Page 1

HVLP SMARTSELECT

INSTRUCTION MANUAL

TM

SPRAYER

Catalog Number

BDPH200

Thankyou for choosing Black & Decker! Goto

www.BlackandDecker.com/NewOwner to register your new product.

PLEASEREAD BEFORE RETURNINGTHIS PRODUCT FORANY REASON:

Ifyou havea question orexperience a problem with your Black & Decker purchase,go to

WWW.BLACKANDDECKER.COM/INSTANTANSWERSfor instant answers24 hoursa day.

If you canʼt find the answer or do not have access to the internet,

call 1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon. - Fri. to speak with an agent.

Please have the catalog number available when you call.

SAVE THIS INSTRUCTION MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZADE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Page 2

TABLE OF CONTENTS

Safety Guidelines - Definitions.......................................................................3

Important Safety Instructions .........................................................................3

General Safety Warnings...............................................................................4

Grounding Instructions...................................................................................4

Extension Cords.............................................................................................4

Components...................................................................................................5

Set-Up............................................................................................................6

Aligning Pickup Tube...................................................................................6

Material Preparation....................................................................................6

Thinning Table.............................................................................................7

Preparation Tips..........................................................................................7

Filling The Canister .....................................................................................7

Operation .......................................................................................................7

Material Flow Adjustment............................................................................7

SmartSelect Nozzle.....................................................................................8

Spraying Technique........................................................................................8

Cleaning.........................................................................................................9

Maintenance / Storage...................................................................................11

Accessories....................................................................................................11

Service Information ........................................................................................11

Warranty.........................................................................................................11

Troubleshooting .............................................................................................12

2

Page 3

SAFETY GUIDELINES - DEFINITIONS

t is important for you to read and understand this manual. The information it contains relates to protecting YOUR

I

AFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

S

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

The following are explanations of important safety hazard pictorials in this manual.

1. Read and understand the

instruction manual.

3. Explosion hazard.

5. Electric shock hazard.

2. Fire hazard.

4. Respiratory hazard.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - To reduce the risks of fire or explosion, electrical shock and the injury to

persons, read and understand all instructions included in this manual. Be familiar with the controls and the proper

usage of the equipment.

• This product is intended for household use only.

WARNING: FIRE OR EXPLOSION HAZARD. Solvent and spray material fumes can

explode or ignite. Severe injury or property damage can occur.

To avoid these risks, take the following preventions:

• Exhaust and fresh air introduction must be provided to keep the air within the spray area free from accumulation of

flammable vapors.

• Avoid all ignition sources such as static electricity sparks, open flames, pilot lights, hot objects, lit tobacco products,

and sparks from connecting and disconnecting power cords or working light switches.

• Fire extinguishing equipment must be present and in good working order.

• Follow the material and solvent manufacturerʼs safety precautions and warnings.

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as lit tobacco

products, motors, and electrical equipment.

• Know the contents of the spray materials and their cleaning solvents. Read all Material Safety Data Sheets (MSDS)

and container labels provided with the spray materials and solvents. Follow the spray material and solvent

manufacturerʼs safety instructions.

• Do not use materials with a flashpoint higher than 60°C ( 140°F). Flashpoint is the temperature that a fluid can

produce enough vapors to ignite (see coating supplier).

WARNING: EXPLOSION HAZARD DUE TO INCOMPATIBLE MATERIALS. Severe injury or

property damage can occur.

To avoid these risks, take the following preventions:

• Do not use bleach.

• Do not use halogenated hydrocarbon solvents such as methylene chloride and 1,1,1 - trichloroethane. They are not

compatible with aluminum and may cause an explosion. If you are unsure of a materialʼs compatibility with

aluminum, contact your coating supplier.

WARNING: HAZARDOUS VAPORS. Spray materials, solvents, and other materials can be harmful

if inhaled or come in contact with the body. Vapors can cause severe nausea, fainting, or poisoning.

To avoid these risks, take the following preventions:

• Use a respirator or mask if vapors can be inhaled. Read all instructions supplied with the mask to be sure it will

provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

3

Page 4

WARNING: ELECTRIC SHOCK HAZARD. May cause severe injury.

Three-Pronged Plug

Grounding Prong

Properly Grounded

Three-Pronged Receptacle

To avoid these risks, take the following preventions

• Keep electrical cord plug and spray gun trigger free from spray material and other liquids. Never hold cord at plug

connections to support cord. Failure to observe may result in an electrical shock.

• Never immerse electrical parts in water or any other liquid. Wipe the exterior of the sprayer with a damp cloth for

cleaning. Always make sure the sprayer is unplugged before taking it apart for cleaning.

• Do not expose unit to rain or wet conditions.

• Do not abuse the cord. Never use the cord to carry the unit or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords immediately.

GENERAL SAFETY WARNINGS

WARNING: GENERAL. Can cause severe injury or property damage.

To avoid these risks, take the following preventions:

• Do not aim the gun at, or spray any person, including self, or animal.

• Do not spray outdoors on windy days.

• Wear protective clothing to keep spray material off skin and hair.

• Follow all appropriate local, state, and national codes governing ventilation, fire prevention, and operation.

• Always use appropriate gloves, eye protection and a respirator or mask when spraying, thinning, mixing, pouring, or

cleaning.

• Do not operate or spray near children. Keep children away from equipment at all times. Keep sprayer out of the reach

of children.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Read all instructions and safety precautions for equipment and spray material before operating any equipment.

• Hearing protection is recommended for extended use.

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock

by providing an escape wire for the electric current. This product is equipped with a cord having a grounding wire with

an appropriate grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING: ELECTRIC SHOCK HAZARD. Improper installation of the grounding plug is able to

result in a risk of electric shock. When repair or replacement of the cord or plug is required, do not connect

the grounding wire to either flat blade terminal. The wire with insulation having an outer surface that is

green with or without yellow stripes is the grounding wire.

This product is for use on a nominal 120-V circuit and has a grounding plug similar to the plug

illustrated in sketch A. Only connect the product to an outlet having the same configuration as

A

the plug. Do not use an adapter with this product.

Check with a qualified electrician or serviceman when the grounding instructions are not

completely understood, or when in doubt as to whether the product is properly grounded. Do

not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a

qualified electrician.

EXTENSION CORDS

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the

plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure to

use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. If an extension

cord is to be used outdoors, it must be marked with the suffix

W-A after the cord type designation. For example, a

designation of SJTW-A would indicate that the cord would be

appropriate for outdoor use. For proper size cords see chart

below.

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

91,4m)

Ampere Rating

More Not more American Wire Gauge

Than Than

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

Minimum Gauge for Cord Sets

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

(0-15,2m) (15,2-30,4m)(30,4-60,9m) (60,9-

WARNING: Some spray materials contain chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. To reduce your exposure wear appropriate safety equipment such as face masks,

gloves, and other appropriate protective equipment. Please review and follow the safety precautions on the paint

container.

4

Page 5

A

11

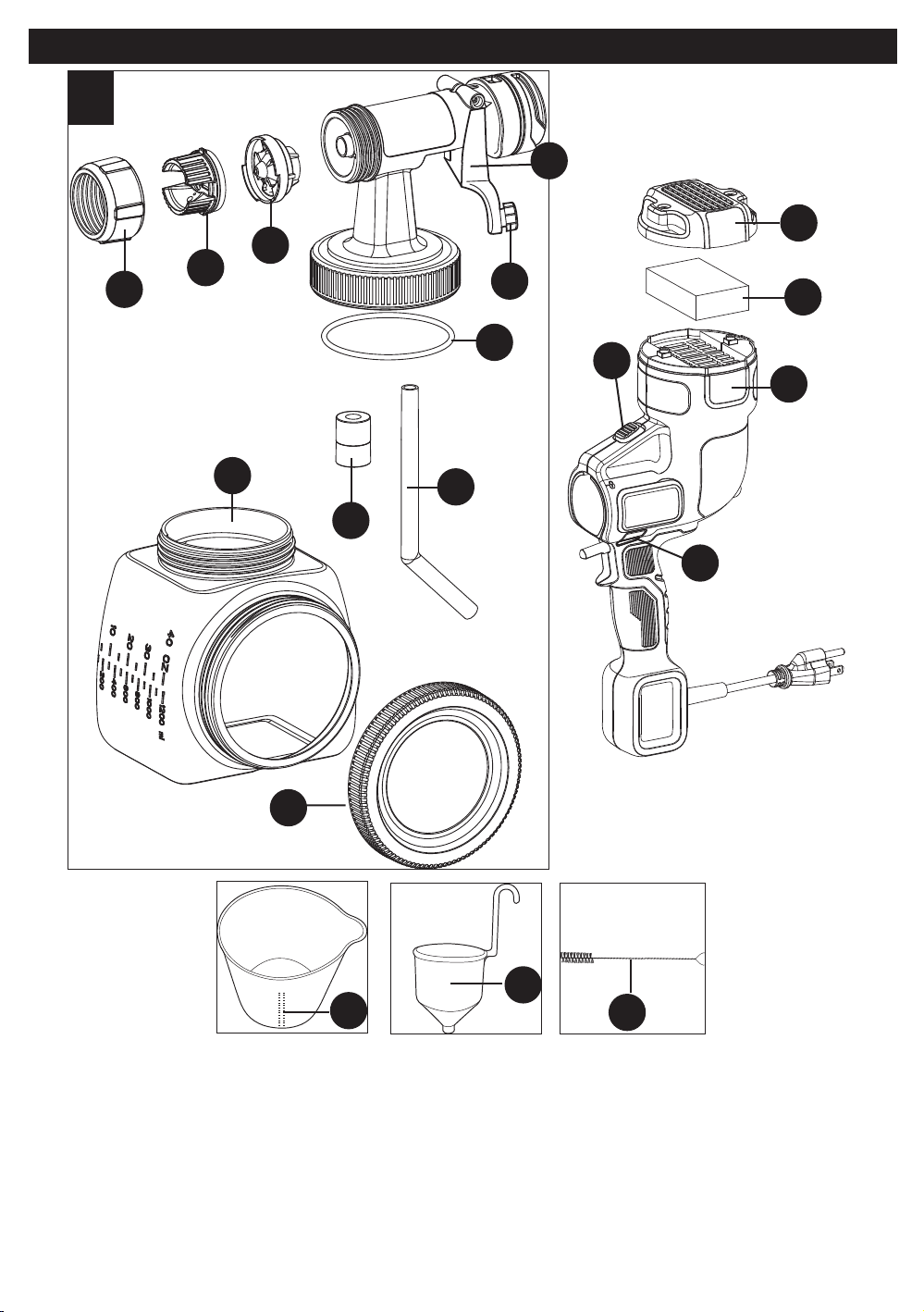

COMPONENTS

6

5

13

12

7

4

14

8

3

1

9

10

2

15

1.) Motor housing

2.) Flow control indicator

3.) Release button

4.) Filter

5.) Filter cover

6.) Trigger

17

16

FUNCTIONAL DESCRIPTION

7.) Material adjustment knob

8.) O-ring

9.) Pickup tube

10.) Check valve

11.) Tip collar

12.) Spray nozzle

5

18

13.) Spray tip

14.) Side fill canister

15.) Lid

3

16.) 2-

17.) Viscosity cup

18.) Cleaning brush

/4 quart mixing bucket

Page 6

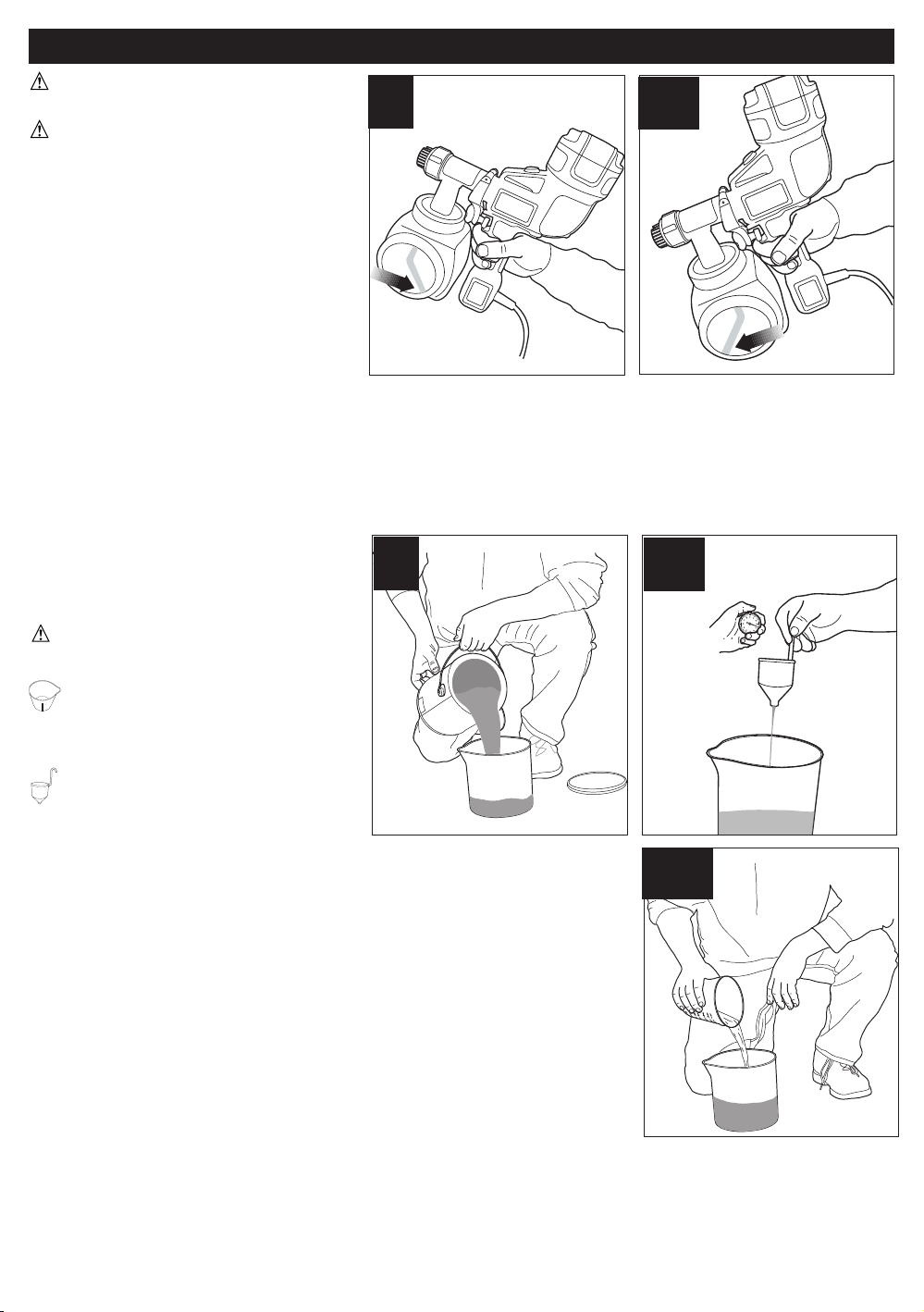

SET-UP

WARNING: Be sure to use appropriate

protective gear and unplug unit.

B

B1

WARNING: Make sure area is well

ventilated and free of flammable vapors.

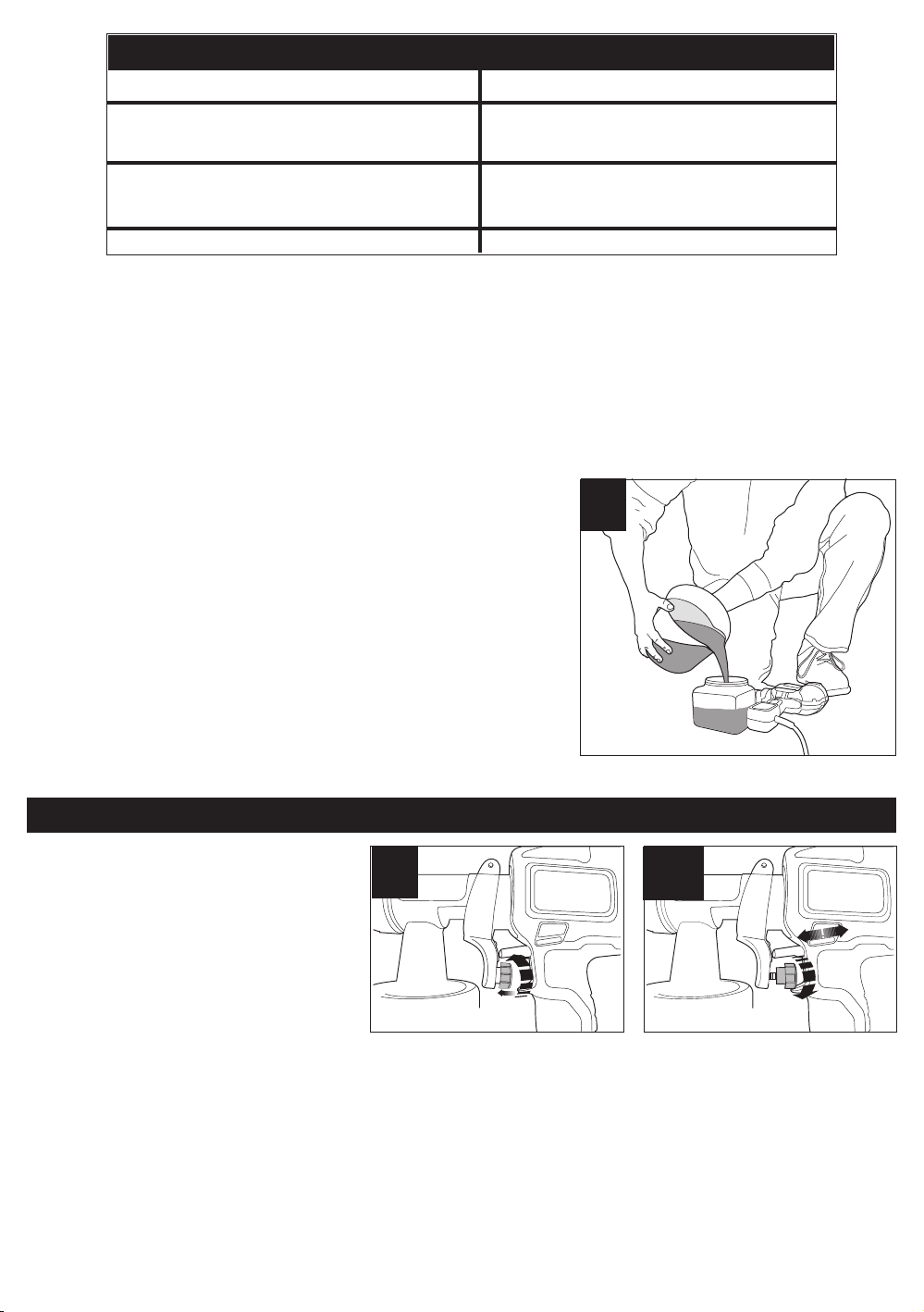

ALIGNING THE PICKUP TUBE (FIGURES B AND B1)

The pickup tube can be aligned in the

direction that you will be doing the most

spraying to help minimize the amount of times

that you will have to refill the canister.

• If you are spraying at an upward angle or

straight on, position the pickup tube

(figure B) toward the back of the canister.

• If you are spraying at a downward angle,

position the pickup tube (figure B1) toward

the front of the canister.

This will ensure you spray as much material as possible before you need to refill.

LIQUID MATERIAL PREPARATION - (FIGURES C, C1 AND C2)

TIP: Make sure the type of material you use can be cleaned with either mineral spirits or paint thinner (for

oil-based paints) or a warm water and soap solution (for water soluble paints like latex). Use drop cloths

during pouring, mixing, and viscosity testing of materials to be sprayed to protect your floors and anything

else in the spraying area that you wish to remain untouched.

The liquid being sprayed may need to be

thinned (diluted) before starting. When

thinning, use the proper liquid thinner

recommended on the container by the

material manufacturer.

C

C1

WARNING: Do not use materials with

a flashpoint higher than 60°C ( 140°F) .

3

A 2-

/4 quart mixing bucket is provided

to use when transferring spray material

from the original container into the

bucket for thinning and measuring

purposes (figure C).

A viscosity test cup is provided to

determine the “runout time” of the material being used.

• Before measuring for the proper viscosity,

stir the material thoroughly.

• Dip the viscosity cup into the material being sprayed and fill the cup completely.

• With the cup held over the material container, measure the amount of time it

takes for the stream of material flowing out to “break” or stop being a constant

stream out of the bottom of the cup (2 minutes or less) (figure C1). This is the

“runout time” Refer to the thinning table for information on the thinning required for

different materials.

• If material needs thinning, add the appropriate liquid thinning material

recommended by the manufacturer (figure C2).

• It is possible to spray latex paint with this unit, however, the required thinning may exceed material manufacturerʼs

recommendation. Thin latex paint so that it runs through viscosity cup in under 2 minutes. The operator should consider the type of application and final location of the project when spraying a material that requires more than 2 minutes to run through the viscosity cup,

6

C2

Page 7

THINNING TABLE

SPRAY MATERIAL RUNOUT TIME

lear and semi-transparent stains and sealers No thinning required

C

Oil based primers, varnishes and polyurethane (Less than 2 minute runout)

Solid color water based stains May require thinning

Water based or latex paints (More than 2 minute runout)

Note: Not recommended for textured paint

PREPARATION TIPS

• Always stir and strain the material thoroughly before use.

• With any spraying job you should always ensure that you have properly prepared the surface to get the best finish.

That is, all surfaces are free from dust, dirt, rust and grease. Lightly pressure wash decks or exterior surfaces and

ensure that they are dry before spraying.

• Even though HVLP sprayers have very little overspray, it is recommended that you mask all edges and other areas

and use drop cloths to protect your floors and anything else in the spraying area that you wish to remain untouched.

• Skin that forms on the top of paint can clog the sprayer. Remove skin before mixing. Strain with a funnel with a filter

attached or through hosiery to remove any impurities that could clog system.

• Before starting have gloves, paper towels, rags etc. available for unexpected spills.

FILLING THE CANISTER - (FIGURE D)

• Check to make sure that the canister is completely screwed onto the

sprayer.

• Lay the sprayer on its side with the canister side lid facing up.

• Unscrew the lid on the side of the canister.

• Pour the properly thinned and strained material to be sprayed into the

side fill canister (figure D). TIP: Use the mixing bucket provided to

pour material from the original material container into the side fill

canister.

• Clean any residual liquid from the threads or sides of the canister and

sprayer.

• Starting the threads evenly, screw the lid completely onto the side fill

canister. Check the lid to make sure it is threaded on squarely and

completely before picking up the sprayer.

D

OPERATION

MATERIAL FLOW ADJUSTMENT

Set the material volume by turning the

material adjustment knob on the trigger of the

sprayer.

• For maximum material flow, thread knob all

the way in as shown in figure E.

• For minimum material flow, thread knob all

the way out as shown in figure E1.

The flow indicator on the side of the sprayer

moves forward (minimal liquid flow) and

backward (maximum liquid flow) as the trigger

is depressed.

TIP: Always test the spray pattern on scrap cardboard or similar material first. Begin with the material

adjustment knob on the highest flow setting (threaded all the way in). If less flow is desired, dial the material

adjustment knob out. Heavier, thicker materials should be sprayed with the knob dialed farther in. Thinner

materials should be sprayed with the knob dialed farther out.

E

E1

7

Page 8

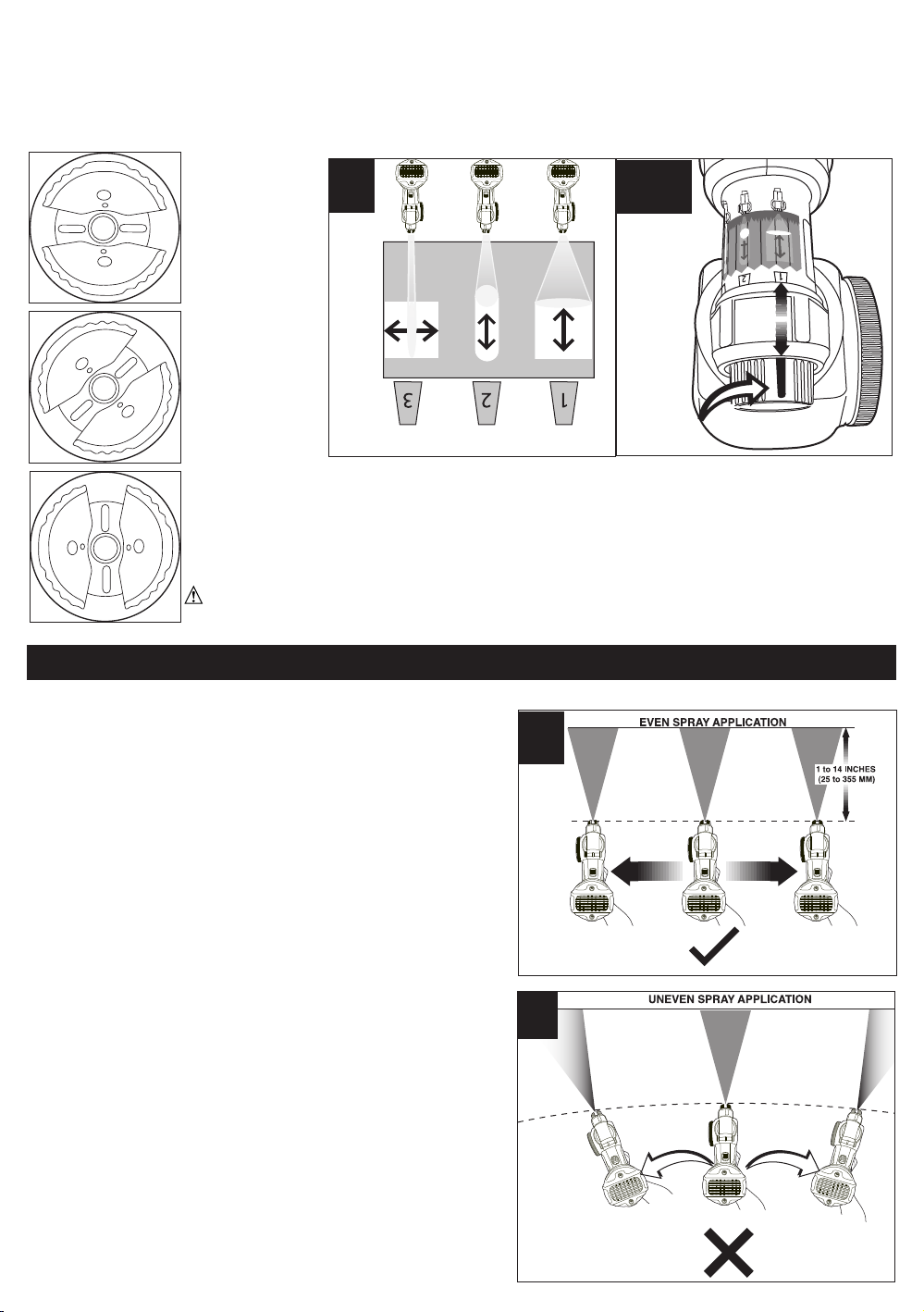

SMART SELECT NOZZLE SELECTION - (FIGURE F)

There are three spray patterns to choose from. They are marked as 1, 2 and 3 on the Smart Select label located on the top

of the sprayer (figure F). To select pattern number 1, turn the spray nozzle and align the green indicator on the spray

nozzle with the number 1 on the label (figure F1).

NOTE: Spray nozzle can only be assembled in one direction. Refer to figure S for proper assembly.

• Pattern number 1

- Horizontal Flat

Jet - Apply up and

down a surface.

• Pattern number 2

- Circular Jet - for

corners, edges and

narrow surfaces.

TIP: Position number 2 has a detent that you can feel when you turn the spray nozzle.

Make sure it locates in the detent.

• Pattern number 3 - Vertical Flat Jet. Apply side to side.

F

WARNING: Risk of injury. Never point the sprayer at any part of the body. Never pull the

trigger while adjusting the spray setting.

DEVELOPING THE PROPER SPRAYING TECHNIQUE

• Practice spraying on a piece of scrap material such as

cardboard to test your spray pattern and become familiar with the

flow control feature of the sprayer.

• Ensure surface to be sprayed is free of dust, dirt, and grease.

F1

G

• Ensure spray area is clean and free of dust that could be blown

onto newly sprayed surfaces.

• Cover any areas not intended to be sprayed.

• Always spray from a minimum of 1 inch (25mm) to a maximum of

14 inches (355mm) (figure G).

• A commonly used method for spraying a large surface is the

“crisscross” pattern. This is done by spraying in horizontal strips

and then crossing over these strips with vertical strips.

• To get an even spray distribution, always keep your arm at the

same distance (figure G) from the surface you are spraying and

avoid moving your wrist (figure H).

• Maintain smooth and consistent speed which will help avoid

inconsistencies. Begin spraying after the pass has begun and

release trigger before stopping the pass.

• Avoid spraying too heavily in any one area. Several lighter

coats are better than one heavy coat which can lead to running

and dripping. Remember that the flow control knob regulates the

amount of liquid that can be sprayed. Turning the flow knob

clockwise increases the flow of liquid. Turning the knob

counterclockwise decreases the flow of liquid. If runs or drips do

occur, have a dry paint brush on hand to smooth them out.

• Turn the power unit off when not spraying for any length of time.

8

H

Page 9

CLEANING

WARNING: Be sure to use appropriate protective gear.

Use drop cloths during pouring, mixing, and viscosity testing of materials to be sprayed to protect your

•

loors and anything else in the spraying area that you wish to remain untouched.

f

• Do not use materials with a flashpoint higher than 60°C ( 140°F) . Flashpoint is the temperature that a fluid can

produce enough vapors to ignite (see coating supplier).

• Make sure clean up area is well ventilated and free of flammable vapors.

• Always spray outdoors when spraying cleaning solution through sprayer.

• Do not submerse power unit.

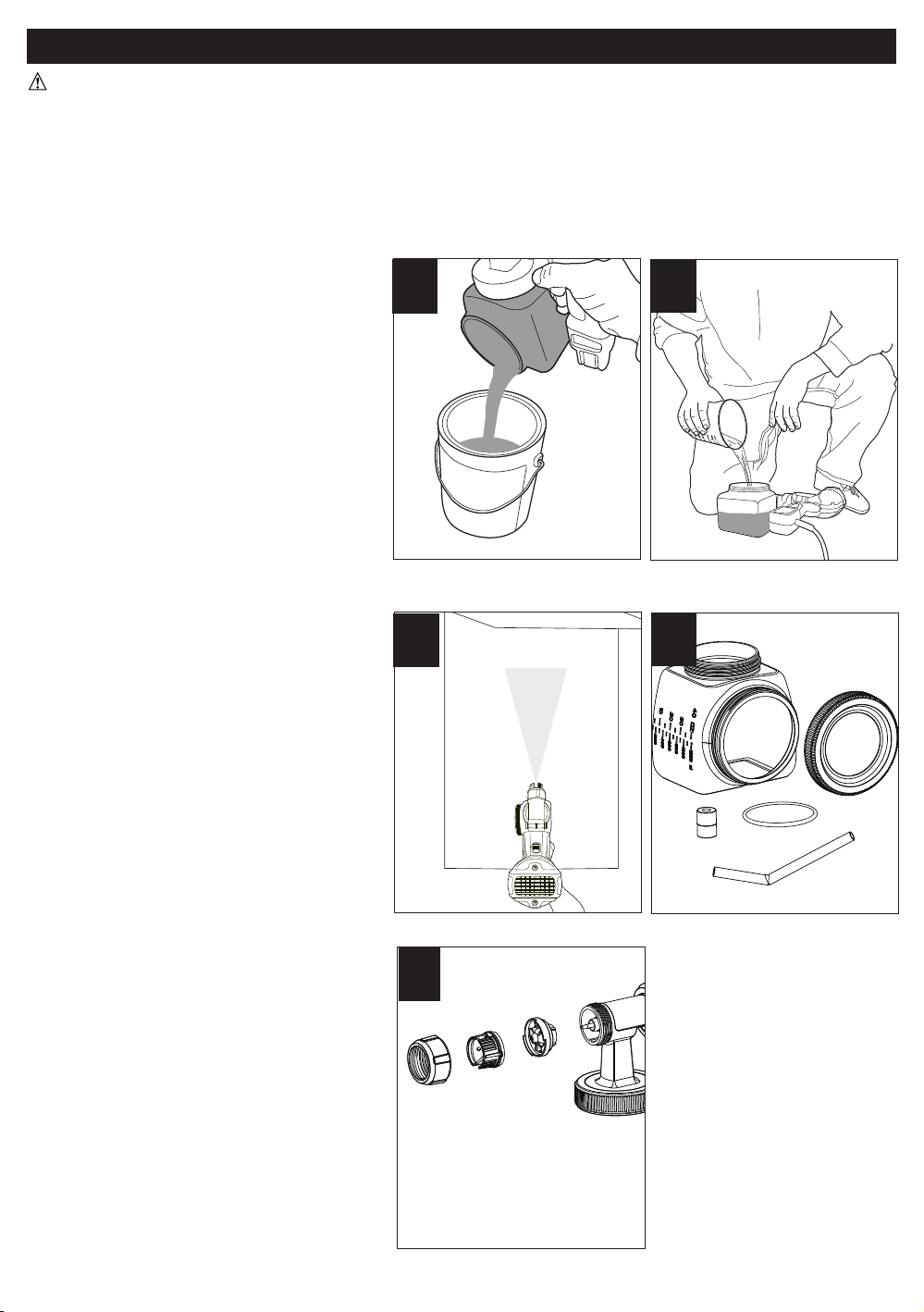

To begin cleaning:

• Unplug the cord from the power source.

• Unscrew the lid from the side of the canister

and pour any remainingliquid back into the

original container (figure I).

• Pour a small amount of the appropriate

cleaning solution into the canister (figure J).

• Warm soapy water for water based

materials

• Manufacturers recommended cleaning

solution for oil based materials

• Replace the lid on the canister securely and

vigorously shake the sprayer.

• Unscrew the lid from the side of the canister

and properly dispose of cleaning solution.

• Refill the canister with a small amount of new

cleaning solution (figure J). Screw lid securely

on canister.

• Plug in the power cord.

• Spray the cleaning solution through the

sprayer onto scrap material for 2 to 3 seconds

(figure K).

I

K

J

L

• Unplug the cord from the power source.

• Remove the canister and unscrew the side lid.

Remove the check valve, pickup tube and o-ring

from the sprayer (figure L). Clean the parts with

the cleaning brush in the appropriate cleaning

solution.

• Unscrew the tip collar and remove the spray

nozzle and spray tip (figure M). Clean all parts

with the cleaning brush in the appropriate

cleaning solution.

M

9

Page 10

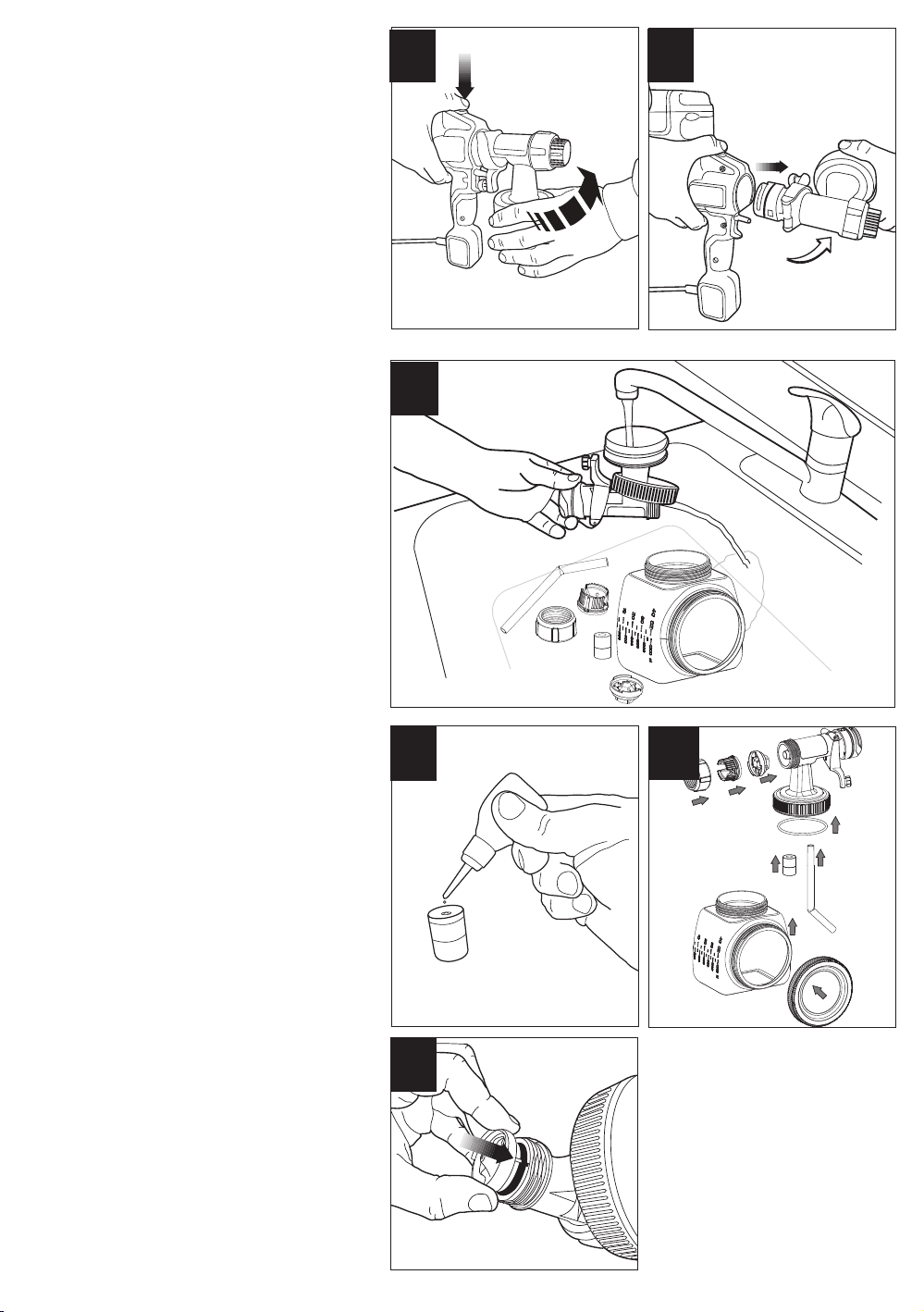

• Separate the nozzle section from the sprayer

motor by pressing the release button on the

motor housing as shown in figure N.

• Grasp the nozzle section and twist until it is

90 degrees to the housing, then pull straight out

(figure O).

• If using water based material, clean the nozzle

section by running water through pickup tube

inlet as shown in figure P. If using oil based

materials, clean pickup tube inlet with the

appropriate cleaning solution. Repeat until

sprayer is completely clean.

• Dry all parts thoroughly.

N

P

O

• Properly dispose of cleaning solution.

• Place a drop of household oil onto the metal

ball in the check valve

(figure Q). IMPORTANT: Lubricating the ball

in check valve, after cleanup, will help to

prevent it from sticking which can clog the

valve and prevent adequate flow of spray

material.

NOTE: When reassembling, place metal ball

end of check valve into sprayer.

• Reassemble sprayer (figure R). NOTE: The

spray tip can only go in one way. The notch

on the spray tip, shown in figure S must

align with the recess in the threads of the

sprayer.

Q

S

R

10

Page 11

• Align the nozzle section 90 degrees to the

motor housing and press it fully into the motor

housing as shown in figure T.

• Grasp the nozzle section and twist it

downward until the pointer on the nozzle

section aligns with the lock symbol on the

motor housing (figure U).

When properly connected, the two pieces will

“snap” into place.

T

MAINTENANCE AND STORAGE

Use only mild soap and damp cloth to clean the power unit. Never let any liquid get

inside the power unit; never immerse any part of the power unit into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (other than those listed in this manual) should be performed by

authorized service centers or other qualified service organizations, always using

identical replacement parts.

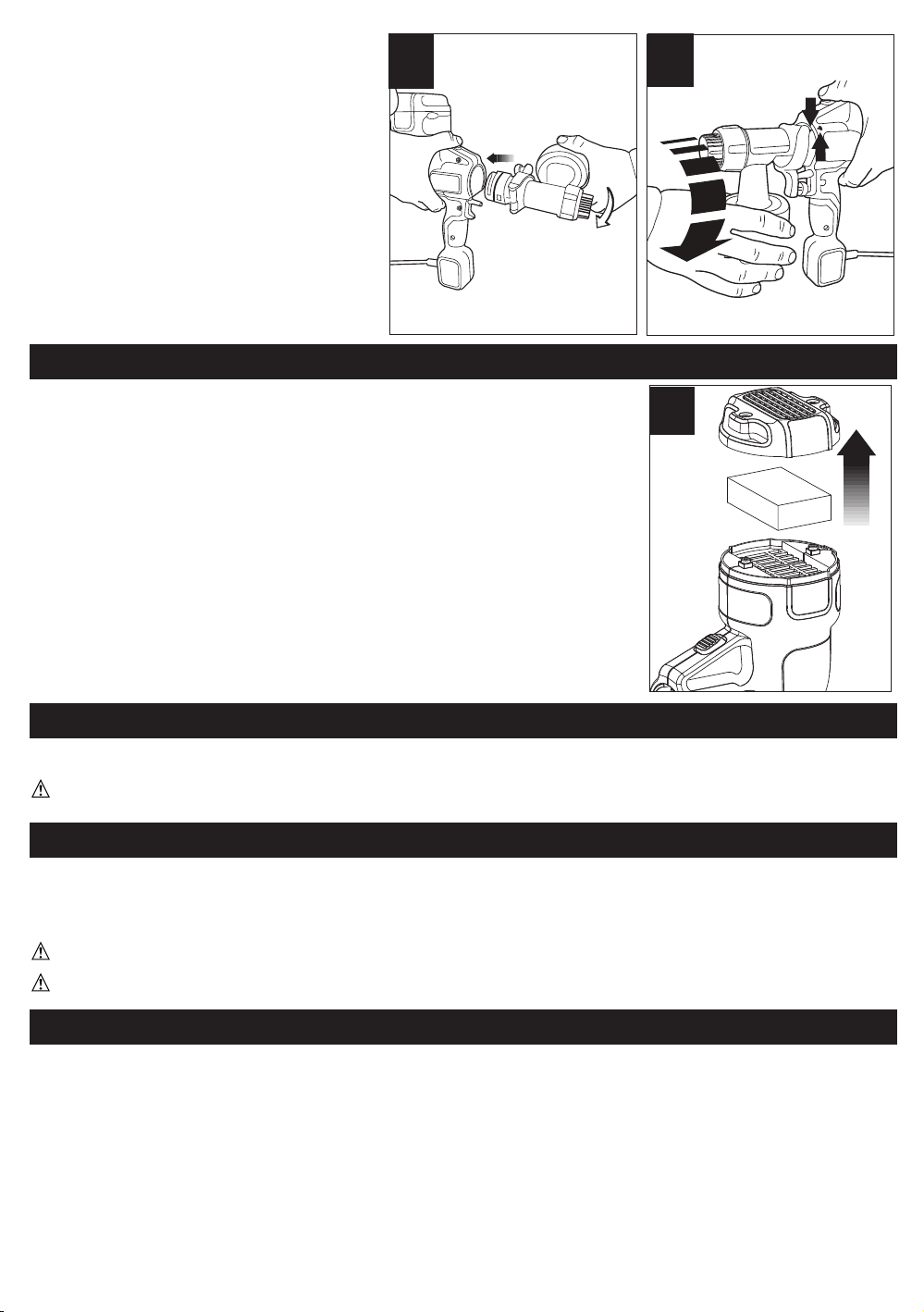

The sprayer contains a washable/reuseable filter (figure V). Check the filter

before and after each use. If dirty, wash with warm water and allow to air dry

before re-installing or replace if necessary.

• To check the filter, remove the filter cover by loosening the two screws in the

cover and pulling the cover off the sprayer. Remove the filter as shown in figure V

and inspect. Replace filter and filter cover. Snugly tighten screws. Never operate

the sprayer without the filter in place. Debris could be sucked in and interfere with

the function of the sprayer.

Make sure unit is clean and dry before storing. Store unit indoors in a dry location.

To prevent damage, wrap the electrical cord so that it is not crimped during

storage.

U

V

ACCESSORIES

Recommended accessories for use with your product are available from your local dealer or authorized service

center. If you need assistance regarding accessories, please call: 1-800-544-6986

WARNING: The use of any accessory not recommended for use with this product could be hazardous.

SERVICE INFORMATION

All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable

power tool service. Whether you need technical advice, repair, or genuine factory replacement parts, contact the Black

& Decker location nearest you. To find your local service location, refer to the yellow page directory under "Tools—

Electric" or call: 1-800-544-6986 or visit www.blackanddecker.com

WARNING:: Tool service must be performed only by qualified repair personnel.

WARNING: When servicing a tool, use only identical replacement parts.

WARRANTY

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The

defective product will be replaced or repaired at no charge in either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased

(provided that the store is a participating retailer). Returns should be made within the time period of the retailerʼs policy

for exchanges (usually 30 to 90 days after the sale). Proof of purchase may be required. Please check with the retailer

for their specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for

repair or replacement at our option. Proof of purchase may be required.Black & Decker owned and authorized Service

Centers are listed under "Tools-Electric" in the yellow pages of the phone directory.

11

Page 12

This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other

rights which vary from state to state or province to province. Should you have any questions, contact the manager of

your nearest Black & Decker Service Center. This product is not intended for commercial use.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America,

check country specific warranty information contained in the packaging, call the local company or see the website for

warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call

1-800-544-6986 for a free replacement.

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Material runs or drips. • Spraying too much material. • Reduce air flow by turning

• Spraying too slowly. • Increase speed of application.

• Spraying too close. • Increase distance from surface.

• Viscosity too thin. • Check dilution

material adjustment knob.

recommendation.

• Too much over spray. • Sprayer too far from surface. • Reduce distance to surface.

• Little or no material being released. • Check valve ball stuck. • Remove check valve. Depress

• Material being sprayed is splattering. • Viscosity of material is too high. • Thin material per manufacturer

• Sprayer pulsates. • Air filter clogged. • Clean or change filter.

• Liquid comes out side of canister. • Lid not on square or tight enough. • Remove lid and reattach

• Too much material being sprayed. • Reduce air flow by turning

material adjustment knob.

ball to loosen.

Add lubricant. See figure Q.

• Spray nozzle/tip clogged. • Clean nozzles.

• Pickup tube loose or clogged. • Check tube.

• Material adjustmentknobsetting too low. • Increase setting.

• Air inlet blocked. • Clean or change air filter.

• Material too thick. • Check viscosity

recommendation.

recommendation.

• Material in canister almost empty. • Refill canister.

squarely and evenly, then tighten

lid securely.

• Paint on threads of canister and lid. • Clean threads on top and sides

of canister and lid.

For assistance with your product, visit our website www.blackanddecker.com for the location of the

service center nearest you or call the BLACK & DECKER help line at 1-800-544-6986.

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Elec-

tric’

– Yellow Pages –

for Service &

Sales

12

Page 13

PULVÉRISATEUR HVLP SMARTSELECT

MODE DʼEMPLOI

M

C

Numéro de catalogue :

BDPH200

Merci dʼavoir choisi Black & Decker!

Consulter le site Web www.BlackandDecker.com/NewOwner

pour enregistrer votre nouveau produit.

À LIRE AVANT DE RETOURNER CE PRODUIT POUR QUELQUE

RAISON QUE CE SOIT :

Si des questions ou des problèmes surgissent après lʼachat dʼun produit

WWW.BLACKANDDECKER.COM/INSTANTANSWERS

pour obtenir des réponses instantanément 24 heures par jour.

Si la réponse est introuvable ou en lʼabsence dʼaccès à l'Internet, composer le

1 800 544-6986 de 8 h à 17 h HNE, du lundi au vendredi, pour parler avec un agent.

Prière dʼavoir le numéro de catalogue sous la main lors de lʼappel.

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

Black & Decker, consulter le site Web

13

Page 14

TABLE DES MATIÈRES

Lignes directrices en matière de sécurité — définitions ................................15

Consignes de sécurité importantes................................................................15

Avertissements de sécurité généraux ...........................................................16

Directives relatives à la mise à la terre .........................................................16

Rallonges .......................................................................................................16

Composants...................................................................................................17

Préparation ....................................................................................................18

Alignement du tube dʼaspiration..................................................................18

Préparation de la matière............................................................................18

Tableau de dilution ......................................................................................19

Conseils de préparation ..............................................................................19

Remplissage de la cartouche......................................................................19

Fonctionnement .............................................................................................19

Réglage du débit du produit .......................................................................19

Buse Smartselect .......................................................................................20

Technique de pulvérisation ............................................................................20

Nettoyage ......................................................................................................21

Entretien/entreposage ...................................................................................23

Accessoires ...................................................................................................23

Information sur les réparations ou lʼentretien.................................................23

Garantie .........................................................................................................23

Dépannage ....................................................................................................24

14

Page 15

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important de lire et de comprendre ce mode dʼemploi. Les informations quʼil contient concernent VOTRE SÉCURITÉ

et visent à ÉVITER TOUT PROBLÈME. Les symboles ci-dessous servent à aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle nʼest pas évitée, causera la mort ou des graves

blessures.

AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle nʼest pas évitée, pourrait causer la

mort ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement dangereuse qui, si elle nʼest pas évitée, pourrait causer

des blessures mineures ou modérées.

AVIS : Utilisé sans le symbole dʼalerte à la sécurité, indique une situation potentiellement dangereuse qui, si elle nʼest

pas évitée, peut résulter en des dommages à la propriété.

Voici une explication des symboles de danger importants utilisés dans le présent manuel.

1. Lire et comprendre le mode

dʼemploi.

3. Risque dʼexplosion.

5. Risque

dʼélectrocution.

2. Risque dʼincendie.

4. Risque pour les

voies respiratoires.

CONSIGNES DE SÉCURITÉ IMPORTANTES

CONSERVER CES DIRECTIVES : Pour réduire les risques dʼincendie ou dʼexplosion, dʼélectrocution et

de blessures, lire et comprendre toutes les directives comprises dans le présent manuel. Se familiariser avec les

commandes et le bon fonctionnement de lʼappareil.

• Ce produit est conçu uniquement pour une utilisation domestique.

AVERTISSEMENT : RISQUE D'INCENDIE OU D'EXPLOSION. Les vapeurs du solvant et

du produit de pulvérisation risquent d'exploser ou de prendre feu. Des blessures graves ou des

dommages matériels risquent de se produire.

Dans le but dʼéviter ces risques, respecter les mesures de prévention suivantes :

• Évacuer lʼair vicié et renouveler lʼapport dʼair frais dans le but de maintenir lʼair de la zone de pulvérisation exempt

de vapeurs inflammables.

• Éviter toutes sources d'inflammation comme les étincelles produites par l'électricité statique, les flammes nues, les

veilleuses, les objets chauds, les produits du tabac allumés et les étincelles provoquées par le branchement ou le

débranchement de cordons d'alimentation ou d'interrupteurs de lampes de travail.

• Toujours avoir un extincteur à portée de main et en bon état de fonctionnement.

• Respecter les précautions et les avertissements des fabricants de la matière et du solvant.

• Ne pas pulvériser de matières inflammables ou combustibles près d'une flamme nue ou de sources d'inflammation

comme les produits du tabac allumés, les moteurs et les appareils électriques.

• Connaître les composants des produits de pulvérisation et des solvants nécessaires à leur nettoyage. Lire toutes les

fiches signalétiques (FS) et les étiquettes de contenant fournies avec le produit de pulvérisation et les solvants.

Respecter les consignes de sécurité des fabricants de produits de pulvérisation et de solvants.

• Ne pas utiliser de matières dont le point d'éclair est supérieur à 60 °C (140 °F). Il sʼagit de la température à laquelle

un liquide peut dégager assez de vapeurs pour prendre feu (consulter le fournisseur dʼapprêt).

AVERTISSEMENT : RISQUE DʼEXPLOSION EN PRÉSENCE DE MATIÈRES INCOMPATIBLES.

Des blessures graves ou des dommages matériels risquent de se produire.

Dans le but dʼéviter ces risques, respecter les mesures de prévention suivantes :

• Ne pas utiliser de javellisant.

• Ne pas utiliser de solvants à base dʼhalon notamment du chlorure de méthylène et du trichloréthane-1.1.1. Ils sont

incompatibles avec lʼaluminium et risquent de provoquer une explosion. En cas de doute sur la compatibilité dʼune

matière avec lʼaluminium, communiquer avec le fournisseur de lʼapprêt.

AVERTISSEMENT : VAPEURS DANGEREUSES. Les produits de pulvérisation, les

solvants et d'autres matières peuvent être nocifs par inhalation ou contact avec le corps. Les vapeurs

peuvent provoquer des nausées graves, des évanouissements ou un empoisonnement.

Dans le but dʼéviter ces risques, respecter les mesures de prévention suivantes :

• Utiliser un respirateur ou un masque sʼil y a risque dʼinhaler des vapeurs. Lire toutes les directives fournies avec le

masque pour sʼassurer quʼil offre la protection nécessaire.

• Porter une protection oculaire.

• Porter les vêtements protecteurs exigés par le fabricant de lʼapprêt.

15

Page 16

AVERTISSEMENT : RISQUE DʼÉLECTROCUTION. Peut entraîner de graves blessures.

Fiche à trois broches

Contact de mise à la terre

Bien mis à la terre

Prise à trois alvéoles

Dans le but dʼéviter ces risques, respecter les mesures de prévention suivantes :

Maintenir la fiche du cordon d'alimentation et la détente du pistolet pulvérisateur exemptes de produit de

•

ulvérisation et d'autres liquides. Ne jamais tenir le cordon par la fiche pour soutenir le cordon. Le non-respect de

p

es directives peut provoquer une décharge électrique.

c

• Ne jamais immerger des composants électriques dans de lʼeau ou tout autre liquide. Pour nettoyer, essuyer la

surface externe du pulvérisateur avec un chiffon humide. Toujours sʼassurer que le pulvérisateur est débranché

avant de le démonter pour le nettoyage.

• Ne pas exposer l'appareil à la pluie ou à à l'humidité.

• Ne pas utiliser le cordon de façon abusive. Ne pas utiliser le cordon pour transporter l'appareil ni tirer dessus pour le

débrancher de la prise de courant. Tenir le cordon éloigné de la chaleur, de lʼhuile, des bords tranchants et des

pièces mobiles. Remplacer immédiatement tout cordon endommagé.

AVERTISSEMENTS DE SÉCURITÉ GÉNÉRAUX

AVERTISSEMENT : GÉNÉRAL. Risque de provoquer des blessures graves ou des dommages matériels.

Dans le but dʼéviter ces risques, respecter les mesures de prévention suivantes :

• Ne pas viser de personnes (y compris vous-même) ou d'animaux avec le pistolet ni ne pulvériser de matière sur eux.

• Ne pas pulvériser à lʼextérieur les jours venteux.

• Porter des vêtements protecteurs pour protéger la peau et les cheveux du produit de pulvérisation.

• Respecter tous les codes locaux, étatiques, provinciaux, territoriaux et nationaux relatifs à la ventilation, à la

prévention des incendies et au fonctionnement.

• Toujours porter des gants, une protection oculaire et un respirateur ou un masque qui conviennent au travail de

pulvérisation, de dilution, de mélange, de versage ou de nettoyage.

• Ne pas utiliser ou pulvériser près dʼenfants. Tenir les enfants à lʼécart de lʼappareil en tout temps. Conserver le

pulvérisateur hors de la portée des enfants.

• Ne pas trop tendre les bras ou se tenir sur une surface instable. Bien conserver son équilibre et une position stable

en tout temps.

• Être vigilant et surveiller le travail effectué.

• Ne pas utiliser lʼappareil en cas de fatigue ou sous lʼemprise dʼalcool ou de drogues.

• Lire toutes les directives et les précautions en matière de sécurité de lʼappareil et de la matière à pulvériser avant de

mettre en marche lʼappareil.

• Le port dʼune protection auditive est recommandé lors dʼutilisation prolongée.

INSTRUCTIONS DE MISE À LA TERRE

Ce produit doit être mis à la terre. En cas de court-circuit électrique, la mise à la terre réduit le risque dʼélectrocution

en fournissant un fil dʼéchappement pour le courant électrique. Ce produit est muni dʼun cordon ayant un fil de mise à

terre avec une prise de mise à la terre adéquate. La fiche doit être branchée sur une prise de courant qui est bien

installée et mise à la terre conformément à tous les codes et à toutes les ordonnances à lʼéchelle locale.

AVERTISSEMENT : RISQUE D’ÉLECTROCUTION. Une mauvaise

A

installation de la fiche de mise à la terre peut entraîner une électrocution. Sʼil faut

réparer ou remplacer le cordon électrique ou la fiche, ne pas relier le fil de mise à

la terre à lʼune des deux branches plates de la fiche. Le fil de mise à la terre est le

conducteur avec isolation qui a une surface extérieure verte avec ou sans rayures

jaunes.

Cet appareil est conçu pour une utilisation avec un circuit nominal de 120 V. Il comporte une

fiche avec mise à la terre semblable à celle illustrée au schéma A. Connecter uniquement lʼappareil dans une prise

ayant la même configuration que la fiche. Ne pas utiliser dʼadaptateur avec ce produit.

Vérifier auprès dʼun électricien ou dʼun réparateur professionnel si les directives de mise à la terre ne sont pas

parfaitement comprises ou en cas de doute sur le fait que le produit est correctement mis à la terre ou non. Ne pas

modifier la fiche fournie; si elle ne sʼinsère pas dans la prise de courant, faire installer une prise appropriée par un

électricien professionnel.

RALLONGES

Utiliser uniquement une rallonge à trois fils qui possède

une fiche de mise à la terre à trois lames et une prise à

trois fentes correspondant à la fiche du produit. Sʼassurer

que la rallonge est en bon état. Lorsquʼune rallonge est

utilisée, sʼassurer dʼutiliser un calibre suffisamment élevé

pour assurer le transport du courant nécessaire au

fonctionnement de lʼappareil. Une rallonge de calibre

inférieur causera une chute de tension de ligne et donc une

perte de puissance et une surchauffe. Si la rallonge est

destinée à lʼusage extérieur, le suffixe W-A doit être inscrit

après la classification de la rallonge. Par exemple, un code

SJTW-A indiquerait un cordon dʼalimentation adéquat pour

un usage extérieur. Pour connaître les cordons de bon

calibre à utiliser, consulter le tableau suivant.

Tension Longueur totale du cordon en pieds

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen des fils (AWG)

moins plus

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

16

Calibre minimal des cordons de rallonge

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

(0-15,2m) (15,2-30,4m)(30,4-60,9m) (60,9-91,4m)

Page 17

AVERTISSEMENT : Certains produits de pulvérisation renferment des produits chimiques reconnus par lʼÉtat

de la Californie pour causer le cancer, des anomalies congénitales ou d'autres dangers pour la reproduction. Pour

réduire l'exposition à ces produits chimiques, porter un équipement de sécurité adéquat, à savoir un masque, des

gants et tout autre équipement protecteur approprié. Passer en revue et suivre les mesures de sécurité figurant sur le

contenant de produit de pulvérisation.

COMPOSANTS

A

6

5

13

12

11

7

4

14

8

3

1

9

10

2

15

1.) Carter du moteur

2.) Indicateur du réglage de

débit

3.) Bouton de dégagement

4.) Filtre

5.) Couvercle du filtre

6.) Détente

17

16

DESCRIPTION FONCTIONNELLE

7.) Bouton de réglage du produit

8.) Joint torique

9.) Tube dʼaspiration

10.) Clapet

11.) Bague dʼextrémité

12.) Buse de pulvérisation

13.) Chapeau dʼair

17

18

14.) Cartouche à remplissage

latéral

15.) Couvercle

16.) Seau de mélange de 2,6 l

(2 3/4 pintes)

17.) Coupe consistométrique

18.) Brosse de nettoyage

Page 18

PRÉPARATION

AVERTISSEMENT : S'assurer

d'utiliser l'équipement de protection approprié

et débrancher l'appareil.

B

AVERTISSEMENT : Sʼassurer que la

zone est bien ventilée et quʼelle est exempte

de vapeurs inflammables.

ALIGNEMENT DU TUBE DʼASPIRATION

(FIGURES B ET B1)

Il est possible dʼaligner le tube dʼaspiration

dans la principale direction de pulvérisation

pour éviter de remplir à tout moment la

cartouche.

• Pour pulvériser vers le haut ou directement

devant vous, positionner le tube dʼaspiration

(figure B) vers lʼarrière de la cartouche.

• Pour pulvériser vers le bas, positionner le

tube dʼaspiration (figure B1) vers lʼavant de la cartouche.

Ce positionnement vous permettra de

pulvériser un maximum de matière avant de

remplir la cartouche.

PRÉPARATION DE LA MATIÈRE LIQUIDE

(FIGURES C, C1 ET C2)

CONSEIL : Sʼassurer que le type de

matière utilisé peut être nettoyé avec de

lʼessence minérale ou du diluant (pour

les peintures à lʼhuile) ou une solution

dʼeau chaude savonneuse (pour les

peintures solubles dans lʼeau comme le

latex). Utiliser des toiles de protection au

moment de verser et de mélanger la

peinture à pulvériser et lors des essais

de viscosité afin de protéger vos

planchers et tout ce qui doit rester intact

dans la zone de pulvérisation.

Il peut être nécessaire de diluer le liquide à

pulvériser avant de commencer. Pour ce

faire, utiliser le bon produit diluant recommandé sur le contenant par le fabricant

de la matière.

C

AVERTISSEMENT : Ne pas utiliser de matières dont le point d'éclair est

supérieur à 60 °C (140 °F).

B1

C1

C2

Utiliser le seau de 2,6 L (2 3/4 pintes) fourni pour transférer la matière à

pulvériser du contenant original au moment de la diluer et de la mesurer

(figure C).

Une coupe consistométrique est fournie pour déterminer la « vitesse de

vidage » de la matière à utiliser.

• Avant de mesurer la bonne viscosité, mélanger bien à fond la matière.

• Enfoncer la coupe consistométrique dans la matière à pulvériser et la remplir

complètement.

• Tenant la coupe au-dessus du contenant du produit, mesurer le temps écoulé

avant que le flux de liquide ne se « brise » ou ne cesse d'être un flux constant qui

sort du fond de la coupe (2 minutes ou moins) (figure C1). C'est ce qu'on appelle

la « vitesse de vidage ». Consulter le tableau de dilution pour en savoir davantage sur la dilution requise pour différentes matières.

• Sʼil faut diluer la matière, utiliser le bon diluant recommandé par le fabricant

(figure C2).

• Il est possible de pulvériser une peinture au latex avec cet appareil. Il se peut toutefois que le taux de dilution

nécessaire surpasse les recommandations du fabricant. Diluer la peinture au latex pour quʼelle coule du fond de la

coupe consistométrique en moins de deux minutes. Lʼopérateur de lʼappareil doit tenir compte du type dʼapplication

et de lʼemplacement final du projet lors de la pulvérisation dʼune matière qui exige plus de deux minutes pour

sʼécouler du fond de la coupe consistométrique.

18

Page 19

TABLEAU DE DILUTION

MATIÈRE À PULVÉRISER VITESSE DE VIDAGE

Teintures et agents de scellement transparents Aucune dilution requise

et semi-transparents

Apprêts, vernis et polyuréthanne à base dʼhuile (Moins de deux minutes dʼécoulement)

Teintures à base dʼeau de couleur unie Peut exiger une dilution

Peintures à base dʼeau ou au latex (Plus de deux minutes dʼécoulement)

Remarque : lʼappareil nʼest pas recommandé

pour la peinture avec texture

CONSEILS DE PRÉPARATION

• Toujours mélanger et filtrer la matière avant de lʼutiliser.

• Toujours bien préparer la surface pour optimiser le fini lors de tout travail de pulvérisation. Autrement dit, toutes les

surfaces doivent être exemptes de poussières, de saletés, de rouille et de graisse. Laver sous pression légère les

terrasses ou les surfaces extérieures et laisser sécher avant de pulvériser.

• Quoique les pulvérisateurs HVLP provoquent très peu dʼéclaboussures, il est recommandé de bien couvrir tous les

coins et autres zones et

dʼutiliser des toiles de protection sur les planchers et tout autre objet de la zone de pulvérisation qui doivent demeurer

intacts.

• La pellicule qui se forme à la surface de la peinture risque dʼobstruer le pulvérisateur. Retirer la pellicule avant de

mélanger. Tamiser avec un entonnoir muni dʼun filtre ou à travers un bas de nylon pour retirer toutes impuretés qui

risquent dʼobstruer le système.

• Avant de commencer, se munir de gants, dʼessuie-tout, de torchons, etc., en cas dʼaccidents.

REMPLISSAGE DE LA CARTOUCHE (FIGURE D)

• Sʼassurer que la cartouche est complètement vissée au pulvérisateur.

• Coucher le pulvérisateur sur le côté avec le couvercle latéral de la

cartouche vers le haut.

• Dévisser le couvercle sur le côté de la cartouche.

• Remplir la cartouche à remplissage latéral avec la matière bien diluée et

filtrée (figure D). CONSEIL : Utiliser le seau à mélanger pour

transférer la matière de son contenant dʼorigine à la

cartouche à remplissage latéral.

• Nettoyer toute trace de liquide du filetage ou des côtés de la cartouche

et du pulvérisateur.

• Commencer par bien engager le couvercle sur le filetage, puis le

visser complètement sur la cartouche à remplissage latéral. Vérifier la

bonne insertion du couvercle avant de prendre le pulvérisateur.

D

FONCTIONNEMENT

RÉGLAGE DU DÉBIT DU PRODUIT

Régler le volume du produit en tournant le

bouton de réglage logé sur la détente du

pulvérisateur.

• Pour obtenir un débit maximal du produit,

tourner le bouton vers lʼintérieur, jusquʼau

bout comme le montre la figure E.

• Pour obtenir un débit minimal du produit,

tourner le bouton vers lʼextérieur, jusquʼau

bout comme le montre la figure E1.

Lʼindicateur de débit, situé sur le côté du

pulvérisateur, avance (débit minimal de liquide) et

recule (débit maximal de liquide) lorsque la détente est enfoncée.

CONSEIL : Toujours vérifier dʼabord la forme de dispersion du jet sur un vieux morceau de carton ou sur tout

autre matériau similaire. Mettre dʼabord le bouton de réglage du produit à la position de débit la plus élevée

(bouton tourné complètement vers lʼintérieur). Si un débit réduit est souhaité, tourner le bouton de réglage du

produit vers lʼextérieur. Pour la pulvérisation des produits lourds et épais, le bouton doit être réglé vers

lʼintérieur. Pour la pulvérisation des produits plus fluides, le bouton doit être réglé vers lʼextérieur.

E

E1

19

Page 20

ÉLECTION DE LA BUSE SMARTSELECT (FIGURE F)

S

l est possible de choisir entre trois formes de jet. Elles sont inscrites comme 1, 2 et 3 sur lʼétiquette Smartselect insérée sur

I

e dessus du pulvérisateur (figure F). Pour sélectionner la première forme de jet, tourner la buse et aligner lʼindicateur vert

l

e la buse avec le numéro 1 sur lʼétiquette (figure F1).

d

REMARQUE : La buse de pulvérisation ne sʼassemble que dans une seule direction. Consulter la figure S pour

connaître le bon mode dʼassemblage.

• Pulvérisation no 1 :

jet horizontal plat.

Application de haut

en bas sur la surface.

• Pulvérisation no 2 :

jet circulaire.

Application dans les

coins et sur les

surfaces et les

rebords étroits.

CONSEIL : La position numéro 2 comporte un cran perceptible lorsque la buse de pulvérisation est tournée. Sʼassurer que la buse est bien dans le cran.

• Pulvérisation no 3 : jet vertical plat. Application en balayage dʼun côté à lʼautre.

F

F1

AVERTISSEMENT : Risque de blessures. Ne jamais pointer le pulvérisateur sur une

partie quelconque du corps. Ne jamais appuyer sur la détente en réglant la pulvérisation.

MISE AU POINT DʼUNE BONNE TECHNIQUE DE PULVÉRISATION

• Pratiquer la pulvérisation sur une matière mise au rebut, comme

un morceau de carton, pour tester le jet et se familiariser avec la

fonction de commande du débit de pulvérisation.

• Sʼassurer que la surface à pulverise est exempte de poussière,

de saleté et de graisse.

• Sʼassurer que la zone de pulvérisation est propre et exempte de

poussières qui pourraient être soufflées sur les surfaces

nouvellement peintes.

• Couvrir toutes les zones à protéger de la pulvérisation.

• Toujours pulvériser à une distance minimum de 25 mm (1 po) et

à une distance maximum de 355 mm (14 po) (figure G).

• Une méthode courante utilisée pour pulvériser une surface

importante consiste à pulvériser en croix. On commence par la

pulvérisation de bandes horizontales, puis on repasse à la

verticale sur ces bandes.

• Pour obtenir une pulvérisation uniforme, toujours maintenir votre

bras à la même distance (figure G) de la surface à

pulvériser.

Éviter de déplacer votre poignet (figure H).

• Maintenir une vitesse constante et régulière pour produire une

couche uniforme. Commencer la pulvérisation après le début du

déplacement et relâcher la détente avant la fin de la pulvérisation

de la bande.

• Éviter de pulvériser une couche épaisse au même endroit.

Plusieurs couches minces sont meilleures quʼune seule couche

épaisse qui peut former des coulisses et des gouttes. Se

rappeler que le bouton de commande de débit règle la quantité

de liquide à pulvériser. Tourner le bouton de débit en sens

horaire augmente le débit. Tourner le bouton en sens antihoraire

réduit le débit de liquide. En cas de coulisses de peinture ou de

formation de gouttes, passer un coup de pinceau sec pour les

lisser.

• Éteindre le bloc dʼalimentation si aucune pulvérisation nʼest

effectuée durant une certaine période de temps.

20

APPLICATIONUNIFORME DE LAMATIÈRE

G

APPLICATION IRRÉGULIÈRE DE LA MATIÈRE

H

PULVÉRISÉE

PULVÉRISÉE

1 à 14 po

(25 à 35 mm)

Page 21

NETTOYAGE

AVERTISSEMENT :

tiliser des toiles de protection au moment de verser et de mélanger la peinture à pulvériser et lors des essais de vis-

U

osité afin de protéger vos planchers et tout ce qui doit rester intact dans la zone de pulvérisation.

c

• Ne pas utiliser de matières dont le point d'éclair est supérieur à 60 °C (140 °F). Il sʼagit de la température à laquelle

un liquide peut dégager assez de vapeurs pour prendre feu (consulter le fournisseur dʼapprêt).

• Sʼassurer que lʼaire de nettoyage est bien ventilée et exempte de vapeurs inflammables.

• Toujours pulvériser à lʼextérieur lors de lʼutilisation dʼune solution de nettoyage dans lʼappareil.

• Ne pas immerger le bloc dʼalimentation.

Pour amorcer le nettoyage :

• Débrancher le cordon de la source

dʼalimentation.

• Dévisser le couvercle sur le côté de la

cartouche et verser tout liquide restant dans le

contenant original (figure I).

• Verser une petite quantité dʼune solution de

nettoyage appropriée dans la cartouche

(figure J).

• Utiliser une eau savonneuse chaude

pour les matières à base dʼeau.

• Pour les matières à base dʼhuile, utiliser

la solution de nettoyage recommandée par

les fabricants.

• Revisser solidement le couvercle sur la

cartouche et secouer vigoureusement le

pulvérisateur.

• Dévisser le couvercle sur le côté de la

cartouche et éliminer adéquatement la solution

de nettoyage.

• Remplir la cartouche avec une petite quantité

de solution de nettoyage fraîche (figure J).

Visser solidement le couvercle sur la

cartouche.

Brancher le cordon dʼalimentation.

• Pulvériser la solution de nettoyage dans le

pulvérisateur sur une matière mise au rebut

pendant 2 à 3 secondes (figure K).

• Débrancher le cordon de la source

dʼalimentation.

• Déposer la cartouche et dévisser le couvercle

latéral. Déposer le clapet, le tube dʼaspiration

et le joint torique du pulvérisateur. Nettoyer les

pièces avec la brosse de nettoyage et la bonne

solution de nettoyage (figure L).

S'assurer d'utiliser l'équipement de protection approprié.

I

K

J

L

• Dévisser la bague de lʼextrémité et déposer la

buse et le chapeau dʼair.

Nettoyer toutes les pièces avec la brosse de

nettoyage et la bonne solution de nettoyage

(figure M).

• Détacher la buse du moteur du pulvérisateur en enfonçant le bouton de dégagement, logé sur le carter du moteur,

comme le montre la

M

21

Page 22

figure N.

• Saisir la buse et la tourner à 90 degrés du

carter, puis la dégager en tirant dessus

(figure O).

• Si une matière à base dʼeau est utilisée,

nettoyer le pulvérisateur en aspirant de lʼeau

courante par le tube dʼaspiration comme lʼillustre la figure P. Dans le cas de matières à base dʼhuile, nettoyer lʼentrée

du tube dʼaspiration avec la solution de nettoyage appropriée. Répéter jusquʼau nettoyage

complet du

pulvérisateur.

• Bien sécher toutes les pièces.

• Éliminer adéquatement la solution de

nettoyage.

N

P

O

• Appliquer une goutte dʼhuile commune sur la

bille métallique du clapet (figure Q).

IMPORTANT : La lubrification de la bille du

clapet après le nettoyage contribuera à

lʼempêcher de coller et dʼobstruer le clapet

permettant ainsi dʼoptimiser le débit de

matière à pulvériser.

REMARQUE : Lors du remontage, placer

lʼextrémité de la bille métallique du clapet dans

le pulvérisateur.

• Assembler de nouveau le pulvérisateur

(figure R).

REMARQUE : Le chapeau dʼair sʼinsère

uniquement dans une direction. Lʼencoche

du chapeau dʼair montré à la figure S doit

sʼaligner avec la fente du

filetage du pulvérisateur.

Q

S

R

• Aligner la buse pour quʼelle soit à 90 degrés

du carter de moteur, puis lʼenfoncer

complètement dans le carter comme le montre

la figure T.

22

Page 23

• Saisir la buse et la tourner vers le bas de

manière à ce que le pointeur de la buse

sʼaligne sur le symbole de verrouillage apposé

sur le carter du moteur (figure U).

Si elles sont bien assemblées, les deux pièces

sʼenclencheront en place.

T

ENTRETIEN ET ENTREPOSAGE

Nʼutiliser quʼun détergent doux et un chiffon humide pour nettoyer le bloc

dʼalimentation. Ne jamais laisser de liquide pénétrer dans le bloc dʼalimentation

et nʼimmerger aucune pièce du bloc dʼalimentation dans un liquide.

IMPORTANT : Pour garantir la SÉCURITÉ et la FIABILITÉ du produit, les

réparations, lʼentretien et le réglage (autre que ceux énumérés dans ce manuel)

doivent être réalisés par un centre de réparation autorisé ou tout autre centre de

réparation professionnel, et des pièces de rechange identiques doivent être

utilisées.

Le pulvérisateur contient un filtre réutilisable et lavable (figure V). Vérifier lʼétat du

filtre avant et après chaque utilisation. Sʼil est sale, le nettoyer à lʼeau chaude et le

laisser sécher à lʼair avant de le réinstaller ou de le remplacer au besoin.

• Pour vérifier le filtre, enlever le couvercle du filtre. Pour ce faire, desserrer les

deux vis, puis retirer le couvercle du pulvérisateur. Déposer le filtre comme lʼillustre

la figure V et lʼinspecter. Remettre le filtre et son couvercle en place. Bien serrer

les vis. Ne jamais utiliser le pulvérisateur si le filtre nʼest pas en place. Des débris

risquent dʼêtre aspirés et de nuire au fonctionnement du pulvérisateur.

Sʼassurer que lʼappareil est propre et sec avant de le ranger. Conserver

lʼappareil à lʼintérieur au sec. Pour prévenir tout dommage, bien enrouler le

cordon dʼalimentation pour éviter de le plier en cours dʼentreposage.

U

V

ACCESSOIRES

Les accessoires recommandés pouvant être utilisés avec lʼoutil sont disponibles auprès de votre distributeur local ou

centre de réparation autorisé. Pour tout renseignement concernant les accessoires, composer le : 1 800 544-6986.

AVERTISSEMENT : lʼutilisation de tout accessoire non recommandé avec cet outil pourrait sʼavérer dangereuse.

INFORMATION SUR LES RÉPARATIONS

Tous les centres de réparation Black & Decker sont dotés de personnel qualifié en matière dʼoutillage électrique; ils

sont donc en mesure dʼoffrir à leur clientèle un service efficace et fiable. Que ce soit pour un avis technique, une

réparation ou des pièces de rechange authentiques installées en usine, communiquer avec lʼétablissement Black &

Decker le plus près de chez vous. Pour trouver lʼétablissement de réparation de votre région, consulter le répertoire

des Pages jaunes à la rubrique « Outils électriques » ou composer le numéro suivant : 1 800 544-6986 ou consulter

le site www.blackanddecker.com

AVERTISSEMENT : Toute réparation ne doit être effectuée que par des réparateurs professionnels.

AVERTISSEMENT : Pour réparer un outil, nʼutiliser que des pièces de rechange identiques.

GARANTIE

Garantie complète de deux ans pour une utilisation domestique

Black & Decker (É.-U.) Inc. garantit ce produit pour une durée de deux ans contre tout défaut de matériau ou de

fabrication. Le produit défectueux sera remplacé ou réparé sans frais de lʼune des deux façons suivantes :

La première façon consiste en un simple échange chez le détaillant qui lʼa vendu (pourvu quʼil sʼagisse dʼun détaillant

participant). Tout retour doit se faire durant la période correspondant à la politique dʼéchange du détaillant

(habituellement, de 30 à 90 jours après lʼachat). Une preuve dʼachat peut être requise. Vérifier auprès du détaillant

pour connaître sa politique concernant les retours hors de la période définie pour les échanges.

23

Page 24

La deuxième option est dʼapporter ou dʼenvoyer le produit (transport payé dʼavance) à un centre de réparation autorisé

ou à un centre de réparation de Black & Decker pour faire réparer ou échanger le produit, à notre discrétion. Une

preuve dʼachat peut être requise. Les centres Black & Decker et les centres de service autorisés sont répertoriés dans

les pages jaunes, sous la rubrique « Outils électriques ».

Cette garantie ne sʼapplique pas aux accessoires. Cette garantie vous accorde des droits légaux spécifiques et vous

pourriez avoir dʼautres droits qui varient dʼun État ou dʼune province à lʼautre. Pour toute question, communiquer avec

le directeur du centre de réparation Black & Decker le plus près de chez vous. Ce produit nʼest pas destiné à un usage

commercial.

REMPLACEMENT GRATUIT DES ÉTIQUETTES DʼAVERTISSEMENT : si les étiquettes dʼavertissement deviennent

illisibles ou sont manquantes, composer le 1 800 544-6986 pour en obtenir le remplacement gratuit.pages of the phone

directory.

DÉPANNAGE

Problème Cause possible Solution possible

• La matière coule ou dégoutte. • La couche pulvérisée est trop épaisse. • Réduire le débit dʼair en tournant le

• La pulvérisation est trop lente. • Augmenter la vitesse dʼapplication.

• La pulvérisation est trop près de la • Augmenter la distance de la surface.

surface.

• La matière est trop liquide. • Vérifier les recommandations en

• Éclaboussure excessive. • Pulvérisateur trop éloigné de la surface.• Réduire la distance de la surface.

• Pulvérisation excessive de matière. • Réduire le débit dʼair en tournant le

• Trop peu de matière pulvérisée ou • La bille métallique du clapet est collée. • Déposer le clapet. Enfoncer la bille pour

aucune matière pulvérisée. la dégager.Lubrifier. Consulter la

• Buse de pulvérisation/chapeau dʼair • Nettoyer les buses.

obstrué.

• Tube dʼaspiration lâche ou obstrué. • Vérifier le tube.

• Bouton de réglage du produit à une • Mettre à une position plus élevée.

position trop basse.

• Entrée dʼair obstruée. • Nettoyer ou remplacer le filtre à air.

• Matière trop épaisse. • Vérifier les recommandationsen

• La matière pulvérisée éclabousse. • La viscositéde la matière est trop • Diluer la matière selon les

élevée. recommandations du fabricant.

• Le pulvérisateur vibre. • Le filtre à air est obstrué. • Nettoyer ou remplacer le filtre.

• La cartouche est presque vide. • Remplir la cartouche.

• Du liquide sʼéchappe sur le côté • Le couvercle est mal inséré ou pas • Déposer le couvercle et le

de la cartouche. assez serré. réinsérer bien droit, puis le visser

• Traces de peinture sur le filetage de • Nettoyer le dessus et les côtés

la cartouche et le couvercle. de la cartouche et du couvercle.

bouton de réglage du produit.

matière de dilution.

bouton de réglage du produit.

figure Q.

matière de viscosité.

solidement.

Pour de lʼaide avec lʼoutil, consulter notre site Web www.blackanddecker.com pour lʼemplacement du centre de

réparation le plus près ou communiquer avec lʼassistance BLACK & DECKER au 1 800 544-6986.

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

24

Page 25

M

T

PULVERIZADOR SMARTSELECT

DE ALTO

VOLUMEN Y BAJA PRESIÓN (HVLP)

MANUAL DE INSTRUCCIONES

Catálogo N°

BDPH200

Gracias por elegir Black & Decker!

Visite www.BlackandDecker.com/NewOwner

para registrar su nuevo producto.

LEA EL MANUAL ANTES DE DEVOLVER

ESTE PRODUCTO POR CUALQUIER MOTIVO:

Si tiene una consulta o algún inconveniente con su producto Black & Decker, visite

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

para obtener respuestas instantáneas las 24 horas del día.

Si no encuentra la respuesta o no tiene acceso a Internet, llame al 1-800-544-6986 de

lunes a viernes de 8 a. m. a 5 p. m. hora del Este para hablar con un agente.

Cuando llame, tenga a mano el número de catálogo.

CONSERVE ESTE MANUAL PARA FUTURAS CONSULTAS.

25

Page 26

ÍNDICE

Normas de seguridad: Definiciones ..............................................................27

Instrucciones de seguridad importantes .......................................................27

Advertencias de seguridad general ...............................................................28

Instrucciones de conexión a tierra ................................................................28

Cables prolongadores ...................................................................................28

Componentes ................................................................................................29

Instalación .....................................................................................................30

Alineación del tubo de recogida ..................................................................30

Preparación del material ............................................................................30

Tabla de dilución .........................................................................................31

Consejos de preparación ...........................................................................31

Llenado del depósito ..................................................................................31

Funcionamiento .............................................................................................31

Ajuste de flujo del material ..........................................................................31

Boquilla SmartSelect ..................................................................................32

Técnica de pulverización ...............................................................................32

Limpieza ........................................................................................................33

Mantenimiento/Almacenamiento....................................................................35

Accesorios......................................................................................................35

Información de mantenimiento.......................................................................35

Garantía ........................................................................................................36

Detección de problemas ................................................................................36

26

Page 27

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La información que contiene se relaciona con la protección de SU

EGURIDAD y la PREVENCIÓN DE PROBLEMAS. Los símbolos que siguen se utilizan para ayudarlo a reconocer

S

esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita, provocará la muerte o lesiones graves.

PRECAUCIÓN: indica una situación de peligro potencial que, si no se evita, provocará lesiones leves o moderadas.

AVISO: u

provocar daños en la propiedad.

Las siguientes son explicaciones de importantes gráficos de los peligros para la seguridad contenidos en

este manual.

tilizado sin el símbolo de alerta de seguridad indica una situación de peligro potencial que, si no se evita, puede

1. Lea y comprenda el manual de

instrucciones.

3. Peligro de explosión.

5. Peligro de

descarga

eléctrica.

2. Peligro de incendio.

4. Peligro para las

vías respiratorias.

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

CONSERVE ESTAS INSTRUCCIONES: Para reducir los peligros de incendio o explosión, descarga

eléctrica y lesiones a personas, lea y comprenda todas las instrucciones incluidas en este manual. Familiarícese con

los controles y con el uso adecuado del equipo.

• Este producto está diseñado únicamente para uso doméstico.

ADVERTENCIA: PELIGRO DE INCENDIO O EXPLOSIÓN. Los vapores de los

solventes y los materiales pulverizados pueden explotar o encenderse. Esto puede provocar

lesiones graves o daños a la propiedad.

Para evitar estos peligros, tome las precauciones siguientes:

• Se deberá evacuar el aire e introducir aire fresco para mantener el aire en el área de pulverización libre de la

acumulación de vapores inflamables.

• Evite todas las fuentes de ignición como las chispas de la electricidad estática, las llamas expuestas, las llamas

piloto, los objetos calientes, los productos de tabaco encendidos y las chispas producidas por la conexión y

desconexión de cables de alimentación o interruptores de luz de trabajo.

• Deberá haber presentes equipos de extinción de incendios y estos deben estar en buenas condiciones.

• Respete las precauciones y advertencias de seguridad del fabricante de los materiales y los solventes.

• No pulverice materiales inflamables o combustibles cerca de una llama expuesta o de fuentes de ignición como

productos de tabaco encendidos, motores y equipos eléctricos.

• Infórmese del contenido de los materiales pulverizados y de sus solventes de limpieza. Lea todas las hojas de datos

de seguridad del material (HDSM) y las etiquetas de los envases que vienen con el material pulverizado y los

solventes. Siga las instrucciones de seguridad del fabricante para los materiales pulverizados y los solventes.

• No utilice materiales con un punto de ignición inferior a 60 °C (140 °F). El punto de ignición es la temperatura a la

que un líquido puede producir suficientes vapores para arder (consulte el proveedor del revestimiento).

ADVERTENCIA: PELIGRO DE EXPLOSIÓN DEBIDO A MATERIALES INCOMPATIBLES. Esto

puede provocar lesiones graves o daños a la propiedad.

Para evitar estos peligros, tome las precauciones siguientes:

• No utilice lejía.

• No utilice solventes de hidrocarburo halogenado como el cloruro de metileno y el 1,1,1-tricloroetano. Estos no son

compatibles con el aluminio y pueden provocar una explosión. Si no está seguro de la compatibilidad de un material

con el aluminio, comuníquese con el proveedor del revestimiento.

ADVERTENCIA: VAPORES PELIGROSOS. Los materiales pulverizados, los solventes, los

insecticidas y otros materiales pueden ser perjudiciales si se inhalan o entran en contacto con el cuerpo.

Los vapores pueden provocar graves náuseas, desmayos o envenenamiento.

Para evitar estos peligros, tome las precauciones siguientes:

• Utilice un respirador o máscara si se pueden inhalar los vapores. Lea todas las instrucciones que vienen con la

máscara para asegurarse de que proporcionará la protección necesaria.

• Use anteojos de protección.

• Use ropa de protección según lo requiera el fabricante del revestimiento.

ADVERTENCIA: PELIGRO DE DESCARGA ELÉCTRICA. Puede provocar lesiones graves.

27

Page 28

Para evitar estos peligros, tome las precauciones siguientes:

Enchufe de tres patas

Pata de conexión a tierra

Correctamente conectado a tierra

Receptáculo para tres patas

• Mantenga el enchufe del cable eléctrico y el gatillo de la pistola pulverizadora libres de materiales pulverizados y de

otros líquidos. Nunca sostenga el cable por las conexiones del enchufe para sujetar el mismo. El incumplimiento de

esta instrucción puede provocar una descarga eléctrica.

• Nunca sumerja las piezas eléctricas en agua ni en ningún otro líquido. Pase un paño húmedo por el exterior del

pulverizador para limpiarlo. Siempre asegúrese de que el pulverizador esté desenchufado antes de desarmarlo para

limpiarlo.

• No exponga la unidad a la lluvia ni a condiciones de humedad.

• No maltratealcable. Nunca use elcablepara transportarla unidad ni para sacar elenchufedel tomacorriente. Mantenga el

cable alejado del calor, el aceite, los bordes filosos o las piezas móviles. Reemplace los cables dañadosinmediatamente.

ADVERTENCIAS DE SEGURIDAD GENERAL

ADVERTENCIA:

GENERAL. Puede provocar lesiones graves o daños a la propiedad.

Para evitar estos peligros, tome las precauciones siguientes:

• No apunte la pistola ni pulverice con ella a ninguna persona, incluido usted mismo, ni a un animal.

• No pulverice al aire libre en días ventosos.

• Use ropa de protección para mantener el material pulverizado lejos de la piel y el cabello.

• Respete todos los códigos locales, estatales y nacionales correspondientes que rigen la ventilación, la prevención de

incendios y el funcionamiento.

• Siempre use guantes, protección para los ojos y un respirador o máscara adecuados al pulverizar, diluir, mezclar,

verter o limpiar.