Page 1

INSTRUCTION

MANUAL

MANUAL DE

INSTRUCCIÓN

MODELS 1653A & 1655A

MODELOS 1653A & 1655A

Isolated-Variable

AC POWER SUPPLY

Aislada, variable

FUENTE DE PODER DE AC

Page 2

TEST INSTRUMENT SAFETY

WARNING

An electrical shock causing 10 milliamps of current to pass through the heart will stop most human heartbeats. Voltage as low as 35

volts dc or ac rms should be considered dangerous and hazardous since it can produce a lethal current under certain conditions. Higher

voltages are even more dangerous. Your normal work habits should include all accepted practices to prevent contact with exposed high

voltage, and that will steer current away from your heart in case of accidental contact with a high voltage. You will significantly

reduce the risk factor if you know and observe the following safety precautions:

1. The B+K Precision Models 1655A and 1653A AC Power Supplies are sources of high voltage ac. The person using the

instrument should be a qualified electronics technician or otherwise trained and qualified to work with high voltage.

2. Use only a polarized 3-wire ac outlet. This assures that the power supply chassis, case, and ground terminal are connected to a

good earth ground and reduces danger from electrical shock.

3. When servicing any equipment equipped with a two-wire ac plug, treat it as “hot chassis” type and connect it to the ISOLATED

OUTPUT outlet of the ac power supply. Even some equipment with a polarized plug is the “hot chassis” type.

4. Never connect two pieces of “hot chassis” equipment to ISOLATED OUTPUT outlets simultaneously. There may be a serious

shock hazard between two chassis.

5. Don’t expose high voltage needlessly. Remove housings and covers only when necessary. Turn off equipment while making

test connections in high-voltage circuits. Discharge high-voltage capacitors after removing power.

6. If possible, familiarize yourself with the equipment being tested and the location of its high voltage points. However,

remember that high voltage may appear at unexpected points in defective equipment.

7. Use an insulated floor material or a large, insulated floor mat to stand on, and an insulated work surface on which to place

equipment; and make certain such surfaces are not damp or wet.

8. Use the time proven “one hand in the pocket” technique while handling an instrument probe. Be particularly careful to avoid

contacting a nearby metal object that could provide a good ground return path.

9. When testing ac powered equipment, remember that ac line voltage is usually present on some power input circuits such as the

on-off switch, fuses, power transformer, etc. any time the equipment is connected to an ac outlet, even if the equipment is

turned off.

10. Never work alone. Someone should be nearby to render aid if necessary. Training in CPR (cardio-pulmonary resuscitation)

first aid is highly recommended.

Page 3

Instruction Manual

for

MODELS 1653A & 1655A

Isolated, Variable

AC POWER SUPPLY

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

Page 4

TABLE OF CONTENTS

page

TEST INSTRUMENT SAFETY..................... inside front cover

FEATURES................................................................................ 3

SPECIFICATIONS ....................................................................4

CONTROLS AND INDICATORS ............................................6

OPERATING INSTRUCTIONS.............................................. 12

Precautions ...............................................................................13

Troubleshooting: Using the AC Power Supply as an

Isolation Transformer .......................................................16

Troubleshooting: Using the AC Power Supply as a

Variable AC Voltage Source. ......................................….21

Troubleshooting: Using the AC Power Supply to

Measure Electrical Loads..................................................23

Using the Model 1655A as a Leakage Tester ........................... 25

Soldering Iron Temperature Control.........................................27

page

CIRCUIT DESCRIPTION..........................................................29

MAINTENANCE AND CALIBRATION..................................30

Preventive Maintenance...............................................................30

Returning for Service...................................................................30

Fuse Replacement........................................................................30

Auto-Transformer Brush Replacement........................................31

Calibration Adjustments..............................................................31

Performance Tests........................................................................34

Troubleshooting...........................................................................35

CUSTOMER SUPPORT.............................................................37

WARRANTY INFORMATION.................................................38

Warranty Service Instructions......................................................38

Spanish Manual............................................................................39

2

Page 5

WIDE VOLTAGE RANGE

Output voltage continuously variable from 0 to 150VAC.

WIDE CURRENT RANGE

Model 1655A

Heavy duty unit handles virtually all servicing needs.

Output current up to 3 amps continuous, 4 amps

intermittent.

Model 1653A

Handles many servicing needs. Output current up to 2

amps continuous.

WIDE LOAD MEASUREMENT CAPABILITY

Model 1655A

Built in multi-function meter. 0-150V. Two current

ranges of 0-2A and 0-4A for improved resolution. Current

scales also calibrated in VA at 120V.

Model 1653A

Built in dual-purpose meter measures output voltage from 0150V and output current from 0-2A.

ISOLATED OUTPUT VOLTAGE

Built-in isolation transformer for safe servicing of “hot

chassis” equipment. One isolated outlet on Mode 1653A, two

isolated outlets on Model 1655A for greater convenience.

Unless otherwise stated, all information in this section applies equally to Model 1653A and 4655A

FEATURES

BUILT-IN METER

protection

-

POWER LINE LEAKAGE TEST

EXPANDED LEAKAGE SCALE

full scale. Overload protected.

Built-in solid state soldering iron temperature control.

CIRCUIT BREAKER OVERLOAD PROTECTION

SOLDERING IRON TEMPERATURE CONTROL

3

Model 1655A

3-1/4 inch meter. Multi-color scales. Overrange

Model 1653A

2 inch meter. Overrange protection.

---Model 1655A offers the following additional features--

OSHA, UL, and CSA power line leakage test capability; fast

and safe measurement.

0-5mA (0-5000µA) leakage scale is expanded in most

commonly used 100-500µA portion, compressed to 5 mA

Isolated output protected by easily reset circuit breaker.

Built-in solid state soldering iron temperature control

Page 6

SPECIFICATIONS

OUTPUT ISOLATION

Leakage less than 0.1mA (25ºC, 50% relativ

VOLTAGE ADJUSTMENT RANGE

0-150VAC, with input at 120VAC

VOLTAGE/CURRENT SENSING

Sine wave average, calibrated in RMS

MAXIMUM CURRENT (Isolated)

3A continuous, 4A intermittent (0-130V). Intermittent not to

exceed 4 minutes at 4A followed by 5 minutes at 1A max.

METER SCALES

Voltage.................................................................... :0-150V

Current:. .......................................................................0-2A

.........................................................................0-4A

Volt-Amps (Voltage Set to 120)............................ 0-240VA

................................................................. 0-480VA

Leakage ......................0 to 5mA (5,000µA), expanded scale

METER ACCURACY (25ºC)

Volts:.........±5% (typical) of full scale (calibrated @ 120VAC)

Current:.............................................±5% (typical) of full scale

Leakage:............................................................±5% @ 500µA

MODEL 1655A

e humidity.)

OUTPUT ISOLATION

Leakage less than 0.1mA (25ºC, 50% relativ

VOLTAGE ADJUSTMENT RANGE

0-150VAC, with input at 120VAC

VOLTAGE/CURRENT SENSING

Sine wave average, calibrated in RMS.

MAXIMUM CURRENT (Isolated)

2A continuous (0-130V).

METER SCALES

Voltage:.........................................................................0-150V

Current:.............................................................................0-2A

METER ACCURACY (25ºC)

Volts:........±5% (typical) of full scale (calibrated @ 120VAC)

Current:............................................±5% (typical) of full scale

MODEL 1653A

e humidity)

4

Page 7

MODEL 1655A

AC INPUT

120 VAC, 60Hz, 600 VA*

OPERATING TEMPERATURE RANGE

0° C to +40°C.

STORAGE TEMPERATURE

-30° C to +60°C.

WEIGHT

22lb (10kg.)

DIMENSIONS (WxHxD)

10.5” x 5.7” x 12” (267 x 145 x 305 mm)

PEAK CURRENT (Inrush)

30 A max (inrush limited to one cycle at 30A).

SOLDER IRON TEMPERATURE CONTROL

70% - 99% of power line (100W max).

MODEL 1653A

AC INPUT

120 VAC, 60Hz, 300 VA*

OPERATING TEMPERATURE RANGE

0°C to +40°C.

STORAGE TEMPERATURE

-30°C TO +60°C.

WEIGHT

12 lb (5.5 kg).

DIMENSIONS (WxHxD)

5.5” x 6.5” x 10.5” (140 x 165 x 267 mm).

NOTE: Specifications and information are subject to change

without notice. Please visit www.bkprecision.com for the most

current product information. *For 220V input, order model

number 1655A-220V or 1653A-220V.

5

Page 8

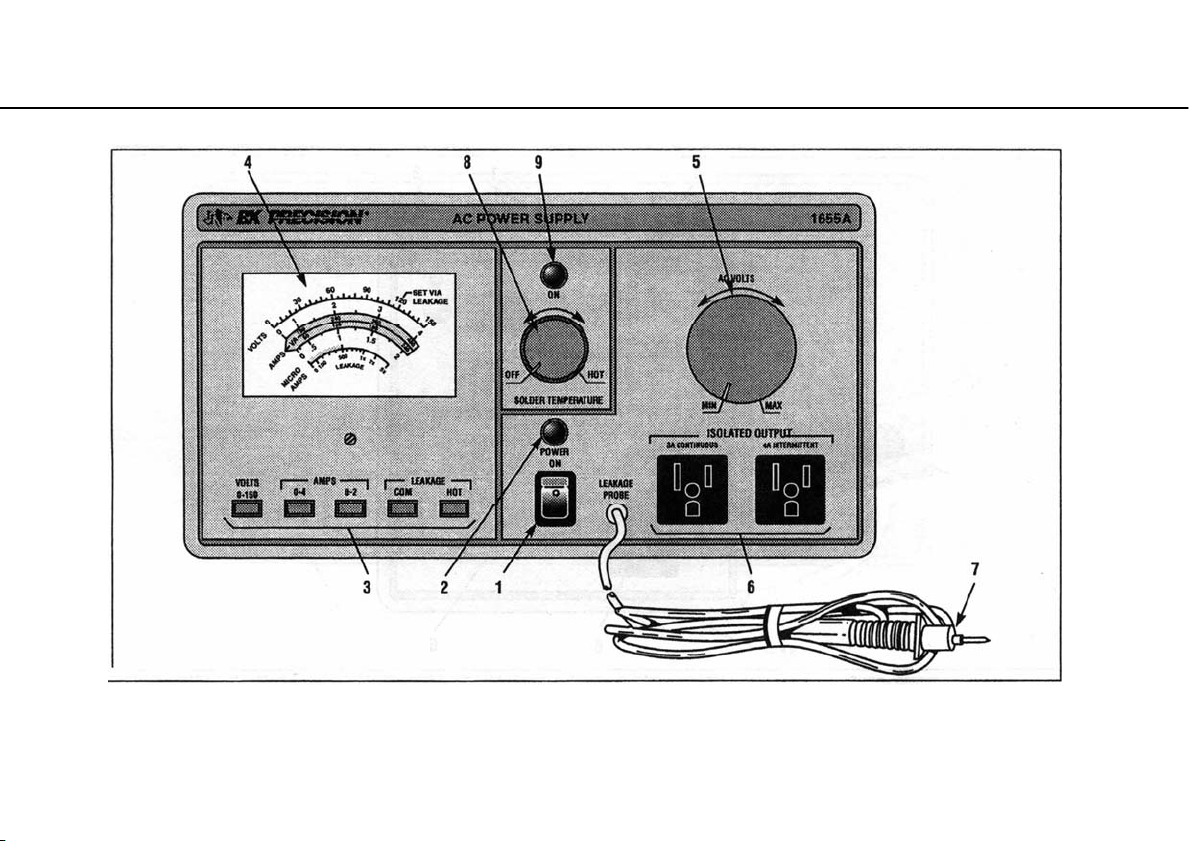

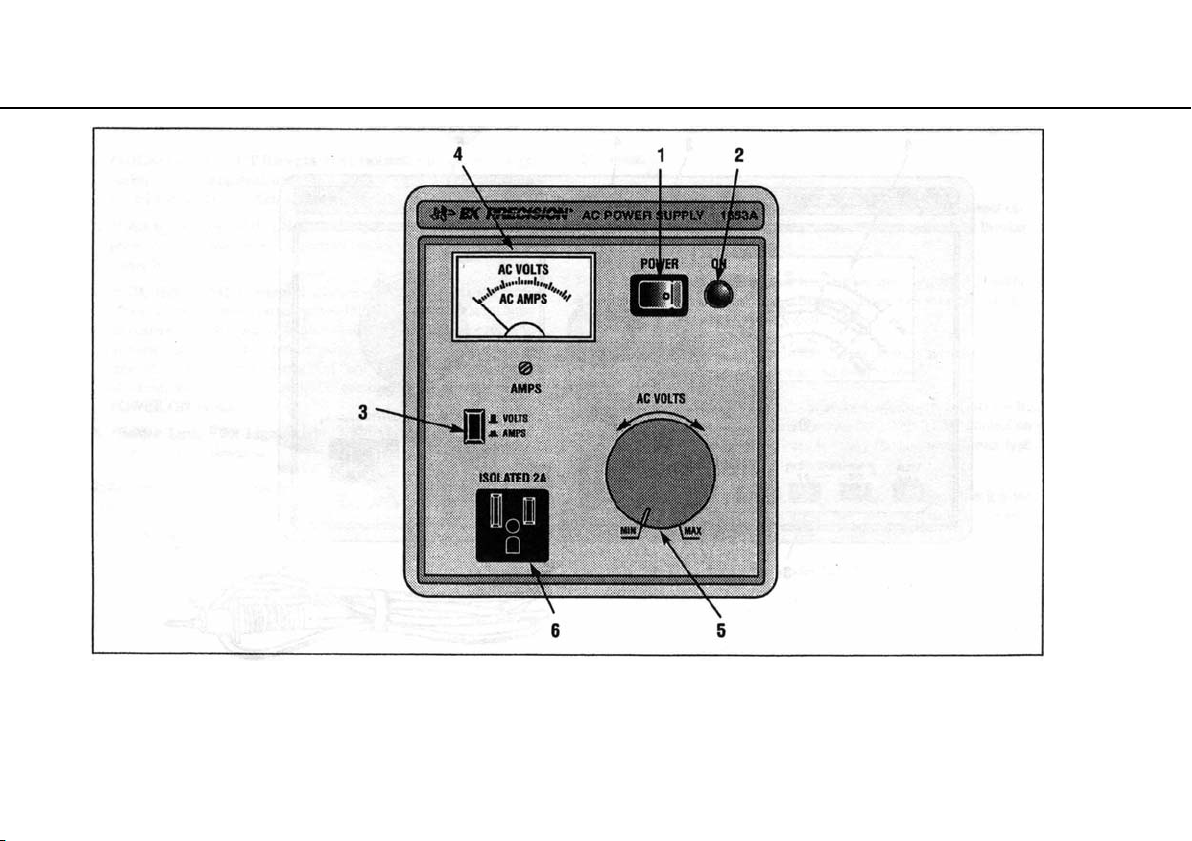

FRONT PANEL CONTROLS

(Refer to Fig. 1 and 2)

1. POWER ON Switch.

2. POWER ON Pilot Light.

3. Function Switch.

Model 1655A

Five interlocking pushbutton switches which select

function and meter scale. Pressing a button releases

the previous selection. The following selections are

available:

VOLTS. Connects meter to measure voltage at

ISOLATED OUTPUT. Use 0-150 VOLTS

scales on meter. Voltage is adjustable with AC

VOLTS control.

AMPS 0 – 4. Connects meter to measure current of

ISOLATED OUTPUT. USE 0-4 AMPS scale on

meter. When voltage is set to 120 VAC, the 0-480

VA scale may be used to measure the output load

in volt-amps

AMPS 0-2. Connects meter to measure current of

ISOLATED OUTPUT. Use 0-2 AMPS scale on

meter. When voltage is set to 120VAC, the

0-240VA scale may be used to measure the

output load in volt-amps.

CONTROLS AND INDICATORS

LEAKAGE COM. Connects meter to measure leakage with

respect to common side of ac line. Use LEAKAGE scale on

meter. Voltage must be preset to 120VAC for accurate

leakage measurements.

LEAKAGE HOT. Connects meter to measure leakage with

respect to hot side of ac line. Use LEAKAGE scale on

meter. Voltage must be preset to 120VAC for accurate

leakage measurements.

Model 1653A

Alternate action pushbutton switch selects function of meter.

Push once to latch button in AMPS (in) position. Push again to

release button to VOLTS (out) position. The following

selections are available:

VOLTS. Connects meter to measure voltage at ISOLATED

OUTPUT. Use 0-150 VOLTS scale on meter. Voltage is

adjustable with AC Volts control.

AMPS. Connects meter to measure current of ISOLATED

OUTPUT. Use 0-2 AMPS scale on meter.

4. Meter. Appropriate scale is selected by function switch.

5. AC VOLTS Control. Adjusts voltage at ISOLATED

OUTPUT receptacle(s) from 0 to 150 volts.

6

Page 9

6. ISOLATED OUTPUT Receptacle(s). Isolated,

variable ac voltage outlet(s). The equipment under test

plugs in here. Single outlet on Model 1653A. Dual

outlets on Model 1655A.

7. *Leakage Probe. With LEAKAGE function selected,

touching probe tip to exposed metallic parts of

equipment under test checks power line leakage.

8. *SOLDER TEMP Control. Full counterclockwise

rotation turns off soldering iron outlet on rear panel.

Initial clockwise rotation turns on outlet at standby

(warm) temperature. Further clockwise rotation

increases soldering iron temperature. Temperature

adjustment is tapered, allowing fine adjustment of “hot”

temperature at upper end of adjustment range. This

control is completely independent of the POWER ON

switch.

9. *Solder Temp Pilot Light. Lights whenever soldering

iron outlet on rear panel is powered.

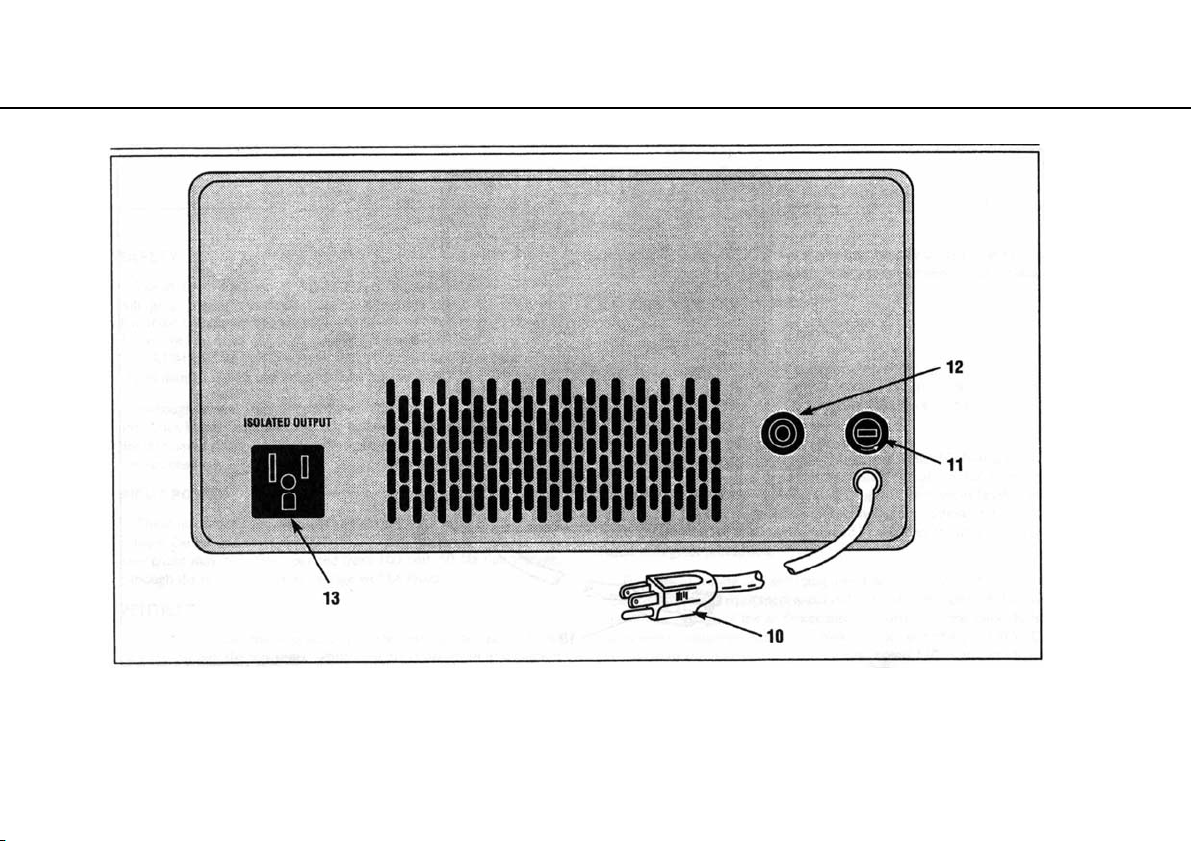

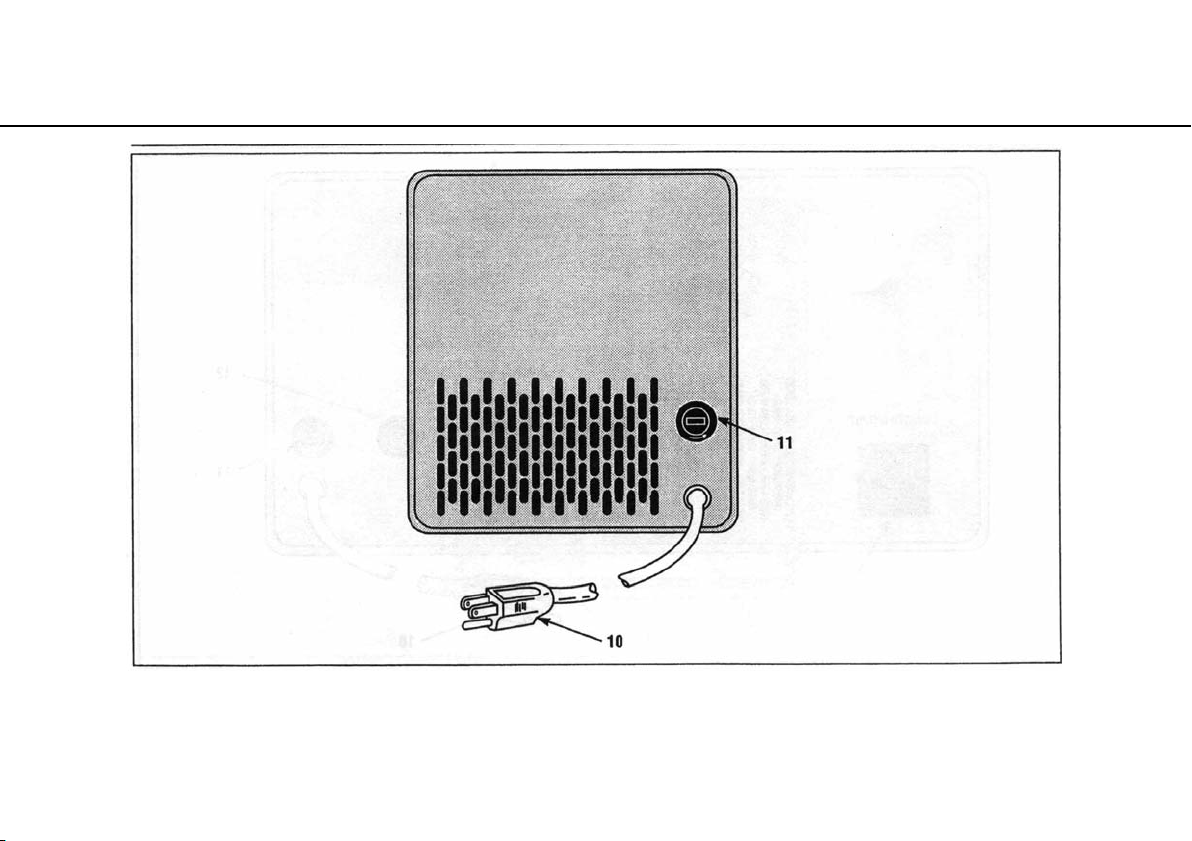

REAR PANEL CONTROLS

(Refer to Fig. 3 and 4)

10. AC Power Cord.

*=Model 1655A Only.

11. Fuse.

Model 1655A

4A fuse protects auto-transformer against excessive output

current at low voltages which may not trip the input

circuit breaker.

Model 1653A

3A line fuse protects against excessive input current. An

internal 3A fuse protects against excessive output current

at low voltages which may not blow the input fuse.

12. *Circuit Breaker. 3.15A circuit breaker protects against

excessive input current. Remove overload and push to

reset.

13. *Soldering Iron Outlet. AC outlet for soldering iron. Duty

cycle, and thus temperature, is variable with SOLDER

TEMP control on front panel. This outlet is intended only

for non-transformer type soldering irons rated at 100 watts

or less.

*=Model 1655A Only

7

Page 10

Figure 1. Front Panel Controls and Indicators, Model 1655A

8

Page 11

Figure 2. Front Panel Controls and Indicators, Model 1653A

9

Page 12

Figure 3. Rear Panel Controls and Indicators, Model 1655A

10

Page 13

Figure 4. Rear Panel Controls and Indicators, Model 1653A

11

Page 14

OPERATING INSTRUCTIONS

PRECAUTIONS

SAFETY

The Model 1655A and 1653A AC Power Supplies are sources

of high voltage ac. Improper or careless use could result in fatal

electrical shock. The most commonly encountered conditions

which may pose a shock hazard are identified and corresponding

precautions listed in the TEST INSTRUMENT SAFETY section

which starts on the side front cover of this manual. Know and

observe these precautions.

Although Model 1655A is equipped with dual isolated outlets,

only one “hot Chassis” equipment should be connected at a time.

Unless the line-to-chassis relationship is identical, a shock hazard

will exist between the two chassis.

INPUT POWER

These instruments are intended for use only with 120 volt,

60Hz line voltage. Do not operate from 50Hz, or 220-240 volt

power systems. The instrument may be safely operated from 100

volt, 60Hz line voltage, although the maximum output voltage

will be lower.

VENTILATION

The holes in the case provide convection cooling (hot air rises

and escapes through the top vents, while cool air is drawn in to

replace it through the bottom). Never block these ventilation

holes with a manual, schematic diagram, other equipment, etc. If

the air is blocked, the temperature inside the ac power supply may

become excessive and cause failure of the unit. Similarly, avoid

operating locations near sources of heat.

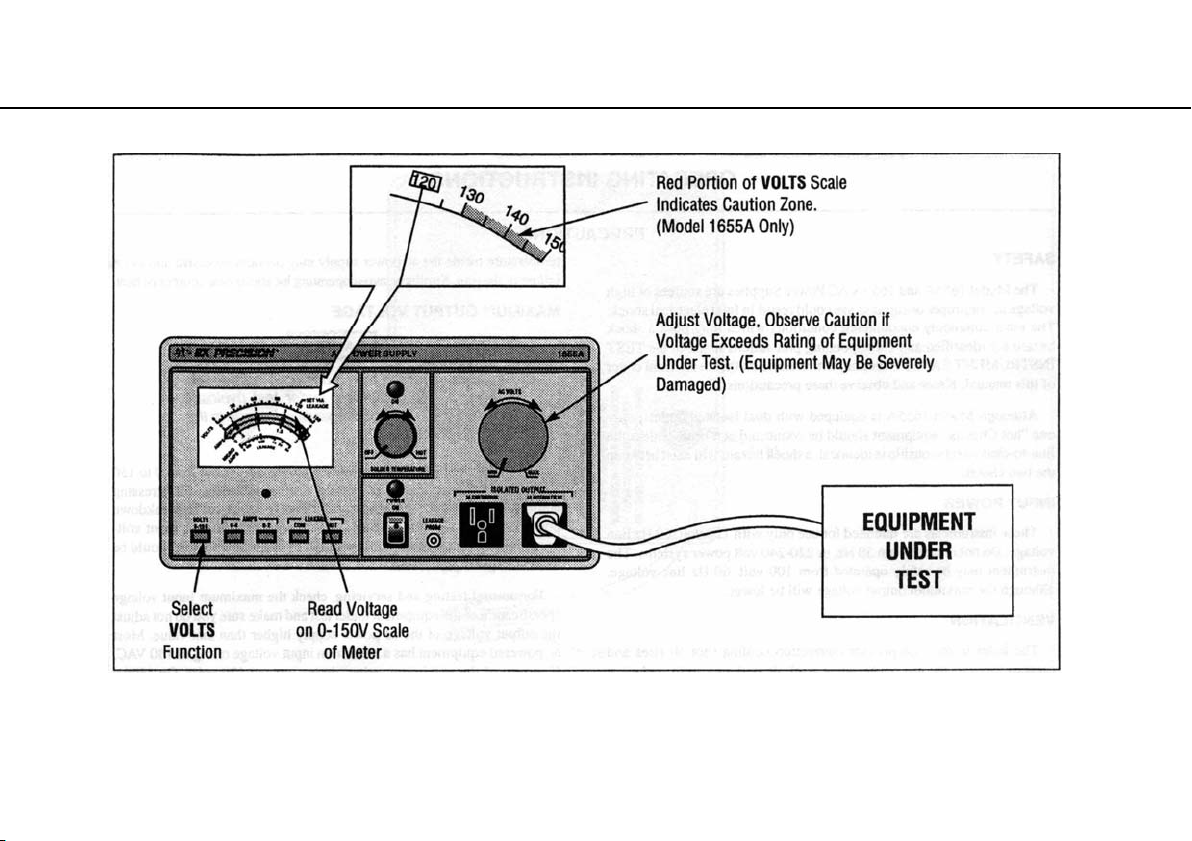

MAXIMUM OUTPUT VOLTAGE

Exceeding the maximum input voltage rating of the equipment

under test (typically 130VAC) may cause severe damage to the

The output voltage of the ac power supply is adjustable from 0

to 150VAC. This is very useful in certain testing situations for

stressing equipment beyond its normal operating range to

determine its breakdown point. However, for most testing and

servicing applications, input voltages higher than the maximum

specified by the manufacturer should be used with great

precaution.

For normal testing and servicing, check the maximum input

voltage specification of the equipment under test and make sure

you do not adjust the output voltage of the ac power supply

higher than that value. Most ac powered equipment has a

maximum input voltage rating of 130VAC. If unsure of the

maximum rating, do not exceed 130 VOLTS. On Model 1655A,

the 130-150 volt portion of the VOLTS scale is red as a reminder

that caution should be observed.

CAUTION

equipment.

12

Page 15

Figure 5. Observe Caution Above 130V.

13

Page 16

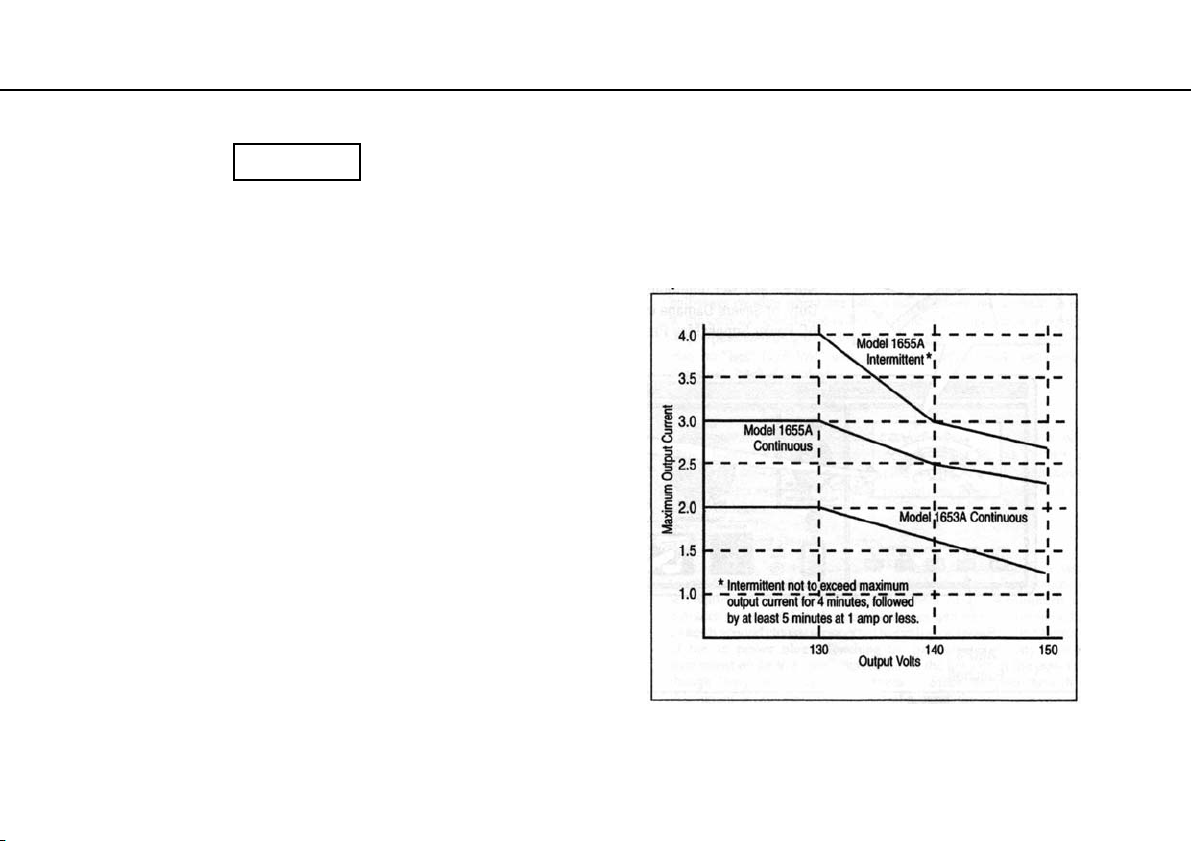

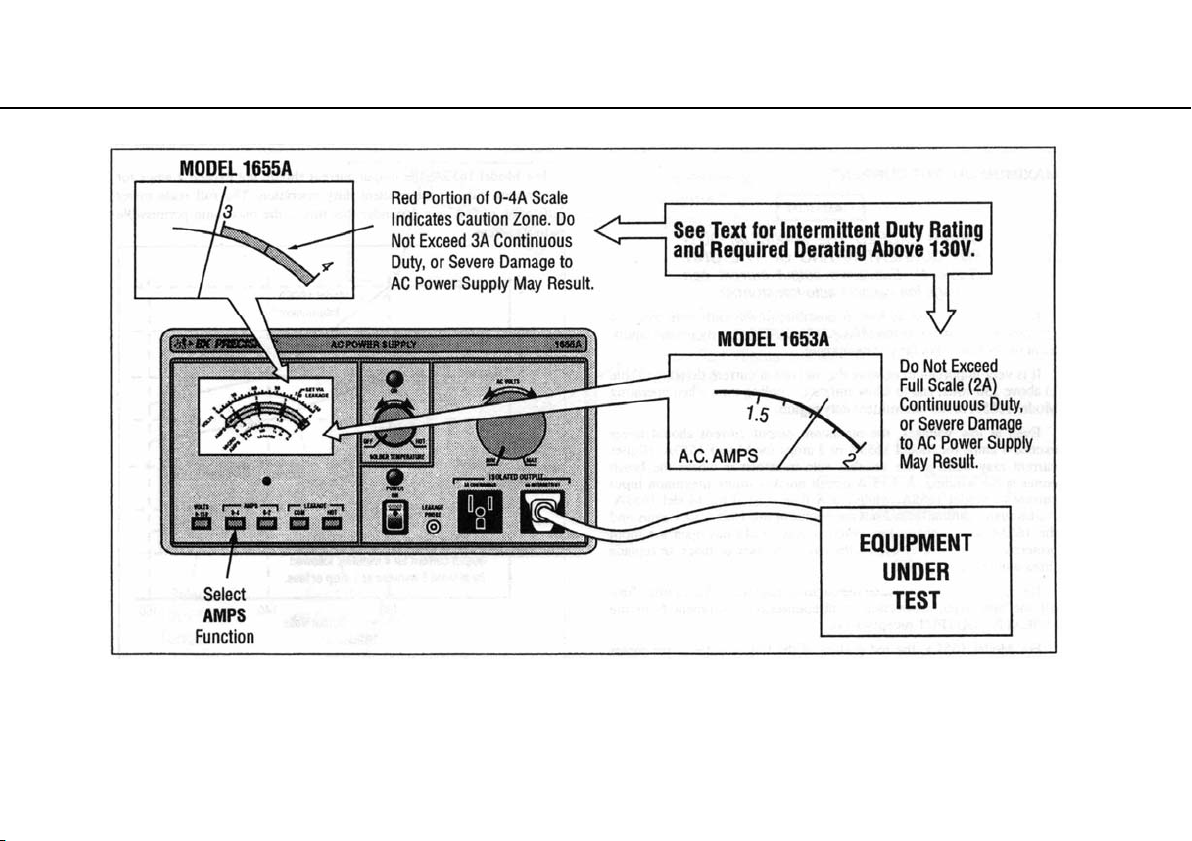

MAXIMUM OUTPUT CURRENT

NEVER EXCEED THE MAXIMUM OUTPUT CURRENT

RATING OF THE UNIT (Table 1). Excessive output current

can damage the variable auto-transformer.

Keep output current as low as possible; power only one piece

of equipment at a time. Use the ISOLATED OUTPUT only for

the equipment under test – not for the test equipment.

It is very important to observe the maximum current derating

(Table 1) above 130 volts, and to allow sufficient cooling time

when operating Model 1655A in the intermittent duty region.

Even at low voltages, the maximum output current should

never exceed 4 amps for Model 1655A or 2 amps for Model

1653A. Higher current may damage the variable autotransformer where the brush contacts the winding. A 3.15A

circuit breaker limits maximum input current to Model 1655A,

while a 3A fuse is used for Model 1653A. Additionally, output

fuses limit the output of the 1655A to 4 amps and the 1653A to 3

amps at low voltages that would not open the input protective

device. Never bypass the circuit breaker or fuses, or replace fuses

with a higher value.

Remove the overload to reset the circuit breaker or replace a

fuse. Turn off the unit when connecting or disconnecting

equipment from the ISOLATED OUTPUT receptacle(s).

CAUTION

For Model 1655A, the red portion of the 0-4A scale of the

meter indicates the caution zone (over 3A). This is a reminder

that only intermittent duty operation is permitted.

For Model 1635A, the output current should not exceed 2 amps

for continuous duty or intermittent duty operation. The full scale

meter indication of 2A is a reminder that this is the maximum

permissible output current.

14

Table 1. Maximum Output Current Derating.

Page 17

Figure 6. Maximum Current Considerations.

15

Page 18

Troubleshooting: Use As Isolation Transformer OPERATING INSTRUCTIONS

TROUBLESHOOTING: USING THE AC POWER SUPPLY AS ISOLATION TRANSFORMER

THE HAZARD

Most equipment with a 2-Wire Plug is Transformerless

Most recent television receivers and other consumer products

such as stereo amplifiers, tuners, tape decks, etc. do not contain

an isolation transformer. Such products often have a plastic or

wood cabinet which completely insulates the chassis and prevents

the user from touching it. However, when the cabinet is removed

for servicing the product, the chassis is exposed and may become

an electrical shock hazard to the service technician.

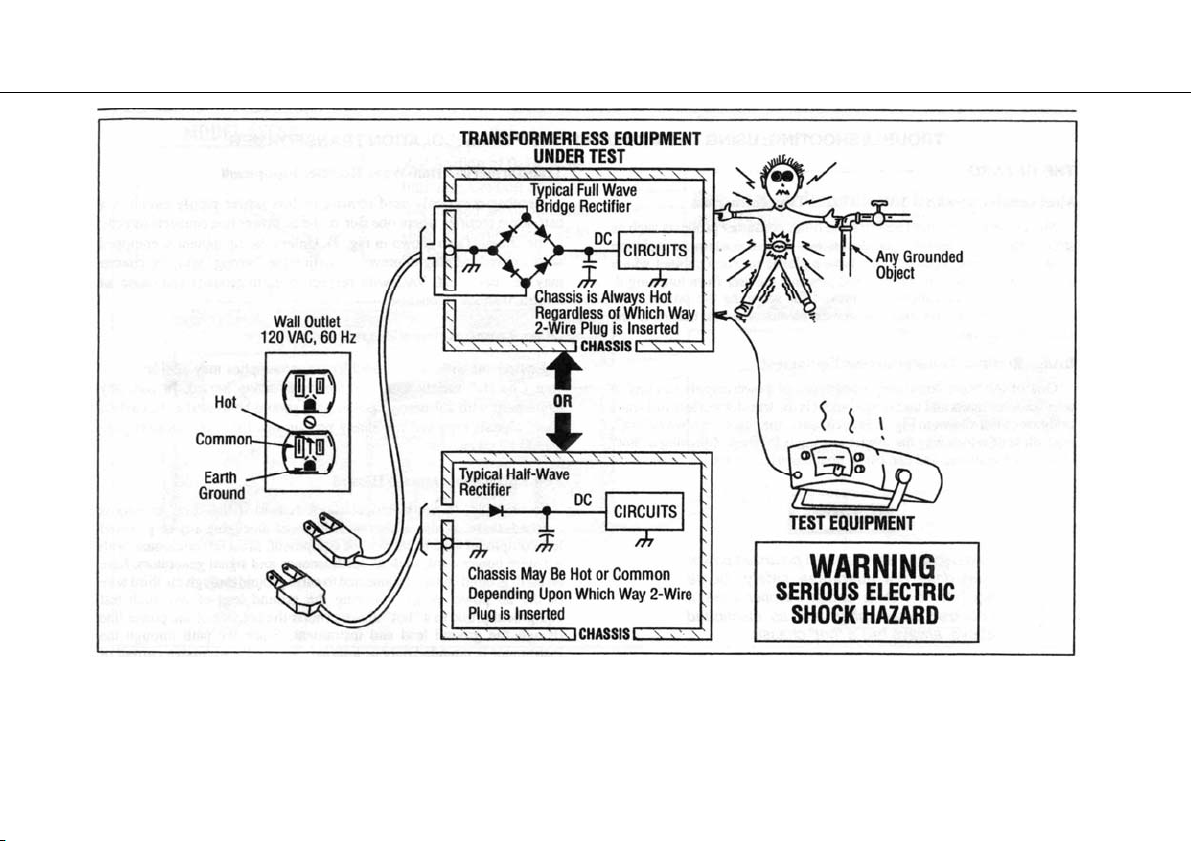

Bridge Rectifier Transformerless Equipment

One of the most commonly used types of power supply circuits

in television receivers and audio equipment is the transformerless

full wave bridge rectifier shown in Fig 7. In such cases, the

chassis is always “hot”, regardless of which way the 2-wire ac

plug is inserted. Touching a “hot” chassis is hazardous and can

cause fatal electrical shock.

Just because a unit uses a polarized power plug does not

guarantee safety. Some equipment with a bridge rectifier uses a

polarized power plug, and as mentioned above, always has a

WARNING

“hot” chassis.

Transformerless Half-Wave Rectifier Equipment

Another commonly used transformerless power supply circuit

is a half-wave rectifier where one side of the ac power line

connects directly to the chassis (also shown in Fig. 7). Unless the

equipment is equipped with a polarized plug to prevent insertion

the “wrong” way, the chassis may be “hot” (120VAC with

respect to earth ground) and cause an electrical shock if touched.

Other Transformerless Hazards

Equipment with voltage doubler power supplies may also be of

the “hot Chassis” variety and pose the same safety hazard. In

fact, and equipment with a 2-wire ac power plug should be treated

as hazardous “hot” chassis type and the safety precautions listed

on the next page should be taken.

Test Equipment Damage Hazard

In addition, to the electrical shock hazard if the “hot” chassis is

touched, there is also a high probability of damaging any acpowered test equipment used to service the equipment. Most test

equipment with a 3-wire power cord, such as oscilloscopes and

signal generators, have an earth ground chassis (connected to

earth ground through the third wire of the ac power plug).

Touching the ground lead of any such test equipment probe to a

“hot” chassis shorts the hot side of the power line through the

ground lead and instrument. Since the path through the

instrument is intended only as a signal ground, the excessive

current of a direct power line short may cause extensive damage

to the test equipment or to the equipment under test.

16

Page 19

Figure 7. Servicing “Hot Chassis” Equipment Can Pose a Serious Shock Hazard.

17

Page 20

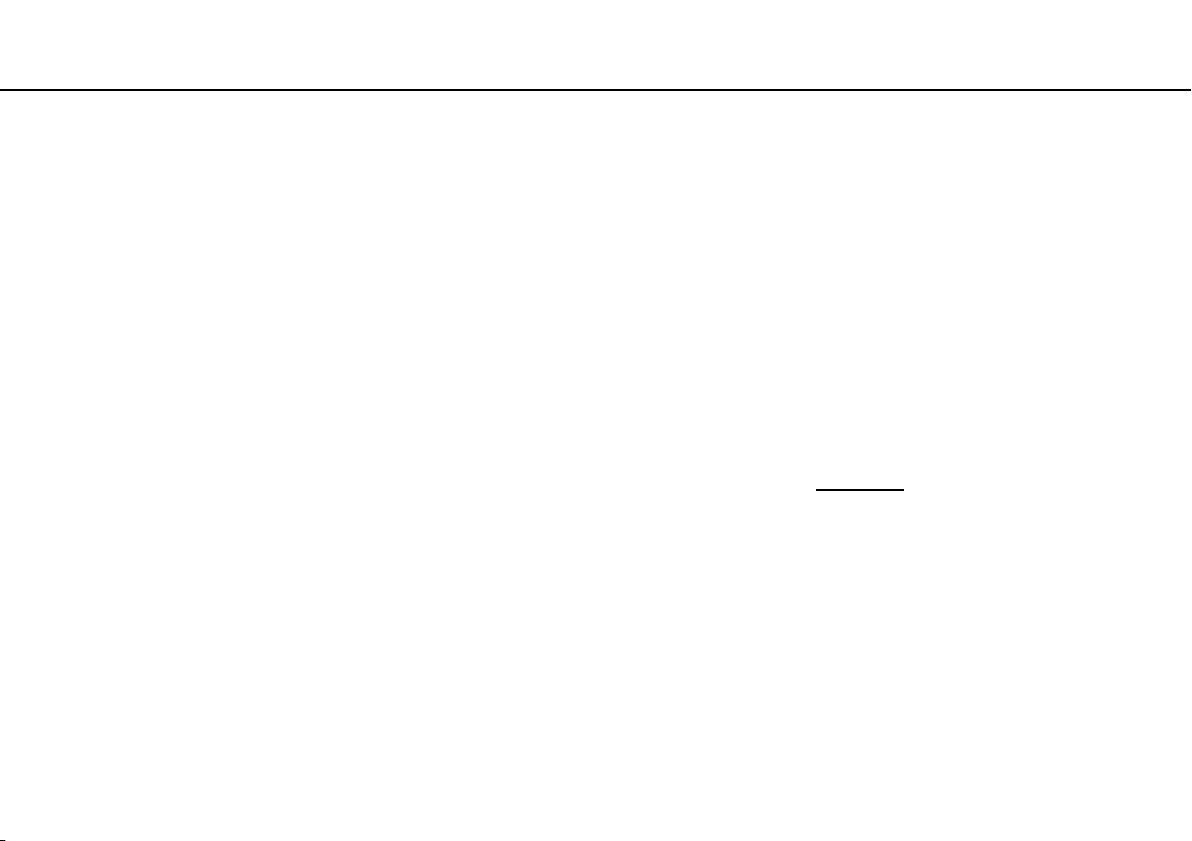

THE SOLUTION

Don’t Ground the Chassis

Simply connecting a test lead from the chassis to a good earth

ground is not a satisfactory solution. If the chassis is “hot”, this

places a direct short from the “hot” side of the power line to earth

ground. Hopefully, this would only trip the circuit breaker for the

wall outlet. But a wall outlet is a very high energy source, and

before the circuit breaker is tripped, the grounding test lead may

“weld” or “disintegrate”, or severe damage may occur to the

equipment under test.

Use An Isolation Transformer

For servicing “Hot Chassis” equipment, always connect an

isolation transformer between the wall outlet and the equipment

under test. The Model 1655A or 1653A AC Power Supply

includes such an isolation transformer, among its many other

features.

As shown in Fig. 8, when an isolation transformer is used, the

chassis of the equipment under test is electrically isolated from

both sides of the power line. The chassis of the equipment under

test may not be grounded by connecting a test lead from the

chassis to a convenient earth ground (such as an earth ground

terminal of the test equipment).

Summary

Any piece of equipment with a 2-wire power plug may be the

“hot chassis” type, even if it is equipped with a polarized plug.

There is not disadvantage to using an isolation transformer, even

if the equipment under test already includes its own isolation

transformer. Therefore, for safety, treat all equipment with a 2-

wire power cord as “hot chassis” and use the ISOLATED

OUTPUT of the 1655A or 1653A AC Power Supply for servicing

such equipment.

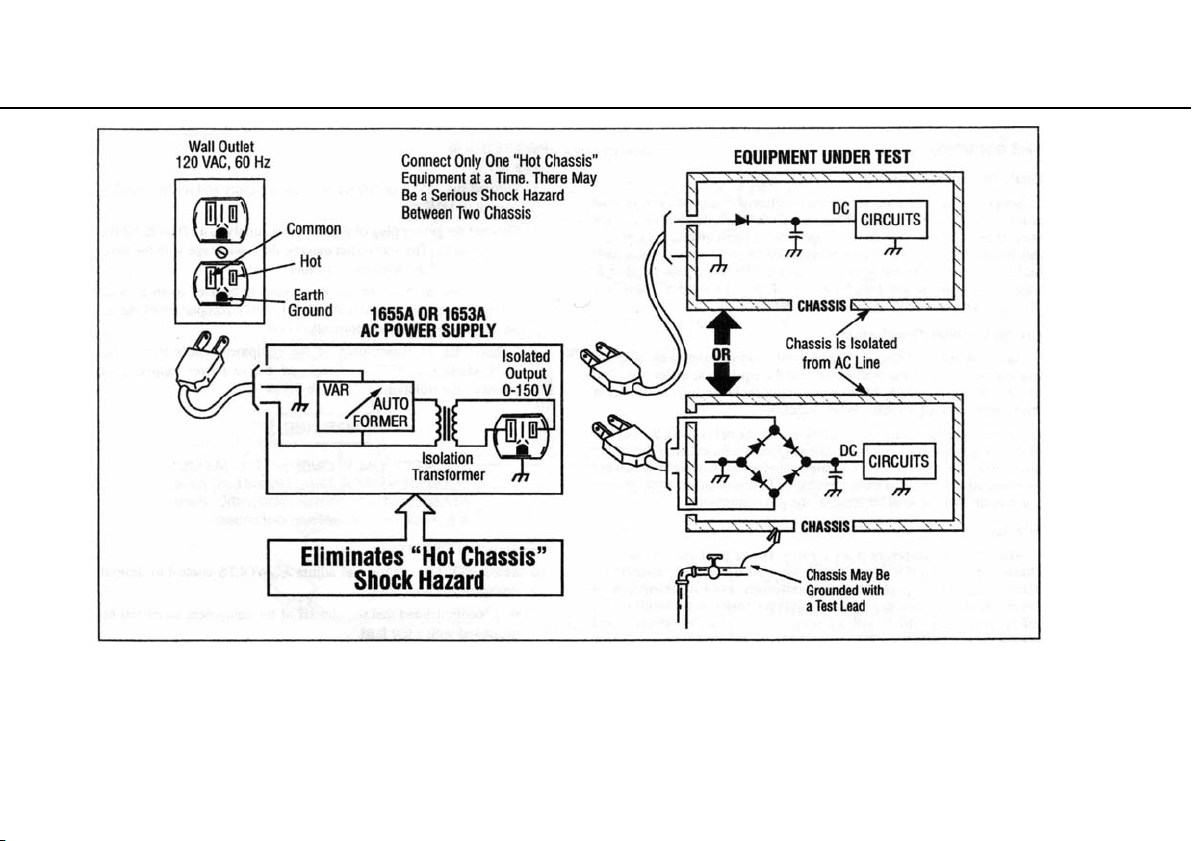

PROCEDURE

(refer to Fig. 9)

1. Turn off the 1655A or 1653A AC Power Supply and set

AC Volts control to MIN.

2. Connect the power plug of the ac power supply to a 120

volt, 60 Hz ac wall outlet. The wall outlet must be the 3wire type with the third wire returned to a good earth

ground.

3. Connect any ac powered test equipment to be used to an

ac wall outlet (do not use the ISOLATED OUTPUT

receptacles of the ac power supply for test equipment).

4. Connect the ac power plug to the equipment under test to

the ISOLATED OUTPUT receptacle of the ac power

supply. This provides the isolation as shown in Fig. 8.

WARNING

CONNECT ONLY ONE “HOT CHASSIS” EQUIPMENT AT

A TIME. Unless both have an identical line-to-chassis

relationship, there is a shock hazard between two chassis.

5. Turn the POWER ON.

6. Select VOLTS function and adjust AC VOLTS control to

desired voltage (typically 120V).

7. It is recommended that the chassis of the equipment under

test be grounded with a test lead.

18

Page 21

OPERATING INSTRUCTIONS Troubleshooting: Use As Isolation Transformer

Figure 8. Eliminating the Hazard of Servicing Transformerless Equipment

19

Page 22

Figure 9. Using the AC Power Supply as an Isolation Transformer

20

Page 23

OPERATING INSTRUCTIONS Troubleshooting: Use As Variable Voltage Source

TROUBLESHOOTING: USING THE AC POWER SUPPLY AS A VARIABLE AC VOLTAGE SOURCE

VARIABLE VOLTAGE SOURCE

Both the Model 1655A and 1653A AC Power Supplies offer

continuously variable output voltage from 0 to 150VAC. Several

applications are listed below, but the versatile instruments may be

used in any application where an ac power source of any value

from 0 to 150 volts is required, and within the maximum current

rating of the instrument.

24 VOLT APPLICATIONS

Class II industrial control equipment operates from nominal 24

volt, 60 Hz ac power. Such equipment is widely used in

industrial plants. These power supplies can be adjusted to 24

volts ac for bench servicing of the equipment.

130-150 VOLT APPLICATIONS

The ability to go higher then 130 volts is indispensable in

component and equipment testing where specifications must be

exceeded to verify designs and overvoltage margins.

TROUBLESHOOTING EQUIPMENT THAT BLOWS

FUSES

One of the problems with troubleshooting equipment with a

severe overload or short is that it repeatedly trips its circuit

breaker or blows fuses. Full power cannot be applied long

enough for normal voltage and waveform measurements to be

performed. The variable voltage feature permits operation at a

lower voltage that does not activate the protective device; testing

and troubleshooting can be performed with power applied.

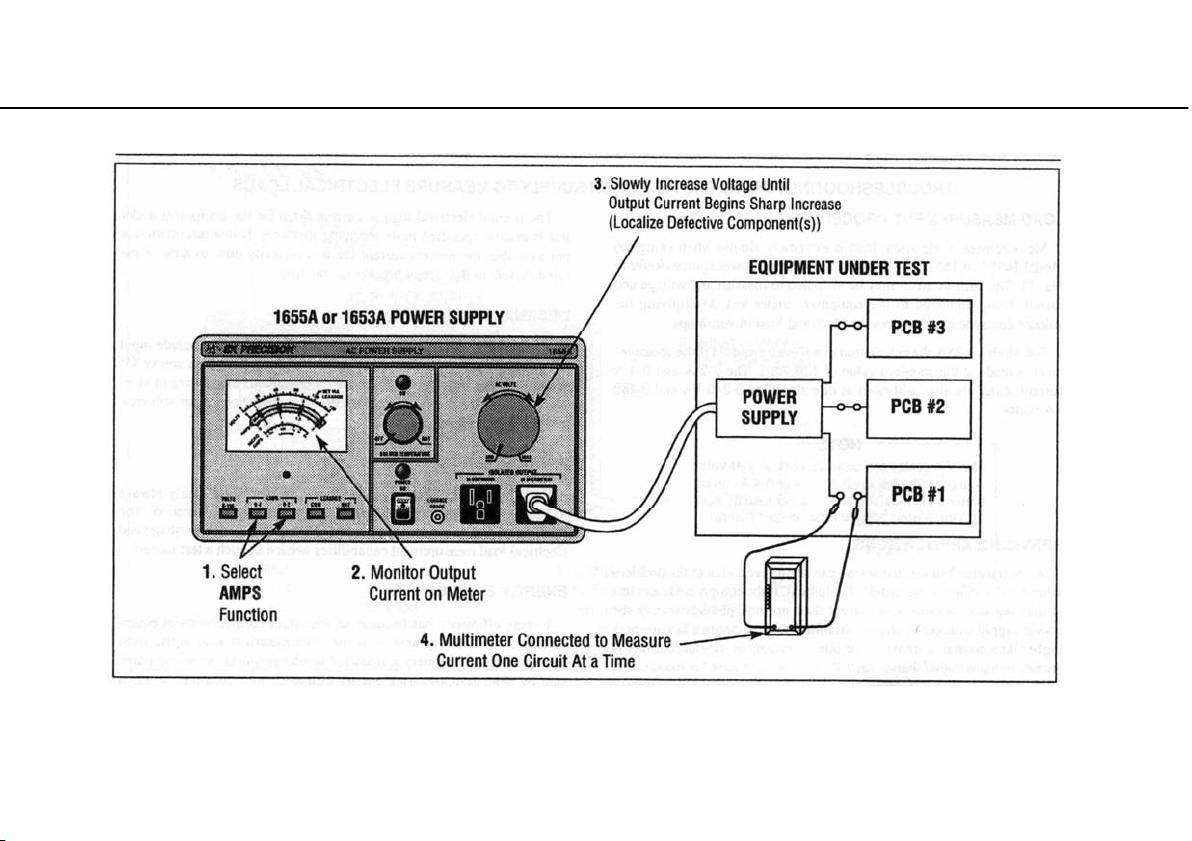

Using the Model 1655A or 1653A AC Power Supply as shown

in Fig. 10, voltage can be set to 0 volt and slowly increased while

monitoring the current. Problems such as a defective circuit

breaker that open too soon are quickly spotted. If current reaches

its normal value (typically, about 70% of the fuse of protective

device rating) at a low voltage such as 20 volts, there is a major

short in the power supply or one of the main power distribution

circuits. If current increases to its normal value more gradually,

allowing voltage to approach 100 volts or more, an overload in

one of the circuits is probably the cause. Current that increases

sharply above a certain voltage may indicate electrical breakdown

or arcing within a component. Voltage or current measurements

in various circuits (see Fig. 10) while varying the input voltage

can help isolate the fault.

INPUT VOLTAGE SPECIFICATION TESTING

Most ac powered equipment is specified to operate over a

range of input voltage such as 120VAC ±10%. Complete

performance testing cannot be conducted without a variable ac

source. Some testing may merely consist of measuring regulated

dc voltages while varying the ac source voltage; with other tests

conducted at nominal line voltage.

LOW OR HIGH LINE VOLTAGE RELATED FAILURES

Occasionally, an equipment malfunctions only during

conditions of low or high line voltage. Troubleshooting of such

problems is almost impossible without a variable ac voltage

source. Either Model 1655A or 1653A AC Power Supply serves

as a variable ac voltage source.

21

Page 24

Troubleshooting: Use As Variable Voltage Source OPERATING INSTRUCTIONS

Figure 10. Using the Variable Voltage Feature to Troubleshoot Equipment with Short Circuit

22

Page 25

OPERATING INSTRUCTIONS Troubleshooting: Load Measurement

TROUBLESHOOTING: USING THE AC POWER SUPPLY TO MEASURE ELECTRICAL LOADS

LOAD MEASUREMENT PROCEDURE

Measurement of electrical load is extremely simple when using

the Model 1655A or 1653A AC Power Supply as the power

source. Refer to Fig. 11. The built-in meter may be switched to

measure the voltage and current being delivered to the equipment

under test. Multiplying the voltage times the current give the

electrical load in volt-amps.

For Model 1655A the calculations is not even required if the

measurement is made at the standard value of 120 volts. The

0-2A and 0-4A current scales are also calibrated as direct reading

0-24VA and 0-480VA scales.

NOTE

The VA scales are accurate only at 120 volts. At other voltages,

use the 0-2A or 0-4A current scales and calculate the electrical

load by multiplying output voltage times output current.

SERVICING APPLICATIONS

An initial check of electrical load can often give a clue to the

problem when troubleshooting electronics equipment. If the

equipment under test is drawing considerably less current than

normal, perhaps one of the power supply voltages is absent,

disabling several circuits. If current is higher than normal, a

transistor or other component may be shorted. If current remains

higher than normal after other faults have been corrected, a leaky

filter capacitor is suspected. Such problems should be corrected

to prevent another impending failure.

The normal electrical load or current drain for the equipment

under test is usually specified in its servicing literature. If that

information is not available, the normal current drain is typically

60% to 80% of the rated current of the circuit breaker or line fuse.

DESIGN APPLICATIONS

The design goals of any ac powered electronic product include

input power requirements. Using the ac power supply as the

power source for breadboard and prototype units provides

continuous monitoring of electrical load for various circuit

configurations, at various input voltages, and at various

temperatures.

PRODUCTION TESTING

Final testing of electrical and electronics equipment nearly

always includes monitoring of electrical load in all modes of

operation. The B+K Precision ac power supplies provide both

variable voltage and electrical load measure meant capabilities

needed in such a test station.

ENERGY EFFICIENCY

Energy efficiency has become an important consideration in

equipment selection. Equipment with the least electrical load is

the most energy efficient. The electrical load of similar products

can be compared side by side, demonstrating energy efficiency to

a customer in terms readily understood by a layman.

23

Page 26

Troubleshooting: Load Measurement OPERATING INSTRUCTIONS

Figure 11. Measuring Electrical Load

24

Page 27

OPERATING INSTRUCTIONS Leakage Tester

USING THE MODEL 1655A AS A LEAKAGE TESTER

STANDARD LEAKAGE TEST

As previously mentioned, most equipment with a 2-wire ac

power plug is the “hot chassis” type. The plastic or wood cabinet

normally insulates the chassis so the user cannot touch it. Other

exposed metal parts such as antennas, antenna terminals, knob

shafts, screw heads, handles, etc. are also insulated (or isolated

with very high resistance) to protect the user from electrical shock

Most equipment manufacturers specify a leakage test after

reassembly of the equipment to insure the continued protection of

the user from electrical shock.

The standard leakage test requires a leakage probe consisting

of a test lead in series with a 1.5kΩ, 10 watt resistor parallel by a

0.15µF capacitor. One end of the leakage probe is connected to

an earth ground. Voltage across the resistor is measured on an ac

voltmeter as the leakage probe is touched to each exposed metal

part of the equipment. An isolation transformer must not be used

during the standard leakage test, and the entire test must be

repeated with the ac power plug reversed, even if an adapter is

required to reverse the connections of a polarized plug.

The maximum permissible leakage specified by OSHA, UL,

and CSA is 500µA. Some manufacturers specify a lower limit for

a greater margin of safety.

THE SIMPLER METHOD

The Model 1655A AC Power Supply includes a built-in

leakage tester that greatly simplifies the leakage test (Fig. 12).

The equipment under test remains connected to the

ISOLATED OUTPUT, just as if it was for servicing. The voltage

was probably already preset to 120 volts at the conclusion of

servicing.

The permanently attached leakage probe of the ac power

supply is merely touched to each exposed metal part of the

equipment under test (antenna, terminals, tuner knob, knob shafts,

handle, screw heads, etc.)

No separate voltmeter nor conversion of results is required.

Just press the LEAKAGE button and read leakage directly from

the LEAKAGE scale of the meter in microamps (in milliamps for

higher values of leakage). See the manufacturer’s service

literature for the maximum permissible leakage. However,

leakage in excess of 500µA is considered hazardous in any

equipment. Locate and correct the cause of leakage.

The expanded scale meter gives good resolution in the normal

100 to 500µA range. Reading give up to 5mA are measured on a

compressed scale. The amount of excess leakage can be a clue to

the type of leakage path. A full scale meter reading probably

indicates a direct short to the power line, but the meter is

protected from damage.

The leakage probe may also be used to verify proper wiring of

equipment with polarized plug; there should be very low leakage

from the chassis to common and full scale leakage to hot.

Leakage of equipment with a 3-wire power plug is performed

in the same manner as for 2-wire equipment.

25

Page 28

Figure 12. Power Line Leakage Testing.

26

Page 29

OPERATING INSTRUCTIONS Soldering Iron Temperature Control

)

SOLDERING IRON TEMPERATURE CONTROL (MODE 1655A ONLY

THE NEED FOR TEMPERATURE CONTROL

Most servicing work requires the use of a soldering iron. If the

soldering iron is plugged in only when it is needed, time is wasted

waiting for the iron to heat up. But if it is left plugged in all the

time, oxidation quickly erodes the tip. Also, soldering iron

temperature varies with line voltage. Some irons reach the ideal

temperature at 105 to 110 volts. As a result, at 120 volts, some

soldering irons are too hot, which can more easily damage

components being replaced or cause separation of circuit board

plating.

THE SOLUTION

(refer to Fig. 13)

The solution to the problem just described is a variable ac

voltage source. The soldering iron could be kept warm to reduce

oxidation of the tip, quickly brought to operating temperature

when needed, and adjusted to the exact temperature desired.

The Model 1655A AC Power Supply includes a built-in

soldering iron temperature control feature. A separate ac outlet is

provided on the rear panel. The output duty cycle at this outlet is

variable from about 70% to 99%, or the outlet can be switched off

when not in use. This outlet is intended for a soldering iron only.

It is not intended for transformer type soldering irons nor irons

rated at greater than 100 watts.

Temperature is adjusted with the SOLDER TEMP control on

the front panel. A relatively low temperature setting is

recommended between periods of soldering iron use to reduce

oxidation of the tip. This setting keeps the iron warm enough that

it can be quickly brought to operating temperature when needed.

The temperature control is non-linear, allowing for a larger

temperature variation at the low end and more precise

temperature control at the HOT end. The exact temperature

desired can be easily achieved.

The soldering iron temperature control is entirely independent

of the isolated variable voltage output, including separate on-off

switches and pilot lights. Thus the soldering iron temperature

control feature may be used with or without the other features of

the instrument.

SUMMARY OF PROCEDURE

(refer to Fig. 13)

1. Set the SOLDER TEMP control to OFF

2. Connect the ac power plug of the soldering iron to the

outlet on the rear panel of the Model 1655A AC Power

Supply. THIS OUTLET IS FOR A SOLDERING

IRON ONLY. Do not connect electronic equipment

here.

3. Turn the SOLDER TEMP control clockwise to the on

position. The amber pilot lamp will light.

4. Between periods of soldering iron use, reduce

temperature to minimize oxidation of the tip.

5. When ready to use the soldering iron, adjust the

SOLDER TEMP control to the desired temperature.

Experience will quickly determine the typical setting

for a given soldering iron.

27

Page 30

Figure 13. Using the Variable Soldering Iron Temperature Feature.

28

Page 31

Refer to the separately supplied schematic diagram while

reading the following circuit descriptions.

VARIABLE VOLTAGE CIRCUIT

Input power is applied through the POWER ON switch to

variable auto-transformer TI. The output of TI is set with the AC

VOLTS control from 0 to 150 volts. The selected amount of

voltage is applied across isolation transformer T2 to the

ISOLATED OUTPUT receptacle(s).

Model 1653A is protected by input fuse F1, while Model

1655A uses circuit breaker CB1. This limits the maximum input

current. Additional protection for the auto-transformer is offered

by fuse F2, which limits the maximum output current at low

voltages which would not open the protective device in the input

circuit. In Model 1655A, this is a 4-amp fuse on the rear panel.

In Model 1653A, a 3-amp internal fuse is used.

METERING CIRCUIT

Since the output of the unit is ac, the meter is connected across

a bridge rectifier to provide the dc necessary for meter operation.

The rectifier circuit senses the average level, while the meter is

calibrated to read the equivalent rms value of a sine wave voltage

the back-to-back diodes connected directly across the meter limit

maximum voltage and thus offer overrange protection.

When the VOLTS function is selected, the voltage across the

ISOLATED OUTPUT is applied to the meter circuit. The meter

is shunted by the VOLTAGE CAL trim pot which calibrates the

voltage scale.

A 1-ohm current sensing resistor (two series 0.5-ohm in Model

1655A) develops a voltage proportional to output current. In the

AMPS function, this voltage is applied across the meter circuit.

The meter is now shunted by the AMPS CAL trim pot which

calibrates the 2 amp current scale. In Model 1655A, the 4 amp

scale is selected by sensing the voltage developed across only one

of the 0.5-ohm resistors.

When the LEAKAGE function is selected (Model 1655A only)

the current from the leakage probe is applied to the meter circuit.

Diodes D4 and D5 are reverse biased below 500 µA for expanded

scale feature. At higher leakage current, the diodes become

forward biased and shunt part of the current to compress the

meter scale.

SOLDERING IRON TEMERATURE CONTROL CIRCUIT

(Model 1655A Only) Input power is applied through triac TR1

to the soldering iron outlet on the rear panel. Breakdown diode

D1 does not gate the triac into conduction until its 30 volt

threshold is reached. Thus, the triac does not conduct for the

entire input cycle. SOLDER TEMP control R2 forms part of an

RC phase shift network which varies the phase of the trigger

voltage in relation to the anode voltage of the triac. This varies

the non-conduction period, which adjusts the soldering iron

temperature. The circuit is automatically reset each time the ac

passes through zero.

29

Page 32

1. The following instructions are for use by qualified

service personnel only. To avoid electrical shock, do

not perform servicing other than contained in the

operating instructions unless you are qualified to do so.

2. When the unit is plugged into an ac outlet, even if the

POWER ON switch is off, ac line voltage is present as

some input power circuits. Observe caution any time

the case is removed from the instrument.

PREVENTIVE MAINTENANCE

Do not overload the instrument. Excessive output current can

damage the variable auto-transformer. Prolonged use at high

current accelerates failure. Keep output current as low as

possible, and never exceed the maximum rating of the unit. If

possible, power only one piece of equipment at a time. Use the

ISOLATED OUTPUT only for the equipment under test-not for

other test equipment. It is very important to observe the

maximum current derating (Table 1) above 130 volts, and to

allow sufficient cooling time when operating Model 1655A at

greater than 3 amps outlet.

Periodic inspection of the brush on the variable contact of the

auto-transformer is recommended. Badly worn or arcing brushes

should be replaced. See the AUTO-TRANSFORMER BRUSH

REPLACEMENT paragraph for replacement procedures.

WARNING

RETURNING FOR SERVICE

If you have encountered a problem with your unit and choose

to return it for service, check the following before returning.

1. Is the circuit breaker reset (Model 1655A)? See FUSE

REPLACEMENT paragraph below if required.

2. Are the fuses okay? See FUSE REPLACEMENT

paragraph below if required.

FUSE REPLACEMENT

The ac power supply will trip its circuit breaker or blow a fuse

only if it is severely overloaded or a failure occurs in the

instrument. Always turn off the unit to reset the circuit breaker or

replace a fuse. If fuses are internal, unplug the instrument from

its wall outlet before attempting replacement. Before turning the

unit back on, reduce the output voltage or remove the overload

that caused the blown fuse. Replace the fuse only with the

original type and value-never one of a large value. A larger value

may create a fire and safety hazard, or cause serious damage to

the equipment. Also refer to the following specific fuse

replacement information for each model.

Model 1653A

If the instrument is severely overloaded at higher output

voltages, fuse F1 on the rear panel will blow. The unit will stop

operating and the pilot light will go off. If the instrument is

severely overloaded at low output voltage, internal fuse F2 will

blow. In this case, there will be no output but the pilot light will

stay on. Fig. 14 shows the location of the fuses. Replace fuse F1

only with a 3-amp slow-blow type 3AG.

30

Page 33

Model 1655A

If this instrument is severely overloaded at higher output

voltages, circuit breaker CB1 on the rear panel will trip. The unit

will stop operating and the POWER ON pilot light will go off.

Remove the overload and push the button on the circuit breaker to

reset. A severe overload at low output voltage will blow fuse F2 on

the rear panel. In this case, there will be no output but the pilot

light will stay on. If the soldering iron outlet is overloaded, internal

fuse F1 will blow. If so, the SOLDER TEMP pilot light will go off.

Fig. 15 shows the fuse locations. Replace fuse F1 only with a 1amp normal blow type 3AG. Replace fuse F2 only with a 4-amp

slow-blow type 3AG.

AUTO-TRANSFORMER BRUSH REPLACEMENT

To replace the brush, unplug the instrument, then gently lift the

brush from the brush track. Grasp the old brush assembly and snap

it out of position by pulling radially. Install the new brush assembly

by lifting the spring arm and snapping the new brush assembly into

position.

It is imperative that newly installed or re-installed brushes

be seated correctly on the brush track for proper operation of

the transformer. With the power off, insert a piece of garnet

paper (non-metallic) between the brush and brush track, rough

side toward the brush. A few swing of the brush over the

garnet paper will mate the brush contact face to the brush

track. Remove the garnet paper and blow away loose particles

before applying power.

CALIBRATION ADJUSTMENTS

This unit was carefully checked and calibrated at the factory

prior to shipment. Readjustment is recommended only if

repairs have been made in a circuit that affects calibration, or it

you have reason to believe the unit may be out of calibration.

Locations of the calibration adjustments are shown in Fig. 14

(Model 1653A) and 15 (Model 1655A).

Test Equipment Required

1. Multimeter, ac voltage accuracy of 0.5% or better at

120 V, 60Hz, ac current accuracy of 1% or better at

500 microamps and 2 amps, 60Hz. B+K Precision

Model 2831D or equivalent.

2. 60 ohm, 240 watt resistive power supply load. Must be

capable of dissipating 2 amps at 120 VAC. A variable

electronic load of sufficient power rating may be used,

or parallel light bulbs totaling 240 watts are suitable.

31

Page 34

MAINTENANCE AND CALIBRATION

Figure 14. Location of Fuses and Calibration Adjustments, Model 1653A.

32

Page 35

Figure 15. Location of Fuses and Calibration Adjustments, Model 1655A.

33

Page 36

Meter VOLTS Calibration

1. With the power supply turned off, adjust the mechanical

zero of the meter to exact zero.

2. Connect an external multimeter of ±0.5% or better ac

voltage accuracy to the ISOLATED OUTPUT.

3. Turn on the ac power supply and set the AC VOLTS

control for 120 volts on the multimeter

4. Set function switch to VOLTS and adjust VOLTS CAL

(R6 for Model 1653A, R14 for Model 1655A) for 120

volts on built-in meter.

Meter AMPS Calibration

1. Connect a 60 ohm, 240 watt resistive load to the

ISOLATED OUTPUT receptacle. Parallel light bulbs

totaling 240 watts is suitable.

2. Connect a calibrated multimeter of 1% or better ac current

accuracy in series with the load to measure each current.

Set the multimeter to a 2-amp range.

3. Turn on the ac power supply and slowly increase the

output voltage until the multimeter measures 2.0 amps.

4. Set the function switch to AMPS and adjust AMPS CAL

(R7 for Model 1653A, R12 for Model 1655A) for 2.0

amps on the built-in meter.

5. For Model 1655A, adjust calibration on the 0-2A range.

The adjustment calibrates both scales. If 0-4A range is

inaccurate, replace R5 and R6 with matched equal

resistors and repeat calibration adjustment.

Meter LEAKAGE Calibration (Model 1655A only)

1. Connect the leakage probe in series with a 220 kΩ, ¼ watt

resistor.

2. Connect a calibrated multimeter of 1% or better ac current

accuracy in series with the 220kΩ resistor and leakage

probe. Set the multimeter to measure 500µA ac current.

3. Carefully connect the other lead of the multimeter to the

hot side of the ISOLATED OUTPUT receptacle. Adjust

the AC VOLTS control for exactly 500µA on the

multimeter.

4. Select the LEAKAGE function and adjust LEAKAGE

CAL (R11) for 500µA on the built-in meter.

PERFORMANCE TESTS

The following checks test all functions of the ac power supply

for proper operation. The sequence of the checks also provides a

logical symptom and fault isolation technique for troubleshooting.

After troubleshooting and repair, these tests should be performed

to assure that all faults have been corrected.

1. Before the power supply is turned on, the meter should

rest at exact zero. If mechanical zero adjustment is

required, calibration adjustments should be rechecked.

2. Set the POWER ON switch to on. The POWER ON pilot

light should illuminate.

3. Set the function switch to VOLTS and rotate the AC

VOLTS control to minimum (fully counterclockwise).

The output should go to zero as read on the front panel

meter.

34

Page 37

4. Rotate the AC VOLTS control to maximum. The control

should rotate smoothly and the output voltage should

increase smoothly to 150 volts, as read on the meter. TO

check mete calibration, measure voltage with calibrated

external meter at 120 volts and compare reading to front

panel meter.

5. Reduce the voltage to minimum and connect a load to the

ISOLATED OUTPUT. A load consisting of light bulbs

totaling 240 watts is preferred. Set the function switch to

AMPS and increase the AC VOLTS control until the

meter reads 2 amps (or 120 volts, whichever occurs first).

To check meter calibration, measure current with

calibrated external meter at 2.0 amps and compare to front

panel meter.

6. For Model 1655A, check that the meter reads 2 amps on

both the 0-2A and 0-4A range.

7. For Model 1655A, check the leakage function as follows:

a. Reduce the voltage to minimum and connect the

leakage probe to the hot side of the ISOLATED

OUTPUT.

b. Select the LEAKAGE function and slowly

increase the AC VOLTS control until meter reads

500 µA on the leakage scale. This should occur at

about 6 volts. To check meter calibration, measure

leakage current with calibrated external meter and

compare to front panel meter.

c. Increase the AC VOLTS control until the meter

reads 5mA on the leakage scale. This should

occur at about 60 volts. With the reverse polarity

of LEAKAGE function, the meter should read

zero.

d. Change the leakage probe to the common side of

the ISOLATED OUTPUT and select both

polarities of the LEAKAGE function. One

polarity should read zero and the other should

indicate 5mA of leakage.

8. For Model 1655A, check the soldering iron temperature

control function as follows:

a. Connect a load to the soldering iron outlet on the

rear panel. A lamp of 25 to 100 watts is preferred,

or a soldering iron may be used. Turn on the

SOLDER TEMP control. The amber pilot light

should illuminate.

b. Connect an ac voltmeter across the load and vary

the SOLDER TEMP control from minimum to

maximum. At 120 volts line voltage, the light

bulb intensity should vary and the voltmeter

should read from roughly 85 volts at minimum to

118 volts at maximum (this variation will not be

achieved unless a load is connected).

TROUBLESHOOTING

If the previously listed “Performance Tests” are performed in

the sequence listed, this provides a logical approach to defining

symptoms and isolating defective circuitry. The following

information may help further isolate the problem

35

Page 38

No POWER ON Pilot Light

This symptom indicates either a fault in the primary power

circuit, or a tripped circuit breaker (Model 1655A) or blown fuse

(Model 1653A). The following checks should isolate the

problem.

1. Make sure the unit is plugged into a “live” outlet.

2. Reset the circuit breaker (Model 1655A) or check the rear

panel fuse and replace if burned out (Model 1653A).

3. If the circuit breaker or fuse is okay, verify whether there

is any output from the supply; select VOLTS function and

note meter reading on 0-150V scale. If output is

available, the pilot light bulb is probably defective. If no

output is noted, the trouble is probably an open in the

power transformer primary circuit. Check continuity of

the power cord, fuseholder, POWER ON switch, variable

auto-transformer, and the wiring interconnecting these

parts.

4. If circuit breaker does not trip again, or replacement fuse

does not burn out when unit is turned on, previous fault

may have been caused by an overload connected at the

ISOLATED OUTPUT.

5. If circuit breaker trips again, or replacement fuse burns

out, check for shorted variable auto-transformer or power

transformer.

No Output-Pilot Light Okay

1. If no output voltage is indicated on the front panel meter,

check voltage at ISOLATED OUTPUT with external ac

voltmeter.

2. If no voltage is measured on external meter, check rear

panel fuse (Model 1655A ) or internal fuse F2 (Model

1653A) and replace if burned out. If fuse is okay, check

brush of variable auto-transformer. Check for open

winding in isolation transformer or open current sensing

resistor.

3. If voltage is measured on external meter, but none is

indicated on front panel meter, see troubleshooting

procedure in next paragraph.

Incorrect or No VOLTS, AMPS, or LEAKAGE Meter Reading

1. Check meter reading in all three functions to further

isolate the fault.

2. For inaccuracy, perform calibration adjustments. If no

reading or inability to adjust to correct reading, a defective

component is indicated.

3. If trouble appears in more than one mode, check bridge

rectifier diodes, meter, and series resistors. If trouble is in

one mode only, check function switch and associated

metering resistors.

SOLDER TEMP Operation Abnormal (Model 1655A Only)

1. If no SOLDER TEMP pilot light, check internal fuse F1

and replace if burned out. If fuse is good, check voltage at

soldering iron outlet. If voltage at outlet is okay, pilot

lamp is defective.

2. If pilot light is okay, but no output voltage or incorrect

output voltage, check triac TR1, breakdown diode D1,

resistors R1, R2, and R3, capacitors C1, C2, and inductor

L1.

36

Page 39

Service Information

Warranty Service: Please return the product in the original packaging with proof of purchase to the address below. Clearly state in writing

the performance problem and return any leads, probes, connectors and accessories that you are using with the device.

Non-Warranty Service: Return the product in the original packaging to the address below. Clearly state in writing the performance problem

and return any leads, probes, connectors and accessories that you are using with the device. Customers not on open account must include

payment in the form of a money order or credit card. For the most current repair charges please visit www.bkprecision.com and click on

“service/repair”.

Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat-rate repair charge for Non-Warranty Service does not include

return shipping. Return shipping to locations in North American is included for Warranty Service. For overnight shipments and non-North

American shipping fees please contact B&K Precision Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return shipping address, contact name, phone number and description of

problem.

37

Page 40

LIMITED ONE YEAR WARRANTY

B&K Precision Corp. warrants to the original purchaser that its product and the component parts thereof, will be free from defects in

workmanship and materials for a period of three years from the date of purchase.

B&K Precision Corp. will, without charge, repair or replace, at its option, defective product or component parts. Returned product must be

accompanied by proof of the purchase date in the form of a sales receipt.

To obtain warranty coverage in the U.S.A., this product must be registered by completing a warranty registration form on

www.bkprecision.com within fifteen (15) days of purchase.

Exclusions: This warranty does not apply in the event of misuse or abuse of the produc t or as a resul t of unauthorized alternations or

repairs. It is void if the serial number is alternated, defaced, or removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages resulting from loss of use.

Some states do not allow limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific rights and you may have other rights, which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Model Number: _________________________________ Date Purchased: _________________________________

38

Page 41

SEGURIDAD DEL INSTRUMENTO

ADVERTENCIA

Una descarga eléctrica que permita el paso de 10mA por el corazón suspenderá sus latidos en la mayoría de los casos y es causa de muerte.

Voltajes tan bajos como de 35V dc o ac deben considerarse de peligro ya que pueden causar corrientes letales en ciertas condiciones. Dicho

peligro es aún mayor para voltajes más altos. Sus hábitos de trabajo normales deben incluír todas las prácticas aceptadas para prevenir

descargas de alto voltaje y desviar corrientes que pudieran fluir al corazón en caso de contacto accidental con voltajes altos. Para reducir

riesgos, siga y observe las precauciones siguientes:

1. Las fuentes de poder de AC B+K Precision modelos 1655A y 1653A son fuentes de alto voltaje AC. El operador del instrumento

debe ser un técnico electrónico calificado o bien poseer el entrenamiento y calificaciones para trabajar con voltajes altos.

2. Use sólo clavijas polarizadas de 3 puntas. Esto asegura que el chasis, gabinete y punta de tierra de la SALIDA AISLADA estén

conectados a una buena tierra, lo que reduce el peligro de una descarga eléctrica.

3. Al dar servicio a cualquier equipo con una clavija de 2 puntas AC, trátelo como un “chasis caliente” y conéctelo a la terminal

SALIDA AISLADA (“ISOLATED OUTPUT”) de la fuente. Incluso algunos equipos con clavija polarizada son del tipo “chasis

caliente”.

4. Nunca conecte 2 equipos de “chasis caliente” a SALIDA AISLADA simultáneamente. Puede existir un serio peligro de descarga.

5. No se exponga a altos voltajes sin necesidad. Remueva cubiertas protectoras sólo en caso necesario. Apague el equipo durante el

proceso de conexión a circuitos de alto voltaje. Descargue los capacitores de alto voltaje al remover la energía.

6. De ser posible, familiarícese con el equipo bajo prueba y la localización de sus puntos de alto voltaje. Recuerde, sin embargo, que al

alto voltaje puede aparecer en lugares inesperados de equipos defectuosos.

7. Use pisos o tapetes de material aislante para pararse, y una superficie aislante para colocar el equipo, asegurándose que dichas

superficies no estén húmedas o mojadas.

8. Use la conocida técnica de mantener “una mano en el bolsillo” al manejar puntas de prueba del instrumento. Evite en particular el

tocar un objeto metálico cercano que pudiera formar una buena trayectoria de retorno a tierra.

9. Recuerde que equipos activados por fuentes de AC presentan voltaje de ac en ciertos circuitos de entrada como el interruptor de

encendido, fusibles, transformador de poder, etc. mientras estén conectados a la clavija de ac, aún cuando estén apagados.

10. Nunca trabaje sólo. Alguien debe estar cerca para prestarle auxilio en caso necesario. Se recomienda que esté entrenado en primeros

auxilios de CPR (resucitación cardio-pulmonar).

39

Page 42

Manual de usuario de

MODELOS 1653A & 1655A

Aislada, variable

FUENTE DE PODER DE AC

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

Page 43

TABLA DE CONTENDIDO

Página

Página

SEGURIDAD DEL INSTRUMENTO............ Segunda de forros

CARACTERISITICAS ............................................................42

ESPECIFICACIONES .............................................................43

CONTROLES E INDICADORES ...........................................45

INSTRUCCIONES DE OPERACIÓN..................................... 51

Precauciones.............................................................................51

Localizando averías: Uso de la fuente de poder AC como

transformador de aislamiento ...................................................55

Localizando averías: Uso de la fuente de poder AC como fuente

variable de voltaje AC..............................................................60

Localizando averías: Uso de la fuente de poder AC para medir

cargas eléctricas........................................................................ 62

Uso del modelo 1655A como medidor de fugas....................... 64

Control de temperatura del cautín soldador..............................66

DESCRIPCIÓN DEL CIRCUITO............................................68

MANTENIMIENTO Y CALIBRACIÓN.................................69

Mantenimiento preventive ........................................................69

Devolución para servicio ..........................................................69

Reemplazo de fusible................................................................69

Reemplazo de la escobilla del auto transformador....................70

Ajustes de calibración...............................................................70

Pruebas de desempeño..............................................................73

Localización de averías.............................................................74

SOPORTE AL CLIENTE...................................................76, 77

Información sobre garantía .......................................................77

41

Page 44

CARACTERÍSTICAS

RANGO DE VOLTAJA AMPLIO

La salida de voltaje varía continuamente de 0 a 150VAC

RANGO DE CORRIENTE AMPLIO

Modelo 1655A

Unidad de trabajo pesado que maneja virtualmente todo tipo

de necesidades de servicio. Corriente de salida variable

continuamente hasta 3 amps, y hasta 4 amps

intermitentemente.

Modelo 1653A

Maneja muchas necesidades de servicio. Corriente de salida

variable continuamente hasta 2 amps.

CAPACIDAD DE MEDICION DE CARGA AMPLIA

Modelo 1655A

Medidor multifunción interconstruido de 0 a 150V. 2 rangos

de corriente de 0-2A y 0-4A para resolución mejorada. Las

escalas de corriente están calibradas también en VA a 120V.

Modelo 1653A

Medidor inter construído dual, mide voltaje de salida de 0150V y corriente de salida de 0-2A.

VOLTAJE DE SALIDA AISLADO

Transformador de aislamiento inter construido para operación

segura con equipo de “chasis caliente”. Una salida aislada en el

modelo 1653A, y 2 en el modelo 1655A para mayor

conveniencia.

A menos que se indique lo contrario, la información de esta sección aplica igualmente para los modelos 1653A y 1655A

MEDIDOR INTERCONSTRUIDO

Modelo 1655A

Medidor de 3-1/4 de pulgadas. Escalas multicolores.

Protección contra sobrecarga

Modelo 1653A

Medidor de 2 pulgadas. Protección contra sobrecarga

---El modelo 1655A presenta adicionalmente las características

siguientes---

PRUEBA DE FUGA EN LINEA DE PODER

Capacidad de medición de fugas de línea de poder OSHA, UL y

CSA. Medición rápida y segura.

ESCALA DE FUGA EXPANDIDA

La escala de 0-5mA (0 – 5000A) se expande en la región más

utilizada de 100 – 500A, comprimida a 5mA de

plena escala. Con protección contra sobrecarga.

PROTECCIÓN CONTRA SOBRECARGA POR

INTERRUPTOR DE CIRCUITO (“BREAKER”)

Salida aislada protegida por interruptor de circuito de fácil

restauración

CONTROL DE TEMPERATURA DE CAUTIN SOLDADOR

Control de temperatura del cautín inter construído

42

Page 45

MODELO 1655A

ESPECIFICACIONES

MODELO 1653A

AISLAMIENTO DE SALIDA

Fuga menos de 0.1mA (25°C, 50% humedad relativa).

RANGO DE AJUSTE DE VOLTAJE

0-150VAC, con entrada de 120VAC

DETECCIÓN DE VOLTAJE/CORRIENTE

Promedio de onda senoidal, calibrada en RMS

CORRIENTE MÁXIMA (Aislada)

3A continuos, 4A intermitentes (0-130V). La corriente

intermitente no debe exceder de 4 minutos a 4A, seguida de 5

minutos a 1A.

ESCALAS DEL MEDIDOR

Voltaje: ..........................................................................0-150V

Corriente: ...........................................................................0-2A

.....................................................................................0-4A

Volts-Amps (Voltaje establecido a 120V)...................0-240VA

.................................................................................0-480VA

Fuga ...............................0 a 5mA (5,000µA), escala expandida

PRECISION DEL MEDIDOR

Volts: .....±5% (typical) a plena escala (calibración @ 120VAC)

Corriente: ........................................±5% (typical) a plena escala

Fuga ...................................................................±5% @ 500A

AISLAMIENTO DE SALIDA

Fuga menos de 0.1mA (25°C, 50% humedad relativa).

RANGO DE AJUSTE DE VOLTAJE

0-150VAC, con entrada de 120VAC

DETECCIÓN DE VOLTAJE/CORRIENTE

Promedio de onda senoidal, calibrada en RMS

CORRIENTE MÁXIMA (Aislada)

2A continuos (0-130V).

ESCALAS DEL MEDIDOR

Voltaje: ..........................................................................0-150V

Corriente: ...........................................................................0-2A

PRECISION DEL MEDIDOR

Volts: ...±5% (typical) a plena escala (calibración @ 120VAC)

Corriente: ....................................±5% (typical) a plena escala

43

Page 46

MODELO 1655A

POTENCIA DE ENTRADA

9$&±9$&+]

RANGO DE TEMPERATURA DE OPERACIÓN

0 °C a +40 °C

TEMPERATURA DE ALMACENAMIENTO

- 30 °C a + 60 °C

PESO

22 lb. (10Kg.)

DIMENSIONES

10.5”x5.7”x12” (267x145x305mm)

CORRIENTE PICO (Irrupción)

30A máxima (irrupción limitada a 1 ciclo a 30A).

CONTROL DE TEMPERATURA DEL CAUTIN

SOLDADOR

70% - 99% de la potencia de línea (100 W max)

MODELO 1653 A

POTENCIA DE ENTRADA

108 VAC – 132VAC, 60Hz.

RANGO DE TEMPERATURA DE OPERACIÓN

0 °C a +40 °C

TEMPERATURA DE ALMACENAMIENTO

-30 °C a + 60 °C

PESO

12 lb. (5.5Kg.)

DIMENSIONES

5.5”x6.5”x10.5” (140x165x267mm)

NOTA: Las especificaciones y la información están conforme a

cambio sin el aviso de B&K Precision Corp. Por favor visite

www.bkprecision.com

información de nuestros productos.

para las especificaciones más corriente y

44

Page 47

CONTROLES DEL PANEL FRONTAL

(Refiérase a las Figs. 1 y 2)

1. Interruptor de encendido POWER ON

2. Luz piloto de encendido

3. Interruptor de funciones

Modelo 1655A

Cinco botones pulsadores entrelazados para

seleccionar función y escala del medidor. La

opresión de un botón anula la selección previa. Se

tienen las opciones siguientes:

VOLTS. Conecta al medidor para medir voltaje en

ISOLATED OUTPUT. Use las escalas 0-150V del

medidor. El voltaje es ajustable por el control AC

VOLTS.

AMPS 0-4. Conecta al medidor para medir corriente en

ISOLATED OUTPUT. Use la escala 0-4 AMPS del

medidor. Cuando el voltaje se establece en 120 VAC, la

escala 0-480VA puede usarse para medir la carga de

salida en volts-amperes.

AMPS 0-2. Conecta al medidor para medir corriente en

ISOLATED OUTPUT. Use la escala 0-2 AMPS del

medidor. Cuando el voltaje se establece en 120 VAC, la

CONTROLES E INDICADORES

escala 0-240VA puede usarse para medir la carga de

salida en volts-amperes.

LEAKAGE COM. Conecta al medidor para medir fuga respecto

LEAKAGE HOT. Conecta al medidor para medir fuga respecto

Modelo 1655A

VOLTS. Conecta al medidor para medir voltaje en ISOLATED

AMPS. Conecta al medidor para medir corriente en ISOLATED

al cable común de la línea de AC. Use la escala LEAKAGE del

medidor. El voltaje debe establecerse en 120VAC para obtener

mediciones precisas.

al cable caliente de la línea de AC. Use la escala LEAKAGE

del medidor. El voltaje debe establecerse en 120 VAC para

obtener mediciones precisas.

Un botón pulsador de acción alternante selecciona función o

medidor. Pulse una vez para enganchar el botón en posición

AMPS (in). Pulse de nuevo para liberarlo a la posición VOLTS

(out). Se dispone de las selecciones siguientes:

OUTPUT. Use las escalas 0-150V del medidor. El voltaje es

ajustable por el control AC VOLTS.

OUTPUT. Use la escala 0-2 AMPS del medidor

4. Medidor. La escala apropiada se selecciona por medio

del interruptor de funciones

5. Control AC VOLTS. Ajusta el voltaje del receptáculo

ISOLATED OUTPUT de 0 a 150 volts

45

Page 48

CONTROLES E INDICADORES

6. RECEPTÁCULO DE ISOLATED OUTPUT.

Salidas aisladas de voltaje ac variable. Aquí se conecta

el equipo bajo prueba. Una salida en el modelo 1653A.

Dos salidas en el modelo 1655A.

7. *Punta de prueba de fuga. Al seleccionar la función

LEAKAGE, se prueba la fuga de la línea tocando con la

punta diversas partes metálicas expuestas del equipo.

8. *Control SOLDER TEMP. La rotación completa en

sentido contrario a las manecillas del reloj de la perilla

apaga la salida del cautín soldador. Una rotación inicial

en el sentido de las manecillas enciende la salida a una

temperatura de reserva (tibia); una rotación mayor

incrementa la temperatura del cautín. El ajuste de

temperatura es progresivo, permitiendo el ajuste fino de

temperatura “caliente” al límite superior del rango. Este

control es completamente independiente del de

encendido POWER ON.

9. *Luz piloto de Solder Temp. Se enciende cuando la

salida de cautín en el panel trasero está activada.

CONTROLES DEL PANEL TRASERO

(Refiérase a las Figs. 3 y 4)

10. Cable de AC *=Modelo 1655A

solamente

11. Fusible

Modelo 1655A

El fusible de 4A protege al auto-transformador contra

corrientes de salida excesivas a voltajes bajos que no

alcancen a accionar al interruptor (“breaker”) de

entrada.

Modelo 1653A

Un fusible de línea de 3A protege contra corrientes de

entrada excesivas. Un fusible interno de 3A protege

contra corrientes de salida excesivas a voltajes bajos

que no alcancen a fundir el fusible de entrada.

12. *Interruptor de circuito de entrada (“breaker”).

Este interruptor de 3.15A protege contra corrientes

excesivas. Remueva la sobrecarga y presione para

restaurar.

13. *Clavija del cautín soldador. Clavija de AC para el

cautín. El factor de trabajo, y por tanto, la temperatura,

puede variarse mediante el control SOLDER TEMP del

panel frontal. Opera para cautines sin transformador de

100 watts o menos.

*=Modelo 1655A solamente

46

Page 49

CONTROLES E INDICADORES

Figura 1. Controles e indicadores frontales del modelo 1655A

47

Page 50

CONTROLES E INDICADORES

Figura 2. Controles e indicadores frontales del modelo 1653A

48

Page 51

CONTROLES E INDICADORES

Figura 3. Controles e indicadores traseros del modelo 1655A

49

Page 52

CONTROLES E INDICADORES

Figura 4. Controles e indicadores del modelo 1653A

50

Page 53

SEGURIDAD

Las fuentes de poder 1653A y 1655A son fuentes de alto

voltaje AC. Su uso negligente o inapropiado puede resultar en

choque eléctrico fatal. Las condiciones más usuales que pueden

implicar un riesgo de choque y las precauciones correspondientes

están identificadas en la sección de SEGURIDAD DEL

INSTRUMENTO en la segunda de forros de este manual.

Conozca y observe dichas precauciones.

Aunque el modelo 1655A está equipado con 2 enchufes

aislados, sólo un equipo con “chasis caliente” puede conectarse a

la vez. A menos que la relación línea-chasis sea idéntica, existe el

riesgo de choque entre ambos chasises.

ALIMENTACION ELECTRICA DE ENTRADA

Estos instrumentos sólo pueden utilizarse con voltaje de línea

de 120VAC, 60Hz. No los opere con líneas de 50Hz, o de 220240 volts. Puede operarlos con 100VAC, 60Hz con seguridad,

pero el voltaje de salida máximo será menor.

VENTILACIÓN

Los hoyos del gabinete proveen enfriamiento de convección

(El aire caliente se levanta y escapa al través de los huecos

superiores, mientras que aire frío es atraído por la base). Nunca

bloquee estos hoyos de ventilación con manuales, diagramas u

PRECAUCIONES

otros equipos, etc. Si el flujo de aire se bloquea, la temperatura

interna puede elevarse excesivamente y provocar fallas en la

unidad. Similarmente, evite operar cerca de fuentes de calor.

VOLTAJE MÁXIMO DE SALIDA

PRECAUCION

Si el voltaje de entrada excede al máximo permitido

del equipo bajo prueba (típicamente 130VAC, puede

causar daños severos al equipo.

El voltaje máximo de salida de la fuente de poder es ajustable

de 0 a 150VAC. Esto es muy útil en ciertas condiciones de prueba

al operar un equipo más allá de su rango para determinar su punto

de ruptura. Sin embargo, para la mayoría de las aplicaciones de

prueba y servicio, al aplicar voltajes superiores a los máximos

especificados debe tener la mayor precaución.

Para pruebas y servicio normales, verifique el voltaje máximo

de entrada del equipo bajo prueba para asegurarse de que la

fuente de poder no exceda de dicho máximo. La mayoría de los

equipos soportan hasta 130VAC; si no está seguro del máximo,

no exceda de 130VAC. La porción de la escala de 130-150VAC

del modelo 1655A se muestra con color rojo indicando que debe

observarse la máxima precaución.

51

Page 54

Precauciones INSTRUCCIONES DE OPERACIÓN

La porción roja de la

escala de VOLTS

indica zona de

precaución

Ajuste el voltaje, observe

precaución si el

Voltaje excede el máximo del

equipo bajo

Prueba. (El equipo puede

dañarse seriamente)

EQUIPO

BAJO

PRUEBA

Seleccione

función

Lea voltaje en

escala o-150V

Del medidor

Figura 5. Observe precaución arriba de 130V

52

Page 55

CORRIENTE MÁXIMA DE SALIDA

PRECAUCION

NUNCA EXCEDA EL VALOR DE CORRIENTE

MÁXIMA DE SALIDA DE LA UNIDAD (Tabla 1)

La corriente de salida en exceso puede dañar al

Auto-transformador variable

Mantenga la corriente de salida tan baja como sea posible.

Conecte sólo un equipo a la vez. Use la salida ISOLATED

OUTPUT sólo para el equipo bajo prueba – No para equipo de

medición.

Es muy importante observar la disminución de la corriente

máxima (Tabla 1) arriba de 130V, y permitir suficiente tiempo de

enfriamiento al operar el modelo 1655A en la región de ciclo

intermitente.

Aún a voltajes bajos, la corriente de salida máxima nunca debe

exceder de 4 Amps en el modelo 1655A o 2 Amps en el modelo

1653A. Corrientes mayores pueden dañar al auto- transformador

donde la escobilla hace contacto con el embobinado. El

interruptor de entrada tipo “breaker” de 3.15A limita la corriente

de entrada del 1655A, mientras que un fusible de 3 A se usa en el

1653A. Además, se cuenta con fusibles de salida de 4 A para el

1655A y de 3 A para el 1653A a bajos voltajes que no abren el

“breaker” de entrada. Nunca cortocircuite el interruptor de

entrada o los fusibles, o reemplace éstos por fusibles de mayor

valor.

Remueva la fuente de sobrecarga para restaurar el “breaker” o