Page 1

№¿6

J3|de)s Ц^^ìi 3!J)33|3

lenueiAi uoipnj}su|

•V'S'ri 98EIZ aw 'uosmol 'pBoy eddop 1 10£ "mi (*S'nl t ^3e|a

YS n U! paiuud 3661 (a) (QD-26ci3S)

SO-ieolW 'ON uiJOd

sajes ^ aaiAias ioj

- saBej MO||a^ -

,3j43a|3-s|ooi, aa$

•3U| 'sauoiejoqei sjaiumjapun

Aq paisii St lonpojd aqi sueauj

aieidaiiieu aijj uo loqiuAs sjqx

usioao^Mavia '

K3

Black & Decker Power Tools.

Your new 9701 Electric Flush

Stapler features a universal staple

magazine that accepts all commonly

available heavy duty staples (.050"

wire) from 1/4" to 9/16" long.

Controlled stapling power and the

ability to flush staple up to 1/8" from

any wall makes your new stapler a

valuable addition to your workshop.

Built in America with Black &

Decker's traditional high regard for

quality, your 9701 will deliver years of

dependable service.

Please take a few minutes to

thoroughly read this informative

instruction manual. Only with a

complete understanding of your

stapler's features will you be able to

take advantage of your tool and its

many uses. Save this manual for

future use.

Don't forget to send in the owner's

registration card. Thank you for

selecting Black & Decker!

ojsauoiBJoqei sjaiuMjapup) Aq paisij s\ |Ooistqi 's|oojjapaQ ig >|DB|gisoui a>in

lOBjuoo 'SLiopsanb Aue aAeq noA p|noqs ’Sieis oj aieqs uioj^ Ajba qoiqAA siqBu jaqio

3ABq Abuu noA pue siqBu |86a| oqpads noA saAiB Ajubjjbaa siqj^ 'sauossaooB oj A|ddB

lou saop Aiubjjbaa siqx "uopdo jno jb JiBdaj jo luaujaasidaj aaj^ jo^ saBod aao||3A aqj

ui „oiJioaig s|ooi„ japun paisq 'uoqBJS sapjas pazijoqmy jo jajuag aDiAjag ja>|oao

^ ^oB|a B 01 paujniaj aq os(b Abuj pun aqx ’(pajinbaj aq Ablu aseqojnd p pojd)

luaiJuaoB|daj aaji joi (jaiieiaj BuiiBdioiued b h) ja||as aqi oi 'pmdajd uopBuodsueji

'Ijun aia|duioo aqi ujniaj asBaig ‘diqsuBUJJiJOM jo ibubibuj Aiiobi oi anp ajB leqi

sioapp AuB isuibBb sjeaA oaai joilonpojd stqi siubjjbaa -ou| Cs-n) Ja>|oaQ >g ^oeig

■siuaiuajinbaj Aja^es juaBuuis siaaiu p leqi ajnsua

■jaBeu6i/\j jaiuag aaiAjag ja^joag tg >jOB|a isajeau jnoA

(Aiuejje/w jea^ o/wx ||nj v) Aiuejje/v\ asp auiOH

■jaiuag aoiAjag ja>|oao >8 >jaeig b oi q at^Bi Abuj noA jo (japBiaj BuiiBdioiusd

6 SI n li) luaujaoBjdaj aajj. b joj asBqojnd p aoBid aqi oi |ooi aqi ujniaj Abuj noA

'I33|ap 8 j.0 asBO u| 'iBqi saiBis Aiubjjbaa asn aujoq jBaA oaai lini s.jat^oag ^ ^OBjg

aojAjas paiiiiBob jaqio Jo sjaiuag aojAiag Jaijoag ig >|OB|g Aq paiujoijad aq pinoqs

luauJisnlpB puB aouBuaiuiBiu 'sjiBdaj 'AiHiavnaa Pue Ai3d\s^S Pnpojd ajnssB oi

■siJBd luauiaoBidaj ja>ioaa >|oe|g Buisn sAbaa|b 'suoiiezmeBjo

lue)JOdui|

aqi UO uAAoqs ajs sassajppo jaiuag aoiAjag uaiuag aopjas ja>|oag ig >|OB|g |B00| jroA

011! puas jo a^Bi 'aoiAjas ajinbaj jaAa pjnoqs jajdsis jnoA isqi luaAa A|a>ijiun aqi u(

•pinbii 8 Olili |ooi aqi p UBd Aue asjaujuji jaAau .'|ooi aqi apisui laB pmbi( Aub

laj jaA3|\| siDnpojd JBiiuip Jo spinn BuiuBap Ajp PauuiqilUjBd Jo janboB] 'auquadjni

'auijossB asn lou op os|v ’oiiSB|d aqi aBsuisp A|snouas p|noo qaiqAA s(B3iujaqo uibiuod

SJ3UB3|0 pjoqasnoq Auei/^ ‘looi aqi usajo oi qiop duisp b puB dsos ppuj A|uo asg

(001 jnoA qi!M pa^OBd pjBO uoiiBJisiBaj sjbuaao

uojieajjqn-] ig Gujueap

Important Safety Instructions

WARNING; When using Electric Tools, basic safety precautions should always be followed to

reduce the risk of fire, electric shock, and personal injury, including the following;

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don't expose power tools to rain. Don't use power

tools in damp or wet locations. Keep work area well lit.

3. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces. For

example; pipes, radiators, ranges, refrigerator enclosures.

4. KEEP CHILDREN AWAY. All visitors should be kept away from work area. Do not let visitors

contact tool or extension cord.

5. STORE IDLE TOOLS. When not in use, tools should be stored in dry, and high or locked-up

place — out of reach of children.

6. DON'T FORCE TOOL It will do the job better and safer at the rate for which it was intended.

7. USE RIGHT TOOL Don't force small tool or attachment to do the job of a heavy-duty tool. Don’t

use tool for purpose not intended, for example, don't use circular saw for cutting tree limbs or

togs.

8. DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be caught in moving parts.

Rubber gloves and nonskid footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

9. USE SAFETY GLASSES. Also use face or dustmask if cutting operation is dusty.

10. DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep

cord from heat, oil, and sharp edges.

11. SECURE WORK. Use clamps, ora vise to hold work. It's safer than using your hand and it frees

both hands to operate tool.

12. DON'T OVERREACH. Keep proper footing and balance at all times,

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safe performance.

Follow instructions for lubricating and changing accessories. Inspect tool cords periodically

and if damaged have repaired by authorized service facility. Inspect extension cords

periodically and replace if damaged. Keep handles dry, clean and free from oil and grease.

14. DISCONNECT TOOLS. When not in use, before servicing, and when changing accessories,

such as blades, bits, cutters.

15. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and

adjusting wrenches are removed from tool before turning it on.

16. AVOID UNINTENTIONAL STARTING. Don't carry plugged-in tool with finger on switch. Be sure

switch is off when plugging in.

17. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension cords

intended for use outdoors and so marked.

18. STAY ALERT. Watch what you are doing. Use common sense. Do not operate tool when you

are tired.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction manual. Have defective switches replaced

by authorized service center. Do not use tool if switch does not turn it on and off.

20. DO NOT OPERATE portable electric tools near flammable liquids or in gaseous or explosive

atmospheres. Motors in these tools normally spark, and the sparks might ignite fumes.

READ ALL INSTRUCTIONS

Page 2

Safety Rules for Staplers

1. DONOTAnEMPTTODRIVE

STAPLES WITHOUT FIRMLY

ENGAGING THE WORK SURFACE.

2. UNLOAD STAPLES BEFORE

STORAGE.

CAUTION: When stapling into walls,

floors or wherever "live" electrical wires

may be encountered, DO NOT TOUCH

ANY METAL PARTS OF THE TOOL! Hold

the tool only by the plastic handle to

prevent electrical shock if you staple

into a "live" wire.

Double-Insulation

Your Stapler is DOUBLE-INSULATEB

to give you added safety. This means

that it is constructed throughout with

TWO separate “layers" of electrical

insulation or one DOUBLE thickness of

insulation between you and the tool's

electrical system.

Tools built with this improved

insulation system are not intended to be

grounded. As a result, your tool is

equipped with a two-pronged plug

which permits you to use any

conventional 120 volt electrical outlet

without concern for maintaining a

ground connection.

NOTE: DOUBLE-INSULATION does

not take the place of normal safety

precautions when operating this tool.

The improved insulation system is for

added protection against injury resulting

from a possible electrical insulation

failure within the tool.

CAUTION: When servicing DoubleInsulated Tools, USE ONLY IDENTICAL

REPLACEMENT PARTS. Replace or

repair damaged cords.

Power Supply

Make sure that your power supply

agrees with the nameplate marking on

your stapler. Your stapler was designed

to operate on 120 Volts AC Only. This

means standard 120 volt household

power. All Black & Decker tools are

factory tested, if this tool does not

operate, check the power supply.

Extension Cords

Double-Insulated tools have 2 wire

cords, and can be used with 2 wire or 3

wire extension cords. Only round

jacketed extension cords should be used,

and we recommend that they be listed by

Underwriters' Laboratories (U.L.j. If the

extension will be used outside, the cord

must be suitable for outdoor use. Any

cord marked as outdoor (the letters

"WA" on the cord jacket indicate a cord

recommended for outdoor use) can also

be used for indoor work.

An extension cord must have

adequate wire size (AWG or American

Wire Gauge) for safety, and to prevent

loss of power and overheating. The

smallerthe gauge number of the wire

the greater the capacity of the cable,

that is 16 gauge has more capacity than

18 gauge. When using more than one

extension cord to make up the total

length, be sure each individual extension

contains at least the minimum wire size.

MINIMUM WIRE GAUGE

REQUIREMENTS FOR THIS STAPLER:

UP TO 25 FEET —16 GAUGE

UPTO 50 FEET —14 GAUGE

Before using an extension cord

inspect it for loose or exposed wires,

damaged insulation, and defective

fittings. Make any needed repairs or

replace the cord if necessary. Black &

Decker has extension cords available

that are U.L. listed for outdoor use.

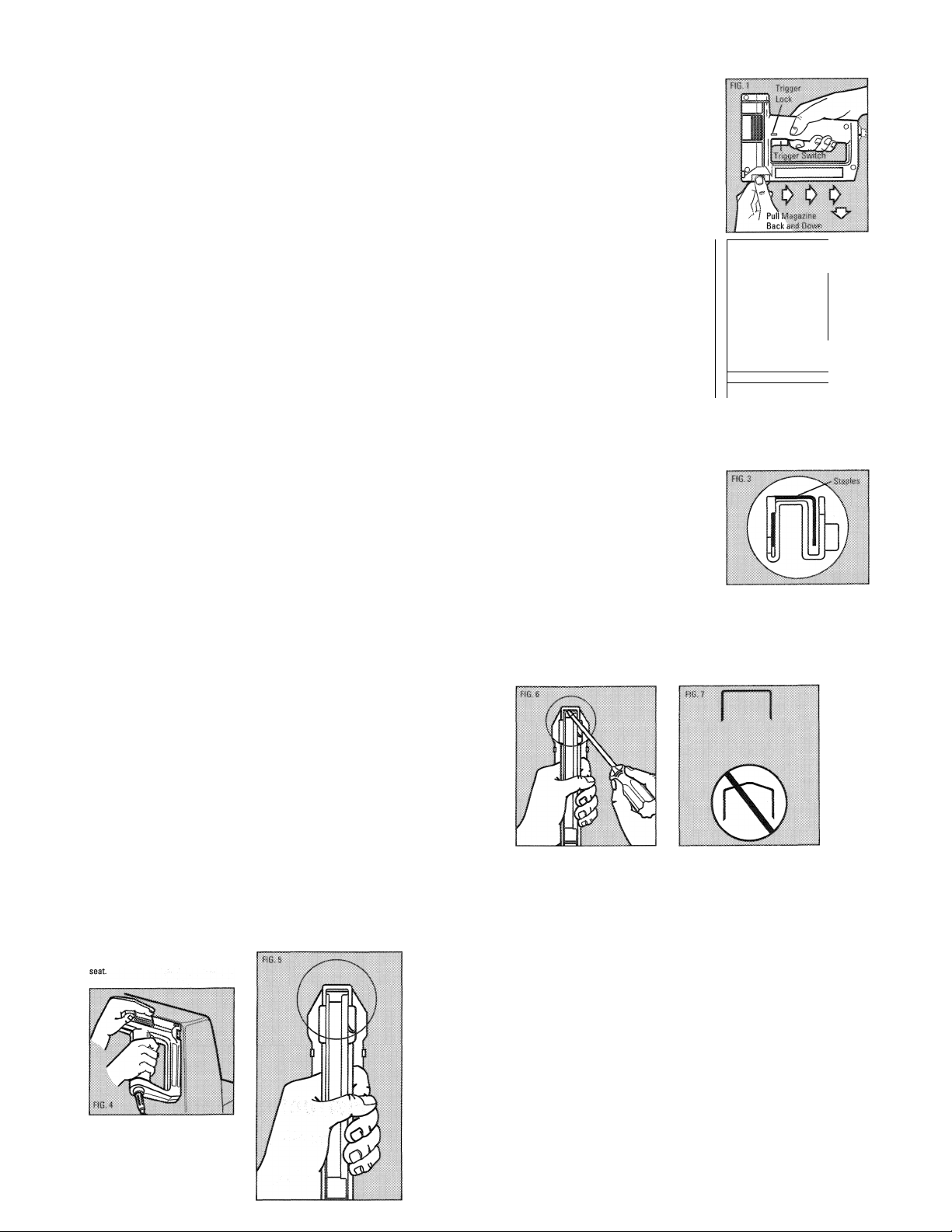

Loading Staples

(UNPLUG Stapler From

Power Supply)

1. Grasp the stapler as shown in

Figure 1 and pull the magazine

back and down as indicated by

the arrows. This will unlock and

open the magazine.

2. Load the staples as shown in

Figures 2 and 3.

3. Close the magazine by swinging it up

into place and pulling it back as you

did in Figure 1. When released, it will

lock itself automatically.

Trigger Switch

The trigger switch is located on the

underside of the handle, as shown in

Figure 1. A staple will be driven each

time the trigger switch is depressed.

NOTE: The switch must be released after

each staple.

MAKE SURE YOUR FINGER IS NOT

DEPRESSING THE TRIGGER SWITCH

WHEN PLUGGING THE TOOL INTO THE

POWER SUPPLY. THIS WILL CAUSE THE

STAPLER TO FIRE IMMEDIATELY.

Trigger Lock

Your stapler is equipped with a trigger

lock to prevent accidental firing. It is

located just above the trigger switch as

Figure 1. To unlock the trigger,

shown in

push the lock button to the right until it's

flush with the stapler body. To lock the

trigger, push the lock button (from the

right side of the tool) to the left.

DO NOT ATTEMPT TO DISABLE OR

OVERRIDE THE TRIGGER LOCK IN ANY

WAY.

m ^ Yi '

1 Ik

\Vl\N

Itsplci \

liiilllliiil

L t

\\

\

\ \\

VI

Controlled Power

Your stapler has been engineered to

deliver the optimum power for each

stroke in practically any material. What

this means is that when you're working

with hard materials, the tool has plenty

of power to drive most staples flush to

the surface. When you're working with

soft fabric or plastic foam, the stapler

will drive staples flush to the surface but

no deeper. Material is held firmly but not

torn through.

Stapling

Hold the stapler as shown in Figure 4

with one hand holding the handle and

the other hand pressing firmly down on

the top of the tool to hold the base

against the material being stapled.

If you find that the tool is not driving

the staples fully into the wood, use a

shorter length staple. Generally

speaking, the optimum staple length is

the longest that the stapler will fully

Jamming

In the event that your stapler should

ever become jammed, it's a very simple

task to clear the jam and continue the

job.

Follow the steps below to clear a

jammed stapler.

1. UNPLUG the stapler.

2. Closely examine the underside of the

tool and compare it to Figures. If the

striker is stuck down as shown in

Figure 5, gently push it back in with a

screwdriver as demonstrated by

Figure 6.

3. If the striker is not stuck down and

the stapler is jammed, a staple must

be misaligned in the magazine. Clear

the stapler by opening the magazine

and removing any misaligned or

jammed staple.

4. Close the magazine and continue

working.

Staples

For best results, the use of Black &

Decker staples is recommended.

However, your stapler has been

designed to accept most major brands of

staples that are commonly available.

The accessories and fasteners listed

in this manual are available at additional

cost from your local dealer or Black &

Decker Service Center.

If you need assistance in locating any

accessory or fastener, please contact;

Black & Decker (U.S.) Inc., User

Services Dept, Black & Decker (U.S.),

Inc. 701 E. Joppa Rd. Towson, MD 21286

Recommended accessories and

fasteners for use with your tool are

listed below. CAUTION: The use of any

other accessory or attachment might be

hazardous or cause damage to the tool.

A few staple manufacturers produce

staples like the one shown in Figure 7.

Your stapler will drive these staples but

they will not feed properly and their use

is not recommended.

For best results, use only Black &

Decker staples. Black & Decker makes

staples in five different leg lengths and

three widths. All of them fit in your 9701

Stapler.

STAPLES (Box of 1,000)

.50 ".WIDE .050" WIRE

1/4" H-Duty Staple

5/16" H-Duty Staple

3/8" H-Duty Staple

1/2" H-Duty Staple

9/16" H-Duty Staple

9/16" Ceiling Tile Staple

.42" WIDE (also fit Arrow

Staplers) .050" WIRE

1/4" H-Duty Staple

5/16" H-Duty Staple

3/8" H-Duty Staple

1/2" H-Duty Staple

9/16" H-Duty Staple

9/16" Ceiling Tile Staple

.52" WIDE (also fit Swingline

Staplers) .050" WIRE

1/4" H-Duty Staple

5/16" H-Duty Staple

3/8" H-Duty Staple

1/2" H-Duty Staple

9/16" H-Duty Staple

9/16" Ceiling Tile Staple

CAUTION: THE USE OF ANY OTHER

FASTENERS MIGHT BE HAZARDOUS.

We strongly recommend that Safety

Glasses be worn when using this tool.

Loading...

Loading...