Page 1

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 2000. Black Box Corporation. All rights reserved.

Page 2

CUSTOMER

SUPPORT

INFORMATION

Order toll-free in the U.S. 24 hours, 7 A.M. Monday to midnight Friday: 877-877-BBOX

FREE technical support, 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mail order: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

AUGUST 2000

SM700A SM707C SM722C

SM701A SM708C SM723C

SM701C SM709C SM724C

SM702C SM710C SM730

SM705C SM720C SM740

SM706C SM721C SM750A

Pro Switching System

ALM

A

B

RS-530

MON

TD

RD

RTS

CTS

DCE

DTE

DCD

TM

BK

TS

LP

ALM

A

B

RS-530

MON

TD

RD

RTS

CTS

DCE

DTE

DCD

TM

BK

TS

LP

ALM

A

B

RS-530

MON

TD

RD

RTS

CTS

DCE

DTE

DCD

TM

BK

TS

LP

ALM

A

B

RS-530

MON

TD

RD

RTS

CTS

DCE

DTE

DCD

TM

BK

TS

LP

ALM

A

B

RS-530

MON

TD

RD

RTS

CTS

DCE

DTE

DCD

TM

BK

TS

LP

ALM

A

B

RS-232

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

BK

TS

LP

ALM

A

B

RS-232

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

BK

TS

LP

ALM

A

B

RS-232

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

BK

TS

LP

ALM

A

B

RS-232

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

BK

TS

LP

ALM

A

B

RS-232

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

BK

TS

LP

ALM

A

B

RS-232

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

BK

TS

LP

ALM

A

B

RS-232

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

BK

TS

LP

A

B

MON

ALM

A

B

V.35

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

ALM

A

B

V.35

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

ALM

A

B

V.35

MON

TD

RD

RTS

CTS

DSR

DCD

DTR

RI

GANG

PS1

FAN

FAIL

OK

PS2

FAN

FAIL

OK

NORM

SET

LAMP

TEST

RESET

LINK

ON

M

O

D

E

M

C

O

M

P

M

O

N

A

M

O

N

B

Page 3

Page 4

1

FCC INFORMATION

FEDERAL COMMUNICATIONS COMMISSION

AND

INDUSTRY CANADA

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio frequency energy and if not

installed and used properly, that is, in strict accordance with the manufacturer’s

instructions, may cause interference to radio communication. It has been tested

and found to comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are designed to

provide reasonable protection against such interference when the equipment is

operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct the

interference.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital

apparatus set out in the Radio Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique publié par Industrie Canada.

Page 5

2

PRO SWITCHING SYSTEM

NORMAS OFICIALES MEXICANAS (NOM)

ELECTRICAL SAFETY STATEMENT

INSTRUCCIONES DE SEGURIDAD

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de

que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para

referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de

operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca

de la tina de baño, lavabo, sótano mojado o cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que

sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea

recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá

a lo descrito en las instrucciones de operación. Todo otro servicio deberá ser

referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no

interfiera su uso. La colocación del aparato eléctrico sobre una cama, sofá,

alfombra o superficie similar puede bloquea la ventilación, no se debe colocar

en libreros o gabinetes que impidan el flujo de aire por los orificios de

ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor

como radiadores, registros de calor, estufas u otros aparatos (incluyendo

amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del

tipo descrito en el instructivo de operación, o como se indique en el aparato.

Page 6

3

NOM STATEMENT

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización

del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no

sean pisados ni pellizcados por objetos colocados sobre o contra ellos,

poniendo particular atención a los contactos y receptáculos donde salen del

aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las

recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas

de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea

usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean

derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su

desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 7

4

PRO SWITCHING SYSTEM

TRADEMARKS USED IN THIS MANUAL

VT100™ is a trademark of Digital Equipment Corporation.

Any other trademarks mentioned in this manual are acknowledged to be the

property of the trademark owners.

Page 8

5

CONTENTS

Contents

Chapter Page

1. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Entire Pro Switching System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.1 Two-Part Card Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Front/Rear Card Combinations . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.3 Supported Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.4 Supported Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.5 Line Card Switches and Indicators . . . . . . . . . . . . . . . . . . . . . 16

2.2.6 Control Card Switches and Indicators . . . . . . . . . . . . . . . . . . 16

2.3 System Management Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.1 HP OpenView Windows Graphic Interface . . . . . . . . . . . . . . 17

2.3.2 Monitoring/Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3.3 Alarming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.4 Alarm Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.5 Alarm-Triggered Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.6 Switching Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.7 Network Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.8 Customer Account IDs and Courtesy Terminals . . . . . . . . . . 19

2.3.9 Remote PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.10 Open Communication Port . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.11 Open Channel to Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.12 Network Health Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.13 History Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.14 Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Control Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.1 Racks and the Management PC at Sites . . . . . . . . . . . . . . . . . 20

2.4.2 Dialog with Dialup Sites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4.3 Polling Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5 System Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3. Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Switching and Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 A/B Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.2 Three-Cavity Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page 9

6

PRO SWITCHING SYSTEM

Chapter Page

3.1.3 Four-Cavity Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Monitoring Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4. Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1 Rackmount Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.1 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.2 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Control Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.1 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.3 Front Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4 Rear Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.5 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.6 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7 System Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.8 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.8.1 Blank Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.8.2 Patch Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1 Preparing the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1.1 Fill Out the Rack Description Guide . . . . . . . . . . . . . . . . . . . 40

5.1.2 Configure the Control Card and DIP Switches . . . . . . . . . . . 42

5.1.3 Installing Rack Components . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.1.4 Enter IP Address into Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2 Installing the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2.1 Mounting the Rack into the Cabinet . . . . . . . . . . . . . . . . . . . 57

5.2.2 Connecting Line Card Cables for Switch/Patch Cards . . . . 57

5.2.3 Connecting 10BASE-T Cable . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2.4 Power Up and LED Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3 Software/Management Installation. . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.1 Installing the Management PC . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.2 Install HP OpenView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.3 Install SNMP Application Software. . . . . . . . . . . . . . . . . . . . . 59

5.4 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1.1 SNMP Application Software . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Page 10

7

CONTENTS

Chapter Page

6.1.2 HP OpenView User’s Guide . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1.3 Network Map and Database . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1.4 Map Concepts and Structure . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1.5 Map Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2 Initializing PC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2.1 Basic Information You Will Need . . . . . . . . . . . . . . . . . . . . . . 71

6.2.2 Preliminary Notes and Cautions . . . . . . . . . . . . . . . . . . . . . . . 72

6.3 Creating a System Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.4 HP OpenView Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.4.1 Starting HP OpenView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.4.2 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.3 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.4.4 Edit Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.4.5 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.4.6 Monitor Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.4.7 Control Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.4.8 Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.4.9 Window Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.4.10 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.5 Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.5.1 Site Description Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.5.2 Rack Description Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.5.3 Line Description Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.5.4 Switch Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.5.5 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

6.5.6 Rack Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6.5.7 Line Card Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6.5.8 Switch Schedule Definition Screen . . . . . . . . . . . . . . . . . . . . 131

6.5.9 Standard Alarm Definition Screen . . . . . . . . . . . . . . . . . . . . . 132

6.5.10 Alarm Triggered Switching Screen. . . . . . . . . . . . . . . . . . . . 134

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

8. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.1 Power Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.2 Control Card Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.3 Switching Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.4 PC Control Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Appendix A. Rack Description Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Page 11

8

PRO SWITCHING SYSTEM

Chapter Page

Appendix B. Pin Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Appendix C. HDX2000L Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

C.1 Functions List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

C.2 Parameters List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

C.3 Sample Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

C.4 Debug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Appendix D. Proprietary MIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

D.1 MIB Path Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

D.2 Rack Global Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

D.3 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

D.4 Gang Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

D.5 Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

D.6 Line Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

D.7 Hardware Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

D.8 Alarm Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

D.9 Alarm-Triggered Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

D.10 Time-Triggered Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

D.11 Bus-Triggered Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

D.12 Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

D.12.1 Generic Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

D.12.2 Specific Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Page 12

9

CHAPTER 1: Specifications

1. Specifications

1.1 Cards

Connectors—SM720C: (3) DB25 female; SM721C: (3) M/34 female; SM722C:

(3) DB15 female; SM723C: (3) RJ-11; SM724C: (3) RJ-45

Indicators—SM705C-SM707C: (8) LEDs for transition activity

Power—From the Rack Chassis

1.2 Entire Pro Switching System

Protocols—Transparent to all protocols and speeds

Control Options—HP OpenView Windows, SNMP, or watchdog timer

Control Communication—RS-232/V.24; 1200 to 9600 baud; 7 data bits, even

parity, 1 or 2 stop bits

Management PC Requirements—486 PC running at 66 MHz with a 31⁄2" 1.44 MB

floppy disk drive, a color monitor, a mouse, sufficient serial communication

ports to access all sites, and the following memory:

Extended memory: 8 MB

Hard disk space: 5 MB

+15K per rack.

System Capacity—OpenView control: 256 sites, 256 racks per site; SNMP control:

256 sites, 256 racks per site; Watchdog timer: Unlimited sites, 256 racks per site

Status Activity LEDs—RS-232/V.24 and V.35: TD, RD, RTS, CTS, DSR, DCD,

DTR, RI; RS-530: TD, RD, RTS, CTS, DCE, DTE, DCD, TM

Alarms—Triggered on MARK, SPACE, or NO DATA: RS-232/V.24: TD, RD, RTS,

CTS, DSR, DCD, DTR, RI, TC, RC, EC, SQD; V.35: TD, RD, RTS, CTS, DSR,

DCD, DTR, LL, TC, RC, EC, RL; RS-530: TD, RD, RTS, CTS, DCE, DTE, DCD,

TM, TC, RC, EC, RL

Page 13

10

PRO SWITCHING SYSTEM

Switching—RS-232/V.24: 3 conductors, pins 1 (shield ground) and 7 (signal

ground) are not switched; V.35: 19 conductors: RTS (C), CTS (D), DSR (E),

DCD (F), DTR (H), LL (J), TM (K), TP (L), RL (BB), TD (P, S), RD (R, T),

RC (V, X), EC (U, W), TC (Y, AA), pins A (shield ground) and B (signal

ground) are not switched; RS-530: 23 conductors, pins 1 (shield ground) and 7

(signal ground) are not switched; Other cards: All conductors are switched

Patching—RS-232/V.24: 23 conductors, pin 7 (signal ground) is common; V.35:

19 conductors: C, D, E, F, H, J, K, L, P, R, S, T, U, V, W, X, Y, AA, BB, pin B

(signal ground) is common; RS-530: 23 conductors, pin 7 (signal ground) is

common

Monitoring Bus—(1) analog bus, (1) digital bus: RS-232/V.24: TD, RD, RTS,

CTS, DSR, DCD, SCTS, TC, SRD, RC, DTR, SQD, RI, DSRS, EC, TI, pin 7

(signal ground) is common; V.35: TD, RD, RTS, CTS, DSR, DCD, DTR, LL,

RC, EC, TC, pin B (signal ground) is common; RS-530: 23 conductors, pin 7

(signal ground) is common

Relays—Switching: Latching; Monitoring bus: Nonlatching; Contact material:

Gold-clad silver; Initial contact resistance: 50 milliohms; Expected life

(number of operations): 10,000,000

Interface—Digital: RS-232, RS-530, V.35; Analog: RJ-11, RJ-45

Operating Temperature—32 to 104°F (0 to 40°C)

Maximum Humidity—Up to 95%, noncondensing

Power—From Power Supply Module (SM750A): 115/230 VAC, autoselectable

Size—SM700A: 8.75"H x 19"W x 13.25"D (22.2 x 48.3 x 33.6 cm)

Weight—45 lb. (20.4 kg) fully configured

Page 14

11

CHAPTER 2: Introduction

2. Introduction

The Pro Switching System is an advanced system for managing data lines and data

networks. It has a broad range of capabilities and can adapt to small and large

applications.

Once you set up the system, it provides “hands-free” management. The

predefined switching and backup tasks are performed automatically. If a line

generates an alarm, the system reroutes the data through a backup line and reports

the problem. Also, it lets you monitor and test any line in the network.

For remote management, the 2000 Windows SNMP OpenView 7.2 application

software lets you control racks via SNMP over IP networks.

The Pro Switching System features:

Functions:

• Three- and four-cavity patching

• A/B switching

• Single-line, gang, and group switching

• User-defined alarms

• Alarm- and time-triggered switching

• Remote status monitoring for testing faulty lines

• Break to DTE or DCE for remote test/access

• Non-intrusive bridging for monitoring

Hardware:

• Intermixing of switching and patching cards within the same rack

• Digital and analog monitoring buses

• Switching performed via latching relays

• Redundant power units with separate power feeds

• Dimensions: 19" (48.3 cm) wide, 8.75" (22.2 cm) high, 13.25" (33.7 cm) deep.

Page 15

12

PRO SWITCHING SYSTEM

Control/Software:

• SNMP

• PC (HP OpenView Windows)

• ASCII character strings

• Async terminal menus

• Central control of remote test equipment

• Provides database including network performance evaluation

The rest of this chapter describes the features of the Pro Switching System in

more detail. It also provides sample applications at the end of the chapter. Read

this chapter for a more comprehensive understanding of the system.

2.1 System Architecture

The System architecture of the Pro Switching System has three levels: line level,

rack level, and site level.

At the Line level, data lines pass through line cards.

Figure 2-1. Line Level.

Page 16

13

CHAPTER 2: Introduction

The line level has the following capabilities:

• A/B switching

• Two-, three-, and four-cavity patching

(Refer to Chapter 3, Functions, for descriptions.)

At the Rack level, the line cards are mounted in racks. Each rack has its own

microprocessor-based control card.

The rack level has line bridging and breaking via monitoring bus.

(Refer to Chapter 3, Functions, for descriptions.)

Figure 2-2. Fully Loaded Rack.

At the Site level, each rack control card communicates with a system

management device (for example, a PC).

The site level has the following capabilities:

• group switching

• scheduled switching

• default switching

• alarm monitoring (reporting to system management and selectively to

customer courtesy terminals)

• alarm-triggered switching, with or without fallback

Page 17

14

PRO SWITCHING SYSTEM

Figure 2-3. Site Level.

• system health check

• database report generation

• system security functions (software and hardware pass codes)

• multiple site management (up to 256 racks per site; up to 256 sites per system)

(Refer to Chapter 6, Operation, for descriptions.)

2.2 Hardware Features

2.2.1 TWO-P

ARTCARDDESIGN

A unique two-part card design provides flexibility. The front card (front-inserted)

plugs into the rear card (rear-inserted) (see Figure 2-4). Together, they manage

one data line.

Generally, the front card contains the switching and patching circuitry, and the

rear card contains the cable interface circuitry.

Network

Page 18

15

You can insert and remove front cards without removing rear cards or cables.

Figure 2-4. Front and Rear Cards.

2.2.2 F

RONT-REARCARDCOMBINATIONS

Each front card is compatible with a specific rear card.

2.2.3 S

UPPORTEDINTERFACES

The system supports the following interfaces: RS-232/V.24, V.35, RS-530, DB15, RJ11, RJ-45.

2.2.4 S

UPPORTEDCONNECTORS

The system supports these connectors: DB25, V.35 “M” type, DB15, RJ-11, RJ-45.

Figure 2-5 illustrates the mixing of connectors in a rack.

Page 19

16

PRO SWITCHING SYSTEM

Figure 2-5. Mixing Connectors in a Rack.

2.2.5 L

INECARD

S

WITCHES ANDINDICATORS

Each Switching card has a switch on the front panel for manual control. Each card

also has LED indicators.

(Refer to Chapter 4, Components, for a full description of line card switches

and LEDs.)

2.2.6 C

ONTROLCARDSWITCHES ANDINDICATORS

The rack control card has a five-button switch panel for gang switching (see Figure

2-6). You can enable/disable this function by a key switch. When you press a

button, all cards in the rack that have the indicated capability switch.

For example, if you press the B button, all A/B switching cards in the rack will

switch to B.

Switching is performed by latching relays, which, if the power fails, remain in

the last switched position and continue to pass data.

The control card also has a Lamp Test button to test the rack LEDs. A reset

button reboots the system (warm or cold reboot, depending on a DIP-switch

setting).

Control Card LEDs indicate Power Supply, Fan, and System Status.

C

D

C

O

I

O

N

G

M

T

M

R

O

I

L

N

1

C

C

O

O

M

N

M

T

R

O

O

U

L

T

2

FUSE RATING: T3.0A

250V~ONLY

100-240V 50-60HZ

I

T

A

L

A

A

N

A

L

O

G

MON

BUS

A

U

B

X

P

O

R

T

P

O

W

E

R

C

O

1

M

P

O

W

E

R

2

A

A

A

B

COM

C

O

M

A

A

A

A

B

B

B

B

B

B

C

C

C

C

O

O

M

O

M

M

C

O

O

M

M

A

A

A

A

B

B

COM

C

O

M

COM

A

B

B

B

C

C

O

O

M

M

A1

A2

A3

A

A4

B1

B2

B3

B4

C1

B

C2

C3

C4

C

O

M

Page 20

17

CHAPTER 2: Introduction

(Refer to Chapter 4, Components, for a full description of control card switches

and LEDs.)

Figure 2-6. Control Card Switches and Indicators.

2.3 System Management Features

2.3.1 HP O

PENVIEWWINDOWSGRAPHICINTERFACE

Pro Switching System software running on a PC under HP OpenView for Windows

mediates System Management.

OpenView is an open software product, allowing you to manage devices from

different vendors. It allows you to create a map of the network using a supplied set

of icons. A color code indicates the status of each device in the network.

The Pro Switching System network management can control up to 256 sites,

each comprising up to 256 interconnected racks. You interact with the system via

the map icons and a series of subordinate screen displays.

Page 21

18

PRO SWITCHING SYSTEM

The displays include realistic front and rear views of the rack mount and the

line cards. They show the current switched state of all lines and the status of

monitored leads.

The screen displays functional switch buttons. If you click on a displayed button,

the equivalent hardware operation occurs at the site. For example, if you click on

gang-switch button A, a gang switch to A operation occurs at the rack (as long as

the key switch is in the ENABLE [unlocked] position).

The software also displays LEDs in real time. In other words, when an LED

lights at a rack, it also lights in the on-screen display.

If you click on the display of a line card, the system displays a window that

describes the line and the status of the monitored signals on the leads.

2.3.2 M

ONITORING/TESTING

Two common monitoring buses—a digital bus and an analog bus—provide access

for monitoring and testing each line with or without interrupting data flow.

Upon command, the system can connect a line on any rack to the rack’s digital

or analog monitoring bus.

When the monitoring buses of several racks are daisy-chained together, you can

create a bus definition, specifying the racks that are connected in this way. This

gives you easy access for monitoring bus operations. See Figure 2-7 for an example

of a monitoring bus.

Figure 2-7. Monitoring Bus.

Page 22

19

CHAPTER 2: Introduction

2.3.3 A

LARMING

You can define failure criteria for each signal online, based on the sensing of

SPACE, MARK, or NO DATA conditions and their duration. You can define

different criteria for different times of the day.

2.3.4 A

LARM

B

OX

A port can be dedicated to let you connect an alarm box. The alarm box responds

to alarm signals received by the PC, producing a visual or auditory signal to alert

you.

2.3.5 A

LARM

-T

RIGGEREDSWITCHING

You can predefine a lead alarm to trigger specified switching operations whenever

it occurs. You can also program the system to switch back when the condition has

been corrected. You can define different criteria for different times of the day.

2.3.6 S

WITCHINGOPTIONS

You can apply PC-controlled switching operations—manual, backup, alarmtriggered, scheduled, and default (single-keystroke)—selectively to one line at a

time, if desired. You also can create and name groupings of sites, racks, and/or

lines to switch simultaneously.

2.3.7 N

ETWORKSECURITY

You assign each user a password and an appropriate level of access to network

operations.

2.3.8 C

USTOMERACCOUNTIDS ANDCOURTESYTERMINALS

You can define customer account IDs for assignment to one or more lines and/or

racks. This assignment enables selective routing of status and alarm information to

one or more courtesy terminals. Customers viewing courtesy terminals can observe

what is happening on their own lines but not on the lines of other customers.

2.3.9 R

EMOTE

PC

You can connect one or more remote PCs to the dedicated communication ports.

A user at a remote PC can perform switching, and can view and acknowledge

alarms in the same ways as the user at the central PC.

Page 23

20

PRO SWITCHING SYSTEM

2.3.10 O

PENCOMMUNICATIONPORT

The Open Communication Port function lets you select one of the system’s

communication ports to which a modem or terminal is connected. Then, via the

PC, you can communicate directly with the connected device.

2.3.11 O

PEN

C

HANNEL TOMODEM

At the PC, you can open a channel to any online modem and communicate

directly with the modem for non-intrusive testing and diagnosis.

2.3.12 N

ETWORKHEALTHCHECK

To detect rack failures that preclude alarms, the PC runs a health check,

attempting to communicate with each rack. If a rack fails to respond, the PC

reports this failure.

Sites that are always online with the central PC are checked continuously. For

off-line sites, you can define a Health Check Schedule, specifying times when these

sites will be checked.

2.3.13 H

ISTORYFILES

All alarms are written to the Session Alarm History file, which you may display

and/or clear at any time.

Alarms are also written to a separate ASCII log file on the hard disk. Another

ASCII log file maintains a record of important system events and operator actions.

2.3.14 W

ATCHDOGTIMER

The optional Watchdog Timer application switches users between two computer

systems, substituting a standby system for a failed system.

2.4 Control Communication

2.4.1 R

ACKS AND THEMANAGEMENT

PC ATS

ITES

A Pro Switching System rack that is connected via its COMM IN port with the

management PC comprises a Pro Switching System site. The rack connected in this

way is the Primary Rack. At this site, other racks called Secondary Racks can

connect to the Primary Rack via their communication ports in daisy-chain fashion.

The location of the Management PC is referred to as the Primary Management

Site. The Management PC can communicate with up to 256 Pro Switching System

sites. This communication can be routed through the communication ports of the

Page 24

21

CHAPTER 2: Introduction

PC or through up to 64 auxiliary communication ports mounted on intelligent

serial multi-port units.

The connections between the PC and the rack can be of two types:

1. Dedicated line between the PC and a site. The site is always online with the PC

(hardwired).

2. Dialup modem connection between the PC and a site (see Figure 2-8). The

connection is established when needed.

You can program communication ports from the PC to be either dedicated

ports or dialup modem ports.

Figure 2-8. Dialup Connection.

2.4.2 D

IALOG WITHDIALUPSITES

Normally, all dialup sites are off-line. You initiate the dialing of the site’s telephone

number when you execute a command that requires communications with a rack

on a dialup site. When the connection is established, the remote site comes online

and polling starts.

From the moment you make the connection, you can send commands to the

racks on that site and receive status data from the racks.

Page 25

22

PRO SWITCHING SYSTEM

If an alarm is generated or restored to normal in a rack at a dialup site, and the site

is off-line, the dialup site dials the central PC.

When the connection is established, the dialup site comes online. The PC

responds to the connection by polling the dialup site and obtaining information

about current status and configuration. Then, the PC disconnects the dialup site.

2.4.3 P

OLLINGPROCEDURES

Generally, racks on dedicated ports are polled individually by the PC. However, if a

switching/monitoring screen for the rack is displayed, this rack is polled more

frequently in order to acquire “real-time” information about it for display on the

screen.

2.5 System Expansion

The Pro Switching System is flexible and modular. You can begin with a small local

system—a rack and a few cards. As your needs grow, you can add more cards and

racks to create a large site; then add more sites to create a global network. You can

incorporate new functions and interfaces as they come into use.

Page 26

23

CHAPTER 3: Functions

3. Functions

This chapter describes the functions of the Pro Switching System, including

switching and patching options and the monitoring bus. The chapter also

describes the system configuration options.

3.1 Switching and Patching

The Pro Switching System offers these switching and patching options:

• A/B switching

• Three-cavity patching

• Four-cavity patching

3.1.1 A/B S

WITCHING

A/B switches have three ports: A, B, and COMMON. You can connect the line at

the COMM IN port to the line at the A port or the B port. Figure 3-1 shows an A/B

switch in which the COMMON port is connected to the A port.

Figure 3-1. A/B Switching.

The switch uses latching relays, which remain in the last switched position if the

power fails.

A/B switches are available for use with the following interfaces: RS-232/V.24,

RS-530, V.35, DB15, RJ-11, and RJ-45.

3.1.2 T

HREE-CAVITYPATCHING

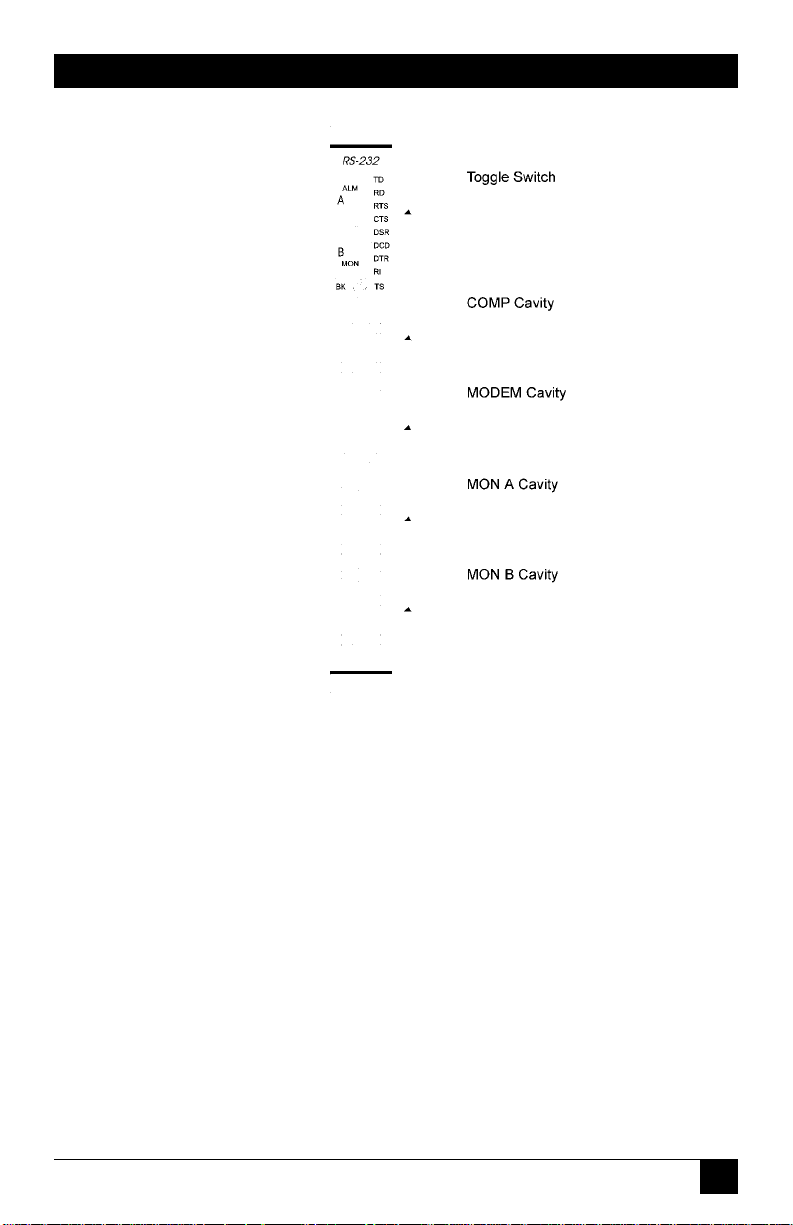

These cards have three patch cavities: COMP, MODEM, and MON. Figure 3-2

shows three-cavity patching. Normally, the DTE is connected to the DCE.

Page 27

24

PRO SWITCHING SYSTEM

Figure 3-2. Three-Cavity Patching.

When you insert a patch cord into the MON cavity, it is connected to the circuit

between the DTE and the DCE. This is a bridge connection, and the circuit is not

broken. You can monitor the signals.

When you insert a patch cord into the COMP cavity, the circuit is broken and

the cord is connected to the DTE. You can test the DTE.

When you insert a patch cord into the MODEM cavity, the circuit is broken and

the cord is connected to the DCE. You can test the DCE.

Three-cavity patching is available for use with the following interfaces: RS-232,

V.35, and RS-530.

3.1.3 F

OUR-CAVITYPATCHING

These cards have A/B switching and four patch cavities: COMP, MODEM, MON A,

and MON B. Figure 3-3 shows four-cavity patching when the switch is in the A

position. Normally, the appropriate DTE is connected to the DCE.

Page 28

25

CHAPTER 3: Functions

Figure 3-3. Four-Cavity Patching.

When you insert a patch cord into the MON A cavity, it connects to the circuit

between DTE A and the DCE. When you insert a patch cord into the MON B

cavity, it connects to the circuit between DTE B and the DCE. The circuits are not

broken. You can monitor the signals.

When you insert a patch cord into the COMP cavity, the circuit is broken and

the cord is connected to the appropriate DTE. You can test the connected DTE.

When you insert a patch cord into the MODEM cavity, the circuit is broken and

the cord is connected to the DCE. You can test the DCE.

Four-cavity patching is available for use with the following interfaces: RS-232,

V.35, and RS-530.

3.2 Monitoring Bus

The Pro Switching System has two monitoring buses: a digital monitoring bus and

an analog monitoring bus. You can connect a monitoring bus to any line in the

system, allowing monitoring and testing equipment to access that line. When a line

is connected to the monitoring bus, the corresponding card’s MONITOR LED

lights. Figure 3-4 shows a monitoring bus.

Typically, the DTE is connected to the DCE.

Page 29

26

PRO SWITCHING SYSTEM

You can connect the monitoring bus to a line in any of three configurations,

which correspond to the patching functions. You can bridge, break to DTE, or

break to DCE.

When you bridge a line, the equipment is connected to the circuit between the

DTE and the DCE. The circuit is not broken, and you can monitor the signals.

When you break to DTE, the circuit is broken and the equipment is connected

to the DTE. You can test the DTE.

When you break to DCE, the circuit is broken and the equipment is connected

to the DCE. You can test the DCE.

The buses use non-latching relays, which return to their normal settings if the

power fails.

The monitoring buses are available for use with the following interfaces: RS-232,

RS-530, and RJ-11.

Figure 3-4. Monitoring Bus. The line card in slot 2 is configured for break

to DTE.

(All other line cards are normal-through.)

Page 30

27

CHAPTER 3: Functions

Figure 3-5. Normal-Through.

Figure 3-6. Bridge.

Page 31

28

PRO SWITCHING SYSTEM

Figure 3-7. Break to DTE.

Figure 3-8. Break to DCE.

3.3 Configurations

There are two types of rack configurations:

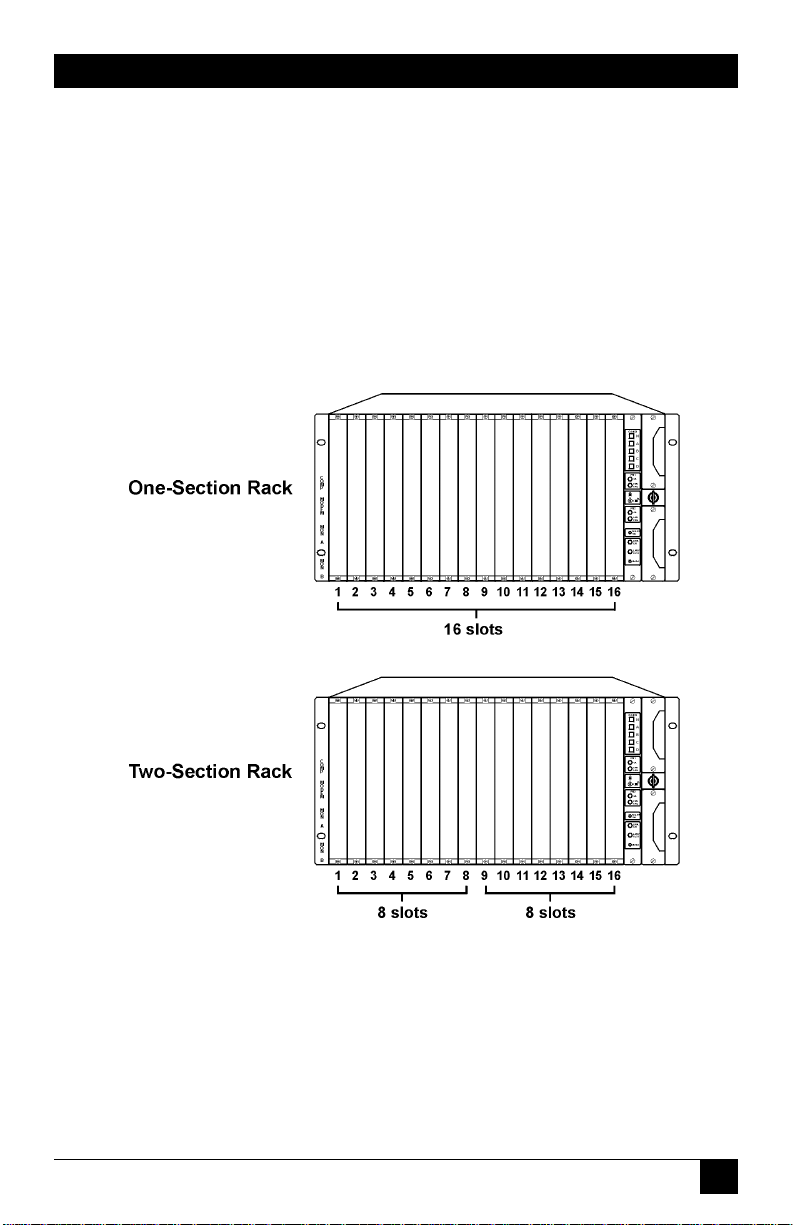

1. One-section rack: In the one-section rack, the bus can connect to all 16 slots

(see Figure 3-9). By default, the rack you receive is configured to be a onesection rack.

2. Two-section rack: You can use DIP switches to split the rack into two sections.

Page 32

29

CHAPTER 3: Functions

That is, one bus connects to eight slots, and the other bus connects to the

other eight slots (see Figure 3-9).

Switch/patch cards provide AB switch with optional patch capabilities. Normally,

you will place these cards in a one-section rack. Place the cards in any combination

and in any order.

NOTE

Place the spare card in the rightmost slot of a section. Place the online

cards in the other slots.

Figure 3-9. Rack Configurations.

Page 33

30

PRO SWITCHING SYSTEM

4. Components

This chapter describes the Pro Switching System components and component

functions, and provides model numbers.

4.1 Rackmount Chassis

The Rackmount Chassis (SM700A) has 16 slots for front cards, 16 slots for rear

cards, one slot (the rightmost slot) for the control card, and two slots for power

supplies.

The Rackmount Chassis must include a control card and at least one power

supply (115/230 VAC) to operate properly. If you want power redundancy

(backup), the rack must include two power supplies.

Figure 4-1. Rackmount Chassis Front Ports.

4.1.1 C

ONTROLS

• Key Switch: A key switch on the front of the rack enables or disables manual

operation. This prevents accidental switching from the front of the rack.

To enable manual operation, turn the key to the horizontal (unlocked)

position (represented by the icon of the open padlock on the control card).

See Figure 4-2.

To disable manual operation, turn the key to the vertical (locked) position

(represented by the icon of the closed padlock on the control card).

Page 34

31

CHAPTER 4: Components

Figure 4-2. Key Switch Unlocked.

4.1.2 P

ORTS

• COMM[unication] ports: On the rear of the rack, there are two

communication ports: COMM IN (DB25 male) and COMM OUT (DB25

female). For some system setups, use these ports to connect the rack to the

managing PC. However, for SNMP setups, use the 10BASE-T connector on the

control card to connect the rack to the managing PC.

• MON[itoring] ports: On the rear of the rack, there are two monitoring ports:

ANALOG (RJ-45 female) and DIGITAL (DB25 female). Use these ports to

connect monitoring buses together and to connect monitoring and testing

equipment to the buses.

• AUX[iliary] port: On the rear of the rack, there is one auxiliary port: AUX

(DB9 female). Use this port to set SNMP/Telnet configurations for the rack

when you can’t access the rack through the 10BASE-T connector (on the

control card).

• Power connectors: The rear of the rack contains two power connectors:

POWER 1 and POWER 2. Use these connectors to attach power sources to the

corresponding power supplies.

Page 35

32

PRO SWITCHING SYSTEM

Figure 4-3. Rackmount Chassis Rear Ports.

4.2 Control Cards

Table 4-1. Control Cards

Model Description

SM701C SNMP 10BASE-T

SM702C VT100™

The control card coordinates all rack functions, communicates with other racks,

and communicates with the management PC. Each rack must have one control

card, inserted into the rightmost slot.

4.2.1 C

ONTROLS

• GANG: There are five gang switches: N, A, B, C, and D. When the key switch is

in the horizontal position, you can use these switches to change all lines in a

rack. If you press A, B, C, or D, the control card switches all lines in the rack to

that position. If you press N, the control card switches all lines in the rack to

the normal position. Use the NORM SET pushbutton to define the normal

position for all lines.

• NORM SET: This pushbutton sets the N gang switch. When you press this

button, the Pro Switching System stores the current switch settings of each line

Page 36

33

CHAPTER 4: Components

as the normal position. Then, when you press the N gang switch, all lines

switch to the normal position.

• LAMP TEST: This pushbutton lights all LEDs in the rack. You can use it to

determine if an LED is operating correctly.

• RESET: This switch performs a warm reset or a cold reset, depending on its

associated DIP switch setting. A warm reset reboots the CPU without affecting

the operator-programmed data that is stored in CPU RAM (for example, alarm

definitions). A cold reset reboots the CPU and deletes all operatorprogrammed data that is stored in the CPU RAM, reinitializing the system.

4.2.2 LED

S

• OK (green): There is one OK LED for power supply 1 (PS1) and one for

power supply 2 (PS2). When lit, this LED indicates that the relevant power

supply is functioning.

• FAN FAIL (red): There is one FAN FAIL LED for PS1 and one for PS2. When

lit, this LED indicates that the fan in the relevant power supply is not

functioning.

• LINK ON (green): This LED, when lit, indicates that the control card is

functioning and capable of communicating with other racks and with the

central PC. When not lit, this LED indicates that the control card has failed.

When the control card fails, COMM IN is physically shorted to COMM OUT,

bypassing the failed control card.

Page 37

34

PRO SWITCHING SYSTEM

Figure 4-4. Control Card.

Page 38

35

CHAPTER 4: Components

4.3 Front Cards

Table 4-2. Switch/Patch Front Cards

Model Interface Switch Patch Switched # of LEDs Alarms Mon. Bus Compatible

Cond. Slots Rear

Cards

SM705C RS-232/V.24 A/B 4-cavity 23 1 √√√SM720C

SM706C V.35 A/B 4-cavity 19 1 √√ SM721C

SM707C RS-530 A/B 4-cavity 23 1 √√√SM720C

SM708C DB15 SM722C

SM709C RJ-11 A/B — 4 1 SM723C

SM710C RJ-45 A/B — 8 1 SM724C

Front cards work with rear cards to manage lines. The front card contains the

switching and patching circuitry, while the rear card contains the cable interface

circuitry. The front card and the rear card mate when they are inserted into the

rack.

In a rack, there are 16 slots for front cards and 16 corresponding slots for rear

cards. The cards occupy one slot. The front cards are called Switch/Patch Cards.

S

WITCH/PATCHCARDS

Switch/patch cards provide A/B switching with optional patching capabilities.

Switch/patch cards are available for use with RS-232, V.35, RS-530, RJ-11, RJ-45,

and DB15 interfaces. Each switch/patch card occupies one slot.

Controls

A/B switch cards have a toggle switch with two settings: A and B. To change the

switch to the A position, move the toggle switch toward the A setting. To change

the switch to the B position, move the toggle switch toward the B setting.

LEDs

Switch/patch cards have some or all of the following LEDs:

• Switch position (green): Pro Switching System cards, where appropriate,

indicate switch position. For example, A/B switch cards indicate if the line is

currently switched to the A or B position.

Page 39

36

PRO SWITCHING SYSTEM

• Signals (red): Some Pro Switching System cards include LEDs that indicate the

current status of signals. For example, RS-232 cards with LEDs indicate the

status of TD, RD, RTS, CTS, DSR, DCD, DTR, and RI.

• ALM (red): When flashing, indicates that the line passing through this card is

generating an alarm condition.

• MON (green): When lit, indicates that the line is currently connected to the

monitoring bus. The connection is made for monitoring and testing

operations.

• BK (red): When lit, indicates that the line is currently broken. The break is

made for testing operations.

• TS (red): Not used.

• LP (red): Not used.

Patch Cavities

Switch/patch cards can have up to four patch cavities, which allow you to monitor

and test the lines. Normally, data transmission is normal through. That is, the DTE

is connected to the DCE. However, if you connect a patch cord to a patch cavity,

you can monitor or test the line as follows:

• COMP: When you insert a patch cord into the COMP cavity, the circuit is

broken and the cord is connected to the DTE. You can use this connection to

test the DTE.

• MODEM: When you insert a patch cord into the MODEM cavity, the circuit is

broken and the cord is connected to the DCE. You can use this connection to

test the DCE.

• MON A: When you insert a patch cord into the MON A cavity, it is connected

to the circuit between the DTE A port and the DCE port. The circuit is not

broken. You can use this connection to monitor the signals.

• MON B: When you insert a patch cord into the MON B cavity, it is connected

to the circuit between the DTE B port and the DCE port. The circuit is not

broken. You can use this connection to monitor the signals.

Page 40

37

CHAPTER 4: Components

Figure 4-5. Switch/Patch Card.

4.4 Rear Cards

Rear cards work with front cards to manage lines. The front card contains the

switching and patching circuitry; the rear card contains the cable interface

circuitry. The front card and the rear card mate when they are inserted into a rack.

Rear cards and front cards that mate must be compatible. See the description of

the front card (Section 4.3) for a list of the compatible rear cards.

In a rack, there are 16 slots for front cards, and 16 corresponding slots for rear

cards. The cards occupy one slot.

Rear cards have ports that correspond with their applications. They also have a

slot number window that indicates the number of the slot in which the card is

installed.

Page 41

38

PRO SWITCHING SYSTEM

Table 4-3. Rear Cards

Model Application # of Slots Connectors

SM720C A/B switch (and patch) 1 A, B, Common: DB25F

SM721C A/B switch (and patch) 1 A, B, Common: V.35F

SM722C A/B switch (and patch) 1 A, B, Common: DB15F

SM723C A/B switch 1 A, B, Common: RJ-11

SM724C A/B switch 1 A, B, Common: RJ-45

4.5 Power Supplies

Power supplies allow you to supply power to a rack. You can have one or two (for

redundant power) power supplies in a rack. There is one type of power supply: the

SM750A. It’s a 115/230-VAC, 50- to 60-Hz auto-selectable power supply.

Table 4-4. Power Supply

Model Description

SM750A Power supply, 115/230 VAC, 50-60 Hz (auto-selectable)

4.6 Software

To control the Pro Switching System from a PC, you need the Pro Switching

System Software (SM701A). This software works as an application under HP

OpenView Windows.

Table 4-5. Software

Model Description

SM701A Pro Switching System Software

Page 42

39

CHAPTER 4: Components

4.7 System Cables

System cables connect racks to the central PC via COMM ports. The first rack at a

site is connected to the central site; the other racks are daisychained together. For

SNMP applications, you don’t need to connect system cables to the COMM ports.

4.8 Accessories

4.8.1 B

LANK

P

ANELS

Blank panels cover empty slots in the rack.

Table 4-6. Blank Panels

Model Description

SM730 Blank Panel, Unused rear slot

SM740 Blank Panel, Unused front slot

4.8.2 P

ATCHCORDS

Patch cords allow you to connect equipment to patch cavities. Patch cords are

available in a variety of lengths and with a variety of connectors. Call Technical

Support for more information.

Page 43

40

PRO SWITCHING SYSTEM

5. Installation

This chapter shows you how to install a Pro Switching System for SNMP

management.

5.1 Preparing the Rack

“Preparing the rack off-site” sets up the rack so that a technician can quickly install

the rack on-site, leave, and let the network manager perform the necessary

SNMP/Telnet configurations to the rack remotely.

To prepare the rack:

• Fill Out the Rack Description Guide (Section 5.1.1)

• Configure the Control Card (Section 5.1.2)

• Install Components (Section 5.1.3)

• Enter IP address into rack (Section 5.1.4)

5.1.1 F

ILLOUT THERACKDESCRIPTIONGUIDE

1. Make the appropriate number of photocopies of the Rack Description Guide

sheet (shown in Appendix A) for the number of racks to be installed.

2. Complete the information on the sheets for each rack. (See the “Rack

Description Guide Example” on the next page.)

3. Make two photocopies of the completed sheets.

4. Give one set of sheets to the installation technician. Give another set to the

network manager. Store the original sheets in a master file.

Page 44

41

CHAPTER 5: Installation

Rack Description Guide Example

Site name:

Password (DIP switches):

Rack name:

Rack address (DIP switches):

Baud rate:

IP Address:

Application: Switch/patch

Slot: Connection:

1 A: Satellite, B: Telco, C: User001

2 A: Satellite, B: Telco, C: User002

3 A: Satellite, B: Telco, C: User003

4 A: Satellite, B: Telco, C: User004

5 A: Satellite, B: Telco, C: User005

6 A: Satellite, B: Telco, C: User006

7 A: Satellite, B: Telco, C: User007

8 A: Satellite, B: Telco, C: User008

9 A: Satellite, B: Telco, C: User009

10 A: Satellite, B: Telco, C: User010

11

12

13

14

15

16

Page 45

42

PRO SWITCHING SYSTEM

5.1.2 C

ONFIGURE THECONTROLCARD AND

DIP S

WITCHES

Each rack must have one control card, which is inserted into the rightmost slot of

the rack. The control card coordinates all rack functions, communicates with other

racks, and communicates with the management PC.

Before installing the control card, you must configure its battery jumper and

DIP switches.

Figure 5-1. Control Card.

CAUTION

Cards are electrostatic-discharge (ESD) sensitive. To prevent ESD

damage, always wear grounding wrist straps when touching, removing,

or inserting cards. Store and transport cards in sealed, static-shielding

bags.

NOTE

Before installing the control card, the battery must be enabled.

Configuring the Battery Jumper

1. Locate the battery jumper pins, located above the battery and labeled JP1, on

the control card. (The control card normally ships with the battery disabled—

its jumper rests on only one of the pins, disabling the battery during storage

and transportation.)

Page 46

43

CHAPTER 5: Installation

2. To activate the battery, connect the pins for a two-pin group by placing the

jumper across both pins. For a three-pin group, connect jumper cap across

the two pins labeled ON.

NOTE

To disable the battery on the control card, for a two-pin jumper group

disconnect the jumper cap across both pins so they rest on only one

pin. For a three-pin jumper group, connect the jumper cap across two

pins labeled OFF.

Setting the Configuration DIP Switches (DS5)

The configuration DIP switches set the following:

• Enable/disable rack password

• Cold/warm RESET button configuration

• Enable/disable NORM SET and N gang switch buttons

• Communication baud rate

Tables 5-1 through 5-4 illustrate the DIP-switch settings.

DIP Switch Tables

Table 5-1. DIP Switches at DS7

Switch Position In order to… Notes

1 ON Enable the Ethernet port.

OFF Disable the Ethernet port.

2 OFF – Always set to OFF.

3 ON Enable the AUX port.

OFF Disable the AUX port.

Page 47

44

PRO SWITCHING SYSTEM

Table 5-2. DIP Switches at DS6

Switch Position In order to… Notes

1 to 8 OFF – Always set to OFF.

Table 5-3. DIP Switches at DS5

Switch Position In order to… Notes

1 ON Disable the password. All racks at a site must use the

same password.

OFF Enable the password. When you enable the

password, the management

PC uses the password to

communicate with the rack.

When you disable the

password, the management

PC disregards the password.

2 ON Configure the RESET button A cold reset erases all user-

to perform a “cold” reset programmed system parameter

when pressed. data that are stored in

the Pro Switching System RAM

and reboots the CPU,

reinitializing the system.

OFF Configure the RESET button A warm reset reboots the CPU

to perform a “warm” reset without affecting the userwhen pressed. programmed system

system parameter data (such

as alarm definitions) that are

stored in the Pro Switching

System RAM.

Page 48

45

CHAPTER 5: Installation

Table 5-3 (continued). DIP Switches at DS5

Switch Position In order to… Notes

3 ON Disable the NORM SET and When you enable

N gang switch buttons. NORM SET, you can

use the control card

NORM SET switch

and the N gang

switch. When you

disable NORM

OFF Enable the NORM SET and SET, you cannot use

N gang switch buttons. these switches.

4, 5, 6 OFF – Always set to OFF.

7, 8 7 8 All racks at a site

ON ON Set the baud rate to 2400 bps. must use the same

OFF ON Set the baud rate to 4800 bps. baud rate. The baud

ON OFF Set the baud rate to 9600 bps. rate DIP switches set

OFF OFF Set the baud rate to 19200 bps. the baud rate for

communication

between the rack and

the management PC.

Page 49

46

PRO SWITCHING SYSTEM

Table 5-4. DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

ON ON ON ON ON ON ON ON 000

off ON ON ON ON ON ON ON 001

ON off ON ON ON ON ON ON 002

off off ON ON ON ON ON ON 003

ON ON off ON ON ON ON ON 004

off ON off ON ON ON ON ON 005

ON off off ON ON ON ON ON 006

off off off ON ON ON ON ON 007

ON ON ON off ON ON ON ON 008

off ON ON off ON ON ON ON 009

ON off ON off ON ON ON ON 010

off off ON off ON ON ON ON 011

ON ON off off ON ON ON ON 012

off ON off off ON ON ON ON 013

ON off off off ON ON ON ON 014

off off off off ON ON ON ON 015

ON ON ON ON off ON ON ON 016

off ON ON ON off ON ON ON 017

ON off ON ON off ON ON ON 018

off off ON ON off ON ON ON 019

ON ON off ON off ON ON ON 020

off ON off ON off ON ON ON 021

ON off off ON off ON ON ON 022

off off off ON off ON ON ON 023

ON ON ON off off ON ON ON 024

off ON ON off off ON ON ON 025

ON off ON off off ON ON ON 026

off off ON off off ON ON ON 027

ON ON off off off ON ON ON 028

off ON off off off ON ON ON 029

ON off off off off ON ON ON 030

off off off off off ON ON ON 031

ON ON ON ON ON off ON ON 032

Page 50

47

CHAPTER 5: Installation

Table 5-4. DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

off ON ON ON ON off ON ON 033

ON off ON ON ON off ON ON 034

off off ON ON ON off ON ON 035

ON ON off ON ON off ON ON 036

off ON off ON ON off ON ON 037

ON off off ON ON off ON ON 038

off off off ON ON off ON ON 039

ON ON ON off ON off ON ON 040

off ON ON off ON off ON ON 041

ON off ON off ON off ON ON 042

off off ON off ON off ON ON 043

ON ON off off ON off ON ON 044

off ON off off ON off ON ON 045

ON off off off ON off ON ON 046

off off off off ON off ON ON 047

ON ON ON ON off off ON ON 048

off ON ON ON off off ON ON 049

ON off ON ON off off ON ON 050

off off ON ON off off ON ON 051

ON ON off ON off off ON ON 052

off ON off ON off off ON ON 053

ON off off ON off off ON ON 054

off off off ON off off ON ON 055

ON ON ON off off off ON ON 056

off ON ON off off off ON ON 057

ON off ON off off off ON ON 058

off off ON off off off ON ON 059

ON ON off off off off ON ON 060

off ON off off off off ON ON 061

ON off off off off off ON ON 062

off off off off off off ON ON 063

ON ON ON ON ON ON off ON 064

off ON ON ON ON ON off ON 065

Page 51

48

PRO SWITCHING SYSTEM

Table 5-4 (continued). DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

ON off ON ON ON ON off ON 066

off off ON ON ON ON off ON 067

ON ON off ON ON ON off ON 068

off ON off ON ON ON off ON 069

ON off off ON ON ON off ON 070

off off off ON ON ON off ON 071

ON ON ON off ON ON off ON 072

off ON ON off ON ON off ON 073

ON off ON off ON ON off ON 074

off off ON off ON ON off ON 075

ON ON off off ON ON off ON 076

off ON off off ON ON off ON 077

ON off off off ON ON off ON 078

off off off off ON ON off ON 079

ON ON ON ON off ON off ON 080

off ON ON ON off ON off ON 081

ON off ON ON off ON off ON 082

off off ON ON off ON off ON 083

ON ON off ON off ON off ON 084

off ON off ON off ON off ON 085

ON off off ON off ON off ON 086

off off off ON off ON off ON 087

ON ON ON off off ON off ON 088

off ON ON off off ON off ON 089

ON off ON off off ON off ON 090

off off ON off off ON off ON 091

ON ON off off off ON off ON 092

off ON off off off ON off ON 093

ON off off off off ON off ON 094

off off off off off ON off ON 095

Page 52

49

CHAPTER 5: Installation

Table 5-4 (continued). DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

ON ON ON ON ON off off ON 096

off ON ON ON ON off off ON 097

ON off ON ON ON off off ON 098

off off ON ON ON off off ON 099

ON ON off ON ON off off ON 100

off ON off ON ON off off ON 101

ON off off ON ON off off ON 102

off off off ON ON off off ON 103

ON ON ON off ON off off ON 104

off ON ON off ON off off ON 105

ON off ON off ON off off ON 106

off off ON off ON off off ON 107

ON ON off off ON off off ON 108

off ON off off ON off off ON 109

ON off off off ON off off ON 110

off off off off ON off off ON 111

ON ON ON ON off off off ON 112

off ON ON ON off off off ON 113

ON off ON ON off off off ON 114

off off ON ON off off off ON 115

ON ON off ON off off off ON 116

off ON off ON off off off ON 117

ON off off ON off off off ON 118

off off off ON off off off ON 119

ON ON ON off off off off ON 120

off ON ON off off off off ON 121

ON off ON off off off off ON 122

off off ON off off off off ON 123

ON ON off off off off off ON 124

off ON off off off off off ON 125

ON off off off off off off ON 126

off off off off off off off ON 127

ON ON ON ON ON ON ON off 128

Page 53

Table 5-4 (continued). DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

off ON ON ON ON ON ON off 129

ON off ON ON ON ON ON off 130

off off ON ON ON ON ON off 131

ON ON off ON ON ON ON off 132

off ON off ON ON ON ON off 133

ON off off ON ON ON ON off 134

off off off ON ON ON ON off 135

ON ON ON off ON ON ON off 136

off ON ON off ON ON ON off 137

ON off ON off ON ON ON off 138

off off ON off ON ON ON off 139

ON ON off off ON ON ON off 140

off ON off off ON ON ON off 141

ON off off off ON ON ON off 142

off off off off ON ON ON off 143

ON ON ON ON off ON ON off 144

off ON ON ON off ON ON off 145

ON off ON ON off ON ON off 146

off off ON ON off ON ON off 147

ON ON off ON off ON ON off 148

off ON off ON off ON ON off 149

ON off off ON off ON ON off 150

off off off ON off ON ON off 151

ON ON ON off off ON ON off 152

off ON ON off off ON ON off 153

ON off ON off off ON ON off 154

off off ON off off ON ON off 155

ON ON off off off ON ON off 156

off ON off off off ON ON off 157

ON off off off off ON ON off 158

off off off off off ON ON off 159

ON ON ON ON ON off ON off 160

off ON ON ON ON off ON off 161

50

PRO SWITCHING SYSTEM

Page 54

51

CHAPTER 5: Installation

Table 5-4 (continued). DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

ON off ON ON ON off ON off 162

off off ON ON ON off ON off 163

ON ON off ON ON off ON off 164

off ON off ON ON off ON off 165

ON off off ON ON off ON off 166

off off off ON ON off ON off 167

ON ON ON off ON off ON off 168

off ON ON off ON off ON off 169

ON off ON off ON off ON off 170

off off ON off ON off ON off 171

ON ON off off ON off ON off 172

off ON off off ON off ON off 173

ON off off off ON off ON off 174

off off off off ON off ON off 175

ON ON ON ON off off ON off 176

off ON ON ON off off ON off 177

ON off ON ON off off ON off 178

off off ON ON off off ON off 179

ON ON off ON off off ON off 180

off ON off ON off off ON off 181

ON off off ON off off ON off 182

off off off ON off off ON off 183

ON ON ON off off off ON off 184

off ON ON off off off ON off 185

ON off ON off off off ON off 186

off off ON off off off ON off 187

ON ON off off off off ON off 188

off ON off off off off ON off 189

ON off off off off off ON off 190

off off off off off off ON off 191

Page 55

52

PRO SWITCHING SYSTEM

Table 5-4 (continued). DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

ON ON ON ON ON ON off off 192

off ON ON ON ON ON off off 193

ON off ON ON ON ON off off 194

off off ON ON ON ON off off 195

ON ON off ON ON ON off off 196

off ON off ON ON ON off off 197

ON off off ON ON ON off off 198

off off off ON ON ON off off 199

ON ON ON off ON ON off off 200

off ON ON off ON ON off off 201

ON off ON off ON ON off off 202

off off ON off ON ON off off 203

ON ON off off ON ON off off 204

off ON off off ON ON off off 205

ON off off off ON ON off off 206

off off off off ON ON off off 207

ON ON ON ON off ON off off 208

off ON ON ON off ON off off 209

ON off ON ON off ON off off 210

off off ON ON off ON off off 211

ON ON off ON off ON off off 212

off ON off ON off ON off off 213

ON off off ON off ON off off 214

off off off ON off ON off off 215

ON ON ON off off ON off off 216

off ON ON off off ON off off 217

ON off ON off off ON off off 218

off off ON off off ON off off 219

ON ON off off off ON off off 220

off ON off off off ON off off 221

ON off off off off ON off off 222

off off off off off ON off off 223

ON ON ON ON ON off off off 224

Page 56

53

CHAPTER 5: Installation

Table 5-4 (continued). DIP-Switch Settings at DS3 and DS4

To set the password (DS3) to…

Set Switches 1 through 8 to… To set the rack address (DS4) to…

12345678

off ON ON ON ON off off off 225

ON off ON ON ON off off off 226

off off ON ON ON off off off 227

ON ON off ON ON off off off 228

off ON off ON ON off off off 229

ON off off ON ON off off off 230

off off off ON ON off off off 231

ON ON ON off ON off off off 232

off ON ON off ON off off off 233

ON off ON off ON off off off 234

off off ON off ON off off off 235

ON ON off off ON off off off 236

off ON off off ON off off off 237

ON off off off ON off off off 238

off off off off ON off off off 239

ON ON ON ON off off off off 240

off ON ON ON off off off off 241

ON off ON ON off off off off 242

off off ON ON off off off off 243

ON ON off ON off off off off 244

off ON off ON off off off off 245

ON off off ON off off off off 246

off off off ON off off off off 247

ON ON ON off off off off off 248

off ON ON off off off off off 249

ON off ON off off off off off 250

off off ON off off off off off 251

ON ON off off off off off off 252

off ON off off off off off off 253

ON off off off off off off off 254

off off off off off off off off 255

Page 57

54

PRO SWITCHING SYSTEM

To Set the Configuration DIP Switches

1. Locate the DIP switch sets labeled DS7, DS6, and DS5 on the control card.

2. Use the DIP switch tables to set the DS7, DS6, and DS5 DIP switches. Tables 51 through 5-3 show the switch settings and provide notes that describe the

DIP switch functions.

Setting the Rack Address DIP Switches (DS4)

The rack address DIP switches set the address that the management PC uses to

distinguish each rack.

Rack addresses can have any value between 0 and 255. However, each rate at a

site must have a unique rack address.

1. Locate the DIP switch sets labeled DS4 on the control card.

2. Use Table 5-4 to set the DS4 DIP switches. The table shows the switch settings

for each rack address.

NOTE

When assigning rack addresses, make sure that each rack at a site has

a unique address.

Setting the Password DIP Switches (DS3)

If you enabled the password DIP switch (switch 1 on DS5), you must set the

password DIP switches (DS3) to assign a numeric password to the rack. If you

disabled the password, skip this step.

The password DIP switches set the password that the management PC must use

when communicating with the rack. The password can have any value between 0

and 255. However, each rack at a site must have the same password.

1. Locate the DIP switch sets labeled DS3 on the control card.

2. Use Table 5-4 to set the DS3 DIP switches. The table shows the switch settings

for each password.

Installing the Control Card

1. Insert the control card into the rightmost slot of the rack.

2. Secure the card in the rack by tightening the screws.

Page 58

55

CHAPTER 5: Installation

5.1.3 I

NSTALLINGRACKCOMPONENTS

A rack has 16 slots for front cards, 16 slots for rear cards, one slot for the control

card, and two slots for power supplies.

To operate, a rack must include a control card and at least one power supply. If

you want power redundancy (power backup), the rack must include two power

supplies.

Front and Rear Cards

In each rack, you can install front and rear cards for switching/patching.

To Install Switch/Patch Cards

1. Insert the front cards and tighten the screws. You need not fill all slots in a

rack or fill slots in any particular order.

2. Insert the corresponding rear cards and tighten the screws.

To Install the Power Supplies

Insert the power supplies into the power supply slots located on the front right side

of the rack. If you are only installing one power supply, you can insert it into either

slot.

To Power Up and Test the LEDs

1. Connect the chassis ground stud to ground. The ground stud is located just

below the power cord connectors on the rear of the rack.

2. Connect the power cords. For each power supply, connect one end of a

power cord to the power connector at the rear of the rack. Connect the other

end of the power cord to a power source. The rack automatically powers up as

soon as you connect the power cords.

3. Test the LEDs by pressing the LAMP TEST button on the front of the control

card. All LEDs in the rack should light.

5.1.4 E

NTER

IP A