Page 1

INSTRUCTION

MANUAL

M

RAPIDROLLER

Catalog Number BDPR400

T

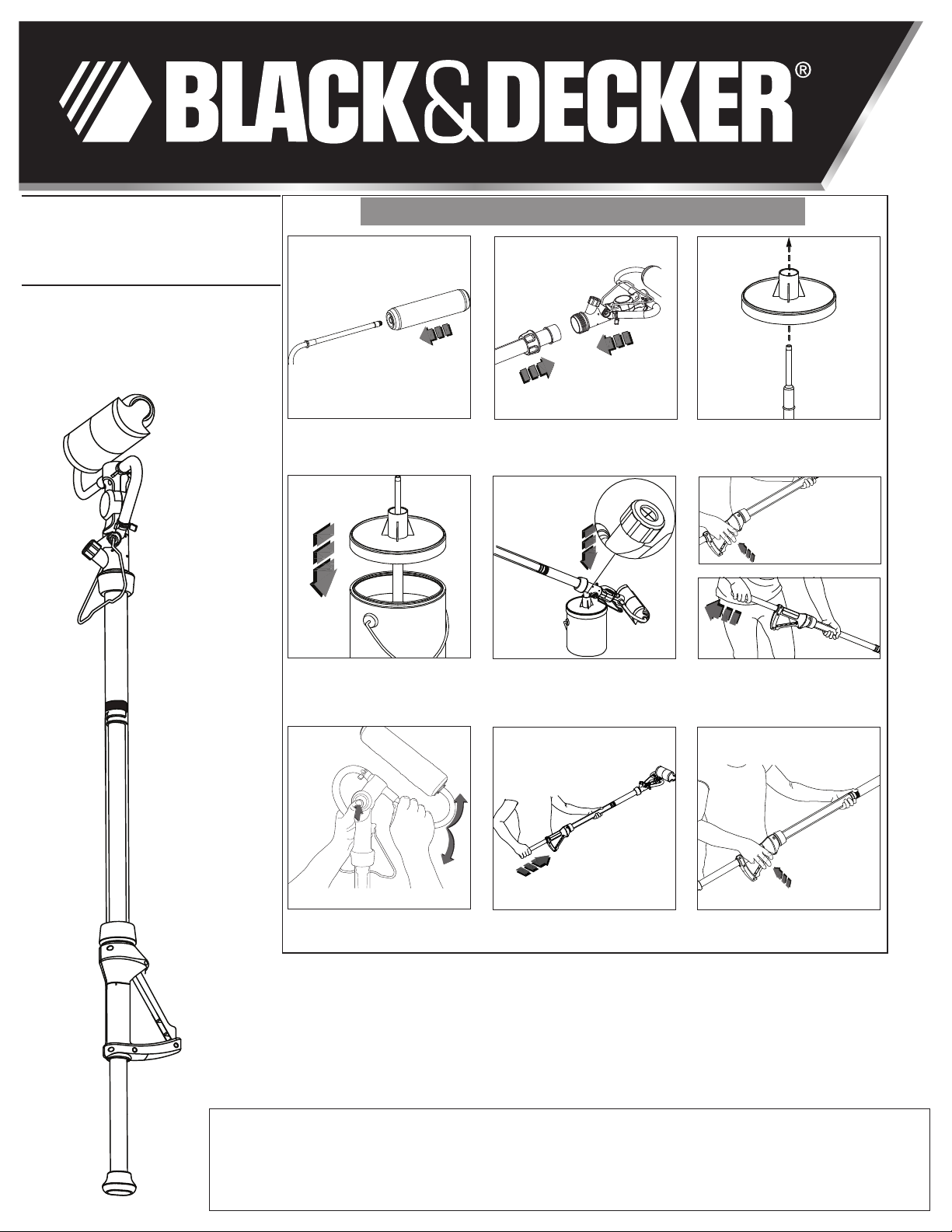

QUICK START GUIDE

Push roller assembly over roller

frame until it snaps into place.

Snap paint can cover onto paint

can. (See “Filling RAPIDROLLER”

section if cover does not fit.)

Thread handle collar on roller frame.

Push fill valve down over fill tube

until orange cap is completely

covered.

Insert fill tube into paint can cover.

Squeeze trigger to free up the

plunger. Pull back plunger to draw

paint. (May take some force).

Adjust roller head to desired angle. Begin rolling on wall and push plunger

to fill head and roller with paint.

Squeeze trigger for additional paint.

Thank you for choosing Black & Decker! Go to

www.BlackandDecker.com/NewOwner to register your new product.

If you have a question or experience a problem with your Black & Decker purchase,

go to HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS for instant answers 24 hours a day.

If you can’t find the answer or do not have access to the internet, call 1-800-544-6986 from 8 a.m. to 5 p.m.

EST Mon. -- Fri. to speak with an agent. Please have the catalog number available when you call.

See inside this instruction manual for complete instructions.

Lire le mode d’emploi pour connaître les directives en entier.

Consulte el interior de este manual de instrucciones para ver las

instrucciones completas.

Page 2

WARNING: To reduce the risk of injury, user must read and understand the instruction manual before using the RAPIDROLLER

PETROLEUMJELLY

LAGELEE DE PETROLE

LAJALEA DE PETROLEO

WARNING: Some paints contain chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. To

reduce your exposure wear appropriate safety equipment such as face masks, gloves, and other appropriate protective equipment. Please review

and follow the safety precautions on the paint container.

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR SAFETY and PREVENTING

PROBLEMS. The symbols below are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in

property damage.

TM

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

• Do not use RAPIDROLLER

damage.

• For use only with water soluble and most oil based paints and stains. Not for use with oil based paints and stains that require cleaning solutions

stronger than mineral spirits (refer to label on original paint container). Do not use with paint removers, or the like. Liquids other than paint or

stain may damage product and result in injury to persons or property damage.

• Read the label on the original paint container and follow all directions. Failure to do so may result in injury to persons or property damage.

• Use proper eye protection and other safety equipment for skin and respiratory protection when mixing the paint, and when filling, using, and

cleaning the product. Paint and its fumes can cause personal injury.

• To reduce the risk of injury, use only in a well ventilated area.

• Thoroughly clean and rinse product after using with a particular paint. Mixing different paints in the product may result in property damage.

• To reduce the risk of injury, use only recommended accessories.

• When servicing, use only identical replacement parts. Failure to do so may result in personal injury.

M

T

for purposes other than described in this manual. Failure to do so may result in injury to persons and or property

SAVE THESE INSTRUCTIONS

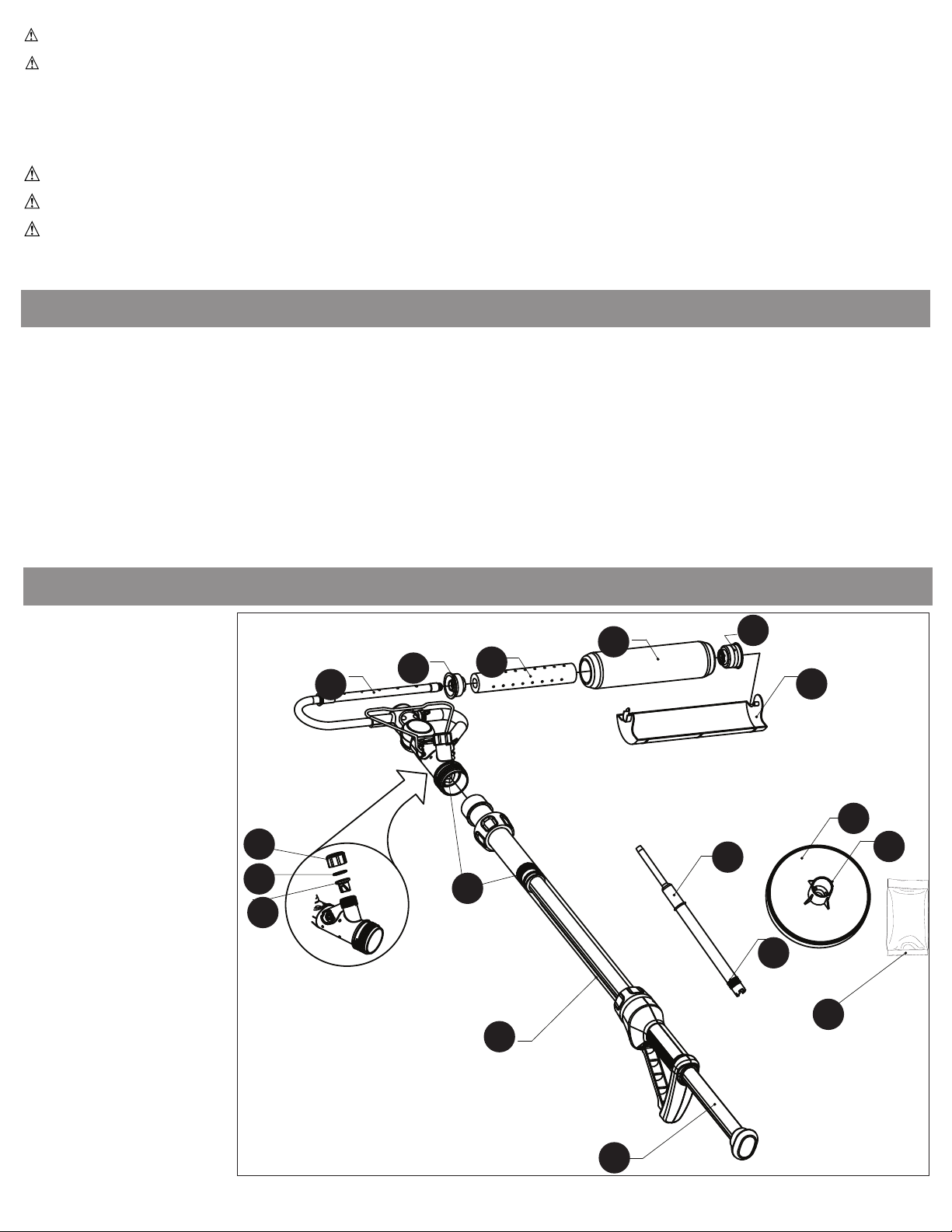

FUNCTIONAL DESCRIPTION

1.)

Plunger

2.) Handle Assembly

3.) O-Rings

4.) Duck Bill Valve

5.)

Wiper Seal

6.) Orange Fill Cap Cover

7.) Roller Frame

8.) Inner End Cap

9.) Roller Core

10.) 3/8 in. perforated roller

11.) Outer End Cap

12.) Spatter Shield

13.) Can Cover

14.) Shroud

6

5

4

COMPONENTS

8

7

9

3

2

10

11

12

13

15

14

16

17

15. Fill Tube

16.) Hose Extension Ribs

17.) Petroleum Jelly

1

2

Page 3

M

T

Tips for painting with the RAPIDROLLER

• Only use a perforated roller cover. Standard roller covers will not work.

• Inspect roller cover for lint before painting, if needed wash and dry before using.

• When using the R

fill may be needed.

• Keep roller moving while pushing plunger in or squeezing trigger to prevent dripping.

• Stop pushing plunger in or squeezing trigger if the roller starts to skid, slide or drip.

• When painting in tight areas partially fill R

• When leaving R

from bag.

• Make sure the type of paint you use can be cleaned with either mineral spirits (for oil-based paints) or a warm water and soap solution (for water

soluble paints like latex).

Use drop cloths to protect your floors and anything else in the room that you do not want accidentally splattered with paint.

•

• Whenusing kickstand, alwayspivot head to straight position and release pressureby pulling plunger out slightly.

APIDROLLER

PIDROLLER

A

TM

for the first application, it will take most of the paint in the RAPIDROLLERTMt ube to saturate the roller cover. A second

M

TM

unattended for a longer period of time, wrap roller in a plastic bag to prevent drying, removing as much air as possible

APIDROLLER

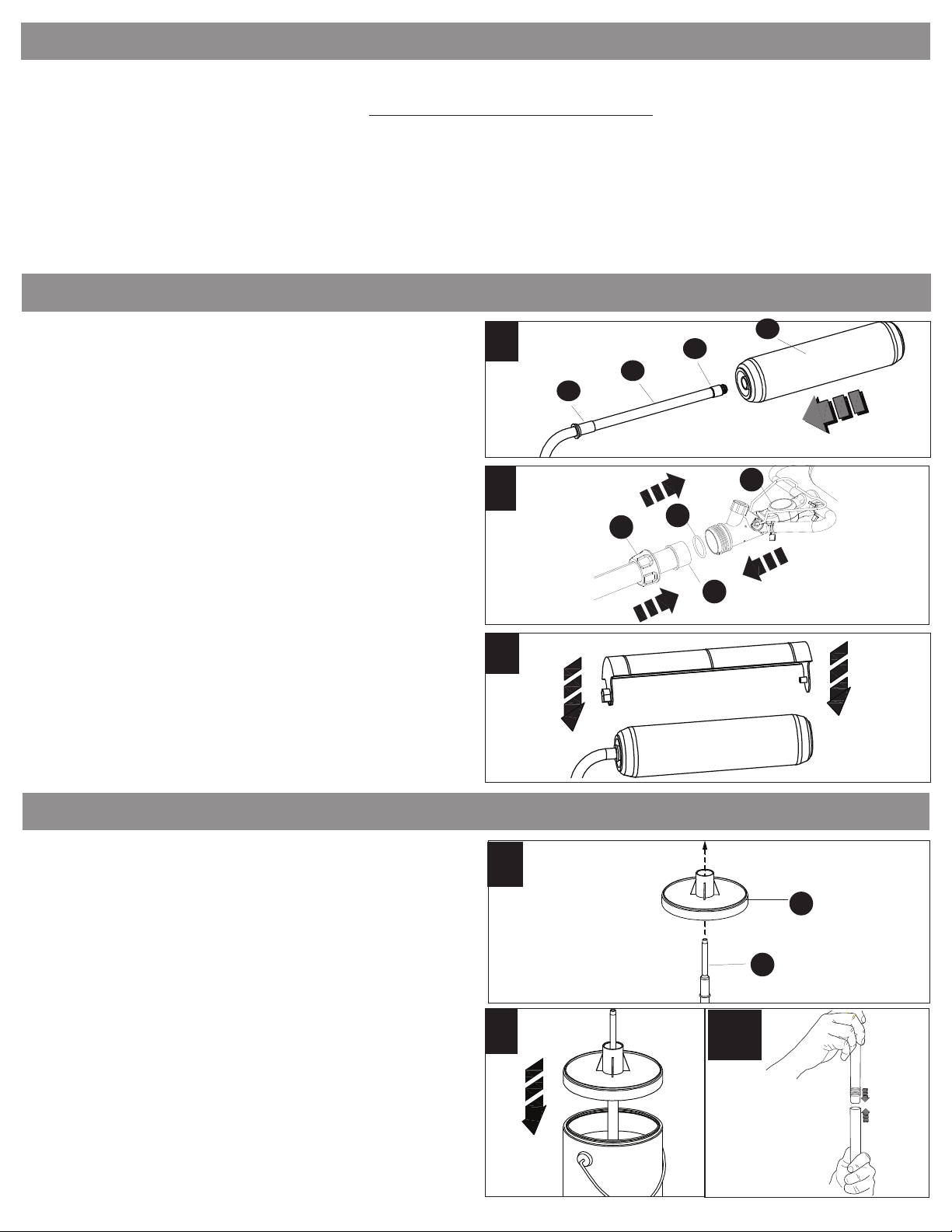

Preparing the RAPIDROLLER

T

or pivot the frame . This reduces its overall length.

M

T

to paint

1.) Lubricate part (a) and (b) using petroleum jelly provided. Attach

assembled roller (c) onto R

assembly snaps into locking clip on outer end cap.

2.) Push roller frame (a) over end of handle assembly (d) ensuring O-ring

(b) is seated inside roller frame. Thread handle assembly collar (c)

snugly onto threads of roller frame (a).

3.) The spatter shield helps reduce spatter when painting, especially on

ceilings. Position the spatter shield by rotating around roller frame.

NOTE: Spatter shield is also helpful to prevent dripping when

APIDROLLER

R

spatter shield under roller.

TM

is resting on kickstand and is not in use. Just position

APIDROLLER

TM

frame (d). Make sure roller

A

B

C

a

c

b

d

a

c

b

d

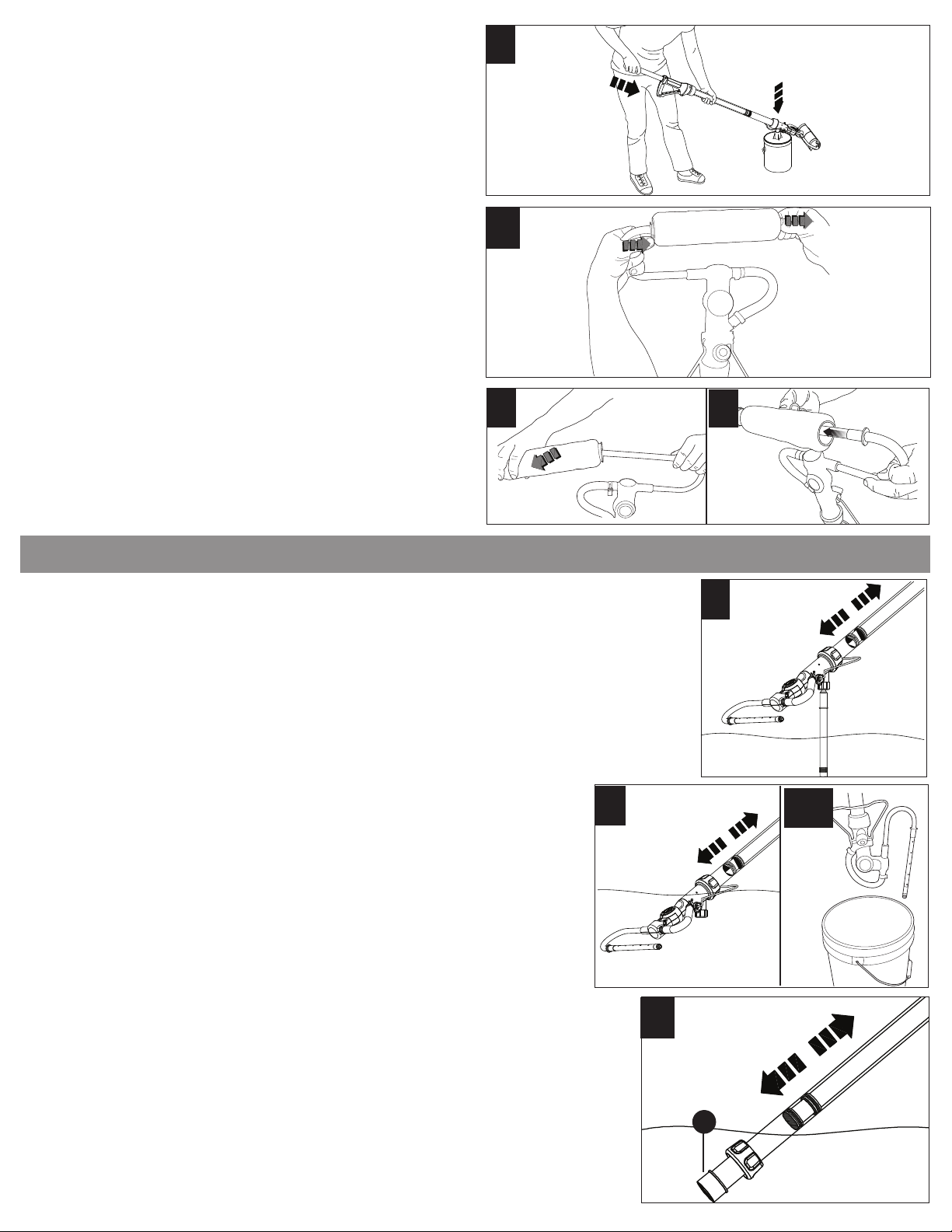

Filling the RAPIDROLLERTMwith paint

1.) Insert the small end of the fill tube (a) through the hole in the bottom

side of the paint can cover (b).

Push in until tight and to the ridge of the fill tube.

2.) Snap paint can cover onto paint can (fig. E). Lubricate top of fill tube

stem with a small amount of petroleum jelly included in carton.

NOTE: The can cover will not fit on some paint containers. It can be

stretched over larger cans or compressed slightly by squeezing to fit

smaller cans.

To fill the R

container, omit the can cover and place fill tube directly into container.

Hold the fill tube with hand to stabilize as needed.

A fill tube can clip is available as an optional accessory for use with other

size containers. See “Accessories”.

For deeper containers like 5 gallon pails, fit a section of ¾ inch I.D. (inner

diameter) clear tubing over the ribs of the fill tube to extend it

(fig. E1) and clip to side of pail with fill tube can clip. Cut bottom end of

tubing at slight angle. Tubing is available at most hardware stores.

APIDROLLER

TM

when the can cover does not fit your paint

3

D

E

b

a

E1

Page 4

M

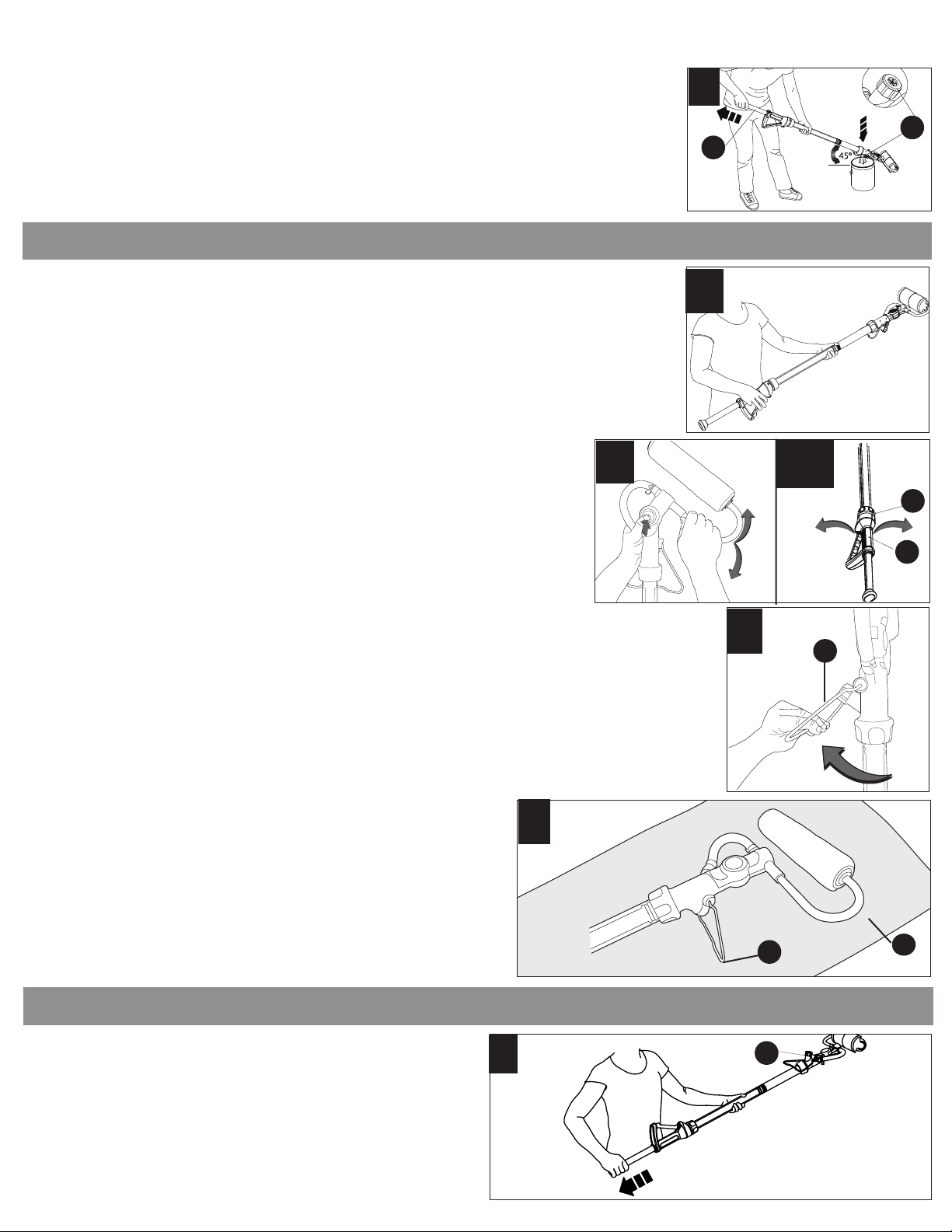

3.) Hold the RAPIDROLLER

on the fill tube. MAKE SURE THE ORANGE FILL CAP COVER (a) IS COMPLETELY COVERED BY SHROUD OF CAN COVER.

NOTE: Remove cardboard spacer, and squeeze trigger to free up the plunger.

Pull plunger (b) all the way back to draw paint into R

is full you are ready to start painting. Lift RAPIDROLLERTMslowly off fill tube.

OTE: If you do not receive a complete fill the first time, push plunger slowly to return paint to can and

N

hen pull back plunger making sure angle is correct and orange fill cap cover is fully seated.

t

T

at a 45 degree angle and place the fill valve (a) over the fill tube. Gently push the RAPIDROLLER

APIDROLLER

TM

. (This may take some force.) Once tube

F

M

T

down until it bottoms

b

M

T

Painting with the RAPIDROLLER

1.) Begin rolling on wall and push plunger handle or squeeze trigger to feed paint into the roller cover.

NOTE: Initial saturation of the roller may require the full amount of paint from the first fill. Fill

R

APIDROLLER

ELPFUL HINTS

H

• The trigger only needs to be squeezed when paint is needed.

• If you are getting a dot pattern when painting, apply more paint.

• If the roller is sliding on the surface, apply less paint.

• You may notice petroleum jelly within the handle. This is necessary and will help in its operation and will

not affect the paint.

2.) The roller head can be adjusted to three different angles. Press the orange button on the

roller head to change the angle from straight to 40 or 80 degrees. Use straight on for

general painting and 40 or 80 degree angles for hard to reach places or when painting

close to ceiling or edging (fig. H).

NOTE: The handle (a) can be rotated to make it more comfortable when painting with an

angled roller frame.

To rotate handle to desired position, loosen collar (b), adjust handle and retighten collar

(fig H1).

TM

as needed.

H

G

H1

a

b

a

3.) When not in use rest theR

• When using kickstand, R

• When painting, kickstand should be pointed away from roller to avoid getting spatter on kickstand.

• Always rotate roller to the straight position before pacing on kickstand.

• To prevent drips, relieve pressure on R

NOTE: Attaching the spatter guard when using the kickstand helps insure that any dripping paint is contained.

APIDROLLER

APIDROLLER

TM

on the convenient kickstand (a).

TM

should always be on a drop cloth (b) or over newspaper in case of drips.

APIDROLLER

TM

by pulling plunger out slightly.

J

TM

Cleaning the RAPIDROLLER

1.) Pull plunger back to draw excess paint from roller frame into tube.

HINT: Place thumb over orange fill cap cover (a) to help remove the most

paint from the frame prior to pulling back plunger.

K

I

a

a

b

a

4

Page 5

2.) Return paint from RA

degree angle and pushing fill valve onto fill tube until it bottoms on fill

tube. Make sure orange fill valve is completely covered by shroud of can

lid. Push plunger in until it stops.

PIDROLLER

TM

to can by holding RA

PIDROLLER

TM

at a 45

L

3.) Scrape excess paint into can from roller.

Remove the roller by grasping the outer end cap and the roller frame and

using your thumb on the opposite hand to push the roller off as shown.

HINT: Wear disposable gloves or use a plastic bag over roller to keep

your hands clean.

4.) Remove the inner end cap by inserting the metal tube of the roller frame

into the cap about 1 inch and at an angle. Pull the roller frame gently

towards you (fig. N).

Remove the roller core. Empty any remaining paint.

Remove the outer cap by inserting the roller frame into the roller and

gently pushing the cap off (fig. O).

M

N

Cleaning the RAPIDROLLER

1.) Remove the fill tube from the paint can lid and push

it directly into the fill valve. When cleaning water soluble paints, submerge the fill tube into warm, soapy

water and pull the plunger in and out 5 or more times. When using oil based paints, instead of water, use

proper cleaning solvent listed on manufacturers container and dispose of properly.

HINT: Use a sink, a wash tub, or any container that will hold water to perform above flushing process.

Replace water when dirty or when moving to the next step.

O

TM

P

2.) Remove the fill tube. Then submerge the roller frame, and ensuring the fill valve is also

under water, pull the plunger in and out 5 or more times (fig. Q).

HINT: When using a small container, pivot the roller frame to the 80 degree position to fit

inside container (fig. Q1).

3.) Remove roller frame and continue cleaning as needed. Submerge the handle in the warm, soapy

water and pull the plunger in and out 5 or more times.

HINT: Wipe off remaining paint from the end of plunger (a).

5

Q

Q1

R

a

Page 6

4.) Unthread valve cap and remove wiper seal and duck bill valve to clean.

Rinse all remaining parts and drain all fluid from the RAPIDROLLERTM.

5.) Remove tubing from frame (if needed) by pinching hose clamps. Flush

frame and tubing. Replace tubing and secure with hose clamps.

6.) Always purchase a perforated roller cover. A standard roller will not

work.

S

Lubricating the RAPIDROLLER

Lubrication helps with normal operation and should be done after cleaning and before each use.

1.) Turn the threaded assembly collar (a) near the trigger counterclockwise until the main

tube assembly slides off.

NOTE: When reassembling, black threaded collar (a) should be towards trigger handle.

T

S1

TM

a

2.) Apply petroleum jelly around and in between the rubber seals shown. Reassemble making sure the

rubber seals are not twisted or damaged. Tighten the locking collar.

3.) Apply petroleum jelly to the duck bill valve and wiper seal and replace within unit threading the

valve cap back into place.

4.) Apply petroleum jelly to the inner seals on the end caps (c & d) then

assemble the roller by placing the core (a) inside of roller cover (b) and

attaching end caps and as shown.

W

V

U

b

c

a

d

6

Page 7

Accessories

Recommended accessories for use with your RAPIDROLLERTMare available from your local dealer or authorized service center.

If you need assistance regarding accessories, please call: 1-800-544-6986

WARNING: The use of any accessory not recommended for use with this tool could be hazardous.

ill tube can clip - for use with containers which do not fit the round can cover provided. Available through a

F

Black & Decker Service Center.

When using larger containers such as a five gallon bucket, use the fill tube can clip with a length of 3/4 inch

I.D. tubing available at most large home centers. The tubing fits over the ribbed end of the fill tube.

Perforated roller sleeves are available at hardware stores.

Troubleshooting

PROBLEM SOLUTION

Takes a long time for paint to appear on surface. See first note on “Painting with the RAPIDROLLERTM”. May take a

second fill.

Air is drawn into handle instead of paint. Slowly push handle in to expel air. Remove and reinsert product on

fill tube. Be sure fill tube is fully seated in valve body. If necessary,

apply petroleum jelly to fill tube which makes it easier to seat fill tube

and valve body.

Make sure O-ring is in place between handle assembly and roller

frame and well lubricated.

Difficult to insert or remove fill tube from valve. Put petroleum jelly in fill port opening and or fill tube.

Handle is difficult to move in and out. Lubricate rubber seals at end of plunger, or twist plunger slightly to

break seal.

Paint leaks out end cap. Make sure both end caps are pushed snugly into and are even with

the end of roller cover. If they are OK, remove end caps, clean out

any old paint and relubricate with petroleum jelly.

Paint leaks out of fill valve. Lubricate valve with petroleum jelly.

Make sure wiper seal is in place.

For assistance with your product, visit our website www.blackanddecker.com for the location of the service center nearest you or

call the BLACK & DECKER help line at 1-800-544-6986.

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool

service. Whether you need technical advice, repair, or genuine factory replacement parts, contact the Black & Decker location

nearest you. To find your local service location, refer to the yellow page directory under "Tools—Electric" or call: 1-800-544-6986 or

visit www.blackanddecker.com

Warranty

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product

will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the

store is a participating retailer). Returns should be made within the time period of the retailerʼs policy for exchanges (usually 30 to 90

days after the sale). Proof of purchase may be required. Please check with the retailer for their specific return policy regarding returns

that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for repair or

replacement at our option. Proof of purchase may be required. Black & Decker owned and authorized Service Centers are listed

under "Tools-Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other rights which vary

from state to state or province to province. Should you have any questions, contact the manager of your nearest Black & Decker

Service Center. This product is not intended for commercial use.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, check country

specific warranty information contained in the packaging, call the local company or see the website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-544-6986 for a free

replacement.

Black & Decker (U.S.) Inc.,

Imported by

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

7

Page 8

GUIDE

D’UTILISATION

M

RAPIDROLLER

Numéro de catalogue

BDPR400

T

GUIDE DE DÉMARRAGE RAPIDE

Pousser l’ensemble rouleau sur le

bâti du rouleau de manière à

l’enclencher en place.

Fermer solidement le couvercle sur le

contenant de peinture. (Se reporter à

la section « Remplir le R

si le couvercle n’est pas compatible.)

APIDROLLER »

Visser la bague de la poignée sur le

bâti du rouleau.

Enfoncer le robinet de remplissage

sur le tube de remplissage de

manière à couvrir complètement le

capuchon orange.

Insérer le tube de remplissage

dans le couvercle du contenant de

peinture.

Presser la détente pour dégager le

piston. Tirer sur le piston pour

aspirer la peinture. (Une certaine

force peut être requise.)

Régler la tête du rouleau à l’angle

souhaité.

Appliquer le rouleau sur le mur et

enfoncer le piston pour remplir de

peinture la tête du rouleau et le rouleau.

Presser la détente pour ajouter de

la peinture.

Merci d’avoir choisi Black & Decker!

Consulter le site Web www.BlackandDecker.com/NewOwner

pour enregistrer votre nouveau produit.

Si des questions ou des problèmes surgissent après l’achat d’un produit Black & Decker,

consulter le site Web HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS pour obtenir des réponses

instantanément 24 heures par jour. Si la réponse est introuvable ou en l’absence d’accès à l'Internet, composer le

1 800 544-6986 de 8 h à 17 h HNE, du lundi au vendredi, pour parler avec un agent.

Prière d’avoir le numéro de catalogue sous la main lors de l’appel.

Lire le mode d’emploi pour connaître les directives en entier.

8

Page 9

A

a

d

b

c

B

b

c

d

a

C

E

E1

D

b

a

F

a

b

G

I

a

H

J

H1

a

b

a

b

9

Page 10

K

a

L

M

P

R

N

Q

S

O

Q1

S1

T

V

a

a

U

W

d

a

b

c

10

Page 11

M.

PETROLEUMJELLY

LAGELEEDE PETROLE

LAJALEADE PETROLEO

AVERTISSEMENT : Pour réduire le risque de blessures, lʼutilisateur doit lire et comprendre le mode dʼemploi avant dʼutiliser le RAPIDROLLER

AVERTISSEMENT : Certaines peintures renferment des produits chimiques reconnus par lʼÉtat de la Californie pour causer le cancer, des

anomalies congénitales ou dʼautres dangers pour la reproduction. Passer en revue et suivre les mesures de sécurité figurant sur le contenant de

peinture.

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode dʼemploi. Les informations quʼil contient concernent VOTRE SÉCURITÉ et visent à

ÉVITER TOUT PROBLÈME. Les symboles ci-dessous servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle nʼest pas évitée, causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle nʼest pas évitée, pourrait causer la mort ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement dangereuse qui, si elle nʼest pas évitée, pourrait causer des blessures mineures ou modérées.

AVIS : Utilisé sans le symbole dʼalerte à la sécurité, indique une situation potentiellement dangereuse qui, si elle nʼest pas évitée, peut résulter en des

dommages à la propriété.

T

DIRECTIVES DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT :

• Ne pas utiliser RAPIDROLLER

personnes ou des dommages matériels.

• À utiliser uniquement avec la plupart des peintures et des teintures solubles à lʼeau et à lʼhuile. Ne convient pas aux peintures et aux teintures à

lʼhuile qui requièrent une solution de nettoyage plus forte que lʼessence minérale (consulter lʼétiquette figurant sur le contenant de peinture initial).

Ne pas utiliser avec des décapants ou autres produits semblables. Les liquides autres que la peinture ou la teinture peuvent endommager le

produit et causer des blessures à des personnes ou des dommages matériels.

• Lire lʼétiquette figurant sur le contenant de peinture dʼorigine et suivre toutes les directives. Négliger de le faire risque de causer des blessures à

des personnes ou dʼendommager des biens matériels.

• Utiliser une protection oculaire adéquate et tout autre équipement de sécurité pour protéger la peau et les voies respiratoires au moment de mélanger la

peinture et au moment de remplir, dʼutiliser et de nettoyer le produit. La peinture et ses émanations peuvent causer des blessures corporelles.

• Pour réduire le risque de blessure, utiliser le produit uniquement dans un endroit bien ventilé.

• Nettoyer le produit en profondeur et le rincer à grande eau après lʼavoir utilisé avec une peinture. Mélanger différentes peintures dans le produit

peut causer des dommages aux biens matériels.

• Pour réduire le risque de blessures, utiliser uniquement les accessoires recommandés.

• Pour la réparation du produit, utiliser uniquement des pièces de rechange identiques. Négliger de le faire risque de causer des blessures corporelles.

TM.

à dʼautres fins que celles décrites dans le présent manuel. Négliger de le faire peut entraîner des blessures à des

CONSERVER CES DIRECTIVES.

COMPOSANTS

DESCRIPTION

FONCTIONNELLE

1.) Piston

2.) Ensemble poignée

3.) Joints toriques

4.) Valve à bec de canard

5.) Joint racleur

6.) Capuchon orange pour le

bouchon du tube de

remplissage

7.) Bâti du rouleau

8.) Embout intérieur

9.) Âme de rouleau

10.) Rouleau perforé de

9 mm (3/8 po)

11.) Embout extérieur

12.) Écran antiéclaboussures

13.) Couvercle de contenant

14.) Déflecteur

15.) Tube de remplissage

16.) Nervures de rallonge du

tube

17.) Gelée de pétrole

5

6

4

7

8

10

9

3

2

11

12

13

14

15

16

17

1

TM

Conseils pour peindre avec le RAPIDROLLER

• Utiliser uniquement un rouleau perforé. Le rouleau standard ne conviendra pas.

• Inspecter le rouleau à la recherche de peluches avant de peinturer. Le laver et lʼassécher avant de lʼutiliser si cʼest nécessaire.

• Lors de lʼutilisation du RAPIDROLLER™ pour la première application, il faudra presque toute la peinture contenue dans le tube RAPIDROLLER™ pour

saturer le rouleau. Il peut falloir un deuxième remplissage.

• Ne pas maintenir le rouleau immobile au moment dʼenfoncer le piston ou de presser la détente afin dʼéviter tout égouttement.

• Cesser dʼenfoncer le piston ou de presser la détente si le rouleau se met à déraper, à glisser ou à sʼégoutter.

• Pour peinturer dans des endroits restreints, remplir partiellement le R

• Si le RAPIDROLLER™ est laissé sans surveillance, durant une certaine période de temps, envelopper le rouleau dans un sac en plastique, pour

éviter quʼil ne sèche, et enlever tout lʼair possible contenu dans le sac.

• Sʼassurer que le type de peinture utilisé peut être nettoyé soit avec de lʼessence minérale (pour les peintures à lʼhuile) ou une solution dʼeau

chaude savonneuse (pour les peintures solubles dans lʼeau comme le latex).

• Utiliser des toiles de protection pour protéger vos planchers et toute autre chose qui se trouve dans la pièce contre les éclaboussures

accidentelles de peinture.

• Si la béquille est utilisée, toujours pivoter la tête à angle droit et relâcher la pression en tirant légèrement sur le piston.

APIDROLLER™ou pivoter le bâti. Cela réduit sa longueur totale.

11

Page 12

Préparer le RAPIDROLLER™ pour peindre

1.) Lubrifier les pièces (a) et (b) avec la gelée de pétrole fournie. Fixer le rouleau assemblé (c) sur le bâti (d) du RAPIDROLLER™. Sʼassurer que

lʼensemble rouleau sʼenclenche dans la pince dʼautoblocage située sur lʼembout extérieur (fig. A).

2.) Pousser le bâti (a) sur lʼextrémité de lʼensemble poignée (d) en sʼassurant que le joint torique (b) repose bien à lʼintérieur du bâti du rouleau.

Bien visser la bague (c) de lʼensemble poignée sur les filets du bâti du rouleau (a) (fig. B).

3.) Lʼécran antiéclaboussures permet de réduire les éclaboussures au moment de peindre, surtout dans le cas des plafonds. Positionner lʼécran

antiéclaboussures en le tournant autour du bâti du rouleau (fig. C).

REMARQUE : Lʼécran antiéclaboussures est aussi utile pour éviter lʼégouttement lorsque le RAPIDROLLER™ repose sur la béquille et nʼest pas

utilisé. Il suffit de placer lʼécran antiéclaboussures sous le rouleau.

Remplir le RAPIDROLLER™ de peinture

1.) Insérer la petite extrémité du tube de remplissage (a) dans le trou pratiqué dans la partie inférieure du couvercle du contenant de peinture (b).

nfoncer lʼextrémité jusquʼà la saillie du tube de remplissage, de manière à ce quʼelle soit serrée (fig. D).

E

2.) Fermer solidement le couvercle sur le contenant de peinture (fig. E). Lubrifier la tige supérieure du tube de remplissage avec un peu de gelée

e pétrole, comprise dans la boîte.

d

REMARQUE : Le couvercle ne sera pas compatible avec certains contenants de peinture. Il peut être étiré pour convenir aux gros contenants ou

tre légèrement comprimé pour sʼajuster aux petits contenants.

ê

Pour remplir le R

ube de remplissage directement dans le contenant. Tenir manuellement le tube de remplissage pour stabiliser ce dernier au besoin.

t

Une pince à contenant pour tube de remplissage est offerte comme accessoire facultatif pouvant servir pour des contenants de taille différente.

Se reporter à la section « Accessoires ».

Pour les contenants plus profonds comme les seaux de 19 litres (5 gallons), adapter une section de tube transparent, dʼun diam. intérieur de 19

mm (3/4 po), aux rainures du tube de remplissage pour lʼallonger (fig. E1) et fixer sur le côté du seau avec la pince à contenant pour tube de

remplissage. Couper lʼextrémité basse du tube, légèrement en diagonale. La tubulure est en vente dans la plupart des quincailleries.

3.) Tenir le R

R

APIDROLLER™ de manière à ce quʼil repose contre le tube de remplissage. SʼASSURER QUE LE CAPUCHON ORANGE DU BOUCHON DU

TUBE DE REMPLISSAGE (A) EST ENTIÈREMENT RECOUVERT PAR LE DÉFLECTEUR DU COUVERCLE DU CONTENANT (fig. F).

REMARQUE : Enlever la cale en carton, puis presser la détente pour dégager le piston.

Tirer complètement sur le piston (b) pour aspirer la peinture dans le R

rempli, le produit est prêt pour peindre. Soulever lentement le R

REMARQUE : Si le remplissage ne se fait pas complètement la première fois, pousser lentement le piston pour remettre la peinture dans le

contenant, puis tirer dessus en sʼassurant que lʼangle est bon et que le capuchon orange pour le bouchon du tube de remplissage est bien assis.

APIDROLLER™ lorsque le couvercle nʼest pas compatible avec votre contenant de peinture, ne pas utiliser le couvercle et placer le

APIDROLLER™ à un angle de 45 degrés, puis placer le robinet de remplissage (a) sur le tube de remplissage. Enfoncer doucement le

APIDROLLER™. (Une certaine force peut être requise.) Une fois le tube

APIDROLLER™ du tube de remplissage.

Peindre avec le RAPIDROLLER™

1.) Appliquer le rouleau sur le mur, puis enfoncer le piston ou presser la détente pour alimenter le rouleau en peinture (fig. G).

REMARQUE : Pour saturer le rouleau la première fois, il peut falloir toute la peinture obtenue au premier remplissage. Remplir le

APIDROLLER™ au besoin.

R

CONSEILS PRATIQUES

• La détente ne doit être pressée que lorsque de la peinture est requise.

• Si la peinture forme des points à lʼapplication, cela signifie quʼil faut ajouter de la peinture.

• Si le rouleau glisse à la surface, appliquer moins de peinture.

• On peut constater la présence de gelée de pétrole dans la poignée.

Cʼest nécessaire et cela facilitera le fonctionnement du produit sans compromettre la peinture.

2.) La tête du rouleau peut être réglée à trois angles différents. Enfoncer le bouton orange, logé sur la tête du rouleau, pour modifier lʼangle et

passer dʼun angle droit à un angle de 40 ou de 80 degrés. Utiliser un angle droit pour la peinture générale et les angles de 40 et de 80 degrés

pour les endroits difficiles à atteindre ou lorsquʼil faut peindre près du plafond ou les bordures (fig. H).

REMARQUE : La poignée (a) peut être tournée pour accroître le confort au moment de peinturer avec un bâti de rouleau incliné.

Pour tourner la poignée à la position souhaitée, desserrer la bague (b), régler la poignée, puis resserrer la bague (fig. H1).

3.) Lorsquʼil nʼest pas utilisé, déposer le R

• Lorsque la béquille est utilisée, le R

(fig. J).

• Au moment de peindre, la béquille doit pointer à lʼopposé du rouleau pour éviter quʼelle ne soit éclaboussée.

• Toujours tourner le rouleau à angle droit avant dʼappliquer la béquille.

• Pour éviter les gouttes, enlever la pression du R

REMARQUE : Fixer lʼécran antiéclaboussures lors de lʼutilisation de la béquille permet de contenir tout égouttement de peinture.

APIDROLLER™ sur la béquille (a) pratique (fig. I).

APIDROLLER™ doit toujours être mis sur une toile de protection (b) ou du papier journal en cas dʼégouttement

APIDROLLER™ en tirant légèrement sur le piston.

Nettoyer le RAPIDROLLER™

1.) Tirer sur le piston pour aspirer, dans le tube, la peinture en excès du bâti du rouleau (fig. K).

CONSEIL : mettre le pouce sur le capuchon orange pour le bouchon du tube de remplissage (a) pour mieux enlever une grande partie de la

peinture du bâti avant de tirer sur le piston.

2.) Remettre la peinture contenue dans le R

pousser le robinet de remplissage de manière à ce quʼil repose bien contre le tube de remplissage. Sʼassurer que le robinet de remplissage

orange est complètement recouvert par le déflecteur du couvercle du contenant. Pousser le piston jusquʼà ce quʼil sʼarrête (fig. L).

3.) Racler la peinture en excès du rouleau, dans le contenant.

Pour retirer le rouleau, saisir lʼembout extérieur et le bâti du rouleau, et pousser sur le rouleau avec le pouce de lʼautre main, comme il est illustré

(fig. M).

CONSEIL : Porter des gants jetables ou utiliser un sac de plastique sur le rouleau pour ne pas se salir les mains.

4.) Retirer lʼembout intérieur en insérant de biais, dʼenviron 25 mm (1 po), le tube métallique du bâti du rouleau dans lʼembout. Tirer doucement,

vers vous, le bâti du rouleau (fig. N).

Enlever lʼâme du rouleau. Vider tout restant de peinture.

Enlever lʼembout extérieur en insérant le bâti dans le rouleau et en poussant doucement sur lʼembout pour le déloger (fig. O).

APIDROLLER™ dans le contenant. Pour ce faire, tenir le RAPIDROLLER™ à un angle de 45 degrés et

Nettoyer le RAPIDROLLER™

1.) Retirer le tube de remplissage du couvercle du contenant de peinture, puis lʼenfoncer directement dans le robinet de remplissage. Pour éliminer

des peintures solubles dans lʼeau, immerger le tube de remplissage dans de lʼeau chaude savonneuse, puis tirer sur le piston et le pousser à au

moins 5 reprises. Pour les peintures à lʼhuile, utiliser un solvant de dégraissage, indiqué sur le contenant du fabricant, plutôt que de lʼeau et

éliminer les déchets adéquatement. CONSEIL : Utiliser un évier, une baignoire ou tout contenant pouvant contenir lʼeau pour procéder au

processus de rinçage. Remplacer lʼeau lorsquʼelle est sale ou au moment de passer à lʼétape suivante (fig. P).

12

Page 13

2.) Retirer le tube de remplissage. Puis immerger le bâti du rouleau en sʼassurant que le robinet de remplissage se trouve aussi sous lʼeau, puis

tirer sur le piston et le pousser au moins à 5 reprises (fig. Q).

CONSEIL : Si un petit contenant est utilisé, pivoter le bâti du rouleau à un angle de 80 degrés pour lʼinsérer dans le contenant (fig. Q1).

3.) Enlever le bâti du rouleau et continuer le nettoyage au besoin. Immerger la poignée dans de lʼeau chaude savonneuse, puis tirer sur le piston et

le pousser à au moins 5 reprises (fig. R). CONSEIL : Essuyer la peinture restante couvrant lʼextrémité du piston (a).

4.) Dévisser le bouchon du robinet, puis enlever le joint racleur et la valve à bec de canard pour les nettoyer. Rincer les pièces restantes et drainer

tout liquide du R

5.) Retirer le tube du bâti (au besoin) en pinçant les colliers de serrage de tuyau. Rincer le bâti et le tube. Remettre le tube et le fixer avec les

colliers de serrage de tuyau (fig. S1).

6.) Toujours acheter un rouleau perforé. Un rouleau standard ne conviendra pas.

APIDROLLER™ (fig. S).

Lubrifier le RAPIDROLLER™

a lubrification favorise un fonctionnement normal et doit être réalisée après le nettoyage et avant chaque utilisation du produit.

L

1.) Tourner, dans le sens antihoraire, la bague filetée de lʼensemble (a), située près de la détente, de manière à ce que lʼensemble tube principal se

détache. REMARQUE : lors du réassemblage, le collier fileté noir (a) doit faire face à la poignée de déclenchement.

2.) Appliquer de la gelée de pétrole autour des joints dʼétanchéité en caoutchouc illustrés et entre ceux-ci. Procéder au réassemblage en sʼassurant

que les joints dʼétanchéité en caoutchouc ne sont pas tordus ni endommagés. Serrer la bague de blocage.

3.) Appliquer de la gelée de pétrole à la valve à bec de canard et au joint racleur, puis les remettre dans lʼunité et revisser le capuchon du robinet en

place.

4.) Appliquer de la gelée de pétrole aux joints intérieurs des embouts (c et d), puis assembler le rouleau en insérant lʼâme (a) dans le rouleau (b),

puis en posant les embouts comme il est illustré.

Accessoires

Les accessoires recommandés pouvant être utilisés avec le R

réparation autorisé de votre région. Pour obtenir de lʼaide concernant les accessoires, composer le : 1 800 544-6986

AVERTISSEMENT : Lʼutilisation de tout accessoire non recommandé avec cet outil pourrait sʼavérer dangereuse.

Pince à contenant pour tube de remplissage : à utiliser avec les contenants non compatibles avec le couvercle rond fourni.

Offerte dans un centre de réparation Black & Decker.

Pour les gros contenants comme les seaux de 19 litres (5 gallons), utiliser la pince à contenant pour tube de remplissage avec

une section de tube, dont le diam. intérieur est de 19 mm (3/4 po), offerte dans la plupart des grands centres de rénovation. Le

tube sʼadapte à lʼextrémité nervurée du tube de remplissage. Les manchons de rouleau perforés sont offerts dans les quincailleries.

APIDROLLER™ sont offerts auprès du distributeur ou du centre de

Dépannage

PROBLÈME SOLUTION

Il faut beaucoup de temps à la peinture pour Se reporter à la première remarque « Peindre avec le RAPIDROLLER ».

apparaître à la surface du rouleau. Il peut falloir un deuxième remplissage.

De lʼair, plutôt que de la peinture, est aspiré Enfoncer lentement la poignée pour expulser lʼair. Retirer le produit et le réinsérer

dans la poignée. dans le tube de remplissage. Sʼassurer que le tube de remplissage est bien

Difficulté à insérer le tube de remplissage dans Mettre de la gelée de pétrole dans lʼorifice de remplissage, le tube de

le robinet ou à lʼen retirer. remplissage ou les deux.

La poignée est difficile à rentrer et à sortir. Lubrifier les joints dʼétanchéité en caoutchouc, situés à lʼextrémité du

La peinture fuit par un embout. Sʼassurer que les deux embouts sont bien enfoncés et quʼils sont de

La peinture fuit par le robinet de remplissage. Lubrifier le robinet avec de la gelée de pétrole. Sʼassurer que le joint

Pour obtenir de lʼaide concernant le produit, consulter notre site Web www.blackanddecker.com pour connaître lʼemplacement du centre de

réparation le plus près ou communiquer avec lʼassistance BLACK & DECKER au 1 800 544-6986.

Information sur les réparations

Tous les centres de réparation Black & Decker sont dotés de personnel qualifié en matière dʼoutillage électrique; ils sont donc en mesure dʼoffrir à

leur clientèle un service efficace et fiable. Que ce soit pour un avis technique, une réparation ou des pièces de rechange authentiques installées

en usine, communiquer avec lʼétablissement Black & Decker le plus près de chez vous. Pour trouver lʼétablissement de réparation de votre région,

consulter le répertoire des Pages jaunes à la rubrique « Outils électriques » ou composer le numéro suivant : 1-800-544-6986 ou consulter le site

www.blackanddecker.com

Garantie - Garantie complète de deux ans pour une utilisation domestique

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout défaut de matériau ou de fabrication. Le produit défectueux

sera remplacé ou réparé sans frais de lʼune des deux façons suivantes :

La première façon consiste en un simple échange chez le détaillant qui lʼa vendu (pourvu quʼil sʼagisse dʼun détaillant participant). Tout retour doit se

faire durant la période correspondant à la politique dʼéchange du détaillant (habituellement, de 30 à 90 jours après lʼachat). Une preuve dʼachat peut

être requise. Vérifier auprès du détaillant pour connaître sa politique concernant les retours hors de la période définie pour les échanges.

La deuxième option est dʼapporter ou dʼenvoyer le produit (transport payé dʼavance) à un centre de réparation autorisé ou à un centre de réparation

de Black & Decker pour faire réparer ou échanger le produit, à notre discrétion. Une preuve dʼachat peut être requise. Les centres Black & Decker et

les centres de service autorisés sont répertoriés dans les pages jaunes, sous la rubrique « Outils électriques ».

Cette garantie ne sʼapplique pas aux accessoires. Cette garantie vous accorde des droits légaux spécifiques et vous pourriez avoir dʼautres droits

qui varient dʼun État ou dʼune province à lʼautre. Pour toute question, communiquer avec le directeur du centre de réparation Black & Decker le plus

près de chez vous. Ce produit nʼest pas destiné à un usage commercial.

REMPLACEMENT GRATUIT DES ÉTIQUETTES DʼAVERTISSEMENT : si les étiquettes dʼavertissement deviennent illisibles ou sont manquantes,

composer le 1 800 544-6986 pour en obtenir le remplacement gratuit.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

appuyé contre le corps du robinet. Le cas échéant, appliquer de la gelée de

pétrole au tube de remplissage, ce qui permet dʼasseoir plus facilement le tube

de remplissage et le corps du robinet. Sʼassurer que le joint torique est en

place, entre lʼensemble poignée et le bâti du rouleau, et quʼil est bien lubrifié.

piston, ou tourner légèrement le piston pour briser lʼadhérence.

niveau avec les extrémités du rouleau. Sʼils sont corrects, retirer les embouts,

enlever toute vieille peinture et les relubrifier avec de la gelée de pétrole.

racleur est en place.

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

13

Page 14

MANUAL DE

INSTRUCCIONES

GUÍA DE INICIO RÁPIDO

RAPIDROLLER

TM

Catálogo N°BDPR400

Empuje el ensamblaje del rodillo sobre

el armazón del rodillo hasta que encaje

en su lugar produciendo un chasquido.

Encaje la tapa para la lata de pintura

sobre la lata de pintura. (Si la cubierta

no calza, consulte la sección

“Llenado del rodillo RAPIDROLLER”.)

Enrosque el collar del mango en el

armazón del rodillo.

Empuje la válvula de llenado hacia

abajo sobre el tubo de llenado

hasta que el tapón naranja esté

completamente cubier to.

Inserte el tubo de llenado en la

tapa para la lata de pintura.

Oprima el gatillo para liberar el émbolo.

Tire del émbolo hacia atrás para extraer

pintura.(Es posible que sea necesario

aplicar algo de fuerza para hacerlo).

Ajuste el cabezal del rodillo en el

ángulo deseado.

Comience a hacerlo rodar sobre la

pared y empuje el émbolo para llenar

el cabezal y el rodillo con pintura.

Oprima el gatillo para cargar más

pintura.

Gracias por elegir Black & Decker!

Visite www.BlackandDecker.com/NewOwner para registrar su

nuevo producto.

Si tiene una consulta o algún inconveniente con su producto Black & Decker, visite

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

para obtener respuestas instantáneas las 24 horas del día.

Si no encuentra la respuesta o no tiene acceso a Internet, llame al 1-800-544-6986 de lunes a viernes de 8 a. m. a 5 p. m.

hora del Este para hablar con un agente. Cuando llame, tenga a mano el número de catálogo.

Consulte el interior de este manual de instrucciones para ver las

instrucciones completas.

14

Page 15

A

a

d

b

c

B

b

c

d

a

C

E

E1

D

b

a

F

a

b

G

I

a

H

J

H1

a

b

a

b

1515

Page 16

K

a

L

M

P

R

N

Q

S

O

Q1

S1

T

V

a

a

U

W

d

a

b

c

1616

Page 17

ADVERTENCIA: Para reducir el riesgo de lesiones, el usuario debe leer y comprender el manual de instrucciones antes de utilizar el rodillo

PETROLEUMJELLY

LAGELEEDE PETROLE

LAJALEADE PETROLEO

APIDROLLEr

R

ADVERTENCIA: Algunas pinturas contienen sustancias químicas reconocidas por el Estado de California como causantes de cáncer, defectos

de nacimiento u otros problemas reproductivos. Revise y respete las precauciones de seguridad que aparecen en el recipiente de pintura.

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La información que contiene se relaciona con la protección de SU SEGURIDAD y la

PREVENCIÓN DE PROBLEMAS. Los símbolos que siguen se utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita, provocará la muerte o lesiones graves.

PRECAUCIÓN: indica una situación de peligro potencial que, si no se evita, provocará lesiones leves o moderadas.

AVISO: utilizado sin el símbolo de alerta de seguridad indica una situación de peligro potencial que, si no se evita, puede provocar daños en la propiedad.

TM

.

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

ADVERTENCIA:

• No utilice el rodillo R

provocar lesiones a personas y/o daños a la propiedad.

• Para uso únicamente con pinturas y tintes solubles en agua y la mayoría de las pinturas y tintes a base de aceite. No debe utilizarse con pinturas

y tintes a base de aceite que requieran soluciones de limpieza más fuertes que los alcoholes minerales (consulte la etiqueta en el envase original

de la pintura). No lo utilice con removedores de pintura ni similares. Los líquidos que no sean pintura o tinte pueden dañar el producto y provocar

lesiones a personas o daños a la propiedad.

• Lea la etiqueta del recipiente original de la pintura y siga todas las instrucciones. El incumplimiento de estas instrucciones podría resultar en

lesiones a las personas o daños a la propiedad.

• Use protección adecuada para los ojos y otros equipos de seguridad para la piel y protección para las vías respiratorias al mezclar la pintura y al

llenar, utilizar y limpiar el producto. La pintura y sus vapores pueden provocar lesiones personales.

• Para reducir el riesgo de lesiones, utilícelo únicamente en un área bien ventilada.

• Limpie y enjuague el producto minuciosamente después de utilizarlo con una determinada pintura. El resultado de la mezcla de distintas pinturas

en el producto podría resultar en daños a la propiedad.

• Para reducir el riesgo de lesiones, utilice únicamente los accesorios recomendados.

• Al realizar el mantenimiento, utilice únicamente piezas de repuesto idénticas. El incumplimiento de esta instrucción podría resultar en lesiones

personales

.

APIDROLLEr

TM

para propósitos distintos de los descritos en este manual. Si no se cumple con esta indicación, se podrían

CONSERVE ESTAS INSTRUCCIONES

COMPONENTES

DESCRIPCIÓN DE LAS

FUNCIONES

1.) Émbolo

2.) Ensamblaje del mango

3.) Juntas tóricas

4.) Válvula pico de pato

5.) Sello rascador

6.) Cubierta anaranjada del

tapón de llenado

7.) Armazón del rodillo

8.) Tapón del extremo interior

9.) Núcleo del rodillo

10.) Rodillo perforado de 9 mm

(3/8 pulgada)

11.) Tapón del extremo exterior

12.) Protector contra

salpicaduras

13.) Cubierta para la lata

14.) Corona

15.) Tubo de llenado

16.) Nervaduras de la

extensión de manguera

17.) Vaselina

5

6

4

7

8

10

9

3

2

11

12

13

14

15

16

17

1

TM

Consejos para pintar con el rodillo RAPIDROLLER

• Utilice únicamente una cubierta para rodillo perforado. Las cubiertas para rodillos estándar no funcionarán.

• Antes de pintar, inspeccione para detectar pelusa en la cubierta del rodillo; si es necesario, lávela y séquela antes del uso.

• Al utilizar el rodillo R

cubierta del rodillo. Es posible que sea necesario llenarlo nuevamente.

• Para evitar que el rodillo gotee, manténgalo en movimiento mientras empuja el émbolo hacia adentro o mientras oprime el gatillo.

• Deje de empujar el émbolo hacia adentro o de oprimir el gatillo si el rodillo comienza a patinar, resbalar o gotear.

• Al pintar en áreas estrechas, llene parcialmente el rodillo R

• Al dejar el rodillo R

mayor cantidad de aire posible de la misma.

• Asegúrese de que el tipo de pintura que utiliza se pueda limpiar con alcohol mineral (para pinturas a base de aceite) o una solución de agua tibia

y jabón (para pinturas solubles en agua como el látex).

• Utilice una tela u otro material para proteger los pisos y cualquier otro objeto en la habitación que no desee salpicar accidentalmente con pintura.

• Al utilizar el soporte, siempre pivote el cabezal a la posición recta y libere presión tirando levemente del émbolo hacia afuera.

APIDROLLEr

APIDROLLEr

TM

para la primera aplicación, se necesitará la mayor parte de la pintura en el tubo del rodillo para impregnar la

TM

sin usar durante un período prolongado, envuélvalo en una bolsa plástica para evitar que se seque y extraiga la

APIDROLLEr

TM

o pivote el armazón. Esto reduce su longitud total.

1717

Page 18

M

T

Preparación del rodillo RAPIDROLLER

.) Lubrique las piezas (a) y (b) utilizando la vaselina provista. Conecte el rodillo ensamblado (c) al armazón (d) del rodillo R

1

segúrese de que el ensamblaje del rodillo encaje en el sujetador de bloqueo sobre el tapón del extremo exterior produciendo un chasquido.

A

para pintar

APIDROLLEr

TM

Fig. A).

(

2.) Empuje el armazón del rodillo (a) sobre el extremo del ensamblaje del mango (d) asegurándose de que la junta tórica (b) esté asentada dentro

del armazón del rodillo. Enrosque el collar del ensamblaje del mango (c) de manera que quede bien ajustado sobre las roscas del armazón del

rodillo (a) (Fig. B).

3.) El protector contra salpicaduras ayuda a reducir las salpicaduras al pintar, especialmente los cielos razos. Ubique el protector contra

salpicaduras haciéndolo girar alrededor del armazón del rodillo (Fig. C).

NOTA: El protector contra salpicaduras sirve además para evitar que el rodillo R

APIDROLLEr

TM

gotee cuando se apoya sobre el soporte y no está

en uso. Simplemente ubique el protector contra salpicaduras debajo del rodillo.

Llenado del rodillo RAPIDROLLERTMcon pintura

1.) Inserte el extremo pequeño del tubo de llenado (a) a través del orificio en la parte inferior de la tapa para la lata de pintura (b). Empújelo hacia

adentro hasta que quede ajustado contra el borde del tubo de llenado (Fig. D).

2.) Encaje la tapa para la lata de pintura sobre la lata de pintura (Fig. E). Lubrique la parte superior del vástago del tubo de llenado con una

cantidad pequeña de vaselina incluida en la caja.

NOTA: La cubierta para la lata no calzará en algunos recipientes de pintura. Ésta se puede estirar sobre latas más grandes o comprimirse

levemente para que calce con latas más pequeñas.

Para llenar el rodillo R

APIDROLLEr

TM

cuando la cubierta para la lata no calza con el recipiente de pintura, omita la cubierta para la lata y coloque el

tubo de llenado directamente dentro del recipiente. Sostenga el tubo de llenado con la mano para estabilizarlo según se requiera.

Una pinza está disponible para sujetar el tubo de llenado a la lata como un accesorio opcional para su uso con recipientes de otros tamaños.

Consulte “Accesorios”.

Para recipientes más profundos, como cubos de 19 l (5 galones), ajuste un trozo de tubería transparente de 19 mm (¾ pulgada) de diámetro

interno sobre los resaltes del tubo de llenado para extenderlo (Fig. E1) y use la pinza para sujetarlo al costado del cubo. Corte el extremo inferior

del tubo con un pequeño ángulo. Hay tubería disponible en la mayoría de las ferreterías.

3.) Sostenga el rodillo R

APIDROLLEr

TM

en un ángulo de 45 grados y coloque la válvula de llenado (a) sobre el tubo de llenado. Empuje suavemente el

rodillo RAPIDROLLErTMhacia abajo hasta que llegue al fondo del tubo de llenado (Fig. F).

ASEGÚRESE DE QUE LA CUBIERTAANARANJADA DEL TAPÓN DE LLENADO (a) ESTÉ COMPLETAMENTE CUBIERTO POR LA

CORONA DE LA CUBIERTA PARA LA LATA.

NOTA: Retire el separador de cartón y oprima el gatillo para liberar el émbolo.

Tire del émbolo (b) completamente hacia atrás para llevar pintura al rodillo R

APIDROLLEr

TM

. (Es posible que sea necesario aplicar algo de fuerza

para hacerlo). Una vez que el tubo esté lleno, todo está listo para comenzar a pintar. Levante el rodillo RAPIDROLLErTMlentamente para separarlo

del tubo de llenado.

NOTA: Si no logra un llenado completo la primera vez, empuje el émbolo lentamente para devolver algo de pintura a la lata y luego vuelva a tirar

del émbolo asegurándose de que el ángulo sea el correcto y de que la cubierta anaranjada del tapón de llenado esté completamente asentada.

TM

Pintado con el rodillo RAPIDROLLER

1.) Comience a mover el rodillo sobre la pared y empuje el mango del émbolo u oprima el gatillo para alimentar pintura hacia la cubierta del rodillo.

NOTA: Es posible que la impregnación inicial del rodillo requiera toda la pintura del primer llenado. Rellene el rodillo R

APIDROLLEr

según se requiera (Fig. G).

CONSEJOS ÚTILES

• El gatillo sólo debe oprimirse cuando se requiere pintura.

• Si se produce un patrón de puntos al pintar, aplique más pintura.

• Si el rodillo se resbala sobre la superficie, aplique menos pintura.

• Es posible que note la presencia de vaselina dentro del mango. Esto es necesario y ayudará al funcionamiento del mismo sin afectar la pintura.

2.) El cabezal del rodillo se puede ajustar en tres ángulos distintos. Oprima el botón anaranjado del cabezal del rodillo para cambiar el ángulo de

recto (0 grados) a 40 u 80 grados. Utilice la posición recta para pintura en general y los ángulos de 40 u 80 grados para lugares difíciles de

alcanzar o al pintar cerca de cielos razos o bordes (Fig. H).

NOTA: El mango (a) se puede hacer girar para una mayor comodidad al pintar cuando el armazón del rodillo esté con un ángulo.

Para hacer girar el mango a la posición deseada, afloje el collar (b), ajuste el mango y vuelva a apretar el collar (Fig. H1).

3.) Cuando no esté en uso, apoye el rodillo R

• Al utilizar el soporte, el rodillo R

APIDROLLEr

APIDROLLEr

TM

siempre debe estar sobre una tela protectora (b) o sobre periódicos en caso de que gotee (Fig. J).

TM

sobre el cómodo soporte (a) (Fig. I).

• Al pintar, el soporte debe apuntar en dirección opuesta al rodillo para evitar salpicaduras sobre el mismo.

• Siempre haga girar el rodillo a la posición recta antes de apoyarlo sobre el soporte.

• Para evitar goteos, libere la presión del rodillo R

APIDROLLEr

TM

tirando del émbolo levemente hacia afuera.

NOTA: La colocación del protector contra salpicaduras al utilizar el soporte ayuda a asegurar la contención de todo goteo de pintura.

TM

TM

Limpieza del rodillo RAPIDROLLER

1.) Tire del émbolo hacia atrás para extraer el exceso de pintura del armazón del rodillo al tubo (Fig. K).

CONSEJO: Coloque un pulgar sobre la cubierta del tapón de llenado naranja (a) para ayudar a extraer la mayor cantidad de pintura posible del

armazón antes de mover el émbolo hacia atrás.

2.) Devuelva la pintura del rodillo R

APIDROLLEr

el tubo de llenado hasta que llegue al fondo del tubo de llenado. Asegúrese de que la válvula anaranjada de llenado esté completamente cubierta

por la corona de la tapa para la lata. Empuje el émbolo hasta que se detenga (Fig. L).

3.) Raspe el exceso de pintura desde el rodillo hacia la lata.

Retire el rodillo sujetando el tapón del extremo exterior y el armazón del rodillo, y utilizando el pulgar de la otra mano para empujar el rodillo hacia

afuera como se muestra (Fig. M).

CONSEJO: Use guantes desechables o coloque una bolsa plástica sobre el rodillo para mantener sus manos limpias.

4.) Retire el tapón del extremo interior insertando el tubo metálico del armazón del rodillo dentro del tapón alrededor de 25 mm (1 pulgada) y con

un ángulo pequeño. Tire del armazón del rodillo suavemente hacia usted (Fig. N).

Retire el núcleo del rodillo. Vacíe todo remanente de pintura.

Retire el tapón exterior insertando el armazón del rodillo dentro del rodillo y empujando el tapón suavemente hacia afuera (Fig. O).

TM

a la lata sosteniendo el rodillo en un ángulo de 45 grados y empujando la válvula de llenado sobre

1818

Page 19

TM

Limpieza del rodillo RAPIDROLLER

1.) Retire el tubo de llenado de la tapa para la lata de pintura y empújelo directamente dentro de la válvula de llenado. Al limpiar pinturas solubles

en agua, sumerja el tubo de llenado dentro de agua jabonosa tibia y mueva el émbolo hacia adentro y hacia afuera 5 veces o más. Al utilizar

pinturas a base de aceite, en lugar de agua utilice un solvente de limpieza adecuado según lo indicado en el recipiente del fabricante y elimínelo

debidamente (Fig. P).

CONSEJO: Utilice un lavabo, una tina de lavado o cualquier recipiente que permita contener agua para efectuar el proceso de lavado antedicho.

Reemplace el agua cuando se ensucie o al ir al paso siguiente.

2.) Retire el tubo de llenado. Luego, sumerja el armazón del rodillo y, asegurándose de que la válvula de llenado también quede bajo el agua,

mueva el émbolo hacia adentro y hacia afuera 5 veces o más (Fig. Q).

CONSEJO: Al utilizar un recipiente pequeño, pivote el armazón del rodillo hasta la posición de 80 grados para que quepa dentro del mismo

(Fig. Q1).

3.) Retire el armazón del rodillo y siga limpiando según se requiera. Sumerja el mango en el agua jabonosa tibia y mueva el émbolo hacia adentro

y hacia afuera 5 veces o más (Fig. R).

CONSEJO: Limpie los restos de pintura del extremo del émbolo (a).

4.) Desenrosque el tapón de la válvula y retire el sello rascador y la válvula pico de pato para limpiarlos. Enjuague todas las piezas restantes y

drene todo el líquido del rodillo R

.) Quite la tubería del armazón (si fuera necesario) aplicando las pinzas para manguera. Lave el armazón y la tubería. Vuelva a colocar la tubería

5

sujétela con las pinzas para manguera (Fig. S1).

y

6.) Siempre compre una cubierta perforada para el rodillo. Una cubierta estándar para rodillos no funcionará

APIDROLLER™ (Fig. S).

.

M

T

Lubricación del rodillo RAPIDROLLER

La lubricación contribuye a un funcionamiento normal y debe realizarse después de la limpieza y antes de cada uso.

1.) Gire el collar del ensamblaje roscado hacia la izquierda (a) cerca del gatillo hasta que el ensamblaje del tubo principal se deslice hacia afuera.

NOTA: Al reensamblar, el collar roscado negro (a) debe apuntar hacia el mango del gatillo.

2.) Aplique vaselina alrededor y entre los sellos de goma que se muestran. Vuelva a ensamblar asegurándose de que los sellos de goma no estén

torcidos ni dañados. Ajuste el collar de bloqueo.

3.) Aplique vaselina en la válvula pico de pato y el sello rascador, y vuelva a colocarlos dentro de la unidad enroscando nuevamente el tapón de la

válvula en su lugar.

4.) Aplique vaselina en los sellos interiores de los tapones de los extremos (c y d) y luego ensamble el rodillo colocando el núcleo (a) dentro de la

cubierta del rodillo (b) y fijando los tapones de los extremos como se muestra.

Accesorios

Los accesorios que se recomiendan para uso con el rodillo RAPIDROLLErTMestán disponibles en su distribuidor local o el

centro de mantenimiento autorizado. Si necesita ayuda con respecto a los accesorios, llame al: 1 800 544-6986

ADVERTENCIA: El empleo de cualquier accesorio no recomendado para uso con esta herramienta puede ser peligroso.

Pinza para sujetar el tubo de llenado a la lata: para uso con recipientes que no calcen con la cubierta para lata redonda

provista. Disponibles en los centros de mantenimiento de Black & Decker.

Al utilizar recipientes más grandes, como un cubo de 19 l (5 galones), coloque la pinza para sujetar el tubo de llenado al

recipiente con un trozo de tubería de 19 mm (3/4 pulgada) de D.I. disponible en la mayoría de los centros de artículos para

el hogar. La tubería calza sobre el extremo del tubo de llenado con nervaduras.

Las fundas perforadas para rodillos están disponibles en ferreterías.

Detección de problemas

La pintura tarda mucho en aparecer sobre la Consulte la primera nota de “Pintado con el rodillo RAPIDROLLErTM”.

PROBLEMA

superficie. Es posible que se requiera un segundo llenado.

Se absorbe aire en lugar de pintura hacia el mango. Empuje el mango lentamente para expulsar el aire. Extraiga y vuelva

a insertar el producto en el tubo de llenado. Asegúrese de que el tubo

de llenado esté completamente asentado en el cuerpo de la válvula.

Si es necesario, aplique vaselina en el tubo de llenado para facilitar

que se asienten el tubo de llenado y el cuerpo de la válvula.

Asegúrese de que la junta tórica esté bien lubricada y se encuentre

en su lugar entre el ensamblaje del mango y el armazón del rodillo.

Dificultad para insertar o retirar el tubo de llenado Aplique vaselina en la entrada del orificio de llenado y/o en el

de la válvula. tubo de llenado.

Dificultad para mover el mango hacia adentro o Lubrique los sellos de goma en el extremo del émbolo o haga

hacia afuera. girar el émbolo levemente para romper el sello.

La pintura se sale por los tapones de los extremos. Asegúrese de que ambos tapones de los extremos estén bien

ajustados adentro y al ras con el extremo de la cubierta del

rodillo. Si están bien, retire los tapones de los extremos, elimine

todo resto de pintura antigua y vuelva a lubricar con vaselina.

La pintura se sale por la válvula de llenado. Lubrique la válvula con vaselina. Asegúrese de que el sello

rascador esté en su lugar.

SOLUCIÓN

Para conocer la ubicación del centro de mantenimiento más cercano a fin de recibir ayuda con su producto, visite nuestro sitio Web

www.blackanddecker.com o llame a la línea de ayuda BLACK & DECKER al 1-800-544-6986.

Información de mantenimiento

Todos los Centros de servicio de Black & Decker cuentan con personal altamente capacitado dispuesto a brindar a todos los clientes un servicio

eficiente y confiable en la reparación de herramientas eléctricas. Si necesita consejo técnico, reparaciones o piezas de repuesto originales de

fábrica, póngase en contacto con el centro de servicio de Black & Decker más cercano a su domicilio. Para ubicar su centro de servicio local,

consulte la sección “Herramientas eléctricas” (Tools-Electric) de las páginas amarillas, llame al 1-800-544-6986 o visite nuestro sitio

www.blackanddecker.com.

1919

Page 20

SECCI N

AMARILLA

Si funciona…

yfunciona muy bien.

Garantía

Garantía completa de dos años para uso en el hogar

Black & Decker (Estados Unidos) Inc. ofrece una garantía de dos años por cualquier defecto del material o de fabricación de este producto. El

producto defectuoso se reparará o reemplazará sin costo alguno de dos maneras.

La primera opción, el reemplazo, es devolver el producto al comercio donde se adquirió (siempre y cuando se trate de un comercio participante).

Las devoluciones deben realizarse conforme a la política de devolución del comercio (generalmente, entre 30 y 90 días posteriores a la venta). Le

ueden solicitar comprobante de compra. Consulte en el comercio acerca de la política especial sobre devoluciones una vez excedido el plazo

p

establecido.

La segunda opción es llevar o enviar el producto (con flete pago) a un Centro de servicio propio o autorizado de Black & Decker para su reparación

o reemplazo según nuestro criterio. Le pueden solicitar el comprobante de compra. Los Centros de servicio autorizados y de propiedad de Black &

Decker se detallan en la sección “Herramientas eléctricas” (Tools-Electric) de las páginas amarillas de la guía telefónica.

Esta garantía no se extiende a los accesorios. Esta garantía le concede derechos legales específicos; usted puede tener otros derechos que

ueden variar según el estado o la provincia. Si tiene alguna pregunta, comuníquese con el gerente del Centro de servicio de Black & Decker de

p

su zona. Este producto no está diseñado para uso comercial.

AMÉRICA LATINA: esta garantía no se aplica a los productos que se venden en América Latina. Para los productos que se venden enAmérica

Latina, debe consultar la información de la garantía específica del país que viene en el empaque, llamar a la compañía local o visitar el sitio Web a

fin de obtener esa información.

· GARANTÍA BLACK & DECKER · BLACK & DECKER WARRANTY

. SOLAMENTE PARA PROPOSITOS DE MEXICO

Distributor Name · Sello firma del distribuidor

Date of purchase · Fecha de compra Invoice No. · No. de factura

PRODUCT INFOMATION · IDENTIFICACIÓN DEL PRODUCTO

Cat. No. · Catalogo ó Modelo Serial Number · No. de serie

Name · Nombre Last Name · Apellido

Address · Dirección City · Ciudad State · Estado

Postal Code · Código Postal Country · País Telephone · No. Teléfono

2 AÑOS DE GARANTIA

Este producto cuenta con dos años de garantía a partir de la fecha de compra contra cualquier defecto de su funcionamiento, así como cualquier

falla debido a materiales empleados para su fabricación ó mano de obra defectuosa.

Nuestra garantía incluye la reparación o reposición del producto y/o componentes sin cargo alguno para el cliente incluyendo la mano de obra,

esta incluye los gastos de trasportación erogados para lograr cumplimiento de esta garantía en los domicilios diversos señalados.

Para hacer efectiva esta garantía deberá presentar su herramienta y esta póliza sellada por el establecimiento comercial donde se adquirió el

producto.

Nos comprometemos a entregar el producto en un lapso no mayor a 30 días hábiles contados a partir de la fecha de recepción del mismo en

nuestros talleres de servicio autorizados.

ESTA GARANTIA NO APLICA CUANDO:

El producto se hubiese utilizado en condiciones distintas a las normales.El producto no hubiese sido operado de acuerdo con el instructivo de uso

que se acompaña. El producto hubiese sido alterado o reparado por personas no autorizadas por nosotros.

Importador: Black & Decker S.A. de .C.V, Bosque de Cidros Acceso Radiatas No.42, 3ra.Seccion de Bosques de las lomas, C.P.05120, Mexico,

D.F. Tel: (01 55) 5326 7100

SOLAMENTE PARA PROPOSITOS DE MEXICO

Grupo Realsa en herramientas,

S.A. de C.V.

Súper Manzana 69 MZ.01 Lote 30

(Av. Torcasita)

Col. Puerto Juárez

Cancún, Quintana Roo

Tel. 01 998 884 72 27

Ferre Pat de Puebla, S.A. de C.V.

16 de Septiembre No. 6149

Col. El Cerrito

Puebla, Puebla

Tel. 01 222 264 12 12

Ferre Pat de Puebla, S.A. de C.V.

Ejército Mexicano No. 15

Col. Ejido 1ro. de Mayo

Boca del Rio, Veracruz

Tel. 01 229 167 89 89

Servicio de Fabrica Black & Decker,

S.A. de C.V.

Lázaro Cardenas No. 18

Col. Obrera

Distrito Federal

Tel. 55 88 95 02

PARA OTRAS LOCALIDADES LLAME AL 01 800 847 2309 o 01 800 847 2312.

Representaciones Industriales

Robles, S.A. de C.V.

Tezozomoc No. 89

Col. La Preciosa

Distrito Federal

Tel. 55 61 86 82

Gpo. Comercial de Htas. y

Refacciones de Occidente,

S.A. de C.V.

Av. La Paz No. 1779

Col. Americana, S. Juaréz

Guadalajara, Jalisco

Tel. 01 33 38 25 69 78

Herramientas y Equipos

Profesionales

Av. Colón 2915 Ote.

Col. Francisco I. Madero

Monterrey, Nvo. León

Tel. 01 81 83 54 60 06

Htas. Portátiles de Chihuahua,

S.A. de C.V.

Av. Universidad No. 2903

Col. Fracc. Universidad

Chihuahua, Chihuahua

Tel. 01 614 413 64 04

Fernando González Armenta

Bolivia No. 605

Col. Felipe Carrillo Puerto

Cd. Madero, Tampico

Tel. 01 833 221 34 50

Perfiles y Herramientas de Morelia

Gertrudis Bocanegra No. 898

Col. Ventura Puente

Morelia, Michoacán

Tel. 01 443 313 85 50

Enrique Robles

Av. de la Solidaridad No. 12713

Col. La Pradera

Irapuato, Guanajuato

Tel. 01 462 626 67 39

Hernández Martinez Jeanette

Prolongación Corregidora Nte. No. 1104

Col. Arboledas

Queretaro, Qro.

Tel. 01 442 245 25 80

Cat. No. BDPR400 Form No. 90571314 January 2011

Copyright©2011 Black & Decker Printed in China

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

BLACK & DECKER S.A. DE C.V.

COL. BOSQUES DE LAS LOMAS., 05120 MÉXICO, D.F

TEL. (01 55) 5326 7100, 01 800 847 2309/01 800 847 2312

20

Vea “Herramientas

eléctricas (Tools-Electric)”

– Páginas amarillas –

para Servicio y ventas

Loading...

Loading...