

the polisher do the work.

Warning! Before working, let it operate for no less

one minute without load. First, ensure that the

polisher disc is resting on the work surface. Grasp

polisher and turn it on. Move it in long, sweeping

strokes along the surface, letting it do the work.

Handy hints

• This polisher is a random orbit polisher. it is

designed to wobble. The wobbling motion

produces the fi ne, swirl free fi nish.

• For best results, use light pressure only, letting

the polisher do the work.

• Exercise caution around edges, corners or

small surface areas. Prolonged polishing on

edges and corners can damage these areas.

Page 9

9

ENGLISH

• Polishing bonnet can be hand washed in warm

water and mild detergent. It can be machine

dried at the lowest setting however air drying

is recommended. DO NOT USE ABRASIVE

COMPOUNDS. Liquid wax is recommended to

use with this polisher.

• The polishing bonnet is only to be used for the

fi nal buff. Do not use it to apply wax.

Maintenance

Your tool has been designed to operate over a long

period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon

proper tool care and regular cleaning.

Warning! Before performing any

maintenance, switch off and unplug the

tool.

• Regularly clean the ventilation slots in your tool

using a soft brush or dry cloth.

• Regularly clean the motor housing using

a damp cloth. Do not use any abrasive or

solvent-based cleaner.

Accessories

The performance of your tool depends on the

accessory used. Black & Decker accessories are

engineered to high quality standards and designed

to enhance the performance of your tool. By using

these accessories you will get the very best from

your tool.

Specifi cations

BPGP1518

Voltage

KS V 230

Power W 1300

Rated Speed /min 3600

Disc diameter mm 180

Spindle size M14

Weight Kg 3.6

Noise Lp dB(A) 93.0

Lw dB(A) 104.0

K dB(A) 3

Vibration a

h

m/s² 3.1

K m/s² 1.5

Protecting the environment

Separate collection. This product must

not be disposed of with normal household

waste.

Should you fi nd one day that your Black & Decker

product needs replacement, or if it is of no further

use to you, do not dispose of it with household

waste. Make this product available for separate

collection.

Separate collection of used products and

packaging allows materials to be recycled

and used again. Reuse of recycled

materials helps prevent environmental

pollution and reduces the demand for raw

materials.

Local regulations may provide for separate

collection of electrical products from the

household, at municipal waste sites or by the

retailer when you purchase a new product.

Black & Decker provides a facility for the collection

and recycling of Black & Decker products once

they have reached the end of their working life. To

take advantage of this service please return your

product to any authorised repair agent who will

collect them on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

Black & Decker offi ce at the address indicated

in this manual. Alternatively, a list of authorised

Black & Decker repair agents and full details of our

after-sales service and contacts are available on

the Internet at: www.2helpU.com.

Service information

Black & Decker offers a full network of companyowned and authorized service locations. All

Black & Decker Service Centers are staffed with

trained personnel to provide customers with

effi cient and reliable power tool service. For

more information about our authorized service

centers and if you need technical advice, repair,

or genuine factory replacement parts, contact the

Black & Decker location nearest you, or visit us at

www.BlackandDecker-la.com.

Page 10

10

ENGLISH

EC declaration of conformity

MACHINERY DIRECTIVE

BPGP1518

Black & Decker declares that these products

described under "Technical data" are in compliance

with: 2006/42/EC, EN 60745-1, EN 60745-2-3.

These products also comply with Directive

2014/30/EU and 2011/65/EU. For more

information, please contact Black & Decker at

the following address or refer to the back of the

manual.

The undersigned is responsible for compilation of

the technical fi le and makes this declaration on

behalf of Black & Decker.

R. Laverick

Engineering Manager

Black & Decker Europe

210 Bath Road, Slough

Berkshire, SL1 3YD

United Kingdom

08/07/2014

Guarantee

Black & Decker is confi dent of the quality of its

products and offers an outstanding guarantee. This

guarantee statement is in addition to and in no way

prejudices your statutory rights. The guarantee is

valid within the territories of the Member States of

the European Union and the European Free Trade

Area.

If a Black & Decker product becomes defective

due to faulty materials, workmanship or lack of

conformity, within 24 months from the date of

purchase, Black & Decker guarantees to replace

defective parts, repair products subjected to

fair wear and tear or replace such products to

make sure of the minimum inconvenience to the

customer unless:

• The product has been used for trade,

professional or hire purposes.

• The product has been subjected to misuse or

neglect.

• The product has sustained damage through

foreign objects, substances or accidents.

• Repairs have been attempted by persons

other than authorised repair agents or

Black & Decker service staff.

To claim on the guarantee, you will need to submit

proof of purchase to the seller or an authorised

repair agent. You can check the location of your

nearest authorised repair agent by contacting

your local Black & Decker offi ce at the address

indicated in this manual. Alternatively, a list of

authorised Black & Decker repair agents and full

details of our aftersales service and contacts are

available on the Internet at: www.2helpU.com.

Please visit our website

www.blackanddecker.co.uk to register your

new Black & Decker product and to be kept up to

date on new products and special offers. Further

information on the Black & Decker brand and our

range of products is available at

www.blackanddecker.co.uk.

Page 11

11

TÜRKIYE

Genel Güvenlik Kuralları

Uyarı! Bütün güvenlik uyarılarını ve

talimatlarını okuyun ve anlayın. Aşağıda

belirtilen tüm talimatlara herhangi birisine

uyulmaması elektrik çarpması, yangın

ve/veya ciddi yaralanma riskine neden

olabilir.

Kullanım amacı

BPGP1518 ağır hizmet tipi polisaj makineniz boyalı

veya tamamlanmamış metal, fi berglas ve kompozit

yüzeylerin profesyonel polisaj uygulamaları için

tasarlanmıştır. Bunlarla sınırlı olmamak kaydıyla

yaygın kullanım örnekleri: otomotiv / deniz

taşıtları / RV / motosiklet detaylandırma ve yüzey

düzeltmesi, tekne yapımı ve onarımı, ve metal

veya beton son kat işleri.

Islak koşullarda veya yanıcı sıvı ya da gazların

mevcut olduğu ortamlarda KULLANMAYIN.

Güvenlik talimatları

Uyarı! Bütün güvenlik uyarılarını ve

talimatlarını mutlaka okuyun. Aşağıda

yer alan uyarılar ve talimatların herhangi

birisine uyulmaması elektrik çarpması,

yangın ve/veya ciddi yaralanma riskine

neden olabilir.

Bütün uyarı ve güvenlik talimatlarını ileride

bakmak üzere saklayın. Aşağıda yer alan

uyarılardaki «elektrikli alet» terimi şebeke

elektriğiyle (kablolu) veya akü/pille (şarjlı) çalışan

elektrikli aletinizi ifade etmektedir.

1. Çalışma alanının güvenliği

a. Çalışma alanını temiz ve aydınlık tutun.

Karışık ve karanlık alanlar kazaya davetiye

çıkartır.

b. Elektrikli aletleri, yanıcı sıvılar, gazlar

ve tozların bulunduğu yerler gibi yanıcı

ortamlarda çalıştırmayın. Elektrikli aletler,

toz veya dumanları ateşleyebilecek kıvılcımlar

çıkartır.

c. Bir elektrikli aleti çalıştırı

rken çocuklardan

ve etraftaki kişilerden uzak tutun. Dikkatinizi

dağıtıcı şeyler kontrolü kaybetmenize neden

olabilir.

2. Elektrik güvenliği

a. Elektrikli aletlerin fi şleri prizlere uygun

olmalıdır. Fiş üzerinde kesinlikle hiçbir

değişiklik yapmayın. Topraklı elektrikli

aletlerde hiçbir adaptör fi şi kullanmayın.

Değiştirilmemiş fi şler ve uygun prizler elektrik

çarpması riskini azaltacaktır.

b. Borular, radyatörler, ocaklar ve buzdolapları

gibi topraklanmamış yüzeylerle vücut

temasından kaçının. Vücudunuzun

topraklanması halinde yüksek bir elektrik

çarpması riski vardır.

c. Elektrikli aletleri yağmura maruz bırakmayın

veya ıslatmayın. Elektrikli alete su girmesi

elektrik çarpması riskini arttıracaktır.

d. Elektrik kablosunu uygun olmayan

amaçlarla kullanmayın. Elektrikli aleti

kesinlikle kablosundan tutarak taşımayın,

çekmeyin veya prizden çıkartmayın.

Kabloyu sıcaktan, ya

ğdan, keskin

kenarlardan veya hareketli parçalardan

uzak tutun. Hasarlı veya dolaşmış kablolar

elektrik çarpması riskini arttırır.

e. Elektrikli bir aleti açık havada

çalıştırıyorsanız, açık havada kullanıma

uygun bir uzatma kablosu kullanın.

Açık havada kullanıma uygun bir kablonun

kullanılması elektrik çarpması riskini azaltır.

f. Eğer bir elektrikli aletin nemli bir bölgede

çalıştırılması zorunluysa, bir artık akım

aygıtı (RCD) korumalı bir kaynak kullanın.

Bir RCD kullanılması elektrik şoku riskini

azaltır.

Not: «Artık Akım Aygıtı (RCD)» tanımı, «Kaçak

Akım Koruma Cihazı (GFCI)» veya «Toprak

Kaçağı Devre Kesici (ELCB)» tanımları ile

değiştirilebilir.

3. Kişisel güvenlik

a. Elektrikli bir aleti kullanırken her zaman

dikkatli olun, yaptığınız işe yoğunlaşın

ve sağduyulu davranın. Elektrikli bir aleti

yorgunken veya ilaç ya da alkolün etkisi

altındayken kullanmay

ın. Elektrikli aletleri

kullanırken bir anlık dikkatsizlik ciddi kişisel

yaralanmayla sonuçlanabilir.

b. Kişisel koruyucu ekipmanları mutlaka

kullanın. Daima koruyucu gözlük takın.

Koşullara uygun toz maskesi, kaymayan

güvenlik ayakkabıları, baret veya kulaklık gibi

koruyucu donanımların kullanılması kişisel

yaralanmaları azaltacaktır.

c. İstem dışı çalıştırılmasını önleyin. Aleti

güç kaynağına ve/veya aküye bağlamadan,

yerden kaldırmadan veya taşımadan önce

düğmenin kapalı konumda olduğundan

emin olun. Aleti, parmağınız düğme üzerinde

bulunacak şekilde taşımak veya açık

konumdaki elektrikli aletleri elektrik şebekesine

bağlamak kazaya davetiye çıkartır.

Page 12

12

TÜRKIYE

d. Elektrikli aleti açmadan önce tüm ayarlama

anahtarlarını çıkartın. Elektrikli aletin hareketli

bir parçasına takılı kalmış bir anahtar kişisel

yaralanmaya neden olabilir.

e. Ulaşmakta zorlandığınız yerlerde

kullanmayın. Daima sağlam ve dengeli basın.

Bu, beklenmedik durumlarda elektrikli aletin

daha iyi kontrol edilmesine olanak tanır.

f. Uygun şekilde giyinin. Bol elbiseler

giymeyin ve takı takmayın. Saçınızı,

elbiselerinizi ve eldivenlerinizi hareketli

parçalardan uzak tutun. Bol elbiseler ve

takılar veya uzun saç hareketli parçalara

takılabilir.

g. Eğer kullandığınız üründe toz emme ve

toplama özellikleri olan ataşmanlar varsa

bunların bağlı olduğundan ve doğru şekilde

kullanıldığından emin olun. Bu ataşmanların

kullanılması tozla ilgili tehlikeleri azaltabilir.

4. Elektrikli aletlerin kullanımı ve bakımı

a. Elektrikli aleti zorlamayın. Uygulamanız

için doğ

ru elektrikli aleti kullanın. Doğru

elektrikli alet, belirlendiği kapasite ayarında

kullanıldığında daha iyi ve güvenli çalışacaktır.

b. Düğme açmıyor ve kapatmıyorsa elektrikli

aleti kullanmayın. Düğmeyle kontrol

edilemeyen tüm elektrikli aletler tehlikelidir ve

tamir edilmesi gerekmektedir.

c. Herhangi bir ayarlama, aksesuar değişimi

veya elektrikli aletlerin saklanması

öncesinde fi şi güç kaynağından çekin ve/

veya aküyü elektrikli aletten ayırın. Bu tür

önleyici güvenlik tedbirleri aletin istem dışı

olarak çalıştırılması riskini azaltacaktır.

d. Elektrikli aleti, çocukların ulaşamayacağı

yerlerde saklayın ve elektrikli aleti

tanımayan veya bu talimatları bilmeyen

kişilerin elektrikli aleti kullanmasına

izin vermeyin. Elektrikli aletler, eğitimsiz

kullanıcıların elinde tehlikelidir.

e. Elektrikli aletleri iyi durumda muhafaza

edin. Hareketli parçalardaki hizalama

hatalarını ve tutuklukları, parçalardaki

kırılmalar ve elektrikli aletin çalışmasını

etkileyebilecek tüm diğer koşulları kontrol

edin. Hasarlı ise, elektrikli aleti kullanmadan

önce tamir ettirin. Kazaların çoğu,

elektrikli aletlerin bakımının yeterli şekilde

yapılmamasından kaynaklanır.

f. Kesim aletlerini keskin ve temiz tutun.

Bakımı uygun şekilde yapılmış keskin kesim

uçlu kesim aletlerinin sıkışma ihtimali daha

düşüktür ve kontrol edilmesi daha kolaydır.

5. Servis

a. Elektrikli aletinizi, sadece orijinal yedek

parçaların kullanıldığı yetkili servise

tamir ettirin. Bu, elektrikli aletin güvenliğinin

muhafaza edilmesini sağlayacaktır.

6. Elektrik güvenliği

Bu alet çift yalıtımlıdır. Bu yüzden hiçbir

topraklama kablosuna gerek yoktur. Her

zaman şebeke geriliminin aletin üretim

etiketinde belirlenmiş değerlere uyup

uymadığını kontrol edin.

Uyarı! Elektrik kablosu hasarlı ise, bir

tehlike oluşmasını önlemek için üretici ya

da yetkili Black & Decker Servis Merkezi

tarafından değiştirilmelidir. Elektrik

kablosu Black & Decker yetkili servisi

haricinde değiştirilirse, garanti geçerli

olmayacaktır.

7. Alet Üzerindeki Etiketler

Aletin etiketinde aşağıdaki semboller bulunabilir:

Tüm

talimatları

okuyun.

Hz Hertz 2.Sınıf

Yap ısı

Koruyucu

gözlük

takın.

W Watt Topraklı

terminal

Kulaklık

takın.

min dakikalar Güvenlik

uyarı

sembolü

V Volt

Dalgalı

akım

../min Dakikada

devir veya

darbe

sayısı

A Amper

Doğru

akım

n

0

Yüksüz hızı

Özel Ek Güvenlik Talimatları Bütün

Uygulamalar İçin Güvenlik Talimatları

• Bu elektrikli alet bir polisaj makinesi

olarak kullanılmak üzere tasarlanmıştır.

Bu elektrikli alet ile verilen tüm güvenlik

uyarıları, talimatlar, resimli açıklamalar ve

teknik özellikleri okuyun. Aşağıda belirtilen

tüm talimatların herhangi birisine uyulmaması

elektrik çarpması, yangın ve/veya ciddi

yaralanma riskine neden olabilir.

• Taşlama, zımparalama, fırçalama veya

kesme işlerinin bu elektrikli alet ile

yapılması tavsiye edilmez. Elektrikli aletin

tasarlanma amacı dışındaki işlemler tehlike ve

kişisel yaralanmalara neden olabilir.

Page 13

13

TÜRKIYE

• Üretici fi rma tarafından özel olarak

tasarlanmamış ve tavsiye edilmemiş

aksesuarları kullanmayın. Aksesuarın

elektrikli aletinize takılabilir olması güvenli

bir çalışma temin edeceği anlamına

gelmemektedir.

• Aksesuarın nominal hızı en az elektrikli

alet üzerinde yazan maksimum hıza eşit

olmalıdır. Nominal hızından daha hızlı çalışan

aksesuarlar kırılabilir ve etrafa saçılabilir.

• Aksesuarınızın dış çapı ve kalınlığı elektrikli

aletinizin kapasite oranı içinde olmalıdır.

Yanlış ebatlı aksesuarlar yeteri kadar

korunamaz ve kontrol edilemez.

• Metrik dişli aksesuarlar taşlamanın mil

boyutuna uymalıdır. Flanşla monte edilen

aksesuarların delikleri fl anşın geçme

çap

ına uygun uymalıdır. Elektrikli aletin

montaj donanımına uymayan aksesuarlar

dengesiz çalışır, aşırı titreşim yapar ve kontrolü

kaybetmeye neden olabilir.

• Hasar görmüş olan bir aksesuarı

kullanmayın. Her kullanımdan önce

aksesuarları inceleyin, örneğin diski talaş

ve çatlaklara karşı, tabanı çatlak, kopma

ya da aşırı kullanıma karşı, tel fırçayı

gevşek ya da kırık tellere karşı kontrol edin.

Elektrikli alet ya da aksesuar düşürülürse,

hasar olup olmadığını kontrol edin ya

da sağlam aksesuar takın. Aksesuarın

incelenmesi ve monte edilmesinden sonra

bir dakika boyunca elektrikli aleti boşta ve

maksimum hızda çalıştırın. Bu test süresince

hasarlı aksesuarlar normal olarak kırılarak

dağılacaktır.

• Kiş

isel koruyucu ekipmanları mutlaka

kullanın. Uygulamaya bağlı olarak yüz

kalkanı, koruyucu gözlük ya da güvenlik

gözlükleri kullanın. Yeri geldiğinde küçük

aşındırıcı maddeleri ya da işleme tabi

tutulan parçaları durdurabilen toz maskesi,

kulaklık, eldiven ve iş önlüğü giyin. Göz

koruması, çeşitli işlemler sonucu açığa

çıkan uçan parçacıkları durdurabilmelidir.

Toz maskesi ya da gaz maskesi yaptığınız

işlem sonucu açığa çıkan parçacıkları

fi ltreleyebilmelidir. Uzun süreli yüksek şiddetli

gürültüye maruz kalınması işitme kaybına

neden olabilir.

• Çevrede bulunan şahısları çalışma

alanından uzakta güvenli bir mesafede

tutun. Çalışma alanına giren şahıslar kişisel

koruyucu ekipman giymelidir. İşleme tabi

tutulan parçanın ya da kırık bir aksesuarın

parçacıkları fırlayabilir ve çalışma alanının

yakın çevresinde yaralanmalara neden olabilir.

• Kesme aksesuarı

nın gizli kablolara veya

kendi kablosuna temas edebileceği yerlerde

çalışma yaparken elektrikli aleti yalıtımlı

kavrama yüzeylerinden tutun. Kesme

aksesuarının «akım taşıyan» bir kabloya

temas etmesi durumunda elektrikli aletin metal

kısımları da «akım taşır» hale gelecek ve

kullanıcının çarpılmasına neden olabilir.

• Üzerinde çalıştığınız parçayı sabitlemek

ve desteklemek için kelepçeler veya

başka pratik yöntemler kullanın. Parçayı

elle veya vücudunuza dayamanız dengesiz

durmasına neden olacaktır ve aletin kontrolünü

kaybetmenize yol açabilir.

• Kabloyu dönen aksesuardan uzak tutun.

Kontrolü kaybederseniz kablo kesilebilir ya

da kopabilir ve eliniz ya da kolunuz dönen

aksesuar içine çekilebilir.

• Aksesuar tamamen durmadıkça elektrikli

aleti asla yere koymayın. Dönen aksesuar

yüzeyi yakalayabilir ve elektrikli aleti

kontrolünüzden çıkarabilir.

• Elektrikli aleti yanınızda taşırken

çalıştırmayın. Kaza ile temas halinde, dönen

aksesuar giysinize takılabilir, aksesuarı

vücudunuza doğru çekebilir.

• Elektrikli aletin hava çıkışlarını düzenli

olarak temizleyin. Motor fanı, tozu muhafaza

içine çeker ve aşırı metal toplanması

elektriksel tehlike yaratabilir.

• Elektrikli aleti yanıcı

malzemelerin

yakınında çalıştırmayın. Kıvılcım bu

malzemeleri tutuşturabilir.

• Sıvı soğutucu gerektiren aksesuarlar

kullanmayın. Su ya da diğer sıvı soğutucuların

kullanılması elektrik çarpması ya da şok ile

sonuçlanabilir.

Geri tepme ve ilgili uyarılar

Geri tepme, sıkışmış veya takılmış bir polisaj

tabanı veya diğer aksesuarlara verilen ani

tepkidir. Sıkışma veya takılma dönen aksesuarın

aniden durmasına neden olur, bu daha sonra

temas noktasında elektrikli aletin kontrolsüzce,

aksesuarın dönme yönünün tersine doğru

zorlanmasına yol açar.

Örneğin, bir polisaj tabanı, işleme tabi tutulan

parçaya takılır ya da sıkışırsa; sıkışma noktasına

giren disk kenarı malzemenin yüzeyine saplanarak,

diskin geri tepmesine ya da fırlamasına neden

olabilir. Disk, sıkışma noktasındaki hareket yönüne

Page 14

14

TÜRKIYE

bağlı olarak ya kullanıcıya doğru ya da kullanıcıdan

uzağa fırlayabilir. Aşındırıcı diskler bu koşullar

altında kırılabilir.

Geri tepme, elektrik aletin yanlış kullanılmasından

ve/veya yanlış çalıştırma işlemleri veya

koşullarından kaynaklanır ve aşağıda da belirtilen

uygun tedbirler alınarak önlenebilir:

• Elektrikli aleti sıkıca tutun, vücudunuzu ve

kolunuzu geri tepme gücüne karşı koyacak

şekilde konumlandırın. Geri tepmeye

ya da çalıştırma sırasındaki döndürme

momenti tepkisine karşı maksimum kontrol

sağlamak için eğer varsa yan tutma kolunu

kullanın. Doğru önlemler alınırsa döndürme

momenti tepkileri ya da geri tepmeler kullanıcı

tarafından kontrol edilebilir.

• Döner aksesuar civarına asla elinizi

sokmayın. Aksesuar elinizde geri tepme etkisi

yapabilir.

• Geri tepmenin meydana gelmesi

durumunda vücudunuzu elektrikli aletin

hareket edeceği alanda bulundurmayın.

Geri tepme hareketi aleti takılma noktasında

disk hareketine ters yönde itecektir.

• Köşe, keskin kenarlar vb. yerlerle çalışırken

özellikle dikkatli olun. Aksesuarı

n

sekmesinden ve takılmasından kaçının.

Köşeler, keskin kenarlar ya da sektirme

hareketi döner aksesuarı engelleme

eğilimindedir ve kontrolün kaybedilmesine ya

da geri tepmeye neden olabilir

• Zincirli testere zinciri, ahşap oyma bıçağı

ya da dişli daire/gönye testere bıçağı

takmayın. Bu tür bıçaklar sık sık geri tepme ve

kontrol kaybı oluşturur.

Polisaj uygulamalarına özel ilave

güvenlik uyarıları

• Polisaj bonesinin sarkan kısımlarının ya da

bağlantı iplerinin serbestçe dönmesine izin

vermeyin. Sarkan bağlantı iplerini bonenin

içine sokun ya da kesin. Sarkan veya dönen

bağlantı ipleri parmaklarınıza dolanabilir veya

çalışma malzemesine takılabilir.

Özel Güvenlik Kuralları

Aksesuarlar, aletin uyarı etiketinde tavsiye

edilen veya daha yüksek hız seviyeli

olmalıdır. Nominal hızından daha hızlı çalışan

diskler ve diğer aksesuarlar etrafa saçılabilir ve

yaralanmalara neden olabilir.

Polisaj aletinin gizli kablolara veya kendi

kablosuna temas edebileceği yerlerde çalışma

yaparken elektrikli aleti yalıtımlı kavrama

yüzeylerinden tutun. Aletin «akım taşıyan» bir

kabloya temas eden metal kısımları da «akım

taşır» hale gelecek ve kullanıcının çarpılmasına

neden olabilir.

• Zımpara, kesme, taşlama, delme ve diğer

inşaat faaliyetleri sırasında toz ile uzun

süreli temastan kaçının. Koruyucu giysiler

giyin ve açıkta kalan yerlerinizi sabun ve su

ile yıkayın. Tozun ağıza, göze girmesi veya

cilt üzerinde bulunması zararlı kimyasallar

emilimini teşvik edebilir.

• Daima koruyucu gözlük takın.

• Polisaj bonesinin taban üzerinde düzgün bir

şekilde oturduğundan emin olun.

• Ellerinizi ve parmaklarınızı dönen boneden

uzakta tutun.

• Aleti çalıştırmadan önce tabanın serbest

ve etrafa zarar vermeyecek şekilde

dönebileceğinden emin olun.

• Bone, düzenli olarak aşınma durumu, kir veya

toplanmış birikinti için kontrol edilmelidir.

Uyarı! Güç kablosunun dönen bone ile

temas etmesine izin vermeyin, kablo hızla

boneye dolanabilir. Bu gerçekleşirse aleti

durdurun, fi şini çekin ve kabloyu çözün.

Kablo hasarlı ise tamir veya değişim için

yerel servis merkezine getirin.

• Hasarlı veya yırtılmış boneyi asla kullanmayın.

• Uygun kıyafet giyin, kısa kollu giysiler, iş

tulumu gibi geniş veya bol kıyafetleri giymeyin.

• Polisaj bonesi iş parçasının yüzeyine temas

etmeden aleti çalıştırmayın.

• Araba gövdesi üzerinde herhangi bir keskin

veya çıkıntılı nesne etrafında polisaj yaparken

son derece dikkatli olun.

Uyarı! Aşındırıcı veya silme macunları

kullanmayın. Bu ürünlerin aşındırıcı

içeriği boyalı yüzeylere zarar verebilir.

Uyarı! Aleti kullanırken koruyucu kulaklık

takın. Bazı koşullarda ve kullanım

süresine göre bu aletin gürültüsü işitme

kaybına neden olabilir.

Titreşim

Teknik veriler ve uygunluk beyanatı içerisinde

belirtilen titreşim emisyon değerleri EN60745

tarafından belirlenen standart bir test yöntemine

uygun olarak ölçülmektedir ve diğer bir aletle

karşılaştırma yaparken kullanılabilir. Beyan edilen

Page 15

15

TÜRKIYE

titreşim emisyon değeri aynı zamanda maruz

kalmanın önceden değerlendirilmesinde de

kullanılabilir.

Uyarı! Elektrikli aletin mevcut kullanımı sırasındaki

titreşim emisyon değeri, aletin kullanım yöntemine

bağlı olarak, beyan edilen değere göre farklılık

sergileyebilir. Titreşim düzeyi belirlenen seviyenin

üzerinde artış gösterebilir.

İşyerinde düzenli olarak elektrikli alet kullanan

çalışanları korumak amacıyla 2002/44/EC

tarafından getirilen elektrik güvenliği önlemlerini

belirlemek üzere titreşime maruz kalmayı

değerlendirirken, çalışma döngüsü içerisinde

örneğin aletin kapalı olduğu ve aktif durumda

olmasının yanı sıra boşta çalıştığı zamanlar gibi,

bütün zaman dilimleri dahil olmak üzere mevcut

kullanım durumu ve aletin kullanım şekli göz

önünde bulundurularak değerlendirilmelidir.

Uzatma kablolarının kullanımı

Kullanmadan önce uzatma kablosunun iyi durumda

olduğundan emin olun. Alet ile her zaman uygun

boyutta uzatma kablolarını kullanın - aletin

çekeceği akımı taşıyabilecek güçte ve farklı

uzunluklardaki kablolar için uygun tel ölçüsüne

sahip. Daha küçük ölçüde bir kablonun kullanılması

güç ve aşırı ısınma kaybıyla sonuçlanan hat

voltajının düşüşüne neden olacaktır. Uygun kablo

boyutları için aşağıdaki tabloya bakınız.

Kablo setleri için minimal ölçüler

Volt Kablonun toplam uzunluğu (m)

120 V~ 0-25 26-50 51-100 101-150

220 V~ 0-50 51-100 101-200 201-300

Amper

Daha fazla

Daha fazla

değil

Amerikalı tel ölçer

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Tavsiye edilmiyor

Özellıkler

1. Açma/kapama tetiği

2. Değişken hız ayar düğmesi

3. Kesintisiz çalıştırma düğmesi

4. Yan kol

5. Mil kilidi düğmesi

Motor

Uyarı! Her zaman şebeke geriliminin

aletin üretim etiketinde belirlenmiş

değerlere uyup uymadığını kontrol edin.

Kurulum

Montaj ve ayarlama

• Milin üzerine polisaj diskini yerleştirin, içbükey

tarafı mile doğru bakacak şekilde emniyet

somununu milin üzerine takın ve iki delikli

anahtar ile sıkın.

• Dış mili,milin üzerine yerleştirin. Elastik

yüzeyini genişleterek yün kumaşı dış mili

kaplayacak şekilde üzerine takın. Kontrol için

üç dakikadan fazla yüksüz çalışmasına izin

verin.

Uyarı! Aleti kapatın ve fi şini şebekeden

çekin.

Çalışmadan önce

Not: Sadece araba gövdesi polisajı aşağıda tarif

edilecek olmakla beraber, bu polisaj makinesi,

parke zeminler, mobilya, tekneler ve arada bir

parlatılabilecek diğer yüzeyler gibi çok farklı

düz yüzeylerde cilalama yeteneğine sahiptir.

Başlamadan önce arabanın gövdesinin temiz ve

kuru olduğundan emin olun. Çalışma alanı da

kuru olmalıdır. Gerekirse polisajdan önce genel bir

temizleyici yardımıyla yol katranını çıkartın. Ayrıca

aşırı yağ lekelerini ve böcek artıklarını çıkartın.

Doğru bir çalışma hızının seçilmesi

Döner parçanın çalışma hızı, hız ayarı ile kontrol

edilir. Hız ayar kademeleri rakamla gösterilir.

Hız ayar düğmesi en alt konumdan yukarı doğru

döndürüldükçe (örnek olarak 1’den, 2’ye) çalışma

parçası daha hızlı döner.

Kullanım

• Polisaj makinesinin fi şini şebekeye takmadan

önce aletin kapalı olduğundan emin olun.

• Aleti açmak için, açma/kapama tetiğine basın.

Aleti kapatmak için açma/kapama tetiğine bir

daha basın.

HER ZAMAN YÜZEYE DAYAYARAK ALETİ

ÇALIŞTIRIN VE DURDURUN. Kabloyu

omzunuzun üzerine yerleştirin ve ilk olarak

düz yüzeylerde çalışın- kaput, gövde ve tavan.

Çapraz olarak geniş, çizgisel hareketlerle yüzeyi

hızlı bir şekilde kapsayın. Polisaj makinesine

fazla BASTIRMAYIN. Basınç değil, makinenin

hareketi en iyi bir şekilde işi yapar.

Page 16

16

TÜRKIYE

• Düz yüzeyleri pasta cila ile kapladıktan sonra

arabanın yan tarafl arını işleyin. Kablo serbest

olarak sarkmalıdır. Kapılar ve çamurluklar

üzerinde çapraz hareketi kullanmak gerekmez.

• Makine üzerine temiz bir polisaj bonesi takın.

• Pasta cilayı yayarak parlatın. Uzun geniş ve

çapraz hareketlerle çalışın. Aşırı bastırmayın.

Polisaj makinesine işi yapmaya izin verin.

Uyarı! Çalışmaya başlamadan önce aleti en

az bir dakika yüksüz çalıştırın. İlk olarak polisaj

diskinin çalışma yüzeyi üzerinde olduğundan emin

olun. Aletin kolunu tutun ve aleti çalıştırın. Yüzey

üzerinde uzun ve geniş hareketler yapın ve aletin

işi yapmasına izin verin.

Yararlı tavsiyeler

• Bu polisaj makinesi eksantrik bir alettir.

Titreşimle dönmek için tasarlanmıştır. Eksantrik

hareket pürüzsüz ve kesintisiz bir parlatma

sağlar.

• En iyi sonuçlar için sadece hafi f bir basınç

uygulayın ve makinenin işi yapmasına izin

verin.

• Kenarlar, köşeler veya küçük alanların

çevresinde çalışırken dikkatli olun. Kenarlarda

ve köşelerde uzun süreli polisaj işlemleri bu

alanlara zarar verebilir.

• Polisaj bonesi sıcak su ve yumuşak deterjanla

elle yıkanabilir. Bone, çamaşır makinesinde

kurutulabilir, ancak havayla kurutulması tavsiye

edilir.

• AŞINDIRICI MACUNLARI KULLANMAYIN.

Bu polisaj makinesi ile sıvı pasta cilanın

kullanılması tavsiye edilir.

• Polisaj bonesi sadece son cilalama için

kullanılabilir. Pasta cilayı uygulamak için

boneyi kullanmayın.

Bakım

Aletiniz minimum bakımla uzun bir süre

çalışacak şekilde tasarlanmıştır. Kesintisiz olarak

memnuniyet verici bir şekilde çalışması gerekli

özenin gösterilmesine ve düzenli temizliğe bağlıdır.

Uyarı! Bakımdan önce aletin kapalı ve

fi şinin çekilmiş olduğundan emin olun.

• Aletinizdeki havalandırma deliklerini yumuşak

bir fırça veya kuru bir bezle düzenli olarak

temizleyin.

• Motor muhafazasını düzenli olarak nemli

bir bezle silin. Aşındırıcı veya çözücü bazlı

temizleyiciler kullanmayın.

Aksesuarlar

Aletinizin performansı kullanılan aksesuara

bağlıdır. Black & Decker aksesuarları, yüksek

kalite standartlarına göre üretilmiş ve aletinizin

performansını arttıracak şekilde tasarlanmıştır. Bu

aksesuarları kullanarak, aletinizden en iyi verimi

alacaksınız.

Teknik özellikler

BPGP1518

Voltaj

KS V 230

Güç W 1300

Yüksüz hızı dev/dak. 3600

Disk çapı mm 180

Mil boyutu M14

Ağırlık Kg 3,6

Ses Lp dB(A) 93,0

Lw dB(A) 104,0

K dB(A) 3

Titreşim a

h

m/s² 3,1

K m/s² 1,5

Çevrenin korunması

Ayrı olarak atın. Bu ürün, normal evsel

atıklarla birlikte atılmamalıdır.

Black & Decker ürününüzün değiştirilmesi

gerektiğini düşünmeniz veya artık kullanılamaz

durumda olması halinde onu, evsel atıklarla birlikte

atmayın. Bu ürünü, ayrı olarak toplanacak şekilde

atın.

Kullanılmış ürünlerin ve ambalajların

ayrı olarak toplanması bu maddelerin

geri dönüşüme sokularak yeniden

kullanılmasına olanak tanır. Geri

dönüşümlü maddelerin tekrar kullanılması

çevre kirliliğinin önlenmesine yardımcı olur

ve ham madde ihtiyacını azaltır.

Yerel yönetmelikler, elektrikli ürünlerin evlerden

toplanıp belediye atık tesislerine aktarılması

veya yeni bir ürün satın alırken perakende satıcı

tarafından toplanması yönünde hükümler içerebilir.

Black & Decker, hizmet ömrünün sonuna ulaşan

Black & Decker ürünlerinin toplanması ve geri

dönüşme sokulması için bir imkan sunmaktadır. Bu

hizmetin avantajlarından faydalanmak için, lütfen,

ürününüzü bizim adımıza teslim alacak herhangi

bir yetkili servise iade edin.

Bu kılavuzda belirtilen listeden size en yakın

yetkili tamir servisinin yerini öğrenebilirsiniz. Ya

Page 17

17

TÜRKIYE

Eğer bir Black & Decker ürünü, satın alma

tarihinden itibaren 24 ay içinde hatalı malzeme,

işçilik ya da uygunsuzluk nedeniyle bozulursa,

müşteriye mümkün olabilecek en az sorunu

yaşatarak Black & Decker hatalı kısımları

değiştirmeyi, adil bir şekilde aşınmış ve yıpranmış

ürünleri tamir etmeyi veya değiştirmeyi garanti

eder. Ancak bu belirtilenler şu durumlar dışında

geçerlidir:

• Ürün ticari veya profesyonel amaçlarla

kullanılmışsa veya kiraya verilmişse;

• Ürün yanlış veya amaç dışı kullanılmışsa;

• Ürün yabancı nesnelerden, maddelerden veya

kaza sırasında zarar görmüşse;

• Yetkili tamir servisleri veya Black & Decker

servis ekibinden başkası tarafından tamir

edilmeye çalışılmışsa.

Garanti talebinde bulunmak için, satıcıya

veya yetkili tamir servisine satın aldığınıza

dair ispat sunmalısınız. Fatura ve garanti kartı

gerekmektedir. Bu kılavuzda belirtilen listeden

size en yakın yetkili tamir servisinin yerini

öğrenebilirsiniz. Ya da, alternatif olarak internet’ten

Black & Decker yetkili tamir servislerinin listesini

ve satış sonrası hizmetlerimizle ilgili tüm bilgiler ve

temas bilgilerine aşağıdaki siteden ulaşabilirsiniz.

www.2helpU.com

Sanayi ve Ticaret Bakanlığı tebliğince kullanım

ömrü 10 yıldır.

Türkiye Distribütörü

KALE HIRDAVAT VE MAKİNA A.Ş.

Defterdar Mah. Savaklar Cad. No. 15

34050 Edirnekapı Eyüp İstanbul

Tel: (0212) 533 52 55 (Pbx)

Faks: (0212) 533 10 05

E-posta: info@kalemakina.com

da, alternatif olarak internet’ten Black & Decker

yetkili tamir servislerinin listesini ve satış sonrası

hizmetlerimizle ilgili tüm bilgiler ve temas bilgilerine

aşağıdaki siteden ulaşabilirsiniz.

www.2helpU.com.

Servis bilgileri

Black & Decker, yaygın bir yetkili servis ağı

sunmaktadır. Tüm Black & Decker Servis

Merkezleri müşterilere etkili ve güvenilir elektrikli

el aleti hizmeti sunmak için eğitimli personel

ile donstılmıştır. Yetkili servis merkezlerimiz

hakkında daha fazla bilgi almak istiyorsanız veya

teknik danışmanlık, onarım ya da orijinal fabrika

yedek parçası ihtiyacınız varsa, size en yakın

Black & Decker satış noktasına başvurun veya

www.blackanddecker.com.tr adresini ziyaret

edin.

AT Uygunluk Beyanatı

MAKİNE DİREKTİFİ

BPGP1518

Black & Decker, «Teknik özellikleri» bölümünde

açıklanan bu ürünlerin aşağıda belirtilen

yönergelere uygun olduğunu beyan eder: 2006/42/

EC, EN 60745-1, EN 60745-2-3.

Bu ürünler aynı zamanda Direktif 2004/30/EU ve

2011/65/EU ile de uyumludur. Daha fazla bilgi

için, lütfen aşağıdaki adresten Black & Decker ile

irtibata geçin veya kılavuzun arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik

dosyanın derlenmesinden sorumludur ve bu

beyanı Black & Decker adına vermiştir.

R. Laverick

Mühendislik Müdürü

Black & Decker Europe

210 Bath Road, Slough

Berkshire, SL1 3YD

İngiltere

08/07/2014

Garanti

Black & Decker, ürünün kalitesinden emindir ve bu

yüzden kanunlarda belirtilen taleplerin üstünde bir

garanti verir. Ayrıca bu garanti hiçbir şekilde garanti

ile ilgili kanuni haklarınızı ihlal etmez ve haklarınızı

hiç bir şekilde kısıtlamaz. İşbu garanti Avrupa

Birliği’ne üye ülkeler ile Avrupa Serbest Ticaret

Bölgesi sınırları dahilinde geçerlidir.

Page 18

18

TÜRKIYE

Şehir Yetkili Servis Adres Telefon

1 Adana Emin Elektrik Bobinaj Kızılay Cad. 9 Sok. No: 9/D 0322 351 80 46

2 Afyon Emek Motor Karaman Mah. Gazlı Göl Cad. No: 15 0272 212 11 14

3 Ağr Tamgüç Bobinaj Kağızman Cad. No: 42 0472 215 70 41

4 Amasya Akotek Ticaret Yeniyol Cad. No: 85 0358 218 71 19

5 Ankara Orhan Bobinaj Yalınç Sok. No: 17 Siteler 0312 350 95 29

6 Ankara Orhan Bobinaj Şube 41. Sok. No: 39 Ostim 0312 385 92 92

7 Ankara Yiğit Bobinaj 668. Sok. No: 8 Eminel Koop. İvedik Ostim 0312 395 05 37

8 Ankara Başak Elektrik Ahievran Cad. 36. sok. No: 2 Ostim 0312 386 20 84

9 Antalya E.B.A Elektrik San. Sit. 682. Sok No: 38 0242 345 36 22

10 Antalya Yaşar Bobinaj Aşağı Pazarcı Mah. San. Girişi No: 19 Manavgat 0242 742 44 07

11 Antalya Uslu Bobinaj G. Pınarı Mah. Oba Yolu Üzeri no: 27/C Alanya 0242 511 57 01

12 Aydın Tacıroğlu Kaya Bobinaj 1.San. Sit. Üst San. Cad. 2. Sok. No: 31/A 0256 212 70 48

13 Aydın Saydam Motor Küçük San. Sit. Çubukçu Sok. No: 2/B Söke 0256 512 81 91

14 Aydın Özgür Bobinaj Kuşadası San. Sit. j Blok no:13 Kuşadası 0256 622 1373

15 Aydın Ege Bobinaj Yeni Mah Atatürk Bul. No:206/E Didim 0256 811 05 95

16 Balıkesir Tezger Bobinaj Yeni San. Sit. Cumhuriyet Cad. 198/A 0266 246 23 01

17 Balıkesir Küre Bobinaj Atatürk Cad. No: 104 Bandirma 0266 718 46 79

18 Batman Topiz Bobinaj Cumhuriyet Cad. 1512 Sok. No: 50 0488 214 87 70

19 Bolu Kilitçi Ticaret Aşağı Soku San. Sit. 37.Blok No:16 0374 215 43 64

20 Bursa Vokart Ltd. Şti. Gazcılar Cad. Erikli Bahçe Sok. No: 7/B 0224 254 48 75

21 Çanakkale Kısacık Bobinaj Namık Kemal Mah. Kaynak Sok. No: 41 0286 217 96 71

22 Çanakkale Ovalı Bobinaj Hamdibey Mah. İstiklal Cad. No: 160 Biga 0286 316 49 66

23 Çorum Emek Bobinaj Küçük San. Sit. 23. Cad No: 5/C 0364 234 68 84

24 Denizli Örsler Bobinaj Sedef Çarşısı 9/10 0258 261 42 74

25 Diyarbakir Çetsan Elektrik San. Sit. Karakol Sok. No: 1 0412 237 29 04

26 Düzce Yıldız Makina Burhaniye Mah. Gen. Kazım Sok. No: 10 0380 514 70 56

27 Edirne Efe Bobinaj Küçük San. Sit. 22. Blok 0284 225 35 73

28 Edirne Demir Bobinaj San. Sit. 7. Blok No: 3 Keşan 0284 714 38 26

29 Elazığ Kalender Elektrik Bobinaj San. Sit. 11. Sok No: 46 0424 224 85 01

30 Erzincan Ümit Elektrik Makina San. Çarşısı 770 Sok. No: 71 0446 224 08 01

31 Erzurum Bursan Bobinaj San. Sit. 5. Blok No: 135 0442 242 77 28

32 Eskişehir Escom Elektronik Kırmızı Toprak Mah. Ali Fuat Güven Cad. No 31/A 0222 224 15 30

33 Gaziantep Eser Bobinaj K.S.S A Blok 11. Cad.25. Ada No: 55 Ş.Kamil 0342 235 30 84

34 Gaziantep Karaşahin Bobinaj İsmet Paşa Mah. Şenyurt Cad. No: 35 0342 231 17 33

35 Hatay Öz Kardeş Bobinaj Yeni San. Sit. 38/A Blok No: 34 0326 221 22 91

36 Isparta İzmir Bobinaj Yeni San. Sit. 6 Blok No: 28 0246 223 70 11

37 İstanbul Akel El. Servis Hizmetleri Nato Yolu Caddesi Özgün Sok No: 1 Y.Dudullu 0216 540 53 55

38 İstanbul Birlik Elektromekanik Perpa Tic. Mer. B Blok Mavi Avlu Kat.4 No: 318 Okmeydanı 0212 222 94 18

39 İstanbul Fırat Dış Ticaret Tersane Cad. Kuthan No: 38 Kat 3 Karaköy 0212 252 93 43

40 İ

stanbul Kardeşler Bobinaj Çağlayan Mah. Sinanpaşa Cad.No: 5 Çağlayan 0212 224 97 54

41 İstanbul Mert Elektrik İkitelli Org. Demirciler San. Sit. D-2 Blok No: 280 İkitelli 0212 549 65 78

42 İstanbul Svs Teknik İstasyon Cad. Gibtaş San. Sit. F Blok No: 24 Tuzla 0216 446 69 39

43 İstanbul Tarık Makina Bağdat Cad. Adali Sok. No: 8 Maltepe 0216 441 05 59

44 İstanbul Tekniker Bobinaj Birlik San. Sit. 1. Cad. K.Dükkanlar No: 15 Beylikdüzü 0212 875 17 78

45 İstanbul Orijinal Elektrik Bağlar Mah. Mimar Sinan Cad. No:24 Güneşli 0212 515 67 71

46 İzmir Birlik Bobinaj 2824 Sok. No: 18/1. San. Sit. Halkapınar 0232 458 39 42

47 İzmir Boro Cıvata 1203/2 Sok. No: 21-B Yenişehir 0232 469 80 70

48 İzmir Çetin Bobinaj Cüneyt Bey Mah. İbrahim Turan Cad. No 98/A Menderes 0232 782 10 84

49 İzmir Doruk Hırdavat 1426 Sok. No: 14 Hurdacılar Sitesi Doğanlar Bornova 0232 478 14 12

50 Karaman Özüm Elektrik Bobinaj Yeni San. Sit. 735. SoK. No: 2 0338 212 32 69

51 Kastamonu Teknik Bobinaj İnönü Mah. İnebolu Cad. No: 132 0366 212 62 26

52 Kayseri Akın Elektrik Bobinaj Eski San. Bölgesi 5. Cad. No: 8 0352 336 41 23

53 Kırklareli Tarık Elektronik K.İbrahim Mah. M.Kemal Bulvarı No: 72/C 0288 214 19 72

54 Kırklareli Yalçın Bobinaj Yeni San. Sit. C3 Blok No:55 Lüleburgaz 0288 412 41 97

55 Kocaeli Efe Elektrik Bobinaj Körfez San. Sit. 12. Blok No: 13 0262 335 18 94

56 Kocaeli Gülsoy Bobinaj S.Orhan Mah. İlyasbey Cad.1111 Sk No: 5/1 Gebze 0262 646 92 49

57 Kocaeli Teknik Karot Gaziler Mah. İbrahimağa Cad. No:125 Gebze 0262 642 79 10

58 Konya Meb. Murat Elk. Bobinaj Karatay San. Sit. Fatih Mah. Çiçekli Sok. No: 10 0332 235 64 63

59 Konya Sözenler Bobinaj Fevzi Çakmak Mah. Komsan İş Merkezi Anamur 10562 Sok. No:8 0332 342 63 18

60 Kütahya Doğan Bobinaj Yeni San. Sit. 19. Sok: 28/1 0274 231 22 00

61 Malatya Özer Bobinaj Yeni San. Sit. 2. Cad. No: 95 0422 336 39 53

62 Manisa Çavuş Bobinaj Kurtuluş Mah. Fatih Cad. No: 44/A Soma 0236 614 13 78

63 Manisa Uslu Bobinaj Ve Makina Güzelyurt Mah. Kenan Evren San. Sit. 5309 Sok. No: 63/A 0236 236 33 86

64 Mersin Şekerler Elekrik Bobinaj Nusratiye Mah. 5005 Sok. No: 20/A 0324 336 70 98

65 Mersin Üniversal Bobinaj Nusratiye Mah. Çiftçiler Cad.68 Sok. No: 19 0324 233 44 29

66 Muğla Bodrum Makina Türkkuyusu Mah.San. Sit. Ethem Demiröz Sok. No: 8 Bodrum 0252 316 28 51

67 Muğla General Elektrik Bobinaj Taşyaka Mah. San. Sit. 260. Sok. No: 18 Fethiye 0252 612 38 34

68 Muğla Başaran Teknik Beldibi Cad. Sanayi Giri

şi No: 5/C Marmaris 0252 419 20 29

69 Muğla Öztürk Bobinaj Atakent Mah. Çevreyolu Üzeri Dalaman 0252 697 64 98

70 Nevşehir Çiftgüç Soğutma Yeni San. Sit. 8. Blok No: 28 0384 213 19 96

71 Niğde Emek Motor Eski San. Çarşısı 1.Blok No: 2 0388 232 83 59

72 Sakarya Engin Elektrik Bobinaj Maltepe Mah. Orhan Gazi Cad. Şehit Metin Akkuş Sok. No: 19 0264 291 05 67

73 Samsun Akış Bobinaj Ulus Cad.San. Sit. Keresteciler Kısmı No: 40 0362 238 07 23

74 Sivas Bayraktar Elektrik Yeni Çarşı No: 72/C 0346 221 47 55

75 Şanlıurfa Ay Elektrik Samsat Kapı Avşaroğlu Garajı No: 19 0414 215 74 76

76 Tekirdağ Birkan Teknik Şeyhsinan Mah. Ş.Pilot İ.Aksoy Sok. Aksoy Psj. No: 20/7-B ÇORLU 0282 654 50 91

77 Tekirdağ Çetin Elektrik Bobinaj 100.Yıl San. Sit. 14B Blk. No: 10 0282 263 86 60

78 Tokat Çetin Elektrik Bobinaj San. Sit. Camii Altı No: 22 0356 214 63 07

79 Trabzon Akçay Bobinaj Makina Yaylacık Mah.Tosun San Sit No: 3 Akçaabat 0462 227 54 26

80 Trabzon Makina Market Rize Cad. No: 71 Değirmendere 0462 328 14 80

81 Uşak Zengin Bobinaj İslice Mah. Ürem Sok. No: 10/C 0276 227 27 46

82 Van Özen Elektrik Bobinaj Alçekiç Pasajı No: 41 0432 214 22 20

83 Yalova Deniz El. Ser. Hizmetleri Hürriyet Mah. Eski Bursa Cad. No: 39 Altınova 0226 461 22 43

84 Zonguldak Genel Elektromotor Çınartepe Mah.T.T.K 69 Ambarları 4. Kısım 0372 268 08 64

85 Zonguldak Tümen Makina Kışla Sanayi Sit. D Blok No: 17 Kdz.Ereğli 0372 323 74 97

KALE HIRDAVAT V E M AKİNA A.Ş. SERVİS MÜDÜRLÜĞÜ TEL. 0212 533 98 34

zst00242432 - 24-07-2014

Page 19

Page 20

Loading...

Loading...