Page 1

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

POUR LE FRANÇAIS, VOIR LA COUVERTURE ARRIÈRE.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

BBBBDDDDMMMMSSSS111100000000 11110000”””” ((((222255554444MMMMMMMM)))) CCCCOOOOMMMMPPPPOOOOUUUUNNNNDDDD MMMMIIIITTTTEEEERRRR SSSSAAAAWW

WW

BEFORE RETURNING THIS PRODUCT FOR ANY REASON

PLEASE CALL 1-800-HOW-TO (544-6986)

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR BLACK & DECKER PRODUCT,

CALL 1-800-54-HOW-TO (544-6986).

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION AVAILABLE, CATALOG No.,

TYPE No., AND DATE CODE. IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE THE PROBLEM OVER THE PHONE. IF YOU HAVE A SUGGESTION OR COMMENT,

GIVE US ACALL.YOUR FEEDBACK IS VITAL TO BLACK & DECKER.

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ADDITIONAL SPECIFIC SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CARTON CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Read and understand all warnings and operating instructions before using any tool or equipment. When

using tools or equipment, basic safety precautions should always be followed to reduce the risk of personal injury.

Improper operation, maintenance or modification of tools or equipment could result in serious injury and property

damage. There are certain applications for which tools and equipment are designed. Black & Decker strongly

recommends that this product NOT be modified and/or used for any application other than for which it was designed.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

Page 3

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR

SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

SAFETY GUIDELINES - DEFINITIONS

CALIFORNIA PROPOSITION 65

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective

clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from

face and body.

Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

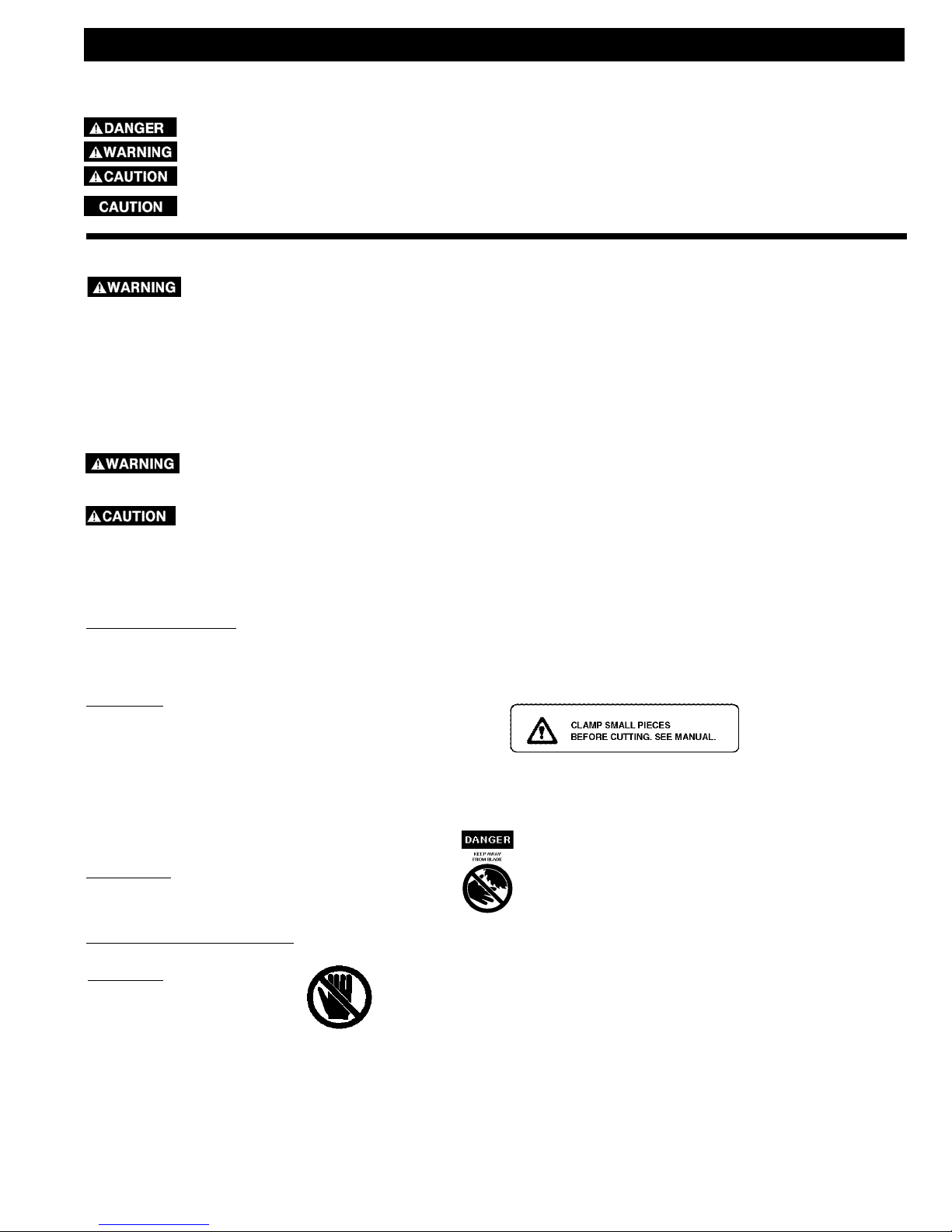

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SAW. WHEN SERVICING, USE

ONLY IDENTICAL REPLACEMENT PARTS. ALWAYS WEAR EYE PROTECTION.

ON FENCE:

CLAMP SMALL PIECES BEFORE CUTTING. SEE MANUAL.

ON GUARD:

DANGER – KEEP AWAY FROM BLADE.

ON GUARD RET

AINER PLATE: “PROPERLY SECURE BRACKET WITH BOTH SCREWS BEFORE USE.”

ALWAYS TIGHTEN ADJUSTMENT KNOBS BEFORE USE. KEEP HANDS 6" FROM PATH OF SAW BLADE. NEVER PERFORM

ANY OPERATION FREEHAND. NEVER CROSS ARMS IN FRONT OF BLADE. THINK! YOU CAN PREVENTACCIDENTS. DO NOT

OPERATE SAW WITHOUT GUARDS IN PLACE. NEVER REACH IN BACK OF SAW BLADE. ALWAYS WEAR EYE PROTECTION.

SHUT OFF POWER AND WAIT FOR BLADE TO STOP BEFORE SERVICING, ADJUSTING TOOL, OR MOVING HANDS.

ON TABLE: (2 PLACES)

Page 4

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT. Failure to follow all instructions listed below, may result in

electric shock, fire, and/or serious personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

1. FOR YOUR OWN SAFETY, READ THE

INSTRUCTION MANUAL BEFORE OPERATING

THE MACHINE. Learning the machine’s

application, limitations, and specific hazards will

greatly minimize the possibility of accidents and

injury.

2. USE CERTIFIED SAFETY EQUIPMENT. Eye

protection equipment should comply with ANSI

Z87.1 standards, hearing equipment should

comply with ANSI S3.19 standards, and dust

mask protection should comply with

MSHA/NIOSH certified respirator standards.

Splinters, air-borne debris, and dust can cause

irritation, injury, and/or illness.

3. DRESS PROPERLY. Do not wear tie, gloves, or

loose clothing. Remove watch, rings, and other

jewelry. Roll up your sleeves. Clothing or jewelry

caught in moving parts can cause injury.

4. DO NOT USE THE MACHINE IN A

DANGEROUS ENVIRONMENT. The use of

power tools in damp or wet locations or in rain

can cause shock or electrocution. Keep your

work area well-lit to prevent tripping or placing

arms, hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating

and changing accessories. Poorly maintained tools and

machines can further damage the tool or machine

and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the

machine, check for any damaged parts. Check

for alignment of moving parts, binding of moving

parts, breakage of parts, and any other

conditions that may affect its operation. A guard

or any other part that is damaged should be

properly repaired or replaced. Damaged parts

can cause further damage to the machine and/or

injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is

a potentially dangerous environment. Children and

visitors can be injured.

9. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure that the switch is in the

“OFF” position before plugging in the power cord.

In the event of a power failure, move the switch

to the “OFF” position. An accidental start-up can

cause injury.

10. USE THE GUARDS. Check to see that all guards

are in place, secured, and working correctly to

prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES

BEFORE STARTING THE MACHINE. Tools,

scrap pieces, and other debris can be thrown at

high speed, causing injury.

12. USE THE RIGHT MACHINE. Don’t force a

machine or an attachment to do a job for which it

was not designed. Damage to the machine

and/or injury may result.

13. USE RECOMMENDED ACCESSORIES. The use

of accessories and attachments not recommended by Black & Decker may cause damage

to the machine or injury to the user.

14. USE THE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition.

When using an extension cord, be sure to use

one heavy enough to carry the current your

product will draw. An undersized cord will cause

a drop in line voltage, resulting in loss of power

and overheating. See the Extension Cord Chart

for the correct size depending on the cord length

and nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge

number, the heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or vise

when you cannot secure the workpiece on the

table and against the fence by hand or when your

hand will be dangerously close to the blade (within

6”).

16. DON’T FORCE THE WORKPIECE ON THE

MACHINE. Damage to the machine and/or injury

may result.

17. DON’T OVERREACH. Loss of balance can make

you fall into a working machine, causing injury.

18. NEVER STAND ON THE MACHINE. Injury could occur

if the tool tips, or if you accidentally contact the cutting

tool.

19. NEVER LEAVE THE MACHINE RUNNING

UNATTENDD. TURN THE POWER OFF. Don’t leave

the machine until it comes to a complete stop. A child or

visitor could be injured.

20. TURN THE MACHINE “OFF”, AND DISCONNECT

THE MACHINE FROM THE POWER SOURCE before

installing or removing accessories, before

adjusting or changing set-ups, or when making

repairs. An accidental start-up can cause injury.

21. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY

REMOVING STARTER KEYS. The accidental

start-up of a machine by a child or visitor could

cause injury.

22. STAY ALERT, WATCH WHAT YOU ARE DOING,

AND USE COMMON SENSE. DO NOT USE THE

MACHINE WHEN YOU ARE TIRED OR UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION. A moment of inattention while

operating power tools may result in injury.

23. THE DUST GENERATED by certain woods and

wood products can be injurious to your health.

Always operate machinery in well-ventilated areas,

and provide for proper dust removal. Use wood

dust collection systems whenever possible.

Page 5

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

ADDITIONAL SPECIFIC SAFETY RULES

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

1. DO NOT OPERATE THIS MACHINE until it is

completely assembled and installed according to the

instructions. A machine incorrectly assembled can

cause serious injury.

2. OBTAIN ADVICE FROM another qualified person if

you are not familiar with the operation of this machine.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections to prevent shock or

electrocution.

4. SECURE THE MACHINE TO A SUPPORTING SURFACE.

Vibration can possibly cause the machine to slide,

walk, or tip over, causing serious injury.

5. USE ONLY CROSSCUT SAW BLADES. Use only

zero-degree or negative hook angles when using

carbide-tipped blades. Do not use blades with deep

gullets. These can deflect and contact the guard, and

can cause damage to the machine and/or serious

injury.

6. USE ONLY BLADES OF THE CORRECT SIZE AND

TYPE specified for this tool to prevent damage to the

machine and/or serious injury.

7. USE A SHARP BLADE. Check the blade to see if it

runs true and is free from vibration. A dull blade or a

vibrating blade can cause damage to the machine

and/or serious injury.

8. INSPECT BLADE FOR CRACKS or other damage

prior to operation. A cracked or damaged blade can

come apart and pieces can be thrown at high speeds,

causing serious injury. Replace cracked or damaged

blades immediately.

9. CLEAN THE BLADE AND BLADE FLANGES prior to

operation. Cleaning the blade and flanges allows you

to check for any damage to the blade or flanges. A

cracked or damaged blade or flange can come apart

and pieces can be thrown at high speeds, causing

serious injury.

10. USE ONLY BLADE FLANGES specified for this tool

to prevent damage to the machine and/or serious

injury.

11. CLEAR THE AREA OF FLAMMABLE LIQUIDS

and/or gas prior to operation. Sparks can occur that

would ignite the liquids and cause a fire or an

explosion.

12. CLEAN THE MOTOR AIR SLOTS of chips and

sawdust. Clogged motor air slots can cause the

machine to overheat, damaging the machine and

possibly causing a short which could cause serious

injury.

13. TIGHTEN THE TABLE CLAMP HANDLE and any

other clamps prior to operation. Loose clamps can

cause parts or the workpiece to be thrown at high

speeds.

14. NEVER START THE TOOL with the blade against the

workpiece. The workpiece can be thrown, causing

serious injury.

15. KEEP ARMS, HANDS, AND FINGERS away from the

blade to prevent severe cuts. Clamp all workpieces

that would cause your hand to be in the “Table

Hazard Zone” (within the red lines).

16. WHEN CUTTING WITH A COMPOUND SLIDING

MITER SAW, PUSH THE SAW FORWARD (AWAY

FROM YOU) and toward the fence. Pulling the saw

toward you can cause the saw to kick upward and

toward you.

17. WHEN USING A SLIDING MITER SAW AS A REGULAR

MITER SAW, LOCK THE SLIDE MECHANISM IN PLACE.

If the slide mechanism is not locked, the saw can kick

back toward you.

18. ALLOW THE MOTOR TO COME TO FULL SPEED

prior to starting cut. Starting the cut too soon can

cause damage to the machine or blade and/or

serious injury.

19. NEVER REACH AROUND or behind the saw blade.

A moving blade can cause serious injury.

20. NEVER CUT FERROUS METALS or masonry. Either

of these can cause the carbide tips to fly off the blade

at high speeds causing serious injury.

21. NEVER CUT SMALL PIECES. Cutting small pieces

can cause your hand to move into the blade, resulting

in serious injury.

22. NEVER LOCK THE SWITCH in the “ON” position.

Setting up the next cut could cause your hand to

move into the blade, resulting in severe injury.

23. NEVER APPLY LUBRICANT to a running blade.

Applying lubricant could cause your hand to move

into the blade, resulting in serious injury.

24. DO NOT PERFORM FREE-HAND OPERATIONS.

Hold the work firmly against the fence and table.

Free-hand operations on a miter saw could cause the

workpiece to be thrown at high speeds, causing

serious injury. Use clamps to hold the work when

possible.

25. AFTER COMPLETING CUT, release power switch

and wait for coasting blade to come to a complete

stop before returning saw to raised position. A

moving blade can cause serious injury.

26. TURN OFF THE MACHINE and allow the blade to

come to a complete stop prior to cleaning the blade

area or removing debris in the path of the blade. A

moving blade can cause serious injury.

27. TURN OFF MACHINE and allow the blade to come

to a complete stop before removing or securing

workpiece, changing workpiece angle, or changing

the angle of the blade. A moving blade can cause

serious injury.

28. PROPERLY SUPPORT LONG OR WIDE WORK-

PIECES. Loss of control of the workpiece can cause injury.

29. NEVER PERFORM LAYOUT, ASSEMBLY, OR SET-UP

WORK on the table/work area when the machine is

running. A sudden slip could cause a hand to move

into the blade. Severe injury can result.

30. TURN THE MACHINE “OFF”, disconnect the

machine from the power source, and clean the

table/work area before leaving the machine. LOCK

THE SWITCH IN THE “OFF” POSITION to prevent

unauthorized use. Someone else might accidentally

start the machine and cause injury to themselves.

32. BEFORE OPERATING THE SAW, check and

securely lock the bevel, miter, and sliding fence

adjustments.

33. ADDITIONAL INFORMATION regarding the safe and

proper operation of power tools (i.e. a safety video) is

available from the Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851

(www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121

Spring Lake Drive, Itasca, IL 60143-3201. Please refer

to the American National Standards Institute ANSI

01.1 Safety Requirements for Woodworking

Machines and the U.S. Department of Labor

regulations.

Page 6

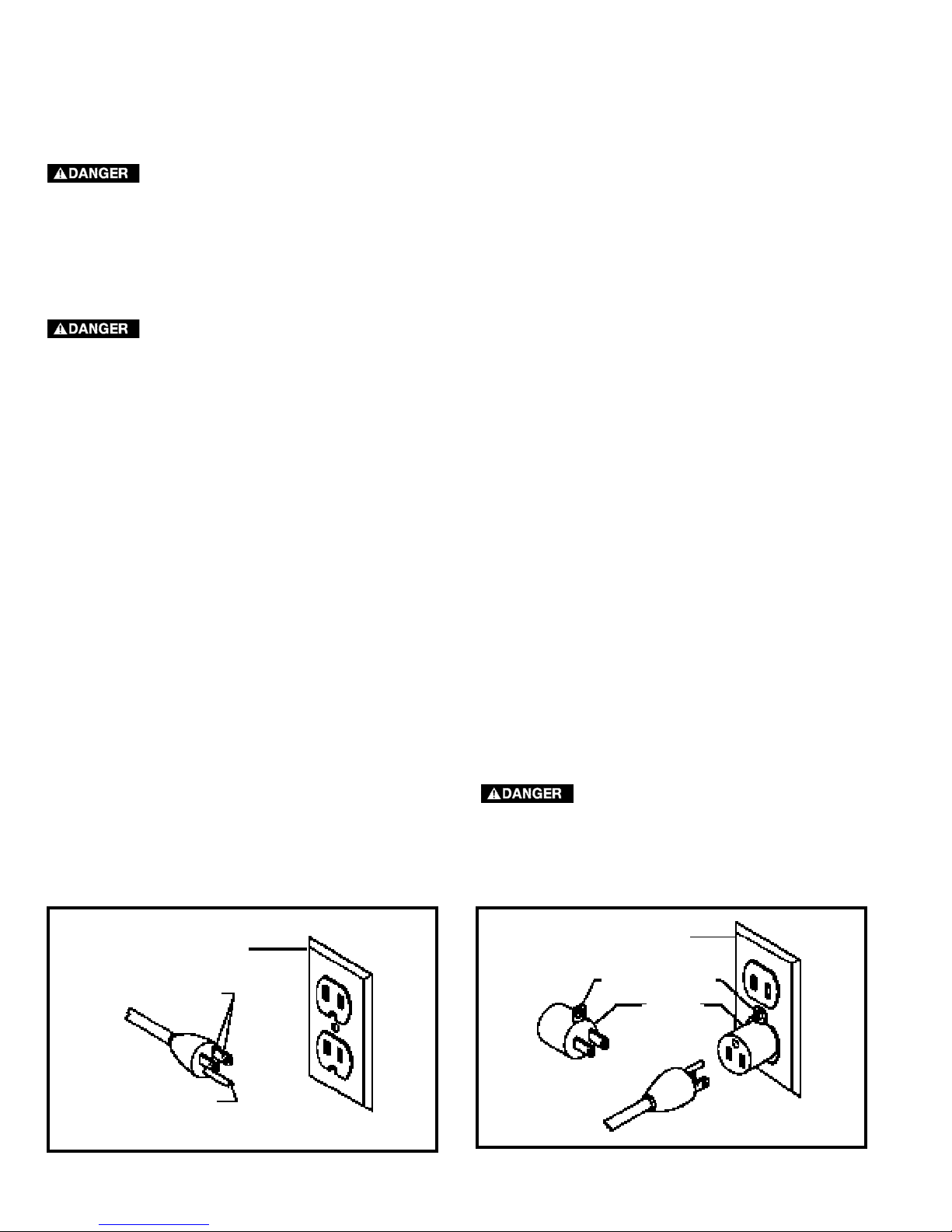

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have 3prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch (s) is in the “OFF” position and be sure that the electric current is of

the same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

2. Grounded, cord-connected machines intended for

use on a supply circuit having a nominal rating less

than 150 volts:

If the machine is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug

illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect

this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box. Whenever

the adapter is used, it must be held in place with a metal

screw.

NOTE: In Canada, the use of a temporary adapter is not

permitted by the Canadian Electric Code.

IN ALL CASES, MAKE CERTAIN THE

RECEPTACLE IN QUESTION IS PROPERLY

GROUNDED. IF YOU ARE NOT SURE HAVE A

QUALIFIED ELECTRICIAN CHECK THE

RECEPTACLE.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is

equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely

understood, or if in doubt as to whether the machine is

properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown in

Fig. A.

Repair or replace damaged or worn cord immediately.

POWER CONNECTIONS

MOTOR SPECIFICATIONS

Your machine is wired for 120 volts, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

Page 7

Remove the miter saw and all loose items from the carton.

Do not lift the miter saw by the switch handle. This action can cause misalignment. Always lift the machine

by the base or the carrying handle.

1. Miter Saw

2. Dust Bag

3. 1/2" Blade Wrench

4. 5mm Hex Wrench

5. Table Lock Handle

ASSEMBLY

ASSEMBLY TOOLS REQUIRED

(Supplied)

* 5mm hex wrench

* 1/2” Blade wrench

(Not supplied)

* Phillips head screwdriver

* A square to make adjustments

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from all unpainted

surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone, gasoline or lacquer thinner for

this purpose). After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

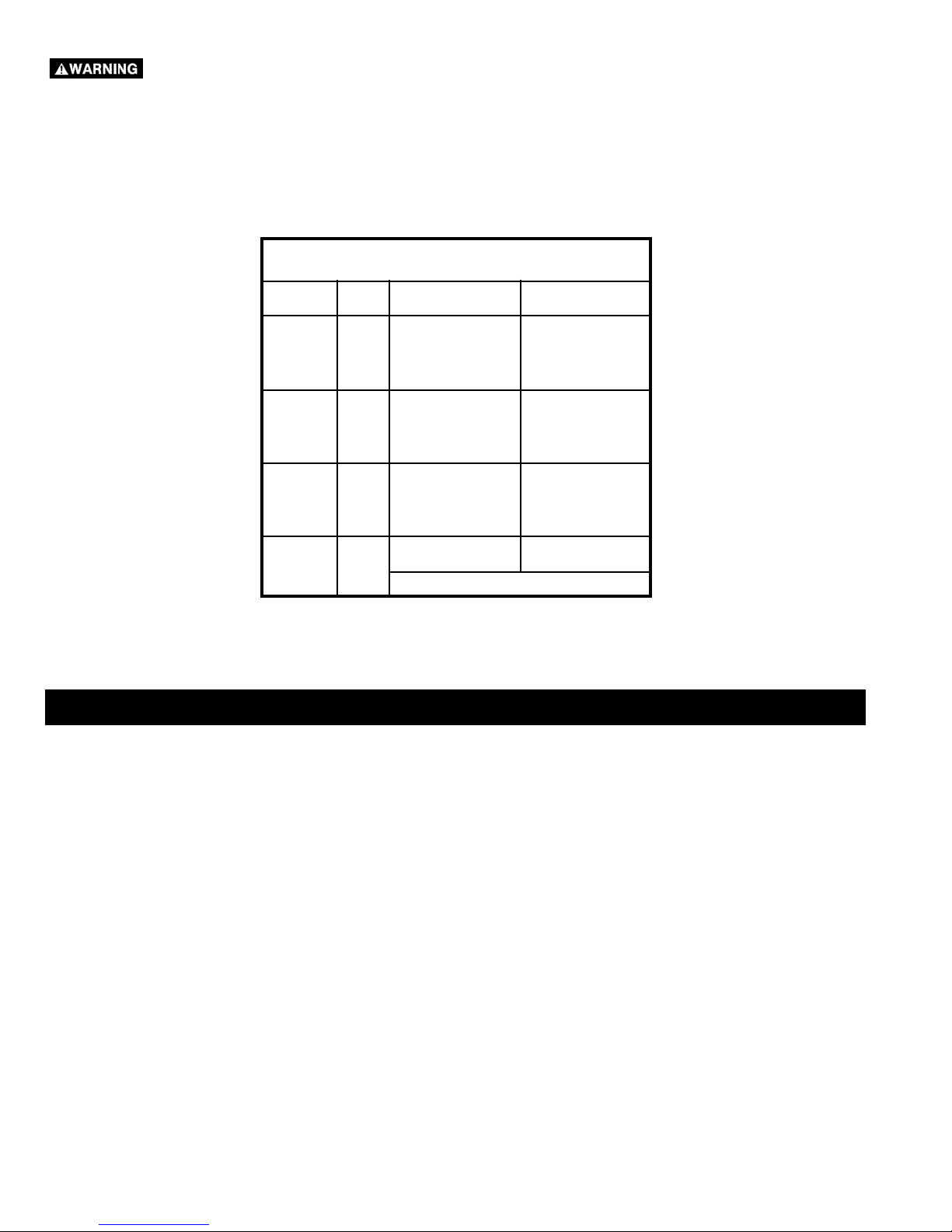

CARTON CONTENTS

2

3

4 5

1

Fig. 2

Fig. 1

Page 8

FOREWORD

Model BDMS100 is a 10" Compound Power Miter Saw designed to cut wood, plastic, and aluminum. Compound angle

and bevel cutting are easy and accurate. It can crosscut up to 5-3/4" x 2-3/8", miter at 45° both left and right up to 41/8" x 2-3/8", bevel at 45° left up to 5-7/8" x 1-9/16", and compound 45° x 45°,4-1/8" x 1-9/16". It has positive miter

stops at 0°, 22.5°, 31.62°, and 45° both left and right, and bevel stops at 0° and 45° adjustable. A dust bag is included

to catch fine dust and wood chips.

FUNCTIONAL DESCRIPTION

EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s

plug. When using an extension cord, be sure to use one heavy enough to carry the current of the machine. An

undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig.3 shows the correct

gauge to use depending on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 120

up to

25 18 AWG

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

up to

25 18 AWG

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

up to

25 16 AWG

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

up to

25 14 AWG

12-16 120 25-50 12 AWG

12-16 120

GREATER THAN 50 FEET NOT RECOMMENDED

NOTICE: The photo on the manual cover illustrates the current production model. All other illustrations contained in

the manual are representative only and may not depict the actual color, labeling, or accessories, and are intended to

illustrate technique only.

Fig. 3

Page 9

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual.

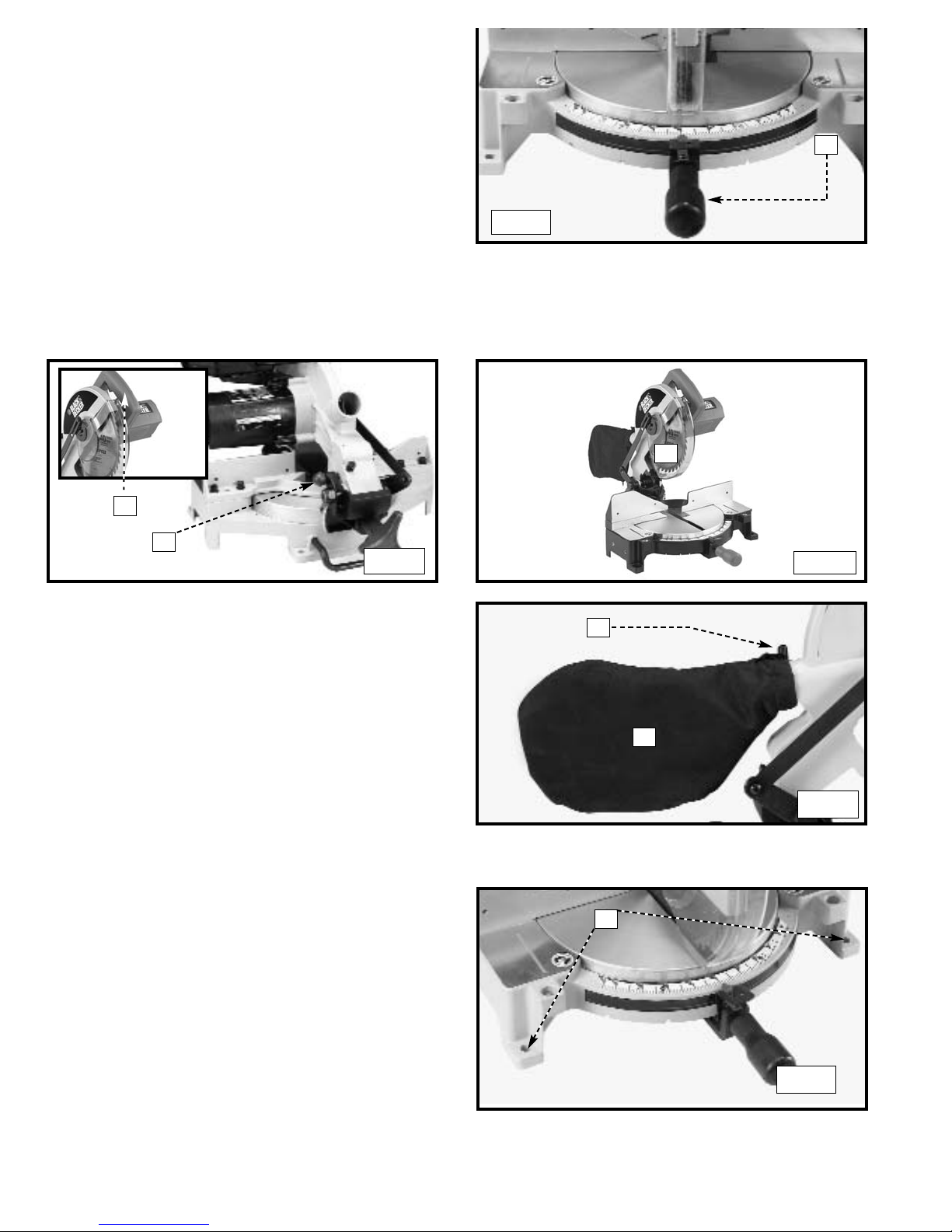

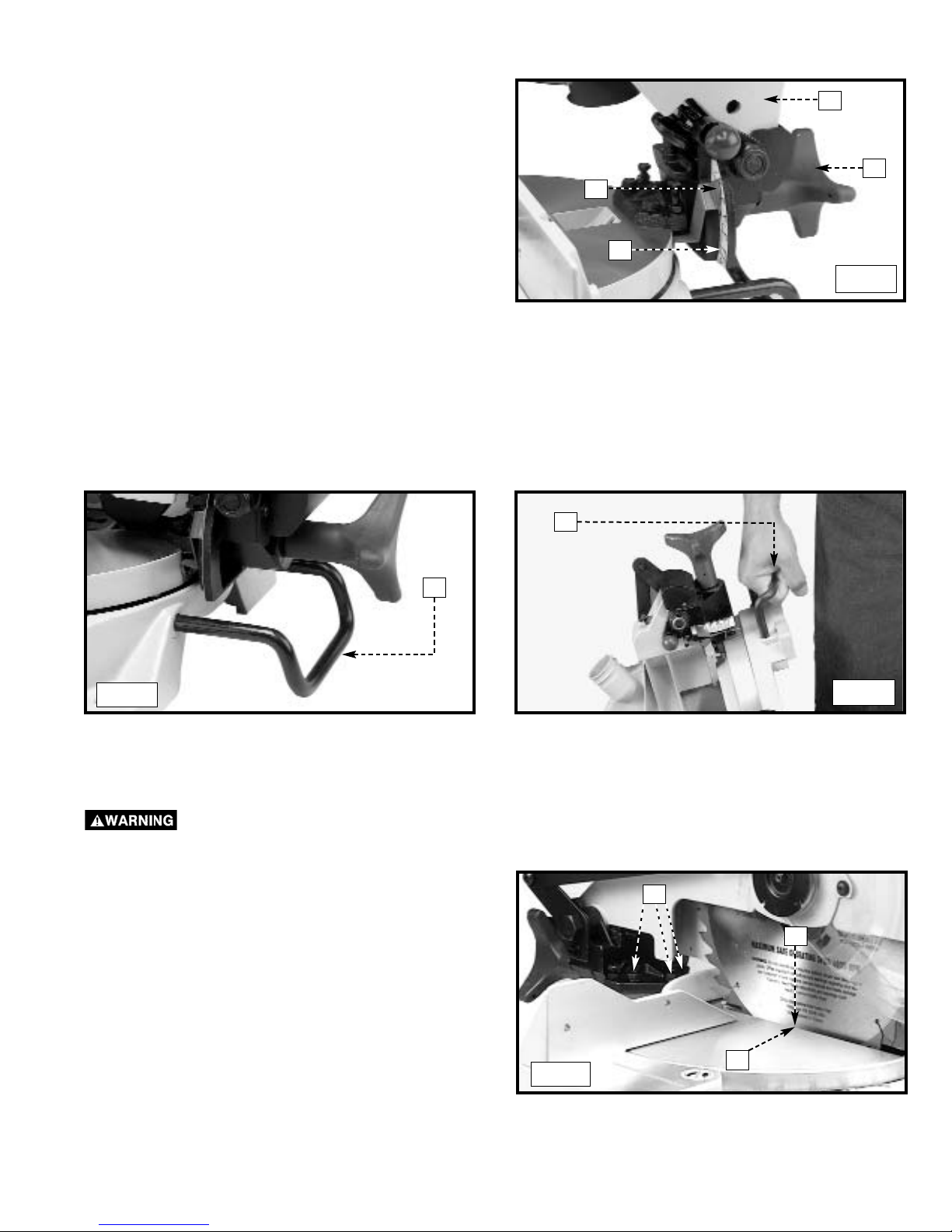

Thread the table lock handle (A) Fig. 4 into the threaded hole (B)

of the arm bracket.

1. Turn the table lock handle (A) Fig. 5 counter-clockwise one

or two turns, and depress the index lever (B) to release the

45° positive stop.

B

A

Fig. 4

ROTATING THE TABLE TO THE 90° DEGREE POSITION

Fig. 5

A

B

Page 10

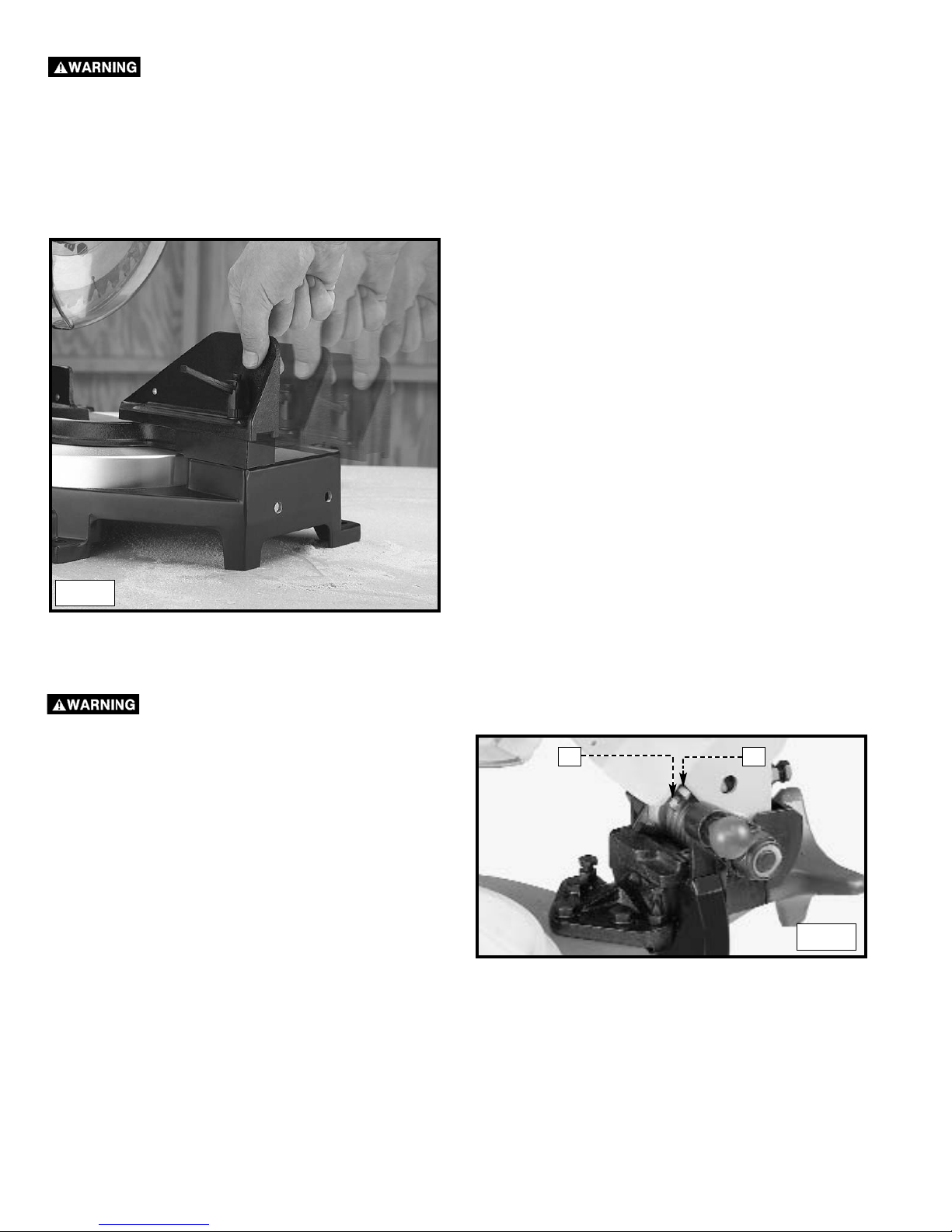

FASTENING THE MACHINE TO A SUPPORTING SURFACE

Before operating your compound miter saw, make sure that it

is firmly mounted to a sturdy workbench or other supporting

surface. Four holes are provided, two of which are shown at (A)

Fig. 10.

When frequently moving the saw from place to place, mount

the saw on a 3/4" piece of plywood, and clamp the plywood to

a supporting surface with “C” clamps.

2. Rotate the table to the left until the index stop engages

with the 90° positive stop (Fig. 6). Tighten the table lock

handle (A).

1. Push down on handle (A), Inset, Fig. 7. Pull out the cuttinghead lock knob (B).

2. Move the cuttinghead (C) to the up position (Fig. 8).

ATTACHING THE DUST BAG

Squeeze the spring clips (A) Fig. 9 of the dust bag (B) and clip

the dust bag (B) over the ribs of the dust chute.

MOVING CUTTINGHEAD TO THE UP POSITION

Fig. 6

A

Fig. 7

Fig. 8

A

B

C

Fig. 9

A

B

A

Fig. 10

Page 11

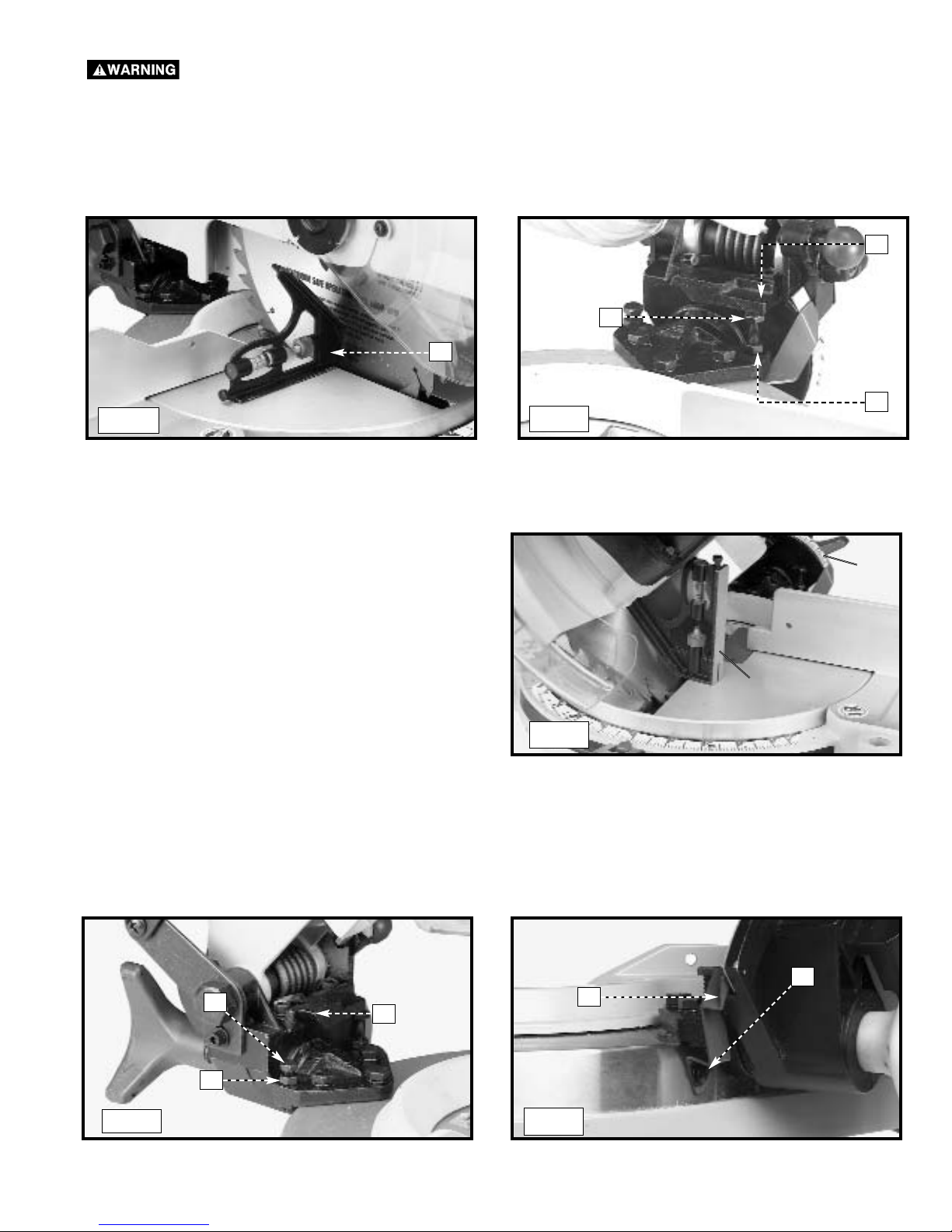

A turning saw blade can be dangerous. After completing cut, release switch trigger (A) Fig. 12, to activate

blade brake. Keep cuttinghead down until blade has come to a complete stop.

The torque developed during braking may loosen the arbor screw (E) Fig. 44. The arbor screw should be checked

periodically and tightened if necessary.

OPERATION

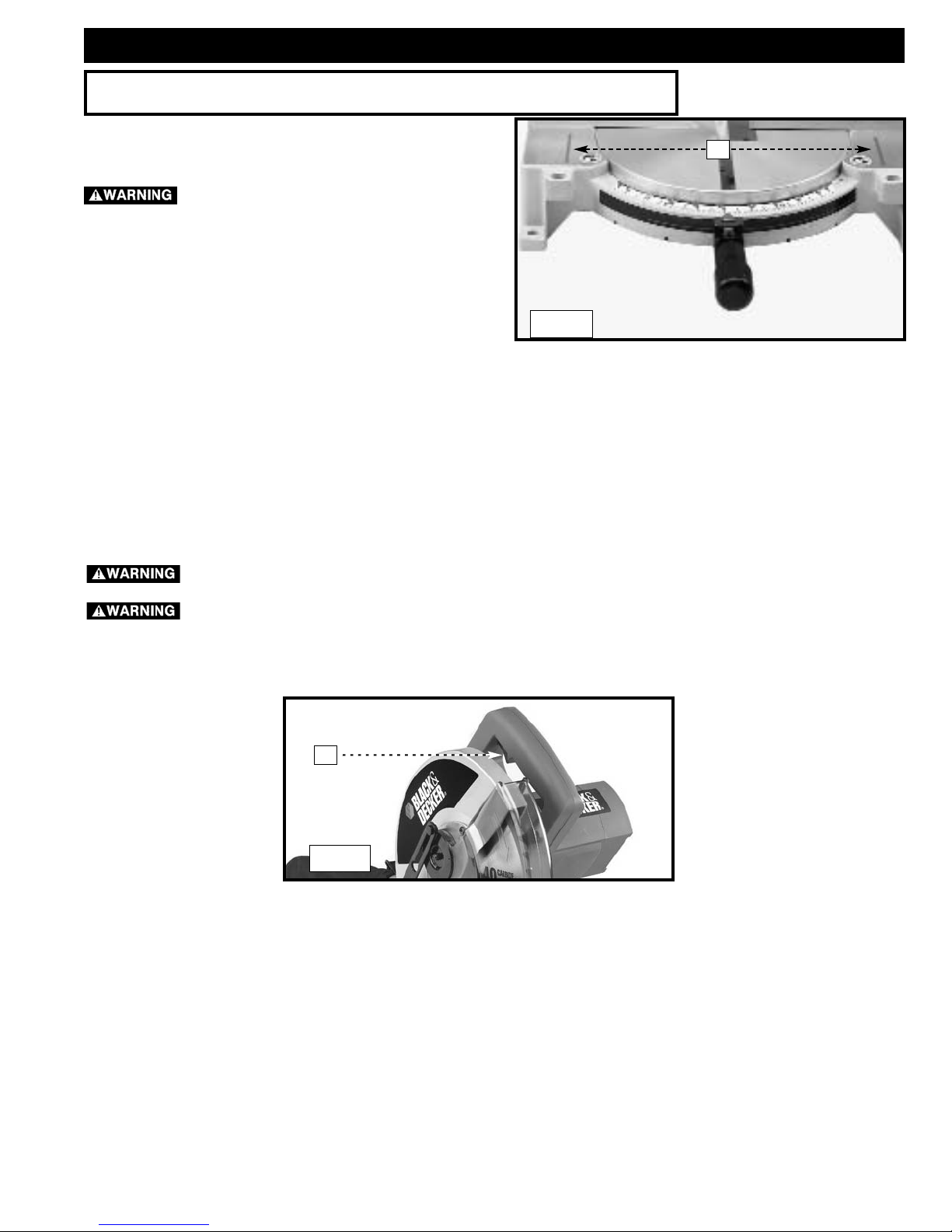

TABLE HAZARD AREA

The area inside the two red lines (A) Fig. 11

on the table is designated as a hazard zone. Never place

your hands inside this area while the machine is running.

STARTING AND STOPPING THE MITER SAW

To start the miter saw, depress the switch trigger (A) Fig. 12. To stop the miter saw, release the switch trigger.

This saw is equipped with an automatic electric blade brake. As soon as the switch trigger (A) Fig. 12, is released, the electric brake

is activated and stops the blade in seconds.

OPERATIONAL CONTROLS AND ADJUSTMENTS

Fig. 11

A

Fig. 12

A

Page 12

ADJUSTING THE POINTER

To transport the saw, always lock the cuttinghead in the down

position. Lower the cuttinghead (A) Fig. 17, and push the

cuttinghead lock knob (B) into the hole in the cutting arm until it

locks the cuttinghead.

IMPORTANT: Carrying the machine by the switch handle will

cause misalignment. Always lift the machine by the base or

by the carrying handle (See Fig. 20).

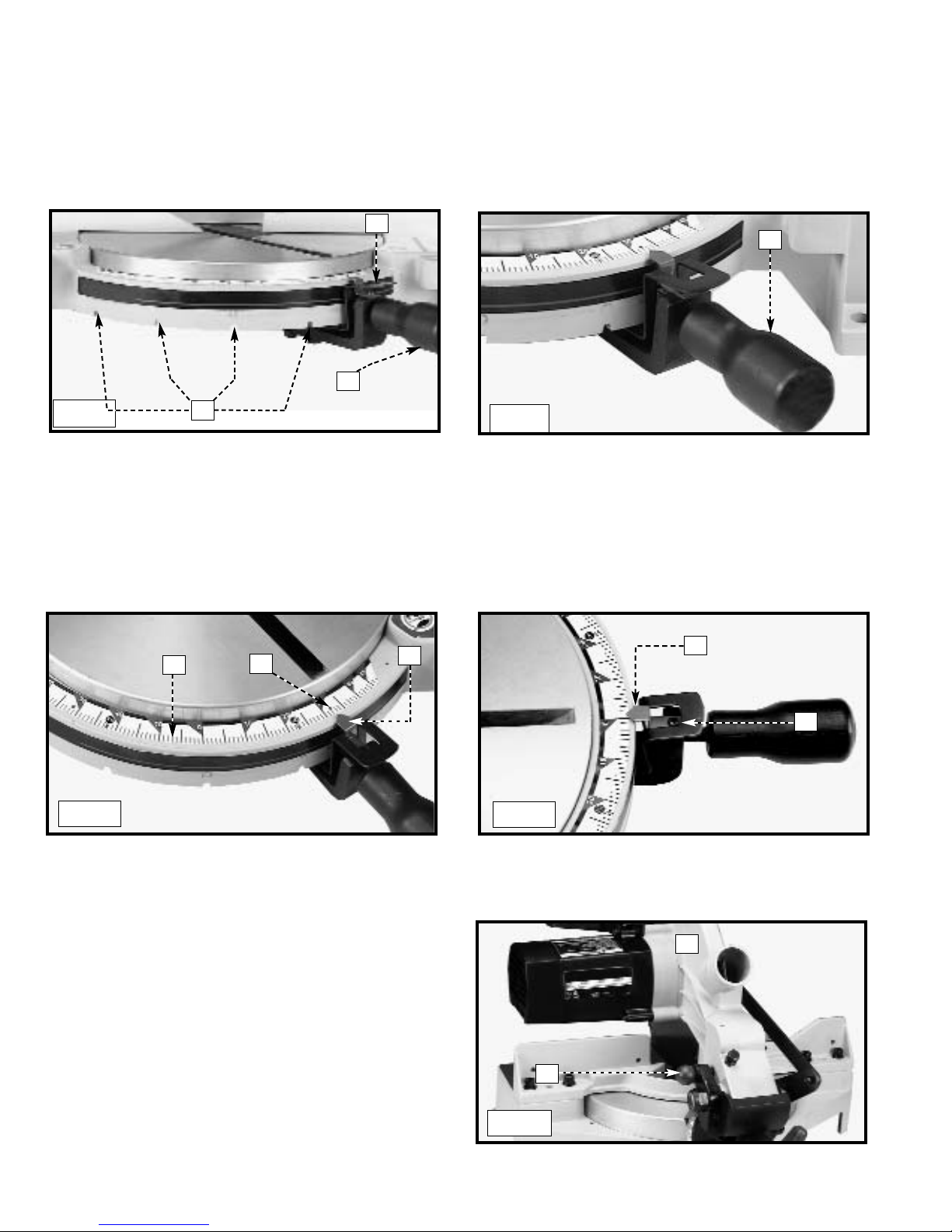

Your miter saw will cut any angle from a straight 90° cut to 47° right and left. Turn the lock handle (A) Fig. 13 counter-clockwise one

or two turns, depress the index lever (B), and move the control arm to the desired angle. Tighten the lock handle (A).

The miter saw is equipped with positive stops at the 0°, 22.5°, 31.62°, and 45° right and left positions. Loosen the lock handle (A)

Fig. 13, and move the control arm until the bottom of the index lever (B) engages into one of the positive stops, four of which are

shown at (C). Tighten the lock handle (A). To disengage the positive stop, depress the index lever (B).

A triangle indicator (D) Fig. 15 is provided on the miter scale at the 31.62° right and left miter positions for cutting crown moulding.

(Refer to the “CUTTING CROWN MOULDING” section of this manual).

IMPORTANT: Always tighten the lock handle (A) Fig. 14 before cutting.

POINTER AND SCALE

The pointer (E) Fig. 15 indicates the angle of cut. Each line on the scale (F) represents 1 degree. When you move the pointer from

one line to the next on the scale, you change the angle of cut by 1 degree.

ROTATING THE TABLE FOR MITER CUTTING

Fig. 13

Fig. 14

C

B

A

A

Fig. 15

F

D

E

To adjust the pointer (E) Fig. 16, loosen the screw (G), adjust the pointer (E), and tighten the screw.

E

G

Fig. 16

LOCKING THE CUTTINGHEAD IN THE DOWN POSITION

A

B

Fig. 17

Page 13

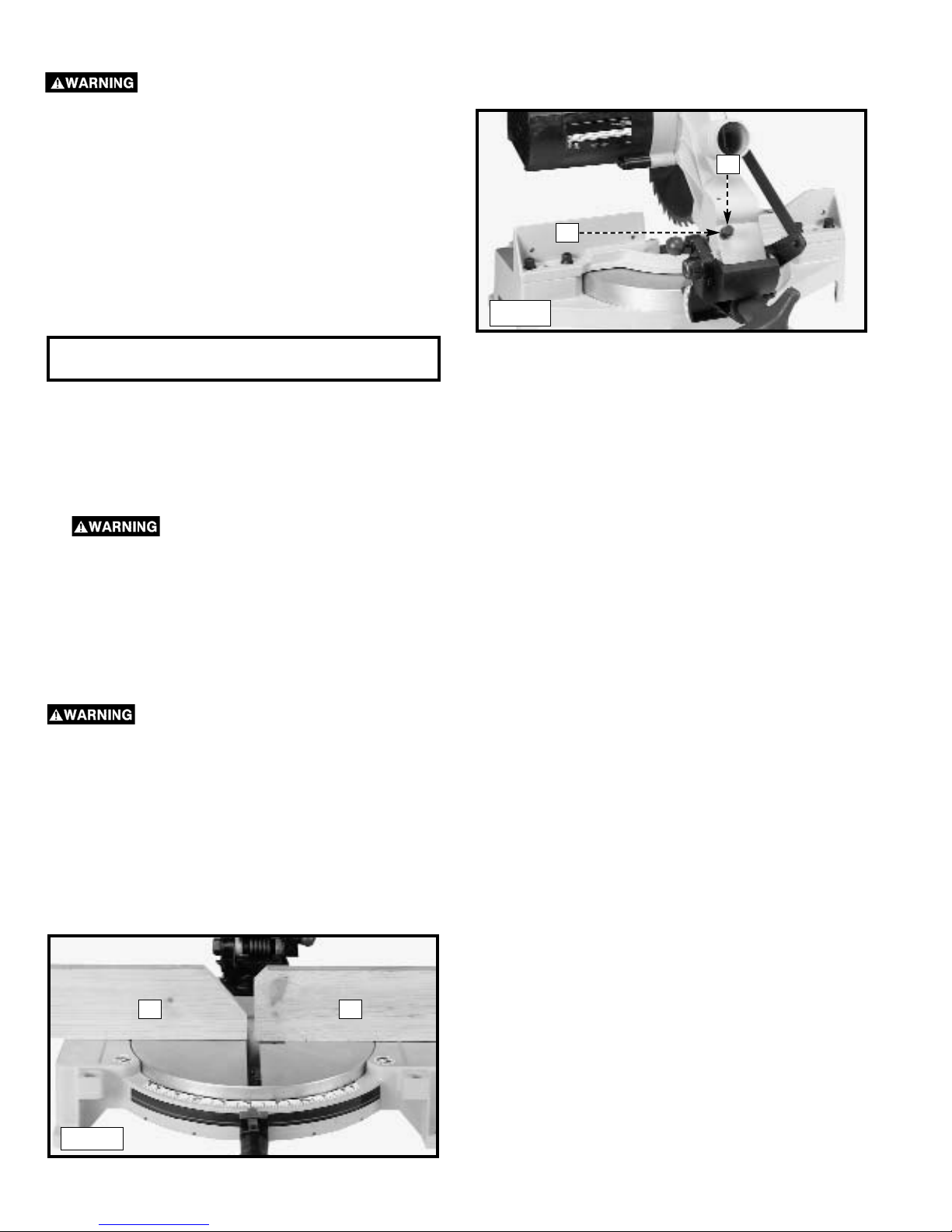

You can tilt the cuttinghead of your compound miter saw to cut

any bevel angle from a 90° straight cut off to a 45° left bevel

angle. Loosen the bevel lock handle (A) Fig. 18, tilt the cutting

arm (B) to the desired angle, and tighten the lock handle (A).

Positive stops are provided to rapidly position the saw blade at

90° and 45° to the table. Refer to the section of this manual

titled “ADJUSTING 90° AND 45° BEVEL STOPS.” The bevel

angle of the cuttinghead is determined by the position of the

pointer (C) Fig. 18 on the scale (D).

A triangle indicator is provided on the bevel scale at the 33.86°

bevel angle for cutting crown moulding. Refer to the

“CUTTING CROWN MOULDING” section of this manual.

A rear support bar (A) Fig. 19 is provided to prevent the machine from tipping to the rear when the cuttinghead returns to the up

position. For maximum support, pull the bar (A) out as far as possible.

You can also use the support bar (A) Fig. 20 to carry the machine.

TILTING THE CUTTINGHEAD FOR BEVEL CUTTING

C

B

A

D

Fig. 18

REAR SUPPORT/CARRYING HANDLE

A

Fig. 19

Fig. 20

A

ADJUSTING THE BLADE PARALLEL TO THE TABLE SLOT

1. Lower the cutting arm. The saw blade (A) Fig. 21 should be

parallel to the left edge (B) of the table opening.

2. To adjust, loosen the three bolts (C) Fig. 21 and move the

cutting arm until the blade is parallel with the left edge (B)

of the table opening and centered in the slot. Tighten the

three bolts (C).

DISCONNECT MACHINE FROM POWER SOURCE!

Fig. 21

C

B

A

Page 14

1. You can limit the downward travel of the saw blade to

prevent it from contacting any metal surfaces of the

machine. Make this adjustment by loosening the locknut

(A) Fig. 23 and turning the adjusting screw (B) in or out.

2. Lower the blade as far as possible. Rotate the blade by

hand to make certain the teeth do not contact any metal

surfaces.

3. Tighten the locknut (A)

Fig. 22

ADJUSTING THE DOWNWARD TRAVEL OF THE SAW BLADE

DISCONNECT MACHINE FROM POWER SOURCE!

Fig. 23

A

B

In order that the saw can bevel to a full 47 degrees left, the left side of the fence can be adjusted to the left to provide clearance. To

adjust the fence, loosen the plastic knob shown in Figure 22 and slide the fence to the left. Make a dry run with the saw turned off and

check for clearance. Adjust the fence to be as close to the blade as practical to provide maximum workpiece support, without

interfering with arm up & down movement. Tighten knob securely. When the bevel operations are complete, don’t forget to relocate the

fence to the right.

NOTE: The guide groove in the left side fence can become clogged with sawdust. If you notice that it is becoming clogged, use a stick

or some low pressure air to clear the guide groove.

FENCE ADJUSTMENT

DISCONNECT MACHINE FROM POWER SOURCE!

Page 15

1. Loosen the bevel lock handle (A) Fig. 18 and move the cutting arm (B) Fig. 18 all the way to the right. Tighten the bevel lock

handle.

2. Place one end of a square (A) Fig. 24 on the table and the other end against the blade. Check to see if the blade is 90° to the

table (Fig. 24).

3. To adjust, loosen the locknut (B) Fig. 25, and turn the screw (C) until the head of the screw (C) contacts the casting (D) when

blade is 90° degrees to the table. Tighten the locknut (B).

4. Loosen the bevel lock handle. Move the cutting arm all the

way to the left bevel position and tighten the bevel lock

handle.

5. Use a combination square (A) Fig. 26 to see if the blade is

at 45° to the table.

6. To adjust, loosen the locknut (E) Fig. 27, and turn the screw (F) until it contacts the casting (G). Tighten the locknut (E).

7. Check to see that the bevel pointer (P) Fig. 28 is pointing to the 45° mark on the bevel scale (S) Fig. 26. To adjust the bevel

pointer (P) Fig. 28, loosen the screw (H) and adjust pointer (P). Tighten the screw (H) securely.

8. These positive stops enable you to rapidly position the blade at the 90° and 45° bevel angle to the table.

A

S

ADJUSTING 90° AND 45° BEVEL STOPS

DISCONNECT MACHINE FROM POWER SOURCE!

Fig. 24

Fig. 25

A

D

C

B

Fig. 26

Fig. 27

Fig. 28

E

G

F

P

H

Page 16

TYPICAL OPERATIONS AND HELPFUL HINTS

1. Before cutting, make certain that the cutting arm and table are at their correct settings and firmly locked in place.

2. Place the workpiece on the table and hold it firmly against the fence.

3. Keep your hands out of the “Hazard Zone”.

4. For best results, cut at a slow, even cutting rate.

5. Never attempt freehand cutting (wood that is not held firmly against the fence and table).

Holes are provided in the fence to attach an auxiliary fence (A) Fig. 30. This auxiliary fence is constructed of straight wood

approximately 1/2" thick by 3" high by 20" long.

MACHINE USE

AUXILIARY WOOD FENCE

When performing multiple or repetitive operations that result in small cut-off pieces (one inch or less), the

saw blade can catch the cut-off pieces and project them out of the machine or into the blade guard and housing, causing

damage or injury. To limit the risk, mount an auxiliary wood fence on your saw (Fig. 30).

NOTE: The auxiliary fence (A) is used ONLY with the saw blade in the 0° bevel position (90° to the table). When you bevel cut (blade

tilted), remove the auxiliary fence.

A

A

Fig. 30

The tension of the cuttinghead return spring was adjusted

at the factory so that the cuttinghead returns to the "up"

position after cutting.

To adjust the spring tension, loosen the locknut (A) Fig.

29 and turn the screw (B) (clockwise to increase or

counterclockwise to decrease the spring tension). After

adjustment, tighten the locknut (A).

ADJUSTING THE TENSION OF THE CUTTINGHEAD RETURN SPRING

DISCONNECT MACHINE FROM POWER SOURCE!

B

A

Fig. 29

Page 17

GENERAL CUTTING OPERATIONS

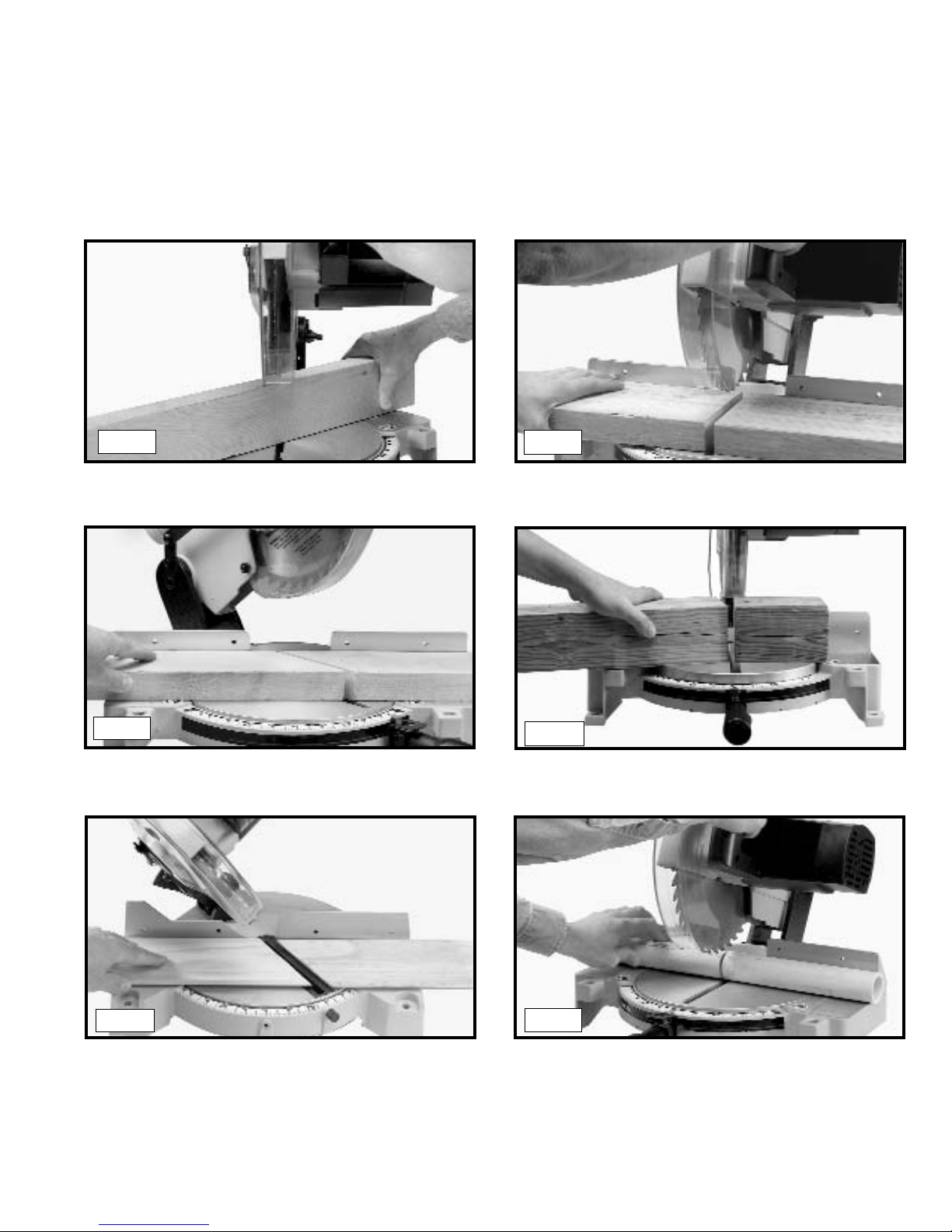

1. Your machine has the capacity to cut standard 2 x 4’s, lying flat or on edge, at the 45° right and left miter angles (Fig. A1 & A2).

2. A standard 2 x 6 can be cut in the 90° straight cut-off position in one pass (Fig. A3).

3. Cutting a standard 4 x 4 can be accomplished with one pass (Fig. A4).

4. This machine has the capacity to accurately cut crown mouldings and other bevel-type cuts (Fig. A5).

5. Cutting various sizes of plastic pipe is an easy job with this machine (Fig. A6). Hold pipe firmly against the fence. Use extra care

and secure pipe firmly when cutting angles into pipe.

A1 A2

A3

A4

A5

A6

Page 18

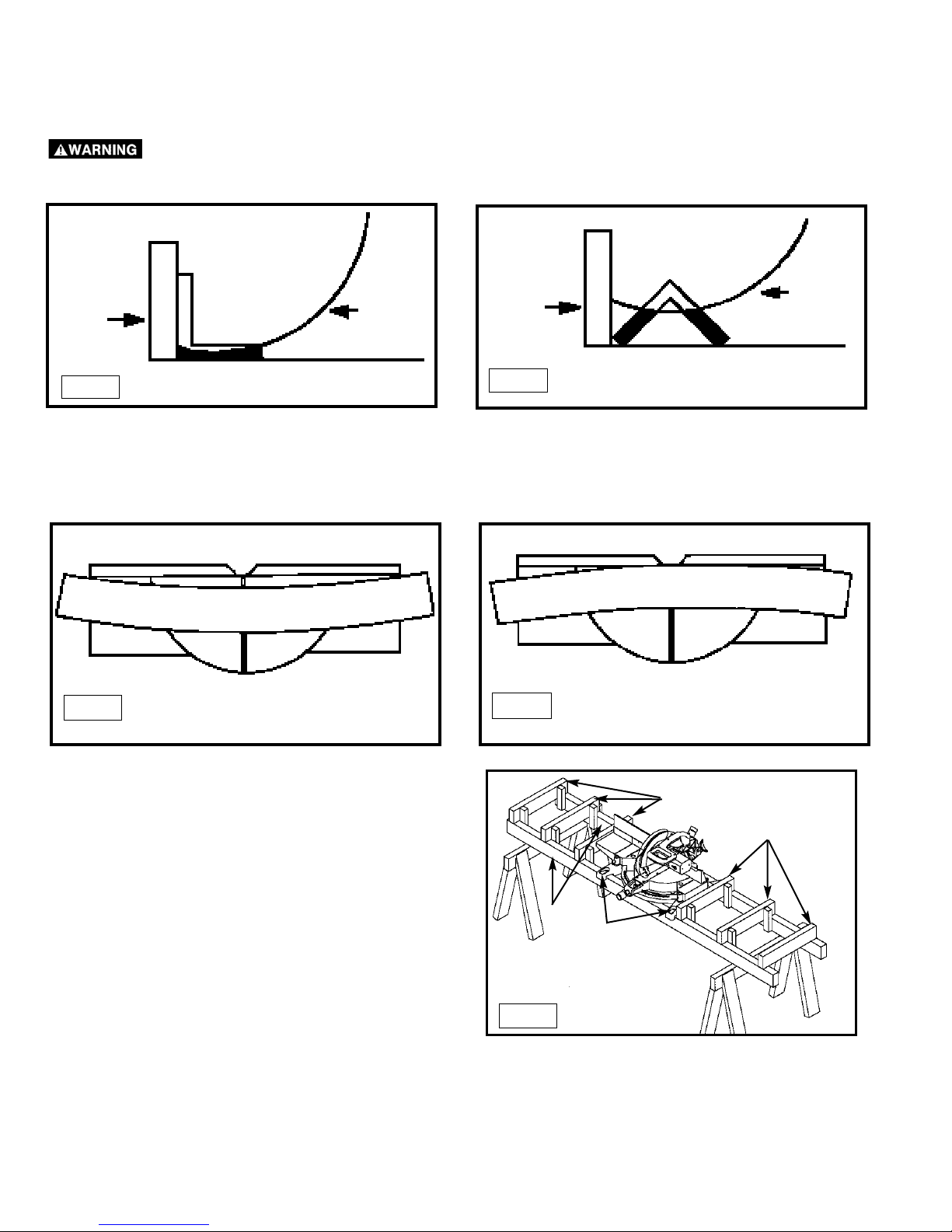

CUTTING BOWED MATERIAL

Check to see if your workpiece is bowed. If it is, make sure the material is positioned on the table as shown in Fig. 33.

If the material is positioned the wrong way, as shown in Fig. 34, the workpiece will pinch the blade near the completion of the cut.

RIGHT

WRONG

C

B

A

C

WORK SUPPORT EXTENSIONS

For support when cutting long pieces, a work support

extension can be constructed. Fig. 35 illustrates the miter saw

mounted to two standard 2 x 4’s (A). Fasten the four mounting

legs (two of which are shown at (B) Fig. 36 to the 2 x 4’s, using

four screws (not supplied) through the four holes in the

mounting legs. The length of the 2 x 4’s (A) can vary,

depending on the kind of work that will need to be cut.

NOTE: Ensure that the top of the support 2 x 4’s (C) are

level with the miter saw table.

This is critical because the distance from the top of the

2 x 4’s (A) to the miter saw table varies from saw to saw. In

most cases, standard 2 x 4’s (C) can used. If these are too

high, cut the 2 x 4s (C) to provide this height or use other

properly-sized wood.

CUTTING ALUMINUM

Aluminum extrusions such as used for making aluminum screens and storm windows can easily be cut with your compound miter

saw. When cutting aluminum extrusions, or other sections that can be cut with a saw blade and are within the capacity of the machine,

position the material so the blade is cutting through the smallest cross-section (Fig. 31). The wrong way to cut

aluminum angles is illustrated in Fig. 32. Be sure to apply a stick wax to the blade before cutting aluminum stock. This stick wax is

available at most industrial mill supply houses. The wax provides proper lubrication and keeps chips from adhering to the blade.

NEVER APPLY LUBRICANT TO THE BLADE WHILE THE MACHINE IS RUNNING.

FENCE

BLADE

WRONG

FENCE

BLADE

RIGHT

Fig. 32

Fig. 31

Fig. 33

Fig. 34

Fig. 35

Page 19

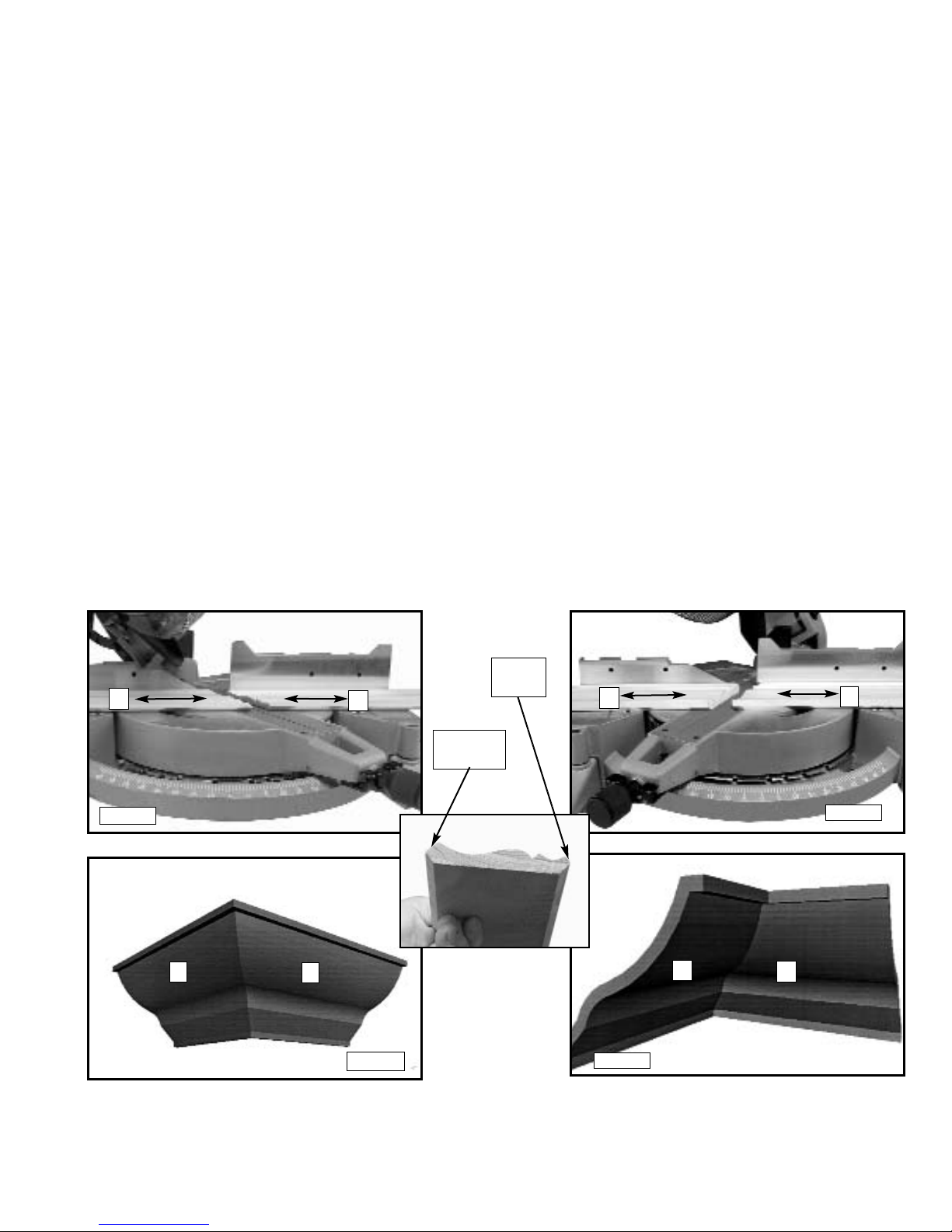

CUTTING CROWN MOULDING

One of the many features of the saw is the ease of cutting crown moulding. The following is an example of cutting both inside and

outside corners on 52°/38° wall angle crown moulding.

1. Move the table to the 31.62° right miter position and lock the table in position. NOTE: A positive stop is provided to find this angle

quickly.

2. Tilt the saw blade to the 33.86° left bevel position and tighten bevel lock handle. NOTE: A triangle indicator is provided on the

bevel scale to find this angle quickly.

3. Place the crown moulding on the table with the CEILING EDGE of the moulding against the fence, and make the cut, as shown

in Fig. 36.

NOTE: The piece of crown moulding used for the outside corner will always be on the right hand side of the blade, as shown at (A)

Fig. 36. The piece of crown moulding used for the inside corner will always be on the left hand side of the blade, as shown at (B)

Fig. 36.

4. To make the matching halves of the inside and outside corners, rotate the table to the 31.62° left miter position.

NOTE: A positive stop is provided to find this angle quickly. The saw blade is already tilted to the 33.86° left bevel position from the

previous cut.

5. Place the crown moulding on the table with the WALL EDGE of the crown moulding against the fence and make the cut. Again,

the piece of crown moulding used for the outside corner will always be on the right side of the blade, as shown at (C) Fig. 37. The

piece of crown moulding used for the inside corner will always be on the left side of the blade, as shown at (D) Fig. 37.

6. Fig. 38 illustrates the two outside corner pieces; (A) being the piece cut at (A) Fig. 36 and (C) being the piece cut at (C) Fig. 37.

7. Fig. 39 illustrates the two inside corner pieces; (B) being the piece cut at (B) Fig. 36, and (D) being the piece cut at (D) Fig. 37.

45-45 CROWN MOULDING

NOTE: If you are cutting crown moulding that is 45°-45°, follow the same procedure above, with the exception that the bevel position

will always be at 30° and the miter position will be 35-1/4° to the right or left.

Fig. 37

Fig. 36

Fig. 38

Fig. 39

D

C

B

A

C

A

B

D

WALL

EDGE

CEILING

EDGE

Page 20

MAINTENANCE

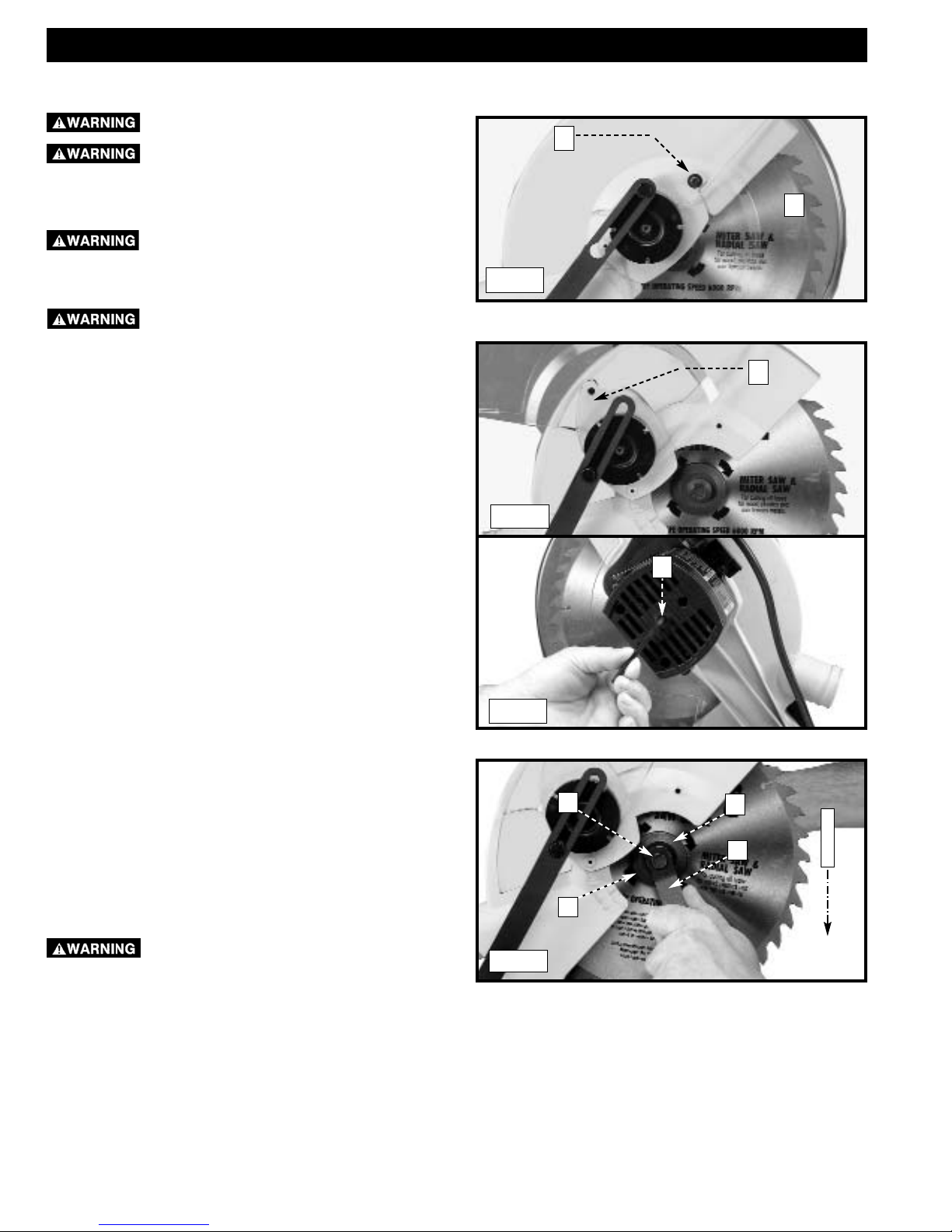

CHANGING THE BLADE

Use only cross-cutting saw blades.

When using carbide-tipped blades, do not

use blades with deep gullets as they can

deflect and contact the guard.

Use only 10" diameter saw blades which are

rated for 5200 rpm or higher and have 5/8"

diameter arbor holes.

1. Remove screw (A) Fig. 40 and rotate cover (B) to the rear

(Fig. 41).

2. To remove the saw blade, insert the hex wrench (C)

Fig. 42 into the hex hole located on the rear end of the

motor shaft to keep the shaft from turning.

3. Use a wrench (G) Fig. 43 to loosen the arbor screw (E) by

turning it clockwise.

4. Remove the arbor screw (E) Fig. 43, the outside blade

flange (F), and the saw blade from the saw arbor.

5. Attach the new saw blade

making certain that the teeth of

the saw blade are pointing down (Fig. 43). Place the

outside blade flange (F) on the arbor, and attach the arbor

screw (E) by turning it counter-clockwise using the wrench

(G) Fig. 43. At the same time, use the hex wrench (C) Fig.

42 to keep the arbor from turning.

6. Rotate the cover back to the front and replace the screw

that was removed in STEP 1.

DISCONNECT MACHINE FROM POWER SOURCE!

Remove wrenches (C) Fig. 42 and (G) Fig. 43

before starting machine.

Fig. 40

Fig. 41

Fig. 42

Fig. 43

A

B

B

C

E

B

G

T

E

E

T

H

F

Page 21

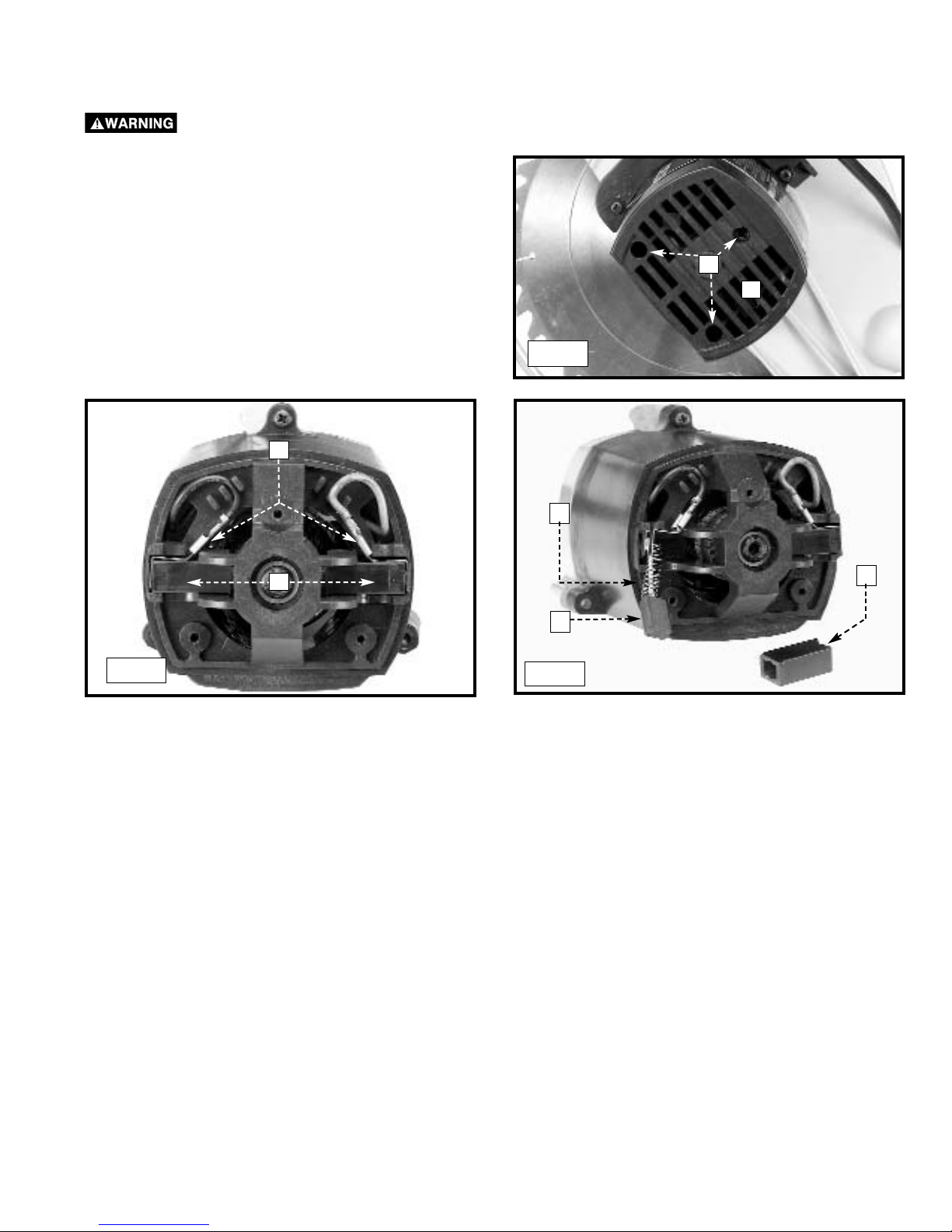

1. Remove three screws (A) Fig. 44 and remove the motor

cover (B).

2. The brushes are located in the two holders (C) Fig. 45.

Remove spade type terminal connector (D) and pull out

brush holders (C).

3. Fig. 46 illustrates one of the brushes (E) removed from the

holder (C). When the carbon on either brush (E) is worn to

3/16" in length or if either spring (F) or shunt wire is

burned or damaged in any way, replace both brushes. If

the brushes are found to be serviceable after re-moving,

reinstall them in the same position.

Brush life varies. It depends on the load on the motor. Check the brushes after the first 50 hours of use for a new machine or after

a new set of brushes has been installed. After the first check, examine them after about 10 hours of use until a replacement is

necessary. To inspect the brushes:

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a

liquid.

IMPORTANT

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement)

should be performed by authorized service centers or other qualified service organizations, always using identical replacement parts.

B

A

Fig. 44

Fig. 45

Fig. 46

D

C

C

E

F

BRUSH INSPECTION AND REPLACEMENT

DISCONNECT MACHINE FROM POWER SOURCE!

Page 22

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE! SAW WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1.Saw not plugged in. 1.Plug in saw.

2.Fuse blown or circuit breaker tripped. 2.Replace fuse or reset

circuit breaker.

3.Cord damaged. 3.Have cord replaced by

authorized service center.

4.Brushes worn out. 4.Have brushes replaced

by authorized service center.

TROUBLE! SAW MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1.Dull blade. 1.Replace blade.

2.Blade mounted backwards. 2.Turn blade around.

3.Gum or pitch on blade. 3.Remove blade and

clean with turpentine.

4.Incorrect blade for work being done. 4.Change the blade.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1.Extension cord too light or too long. 1.Replace with adequate

size cord.

2.Low house current. 2.Contact your electric

company.

TROUBLE! MACHINE VIBRATES EXCESSIVELY

WHAT’S WRONG? WHAT TO DO…

1.Saw not mounted securely. 1.Tighten all mounting

hardware.

2.Stand or bench on uneven floor. 2.Reposition on flat level

surface.

3.Damaged saw blade. 3.Replace blade.

TROUBLE! DOES NOT MAKE ACCURATE MITER CUTS

WHAT’S WRONG? WHAT TO DO…

1.Miter scale not adjusted correctly. 1.Check and adjust.

2.Blade is not square to fence. 2.Check and adjust.

3.Blade is not perpendicular to table. 3.Check and adjust fence.

4.Workpiece moving. 4.Clamp workpiece to

fence or glue 120 grit

sandpaper to fence with

rubber cement.

TROUBLE! MATERIAL PINCHES BLADE

WHAT’S WRONG? WHAT TO DO…

1.Cutting bowed material. 1.Position bowed material

as shown in Figure 35.

Service Information

Black & Decker offers a full network of company-owned and authorized service locations throughout North America. All Black & Decker Service Centers

are staffed with trained personnel to provide customers with efficient and reliable power tool service.

Whether you need technical advice, repair, or genuine factory replacement parts, contact the Black & Decker location nearest you.

To find your local service location, refer to the yellow page directory under "Tools—Electric" or call: 1-800-54-HOW TO (544-6986).

Accessories

Recommended accessories for use with your saw are available from your local dealer or authorized service center. If you need

assistance regarding accessories, please call: 1-800-544-6986. WARNING: The use of any non-recommended accessory may be

hazardous.

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or

repaired at no charge in either of two ways:

The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the store is a participating

retailer). Returns should be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the sale). Proof of purchase

may be required. Please check with the retailer for their specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for repair or replacement at our

option. Proof of purchase may be required. Black & Decker owned and authorized service centers are listed under "Tools-Electric" in the yellow pages of

the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other rights which vary from state to state.

Should you have any questions, contact the manager of your nearest Black & Decker Service Center.

This product is not intended for commercial use.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-544-6986 for a free replacement.

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

TROUBLESHOOTING

Page 23

AVANT DE RETOURNER CE PRODUIT POUR QUELQUE

RAISON QUI SOIT, VEUILLEZ APPELER AU

1-800-54-HOW-TO (544-6986)

MODE D’EMPLOI

SSSSCCCCIIIIEEEE ÀÀÀÀ OOOONNNNGGGGLLLLEEEETTTTSSSS MMMMIIIIXXXXTTTTEEEESSSS DDDDEEEE 11110000 PPPPOOOO ((((222255554444 MMMMMMMM))

))

BBBBDDDDMMMMSSSS1111000000

00

CONSERVER CE MODE D’EMPLOI POUR UN

USAGE ULTÉRIEUR.

Page 24

TABLE DES MATIÈRES

DIRECTIVES DE SÉCURITÉ IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

RÈGLES GÉNÉRALES DE SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

RÈGLES DE SÉCURITÉ SPÉCIFIQUES SUPPLÉMENTAIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

CONTENU DU CARTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

DESCRIPTION FONCTIONNELLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

ASSEMBLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

FONCTIONNEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

RÉPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

ACCESSOIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

GARANTIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

DIRECTIVES DE SÉCURITÉ IMPORTANTES

Lisez et comprenez tous les avertissements et directives d’utilisation avant d’utiliser un outil ou un

équipement. Lorsque vous utilisez des outils ou un équipement, des précautions de base en matière de sécurité

doivent être suivies afin de réduire le risque de blessure personnelle. Un fonctionnement, un entretien ou une

modification inappropriés des outils ou de l’équipement pourraient résulter en de graves blessures ou en des

dommages à la propriété. Certaines applications sont conçues pour des outils et de l’équipement spécifiques. Black

& Decker recommande fortement NE PAS modifier ce produit ou de NE PAS l’utiliser pour une application autre que

celle pour laquelle il a été conçu.

CONSERVER CES DIRECTIVES!

Page 25

certaines poussières produites par les activités de ponçage, de sciage, de meulage, de perçage et autres

activités de construction peuvent contenir des produits chimiques pouvant causer le cancer, des anomalies

congénitales ou d'autres problèmes liés aux fonctions reproductrices. Voici quelques exemples de ces produits

chimiques :

•

le plomb contenu dans les peintures à base de plomb;

•

la silice cristalline de la brique, du ciment et d'autres produits de maçonnerie ;

•

l'arsenic et le chrome provenant du bois traité chimiquement (arséniate de cuivre et de chrome).

Les risques reliés à l'exposition à ces poussières varient selon la fréquence à laquelle l'utilisateur travaille avec ce type de matériaux. Afin

de réduire votre exposition à ces produits chimiques : travailler dans un endroit bien ventilé et porter un équipement de sécurité

approuvé comme un masque anti-poussières conçu spécialement pour filtrer les particules microscopiques.

•

Éviter le contact prolongé avec les poussières produites par les activités de ponçage, sciage, meulage, perçage et autres activités de

construction. Porter des vêtements de protection et laver les parties du corps exposées avec une solution d'eau et de savon. Le fait de

laisser la poussière pénétrer dans la bouche et les yeux ou de la laisser reposer sur la peau, peut promouvoir l'absorption de produits

chimiques nocifs.

l'utilisation de cet outil peut produire et/ou disperser de la poussière, ce qui peut causer des problèmes

respiratoires graves et permanents ou d'autres problèmes médicaux. Toujours porter un appareil respiratoire approuvé par la

NIOSH/OSHA pour se protéger de la poussière. Diriger les particules loin du visage et du corps.

porter un dispositif de protection anti-bruit pendant l’utilisation de l’outil. Dans certaines conditions et selon la

durée d’utilisation, le bruit causé par ce produit peut contribuer à une perte auditive.

Pour plus de commodité et de sécurité, les étiquettes de sécurité suivantes sont apposées sur votre scie à onglet.

SUR LE BOÎTIER DU MOTEUR :

AVERTISSEMENT : POUR SA PROPRE SÉCURITÉ, LIRE LE MODE D’EMPLOI AVANT D’UTILISER LA SCIE. EN CAS DE RÉPARATION,

UTILISER UNIQUEMENT DES PIÈCES DE RECHANGE IDENTIQUES. TOUJOURS PORTER UNE PROTECTION OCULAIRE.

SUR LE GUIDE :

FIXER LES PETITES PIÈCES AVANT DE LES COUPER. VOIR LE MANUEL.

SUR LE P

ARE-MAIN : DANGER – RESTER À L’ÉCART DE LA LAME.

SUR LA PLAQUE DU P

ARE-MAIN : « BIEN FIXER LE SUPPORT AVEC LES DEUX VIS AVANT D’UTILISER L’OUTIL. »

SUR LA T

ABLE (2 ENDROITS)

TOUJOURS BIEN SERRER LES POIGNÉES DE RÉGLAGE AVANT

UTILISATION. GARDER LES MAINS À 15 CM (6 PO) DE LA TRAJECTOIRE DE LA LAME DE LA SCIE. NE JAMAIS EFFECTUER AUCUNE

OPÉRATION À MAIN LEVÉE. NE JAMAIS PASSER LES BRAS DEVANT LA LAME. IL SUFFIT DE RÉFLÉCHIR! DES ACCIDENTS PEUVENT

ÊTRE ÉVITÉS. NE PAS UTILISER LA SCIE SANS QUE LES PARE-MAINS NE SOIENT EN PLACE. NE JAMAIS PASSER LES MAINS À

L’ARRIÈRE DE LA LAME DE LA SCIE. TOUJOURS PORTER UNE PROTECTION OCULAIRE. METTRE L’APPAREIL SOUS TENSION ET

ATTENDRE L’ARRÊT DE LA LAME AVANT DE RÉPARER, RÉGLER L’OUTIL, OU DE DÉPLACER LES MAINS.

PROPOSITION 65 DE LA CALIFORNIE

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ

- DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode d’emploi. Les informations qu’il contient concernent VOTRE SÉCURITÉ et

visent à ÉVITER TOUT PROBLÈME. Les symboles ci-dessous servent à vous aider à reconnaître cette information.

indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des graves blessures.

indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer la mort ou de

graves blessures.

indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer des blessures

mineures ou modérées.

Le terme utilisé sans le symbole d’alerte à la sécurité indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, peut résulter en des dommages à la propriété.

Page 26

RÈGLES GÉNÉRALES DE SÉCURITÉ

1. POUR SA PROPRE SÉCURITÉ,

LIRE LE MODE D’EMPLOI AVANT D’UTILISER

L’OUTIL. En apprenant comment utiliser cet outil, les

restrictions, et les risques qui lui sont propres, vous

réduirez grandement la possibilité d'accidents et de

blessures.

2. UTILISER UN ÉQUIPEMENT DE SÉCURITÉ

HOMOLOGUÉ. Votre protection oculaire doit être

conforme aux normes ANSI Z87.1, vos protecteurs

auditifs aux normes ANSI S3.19, et votre masque

antipoussières aux normes homologuées MSHA/NIOSH.

Les éclats de bois, débris en suspension dans l’air, et

poussières peuvent provoquer des irritations, blessures

et/ou maladies.

3. S’HABILLER DE MANIÈRE APPROPRIÉE. Ne pas

porter de cravate, gants, ou vêtements amples. Retirer

montre, bagues, et autres bijoux. Relever les manches.

Les vêtements ou bijoux coincés dans les pièces mobiles

peuvent causer des blessures.

4. NE PAS UTILISER CET OUTIL DANS UN

ENVIRONNEMENT DANGEREUX. L’utilisation d’outils

électriques dans un endroit humide ou mouillé ou sous la

pluie peut provoquer un choc électrique ou une

électrocution. Tenir la zone de travail bien éclairée pour

éviter de trébucher ou de mettre vos bras, mains et

doigts en danger.

5. CONSERVER TOUS LES OUTILS ET MACHINES DANS

LE MEILLEUR ÉTAT POSSIBLE. S’assurer que vos outils

sont aiguisés et propres afin d’optimiser sécurité et

performance. Suivre les consignes de graissage et de

changement d’accessoires. Les outils et machines mal

entretenus peuvent s'endommager davantage et/ou

provoquer des blessures.

6. VÉRIFIER QUE LES PIÈCES NE SONT PAS

ENDOMMAGÉES. Avant d’utiliser la machine, vérifiez

qu'aucune pièce n'est endommagée. Vérifier l’alignement

des pièces mobiles, la présence de grippage des pièces

mobiles, de rupture de pièces et tout autre problème

pouvant nuire au fonctionnement de l’outil. Un pare-main

(ou tout autre pièce) endommagé doit être réparé et

remplacé adéquatement. Les pièces endommagées

peuvent contribuer à endommager davantage la machine

et/ou provoquer des blessures.

7. GARDER PROPRE LA ZONE DE TRAVAIL. Les zones et

établis encombrés sont souvent des causes d’accidents.

8. ÉLOIGNER LES ENFANTS ET LES VISITEURS. Votre

atelier représente un environnement potentiellement

dangereux. Les enfants et visiteurs peuvent être blessés.

9. RÉDUIRE LE RISQUE DE DÉMARRAGE ACCIDENTEL.

Assurez-vous que l’interrupteur se trouve sur la position

d’arrêt avant de brancher le cordon d’alimentation. En

cas de panne de courant, mettez l’interrupteur sur la

position d’arrêt. Un démarrage accidentel peut provoquer

des blessures.

10. UTILISER LE DISPOSITIF DE PROTECTION. Vérifiez

que toutes les protections sont en place, fixées, et

qu’elles fonctionnent correctement afin d'éviter toute

blessure.

11. RETIRER LES CLÉS ET LES CLÉS DE RÉGLAGE

AVANT DE DÉMARRER LA MACHINE. Des outils,

chutes, et autres débris peuvent être projetés à grande

vitesse, provoquant des blessures.

12. UTILISER L’OUTIL APPROPRIÉ. Ne pas forcer un outil

ou un accessoire à effectuer un travail pour lequel il n’a

pas été conçu. Dans le cas contraire, l'outil peut être

endommagé et/ou vous pourriez vous blesser.

13. UTILISER LES ACCESSOIRES RECOMMANDÉS.

L’utilisation d’accessoires qui n’ont pas été

recommandés par Black & Decker est susceptible

d’endommager la machine ou de blesser l'utilisateur.

14. UTILISER LA RALLONGE ÉLECTRIQUE APPROPRIÉE.

S’assurer que la rallonge est en bon état. Lorsque qu’une

rallonge électrique est utilisée, s’assurer d’en utiliser une

de calibre suffisamment élevé pour assurer le transport

du courant nécessaire au fonctionnement de votre

appareil. Un cordon de calibre inférieur causera une

chute de tension de ligne et donc une perte de puissance

et une surchauffe. Reportez-vous au tableau des

rallonges électriques pour connaître le calibre approprié à

utiliser selon la longueur de la rallonge et l’intensité

nominale de la plaque signalétique. En cas de doute,

utiliser le calibre suivant le plus gros. Plus le numéro de

calibre est petit, plus le cordon est lourd.

15. FIXER LA PIÈCE. Utiliser des fixations ou un étau

lorsque la pièce ne peut pas être fixée manuellement sur

la table et contre le guide, ou lorsque votre main se

trouve dangereusement proche de la lame (à moins de 15

cm (6 po)).

16. NE PAS FORCER LA PIÈCE SUR LA MACHINE. Dans le

cas contraire, l'outil peut être endommagé et/ou vous

pourriez vous blesser.

17. NE PAS TROP TENDRE LES BRAS. Une perte

d’équilibre peut vous faire tomber dans une machine en

fonctionnement, et vous pourriez vous blesser.

18. NE JAMAIS SE TENIR DEBOUT SUR LA MACHINE. Si

l’outil bascule, ou si vous touchez accidentellement l’outil

de coupe, vous pourriez vous blesser.

19. NE JAMAIS LAISSER LA MACHINE FONCTIONNER

SANS SURVEILLANCE. ÉTEINDRE L’APPAREIL. Ne

pas laisser la machine tant qu’elle n’est pas

complètement arrêtée. Un enfant ou un visiteur pourrait

être blessé.

20. ÉTEIGNEZ L’APPAREIL ET DÉBRANCHEZ-LE DE LA

SOURCE D’ALIMENTATION AVANT de poser ou de

retirer tout accessoire, avant d'ajuster ou de modifier les

réglages, ou lorsque vous effectuez une réparation. Un

démarrage accidentel peut provoquer des blessures.

21. S’ASSURER QUE L’ATELIER NE PRÉSENTE PAS DE

DANGER POUR LES ENFANTS EN UTILISANT DES

CADENAS, DES INTERRUPTEURS PRINCIPAUX, OU

EN RETIRANT LES CLÉS DE DÉMARRAGE. En

démarrant accidentellement une machine, un enfant ou

un visiteur pourrait se blesser.

22. ÊTRE VIGILANT, SURVEILLER LE TRAVAIL

EFFECTUÉ, ET FAIRE PREUVE DE JUGEMENT. NE

PAS UTILISER LA MACHINE EN CAS DE FATIGUE OU

SOUS L’INFLUENCE DE DROGUES, D'ALCOOL, OU

DE MÉDICAMENTS. Un moment d’inattention, lorsque

vous utilisez un outil électrique, peut entraîner des

blessures.

23. LA POUSSIÈRE PRODUITE par certains bois et produits

en bois peut nuire à votre santé. Utilisez toujours les

machines dans un endroit bien aéré, et veillez à le

dépoussiérer correctement. Utilisez des systèmes de

dépoussiérage lorsque c’est possible.

LIRE ATTENTIVEMENT TOUTES LES MISES EN GARDE ET DIRECTIVES D’UTILISATION

AVANT D'UTILISER CET ÉQUIPEMENT. À défaut de suivre les directives sous-mentionnées,

un choc électrique, un incendie, des dommages ou une blessure corporelle grave

pourraient survenir.

DIRECTIVES DE SÉCURITÉ IMPORTANTES

Page 27

1. NE FAITES PAS FONCTIONNER CETTE MACHINE avant

qu’elle ne soit entièrement assemblée et installée

conformément à ces directives. Une machine mal

assemblée peut provoquer des blessures graves.

2. DEMANDEZ CONSEIL à une autre personne qualifiée si

vous ne maîtrisez pas assez l'utilisation de cette machine.

3. SUIVRE TOUS LES CODES DE CÂBLAGE et les

connexions électriques recommandées afin d’éviter tout

choc électrique ou électrocution.

4. FIXER LA MACHINE SUR UNE SURFACE DE SUPPORT.

Les vibrations sont susceptibles de faire glisser, « marcher

», ou basculer la machine, ce qui peut provoquer des

blessures graves.

5. UTILISER SEULEMENT DES LAMES POUR COUPES

TRANSVERSALES. N’utilisez que des angles de coupe de

zéro degré ou négatifs lorsque vous utilisez des lames à

pointes carburées. N’utilisez pas des lames à dents très

espacées. Celles-ci peuvent entrer en contact et faire dévier

le pare-main, et peuvent endommager la machine et/ou

provoquer des blessures graves.

6. UTILISER SEULEMENT DES LAMES DE DIMENSION ET

DE TYPE APPROPRIÉS prévues pour cet outil, pour éviter

des dommages à la machine et/ou des blessures graves.

7. UTILISER UNE LAME AIGUISÉE. Vérifiez que la lame

fonctionne bien dans l'axe et qu'elle ne vibre pas. Une lame

émoussée ou une lame qui vibre peut endommager la

machine et/ou provoquer des blessures graves.

8. INSPECTER LA LAME À LA RECHERCHE DE

CRAQUELURES ou autre dommage avant utilisation. Une

lame craquelée ou endommagée peut se détacher et des

fragments peuvent être projetés à grande vitesse, ce qui

peut provoquer des blessures graves. Remplacez les lames

craquelées ou endommagées immédiatement.

9. NETTOYER LA LAME ET LES BRIDES DE LA LAME

avant utilisation. Nettoyer la lame et les brides vous permet

de vérifier que la lame ou les brides ne sont pas

endommagées. Une lame ou une bride craquelée ou

endommagée peut se détacher et des fragments peuvent

être projetés à grande vitesse, ce qui peut provoquer des

blessures graves.

10. UTILISER UNIQUEMENT DES BRIDES DE LAME prévues

pour cet outil afin d'éviter d'endommager la machine et/ou

de provoquer des blessures graves.

11. S’ASSURER QUE L’ESPACE DE TRAVAIL NE CONTIENT

AUCUN LIQUIDE INFLAMMABLE ou de gaz avant

utilisation. Des étincelles peuvent se produire, qui

enflammeraient les liquides et provoqueraient un incendie

ou une explosion.

12. DÉGAGER LES ÉVENTS de toute saleté ou copeau. Des

évents obstrués peuvent provoquer la surchauffe de la

machine, ce qui l’endommagerait et provoquerait peut-être

un court-circuit qui pourrait engendrer des blessures

graves.

13. SERRER FERMEMENT LA POIGNÉE DE FIXATION À LA

TABLE et autres brides de fixation avant utilisation. Si les

brides sont lâches, des pièces ou encore l'ouvrage peuvent

être projetés à grande vitesse.

14. NE JAMAIS DÉMARRER L’OUTIL avec la lame contre

l'ouvrage. L’ouvrage pourrait être projeté, provoquant des

blessures graves.

15. TENIR LES BRAS, LES MAINS, et les doigts éloignés de

la lame afin d'éviter des coupures graves. Fixez toutes les

pièces à cause desquelles vous pourriez déplacer vos

mains dans la « Zone à risque de la table » (délimitée par

les lignes rouges).

16. LORS DE LA COUPE AVEC UNE SCIE COULISSANTE À

ONGLETS MIXTES, POUSSEZ LA SCIE VERS L'AVANT

(EN L’ÉLOIGNANT DE VOUS) et vers le guide. Si vous

ramenez la scie vers vous, celle-ci pourrait se soulever et

vous percuter.

17. LORS DE L’UTILISATION D’UNE SCIE COULISSANTE À

ONGLETS, VERROUILLER LE MÉCANISME COULISSANT

EN PLACE. Si le mécanisme coulissant n’est pas verrouillé,

la scie peut se retourner et vous percuter.

18. LAISSER LE MOTEUR atteindre son plein régime avant

de commencer la coupe. Si vous commencez à couper

trop tôt, ceci peut endommager la machine ou la lame

et/ou provoquer des blessures graves.

19. NE PAS LAISSER LES MAINS AUTOUR de la lame ou

derrière celle-ci. Une lame mobile peut provoquer des

blessures graves.

20. NE JAMAIS COUPER DE MÉTAUX FERREUX ou

d’éléments de maçonnerie. En coupant l'un ou l'autre de

ces matériaux, les pointes carburées peuvent se détacher

de la lame à grande vitesse, provoquant des blessures

graves.

21. NE JAMAIS COUPER DE PETITES PIÈCES. En essayant

de couper des petites pièces, vous pouvez être amené à

déplacer vos mains jusque sur la lame, et être gravement

blessé.

22. NE JAMAIS VERROUILLER L’INTERRUPTEUR en

position de marche. En préparant la coupe suivante, vous

pouvez être amené à déplacer vos mains jusque sur la

lame, et être gravement blessé.

23. NE JAMAIS APPLIQUER DE LUBRIFIANT sur une lame

en fonctionnement. Pour appliquer du lubrifiant, vous

pouvez être amené à déplacer vos mains jusque sur la

lame, et être gravement blessé.

24. N'effectuer AUCUNE opération mains libres. Tenez

l’ouvrage fermement contre le guide et la table. Si vous

tentez d'effectuer une opération mains libres avec une

scie à onglets, l’ouvrage pourrait être

projeté à grande vitesse, provoquant des blessures

graves. Utilisez des brides pour maintenir l’ouvrage

lorsque c’est possible.

25. APRÈS AVOIR TERMINÉ UNE COUPE, relâcher le

commutateur d’alimentation et attendre que la lame, qui

continue de tourner après l’arrêt de la scie, s’immobilise

complètement avant de relever la scie. Une lame mobile

peut provoquer des blessures graves.

26. ÉTEINDRE LA MACHINE et laisser la lame s’immobiliser

complètement avant de nettoyer autour de la lame ou

d’enlever les débris dans la trajectoire de la lame. Une

lame mobile peut provoquer des blessures graves.

27. ÉTEINDRE LA MACHINE et laisser la lame s’immobiliser

complètement avant d’enlever ou de fixer un ouvrage, de

modifier l’angle d’inclinaison

de l’ouvrage ou de la lame. Une lame mobile peut

provoquer des blessures graves.

28. SOUTENIR CORRECTEMENT les ouvrages LONGS OU

LARGES. La perte de contrôle de l'ouvrage peut

provoquer des blessures.

29. NE JAMAIS EFFECTUER D’OPÉRATION DE TRAÇAGE,

D’ASSEMBLAGE, OU DE RÉGLAGE sur la table/l’espace

de travail lorsque la machine est en marche. En glissant

inopinément, votre main pourrait percuter la scie. Des

blessures graves pourraient survenir.

30. ÉTEINDRE LA MACHINE, LA DÉBRANCHER, et nettoyer

la table/l'espace de travail avant de laisser la machine.

Verrouiller l’interrupteur EN POSITION D’ARRÊT afin

d’éviter toute utilisation non autorisée. Il se peut que

quelqu’un démarre accidentellement la machine et se blesse.

32. AVANT D’UTILISER LA SCIE, vérifier et bien verrouiller

les réglages du biseau, des onglets et du guide coulissant.

33. DES INFORMATIONS SUPPLÉMENTAIRES (c.-à-d. une

vidéo sur la sécurité), indiquant comment utiliser des outils

électriques correctement et en toute sécurité, sont

disponibles auprès du Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851, États-Unis

(www.powertoolinstitute.com). Vous pouvez également

vous procurer des informations auprès du National Safety

Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201,

États-Unis. Veuillez vous reporter à la norme ANSI 01.01

de l'American National Standards Institute concernant les

machines de travail du bois, ainsi que la réglementation

du département américain du travail.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES SUPPLÉMENTAIRES

NÉGLIGER DE SUIVRE CES RÈGLES RISQUE D’ENTRAÎNER DES BLESSURES CORPORELLES

GRAVES. SI NO SE SIGUEN ESTAS NORMAS, EL RESULTADO PODRÍA SER LESIONES PERSONALES GRAVES.

CONSERVER CES DIRECTIVES.

Consultez-les souvent et utilisez-les pour donner des directives aux autres.

Page 28

Un circuit électrique séparé doit être utilisé pour vos machines. Ce circuit doit utiliser un câble de calibre 12 au

minimum et doit être protégé par un fusible temporisé de 20 A. Si vous utilisez une rallonge électrique, n’utilisez que

des rallonges à 3 fils pourvues d’une fiche de mise à la terre à 3 lames et un réceptacle correspondant à la fiche de la

machine. Avant de brancher la machine sur le secteur, assurez-vous que le ou les interrupteurs sont en position d'arrêt

et veillez à ce que le courant électrique ait bien les mêmes caractéristiques que celles indiquées sur la machine. Tous

les branchements doivent établir un bon contact. Si la machine fonctionne à basse tension, elle en sera endommagée.

NE PAS EXPOSER LA MACHINE À LA PLUIE NI L’UTILISER DANS UN ENDROIT HUMIDE.

1. Pour toutes les machines mises à la terre,

branchées à un cordon d'alimentation :

En cas de dysfonctionnement ou de panne, la mise à la

terre permet un cheminement de moindre résistance

pour le courant électrique afin de réduire le risque de

choc électrique. Cette machine est munie d’un cordon

d’alimentation doté d’un conducteur de mise à la terre

d’équipement et d’une fiche de mise à la terre. La fiche

doit être branchée sur une prise de courant

correspondante qui est installée et mise à la terre

conformément à tous les codes et à toutes les

ordonnances à l’échelle locale.

Ne pas modifier la fiche fournie; si elle ne s’insère pas

dans la prise de courant, faire installer une prise

appropriée par un électricien professionnel.

Si le conducteur de mise à la terre d’équipement n'est

pas correctement connecté, ceci peut provoquer un choc

électrique. Le conducteur de mise à la terre

d’équipement est le conducteur avec isolation qui a une

surface extérieure verte à rayures jaunes (ou sans). S'il

est nécessaire de faire réparer ou remplacer le cordon

électrique ou la fiche, ne pas connecter le conducteur de

mise à la terre d’équipement à une borne sous tension.

Vérifier auprès d’un électricien ou d’un personnel de

réparation professionnels si les directives de mise à la

terre ne sont pas parfaitement comprises, ou en cas de

doute sur le fait que la machine soit correctement mise à

la terre ou non.

Utiliser uniquement une rallonge à 3 fils pourvue d'une

fiche de mise à la terre à 3 lames et une prise à 3

conducteurs correspondant à la fiche de la machine,

comme le montre la Fig. A.

Réparer ou remplacer immédiatement le cordon s’il est

endommagé ou usé.

2. Pour les machines mises à la terre et branchées à

un cordon d’alimentation utilisées sur un circuit

d’alimentation de régime nominal inférieur à 150 V :

Si la machine est utilisée sur un circuit dont la prise de

courant ressemble à celle de la Fig. A, la machine aura

alors une fiche de mise à la terre semblable à celle de

la Fig. A. Un adaptateur temporaire, qui ressemble à

celui de la Fig. A, peut être utilisé pour connecter cette fiche à

une prise à 2 conducteurs, comme le montre la Fig. B, s’il

n’existe aucune prise de courant correctement mise à la terre.

L’adaptateur temporaire ne doit être utilisé que jusqu’à ce

qu’un électricien qualifié puisse installer une prise électrique

correctement mise à la terre. L’oreille rigide et la cosse de

couleur verte (et tout ensemble semblable) dépassant de

l’adaptateur doivent être connectées à une mise à la terre

permanente, telle qu’une prise correctement mise à la terre.

Chaque fois que l’adaptateur est utilisé, il doit être maintenu

en place par une vis métallique.

REMARQUE : au Canada, l’utilisation d’un adaptateur

temporaire n’est pas autorisée par le Code électrique

canadien.

DANS TOUS LES CAS, S’ASSURER QUE LA

PRISE DE COURANT EN QUESTION EST CORRECTEMENT

MISE À LA TERRE. SI VOUS N’EN ÊTES PAS SÛR,

DEMANDEZ À UN ÉLECTRICIEN PROFESSIONNEL DE

VÉRIFIER LA PRISE.

CONNEXIONS ÉLECTRIQUES

DIRECTIVES DE MISE À LA TERRE

CETTE MACHINE DOIT ÊTRE MISE À LA TERRE LORS DE SON UTILISATION AFIN DE PROTÉGER

L’UTILISATEUR CONTRE TOUT CHOC ÉLECTRIQUE.

Fig. A

Fig. B

PRISE ÉLECTRIQUE MISE À

LA TERRE

LAMES

CONDUCTRICES

LA LAME DE MISE À LA TERRE

EST LA PLUS LONGUE DES

TROIS LAMES

MOYEN DE MISE À LA

TERRE

Adaptateur

PRISE ÉLECTRIQUE MISE

À LA TERRE

CARACTÉRISTIQUES TECHNIQUES DU MOTEUR

Votre machine est conçue pour être alimentée par un courant alternatif de 120 volts et 60 Hz. Avant de brancher la

machine à la source d’alimentation, assurez-vous que l’interrupteur est en position d’arrêt.

Page 29

Retirer du carton la scie à onglets ainsi que toutes les pièces.

Ne pas soulever la scie à onglets par la poignée de la gâchette. Ceci pourrait provoquer un mauvais alignement.

Toujours soulever la machine par la base de la poignée de transport.

1. Scie à onglets

2. Sac à poussière

3. Clé de lame de 12,7 mm (1/2 po)

4. Clé hexagonale de 5 mm

5. Poignée de blocage de la table

OUTILS NÉCESSAIRES POUR

L’ASSEMBLAGE

(Fournis)

* clé hexagonale de 5 mm

* Clé de lame de 12,7 mm (1/2 po)

(Non fournis)

* Tournevis à tête cruciforme

* Une équerre pour effectuer des ajustements

CONTENU DU CARTON

DÉSEMBALLAGE ET NETTOYAGE

Désemballer soigneusement la machine et toutes les pièces de ou des emballage(s) d'expédition. Retirer le revêtement protecteur

de toutes les surfaces non peintes. Le revêtement peut être retiré avec un chiffon doux humidifié avec du kérosène (ne pas utiliser