Page 1

YOU'RE HEARD, LOUD AND CLEAR.

Instruction Manual

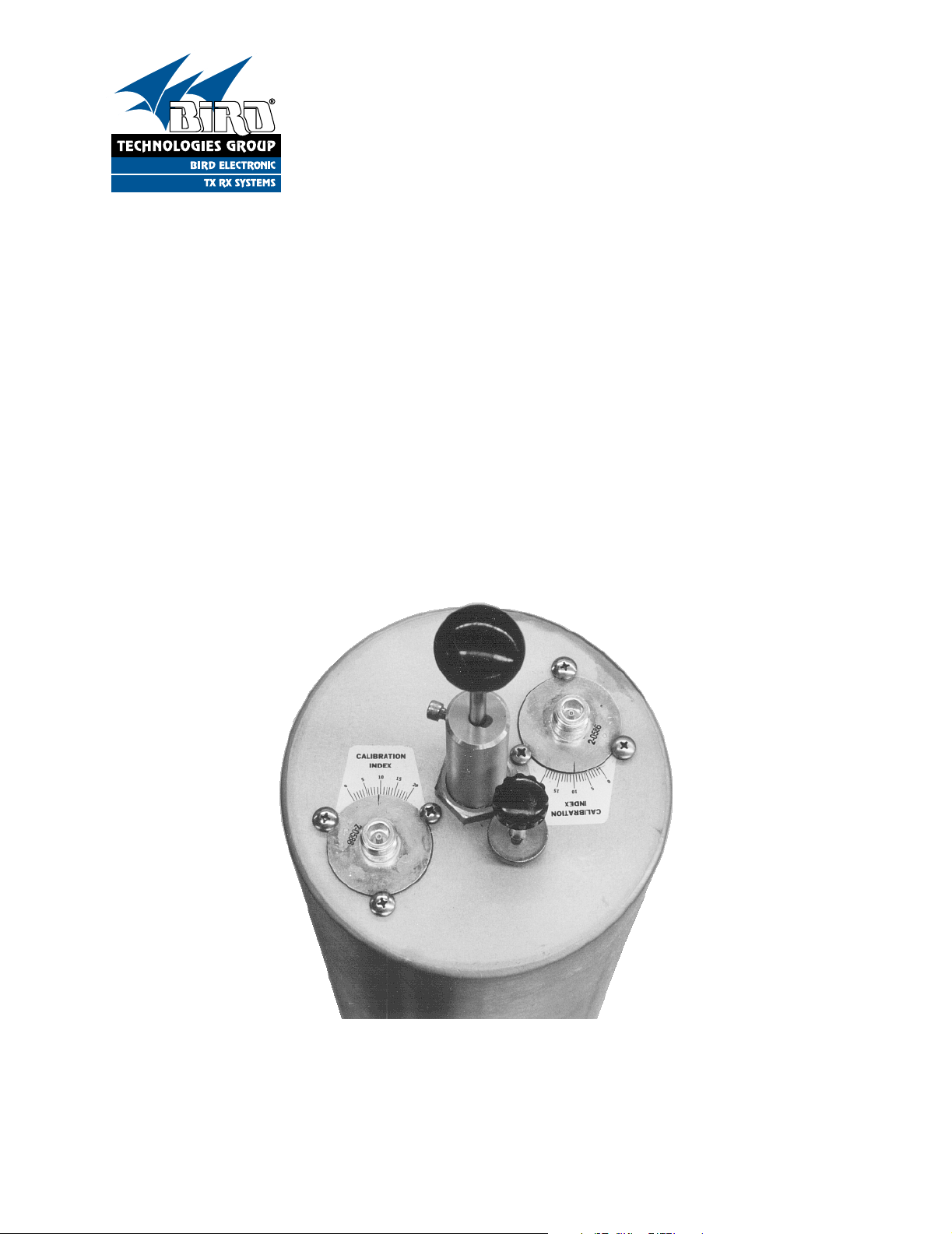

Bandpass Cavity Filters

6 5/8” and 10” Diameter

Manual Part Number

7-9145

8625 Industrial Parkway, Angola, NY 14006 Tel: 716-549-4700 Fax: 716-549-4772 sales@birdrf.com www.bird-technologies.com

Page 2

Warranty

This warranty applies for one year from shipping date.

TX RX Systems Inc. warrants its products to be free from defect in material and workmanship at the time of shipment.

Our obligation under warranty is limited to replacement or repair, at our option, of any such products that shall have

been defective at the time of manufacture. TX RX Systems Inc. reserves the right to replace with merchandise of

equal performance although not identical in every way to that originally sold. TX RX Systems Inc. is not liable for dam-

age caused by lightning or other natural disasters. No product will be accepted for repair or replacement without our

prior written approval. The purchaser must prepay all shipping charges on returned products. TX RX Systems Inc.

shall in no event be liable for consequential damages, installation costs or expense of any nature resulting from the

purchase or use of products, whether or not they are used in accordance with instructions. This warranty is in lieu of all

other warranties, either expressed or implied, including any implied warranty or merchantability of fitness. No representative is authorized to assume for TX RX Systems Inc. any other liability or warranty than set forth above in connection with our products or services.

TERMS AND CONDITIONS OF SALE

PRICES AND TERMS:

Prices are FOB seller’s plant in Angola, NY domestic packaging only, and are subject to change without notice. Federal, State and local sales or excise taxes are not included in prices. When Net 30 terms are applicable, payment is

due within 30 days of invoice date. All orders are subject to a $100.00 net minimum.

QUOTATIONS:

Only written quotations are valid.

ACCEPTANCE OF ORDERS:

Acceptance of orders is valid only when so acknowledged in writing by the seller.

SHIPPING:

Unless otherwise agreed at the time the order is placed, seller reserves the right to make partial shipments for which

payment shall be made in accordance with seller’s stated terms. Shipments are made with transportation charges collect unless otherwise specified by the buyer. Seller’s best judgement will be used in routing, except that buyer’s routing

is used where practicable. The seller is not responsible for selection of most economical or timeliest routing.

CLAIMS:

All claims for damage or loss in transit must be made promptly by the buyer against the carrier. All claims for shortages

must be made within 30 days after date of shipment of material from the seller’s plant.

SPECIFICATION CHANGES OR MODIFICATIONS:

All designs and specifications of seller’s products are subject to change without notice provided the changes or modifications do not affect performance.

RETURN MATERIAL:

Product or material may be returned for credit only after written authorization from the seller, as to which seller shall

have sole discretion. In the event of such authorization, credit given shall not exceed 80 percent of the original purchase. In no case will Seller authorize return of material more than 90 days after shipment from Seller’s plant. Credit

for returned material is issued by the Seller only to the original purchaser.

ORDER CANCELLATION OR ALTERATION:

Cancellation or alteration of acknowledged orders by the buyer will be accepted only on terms that protect the seller

against loss.

NON WARRANTY REPAIRS AND RETURN WORK:

Consult seller’s plant for pricing. Buyer must prepay all transportation charges to seller’s plant. Standard shipping policy set forth above shall apply with respect to return shipment from TX RX Systems Inc. to buyer.

DISCLAIMER

Product part numbering in photographs and drawings is accurate at time of printing. Part number labels on TX RX

products supersede part numbers given within this manual. Information is subject to change without notice.

Bird Technologies Group TX RX Systems Inc.

Page 3

Manual Part Number 7-9145

Copyright © 1996 TX RX Systems, Inc.

First Printing: August 1996

Version Number Version Date

1 08/05/96

Symbols Commonly Used

WARNING

CAUTION or ATTENTION

High Voltage

Use Safety Glasses

ESD Elecrostatic Discharge

Hot Surface

Electrical Shock Hazard

NOTE

Important Information

Bird Technologies Group TX RX Systems Inc.

Page 4

Page 5

dBm

10

1

MHZ/DIV

98.00

MHZ

300

KHZ/RES

0

-10

-20

-30

-40

-50

-60

-70

INSERTION LOSS

40 dB ATT

PASS FREQUENCY

GEN 0 dBM

10 MSEC

Figure 1: Spectrum Analyzer / Tracking Generator display of the Bandpass filter.

Response curve shown for model # 11-29-01 (88 - 108 MHz)

GENERAL DESCRIPTION

The Bandpass cavity filter passes one narrow band

of frequencies (

passband

) and attenuates all

others with increasing attenuation above and below

the pass frequency. Bandpass filters have

adjustable selectivity characteristics which allows a

trade off between insertion loss and selectivity, with

a higher loss giving greater selectivity. Maximum

power handling is determined by the insertion loss

setting. A variety of models are available that cover

the range of frequencies from 30 to 960 MHz. The

portion of the frequency range that each model will

tune across is determined by the cavity's physical

length.

Either 6-5/8" or 10" diameter resonator shells may

be used to construct the filters. The difference

between the two sizes determines the filters

selectivity and it's maximum power dissipation. The

10" diameter filters have slightly higher selectivity

compared to the 6-5/8" models and can safely

dissipate up to 40 Watts of RF Power. The 6-5/8"

filters can dissipate up to 30 Watts. Maximum input

power for the 6" and 10" diameter filters is listed in

table 1. When a filter is operated above 1.0 dB loss

in transmitter applications, we recommend

inserting a ferrite isolator between a transmitter

and the Bandpass filter because the VSWR may

exceed 1.5 : 1.

Insertion loss 6" diameter

Power Rating

10" diameter

Power Rating

0.5 dB 275 Watts 368 Watts

1.0 dB 146 Watts 194 Watts

3.0 dB 60 Watts 80 Watts

Table 1: Input power ratings.

There are two adjustable parameters found in a

bandpass filter including the pass frequency and

the insertion loss. Each of these parameters is

TX RX Systems Inc. Manual 7-9145-1 08/05/96 Page 1

Page 6

Cavity Resonator

Coarse Tuning Rod

Coarse Tuning Lock

10-32 Cap Screw

Calibration Index

Calibration Mark

Input/Output Port

Loop Plate

Assembly

Schematic

Symbol

Loop Plate

Assembly

Input/Output Port

Calibration Mark

Calibration Index

Fine Tuning Rod

Loop Plate

Hold Down Screws

Figure 2: The Bandpass filter.

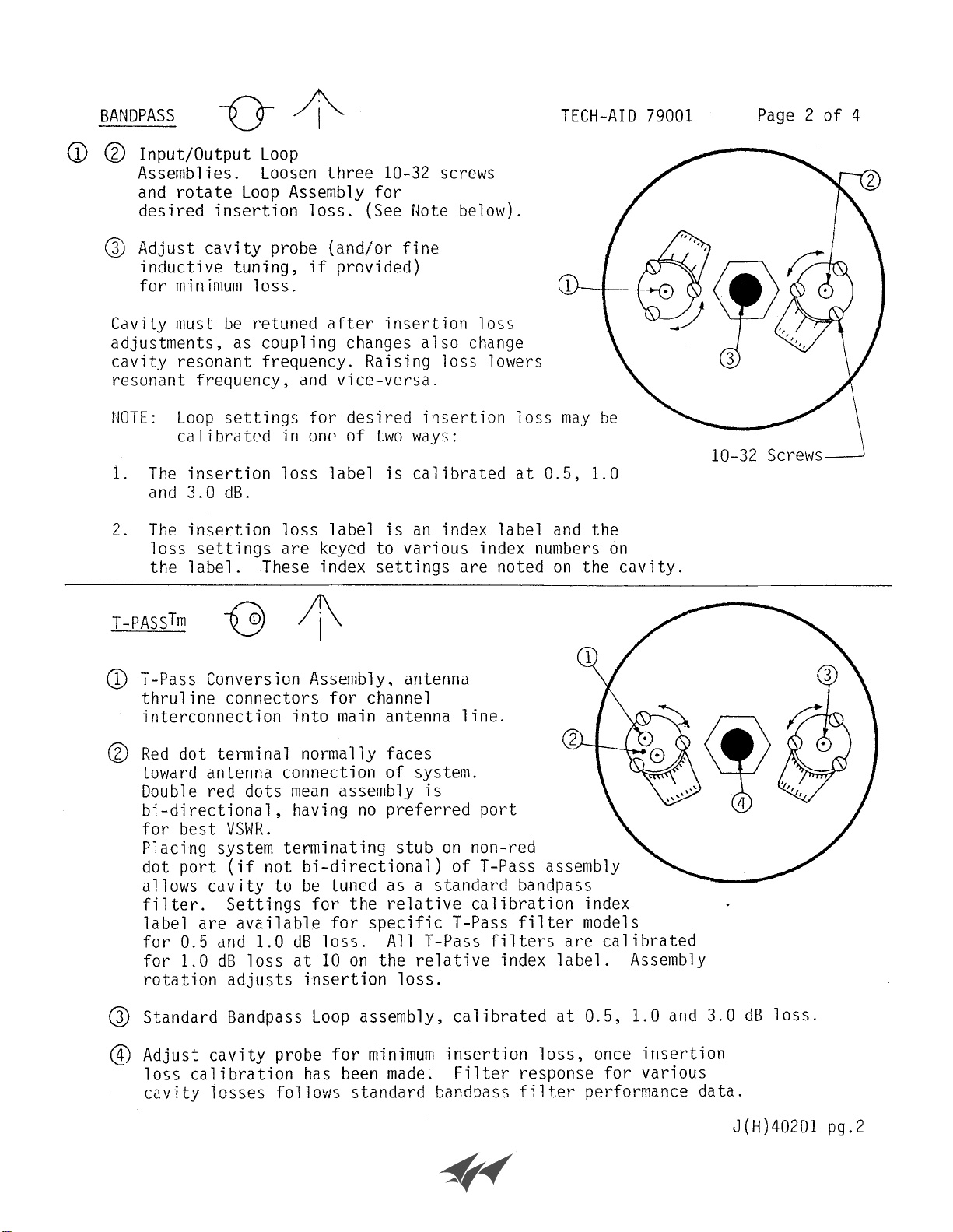

labeled in figure 1. All of the physical components

of the filter are labeled in figure 2, with the

adjustable parts shown in emboldened italics.

Coarse and fine tuning rods are used to adjust the

pass (resonant) frequency. The insertion loss is

changed by rotating the two loop plate assemblies.

TUNING

Required Equipment

The following equipment or its equivalent is

recommended in order to properly perform the

tuning adjustments for the Bandpass filter.

1. IFR A-7550 Spectrum Analyzer with optional

Tracking Generator installed.

2. Double shielded coaxial cable test leads

(RG142 B/U or RG223/U).

3. 5/32" hex wrench.

4. Connector - female union (UG29-N or

UG914-BNC)

5. Connector - tee (UG-107 B/U).

Fine Tuning Lock

Knurled Thumb Nut

General Tuning Procedure

Tuning of the filter requires adjustment of the

frequency.

monitoring the output of a tracking generator after

it passes through the filter. Adjustment of the

insertion loss is optional on units that are preset by

the factory, which is most often the case. To insure

proper tuning of the Bandpass filter, all

adjustments should be performed in the following

order;

1. Preset loops to an index value of 10 if not factory set.

2. Tune the pass frequency.

3. Set the insertion loss if other than 1.0 dB loss is

desired.

4. Fine tune the pass frequency

Cavity Tuning Procedure

1. Setup the analyzer / generator for the desired

frequency and bandwidth (center of display) and

also a vertical scale of 2 dB/div.

The pass frequency is adjusted by

pass

TX RX Systems Inc. Manual 7-9145-1 08/05/96 Page 2

Page 7

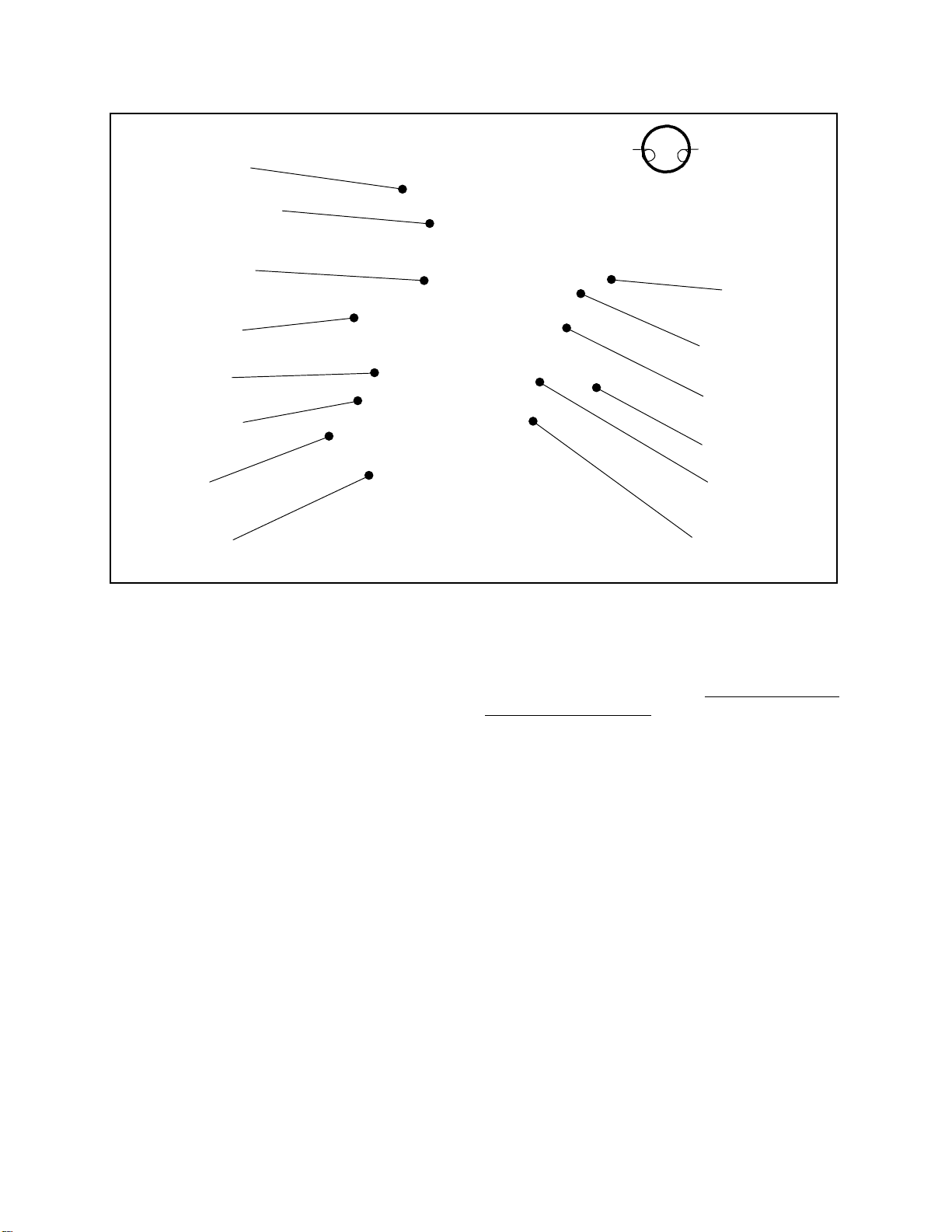

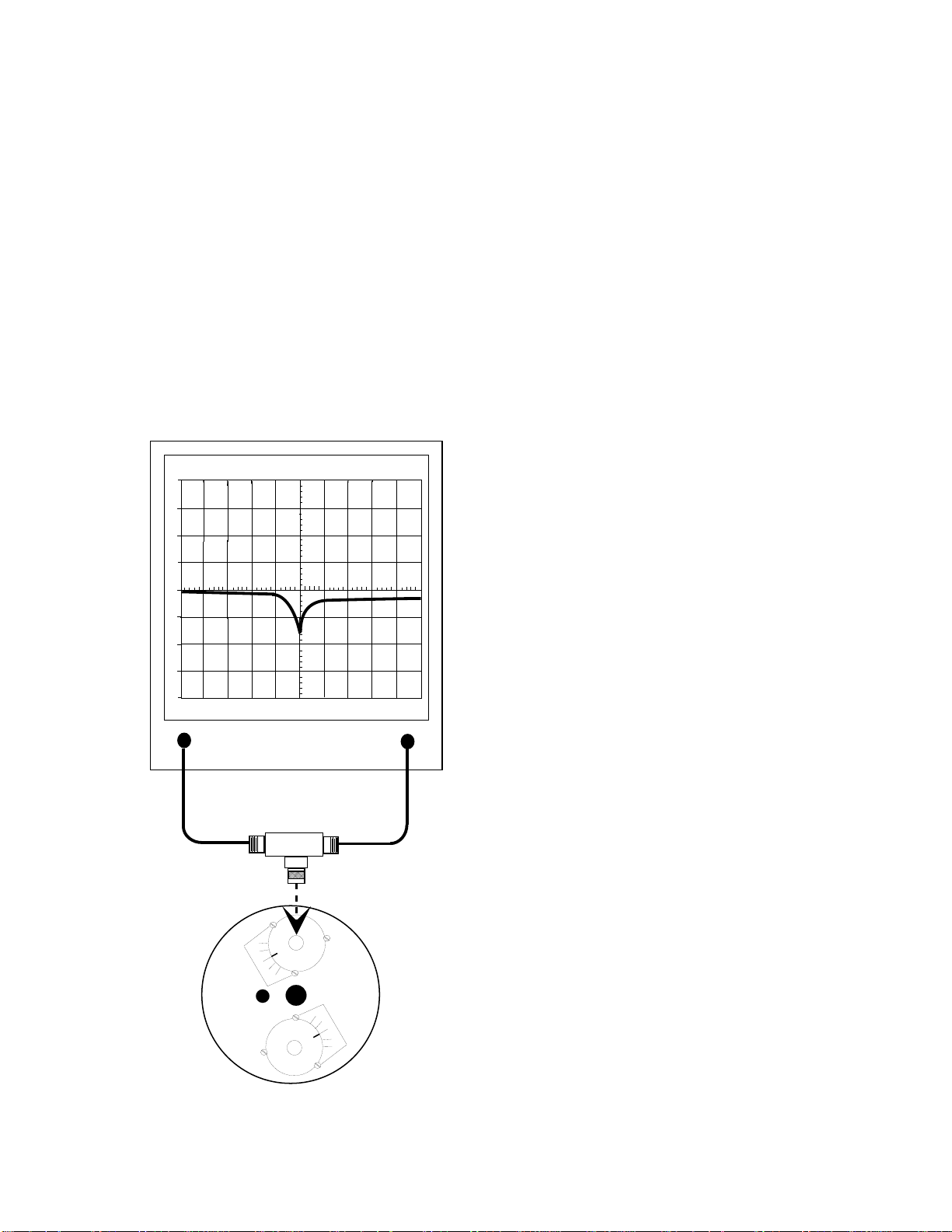

2. The resonant frequency of the filter is checked

by connecting the tracking generator to the input of the cavity filter while the spectrum analyzer is connected to the output, as shown in

figure 3.

50

dB

KHZ / DIV

8

6

4

2

0

-2

-4

-6

-8

dB

40

ANALYZER

98.00

MHZ

ATT

Used to determine 0 dB reference.

BANDPASS

FILTER

GEN

dBM

0

FEMALE UNION

20

15

10

5

0

20

15

10

5

0

Figure 3: Checking cavity tuning.

300

KHZ RES

MSEC

10

GENERATE

3. Insure the IFR A-7550 menu's are set as follows: DISPLAY - line

MODE - live

FILTER - none

SETUP - 50 ohm/dBm/gen1.

4. Set the fine tuning knob at it's mid-point. Adjust

the pass frequency by setting the peak (minimum loss value) of the response curve to the

desired frequency (should be the center-vertical

graticule line on the IFR A-7550's display). See

figure 3. The resonant frequency is adjusted by

using the coarse tuning rod, which is a sliding

adjustment (invar rod) that rapidly tunes the filter's response curve. The resonant frequency is

increased by pulling the rod out of the cavity

and is decreased by pushing the rod into the

cavity. Additionally, the fine tuning rod, also a

sliding adjustment (silver-plated-brass rod ), allows a more precise setting of the response

curve after the coarse adjustment is made. The

resonant frequency is increased by pushing the

fine tuning rod in and is decreased by pulling it

out, the exact opposite of the coarse tuning rod.

5. Once the desired response is obtained using

the coarse and fine tuning rods, they are

"locked" in place. The coarse rod is secured by

tightening the 10-32 cap screw and the fine

tuning rod is held in place by tightening the

knurled thumb nut. Failure to lock the tuning

rods will cause a loss of temperature compensation and detuning of the cavity.

Cavity Tuning Tip

When tuning a cavity that has been in service for

some time it is not unusual to find the main tuning

rod hard to move in or out. This occurs because

TX RX Systems Inc. uses construction techniques

borrowed from microwave technology that provide

large area contact surfaces on our tuning probes.

These silver plated surfaces actually form a

pressure weld that maintains excellent conductivity.

The pressure weld develops over time and must be

broken in order for the main tuning rod to move.

This is easily accomplished by gently tapping the

tuning rod with a plastic screwdriver handle or

small hammer so it moves into the cavity. The

pressure weld will be broken with no damage to the

cavity.

Measuring and Adjusting Insertion Loss

1. A zero reference must first be established at the

IFR A-7550 before the insertion loss can be

measured. This is accomplished by temporarily

placing a "female union" between the generator

output and analyzer input, see figure 3.

2. The flat line across the screen is the generator's

output with no attenuation, this value will become our reference by selecting the "Mode"

main menu item and choosing the "Store"

command.

3. Next select the "Display" main menu item and

choose the "Reference" command. This will

TX RX Systems Inc. Manual 7-9145-1 08/05/96 Page 3

Page 8

cause the stored value to be displayed on the

screen as the 0 dB reference

value.

4. Connect the generator output and analyzer input to the input/output ports of the loop plates

and the insertion loss will be displayed on the

IFR A-7550's screen, refer to figure 3.

5. Insertion loss is usually factory adjusted, at

which time index labels are attached to the top

of the cavity next to the loop plates and calibration marks are stamped into the loop plates

themselves. The index label serves as a relative

index with insertion loss settings keyed to index

numbers on the label. The calibration mark is

normally factory aligned so that the index value

of 10 will be equal to an insertion loss of 1.0 dB.

The relative index labels are used to log specific

filter performance. Insertion loss can be adjusted by loosening the 10-32 hold down screws

and rotating the loop plates.

6. Rotating the loop plate assemblies and moving

the calibration marks above or below 10 causes

the insertion loss to be increased or decreased

(above 10 increases the loss while below 10

decreases it). The insertion loss is adjustable

across a useable range of from 0.5 dB to 3.0

dB. It is important to set both loops to the

same index number so that the cavity's insertion loss remains balanced.

7. The insertion loss setting determines the selectivity of the filter and a change of loss will cause

a shift in the width of the passband. The pass

frequency of the cavity must be retuned after

the insertion loss is adjusted, as changes in

coupling also change the cavity's resonant frequency. Repeat steps 4 and 5 of the cavity tuning procedure in order to complete the cavity's

tuning.

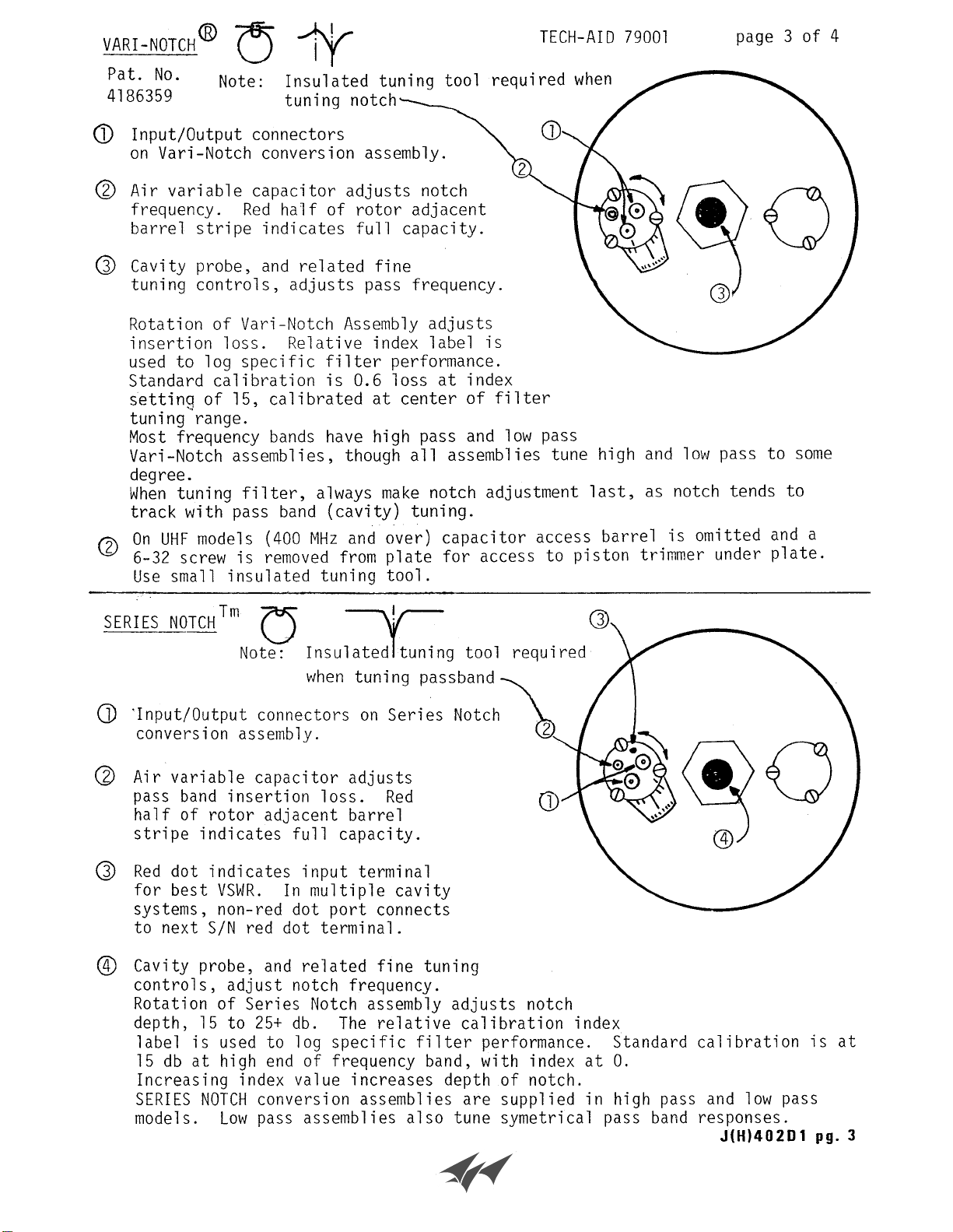

CONVERTING CAVITY RESONANT FILTERS

TX RX Systems Inc. produces four types of cavity

filters, including the Vari-Notch®, Series-Notch®,

Bandpass, and T-Pass®. The cavity resonator shell

along with the coarse and fine tuning controls are

standard subassemblies found in each type of filter

for a specified frequency band. Differences

between the types are determined by the loop plate

assemblies installed in the filter.

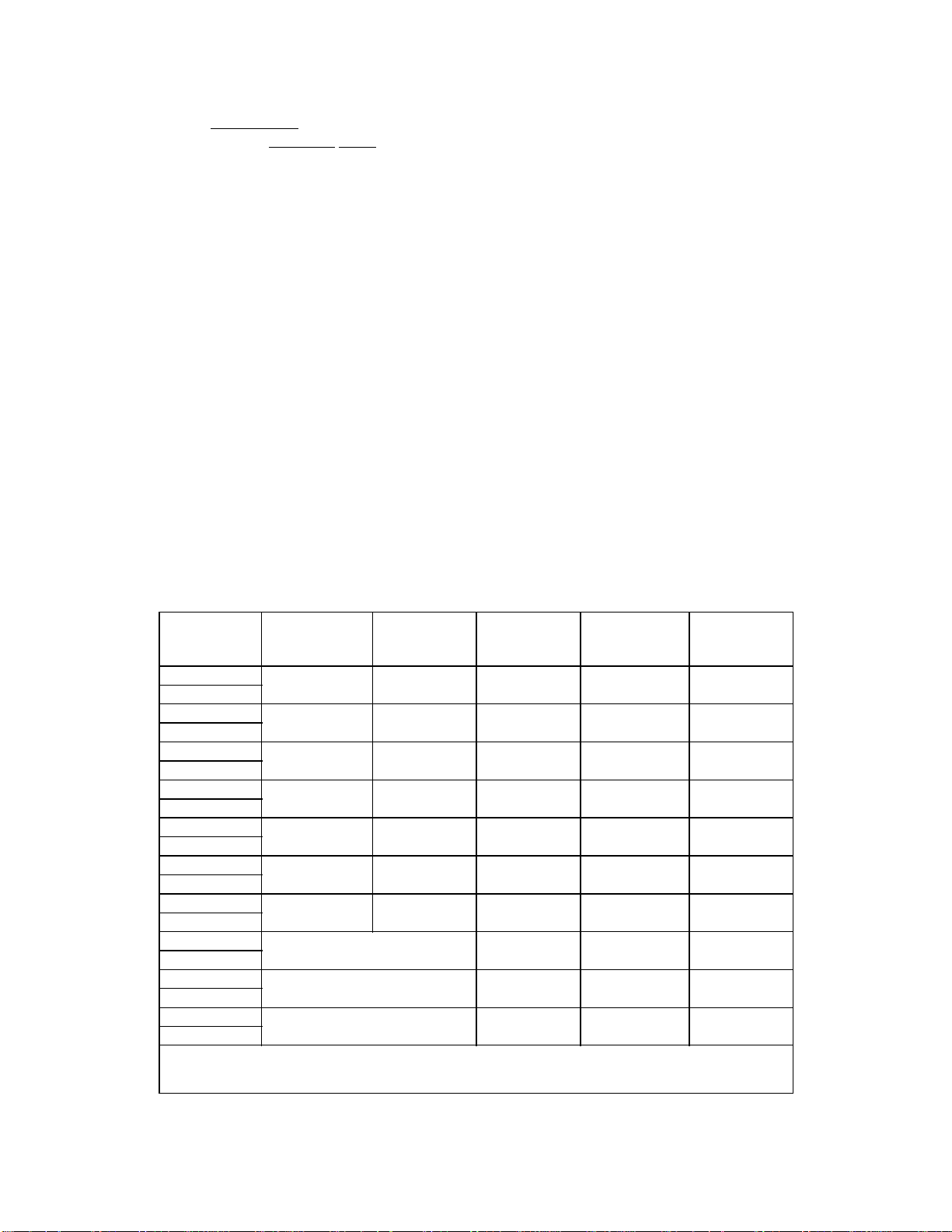

Bandpass

Filter Part #

11-28-01

11-28-05

11-29-01

11-29-05

11-35-01

11-35-05

11-36-01

11-36-05

11-37-01

11-37-05

11-54-01

11-54-05

11-55-01

11-55-05

11-65-01/-11

11-65-05/-25

11-69-01/-11

11-69-05/-25

11-70-01/-11

11-70-05/-25

Note: The last two digits of the filters model number indicate it's diameter and wavelength as listed below;

1.) Last digit of "01" indicates 6-5/8" diameter and 1/4 λ. 2.) Last digit of "11" indicates 6-5/8" diameter and 3/4 λ.

3.) Last digit of "05" indicates 10" diameter and 1/4 λ. 4.) Last digit of "25" indicates 10" diameter and 3/4 λ.

Vari-Notch

Lowpass Conversion

Kit Part #

76-28-02 76-28-03 76-28-04 76-28-05 76-28-07

76-29-02 76-29-03 76-29-04 76-29-05 76-29-07

76-35-02 76-35-03 76-35-04 76-35-05 76-35-07

76-36-03 76-36-04 76-36-05 76-36-06 76-38-01

76-37-03 76-37-04 76-37-05 76-37-06 76-38-01

N/A N/A N/A N/A 76-53-01

N/A N/A N/A N/A 76-53-01

76-65-03 76-65-04 76-65-05 76-67-01

76-69-03 76-69-04 76-69-05 76-67-01

76-70-03 76-70-04 7670-05 76-67-01

Vari-Notch

Highpass

Conversion

Kit Part #

Series-Notch

Lowpass

Conversion

Kit Part #

Series-Notch

Highpass

Conversion

Kit Part #

T-Pass

Conversion

Kit Part #

Table 2: Conversion kit part numbers.

TX RX Systems Inc. Manual 7-9145-1 08/05/96 Page 4

Page 9

The filter's loop plate assembly may be changed in

order to convert the cavity from one type of filter to

another. Conversion kits can be ordered which

contain all required parts for the conversion. The

available conversion kits are listed by part number

in table 2. Refer to the appropriate TX RX Systems

Inc. manual for the specific filter type once the kit is

installed.

Converting to Bandpass

When converting a Series-Notch or Vari-Notch filter

into a Bandpass filter an additional index label must

be applied to the cavity. Follow the procedure listed

below for correct placement.

2. The bandpass loop plate installed at the position of the existing index label should be rotated

until it's calibration mark aligns with the index

value of 10 and then tightened down into place

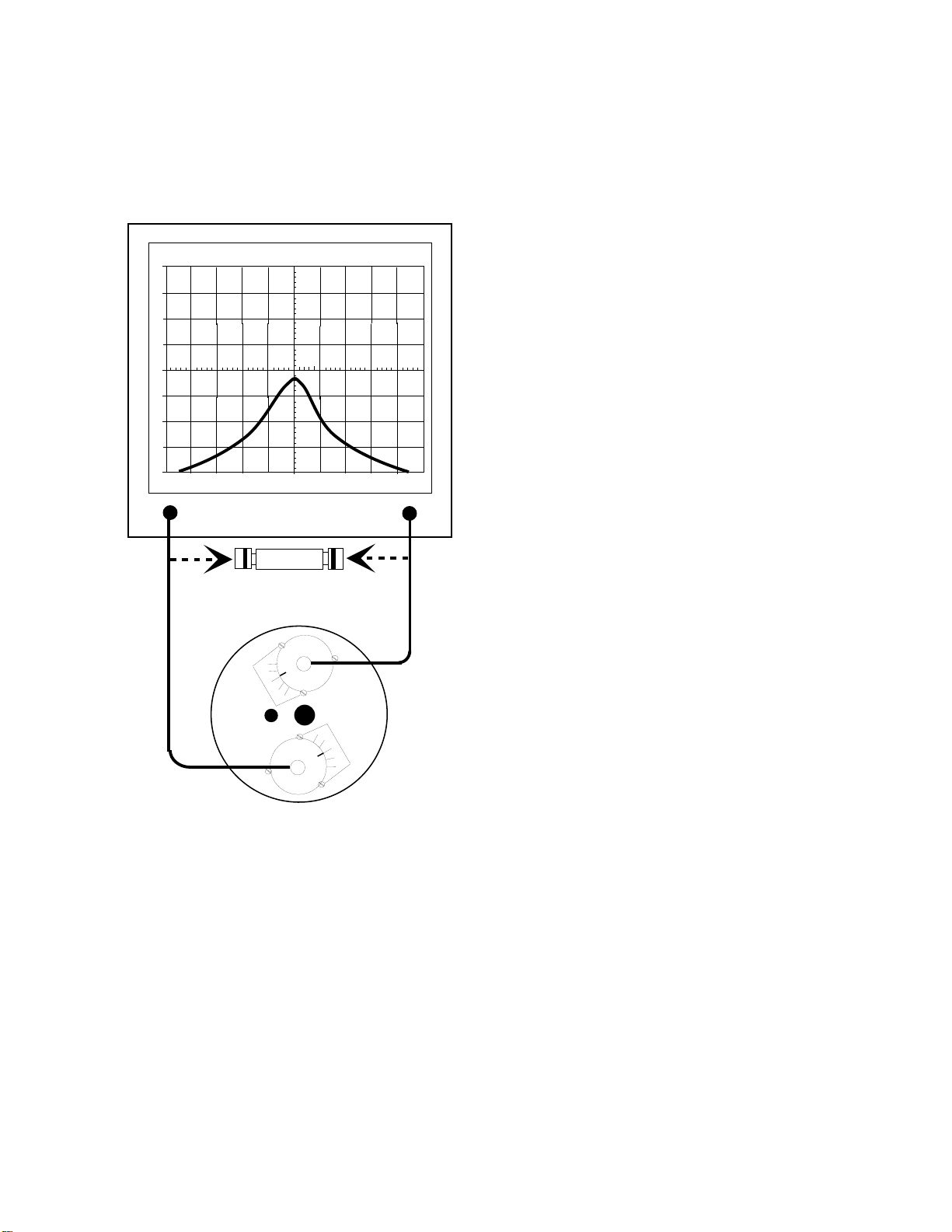

3. Measure its rejection notch as shown in figure 4

and record the value for comparison with the

unlabeled port. The amplitude of the rejection

notch is directly proportional to the insertion

loss .

4. Connect the tee to the remaining loop plate and

rotate it until its rejection notch is equal in value,

then tighten it down into place.

1. Install the bandpass loop plates into the loop

plates holes of the cavity.

1

dB

MHZ / DIV

40

30

20

10

0

-10

-20

-30

-40

dB

40

ANALYZER

98.00

MHZ

ATT

GEN

dBM

0

TEE CONNECTOR

Attach "UG-107 tee connector"

directly to the input / output port

300

KHZ RES

MSEC

10

GENERATE

5. Apply the second index label so that the value

of 10 lines up with the calibration mark.

6. Tighten all loop hold down screws.

When converting from a T-Pass filter into a

Bandpass the six steps listed above will not be

necessary. The T-Pass filter already has two

properly affixed index labels.

MULTIPLE CAVITY BANDPASS FILTERS

Bandpass filters can be ordered in multiple cavity

arrangements of either two or three combined

cavities. The filters are connected in a cascaded

fashion with the output of each filter fed to the input

port of the succeeding filter. The advantage of this

is that the amount of attenuation provided by each

of the filters is additive.

The interconnecting cable between the two filters,

when cut to the correct length (odd multiple of 1/4

λ), will provide up to 6 dB of additional attenuation

due to a mismatch of impedance between the

cable and the filters. The 6 dB of mismatch

attenuation does not occur at the filters passband

but, only at frequencies where moderate to high

attenuation occurs.

BANDPASS

FILTER

20

15

10

5

0

Because each of the filters in the multi-cavity

arrangement are identical, the passband for the

entire arrangement is generally the same as the

passband for the individual filters. However, each

0

5

10

15

20

filters individual insertion loss is also additive.

When tuning a multi-cavity arrangement, each filter

is tuned individually prior to interconnecting them.

Then each is fine tuned to peak the overall

response of the multi-cavity arrangement.

Figure 4: Measuring the rejection notch.

TX RX Systems Inc. Manual 7-9145-1 08/05/96 Page 5

Page 10

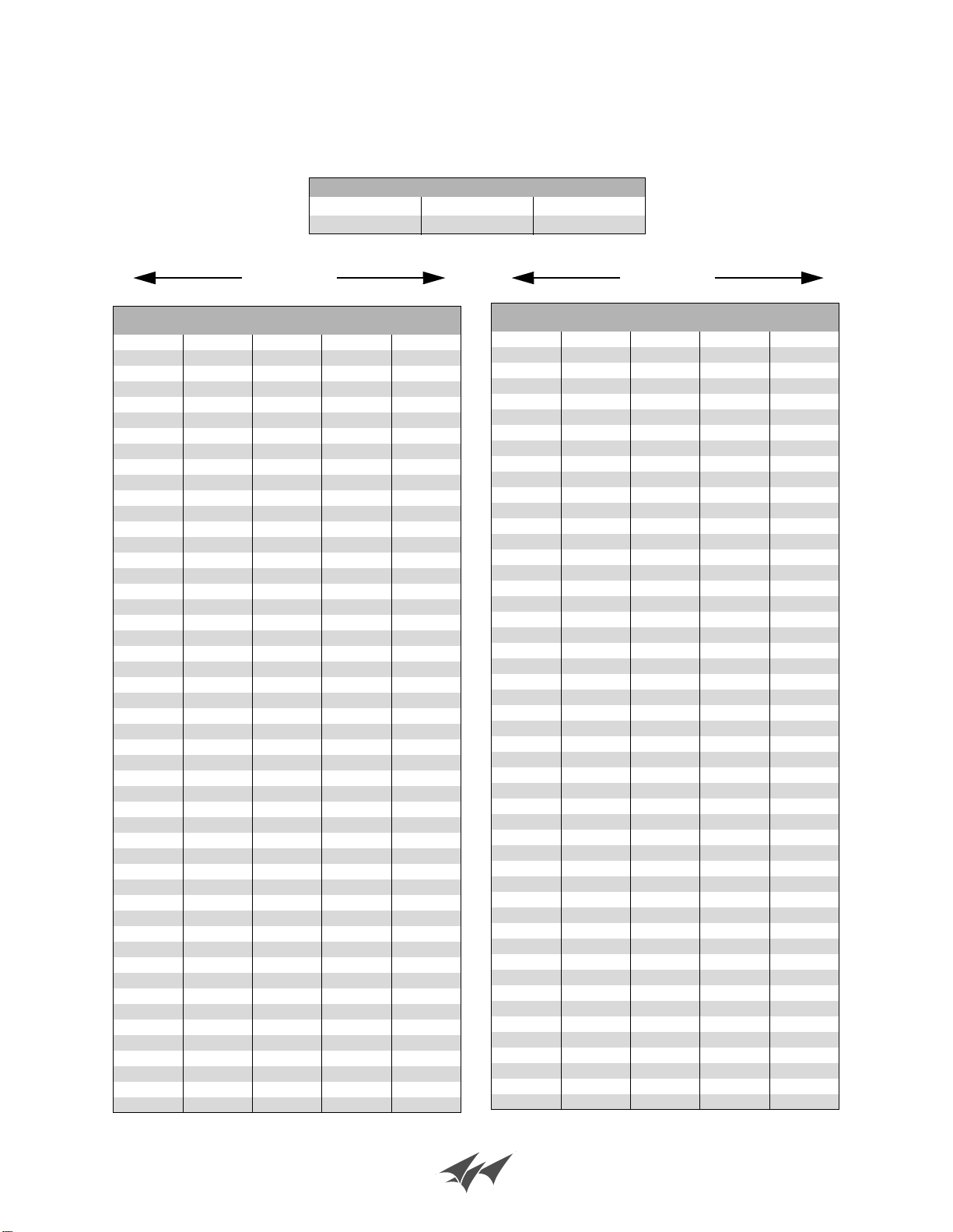

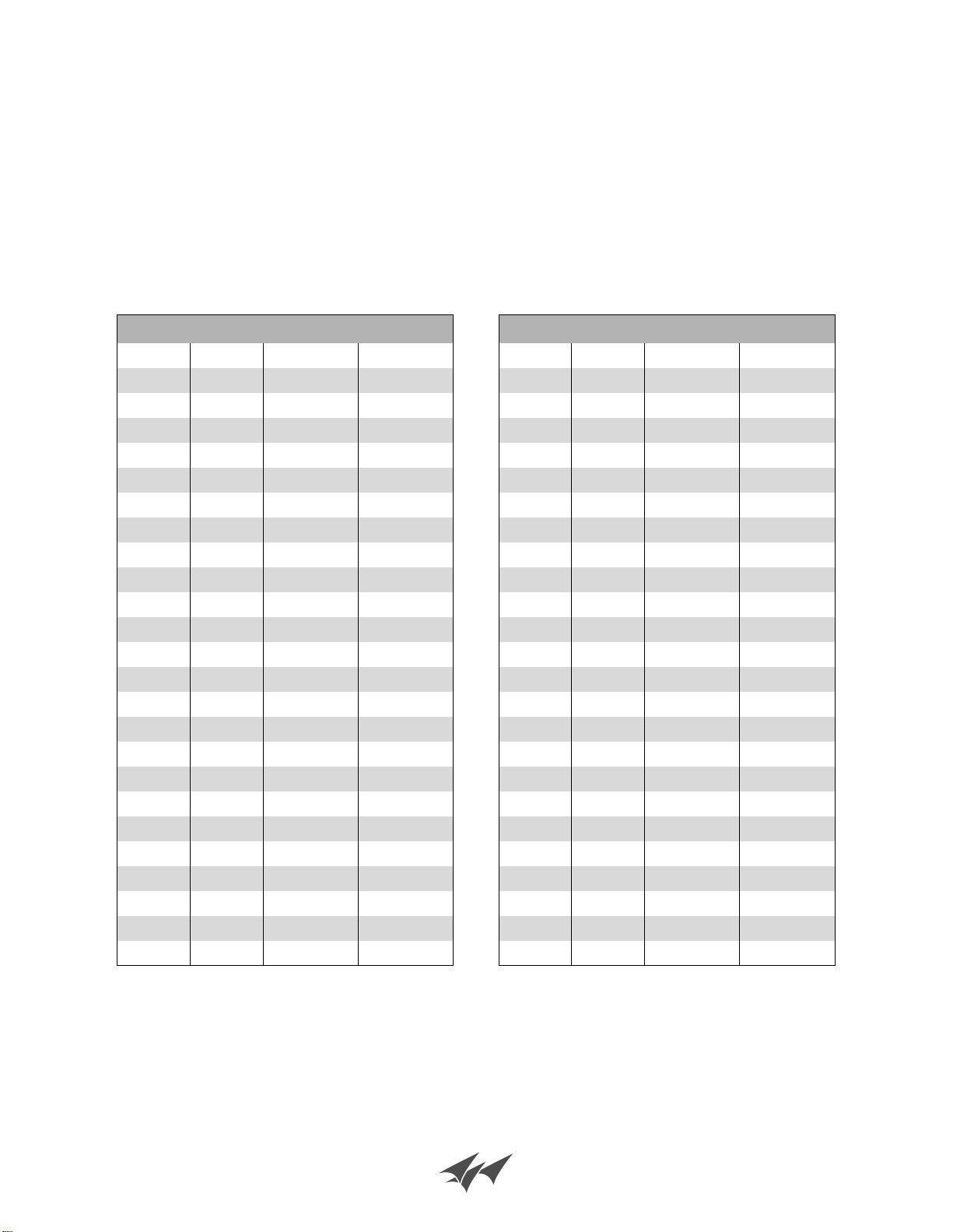

Power Ratio and Voltage Ratio to Decibel

Conversion Chart

Loss or Gain Power Ratio Voltage Ratio

+9.1 dB 8.128 2.851

-9.1 dB 0.123 0.351

- dB +- dB +

Voltage

Ratio

1 1 0 1 1

0.989 0.977 0.1 1.012 1.023

0.977 0.955 0.2 1.023 1.047

0.966 0.933 0.3 1.035 1.072

0.955 0.912 0.4 1.047 1.096

0.944 0.891 0.5 1.059 1.122

0.933 0.871 0.6 1.072 1.148

0.923 0.851 0.7 1.084 1.175

0.912 0.832 0.8 1.096 1.202

0.902 0.813 0.9 1.109 1.23

0.891 0.794 1 1.122 1.259

0.881 0.776 1.1 1.135 1.288

0.871 0.759 1.2 1.148 1.318

0.861 0.741 1.3 1.161 1.349

0.851 0.724 1.4 1.175 1.38

0.841 0.708 1.5 1.189 1.413

0.832 0.692 1.6 1.202 1.445

0.822 0.676 1.7 1.216 1.479

0.813 0.661 1.8 1.23 1.514

0.804 0.646 1.9 1.245 1.549

0.794 0.631 2 1.259 1.585

0.785 0.617 2.1 1.274 1.622

0.776 0.603 2.2 1.288 1.66

0.767 0.589 2.3 1.303 1.698

0.759 0.575 2.4 1.318 1.738

0.75 0.562 2.5 1.334 1.778

0.741 0.55 2.6 1.349 1.82

0.733 0.537 2.7 1.365 1.862

0.724 0.525 2.8 1.38 1.905

0.716 0.513 2.9 1.396 1.95

0.708 0.501 3 1.413 1.995

0.7 0.49 3.1 1.429 2.042

0.692 0.479 3.2 1.445 2.089

0.684 0.468 3.3 1.462 2.138

0.676 0.457 3.4 1.479 2.188

0.668 0.447 3.5 1.496 2.239

0.661 0.437 3.6 1.514 2.291

0.653 0.427 3.7 1.531 2.344

0.646 0.417 3.8 1.549 2.399

0.638 0.407 3.9 1.567 2.455

0.631 0.398 4 1.585 2.512

0.624 0.389 4.1 1.603 2.57

0.617 0.38 4.2 1.622 2.63

0.61 0.372 4.3 1.641 2.692

0.603 0.363 4.4 1.66 2.754

0.596 0.355 4.5 1.679 2.818

0.589 0.347 4.6 1.698 2.884

0.582 0.339 4.7 1.718 2.951

0.575 0.331 4.8 1.738 3.02

0.569 0.324 4.9 1.758 3.09

Power

Ratio

dB

Voltage

Ratio

Power

Ratio

Voltage

Ratio

0.562 0.316 5 1.778 3.162

0.556 0.309 5.1 1.799 3.236

0.55 0.302 5.2 1.82 3.311

0.543 0.295 5.3 1.841 3.388

0.537 0.288 5.4 1.862 3.467

0.531 0.282 5.5 1.884 3.548

0.525 0.275 5.6 1.905 3.631

0.519 0.269 5.7 1.928 3.715

0.513 0.263 5.8 1.95 3.802

0.507 0.257 5.9 1.972 3.89

0.501 0.251 6 1.995 3.981

0.496 0.246 6.1 2.018 4.074

0.49 0.24 6.2 2.042 4.169

0.484 0.234 6.3 2.065 4.266

0.479 0.229 6.4 2.089 4.365

0.473 0.224 6.5 2.113 4.467

0.468 0.219 6.6 2.138 4.571

0.462 0.214 6.7 2.163 4.677

0.457 0.209 6.8 2.188 4.786

0.452 0.204 6.9 2.213 4.898

0.447 0.2 7 2.239 5.012

0.442 0.195 7.1 2.265 5.129

0.437 0.191 7.2 2.291 5.248

0.432 0.186 7.3 2.317 5.37

0.427 0.182 7.4 2.344 5.495

0.422 0.178 7.5 2.371 5.623

0.417 0.174 7.6 2.399 5.754

0.412 0.17 7.7 2.427 5.888

0.407 0.166 7.8 2.455 6.026

0.403 0.162 7.9 2.483 6.166

0.398 0.159 8 2.512 6.31

0.394 0.155 8.1 2.541 6.457

0.389 0.151 8.2 2.57 6.607

0.385 0.148 8.3 2.6 6.761

0.38 0.145 8.4 2.63 6.918

0.376 0.141 8.5 2.661 7.079

0.372 0.138 8.6 2.692 7.244

0.367 0.135 8.7 2.723 7.413

0.363 0.132 8.8 2.754 7.586

0.359 0.129 8.9 2.786 7.762

0.355 0.126 9 2.818 7.943

0.351 0.123 9.1 2.851 8.128

0.347 0.12 9.2 2.884 8.318

0.343 0.118 9.3 2.917 8.511

0.339 0.115 9.4 2.951 8.71

0.335 0.112 9.5 2.985 8.913

0.331 0.11 9.6 3.02 9.12

0.327 0.107 9.7 3.055 9.333

0.324 0.105 9.8 3.09 9.55

0.32 0.102 9.9 3.126 9.772

Power

Ratio

dB

Voltage

Ratio

Power

Ratio

Bird Technologies Group TX RX Systems Inc.

Page 11

Bird Technologies Group TX RX Systems Inc.

Page 12

Bird Technologies Group TX RX Systems Inc.

Page 13

Bird Technologies Group TX RX Systems Inc.

Page 14

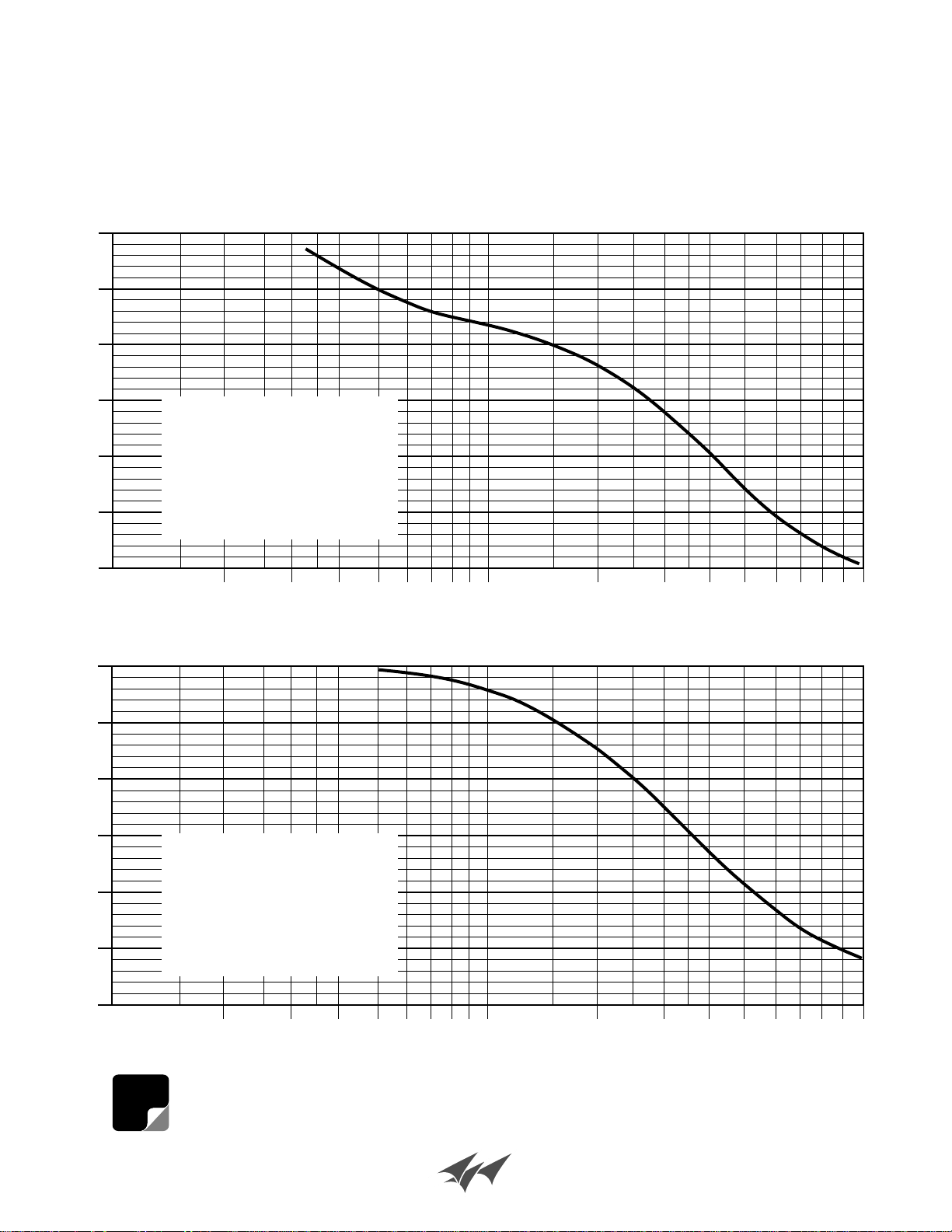

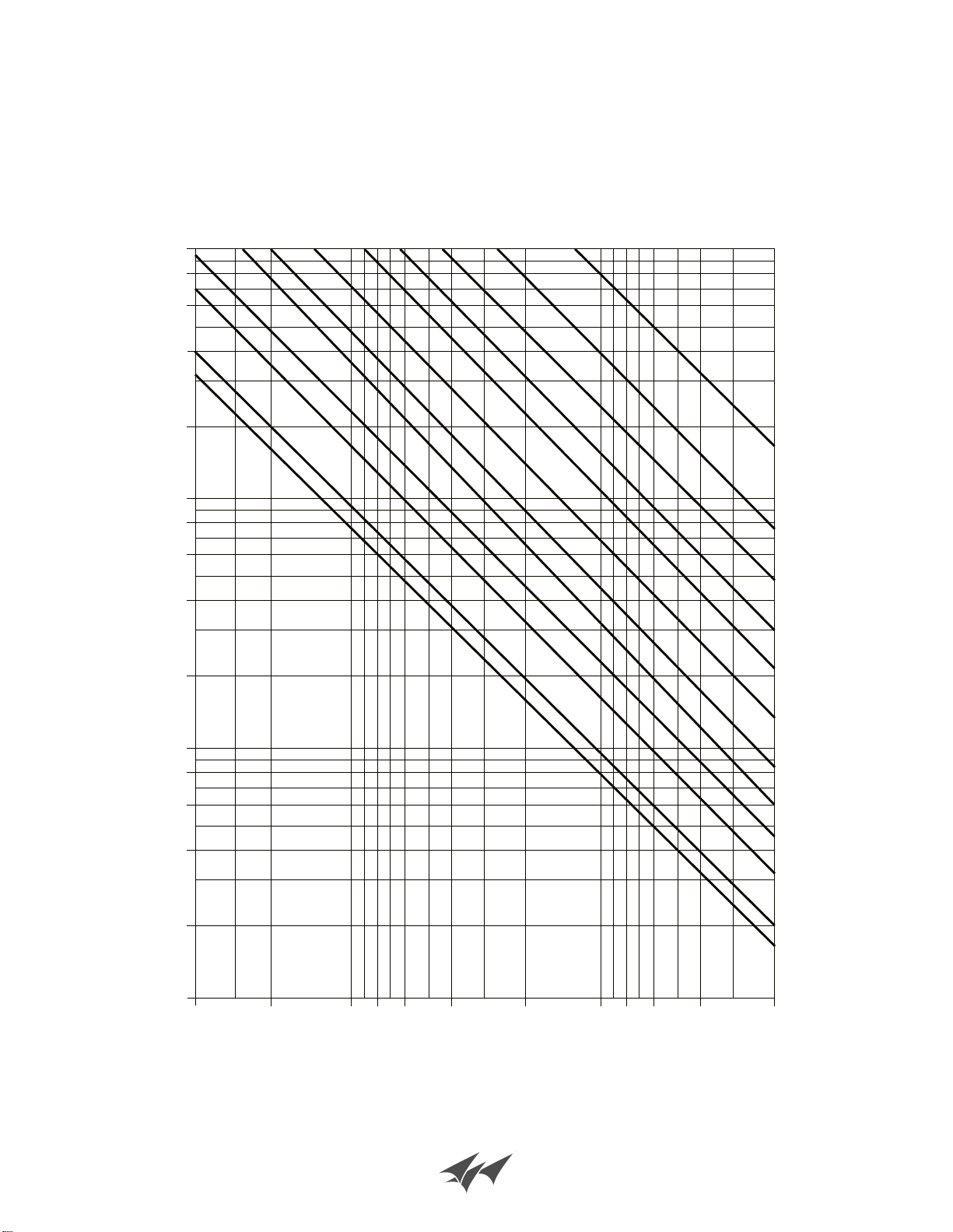

Isolation Curves for Transmitter/Receiver

The curves shown below for use with filters, duplexers, and multicouplers, indicate the

amount of isolation or attenuation required between a typical 100 watt transmitter and its

associated receiver at the TX (carrier suppression) and RX (noise suppression) frequency

which will result in no more than a 1 dB degradation of the 12 dB SINAD sensitivity.

100

90

80

70

Attenuation

60

50

40

100

132 - 174 MHz Band

For TX Power of:

25 watts -

50 watts 100 watts 250 watts 350 watts -

.2 .3 .4 .5 .6 .7 .8 .9 1 2 3 4 5 6 7 8 9 10

400 - 512 MHz Band

subtract 6 dB

subtract 3 dB

no correction

add 4 dB

add 5.5 dB

Frequency Separation (MHz)

90

80

70

Attenuation

60

50

40

NOTE

For TX Power of:

25 watts -

50 watts 100 watts 250 watts 350 watts -

.2 .3 .4 .5 .6 .7 .8 .9 1 2 3 4 5 6 7 8 9 10

These are only "typical" curves. When accuracy is required, consult the radio manufacturer.

subtract 6 dB

subtract 3 dB

no correction

add 4 dB

add 5.5 dB

Frequency Separation (MHz)

Bird Technologies Group TX RX Systems Inc.

Page 15

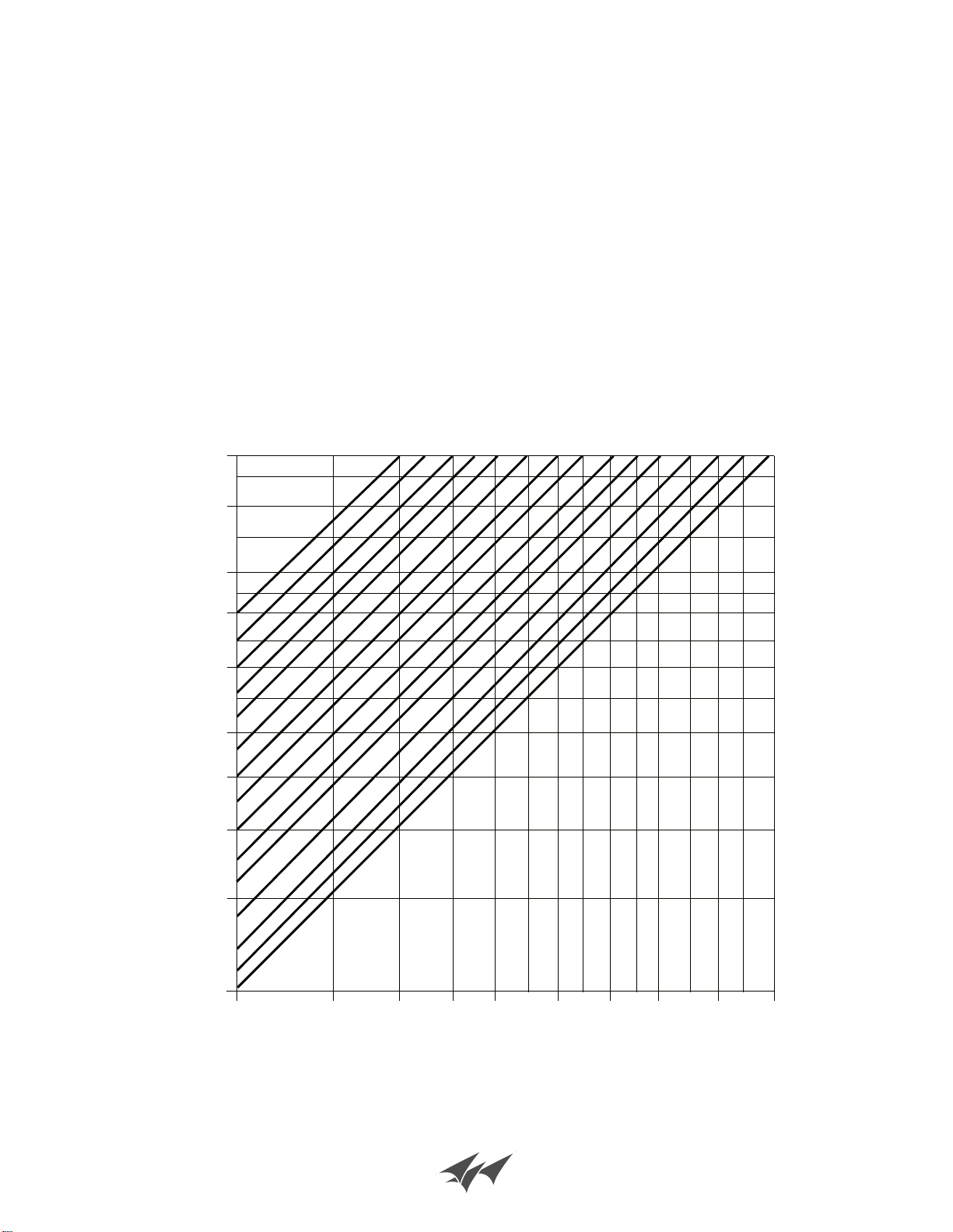

POWER IN/OUT

VS

INSERTION LOSS

The graph below offers a convenient means of determining the insertion loss of filters, duplexers,

multicouplers and related products. The graph on the back page will allow you to quickly determine

VSWR. It should be remembered that the field accuracy of wattmeter readings is subject to

considerable variance due to RF connector VSWR and basic wattmeter accuracy, particularly at low

end scale readings. However, allowing for these variances, these graphs should prove to be a useful

reference.

INSERTION LOSS (dB)

500

400

300

250

200

150

125

INPUT POWER (Watts)

100

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

.50

.25

75

50

50

75 100

125 150 200

250

300

400

500

OUTPUT POWER (Watts)

FOR LOWER POWER LEVELS

DIVIDE BOTH SCALES

BY 10 (5 TO 50 WATTS)

Bird Technologies Group TX RX Systems Inc.

Page 16

500

400

300

200

100

50

40

30

20

POWER FWD./REV.

VS

VSWR

V

S

W

R

1.1:1

1.15:1

1.2:1

10

FORWARD POWER (Watts)

5.0

4.0

3.0

2.0

1.0

0.5

40

20

10

8.0 6.0

4.0

2.0

REFLECTED POWER (Watts)

FOR OTHER POWER LEVELS

MULTIPLY BOTH SCALES

BY THE SAME MULTIPLIER

1.0 0.8

0.6

0.4

1.25:1

1.3:1

1.4:1

1.5:1

1.6:1

1.8:1

2.0:1

2.5:1

3.0:1

0.2

Bird Technologies Group TX RX Systems Inc.

Page 17

Power Conversion Chart

dBm to dBw to Watts to Volts

dBm dBw Watts

80 50 100kW 2236

75 45 31.6 kW 1257

70 40 10.0 kW 707

65 35 3.16 kW 398

60 30 1000 224

55 25 316 126

50 20 100 70.7

45 15 31.6 39.8

40 10 10.0 22.4

38 8 6.31 17.8

36 6 3.98 14.1

34 4 2.51 11.2

32 2 1.58 8.90

30 0 1.00 7.07

29 -1 0.79 6.30

28 -2 0.63 5.62

27 -3 0.50 5.01

26 -4 0.40 4.46

25 -5 0.32 3.98

24 -6 0.25 3.54

23 -7 0.20 3.16

22 -8 0.16 2.82

21 -9 0.13 2.51

20 -10 0.10 2.24

19 -11 79 mW 1.99

Volts 5 0 Ω

dBm dBw Watts

18 -12 63 mW 1.78

17 -13 50 mW 1.58

16 -14 40 mW 1.41

15 -15 32 mW 1.26

14 -16 25 mW 1.12

13 -17 20 mW 1.00

12 -18 16 mW 0.890

11 -19 13 mW 0.793

10 -20 10 mW 0.707

9 -21 7.9 mW 0.630

8 -22 6.3 mW 0.562

7 -23 5.0 mW 0.501

6 -24 4.0 mW 0.446

5 -25 3.2 mW 0.398

4 -26 2.5 mW 0.354

3 -27 2.0 mW 0.316

2 -28 1.6 mW 0.282

1 -29 1.3 mW 0.251

0 -30 1.0 mW 0.224

-5 -35 316 uW 0.126

-10 -40 100 uW 0.071

-15 -45 31.6 uW 0.040

-20 -50 10 uW 0.022

-25 -55 3.16 uW 0.013

-30 -60 1 uW 0.007

Volts 50Ω

Bird Technologies Group TX RX Systems Inc.

Page 18

Free Space Path Loss Estimator

Frequency in MHz

50 150 170 450 500 800 900

0.1 50.58 60.12 61.21 69.66 70.58 74.66 75.68

0.25 58.54 68.08 69.17 77.62 78.54 82.62 83.64

0.5 64.56 74.10 75.19 83.64 84.56 88.64 89.66

1 70.58 80.12 81.21 89.66 90.58 94.66 95.68

2 76.60 86.14 87.23 95.68 96.60 100.68 101.71

3 80.12 89.66 90.75 99.21 100.12 104.20 105.23

4 82.62 92.16 93.25 101.71 102.62 106.70 107.73

5 84.56 94.10 95.19 103.64 104.56 108.64 109.66

6 86.14 95.68 96.77 105.23 106.14 110.22 111.25

7 87.48 97.02 98.11 106.57 107.48 111.56 112.59

8 88.64 98.18 99.27 107.73 108.64 112.72 113.75

9 89.66 99.21 100.29 108.75 109.66 113.75 114.77

10 90.58 100.12 101.21 109.66 110.58 114.66 115.68

Path Length (miles)

12 92.16 101.71 102.79 111.25 112.16 116.25 117.27

14 93.50 103.04 104.13 112.59 113.50 117.58 118.61

16 94.66 104.20 105.29 113.75 114.66 118.74 119.77

18 95.68 105.23 106.31 114.77 115.68 119.77 120.79

20 96.60 106.14 107.23 115.68 116.60 120.68 121.71

30 100.12 109.66 110.75 119.21 120.12 124.20 125.23

40 102.62 112.16 113.25 121.71 122.62 126.70 127.73

50 104.56 114.10 115.19 123.64 124.56 128.64 129.66

Formula: Path Loss (dB) = 36.6 + 20 log (MHz) + 20 log (miles)

Bird Technologies Group TX RX Systems Inc.

Page 19

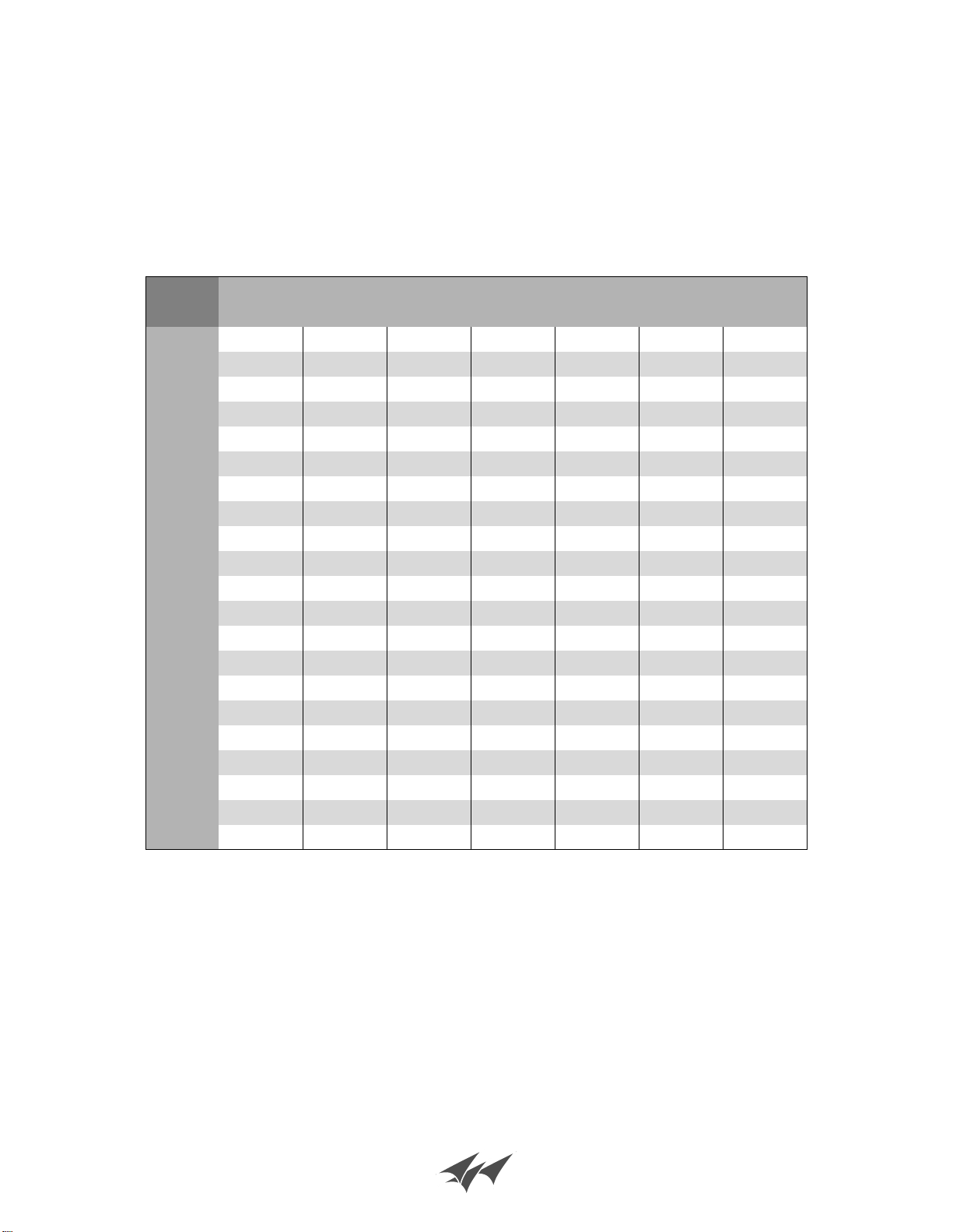

Return Loss vs. VSWR

Watts to dBm

Return Loss VSWR

30 1.06

25 1.11

20 1.20

19 1.25

18 1.28

17 1.33

16 1.37

15 1.43

14 1.50

13 1.57

12 1.67

11 1.78

10 1.92

9 2.10

Watts dBm

300 54.8

250 54.0

200 53.0

150 51.8

100 50.0

75 48.8

50 47.0

25 44.0

20 43.0

15 41.8

10 40.0

5 37.0

4 36.0

3 34.8

2 33.0

1 30.0

dBm = 10log P/1mW

Where P = power (Watt)

Insertion Loss

Input Power (Watts)

50 75 100 125 150 200 250 300

3 25 38 50 63 75 100 125 150

2.5 28 42 56 70 84 112 141 169

2 32 47 63 79 95 126 158 189

1.5 35 53 71 88 106 142 177 212

1 40 60 79 99 119 159 199 238

Insertion Loss

.5 45 67 89 111 134 178 223 267

Output Power (Watts)

Free Space Loss

Distance (miles)

.25 .50 .75 1 2 5 10 15

150 68 74 78 80 86 94 100 104

220 71 77 81 83 89 97 103 107

460 78 84 87 90 96 104 110 113

860 83 89 93 95 101 109 115 119

940 84 90 94 96 102 110 116 120

Frequency (MHz)

1920 90 96 100 102 108 116 122 126

Free Space Loss (dB)

Free space loss = 36.6 + 20log D + 20log F

Where D = distance in miles and F = frequency in MHz

Bird Technologies Group TX RX Systems Inc.

Page 20

8625 Industrial Parkway, Angola, NY 14006 Tel: 716-549-4700 Fax: 716-549-4772 sales@birdrf.com www.bird-technologies.com

Loading...

Loading...