Page 1

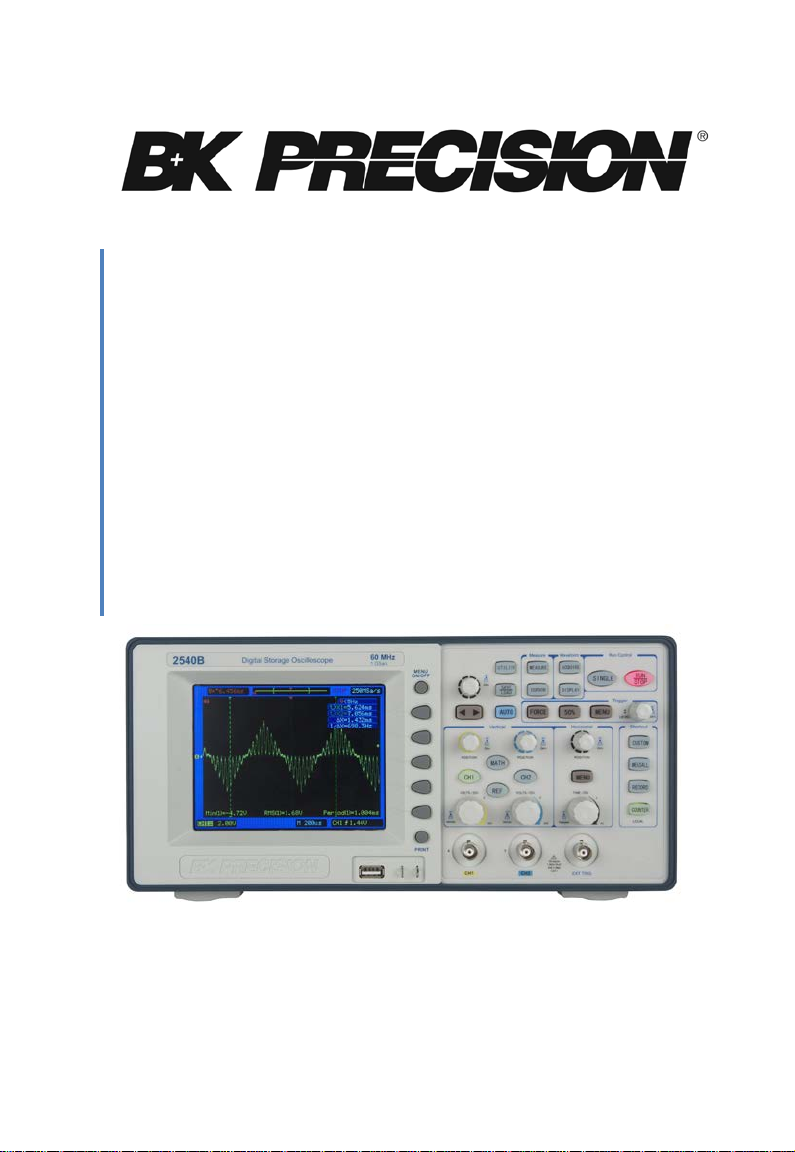

Model: 2540B, 2542B, 2540B-GEN,

USER MANUAL

2542B-GEN

Digital Storage

Oscilloscopes

Page 2

2 3

Page 3

Safety Summary

The following safety precautions apply to both operating and

maintenance personnel and must be observed during all phases

of operation, service, and repair of this instrument. Before

applying power, follow the insta lla tion instructions and become

familiar with the operating instr uctions for this instrument.

If this device is damaged or something is missing, contact the

place of purchase immediately.

This manual contains information and warnings that must be

followed to ensure safe operation as well as to maintain the

oscilloscope in a safe condition.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet

must be connected to an electrical gro und. This instrument is

grounded through the ground conductor of the supplied,

three-conductor ac power cable. The power cable must be

plugged into an approved three-conductor electrical outlet. Do

not alter the ground conne ction. Wi t hout the protective ground

connection, all accessible conductive parts (including control

knobs) can render an electric shock. The power jack and

mating plug of the power cable must meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable

gases or fumes. Operation of any electrical instrument in such

an environment constitutes a definite safety hazard.

Page 4

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel.

Component replacement and internal adjustments must be made

by qualified maintenance personnel. Disconnect the power

cord before removing the instrument covers and replacing

component s . Under cer tain conditions, even with the power

cable removed, dangerous voltages may exist. To avoid

injuries, always disconnect power and discharge circuits before

touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service or adjustment unl ess another

person, capable of rendering first aid and resuscitation, is

present.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any unauthorized

modifications to this instrument. Return the instrument to

B&K Precision for service and repair to ensure that safety

features are maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, suc h as the following

examples, denote a hazard and appear throughout this manual.

Follow all instructions containe d in these statements.

A WARNING statement calls atte ntion to an operating

procedure, practice, or condition, which, if not followed

correctly, could result in injury or d eath to personnel.

4

Page 5

CAUTION:

Before connecting the line cord to the AC mains,

check the rear panel AC line voltage indicator.

Applying a line voltage other than the indicated

acceptable

This product uses components which can be

damaged by electro-static discharge (ESD). To

avoid damage, be sure to follow proper procedures

for handling, storing and transporting parts and

subassemblies which contain ESD-sensitive

components.

CAUTION:

A CAUTION statement calls attention to an operating

procedure, practice, or condition, which, if not followed

correctly, could result in da mage to or destruction of part or all

of the product.

voltage can destroy the instrument.

5

Page 6

Compliance Statements

Disposal of Old Electrical & Electronic Equipment

(Applicable in the European

Union and other European countries with separate

collection systems)

This product is subject to Directive

2002/96/EC of the European

Parliament and the Council of the

European Union on waste

electrical and electronic equipment

(WEEE) , and in jurisdictions

adopting that Directiv e, i s m ar ked a s

being put on the market after A ugust

13, 2005, and should not be

disposed of as unsorted

municipal waste. Please utilize y our

local WEEE collection facilities in

the disposition of this product and

otherwise observe all applicable

requirements.

6

Page 7

Safety Symbols

Electrical Shock hazard.

On (Power). This is the In position of the power

Chassis (or earth) ground symbol.

This symbol on an instrument indicates caution.

For details, the user should refer to the operating

instructions in the manual.

switch when instrument is ON.

Off (Power). This is the Out position of the

power switch when instrument is OFF.

This symbol is a power switch located at the top

of the oscilloscope. Pressing this button toggles

the oscilloscope’s state between power on and

power off mode.

7

Page 8

CAT I

Operating

0 °C to 40 °C

IEC Measurement Category I.

(400V)

Inputs may be connected to

mains (up to 400 VAC) under

Category I overvoltage conditions.

Environmental Conditions

Environment

Storage Humidity

Storage Environment -20 °C to +50 °C

Pollution degree Pollution degree 2

0 – 80% R.H.

Notations

TEXT – Denotes buttons on the oscilloscope.

Text – Denotes softkeys from the menu system, selectable

by pressing corresponding menu softkey buttons.

8

Page 9

Table of Contents

1 GETTIN G STARTED ..................................................... 14

1.1 Introduction ..................................................... 15

1.2 Package Contents ........................................... 16

1.3 Input Power Requirements .............................. 17

1.4 Panel and Screen Display ............................... 18

Front Panel Display ..................................................... 18

Back Panel Display ...................................................... 21

LCD Main Screen Display ............................................ 22

1.5 Quick Check .................................................... 24

Power On Check .......................................................... 24

Basic Check ................................................................. 25

1.6 Probe Safety ................................................... 27

1.7 Probe Attenuation............................................ 28

1.8 Probe Compensation ....................................... 28

2 BASIC OPERATION ................................................... 31

2.1 Using Quick Help............................................. 32

2.2 Using Autoset .................................................. 33

2.3 Vertical Controls .............................................. 35

Vertical Position Knob (CH1, CH2) .............................. 35

Vertical Scale Control (CH1, CH2) .............................. 36

Channel Keys CH1, CH2 ............................................ 37

CH1, CH2 Menu .......................................................... 37

MATH Functions .......................................................... 46

REF Function ............................................................... 52

9

Page 10

2.4 Horizontal Controls ......................................... 55

Horizontal Position Control ...........................................56

Horizontal Scale Control ...............................................56

Main - Horizontal Mode ................................................58

Delayed - Horizontal Mod e ...........................................60

X-Y Horizontal Mode.....................................................62

Roll - Horizontal Mode ..................................................63

2.5 Trigger Controls .............................................. 65

2.6 RUN Controls ................................................. 78

3 MENU OPERATION ................................................... 79

3.1 UTILITY Menu ................................................ 80

I/O Setup .......................................................................84

System Setup ...............................................................91

Service ..........................................................................96

Pass/Fail .......................................................................98

3.2 MEASURE Menu .......................................... 102

Voltage Measurements ...............................................103

Time Measurements ...................................................107

3.3 ACQUIRE Menu ........................................... 115

Record Wavefrom .......................................................119

Playback Record .........................................................120

Save/Recall the Record ..............................................122

Exit Record Function ..................................................123

3.4 SAVE/LOAD Menu ....................................... 124

Internal Storage ..........................................................125

10

Page 11

External Storage ........................................................ 127

Firmware Update ....................................................... 131

3.5 CURSOR Menu ............................................. 132

Manual Mode ............................................................. 133

Track Mode ................................................................ 135

AUTO Mode ............................................................... 137

3.6 DISPLAY Menu ............................................. 138

4 SHORTCUT MENU (2540B/2542B only) .................. 141

4.1 Shortcut Controls........................................... 142

CUSTOM Button ........................................................ 142

MEASALL Button ....................................................... 144

RECORD Button ........................................................ 145

COUNTER/LOCAL Button ......................................... 145

5 ARBITRARY WAVEFORM GENERATOR

(2540B-GEN/2542B-GEN only) ..................................... 147

5.1 Waveform Generator Controls ....................... 148

MENU/GRAPH Button ............................................... 148

FREQ/CAPTUR E Button ........................................... 150

AMPL/LOCAL Button ................................................. 151

ON/OFF Button .......................................................... 152

5.2 Generator Menu ............................................ 152

Sine Output ................................................................ 153

Square Output ........................................................... 154

Pulse Output .............................................................. 155

Built-in Arbitrary Waveform Output ............................ 156

User Programmable Arbitrary Waveform Output....... 160

11

Page 12

AM Modulation ............................................................168

FM Modulation ............................................................170

Pulse Width Modulation ..............................................172

DC Offset Modulation (DCOM) ...................................174

Frequency Sweep .......................................................176

Burst Frequency .........................................................178

FSK and PSK Modulation ...........................................180

5.3 Output Terminals .......................................... 182

GEN OUT ...................................................................182

MOD OUT ...................................................................182

6 QUICK START GUIDE ............................................. 185

6.1 Making Simple Measurements ...................... 186

6.2 Capture Single Shot Signal ........................... 188

6.3 Reduce Random Noise on a Signal .............. 190

6.4 Triggering a Video Signal .............................. 192

6.5 PASS/FAIL Measurement ............................. 194

6.6 Using Waveform Recorder ............................ 196

6.7 Making Cursor Measurements ...................... 200

6.8 Output Basic Sine Waveform ........................ 206

6.9 Output Amplitude Modulated Waveform ....... 207

6.10 Create Waveform with Added Noise ............. 210

6.11 Capture and Output Math Waveform ............ 211

7 REMOTE CONTROL ................................................ 213

7.1 Comsoft Software ......................................... 214

7.2 Web Browser GUI ......................................... 214

8 TROUBLESHOOTING GUIDE ................................. 215

12

Page 13

8.1 System Message ........................................... 216

8.2 General Problems ......................................... 220

9 SPECIFICATIONS .................................................... 223

9.1 Digital Storage Oscilloscope Specifications ... 224

9.2 Arbitrary Waveform Generator Specifications 231

9.3 General Specifications .................................. 236

9.4 Certification ................................................... 237

Appendix A: Performance Verification Procedure ..... 238

DC Gain Accuracy ................................................... 239

Bandwidth ................................................................ 241

Trigger Sensitivity .................................................... 242

Time Scale Accuracy ............................................... 243

Appendix B: Disabling Auto Function ......................... 244

13

Page 14

Getting Started

1 GETTING STARTED

• Introduction

• Package Contents

• Input Power Requirements

• Panel and Screen Display

• Quick Check

• Probe Safety

• Probe Attenuation

• Probe Compensation

14

Page 15

Getting Started

1.1 Introduction

The 2540B and 2542B are part of a series of portable digital

storage oscilloscopes (DSOs) that offer up to 10 0 MHz

bandwidth with a 1 GSa/s sample rate. The 2540B-GEN

and 2542B-GEN models offer the same, with the addition of a

built-in arbitrary waveform generator in the same form factor.

Features

• 60/100 MHz bandwidth (60 MHz: 2540B, 2540B-GEN

/ 100 MHz: 2542B, 2542B-GEN)

• 1 GSa/s sample rate

• Bright 5.7” TFT color display

• Deep waveform memory up to 2.4 Mpts (accessible

via remote interface)

• Shortcut keys for quick access of frequently used

functions (for models 2540B and 2542B only)

• Built-in arbitrary waveform generator (for models

2540B-GEN and 2542B-GEN only)

• Versatile triggering capabilities including pulse width,

line-selectable video, slope, and alternating trigger

• 24 automatic measurements

• Digital filter with adj ust a ble limits, pass/fail testing,

and waveform recorder mode

• Ten different language user interfaces

• For educators – ability to disable the Auto Set button

15

Page 16

Getting Started

• LAN and USB device connectivity for remote PC

control through Comsoft PC software

• USB host port for convenient storing and recalling of

waveform data, setups, and screenshots on a USB

flash drive

1.2 Package Contents

The digital storage oscilloscopes are shipped with the

following contents:

• 2540B/2542B/2540B-GEN/2542B-GEN Digital

Storage Oscilloscope

• User Manual

• Certificate of calibration

• USB (Type A to B) communication cable

• AC Power Cord

• Two 150 MHz 1x/10x passive oscillos cope pr obes

• One BNC-to-BNC cable (for models 2540B-GEN and

2542B-GEN only)

Please locate each item from the original packaging and

contact B&K Precision immediately if something is missing.

16

Page 17

Getting Started

Input Voltage Range: ~99 V to 242 VAC

Rating: 50VA Max.

1.3 Input Power Requirement s

The 2540B, 2542B, 2540B-GEN, and 2542B-GEN DSOs do

not require a line fuse when different voltage lines are used

for powering the instrument. The power input requirements

are:

Input Frequency: 47 Hz to 440 Hz

Before connecting the instrument from an AC outlet, please

verify that the above power input requirements are met.

Connecting incorrect AC power input to the instrument is

dangerous and may damage the instrument, voiding its

warranty.

17

Page 18

Getting Started

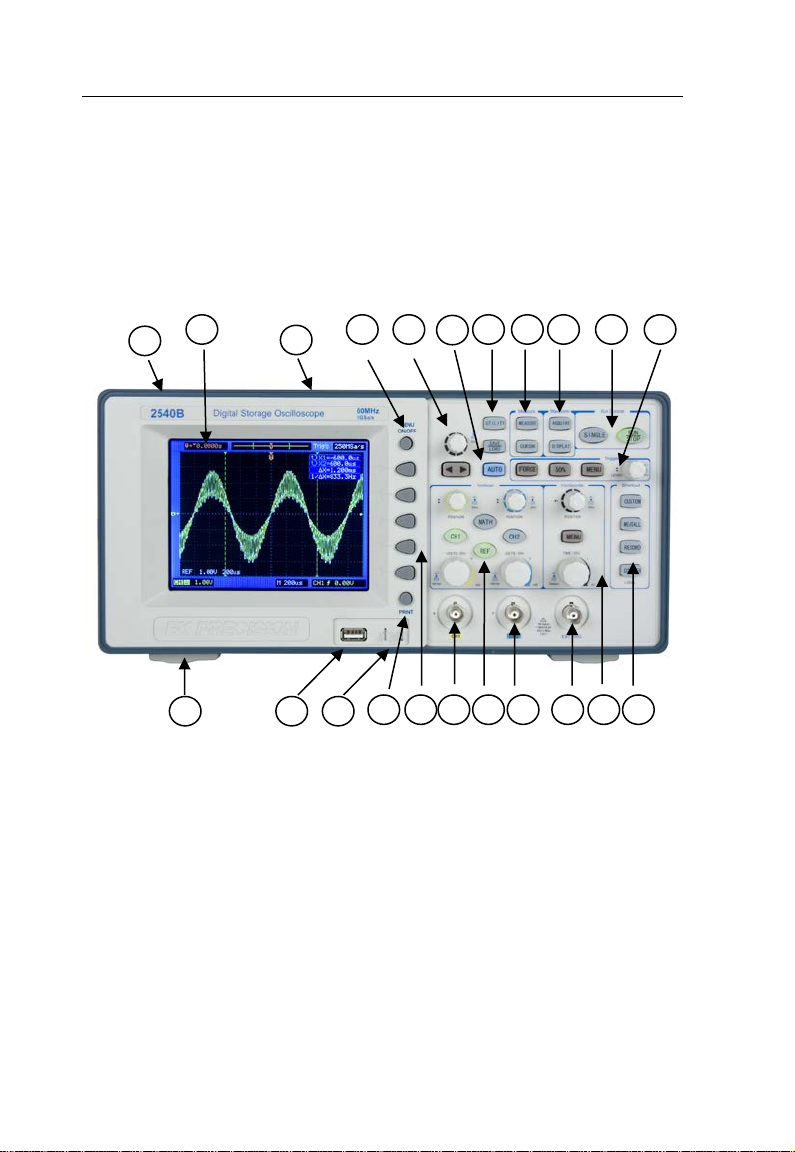

1 2 4 5 7 8 9

10

12

13

14

15

16

17

18

19

20

21

22

11 6 3

(top)

(top)

(bottom)

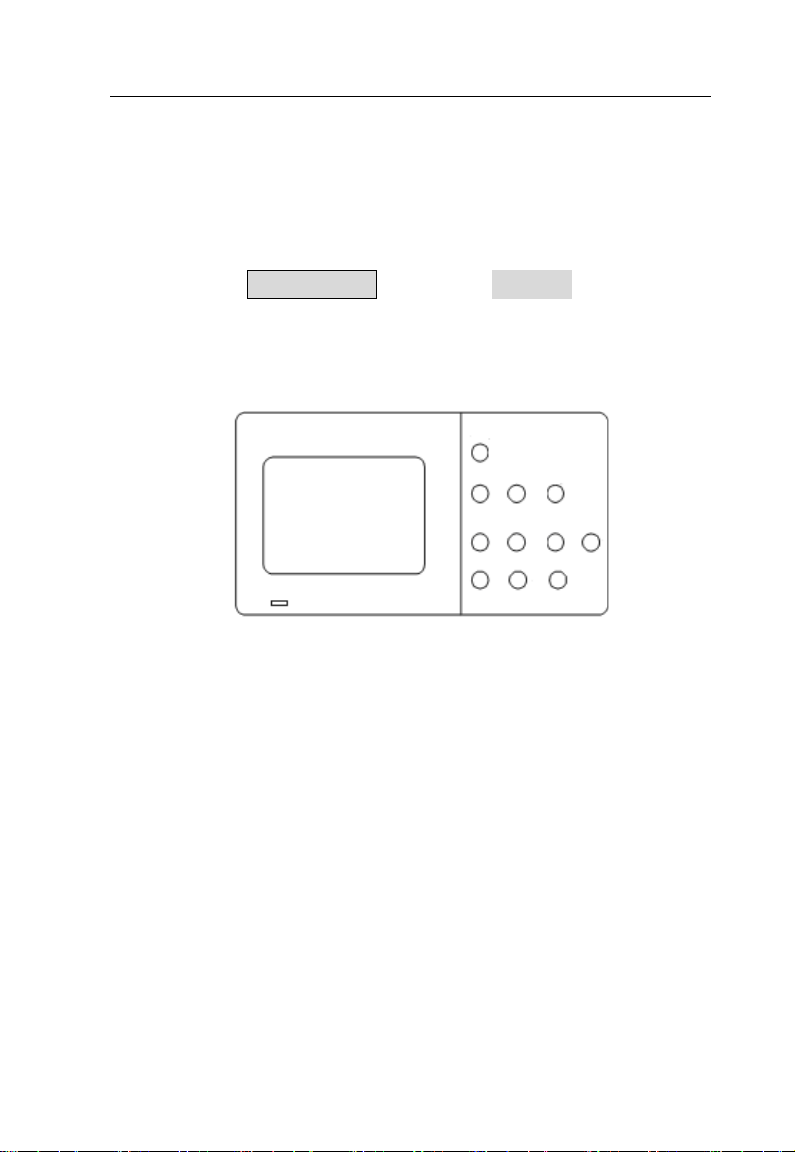

1.4 Panel and Screen Display

Front Panel Display

Figure 1 - Model 2540B

18

Page 19

Getting Started

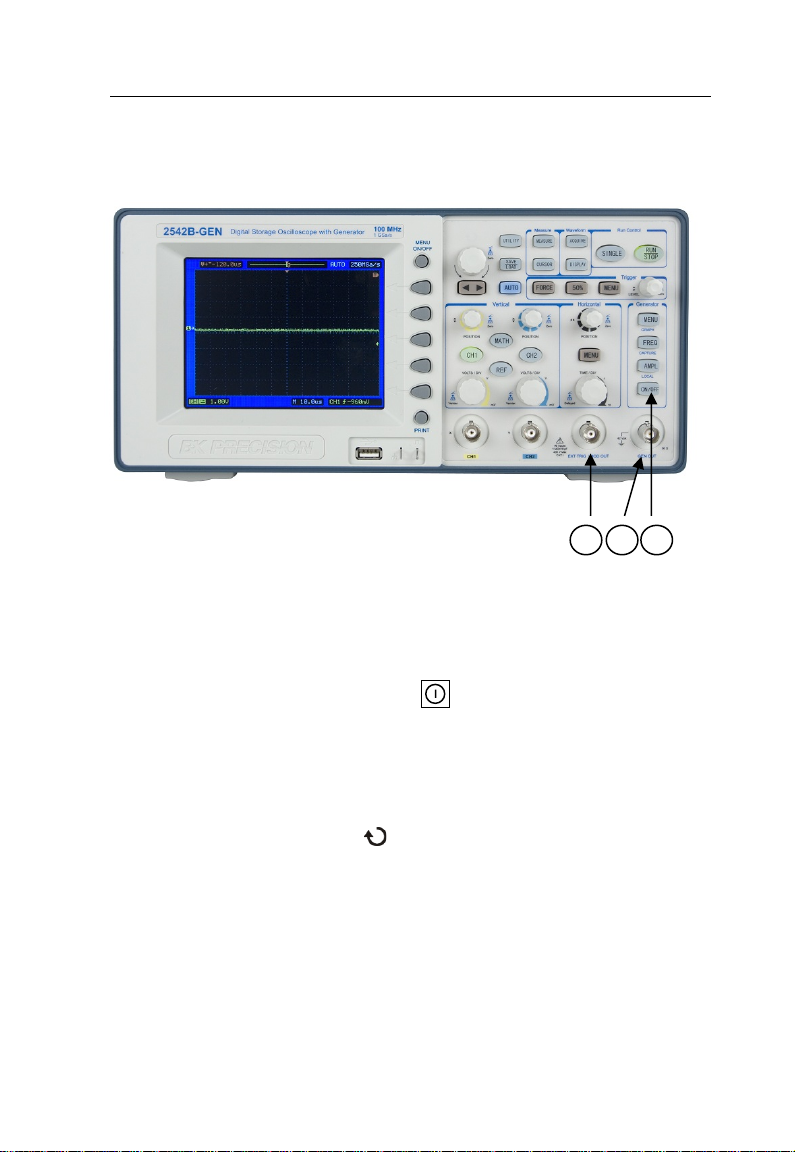

12

23

14

Figure 2 - Model 2542B-GEN

1. Power ON/OFF button (top panel)

2. LCD display screen

3. Carrying handle (top panel)

4. Menu ON/OFF button

5. Adjustment knob

6. AUTO SET button

7. UTILITY & SAVE/LOAD menu buttons

8. MEASURE & CURSOR menu buttons

9. ACQUIRE & DISPLAY menu buttons

10. RUN control ( SINGLE & RUN/STOP) buttons

19

Page 20

Getting Started

11. TRIGGER controls

12. (for models 2540B/2542B) Shortcut buttons & Local

key (Alternate function of COUNTER button; used to

set unit to local mode when in remote mode)

(for models 2540B-GEN/2542B-GEN) Function keys

to setup arbitrary waveform generator:

MENU / GRAPH button

FREQ / CAPTURE button

AMPL / LOCAL button

ON/OFF button

13. HORIZONTAL controls

14. EXT TRIG BNC terminal

(For models 2540B-GEN/2542B-GEN) EXT TRIG and

MOD OUT BNC terminal

15. Channel 2 BNC input

16. VERTICAL controls

17. Channel 1 BNC input

18. FUNCTION buttons (for soft panel menu)

19. PRINT button

20. Probe compensation terminal

21. USB host interface (supports most USB flash drives)

22. Tilt feet (bottom)

23. (For models 2540B-GEN/2542B-GEN only) GEN

OUT BNC terminal

20

Page 21

Getting Started

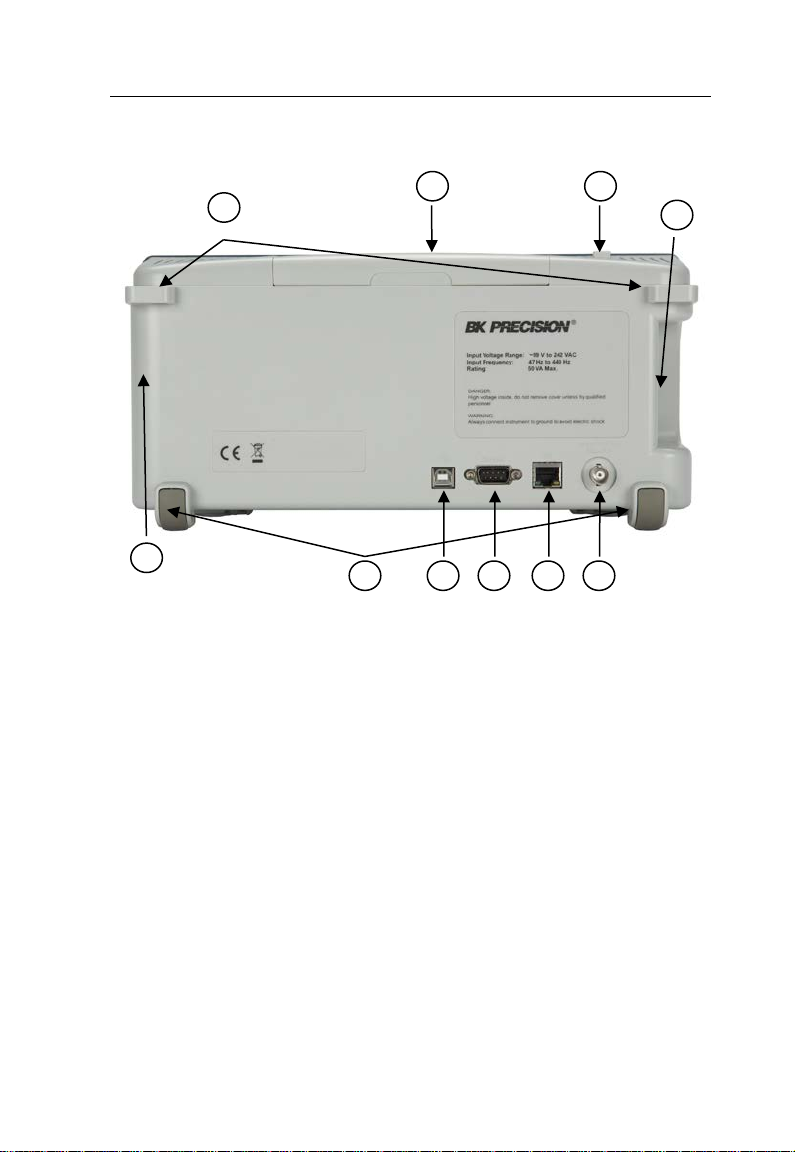

1

2 3 5 6 7 8 9

4

10

(side)

(side)

Back Panel Display

1. Security loops

2. Carrying handle

3. Power ON/OFF button

4. AC line input (side panel)

5. Pass/Fail output (isolated)

6. LAN interface port

7. RS232 serial interface port

8. USB device interface port

9. Rear rubber feet

10. Ventilation fan (side panel)

21

Page 22

Getting Started

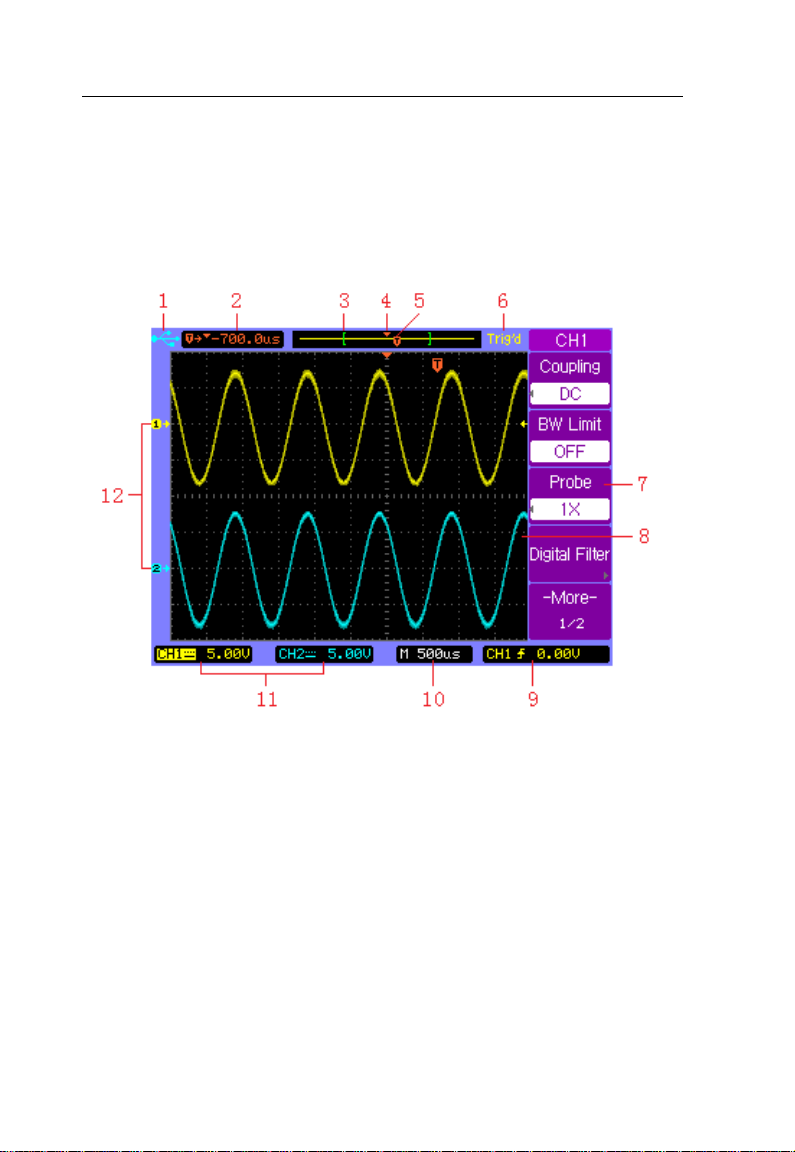

LCD Main Screen Display

The oscilloscope display contains channel acquisitions, setup

information, measurement results, and soft keys for setting

up various parameters.

1. The USB icon appears when a USB drive is inserted into

the front USB host port and ready to be used. When

instrument is in remote mode, it will display “Rmt”

indicator instead.

2. Readout showing the trigger position relative to the

horizontal center of the screen.

22

Page 23

Getting Started

3. The square brackets show the location of current display

window within the whole captured waveform. The

captured waveform color corresponds with the active

waveform color (CH1: yellow; CH2: cyan).

4. Horizontal center position icon shows the horizontal

center location within the captured waveform.

5. Trigger position icon shows the trigger location within the

record waveform.

6. Acquisition status:

AUTO – “Auto” mode.

STOP – Stop acquiring waveform data.

WAIT – Waiting to be triggered.

Trig’d – DSO has seen a trigger and is acquiring

post-trigger data.

Trig? – Looking for trigger

ROLL – When horizontal mode is set to “Roll”

7. Soft key menu which allows you to set up additional

parameters from front-panel soft keys.

8. The display area contains the waveform acquisitions,

channel identifiers, trigger and ground level indicators.

Each channel’s information appears in their respective

color.

9. Trigger readout shows trigger information such as trigger

source, trigger type as well as trigger level.

23

Page 24

Getting Started

10. Horizontal readout shows the Main or Delayed time

base.

11. Channel readouts show the scale factor, coupling,

bandwidth limit, digital filter, and invert status.

12. Waveform baseline icons show the zero-volt level of the

waveforms. The icon colors correspond to the waveform

colors.

1.5 Quick Check

Upon receiving the instrument, inspect for any noticeable

physical damages or unresponsive panel buttons. If there

are any problems, please contact B&K Precision

immediately.

Power On Check

Connect the AC Power Cord to the power input socket on the

side of the DSO. Press down the power switch button at the

top of the DSO to the ON position ( ). Verify that the

instrument turns on and the LCD screen goes into an initial

boot screen.

Press any key for the screen to load into the main screen

showing the graticule. Contact B&K Precision if the DSO

fails to load the main screen.

24

Page 25

Getting Started

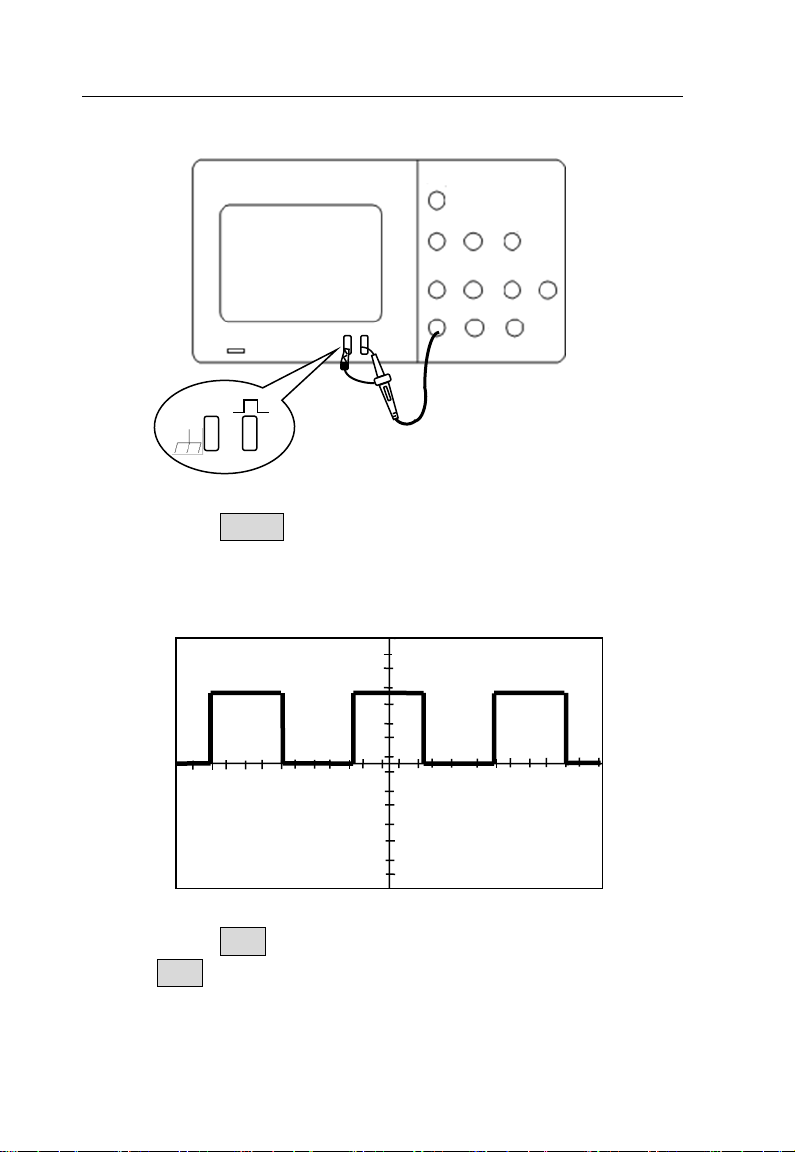

Basic Check

Please follow the steps below when checking the

oscilloscope’s functionality.

1. Power on the oscilloscope.

Press SAVE/LOAD and Select Factory to set DSO to

factory settings. The probe default attenuation is 1X.

2. Set the switch to 1X on the probe and connect the

probe to channel 1 on the oscilloscope. To do this,

align the slot in the probe connector with the key on

the CH 1 BNC, push to connect, and twist to the right

to lock the probe in place. Connect the probe tip and

reference lead to the probe compensation terminal.

25

Page 26

Getting Started

3. Press AUTO to show the 1 kHz frequency square

wave in a few seconds.

4. Press CH1 two times to cancel the channel 1, Press

CH2 to c hange screen into channel 2, reset the

channel 2 and repeat step 2 and step 3 for CH2.

26

Page 27

Getting Started

1.6 Probe Safety

A guard around the probe body provides a finger barrier for

protection from electric shock.

Connect the probe to the oscilloscope and connect the

ground terminal to ground before you take any

measurements.

Note: To avoid electric shock when using the probe,

keep fingers behind the guard on the probe body.

Note: To avoid electric shock while using the probe, do

not touch metallic portions of the probe head

while it is connected to a voltage source. Connect

the probe to the oscilloscope and connect the

ground terminal to ground before you take any

measurements.

27

Page 28

Getting Started

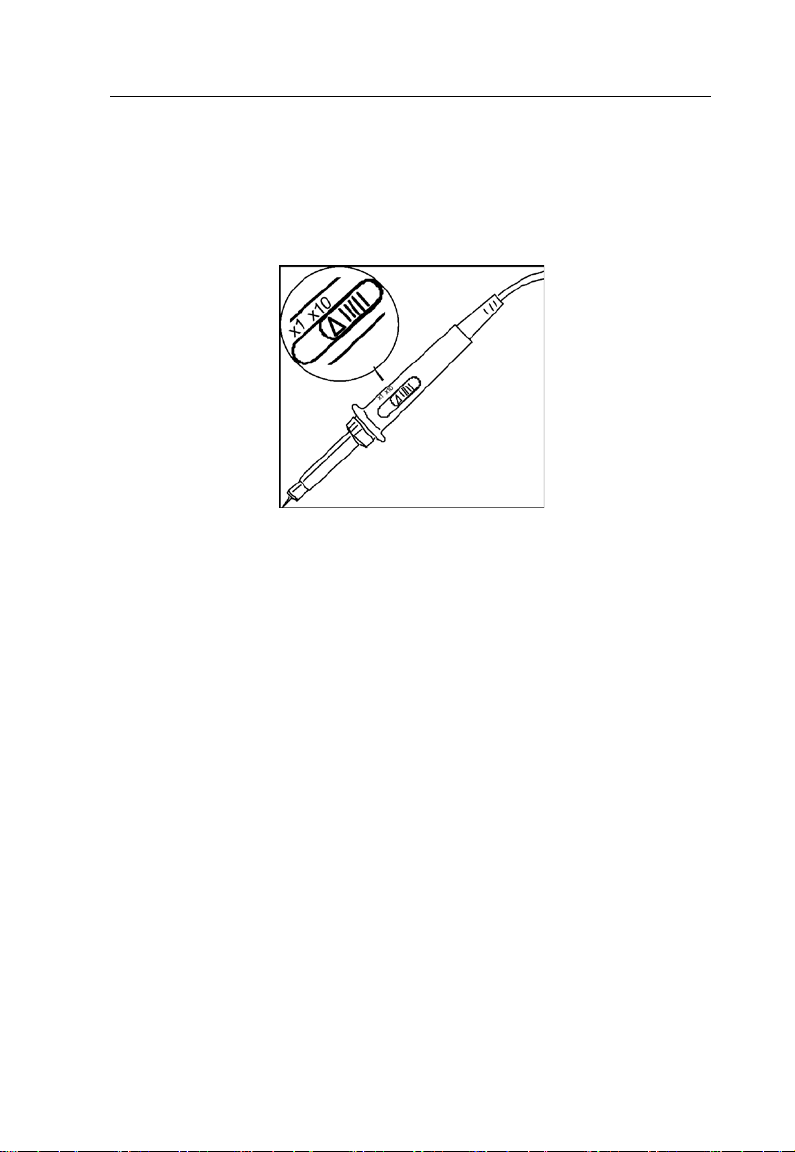

1.7 Probe Attenuation

Probes are available with various attenuation factors which

affect the vertical scale of the signal.

You can push a vertical menu button (such as the CH 1

button), and select the Probe option that matches the

attenuation factor of your probe.

Note: The default setting for the Probe option is 1X.

Be sure that the attenuation switch on the probe matches the

Probe option in the oscilloscope. The included probes can

switch between 1X and 10X.

Note: When the attenuation switch is set to 1X, the

probe limits the bandwidth of the oscilloscope to

10 MHz (according to Probe spec). To use the full

bandwidth of the oscilloscope, be sure to set the

switch to 10X.

1.8 Probe Compensation

Perform this adjustment to match your probe to the input

channel. This should be done whenever you attach a passive

28

Page 29

Getting Started

probe for the first time to any input channel. A poorly

compensated probe can introduce measurement errors.

1. Set both the probe and the oscilloscope attenuation

factor to X10 respectively.

2. Connect the oscilloscope probe to channel 1. Attach the

probe tip and reference lead to the probe compensation

terminal and to the chassis ground terminal, then press

AUTO key.

3. Use a nonmetallic tool to adjust the trimmer capaci to r on

the probe for the flattest pulse possible (see “Correct

compensation” image below). The trimmer capacitor is

located either on the probe BNC connector or above the

probe attenuation switch.

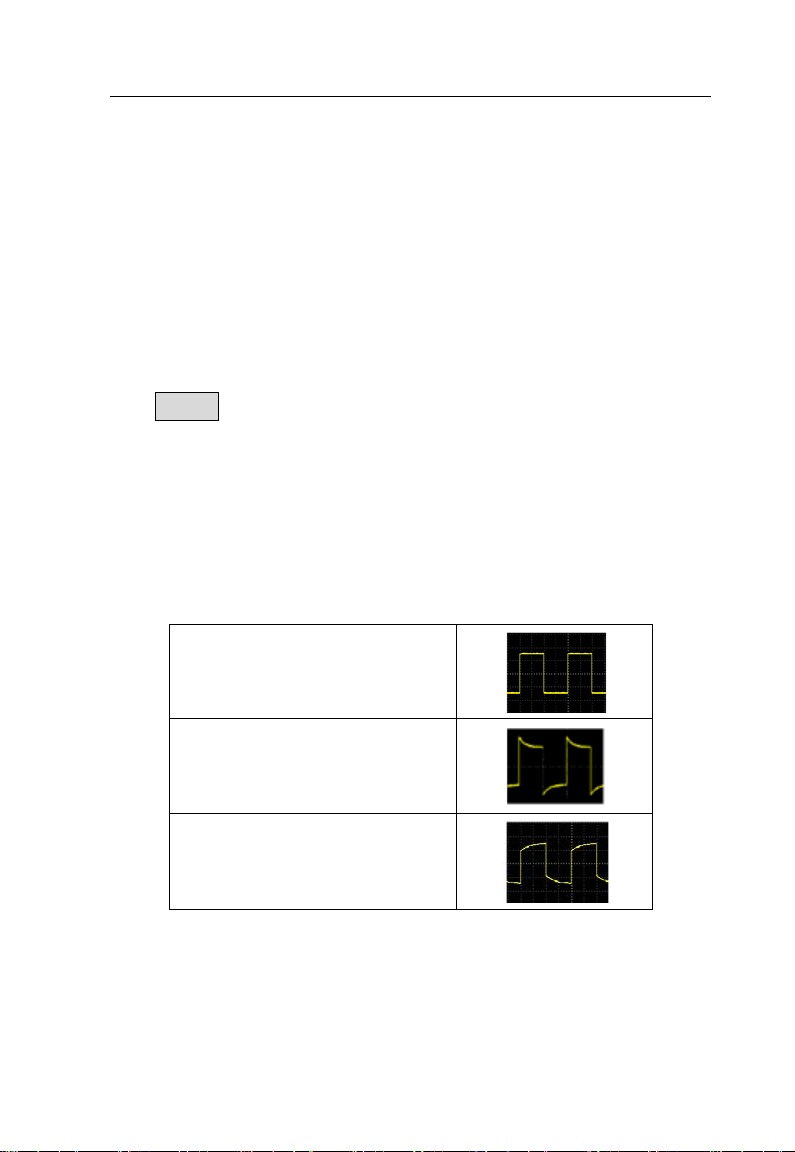

Correct compensation

Over compensated

Under compensated

4. Connect probes to channel 2. Repeat the above steps.

This matches each probe to each channel.

29

Page 30

Page 31

Basic Operation

2 BASIC OPERATION

• Using Quick Help

• Using Autoset

• Vertical Controls

• Horizontal Controls

• Trigger Controls

• RUN Controls

31

Page 32

Basic Operation

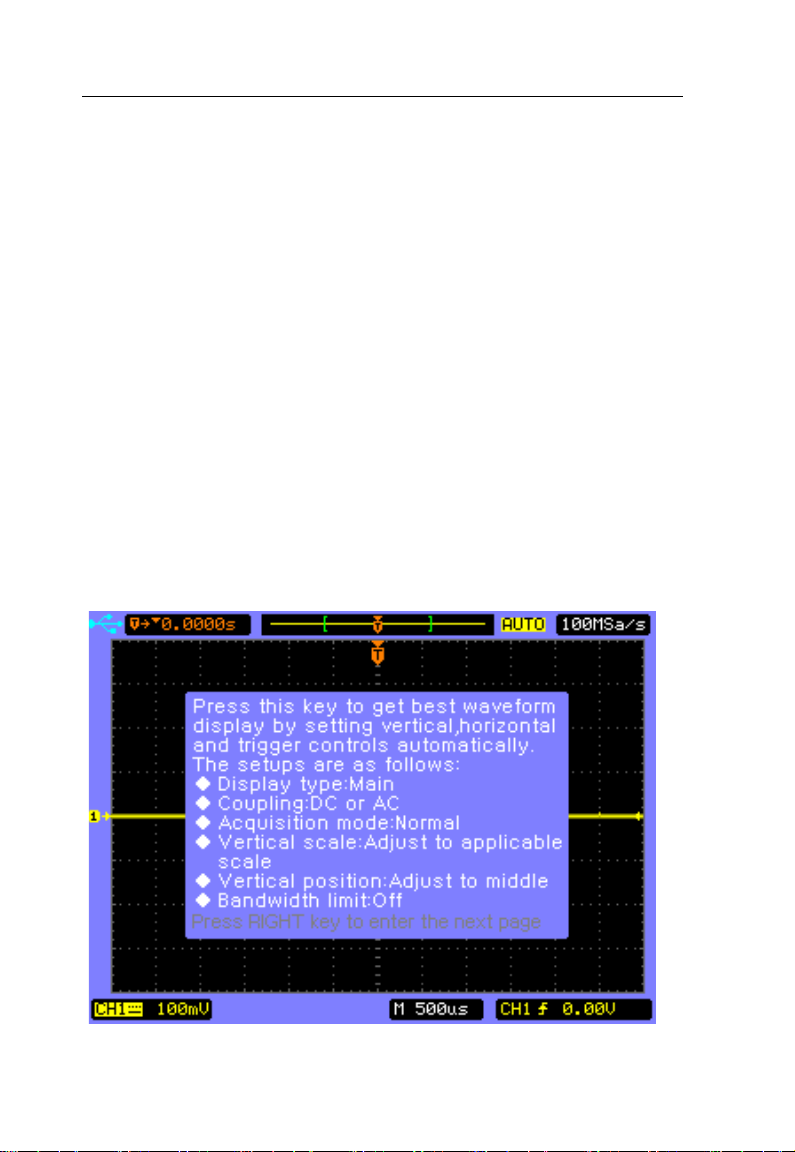

2.1 Using Quick Help

The digital storage oscilloscope has a quick help system that

provides a description of functionality for each front panel

keys and soft panel keys.

Press and hold down the key or the softkey that you want to

see help description for. The help information will display and

remain at the center of the screen as shown below until

another key is pressed or a knob is turned.

Note: Quick help is not available for CUSTOM shortcut

key. Refer to “CUSTOM Button” section for

details on its usage.

32

Page 33

Basic Operation

If there are more than one page of help information, press the

key to browse the previous or next pages.

2.2 Using Autoset

The 2540B/2542B/2540B-GEN/2542B-GEN oscilloscopes

provide an Autoset function which sets the vertical, horizontal,

and trigger controls automatically for optimal display of the

signal(s) connected at either or both CH1 and CH2.

Autoset function detects, turns on, and scales any channel

with a repetitive waveform if it meets the following

requirements:

• Frequency of at least 50Hz

• Duty cycle greater than 0.5%

• Amplitude of at least 10 mVpp

Note: Any channels that do not meet these requirements

are turned off.

When you are using more than one channel, the Autoset

function sets the vertical controls for each channel and uses

CH1 to set the horizontal and trigger controls.

To configure the oscilloscope quickly and automatically to

see connected signals, press the AUTO key. The

oscilloscope will take a few seconds to automatically set

33

Page 34

Basic Operation

various parameters. If signal is found, it will beep once and

open the AUTO menu before displaying the signal. If there

are no signals, no beep will occur and a display message will

read “No signal is found”.

To configure the oscilloscope to display multiple cycles, press

Multi-Cycle softkey in the AUTO menu.

To configure the oscilloscope to display a single cycle, press

Single Cycle softkey in the AUTO menu.

To undo the effects of Autoset, press the Undo Autoset

softkey in the AUTO menu before pressing any other key.

This is useful when you have unintentionally pressed the

AUTO key or do not like the settings Autoset has selected

and want to return to your previous settings.

34

Page 35

Basic Operation

Note: Auto set function can be disabled. See

“Appendix B: Disabling Auto Function” for details

2.3 Vertical Controls

Vertical controls

Vertical Position Knob (CH1, CH2)

Turn the small vertical position knob above the channel key

to move the channel’s waveform and its g r ound level icon ( )

up or down on the display. The voltage value momentarily

displayed (shown below) in the bottom left corner of the

display represents the voltage difference between the vertical

center of the display and the ground level ( ).

35

Page 36

Basic Operation

Press the vertical position knob to bring the channel’s

waveform and its ground level icon ( ) directly back to t he

vertical center of the display.

Vertical Scale Control (CH1, CH2)

Turn the large vertical scale k nob below the channel key to

set the scale factor for the channel. The vert ical scale knob

changes the channel scale in a 1-2-5 step sequence. The

channel scale factor value is displayed in the bottom left

portion of the display.

Press the vertical scale knob to toggle between Fine and

Coarse control. When fine is selected, you can change the

channel’s vertical sensitivity in smaller resolution. When

36

Page 37

Basic Operation

coarse is selected, the vertical scale knob changes the

channel scale in a 1-2-5 step sequence.

Channel Keys CH1, CH2

Press the channel key from the front panel to display the

channel’s menu and turn the display of the channel on or off.

The channel is displayed when the key is illuminated.

The channel menu of a channel must be displayed first

before you can turn off the channel. For example, suppose

CH1 and CH2 are both displayed and the CH2 menu is also

displayed. In order to turn CH1 off, you should press the CH1

key fir st to show CH1 menu on the display, then press CH1

key again to turn off CH1.

CH1, CH2 Menu

Press the channel key CH2 to display the channel’s menu

and turn on the channel display.

Channel Coupling

Press the channel key CH2, then press the Coupling softkey

to select AC coupling mode.

AC coupling places a high pass filter in series with the input

signal that blocks the DC component of the input signal. AC

coupling is useful for viewing waveforms with large DC

offsets.

37

Page 38

Basic Operation

AC Coupling

Press the channel key CH2, then press the Coupling softkey

again to select DC coupling mode.

DC coupling passes both AC and DC components of the

input signal. DC coupling is useful for viewing low frequency

waveforms that do not have large DC offsets.

DC Coupling

38

Page 39

Basic Operation

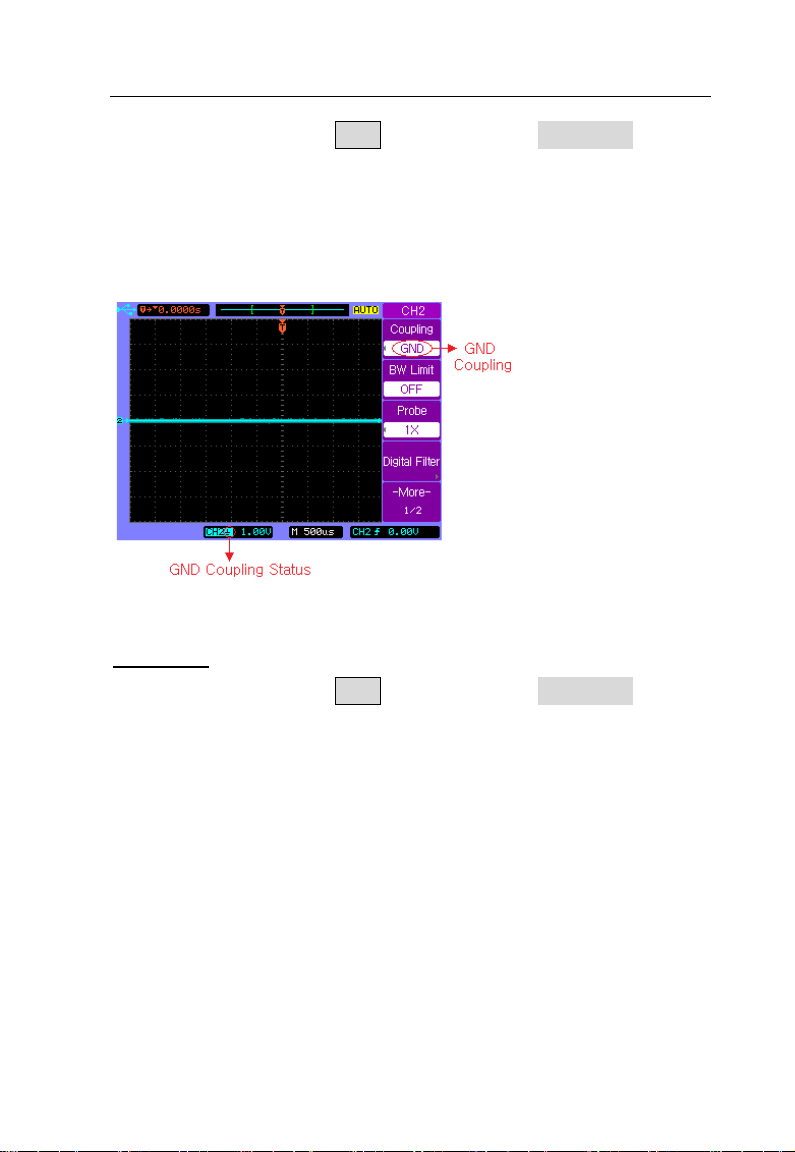

Press the channel key CH2, then press the Coupling softkey

until GND coupling is selected.

GND mode blocks both AC and DC components of the input

signal and connect the input to the ground level.

GND Coupling

BW Limit

Press the channel key CH2, then press the BW Limit softkey

to turn the bandwidth limit on or off for the selected channel 2.

When it is off, it passes both the high and low frequency

components.

39

Page 40

Basic Operation

BW Limit off

When it is on, the maximum bandwidth for the channel is

approximately 20 MHz. For waveforms with frequencies

below this, turning bandwidth limit on removes unwanted high

frequency noise from the waveform.

BW Limit on

40

Page 41

Basic Operation

Probe Attenuation Setting

Probes are available with various attenuation factors which

affect the vertical scale of the signal. You can manually select

the factor that matches the attenuation of your probe.

For example, to match a probe set to 10X connected to CH2,

press the channel key CH2, and then press the Probe

softkey and select 10X.

Press the Probe softkey again and select 1X when a probe

with 1:1 attenuation factor is connected to CH2.

Set Probe Attenuation Factor to 1X

41

Page 42

Basic Operation

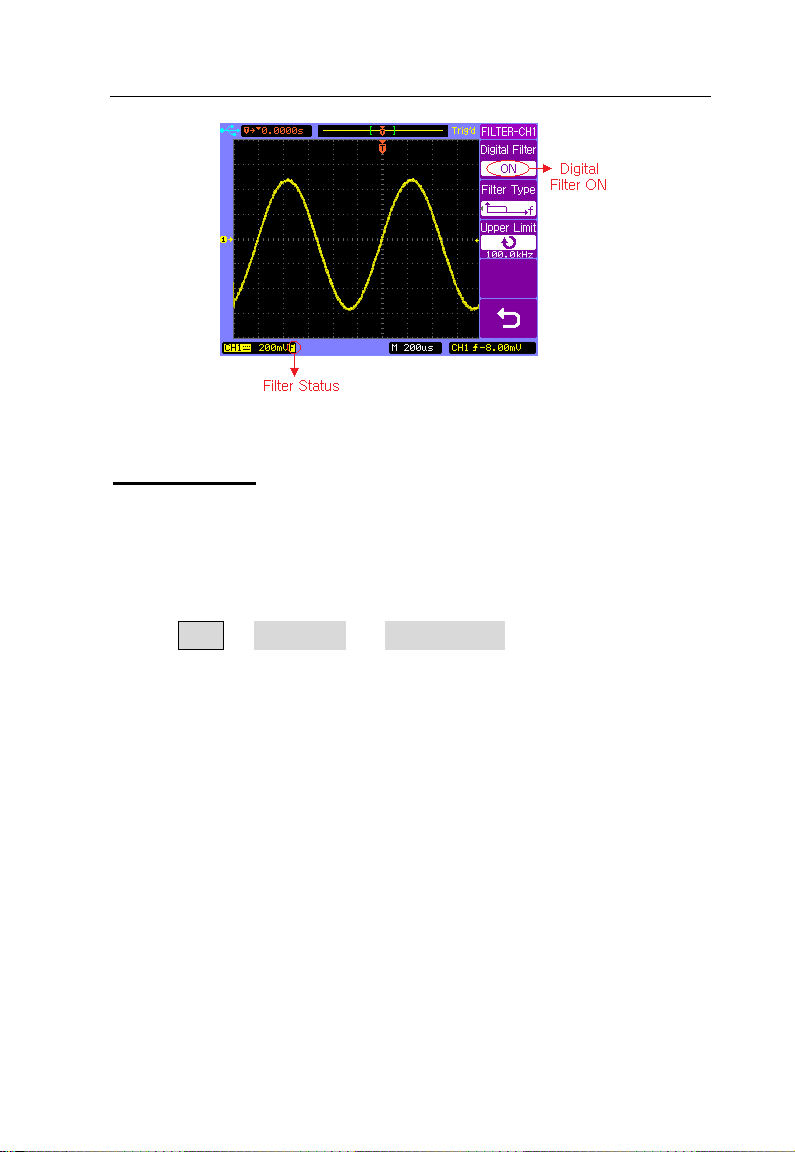

Digital Filter

Each channel has built-in digital filters that can be applied to

the connected signal.

Press the channel key CH1, then press the Digital Filter

softkey to display the FILTER-CH1 menu. Four kinds of f ilter

types are available:

1. Low pass filter

2. High pass filter

3. B and pass filter

4. B and block filter

Press the Upper Limit or Lower Limit softkey and then

adjust the Entry knob to set the high and/or low

frequency range for the filter.

Digital Filter is off

42

Page 43

Basic Operation

Digital Filter is on

Vertical Scale

Turn the large vertical scale knob below the channel key to

set the scale factor for the channel. The channel scale factor

value is displayed in the bottom left portion of the display.

Press CH2→ More 1/2 → Volts Scale to select Coarse or

Fine adjustment. You can also press the large vertical scale

knob to toggle between Fine and Coarse. When Coarse is

selected, the vertical scale knob changes the channel scale

in a 1-2-5 step sequence. When Fine is selected, the vertical

scale knob changes the channel scale in a smaller resolution.

43

Page 44

Basic Operation

Fine Vertical Scale

Vertical Invert

Press CH2→ More 1/2 → Invert to set Invert on or off. When

Invert is turned on, the voltage values of the displayed

waveform are inverted. Invert affects how a channel is

displayed, but does not affect triggering. If the oscilloscope is

set to trigger on a rising edge, it remains set to trigger on the

same edge after the channel is inverted.

Inverting a channel will also change the result of any math

function selected in the MATH menu or any measurement.

44

Page 45

Basic Operation

Vertical Invert off

Vertical Invert on

45

Page 46

Basic Operation

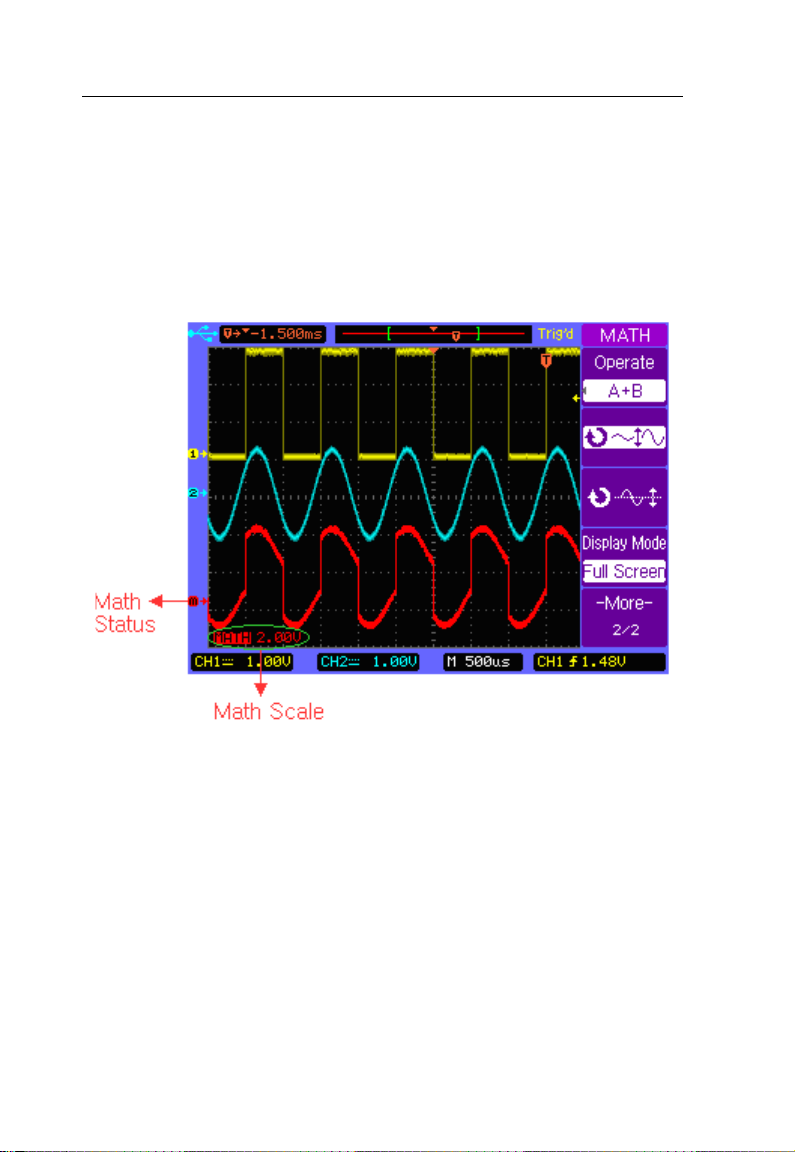

MATH Functions

Dual Waveform Calculation

Press MATH channel key to turn on the MATH menu, p age

½.

Softkey Options Description

A+B Add A and B

Operate

Source A

Source B

Invert

More 1/2

A-B Subtract B from A

A X B Multiply A by B

FFT Access FFT menu

CH1 Select CH1 as Source A

CH2 Select CH2 as Source A

CH1 Select CH1 as Source B

CH2 Select CH2 as Source B

ON Math invert ON

OFF Math invert OFF

---- Select page 2/2

46

Page 47

Basic Operation

Display Math waveform

Press softkey More 1/2 to display MATH menu page 2/2.

Softkey Options Description

A+B Add A and B

Operate

Display

Mode

More 2/2

A-B Subtract B from A

A X B Multip ly A by B

FFT Access FFT menu

Split

Screen

Full

Screen

---- Select page 1/2

Vertical scale control

Vertical position control

Split the display into Main

and Math sections

in full screen

47

Page 48

Basic Operation

Example:

Select the A+B math function, then select CH1 as the Source

A, and select CH2 as the Source B. The resulting math

waveform will look like below:

Math A+B

48

Page 49

Basic Operation

FFT Spectrum Analysis

You can use the FFT function to measure harmonic

components and distortion in systems, to characterize noise

in DC power supplies, and to analyze vibration.

Press MATH channel key to turn on the MATH menu page

1/2, and then press Operate softkey to select FFT. The FFT

menu page 1/2 will be displayed.

Softkey Options Description

A+B Add A and B

Operate

A-B Subtract B from A

A X B Multiply A by B

FFT Access FFT menu

CH1 Select CH1 for FFT

Source

CH2 Select CH2 for FFT

Rectangular Use Rectangular window

Window

Scale

More 1/2

Hanning Use Hanning window

Hamming Use Hamming window

Blackman Use Blackman window

Flattop Use Flattop window

Vertical scale in dBV

dBV RMS

RMS

V RMS Vertical scale in V RMS

---- Select page 2/2

49

Page 50

Basic Operation

Softkey

Options

Description

More 2/2

Press softkey More 1/2 to display FFT menu page 2/2.

A+B Add A and B

Operate

A-B Subtract B from A

A X B Multip l y A by B

FFT Access FFT menu

Split

Display

Mode

Screen

Full

Screen

---- Select page 1/2

Vertical scale control

Vertical position control

Split the display into Main

and Math sections

Display Math waveform in

full screen

50

Page 51

Basic Operation

Example:

Select CH1 as the Source for FFT, select Rectangular

Window, set Scale to dBV RMS, and then the FFT waveform

will look like below. You can also measure the amplitude and

frequency of the corresponding point with the manual cursors

(See “

CURSOR Menu”).

FFT Spectrum Analysis

51

Page 52

Basic Operation

REF Function

The REF function allows users to store and recall a waveform

as a reference. This is useful for comparing and analyzing

signals from different systems.

Press REF channel key to turn on the REF menu, page 1/2.

Softkey Options Description

Source

CH1 Save CH1 as reference

CH2 Save CH2 as reference

Volts

Scale

Coarse Coarse vertical scaling

Fine Fine vertical scaling

More

1/2

---- Select page 2/2

REF vertical scale control

REF vertical position control

52

Page 53

Basic Operation

2/2

Press softkey More 1/2 to display REF menu, page 2/ 2.

Softkey Options Description

Invert

ON REF invert ON

OFF REF invert OFF

Internal

Storage

External

Storage

INTERNAL

menu

EXTERNAL

menu

Save the reference

waveform to the

internal memory

Save the reference

waveform to the

USB mass storage

device

More

---- Select page 1/2

Press REF channel key to turn on the REF m enu page 1/2,

press softkey More 1/2 to display REF menu page 2/2. Load

the latest saved reference waveform from the internal

memory by selecting Internal Storage or locate and load

reference waveform file from the external memory by

selecting External Storage.

You can use the horizontal position and scale control knob to

change the time base of the reference waveform.

53

Page 54

Basic Operation

Press or softkey and turn the Entry knob

to change the vertical scale or position of the reference

waveform.

Press REF→ Internal Storage → Save to save the

waveform of the Source channel as the reference waveform

to the internal memory.

Save a Reference waveform

Note: The reference waveform function is unavailable

when X-Y mode is selected.

54

Page 55

Basic Operation

2.4 Horizontal Controls

Use the horizontal controls to adjust the time base, adjust the

trigger location, and to examine waveform details more

closely.

Horizontal Controls

55

Page 56

Basic Operation

Horizontal Position Control

When the oscilloscope is running, this control lets you set the

acquisition window relative to the trigger point. When the

oscilloscope is stopped, you can turn this knob to pan

through the data horizontally. This lets you see the captured

waveform before the trigger or after the trigger.

The trigger position is marked with the indicator “ ” at the top

of the graticule and also in the waveform record data icon at

the top of the screen.

The small inverted triangle () is the time reference indicator.

When you change the horizontal scale, the waveforms

contract or expand about this point.

Press the horizontal position control knob key to set the time

delay to zero, and the trigger position indicator ( ) will move

right below the time reference indicator().

Note: The horizontal position control is unavailable

when X-Y horizontal mode is selected.

Horizontal Scale Control

Use the horizontal scale control to adjust the time base. The

scale expands or contracts around the center of the screen.

The horizontal scale factor can be set in a 1-2-5 sequence.

56

Page 57

Basic Operation

Softkey

Options

Description

1/2

Press the horizontal scale control knob to toggle between

Main and Delayed horizontal display mode.

Horizontal MENU key

Press the horizontal MENU k ey to display the HORIZONTAL

menu. This menu lets you select t he horizontal mode: Main,

Delayed, Roll, or X-Y.

Press the horizontal MENU k ey to display the HORIZONTAL

menu page 1/2.

Main

Delayed

X-Y

Roll

-More-

√ Main mode is ON

---- Main mode is OFF

√ Delayed mode is ON

---- Delayed mode is OFF

√ X-Y mode is ON

---- X-Y mode is OFF

√ Roll mode is ON

---- Roll mode is OFF

---- Select page 2/2

57

Page 58

Basic Operation

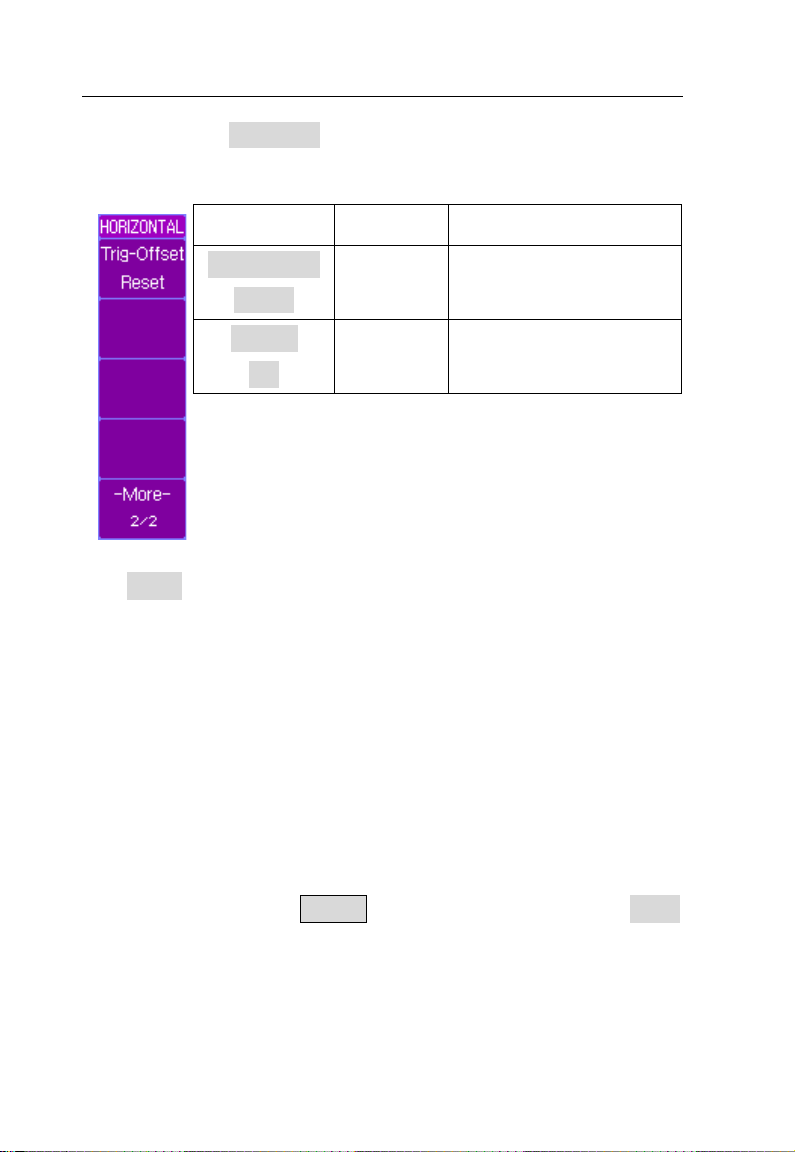

Reset the delay time

Press softkey More 1/2 to display the HORIZONTAL menu

page 2/2.

Softkey

Trig-Offset

Reset

-More2/2

Options Description

---to zero

---- Select page 1/2

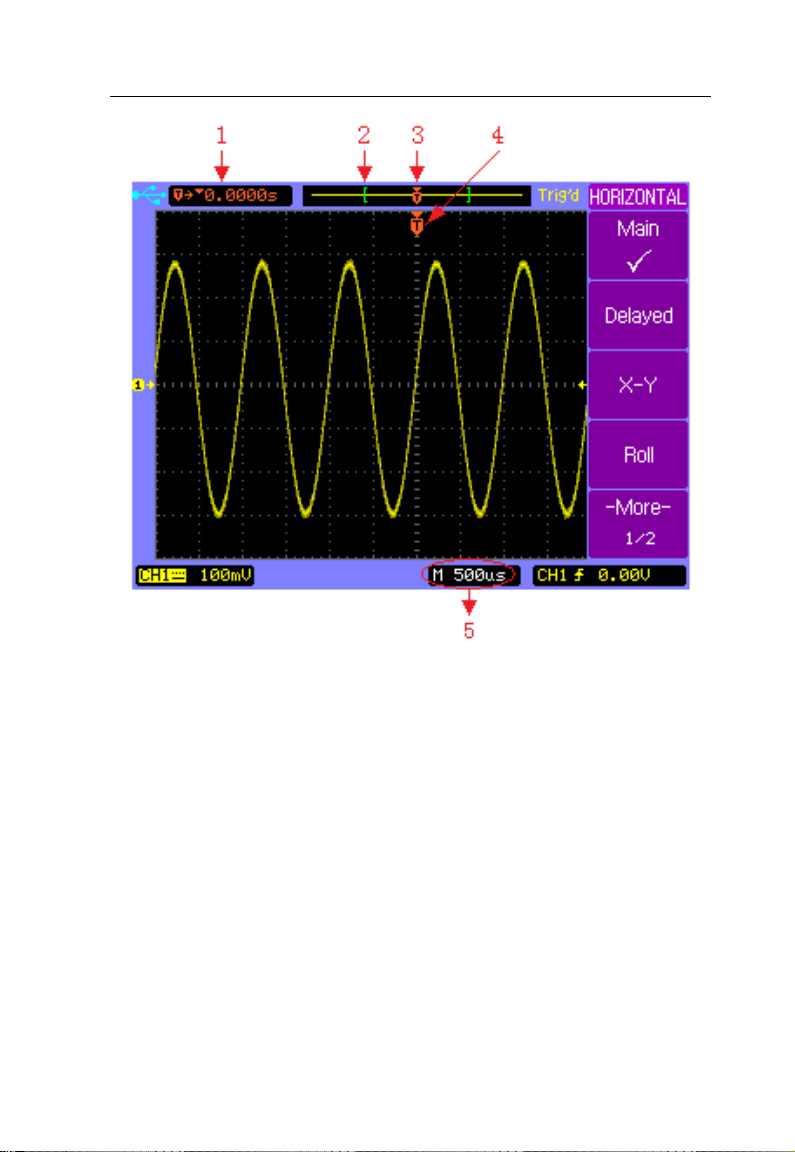

Main - Horizontal Mode

Main horizontal mode is the normal viewing mode for the

oscilloscope. When the oscilloscope is stopped, you can use

the horizontal controls to pan and zoom the waveform. When

the oscilloscope is running in Main mode, use the horizontal

scale knob to change horizontal scale factor and use the

horizontal position knob to set the delay time. The time

base (second/division) value is displayed at the bo ttom of the

screen.

Press the horizontal MENU key and then press the Main

softkey to select the main horizontal mode.

58

Page 59

Basic Operation

Main Horizontal Mode

1. Readout shows the delay time or the trigger location

within the record data relative to the time reference point

().

2. The square brackets show the location of current display

window within the record data.

3. Trigger position within the record data.

4. Trigger position on the current waveform display window.

5. Main time base.

59

Page 60

Basic Operation

Delayed - Horizontal Mode

Delayed horizontal mode is an expanded version of main

mode. When Delayed mode is selected, the display divides i n

half. The top half of the display shows the normal waveform

and bottom half displays the delayed waveform.

Delayed waveform is a magnified portion of the normal

waveform. You can use delayed waveform to locate and

horizontally expand part of the normal waveform for a more

detailed analysis of signals.

The area of the normal display that is expanded is marked on

each end with a vertical shaded area. The unshaded area

shows what portion of the normal waveform is expanded in

the lower half.

To change the time base for the delayed window, turn the

horizontal scale knob. As you turn the knob, the time base for

the delayed window is displayed just above the main time

base.

To change the time base for the normal window, press the

Main softkey, then turn the horizontal scale control knob.

Connect a triangle signal source to CH1, press the horizontal

MENU k ey and then press the Delayed softkey to enter the

Delayed mode. You can also press the horizontal scale

60

Page 61

Basic Operation

control knob key to toggle between Main and Delayed mode

directly.

Delayed Horizontal Mode

61

Page 62

Basic Operation

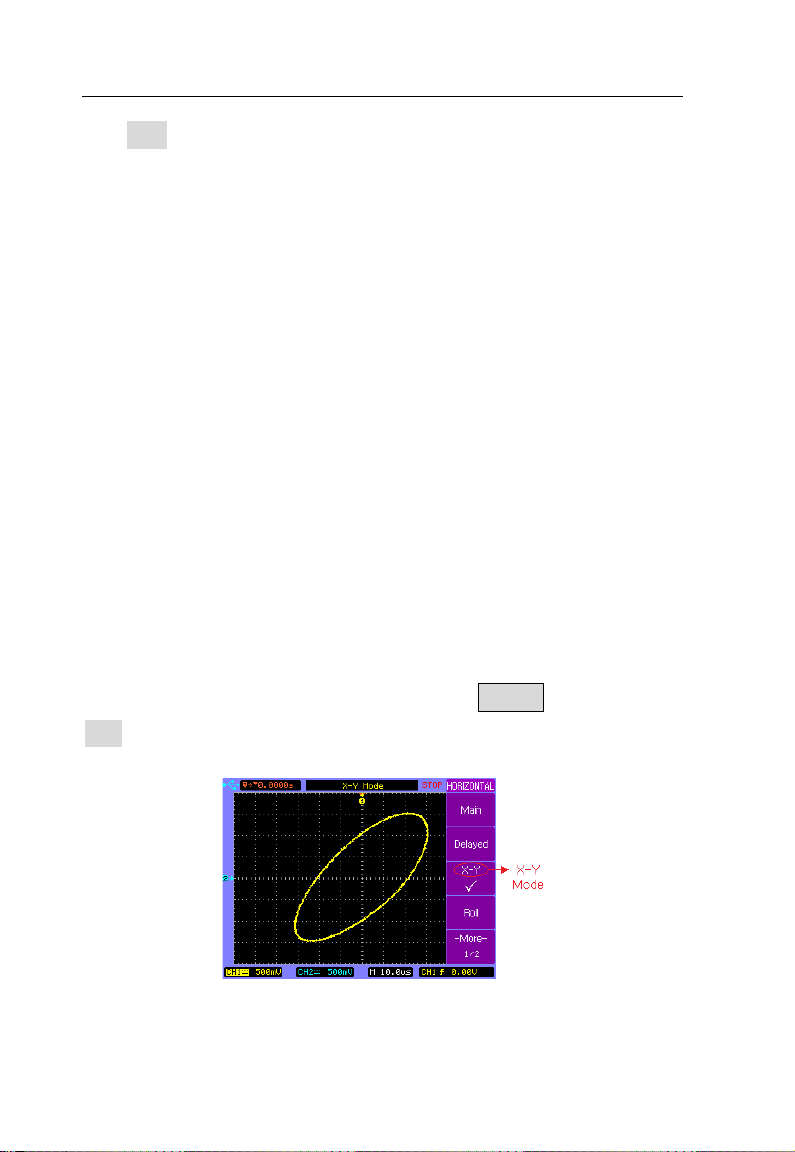

X-Y Horizontal Mode

X-Y mode changes the display from a volts-versus-time

display to a volts-versus-volts display. The time base is

turned off. CH1 amplitude is plotted on the X axis and CH2

amplitude is plotted on the Y axis.

You can use X-Y mode to compare frequency and phase

relationships between two signals. X-Y mode can also be

used with transducers to display strain versus displacement,

flow versus pressure, voltage versus current, or voltage

versus frequency.

In order to get a better view of the waveform, proper vertical

scale should be selected before selecting the X-Y mode.

Use X-Y mode to compare two signals with the same

frequency and different phase. Connect the two si gnal to CH 1

and CH2 respectively. Press horizontal MENU key and then

X-Y softkey to select X-Y mode.

X-Y Horizontal Mode

62

Page 63

Basic Operation

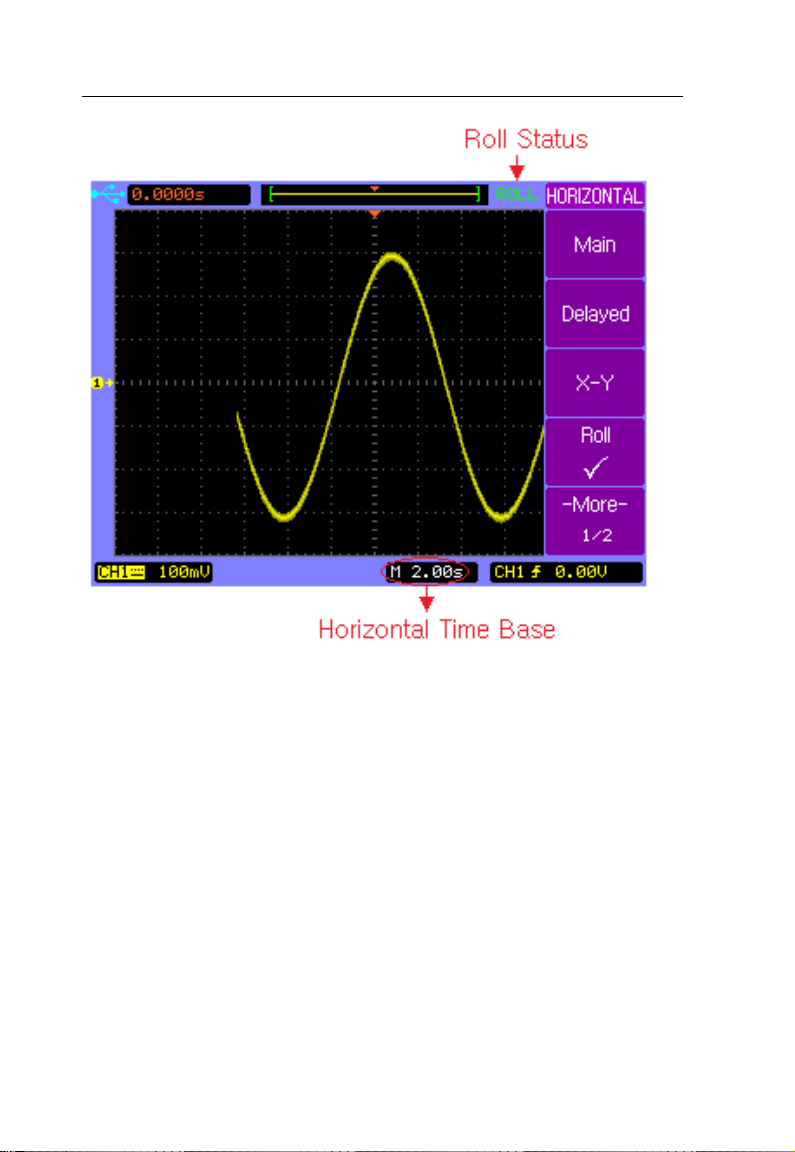

Roll - Horizontal Mode

Roll mode causes the waveform to move slowly across the

screen from right to left.

Note: It only operates on time base settings of 500

ms/div or slower. If the current time base setting

is faster than the 500 ms/div limit, it will be set to

500 ms/div when Roll mode is selected.

In Roll mode there is no trigger. The fixed reference point on

the scr een is the right edge of the scr een and refers to t he

current moment in time. Events that have occurred are

scrolled to the left of the reference point. Since there is no

trigger, no pre-trigger information is available.

If you would like to pause the display after a full screen of

acquisition in Roll mode, pres s t he SINGLE key. To clear the

display and restart another full screen acquisition in Roll

mode, press the SINGLE key again.

Press the horizontal MENU key and then press the Roll

softkey to select the Roll mode. The waveform will move

slowly across the screen from right to left.

The fastest time base is 500 ms in roll mode.

63

Page 64

Basic Operation

Roll Horizontal Mode

64

Page 65

Basic Operation

2.5 Trigger Controls

The trigger controls determine when the oscilloscope starts to

acquire and display the waveform. When a trigger is found,

the oscilloscope will acquire sufficent data to display the

waveform.

Note: Trigger controls are functional when the

oscilloscope works under Main or Delayed

horizontal mode.

Trigger Controls

65

Page 66

Basic Operation

Trigger Control MENU key

Press the trigger control MENU key to show the TRIGGER

menu and then press the Type softkey to select Edge, Pulse

or Video.

Set to 50% key

Press the 50% key to set the trigger level to the 50%

amplitude level of the trigger source waveform.

Force Trigger key

Press the FORCE key to force an immediate trigger event,

even in the absence of a signal. This function is useful in

following situations :

If you do not see a waveform on the screen when using

Normal trigger mode, press the FORCE key to acquire the

signal baseline to verify that it is on the screen.

After you press the SINGLE k ey to set up for a single shot

acquisition, you can press the FORCE key to test and verify

the control settings.

Trigger Level Control

Use the trigger level control knob to adjust the trigger level.

When you change the trigger level, a horizontal red line

temporarily appears to show you the level position on screen.

66

Page 67

Basic Operation

After the line disappears, the trigger level is marked with a

small left arrow.

Auto and Normal Trigger Modes

Press the trigger MENU key to display the TRIGGER menu

and press the Mode softkey to select Auto or Normal trigger

mode.

Auto mode

Use the auto trigger mode for signals other than

low-repetitive-rate signals and for unknown signal levels. To

display a DC signal, you must use Auto trig ger mode since

there is no edge to trigger on.

When you press RUN/STOP key to start acquiring, the

oscilloscope first fill the pre-trigger buffer. It starts to search

for a trigger after the pre-trigger buffer is filled, and continues

to flow data through this buffer whi le it searches for the tri gger.

While searching for the trigger, the oscilloscope overflows the

pre-trigger buffer; the first data put into the buffer is the first

pushed out. When a trigger is found, the pre-trigger buffer will

contain the events that occurred just before the trigger. If no

trigger is found, the oscilloscope generates a trigger and

displays the data as though a trigger had occurred. In this

case, the background of the Auto indicator at the top of the

67

Page 68

Basic Operation

display will flash, indicating that the oscilloscope is force

triggered.

When you press the SINGLE key, the oscilloscope will fill the

pre-trigger buffer, and continue to flow data through the

pre-trigger buffer until the Auto trigger overrides the search

and forces a trigger. At the end of the trace, the oscilloscope

will stop and display the results.

Normal mode

Use Normal trigger mode for low repetitive-rate signals or

when Auto trigger is not required.

In Normal mode the oscilloscope must fill the pre-trigger

buffer with data before it will begin searching for a trigger

event. While searching for the trigger, the oscilloscope

overflows the pre-trigger buffer; the first data put into the

buffer is the first pushed out.

When the trigger event is found, the oscilloscope will fill the

post-trigger buffer and display the results. If the acquisition

was initiated by RUN/STOP, the process repeats. If the

acquisition was initiated by SINGLE, then the acquisition

stops.

In either Auto or Normal mode, the trigger may be missed if

the oscilloscope’s pre -tr igger buffer is not full yet.

68

Page 69

Basic Operation

Holdoff Function

Holdoff sets the amount of time that the oscilloscope will wait

before re-initializing the trigger circuit. You can use the

holdoff function to stabilize the display of complex waveforms.

With the holdoff function, you can synchronize triggers. The

oscilloscope will trigger on one edge of the waveform, and

ignore further edges until the holdoff time is up. The

oscilloscope will then re-initialize the trigger circuit to wait for

the next edge trigger. This allows the oscilloscope to trigger

on a repeating pattern in a waveform.

Turn the Entry knob to increase or decrease the trigger

hold off time shown in the Holdoff softkey. To get a stable

trigger on the pulse burst shown on the screen, set the

holdoff time to be slightly less than the period of the pulse

burst.

Holdoff Function

69

Page 70

Basic Operation

Video

Video triggering

Edge

Edge triggering

Pulse

Pulse width triggering

CH1

Trigger on CH1

CH2

Trigger on CH2

AC Line

Trigger on AC line signal

gger even without a

valid event

Trigger only on a valid

event

Trigger

Setup

Select trigger SETUP

menu.

Edge Trigger

Use the Edge triggering to trigger on the rising or falling edge

of the input signal at the trigger threshold.

Press trigger control MENU key to display the TRIGGER

menu, then press Type softke y to select E dge trigger.

Softkey Options Description

Type

EXT Trigger on EXT

Source

EXT/5 Trigger on EXT/5

Slope

Mode

Alternating

Auto

Normal

----

70

Trigger on CH1 and

CH2 alternately

Rising edge of a signal

Falling edge of a signal

Tri

Page 71

Basic Operation

Note: (For models 2540B-GEN and 2542B-GEN only)

When Source is set to EXT or EXT/5, the EXT

TRG/MOD OUT BNC terminal will function as an

external trigger terminal. When Source i s set to

all other options, the same terminal will function

as the modulation waveform output that is par t of

the built-in arbitrary waveform generator.

Pulse Width Trigger

Pulse width triggering sets the oscilloscope to trigger on a

positive or negative pulse of a specified width from 20 ns to

10 s.

Press trigger control MENU key to display the TRIGGER

menu page 1/2, then press Type softkey to select Pulse

trigger.

Softkey Options Description

Video Video triggering

Type

Edge Edge triggering

Pulse Pulse width triggering

CH1 Trigger on C H1

CH2 Trigger on C H2

EXT Trigger on EXT

Source

EXT/5 Trigger on EXT/5

Alternating

CH1 and CH2

alternately

71

Page 72

Basic Operation

Setup

Positive greater than

Positive equal

Positive within

Pulse

Mode

Positive less than

Negative greater than

Negative equal

Negative within

Negative less than

Pulse

Set the pulse width

More 1/2

---- Select page 2/2

Note: (For models 2540B-GEN and 2542B-GEN only)

When Source is set to EXT or EXT/5, the EXT

TRG/MOD OUT BNC terminal will function as an

external trigger terminal. When Source i s set to

all other options, the same terminal will function

as the modulation waveform output that is part of

the built-in arbitrary waveform generator.

Press trigger control MENU key to display the TRIGGER

menu, press Type softkey to select Pulse trigger and then

press the More 1/2 softkey to display TRIGGER menu p age

2/2.

72

Page 73

Basic Operation

en without a

Trigger only on a valid

Select trigger SETUP

Softkey Options Description

Video Video tr igger ing

Type

Edge Edge triggering

Pulse Pulse width triggering

Auto

Mode

Normal

Trigger

Setup

More

2/2

Trigger ev

valid event

event

---menu

---- Select page 1/2

73

Page 74

Basic Operation

Trigger on CH1 and

More 1/2

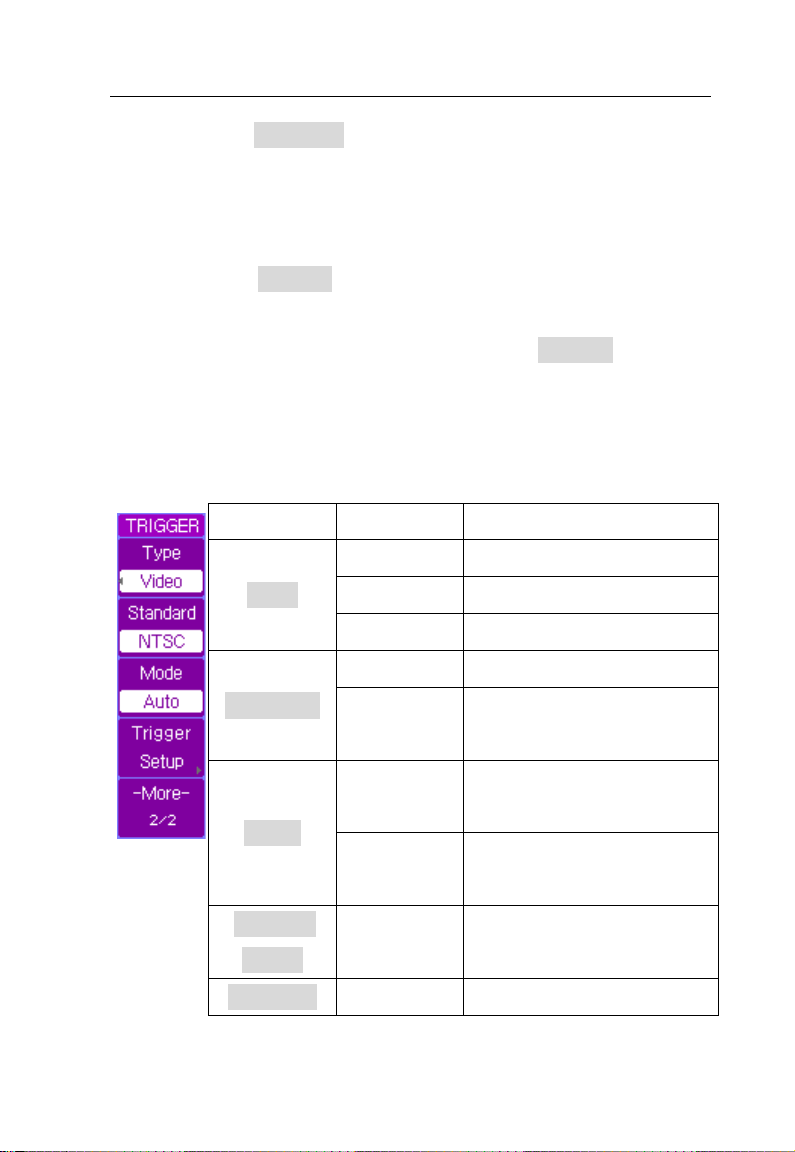

Video Trigger

Choose video triggering to trigger on the odd fields, even

fields, or on all the lines of a NTSC or PAL/SECAM video

signal.

Press trigger control MENU key to display the TRIGGER

menu, then press Type softkey to select Video trigger.

Softkey Options Description

Video Video triggering

Type

Source

Polarity

Sync

Edge Edge triggering

Pulse Pulse width triggering

CH1 Trigger on CH1

CH2 Trigger on CH2

EXT Trigger on EXT

EXT/5 Trigger on EXT/5

Alternating

Odd Field Trigger on odd fields

Even Field Trigger on even fields

All Lines Trigger on all lines

Line # Trigger on specific line

---- Select page 2/2

CH2 alternately

Positive polarity

Negative polarity

74

Page 75

Basic Operation

PAL/SECAM

Trigger on PAL or

Trigger only on a valid

Trigger even without a

Select trigger SETUP

More 2/2

Press softkey Mo re 1/2 to display the TRIGGER menu page

2/2.

Note: (For models 2540B-GEN and 2542B-GEN only)

When Source is set to EXT or EXT/5, the EXT

TRG/MOD OUT BNC terminal will function as an

external trigger terminal. When Source i s set to

all other options, the same terminal will function

as the modulation waveform output that is part of

the built-in arbitrary waveform generator.

Softkey Options Description

Video Video t r iggering

Standard

Type

Mode

Trigger

Setup

Edge Edge triggering

Pulse Pulse width triggering

NTSC Trigger on NTSC signal

SECAM signal

Normal

event

Auto

valid event

---menu

---- Select page 1/2

75

Page 76

Basic Operation

Softkey

Options

Description

by turning the entry

Set up the holdoff time

Reset

eturn to the TRIGGER

Press softkey Trigger Setup from the TRIGGER menu page

2/2 to display the trigger SETUP menu.

Set the trigger sensitivity

Sensitivity

knob

AC AC coupling

DC

DC coupling

Coupling

LF Reject Reject low frequencies

Holdoff

HF Reject

Reject high frequencies

between two consecutive

triggers

Holdoff

Reset the holdoff ti me to

---default value 100 ns

R

---menu

Note: There will be no coupling menu item when video

trigger mode is selected in the trigger SETUP

menu.

76

Page 77

Basic Operation

The following figures show the video wavef orms trigg ered on

odd fields and on a specific line 6.

Trigger on odd fields

Trigger on specific line 6

77

Page 78

Basic Operation

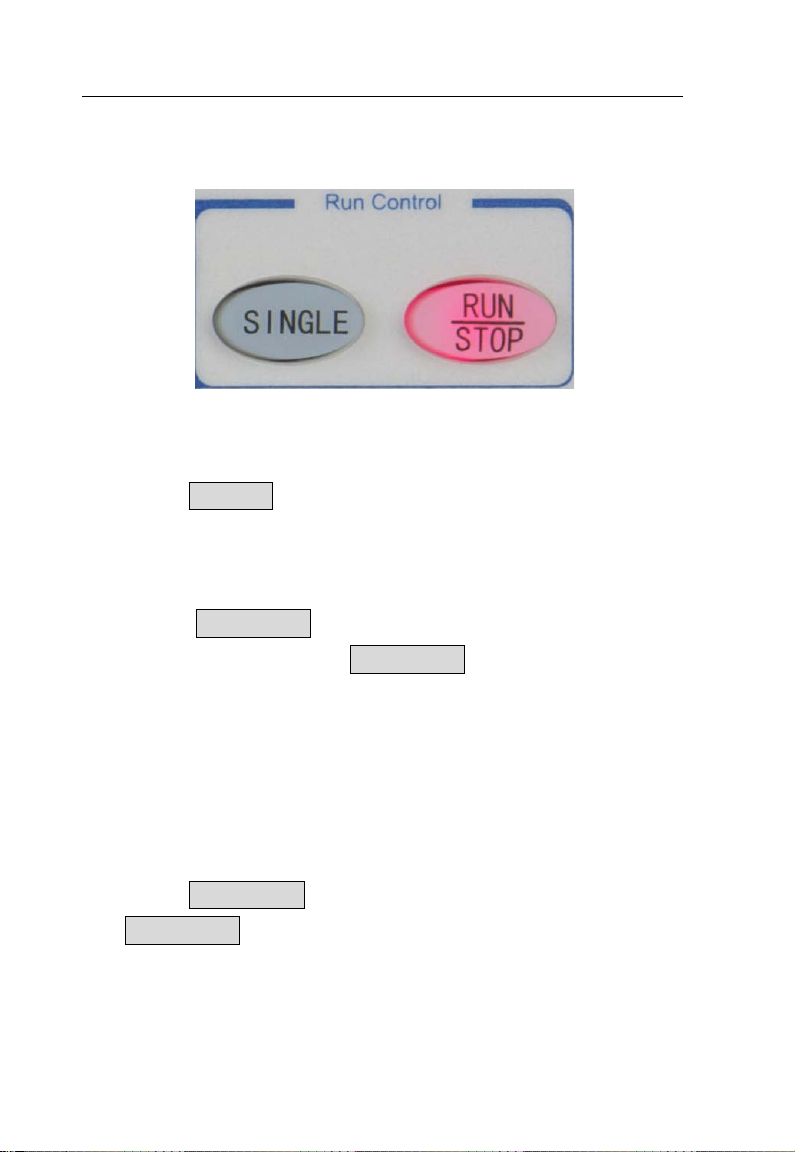

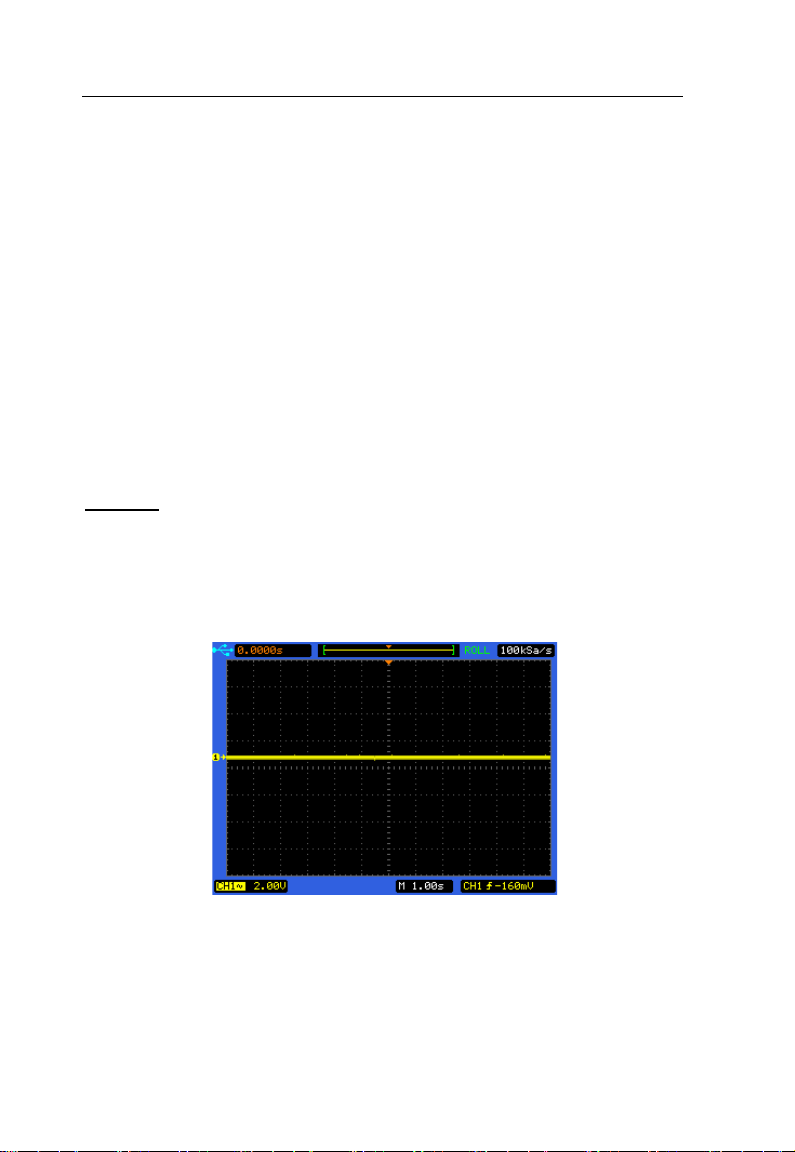

2.6 RUN Controls

Run controls

Press the SINGLE key to execute a single-shot acquisition.

The key will illuminate in orange until the oscilloscope is

triggered.

Press the RUN/STOP key to make the oscilloscope start

looking for a trigger. The RUN/STOP key will illuminate in

green. When the trigger mode is set to Normal mode, the

display will not update until a trigger is found. If the trigger

mode is set to Auto mode, the oscilloscope looks for a trigger,

and if no trigger is found, it will be triggered automatically and

the waveform of input signals will be shown immediately.

Press the RUN/STOP key again to stop acquiring data and

the RUN/STOP key will illuminate in red. Now you can pan

across and zoom in on the acquired waveform.

78

Page 79

Menu Operation

3 MENU OPERATION

• UTILITY Menu

• MEASURE Menu

• ACQUIRE Menu

• SAVE/LOAD Menu

• CURSOR Menu

• DISPLAY Menu

79

Page 80

Menu Operation

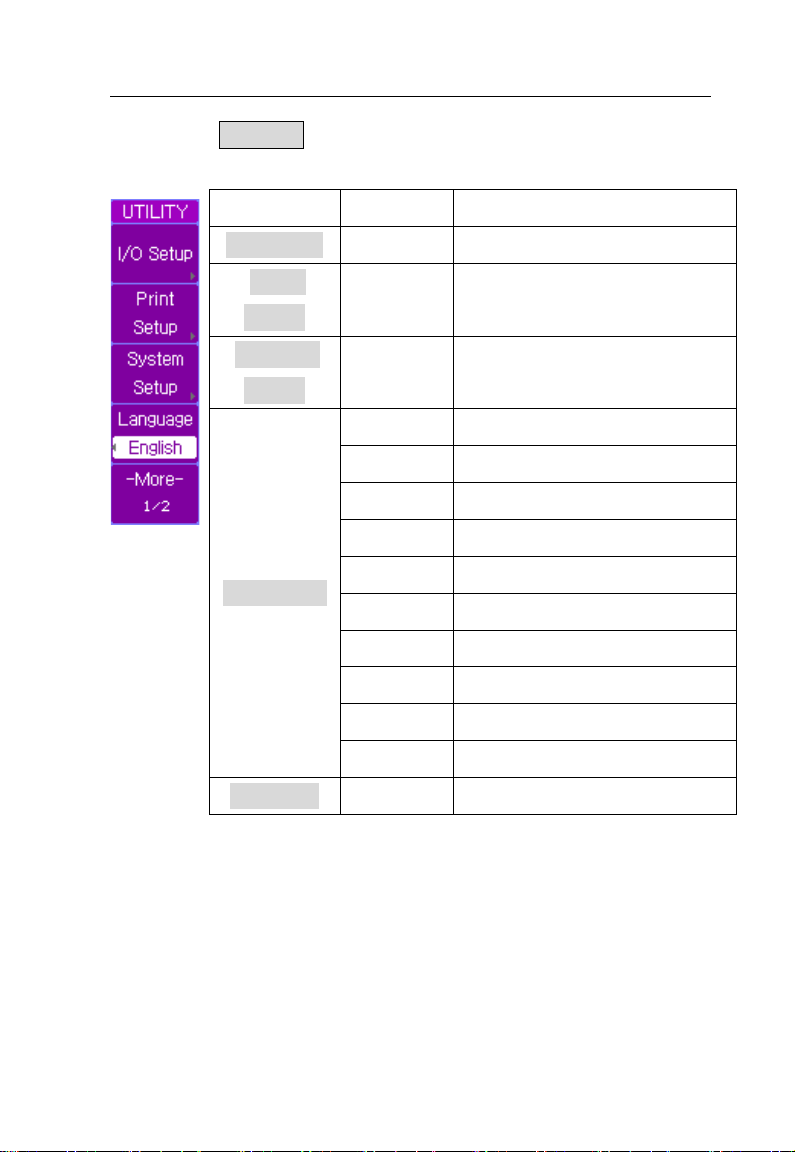

3.1 UTILITY Menu

Press the UTILITY menu key to show the UTILITY menu.

UTILITY Menu key

80

Page 81

Menu Operation

I/O Setup

I/O SETUP

Português

Press the UTILITY key to display the UTILITY menu page

1/2.

Softkey Options Description

Print

Setup

System

Setup

Language

More 1/2

----

----

----

简体中文 Simplified Chinese

繁軆中文 Traditional Chinese

English English language

한국의 Korean language

日本語 Japanese language

Pyccкий Russian language

Français French language

Español Spanish language

Polski Polish language

---- Select menu page 2/2

Select

Select PRINT menu

Select SYSTEM menu

Portugues e language

menu

81

Page 82

Menu Operation

Service

Service

Press the More 1/2 softkey to display the UTILITY menu

page 2/2.

Softkey Options Description

----

Pass/Fail

Self-Cal

Fast-Cal

More 2/2

Self-Calibration

If you want to maximize measurement accuracy, you can

perform a self-calibration.

Self-calibration uses the internally generated signals to

optimize circuits that affect channel scale, offset and trigger

----

RUN/STOP

AUTO

ON

OFF Turn off fast calibration

---- Select menu page 1/2

Select

Select PASS/FAIL

menu

Start self-calibration

Exit self-calibration

Fast calibrate the

vertical position

menu

parameters for all the divisions over the full range.

Disconnect all inputs and allow the oscilloscope to warm up

at least 30 minutes before performing self-calibration.

82

Page 83

Menu Operation

Press UTILITY → Self-Cal to display the self-calibration

page. Press AUTO key to exit the Self-Calibration, or press

RUN k ey to start the self-calibration.

Self Calibration

Note: Warm up the oscilloscope at least 30 minutes

before performing self-calibration. Do not have

anything connected to any of the inputs. Doing

so will create errors and instrument may fail to

calibrate properly.

83

Page 84

Menu Operation

Softkey

Options

Description

USB

Device

Select USB

interface

interface

Available baud

38400

Network

Settings

UTILITY

Fast-Calibration

Fast calibration is ideally used to calibrate the instrument to

remedy the effects of temperature drift causing an offset drift.

It calibrates the center position of each Volt/Div setting, but

not for the full range. This is different compare to

self-calibration, in which the channel scale, offset, and trigger

are calibrated.

I/O Setup

Press UTILITY → I/O Setu p to display the I/O SETUP menu.

Type

Baud

Rate

RS232C

Select RS232C

interface

LAN

---- Select LAN menu

----

84

Select LAN

rate: 2400, 4800,

9600, 19200,

Return to the

menu

Page 85

Menu Operation

↑↓

Press Network Settings softkey to display the LAN menu.

Softkey Options Description

IP address together with

subnet mask and

ON

DHCP

OFF

----

OK ----

----

----

gateway address will be

set by DHCP server

automatically.

You have to set IP

address, subnet mask

and gateway address

manually.

Move the cursor position

vertically (available when

DHCP is OFF).

Move the cursor position

horizontally (available

when DHCP is OFF).

Confirm and apply the

current settings.

Return to the I/O SETUP

menu

85

Page 86

Menu Operation

Follow the following steps to manually configure the LAN

interface:

Set the IP Address. Contact your network administrator

for the IP address to use. All IP addresses take the

dot-notation form “nnn.nnn.nnn.nnn” where “nnn” in each

case is a byte value in the range 0 through 255. M ove the

cursor to the IP address position and change the IP

address using the entry knob.

Set the Subnet Mask. The subnet mask is required if

your network has been divided into subnets. Move the

cursor to the subnet mask position and enter the subnet

mask in the IP address format using the entry knob.

Set the Gateway IP. The gateway address is the

address of a gateway which is a device that connects tw o

86

Page 87

Menu Operation

networks. Move the cursor to the Gateway IP position

and enter the gateway address in the IP address format

using the entry knob.

Set the DNS IP. DNS is an internet service that

translates domin names into IP addresses. Move the

cursor to the DNS IP position and enter the address of

the DNS server in the IP address format using the entry

knob.

Note: If you are manually entering the LAN settings,

you may need to restart the oscilloscope for

settings to apply. If you are using DHCP, first

turn on DHCP, then select OK and wait a few

seconds until the Configure Status shows

“DHCP”. Otherwise, it may not be able detect the

correct DHCP settings from the connected

network. We recommend configuring with

DHCP.

Note: The instrument does not support socket or telnet

connection. When interfacing over LAN, if

settings were changed or refreshed (from

selecting OK from softpanel menu), the

instrument may need to be rebooted first before it

can be connected for remote control.

87

Page 88

Menu Operation

Print to

Print Setup

Press UTILITY → Print Setup to display the PRINT menu.

Softkey Options Description

File Print to file

BMP(8Bit) 8-Bit BMP file format

File Type

Screen

Print To

The P ri nt To softkey option configures what file type to store

when the PRINT key is pressed.

Note: The file can only be stored through an external

USB storage device connected to the front USB

host port.

To store a file to external USB drive, do the following:

BMP(24Bit) 24 Bit BMP file format

CSV CSV file format

Normal Normal BMP picture

Inverted Inverted color BMP picture

Return to the UTILITY

----

menu

1. Connect a USB flash drive to the USB host connector

on the front panel.

88

Page 89

Menu Operation

2. Press File Type softkey to select the file format you

want.

3. Press the PRINT key to save the file to the USB drive.

If BMP is selected, it will take a screen capture of the

display and store it as a .BMP file. If CSV is selected,

it will store the CSV data that represents the

waveform on the display.

Note: The BMP options will print out everything that is

as shown when PRINT key is pressed, including

the opened softkey menu. To get a screen

capture without an opened softkey menu, please

use the MENU ON/OFF key to turn off the menu on

the display before printing to a file.

File Type

BMP(8 bit) – Stores in .BMP file format with 8 bit color

resolution.

Note: Some software or image viewer may not be able

to view this file format.

BMP(24 bit) – Stores in .BMP file format with 24 bit color

resolution.

89

Page 90

Menu Operation

CSV – Stores the waveform data captured on the frame of

the screen into CSV file format. Depending on the timebase,

the maximum number of points that can be stored into CSV is

1200 pts.

Note: Deep memory data cannot be store d into a .CSV

file to a USB flash drive. It can only be obtained

by remote control over USB, RS232, or LAN

interface located in the rear panel of the

instrument.

Screen

Normal – Prints the screen with normal colors.

Inverted – Prints the screen with inverted colors.

Normal

90

Page 91

Menu Operation

More 1/2

Inverted

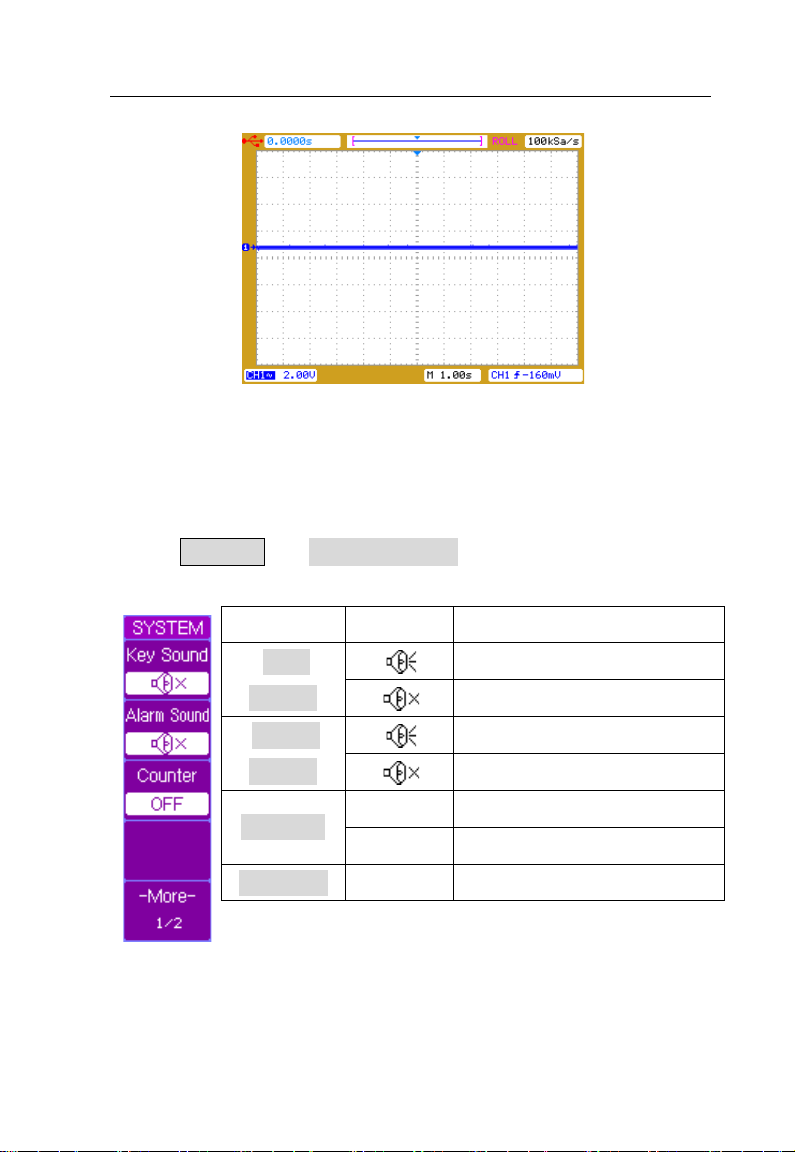

System Setup

Press UTILITY → System Setup to display the SYSTEM

menu page 1/2.

Softkey Options Description

Key

Sound

Alarm

Sound

Counter

ON Frequency counter on

OFF Frequency counter off

---- Select menu page 2/2

91

Key press sound on

Key press sound off

Alarm sound on

Alarm sound off

Page 92

Menu Operation

Frequency Counter

Select the Counter softkey to toggle between enabling and

disabling frequency counter shown on screen.

Press the More 1/2 softkey to display the SYSTEM menu

page 2/2.

Softkey Options Description

ON Key Lock function on

Key Lock

Password

Change

Password

More 2/2

Note: The default password is “111111”

OFF

ON Password protection on

OFF

---- Return to the UTILITY menu

---- Select menu page 1/2

Key Lock function off, a

password is required when

Password is ON

Password protection off, a

password is required when

Password is ON

The old password is

required to change the

password

92

Page 93

Menu Operation

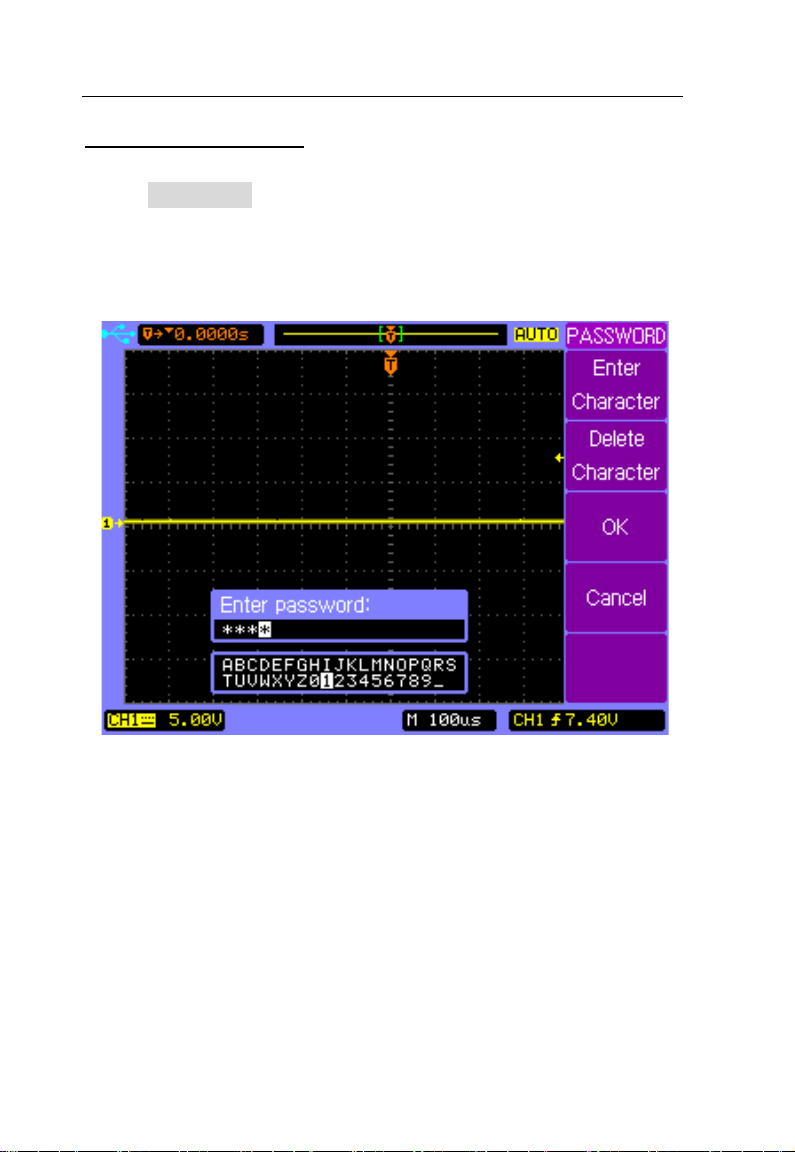

Key Lock

Press UTILITY → System Setup → Key Lock to lock the

front panel operation, all the keys and controls. When key

lock is on, all keys are disabled except MENU ON/OFF key

and the five softkeys. When front panel is locked a red lock

icon is displayed at the top-left corner of the scree n. Corr ect

password is required to unlock the front panel operation w hen

Password is ON as shown below. The default password is

“111111”.

93

Page 94

Menu Operation

Password Protection

Press Password softk e y f r om t h e SYSTEM m enu 2/ 2 to t urn

off the Password protection function, correct password is

required as shown below.

94

Page 95

Menu Operation

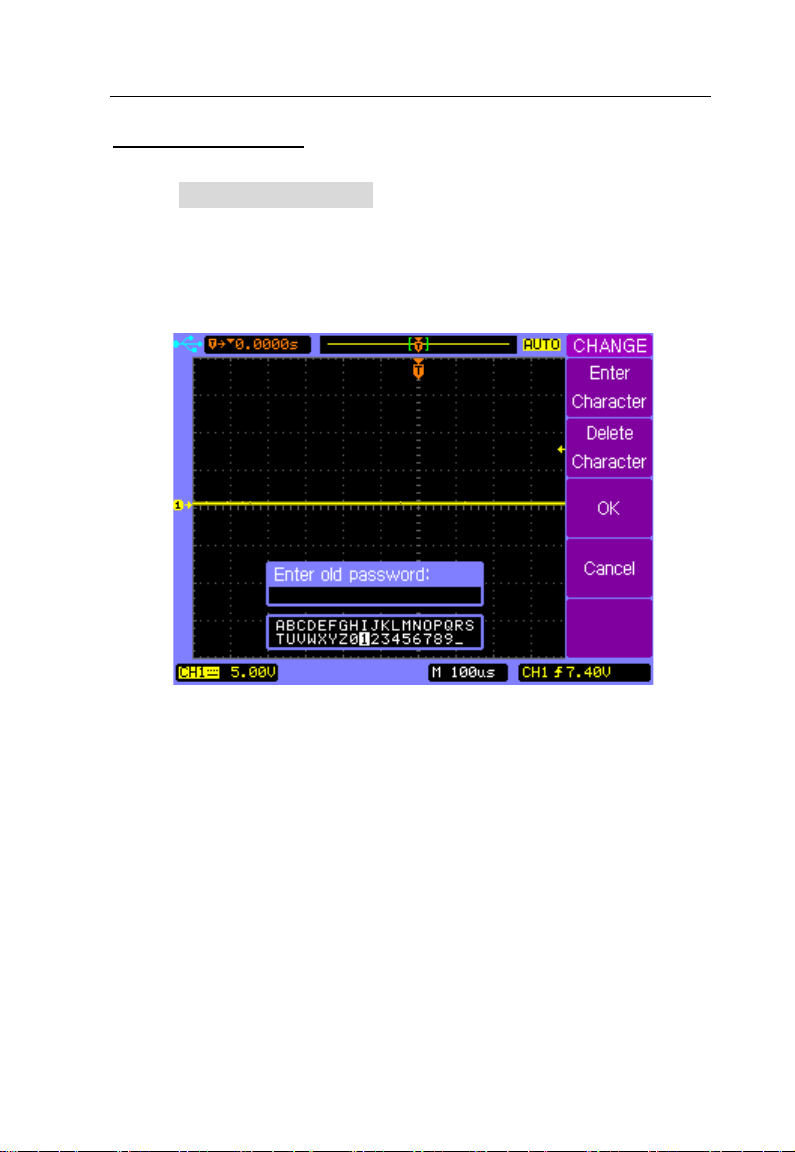

Change Password

Press Change Password softkey from the SYSTEM menu

page 2/2 to display the CHANGE menu. The old password is

required before entering and confirming the new passw ord a s

shown below.

95

Page 96

Menu Operation

k the key and

Service

Press UTILITY → Service to display the Service menu.

Softkey Options Description

Display system

System

Information

Screen

Test

Key Test

information: Model,

----

---- Test the LCD screen

----

----

Serial number,

Software version,

Installed modules

Chec

control operation

Return to the UTILITY

menu

96

Page 97

Menu Operation

System Information

Press UTILITY → Service to display the Service menu, and

then press the System Info softkey to display the system

informations, such as Model, Serial number, Power up times,

Software version and a list of installed modules.

System Information

97

Page 98

Menu Operation

Pass/Fail

The oscilloscope first measures the input source signal and

compares it with Pass/Fail settings, and then outputs the

Pass/Fail result.

Press UTILITY → Pass/Fail to display the PASS/FAIL menu

1/2.

Softkey Options Description

Enable Test

Source

Operate

Setup Mask

More 1/2

ON Pass/Fail function on

OFF Pass/Fail function off

CH1 Source signal CH1

CH2 Source signal CH2

Start Pass/Fail test

---- Set up the regulations

---- Display the menu 2/2

Stop Pass/Fail test

98

Page 99

Menu Operation

Press More 1/2 to display the PASS/FAIL menu 2/2.

Softkey Options Description

Msg

Display

Output

Stop on

Output

ON

Pass/Fail count message

on

Pass/Fail count message

OFF

off

Output on Pass

PASS

waveforms

Output and alarm on Pass

PASS+

waveforms

FAIL Output on Fail waveforms

Output and alarm on Fail

FAIL+

waveforms

ON Stop sampling on output

Continue sampling on

OFF

output

Return to the UTILITY

---menu

More 2/2

Note: Pass/Fail function is not available when X-Y

mode is selected.

----

99

Display the menu page

1/2

Page 100

Menu Operation

Softkey

Options

Description

X Mask

Set horizontal tolerance

Y Mask

Create

Mask

Create the PASS/FAIL

tolerance mask

PASS/FAIL menu

1/2

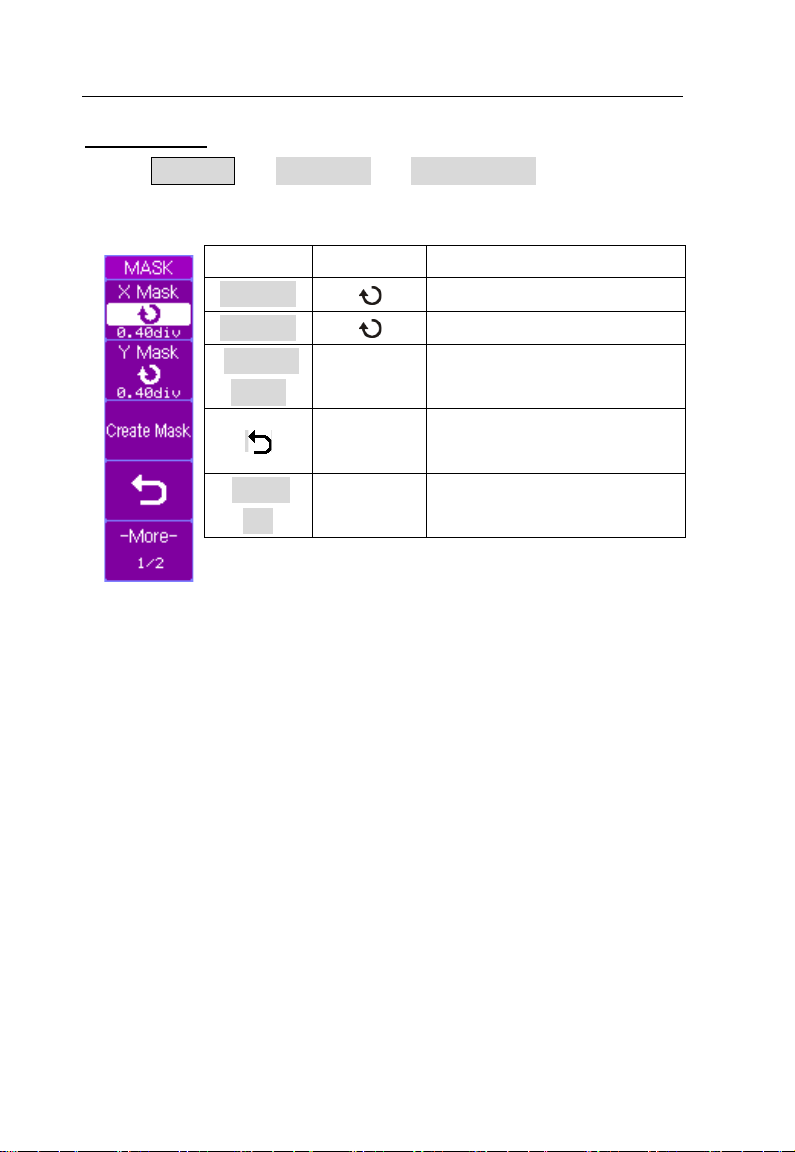

Setup Mask

Press UTILITY → Pass/Fail → Setup Mask to display the

MASK menu 1/2.

Set vertical tolerance

----

More

----

----

Return to the

Display the menu 2/2

100

Loading...

Loading...