Page 1

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

Pressure Washer

Catalog Number BDP2600

Th a n k y o u f o r c h o o s i n g Bl a c k & De c k e r !

g

o T o w w w .Bl a c k a n D De c k e r .c o m /ne w ow n e r

T o r e g i s T e r y o u r n e w p r o D u c T .

Cat No. BDP2600 Part No. N051884 Rev. 1

Copyright © 2010 Black & Decker

SAVE THIS INSTRUCTION MANUAL FOR FUTURE REFERENCE.

Page 2

2- ENG

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols below. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided,

may result in property damage.

CONSUMER SAFETY INFORMATION

WARNING: This product may not be equipped with a spark arresting

muffler. If the product is not equipped and will be used around flam ma ble

ma teri als, or on land covered with materials such as agricultural crops, forest,

brush, grass, or other similar items, then an ap proved spark arrester must

be installed and is legally required in the state of California. It is a violation

of California statutes section 130050 and/or sec tions 4442 and 4443 of the

California Public Re sourc es Code, unless the engine is equipped with a spark

arrester, as defined in section 4442, and maintained in ef fec tive work ing order.

Spark arresters are also required on some U.S. For est Service land and may

also be legally required under other statutes and or di nanc es.

WARNING: This product contains chemicals known to the State of

California to cause cancer, and birth defects or other reproductive harm. Wash

hands after handling.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Do not operate this unit until you have read and understand this

Operators Manual and the Engine Owners Manual for Safety, Operation, and

Maintenance Instructions.

read and save these instructions

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilled gas o line and it’s vapors

can be come ignited from cigarette

sparks, electrical arcing, exhaust

gases and hot engine components

such as the muffler.

• Shut off en gine and allow it to cool

before adding fuel to the tank.

• Use care in fill ing tank to avoid

spilling fuel. Move pressure washer

away from fueling area before

starting en gine.

Page 3

3 - ENG

• Heat will ex pand fuel in the tank

which could result in spillage and

pos si ble fire explosion.

• Fill tank to 1/2 inch (12.7 mm) below

bottom of filler neck to provide space

for fuel expansion.

• Operating the pressure washer in

an ex plo sive en viron ment could

re sult in a fire.

• Operate and fuel equipment in

well-ven ti lat ed areas free from

ob struc tions. Equip areas with fire

extinguisher suit able for gas o line

fires.

• Materials placed against or near

the pressure washer can in ter fere

with its proper ventilation fea tures

caus ing overheating and possible

ig ni tion of the materials.

• Never op er ate pressure wash er in

an area containing dry brush or

weeds.

• Muffler exhaust heat can damage

paint ed sur fac es, melt any material

sen si tive to heat (such as siding,

plas tic, rub ber, vinyl or the pressure

hose, itself), and dam age live

plants.

• Always keep pressure washer a min

i mum of 4 feet (1.2 m) away from

sur fac es (such as houses, au to mobiles or live plants) that could be

damaged from muffler exhaust heat.

• Improperly stored fuel could lead

to acciden tal ignition. Fuel im proper ly secured could get into the

hands of children or oth er un qual

i fied persons.

• Store fuel in an OSHAap proved

contain er, in a se cure location away

from work area.

• Use of acids, toxic or cor ro sive

chemicals, poisons, in sec ti cides, or

any kind of flam ma ble solvent with

this product could re sult in se ri ous

injury or death.

• Do not spray flammable liquids

DANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Breathing ex haust fumes will cause

se ri ous injury or death! En gine

exhaust con tains carbon mon oxide, an odorless and deadly gas.

• Operate pressure washer in a well

ventilated area. Avoid en closed

areas such as ga rag es, base ments,

etc.

• Never op er ate unit in a lo ca tion

occupied by humans or animals.

• Some clean ing fluids con tain sub

stanc es which could cause injury to

skin, eyes or lungs.

• Use only clean ing fluids spe cif i cal

ly rec om mend ed for high-pressure

washers. Fol low manufacturers

recommendations. Do not use

chlorine bleach or any other

corrosive compound.

Page 4

4- ENG

DANGER: RISK OF FLUID INJECTION AND LACERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your pressure washer operates at

fluid pressures and velocities high

enough to penetrate human and

animal flesh, which could result in

amputation or other serious injury.

Leaks caused by loose fittings or

worn or damaged hoses can result

in injection injuries. DO NOT TREAT

FLUID INJECTION AS A SIMPLE

CUT! See a physician immediately!

• Inspect the highpressure hose

regularly. Replace the hose

immediately if it is damaged, worn,

has melted from contacting the

engine, or shows any signs of cracks,

bubbles, pinholes, or other leakage.

Never grasp a high-pressure hose

that is leaking or damaged.

• Never touch, grasp or attempt to

cover a pinhole or similar water

leak on the high-pressure hose.

The stream of water IS under high

pressure and WILL penetrate skin.

• Never place hands in front of

nozzle.

• Direct spray away from self and

others.

• Make sure hose and fit tings are

tightened and in good condition.

Never hold onto the hose or fittings

during op er a tion.

• Do not allow hose to contact

muffler.

• Never attach or remove wand

or hose fittings while sys tem is

pressurized.

• Injuries can result if system pressure

is not reduced before attempting

maintenance or disassembly.

• To relieve sys tem pres sure, shut off

engine, turn off water sup ply and

pull gun trigger until water stops

flowing.

• Use only hoses and accessories

rated for pressure higher than your

pressure washer's psi.

DANGER: RISK OF INJURY FROM SPRAY

WHAT CAN HAPPEN HOW TO PREVENT IT

• Highvelocity fluid spray can cause

objects to break, propelling particles

at high speed.

• Light or unsecured objects can

become hazardous projectiles.

• Always wear ANSIapproved Z87.1

safety glasses. Wear protective

clothing to protect against accidental

spraying.

• Never point wand at or spray people

or animals.

• Always secure trigger lock when

wand is not in service to prevent

accidental operation.

• Never permanently secure trigger in

pull-back (open) position.

Page 5

5 - ENG

DANGER: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe op er a tion of your pressure

wash er could lead to se ri ous in ju ry

or death to you or others.

• Do not use chlorine bleach or any

other corrosive compound.

• Be come fa mil iar with the op er a

tion and con trols of the pressure

washer.

• Keep operating area clear of all

persons, pets and obstacles.

• Do not operate the product when

fatigued or under the influence of

alcohol or drugs. Stay alert at all

times.

• Never defeat the safety fea tures of

this prod uct.

• Do not op er ate machine with

missing, broken or un au tho rized

parts.

• Never leave wand unattended while

unit is running.

• If proper starting procedure is not

followed, engine can kickback

causing serious hand and arm

injury.

• If engine does not start after two

pulls, squeeze trigger of gun to

relieve pump pressure. Pull starter

cord slowly until resistance is felt.

Then pull cord rapidly to avoid

kickback and prevent hand or arm

injury.

• The spray gun/wand is a powerful

clean ing tool that could look like a

toy to a child.

• Keep chil dren away from the

pressure washer at all times.

• Reactive force of spray will cause

gun/wand to kickback, and could

cause the op er a tor to slip or fall

or misdirect the spray. Im prop er

control of gun/wand can re sult in

in ju ries to self and others.

• Do not over reach or stand on an

unstable support.

• Do not use pressure washer while

standing on a ladder.

• Grip gun/wand firmly with both

hands. Expect the gun to kickback

when triggered.

Page 6

6- ENG

DANGER: RISK OF INJURY OR PROP ER TY DAMAGE WHEN

TRANSPORTING OR STORING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Fuel or oil can leak or spill and could

result in fire or breathing hazard.

Se ri ous in ju ry or death can re sult.

Fuel or oil leaks will dam age carpet,

paint or oth er surfaces in ve hi cles or

trailers.

• If pressure washer is equipped with

a fuel shut-off valve, turn the valve to

the OFF position before transporting

to avoid fuel leaks. If pres sure wash-

er is not equipped with a fuel shut

off valve, drain the fuel from tank

before trans port ing. Only trans port

fuel in an OSHAapproved container.

Al ways place pressure washer on a

protective mat when transporting to

protect against dam age to vehicle

from leaks. Re move pres sure washer

from vehicle immediately upon arrival

at your destination.

WARNING: RISK OF BURSTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Over inflation of tires could result

in serious injury and property

damage.

• Use a tire pressure gauge to check

the tires pressure before each use

and while inflating tires; see the tire

sidewall for the correct tire pressure.

NOTE: Air tanks, compressors and

similar equipment used to inflate tires

can fill small tires similar to these very

rapidly. Adjust pressure regulator on

air supply to no more than the rating

of the tire pressure. Add air in small

increments and frequently use the

tire gauge to prevent over inflation.

• Highvelocity fluid spray directed at

pneumatic tire sidewalls (such as

found on automobiles, trailers and

the like) could damage the sidewall

resulting in serious injury.

• On pressure washers rated above

1600 PSI (110 Bar) use the widest fan spray (40º nozzle) and keep

the spray a minimum of 8" (20 cm)

from the pneumatic tire sidewall. Do

not aim spray directly at the joint

between the tire and rim.

WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Con tact with hot sur fac es, such

as engines exhaust com po nents,

could result in se ri ous burn.

• During op er a tion, touch only the

control surfaces of the pres sure

washer. Keep children away from

the pres sure washer at all times.

They may not be able to recognize

the haz ards of this product.

Page 7

7 - ENG

WARNING: RISK OF CHEMICAL BURN

WHAT CAN HAPPEN HOW TO PREVENT IT

• Use of acids, toxic or cor ro sive

chemicals, poisons, in sec ti cides, or

any kind of flam ma ble solvent with

this product could re sult in se ri ous

injury or death.

• Do not use ac ids, gasoline, ker

o sene, or any other flammable

materials in this product. Use only

household de ter gents, cleaners and

degreasers recommended for use in

pres sure washers.

• Wear pro tec tive clothing to protect

eyes and skin from con tact with

sprayed materials.

WARNING: RISK OF ELEC TRI CAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spray di rect ed at elec tri cal outlets or

switch es, or ob jects con nect ed to

an elec tri cal circuit, could re sult in

a fatal electrical shock.

• Unplug any elec tri cal ly op er at ed

product before attempting to clean

it. Direct spray away from electric

out lets and switches.

WARNING: RISK OF

INJURY FROM LIFTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result from

attempting to lift too heavy an

object.

• The pressure washer is too heavy

to be lifted by one person. Obtain

assistance from others before

lifting.

read and save these instructions

NOTE: Photographs and line drawings used in this manual are for reference only

and do not represent a specific model.

Page 8

8- ENG

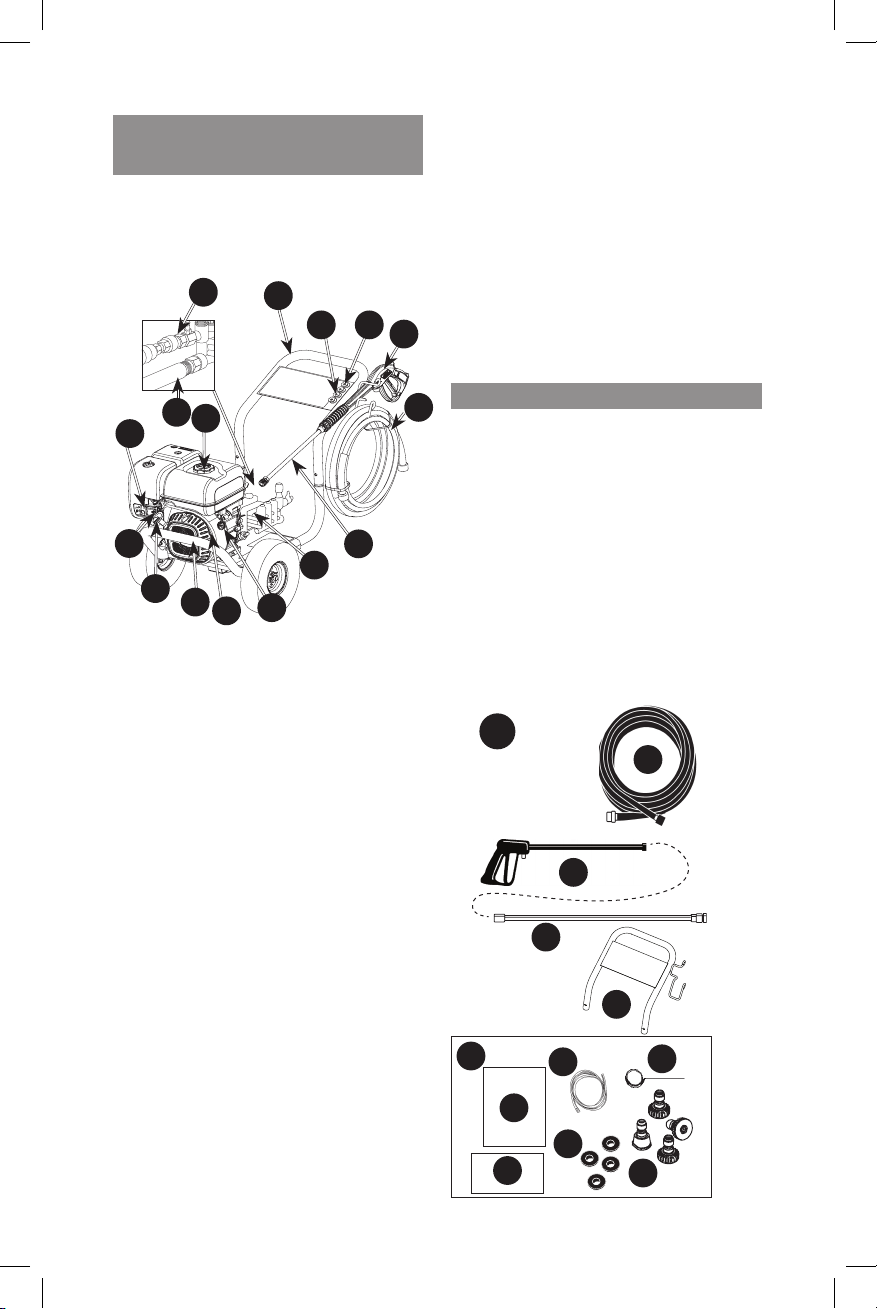

GET TO KNOW THE

PRESSURE WASER

Compare the illustrations with your unit

to familiarize yourself with the location

of various controls and adjustments.

Save this manual for future reference.

D

O

N

H

I

J

C

A

Q

L

K

B

G

E

F

M

A. Quick Connect Nozzles

B. Nozzle Holder

C. Handle

D. High Pressure Hose: Carries the

pressurized water from the pump

to the gun and spray wand.

E. Pump Outlet

F. Pump Inlet

G. High Pressure Pump: Increases

the pressure of the water supply.

H. Engine ON/OFF Switch: Enables

and disables ignition system.

I. Engine: Drives the high pressure

pump. Refer to the engine manual

for location and operation of engine

controls.

J. Frame

K. Starter Grip: Pulling starter grip

operates recoil starter to crank

engine

L. Choke Control: Opens and closes

carburetor choke valve.

M. Fuel Valve Lever: Opens/closes

connection between fuel tank and

carburetor.

N. QuickConnect Spray Wand:

Allows the user to quickly change

out high-pressure nozzles. Refer to

Spray Wand Nozzles.

O. Spray Gun: Connects with spray

wand to control water flow rate,

direction, and pressure.

P. Chemical Hose (not shown): Feeds

cleaning agents into the pump to

mix with the water. See How To

Apply Chemicals/Cleaning Solvents

instructions in this section.

Q. Gas fill

CARTON CONTENTS

A. Quick Connect Nozzles

B. Nozzle Holder

C. Handle

D. High Pressure Hose

I/J. Engine Frame and Wheel

Assembly

N. Quick Connect Spray Wand

O. Spray Gun

P. Chemical Hose

R. Operation Manual

S. Engine Manual

T. Nozzle Cleaning Tool

U. Bagged Parts

I/J

D

O

N

C

R

U

S

P

T

B

A

Page 9

9 - ENG

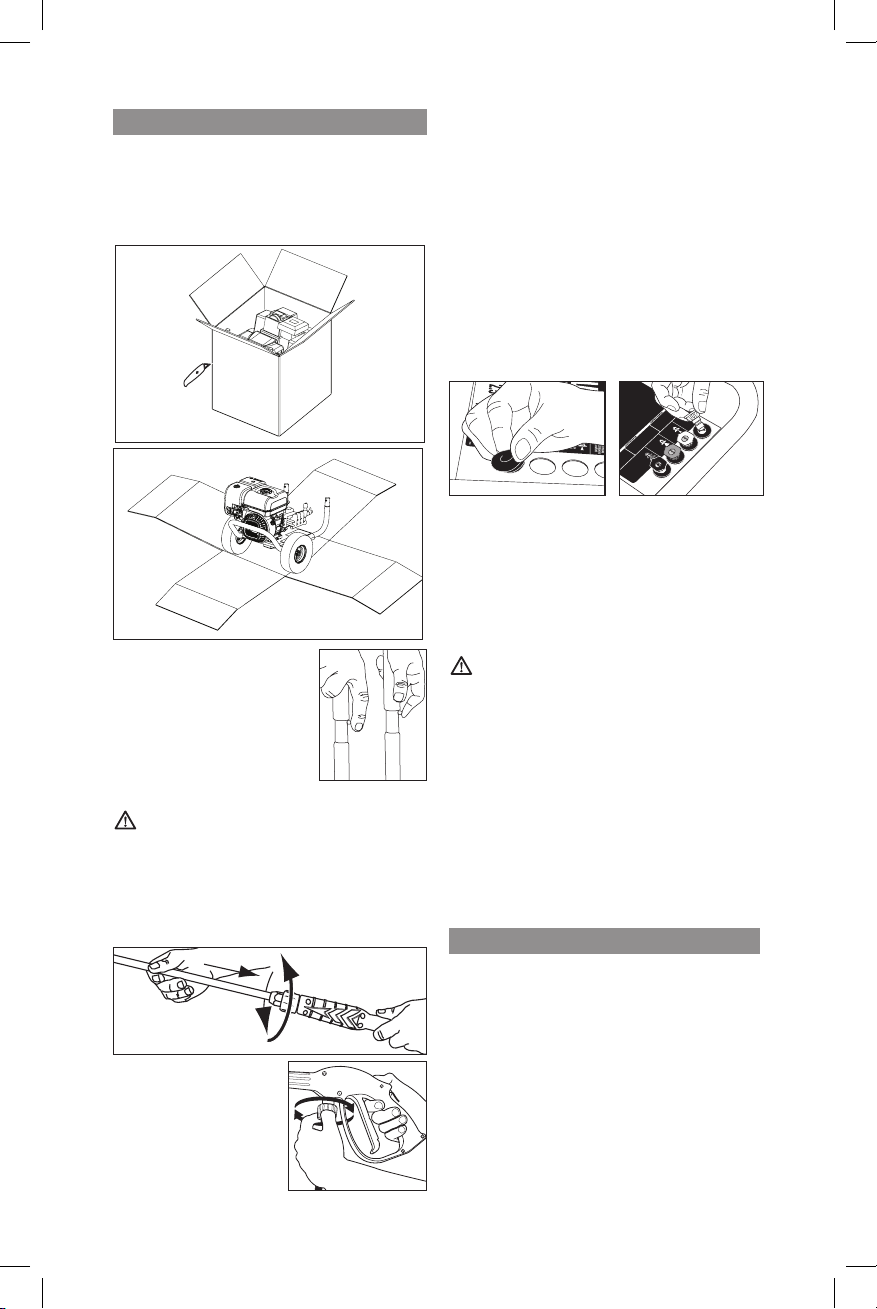

ASSEMBLY INSTRUCTIONS

1. Locate and remove all loose parts

from the carton.

2. Cut four corners of the carton

from top to bottom and lay the

panels flat.

3. Place handle (C)

onto frame (J),

depress the snap

buttons, and slide

the handle assembly

onto the frame until

snap buttons snap

into place.

CAUTION: Risk of personal injury.

Avoid placing hands between handle

and frame when assembling to prevent pinching.

4. Connect wand (N) to gun (O).

Tighten securely.

5. Attach high

pressure hose

(D) to gun (O).

T i g h t e n

se curely.

6. To Assemble Quick Connect

Grommets:

a. Squeeze grommet and place

into hole, fitting groove to rim.

b. Push grommet into place.

c. Repeat steps until all grommets

are assembled.

7. Remove four colored quick connect

nozzles (A) from plastic bag and

insert them into correct grommet on

the nozzle holder. NOTE: Nozzles

are color coded to match colored

nozzles on panel.

NOTE: The high pressure pump was

filled with oil at the factory. There is

no need to add oil at this time, see the

Maintenance section of this manual

for Maintenance information.

8. Roll the unit off the carton and

discard carton.

WARNING: Risk of bursting. Use a

tire pressure gauge to check the tires

pressure before each use and while

inflating tires; see the tire sidewall for

the correct tire pressure.

NOTE: Air tanks, compressors and

similar equipment used to inflate tires

can fill small tires similar to these very

rapidly. Adjust pressure regulator on

air supply to no more than the rating of

the tire pressure. Add air in small incre-

ments and frequently use the tire gauge

to prevent over inflation.

OPERATING INSTRUCTIONS

PRESSURE WASHER

TERMINOLOGY

PSI: Pounds per Square Inch. The unit of

measure for water pressure. Also used

for air pressure, hydraulic pressure, etc.

GPM: Gallons Per Minute. The unit of

measure for the flow rate of water.

CU: Cleaning Units. GPM multiplied by

PSI. GPM x PSI = CU

Page 10

10- ENG

Bypass Mode: Allows water to

re-circulate within pump when the gun

trigger is not pulled.

NOTICE: Allowing the unit to run for

more than two minutes without the

gun trigger pulled could cause overheating and damage to the pump.

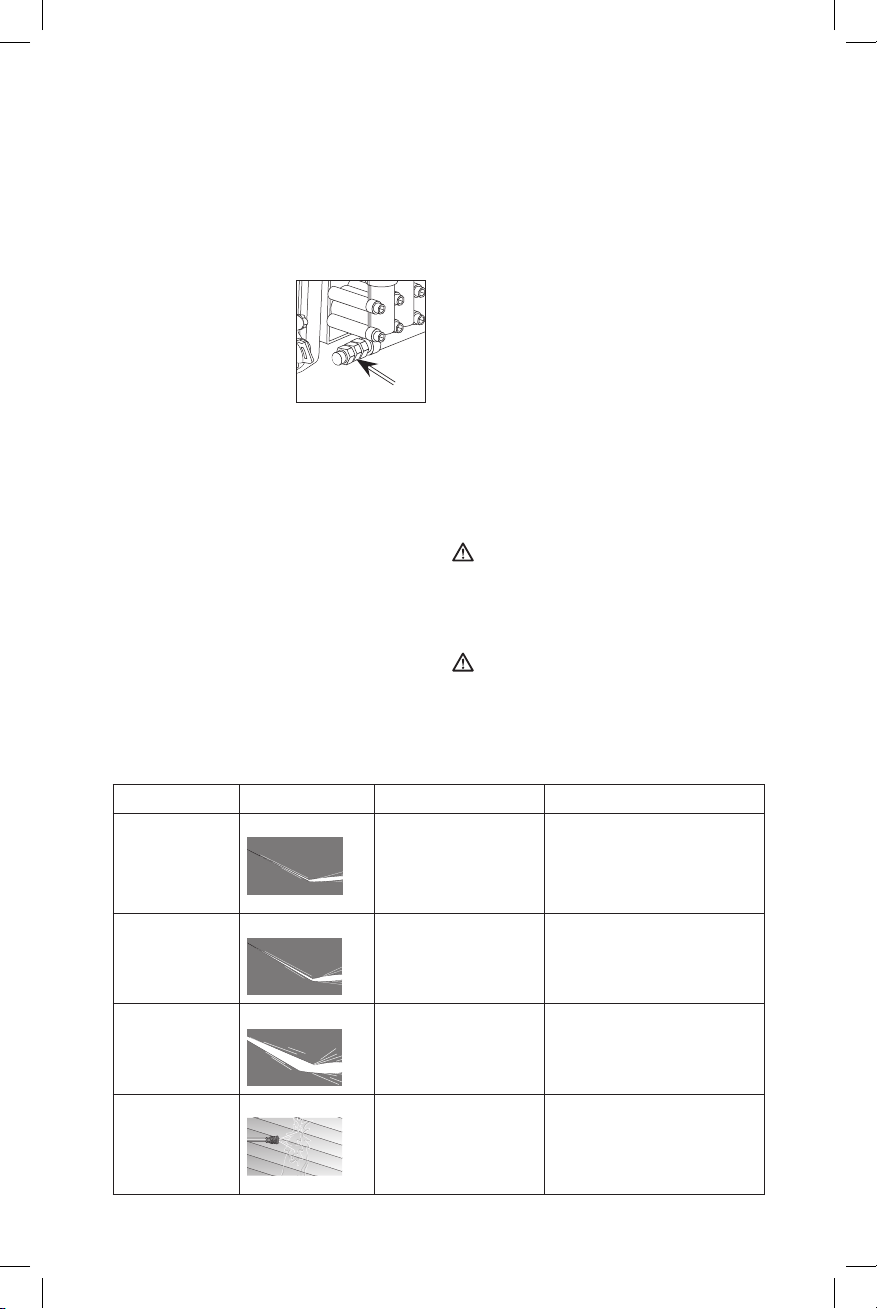

Thermal Relief Valve:

When the temperature

inside the pump rises

too high the valve will

open and release a

gush of water in an

effort to lower the temperature inside the pump. The valve will

then close.

Chemical Injection System: Mixes

cleaners or cleaning solvents with the

water to improve cleaning effectiveness.

Water Supply: All pressure washers must

have a source of water. The minimum

requirements for a water supply are 20 psi

and 5 gallons per minute.

PRESSURE WASHER

OPERATING FEATURES

Pressure Adjustments

The pressure setting is preset at the factory to achieve op ti mum pres sure and

cleaning. If you need to lower the pressure, it can be accomplished by these

meth ods.

1. Back away from the sur face to be

cleaned. The further away you are,

the less the pressure will be on the

surface to be cleaned.

2. Change to the 40º nozzle - (white)

this nozzle delivers a less powerful

stream of water and a wider spray

pattern.

NOTICE: DO NOT attempt to increase

pump pressure. A higher pressure

setting than the factory set pressure

may damage pump.

Spray Wand Nozzles

The nozzles for the spray wand are

stored in the nozzle holder on the panel

assembly. Colors on the panel identify

nozzle location and spray pattern. Refer

to the following chart to choose the correct nozzle for the job to be performed.

Changing Nozzles on Spray Wand

DANGER: Risk of fluid injection. Do not direct discharge stream

toward persons, unprotected skin,

eyes or any pets or animals. Serious

injury will occur.

WARNING: Flying objects could

cause risk of serious injury. Do not

attempt to change nozzles while

pressure washer is running. Turn

engine off before changing nozzles.

Nozzle Color Spray Pattern Uses Surfaces*

Red

0˚ powerful pinpoint

for spot cleaning

of hard, unpainted

surfaces or for high

reach areas

unpainted metal or

concrete;

DO NOT use on wood

Yellow

15˚

intense cleaning

of unpainted hard

surfaces

grills, driveways, concrete

or brick walkways,

unpainted brick or stucco

White

40

˚

cleaning of painted

or delicate surfaces

Auto/RV, marine, wood,

painted brick and stucco,

vinyl, painted siding

Black

low pressure

applies cleaning

solutions

Low pressure spray is safe

on all surfaces. Always

verify compatibility of

cleaning solution prior to

use.

Page 11

11 - ENG

1. Pull quick

connect coupler back and

insert nozzle.

2. Release quick

connect coupler and twist

nozzle to make sure it is secure in

coupler.

WARNING: Flying object could

cause risk of serious injury. Ensure

nozzle is completely inserted in quickconnect socket and quick-connect

snap ring is fully engaged (forward)

before squeezing gun trigger.

How to Apply Chemicals/cleaning

Solvents

Applying chemicals or cleaning solvents

is a low pressure operation. NOTE: Use

only soaps and chemicals designed

for pressure washer use. Do not use

bleach.

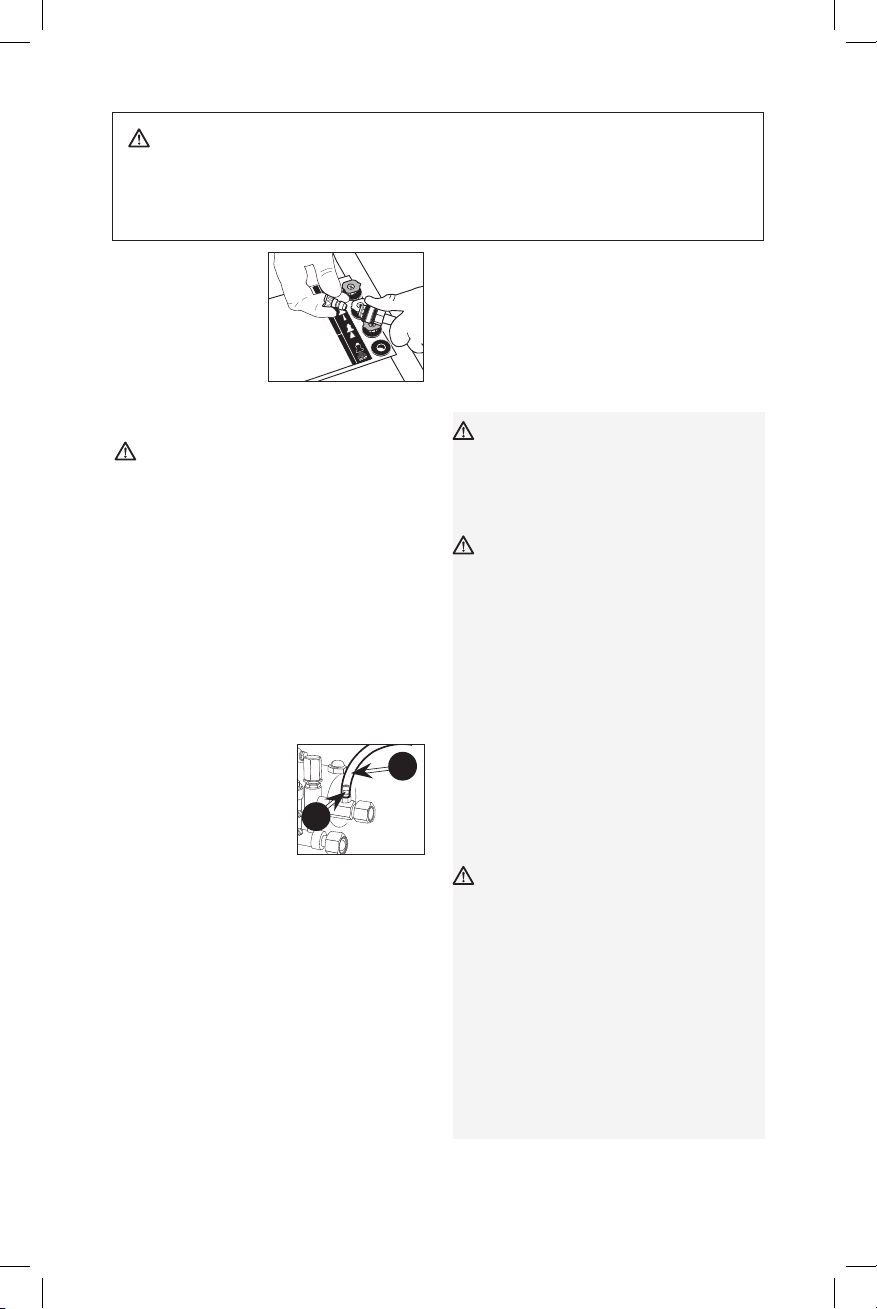

To Apply Chemicals:

1. Press chemical

T

P

hose (P) onto

barbed fitting (T)

located near high

pressure hose

connection of

pump as shown.

2. Place other end of chemical hose

with filter on it into container holding chemical/cleaning solution.

NOTE: For every 7 gallons of water

pumped 1 gallon of chemical/

cleaning solution will be used.

3. Install low pressure (black) noz-

zle into quick connect fitting of

spray wand, see How To Use

Spray Wand paragraph in this sec-

tion.

4. After use of chemicals, place

chemical hose into container of

clean water and draw clean water

through chemical injection sys-

tem to rinse system thoroughly. If

chemicals remain in the pump it

could be damaged. Pumps damaged due to chemicals will not be

covered under warranty.

NOTE: Chemicals and soaps will not

siphon when spray wand is in the high

pressure setting.

WARNING: To reduce the risk

of injury, read the pressure washer

instruction manual and the engine

instruction manual before starting

pressure washer.

DANGER: Risk of fluid injection

and laceration. When using the highpressure setting, DO NOT allow the

high-pressure spray to come in contact with unprotected skin, eyes, or

with any pets or animals. Serious

injury will occur.

• Your washer operates at fluid pressures

and velocities high enough to penetrate

human and animal flesh, which could

result in amputation or other serious

injury. Leaks caused by loose fittings or

worn or damaged hoses can result in

injection injuries. DO NOT TREAT FLUID

INJECTION AS A SIMPLE CUT! See a

physician immediately!

WARNING: Risk of Fire,

Asphyxiation and Burn. Never fill fuel

tank when engine is running or hot.

Do not smoke when filling fuel tank.

• NEVER fill fuel tank completely. Fill tank

to 1/2 inch )12.7 mm) below bottom

of filler neck to provide space for fuel

expansion. Wipe any fuel spillage from

engine and equipment before starting

engine.

• NEVER run engine in doors or in en closed,

poorly ven ti lat ed areas. En gine exhaust

con tains carbon mon ox ide, an odorless

* CAUTION: The high pressure spray from your pressure washer is capable of

causing damage to surfaces such as wood, glass, automobile paint, auto striping and trim, and delicate objects such as flowers and shrubs. Before spraying,

check the item to be cleaned to assure yourself that it is strong enough to resist

damage from the force of the spray.

Page 12

12- ENG

and deadly gas.

• DO NOT let hoses come in contact

with very hot engine muffler during or

immediately after use of your pressure

washer. Damage to hoses from contact

with hot engine surfaces will NOT be

covered by warranty.

NOTICE: Risk of property damage.

NEVER pull water supply hose to move

pres sure washer. This could damage

hose and/or pump inlet.

• DO NOT use hot water, use cold water

only.

• NEVER turn water supply off while pressure washer engine is running or damage to pump will result.

• DO NOT stop spraying water for more

than two minutes at a time. Pump operates in bypass mode when spray gun

trigger is not pressed. If pump is left in

bypass mode for more than two minutes

internal components of the pump can

be damaged.

If you do not understand these precautions, please call

1-800-544-6986 to

speak to a service representative for further instructions.

STARTING

Prior to starting, refer to your engine

manual for proper starting procedure.

1. In a well ventilated outdoor area

add fresh, high quality, unleaded

gasoline with a pump octane rating

of 86 or higher. Do not overfill. Wipe

up spilled fuel before starting the

engine. Refer to Engine Owners

Manual for correct procedure.

2. Check engine oil level. See

Engine Owners Manual for correct

procedure.

3. Connect the water hose to the

water source. Turn the water

source on to remove all air from

the hose. When a steady stream

of water is present, turn the water

source off.

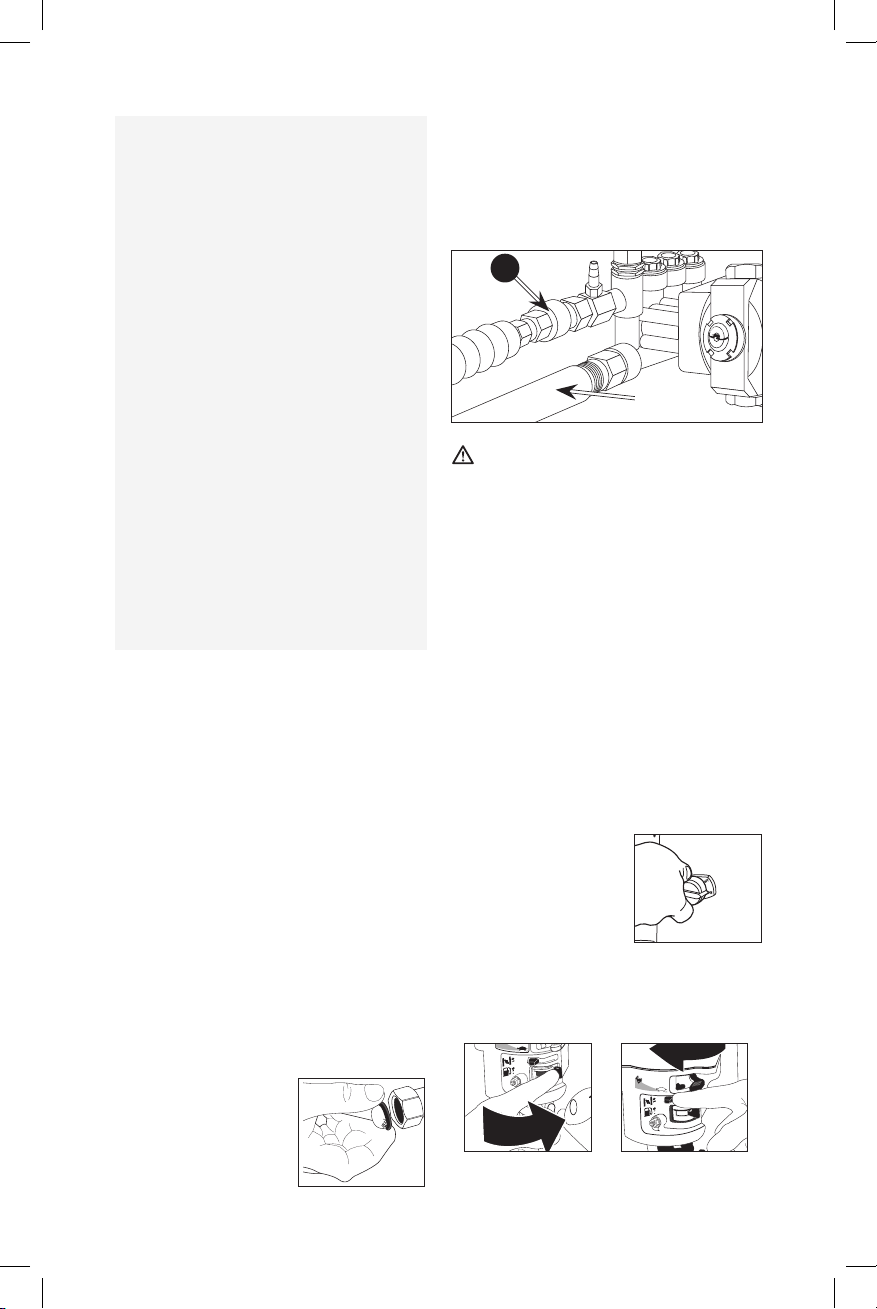

4. Verify the filter

screen is in water

inlet of pump.

NOTE: Cone side

faces out.

5. Connect water source to pump

inlet. NOTE: Water source must

provide a minimum of 5 gallons

(18.9 liters) per minute at 20 psi

(137.9 kPa).

Water

Source

D

WARNING: To reduce the possibility of contamination always protect

against backflow when connected to

a potable water system.

6. Connect high pressure hose to

pump outlet.

7. If applying a chemical or clean-

ing solution, see How To Apply

Chemicals/Cleaning Solvents

instructions in this section.

8. Turn water source on.

NOTICE: Risk of property damage.

Failure to do so could cause damage

to the pump.

9. Remove all air from the pump and

high pressure hose by depressing

trigger until a steady stream of

water is present.

10.

Turn the engine

ON/OFF switch

(H) to the ON

position.

11.

Place the fuel

valve lever (M) in

the ON postion.

12. If the engine is cold, move the

choke (L) to the CLOSED position

as shown.

Page 13

13 - ENG

13. WARNING: Risk of unsafe

operation. Pull starter grip slowly

until resistance is felt. Then pull

starter grip (I) rapidly to avoid

kickback and prevent hand or

arm injury.

NOTE: Do not allow the starter grip to

snap back. Return it gently by hand.

WARNING: Risk of unsafe opera-

tion. If engine does not start after two

pulls, squeeze trigger of gun to relieve

pump pressure. Pull starter cord slowly

until resistance is felt. Then pull cord

rapidly to avoid kickback and prevent

hand or arm injury.

NOTE: If the oil level in the engine is

low, the engine will not start. If the

engine does not start, check the oil level

and add oil as needed.

14. As the engine

warms up, move

the choke to the

OPEN position.

15. Depress trigger

on gun to start

water flow.

WARNING: Risk of unsafe opera-

tion. Stand on a stable surface and

grip gun/spray wand firmly with both

hands. Expect the gun to kick when

triggered.

16. Release trigger to stop water

flow.

DANGER: Risk of injury from

spray. Always engage the trigger lock

when gun is not in use. Failure to do

so could cause accidental spraying.

Trigger Lock Engaged

17. Adjust nozzle spray for the task

being performed. See How To Use

Wand instructions in this section.

SHUTTING DOWN

1. After each use, if you have applied

chemicals, place chemical hose

into container of clean water and

draw clean water through chemical

injection system to rinse system

thoroughly.

NOTICE: Risk of property damage.

NEVER turn the water off with the

engine running. Failure to do so could

cause damage to the pump.

2. Place the engine ON/OFF switch to

the OFF Position.

3. Place the fuel valve lever (M) in the

OFF postion.

4. Turn water source off.

5. Pull trigger on spray gun to

relieve any water pressure in hose

or spray gun.

6. See Storage section in this manu-

al for proper storage procedures.

MAINTENANCE

WARNING: Risk of burn hazard.

When performing maintenance, you

may be exposed to hot surfaces,

water pressure or moving parts that

can cause serious injury or death.

WARNING: Risk of fire hazard.

Always disconnect, spark plug wire,

let the engine cool and release all

water pressure before performing any maintenance or repair. The

engine contains flammable fuel. Do

not smoke or work near open flames

while performing maintenance.

To ensure efficient operation and longer

life of your pressure washer, a routine

maintenance schedule should be prepared and followed. If the pressure

washer is used in unusual conditions,

such as high-temperatures or dusty

conditions, more fre quent maintenance

checks will be required.

Page 14

14- ENG

Engine

Consult the Engine Owners Manual for

the man u fac tur er's recommendations

for any and all maintenance.

Pump

NOTE: The pump was filled with oil at

the factory.

Change pump oil after the first 10

hours of operation and every 250 hours

thereafter.

To Check Oil

The oil level should

BB

CC

AA

come to the dot in

the middle of the

sight glass (AA).

How To Change

Pump Oil

1. Loosen pump

oil fill plug (BB).

2. Place a con-

tainer under the oil drain plug

(CC).

3. Remove pump oil drain plug.

4. After oil is drained, replace oil drain

plug. Tighten securely.

5. Remove pump oil plug and fill with

8.5 oz. (251 ml) of 30W non detergent oil.

6. Replace pump oil plug and tighten

securely.

Nozzle Cleaning

If the nozzle becomes clogged with foreign materials, such as dirt, excessive

pressure may develop. If the nozzle

becomes partially clogged or restricted,

the pump pressure will pulsate. Clean

the nozzle immediately using the nozzle

kit supplied and the following instruc-

tions:

1. Shut off the pressure washer and

turn off the water supply.

2. Pull trigger on gun handle to relieve

any water pressure.

3. Disconnect the spray wand from

the gun.

4. Remove the high-pressure nozzle

from the spray wand. Remove any

obstructions with the nozzle cleaning tool provided and backflush

with clean water.

5. Direct water supply into spray wand

to backflush loosened particles for

30 seconds.

6. Reassemble the nozzle to the

wand.

7. Reconnect spray wand to gun and

turn on water supply.

8. Start pressure washer and place

spray wand into high pressure setting to test.

How to Clean the Water Inlet Filter

This screen filter should be checked

periodically and cleaned if necessary.

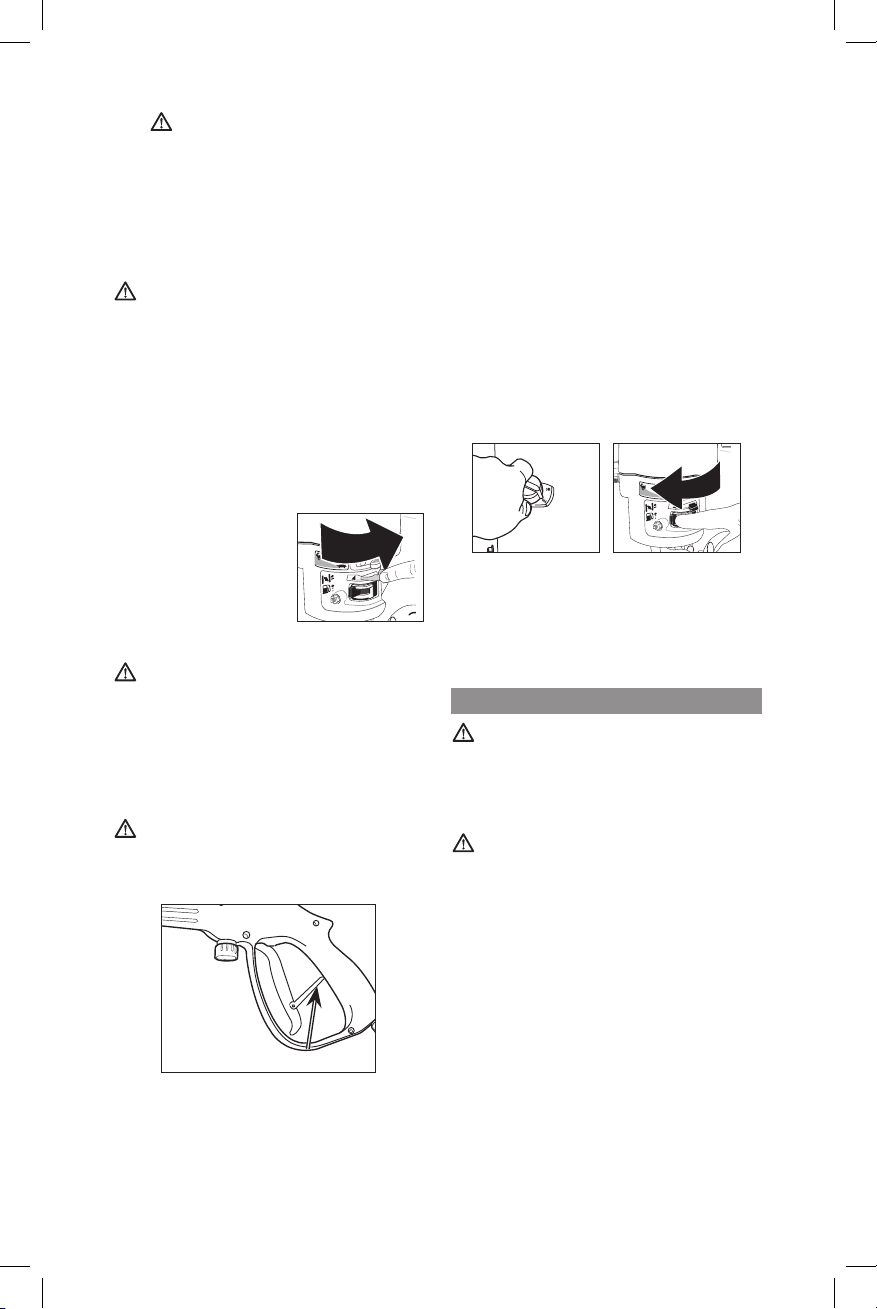

1. Remove filter by

grasping end and

removing it from

water inlet of

pump as shown.

2. Clean filter

by flushing it with water on both

sides.

3. Re-insert filter into water inlet of

pump. NOTE: Cone side faces

out.

NOTE: Do not operate pressure washer

without filter properly installed.

STORAGE

Engine

Consult the Engine Owners Manual for

the manufacturer's recommendations

for storage.

Pump

The manufacturer recommends using

a pump protector/winterizer when

storing the unit for more than 30 days

and/or when freezing temperatures

are expected. A pump protector/

winterizer is availabe at the store where

the pressure washer was purchased.

If a pump protector/winterizer is not

available, RV antifreeze needs to be

run through the pump as outlined in the

steps below.

Page 15

15 - ENG

NOTE: Using a pump protector/ winterizer or RV antifreeze is to provide

proper lubrication to the internal seals

of the pump regardless of temperature

or environment.

1. Obtain a funnel,

6 oz. (170 mL)

of RV antifreeze

and 16–36 inch

(40–91cm) of

garden hose

with a male

hose connector attached to one end.

NOTICE: Risk of property damage. Use

only RV antifreeze. Any other an ti freeze

is corrosive and can damage pump.

2. Disconnect spark plug wire.

3. Connect length of garden hose to

water inlet of pump.

4. Add RV antifreeze to hose as

shown.

5. Pull engine starter rope slowly sev-

eral times until an ti freeze comes

out of high-pressure hose con nection of pump.

6. Remove garden hose from water

inlet of pump.

7. Reconnect spark plug wire.

Pressure Washer

1. Drain all water from high pressure

hose, coil it, and store it in cradle

of the pressure washer handle.

2. Drain all water from spray gun and

wand by holding spray gun in a

vertical position with nozzle end

pointing down and squeezing trigger. Store in gun holder.

3. Store chemical hose so it is pro-

tected from dam age.

4. If space is needed, remove handles

and replace as shown.

ACCESSORIES

DANGER: Risk of fluid injection.

When using replacement lances or

guns with this pressure washer, DO

NOT use a lance and/or lance/gun

combination that is shorter in length

than what was provided with this

pressure washer as measured from

the nozzle end of the lance to the

gun trigger.

NOTICE: The use of any other acces-

sory not recommended for use with

this tool could be hazardous. Use only

accessories rated equal to or greater

than the rating of the pressure washer.

SPECIFICATIONS

Model BDP2600

PSI Max 2600 (17926 kPa)

Operating PSI 2340 (16134 kPa)

GPM Max 2.5

Operating GPM 2.25

SERVICE INFORMATION

Do not return this product to your

retailer. Black & Decker offers a full

network of company-owned and authorized service locations throughout North

America. All Black & Decker Service

Centers are staffed with trained personnel to provide cutomers with efficient

and reliable power tool service.

Whether you need technical advice,

repair, or genine factory replacement

parts, contact the Black & Decker location nearest you.

To find your local service location, refer to

the yellow page directory under “Tools—

Electric” or call: 1-800-544-6986.

Page 16

16- ENG

TWO-YEAR HOME USE WARRANTY

WARRANTY ON PRODUCT

COMPONENTS EXCLUDING PUMP

Black & Decker (U.S.) Inc. warrants

to the original purchaser that the

frame, wheels, gun, hose, wand, spray

nozzle(s) and other components of the

Black & Decker pressure washers covered under this warranty are free from

defects in material and workmanship

for two year from

the date of purchase.

WARRANTY ON PUMP

Black & Decker warrants to the original

purchaser that the pump of the Black

& Decker pressure washers covered

under this warranty is free from defects

in material and workmanship for two

years from the date of purchase. The

two year limited warranty applies to

the pump only. Black & Decker will

repair or replace, at Black & Decker's

option, products or components which

have failed within the above warranty periods. Service will be scheduled

according to the normal work flow and

business hours at the service center

location, and the availability of replacement parts. All decisions of Black &

Decker with regard to this limited warranty shall be final. This warranty gives

you specific legal rights, and you may

also have other rights which vary from

state to state.

RESPONSIBILITY OF ORIGINAL

PURCHASER (Initial User):

• To process a warranty claim on

your Black & Decker pressure

washer, return it to the place of

purchase.

• Retain original cash register sales

receipt as proof of purchase for

warranty work.

• Use reasonable care in the operation and maintenance of the product as described in the Owners

Manual(s).

THIS WARRANTY DOES NOT

COVER:

• Merchandise sold as reconditioned, used as rental equipment,

or floor or display models.

• Merchandise that has become

damaged or inoperative because

of ordinary wear, misuse, cold,

heat, rain, excessive humidity,

freeze damage, use of improper

chemicals, negligence, accident,

failure to operate the product in

accordance with the instructions

provided in the Owners Manual(s)

supplied with the product, improper maintenance, the use of accessories or attachments not recommended by Black & Decker, or

unauthorized repair or alterations.

• Repair and transportation costs of

merchandise determined not to be

defective.

• Costs associated with assembly,

required oil, adjustments or other

installation and start-up costs.

• Expendable parts or accessories

supplied with the product which are

expected to become inoperative or

unusable after a reasonable period

of use, including but not limited to

springs, nozzles, o-rings, washers,

and similar accessories.

• Merchandise sold by Black &

Decker which has been manufactured by and identified as the

product of another company, such

as gasoline engines. The product

manufacturer’s warranty, if any, will

apply.

• ANY INCIDENTAL, INDIRECT

OR CONSEQUENTIAL LOSS,

DAMAGE, OR EXPENSE THAT

MAY RESULT FROM ANY DEFECT,

FAILURE OR MALFUNCTION OF

THE PRODUCT IS NOT COVERED

BY THIS WARRANTY. Some states

do not allow the exclusion or limita-

tion of incidental or consequential

damages, so the above limitation

or exclusion may not apply to you.

• IMP LIED WARRANTIES,

INCLUDING THOSE OF

MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE,

ARE LIMITED TO TWO YEAR

FROM THE DATE OF ORIGINAL

PURCHASE. Some states do not

allow limitations on how long an

implied warranty lasts, so the above

limitations may not apply to you.

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Page 17

17 - ENG

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE CORRECTION

Engine will

not start (see

Engine Manual

for further

engine

troubleshooting)

No fuel. Add Fuel.

Pressure builds up after two

pulls on the recoil starter or

after initial use.

Squeeze gun trigger to relieve

pres sure.

Choke lever in the "No Choke"

position.

Move choke to the "Choke"

po si tion.

Spark plug wire not attached. Attach spark plug wire.

Engine switch in OFF

po si tion.

Place engine switch in on posi-

tion.

Choke lever in the "Choke"

position on a "hot" engine

or an engine that has been

exposed to thermal heat for a

long period of time.

Move choke to the "No Choke"

po si tion.

Fuel valve closed. Move the fuel valve lever to the

OPEN position.

No or low

pressure

(initial use)

Spray wand not in high pressure.

See How to Use Spray Wand

instructions in the Operation

Section.

Low water supply. Water supply must be at least

5 GPM @ 20 psi.

Leak at high pressure hose

fitting.

Repair leak. Apply sealant tape

if necessary.

Nozzle obstructed. See Nozzle Cleaning instruc-

tions in the Maintenance sec-

tion.

Water filter screen clogged. Remove and clean filter.

No or low

pressure

(initial use)

Air in hose. Turn off the engine, then the

water source. Disconnect the

water source from the pump

inlet and turn the water source

on to remove all air from the

hose. When there is a steady

stream of water present, turn

water source off. Re- con nect

water source to pump inlet and

turn on wa ter source. Squeeze

trigger to re move re main ing air

Choke in the “Choke” position. Move choke to the “No Choke”

po si tion.

High pressure hose is too

long.

Use high pressure hose under

100 feet (30 m).

Page 18

18- ENG

PROBLEM CAUSE CORRECTION

Will not draw

chemicals

Spray wand not in low pressure.

See How to Use Spray Wand

paragraph in the Operation

Section.

Chemical filter clogged. Clean filter.

Chemical screen not in clean-

ing solution.

Make sure end of chemical

hose is fully submerged into

cleaning solution.

Chemical too thick. Dilute chemical. Chemical

should be the same consistency

as water.

Pressure hose is too long Lengthen water supply hose

instead of high pressure hose.

Chemical build up in chemical

injector.

Contact B&D Customer

Service Representative at

1-800-544-6986.

No or low

pressure

(after period of

normal use)

Worn seal or packing Contact B&D Customer

Service Representative at

1-800-544-6986.

Worn or obstructed valves. Contact B&D Customer

Service Representative at

1-800-544-6986.

Worn unloader piston. Contact B&D Customer

Service Representative at

1-800-544-6986.

Water leaking

at gun/spray

wand connection

Worn or broken o-ring. Check and replace.

Loose hose connection. Tighten.

Water leaking

at pump

Loose connections. Tighten.

Piston packings worn. Contact B&D Customer

Service Representative at

1-800-544-6986.

Worn or broken o-rings. Contact B&D Customer

Service Representative at

1-800-544-6986.

Pump head or tubes damaged

from freezing.

Contact B&D Customer

Service Representative at

1-800-544-6986.

Pump Pulsates Nozzle obstructed. See Nozzle Cleaning para-

graph in the Maintenance sec-

tion for the correct procedure.

Page 19

19 - ENG

PROBLEM CAUSE CORRECTION

Oil leaking at

pump

Oil seals worn.

Contact B&D Customer

Service Representative at

1-800-544-6986.

Loose drain plug.

Tighten.

Worn drain plug o-ring.

Check and replace.

Worn fill plug o-ring. Check and replace.

Pump overfilled. Check for correct amount.

Incorrect oil used. Drain and fill with correct amount

and type of oil.

Vent plug is clogged. Clean vent plug; blow air through it

to remove any blockage. If prob lem

per sists, replace plug.

Page 20

20- ENG

Page 21

¡gr a c i a s p o r e l e g i r Bl a c k & De c k e r !

V

a y a a w w w .Bl a c k a n D De c k e r .c o m /ne w ow n e r

p a r a

r e g i s T r a r s u n u e V o p r o D u c T o .

MANUAL DE INSTRUCCIONES

Lavadora a presión

Número de catálogo BDP2600

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Page 22

22- SP

DEFINICIONES DE NORMAS DE SEGURIDAD

Este manual contiene importante información para que usted sepa y comprenda.

Esta información se relaciona con la protección de SU SEGURIDAD Y LA

PREVENCIÓN DE PROBLEMAS AL EQUIPO. Para ayudarlo a reconocer esa

información, utilizamos los símbolos indicados más abajo. Sírvase leer el

manual y prestar atención a dichos símbolos.

PELIGRO: Indica una situación de peligro inminente que, si no se evita,

provocará la muerte o lesiones graves.

ADVERTENCIA: Indica una situación de peligro potencial que, si no se evita,

podría provocar la muerte o lesiones graves.

ATENCIÓN: Indica una situación de peligro potencial que, si no se evita,

posiblemente provocaría lesiones leves o moderadas.

AVISO: Se refiere a una práctica no relacionada a lesiones corporales que de

no evitarse puede resultar en daños a la propiedad.

INFORMACIÓN DE SEGURIDAD PARA EL CONSUMIDOR

ADVERTENCIA: Esta unidad podría no estar equipada con un cortachispas

en el silenciador del escape. Si esta unidad se usa alrededor de materiales

inflamables o en suelo cubierto con materiales tales como productos

agrícolas, forestales, arbustos u otros similares, se debe instalar un corta

chispas autorizado, y en el estado de California es obligatorio por ley que esté

provisto de corta chispas y mantenido en buen estado de funcionamiento

de acuerdo a las secciones 130050 y/o secciones 4442 y 4443 del Código

de Recursos Públicos Naturales. El cortachispas también se requiere en

algunas jurisdicciones del Servicio Forestal del Gobierno de los EE.UU. y

también puede ser obligatororio por otros estatutos y ordenanzas.

ADVERTENCIA: Este producto contiene sustancias químicas reconocidas

por el Estado de California como causantes de cáncer, defectos de

nacimiento u otros problemas reproductivos. Lávese las manos después de

utilizarlo.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA: No opere este equipo hasta haber leído y entendido las

instrucciones de seguridad, operación y mantenimiento en este Manual del

Operador y en el Manual del Propietario del Motor.

Lea Y conserve estas instrucciones

Page 23

23 - SP

PELIGRO: RIESGO DE EXPLOSIÓN O INCENDIO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La gasolina derramada y sus

vapores pueden encenderse a

causa de chipas de cigarrillos,

arcos eléctricos, gases de escape

y componentes calientes del motor,

como el silenciador

• Apague el motor y deje que se

enfríe antes de poner combustible

en el tanque.

• Sea cuidadoso al llenar el

tanque para evitar el derrame de

combustible. Aleje la lavadora a

presión del área combustible antes

de poner en marcha el motor.

• El calor expandirá el combustible

dentro del tanque, lo que podría

provocar un derrame y una posible

explosión o incendio.

• Llene el tanque hasta 12,7 mm

(1/2 pulg.) por debajo de la parte

inferior del cuello de llenado, a fin de

brindar espacio para la expansión

del combustible.

• La operación de la lavadora a

presión en un entorno explosivo

podría provocar un incendio.

• Opere y coloque combustible al

equipo en áreas bien ventiladas y

libres de obstrucciones. Equipe las

áreas con un extintor de incendios

adecuado para incendios por

gasolina.

• La colocación de materiales contra

o cerca de la lavadora a presión

puede interferir con la ventilación

adecuada del equipo, lo que

causaría un sobrecalentamiento y

podría encender los materiales.

• Nunca opere la lavadora a presión

en un área que tenga malezas

secas.

• El calor del escape del silenciador

puede dañar las superficies pintadas,

derretir los materiales sensibles

al calor (como revestimientos

interiores, plástico, goma, vinilo o

la propia manguera de presión) y

perjudicar a las plantas naturales.

• Mantenga siempre la lavadora a

presión a una distancia mínima de

1,2 m (4 pies) de las superficies

(tales como casas, automóviles o

plantas naturales) que podrían sufrir

daños por el calor del escape del

silenciador.

• El combustible que no se almacena

en forma correcta podría causar

la ignición accidental. Si no se lo

resguarda adecuadamente, podría

terminar en manos de niños u otras

personas no calificadas.

• Almacene el combustible dentro de

un contenedor aprobado por OSHA

en un lugar seguro, lejos del área de

trabajo.

• El uso de ácidos, productos

químicos tóxicos o corrosivos,

venenos, insecticidas o cualquier

clase de solventes inflamables

con esta unidad, podría ocasionar

lesiones serias o la muerte.

• No rocíe líquidos inflamables .

Page 24

24- SP

PELIGRO:

RIESGO RESPIRATORIO (ASFIXIA)

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La inhalación de vapores de

escape causará lesiones graves

o la muerte. El escape del motor

contiene monóxido de carbono, un

gas inodoro que es fatal.

• Opere la lavadora a presión en

un área bien ventilada. Evite los

lugares cerrados como garajes,

sótanos, etc.

• Nunca opere la unidad en un lugar

en el que haya otras personas o

animales.

• Algunos líquidos para limpieza

contienen sustancias que podrían

causar lesiones en la piel, los ojos

o los pulmones.

• Utilice solamente limpiadores

recomendados específicamente

para lavadoras a alta presión.

Siga las recomendaciones de los

fabricantes. No use lejía de cloro ni

otro compuesto corrosivo.

PELIGRO: RIESGO DE INYECCIÓN DE LÍQUIDO Y LACERACIÓN

¿QUÉ PUEDE SUCEDER?

• Su lavadora a presión opera el

líquido con una presión y velocidad

lo suficientemente altas como

para penetrar la carne humana y

animal, y por ello podría ocasionar

una amputación u otra lesión

grave. Las pérdidas causadas por

accesorios sueltos o mangueras

dañadas pueden producir lesiones

por inyección. NO TRATE LA

INYECCIÓN DE LÍQUIDO COMO

SI FUERA UN SIMPLE CORTE

Consulte al médico de inmediato.

CÓMO EVITARLO

• Inspeccione la manguera de alta

presión periódicamente. Reemplace

la manguera de inmediato si está

dañada, gastada, se derritió por

contacto con el motor o evidencia

signos de grietas, burbujas,

agujeros u otros tipos de pérdida.

Nunca tome una manguera de alta

presión que tenga una pérdida o

esté dañada.

• Nunca toque, tome ni trate de cubrir

un agujero o causa de pérdida de

agua similar en la manguera de alta

presión. El flujo de agua ESTÁ a alta

presión y PENETRARÁ la piel.

• Nunca coloque las manos frente a

la boquilla.

• No dirija el pulverizador hacia sí

mismo u otras personas.

• Asegúrese de que la manguera y

los accesorios estén ajustados y

en buenas condiciones. Nunca se

sujete de la manguera ni de los

accesorios durante la operación.

• No permita que la manguera entre

en contacto con el silenciador.

• Nunca coloque ni quite la varilla ni los

accesorios de la manguera mientras

el sistema esté presurizado.

Page 25

25 - SP

• Podría resultar herido si la presión

del sistema no se reduce antes de

intentar realizarle mantenimiento o

desarmarlo.

• Para aliviar la presión del sistema,

apague el motor, cierre el suministro

de agua y hale del disparador de

la pistola hasta que deje de salir

líquido.

• Utilice solamente mangueras y

accesorios calificados para soportar

presiones superiores al PSI de su

lavadora a presión.

PELIGRO: RIESGO DE LESIÓN POR PULVERIZACIÓN

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La pulverización de líquidos a

alta velocidad puede hacer que

los objetos se rompan y lancen

partículas a gran velocidad.

• Use siempre gafas de seguridad

aprobadas según la ANSI Z87.1.

Utilice ropa que lo proteja de una

pulverización accidental.

• Nunca apunte el pulverizador a

personas o animales.

• Los objetos livianos o no

asegurados pueden convertirse en

proyectiles peligrosos.

• Asegure siempre el bloqueador del

disparador cuando la varilla no esté

en uso para evitar la operación

accidental.

• Nunca asegure el disparador

hacia atrás, en posición abierta

permanente.

PELIGRO:

RIESGO DE OPERACIÓN INSEGURA

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La operación insegura de su

lavadora a presión podría producir

lesiones graves o la muerte, a usted

mismo o a otras personas.

• No utilice lejía de cloro ni otro

compuesto corrosivo.

• Familiarícese con las operaciones

y los controles de la lavadora a

presión.

• Mantenga el área de operaciones

libre de personas, mascotas y

obstáculos.

• No opere el producto cuando esté

cansado o bajo la influencia de

alcohol o drogas. Manténgase

alerta en todo momento.

• Nunca anule las características de

seguridad de este producto.

• No opere la máquina si faltan

piezas, están rotas o no son las

autorizadas.

• Nunca deje la varilla sin atención

mientras la unidad está en

funcionamiento.

Page 26

26- SP

• Si no se sigue el procedimiento

de puesta en marcha adecuado,

el motor puede retroceder, lo que

podría causar daños graves a las

manos y los brazos.

• Si el motor no arranca después

de halar dos veces, apriete el

disparador de la pistola para aliviar

la presión de la bomba. Hale del

cable de arranque lentamente

hasta sentir cierta resistencia.

Entonces, hale de él rápidamente

para evitar el retroceso y que se

produzcan lesiones en las manos o

los brazos.

• La pistola/varilla pulverizadora

es una herramienta de limpieza

poderosa, que podría parecer un

juguete ante los ojos de un niño.

• Mantenga a los niños alejados

de la lavadora a presión en todo

momento.

• La fuerza reactiva de la

pulverización hará que la pistola/

varilla retroceda, lo cual podría

hacer que el operador se resbale,

caiga o apunte el pulverizador

hacia una dirección incorrecta. El

control inadecuado de la pistola/

varilla puede causar lesiones al

usuario y a otras personas.

• No se estire demasiado ni se pare

en una superficie que no brinde

estabilidad.

• No use la lavadora a presión cuando

esté subido a una escalera.

• Agarre la pistola/varilla firmemente

con ambas manos. Espere que

la pistola retroceda cuando la

dispare.

PELIGRO: RIESGO DE LESIÓN O DAÑO A LA PROPIEDAD AL

TRANSPORTAR O ALMACENAR LA UNIDAD

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Se puede producir una pérdida o

derrame de combustible y aceite,

lo cual podría generar peligro

de incendio o inhalación. Puede

causar lesiones graves o la muerte.

Los derrames de combustible o

aceite dañarán alfombras, pintura

y otras superficies de vehículos o

remolques.

• Si la lavadora a presión está

equipada con una válvula de

cierre de combustible, colóquela

en la posición cerrada antes de

transportar la unidad, a fin de

evitar pérdidas de combustible. Si

la lavadora no está equipada con

esta válvula, drene el combustible

del tanque antes de transportarla.

Sólo transporte combustible en un

contenedor aprobado por OSHA.

Coloque siempre la lavadora a

presión en un tapete protector

cuando la transporte, para proteger

al vehículo de daños por pérdidas.

Baje la lavadora a presión del

vehículo inmediatamente una vez

que haya llegado a destino.

Page 27

27 - SP

ADVERTENCIA: RIESGO DE DE ESTALLIDO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• El inflado excesivo de los

neumáticos podría causar lesiones

graves y daño a la propiedad.

• Utilice un medidor de presión

de neumáticos para controlar la

presión de éstos antes de cada

uso y mientras los infla; observe el

flanco para ver la presión correcta

del neumático.

NOTA: Los tanques de aire, los

compresores y el equipo similar

que se usa para inflar neumáticos

pueden llenar neumáticos pequeños

como éstos con mucha rapidez.

Ajuste el regulador de presión sobre

el suministro de aire a un valor

no superior a la calificación de

la presión del neumático. Agregue

aire en forma gradual y use con

frecuencia el medidor de presión

de neumáticos para evitar inflarlos

en exceso.

• La pulverización de líquidos a alta

velocidad dirigida hacia los flancos

de los neumáticos (como los de

los automóviles, remolques y otros

vehículos similares) podría dañar el

flanco y provocar lesiones graves.

• En las lavadoras a presión de más

de 1600 PSI (110 barios) utilice

la pulverización en abanico más

ancha (boquilla de 40º) y pulverice

a una distancia mínima de 20 cm

(8 pulg.) del flanco del neumático.

No pulverice directamente sobre

la unión entre el neumático y el

borde.

ADVERTENCIA: RIESGO DE SUPERFICIES CALIENTES

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• El contacto con superficies calientes,

tales como los componentes de

escape de motores, podría causar

quemaduras graves.

• Durante la operación, toque

solamente las superficies de los

controles de la lavadora a presión.

Mantenga a los niños alejados

de la lavadora a presión en todo

momento. Es posible que ellos no

reconozcan los peligros de este

producto.

Page 28

28- SP

ADVERTENCIA: RIESGO DE QUEMADURA QUÍMICA

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• El uso de ácidos, químicos tóxicos

o corrosivos, venenos, insecticidas

o cualquier tipo de solvente

inflamable con este producto

podría provocar una lesión grave

o la muerte

• No utilice ácidos, gasolina,

kerosén o cualquier otro material

inflamable en este producto. Sólo

use detergentes, limpiadores

y desgrasadores domésticos

recomendados para su aplicación

en lavadoras de presión.

• Utilice ropa que le proteja los

ojos y la piel del contacto con los

materiales pulverizados.

ADVERTENCIA: RIESGO DE DESCARGA ELÉCTRICA

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La pulverización de tomacorrientes

o interruptores eléctricos, u objetos

conectados a un circuito eléctrico

podría provocar una descarga

eléctrica fatal.

• La pulverización de tomacorrientes

o interruptores eléctricos, u objetos

conectados a un circuito eléctrico

podría provocar una descarga

eléctrica fatal.

ADVERTENCIA: RIESGO DE LESIÓN POR LEVANTAR

MUCHO PESO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• El intento de levantar un objeto muy

pesado puede provocar lesiones

graves.

• La lavadora a presión es demasiado

pesada como para que la levante

una sola persona. Consiga la ayuda

de otras personas para levantarla.

Lea Y conserve estas instrucciones

NOTA: Las fotografías y los dibujos lineales utilizados en este manual son solo

referencias y no representan un modelo específico.

FAMILIARÍCESE CON LA

LAVADORA A PRESIÓN

Compare las ilustraciones con su unidad

para familiarizarse con la ubicación de

sus controles y regulaciones. Conserve

este manual para referencias futuras.

D

O

N

H

I

J

C

A

Q

L

K

B

G

E

F

M

Page 29

29 - SP

A. Boquillas de conexión rápida

B. Portaboquillas

C. Manillar

D. Manguera de alta presión: Lleva el

agua a presión desde la bomba a la

pistola y el tubo aplicador.

E. Salida de la bomba

F. Entrada de la bomba

G. Bomba de alta presión (ubicada en

el interior del casco): Incrementa la

presión del suministro de agua.

H. Interruptor de encendido/apagado

del motor: Conecta y desconecta

el sistema de ignición del motor.

I. Motor: Acciona la bomba de alta

presión. Refiérase al manual del

motor para la operación y locación

de los controles del motor en la

lavadora.

J. Marco

K. Manija de arranque: Tirando esta

manija se acciona el arrancador con

resorte de retroceso que arranca el

motor.

L. Control de cebado: Abre y cierra la

válvula de cebado del carburador.

M. Leva de la válvula combustible:

Abre y cierra la conexión entre

el tanque de combustible y el

carburador.

N. Tubo Aplicador de Conexión

Rápida: Permite que el usuario

cambie las boquillas de alta

presión rápidamente. Refiérase a

las instrucciones Para su Uso.

O. Pistola rociadora: Se conecta al

tubo aplicador para controlar el

volumen del flujo del agua, su

dirección y la presión.

P. Manguera para Químicos (no

mostrada): Alimenta los líquidos

limpiadores a la bomba para

mezclarlos con agua. Refiérase a las

instrucciones Para la Aplicación

de Químicos y Solventes

Limpiadores.

Q. Relleno de gas

CONTENIDO DE LA CAJA

A. Boquillas de conexión rápida

B. Portaboquillas

C. Manillar

D. Manguera de alta presión

I/J. Bastidor del motor y conjunto de

ruedas

N. Tubo aplicador de conexión rápida

O. Pistola rociadora

P. Manguera de químicos

R. Manual del operador

S. Manual del motor

T. Herramienta limpiadora de

boquillas

U. Piezas embolsadas

I/J

D

O

N

C

R

U

S

P

T

B

A

INSTRUCCIONES PARA ARMAR

1. Busque todas las partes sueltas

de la caja y retírelas.

2. Corte las cuatro esquinas de la

caja desde la parte superior hacia

abajo y coloque los paneles en

posición horizontal.

Page 30

30- SP

3. Coloque el manillar

(C) en el bastidor

(J), presione los

bot o nes de

enganche y deslice

el manillar en el

bastidor hasta que

los botones enganchen en

posición.

ATENCIÓN: Riesgo de lesión per-

sonal. Evite colocar las manos entre

el mango y el marco cuando realice el

ensamblado para no pellizcarse.

4. Conecte el tubo aplicador (N) a la

pistola (O) y ajústelo firmemente.

5. Conecte la

manguera de

alta presión (D)

a la pistola (O)

y ajústela

firmemente.

6. Par a el

ensamblado de los ojales de la

conexión rápida:

a. Comprima los ojales e

instálelos dentro del orificio de

la ranura del borde.

b. Presione el ojal colocándolo

en su sitio.

c. Repita los pasos hasta que

todos los ojales estén en

posición.

7. Saque las cuatro boquillas (A)

de conexión rápida de la bolsa

plástica e insértelas en las

abrazaderas correspondientes

en el portaboquillas. NOTA: Las

boquillas están codificadas por

colores que coinciden con su

abrazadera en el panel.

NOTA: La bomba de alta presión se llenó

con aceite en la fábrica. No hay necesidad

de agregarle aceite en este momento; vea

la sección Mantenimiento en este manual

para efectuar el mantenimiento de esta

bomba.

8. Retire la unidad de la caja y

deseche esta última.

ADVERTENCIA: Antes de hacer

funcionar la lavadora a presión,

extraiga el tapón usado para el

embarque y reemplácelo por el tapón

con varilla medidora de aceite.

NOTA: Los tanques de aire, los

compresores y el equipo similar que se

usa para inflar neumáticos puede llenar

neumáticos pequeños como éstos con

mucha rapidez. Ajuste el regulador de

presión en el suministro de aire a un

valor que no supere el de la presión

del neumático. Agregue aire en forma

gradual y use con frecuencia el medidor

de presión de neumáticos para evitar

sobre inflarlos.

INSTRUCCIONES DE OPERACIÓN

TERMINOLOGÍA DE LA

LAVADORA A PRESIÓN

PSI: (Pounds per Square Inch) Lb/

Pulg

2

. Es una unidad de medida para la

presión del agua. También se usa para

medir la presión neumática, presión

hidráulica, etc. Equivale a 49 pascales.

GPM: (Gallons per Minute). Galones

por minuto. Es la unidad de medida

para el flujo de agua. Equivale a 6,89

kPa.

CU: (Unidades de limpieza) GPM

multiplicadas por psi. lpm • kPa =

Unidades limpiadoras

Page 31

31 - SP

Modo de Derivación: Permite que el

agua recircule dentro de la bomba

cuando el gatillo no está presionado.

AVISO: No permita que la unidad

funcione por más de dos minutos

sin apretar el gatillo porque se

recalentará y se dañará bomba.

Válvula térmica de

seguridad: Cuando la

temperatura dentro de

la bomba se eleva

demasiado, la válvula

se abre y deja escapar

un chorro de agua

para bajar la temperatura. Luego se

cierra la válvula.

Sistema de Inyección de Productos

Químicos: Mezcla los limpiadores

o solventes con agua para mejorar la

eficiencia del lavado.

Suministro de agua: Todas las lavadoras

a presión deben tener un suministro de

agua. Los requerimientos mínimos para

el suministro del agua son 137,8 kPa y

22,7 L/min (5 Gal/min).

CARACTERÍSTICAS DE

OPERACIÓN DE LA LAVADORA

A PRESIÓN

Regulación de la Presión

La presión viene regulada de fábrica

con el objeto de lograr la presión óptima

para la limpieza. Si usted necesitase

reducir la presión, podrá hacerlo con

los siguientes métodos:

1. Retírese de la superficie por

lavarse. Cuanto más alejado usted

se encuentre, menor presión habrá

sobre la superficie a lavarse.

2. Cambie a la boquilla de 40° (blanca), esta boquilla produce un

chorro menos potente de agua y

un patrón de rociado más amplio.

AVISO:

No intente incrementar la presión

de la bomba. Una graduación superior

a la que trae de fábrica puede dañar la

bomba.

Boquillas para la varilla

pulverizadora

Las boquillas para la varilla pulverizadora

están guardadas en el soporte para

boquillas en el ensamblado del panel.

Los colores del panel identifican la

ubicación de la boquilla y el patrón

de pulverización. Consulte el cuadro

siguiente a fin de elegir la boquilla

correcta para el trabajo por realizar.

Cambio de las Boquillas de la Varilla

Pulverizadora

DANGER: Riesgo de inyección de

líquido. No dirija el flujo de agua hacia

personas, piel y ojos desprotegidos, ni

animales o mascotas. Se producirán

lesiones graves.

ADVERTENCIA: Los objetos

despedidos podrían causar lesiones

graves. NO intente cambiar las

boquillas mientras la lavadora a

presión está funcionando. Apague el

motor antes de hacerlo.

1. Tire el acople

de conexión

r á p i d a

haciatrás e

inserte la

boquilla.

2. Libere el

acople y gire la boquilla para

asegurarse de que está asegurada

dentro del acople.

ADVERTENCIA: Los objetos

despedidos podrían causar lesiones

graves. Asegúrese de que la boquilla

esté completamente insertada en

el adaptador de conexión rápida y

que el anillo a presión de conexión

rápida esté totalmente asegurado

(hacia adelante) antes de oprimir el

disparador de la pistola.

Page 32

32- SP

Color de la

Boquilla

Patrón (Abanico)

de Rociado

Usos Superficies *

Rojo

0˚

gran capacidad de

localización para

limpiar manchas en

superficies difíciles

y sin pintar o para

alcanzar áreas

elevadas

hormigón o metal sin

pintar

NO usar en madera

Amarillo

15˚

limpieza intensa de

superficies difíciles y

sin pintar

parrillas, entradas de

automóviles, sendas de

ladrillo u hormigón, estuco

o ladrillo sin pintar

Blanco

40

˚ limpieza de superfi-

cies pintadas o delicadas

Automóviles/vehículos

recreativos, embarcaciones, madera, estuco

y ladrillo pintado, vinilo,

revestimiento exterior pintado

Negro

low pressure

applies cleaning

solutions

la pulverización con baja

presión es segura en

todas las superficies.

verifique siempre la

compatibilidad de la

solución de limpieza antes

de usar.

*

ATENCIÓN: El chorro de alta presión de la lavadora puede dañar superfi-

cies como: madera, vidrio, pintura de automóviles, molduras y decoraciones de

automóviles y objetos delicados tales como flores y arbustos. Antes de rociar,

examine el objeto a lavarse para asegurarse que sea lo suficientemente robusto

como para que no se dañe con la fuerza del chorro.

Cómo Emplear Productos Químicos

y Solventes Para Limpieza

El empleo de productos químicos

o solventes para limpieza es una

operación de baja presión. NOTA: Utilice

solamente jabones y productos químicos

diseñados para el uso en lavadoras a

presión. No use blanqueadores.

Aplicación de productos químicos:

1. Presione la

T

P

manguera de

p r o d u c t o s

químicos (P) en

el acople (T)

a r p o n a d o

ubicado cerca de

la conexión de la manguera de

alta presión de la bomba tal como

se muestra.

2. Coloque el otro extremo de la

manguera de productos químicos

(con su filtro instalado) dentro del

contenedor del producto químico

o solución de limpieza. NOTA: Se

usa 3,785 litros de solución química

limpiadora por cada 26,495 litros

de agua que se bombea.

3. Regule la boquilla multirregulable

para la presión más baja. Lea el

párrafo Uso del Tubo Aplicador,

en esta sección.

4. Luego de usar productos

químicos, coloque la manguera

dentro de un recipiente con agua

limpia y succiónela a través del

sistema de inyección química,

a fin de enjuagar el sistema

completamente. Si los productos

químicos permaneciesen en la

bomba, ésta podría dañarse. Los

Page 33

33 - SP

daños a las bombas ocasionados

por productos químicos no están

cubiertos por la garantía.

NOTA: Cuando el tubo aplicador

esté regulado para presión alta, no

succionará los productos químicos o

jabón.

AVERTENCIA: Para reducir el

riesgo de lesión, lea los manuales

de instrucciones de la lavadora a

presión y del motor antes de poner

en marcha la unidad.

PELIGRO: Riesgo de inyección de

líquido y laceración. Cuando utilice

la configuración de alta presión, NO

permita que el pulverizador entre en

contacto con personas, piel y ojos

desprotegidos, ni con animales o

mascotas. Se producirán lesiones

graves.

• Su lavadora opera el líquido

con una presión y velocidad lo

suficientemente altas como

para penetrar la carne humana

y animal, y esto podría provocar

una amputación u otra lesión

grave. Las pérdidas causadas por

accesorios sueltos o mangueras

dañadas pueden provocar

lesiones por inyección. NO TRATE

LA INYECCIÓN DE LÍQUIDO

COMO SI FUERA UN SIMPLE

CORTE. Consulte a un médico de

inmediato.

AVERTENCIA: Riesgo de incendio,

asfixia y quemadura. Nunca llene el

tanque de combustible cuando el

motor esté encendido o caliente. No

fume mientras llena el tanque.

• Nunca llene el tanque de

combustible por completo. Llene

el tanque hasta 12,7 mm (1/2 pulg.)

por debajo de la parte inferior

del cuello de llenado, a fin de

brindar espacio para la expansión

del combustible. Limpie cualquier

derrame de combustible del motor

y el equipo antes de poner en

marcha el motor.

• Nunca encienda el motor bajo

techo ni en áreas cerradas y poco

ventiladas. El escape del motor

contiene monóxido de carbono, un

gas inodoro que es fatal.

• NO deje que las mangueras entren

en contacto con el silenciador del

motor, que estará muy caliente,

durante o inmediatamente después

de usar la lavadora a presión. La

garantía NO cubrirá el daño a las

mangueras que se produzca por

el contacto con superficies muy

calientes del motor.

AVISO: Riesgo de daño a la

propiedad. Nunca tire de la manguera

de suministro de agua para mover

la lavadora a presión. Esta acción

podría dañar la manguera y/o la

entrada de la bomba.

• NO use agua caliente, sólo agua

fría.

• Nunca cierre el suministro de agua

mientras el motor de la lavadora

a presión esté encendido, esto

dañaría la bomba.

• NO detenga la pulverización de

agua durante más de dos minutos

por vez. La bomba opera en

modo de derivación cuando no

se presiona el disparador de la

pistola pulverizadora. Si la bomba

queda en modo de derivación

durante más de dos minutos, sus

componentes internos podrían

dañarse.

Si no comprende estas instrucciones,

sírvase llamar al 1-800-544-6986,

para conversar con un representante

de servicio que le provea información

adicional.

ARRANQUE

Antes de arrancar, refiérase al

procedimiento de arranque en el

manual de su motor.

1. En una zona bien ventilada

externa, agregue gasolina nueva, de

alta calidad, sin plomo, identificada

en el surtidor de combustible con

86 octanos o más. No llene en

Page 34

34- SP

exceso. Limpie cualquier derrame

de combustible del motor y del

equipo antes de poner el motor

en marcha. Para informarse del

procedimiento correcto, refiérase

al manual del motor.

2. Verifique el nivel de aceite

del motor. Para informarse del

procedimiento correcto, refiérase al

manual del propietario del motor.

3. Conecte la manguera de agua a

la fuente de agua. Abra la fuente

de agua para quitarle todo el aire

a la manguera. Cuando haya un

flujo de agua constante, apague la

fuente de agua.

4. Verifique que la

malla del filtro

esté en la entrada

de agua de la

bomba. NOTA: El

lado cónico mira

hacia afuera.

5. Conecte el suministro de agua

a la entrada de la bomba.

NOTA: El agua suministrada debe

tener un promedio de 18,925 l/

min (5 galones) por minuto a 137,8

kPa.

Alimentación

del agua

D

AVERTENCIA: Para reducir

la posibilidad de contaminación

proteja siempre el sistema contra