Page 1

VersaDoc

Imaging System

User’s Manual

for Catalog Numbers

1708010, 1708011, 1708030

1708031, 1708140, 1708141, 1708050, 1708051

Copyright 2001 Bio-Rad Laboratories Inc.

Manual Part Number 4000183 Rev. E

Page 2

Page 3

Welcome

Dear Customer,

On behalf of Bio-Rad Laboratories, we would like to thank you for investing in the

VersaDoc

high quality imaging.

One of the best ways to familiarize yourself with the capabilities of your new VersaDoc

system is to read this manual. In it, you will learn how to set up the system and operate

all hardware components. It is also recommended that you read the accompanying

software manual to familiarize yourself with general acquisition functions and data

analysis. After reading this manual, please keep it close to your system so that it can be

conveniently referred to.

Your VersaDoc system is protected by a comprehensive instrument warranty agreement.

Please read this manual thoroughly, so that you fully understand the coverage provided

and are aware of your rights and responsibilities. One of the responsibilities of system

ownership is regular maintenance. Following the maintenance instructions provided with

this manual will help to keep your system and peripherals functioning optimally and will

protect your investment. Please also keep in mind that Bio-Rad offers a range of

comprehensive service agreements that can be tailored to meet your specific needs.

Bio-Rad Laboratories is dedicated to your total satisfaction and would be pleased to

answer any questions that you may have.

How to Contact Bio-Rad Laboratories

In the United States you can reach Bio-Rad Laboratories at the following numbers:

For general information

Toll free: 1-800- 4BIORAD

1-800-424-6723

Fax: 1-510-741-5802

email: lsg.techserv.us@bio-rad.com

For service or technical assistance

Toll free: 1-800-424-6723

Fax: 1-510-741-5802

For information concerning Bio-Rad Laboratories and its products, visit our Worldwide

Web site at http://www.bio-rad.com

Imaging System and we are sure that it will provide you with many years of

Page 4

Page 5

Table of Contents

Section 1 General Information PAGE #

1.1 About this Manual 1-1

1.2 Safety Information 1-2

1.2.1 General Cautions 1-2

1.2.2 General Warnings 1-2

1.2.3 Power Safety Information 1-3

1.2.4 UV Safety Information 1-3

Section 2 Introduction

2.1 System Capabilities 2-1

2.2 System Description 2-1

2.3 Mechanical Description 2-3

2.4 Overview of the Imaging Process 2-4

2.5 Illumination Flat Fielding 2-4

Section 3 System Installation

3.1 Operating Requirements 3-1

3.1.1 System Location 3-1

3.1.2 Power Requirements 3-1

3.1.3 Host Computer Recommendations 3-2

3.2 System Setup 3-2

3.2.1 Unpacking 3-3

3.2.2 Shipping Check 3-3

3.2.3 Coupling the Camera Module to the Enclosure 3-5

3.2.4 Installing VersaDoc 1000,3000,4000 3-6

3.2.5 Installing VersaDoc 5000 3-8

3.2.6 Installing the Epi Illumination Modules 3-12

3.2.7 Electrical and Communication Connections 3-13

3.2.8 Installing Filters 3-21

3.2.9 Installing the Lens 3-23

Section 4 System Operation

4.1 Starting the VersaDoc 4-1

4.2 Overview of Operating Steps 4-1

4.3 Detailed Operating Procedures 4-2

4.3.1 Opening the Acquisition Window 4-2

4.3.2 Selecting the Application 4-3

4.3.3 Placing the Sample in the Imaging Chamber 4-3

4.3.4 Lens Selection and Setup 4-4

4.3.5 Aperture Adjustment 4-5

4.3.6 Zoom Adjustment 4-5

4.3.7 Focus Adjustment 4-6

4.3.8 Exposure Time 4-6

4.3.9 Acquiring the Image 4-7

Page 6

Section 5 Care and Maintenance PAGE #

5.1 General Maintenance 5-1

5.1.1 Cleaning the Sample Platen 5-1

5.1.2 Cleaning the UV Transilluminator Filter Glass 5-1

5.1.3 Cleaning the Lens 5-2

5.1.4 Cleaning the Emission Filters 5-2

5.2 Replacing lamps in Illumination Sources 5-2

5.2.1 Replacing lamps in the Transilluminator Module 5-2

5.2.2 Replacing Lamps in the Epi- illumination Module 5-4

5.3 Lens and Filter Storage 5-5

Section 6 Troubleshooting & Technical Information

6.1 Problem Solving Guide 6-1

6.2 Technical Service 6-3

6.3 VersaDoc System Specifications 6-4

6.4 Warranty Information 6-6

6.5 Glossary of Terms 6-7

6.6 Parts List 6-8

Page 7

Section 1

General Information

1.1 About this Manual

This manual provides instructions for installing, operating and maintaining the

VersaDoc Imaging System. This manual uses certain conventions to

facilitate understanding of the text material and to assist operators in using the

VersaDoc system.

Conventions

Left and right sides of the instrument are as viewed from the front (operator’s

position) unless otherwise stated.

Commands that are typed in from the keyboard are referred to as <xxxx>, and

when you are expected to use the mouse pointer to activate a button it will be

referred to as CLICK xxxx. When you are expected to click and drag the

mouse to a certain item it will be referred to as SELECT xxxx.

Notes, Cautions and Warnings

Notes, cautions and warnings are used to highlight certain operating

procedures and recommendations.

A note indicates a special procedure, an exception to normal operation or

something else of specific interest to the reader. Notes are preceded by the

word “Note” in italics.

A caution precedes an operational step that could damage the instrument or

destroy data unless the operator takes certain precautions. Cautions are

located in the main text, are preceded by a Caution: statement and are

accompanied by a “Caution Symbol” in the left margin.

A warning precedes an operating procedure that could cause injury to the

operator if not followed correctly. Warnings are located in the main text, are

preceded by a Warning: statement and are accompanied by a “Warning

Symbol” in the left margin.

User’s Manual • 1-1

Page 8

1.2 Safety Information

This instrument is meant for Laboratory use only and should not be

used in any other way or manner that is not specified in this Manual.

Your safety and the safety of others are very important to us. To help you

make informed decisions about safety, we have provided comprehensive

operating procedures and safety information in this manual and on labels

affixed to instrumentation. This information will alert you to any potential

hazards. It is the user's responsibility to take time and read and understand

the Safety Information and put it to the best use for a Safe operation of the

system.

1.2.1 General Cautions

Caution: Ensure that all of the systems ventilation openings are free of

interference. Excessive heat build up in the instrument may effect performance

or cause operational failure.

Caution: With the exception of cleaning or replacing light bulbs, refer all

servicing to qualified Bio-Rad personnel or their agents. If you experience

technical difficulties with the instrument contact Bio-Rad to schedule a service

appointment. The instrument should not be modified or altered in any way.

Alteration of this instrument voids the manufacturer’s warranty and may create a

potential safety hazard for the user.

Caution: Bio-Rad is not responsible for any injury or damage caused by the use

of this instrument for purposes other than that for which it is intended or by the

modification of this instrument when not performed by qualified Bio-Rad

personnel or an authorized agent.

1.2.2 General Warnings

Warning: This instrument must be connected to an appropriate AC voltage

outlet that is properly grounded.

Warning: There are hazardous voltages inside the rear panel of the

VersaDoc. Do not remove the cover to the Electronics back panel when the

instrument is connected to AC power.

Warning: Do not defeat any instrument interlocks; they are designed to

prevent user injury.

Warning: The

you have purchased. Exercise caution when lifting the instrument. It is

recommended that at least two persons lift the instrument. Lift the instrument

by the bottom plate. Never lift the instrument by opening at the top which is

the plastic camera mounting plate because this will cause light leaks and

damage the camera mounting plate.

VersaDoc weighs 44 kg (96 lbs.) depending on which camera

User’s Manual • 1-2

Page 9

1.2.3 Power Safety Information

The VersaDoc contains high voltage circuits. The user must disconnect the

power cord prior to opening the rear access panel, or removing the lamp

modules for bulb replacement.

WARNING: It is mandatory for the users to power down the system and

disconnect the AC mains from the unit before performing any disassembly or

repair to the instrument.

The VersaDoc system is designed and certified to meet EN61010 Safety and

EN61326 +A1 Electromagnetic Compliance requirements, which are

internationally accepted safety standards. Certified products are safe to use

when operated in accordance with the instruction manual. This safety

certification does not extend to uncertified equipment or accessories, even

when connected to the VersaDoc system.

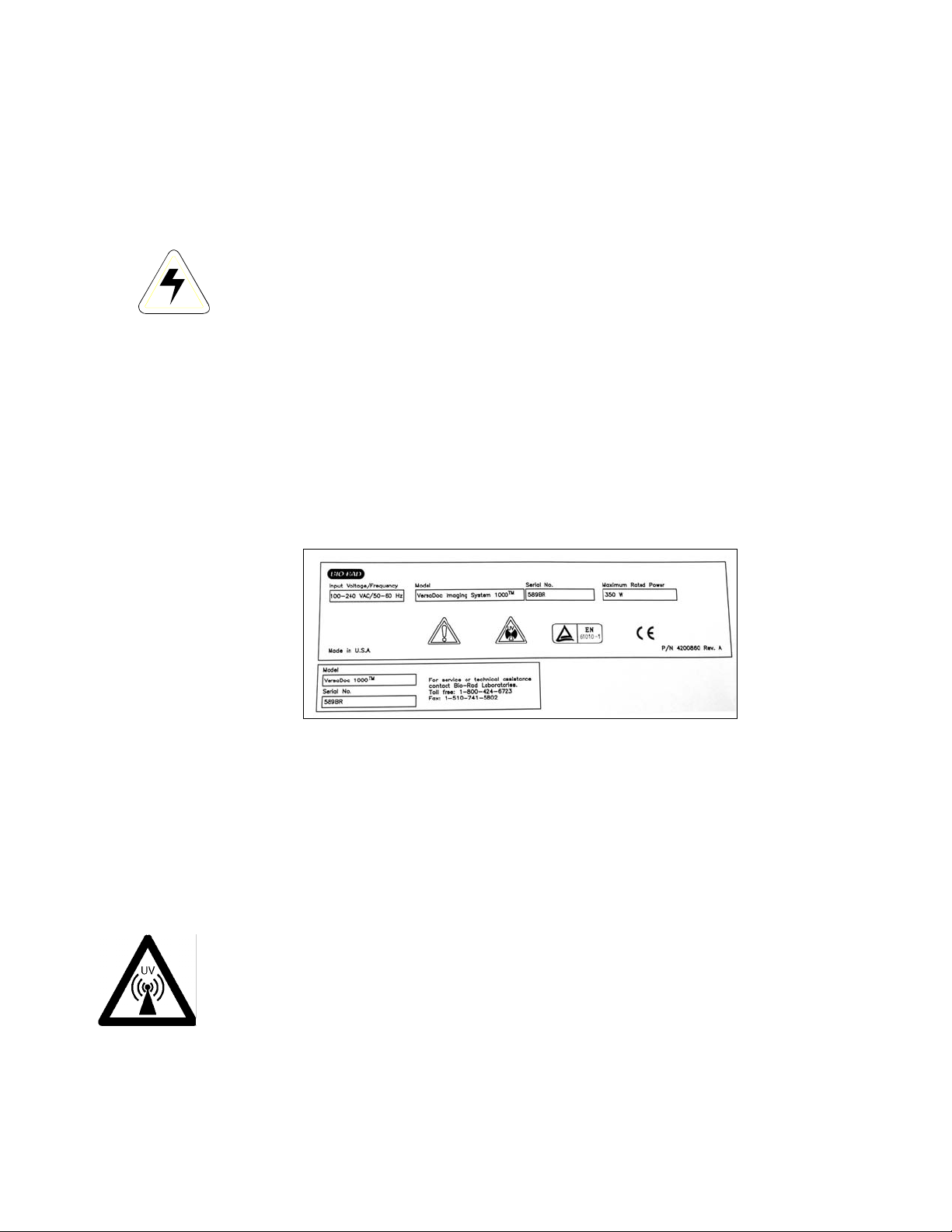

Figure 1.1 shows the serial number certification label, which is found on the

rear panel of the VersaDoc system. This label provides manufacturing data

and safety compliance information about the instrument.

Figure 1.1

For easy customer access the instrument serial number information located at

two places in your system.

1. On the rear of the instrument

2. Inside the main door

1.2.4 UV Safety Information

This instrument uses a powerful source of UV radiation and may cause

damage to unprotected eyes and skin. The VersaDoc provides safety

interlocks on both the main door and the sliding UV transilluminator module

to protect the user from accidental UV exposure. A plastic UV shield is

provided for convenience, however, it may not be adequate to protect you

from accidental UV exposure. You must use additional personal UV

protection like UV protective eyeglasses, gowns, gloves etc.

User’s Manual • 1-3

Page 10

Warning: Do not remove the rear access panel when power is supplied to the

instrument or defeat the UV safety interlock. Attempting to operate the unit

with the cover removed may damage the instrument and expose the operator

to UV radiation.

Warning: Use of controls or adjustments, or performance of procedures other

than those specified herein may result in exposure to hazardous UV radiation.

How to Contact Bio-Rad Laboratories

In the United States you can reach Bio-Rad Laboratories at the

following numbers:

For general information

Toll free: 1-800- 4BIORAD

1-800-424-6723

Fax: 1-510-741-5802

email: lsg.techserv.us@bio-rad.com

For service or technical support

Toll free: 1-800-424-6723

Fax: 1-510-741-5802

For information concerning Bio-Rad Laboratories and its

products, visit our Worldwide Web site at http://www.bio-

rad.com

User’s Manual • 1-4

Page 11

Section 2

Introduction

2.1 VersaDoc System Capabilities

The VersaDoc Imaging System is a quantitative imaging system for capturing high

resolution digital images from single and multi-color fluorescence,

chemiluminescence, chemifluorescence and colorimetric samples. Using cooled CCD

technology in combination with a unique ultraviolet illumination mechanism and a

highly efficient optical design, the VersaDoc offers researchers the sensitivity,

uniformity, flexibility and dynamic range they require for the analysis of

electrophoretic and microplate samples, among others. With direct imaging and

automated acquisition, this system can increase laboratory throughput and eliminate

the need for chemiluminescent detection using x-ray film.

Flexible Design:

The VersaDoc Imaging system has a very flexible design. The light tight enclosure

can accommodate any of the offered camera modules. The user has the option to

upgrade to any of the four standard models. The standard VersaDoc comes with

every feature included. The VersaDoc 1000L, 3000L, 4000L and 5000L come with

light tight enclosure, camera and filter wheel. The user has the option to choose a

variety of illumination modules to fit their needs. This allows customization of the

system by selecting the type of camera and the type of illumination you need.

Additionally, all systems can be upgraded.

2.2 System Description

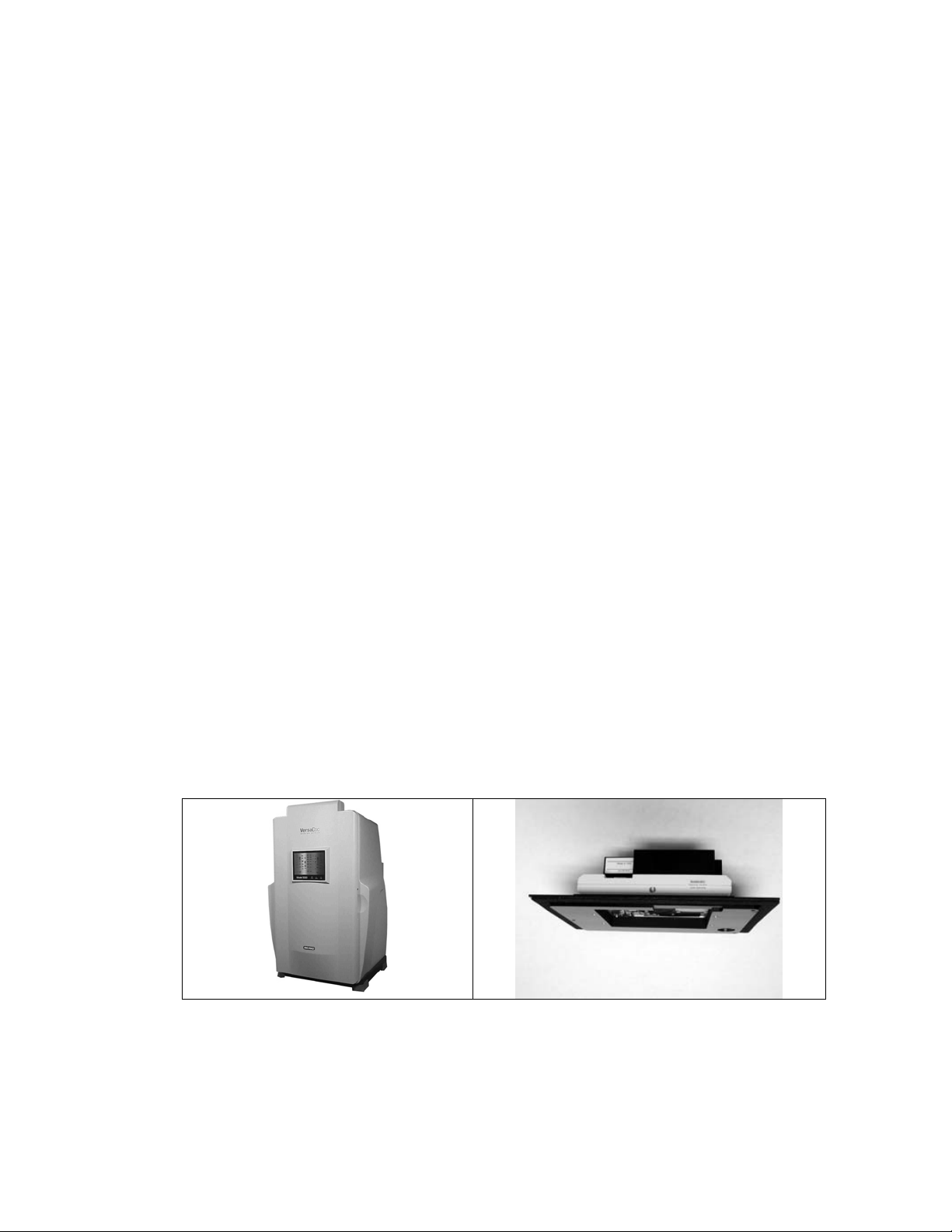

Figure. 2.1 The VersaDoc Imaging System.

The VersaDoc combines several key components into a unique, powerful and fully

integrated image analysis system:

User’s Manual • 2-1

Page 12

(1) Cooled CCD Technology

The VersaDoc system uses cooled CCD technology for image capture and improves

image quality by reducing background noise and enhancing the signal to noise ratio.

This is particularly important for low light chemiluminescence and fluorescence

applications.

(2) Unique Trans and Epi-illumination Source

The VersaDoc system incorporates unique trans and epi-illumination modules for

both UV and white light excitation. This provides high-sensitivity imaging of a variety

of fluorescent, chemifluorescent and colorimetric samples. The broad bandwidth UV

excitation (290-365 nm) supports the detection of a broad range of fluorescent dyes

in contrast to the limited number of dyes, which may be excited using a single

wavelength visible laser.

(3) Interchangeable Lens

The

VersaDoc is supplied with two standard lenses. One zoom and one 50 mm

mono-focal.

Depending upon which VersaDoc system has been purchased, either a 20-40 mm or

the 28-80 mm zoom lens will be included. This zoom lens is ideal for most

fluorescence and colorimetric applications.

The 50 mm, f1.4 fixed lens has a high light collection efficiency and is the lens

recommended for all chemiluminescence applications.

You may purchase an optional 105 mm lens that can be used for imaging small

samples at high resolution. The VersaDoc will accommodate most Nikon f-mount

lenses with a minimum operating distance (MOD) of 0.65 m.

It is highly recommended that lenses be purchased through Bio-Rad, as some Nikon

lenses require modification before they can be inserted into the filter wheel housing.

Use of an unmodified lens may result in damage to either the instrument or lens

mount.

(4) Emission Filters

An eight-position emission filter wheel has been incorporated into the optical design

of the VersaDoc to permit multi-color image discrimination and the detection of many

different fluorescent dyes. The VersaDoc is supplied with four standard filters. Filter

#1 (520LP-Long Pass) is optimized for single color detection of ethidium bromide,

DNAStar, SYBR

Red, SYPRO

Green, SYBR Gold, Radiant Red, SYPRO Orange, SYPRO

Ruby, Texas Red, Cy2, Cy3 and most fluorescein and rhodamine

derivatives. Filters #2 (530BP60) and #3 (610LP) are for the independent detection of

green (fluorescein) and red (Texas Red) fluorescence in multiple colored samples.

These filters effectively support multiplexing analysis for increased sample throughput

and more accurate molecular weight determination. Filter #4 is a clear filter that can

be used for white light applications. Filter positions (Filter #6 #7 & #8) are available to

users for the installation of application specific custom filters. Filter position #5 should

be left vacant for the optimized collection of chemiluminescent samples.

User’s Manual • 2-2

Page 13

(5) Quantity One 1-D Analysis Software

The Quantity One software permits user-friendly control of the VersaDoc Imaging

System and accurate analysis of the captured image or data. Quantity One is

designed for operation in a Windows or Macintosh environment and supports fully

automated application-based image acquisition.

NOTE: Windows NT does not support USB therefore all WINDOWS NT based systems must use a

Serial Communications port.

The Quantity One package allows substantial flexibility in the presentation of captured

images and provides many tools for data analysis. These include molecular weight

determination, automated lane and band finding, accurate concentration analysis,

VNTR and differential display studies and colony counting. Please refer to the

Quantity One instruction manual for a full description of this software package.

2.3 Mechanical Description

The VersaDoc Imaging System is a modular system and it consists of the following

main hardware components. See figure 2.2.

1. The light tight enclosure, which integrates the sliding UV transillumination module,

two epi-illumination modules, chemiluminescence tray, access to the filter wheel,

lenses and all the electronics needed for controlling the lights and filterwheel.

2. The camera module, which integrates the cooled CCD camera.

3. Depending on which model of VersaDoc you have (1000, 3000, 4000 or 5000),

you will have the corresponding camera module but the light tight enclosure will

be the same.

4. VersaDoc is also available in a "LITE" versions (1000L, 3000L, 4000L or 5000L)

where no illumination sources are included. The unit is offered with a light tight

enclosure and a camera with a filter wheel. All illumination modules, lenses, and

filters are customized for your specific needs.

Light Tight Enclosure Camera Module

Figure. 2.2. Components of the VersaDoc system.

User’s Manual • 2-3

Page 14

2.4 Overview of the Imaging Process

The acquisition and analysis of image data using VersaDoc technology is a simple

five-part process.

Step 1: Samples to be imaged are placed on the transilluminator module.

Step 2: The appropriate imaging method is selected in the VersaDoc acquisition

window of Quantity One.

Step 3: The sample is aligned using the positioning template in the Quantity One

acquisition window.

Step 4: If required, the imaging lens is zoomed and focused onto the sample to obtain

the highest quality image.

Step 5: The desired collection time for an aperture setting of the lens is selected and

the image is captured. In cases where Flat Fielding is selected, a reference image is

also acquired (see below). Once the sample image is collected and saved, this

Image can then be reviewed and analyzed using the appropriate tools bundled in the

Bio-Rad software package. Please refer to the software manual for further details.

2.5 Illumination Flat Fielding:

A uniform images are essential for quantitative analysis. The VersaDoc Imaging

System features a proprietary algorithm that allows elimination of image nonuniformities caused by lens, illumination source. Optimization of the image uniformity

is made possible via the Illumination Flat Fielding function in the image acquisition

portion of the software.

NOTE: This feature is only for imaging applications that utilize a UV or white

light transillumination source.

Illumination Flat Fielding when using the UV transilluminator:

The software takes an initial image and then prompts the user to remove the sample

and to place the VersaDoc Fluorescent Reference Plate provided with your system

on the UV Transilluminator.

Illumination Flat Fielding when using the white light conversion screen:

The software will prompt the user at the beginning of the image acquisition to place

the VersaDoc white light conversion screen on the UV transilluminator. The sample is

placed on the conversion screen; an initial image is taken. The software then

prompts the user to remove the sample from the VersaDoc white light conversion

screen and then finishes image acquisition.

User’s Manual • 2-4

Page 15

Section 3

System Installation

3.1 Operating Requirements

3.1.1 System Location

The VersaDoc system should be located in an area that is free of excessive dust or

moisture, strong magnetic fields or ionizing radiation. It is also highly recommended that the

ambient temperature be stable and within the range of 10°C to 28°C (21°C is optimal) and

that the relative humidity not exceed 70%, non-condensing.

Warning: Care should be taken when lifting and moving the VersaDoc system

to avoid personal injury. It is recommended that two people, one on each side

of the instrument lift the VersaDoc enclosure from the bottom.

The VersaDoc should be placed on a level bench top with a minimum depth of 70 cm and a

height clearance of 180 cm, where there is adequate ventilation for the system’s cooling

fans to operate. The system’s feet allow enough clearance for easy removal of your hands

from underneath the instrument once the system has been placed on the bench.

In placing the VersaDoc, users should also allow for easy access to the main power switch,

which is located on the lower right hand side of the system’s rear panel. The instrument

should be placed where there is adequate room to insert the samples into the front of the

enclosure and where it can be easily connected to the host computer. The maximum

distance between the host computer and the instrument should be two meters. (instrument

is supplied with cables long enough for such distances).

Note: The host computer should be located at a workstation that minimizes

operator fatigue.

3.1.2 Power Requirements

The VersaDoc system and its host computer should be connected to a stable grounded

power outlet on a circuit free of electrical noise. In addition, a high quality electrical surge

suppressor/line filter with a 10 Amp or higher rating should be used to avoid damage from

AC fluctuations. Only a grounded 3-pin power cord should be used to connect power.

The VersaDoc is designed for operation at an input voltage of 110-240 VAC, at 50-60 Hz.

Deviation from these operating voltages can lead to slower cooling and heating

process with your deeply cooled CCD camera.

User's Manual • 3-1

Page 16

3.1.3 Host Computer Recommendations

The VersaDoc system is capable of producing large image files of high resolution to easily

handle such large files. A powerful computer is required.

Please refer to your software manual for detailed host computer system and software

requirements. If the computer is not purchased from Bio-Rad, systems compatibility is the

responsibility of the user. Please check with your local Bio-Rad office regarding

compatibility for your specific brand of computer.

3.2 System Setup

There are 3 main phases in the installation of the VersaDoc system:

1. The components are delivered to your laboratory.

2. The system is installed by a trained Bio-Rad representative.

3. Users are trained on the operation of the VersaDoc and accompanying peripherals and

software by a Bio-Rad representative.

The following steps for setup of the VersaDoc requires approximately two hours.

Prepare the VersaDoc hardware:

1. Unpack components

2. Perform shipping check

3. Install the camera module

4. Install the transilluminator module and epi-illumination modules

5. Connect system cables

6. Install emission filters

7. Install lens

8. Connect electrical and host computer communication cables

9. Power up the instrument

Each of these steps is detailed in the following sections.

User's Manual • 3-2

Page 17

3.2.1 Unpacking the VersaDoc System Components

With the exception of operating software, VersaDoc components are shipped in palletsupported boxes. Unpack the components by following the steps listed below:

1. Cut the two steel straps supporting the main instrument package.

2. Remove the top cardboard lid. Remove other packaging materials and secondary boxes

from the top.

3. Slide the outer sleeve off the box vertically. The VersaDoc enclosure can be found

within the box.

4. With the assistance of a helper, remove the VersaDoc from the box. Grip the bottom of

the enclosure on both sides (do not lift the instrument by the front door or electronics

area) and place it on the floor for the next step in the setup procedure. When placing

the enclosure allow clear access to the rear panel for connection of the appropriate

cables.

Warning: Get a helper; a single person should not attempt to lift the VersaDoc.

Warning: To avoid back injury, always bend your knees and keep a straight

back when lifting heavy objects.

Caution: Do not supply power to the instrument until the VersaDoc system has

been set up using the following installation procedures.

5. Open all the other boxes and carefully remove all the items.

6. Perform a shipping check to confirm that the system has been supplied complete.

3.2.2 Shipping Check

During the unpacking process inspect all shipping containers to ensure that you have

received all ordered items and that no boxes are damaged. If items are either missing

or damaged, this should be noted at the time of installation so that it can be immediately

reported to both the shipping company and Bio-Rad manufacturing.

The Quantity One acquisition and analysis software is supplied in a separate box.

User's Manual • 3-3

Page 18

The VersaDoc hardware should arrive complete with the following items:

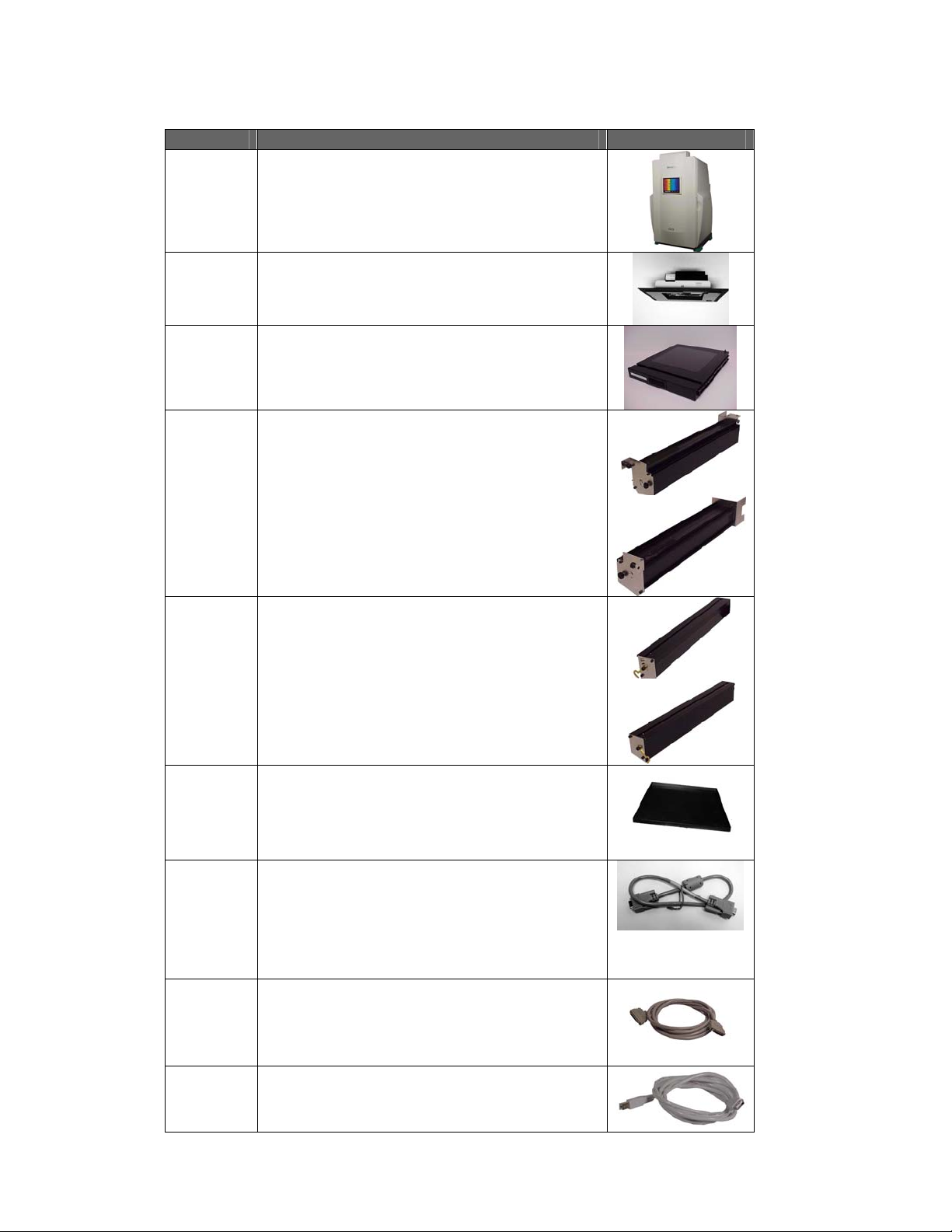

Quantity Item Photo

1 VersaDoc light tight enclosure

1 VersaDoc camera module (Shown Model

1000 camera module, model 3000, 4000

and 5000 are shown later in this section)

1 VersaDoc transilluminator module (already

installed inside the light tight enclosure)

1 Pair of UV epiilluminator modules

1 Pair of White epi illuminator Modules

1 Sample/chemi tray

1 Camera power cable (VersaDoc 1000 and

4000 only)

Or

Fan assembly power cable (VersaDoc 5000

only)

1 Camera AIA interface cable

1 Serial/USB communication cable

User's Manual • 3-4

Page 19

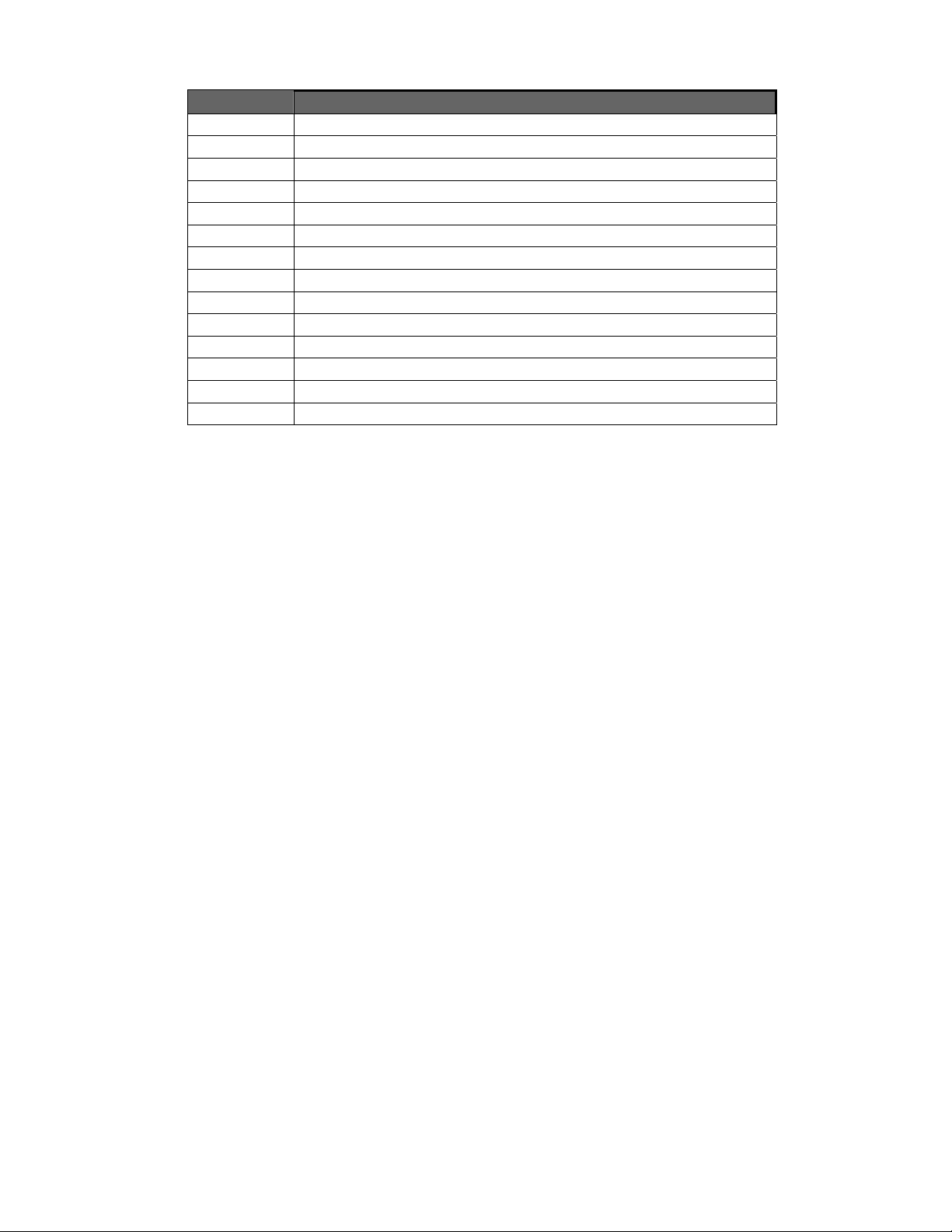

Quantity Item

1 Sample Holder Kit

1 VersaDoc Fluorescent Reference Plate

1 PCI Digitizing Card

1 White Light Conversion Screen (Optional)

5 Filters (530DF70, 520LP, 610LP, Clear, 660Cutoff)

2 Lenses (20-40mm Zoom, 50mm Fixed)*

2 Lenses (28-80mm Zoom, 50mm Fixed)* *

1 Lens and Filter Cleaning Kit

1 Focusing Target

1 Power Cord

1 Instruction Manual

1 Camera Specification File (CD)

1 58mm-52mm Step Down Ring**

1 Warranty Card

* These are provided with VersaDoc 1000 model only

** These are provided with VersaDoc 3000, 4000 and 5000 models

NOTE: Please retain all packaging materials for future transport of the

VersaDoc system. Additional charges will be assessed if packaging is not

available for instrument warranty shipping.

3.2.3 Coupling the Camera Module to the enclosure:

This applies to all camera modules (VersaDoc 1000, 3000, 4000 and 5000). Follow

the procedure outlined below to mount the camera module to the enclosure.

1. Leave the enclosure on the floor for easy access to the camera mount.

2. Correctly position the camera module on the camera mount located at the top of

the enclosure such that the three holes in the camera module adapter plate will

match the three standoffs located in the filter wheel assembly in the camera

mounting plate.

NOTE: The camera module should sit completely flat and square on the

surface of the Enclosure to avoid light leaks

3. Using the 3 cap-head screws and the 9/64” hex key (included), secure the

camera adapter plate to the standoffs. Carefully tighten the screws evenly to

form proper light seal. See figure 3.1 for details.

.

User's Manual • 3-5

Page 20

Three cap head screws to secure the camera to the filter wheel assembly

Three Standoffs

Figure 3.1.

3.2.4 Installing VersaDoc 1000, 3000 ,4000.

Connecting the Cables to the Camera Module:

This procedure applies to the Versa Doc 1000 and 3000 and 4000 systems.

Connecting the camera power cable:

Camera power cord has a DIN connector on each end. The cable with a 9- pin DIN

connector is for the VersaDoc 1000 and 4000 cameras and the cable with a 15-pin

DIN for the VersaDoc 3000. See Figure 3.2

NOTE: VersaDoc 3000 systems with Enclosures that are serial number XXXBR 300 or greater come with

a separate power supply for the camera . This power supply already includes a power cable for the

VersaDoc 3000 camera. VersaDoc 3000 systems

Connect this cable between the camera power socket on the camera module and

the enclosure. Picture shown below is for enclosures with serial numbers below

XXXBR0300:

VersaDoc 1000 and 4000 Camera Power

Connector

9 pin camera power connector on top side

of the rear panel

User's Manual • 3-6

VersaDoc 3000 Camera Power connector

15 pin camera power connector on top side

of the rear panel

Page 21

If your enclosure has a serial number above XXXBR300 then connection should be made

per pictures shown below:

VersaDoc 1000 and 4000

Camera Power Connector

Camera Power connector on

top side of the rear panel

VersaDoc 3000 Camera Power

connector

Camera Power connector on

the cable from camera power

supply

Figure 3.2

NOTE: The VersaDoc 4000 camera must be connected to the same power port as the

VersaDoc 1000

.

Connecting the AIA CABLE:

For VersaDoc 1000 and 3000 and 4000 only:

1. Connect the AIA cable (Part #800-0247) to the AIA port on the camera (See Figure 3.4).

Push the cable to the connector such that it clicks and snaps in place properly.

AIA CONNECTORS

ON EACH END OF

THE CABLE

VERSADOC 1000, 4000

CAMERA AIA CONNECTOR

Figure 3.4

User's Manual • 3-7

VERSADOC 3000 CAMERA

AIA CONNECTOR

Page 22

2. The other end of the AIA cable will be connected to the PCI digitizing card that will be

installed in the PC after software installation as shown later in this procedure.

NOTE: The steps describing the installation procedure for the PCI digitizing card

follows later in this procedure.

3.2.5 Installing VersaDoc 5000

Connecting the cables to the camera module:

1. The VersaDoc 5000 camera module comes with a camera controller unit (CEU) and

Camera Controller Unit

(CEU)

a controller cable. See figure 3.6 below :

Camera Module

Camera Controller Cable

Figure 3.6

2. Couple the VersaDoc 5000 camera module to the enclosure as shown in the section

3.2.3 above. See Figure 3.1 for details.

3. Next connect the CEU to the camera.

Caution: The default voltage setting on the camera power supply

module is 120 VAC. You must follow the instructions below to make

sure proper voltage selection is made and fuse is used for you AC

voltage environment.

Caution: The VersaDoc 5000 camera module has a “BLUE” plug

installed on the connector on the camera. This plug must not be

removed until the module is installed to the enclosure and the

camera controller unit is ready to be connected to the Camera.

Setting the VersaDoc 5000 System Power Supply Voltage (If required):

1. Familiarize yourself with the camera controller unit [CEU]. See Figures 3.7a, b and c

below:

User's Manual • 3-8

Page 23

Figure 3.7a Figure 3.7b

AIA Connector on CEU

Camera

Controller Cable

Connector

Figure 3.7c

2. A small white tab on the AC inlet located on the rear panel indicates the voltage

setting on your camera controller unit. See Figure 3.8

Insert a small screw driver and pull out the tab

White plastic stub

shows the current

voltage setting.

Make sure it

matches with the

local voltage.

3. Pull out the small tab near the AC inlet using a small screwdriver. See Figure 3.8

4. The TAB holds a fuse completely remove it. This will expose a tiny PCB located in a

tiny slot as shown in Figure 3.9

Figure 3.8

User's Manual • 3-9

Page 24

Small PCB in a tiny

f

slot. This side of the

PCB has letters on

this side.

Fuse holder.

Figure 3.9

5. Using the plastic stub on the PCB select the orientation of the board so that the

desired voltage numbers and arrow point towards the socket for the board. The tab

on the inside surface of the stub must match with the notch on the tiny PCB See

Figure 3.10a and 3.10b:

Plastic stub that

shows through

the hole

indicating the

selected voltage

100 VOLT and arrow must

point inward. Insert the

board back into the socket

with the letters facing the

right side

Notch on each side

of the PCB,

Plastic stub that

shows through the

hole indicating the

selected voltage.

NOTCH on each side o

the PCB,

6. Now reinstall the tiny PCB back into it’s socket such that the numbers on it face

towards the right side (towards the Fuse holder inlet)

Setting for 100 volt operation

Figure 3.10 a

230 VOLT and arrow must

point inward. Insert the

board back into the

socket with the letters

230 Volt setting

Figure 3.10b

7. Next remove the Phillips screw that holds the fuse holder and turn the holder around

so that the two 1 amp fuses face towards the socket. See Figure 3.11

User's Manual • 3-10

Page 25

Remove Screw

Figure 3.11

8. Push the tab until it locks in its socket.

9. Check again to make sure that the plastic stub indicates the desired voltage

selection

Connecting the VersaDoc 5000 Camera and CEU Cables

:

1. Connect the AIA cable to the connector labeled AIA on the CEU connector panel.

The other end of this cable will be connected to the PCI digitizing card in your PC.

2. Remove the “BLUE” shorting plug from the camera and connect the camera control

cable between the camera and the CEU. See figure 3.12

Fan Assembly

Power

Connector

Blue Shorting Plug

VesaDoc 5000 Camera Module Blue Shorting plug

Figure 3.12

3. Connect the AC power cord to the AC inlet on the CEU but do not power up the

CEU yet.

4. For units serial number below XXXBR300: Connect the fan power cable from the

fan assembly (5000 models only) to the DB9 power connector located at the top

surface of the electronics module. See picture 3.13A

5. For units with serial number xxxBR300 or higher: Connect the fan power cable

from the fan assembly (5000 models only) to the DB9 power connector

located on the side of the electronics module. Once connected, the system cable

User's Manual • 3-11

Page 26

connections will look similar to the ones shown in Figure 3.13 A or B depending on

th eserial number of the enclosure you may have.

Fig 3.13A

Fig 3.13 B

Fan Cable

Figure 3.13

3.2.6 Installing the Epi modules:

1. Remove the access panel mounted on the ballast panel by unthreading the two

thumbscrews.

Thumb

screws on the

ballast panel

Figure 3.14a

2. If not connected already, connect the transilluminator cable to the connector labeled

“UV TRANSILLUMINATOR” located on the ballast panel on interior rear wall of the

enclosure.

3. To install the epi UV and white modules first install the epi UV module by inserting

the two prongs on its end plate to the slots located at the back wall.

4. Secure the module using the captive screw by lining up the front side of the module

with the hole located in the wall of the instrument. (See Figure 3.14b).

5. Now connect the cable from the epi UV module to the appropriate connector on the

ballast assembly.

User's Manual • 3-12

Page 27

Threaded insert

for captive screw

on the EPI UV

module

Slots for EPI UV

Tongue and Groove mechanism to

hang EPI WHITE from EPI UV.

Figure 3.14b Figure 3.14c

6. Next attach the epi white module to the epi UV module by locking in the tongue and

groove located at the outer top edges of each module. (See figure 3.14c)

7. Now secure the epi white module to the epi UV module using the latch and screw

mechanism located at the front plate of the modules. See Figure 3.15

Figure 3.15

8. Next connect the cable from the epi white module to the appropriate connector on

the ballast assembly.

9. Re-install the access panel to the ballast panel.

NOTE: The plugs for each illumination module are keyed and cannot be interchanged.

Each plug will snap together only to the appropriate socket.

3.2.7 Electrical and Communication Connections

Power

The power entry module of the VersaDoc system is configured for operation at 100/120

VAC, 60 Hz or 220-260 VAC, 50 Hz. After checking that the system’s power switch is

turned off, insert an approved power cord into the power entry module located on the

bottom right of rear panel of the unit. See Figure 3.16

User's Manual • 3-13

Page 28

Warning: This instrument must be connected to an appropriate AC

voltage mains outlet that is properly grounded.

Warning: There are hazardous voltages inside the rear panel of the

VersaDoc. Do not remove the cover to the electronics back panel when

the instrument is connected to AC power.

Power entry module at the

bottom right of the rear

panel

Figure 3.16

VersaDoc Connections:

The VersaDoc is connected to the host computer via a Serial or USB

interface and an AIA interface.

One each of the Serial and USB port is located on the rear right side of the

unit. Use the supplied USB or Serial Cable to connect the PC to the

VersaDoc.

Caution: To prevent damage to the hardware, all instruments must be

turned off before attempting to connect (or disconnect) the unit to the

host computer.

Upon insertion of the Serial or USB cable into the VersaDoc, the Serial or USB

port the PC will automatically select operation and sense the presence of

VersaDoc.

NOTE: Do not turn ON the power to the VersaDoc (and CEU in case of VersaDoc

5000) yet!

Power entry module

User's Manual • 3-14

Page 29

Connecting the AIA Cable to the Computer:

To do this, two things must happen:

i. The software must be installation on the PC which will control this system

ii. The PCI Digitizing card must be installed into the PC where the AIA cable is

to be connected

.

Software Installation:

Please follow the instructions below to install the PC or Mac software for VersaDoc

system:

NOTE: Do not install the PCI card into the PC yet. First install the drivers as

shown below and then install the PCI Card.

PC: based VersaDoc systems:

a. Insert “The Discovery Series” software CD into the CD ROM drive of the PC.

It will go into AUTO RUN mode and the following window will open:

b. Click on “NEXT” the following window will open:

User's Manual • 3-15

Page 30

c. Click on the arrow next to ChemiDoc XRS/VersaDoc drivers to get installer

options. See picture below:

d. If you are installing the drivers on local drive select appropriate option by

scrolling down as shown in the picture below. Click on “NEXT”:

User's Manual • 3-16

Page 31

e. Drivers will be copied to the appropriate location on your hard drive and at the

completion the following window will appear.

f. Click on “FINISH” and the system will shut down. At this time, install the PCI

card into the system and REBOOT the system.

g. As the system re-boots and Windows 2000/XP starts it will find the PCI card and

go through a “FOUND NEW HARDWARE” installation routine and find the

drivers that were just installed.

NOTE: In case the PCI card was installed before the software then go to

section 6 for software troubleshooting. In case of the MAC systems it does

not matter if the PCI Card is installed before or after installing the software

and drivers.

Mac based VersaDoc systems

NOTE: This procedure applies to both Mac OS 9.xx and OS 10.xx based systems.

h. Insert “The Discovery Series” software CD into the CD ROM drive of the MAC.

Installer will open and offer choices.

User's Manual • 3-17

Page 32

i. Choose custom install from the pulldown menu in this window and click on

“INSTALL” The following window will open.

Depending upon the Imaging device you are installing, click on the desired

j.

Imager you want to install and then click on “Install”. The drivers will get loaded

and at the completion of the installation the following window will open

User's Manual • 3-18

Page 33

k. Click on “RESTART” so that the system will start and will now restart.

l. Please read the “README” file before using the system

Installing the PCI digitizing card to the PC:

Caution: Ensure that the VersaDoc system is turned off before Installing the

digitizing card and AIA cable.

1. Now install the digitizing card into a PCI slot in your computer and secure it with

appropriate screw. See Figure 3.17

PCI digitizing card PCI slot inside the PC

Figure 3.17

2. Connect the camera to the digitizing card with the AIA cable. Do not power up the

PC/MAC yet. See section 3.2.9 for powering up the PC.

User's Manual • 3-19

Page 34

3. With both Serial or USB and AIA cables connected, your system will appear as

shown in one of the figures 3.18 a~e below:

:

Fan Cable

Power Cable

AIA Cable

Control

Cable

Serial/USB

Figure 3.18a

VersaDoc 1000, 3000 and 4000 Systems under

Serial # xxxBR300

AIA Cable

Power Cable

Serial/USB

Power Supply

Serial/USB

AIA Cable

Figure 3.18b

VersaDoc 5000 System under Serial # xxxBR300

Fan Cable

Control

Cable

Serial/USB

AIA Cable

Figure 3.18c

VersaDoc 3000 Systems starting Serial # xxxBR300

Camera Power Cable

Serial/USB

Figure 3.18e

VersaDoc 1000 and 4000 Systems starting Serial # xxxBR300

User's Manual • 3-20

Figure 3.18d

VersaDoc 5000 System starting Serial # xxxBR300

AIA Cable

Page 35

Power On Sequence

Normally, the VersaDoc system should be switched on for 30 seconds before

The host computer is powered up. This protocol is required for the computer to

recognize the VersaDoc as a peripheral device.

1. Power up the VersaDoc system first.

2. Also power up the power supply block in case of the VersaDoc 3000 or CEU in case

of the VersaDoc 5000 system.

3. Power up the PC/Mac second.

4. In case of a PC, the VersaDoc system is detected via USB connection. A new

window will indicate that a new USB device has been found.

5. Proceed to the next step to complete the installation

3.2.8 Installing Filters

The VersaDoc is supplied with three emission filters and one clear filter. These

must be installed in the 8-position filter wheel before use. These filters are:

#1 520LP (Long Pass) Used for most single color fluorescent stains and

labels.

#2 530BP (Band Pass) Used for detection of green signal (FITC etc.) in

multi-color fluorescence experiments

#3 610LP (Long Pass) Used for detection of red signals (Texas Red

etc.) in multi- color fluorescence experiments

#4 Clear Used for system focus and some colorimetric

applications.

To install the filters follow the procedure below (Figure 3.19):

1. Ensure that all power and communication cables are connected and that the

VersaDoc system is turned on.

NOTE: Do not power up the PC or MAC yet.

2. Open the main door. This will expose the camera, filter assembly, filter advance

button and the lens mount assembly.

3. Loosen the left side screw of the filter wheel cover and remove the right side

thumbscrew completely by fully unscrewing it. The cover can now be rotated

downward to expose the filter wheel.

4. Push the filter advance button until filter position #1 is in the center front position.

The #1 label should be clearly visible on both sides of the filter slot.

User's Manual • 3-21

Page 36

5. Remove filter #1 from its packaging and check that it is clean, free of dust,

fingerprints and scratches. If the filter is dirty it should be cleaned with the materials

provided in the lens and filter cleaning kit.

6. Holding the filter by the numbered tab with the number in the correct orientation,

carefully slide the filter into the open filter wheel position.

7. Repeat steps 4-5 for the remaining filters (#2, #3, #4)

8. Replace the filter wheel cover and hand-tighten both captive thumbscrews.

9. Close the main door firmly. The filter wheel will automatically reset to the home

position and is now ready for operation.

NOTE: The above procedure can also be used for the installation of custom filters.

Open filter wheel access panel and

rotate it downward as shown

Unpack and carefully install filter 1

Figure 3.19

Advance to position 1

Make sure that filter 1 is all the way

in its slot and positioned straight.

User's Manual • 3-22

Page 37

3.2.9 Installing the Lens

The VersaDoc system is supplied with two standard lenses, a flexible zoom

lens and a high NA 50-mm lens with improved collection efficiency

Zoom Lens for fluorescence and colorimetric imaging

The Tamron zoom lens is recommended for use with all fluorescence and colorimetric

applications and for high intensity chemiluminescence experiments. The zoom

capabilities of this lens supports the imaging of small and large samples. The zoom lens

is not a high numerical aperture (NA) lens and should not be used for low intensity

chemiluminescence experiments.

High Numerical Aperture Lens for Chemiluminescence Imaging

The Nikon 50 mm high NA (f/1.4) lens is designed for optimized light collection

efficiency and should be used for all low intensity chemiluminescence experiments. The

lens can also be used for collecting typical fluorescence and colorimetric images. The

chemiluminescence sample tray may be used to move the sample closer to the camera.

Infrared Cutoff Filter

When performing any fluorescence experiments it is required that the 660 nm infrared

cut-off filter that is supplied with the VersaDoc is installed on the front of collecting lens.

This filter will block any infrared signal that will be generated by the UV bulbs,

substantially reducing image background and improving sensitivity. This filter is not

required for chemiluminescence experiments and should not be used when collecting

low intensity chemiluminescence signals, as it will reduce the amount of signal

collected.

Lens Use Recommendation

For optimal image acquisition, it is recommended that the zoom lens with 660 nm cut-off

filter installed is used for all fluorescence and colorimetric applications. In

chemiluminescence experiments, the 50 mm fixed lens with no cut-off filter is

recommended.

Zoom Lens Installation

To correctly install the zoom lens. Follow the procedure outlined below (Figure

3.20):

1. Remove the lens from its packaging and retain the packaging for future storage.

2. Remove the front lens cap and install the 58mm-52mm step down ring, then the

660 short pass (SP) filter onto the lens.

User's Manual • 3-23

Page 38

3. Remove the protective cover from the lens mount (rear of lens) and check that

the lens is clean. If the lens is dirty it should be cleaned with the materials

provided in the lens and filter cleaning kit.

4. Open the door to the main door and position the lens so that the white line on its

mount matches the white mark on the base (right hand side) of the camera

assembly.

5. Insert the mount of the lens into the base of the camera assembly and turn the

lens counter clockwise (to the left) until you hear it click. The white mark and

setting indicators on the lens should now be directly in front of you.

6. The lens in now locked into position and the lens cap and protective platen

cover can be removed.

Figure 3.20. Steps in zoom lens installation.

High Sensitivity 50 mm Lens Installation

To correctly install the 50 mm high NA lens, follow the procedure outlined below

(Figure 3.21):

1. Remove the lens from its packaging and retain the packaging for future storage.

2. Remove the protective cover from the lens mount (rear of lens) and check that the

lens is clean, free of dust, fingerprints and scratches. If the lens is dirty it should be

cleaned with the materials provided in the lens and filter cleaning kit.

3. Open the door to the main door and position the lens so that the white line and dot

on its mount matches the white mark on the base of the camera assembly.

4. Insert the mount of the lens into the base of the camera assembly and turn the lens

clockwise (to the left) until you hear it click. The main white line and lens settings are

directly in front of you.

User's Manual • 3-24

Page 39

Figure 3.21. Steps in 50 mm lens installation.

5. The lens in now locked into position and the lens cap and protective platen cover

can be removed.

Lens Removal

To remove the lens from the camera housing follow the procedure outlined below

(Figure 3.22):

1. Place the lens cap on lens

2. Hold the lens firmly with your left hand throughout the remainder or the removal process

so that it cannot be dropped accidentally.

Caution: Accidentally dropping the lens could break the UV

transilluminator platen or white light conversion screen. Replacement

of such a broken platen or white light conversion screen is not covered

by warranty or service contract.

3. Depress the red release button on the base of the camera housing. This is located to

the rear, right-hand side of the lens.

4. Rotate the lens in a clockwise direction (to the right) to release it from the housing.

5. Pull the lens down and remove it from the filter wheel assembly.

6. Replace the mount cover. If the lens is not being used for some time it is recommended

that it be stored in its original packaging.

User's Manual • 3-25

Page 40

Proceed to section 4.

Figure 3.22. Steps in lens removal.

User's Manual • 3-26

Page 41

Section 4

Operating the VersaDoc

4.1 Starting the VersaDoc System

Both the VersaDoc and the camera module must be connected to the computer prior to

using the VersaDoc system.

To turn on the VersaDoc press the power switch located on the right-hand side of the rear

panel of the instrument. The green LED on the front will illuminate indicating that the

system is ready and to confirm that power is being supplied and all the internal light

modules are functioning properly. The start up initialization process takes approximately 30

seconds. After this time has elapsed the host computer can be turned on. At this time you

can also power up the power supply or CEU if you have a VersaDoc 3000 or 5000 system.

Note: If the LED indicator fails to illuminate and the instrument is inoperative, check that all power cables

are firmly attached and that power is being supplied to the unit. If the unit still remains inoperative or the

VersaDoc acquisition window cannot be opened on the host computer, please contact the Bio-Rad

Technical Service Department for assistance.

The VersaDoc should be switched on at least 30 seconds before the host computer, to

allow for complete initialization. If the VersaDoc is not fully operational before the computer

is turned on, the system will not be recognized as an attached Serial/USB device and the

camera may not be recognized by the digitizing card thus you will not be able to

communicate with the VersaDoc from the Quantity One acquisition window.

For best imaging results it is recommended that the VersaDoc be allowed to warm-up for

10 minutes before use.

4.2 Overview of Operational Steps

The user will typically complete the following series of steps when acquiring an image using

the VersaDoc:

1. Start the program and open the acquisition window

2. Select the desired application

3. Place the sample on transilluminator platen, converter screen or chemi tray as the case

may be and optimize its position

4. Focus

5. Adjust the lens aperture and zoom

6. Readjust focus if required

7. Select the exposure (acquisition) time

8. Acquire the image

User’s Manual 4-1

Page 42

4.3 Detailed Operating Procedures

4.3.1 Opening the Acquisition Window

After starting your computer, open the Quantity One acquisition and analysis program by

double clicking on the Quantity One icon.

From the FILE menu select VERSADOC to open the instruments acquisition window. The

following window will open on the screen.

Note: If the computer cannot establish communications with the VersaDoc a message will indicate this and

give the user the option of entering a simulation mode.

Figure. 4.1. VersaDoc acquisition screen in Quantity One.

User's Manual • 4-2

Page 43

4.3.2 Selecting the Application

The Quantity One program uses an application-oriented format to simplify user selection of

collection parameters. To correctly set the parameters for collection, simply click the

SELECT button in Step I (Figure 4.1) and identify the application name matching your

sample type. For detailed acquisition instructions please refer to the Quantity One software

instruction manual.

4.3.3 Placing Samples in the Imaging Chamber

The VersaDoc can accommodate a variety of sample types and sizes. The sample stage is

25 X 25 cm. This configuration supports the acquisition of smaller areas of interest within

very large samples. The imaging area is liquid sealed so wet samples may be placed

directly into the imaging chamber on the UV transilluminator platen. With wet samples you

will find it convenient to use the sample holders provided with your VersaDoc system.

These sample holders have suction cups that hold the sample in place and keep it from

sliding around on the polished glass surface.

Caution: The sample stage area is resistant to most research chemicals but may be

damaged by extended contact with strong acid solutions and organic solvents. When

imaging samples exposed to these chemicals, users should wash the sample stage with

water and wipe dry immediately after imaging.

Samples should be placed in the VersaDoc instrument following the steps outlined below:

1. Open the main door.

2. Visually check that the sample platen is clean. If not, clean using an optical cleaning

solution and a soft lint-free towel or lens cleaning tissue.

3. From the VersaDoc acquisition window select the POSITION function in Step II (Figure

4.1). The image display window will now present a real time image of the sample in the

chamber that refreshes rapidly.

4. Position your sample on the imaging platen, using the software generated alignment grid, to

ensure that it is correctly placed and in the center of the viewing area.

Note: When imaging fluorescent gel samples it is recommended that the sample be removed from the glass

or plastic plates of the gel sandwich for good image quality. The glass and plastic will fluoresce when

exposed to UV light and will contribute to background signal.

Sample/Chemi Tray

It is recommended that the Sample/Chemi tray (Figure 4.2) be used for all small

chemiluminescence samples (8 x 8 cm or less). This tray slides onto the guides on the

each epi-illumination assembly and allows the sample to be placed closer to the camera.

Large chemi samples should be imaged on the platen. To insert and remove the chemi

tray, the door to the enclosure must be fully opened.

Note: When using the VersaDoc for non-chemiluminescence applications the sample tray should be

removed from the enclosure, as it will block sample signal from reaching the CCD camera.

When using white light epi illumination the sample tray should be placed on the dark reflective platen of

the transilluminator to avoid unwanted reflections on your image.

User’s Manual 4-3

Page 44

Fig. 4.2. VersaDoc chemi sample tray.

4.3.4 Lens Selection and Setup

The VersaDoc system is supplied with two standard lenses, a flexible zoom lens and a high

numerical aperture 50 mm lens with improved collection efficiency.

For optimal image acquisition, it is recommended that the zoom lens with 660 nm cut-off

filter installed be used for all fluorescence and colorimetric applications. This lens can also

be used for high intensity chemiluminescence experiments, however it is not ideal for this

type of application.

For the best chemiluminescence results, it is recommended that the 50 mm fixed lens with

no cut-off filter be used. The 50 mm high NA (f 1.4) lens is designed for optimized light

collection efficiency and will produce superior images for all low intensity

chemiluminescence experiments. The lens can also be used for collecting typical

fluorescence and colorimetric images, however the imaging area is fixed. This lens is

designed to work in combination with the chemiluminescence sample tray, placing the

sample closer to the camera for improved light collection efficiency

Infrared Cutoff Filter

When performing any fluorescence experiments it is recommended that the 660 nm infrared

cut-off filter that is supplied with the VersaDoc be installed on the front of collecting lens

(see figure 4.3). This filter will block any infrared signal that may be generated by the UV

bulbs, substantially reducing image background and improving sensitivity. This filter is not

required for chemiluminescence experiments and should not be present when collecting

low intensity chemiluminescence signals, as it will reduce the amount of signal collected.

Figure 4.3

User's Manual • 4-4

Page 45

g

Aperture

Ring

Zoom

Ring

Focus

Rin

Zoom Lens 50 mm Fixed focal length lens

FIGURE 4.4

4.3.5 Aperture Adjustment

The aperture or f-stop ring is located at the top of the lens (Figure 4.4) and controls the

amount of light that passes through the lens to be captured by the CCD camera. When the

aperture is fully open, the f-stop number will be smallest, the depth of field will be the lowest

and the most light will pass through the lens. When the aperture is fully closed, the f-stop

number will be largest, the depth of field will be highest and the least light will pass through

the lens. For low signal applications such as chemiluminescence, it is recommended that

the aperture be fully opened to the smallest f-stop value.

Note: When the aperture on the zoom lens is fully closed (largest f-stop setting of 22), the aperture ring

locks. To unlock the aperture ring push the black release button to the right of the f-stop indicator while

turning the ring to the right (counter-clockwise).

Note: The aperture ring on the 50 mm lens will not lock in the fully closed (f-stop 16) position, unless the

user activates the lock mechanism on the lower right hand side of the f-stop indicators. To lock in this

position move the button (white dot) up so that it aligns with the orange indicator. It is not recommended

that the lens be locked in this position for chemiluminescence experiments as this setting allows the least

light through the lens.

4.3.6 Zoom Adjustment

When using the zoom lens the view area of the image can be adjusted by rotating the zoom

ring (Figure 4.4). The zoom ring is located directly below the aperture ring. At maximum

zoom the indicator on the lens will be set to its highest specified focal length 40 or 80 mm

depending on which lens is being used, also the image resolution will be at its best.

The zoom setting can be adjusted and viewed in real time by selecting the POSITION

function in the VersaDoc acquisition window. The image display window will now show a

real-time image of the sample, as it will be captured. This image refreshes every second to

help you optimize your zoom settings.

Note: The 50 mm lens offers no zoom adjustment.

User’s Manual 4-5

Page 46

4.3.7 Focus Adjustment

To focus the lens on the sample for sharp images you must choose the FOCUS button in

the Quantity One acquisition window. This button allows focusing on a small part of the

image. When using this mode the white epi lights turn on automatically and the shutter is

opened and closed repeatedly and the acquisition window is continuously updated to allow

you to focus your lens on the sample. The exposure time during the focus mode is adjusted

automatically to allow proper unsaturated images. If during focus mode the images still

show up saturated, then you must adjust the aperture to a lower setting to view the images

in the focus mode. If the images still show up as saturated (all white), then you may turn off

the epi lights by clicking on the button labeled "Lights On" (see figure 4.1). This will turn off

the white lights and now you may open the main door and adjust the focusing ring (See

Figure 4.5) on the lens to achieve a sharp focus on your sample.

4.3.8 Exposure Time

The exposure time refers to the period of time that the shutter will remain open and light will

pass from the sample to the CCD. As such, the longer the exposure time, the brighter the

captured image will be. For high intensity applications including colorimetric and high

intensity fluorescence experiments, an exposure time of only a few seconds is typically

required. For low intensity applications such as chemiluminescence, an exposure time of

several minutes may be required. The exposure period required to produce an optimal

image varies considerably and may need to be optimized for your particular sample. Typical

exposure conditions for different sample types have been included in Table 4.1 as a guide

to selecting a suitable exposure time. This table also indicates the preferred lens for the

sample and if any accessories are recommended.

Table 4.1. Recommended exposure times and setup

Sample Recommended

Exposure

Fluorescent Stain Gel 3-30 sec. Zoom/IR None

Fluorescence End-Label

Gel

Fluorescent Blot 0.5-5 sec. Zoom/IR Sample/Chemi Tray

Chemifluorescent Blot 0.5-5 sec. Zoom/IR None

Colorimetric Gel 0.1-1 sec. Zoom/IR VersaDoc white light

Colorimetric Blot 0.1 to 1 sec. Zoom/IR Sample/Chemi Tray

X-ray film 0.1-1 sec. Zoom/IR VersaDoc white light

Weak

Chemiluminescence

Strong

Chemiluminescence

30 sec. – 5 min. Zoom/IR None

5-10 min. 50 mm Sample/Chemi Tray (if

10 sec. – 2 min. 50 mm Sample/Chemi Tray (if

Lens &

Filter

Accessories

Used

conversion screen

conversion screen

sample is small)

sample is small)

User's Manual • 4-6

Page 47

4.3.9 Acquiring the Image

To collect the sample image, simply press the ACQUIRE button. The yellow LED on the

front panel of the VersaDoc will flash during acquisition to indicate that the image is being

captured. The software will automatically set all instrument collection parameters and

prompt you to take additional steps for best results.

NOTE: You will notice that after the initial image capture, the software also acquires a dark image. This

image is taken for the same amount of time as the exposure, however, this dark image is acquired with the

camera shutter closed. This provides a very accurate way to measure and remove the dark current noise

from the image.

Once the image is captured, it will be displayed in its own window. You may save the

captured image for storage and/or future analysis.

NOTE: When an application is selected that utilizes UV transilluminator, the software will first acquire an

initial image and then prompt you to remove the sample. You must make sure that the sample platen is free

of any solution from the sample. You will then be prompted to place the VersaDoc Fluorescent Reference

plate.

When your application requires white light transillumination, the software will also prompt

you to place the VersaDoc white light conversion screen on the UV transilluminator platen.

This white light conversion screen absorbs the UV from the UV transilluminator and

converts this broadband UV into white light. See figure 4.5.

Figure 4.5 White Light Conversion Screen

In this application, the software will first take an initial image and then prompt you to

remove the sample.

NOTE: Please make sure that the surface of the VersaDoc white light conversion screen is clean after the

sample has been removed.

After the image has been acquired, its appearance can be optimized. The image may also

be analyzed in various ways using the Quantity One program. Analysis options include

object volume analysis, lane profile analysis including regression analysis and molecular

weight determination, colony counting, fingerprinting, VNTR and differential display studies.

The image and various data reports may also be printed or exported to other software

programs. Please refer to the Quantity One software manual for detailed instructions.

Note: Please refer to the Quantity One software manual for information concerning additional features

available in the acquisition window for VersaDoc.

User’s Manual 4-7

Page 48

Section 5

Care and Maintenance

5.1 General Maintenance

With regular use the VersaDoc system should provide years of trouble-free operation without

any need for regular operator maintenance other than cleaning. If you suspect that the

VersaDoc requires servicing, please contact your local Bio-Rad office.

The outside surface of the VersaDoc should be periodically cleaned with water, mild liquid

soap and a sponge or soft cloth towel.

Caution: Never use abrasive cleaners, solvent based cleaners, alcohol or scouring pads

to clean the external surface of the instrument.

Caution: Always disconnect the VersaDoc from electrical power prior to cleaning the

external surface of the instrument.

5.1.1 Cleaning the Sample Stage Area

The sample platen and sample stage of the VersaDoc should be cleaned between imaging

sessions to optimize image quality. Use powder-free gloves when cleaning the instrument to

avoid fingerprints that may appear during imaging. Never wear powdered gloves when

cleaning the VersaDoc. Clean the sample platen with optical cleaning solution and a lint free

optical tissue. Cleaning kits are available from Bio-Rad and one is supplied with the

instrument.

Caution: It is recommended that water, mild liquid soap and a soft sponge are used to

clean the sample stage. Never use abrasive cleaners, solvent-based detergents or

scouring pads to clean the platen surface.

5.1.2 Cleaning the Transilluminator Platen:

The platen on the transilluminator module should also be periodically cleaned to remove dust

and optimize image quality. To clean the platen, follow the steps outlined below:

1. Turn off the VersaDoc.

2. Open the main door and slide out the transilluminator assembly.

3. Clean the top platen using optical cleaning solution and optical tissue.

4. Once the platen is clean, push the transilluminator back into the enclosure.

User's Manual • 5-1

Page 49

5.1.3 Cleaning the Lens

To optimize image quality it is recommended that any lens used with the VersaDoc be

cleaned before it is installed in the system. Both sides of the lens should be cleaned using an

optical cleaning solution and optical tissue. Avoid touching the glass surfaces of the lens

when installing it into the instrument, as fingerprints will effect image quality.

5.1.4 Cleaning the Emission Filters

To optimize image quality it is recommended that the emission filters installed in the

VersaDoc system are periodically cleaned. Both sides of each emission filter should be

cleaned using an optical cleaning solution and optical tissue. Avoid touching the glass

surfaces of the filter when installing it into the instrument, as fingerprint will effect image

quality.

5.2 Replacing Lamps in Illumination Sources

The life of the broad wavelength UV lamp is approximately 500 to 1000 hours, depending

upon use. As the lamp ages, the required integration time will increase because the intensity

of the UV emission will diminish. If the integration time for image acquisition has increased

more than three-fold, it is recommended that the lamps be replaced. The life of the white

light lamp is approximately 1000 hours.

NOTE: THE LAMPS SHOULD BE REPLACED IN PAIRS FROM ALL ILLUMINATION MODULES.

5.2.1 Replacing the Lamps in the Transilluminator Module

To access the lamps in the transilluminator follow the procedure outlined below.

Caution: Do not touch the glass parts of the lamp or lamp housing. Fingerprints on the

lamp may result in non-uniform illumination. The use of power-free latex gloves is highly

recommended.

Tools required: You will need a #2 Phillips screwdriver and 5/16 size socket wrench to

change the lamps in the transilluminator.

To change the lamp, follow the procedure outlined below (Figure 5.1):

1. Turn off the power to the system.

2. Open the main door to access the UV transilluminator cable.

3. Disconnect the UV transilluminator cable from the ballast assembly.

4. Slide the UV transilluminator module on the slides out completely.

5. There are two release levers on each rail that are made out of black plastic. Pull the

transilluminator module out while pressing down on the lever on the right side and lifting

up the lever on the left. This will allow you to completely disengage the slide rails from

User's Manual • 5-2

Page 50

the guides rails located in the enclosure and the entire transilluminator module will

become free from the enclosure.

Release lever for slides Transilluminator Transilluminator without the cover

Figure 5.1

6. Using the Phillips screwdriver, remove the cover assembly from the transilluminator by

removing four screws. There are two screws on each side of the cover.

7. Using the 5/16" socket wrench, remove the four hex standoffs that hold the baffles on the

lamps of the transilluminator and then gently lift off the baffles exposing the

transilluminator lamps.

Note: Be careful and do not bend the baffles because bending the baffles could lead to deterioration of

uniformity of your UV transilluminator.

8. Remove lamps by holding the metal part of the lamps with the tip of your fingers and

turning them in a rotating movement and by pulling them out of the socket. (See Fig 5.2)

Remove hex standoffs (X4) Remove the baffle exposing the lamp Hold at the metal ends of the

lamps and turn to remove

Figure 5.2

9. Install the replacement lamp by inserting its ends in the sockets and rotating until it clicks

into place.

10. Now reinstall the baffles on the lamps by making sure that they are seated correctly.

11. Reinstall the cover on the transilluminator module. Replace the screws.

12. Carefully reinstall the transilluminator assembly back onto the slides by carefully lining up

the slides into the guides and then gently push in all the way.

NOTE: There is no need to push down or up on the levers, they are only used to remove the

transilluminator assembly.

User's Manual • 5-3

Page 51

13. Next carefully connect the UV transilluminator cable back to the ballast assembly. Turn

the power ON to the system.

14. Make sure that the door is closed.

15. Try an application that requires use of UV transilluminator to make sure that the new

lamps are fully operational.

5.2.2 Replacing lamps in the Epi-illumination module

Tools required: You will need a size 3/32" hex allenkey to change the lamps in the epi

illumination module

The VersaDoc has two epi-illumination modules each contain single white illumination source

and broad bandwidth UV sources. It is recommended that lamps in both the right and left

epi-assemblies must be replaced at the same time.

To change an epi-lamp, follow the procedure outlined below (Figure 5.3):

NOTE: The procedure to remove and replace the lamp in the UV or white light epi modules is the same. The

procedure outlined below applies to both.

1. Turn off the VersaDoc and disconnect all power, removing the power cable.

2. Open the door to the sample compartment.

3. Find the threaded mounting screw that secures the epi modules to the wall of the

enclosure and loosen it to free up the epi module from the wall.

4. Disconnect the epi module cables from the ballast assembly and remove the epi module

completely from the unit and set it on a clean bench.

5. Using a hex 3/32" key remove the three screws that secure the front end plate on the epi

modules and slide out the end piece and filter glass and set aside for future use. See

Figure 5.3.

Remove the end plate using

3/32” Allenkey

View of the epi end

plate

Figure 5.3

User's Manual • 5-4

Filter glass, end plate, allen key, 3 cap head

screws and the end piece

Page 52

6. This exposes the lamps in the epi module for you to replace. To replace the white light

lamp or UV lamp simply grab the two metal ends of the old lamp and carefully rotate to

release it from the sockets. See Figure 5.4

Remove lamp by grabbing the two metal ends and turning the lamp to release from its socket

Figure 5.4

16. Install the replacement white light lamp by placing its ends in the sockets and rotating

until it clicks into place. Be careful not to touch any glass surfaces of the lamp or the filter

glass. Use of latex gloves is highly recommended.

17. Carefully rotate the lamp to make sure it is seated properly.

18. Now reinstall the filter glass, end piece and the end plate. Secure the end plate properly

using the 3 cap head screws and the 3/32” hex Allenkey.

19. Reinstall the epi module in its place and reconnect epi cables to the ballast assembly to

appropriate connectors.

20. Now power up the system and try running the application that use the epi source in which

the lamps were installed to make sure that the lamps are operating normally.

NOTE: THE UV INTERLOCK ON THE MAIN DOOR WILL NOT ALLOW UV EPI TO TURN ON.

ACQUIRE AN IMAGE OF A WHITE PIECE OF PAPER TO ENSURE THAT THE EPI UV LAMPS

THAT YOU JUST INSTALLED ARE WORKING PROPERLY. IF NO IMAGE COMES UP YOU MAY

HAVE A POORLY SEATED LAMP IN THE SOCKET.

To order replacement lamps contact your Bio-Rad Laboratories representative for parts.

5.3 Lens and Filter Storage

Always store unused lenses and filters in their original box and in a low humidity environment

with a stable ambient temperature that does not exceed 30 °C.

Lenses should be wrapped in optical tissue before being placed in their storage box. If your

laboratory is a high humidity environment it is recommended that all emission filters are