INSTALLATION, OPERATION & MAINTENANCE MANUAL

PERFECTA PUMP

®

Electric Submersible Pump

Single Phase

115 V 60 Hz

220 V 50 Hz

Models

GF 32-9

GF 32-9NL

GF 32-9X

IGF 32-9

IGF 32-9NL

IGF 32-9X

TIGF 32-9NL

TIGF 32-9NLX

Read this manual carefully before installing, operating or servicing these pump models. Observe all

safety information. Failure to comply with instructions may result in personal injury and/or property

damage. Please retain these instructions. Version 07/2013

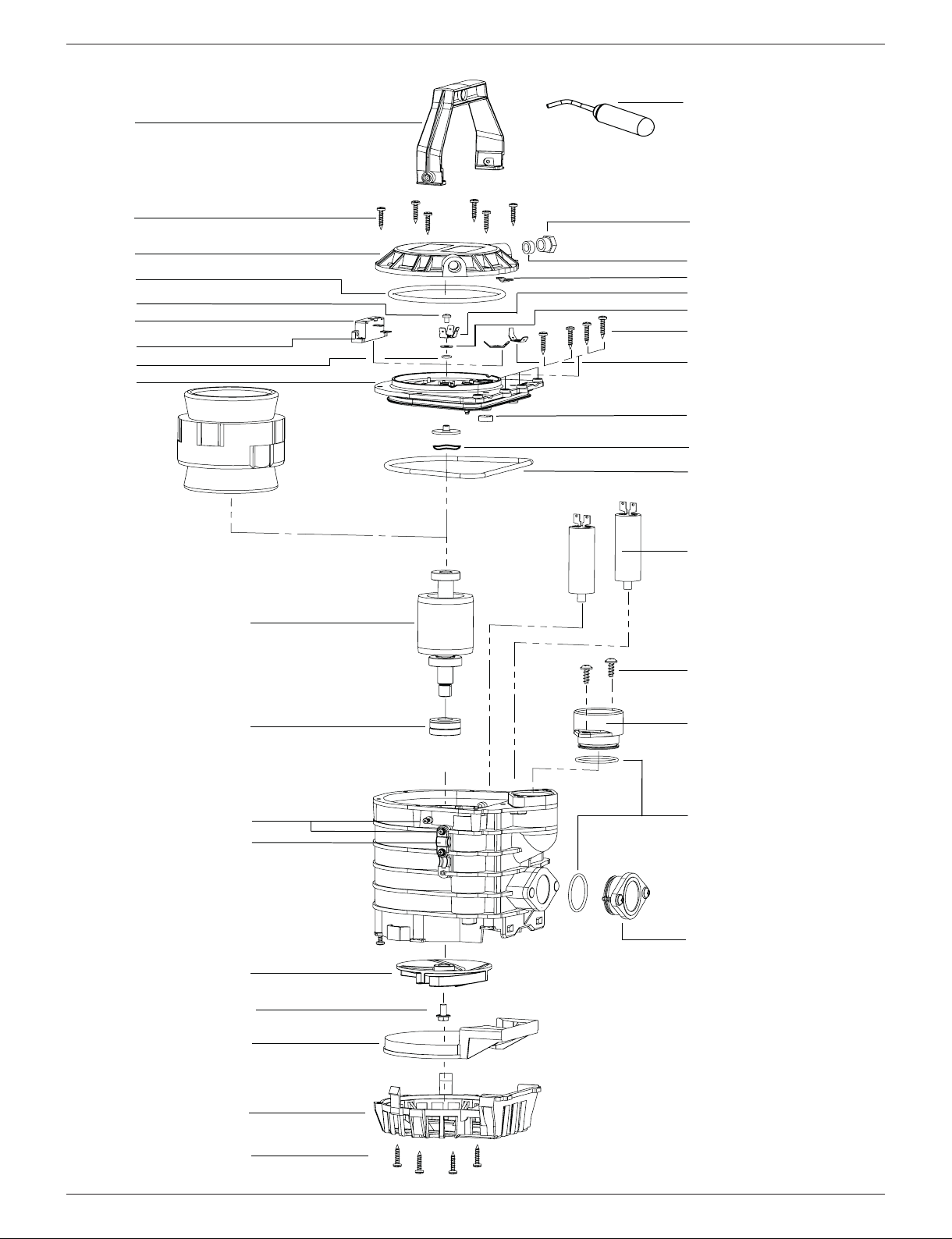

2

1

4

5

3

6

7

8

9

10

11/12/13

14/14.1/14.2

16

15

17

18

19

20

22

21

23

24

25

26

27

28

2

29

32

30/31

34

3

5

33

2

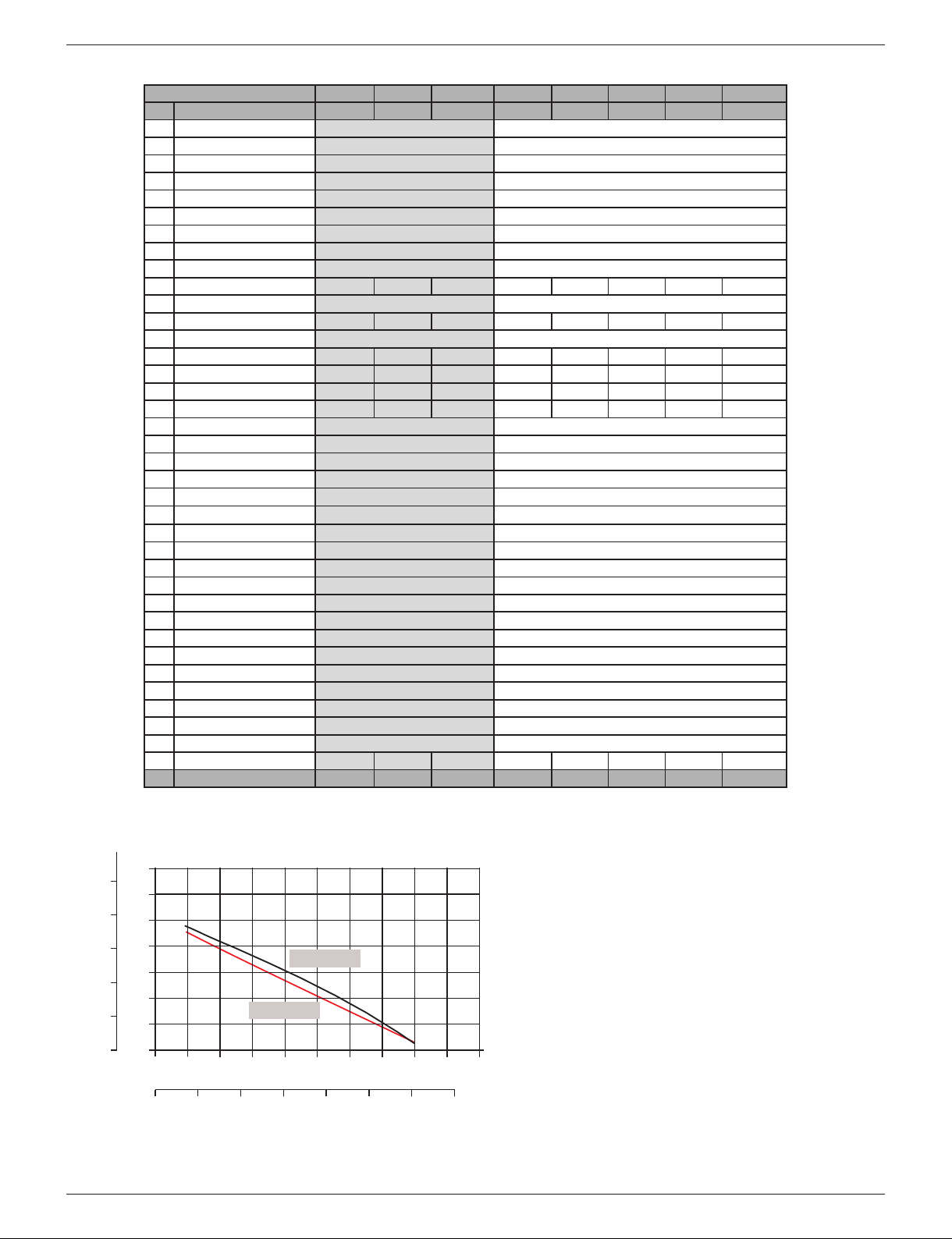

Capacity curve:

35

30

25

20

15

10

5

0

0 5 10 15 20 25 30 35 40 45 50

US GPM

Liters

per second

FEET

METERS

10

8

6

4

2

TOTAL DYNAMIC HEAD

0 25 50 75 100 125 150 175

FLOW RATE

PERFECTA SERIES

®

220 V / 50 Hz

115 V / 60 Hz

Model GF 32-9X IGF 32-9X IGF 32-9XNL GF 32-9 GF 32-9L IGF 32-9 IGF 32-9L TIGF 32-9NL

Pos. Description 201152 201155 201156 201150 201151 20 1153 20 1154 201157

1Pump handle 201787 201787

2Screw 4.2 x 22 201778 201778

3Pump cover 203892 203893

4O-ring 105 x 5 201765 201765

5Screw 201776 201776

6Pump protection relay 204063 --------

7Locking washer 204064 204064

8O-ring 5.6 x 2 201766 201766

9

Pump housing cover 204065 201796

10 Rotor 201762 201795 201795 201762 201762 201795 201795 201745

11 Spacer 201794 201794

12 Shaft seal – Perbunan/FKM 201782 201784 201784 201782 201782 201784 201784 201784

13 Shaft seal – FKM 201784 201784

14 Shaft bolt and serr. washer 017-235 -------- -------- 017-235 017-235 -------- -------- --------

14.1 Shaft bolt -------- 201781 201781 -------- -------- 201781 201781 201751

14.2 Serrated washer -------- 201793 201793 -------- -------- 201793 201793 201793

15 Pull / tension relief 201767 201767 -------- 201767 -------- 201767 -------- --------

16 Screw 2.9 x 13 201780 201780

17 Impeller 204066 201790

18 Pump housing base 201760 201760

19 Suction basket 201757 201757

2

0Outlet cap 201785 201785

21 O-ring 2.5 x 35 201788 201788

22 Threaded outlet 201786 201786

23 Screw 201791 201791

24 Capacitors 204067 201799

25 O-ring 125 x 5 201764 201764

26 Bearing compensating ring 204068 204068

27 Rubber seal 201761 201761

28 Cable connection pin 201783 201783

29 Washer 201775 201775

30 Cable connection pin 201773 20177

31 Serrated washer 201777 201777

32 Pull / tension relief 201768 201768

33 Seal M16 201772 201772

34 Threaded cable grommet 201763 201763

35 Float switch 204069 204069 -------- 201754 -------- 201754 -------- --------

Pos. Description 201152 201155 201156 201150 201151 20 1153 20 1154 201157

Spare parts 220V-pump

Spare parts 115V-pump

NL -> Manual/no float switch

X -> 220V, 50Hz

Technical data

GF 32-9

Pump Material: Noryl GTX 830, 304 S.S Rotor shaft

Seal System: 2 seals (1 FKM, 1 BUNA-N)

Motor Voltage (115 Volt): 115 V, 5.0 Amps, 60 Hz, single-phase std

Motor Voltage (220Volt): 220 V, 2.1 Amps, 50 Hz, single-phase std

Max. Power Consumption: 500 watt

Max. Submersion Depth: 33ʼ (10 m) or limited to length of cable

Overall Dimensions: 7.2ʼʼ (185 mm)

Height Including Handle: 9.8ʼʼ (250 mm)

Weight: 13.5 lbs (6.1kg)

Power Cord (115 Volt): 22ʼ submersible

Power Cord (220 Volt): 16ʼ submersible

Level Regulator: Automatic on/off level control std

Oil filled Motor: Shell Tellus C68 or equal

Thermal Breaker: Capacitor

IGF 32-9

Pump Material: Noryl GTX 830, 316 SS Shaft & Hardware

Seal System: 2 FKM seals

All other components are the same as for GF 32-9. Please see above.

TIGF 32-9

Same as for IGF 32-9 but with all exposed metal parts made of titanium.

and 316 S.S Hardware

ALWAYS DISCONNECT PUMP FROM

LECTRICAL SOURCE BEFORE SERVICING!

E

NOT FOR USE IN FLAMMABLE LIQUIDS!

IMPORTANT:

ACTORY OR YOUR DISTRIBUTOR BEFORE INSTALLATION OR

F

USE.

IN ANY CORROSIVE ENVIRONMENT, CONSULT

cover screws (pos 2) and open top cover. Disconnect wires,

emove motor housing cover (pos 3). Inspect the quality of the oil.

r

If milky or whitish in color, check seals and replace (both seals and

oil) if necessary. To remove rotor, ball bearings and seals, follow

steps described in B. Disassemble pump bottom before

proceeding. Once impeller is off, pull out rotor. Inspect bearings,

replace if necessary. Press out lip seals. Inspect and replace as

necessary.

TROUBLE SHOOTING

ump shuts off:

P

Adjust float switch

Check impeller for free rotation and clogging

Check pump passage, hose or pipe for kink or clog.

Pump is heating up:

Check impeller for free rotation

Check voltage

Pump performance low:

Check for blockage

Check impeller for excessive wear

SERVICE:

Tools needed

Phillips screwdrivers (#1 and #2), locking pliers, 10 mm and 17

mm wrench, ball bearing puller.

A. Disassembly of pump top.

(Check wires, rotor, stator, ball bearings and oil). Remove (pos 39)

handle screws (pos 4). Remove handle. Remove (pos 37) top

B. Disassembly of pump bottom

(strainer, suction cover, impeller) Remove strainer screws (pos

36), remove strainer (pos 6) and suction cover (pos 7). Hold

impeller with vise grip and remove impeller screw (pos 40).

Remove impeller (pos 5). Impeller vanes should have sharp

edges to maximize performance. Replace impeller if vanes are

rounded or dull.

Inspection of pump bottom parts.

Look at lower lip seal parts (pos 27) for visible wear. If damaged

or worn replace both lip seals. To replace lip seals, disassemble

top portion of pump first and remove the oil (see A., disassembly

of pump top).

Note: Both seal openings should face down.

C. Important notes on re-assembly of pump

All O-rings should be lubricated with a silicone based grease, or

lubricated with same oil as in motor, before assembly. Replace

ball bearings to shaft. To re-install inner cover, lubricate bearing

holder. Use a plastic or rubber mallet to lightly tap until cover is in

place. It is important that the bearing is in the absolute center of

the bearing holder when closing the top cover. If not centered, the

shaft will not turn freely.

BJM Pumps, LLC warrants each new pump against defects in workmanship and material for the period of 90 DAYS. It will replace or repair

for the original purchaser, any genuine parts found to be defective upon return to its factory at CT (or other place as designated by it), transportation prepaid by purchaser. The labor involved in replacing defective parts is not warrantable. Other equipment and accessories are warranted only to the extent of the original manufacturerʼs warranty. This warranty does not cover any pump which has been damaged due to careless handling, improper use or application, improper power supply, use in unsuitable liquids, or faulty installa tion. Alteration or repair by other

than BJM Pumps, LLC (or designated service facility) voids this warranty.

BJM Pumps, LLC assumes no liability for damages, losses, inconveniences, direct, or consequential, any kind in respect to the use or operation of the pumps or any equipment or accessory used in connection herewith.

This warranty encompasses the entire understanding between the purchaser and BJM Pumps, LLC and no other person is authorized to extend or alter the terms of the warranty. This warranty is effective only when the warranty certificate card is properly completed and returned

to BJM Pumps, LLC at the time of purchase.

BJM Pumps, LLC

KEEP FOR YOUR RECORDS

Date Purchased:_________________________________________________________________

Model: _____________________Serial No.: __________________________________________

Dealer Name: ___________________________________________________________________

BJM PUMPS, LLC

123 Spencer Plain Rd., P. O. BOX 1138

Old Saybrook, CT 06475

TEL. (860) 399-5937, FAX (860) 399-7784

http://www.bjmpumps.com

Perfecta Pump is a registered trademark of BJM Pumps, LLC

Order-Nr. 099-156 07/2013

Loading...

Loading...