Page 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be followed during all

phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

•

Read and understand the safety and operational information in this manual.

•

Apply all the listed safety precautions.

•

Verify that the voltage selector at the line power cord input is set to the correct line voltage. Operating the instrument

at an incorrect line voltage will void the warranty.

•

Make all connections to the instrument before applying power.

•

Do not operate the instrument in ways not specified by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the safety standards of design,

manufacture, and intended use of the instrument. B&K Precision assumes no liability for a customer’s failure to comply

with these requirements.

Category rating

The IEC 61010 standard defines safety category ratings that specify the amount of electrical energy available and the

voltage impulses that may occur on electrical conductors associated with these category ratings. The category rating is

a Roman numeral of I, II, III, or IV. This rating is also accompanied by a maximum voltage of the circuit to be tested,

which defines the voltage impulses expected and required insulation clearances. These categories are:

Category I (CAT I):

Measurement instruments whose measurement inputs are not intended to be connected to the

mains supply. The voltages in the environment are typically derived from a limited-energy transformer or a battery.

Category II (CAT II):

Measurement instruments whose measurement inputs are meant to be connected to the mains

supply at a standard wall outlet or similar sources. Example measurement environments are portable

tools and household appliances.

Category III (CAT III):

Measurement instruments whose measurement inputs are meant to be connected to the mains

installation of a building. Examples are measurements inside a building’s circuit breaker panel

or the wiring of permanently-installed motors.

Category IV (CAT IV):

Measurement instruments whose measurement inputs are meant to be connected to the primary

power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is specified in this manual

for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or higher than the

instrument’s category rating to maintain the instrument’s category rating. Failure to do so will lower the category rating

of the measuring system.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

3

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains power should be

115 V RMS or 230 V RMS. Use only the power cord supplied with the instrument and ensure it is appropriate for your

country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical safety ground. This

instrument is grounded through the ground conductor of the supplied, three-conductor AC line power cable. The power

cable must be plugged into an approved three-conductor electrical outlet. The power jack and mating plug of the power

cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible conductive parts

(including control knobs) may provide an electric shock. Failure to use a properly-grounded approved outlet and the

recommended three-conductor AC line power cable may result in injury or death.

Unless otherwise stated, a ground connection on the instrument’s front or rear panel is for a reference of potential only

and is not to be used as a safety ground. Do not operate in an explosive or flammable atmosphere.

Do not operate the instrument in the presence of flammable gases or vapors, fumes, or finely-divided particulates.

The instrument is designed to be used in office-type indoor environments. Do not operate the instrument

•

In the presence of noxious, corrosive, or flammable fumes, gases, vapors, chemicals, or finely-divided particulates.

•

In relative humidity conditions outside the instrument’s specifications.

•

In environments where there is a danger of any liquid being spilled on the instrument or where any liquid can condense

on the instrument.

•

In air temperatures exceeding the specified operating temperatures.

•

In atmospheric pressures outside the specified altitude limits or where the surrounding gas is not air.

•

In environments with restricted cooling air flow, even if the air temperatures are within specifications.

•

In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating temperature range is

0∘C to 40∘C and 20% to 80% relative humidity, with no condensation allowed. Measurements made by this instrument

may be outside specifications if the instrument is used in non-office-type environments. Such environments may include

rapid temperature or humidity changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise,

strong electric fields, or strong magnetic fields.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

4

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets on or inside the

instrument, remove the instrument’s power cord, remove the instrument from service, label it as not to be operated,

and return the instrument to B&K Precision for repair. Notify B&K Precision of the nature of any contamination of the

instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants, solvents, acids/bases,

or other such chemicals. Clean the instrument only with a clean dry lint-free cloth or as instructed in this manual. Not

for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component in a life-support

device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and internal adjustments must

be made by qualified service-trained maintenance personnel who are aware of the hazards involved when the instrument’s

covers and shields are removed. Under certain conditions, even with the power cord removed, dangerous voltages may

exist when the covers are removed. To avoid injuries, always disconnect the power cord from the instrument, disconnect

all other connections (for example, test leads, computer interface cables, etc.), discharge all circuits, and verify there

are no hazardous voltages present on any conductors by measurements with a properly-operating voltage-sensing device

before touching any internal parts. Verify the voltage-sensing device is working properly before and after making the

measurements by testing with known-operating voltage sources and test for both DC and AC voltages. Do not attempt

any service or adjustment unless another person capable of rendering first aid and resuscitation is present.

Do not insert any object into an instrument’s ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault condition in the circuit

exists.

Fuse replacement must be done by qualified service-trained maintenance personnel who are aware of the instrument’s fuse

requirements and safe replacement procedures. Disconnect the instrument from the power line before replacing fuses.

Replace fuses only with new fuses of the fuse types, voltage ratings, and current ratings specified in this manual or on

the back of the instrument. Failure to do so may damage the instrument, lead to a safety hazard, or cause a fire. Failure

to use the specified fuses will void the warranty.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

5

Note:

Note:

Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the instrument to

B&K Precision for service and repair to ensure that safety and performance features are maintained.

For continued safe use of the instrument

•

Do not place heavy objects on the instrument.

•

Do not obstruct cooling air flow to the instrument.

•

Do not place a hot soldering iron on the instrument.

•

Do not pull the instrument with the power cord, connected probe, or connected test lead.

•

Do not move the instrument when a probe is connected to a circuit being tested.

Working Environment

Environment

This instrument is intended for indoor use and should be operated in a clean, dry environment.

Temperature

Operating: 0℃ to +40℃

Non-operation:-20℃ to +60℃

Direct sunlight, radiators, and other heat sources should be taken into account when assessing the ambient temperature.

Humidity

Operating: 85% RH, 40 ℃, 24 hours

Non-operating: 85% RH, 65 ℃, 24 hours

Altitude

Operating: less than 3 Km

Non-operation: less than 15 Km

Installation (overvoltage) Category

This product is powered by mains conforming to installation (overvoltage) category II.

Degree of Pollution

The oscilloscopes may be operated in environments of Pollution Degree II.

Degree of Pollution II refers to a working environment which is dry and non-conductive pollution occurs. Occasional

temporary conductivity caused by condensation is expected.

IP Rating

IP20 (as defined in IEC 60529).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

6

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and other European

countries with separate collection systems)

This product is subject to Directive 2002/96/EC of the European Parliament

and the Council of the European Union on waste electrical and electronic equipment

(WEEE), and in jurisdictions adopting that Directive, is marked as being put on the

market after August 13, 2005, and should not be disposed of as unsorted municipal

waste. Please utilize your local WEEE collection facilities in the disposition of this

product and otherwise observe all applicable requirements.

Safety Symbols

Symbol

Description

indicates a hazardous situation which, if not avoided, will result in death or serious injury.

indicates a hazardous situation which, if not avoided, could result in death or serious injury

indicates a hazardous situation which, if not avoided, will result in minor or moderate injury

Refer to the text near the symbol.

Electric Shock hazard

Alternating current (AC)

Chassis ground

Earth ground

This is the In position of the power switch when instrument is ON.

This is the Out position of the power switch when instrument is OFF.

is used to address practices not related to physical injury.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Contents

1

General Information 13

1.1

Product Overview 13

1.2

Features 14

1.3

Contents 15

1.4

Dimensions 15

1.5

Front Panel Overview 16

1.6

Rear Panel Overview 17

1.7

Touch Screen Overview 18

2

Getting Started 19

2.1

Input Power Requirements 19

2.2

Fuse Requirements and Replacement 20

2.3

Preliminary Check 21

2.3.1

Verify AC Input Voltage 21

2.3.2

Connect Power 21

2.3.3

Self-Test 21

2.3.4

Self-Cal 21

2.3.5

Check Model and Firmware Version 21

2.3.6

Function Check 22

2.4

Probe Safety 23

3

Control Panel 25

3.1

Vertical Control 25

3.2

Horizontal Control 26

3.3

Trigger Control 26

3.4

Run/Stop Key 27

3.5

Auto Setup Key 27

3.6

Analysis Keys 27

3.7

Universal Knob 28

3.8

Menu Keys 28

3.9

Other Keys 29

4

Acquisition 30

4.1

Changing Acquisition Mode 30

4.2

Sequence 32

5

History 33

6

Horizontal Control 34

6.1

Adjusting the Horizontal Scale (time/div) 34

6.2

Adjusting the Horizontal Delay (position) 35

6.3

Panning and Zooming Single or Stopped Acquisitions 36

6.4

Horizontal Scale (Coarse/Fine) 36

6.5

Zoom 37

6.6

Roll 38

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

8

7

Vertical Control 39

7.1

Enabling Channels 39

7.1.1

Channel Enable/Disable From the Touch Screen 39

7.2

Vertical Scale 40

7.2.1

Coarse/Fine Adjustment 40

7.3

Vertical Position 40

7.4

Channel Setup 41

7.4.1

Channel Coupling

41

7.4.2

Bandwidth Limit

42

7.4.3

Probe Attenuation

42

7.4.4

Label

43

7.4.5

Apply To

43

7.4.6

Impedance

44

7.4.7

Unit

44

7.4.8

Deskew

44

7.4.9

Invert

45

7.4.10

Trace

45

8

Digital Channels

46

8.1

LP2560 Probe 46

8.2

Connecting the Digital Probes 47

8.3

Acquiring Digital Waveforms 47

8.4

Displaying Digital Channels 48

8.5

Turning Individual Channels On or Off 49

8.6

Logic Threshold for Digital Channels 50

8.7

Displaying Digital Channels as a Bus 50

9

Trigger 52

9.1

Trigger Source 53

9.2

Trigger Types 54

9.2.1

Edge Trigger 54

9.2.2

Slope Trigger 55

9.2.3

Pulse Trigger 57

9.2.4

Video Trigger 59

9.2.5

Window Trigger 62

9.2.6

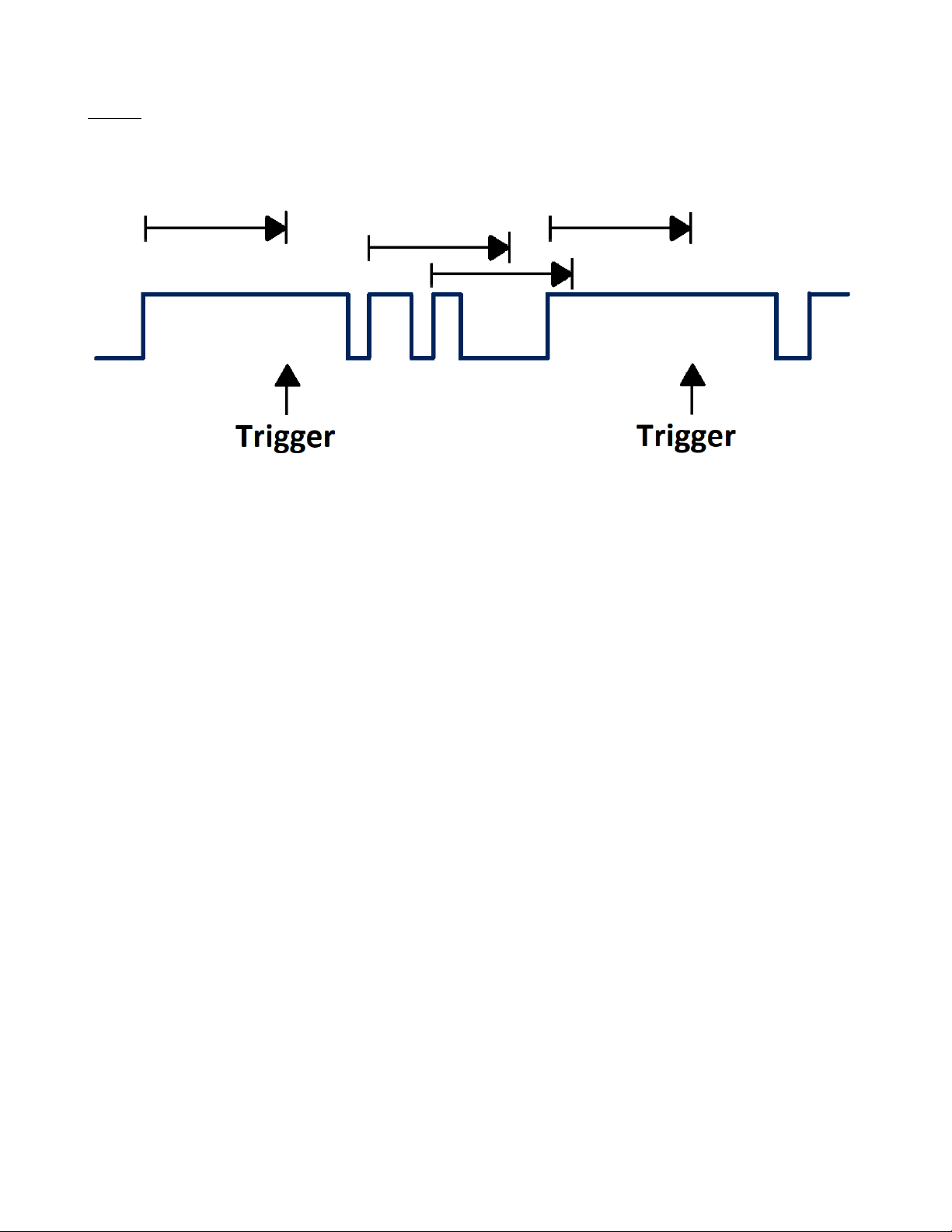

Interval Trigger 64

9.2.7

Dropout Trigger 65

9.2.8

Runt Trigger 67

9.2.9

Pattern Trigger 68

9.3

Trigger Mode 70

9.4

Trigger Level 71

9.5

Trigger Coupling 72

9.6

Trigger Holdoff 73

9.6.1

Holdoff by Time 73

9.6.2

Holdoff by Event 73

9.6.3

Start Holdoff On 74

9.7

Noise Reject 75

9.8

Zone Trigger 76

9.8.1

Creating and Moving Zones 76

10

Serial Trigger and Decode 79

10.1

I2C Trigger and Serial Decode 79

10.1.1

Setup for I2C Signals 79

10.1.2

I2C Trigger 81

10.1.3

I2C Serial Decode 84

10.2

SPI Trigger and Serial Decode 85

10.2.1

Setup for SPI Signals 85

10.2.2

SPI Trigger 88

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

9

10.2.3

SPI Serial Decode 89

10.3

UART Trigger and Serial Decode 90

10.3.1

Setup for UART Signals 90

10.3.2

UART Trigger 91

10.3.3

UART Serial Decode 92

10.4

CAN Trigger and Serial Decode 94

10.4.1

Setup for CAN Signals 94

10.4.2

CAN Trigger 94

10.4.1 CAN Serial Decode 95

10.5

LIN Trigger and Serial Decode 97

10.5.1

Setup for LIN Signals 97

10.5.2

LIN Trigger 97

10.5.1 Interpreting LIN Decode 99

10.6

FlexRay Trigger and Serial Decode 100

10.6.1

FlexRay Signal Configuration 100

10.6.2

FlexRay Trigger 101

10.6.3

FlexRay Serial Decode 102

10.7

CAN FD Trigger and Serial Decode 104

10.7.1

CAN FD Signal Configuration 104

10.7.2

CAN FD Trigger 106

10.7.3

CAN FD Serial Decode 106

10.8

I2S Trigger and Serial Decode 108

10.8.1

I2S Signal Configuration 108

10.8.2

I2S Trigger 111

10.8.3

I2S Serial Decode 112

10.9

MIL-STD-1553B Trigger and Serial Decode 113

10.9.1

MIL-STD-1553B Signal Configuration 113

10.9.2

MIL-STD-1553B Serial Decode 114

10.10

SENT Trigger and Serial Decode 116

10.10.1

SENT Signal Configuration 116

10.10.2

SENT Trigger 118

10.10.3

SENT Serial Decode 121

10.11

Manchester Trigger and Serial Decode 124

10.11.1

Manchester Signal Configuration 124

10.11.2

Manchester Serial Decode 126

11

Cursors 128

11.1

X Cursors 129

11.2

Y Cursors 130

11.3

Display Style 132

11.4

Make Cursor Measurements 133

11.5

Cursors Reference 134

12

Measure 136

12.1

Measurement Modes 136

12.2

Set Measurement Types 138

12.3

Type of Measurement 139

12.3.1

Vertical Measurements 139

12.3.2

Horizontal Measurements 141

12.3.3

Miscellaneous Measurements 142

12.3.4

Delay Measurements 143

12.4

Trend 144

12.5

Simple Measurements 145

12.6

Measurement Statistics 145

12.7

Statistics Histogram 146

12.8

Gate 146

12.9

Amplitude Strategy 147

12.10

Threshold 148

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

10

13

Math 149

13.1

Units for Math Waveforms 150

13.2

Arithmetic 151

13.2.1

Subtraction Example 151

13.2.2

Average 152

13.2.3

ERES 153

13.3

Algebra 154

13.3.1

Differentiate

154

13.3.2

Integrate

155

13.3.3

Square Root

156

13.3.4

Absolute

157

13.3.5

Sign

157

13.3.6

Exp/Exp10

158

13.3.7

Ln/Lg

159

13.3.8

Interpolate

159

13.4

Frequency Analysis (FFT Operation)

160

13.4.1

Setting FFT Parameters 160

13.4.2

Parameter Display Area 162

13.4.3

Vertical 162

13.4.4

Horizontal 163

13.5

FFT Tools 163

13.5.1

Peaks Tool 163

13.5.2

Markers Tool 164

13.5.3

Measure the FFT Waveform 165

13.6

Formula Editor 166

14

Reference Waveform 167

14.1

Save REF Waveform to Internal Memory 167

14.2

Display REF Waveforms 167

15

Search 169

16

Navigate 171

16.1

Navigate by Time 171

16.2

Navigate by Search Event 172

16.3

Navigate by History Frame 173

17

Mask Test 174

17.1

Mask Setup 175

17.1.1

Create Mask 175

17.1.2

Mask Editor 176

17.2

Operation 178

17.3

Pass/Fail Rule 178

18

Counter 179

18.1

Counter Configuration 179

18.2

Mode 180

19

Power Analysis 181

19.1

Power Quality 182

19.1.1

Type 182

19.1.2

Input Setup 183

19.2

Current Harmonics 184

19.2.1

Configuration 184

19.2.2

Standard 184

19.2.3

Parameter Description 185

15.1

Setting

169

15.2

Copy

169

15.3

Results

169

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

11

19.2.4

Input Setup 185

19.3

Inrush Current 186

19.3.1

Input Setup 186

19.4

Switching Loss 187

19.4.1

Deskew Calibration 187

19.4.2

Switching Loss Configuration 188

19.4.3

Conduction Type 188

19.4.4

Input Setup 189

19.5

Slew Rate 190

19.5.1

Connection Guide 190

19.6

Modulation 191

19.6.1

Input Modulation 191

19.7

Output Ripple 192

19.7.1

Output Ripple Input Setup 192

19.8

Turn on/Turn Off 193

19.8.1

Turn On/Turn Off Input Setup 193

19.8.2

Testing Conditions 194

19.9

Transient Response 195

19.9.1

Transient Response Input Setup 195

19.9.2

Transient Response Configuration 196

19.10

PSRR 197

19.10.1

PSRR Configuration 197

19.10.2

PSRR Amplitude 197

19.11

Power Efficiency 198

19.11.1

Power Efficiency Input Setup 198

20

Bode Plot 199

20.1

Bode Plot Configuration 200

20.1.1

Connection 200

20.1.2

Sweep 201

20.1.3

Simple Sweep 201

20.1.4

Editor 203

21

Arbitrary Waveform Generator 204

21.1

AWG Configuration 204

21.1.1

Other Settings 205

22

Save/Recall 206

22.1

Save Type 206

22.2

Internal/External Save and Recall 207

22.3

File Manager 209

23

Utility Menu 211

23.1

System Setting 211

23.1.1

View System Status 211

23.1.2

Sound 211

23.2

Language 211

23.3

Screen Saver 212

23.4

IO Set 212

23.4.1 LAN 212

23.4.2

USB Device 213

23.4.3

Date/Time 213

23.5

Options 214

23.6

Reference Position 214

23.7

Do Self-Test 215

23.7.1

Screen Test 215

23.7.2

Keyboard Test 216

23.7.3

LED Test 217

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

12

23.8

Start Self Cal 218

23.9

Power On Line 218

24

Remote Control 219

24.1

Web Browser 219

24.2

Other Connectivity 220

25

Troubleshooting 221

26

Service Information 223

27

LIMITED THREE-YEAR WARRANTY

224

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

General Information

1.1 Product Overview

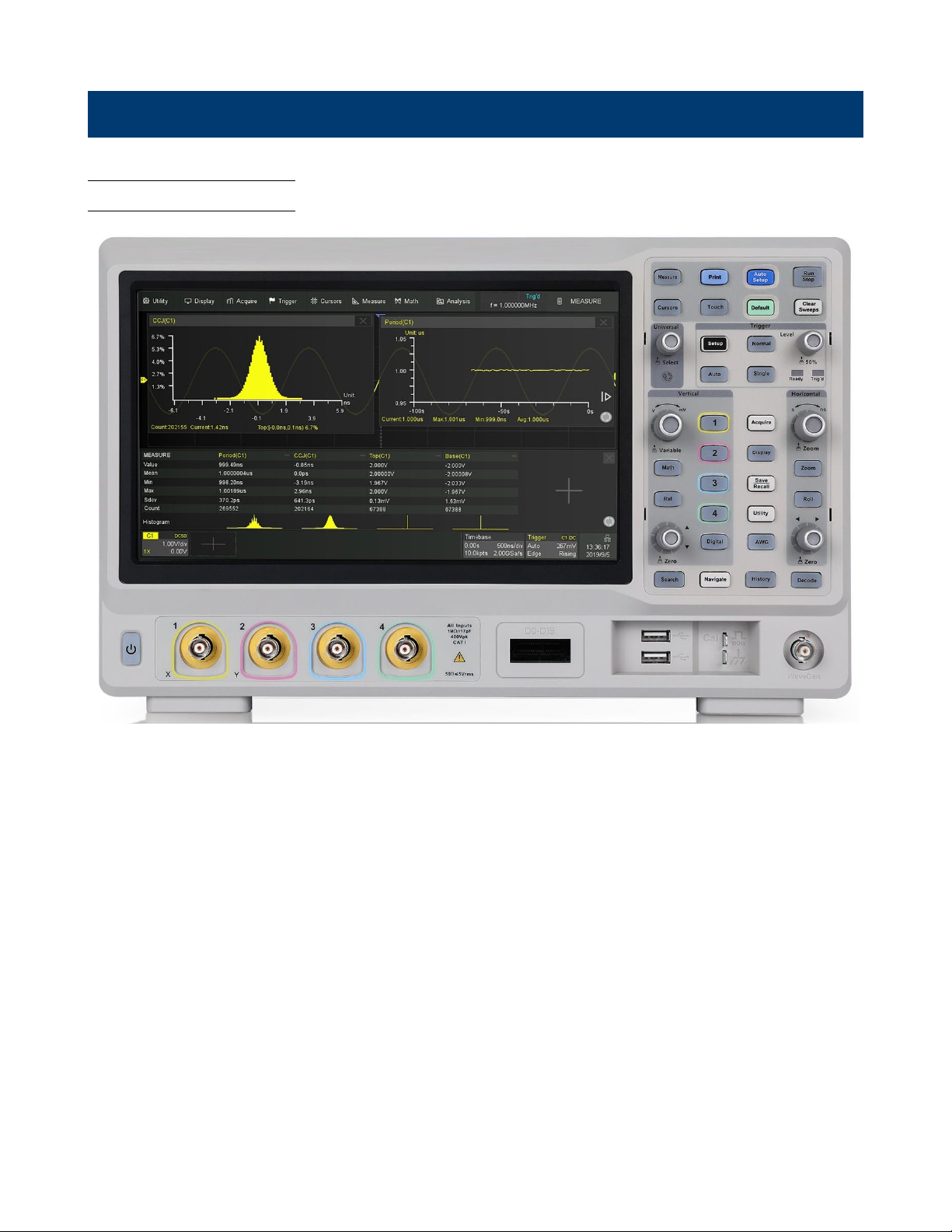

Figure 1.1

2560B

The 2560B Digital Storage (DSO) and Mixed Signal Oscilloscope (MSO) Series delivers advanced features and debug

capabilities for a wide range of applications. With increasing bandwidths to 350 MHz in a 4-channel configuration, each

model offers a maximum sample rate of 2 GSa/s and a maximum memory depth of 200 Mpts. Equipped with a 10.1”

(1024 x 600) capacitive touchscreen and high waveform update rate of 120,000 wfms/s, these oscilloscopes can capture

infrequent glitches with excellent signal fidelity.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

General Information 14

1.2 Features

•

4 Analog channels

•

Maximum sampling rate of 2 GSa/s

•

200 Mpts. memory depth

•

Maximum waveform update rates of 120,000 (normal mode) and 500,000 (sequence mode)

•

History and sequence mode store a maximum of 90,000 frames

•

Large 10.1” TFT-LCD capacitive touchscreen, 1024 x 600 resolution

•

10-bit mode increases vertical resolution

•

Advance triggers with trigger zone support

•

50 MHz DDS waveform generator supports Bode plots

•

Power analysis includes 11 analyzing tools

•

Automatic measurements with statistics and histogram

•

Math function supports 2 traces and a formula editor

•

2 Mpts FFT provides high resolution of frequency spectrum

•

Additional16 digital channels standard in MSO models (option available for DSO)

•

Serial bus decoder supports I2C, SPI, UART, CAN and LIN protocol

•

LAN and USBTMC-compliant USB device port for remote PC control

•

USB Host (x2), Pass/Fail Out and EXT Trig

•

Support SCPI remote control commands

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Note:

General Information 15

1.3 Contents

•

1 x 2560B Digital Storage Oscilloscope (DSO) or Mixed Signal Oscilloscope (MSO)

•

AC Power Cord

•

USB type A to type B cable.

•

Certificate of Calibration

•

Test Report

•

4 oscilloscope probes

Model

2565B

2565B-MSO

2567B

2567B-MSO

2569B

2569B-MSO

Probe

PR150B

PR250B

PR500B

Bandwidth

150 MHz

250 MHz

500 MHz

Attenuation Value

X1, X10

X10

X10

Table 1.1 Probes

•

1 x LP2560 (MSO models)

Ensure the presence of all the items above. Contact the distributor if any items are missing.

1.4 Dimensions

The 2560B series oscilloscope’s dimensions are approximately: 352 mm (13.9 in) x 224.00 mm (8.8 in) x 101 mm (4 in)

(W x H x D).

Figure 1.2 Front View Dimension

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

General Information

16

1.5 Front Panel Overview

The front panel interface allows for control of the unit.

Figure 1.3 Front Panel

Item

Name

Description

Visual presentation of the device function and measurements.

See section Touch Screen Display for more details.

2

Control Panel

Includes control knobs and keys. See section

Control Panel

3

WaveGen

Built-in waveform generator output.

4

Probe Compensation Supplies a 0-3.3 V, 1 kHz square wave for compensating the probes.

5

USB Host Port

USB port used to connect flash drives. (Type A)

6

Digital Input Connector Receives digital signals from the LP2560 digital probe.

7

Analog Input Channels Input channels (Default: 1 MΩ)

8

Power Button Power the unit ON or OFF.

Table 1.2 Front Panel

1

Touch Screen

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

General Information

17

ger types.

1.6 Rear Panel Overview

Figure 1.4

Rear Panel Overview

Item

Name

Description

Outputs the trigger indicator. When Pass / Fail is enabled, outputs the

pass / fail signal.

2

External Trigger Input

The external trigger input can be used as a source in several of the trig-

3

USB Interface

Connect a USB type B to type A to remotely control the unit.

4

LAN

Connect an ethernet cable to remotely control the unit over the network.

lock the instrument to a fixed location using the security lock via the lock

hole. Lock is not included.

AC Power Input

& Fuse Box

Houses the fuse as well as the AC input .

7 Handle

Handle for easy carrying of the instrument.

Table 1.3 Rear Panel

1 Auxiliary Out

5

Safety Lock Hole

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

General Information

18

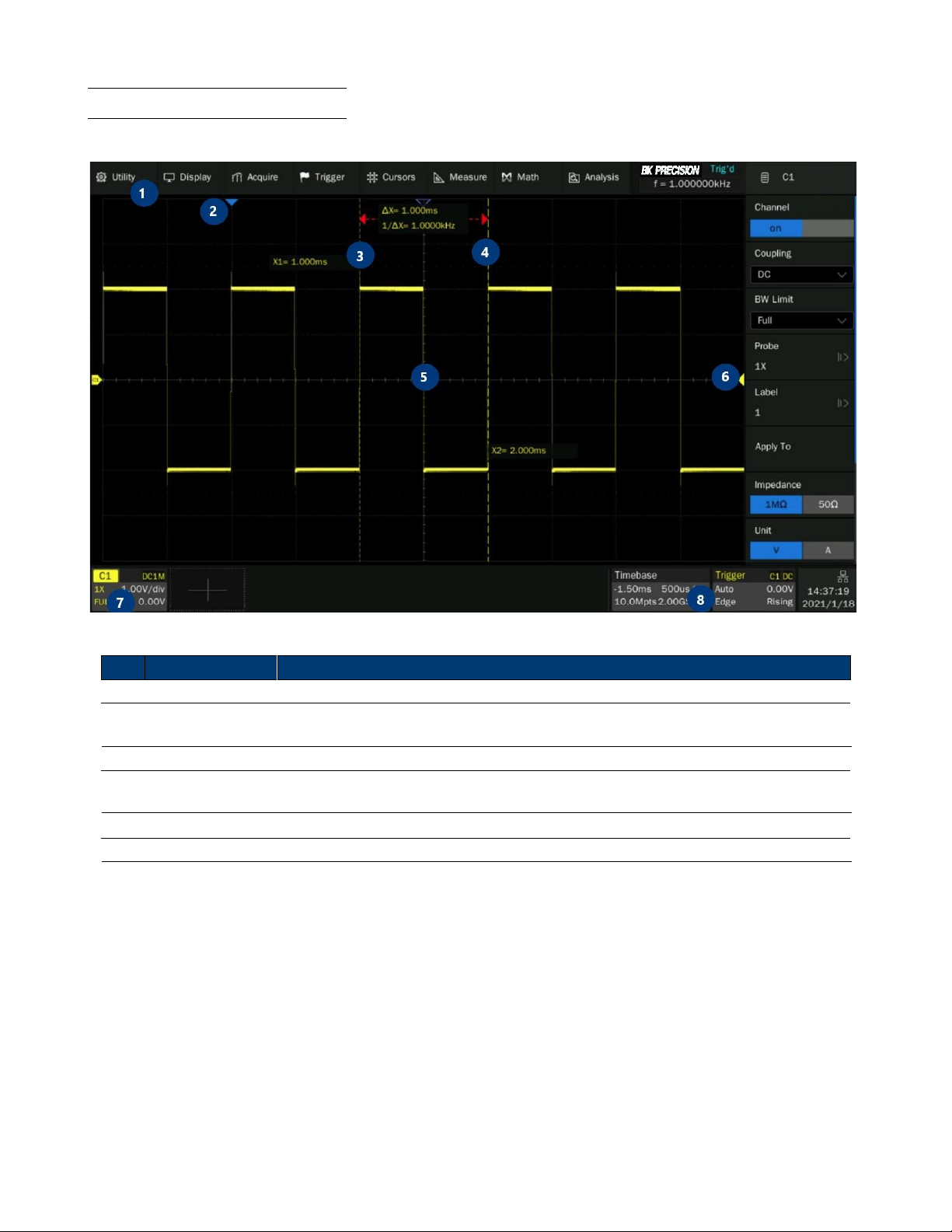

1.7 Touch Screen Overview

Use your fingers to touch, drag, pinch, spread, or draw a selection box.

Figure 1.5

Touch Screen Overview

Item Name

Description

1 Menu Bar

Displays the available options in the selected menu.

Trigger Delay

Indicator

Displays the trigger status.

3 Trigger Status

Displays the trigger status.

USB Host

Port Indicator

Indicates that a USB is connected to the instrument.

5

LAN Port Indicator Indicates the status of the LAN connection.

6

Menu Bar

Displays the available options in the selected menu.

Table 1.4

Touch Screen Overview

2 4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

SHOCK HAZARD:

Getting Started

Before connecting and powering up the instrument, review the instructions in this section.

2.1 Input Power Requirements

The oscilloscope has a universal AC input that accepts line voltage and frequency input within:

Line

Voltage Range

100-120 V

100-240 V

Frequency

400 Hz

50/60 Hz

Power

80W Max

Table 2.1

Before connecting to an AC outlet or external power source, be sure that the power switch is in the OFF position and

verify that the AC power cord, including the extension line, is compatible with the rated voltage/current and that there

is sufficient circuit capacity for the power supply. Once verified, connect the cable firmly.

The included AC power cord is safety certified for this instrument operating in rated range. To

change a cable or add an extension cable, be sure that it can meet the required power

ratings for this instrument. Any misuse with wrong or unsafe cables will void the warranty.

The power cord provides a chassis ground through a third conductor. Verify that your power

outlet is of the three-conductor type with the correct pin connected to earth ground.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Getting Started

20

2.2 Fuse Requirements and Replacement

For continued fire protection at all line voltages replace only with a 2.00 A / 250 V "T" RATED, 5 x 20 mm

fuse.

For safety, no power should be applied to the instrument while changing line voltage

operation. Disconnect all cables connected to the instrument before proceeding.

Check and/or Change Fuse

–

Locate the fuse box next to the AC input connector in the rear panel. (See figure

1.4)

–

Insert a small flathead screwdriver into the fuse box slit to pull and slide out the fuse box as indicated below.

–

Check and replace fuse if necessary. (See figure

2.1)

Figure 2.1

Fuse Removal

Any disassembling of the case or changing the fuse not performed by an

authorized service technician will void the warranty of the instrument

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Getting Started

21

2.3 Preliminary Check

Complete the following steps to verify that the oscilloscope is ready for use.

2.3.1 Verify AC Input Voltage

Verify proper AC voltages are available to power the instrument.

The AC voltage range must meet the acceptable specification stated in section

Input Power Requirements.

2.3.2 Connect Power

Connect the AC power cord to the AC receptacle in the rear panel and press the power switch to turn on the instrument.

The instrument will have a boot up screen while loading, after which the main screen will be displayed.

2.3.3 Self-Test

The instrument has 3 self-test option to test the screen ,keyboard, and the LED back light.

To perform the self-test, please refer to the

Self Test

section for further instructions.

2.3.4 Self-Cal

Self option runs an internal self-calibration procedure that will check and adjust the instrument. To perform the selfcalibration, refer to the Self-Calibration section for further instructions.

2.3.5 Check Model and Firmware Version

The model and firmware version can be verified from within

the menu system.

To view the model and firmware version:

Press the

Utility

button and use the softkeys to select the

System Status

option. The following information will be

displayed:

–

Software Version

–

Uboot-OS Version

–

FPGA Version

–

CPLD Version

–

Hardware Version

–

Scope ID

–

Serial NO.

–

Model

Figure 2.2

System Status

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Getting Started

22

2.3.6 Function Check

Follow the steps below to do a quick check of the oscilloscope’s functionality.

1.

Power on the oscilloscope. Press "Default Setup" to show the result of the self-check.

–

The probe default attenuation is 1X.

2.

Set the switch to 1X on the probe and connect the probe to channel 1.

–

To do this align the slot in the probe connector with the key on the CH1 BNC, push to connect, and twist to the

right to lock the probe in place.

–

Connect the probe tip and reference lead to the Probe Comp connectors.

3.

Press the

AUTO

button to show the 1 kHz frequency and about 3V peak to peak square wave.

Figure 2.3

3 Vpp Square Wave

4.

Repeat steps 1 to 3 for the remaining channels.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Getting Started

23

Shock Hazard:

2.4 Probe Safety

A guard around the probe body provides a finger barrier for protection from electric shock.

Figure 2.4 Probe

Connect the probe to the oscilloscope and connect the ground terminal to the ground before you take any measurements.

To avoid electric shock when using the probe, keep fingers behind the guard on the probe body. To avoid electric shock

while using the probe, do not touch metallic portions of the probe head while it is connected to a voltage source.

Connect the probe to the oscilloscope and connect the ground terminal to ground before you take any measurements.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Getting Started

24

Note:

Probe Attenuation

Probes are available with various attenuation factors which affect the vertical scale of the signal. The Probe Check

function verifies that the probe attenuation option matches the attenuation of the probe.

Press CH 1 once to open the channel menu. Select the probe option that matches the attenuation of the probe.

The default setting for the Probe option is 1 X.

Verify that the attenuation switch on the probe matches the Probe option in the oscilloscope. Switch settings are 1 X

and 10 X.

Probe Compensation

Before taking any measurements using a probe, verify the compensation of the probe and adjust it to match the channel

inputs.

To match your probe to the input channel:

1.

Set the channel’s probe attenuation to 10X.

–

Press the

CH #

key corresponding to the channel the probe is connected to.

–

Use the softkeys to navigate to page 1.

–

Use the softkeys to select

Probe.

–

Use the

Intensity Adjust

knob to select 10X.

2.

Attach the probe tip to the

Compensation Signal Output Terminal 3 V(Cal

) connector and the reference lead to

the Probe Ground terminal connector.

–

Press the

Auto Setup

key to display the square wave.

3.

Check the shape of the displayed waveform.

Undercompensated Correctly Compensated

Overcompensated

Figure 2.5

Probe Compensation

4.

If necessary, adjust your probe’s compensation trimmer pot.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Control Panel

The control panel is designed to operate the basic functions

without having to open the software menu. Most of the front

panel controls duplicate functionality available through the

touch screen.

All the knobs on the front panel are multifunctional.

They can be pushed as well as rotated. Pushing a

knob quickly recalls a specific function, which is

indicated by the silkscreen near to the knob.

The

Control Panel

consist of 9 sections:

•

Vertical Control

•

Horizontal Control

•

Trigger Control

•

Run/Stop Key

•

Auto Setup Key

•

Analysis Keys

•

Universal Knob

•

Menu Keys

•

Other Keys

Figure 3.1 Control Panel

3.1 Vertical Control

Channel Keys

: Press the channel keys to toggle a channel

On

or

Off

, or to access the

channel’s menu. There is one channel on/off key for each analog channel.

Digital Key

: Enable/disable the digitals channels and display the waveforms.

See section Digital Channels for more details.

Math Key

: The

Math

key provides access to the math (add, subtract, etc.) waveform

func

tions.

See section

Math

for more details.

Ref Key

: Toggle the reference function on and off.

Vertical Scale Knob

: Analog channels (C1-C4), digital channels (d), math (F1-F2) and

references (Ref) share the same vertical scale knob. Turn the knob to adjust the gain

(volts/div). Push to alternate between coarse and fine adjustments. When the digital

channel is active, rotate the knob to change the selected digital channel.

Vertical Position Knob

: Analog channels (C1-C4), digital channels (D), math (F1-F2)

and references (Ref) share the same vertical position knob. Turn the knob to adjust the

DC offset or vertical position of the channel. Push to set the position to zero.

Figure 3.2

Vertical Control

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Control Panel

26

3.2 Horizontal Control

Figure 3.3

Horizontal

Control

Horizontal Scale Knob

: Turn the knob to adjust the horizontal scale (time/div). The symbols

above the knob indicate that this control has the effect of spreading out or zooming in on the

waveform using the horizontal scale.

Push the horizontal scale knob to toggle between fine and coarse adjustment.

Zoom Key

: Press the

Zoom

key to split the oscilloscope display into Normal and Zoom sections.

See section Zoom for more details.

Roll Key

: Toggle the roll function on and off. At timebase settings larger than 50 ms/div, it is

recommended to set the oscilloscope to Roll mode so that the waveform is displayed in real time.

See section Roll Mode for more details.

Horizontal Position Knob

: Turn the knob marked to pan through the waveform data

horizontally. The captured waveform before the trigger (turn the knob clockwise) or after the

trigger (turn the knob counterclockwise) can be seen. Panning through the waveform when the

oscilloscope is stopped (not in Run mode) will display the waveform data from the last acquisition

taken.

Push the horizontal position knob to zero the horizontal position.

3.3 Trigger Control

Figure 3.4 Trigger Control

The Trigger controls determine how the oscilloscope triggers to capture data. These controls consist of:

Setup

: Opens the

Trigger Setup

menu. In the

Trigger Setup

menu, the trigger type, source, and options that

affect

all trigger types can be set. See section Triggers for more details.

Normal

: Sets the

Trigger Mode

to

Normal

. In

Normal Mode

acquisitions only occur when the trigger conditions are

met. Otherwise, the oscilloscope holds the last waveform on the display and waits for the next trigger.

Auto

: Sets the

Trigger Mode

to

Auto

. In

Auto Mode

an internal timer triggers the sweep after a preset timeout

period if no trigger has been found so that the oscilloscope continuously updates the display whether a trigger occurs or

not.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Control Panel

27

Single

: Sets the

Trigger Mode

to

Single

. In

Single Mode

data is a single frame that satisfies the trigger conditions is

captured and displayed, and then stops. The following trigger events are ignored until

Single

acquisition is restarted.

Level Knob

: Turn the

Level Knob

to adjust the trigger level for a selected analog channel. Push the knob to set the

level to the waveform’s 50% value. If AC coupling is used, pushing the

Level Knob

sets the trigger level to about 0 V.

Trigger Status

: Indicates when the oscilloscope is waiting for a trigger or when a trigger has occurred.

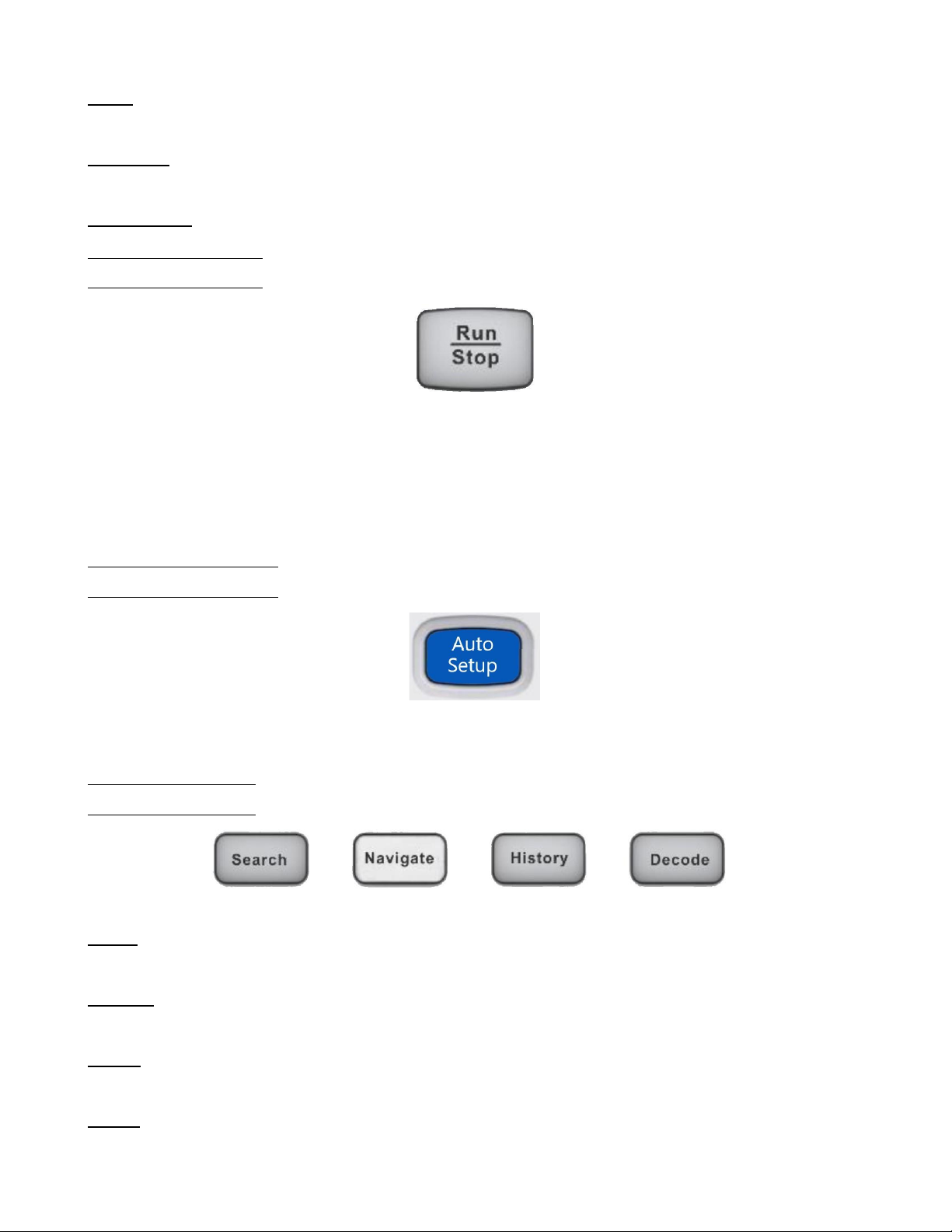

3.4 Run/Stop Key

When the

Run/Stop

key is green, the oscilloscope is running, that is, acquiring data when trigger conditions are met.

To stop acquiring data, press the Run/Stop key.

When the

Run/Stop

key is red, data acquisition is stopped. To start acquiring data, press the

Run/Stop

key.

To capture and display a single acquisition (whether the oscilloscope is running or stopped), press the

Single

key. The

Single

key will remain green until the oscilloscope triggers.

3.5 Auto Setup Key

Pressing the

Auto Setup

key will cause the oscilloscope to determine which channels have activity, and it will turn these

channels on and scale them to automatically configure the input to best display the input signals.

3.6 Analysis Keys

Figure 3.5

Common Functions

Search

: Search for events in the acquired data.

See section Search for more details.

Navigate

: Navigate through captured data via time, search events, or history frame.

See section Navigate for more details.

History

: Divides the oscilloscope’s memory into segments allowing for analysis of individual frames.

See section History for more details.

Decode

: Enable serial decode.

See section Serial Decode for more details.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Control Panel

28

3.7 Universal Knob

Figure 3.6

Universal Knob

3.8 Menu Keys

The

Universal Knob

is used to select items from pop-up menus and to change values. The

function of the

Universal Knob

changes based upon the current menu.

Note that the curved arrow symbol below the knob illuminates whenever the

Universal

Knob

can be used to select a value. Also, note that when the

Universal Knob symbol ap-

pears, you can use the Universal Knob, to select values.

Rotating the

Universal Knob

adjusts the trace intensity. Pushing

the Universal Knob

instantly sets the intensity to 50%.

Acquire

: Access the

Acquire

menu. In the acquire menu Interpolation,

Acquire Mode, Acquisition, Memory Depth, Sequence, and Resolution can be set.

See section Acquire for more details.

Display

: Access the

Display

menu to enable persistence, adjust the display grid (graticule)

intensity, label waveforms, add an annotation, and clear the display.

See section Display for more details.

Save/Recall

: Save oscilloscope setups, screen images, waveform data, or mask files or to

recall setups, mask files or reference waveforms.

See section

Save/Recall

for more details.

Utility

: Access the

Utility

menu, to configure the oscilloscope’s I/O settings, use the file

explorer, set preferences, access the service menu, and choose other options.

AWG

: Built-in waveform generator can output arbitrary, sine, square, ramp, pulse,

DC, noise, and other 45 built-in waveforms. Modulated waveforms are available

except for arbitrary, pulse, DC, and noise waveforms.

See section

Arbitrary Waveform Generator

for more details.

Figure 3.7

Menu Keys

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Control Panel

29

3.9 Other Keys

Press the

Measure

key to access a set of predefined measurements.

See section Measure for more details.

Performs a screenshot save to an external storage device.

The supported format includes .bmp .jpg .png

Enables/Disables the touch screen.

The LED on the button lights to indicate that the touch screen is working.

Enables/disable the cursors. Cursors are used to make custom measurements.

See section Cursors for more details.

Restores the oscilloscope’s default settings.

Clears the displayed data and any measurements, including display persistence, measurement statistics,

average sweeps, and Pass/Fail statistics.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

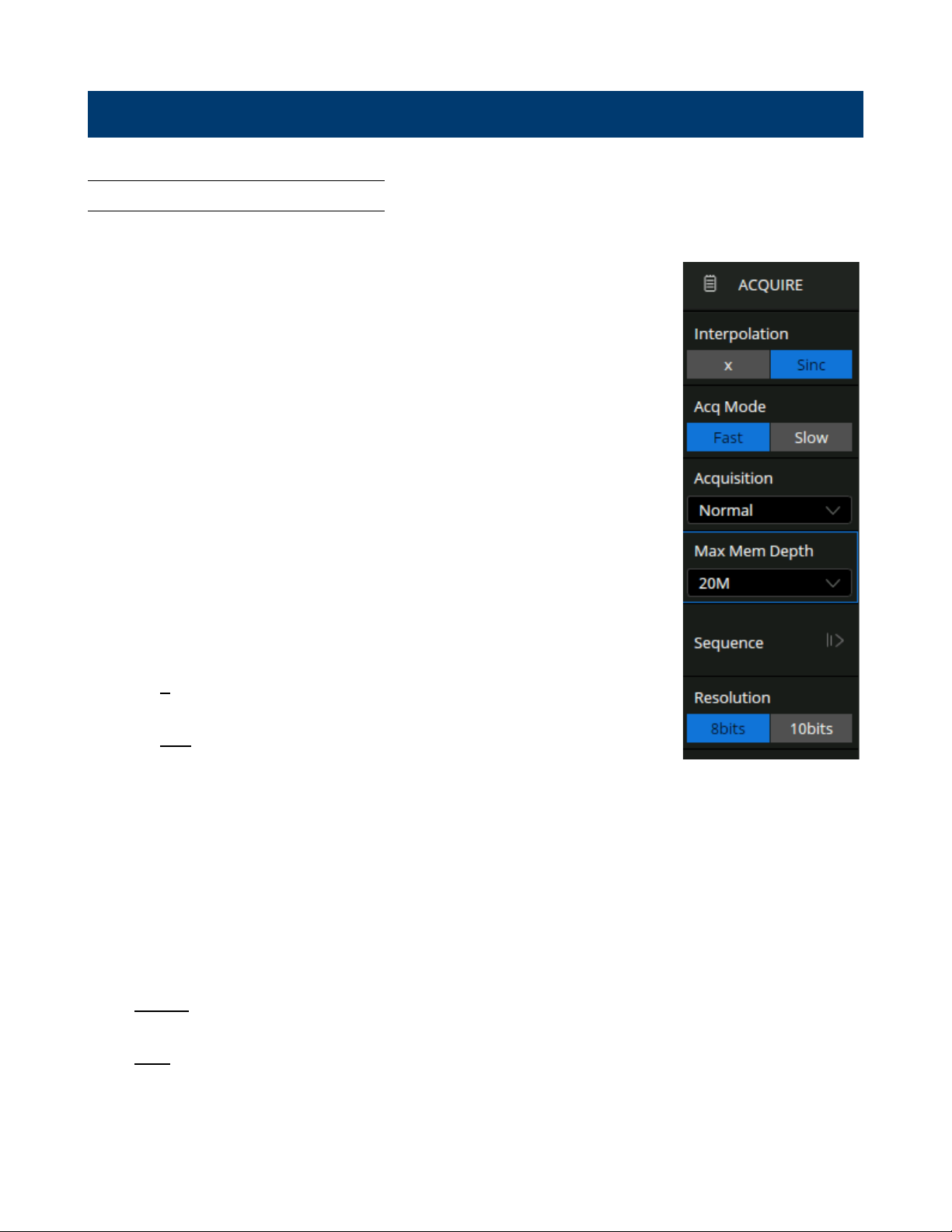

Page 30

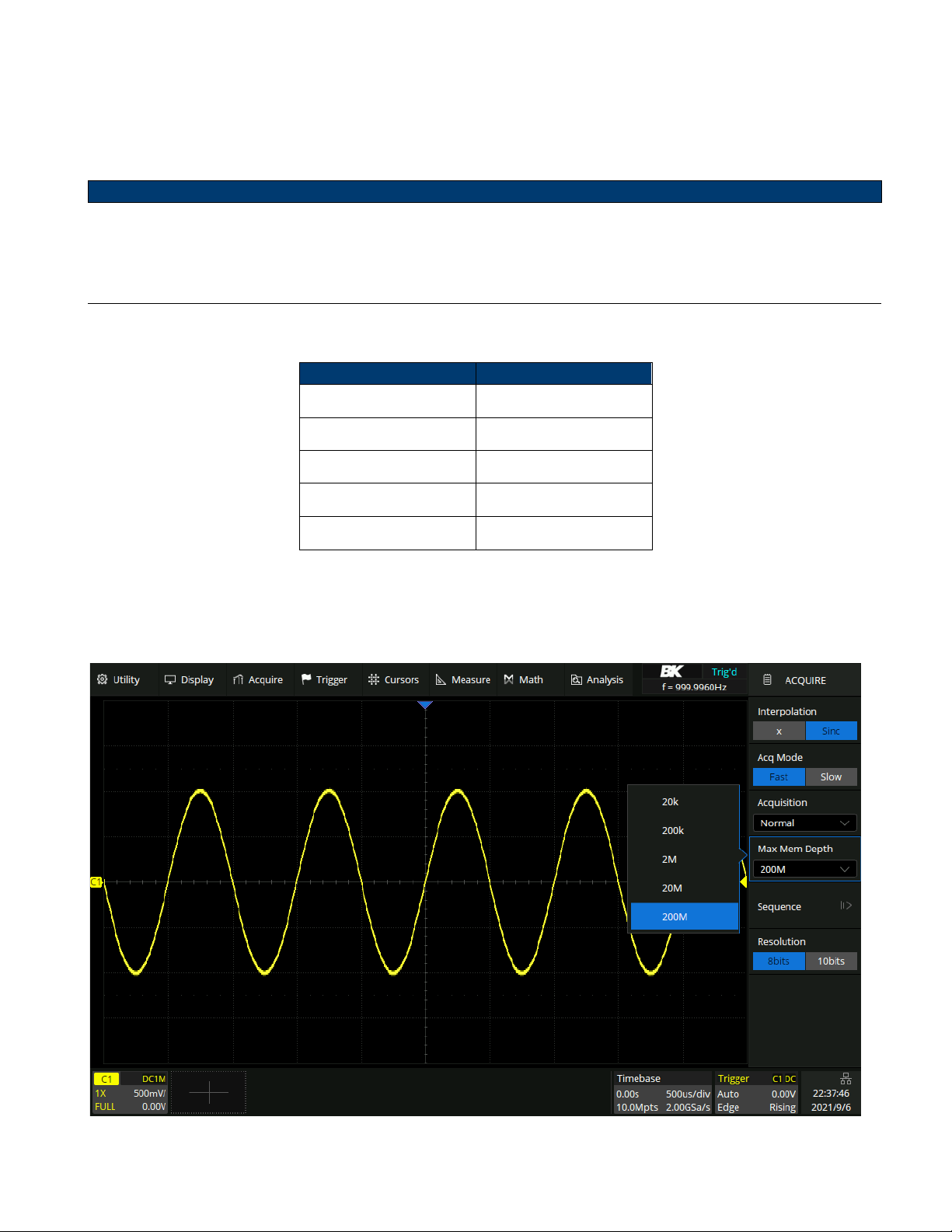

Acquisition

4.1 Changing Acquisition Mode

To change the Acquisition Mode:

•

Use the touchscreen to press the

Acquire Menu

on the

Main Timebase

menu, or press the

Acquire

key on the control panel, or touch the Menu Bar

and select

Acquire > Menu

to recall the Acquire menu on the right side.

–

the

Acquire

menu shown in figure

4.1

will be displayed.

•

Touch

Resolution

to toggle between

8bits

and

10bits

resolution.

–

The vertical resolution. "8-bits" is the default setting.

–

In

10-bits

mode, the vertical resolution is 4x better, while the bandwidth

is limited to about 100 MHz.

•

Touch

Interpolation

to toggle between x and

Sinc.

•

At small timebase settings, the number of original points on the screen

may be less than the number display pixels in the grid area, so

interpolation is necessary to display a continuous waveform. For

example, at 1 ns/div timebase and 2 GSa/s sample rate, the number of

original points is 20, but the grid area includes 1000 horizontal pixels. In

this case, the

oscilloscope needs to interpolate the original points by

50.

–

X

: Linear interpolation, the simplest way of interpolation, connects

two original points with a straight line.

–

Sinc

: Sin(x)/x interpolation, the original point is interpolated

according to the Nyquist reconstruction formula, which has a good

time- domain recovery effect for sine wave. But for step signals/fast

rise

times, it will introduce false overshoot due to the Gibbs phenomenon.

Figure 4.1 Acquire Menu

•

Touch

Acq Mode

to toggle between

Fast

and

Slow

acquisition.

–

Fast

is the default setting. A very high waveform update rate is provided in fast mode.

–

Slow

mode will slow down the waveform update.

•

Touch

Acquisition

to determine how to acquire and process the signal.

•

Normal

: The oscilloscope samples the signal with an equal time interval. For most waveforms, the best display

effect can be obtained using this mode.

•

Peak

: The oscilloscope acquires the maximum and minimum values of the signal within the sample interval so

that the peak (maximum – minimum) in the interval is obtained. This mode is effective to observe occasional

narrow pulses or spurs with a low sample rate, but the noise displayed is larger. In peak mode, the oscilloscope

will display all pulses with a pulse width longer than 400 ps.

•

Touch

Memory Depth

to set the maximum memory depth that is supported.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

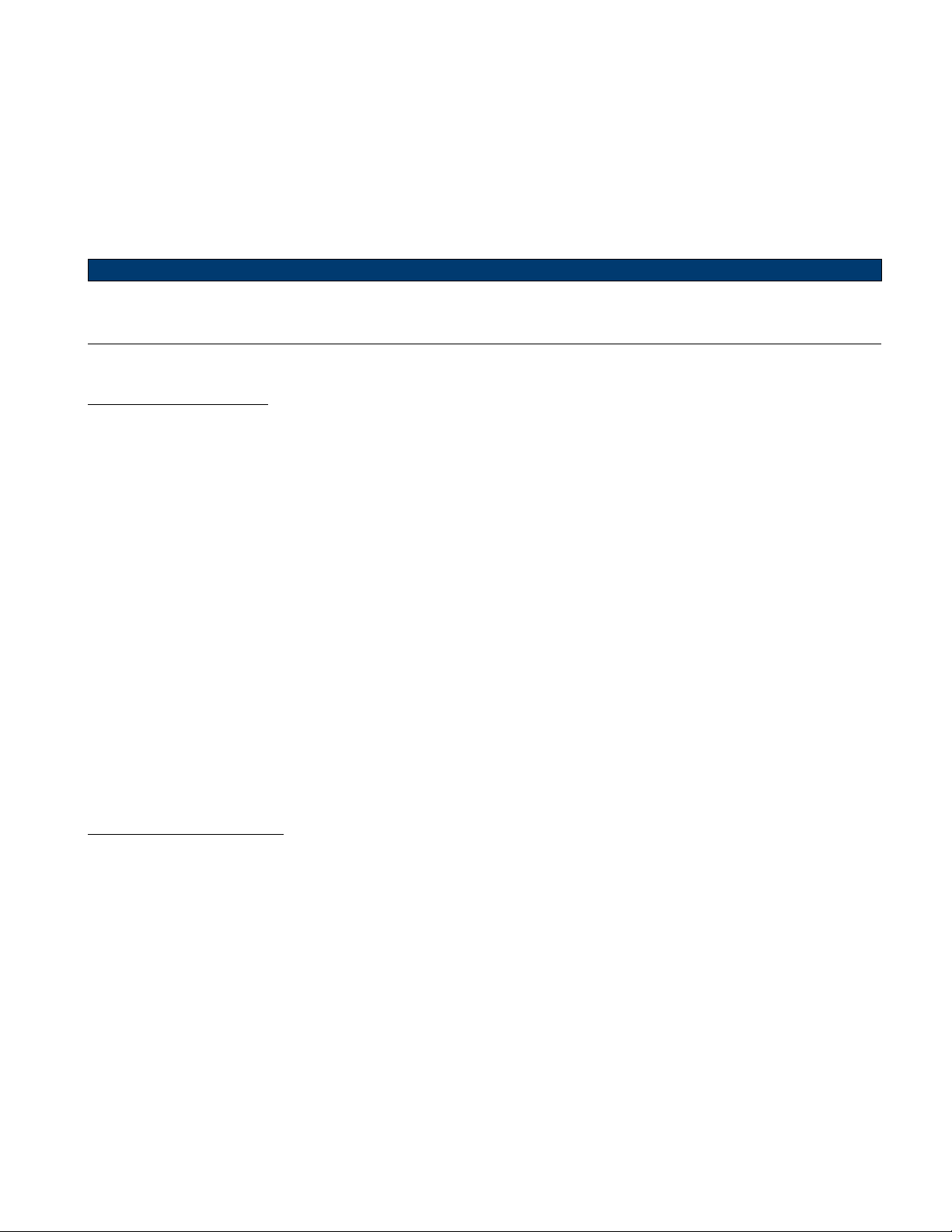

Page 31

Acquisition

31

Note:

–

acquisition time = sample points x sample interval", setting a larger memory depth can achieve a higher sample

rate for a given time base, but more samples require more processing time, degrading the waveform update rate.

With 200 Mpts memory depth, the 2560B series can still run at full sample rate (2 GSa/s) even when set to the

10 ms/div timebase.

The memory depth here is the upper limit of the memory space allocated by the oscilloscope. The actual sample

points are related to the current timebase and may be less than memory depth. The actual sample points

information can be obtained in the timebase descriptor box (see the section "Timebase and Trigger" for details).

The maximum memory depth in single-channel mode is 2 times that of the dual-channel mode, as the following table:

Single-Channel Mode

Dual-Channel Mode

20k

10k

200k

100k 2M 1M

20M

10M

200M

100M

Table 4.1 Memory Depth

Single-channel mode (interleaving mode): Only one of C1/C2 is turned on, and only one of C3/C4 is turned on.

Dual-channel mode (non-interleaving mode): Both C1/C2 are turned on, or both C3/C4 are turned on.

Figure 4.2 Memory Depth

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Acquisition

32

4.2 Sequence

Sequence mode is a fast acquisition mode, which divides the memory depth to multiple segments (up to 90,000), each

of which stores a single shot.

In sequence mode, the oscilloscope only acquires and stores data without processing and displaying, until the specified

segments are acquired. As a result, the dead time between trigger events is minimized, improving the waveform update

rate.

If sequence mode is enabled, the display will not update until all of the sequences have been acquired. The 2560B series

can achieve a minimum 2 s trigger interval in sequence mode, corresponding to a waveform update rate of 500,000

wfms/s.

Sequence mode can capture and record rare events over long time periods. The oscilloscope can capture multiple events

that satisfy the trigger conditions, ignoring the periods of no interest between adjacent events, maximizing the use of

waveform memory. Full accuracy of the acquisition timebase can be used to measure selected segments.

After the acquisition is finished, the oscilloscope will map all the segments together to the screen. To view and analyze

each frame separately, use history mode (see the section " History" for details). History mode provides timestamp labels

for each segment.

Figure 4.3

Sequence

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

History

The history function can record the waveforms of the input channels before press the

Run/Stop

button. In run state,

the oscilloscope records input waveform continually; when the memory is full (reach the maximal frame), the new frames

will cover the old frames and keep the latest frames.

The oscilloscope automatically stores acquired frames. It can store up to 90,000 frames but the number may vary due to

the memory depth and timebase settings. Turn on history mode, then the stored frames can be recalled and measured.

In sequence mode, all waveforms that satisfy the trigger conditions are mapped to the display.

To view a single frame:

1.

Press the

History

button on the front panel to enable the History function.

–

The history menu shown in figure

5.1

will be displayed.

2.

Touch

History

to toggle the history function on and off.

3.

Touch

Frame No.

and use the

Universal Knob

or the virtual keypad to

specify the frame index.

4.

Touch

List

to toggle the list function on and off.

5.

Touch the navigation options on to play backward, stop, or play

forward.

–

Touch

List Time Type

to toggle the type between

Acq Time

and

Delta T.

6.

Touch

Interval Time

to set the playing interval by using the

Universal

Knob or the virtual keypad.

•

In addition to manually specifying a frame, history mode supports autoplay.

–

Touch the option to replay the waveform from the current frame

to the first.

–

Touch the option to stop replay.

–

Touch the option to replay the waveform from the current frame

to the last.

Figure 5.1 History Menu

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Horizontal Control

The horizontal controls include:

•

Touchscreen controls for setting :

–

Horizontal scale and position (delay)

–

Accessing the

Main Timebase

menu.

–

Navigating

•

The horizontal scale and position knobs.

•

The

Zoom

key for quickly enabling/disabling the split-screen zoom display.

•

The

Search

key for finding events on analog channels or in serial decode.

•

The

Navigate

keys for navigating time, search events, or segmented memory acquisitions.

6.1 Adjusting the Horizontal Scale (time/div)

To adjust the horizontal scale:

•

Use the touchscreen horizontal pinch gesture

•

Use the touchscreen controls to open the

Main Timebase

dialog by pressing the timebase descriptor box.

Figure 6.1

Timebase Descriptor Box

–

Press the

Timebase

box to set the horizontal scale by the

virtual keypad.

– Press

to increase and to decrease the horizontal

scale.

•

The

Horizontal Scale Knob

can also be turned to adjust the

horizontal time/div setting.

Figure 6.2

Main Timebase Menu

The

Horizontal Scale Knob

has a different purpose in the

Zoom display.

See section

Zoom

for more details

Note:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Horizontal Control

35

6.2 Adjusting the Horizontal Delay (position)

Figure 6.3 Horizontal Setup

To adjust the horizontal delay (position):

•

Use the touchscreen horizontal drag gesture.

•

Use the touchscreen controls to open the

Main Timebase

dialog by pressing the timebase descriptor box.

Figure 6.4

Timebase Descriptor Box

–

Press the

Delay

box to set the horizontal scale by the

vir

tual keypad. (Figure 6.5)

– Press

to increase and to decrease the horizontal

scale.

•

The

Horizontal Position Knob

can also be turned to adjust

the horizontal time/div setting.

Figure 6.5 Main Timebase Menu

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

Horizontal Control

36

Note:

Changing the delay time moves the trigger point (solid inverted triangle

) horizontally and indicates how far it is

from the time reference point (hollow inverted triangle ). These reference points are indicated along the top of the

display grid.

Figure

6.3

shows the trigger point with the delay time set to 170 µs. The delay time number tells you how far the time

reference point is located from the trigger point. When delay time is set to zero, the delay time indicator overlays the

time reference indicator.

All events displayed left of the trigger point happened before the trigger occurred. These events are called pre-trigger

information, and they show events that led up to the trigger point.

Everything to the right of the trigger point is called post-trigger information. The amount of delay range (pre-trigger

and post-trigger information) available depends on the time/div selected and memory depth.

The horizontal position knob works (in the Normal time mode) while acquisitions are running or when they are stopped.

When running, adjusting the horizontal scale knob changes the sample rate. When stopped, adjusting the horizontal

scale knob lets you zoom into acquired data.

The

Horizontal Position Knob

has a different purpose in the

Zoom display.

See section

Zoom

for more details

6.3 Panning and Zooming Single or Stopped Acquisitions

When the oscilloscope is stopped, use the touchscreen horizontal pinch or drag gestures or use the horizontal scale

and position knobs to pan and zoom your waveform. The stopped display may contain several acquisitions worth of

information, but only the last acquisition is available for pan and zoom.

The ability to pan (move horizontally) and scale (expand or compress horizontally) an acquired waveform is important

because of the additional insight it can reveal about the captured waveform. This additional insight is often gained from

seeing the waveform at different levels of abstraction. You may want to view both the big picture and the specific little

picture details. For example, figure

6.3

demonstrates how these features bring insight on the waveform’s rise time.

6.4 Horizontal Scale (Coarse/Fine)

To change the horizontal scale knob adjustment setting:

•

Push the

Horizontal Scale Knob

to toggle between fine and coarse adjustment.

When Fine is enabled, turning the horizontal scale knob changes the time/div (displayed in the status line at the top of

the display) in smaller increments. The time/div remains fully calibrated when Fine is on.

When Fine is turned off, the Horizontal scale knob changes the time/div setting in a 1-2-5 step sequence.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Horizontal Control

37

6.5 Zoom

Zoom is a horizontally expanded version of the normal display. When Zoom is selected, the display divides into two

windows. The top window covers about a third of the displays. This window displays the normal time/div window. The

area of the normal display that is expanded is outlined with a box and the rest of the normal display is ghosted. The box

shows the portion of the normal sweep that is expanded in the lower half.

The bottom window covers two-thirds of the screen. This window is a magnified portion of the normal time/div window.

Use Zoom to locate and horizontally expand part of the normal window for a more detailed analysis of the waveform.

To enable the Zoom function:

•

Press the

Zoom

key or push the

Horizontal Scale Knob.

–

Zoom can also be enabled using the touch screen. Press the Acquire option located on the Menu Bar. Then

press Zoom.

Figure 6.6 Zoom

To change the time/div for the Zoom window, turn the

Horizontal Scale Knob

. As you turn the knob, the zoomed

window time/div is highlighted in the status line above the waveform display area. The Horizontal scale knob controls

the size of the box.

The Horizontal position knob sets the left-to-right position of the zoom window. Negative delay values indicate you’re

looking at a portion of the waveform before the trigger event, and positive values indicate you’re looking at the waveform

after the trigger event.

To change the time/div of the normal window, turn off Zoom by pressing the

Zoom

key ; then, turn the

Horizontal Scale

Knob.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

Horizontal Control

38

6.6 Roll

Roll causes the waveform to move slowly across the screen from right to left. It only operates on the time bases settings

of 50 ms/div and slower. If the current time base settings are faster than the 50 ms/div limit, it will be set to 50 ms/div

when Roll mode is entered.

To enable the Roll mode:

•

Press the

Roll

key.

–

Roll can also be enabled using the touch screen. Press the

Acquire

option located on the Menu Bar.

Then press

Roll.

In Roll mode there is no trigger. The fixed reference point on the screen is the right edge of the screen and refers to

the current moment in time. Events that have occurred are scrolled to the left of the reference point. Since there is no

trigger, no pre-trigger information is available.

If you would like to pause the display in Roll mode press the

Single

key. To clear the display and restart an acquisition

in Roll mode, press the [Single] key again.

Use Roll mode on low-frequency waveforms to yield a display much like a strip chart recorder. It allows the waveform to

roll across the display.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Vertical Control

The vertical controls include:

•

Touchscreen controls for setting:

–

Vertical scale and position (offset)

– Accessing the

Channel

menus.

•

The vertical scale and position knobs for each analog channel.

•

The channel keys for turning a channel on or off.

Figures

7.2

shows the Channel 1 Menu that appears after pressing the 1 channel key.

7.1 Enabling Channels

Push the channel button (1 - 4) to turn on the corresponding channel. Its channel

descriptor box and Channel menu will appear on the display. Push the same button

again

to disable the channel. The channel menu also has an on/off option.

7.1.1 Channel Enable/Disable From the Touch Screen

Touch the + button shown on figure

7.1

and then select a channel to turn it on. The

selected channel’s descriptor box and a menu box will appear on the display. Touch the

channel descriptor box and then touch the Off button to disable it.

Figure 7.2 Channel 1 Menu

Turn CH 1 On Turn CH 1 Off

Figure 7.1 Front View

Figure 7.3

Channel 1 Menu

Continued

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

Vertical Control

40

7.2 Vertical Scale

The

Vertical Scale Knob

changes the analog channel scale in a 1-2-5

step sequence (with a 1:1 probe attached), unless Fine Adjustment is enabled.

The analog channel’s vertical scale (Volts/div) value is displayed in the

channel’s

descriptor box.

To adjust the vertical scale:

•

Use the touchscreen vertical pinch gesture.

•

Touch the channel descriptor box to open the vertical scale/offset dialog.

•

Turn the

Vertical Scale Knob.

7.2.1 Coarse/Fine Adjustment

Push the channel’s vertical scale knob (or press the channel’s descriptor box then

uncheck Coarse) to toggle between fine and coarse adjustment of the vertical scale.

When

Fine

adjustment is selected, you can change the channel’s vertical sensitivity in

smaller increments. The channel sensitivity remains fully calibrated when

Fine

is on.

When Fine is turned off, turning the

Vertical Scale Knob

changes the channel

sensi

tivity in a 1-2-5 step sequence.

7.3 Vertical Position

The offset voltage value represents the voltage difference between the vertical center

of the display and the ground level (

) icon.

To adjust the vertical position:

•

Use the touchscreen pinch and drag gestures.

•

Touch the channel descriptor box to open the vertical scale/offset dialog.

•

Turn the

Vertical Position Knob

to move the channel’s waveform up or down on

the display.

Figure 7.4

Channel Descriptor Box

Figure 7.5

Vertical Scale/Offset

Dialog

Push the

Vertical Position Knob

to set the ground level to zero.

Note:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Vertical Control

41

Note:

Note:

7.4 Channel Setup

Pressing the

Channel

key to open the corresponding channel menu. As shown in figures

7.2

and

7.3

the following

options can be configured:

•

Channel Coupling

•

BW Limit

•

Probe

•

Label

•

Apply To

•

Impedance

•

Unit

•

Deskew

•

Invert

•

Trace

7.4.1 Channel Coupling

Coupling changes, the channel’s input coupling to either

AC

(alternating current),

DC

(direct current), or

GND

(ground).

DC (Direct Current)

All of the input signal frequency components are passed to the display.

DC coupling is useful for viewing waveforms as low as 0 Hz that do not have large DC offsets.

If the channel is DC coupled, you can quickly measure the DC

component of the signal by simply noting its distance from the ground.

Alternating Current

The signal is capacitively coupled. DC signal components are rejected. See the datasheet for details of the cut-off

frequency.AC coupling is suitable for observing AC signals with DC offset, such as power ripple.

AC coupling is useful for viewing waveforms with large DC offsets.

AC coupling places a 10 Hz high-pass filter in series with the input waveform that removes any DC offset voltage from

the waveform.

If the channel is AC coupled, the DC component of the signal is removed,

allowing for greater sensitivity to display the AC component of the signal.

Ground

The channel is grounded by an internal switch. GND coupling is used to observe the zero offset error of the analog

channels or determine the source of noise in the waveform (from signal or from oscilloscope itself).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

Vertical Control

42

Note:

To set the channel coupling:

1.

Press the desired channel key.

2.

In the

Channel Menu

, use the touchscreen to press the

Coupling

option.

–

A drop-down menu will appear with all 3 coupling option.

–

Use the touchscreen to select the desired coupling.

Channel Coupling

is independent of

Trigger Coupling

. To change trigger coupling see

Trigger Coupling.

7.4.2 Bandwidth Limit

Full bandwidth will pass through signals with high-frequency components, but it also means that noise with high-frequency

components can pass through. When the frequency component of a signal is very low, better signal-to-noise ratios (SNR)

can be obtained by enabling one of the available bandwidth limits.

The 2560 provides two bandwidth limit options: 20 MHz and 200 MHz. The bandwidth limit effectively lowers the input

frequency response of the input to the selected limit value.

For waveforms with frequencies below the bandwidth limit, turning the bandwidth limit on removes unwanted high

frequency noise from the waveform.

To set the bandwidth limit:

1.

Press the desired channel key.

2.

In the

Channel Menu

, use the touchscreen to press the

BW Limit

option.

–

A drop-down menu will appear with three bandwidth options.

–

Use the touchscreen to select the desired bandwidth limit.

7.4.3 Probe Attenuation

This is set automatically if the oscilloscope can identify the connected probe. The 2560 provides 1X, 10X, 100X

and custom probe attenuation factor options. The custom values can be between 10−6 𝑡𝑜 106. The oscilloscope will

automatically convert the vertical scale according to the current probe attenuation factor.

For example, the vertical scale of the oscilloscope under 1X attenuation is 100 mV/div, and the vertical scale will be

automatically set to 1 V/div if the probe attenuation is changed to 10X. If a standard probe with readout terminal is

connected, the oscilloscope will automatically set the probe attenuation to match the probe.

To set the probe attenuation:

1.

Press the desired channel key.

2.

In the

Channel Menu

, use the touchscreen to press the

Probe

option.

–

The

Probe

submenu will appear with four bandwidth options.

–

Use the touchscreen to select the desired probe attenuation.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Vertical Control

43

7.4.4 Label

Customize the label text, of the selected source. The source can be C1 - C4, F1 or F2, and RefA - RefD.

The length of the label is limited to 20 characters. The characters beyond this length will not be displayed.

When the

Display

option is set to “on”, the label will be displayed on the right side of the channel offset indicator.

To set and enable a channel’s label:

1.

Press the desired channel key.

2.

In the

Channel Menu

, use the touchscreen to press the

Label

option.

–

The

Label

submenu will appear.

•

Select a source to assign the label to the specified source.

•

Enable/disable the label using the

Display

option

•

Set the text of the label in the

Label Text

option.

Figure 7.6

Label Submenu

Label On Label Off

Figure 7.7

Label

7.4.5 Apply To

Common functions such as Trigger, Cursor, Measure, FFT, Search, Mask Test, Counter, and AWG can be quickly applied

to the selected channel using the

Apply To

option. Once a function is specified, it will switch directly to the function

menu and automatically set that channel as the source.

To apply a function:

1.

Press the desired channel key.

2.

In the

Channel Menu

, use the touchscreen to press the

Apply To

option.

–

A drop-down menu will appear listing the available functions.

–

Use the touchscreen to select the desired function.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

Vertical Control

44

7.4.6 Impedance

To change the impedance:

1.

Press the desired channel key.

2.

In the

Channel Menu

, use the touchscreen to select either

50 Ω or

1 MΩ.

1 MΩ: When a passive probe with high impedance is connected, the impedance must be set to 1 MΩ, otherwise the

signal will not be detected.

50 Ω: Suitable for high-frequency signals transmitted through 50 Ω coaxial cables and can minimize the amplitude

distortion caused by impedance mismatching.

7.4.7 Unit

Channel sensitivity, trigger level, measurement results, and math functions will reflect the measurement units selected.

To change the units:

1.

Press the desired channel key.

2.

In the

Channel Menu

, use the touchscreen to select either V or A.

Use Volts for a voltage probe.

Use

Amps

for a current probe.

7.4.8 Deskew

When measuring time intervals in the nanoseconds (ns) range, small differences in cable length can affect the

measure

ment. Use Deskew to remove cable-delay errors between any two channels.

For example, two coaxial cables with a 1-inch difference in length could introduce a skew of more than 100 ps. In some

scenarios (e.g. measuring the setup/hold time between clock and data), it may be necessary to compensate the skew

between channels.

The method of compensation: Probe the same signal simultaneously using two channels (including the cables or probes

that you intend to use for measurements) and adjust the deskew parameter of one channel until the waveforms of the

two channels observed on the screen coincide horizontally.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Vertical Control

45

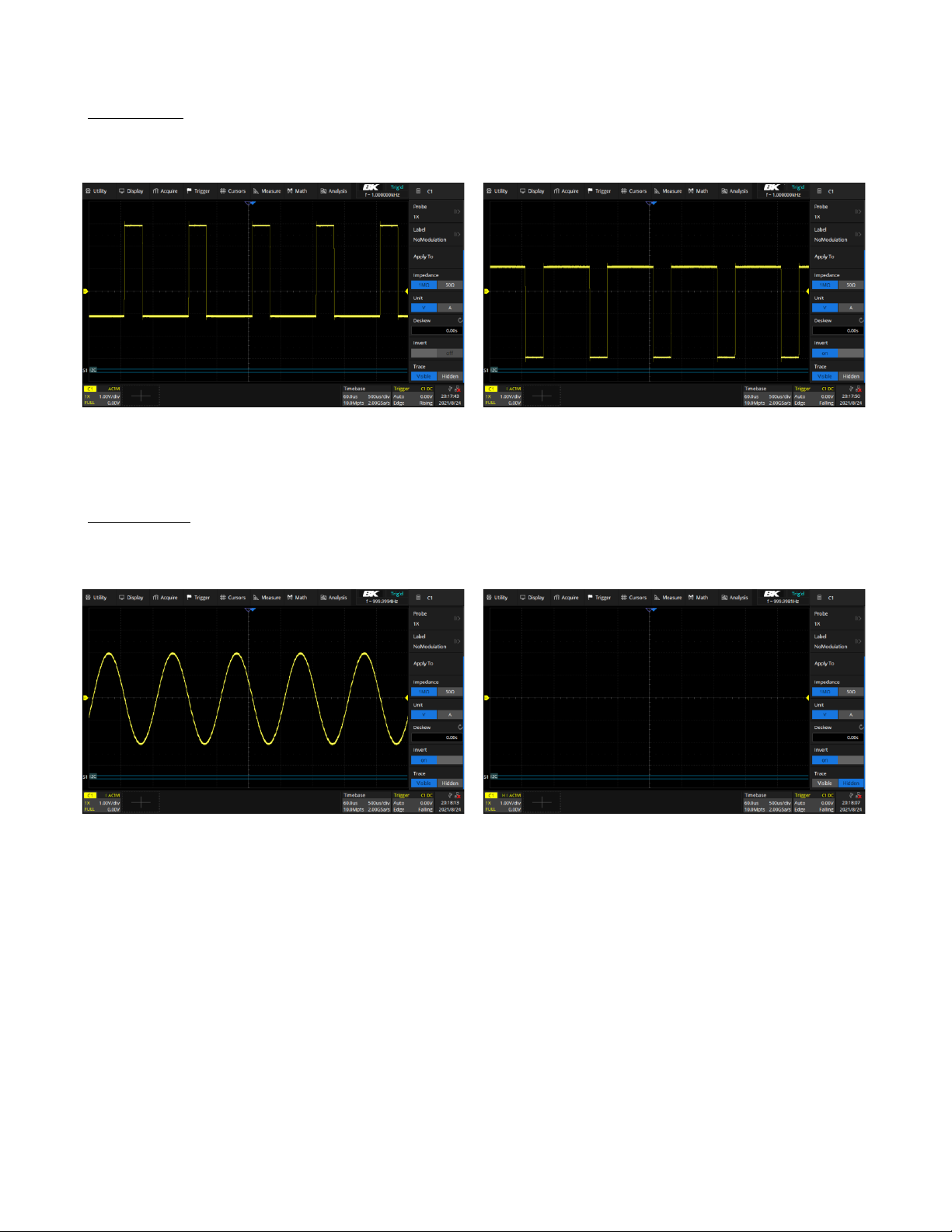

7.4.9 Invert

When

Invert

is enabled, the waveform is displayed 180 degrees opposite to the earth potential. This is a mathematical

inversion and does not physically change the actual potential of the input signal.

Invert Of

Invert On

Figure 7.8

Invert

7.4.10 Trace

When

Visible

is selected, the waveform is displayed.

When

Hidden

is selected, the waveform is not displayed, but the channel is still active.

Visible Hidden

Figure 7.9

Trace

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

Note:

Digital Channels

This chapter describes how to use the digital channels of a Mixed-Signal Oscilloscope (MSO).

The digital channels are standard on the 2560B MSO models and the 2560B Series DSO models have the upgrade license

option.

8.1 LP2560 Probe

The LP2560 is a logic probe designed to monitor up to 16 digital signals at once. The 16 digital channels are separated

into two groups and each group has its threshold, making it possible to simultaneously view data from different logic

families.

The 16-channel color-coded logic probe consists of

two eight-channel pods. To make contact with the

DUT, the probe connects directly to square pins or

clips to test points using the included grabbers.

With an input capacitance of only 18 pF and 100 kΩ

input impedance, the probe protects the integrity of

your signal.

The probe is included with MSO models.

Figure 8.1 LP2560 Probe

To avoid personal injury or damage to the logic probe and any

associated equipment, the following safety precautions should be noted.

The equipment shall be used only for the purposes specified by the manufacturer.

The LP2560 probe is used only for BK’s special series of oscilloscopes. Protection mechanisms can be compromised if

the way the devices connected by the LP2560 are not used for their intended purpose.

Connect and disconnect correctly

.

Excessive bending can damage the cable.

Do not use equipment in humid or explosive environment.

Only used indoors. The LP2560 is designed to be used indoors and should only be operated in a clean, dry environment.

Do not use the equipment when you suspect a problem.

Do not use the LP2560 if any parts are damaged. Maintenance work shall be performed by maintenance personnel with

appropriate qualifications. Keep the product surface clean and dry.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

Digital Channels

47

8.2 Connecting the Digital Probes

1.

If necessary , turn off the power supply to the device under test.

–

Turning off power to the device under test only prevents damage that might occur if two lines are accidentally

shorted when connecting the probes. The oscilloscope can be powered on because no voltage appears at the

probes.

2.

Connect the digital probe cable to the

D0-D15

connector located on the front panel.

3.

Connect a SMD Mini-grabber test clip to one of the digital ground pins of the probe and then connect the grabber

to ground in the device under test.

–

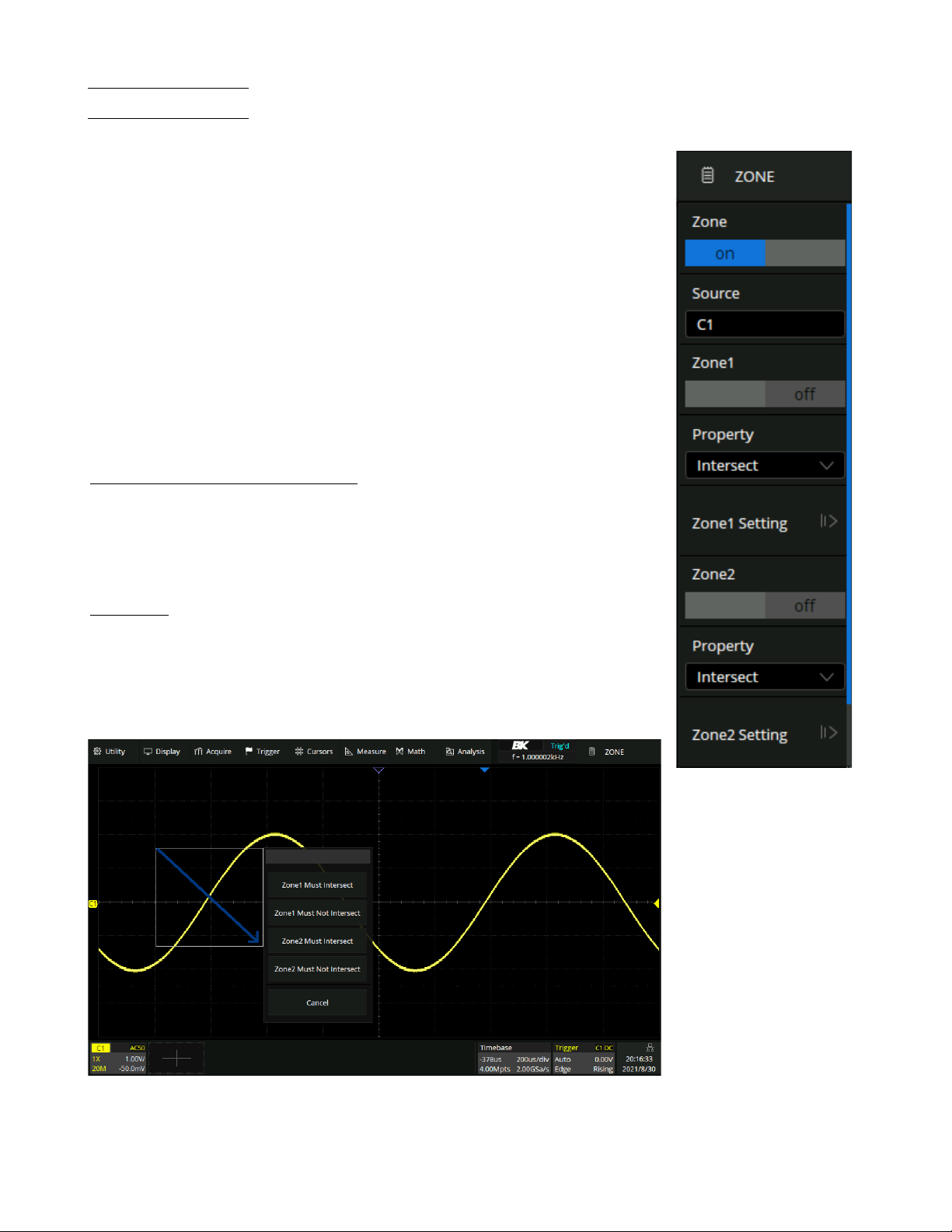

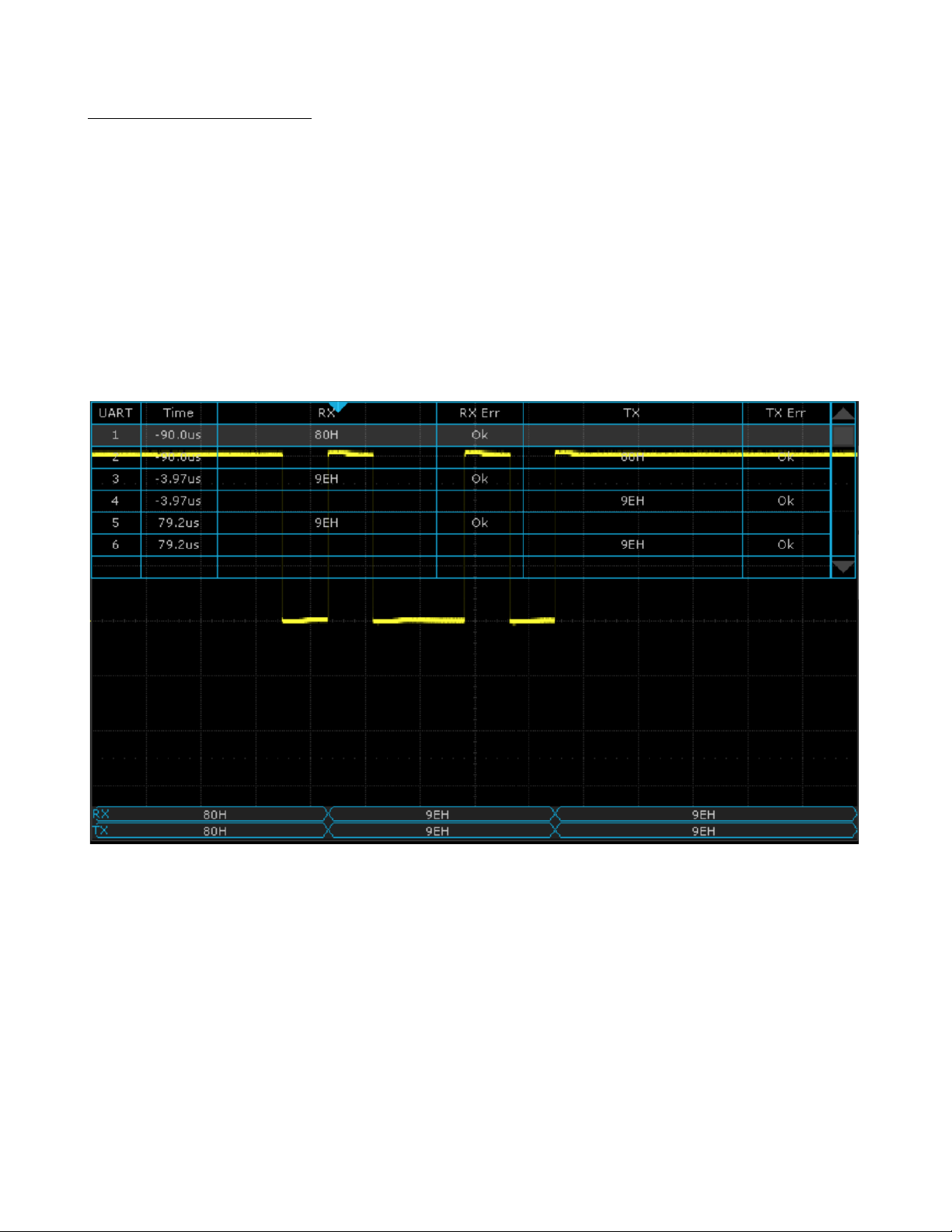

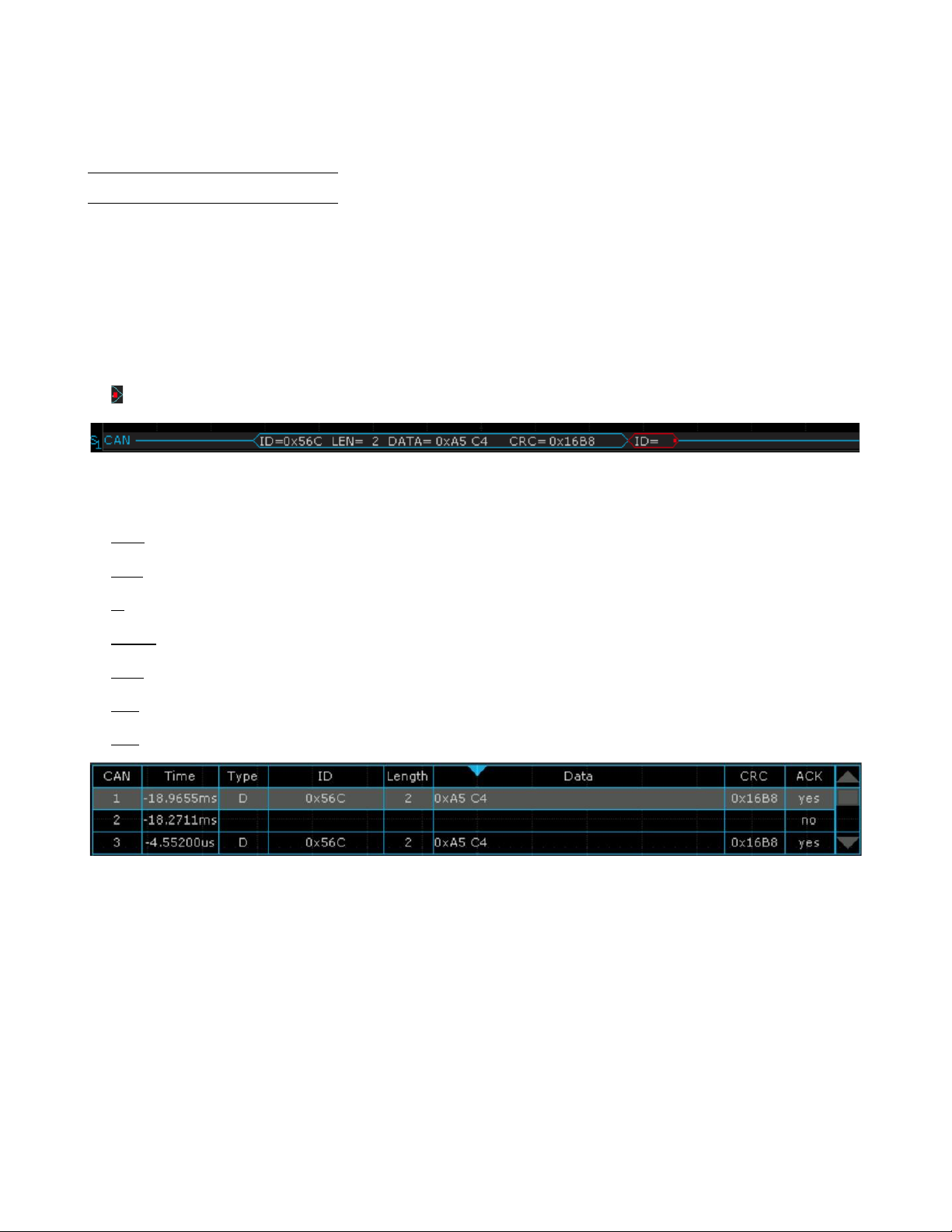

This will improve the signal fidelity and makes sure the oscilloscope gives accurate measurements.