Page 1

Sequi-Gen

Sequi-Gen®GT

Nucleic Acid

Electrophor esis Cell

Instruction Manual

Catalog Numbers

165-3860, 165-3861,

165-3862 and 165-3863

For Technical Service Call Your Local Bio-Rad Office or in the U.S. Call 1-800-4BIORAD (1-800-424-6723)

Sequencing Cell

®

GT

Page 2

Note

To insure best performance from the Sequi-Gen GT electrophoresis system, become fully acquainted with these operating instructions before using the cell. Bio-Rad recommends that you first read these

instructions carefully. Then assemble and disassemble the cell completely without casting a gel. After

these preliminary steps, you should be ready to cast and run a gel.

Bio-Rad also recommends that all Sequi-Gen GT components and accessories be inspected for damage, cleaned as recommended in this manual, and rinsed thoroughly with distilled water before use.

Record the following for you records:

Warranty

Bio-Rad Laboratories warrants the Sequi-Gen GT electrophoresis system against defects in

materials and workmanship for 1 year. If any defects occur in the instrument during this warranty period, Bio-Rad Laboratories will repair or replace the defective parts free. The following defects, however, are specifically excluded:

1. Defects caused by improper operation

2. Repair or modification done by anyone other than Bio-Rad Laboratories or an authorized

agent.

3. Use of fittings or other spare parts supplied by anyone other than Bio-Rad Laboratories.

4. Damage caused by accident or misuse.

5. Damage caused by disaster

6. Corrosion due to use of improper solvent or sample

This warrant does not apply to parts listed below:

1. Platinum wire

2. Glass plates

For any inquiry or request for repair service, contact Bio-Rad Laboratories after confirming the model

and serial number of your instrument.

Model

Catalog No.

Date of Delivery

Warranty Period

Serial No.

Invoice No.

Purchase Order No.

Page 3

Table of Contents

Page

W arranty Information ........................................................................Inside Front Cover

Section 1 General Information....................................................................................1

1.1 Introduction to Sequi-Gen GT DNA Electrophoresis Cell .......................................1

1.2 Specifications .............................................................................................................5

Section 2 Description of Major Parts.........................................................................6

2.1 Sequi-Gen GT Parts ...................................................................................................6

2.2 Gel Reagents and Electrophoresis Buffers ................................................................7

2.3 Electrical Path.............................................................................................................8

Section 3 Cleaning and Maintenance.........................................................................8

3.1 Cleaning and Siliconizing Plates................................................................................8

3.2 Cleaning Plastic Parts.................................................................................................9

Section 4 Operating Instruction................................................................................10

4.1 Before Assembly......................................................................................................10

4.2 Assembling the Glass Plate Sandwich.....................................................................10

4.3 Casting the Gel.........................................................................................................12

4.4 Preparing for Operations..........................................................................................17

4.5 Loading the Gel........................................................................................................18

4.6 Gel Electrophoresis..................................................................................................19

4.7 Disassembly..............................................................................................................20

Section 5 Troubleshooting Guide..............................................................................22

5.1 Operational Troubleshooter .....................................................................................22

5.2 DNA Sequencing Artifacts ......................................................................................23

Section 6 Equipment and Accessories......................................................................26

6.1 Sequi-Gen GT Nucleic Acid Electrophoresis Cells and Accessories.....................26

6.2 Electrophoresis Reagents.........................................................................................30

6.3 Power Supplies and Slab Gel Dryers.......................................................................31

6.4 DNA Template Purification, Sequencing, and Cloning Products...........................31

6.5 Liquid Handling .......................................................................................................32

Section 7 Appendix A- Applications.........................................................................32

7.1 DNA Sequencing Checklist.....................................................................................32

7.2 Standard Gel Protocol ..............................................................................................33

7.3 Gel Drying Autoradiography...................................................................................34

7.4 Applications for Sequi-Gen GT Nucleic Acid Electrophoresis Cell ......................34

7.5 Suggested Reading...................................................................................................35

Page 4

Section 1

General Information

1.1 Introduction to the Sequi-Gen*GT Nucleic Acid Sequencing Cell

The Sequi-Gen GT cell is a modular electrophoresis cell capable of separating nucleic

acids with single base-pair resolution, using a vertical slab gel format. This manual tells you

how to operate and care for your new Sequi-Gen GT cell. Read Sections 1 through 3 before

attempting to assemble the cell. The remainder of the manual gives you detailed procedures,

a troubleshooting guide, and parts lists.

The Sequi-Gen GT cell employs a simple design that provides maximum resolution with

high reproducibility, while eliminating the temperature artifacts which often occur in sequencing gels. Some of the unique features of this sequencing cell are the gel casting method,

durable construction, modular components, and ease of operation, which make this the most

advanced DNA sequencing cell available.

Note:

This manual contains instructions for the Sequi-Gen GT electrophoresis systems only.

Prior to the release of the Sequi-Gen GT systems, Bio-Rad supplied two similar sequencing electrophoresis cell systems: the original Sequi-Gen cell and the Sequi-Gen II cell. This

manual does not provide information on these systems. Contact your Bio-Rad representatives for information on the original Sequi-Gen and the Sequi-Gen II systems.

* US Patent number 4,663,015 issued to Bio-Rad Laboratories.

Safety

The Sequi-Gen GT cell has safety features to protect the operator from injury. These

features include:

• Interlocking safety lids to prevent high voltage buffer shock

• Permanently sealed upper buffer chamber to prevent leaks and arcing

• Plastic components made from self-extinguishing material

• Full-length clamps to shield user from edges of glass plates

• Chemically tempered glass plates that significantly reduce glass plate breaking due to

overheating and routine heating and cooling

• No exposed metallic parts

• Pour spout in lower buffer chamber allows radioactive buffer to be easily and safely

poured for disposal

Important:

This apparatus meets I.E.C. 1010-1†safety standards. Sequi-Gen GT systems are safe to

use when operated in accordance with the instructions. This instrument should not be

modified in any way. Alteration of this instrument will:

• Void the manufacturer’s warranty

• Void the IEC1010-1 safety certification

• Create a potential safety hazard

† IEC1010-1 is an internationally accepted electrical safety standard for laboratory instruments.

1

Page 5

Bio-Rad is not responsible for any injury or damage caused by the use of this instrument

for purposes other than those for which it is intended, or by modifications to the instrument

not performed by Bio-Rad or an authorized agent.

Power to the Sequi-Gen GT cell is supplied by an external DC power supply. This power

supply must be ground isolated in such a way that the DC voltage output floats with respect

to ground. The recommended power supply for this apparatus is the PowerPac 3000 power

supply. The maximum specified operating parameters for the Sequi-Gen GT cell are:

Maximum operating voltage – 3,000 VDC

Maximum operating power – 100 Watts

Electrical current to the Sequi-Gen GT cell enters the unit through the top and bottom

safety covers, providing a safety interlock to the user. Current flow to the cell is broken when

either safety cover is removed. Do not attempt to circumvent this safety interlock. Always

turn the power supply off while working with the sequencing cell when the safety covers are

not connected.

No user-serviceable parts are contained in this apparatus. To insure electrical safety, do

not attempt to service this apparatus.

Caution — Arcing

Arcing within an electrophoresis cell is represented by sparks, smoke, or charred surfaces

created when an electrical short has developed. Arcing can occur if the buffer level drops

below the recommended height, if there is buffer leakage, or if loose electrical connections

exists. If arcing is detected during electrophoresis, immediately remove the source of

electrical current (i.e., turn off the power supply).

Always use a power supply that is capable of detecting electrical conditions that may

cause accidental electrical shock or damage to the apparatus. The PowerPac 3000 power

supply contains safety features such as arc, no load, overload, rapid change in resistance, and

ground leak detection capabilities, that will reduce the chance of accidental electrical shock

and damage to the electrophoresis cell.

Before every use, inspect all plastic parts, glass plates, all electrical cables, jacks, and

receptors for loose connections, cracks, charring, or corrosion. Do not use any part that is

cracked, chipped, charred, or corroded. These parts may cause arcing. Contact your Bio-Rad

representative before using a part that may cause buffer leaking or arcing.

Warning:

Never allow the gel to exceed 60 ˚C. Excessive heat may crack the plates or cause the

silicon bond of the IPC to deteriorate.

Make sure that the upper and lower buffer chambers are filled with buffer during

electrophoresis. Do not allow the buffer level to drop below the level of the short glass plate

of the upper buffer chamber or below the bottom of the IPC assembly in the lower buffer

chamber at any time.

Certain solvents and cleaning agents should be avoided with this unit. Refer to Section 3.2

for compatible solvents, reagents and cleaning agents.

Definition of Symbols

Caution, risk of electrical shock Caution (refer to accompanying documents)

2

Page 6

System Components

Each Sequi-Gen GT system comes with the components listed in Table 1.1. Check your

unit to be sure all items are present. Note any damage to the unit which may have occurred

during shipping. Notify Bio-Rad Laboratories if any items are missing or damaged.

Table 1.1. Sequi-Gen GT System Components

Item Quantity

GT Universal Base 1

Stabilizer Bar 1

GT Safety Covers

1

1

GT IPC, with bonded inner (short) glass plate

2

1

Outer (long) Glass Plate

2

1

GT Clamp Set (left and right clamp)

3

1

Precision Caster Base

1

1

Precision Caster Gasket

1

1

Precision Caster Syringe

4

1

Precision Caster Tubing, 60 cm 1

Precision Caster Luer Tapers 4

IPC Drain Port/Tubing Connector 1

Gel Temperature Indicator 1

Vinyl Spacers, 0.4 mm thick

3

2

Vinyl Sharkstooth Comb, 0.4 mm thick

5

1

Leveling Bubble 1

Instruction Manual 1

1 Parts come in 21 cm or 38 cm widths

2 GT IPC and Glass Plates are 21 x 40, 21 x 50, 38 x 30 cm or 38 x 50 cm sizes

3 GT Clamp Sets and Vinyl Spacers are either 30 cm, 40 cm or 50 cm lengths

4 Syringe sizes are 60 cc for 21 cm systems and 140 cc for 38 cm systems

5 Vinyl Sharkstooth combs are 24 well (25 teeth) for 21 cm units or 49 well (50 teeth) for 38 cm units

See Section 6 for information on accessories and replacement parts.

General Description

The Sequi-Gen GT DNA sequencing cell uses several innovative design features that are

especially useful for DNA/RNA sequencing or other nucleic acid separation applications.

Sequi-Gen GT DNA sequencing cell features and benefits include:

Features Benefits

Unique, horizontal, syringe injected gel Easy gel casting without tape, grease, and

casting method acrylamide spills and waste

Upper buffer chamber heat Provides uniform gel temperature that

distribution system prevents smiling

Permanently sealed upper buffer No gaskets or grease needed to provide leakchamber free electrophoresis

(continued on the next page)

3

Page 7

Features Benefits

A universal base accepts all gel dimensions, Modular system allows different sized

including wide and narrow gel formats of gels to be used with the same lower buffer

various lengths chamber

Injection molded parts Provides years of rigorous use

Chemically tempered glass plates Resists cracking due to overheating

and rough handling

One-piece, lever-operated clamps Conveniently and easily slides onto gel

sandwich, and shields edges of glass plates

from operator contact

Molded chambers with pour spouts or Easy and safe radioactive buffer disposal

drain ports

Machined vinyl spacers and Uniform thickness of combs and spacers

sharkstooth combs reduces well-to-well leakage during

sample loading

Sequi-Gen GT Buffer Heat Dissipation

Uneven dissipation of the Joule heat produced by the gel during electrophoresis causes

electrophoresis artifacts. “Smiling” is a common artifact that develops when a gel sandwich

loses heat more efficiently at the edges than in the center. When a gel runs hotter in the

center, the electrical resistance decreases, and more current flows down the center. As the

current flow increases, the gel heats even more. Thus a positive feedback loop is set up which

results in the lanes near the center of the gel running hotter, and therefore faster, than the

lanes near the edges. Smiling can lead to ambiguity in reading the sequence.

The Sequi-Gen GT cell employs natural convection and conduction of the upper buffer

to distribute heat evenly. The problems of uneven heat dissipation are avoided. Complicated,

expensive thermostatic plates are not necessary.

A thin, transparent, upper buffer chamber, called an IPC (Integral Plate Chamber), acts as

a heat sink across the full area of the gel. Convection occurs any time a slight temperature

gradient develops, mixing the buffer (and heat) to prevent smile patterns from developing.

Convection is the most effective way to distribute heat evenly. The upper buffer dampens

temperature fluctuations in the gel, and adds to the reproducibility of each run. The contact

between the buffer and the gel plate is direct and uniform. Thermal and physical stresses are

reduced. The sample loading wells are always at the same temperature as the gel, resulting in

fewer re-annealing problems. Bubbles of gas, generated by electrolysis along the cathode,

rise through the buffer. These bubbles also help to prevent temperature gradients from

forming by stirring the upper buffer while rising to the top of the IPC chamber.

Sequi-Gen GT Gel Casting

Because of their large size, casting sequencing gels has traditionally been extremely

problematic. Taping the bottom or sides of the glass plate sandwich is time consuming and

does not always result in a perfect seal. Thus, vacuum grease is required to seal corners and

edges. The user must then “wrestle” with the gel mold in order to pour the gel correctly.

Sliding glass plates, or plate dropping methods always result in acrylamide spills and waste.

Cleaning the hazardous neurotoxin after the spills is also time consuming.

4

Page 8

The precision caster allows quick and easy gel casting without acrylamide spills or waste.

By casting the gel with a syringe through the precision caster base, gels can be poured in less

than 1 minute. The gel is cast with the glass plate assembly in the horizontal position. Two

full-length clamps secure the assembly and allow attachment of the precision caster base to

the bottom of the glass plate sandwich. A seal between the caster gasket and the plates is

created without tape or grease. The gel is injected from the bottom of the glass plate sandwich

(via the injection port of the precision caster base) and moves to the top of the glass plates as

a dome-shaped gel front. Acrylamide spills and waste can be eliminated by controlling the flow

of the gel front at the top of the glass plates.

Modular Assembly

There are four IPC dimensions to choose from, as shown in Figure 1.1. One universal

base functions as the lower buffer chamber for all IPC sizes.

Fig. 1.1. Interchangeable sizes.

1.2 Specifications

General Specifications

Base footprint 16 x 48 cm

Maximum unit height 65 cm (50 cm cells); 55 cm (40 cm cells); 45 cm (30 cm cells)

IPC sizes 21 x 40, 21 x 50, 38 x 30 cm and 38 x 50 cm

(width x length)

Actual gel sizes 17 x 40, 17 x 50, 34 x 30 cm, 34 x 50 cm

Gel thickness range 0.25 – 0.75 mm

Nominal gel volumes (0.25 mm) 17 ml (21 x 40 cm); 21 ml (21 x 50 cm); 40 ml (38 x 30 cm);

43 ml (38 x 50 cm)

Nominal gel volumes (0.40 mm) 27 ml (21 x 40 cm); 34 ml (21 x 50 cm); 50 ml (38 x 30 cm);

68 ml (38 x 50 cm)

Minimum upper buffer volumes 500 ml (21 x 40 cm); 575 ml (21 x 50 cm); 650 ml

(38 x 30 cm); 1,400 ml (38 x 50 cm)

Minimum lower buffer volume 350 ml

Maximum lower buffer volume 500 ml

Electrical Specifications

Electrical Safety Certification IEC 1010-1

Rated voltage limit 3,000 volts

Rated power limit 100 watts

Rated temperature limit 60 ˚C

Electrical cables Rated to 3,000 volts (VDC)

Electrical leads Rated to 3,000 volts (VDC)

Banana plugs Rated to 3,000 volts (VDC)

5

21 x 40 cm 21 x 50 cm 38 x 30 cm 38 x 50 cm

Page 9

Construction Specifications

GT IPC panel Injected molded polycarbonate

GT safety covers Injected molded polycarbonate

Universal base Injected molded polycarbonate

Stabilizer bar Injected molded polycarbonate

GT clamp set PVC clamp body

Protruded G10 polyester/glass cam shaft

Polycarbonate insulated stainless steel rod

Glass plates Chemically tempered 4.8 mm float glass

Combs and spacers Plastic or machined vinyl (see Sections 2.7 and 6.1)

Electrodes (IPC and base) Platinum, 0.25 mm diameter

Banana plugs (IPC and base) Gold plated stainless steel, 5.08 cm length

Electrical cables Dual, 20 AWG, tinned copper wire cable

Flame retardant polyurethane insulation jacket

Electrical leads Polyurethane insulated nickel silver, 2.95 cm length

Precision caster base Injection Molded Polycarbonate

Tubing Polyurethane, 3.2 mm internal diameter,

4.8 mm outer diameter

Luer taper Polypropylene, 3.2 mm internal diameter

Gasket Silicon Foam Sponge

Syringe Polypropylene, 60 cc or 140 cc

Drain port connector Polypropylene (quick coupling assembly)

3.2 mm internal flow diameter

Section 2

Description of Major Parts

2.1 Sequi-Gen GT Parts

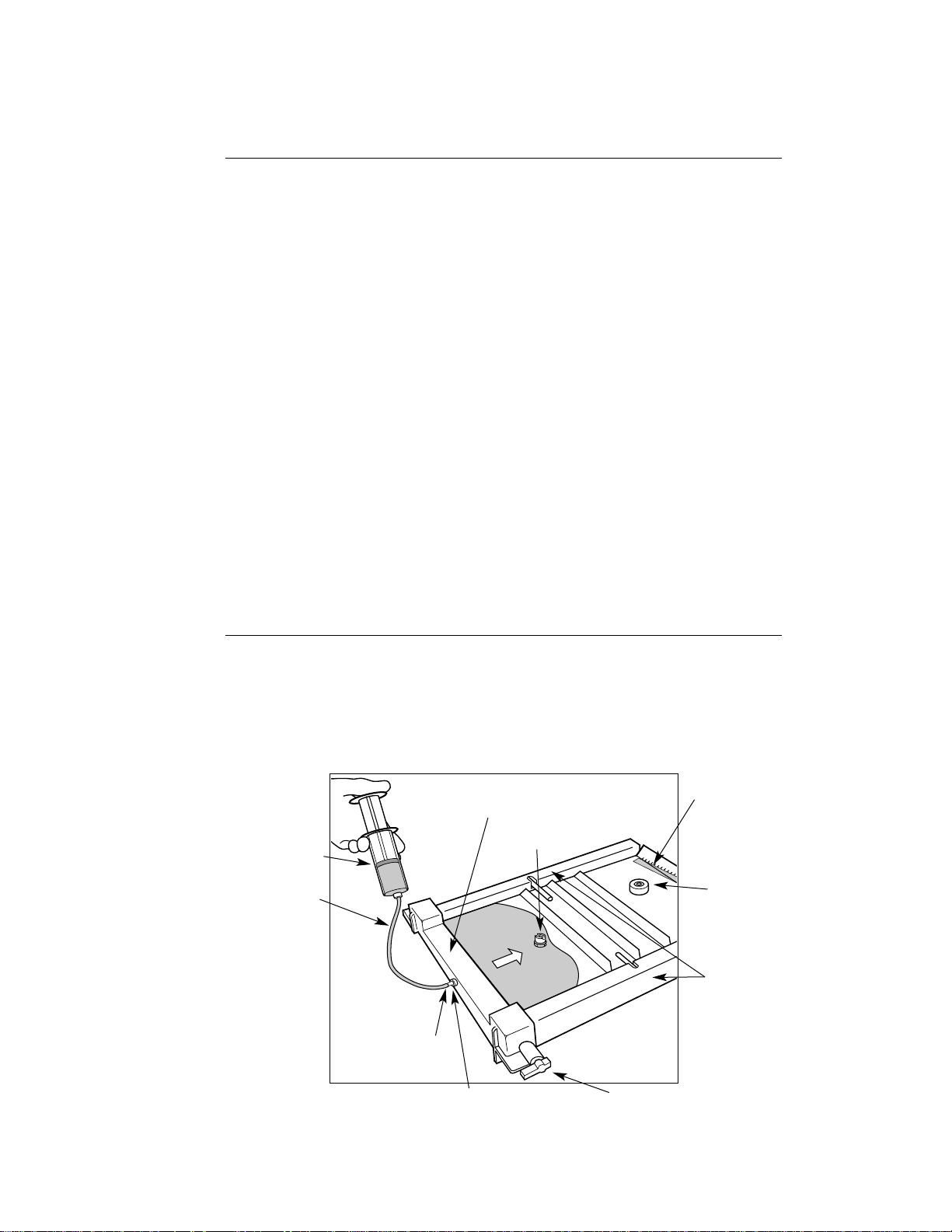

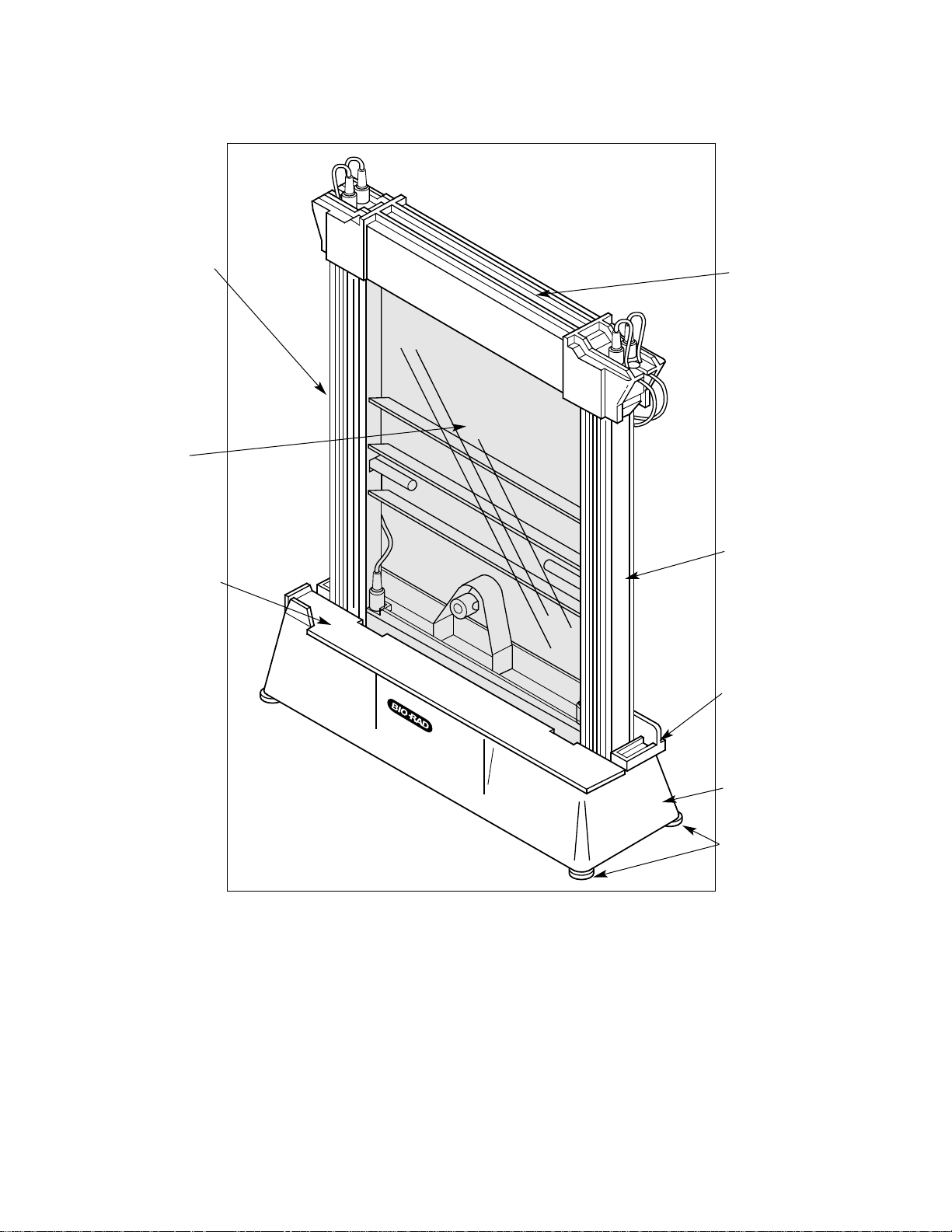

See Figures 2.1 and 2.2 for Sequi-Gen GT part identification.

Fig. 2.1. Sequi-Gen GT gel casting parts.

6

Syringe

Tubing

Luer Taper

Precision Caster Base

Syringe

Sharkstooth Comb

Leveling Bubble

Drain Port

Precision Caster Cam Peg

Precision Caster Base Injection Port

GT Lever Clamps

Page 10

Fig. 2.2. Sequi-Gen GT nucleic acid electrophoresis cell.

2.2 Gel Reagents and Electrophoresis Buffers

For most DNA sequencing or nucleic acid separations, a 19:1 acrylamide:bis solution is

required. A 1x TBE (Tris, boric acid and EDTA) solution is the preferred electrophoresis

buffer. Reproducibility is affected by the quality of the gel and buffer reagents. A full line of

high quality polyacrylamide gel reagents and nucleic acid electrophoresis buffers is available

from Bio-Rad. Premixed reagents and buffers are also available and offer convenience, time

savings, and reproducible results. Each reagent and buffer is purified to meet rigorous quality

control standards. See Section 6.2 for ordering information.

Sequi-Gen

®

GT

Sequencing Cell

7

GT Base

Leveling Feet

GT Bottom

Safety Cover

Stabilizer

Bar

IPC

(Integral

Plate

Chamber)

GT Lever

Clamp

GT Lever

Clamp

GT Top

Safety

Cover

Page 11

2.3 Electrical Path

Both electrode wires are positioned near the bottom of the gel. The upper buffer carries the

current from the cathode up to the top of the plates near the fill spout, where the gel is exposed.

The lower buffer contacts the gel at the bottom edge of the plates in the standard fashion

(See Figure 2.3).

Fig. 2.3. Electrical path through IPC (Integral Plate Chamber) to lower buffer reservoir.

Section 3

Cleaning and Maintenance

3.1 Cleaning and Siliconizing Plates

Important:

To insure “bubble-free” gels using the Sequi-Gen GT precision caster, the glass plates

must be thoroughly cleaned and the outer (long) glass plate siliconized or coated before

each use.

1. Clean both Sequi-Gen GT glass plates (IPC and outer plates) thoroughly before each use.

• Carefully place the plate into the sink and rinse with warm water.

• Pour powdered lab detergent (Alconox [Alconox, Inc.] or Micro [International

Products]) into a gloved hand and add sufficient water to make a paste.

• Apply the paste and scrub the entire glass surface with a gloved hand, using circular

motions.

8

Fill spout

Upper buffer

Polycarbonate

panel

Bonded glass

plate

Gel

Outer glass

plate

Silicone

adhesive bond

IPC

drain port

Lower

buffer

Page 12

• Rinse off all of the detergent with warm water.

• Rinse with deionized water.

• Wipe the cleaned plate with a large lint free tissue to dry.

2. Inspect the plates carefully for pieces of detergent, dried polyacrylamide, or other particles.

Rewash if necessary.

3. Perform siliconizing under a fume hood, to reduce the hazard from breathing silanizing

reagent. Alternatively, several non-toxic, non-corrosive glass plate coating solutions are

commercially available. We recommend siliconizing or coating only the outer (long)

plate, so that when the plates are separated, the gel sticks to the IPC-bound glass plate.

• Use a glass Pasteur pipette to dispense 2 ml of the silanizing reagent onto the front

plate. Coat the plate completely and evenly by spreading the silanizing reagent on the

plate surface with a large lint free tissue, using a motion that travels from the top to the

bottom of the plate.

Caution: Do not siliconize the IPC plate unless hexane, heptane, or water is used as a

solvent in the silanizing reagent. Other organic solvents will craze or damage the IPC

plastic and weaken the adhesive bond.

• Never heat an IPC in an oven. Severe damage will result to the adhesive bond. Use

siliconizing compounds that react, or cure, at room temperature.

Note: If the gels will be fixed or stained, the IPC (short) plate should be siliconized or

coated, since its immersion into fixing or staining solutions is not recommended.

4. Prior to assembling the plates, apply a small amount of ethanol to each plate and rub to

dryness with a tissue. Using the same tissue, clean the spacers.

3.2 Cleaning Sequi-Gen GT Components

1. Rinse the universal base buffer chamber, stabilizer bar, combs, spacers and precision

caster base, gasket, syringe and tubing assembly with a mild detergent solution in warm

water. Use a soft-bristled brush or sponge to remove polyacrylamide gel pieces.

Note: Do not snag or break the electrode wire in the universal base while cleaning.

2. Rinse thoroughly with warm water and air dry.

Compatible Cleaning Agents for Polycarbonate Parts

Chemically compatible cleaners must be used to ensure long life of parts. These include:

• Aqueous solutions of soaps and mild detergents

• Organic solvents:

• Hexane

• Aliphatic hydrocarbons

• Alcohols

• Methanol

• Ethanol

• Isopropyl alcohol

• Dilute acids

9

Page 13

Caution: Do not touch plastic molded parts with solvents that contain chlorinated

hydrocarbons or aromatic hydrocarbons (e.g., carbon tetrachloride, toluene, methyl ethyl

ketone, acetone).

Do not use abrasive or highly alkaline cleaners on the polycarbonate plastic IPC panel.

(The glass may be cleaned with abrasive or strong alkaline detergents, if adequate care is

taken to avoid contact with the plastic panel.)

Do not soak plastic parts in detergents more than 30 minutes.

Cleaning the Clamps

Rinse the clamps with warm water, and wipe any polymerized acrylamide off the clamping

surfaces. Drain the banana plug mounts at the top of the clamps, and wipe the clamping

surfaces dry before each use. Do not use organic solvents to clean the clamps.

Section 4

Operating Instructions

4.1 Before Assembly

1. Thoroughly clean all parts as described in Section 3.

Caution: Certain solvents and cleaning agents should be avoided. Refer to Section 3.2 for

compatible cleaning agents.

2. Depending on the size of the Sequi-Gen GT IPC, make up the appropriate amount of

electrode buffer (typically 1x TBE) from Table 4.1.

Table 4.1. Electrode Buffer Volumes

IPC Size Total Buffer Required Upper Lower

21 x 40 cm 850 ml 500 ml 350 ml

21 x 50 cm 925 ml 575 ml 350 ml

38 x 30 cm 1,000 ml 650 ml 350 ml

38 x 50 cm 1,750 ml 1,400 ml 350 ml

4.2 Assembling the Glass Plate Sandwich

After the Sequi-Gen GT components have been washed and the glass plates siliconized

or coated, assemble the Sequi-Gen GT apparatus. Always wear gloves while handling the

glass plates during assembly to avoid fingerprints on the glass plates. Fingerprints will cause

bubbles to form during gel casting.

Important: Before assembling the Sequi-Gen GT cell, inspect all plastic parts, glass plates,

electrical cables, jacks, and receptors for loose connections, cracks, chips, charring, or

corrosion. Do not use any part that is damaged. These parts may cause buffer leaks or arcing.

1. Clean and siliconize the glass plates as instructed in Section 3.1.

2. Place the IPC flat on the bench with glass plate facing upward (Figure 4.1).

• Position one spacer along each long edge of the IPC glass plate. The bottom edges of

the spacer and the glass plate should be flush and the long edge of the spacer should

be next to the plastic lip of the IPC panel.

10

Page 14

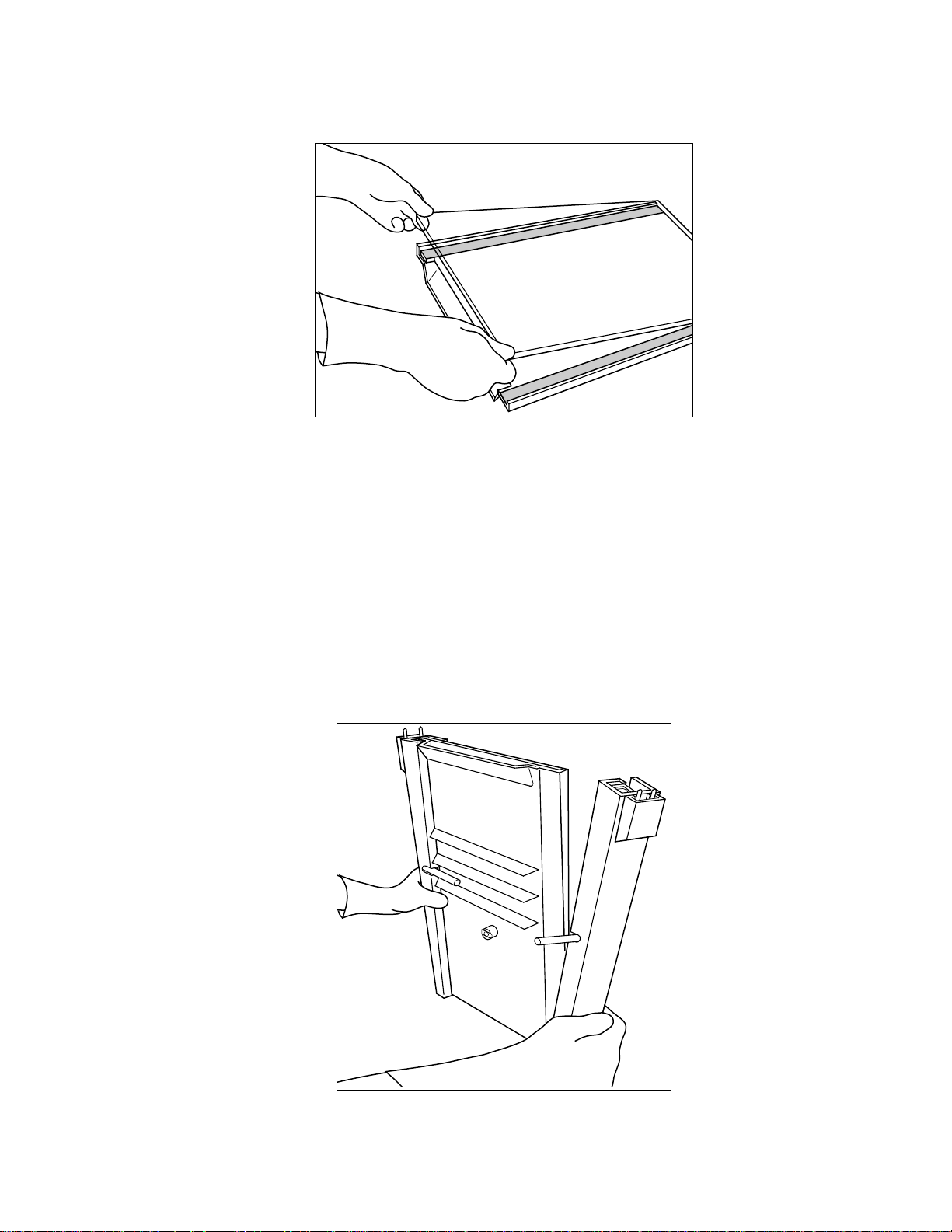

Fig. 4.1. Assembling glass plate sandwich.

3. Place the front (outer, long) glass plate onto the IPC and spacers with the siliconized or

coated surface facing down.

• With both hands, stand the IPC/glass plate sandwich on the benchtop with the outer

glass plate facing away from you.

• Allow the glass plates and spacers to touch the benchtop, to temporarily align the

assembly for gel casting.

4. Slide the clamps over the IPC assembly.

• The levers of the clamps should be on the IPC panel side of the assembly and need to

be facing away from the unit (perpendicular to the IPC panel) for the clamps to slide

easily onto the assembly. Secure the clamps to the IPC/glass plate sandwich by

moving the levers toward the IPC panel (Figure 4.2).

Fig. 4.2. Attaching full-length lever clamps.

11

Page 15

5. Lay the IPC assembly on the benchtop with the IPC panel (drain port side) facing up.

• Check the alignment of the glass plates, spacers and clamps. The bottom of the glass

plates, spacers and clamps should be flush. If either glass plate, spacer, or clamp is

not properly aligned or flush, adjust the alignment by loosening the clamps and move

clamps, glass plates and spacers into alignment (Figure 4.3).

• Tighten the clamps by moving the levers back down towards the IPC after the assembly

is flush.

Fig. 4.3. Alignment of glass plate sandwich.

6. To avoid incompatibility problems between combs and spacers after the gel is cast, check the

fit of the combs in the assembled Sequi-Gen GT cell by trying to place them between the plates.

• If the combs clearly will not fit between the plates without damaging the comb, try a

different comb. Optimally, combs should demonstrate slight resistance to being placed

between the glass plates.

4.3 Casting the Gel

Section 7.1 contains a checklist of required items for DNA sequencing. Polyacrylamide

is a hazardous chemical and neurotoxin. Always wear gloves, lab coat, and safety glasses

while working with polyacrylamide.

1. Prepare the gel solution described in Section 7.1 and 7.2.

• Degas the gel solution for 5-15 minutes under a strong vacuum (≥26 in./Hg) to insure

reproducible gel porosity.

Table 4.2 Required Gel Volumes Using the Precision Caster Assembly

IPC 0.25 mm 0.4 mm 0.75 mm 0.25 – 0.75 mm 0.40 – 1.2 mm

Size spacers spacers spacers wedge spacer wedge spacer

21 x 40 cm 25 ml 35 ml 70 ml 50 ml 60 ml

21 x 50 cm 30 ml 45 ml 90 ml 65 ml 85 ml

38 x 30 cm 40 ml 50 ml 90 ml — —

38 x 50 cm 55 ml 85 ml 170 ml 120 ml 140 ml

12

Page 16

2. Place the precision caster base on the bench with its open cavity facing up. Place the gray

precision caster gasket into the base. The cam pegs in the precision caster must be pulled

out to accommodate the apparatus.

Note: If the gasket is wet, remove any remaining water from the gasket by squeezing it

with a paper towel.

3. Place the bottom edge of the IPC assembly into the precision caster base with the bottom

edge of the assembly resting against the gray gasket of the precision caster base.

4. When the IPC assembly is seated in the caster base, use the cam pegs to connect the base

to the clamps (Figure 4.4).

• Push each cam peg into the corresponding hole on the clamp with the lever in the up

position. Slight downward pressure applied to the top of the IPC assembly may be

required to engage each cam peg.

Fig. 4.4. Attaching precision caster base to IPC assembly.

5. When both pegs are engaged, turn them evenly until moderate resistance is felt or the handles of the cam pegs are perpendicular to the benchtop. This action causes the precision

caster base to fit tightly against the plate assembly.

• Lay the IPC assembly flat on the benchtop with the precision caster base facing toward you.

• Look through the injection port of the base. If the precision caster has been attached

properly, a space should be seen between the two green glass plates (Figure 4.5).

• If the space cannot be seen, loosen the caster base by rotating the cam pegs upward.

Adjust the caster base either up or down until the space between the green glass plates

can be seen and is in the middle of the injection port hole.

• While securing the precision caster base in place with one hand, turn the cam pegs

back to their original position to secure the base to the bottom of the IPC assembly.

13

Page 17

Fig. 4.5. Correct alignment of precision caster base with glass plate sandwich.

6. Lay the IPC assembly and attached precision caster base flat on a bench with the IPC

panel (drain port) facing up and the long edges of the clamps running parallel with the edge

of the benchtop.

• The most even pouring can be obtained by insuring that the assembly is level on the

benchtop. Failure to level the assembly may result in gel leakage. A leveling bubble

is provided to facilitate leveling the IPC assembly. Props (approximately 2 cm ) will

be required at the top of the IPC to level the unit for casting. The unit is now ready for

gel casting. An alternative to the use of props is to cast the gel with the precision caster

positioned off the edge of the lab bench.

Note: If casting a 38 x 50 cm IPC, place the 38 x 50 cm IPC assembly at an incline, with

the top of the apparatus approximately 4-5 cm higher than the bottom. (The bottom of

the apparatus contains the attached precision caster base). After the gel is cast, level the

assembly for gel polymerization.

7. While the gel solution is degassing, prepare a fresh 25% ammonium persulfate solution

(catalog number 161-0700).

• Choose the appropriate syringe and tubing assembly (tubing and luer taper) provided

with the precision caster. Insert the luer taper into the one end of the tubing. Secure the

other end of the tubing onto the luer end of the syringe.

8. When the gel solution has degassed, add 25% APS and TEMED (catalog number 161-0800)

in the recommended amounts (see Section 7.2).

• Swirl the solution gently to mix.

• Slowly pull the required gel volume into the syringe (see Table 4.1).

• Tap air bubbles to the top of the syringe (luer end) and gently force them out. If bub-

bles are inadvertently introduced into the tubing, pinch the portion of the tubing where

the bubbles exist while forcing some of the gel solution out. This should allow the

bubble to exit the tubing with the gel solution.

14

Page 18

9. When all air bubbles are removed from the tubing, place the luer taper into the injection

port of the precision caster base (Figure 4.6). Tighten the luer taper fitting in place on the

injection port of the precision caster base and begin to slowly inject the gel solution. Slow

and even pressure on the syringe plunger will insure uniform gel casting with no

bubbles (Figure 4.7).

Fig. 4.6. Inserting syringe tubing into precision caster base.

Fig. 4.7. Injecting gel solution into glass plate sandwich.

15

Page 19

Note on Gel Bubble Formation

• The following injection times (from the bottom of IPC to the top) were found to result

in bubble-free gels: for 50 cm gels with 0.4 mm spacers, between 40–45 seconds; for

50 cm gels with 0.25 spacers, between 50–65 seconds. Injection times of 10 seconds

or less can result in bubble formation in the gel.

• Bubbles can form at the gel front because of soiled areas or uneven siliconization or

coating of the glass plates.

• To achieve bubble free gels, thoroughly clean both plates and siliconize the outer glass

plate before each use.

• If bubbles begin to form at the gel front, hard tapping on top of the IPC assembly

(above the bubble formation) while slowly injecting the gel solution should eliminate

the bubble. Alternatively, the comb end of the IPC assembly can be momentarily

lifted at an angle to facilitate elimination.

10. Continue to slowly inject the gel solution until the gel solution emerges a few centimeters

from the top of the notched (shorter) glass plate (across the entire width of the gel).

Important: If pouring a 38 x 50 cm IPC, remove the support that created an incline and

lay the unit level on the benchtop (use the Leveling Bubble provided). An additional 2 cm

support will be needed to level the IPC assembly. Some users find it convenient to use two

1.5 ml tube racks as props.

When the gel is past the short plate, lay the syringe on top of IPC assembly until gel

polymerization is complete. Do not remove the luer taper from the precision caster base

injection port, or the gel solution will drain out of the plates. Do not adjust the syringe

plunger after the gel has been cast (Figure 4.8).

11. Insert the comb(s) between the plates to the desired depth.

• If a sharkstooth comb is used, insert the flat edge of the comb no more than 5 mm past

the short glass plate.

• Clamp the comb(s) in place with three large metal binder clamps.

Fig. 4.8. Syringe position for gel polymerization.

16

Page 20

• Alternatively, prior to injecting the gel solution, insert the corner of the comb to facilitate

comb placement and insertion after gel casting.

12. Let the gel polymerize for 30–60 minutes.

• After gel polymerization, remove the luer taper from the precision caster base.

• The syringe, tubing, and luer taper can be cleaned of any remaining polymerized gel

solution by rinsing with hot tap water, followed by a distilled water rinse.

13. Remove the precision caster base from the IPC assembly and clean the caster base and

gasket of polymerized gel solution with tap water, followed by a distilled water rinse.

4.4 Preparing for Operation

1. Adhere a gel temperature indicator onto the outside of the outer plate, somewhere near the

center, to monitor the gel temperature during electrophoresis.

• Place the IPC assembly into the universal base, against the back wall, between the

alignment tabs.

2. Insert the stabilizer bar (Figure 4.9).

• The stabilizer bar should slide into place with a snug fit, locking the IPC to the base

in a vertical position.

• The heads of the screws on the stabilizer bar should push against the front wall of the

base to press the IPC clamps against the back wall of the universal base.

Note: When first setting up your Sequi-Gen GT cell, adjust the screws on the stabilizer

bar if the fit seems too loose or too tight (turning the screws counterclockwise makes the

stabilizer bar fit more tightly). Too much pressure will make it difficult to insert and

remove the stabilizer bar. Too little pressure will result in the stabilizer bar sliding in and

out of position without pressing the IPC against the back wall of the base.

Fig. 4.9. Inserting the stabilizer bar into the universal base.

17

Page 21

3. To avoid buffer spills and cell tipping accidents, adjust the leveling screws on the universal

base, as necessary.

• To insure that the unit will not tip over during electrophoresis, make sure the leveling

feet threaded rods are at least 1 cm deep into the threaded boss of the base.

• At this time, test whether the IPC assembly is properly aligned in the universal base by

attaching the top and bottom safety covers. The IPC assembly may have to be shifted

to the right or the left to properly attach the safety covers. After this final alignment is

complete, remove the safety covers.

4. Fill the upper buffer chamber (the IPC) with running buffer (1x TBE) using the flared

portion of the panel as a fill spout.

• The level of the buffer should be about 1 cm from the top of the fill spout at all times

during the run.

• Remove the comb(s) from between the glass plates.

• Thoroughly rinse the resulting well(s) or gel front using a syringe with a needle,

or disposable plastic transfer pipet (catalog number 223-9911).

• If using a sharkstooth comb, insert the comb with the teeth facing the gel front. Lower

the comb toward the gel surface until the teeth of the comb just touch the gel surface.

5. Fill the lower buffer chamber with 350-500 ml of the running buffer. Refer to Appendix

7.1 for running buffer recipes.

Caution: Do not fill the lower chamber with more than 500 ml of buffer. The lower buffer

chamber holds the entire volume of the upper buffer chamber should a leak develop in the

IPC. Buffer levels over 500 ml will not allow the entire volume of the upper buffer chamber

to be contained in the universal base.

6. Attach the top and bottom safety covers and pre-electrophorese the gel at normal operating

voltage or power (see Section 4.7), if desired, to increase the gel temperature.

• Pre-electrophoresis prior to sample loading will create a uniform gel temperature and

bring the gel temperature to the recommended run temperature. This will help eliminate

any smile patterns from developing early in the run.

Note: Gel electrophoresis buffers can be heated to 50 ˚C in a microwave before adding

buffer into the upper buffer chamber. This will reduce the time needed to bring the gel to

the appropriate run temperature before sample loading, and will greatly reduce

pre-electrophoresis time.

Warning: The upper buffer level may drop slightly due to evaporation as the system

becomes warmer. Make sure that the upper chamber is always filled with buffer during

electrophoresis. Do not allow the buffer level to drop below the level of the notched

(shorter) IPC glass plate at any time during electrophoresis, as this may cause arcing and

cell damage. Additionally, never allow the gel to exceed 60 °C under any circumstance.

This excessive heat may crack the plates or cause the IPC/glass bond to deteriorate.

4.5 Loading the Gel

1. Turn off the power supply, and remove the top safety cover.

• Rinse the well(s) with a syringe with needle, or disposable plastic transfer pipet

(catalog number 223-9911), (to remove urea) before applying the samples to the gel.

18

Page 22

2. Load samples on the gel (see Table 2.1 for recommended sample loading volumes for

all Bio-Rad combs).

• Samples may be applied with a 5 µl Hamilton syringe, or a pipettor fitted with gel

loading tips (use Bio-Rad catalog number 223-9911).

• Syringe loading requires rinsing the needle between samples.

• Be sure to reconnect the upper safety cover before turning on the power supply.

Note: Sample loading is the key to high resolution gels.

• Rinse wells thoroughly before sample loading begins.

• Deposit samples directly on the gel surface.

• Electrophorese the samples into the gel soon after loading (every 4 lane sets) to reduce

sample diffusion and enhance band resolution.

4.6 Gel Electrophoresis

1. Make sure both safety covers are in place.

• Apply the voltage by pressing the Start or Run button on the power supply.

• Verify that current is flowing (note bubbles forming at the cathode wire in the IPC),

and that all electrical connections are solid.

Running the gel with constant power (watts) will result in a constant gel temperature

during the run and reproducible gel electrophoresis.

Power conditions for DNA sequencing gels are usually dictated by gel running temperature. Run sequencing gels at 50 °C for best results. Refer to the following table for

typical power (watts) settings that result in 50 °C runs.

These settings are only guidelines–optimal settings for gels should be determined empirically. Use a temperature indicator (one is included with this unit) to monitor running

temperatures. If the temperature goes above 55 °C, reduce the power output of the supply.

Alternatively, use a power supply with temperature control functions (PowerPac 3000

with temperature probe) to monitor and control gel temperature.

Table 4.3 Approximate Power (Watts) Settings for Operating Sequi-Gen GT Cells

Sequi-Gen GT Gel Recommended

Cell Size Thickness Power Setting

21 x 40 cm 0.25 mm 35-45 W

21 x 40 cm 0.40 mm 40-50 W

21 x 40 cm 0.75 mm 45-55 W

21 x 40 cm 0.25-0.75 mm wedge 45-55 W

21 x 40 cm 0.4-1.2 mm wedge 45-55 W

21 x 50 cm 0.25 mm 45-55 W

21 x 50 cm 0.40 mm 50-60 W

21 x 50 cm 0.75 mm 55-65 W

21 x 50 cm 0.25-0.75 mm wedge 55-65 W

21 x 50 cm 0.4-1.2 mm wedge 55-65 W

(continued on the next page)

19

Page 23

Table 4.3

(continued)

Sequi-Gen GT Gel Recommended

Cell Size Thickness Power Setting

38 x 30 cm 0.25 mm 70-75 W

38 x 30 cm 0.40 mm 70-75 W

38 x 30 cm 0.75 mm 70-75 W

38 x 30 cm 0.25-0.75 mm 70-75 W

38 x 30 cm 0.40-1.20 mm 70-75 W

38 x 50 cm 0.25 mm 70-80 W

38 x 50 cm 0.40 mm 75-85 W

38 x 50 cm 0.75 mm 75-85 W

38 x 50 cm 0.25-0.75 mm wedge 75-85 W

38 x 50 cm 0.40-1.2 mm wedge 75-85 W

Important: Never allow the gel temperature to exceed 60 °C. Severe damage to the glass

or adhesive bond may result.

Caution: Periodically check the level of the upper buffer to make sure that it is at least

1 cm above the short glass plate.

2. Continue gel electrophoresis until the desired fragment size separation is achieved. Typically,

gel electrophoresis times are monitored by observing the dye front mobility of either the

bromophenol blue (“fast blue”) or xylene cyanol (“slow blue”) during the course of electrophoresis. Fragment and dye front mobility as a function of polyacrylamide percentage are

shown in Table 4.4 below, and should be used as a guide for gel electrophoresis monitoring.

Table 4.4 Migration of Single-stranded DNA in Denaturing Polyacrylamide

Gels in Relation to Dye Marker Gel Migration*

Polyacrylamide Bromophenol

Gel Percentage Blue Xylene Cyanol

5% 35 bases 130 bases

6% 26 bases 106 bases

8% 19 bases 75 bases

10% 12 bases 55 bases

* From Ausubel, F. M. et. al., Current Protocols in Molecular Biology, Greene and Wiley, 1993.

4.7 Disassembly

1. When the desired dye front mobility has been achieved, turn off the power supply, and

remove both safety covers.

• The upper buffer chamber can be partially emptied by inserting the drain port

connector (and any attached tubing) into the drain port on the IPC. A “click” will be

heard when the drain port/tubing connector has been properly inserted (Figure 4.10).

• Buffer will begin to drain from the IPC immediately after the connector is inserted

into the drain port.

20

Page 24

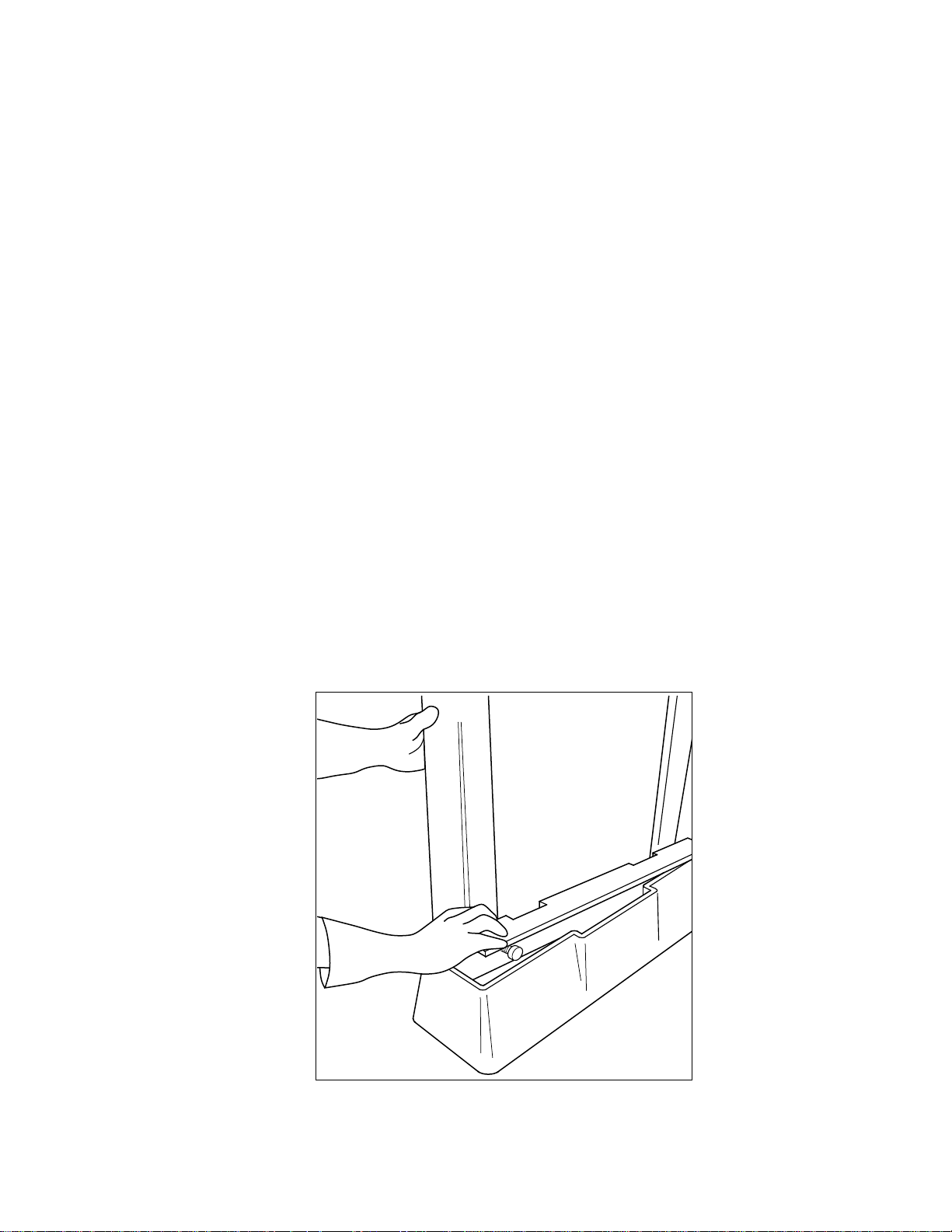

Fig. 4.10. Inserting the drain port connector for upper buffer chamber drainage.

2. After the upper buffer chamber is emptied to the level of the drain port, pull out the

stabilizer bar, and remove the IPC assembly. Blot the bottom edge of the IPC assembly

onto absorbent paper before removing it to a nearby sink.

3. Carefully pour the remaining upper buffer out of the IPC assembly into a sink. Slowly and

carefully pour the lower buffer contained in the universal base into the appropriate sink

or container.

Caution: Never store buffers in an IPC. Never add buffer to an IPC unless the clamps are

in place. The lever clamps provide the necessary force to keep the static head pressure of

the upper buffer from straining the adhesive bond.

4. Remove the clamps from the IPC assembly by first pulling the levers away from the IPC

and then sliding the clamps off the IPC assembly.

• Place the Sequi-Gen GT cell flat on a bench with the outer glass plate facing up.

• Carefully separate the glass plates by pulling up gently near the top of the outer plate.

• After the plates begin separating, carefully determine to which plate the gel is sticking

(the gel should stick to the short (inner, bonded) glass plate on the IPC).

5. When the gel is secured onto one glass plate, carefully place a piece of filter paper

(catalog number 165-0921 ) onto the gel surface. Press firmly on the filter paper to make

the gel adhere.

6. Trim around the filter paper with a razor blade or scissors to remove any excess gel.

• Remove the filter paper and gel by lifting up one end of the filter paper and carefully

peeling the gel off the plate.

• Place the gel, filter paper side down, on the bench and cover it with a piece of plastic

wrap. Use a razor blade or scissors to trim away any excess plastic wrap.

7. The gel is now ready for drying, autoradiography, and interpretation of results. Refer to

Section 7.3 for gel drying and autoradiography procedures.

21

Page 25

Section 5

Troubleshooting Guide

5.1 Operational Troubleshooter

The following table summarizes possible Sequi-Gen GT operational difficulties, probable

causes, and solutions. Refer to Sections 3 and 4 for recommended procedures.

Problem Probable Causes Solution

No gel solution entering gel mold

Gel solution is leaking into the

precision caster base

Gel solution is receding from

the top of the gel

Bubbles in gel

• Luer taper, tubing or syringe

orifices blocked.

• Precision Caster Base injection

port misaligned with gap

between the glass plates

• Precision caster gasket missing

• Gasket hole not aligned with the

injection port of the precision

caster base

• Glass plates and gasket are not

in contact

• Glass plates, spacers and

clamps are not flush at their

bottom edge

• Entire casting assembly (precision caster assembly and IPC

assembly) at too high of an

incline

• Glass plates, spacers and

clamps are not flush

• Entire casting assembly (precision caster assembly and IPC

assembly) at an incline

• Air bubbles injected into the

mold because gel was injected

too quickly

• Gel solution not degassed

• Air trapped in tubing

• Air bubbles trapped in syringe

• Air injected into the gel mold

because gel volume was

inadequate

• Thoroughly clean syringe,

tubing and tapers of dried gel

solution with warm water and

mild detergent (see Section 3)

• Readjust precision caster base

so that white slit can be seen

between the green glass plates

while looking through the

injection port (see section 4)

• Insert gasket into base

• Disassemble precision caster

base from the IPC assembly,

adjust the gasket and reassemble

• Disassemble and make sure the

bottom edges of the clamps,

glass plates and spacers are

flush

• Disassemble and make sure the

bottom edges of the clamps,

glass plates and spacers are flush

• Lower the casting assembly or

completely level the assembly

• Disassemble and make sure the

bottom edges of the clamps,

glass plates and spacers are flush

• Level the casting assembly

• Refer to injection rate recommendations under Note on Gel

Bubble Formation, Section 4.3

• Degas gel before casting

• Remove tubing before drawing

gel solution into the syringe,

then attach tubing and gently

push gel solution through tubing

• Draw gel solution into the

syringe barrel slowly to avoid

introducing bubbles on the side

of the barrel

• See Section 4.4 (Table 4.2) for

suggested gel volumes

22

Page 26

Condition Probable Causes Solutions/Preventions

5.2 DNA Sequencing Artifacts

Electrophoretic artifacts are described below. A DNA sequencing artifact may be defined

as any non-ideal graphic pattern on the X-ray film that reduces your confidence in reading, or

interpreting, a sequence from that film. There are three types of DNA sequencing artifacts:

• Template-dependent artifacts

• Electrophoretic artifacts

• Autoradiographic (or data acquisition) artifacts

Template-specific artifacts are caused by biological or chemical phenomena, and relate

to issues beyond the scope of this manual. Each sequencing method has its own set of potential

sequence-specific artifacts. Section 7.5 contains references that discuss sequence-specific

artifacts.

The basic premise for reading a DNA sequence is that each band on the film exists in a

vertical register that corresponds to one base in the sequence. Non-ideal patterns, caused by

problems in the three categories above, may interfere with the accurate determination of

DNA sequences. The following is a guideline for description and analysis of artifacts in DNA

sequencing gels, especially electrophoretic ones.

Electrophoretic Artifacts

There are many sources of electrophoretic artifacts. To simplify the task of defining an

artifact, we use a systematic description of electrophoretic artifacts, dividing all of the

possible patterns into three hierarchical sub-categories:

• Lane-local artifacts

• Set (template)-local artifacts

Upper buffer level drops too

fast during run

Sparks at the top of the gel

Sparks in lower chamber

Well-forming loading wells

deform when comb pulled out

Unexpected power conditions

Gel sticks to both plates when

opening sandwich

• Normal consequence of IPC

plastic bowing slightly as it

heats up

• Spacers leaking out the sides of

the gel

• Buffer leaks down between gel

and spacers

• Bond failure. Chamber leaking.

Sparks or burn marks in

adhesive.

• Upper buffer level dropped

below minimum level

• Lower buffer level too low or

too high

• Comb inserted too far

• Gel polymerized too long,

dried out

• Comb pulled out too quickly

• Gel not polymerized

• Buffers made incorrectly

• Gel hydrolyzed, more

conductive

• Gel too hot or cold

• Neither plate siliconized

• Both plates siliconized

• Plates unclean

• Outer plate pried off too quickly

• Refill upper buffer chamber

• Caution. Monitor run. Refill

upper buffer chamber.

• Polymerization problem

• Stop the run. Electrical hazard.

IPC needs replacement.

• Refill upper buffer chamber

• 350 ml is minimum, 500 ml is

maximum

• Insert comb minimum distance

• Rinse comb/gel with buffer

before pulling out comb

• Pull comb out slowly

• Refer to Bulletin 1156

• Check buffers

• Remake gel, run gel

cooler

• Run gel at 50 °C

• Siliconize outer plate according

to Section 3.1

• Separate plates slowly

23

Page 27

• Total signal artifacts

Many artifacts appear in more than one sub-category. For example, smile patterns can

exist in lane-local or in total signal situations (or both), but rarely appear in set-local. It is

important to distinguish the extent and location of each artifact before trying to analyze or

troubleshoot the anomalous pattern.

1. Lane-local artifacts

Condition Probable Causes Solutions/Preventions

2. Set-local artifacts

Condition Probable Causes Solutions/Preventions

Smiling within sets

Frowning within sets

Funneling within sets

Non-continuous vertical

register

Band spacing compressed within

a set

Film exposure differences within

a set

• Loading wells not straight

within set

• Molarity problems in the samples of the set

• Loading wells not straight

• Molarity problems in the samples of the set

• Sample molarity too high, or

contamination

• Sample dependent artifact

• Autoradiographic artifact

• Sample dependent artifact

• Sample dependent artifact

• Pour new gel with better lanes

• Check sample and gel buffers

• Pour new gel with better lanes

• Check sample and gel buffers

• Check sample and gel buffers

Smiling bands

Frowning bands

Complex (curvy) bands

Funneling or lane narrowing

Lane widening

Variations in signal intensity

along the lane(s)

Band spacing compressed or

stretched

• Loading wells not straight

• Sample molarity too high

relative to gel

• Sample overloaded

• Sample was allowed to diffuse

into gel too long before

electrophoresis

• Loading wells not straight

• Sample molarity too low relative to gel

• Sharkstooth comb inserted too

far into the gel

• Loading wells not straight or

clean

• Bubble in gel

• Sample molarity too high

• Sample molarity too low

• Sample dependent artifact

• Check sample and gel buffers

• Sample dependent artifact

• Allow gel to polymerize more

completely before removing

comb

• Check sample and gel buffers

• Reduce sample load volume

• Load a set or two at a time

• Pour new gel with better lanes

• Check sample and gel buffers

• Touch the top of the gel with

the teeth

• Allow gel to polymerize more

completely before removing

comb

• Pour new gel without bubbles

• Check sample and gel buffers

• Check sample and gel buffers

24

Page 28

3. Total Signal Artifacts

Condition Probable Causes Solutions/Preventions

Large horizontal exposed areas

of film

High molecular weight area

distorted on film

Fuzzy bands, bands smeared,

resolution problems

Autoradiogram shows large

black spots or radiating

patterns

Film sticks to dried gel

Blank autoradiogram

• Buffer contamination with

label

• Molarity or pH anomaly in gel

causing dehydration (gel

shrinking and bubbles) located

near the top of the gel

• Improper sample loading

• Hydrolyzed gel matrix

• Ionic contaminants in gel

• Polymerization problem

• Improper gel temperature

• Wet plastic wrap or wet gel

• Static electricity sparks

exposed film during handling

• Gel not completely dried

• Hygroscopic urea has bound

water

• Sample dependent problem

• Autoradiography problem

• Clean IPC and buffer containers,

remake buffers

• Gel run too hot, gel buffer

hydrolyzed, gel buffer not

made up correctly, or upper

buffer degraded

• Refer to Section 3.5

• Don’t run gel above 55 °C

• Use only electrophoresis grade

reagents, check purity

• TEMED or APS concentration

too high

• Pre-running gel may result in

better resolution

• Refer to Section 7.1 and 7.2

for protocols

• Refer to bulletin 1156

• Use Gel Temperature Indicator;

50 °C is usually high enough

• Re-expose with dry Saran

Wrap

• Do not rub film prior to placing

or removing film

• Dry gels longer. Remove urea

by soaking gel in methanolacetic acid before drying.

25

Page 29

Section 6

Equipment and Accessories

6.1 Sequi-Gen GT Nucleic Acid Electrophoresis Cells and

Accessories

Catalog

Number Product Description

165-3860 Sequi-Gen GT System*, 21 x 40 cm

165-3861 Sequi-Gen GT System*, 21 x 50 cm

165-3862 Sequi-Gen GT System*, 38 x 30 cm

165-3863 Sequi-Gen GT System*, 38 x 50 cm

165-3802 Sequi-Gen GT/PowerPac 3000 System, 21 x 40 cm, 100/120 V

†

165-3805 Sequi-Gen GT/PowerPac 3000 System, 21 x 40 cm, 220/240 V

†

165-3803 Sequi-Gen GT/PowerPac 3000 System, 21 x 50 cm, 100/120 V

†

165-3806 Sequi-Gen GT/PowerPac 3000 System, 21 x 50 cm, 220/240 V

†

165-3810 Sequi-Gen GT/PowerPac 3000 System, 38 x 30 cm, 100/120 V

†

165-3811 Sequi-Gen GT/PowerPac 3000 System, 38 x 30 cm, 220/240 V

†

165-3804 Sequi-Gen GT/PowerPac 3000 System, 38 x 50 cm, 100/120 V

†

165-3807 Sequi-Gen GT/PowerPac 3000 System, 38 x 50 cm, 220/240 V

†

165-3870 GT IPC Assembly, 21 x 40 cm

165-3871 GT IPC Assembly, 21 x 50 cm

165-3872 GT IPC Assembly, 38 x 30 cm

165-3873 GT IPC Assembly, 38 x 50 cm

165-3880 GT IPC, 21 x 40 cm

165-3881 GT IPC, 21 x 50 cm

165-3882 GT IPC, 38 x 30 cm

165-3883 GT IPC, 38 x 50 cm

165-3644 Outer Glass Plates, 38 x 30 cm, 2

165-3882 Outer Glass Plates, 21 x 40 cm, 2

165-3646 Outer Glass Plates, 21 x 50 cm, 2

165-3649 Outer Glass Plates, 38 x 50 cm, 2

165-3866 GT Universal Base

165-3801 Stabilizer Bar

165-3867 GT Safety Covers, with cables, 21 cm

165-3868 GT Safety Covers, with cables, 38 cm

165-3875 GT Clamp Set, 30 cm

165-3876 GT Clamp Set, 40 cm

165-3877 GT Clamp Set, 50 cm

165-3878 Precision Caster Assembly, 21 cm

26

Page 30

165-3879 Precision Caster Assembly, 38 cm

165-3886 Precision Caster Base, 21 cm

165-3887 Precision Caster Base, 38 cm

165-3888 Precision Caster Gasket, 21 cm

165-3889 Precision Caster Gasket, 38 cm

165-3891 Precision Caster Syringe, 60 cc

165-3892 Precision Caster Syringe, 140 cc

165-3893 Precision Caster Tubing, 60 cm

165-3894 Precision Caster Luer Taper, 4

165-3895 Drain Port Connector, 2

165-3720 Gel Temperature Indicator, 5

Vinyl Spacers

165-3812 Machined Vinyl Spacers, 30 cm, 0.4 mm, red

165-3813 Machined Vinyl Spacers, 30 cm, 0.25 mm, blue

165-3814 Machined Vinyl Spacers, 40 cm, 0.4 mm, red

165-3815 Machined Vinyl Spacers, 40 cm, 0.25 mm, blue

165-3816 Machined Vinyl Spacers, 50 cm, 0.4 mm, red

165-3817 Machined Vinyl Spacers, 50 cm, 0.25 mm, blue

165-3818 Machined Vinyl Spacers, 30 cm, 0.75 mm, grey

165-3819 Machined Vinyl Spacers, 40 cm, 0.75 mm, grey

165-3828 Machined Vinyl Spacers, 50 cm, 0.75 mm, grey

165-3820 Machined Vinyl Wedge Spacers, 40cm, 0.25-0.75mm, blue

165-3821 Machined Vinyl Wedge Spacers, 40cm, 0.4-0.1.2mm, red

165-3822 Machined Vinyl Wedge Spacers, 50cm, 0.25-0.75mm, blue

165-3823 Machined Vinyl Wedge Spacers, 50cm, 0.4-1.2mm, red

Clear Plastic Spacers

165-3710 Plastic Spacers, 40cm, 0.4mm, 10

165-3711 Plastic Spacers, 40cm, 0.25mm, 10

165-3712 Plastic Spacers, 50cm, 0.4mm 10

165-3713 Plastic Spacers, 50cm, 0.25mm, 10

165-3714 Plastic Spacers, 80cm, 0.4mm, 10

165-3715 Plastic Spacers, 80cm, 0.25mm, 10

165-3716 Plastic Spacers, 100cm, 0.4mm, 10

165-3717 Plastic Spacers, 100cm, 0.25mm, 10

* All Sequi-Gen GT systems include: GT IPC assembly (IPC and bonded inner glass plate, outer glass plate, and clamp set), GT

universal base, GT safety covers with cables, stabilizer bar, precision caster assembly (precision caster base, gasket, tubing, luer

tapers, tubing, and syringe), 0.40 mm vinyl sharkstooth comb and spacers, gel temperature indicator, leveling bubble, drain port

connector, and instruction manual.

† All Sequi-Gen GT/PowerPac 3000 systems include the appropriate Sequi-Gen GT system (described above), PowerPac 3000

power supply, PowerPac temperature probe and PowerPac instruction manual.

27

Page 31

Machined Vinyl Combs

Vinyl sharkstooth combs and spacers are machined to maintain a uniform and precise

thickness throughout the length of each spacer and comb and between all vinyl spacers and

combs. All spacers and sharkstooth combs are color-coded based on thickness. Blue

(0.25 mm), red (0.4 mm), and gray (0.75 mm) spacers are available in 30, 40 and 50 cm

lengths. Blue and red sharkstooth combs are available in 15 and 30 cm lengths and a wide

range of well formats including multichannel pipet/microplate-compatible (MP) combs for

high throughput applications.

Catalog Comb Comb Number Well Well Maximum Well

Number Thickness (mm) Length (cm) of Wells Width (mm) Separation (mm) Volume* (µl)

Machined Vinyl Sharkstooth Comb

165-3830 0.25 15 24 6.1 None 4.5

165-3831 0.25 15 36 4.1 None 3.0

165-3832 0.25 15 48 3.1 None 2.3

165-3833 0.25 30 48 6.1 None 4.5

165-3834 0.25 30 72 4.1 None 3.0

165-3835 0.25 30 96 3.1 None 2.3

165-3836 0.40 15 24 6.1 None 7.3

165-3837 0.40 15 36 4.1 None 5.0

165-3838 0.40 15 48 3.1 None 3.7

165-3839 0.40 30 48 6.1 None 7.3

165-3840 0.40 30 72 4.1 None 5.0

165-3841 0.40 30 96 3.1 None 3.7

MP Vinyl Sharkstooth Combs

165-3842 0.25 15 34 None

165-3843 0.25 30 68 None

165-3844 0.25 30 100 None

165-3845 0.40 15 34 None

165-3846 0.40 30 68 None

165-3847 0.40 30 100 None

* Maximum well volumes are calculated values based on an assumed well height. Well height will vary with each user. The well

volumes indicated will vary from run to run and user to user.

28

Page 32

Clear Plastic Combs and Spacers

Well forming combs are 14 cm and 31 cm wide. All plastic well-forming combs,

sharkstooth combs, and spacers are made from inert plastic which does not catalyze or inhibit

polymerization. Thus, the combs are easy to remove without damaging the sample loading wells.

Catalog Comb Comb Number Well Well Maximum Well

Number Thickness (mm) Length (cm) of Wells Width (mm) Separation (mm) Volume* (µl)

Plastic Sharkstooth Comb

165-3700 0.40 15 24 6.1 None 7.3

165-3702 0.40 15 48 3.1 None 3.7

165-3701 0.25 15 24 6.1 None 4.5

165-3703 0.25 15 48 3.1 None 2.3

Plastic Well-forming Comb

165-3684 0.40 14 16 6.7 2.4 42.5

165-3685 0.25 14 16 6.7 2.4 26.5

165-3686 0.40 14 20 4.9 2.4 31.0

165-3687 0.25 14 20 4.9 2.4 19.5

165-3688 0.40 14 36 2.4 1.6 3.6

165-3689 0.25 14 36 2.4 1.6 2.3

165-3692 0.40 31 32 7.4 2.4 47.0

165-3693 0.25 31 32 7.4 2.4 29.5

165-3694 0.40 31 44 4.8 2.4 30.0

165-3695 0.25 31 44 4.8 2.4 18.5

165-3696 0.40 31 60 3.6 1.6 5.5

165-3697 0.25 31 60 3.6 1.6 3.4

165-3698 0.40 31 80 2.3 1.6 3.5

165-3699 0.25 31 80 2.3 1.6 2.2

MP Plastic Well-forming Combs

165-3848 0.40 15 34

165-3849 0.40 30 68

165-3850 0.75 15 34

165-3851 0.75 30 68

* Maximum well volumes are calculated values based on an assumed well height. Well height will vary with each user. The well

volumes indicated will vary from run to run and user to user.

29

Page 33

6.2 Electrophoresis Reagents

Catalog

Number Product Description

Electrophoresis Buffers and Gel Reagents

161-5100 PAGE Reagent Starter Kit,1 includes Acrylamide, 100 g; Bis,

5 g; TEMED, 5 ml; Ammonium Persulfate, 10 g

Premixed Acrylamide Solutions

1,2

161-0154 30% Acrylamide/Bis Solution, 19:1, 500 ml

161-0155 30% Acrylamide/Bis Solution, 19:1, 2 x 500 ml

161-0144 40% Acrylamide/Bis Solution, 19:1, 500 ml

161-0145 40% Acrylamide/Bis Solution, 19:1, 500 ml

Premixed Acrylamide/Bis Powders

1

161-0120 Acrylamide/Bis, 19:1, 30 g

161-0123 Acrylamide/Bis, 19:1, 150 g

Crosslinkers and Catalysts

161-0200 Bis,15 g

161-0201 Bis,150 g

161-0800 TEMED,

1,3

5 ml

161-0801 TEMED,

1,3

50 ml

161-0700 Ammonium Persulfate,

1,3

10 g

Premixed Buffers

161-0741 Premixed 10x TBE Extended Range, 1 L

161-0758 Premixed 10x TBE Extended Range, 6 x 1 L

161-0733 Premixed 10x Tris/Boric Acid/EDTA (TBE), 1 L

161-0756 Premixed 10x Tris/Boric Acid/EDTA (TBE), 6 x 1 L

Powders and Reagents

1

161-0100 Acrylamide, 99.9%, 100 g

161-0101 Acrylamide, 99.9%, 500 g

161-0107 Acrylamide, 99.9%, 1 kg

161-0103 Acrylamide, 99.9%, 2 kg

161-0108 Acrylamide, 99.9%, 5 kg

161-0730 Urea, 250 g

161-0731 Urea, 1 kg

161-0716 Tris, 500 g

161-0719 Tris, 1 kg

161-0750 Boric Acid, 500 g

161-0751 Boric Acid, 1 kg

161-0728 EDTA, 100 g

161-0729 EDTA, 500 g

1. Hazardous shipping charges may apply.

2. Store at 4 °C.

3. For a longer shelf life, store desiccated at room temperature.

30

Page 34

6.3 Power Supplies and Slab Gel Dryers

Catalog

Number Product Description

Power Supplies

165-5056 PowerPac 3000 Power Supply, 110/120 V

165-5057 PowerPac 3000 Power Supply, 220/240 V

165-5059 PowerPac 3000 Power Supply with Temperature Probe, 110/120 V

165-5060 PowerPac 3000 Power Supply with Temperature Probe, 220/240 V

Slab Gel Dryers

165-1752 Model 583 Gel Drying System, 110/120 V; includes Model 583 Gel

Dryer, Vacuum Pump, Trap, tubing and connectors

165-1753 Model 583 Gel Drying System, 220/240 V; includes Model 583 Gel

Dryer, Vacuum Pump, Trap, tubing and connectors

165-1745 Model 583 Slab Gel Dryer, 100/120 V

165-1746 Model 583 Slab Gel Dryer, 220/240 V

165-0959 Sequencing Gel Filter Paper, 35 x 45 cm, 25 sheets

165-0962 Filter Paper Backing, 35 x 45 cm, 25 sheets

165-0963 Cellophane Membrane Backing, 35 x 45, 50 sheets

6.4 DNA T emplate Purification, Sequencing and Cloning Products

Catalog

Number Product Description

DNA Template Purification

732-6100 Quantum Prep™Plasmid Miniprep Kit, 100 preps

DNA Template Sequencing

170-3407 Bst®Premixed Standard Sequencing Kit, 50 reactions

170-3414 Bst Premixed 7-deaza-dGTP Sequencing Kit, 50 reactions

170-3409 Bst adjustable Ratio Sequencing Kit, 50 reactions

DNA Mutagenesis

170-3580 Muta-Gene®M13 In Vitro Mutagenesis Kit, 25 reactions

170-3581 Muta-Gene Phagemid In Vitro Mutagenesis Kit, 25 reactions

31

Page 35

6.5 Liquid Handling

Catalog

Number Product Description

223-9911 Seque/Pro Capillary Tips, 200/Box

223-9912 Seque/Pro Capillary Tips, 200/Box, autoclaved

223-9314 MTP-39 Pipet Tips, 960/Box

223-9319 MTP-39-S Pipet Tips, 960/Box, Sterilized

211-2001 Xcluda Aerosol Barrier Pipet Tips, 0.5–10 µl, 960/Box, Sterilized

211-2006 Xcluda Aerosol Barrier Pipet Tips, 5–20 µl, 960/Box, Sterilized

211-2016 Xcluda Aerosol Barrier Pipet Tips, 20–200µl, 960/Box, Sterilized

223-9480 EZ Micro Test Tube, 1.5 ml, 500/Box

223-9503 EZ Micro Test Tube, 0.5 ml, 500/Box

Section 7

Appendix

7.1 DNA Sequencing Checklist

For DNA sequencing, you will need the following buffers, reagents, and equipment:

1. DNA sequencing samples, suitably labeled. (see Section 6.4)

2. 10x TBE buffer: 108 g Tris base, 55 g boric acid, 9.3 g Na2EDTA•H2O, in 1 liter

deionized H2O, autoclave. The pH of this solution should be 8.3, without adjustment

(see Section 6.2).

3. Acrylamide stock solution, 30%:

A. For low percent gels (4%-10%):

Prepare a 30% stock solution, 19:1 Acrylamide/Bis:

28.5 g Acrylamide

1.5 g Bis-Acrylamide

30.0 g Total up to 100 ml deionized H2O

(see Section 6.2)

B. For medium percent gels (8%-16%):

Prepare a 30% stock solution, 29:1 Acrylamide/Bis:

29.0 g Acrylamide

1.0 g Bis-Acrylamide

30.0 g Total up to 100 ml deionized H2O

(see Section 6.2)

C. For high percent gels (12%-20%):

Prepare a 40% stock solution, 37.5:1 Acrylamide/Bis:

38.96 g Acrylamide

1.04 g Bis-Acrylamide

40.0 g Total up to 100 ml deionized H2O

(see Section 6.2)

4. TEMED (see section 6.2)

32

Page 36

5. Ammonium Persulfate, 25% stock solution: 0.25 g in 1 ml distilled H2O (in a microfuge

tube). Make fresh daily (see Section 6.2).

6. A constant power (or constant voltage) power supply (see Section 6.3).

7. Slab gel dryer(see Section 6.3).

8. Table top micro-centrifuge

9. Gel loading syringe (e.g. Hamilton 701-SN, 28 Gauge, 1.25 inch needle)

10. 1.5 ml microcentrifuge tubes (see Section 6.5)

11. Adjustable pipettors (e.g. Pipetman P-20, P-200, P-1000)

12. Balance

13. Plastic wrap

14. Pipette tips, autoclaved (see Section 6.5)

15. Waterbath or Temp-Block at 95 °C.

16. X-ray film and cassettes (dark-room facilities)

17. Filter Paper (see Section 6.3)

18. Siliconizing solution or glass coating solution

19. Geiger Counter

20. Ice bucket

7.2 Standard Gel Protocol

The following protocol is for a standard 7 M urea, 5% polyacrylamide gel for DNA

sequencing. See Section 4 for additional information on gel casting, sample loading, and gel

electrophoresis. For ordering information on gel reagent and electrophoresis buffers see

Section 6.

1. Combine 63 g of urea, 15 ml of 10x TBE, and 25 ml of 30% acrylamide stock solution.

Bring the volume to 150 ml with distilled water (low heat may be required to dissolve the

urea, but do not boil).

2. Filter the solution through a 0.45 micron mesh filter (optional). Then, degas under strong

vacuum 5–15 minutes to remove dissolved oxygen.

3. Add 150 µl TEMED and 150 µl 25% ammonium persulfate (or one microliter of each

reagent for every milliliter of gel solution) prior to gel casting.

4. Cast the gel according to procedures in Section 4.

Note: Wedge spacers (see Section 6.1) increase the number of readable bases per lane in a

sequencing gel. The use of wedge spacers results in a gel which becomes gradually thicker

toward the bottom. As thickness increases, resistance, voltage, and DNA mobility decrease.

The resulting gel has bands more closely spaced at the bottom. Wedge spacers allow the use

of standard polyacrylamide solution and buffers. No alterations to the gel solution, gel

casting or electrophoresis protocols are required to run DNA sequencing wedge gels.

33

Page 37

7.3 Gel Drying and Autoradiography

The radiolabeled oligonucleotides may be visualized by a variety of techniques involving

autoradiography. For the best resolution and signal intensity, dry DNA sequencing gels

with a slab gel dryer.

1. Transfer sequencing gels to a fresh sheet of filter paper. Wet the gel slightly by misting the

gel with deionized H2O. Lay the dry filter paper on top of the gel, and press firmly. The gel

will stick to the paper. Pick up the gel by lifting the filter paper carefully from one end.

2. Cover the sequencing gel with plastic wrap. Smooth out air bubbles and folds by rubbing

with a paper towel, and trim the edges to fit the slab gel dryer.

3. Set Model 583 Gel Dryer to sequencing cycle. 30 minutes at 80 °C should suffice for

drying thin low percent gels, if the applied vacuum is above 28 inches of mercury or

125 torr. Refer to the dryer’s instruction manual for details.

4. Autoradiograph the gel with high speed X-ray film (such as Kodak XAR) and a suitable

film cassette. Intensifying screens are optional. If 35S radiolabel is used, the gel can be

left on the outer glass plate and fixed in 1 liter of 10% acetic acid, 10% methanol for

15 minutes. This removes hygroscopic urea. The gel may then be dried on filter paper.

Removal of plastic wrap before autoradiography is important because 35S is a weak beta

emitter. Autoradiography of 35S labeled fragments typically requires 1–3 days. (However,

we have found the fixative step unnecessary, even when sequencing with 35S.)

7.4 Nucleic Acid Separation Applications for the Sequi-Gen GT

Electrophoresis System

Several other nucleic acid separation techniques requiring single nucleotide resolution

can be conducted using the Sequi-Gen GT systems. Below is a comprehensive list. Refer to

Sambrook, J., Fritsch, E. F., and Maniatas, T., Molecular Cloning, A Laboratory Manual,

Second Edition, Cold Spring Harbor Laboratory Press, 1989, or Ausubel, F. M., et al., Current

Protocols in Molecular Biology, Greene Publishing Associates and Wiley-Interscience, 1987,

for more information and protocols.

• Microsatellite Analysis

• Single-Strand Conformational Polymorphism (SSCP) studies

• Heteroduplex analysis

• DNA footprinting

• DNA fingerprinting

• RNase protection assays

• S1 nuclease mapping

• Primer extension studies