Page 1

.BIACK&DECKER@

INSTRUCTIONMANUAL

HammerDrills3/8"(10mm)and112"(13mml

SAFETYINSTRUCTIONS

Warning! Whenusingelectricaltools,thefollowingbasicsafetypre-

cautionsshouldalwaysbetakento reducethe risk of fire, electric

shockandpersonalinjury.

Readalltheseinstructionsbeforeattemptingto operatetheproduct

andsavethis booklet.

Keepworkareas clean. Clutteredareasandbenchesinviteinjuries.

Considerthe workareaenvironment.Donotexposethepowertoolto

rainanddo notuseindamporwet locations. Keepsworkareaswell

lit. Donotusethe powertool wherethere maybea risk offire or

explosion.

Guardagainst electric shock. Avoidbodycontact,wherepossible

with earthedorgroundedsurfaces(e.g.pipes,radiators,rangesand

refrigerators).

Keepchildren away. Donotlet visitorsshouldtouchthetool or

extensioncord. All visitorsshouldbekept awayfromthe work area.

Store idle tools. Whennotin use,toolsshouldbestoredin a dry,high

or lockedplace,outofthe reachofchildren.

Donot force the tool. It will deliverbetter performancewhentool is

usedat the recommendedspeed.

Usethe right tool. Donotforcesmalltoolsor attachmentsto dothe

job of a heavy-dutytool. Donot usethetool for purposesnotintended;

for example,donot usea circularsaw to cut a tree limb or logs.

Dress properly. Donotwear looseclothingorjewelry asthey canbe

caughtin movingparts. Rubberglovesandnon-slqdfootwearis

recommendedwhenworkingoutdoors.Wearprotectivehaircovering

to contain long hair.

Usesafety glasses. Use a face or dust mask as well, if the operation

is dUstyorif the tool is beingusedin enclosedspaces.

Connectingdust extraction equipment. If devicesareprovidedfor

the connectionof dustextractionandcollection,ensurethat theseare

connectedandproperlyused,especiallyinconfinedareas.

Donot abuse the cord. Nevercarrythetool by its cordor yankit to

disconnectit from the socket. Keepthe cordawayfrom heat,oil and

sharpedges.

Secure the work. Useclampsor vicesto securelyfastenthe material

youareworkingwith. It is saferthanusinga handandit frees both

handsto operatethetool.

Donot overreach. Keep proper footing and balance at all times.

Maintainthe toolwith care. Keepacuttingtool sharpandcleanfor

betterandsaferperformance.Followthe instructionsfor lubricating

andchangingaccessories.Inspectthetools andcord periodicallyand

if damaged,haverepairedbyanAuthorizedServiceCenter.Inspectthe

extensioncordperiodically,andreplaceif damaged. Keepthe handles

dry,cleanandfreefrom 011andgrease.

Disconnectthe tool. Whennotin use,beforeservicingandwhen

changingaccessoriessuchasblades,bits andclutters.

Removeadjusting key wrenches. Formthe habit ofcheckingto see

that keysandadjustingwrenchesareremovedfromthetool and

replacedinthestorageareabeforeswitchingon.

Avoid unintentional starting. -Donotcarry a plugged-intool with a

fingeronthe switch.Makesuretheswitch ISoff whenthetool is plug-

gingin. .

Useanoutdoorextensioncord. Whenatoolis usedoutdoors,only

useanextensioncordintendedfor outdooruse.

Stayalert. Watchwhat youaredoing,usecommonsenseanddonot

operatethetoolwhentired. .

Checkdamaged parts. Beforefurtheruseofthetool, guardandother

partsthat aredamagedshouldbecarefullycheckedtodetermine

whetherit wouldoperateproperlyandperformits intendedfunction.

Checkforalignmentof movingparts;free runningof movingparts;

breakageof parts;mountingandanyotherconditionsthatmayaffect

itsoperation.

If the guardor otherpartsaredamaged,theyshouldbeproperly

repairedor replacedbyanAuthorizedServiceCenterunlessotherwise

indicatedin the productbooklet. Havedefectiveswitchesreplacedby

anAuthorizedServiceCenter.

Donotusethe tool if the switch doesnotturn on oroff.

Warning! Theuseof anyaccessoryorattachmentotherthanrecom-

mendedinthe productbooklet,maypresentarisk of personalinjury.

Havethe tool repaired by a qualified person. Theelectricaltool is

in accordancewith the relevantsafetyrequirements:A qualifiedper-

sonusingoriginalspareparts shouldonlycarryoutrepairs;otherwise,

this mayresultin considerabledangertothe user.

Savetheseinstructions!

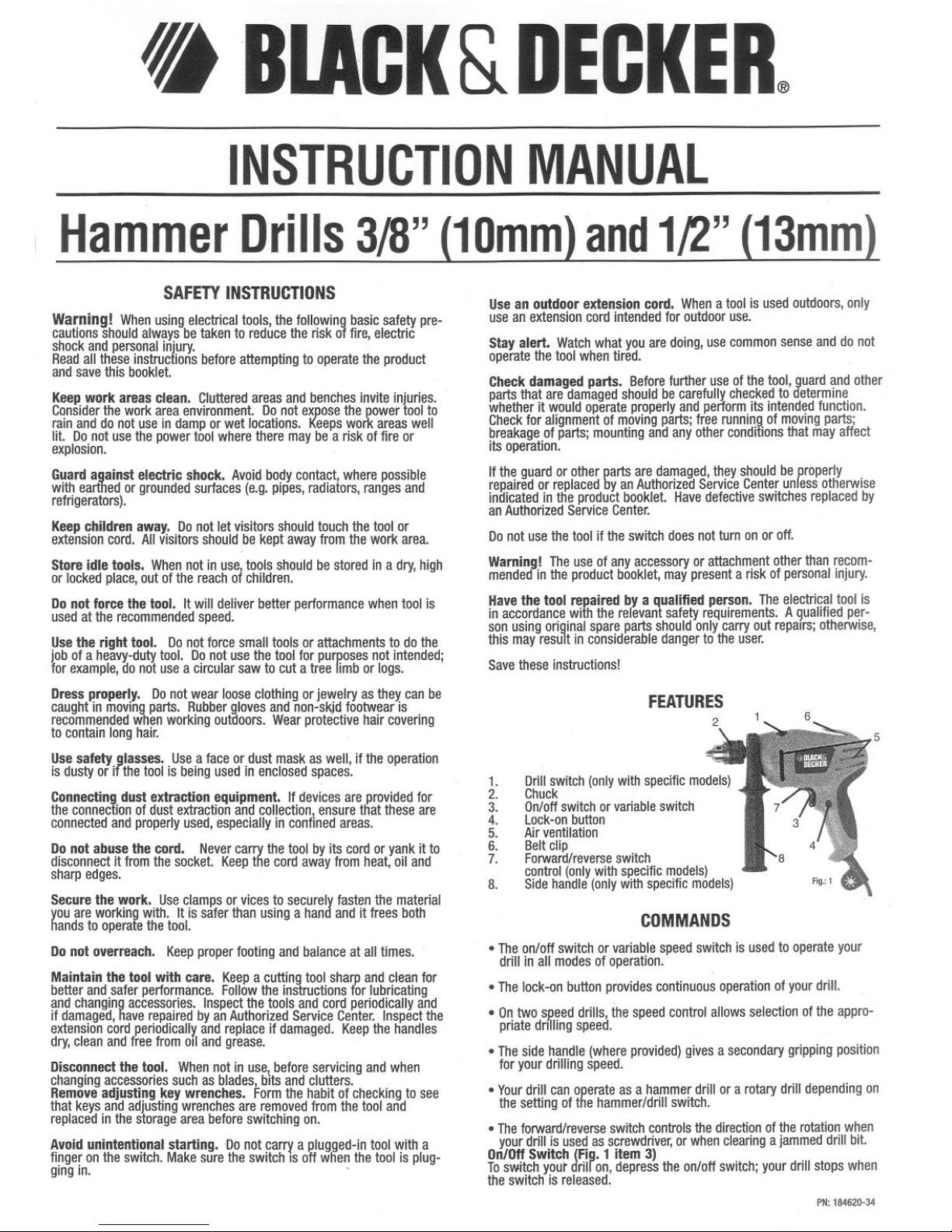

FEATURES

1.

2.

3.

4.

5.

6.

7.

8.

5

Drillswitch(onlywith specificmodels)

Chuck

On/offswitchorvariableswitch

lock-on button

Airventilation

Beltclip

Forward/reverseswitch

control(onlywithspecificmodels)

Sidehandle(onlywith specificmodels)

COMMANDS

.Theon/offswitchorvariablespeedswitchis usedto operateyour

drill in all modesof operation.

.Thelock-onbuttonprovidescontinuousoperationofyourdrill.

.Ontwospeeddrills,the speedcontrolallowsselectionofthe appro-

priatednllingspeed.

.Thesidehandle(whereprovided)givesa secondarygrippingposition

for yourdrilling speed.

.Yourdrill can operateasa hammerdrill or a rotary drill dependingon

the settingof the hammer/drillswitch.

.Theforward/reverse switch controls the direction of the rotation when

yourdrill is usedasscrewdriver,orwhenclearingajammeddrill bit.

On/OffSwitch (Fig. 1 item 3)

Toswitch you~ drill on, depress the on/off switch; your drill stops when

the switch

is released.

PN: 184620-34

Page 2

Lock-onButton (Fig. 1 item 4)

If continuosoperationisrequired,pressthe lock-onbuttonwhile the

on/offswitch ISdepressed(Fig.1 Item3).Tostopwhenoperationis

continuos,depressthe on/off switchagainandrelease.

Percussion Switch (Fig. 1 item 1)

Thisis a specialfeaturein yourdriflthatallowshitting androtatingat

the sametime.

a) Drill Mode ~

Whendrillingwoodandmetal.Usefulfor drilling projectsonly.

b) HammerMode I--

Whendrillingmasonry,setthe hammerswitchin this mode.

TwoSpeed Switch (Fig.1 item 3)

Tosetthetwo-speedswitch in lowspeedpushthe switchmidway

backward"I", to setthe switch in high-speedpushtheswitchall the

waybackward"II".

OPERATIONS

1. ASA GENERALRULE. Forlargesizedrill bits uselow speedsand

for smallerdrill bits usehighspeeds. Onvariablespeeddrills,the

morethe trigger is pressedthefasterthe speed.

2. SETTHESPEEDOFYOURDRILL.

Settheforward/reverseswitch to the desireddirectionof rotation.

Neverchangethesettingof thehammerswitch,orthe

forward/reversewhenyourdrill is in operation.

3. MAINTAINVENTSCLEAROFOBSTRUCTION.Inorderto maintain

yourtoolfrom overheatingandextendthe life of yourtool,maintain

the ventilationareasofyourtoolfree from obstructionall the time.

4. HOWTOPOSIT'')NA DRILLBITONYOURDRILL.Selecttheappro-

priatedrill bit tor the job (fOIl

.

OWthe guidelinesof thetablebelow).

First,makesurethedrill ISunplugged.Holdingtherear sectionof

the chuck,rotatethe front sectionuntilthe jaws of thechuck are

sufficientlyopen.Insertthe drill bit inthe jaws of the chuck.Hold

the rearsectionof the chuckwhile tighteningthefront. Turnthe

chuckkeyclockwiseto tightenthejaws andsecurelygripthe drill

bit. Usethechuckkey in the 3 holesfor betterresults.

A

) ~

L, "..

RIGHT

n

,

(j

.

L~

..

J(Jl

?{

'''-'------

WRONG

5. DRILLING:Makesurethe

materialto bedrilled is

tightly fastenedandwhen

dnllingthin materialsuse

a woodsupr°rt. Always

drill ata 90 angleand

placeenoughpressureon

the drill forthe drill to per-

foratethesurfaceyouare

drilling. Neveruseexces-

siveforcewhen usingyour

drill.

6. ACCESSORIES:Variousaccessoriescanfit yourdrill,allowingyou

to diversifyits use. .

7. SANDINGI POLISHING: Positionthediscasshowninthefigure

below.Placethe rubbersupportin the chuckandturn the chuckkey

'

.

"

.

)~

'

I ~~

."

i)~

1

~

'in.. I ~1

II~-::-~

clockwisetotightenthejawstosecurelyfastenthedisc.Tosetthe

polishingfeaturefollowtheexampleusingtherubberdiscandthe

spindle.

.<'-{-:\_..,-

"'~::f-j{~))er~>:;~.:!T!;t~J

.~ '-../ .,

/' ,

,I '-

'-"" '. - -1'1(~)'i,+rt$~~Y'~Y

i/"- \:'1l

..

= <,':-== \~ //''' '.''''QJ..

, "D, ~~)I;;:::

.

'" \"';:::-

.

u

1

. ., ..

\ I<!-i

, ~'J

\, /,/ ..~..:\.:,"".""=

1-- jiV)§ ':' "7

, --- >1 "\'*--:f"'

.

/'

~- '~

Whensanding,donotput all ~ Yf,

thepressureonthefaceofthe ~~"'-. 1:: ~~-

disc;inclinethe discat an . ... -,~~ . ~

angleon the surface. WRONG" "RIGHi"'""

,y

WRONG

.

J>.:<

.

"

.

~()

~"'" r:§.f,,/'-

...~~.

-.0= ~\

~~~"

Whilesandinguse horizontalandverticalmove-

ments. Avoidcircularmovements.Neversand

onedges,thismaycausedamagetosand

paperaswell asrubberdisc.

ACCESSORIES

Theperformance of any power tool dependsuponthe accessory used.

Black& Deckeraccessories are engineeredto high quality standards and are

designedto enhancethe performanceof your tool. PurchasingBlack and

Deckeraccessories will ensurethe best performanceof your Black and

Deckertool.

IQ]DOUBLEINSULATION

Thetool is double insulated. This meansthat all the external metal parts are

electrically insulated from the main powersupply. This is doneby placing

insulation barriers between the electrical and mechanical componentsmak-

ing it necessaryfor the tool to be earthead(grounded).

NOTE: Doubleinsulation does not take the place of normal safety precau-

tions when operating the tool. The insulationsystem is for addedprotection

against injury resulting from a possible electrical insulation failure within the

tool.

EXTENSIONCABLES- Upto 30m (100ft.) of 3 core extensioncable can be

usedwith undue loss of power.

NOTE:An extension cable should not be usedunless absolutely necessary.

If the use of an extension cable is a must, make sure it is properly wired,

contains the correct rated fuse as recommendedin its literature and is in

goodelectrical condition.

TECHNICALDATA

Thelevel of sound pressureof the tool is in accordancewith U.L.legislation.

It is recommendedthat you take appropriate measuresfor the protection of

your hearing if the sound level seems uncomfortable. The normally equates

to a sound pressure in excessof 85db (A).

Black & Decker do Brasil Ltda - ROD.BR050sin KM167LO05,Parteau 1 BairroDistritoIndustrialII-CEP38056-580- UberabaMG

InscriQaosob 0 n° do CNPJ:53.296.273/0001-91 -I.E.: 701,948.711.00.98 -Industria Brasileira - Origen: Brasil

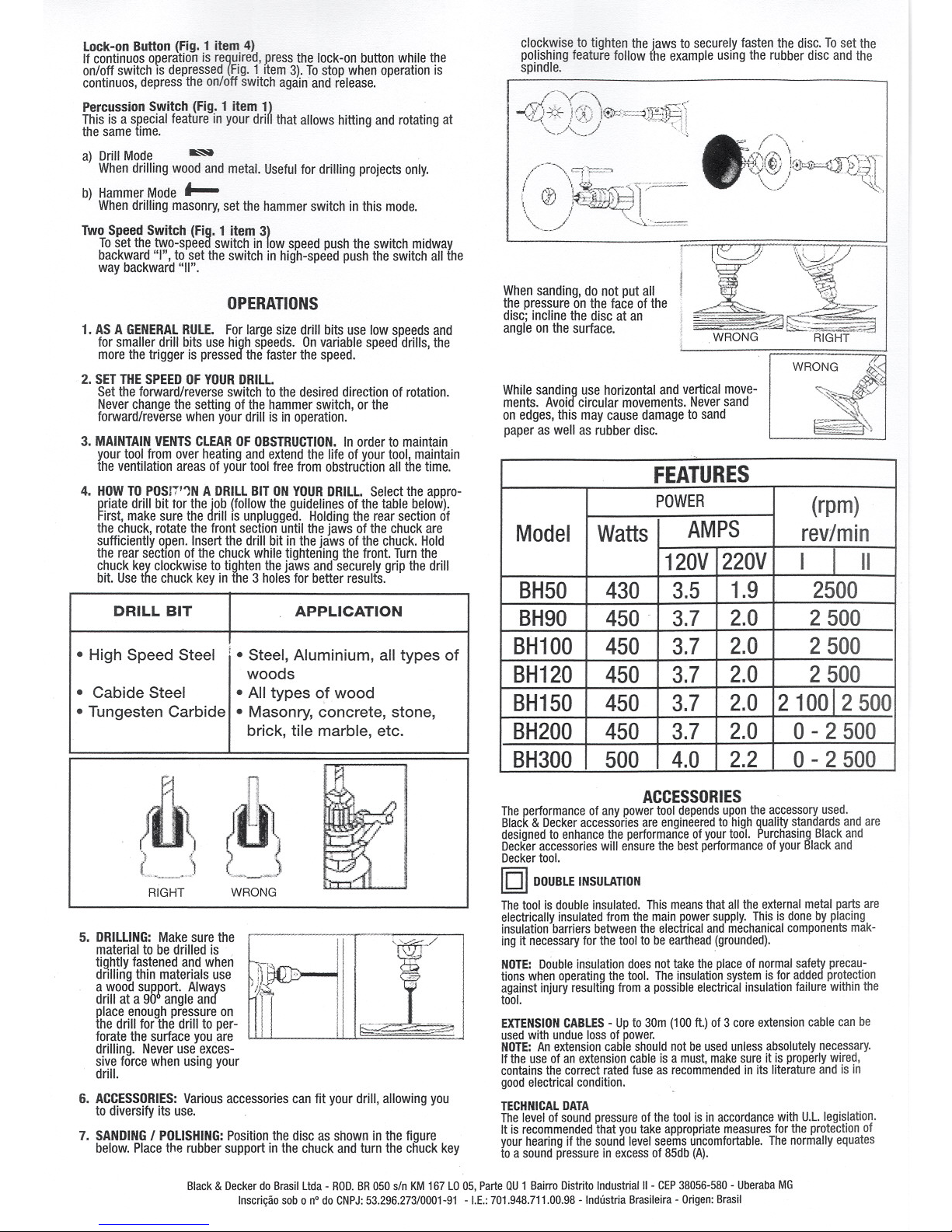

DRILL BIT APPLICATION

. High Speed Steel

i. Steel, Aluminium, all types of

woods

. Cabide Steel

. All types o,fwood

. Tungesten Carbide

. Masonry,concrete, stone,

brick, tile marble, etc.

--

FEATURES

POWER

(rpm)

Model

Watts

AMPS

rev/min

120V

220V I

I

II

BH50 430 3.5

1.9

2500

BH90 450"

3.7

2.0

2 500

BH100

450

3.7

2.0 2500

BH120 450 3.7

2.0

2500

BH150 450 3.7

2.0

210012500

BH200

450 3.7

2.0 0 - 2 500

BH300 500 4.0

2.2

0 - 2500

Loading...

Loading...