Page 1

S3™ and S3e™ Cell Sorters

Instruction Manual

Catalog #145-1001

#145 -1002

#14 5 -10 05

#14 5 -10 0 6

#145-1008

Page 2

Page 3

Bio-Rad Technical Support

For help and technical advice, please contact the Bio-Rad Technical Support department. In the United

States, the Technical Support department is open Monday–Friday, 5:00 AM–5:00 PM, Pacific time.

http://www.bio-rad.com

Bio-Rad Laboratories

Life Science Research

2000 Alfred Nobel Drive

Hercules, CA 94547

Telephone: 510-741-1000

Tele x: 335-358

Toll Fre e: 1-800-4-BIORAD (1-800-424-6723)

Fax: 510-741-5800

Free Fax: 1-800-879-2289

Online technical support and worldwide contact information are available at www.consult.bio-rad.com.

Legal Notices

Agilis is a trademark of Newport Corporation.

Kimwipes is a trademark of Kimberly-Clark Corporation.

Windows is a trademark of Microsoft Corporation.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopy, recording, or any information storage or retrieval system, without

permission in writing from Bio-Rad Laboratories.

Bio-Rad reserves the right to modify its products and services at any time. This instruction manual is subject

to change without notice.

Although prepared to ensure accuracy, Bio-Rad assumes no liability for errors, or for any damages resulting

from the application or use of this information.

Copyright © 2014 by Bio-Rad Laboratories, Inc. All rights reserved.

Instruction Manual | i

Page 4

Bio-Rad Laboratories Resources

Bio-Rad provides many resources for scientists. Table 1 lists available resources and how to locate what you need.

Table 1. Bio-Rad resources.

Resource How to Contact

Local Bio-Rad Laboratories Find local information and contacts on the Bio-Rad Laboratories website by selecting your country

representatives on the homepage (www.bio-rad.com). Find the nearest international office listed on the back of

this manual

Technical support scientists Bio-Rad’s technical support scientists provide our customer with practical and expert solutions.

To find local technical support on the phone, contact your nearest Bio-Rad office. For technical

support in the United States and Canada, call 1-800-424-6723 (toll-free), and select the technical

support option

Service support engineers Maintenance and repairs should be carried out only by authorized service support engineers

For service support in the United States and Canada, call 1-800-424-6723 (toll-free), and select

the technical support option to request service support

Technical notes and literature Go to the Bio-Rad website (www.bio-rad.com). Type a term in the Search box and select

Documents tab to find links to literature

Writing Conventions Used in This Manual

This manual uses the writing conventions listed in Table 2.

Table 2. Conventions used in this manual.

Convention Meaning

Note: Provides helpful information and instructions, including information explained in further detail elsewhere in this manual

WARNING! Explains very important information about something that might injure the researcher, damage the instrument, or

cause data loss

X > Y Instruction to select X and then select Y from a toolbar, menu, or software window

Highlights area of interest on a screenshot

IMPORTANT! Provides important information about necessary actions or common mistakes

ii | S3 and S3e Cell Sorters

Page 5

Safety and Regulatory Compliance

For safe operation of the S3 and S3e Cell Sorter systems, we strongly recommend that you follow the safety specifications listed in

this section and throughout the manual.

Safety Warning Labels

Warning labels posted on the instrument and in this manual warn you about sources of injury or harm. Refer to Table 3 to review the

meaning of each safety warning label.

Table 3. Meaning of safety warning labels.

CAUTION: Shock hazard! This symbol draws attention to a possible injury or danger to life if the associated

directions are not followed correctly

CAUTION: Risk of danger! This symbol identifies components that pose a risk of personal injury or damage to

the instrument if improperly handled. Wherever this symbol appears, consult the manual for further information

before proceeding

CAUTION: Laser hazard! This symbol draws attention to a possible injury or danger to life due to laser radiation

if the associated directions are not followed correctly

CAUTION: Biohazard! This symbol identifies components that may become contaminated with biohazardous material

Instrument Warning Labels

The warning labels shown in Table 4 are displayed on the instrument and refer directly to the safe use of the S3 and

S3e Cell Sorter systems.

Table 4. Instrument safety warning labels.

Warning about risk of shock.

Only qualified, trained technicians should carry out service work on electronic components due to potential

shock hazard

Warning about electronic components.

Electronic components are sensitive to electrostatic charges and can be destroyed by a discharge

Warning about weight of the system.

Lifting should be accomplished with a minimum of two people and only by the inset handles on the instrument

base. Use caution to keep instrument level and handle gently

Warning about handling biohazardous materials.

When handling biohazardous samples or the S3 or S3e System’s waste container, adhere to the recommended

precautions and guidelines in this manual, and comply with any local guidelines specific to your laboratory

and location

Instruction Manual | iii

Page 6

Safe Use Specifications and Compliance

Laser Product Hazard Classification

The intent of the laser hazard classification is to identify hazards to users posed by the laser, and provide appropriate protective

measures. The S3 or S3e laser is a Class 1 laser product that complies with 21 CFR 1040.10 and 1040.11, except for deviations

pursuant to Laser Notice No. 50, dated June 24, 2007 stating that operators are not exposed to harmful levels of laser radiation

during normal operation, maintenance and/or service. During times of repair and/or major service by a trained technician, laser safety

controls for Class 3B lasers must be followed.

WARNING! Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous

laser radiation exposure.

Electrical Safety Information and Classification

The S3 and S3e Systems conform to international regulations encompassing the accessibility of high voltages by the user. Use all

protective housings, interlocks, and shields as identified in this manual. Further information about specific electrical hazards is listed in

the hardware description.

AC Fuse Requirements

Remove power cord before replacing fuses.

Fuses are 5 x 20 mm and must be rated to 250 VAC, 4 A slow blow such as Schurter 0034.3123

AC Power Cord Requirements

Power cord must be IEC 60320-1 compliant with a C13 plug on the instrument end. The power cord must be rated at minimum

250 VAC, 10 A at 60ºC minimum. In the U.S. and Canada, the power cord must be rated at minimum 125 VAC, 10 A at 60ºC minimum.

Position the instrument for easy access to the power switch and the power cord.

Regulatory Compliance

This instrument has been tested and found to be in compliance with all applicable requirements of the following safety and

electromagnetic standards:

n

IEC 61010-1:2010 (3rd Ed.), EN61010-1:2010 (3rd Ed). Electrical Equipment for Measurement, Control, and Laboratory Use - Part 1:

General Requirements.

n

UL/CSA 61010-1:2012 (3rd Ed.), Standard for Safety Electrical Equipment for Electrical Safety (USA, Canda, NRTL)

n

IEC 60825-1:2007(2nd Ed.), EN 60825-1:2007(2nd Ed). Safety of laser products - Part 1: Equipment classification and requirements

n

Class 1 laser product per CDRH requirements and regulations

n

IEC 61010-2-081:2001+A1, EN61010-2-081:2002+A1. Safety requirements for electrical equipment for measurement, control and

laboratory use. Part 2-081: Particular requirements for automatic and semi-automatic laboratory equipment for analysis and other

purposes (includes Amendment 1)

n

EN 61326-1:2006 (Class A) Electrical equipment for measurement, control and laboratory use. EMC requirements, Part 1: General

requirements

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference, in which case the user will be required to correct the interference at his own expense.

Hazards

The S3 and S3e Cell Sorters are designed to operate safely when used in the manner prescribed by the manufacturer. If the S3 or

S3e Cell Sorter or any of its associated components are used in a manner other than prescribed, or if modifications to the instrument

are not performed by a Bio-Rad or other authorized agent, then the warranty on the system will be voided. Service of the S3 or

S3e Cell Sorter should be performed only by Bio-Rad personnel.

Biohazards

The S3 and S3e Cell Sorters are laboratory products. However, if biohazardous samples are present, adhere to the following

guidelines and comply with any local guidelines specific to your laboratory and location.

General Precautions

n

Always wear laboratory gloves, coats, and safety glasses with side shields or goggles

n

Keep your hands away from your mouth, nose, and eyes

n

Completely protect any cut or abrasion before working with potentially infectious materials

iv | S3 and S3e Cell Sorters

Page 7

n

Wash your hands thoroughly with soap and water after working with any potentially infectious material before leaving the laboratory

n

Remove wristwatches and jewelry before working at the bench

n

Store all infectious or potentially infectious material in unbreakable leak-proof containers

n

Before leaving the laboratory, remove protective clothing

n

Do not use a gloved hand to write, answer the telephone, turn on a light switch, or touch anything that other people may touch

without gloves

n

Change gloves frequently. Remove gloves immediately when they are visibly contaminated

n

Do not expose materials that cannot be properly decontaminated to potentially infectious material

n

Upon completion of the operation involving biohazardous material, decontaminate the work area with an appropriate disinfectant

(for example, a 1:10 dilution of household bleach)

n

No biohazardous substances are exhausted during normal operations of this instrument

Disposal of Biohazardous Material

The S3 and S3e Systems include a waste container that may potentially contain hazardous biological materials, depending on the

sample used. Dispose of the following potentially contaminated materials in accordance with laboratory, local, regional, and

national regulations:

n

Content in waste container

n

Reagents

n

Used reaction vessels or other consumables that may be contaminated

Chemical Hazards

The S3 and S3e Systems include a waste container that may potentially contain hazardous chemical materials depending on the

sample used.

Explosive or Flammability Hazards

The S3 and S3e Systems pose no uncommon hazard related to flammability or explosion when used in a proper manner as

specified by Bio-Rad Laboratories.

Electrical Hazards

The S3 and S3e Systems pose no uncommon electrical hazard to operators if installed and operated properly without physical

modification and if connected to a power source of proper specification.

Transport

Moving the S3 and S3e Systems is not recommended after installation. If the system needs to be moved, follow the decontamination

procedure in this manual and remove all bulk fluidics. A QC procedure will be required after a move to ensure instrument is

functioning properly.

Lifting should be performed with a minimum of two people. Lift with the inset handles on the instrument base. Use caution to keep

instrument level, and handle the instrument gently.

Storage

The S3 or S3e System can be stored under the following conditions:

n

Temperature range 5–35°C

n

Relative humidity 20–70%

Disposal

The S3 and S3e Systems contain electronic or electrical materials; it should be disposed of as unsorted waste and must be collected

separately, according to European Union Directive 2002/96/CE on waste and electronic equipment — WEEE Directive. Before

disposal, contact your local Bio-Rad representative for country-specific instructions.

Warranty

The S3 and S3e Cell Sorters and associated accessories are covered by a standard Bio-Rad warranty. Contact your local Bio-Rad

Laboratories office for details of the warranty.

Instruction Manual | v

Page 8

vi | S3 and S3e Cell Sorters

Page 9

Table of Contents

Chapter 1: Introduction 1

1.1 System Components 2

1.2 Installation Requirements 2

Chapter 2: Hardware Description 3

2.1 System Overview 3

2.2 Fluidics System 5

2.3 Optics 9

2.4 Electronics 11

Chapter 3: ProSort™ So ftwar e 13

3.1 Main Software Window 14

3.2 Control Panel 20

3.3 Administrator Tab Toolbar 22

Chapter 4: Getting Started 33

4.1 Checking Bulk Fluidics 33

4.2 Logging In 34

4.3 Daily Startup 35

4.4 Quality Control 36

4.5 Protocols and Workspace 42

Chapter 5: Acquisition 51

5.1 Acquisition Setup 51

5.2 Compensation 55

5.3 Checking or Swapping Fluidics 60

5.4 Optical Filters 62

Chapter 7: Additional Software Features 73

7.1 Debubble 73

7.2 Unclog 73

7.3 Swap Tip 73

7.4 Clean System 74

7.5 Instrument Status Box 75

7.6 Status Bar 75

7.7 Printing 76

7.8 Quality Control Reports 76

7.9 User Reports 77

7.10 Biosafety System 78

Chapter 8: Shutdown 79

8.1 Daily Shutdown 79

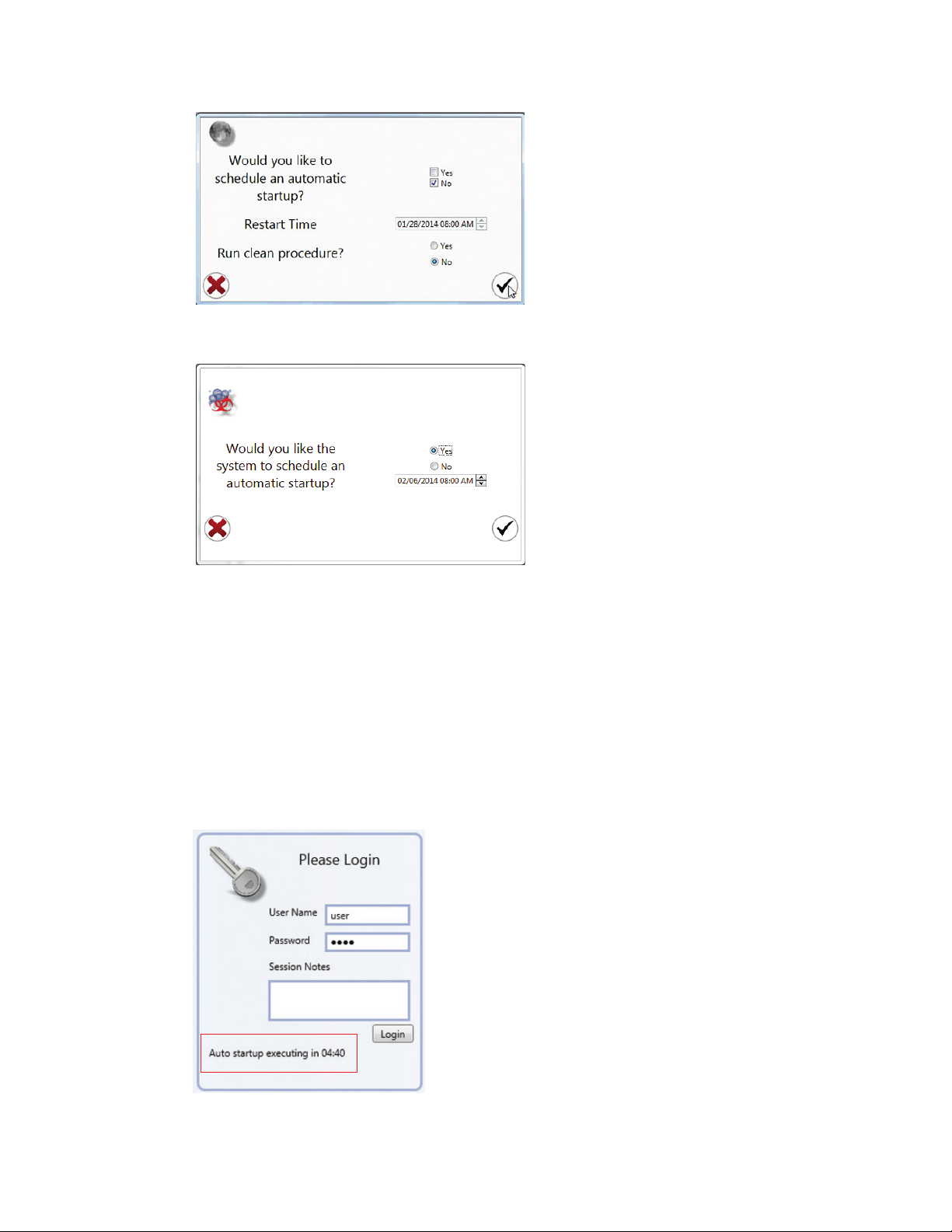

Chapter 9: Automatic Startup 83

9.1 Scheduling an Automatic Startup 83

9.2 Previously Scheduled Automatic Startups 84

Chapter 10: Maintenance 87

10.1 General Maintenance 87

10.2 Dealing with Clogs 88

10.3 Cleaning or Replacing Nozzle Tip 88

10.4 Swap Nozzle Tip Wizard 89

10.5 Optical Filter Cleaning 105

10.6 Disinfectants 105

10.7 Decontamination 105

Chapter 6: Sorting 65

6.1 Sort Setup 65

6.2 Sort Modes 69

6.3 Sort Statistics 69

6.4 Sort Plots 71

Troubleshooting 111

References 115

S3 and S3e Cell Sorter Specifications 117

Ordering Information 119

Instruction Manual | vii

Page 10

viii | S3 and S3e Cell Sorters

Page 11

1

Introduction

The S3™ and S3e™ Cell Sorters are designed to offer affordable, dependable, and simplified

cell sorting. As benchtop cell sorters, the S3 and S3e Cell Sorters are equipped with one or

two lasers and up to four fluorescent detectors, plus forward and side scatters. Samples are

analyzed using the traditional jet-in-air technology, and events can be sorted at high speeds

while maintaining sensitivity and high purity.

Sorting is typically accomplished by breaking the stream of fluid containing particles into

droplets and applying a charge to the stream when a particle passes the criteria to be sorted.

The charged droplet containing the particle is then deflected by an electric field into a collection

vessel. To ensure proper deflection of the correct droplets, proper instrument setup is integral to

achieving high-purity sort results.

By automating the complex presort setup with a unique technology, the S3 and S3e

create a more efficient and consistent workflow.

Key automated features:

n

Startup/shutdown

n

Stream-to-laser alignment

n

Drop delay calculation

n

Droplet break-off monitoring and feedback

n

Phase and deflection adjustments to sort stream

n

Daily QC reporting and trending

n

Collection volume monitoring to prevent overfilling

The S3 and S3e

system. The instrument uses a unique internal buffer chamber system for dilution of 8x sheath

fluid with deioinized (DI) water, allowing users to swap fluids without the need to shut down the

system. This process is known as a “hot swap,” and allows uninterrupted sorting. For more

information, refer to Section 5.3, Checking or Swapping Fluidics.

Cell Sorters include a complete internalized fluidics and temperature control

Cell Sorters

Instruction Manual | 1

Page 12

Introduction

1.1 System Components

The S3 or S3e Cell Sorter complete system includes the following components:

n

S3 or S3e Cell Sorter Instrument, 1 each

n

S3 or S3e Installation Kit, 1 each

S3 cap assembly, white, sheath fluid, 1 each

S3 cap assembly, blue, DI water, 1 each

S3 cap assembly, red, waste, 1 each

S3 fluidics container 4 L size, empty, 2 each

S3 individual filter holder, black, empty, 5 each

S3 forward scatter (FSC) filter holder

with neutral density filter, 2.0, 1 each

S3 filter block A with preset filter

configuration, 1 each

S3 filter block B with preset filter

configuration, 1 each

n

S3 Accessory Kit (optional), 1 each (catalog #145-1065)

S3 nozzle tip, 100 µm, 1 each

S3 nozzle O-rings, 2 each

S3 nozzle alignment disk, 2 each

Neutral density filter, 1.0, 2 each

5 ml tubes, 12 x 75 mm, 1 pack

S3 collection adaptor set, 1 each

Bulk fluidics tray, 3 each

USB cord, 1 each

Ethernet cord, 1 each

Power cord, 1 each

USB drive with ProSort

™

software

Instrument and software manual

Instrument quick guide

2 mm hex driver, 1 each

S3 spanner wrench, 1 each

1 ml syringe, 1 each

Plastic box, 1 each

n

Computer CPU and 24 inch monitor, 1 each (catalog #145-1066)

n

ProFlow

n

ProLine

™

8x Sheath Fluid, preservative free, 5 x 4 L, 1 case (catalog #145-1082)

™

Calibration Beads, 3 x 5 ml, 1 pack (catalog #145-1081) or

ProLine Universal Calibration Beads, 3 x 5 ml, 1 pack (catalog #145-1086)

1.2 Installation Requirements

The S3 and S3e Cell Sorters should be installed by a trained service engineer to ensure proper

operation and calibration of the instrument. If any items are missing or damaged, contact your

local Bio-Rad office for assistance.

Before the S3 and S3e

chosen. The instrument should be located on a sturdy bench or table top, away from any other

instruments that may interfere electrically or mechanically by causing vibration. The bench or

table top must be able to accommodate 198 lb (90 kg), the weight of the instrument. The area

should be free of excessive dust or moisture.

Table 5. Dimensions for instrument alone or with computer and monitor.*

Instrument only (W x D x H) 70 x 65 x 65 cm

Instrument wiith computer and monitor, 116 x 65 x 65 cm

(W x D x H) 46 x 25.5 x 25.5 in

* An additional 61 cm (24 in) of height clearance is needed for service.

Cell Sorters can be installed by a service engineer, a site must be

27.5 x 25.5 x 25.5 in

2 | S3 and S3e Cell Sorters

Page 13

2

Hardware Description

This chapter describes the hardware of the S3™ and S3e™ systems. Understanding the

system’s hardware is essential for proper operation.

2.1 System Overview

The S3 and S3e Systems consist of fluidics, optics, electronics, and software. These can be

broken down into several subsystems (Figure 1).

Access to nozzle assembly

Access to internal

fluidics system

Fig. 1. Front view of the S3 system.

Access to filters

Touch locking system

Sort collection area

Loading stage

Instruction Manual | 3

Page 14

Hardware Description

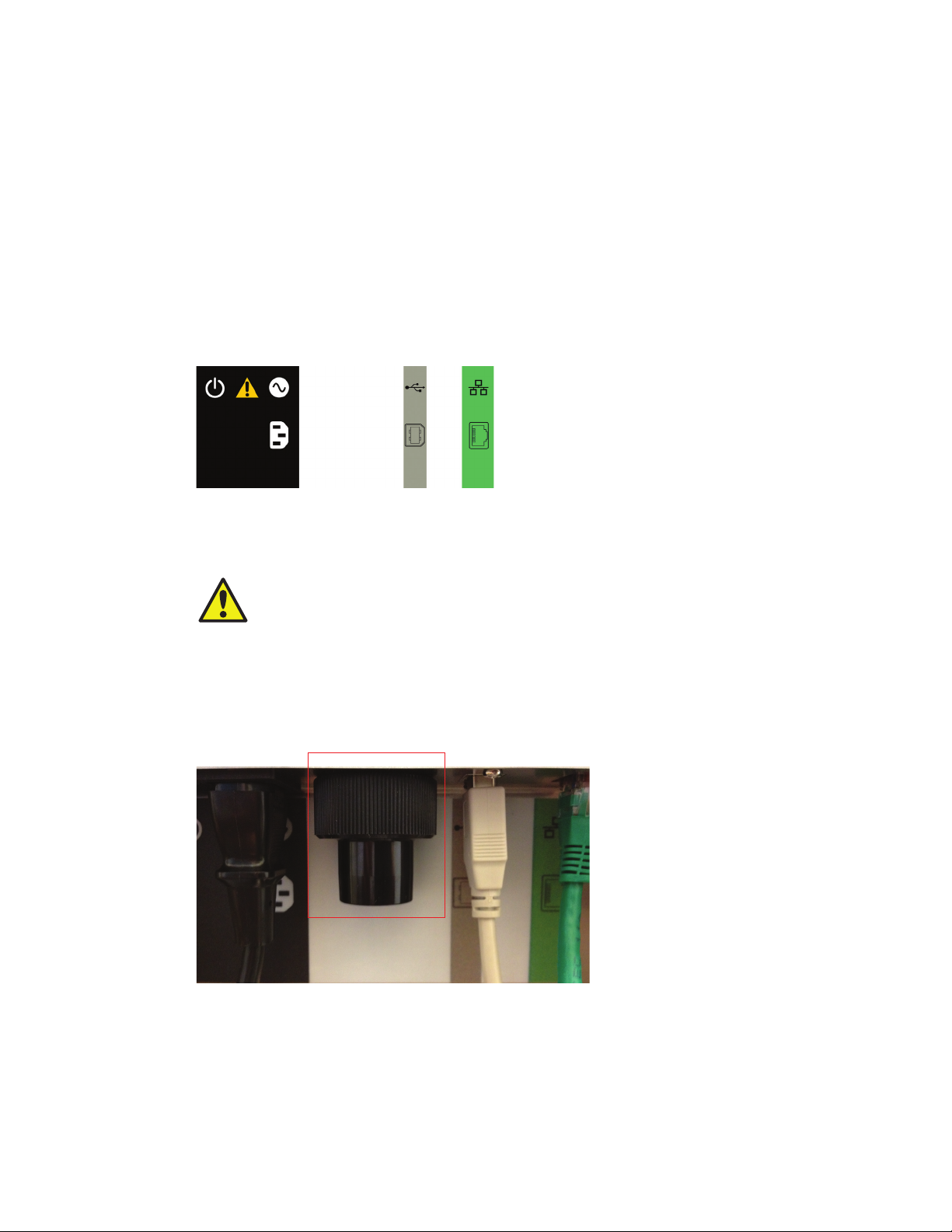

2.1.1 Instrument Back Panel

The rear connector panel of the S3 or S3e system includes these features:

n

Main power switch (black) — press the main power switch to turn on power to the system.

WARNING! The main power switch should not be used to shut down the system.

Perform system shutdown from the ProSort™ software. For more information, refer to

Chapter 8, Shutdown

n

Power input (black) — plug in the power cord here. The system requires 100 or 240 VAC outlet

n

USB port (gray) — use this port to connect the system to the computer for communication

n

Ethernet port (green) — use this port to connect the system to the computer for communication

There is a color-coded guide for proper connection location and orientation (Figure 2).

Fig. 2. Instrument rear connector panel.

CAUTION: Three cords connect the instrument to the computer for power and

communication. Be cautious when walking around the instrument, as these cords

can become a tripping hazard.

2.1.2 Aerosol Evacuation Port

The S3 and S3e systems also include an aerosol evacuation port used to directly evacuate the

sort collection chamber when connected to a biosafety system. This port can be covered when

not in use.

Fig. 3. Aerosol evacuation port.

4 | S3 and S3e Cell Sorters

Page 15

2.2 Fluidics System

The S3 and S3e fluidics system consists of the bulk fluidics, loading stage, nozzle, and sort

collection chamber. The fluidics system supplies sheath fluid, DI water, and sample to the

nozzle, and then collects the waste for proper disposal.

CAUTION: Biohazard! Biosafety is of utmost importance while operating this

instrument. Consult with your local safety officer or review local, state, and federal

regulations to ensure proper handling and disposal of biohazardous substances.

2.2.1 Bulk Fluidics

The S3 and S3e system includes two empty containers as part of the bulk fluidics. Table 6

describes the function of each container.

Table 6. Containers and their functions.

Label Container Function

Biohazardous The waste container holds the system’s fluid after it has run through the nozzle

Waste and waste lines. This container has a red cap and holds 4 liters of fluids.

Sheath Fluid The sheath fluid container holds the 8x sheath fluid for the system. This container

Deionized water The DI water container holds deionized water for mixing with the 8x sheath fluid to

(DI water) create a 1x sheath fluid. This container has a blue cap and holds 4 liters of DI

2.2 Fluidics System

Approximately 9 hours of run time can be performed until the empty container

is filled. The fluid collected in this container should be decontaminated as

appropriate to the application and samples being run on the instrument. Please

verify proper treatment and disposal with your safety officer or local health and

safety bodies

has a white cap and holds 4 liters of fluid. If preferred, 1x sheath fluid may be used

instead. In this case, the DI water container will not be used to dilute the sheath,

but only for rinsing and cleaning. If 1x sheath fluid is used, ensure the option is

checked in the Global Preferences of the software. This setting will apply globally

to the system when set by an administrator. A full container of 8x sheath fluid

has approximately 50 hours of run time, while a full tank of 1x sheath fluid has

approximately 9 hours of run time

water with a run time of approximately 9 hours between refills when using 8x

sheath fluid. The DI water is also used for cleaning at the end of the day and to

rinse the sample probe between samples

Note: The ProFlow™ 8x sheath fluid is diluted with the DI water using an internal fluidics chamber.

Each container uses a quick disconnect

Sheath fluid cap assembly

Sheath fluid container

system for easy swapping (Figure 4).

Both the DI water and the sheath fluid

containers have one connector, while

the waste container has two connectors

for waste fluid from the sorting chamber

and the washing station. Located above

the containers inside the instrument

is a magnetic holder for each quick

disconnect. The magnetic holder will

keep the quick disconnect away from

exchange area.

Fig. 4. Fluidics container highlighting the quick

disconnect system for the sheath fluid container.

Instruction Manual | 5

Quick disconnect

Page 16

Hardware Description

The sheath fluid and DI water are both filtered through a 0.2 µm filter to remove any particulates

from the fluid before circulating through the system. Fluidic levels are monitored by the software

using a weight measurement system. Below each fluidic container is a bulk fluidics tray. Each

tray contains a sensor that translates volume weight into fluidic run time and helps to keep the

system dry while swapping fluidics.

IMPORTANT! Replace filter cartridges on a regular basis. Filter replacement is part

of the annual service preventative maintenance visit. For additional information, refer

to Chapter 10, Maintenance.

2.2.2 Loading Stage

The loading stage consists of two functional stations; sample input and washing. The sample

input station is located in the front position of the loading stage and it supports a 5 ml,

12 x 75 mm tube (Figure 5).

Note: Polypopylene tubes for sample acquisition are recommended, but not required.

When a sample is loaded and ready to run, the loading stage can be moved into the run position.

To move the loading stage into the run position:

1. Push the handle on the loading stage down.

2. Push the loading stage inward.

3. Gently raise the loading stage into the run position.

The locking mechanism automatically engages when the tube is in the run position (Figure 6).

After the tube is locked, the entire sample chamber is pressurized and a short pressure boost is

applied to push the sample to the nozzle. After the boost, the sample line is pinched to prevent

sample flow until acquisition or sorting is selected in the software.

Fig. 6. Loading stage in the run position.Fig. 5. Loading stage in the wash position.

The washing station is located in the back of the loading stage and is not accessible to users.

When the sample input station is accessible, the washing station is automatically engaged.

The washing station is used during startup, shutdown, and in between samples. This will help

to reduce carryover since the sample line is cleared and the outside of the line is washed. The

loading stage is locked in position while washing and sampling.

6 | S3 and S3e Cell Sorters

Page 17

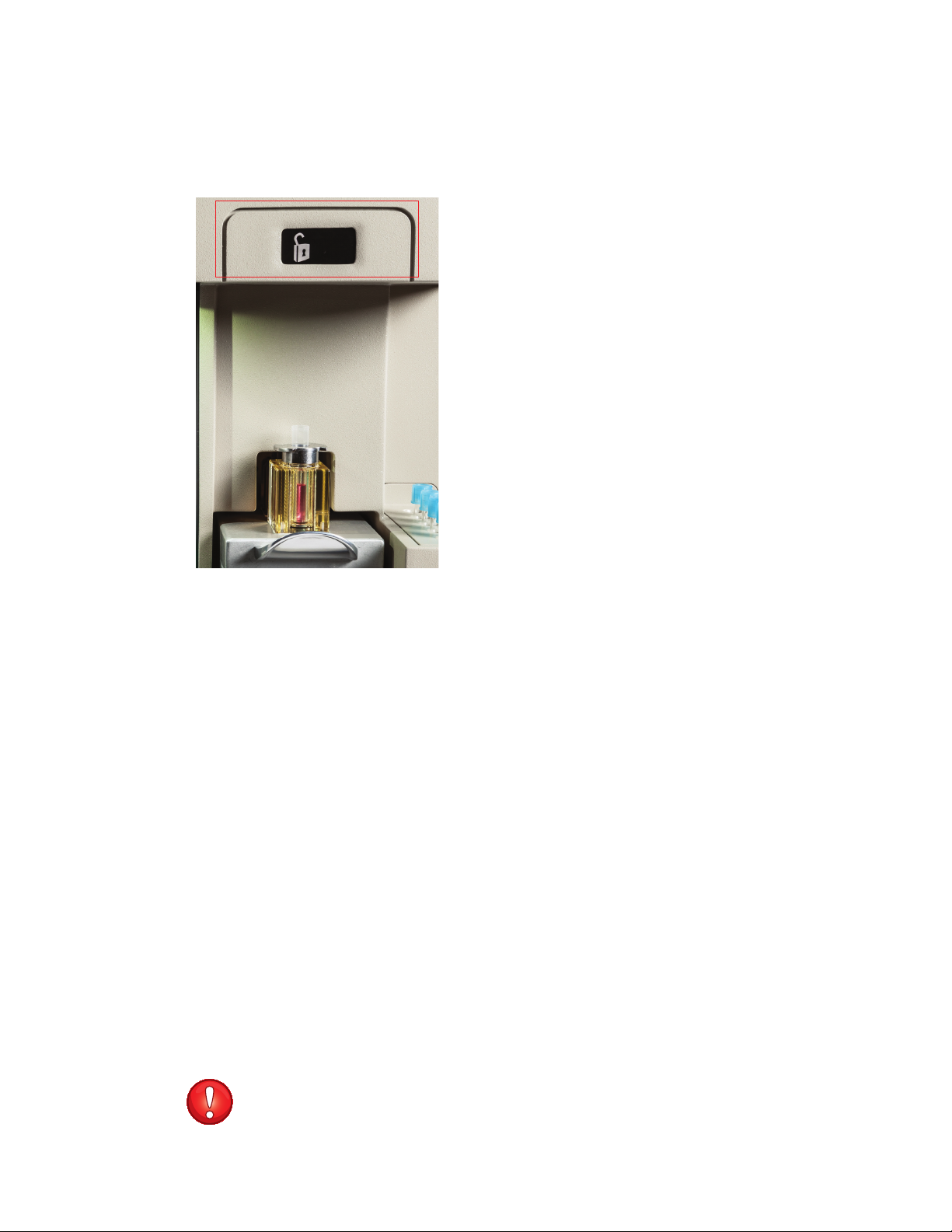

2.2 Fluidics System

During washing, a new sample can be loaded into the sample input station. The status of

the loading stage is displayed by a locked or unlocked padlock symbol located on the touch

locking system screen (Figure 7).

Fig. 7. Touch locking system screen.

To move the loading stage from the run position to the wash position:

1. Press the touch locking system screen until the padlock displays as unlocked. This will

depressurize and unlock the sample station.

2. Push the loading stage handle down, pull forward, and lift up.

WARNING! The loading stage uses a spring to push up into the run or wash position. To prevent

the loading stage from over-springing into position and possibly damaging the instrument,

guide the loading stage into the run or wash position by holding onto the handle for a smooth

movement into position.

Note: If the loading stage is in the wash position and another wash is required, press the touch

locking system screen to perform washing again.

The temperature of the sample input station and the sort tube holder can be controlled from the

ProSort Software via a single Peltier solid state system. The temperature range can be set from

4–37ºC in 1ºC intervals.

The sample input station is capable of mixing the sample. Sample mixing is performed by

vortexing. Users can set the vortexing speed to high, low, or off, depending on the sample type.

Note: It is recommended that resuspended adherent samples are mixed at the high speed to

prevent clumping.

IMPORTANT! It is highly recommended that samples are filtered prior to running. This

will minimize clogs in the sample tube and nozzle tip.

Instruction Manual | 7

Page 18

Hardware Description

2.2.3 Nozzle

The nozzle controls many crucial aspects associated with sorting such as:

n

Creating a stable vibration to generate droplets

n

Hydrodynamically focusing the sample

n

Removing air from the nozzle (debubbling)

The nozzle compartment (Figure 8) can be accessed through the top, front sliding door. The

nozzle tip is a 100 µm orifice for centering the sheath stream to the laser interrogation point. The

tip may be removed for cleaning or to remove a clog from the nozzle stage.

Note: If the nozzle door is opened, lasers will be shuttered, sample will be stopped, and the

stream will be disabled.

IMPORTANT! Refer to Chapter 10, Maintenance, for a detailed procedure on

removal, cleaning, and replacement of the nozzle assembly and nozzle tip. This is

performed using the Swap Nozzle Tip wizard.

CAUTION! Shock hazard! The nozzle door is interlocked and will disable stream

charge when opened. Only qualified and trained personnel can override this interlock.

A B

Fig. 8. Nozzle compartment containing the nozzle stage. A, Agilis System; B, AutoGimbal System.

2.2.4 Sort Collection Chamber

The deflection plates are located in the sort collection chamber (Figure 9). When these plates

are electrostatically charged they direct the sorted droplets into the appropriate tubes. These

plates should remain clean and dry for optimal deflection.

IMPORTANT! Both plates should be cleaned on a regular basis. If a significant

amount of sheath fluid builds up on the plates due to a clog or misalignment, arcing

between the plates can occur. When arcing is sensed by the system’s electronics, the

plates will be disabled and a message will appear in the software. Using a cotton

swab, clean the plates and remove any stray fluid before attempting to sort.

Sorted samples can be collected into three collection vessels listed below.

n

1.5 ml tubes

n

5 ml tubes, 12 x 75 mm

8 | S3 and S3e Cell Sorters

n

8-well strips

n

Microscope glass slides

Page 19

Deflection plates

Fig. 9. Sort collection chamber and deflection plates.

2.3 Optics

The sort positions for each collection vessel are numbered and will correlate to the position

numbering in the software when the sort logic and limits are set. When placing tubes in the

sort chamber for sorting, it is recommended to add media or buffer to the tube to help prevent

sorted cells from drying out and to cushion their collection. The minimum recommended

volume is 0.5 ml of media or buffer for each 5 ml tube. Quick-attaching adaptors are available

for the 8-well strips or microscope slides. Adaptors are part of the accessory kit and they can

be kept inside the fluidics door for storage.

2.3 Optics

The S3 and S3e optics include the laser(s), mirrors, filters, and lenses, which guide the laser

light to the stream of sample and collect scattered and emitted light for detection.

CAUTION! Biohazard! When running samples and sorting, hazardous aerosols may be

created depending on the sample type. To prevent hazardous aerosols from spreading,

keep the green containment door closed as often as possible. Consult with your local

safety officer or review local, state, and federal regulations to ensure proper handling and

disposal of biohazardous substances including samples, sorted fractions, and waste.

CAUTION! Shock hazard! The sort deflection plates in the sort chamber are

charged while sorting. An interlock on the sort chamber door will disable the plates

when opened. Only qualified personnel should override this interlock.

CAUTION! Laser hazard! Laser radiation can be hazardous. Please do not override

optical interlocks or remove light shields, as they are in place for your safety. Only

trained personnel should access the exposed laser beam.

2.3.1 Laser

The S3 and S3e Cell Sorters are installed with a 488 nm, 100 mW laser for cell and particle

interrogation that passes through the system in the sample core. The laser power and shutter

can be controlled through the software interface. An optional 561 nm or 640 nm 100 mW laser

are available as a second excitation source.

Instruction Manual | 9

Page 20

Hardware Description

2.3.2 Beam Shaping Optic (BSO)

The beam shaping optic sits in between the laser(s) and the interrogation point. This serves to

shape and focus the laser beam(s) to optimize the illumination of the cell.

2.3.3 Interrogation

The interrogation point is the point at which the laser beam(s) intercepts the core stream of

the sample. At this point, light is scattered around each individual particle and the particle

fluoresces if any fluorophores are attached.

2.3.4 Light Collection

Light is collected from two directions, forward and side angle. The light can be categorized into

two types — scattered and fluorescent. Scattered light refers to the wavelength of light coming

from the laser, which is scattered when a particle is encountered. Fluorescent light refers to the

light emitted by the fluorophores or dyes attached to the particle or cell after excitation from the

laser. This emitted light is of a higher wavelength than the excitation light and therefore can be

separated and detected using optical filters.

2.3.5 Forward Scatter

Light coming around the particle in the forward direction (same plane as the laser beam) is

collected to give an indication of particle size. By default, the scattered laser light is collected,

but fluorescent light could be collected by changing the filter.

2.3.6 Optical Filters

Optical filters are coated pieces of glass used to divide the spectrum of light into bands for

analysis. By separating and detecting different bands of light, it is possible to understand

multiple properties of each particle.

IMPORTANT! When removing or replacing filters, wear gloves to avoid depositing

smudges and fingerprints on the glass surfaces. Please see Section 10.5, Optical

Filter Cleaning, for specific instructions on cleaning optical filters.

2.3.7 Photomultiplier Tubes (PMTs)

The PMTs are used to detect and amplify the light signals coming from each particle. They are

located behind the optical filters to detect specific bands of light based on the fluorophores that

are attached to the cell.

2.3.8 Cameras

The S3 and S3e Cell Sorters contain several cameras for system alignment and calibration. The

function of each of these cameras is detailed below.

Note: Cameras do not require adjustments by users.

n

Pinhole camera — aligns the stream and laser to the optical detection path. This camera is

viewable only by service personnel and during the nozzle tip swap process

n

Droplet camera — calibrates the droplets and maintains the drop delay. The image of the

break-off can be visualized in the software through the Droplet Monitor option on the home tab

n

Streams camera — calibrates the side streams and aligns them with the collection tubes. This

camera can be visualized in the software through the View Streams option on the home tab

10 | S3 and S3e Cell Sor ters

Page 21

2.4 Electronics

The S3 and S3e electronics process and deliver the emitted light signals to the software for

user analysis. Also included in this subsystem are the deflection plates in the sort chamber and

the safety interlocks.

CAUTION! Shock hazard! Only qualified, trained technicians should carry out

service work on electronic components due to potential shock hazard.

2.4.1 Interlocks

To prevent exposure to laser light and shock hazards, the S3 and S3e systems are equipped

with safety interlocks (Figure 10). On the instrument control panel of the software, the

instrument status box will show visual indicators if these interlocks have been disengaged.

Note: When opened, the nozzle door will close the laser shutters to prevent laser light

exposure. This interlock will also turn off the drop drive and the stream.

IMPORTANT! Open this door only if required to clear a clog or change the nozzle tip.

The QC procedure must be repeated to readjust the alignment and reset the drop

delay if this door is opened.

2.4 Electronics

The sort door interlock will disable the plate voltage. In addition, if sample is running it will

be stopped.

Fig. 10. S3 and S3e safety interlocks.

2.4.2 Pre-Amplifier

The pre-amplifiers are used to boost the signal coming from the PMT.

Laser shutter interlock

Sort door interlock

2.4.3 ADCs

Analog to digital converters (ADCs) convert the electrical signal coming from the pre-amplifier

into a digital signal and transfer that signal to the software for visualization of the data.

Instruction Manual | 11

Page 22

12 | S3 and S3e Cell Sorters

Page 23

3

ProSort™ Software

This chapter describes the features of the ProSort Software. The software is the main interface

for the S3™ or S3e™ Cell Sorter System, giving overall status and providing control.

To start the software, double click the ProSort icon (Figure 11) on the desktop.

Fig. 11. ProSort Sof tware icon.

The login window will appear (Figure 12). This window will also appear when switching users.

Enter your user name and password to log in. Session notes may be added and will be logged

with the user session in the user report for administrative use. These notes will appear in the

user report when viewed.

Note: If an automatic startup has been scheduled, the login and startup windows will appear

different. Please refer to Chapter 9, Automatic Startup for details.

Fig. 12. User login window.

ProSort offers two modes of user control, administrator and user. The administrator mode

provides additional control and access over user mode. Differences between the two modes

are shown in Table 7. For more information on administrator privileges, refer to Section 3.3,

Administrator Tab Toolbar.

Instruction Manual | 13

Page 24

ProSort Software

Table 7. Control differences between administration and user modes.

Control Administrator User

Startup • •

Shutdown • •

RunQC • •

PrintQCreports • •

PrintQCtrendingreports • •

EditQCcriteria •

Viewdroplets • •

Viewdropletsettings • •

Editdropletsettings •

Viewstreamscamera • •

Editstreamsettings •

Acquisition • •

Sort • •

Printanalysisreports • •

Printsortreports • •

Printuserreports •

Changeuserpassword • •

Changeuserrights •

Deleteusers •

Createusers •

Editusers •

Resetotheruserpasswords •

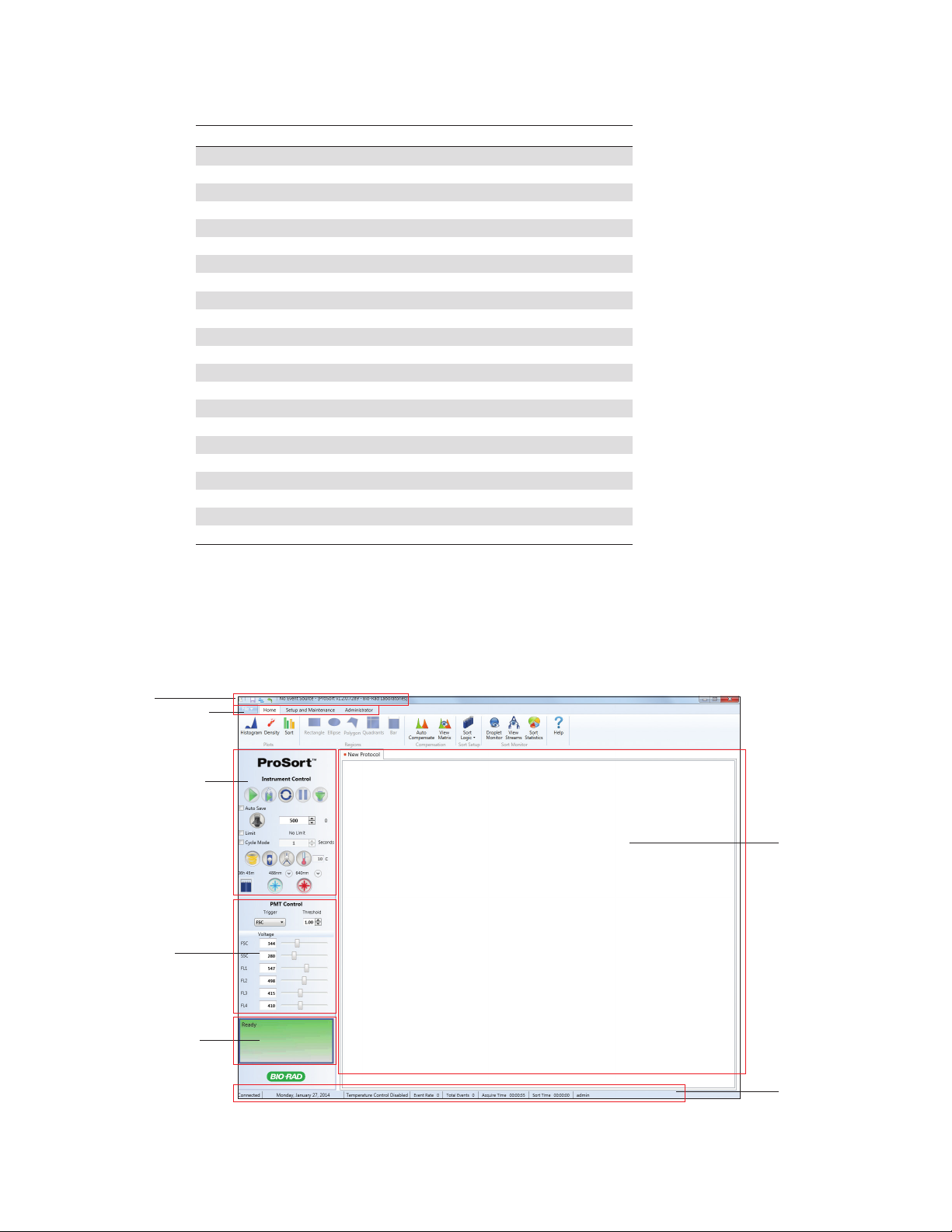

3.1 Main Software Window

The main software window contains tools for system operation and data analysis. Depending

on user control mode, the main software window will either display more or fewer features.

Features available in the main software window for user mode are shown in Figure 13.

Title bar

File menu and tabs

Instrument control

PMT control

Instrument status

box

Workspace

Fig. 13. Main software window for user mode.

14 | S3 and S3e Cell Sorters

Status bar

Page 25

3.1.1 Title Bar Buttons

The title bar of the main software window provides the items listed in Table 8.

Table 8. Title bar buttons in the main software window.

Button Command Function

Save Saves FCS file after acquiring sample

Sign out/ Signs out the current user and returns the software to the login window. If

Switch user the shutdown procedure was not performed prior to sign out, the system will

Undo Certain commands can be undone and reverted to the previously existing

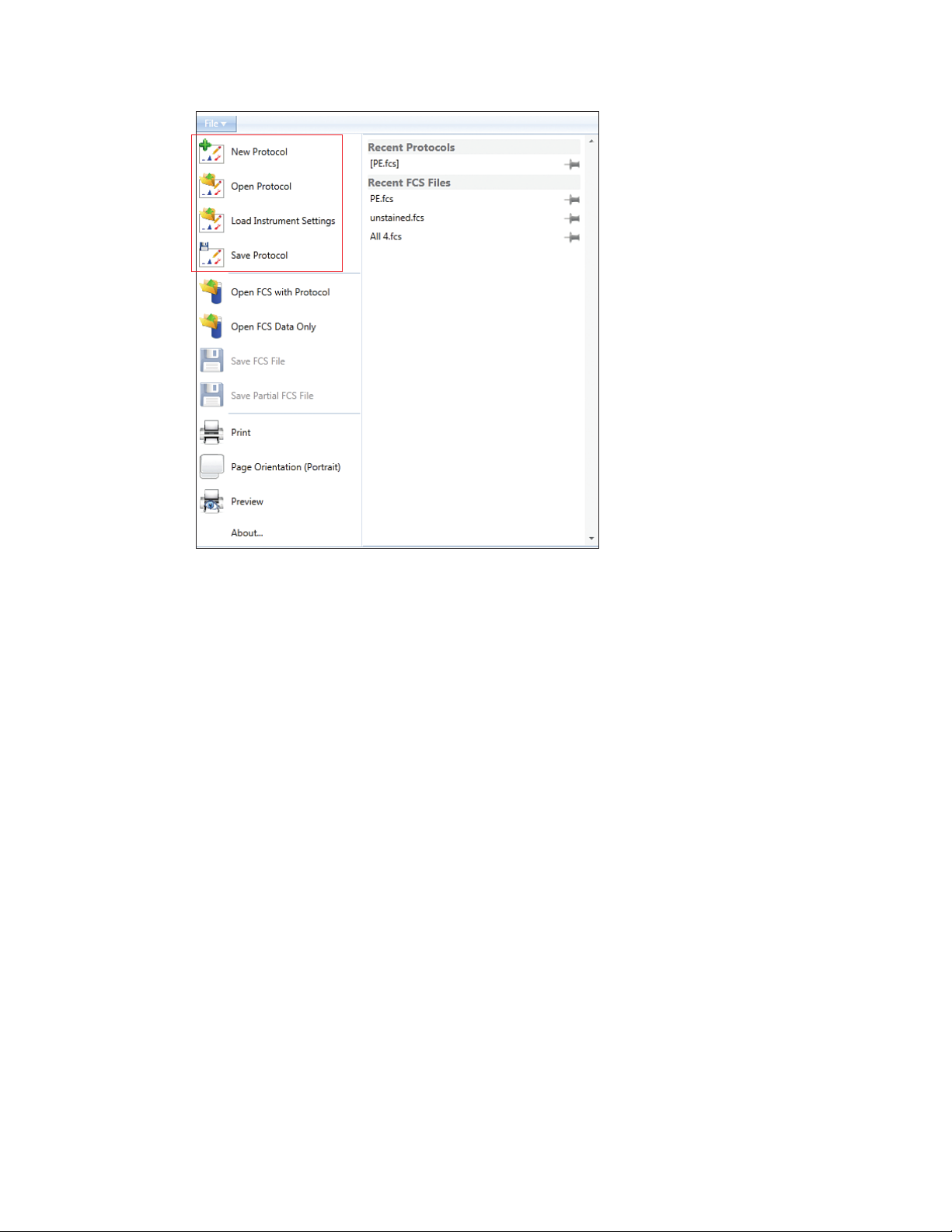

3.1.2 File Menu

The dropdown file menu provides the items listed in Table 9.

Table 9. File menu buttons and their function.

Button Command Function

3.1 Main Software Window

maintain startup and QC. The next user will need to log in to start a new run

state. Examples of functions that can be undone are: deleted region, deleted

gate, deleted histogram or density plot, moved region or gate, creation of a

plot or region, compensation adjustment

New protocol Opens a new protocol tab in the workspace

Open protocol Opens an existing protocol. An FCS file may also be selected at this time. The

protocol used to acquire the data will be loaded from the FCS file

Load instrument Opens an existing protocol’s settings and loads them into the current protocol.

settings The current protocol must be saved

Save protocol Saves the current protocol

Open FCS with Opens FCS file and will load data into the embedded protocol. All contents of

protocol the protocol (such as plots, regions, sort logic, notes) will be displayed

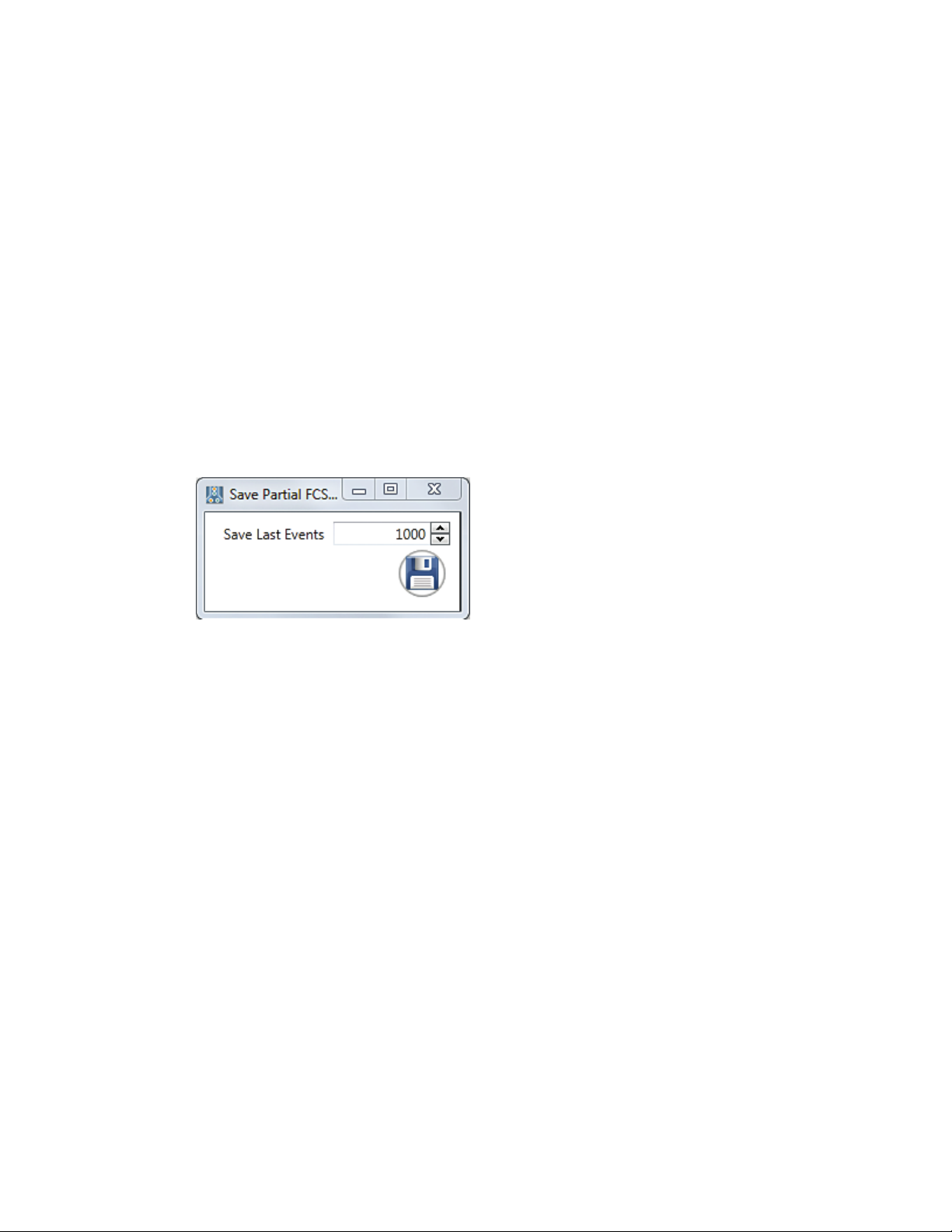

Save FCS file Saves the current FCS file

Save partial Saves the last user defined number of events from the acquired sample. The

FCS file number of events to be saved is entered by the user before saving the file

Print Opens the print window.

Note: Use the print preview option to see where page breaks occur

Page orientation Changes between a printable landscape or portrait workspace

Preview Opens the print preview window

number, serial number, etc.)

Recent Protocols

protocols for the

Recent F CS File s

files for the user

About Displays software information (software, hardware, firmware version

About...

List of recent Lists the recent protocols used by the logged-in user

user that is logged in.

List of recent FCS Lists the recent FCS files used by the logged-in user

that is logged in.

Instruction Manual | 15

Page 26

ProSort Software

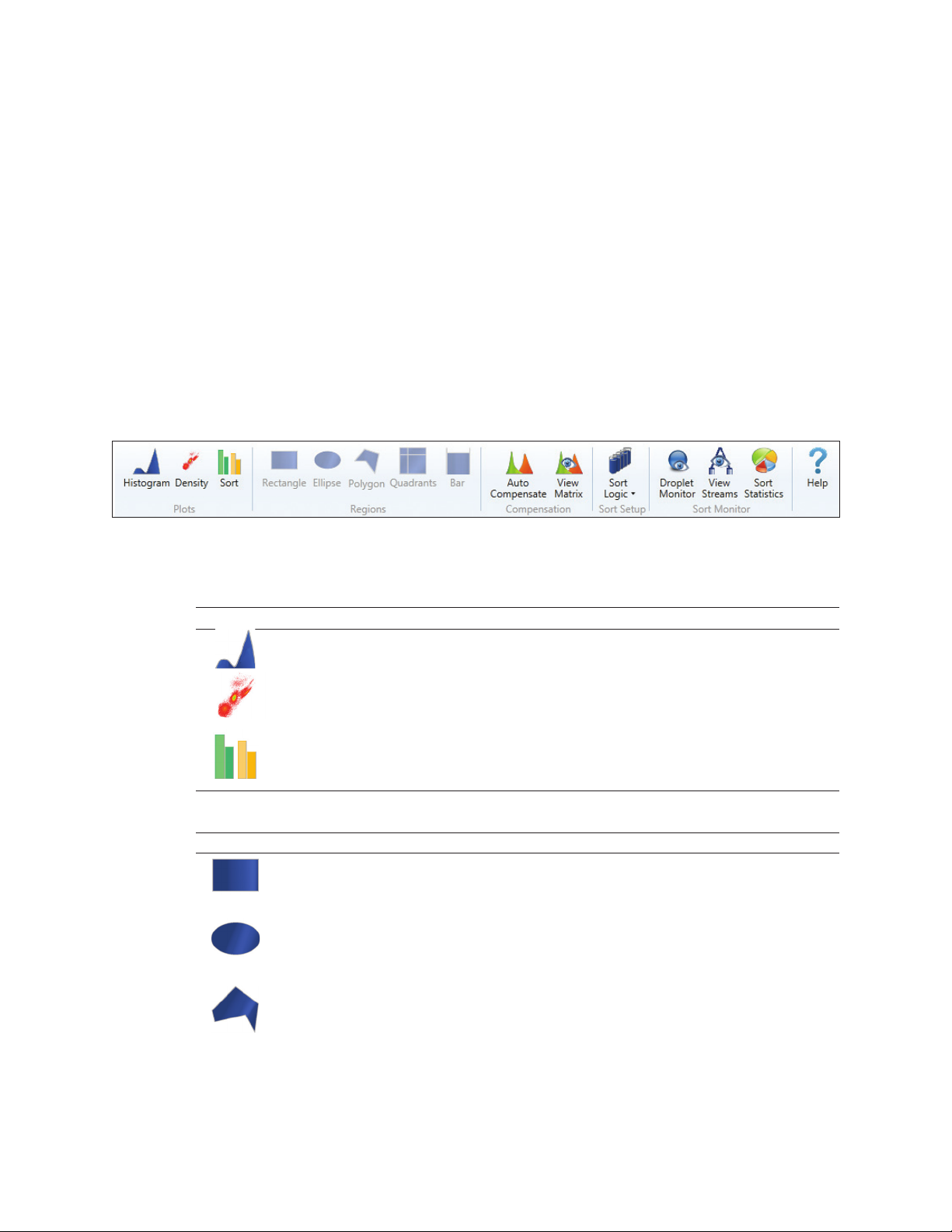

3.1.3 Home Tab Toolbar

The Home tab toolbar consist of six sections for basic workspace functions and sort options

(Figure 14):

n

Plots — available plots for viewing data. Table 10 describes the plots and their functions

n

Regions — different shapes for selecting region of interest. Table 11 describes the regions

and their functions

n

Compensation — perform fluorescence compensation. Table 12 describes the

compensation buttons and their functions

n

Sort Setup — collection vessel and sort logic criteria for a run. Table 13 describes the sort

setup buttons and their functions

n

Sort Monitor — monitor the sort of a run. Table 14 describes the sort monitor buttons and

their functions

n

Help — opens the user manual in PDF format

Fig. 14. Home tab toolbar.

Table 10. Plot buttons and their functions.

Button Name Function

Histogram Adds a new histogram to the current protocol. The histogram can be resized

by dragging the bottom right corner

Density Adds a new density plot to the current protocol. The density plot can be

resized by dragging the bottom right corner

Sort Adds a sort plot to the current protocol. The sor t plot can be resized by

dragging the bottom corner. The sort plot graphically shows the sorts and

aborts in each sort position.

Table 11. Region buttons and their functions.

Button Name Function

Rectangle Adds a rectangular region to the selected density plot. If a density plot is not

selected, this region will be grayed out. The region can be moved, resized,

rotated, and/or deleted

Ellipse Adds an ellipse region to the selected density plot. If a density plot is not

selected, this region will be grayed out. The region can be moved, resized,

rotated, and/or deleted

Polygon Adds a polygon region to the selected density plot. If a density plot is not

Select each desired point and move the mouse cursor outside the density plot

16 | S3 and S3e Cell Sorters

selected, this region will be grayed out

to complete. The region can be moved, resized, and/or deleted

continues

Page 27

3.1 Main Software Window

Table 11. Region buttons and their functions (continued).

Button Name Function

Quadrant Adds a quadrant region to the selected density plot. If a density plot is not selected,

this region will be grayed out. The region can be moved, resized, and/or deleted

Bar Adds a bar region to the selected histogram. If a histogram is not selected, this region

will be grayed out. The region can be moved, resized, and/or deleted

Table 12. Compensation buttons and their functions.

Button Name Function

Auto Opens the Automatic Compensation Calculation Wizard window. This wizard will

Compensation assist in establishing the proper compensation matrix coefficients. Single control

FCS files must be acquired and saved prior to using this feature.

View Matrix Opens the Compensation Matrix window. Users can view and edit the compensation

matrix in this window

Table 13. Sor t Setup buttons and their functions.

Button Command Function

Sort Logic Opens the Sort Logic window. By default, 5 ml tube is selected for the Sort Logic

window. Users can click on the Sort Logic dropdown arrow to select 1.5 ml tube,

8-well strip, or glass slide

5 ml tube Indicates that 5 ml tube is selected as the collection vessel. Individual mode and

limits may be set for each 5 ml tube in each direction

1.5 ml tube Indicates that 1.5 ml tube is selected as the collection vessel. Individual mode and

limits may be set for each 1.5 ml tube in each direction

8-well strip Indicates that 8-well strip is selected as the collection vessel. Sort limits or mode can

be set for each well in an 8-well strip

Glass slide Indicates that glass slide is selected as the collection vessel. Sort limits or mode can

be set for each microscope slide. A maximum of 500 events can be sorted onto each

location on the slide

Table 14. Sort Monitor and help buttons and their functions.

Button Name Function

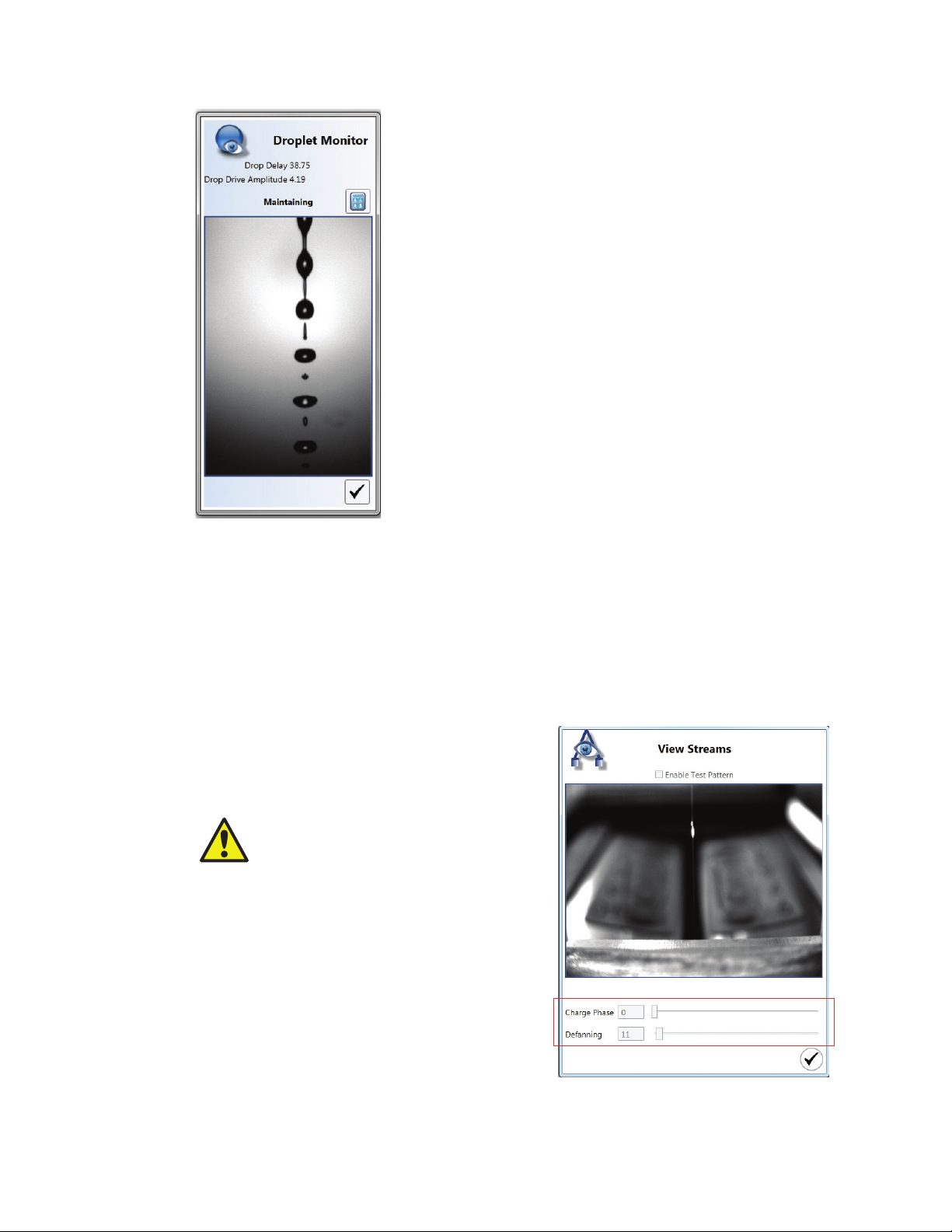

Droplet Monitor Opens the Droplet Monitor window. Droplets will be visible in this window after

performing a QC procedure. The status of droplet maintenance is shown in this window.

The currently set drop delay and drop drive amplitude are also shown in this window

View Streams Opens the View Streams window. This camera shows the sort streams at a point just

above the collection vessel

Sor t Statistics Opens the Sort Statistics window. The window displays sort count, sort rate,

percentage abort count, rate and %, efficiency, etc. Sort Statistics can be added to the

print window for reporting. This window will open automatically when a sort is started

Help Opens a PDF file of the user manual as a reference

Instruction Manual | 17

Page 28

ProSort Software

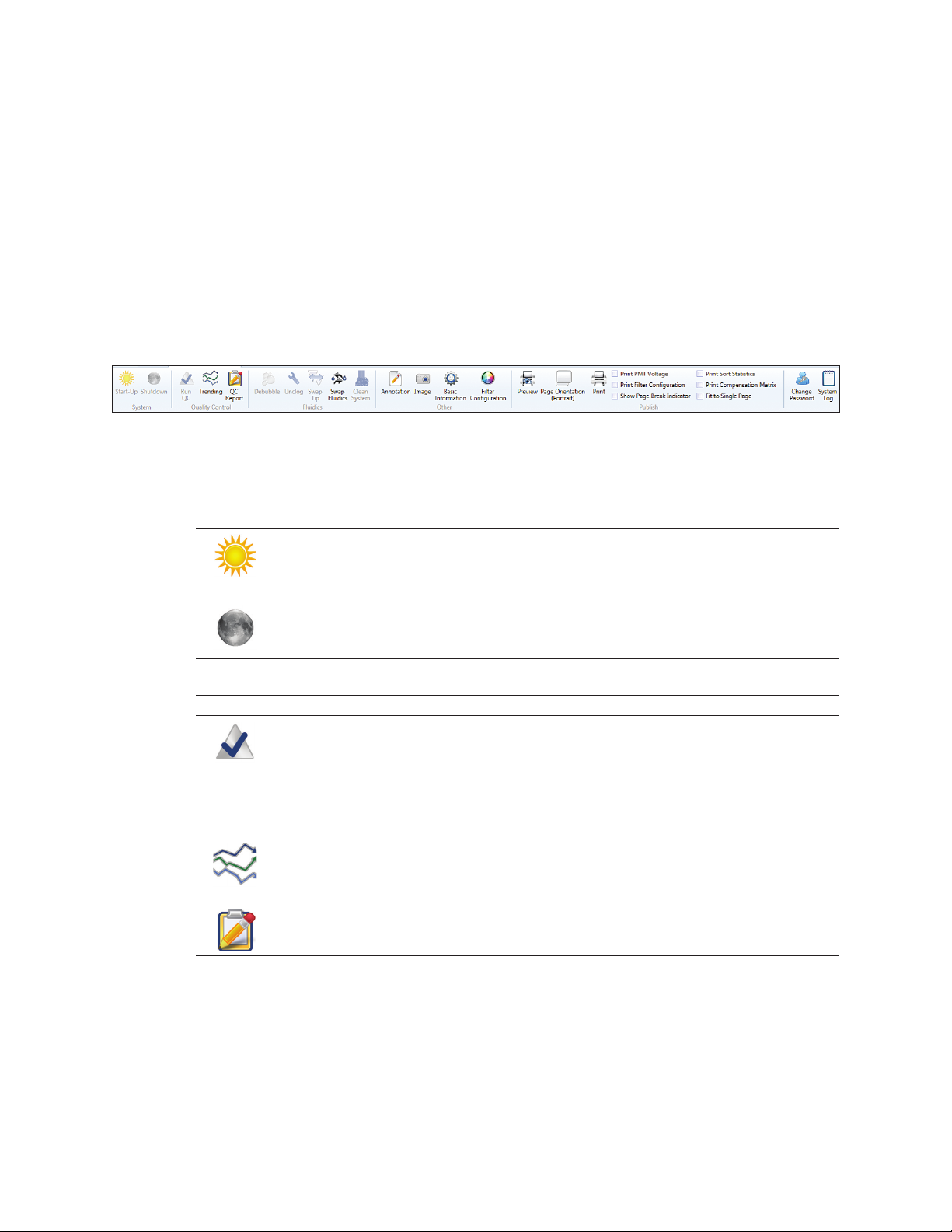

3.1.4 Setup and Maintenance Tab Toolbar

The Setup and Maintenance tab toolbar consists of five sections (Figure 15):

n

System — startup or shutdown the instrument from the software. Table 15 describes the

system buttons and their functions

n

Quality Control (QC) — perform or review QC runs. Table 16 describes the QC buttons and

their functions

n

Fluidics — access common fluidic functions. Table 17 describes the buttons and their functions

n

Other — additional features. Table 18 describes the additional features and their functions

n

Publish — features for supporting publications. Table 19 describes the publish features and

their functions as well as the toolbar’s remaining user buttons and their functions

Fig. 15. Setup and maintenance tab toolbar.

Table 15. System buttons and their functions.

Button Name Function

Start-Up Starts up the system by starting the sheath flow, turning on the laser(s), and

backflushing the sample line

Use this button to start up the system if auto startup has not been selected

Shutdown Shuts down the system. The shutdown button is not active unless the loading

stage is in the wash position. The shutdown button will prompt to clean system

and schedule an auto startup

Table 16. Quality control buttons and their functions.

Button Name Function

Run QC The daily QC procedure ensures optimal system performance and should

be completed every day prior to running samples. The procedure consists of

placing a tube of ProLine

break-off, setting up side streams, adjusting event rate, aligning nozzle,

adjusting PMTs, checking the coefficient of variation (CVs) and voltages,

calculating drop delay, and placing the system in droplet monitor mode. The

progress of this procedure will be displayed on screen

Trending Daily QC data are compiled into trending reports. These reports show trending of

CVs, PMT voltages, drop delays, etc. over a range of dates. This date range may

be selected in the report screen. These reports may be saved and/or printed

QC Report This button shows and allows saving and/or printing of the daily QC report.

This report includes date, user, CV/PMT/droplet info, etc

™

calibration beads on the system, setting the droplet

18 | S3 and S3e Cell Sorters

Page 29

3.1 Main Software Window

Table 17. Fluidics buttons and their functions.

Button Name Function

Debubble Removes bubbles from nozzle

Unclog Allows user to pull vacuum in the case of a nozzle clog. Use this option before

removing the tip for sonication or replacing with a new nozzle tip

Swap Tip Stops the sheath flow to allow nozzle tip replacement. A wizard will appear to

walk the user through a nozzle change. Once the tip has been replaced, QC

needs to be rerun to verify alignment and set the drop delay

Swap Fluidics Allows fluidic containers to be swapped without shutting the system down.

Prepare a full replacement or empty container prior to pressing this button, as

a three-minute timer starts after the button is pressed

Clean Cleaning can be done at low or high pressure. High pressure cleaning will cause

the system to stop maintaining droplets and a QC procedure must be run before

sorting. If cleaning between samples, the low pressure option is recommended

Table 18. Other buttons and their functions.

Button Name Function

Annotation Adds an annotation window to the workspace. Annotations added prior to

saving will be saved to the FCS file’s embedded protocol

Image Allows an image to be added to the workspace. The image can be moved

or deleted. If added prior to saving, this image will be saved to the FCS file’s

embedded protocol

Basic Adds basic information to the print page in the form of a header. This information

Information includes date, time, user login, serial number, filename, event source. If added

prior to saving, this information will be saved to the FCS file’s embedded protocol

Filter Configuration Adds the optical layout to the print page showing PMT and optical filter setup.

This can be modified to match the actual filters if they have been changed. If

added prior to saving, this will be saved to the FCS file’s embedded protocol

Table 19. Publish and user buttons and their functions.

Button Name Function

Preview Displays a preview of the page layout(s) setup prior to printing

Page Orientation Changes between a printable landscape or portrait workspace

Print Opens the print dialog to select printer, number of copies, etc. and print.

Note: Use the print preview option to see where page breaks occur

Print Options Adds additional windows or instrument settings to the page layout for printing.

Change Password Allows the currently logged-in user to change password

System Log Opens window for system log. Displays date, time, error, error details. This

option is helpful when working with technical support and service engineers

for troubleshooting

Instruction Manual | 19

Page 30

ProSort Software

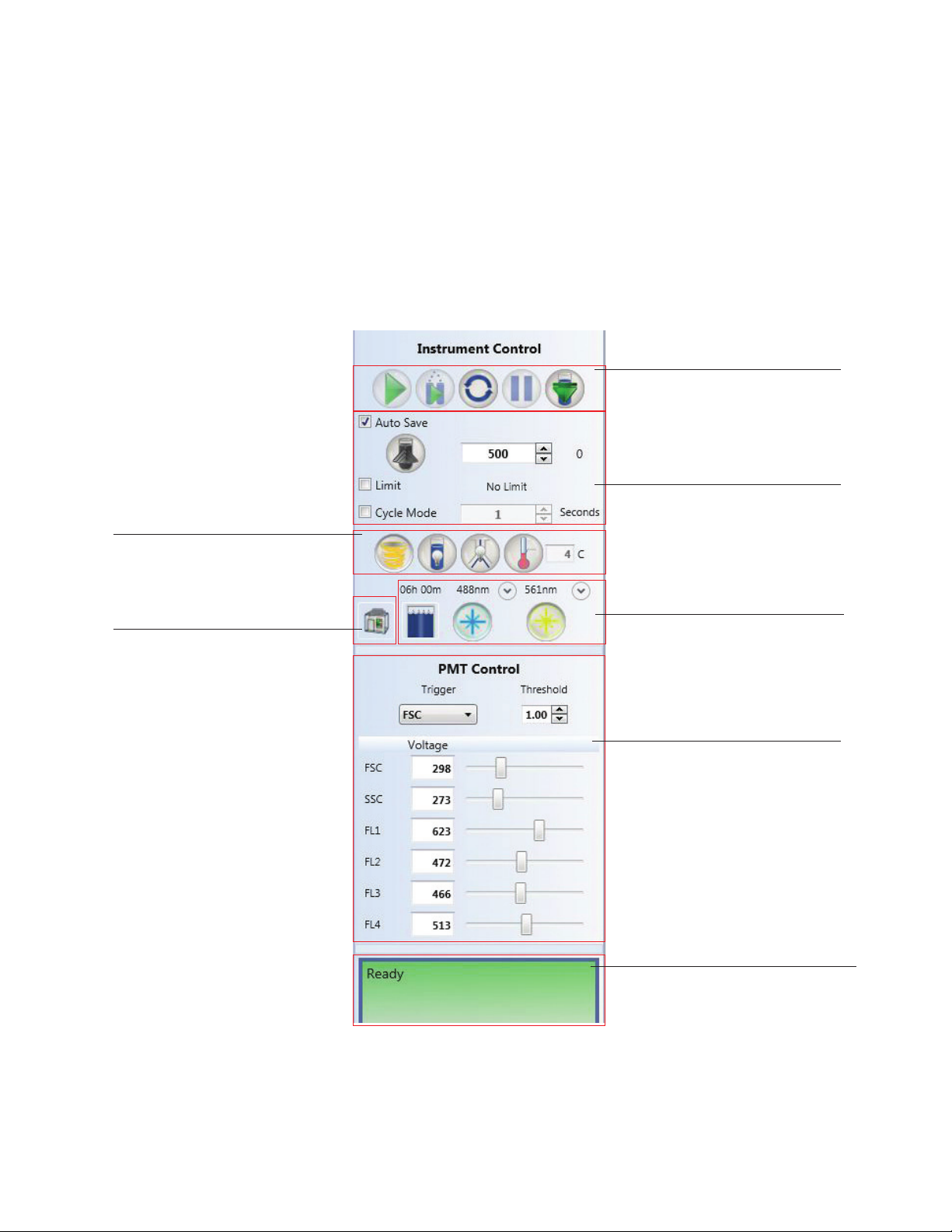

3.2 Control Panel

System operation is performed and monitored with the control panel (Figure 16). The control

panel consists of three parts:

n

Instrument control — controls for performing a run

n

PMT control — controls for modifying the PMTs

n

Instrument status box — displays the status of your instrument

Instrument control buttons are described in Table 20 and PMT control buttons are described in

Table 21.

Sample agitation high/low button

Sample station light on/off button

Sample collection area light on/off button

Temperature control on/off button

Temperature control option

Biosafety System serial number

Biosafety System firmware version

Biosafety System status

Time remaining on filter life

Temperature inside the system

Start/Stop acquisition button

Start/Stop sort button

Refresh data button

Pause/Restart sample acquisition

button

Eject sample tube button

Auto save sample upon reaching limit

Preset sample event rate button

Enter sample event rate

Event limit option

Cycle mode option

Gate limit option

Time remaining with fluidic volume

Fluidics Status window button

Laser on/off button

Laser power options

Fig. 16. Overview of instrument and PMT control panel.

20 | S3 and S3e Cell Sorters

Trigger channel

Threshold value

Alter PMT voltages

Assign values for detection channels

Instrument status box

Indicator of actions required or

needing attention

Page 31

3.2 Control Panel

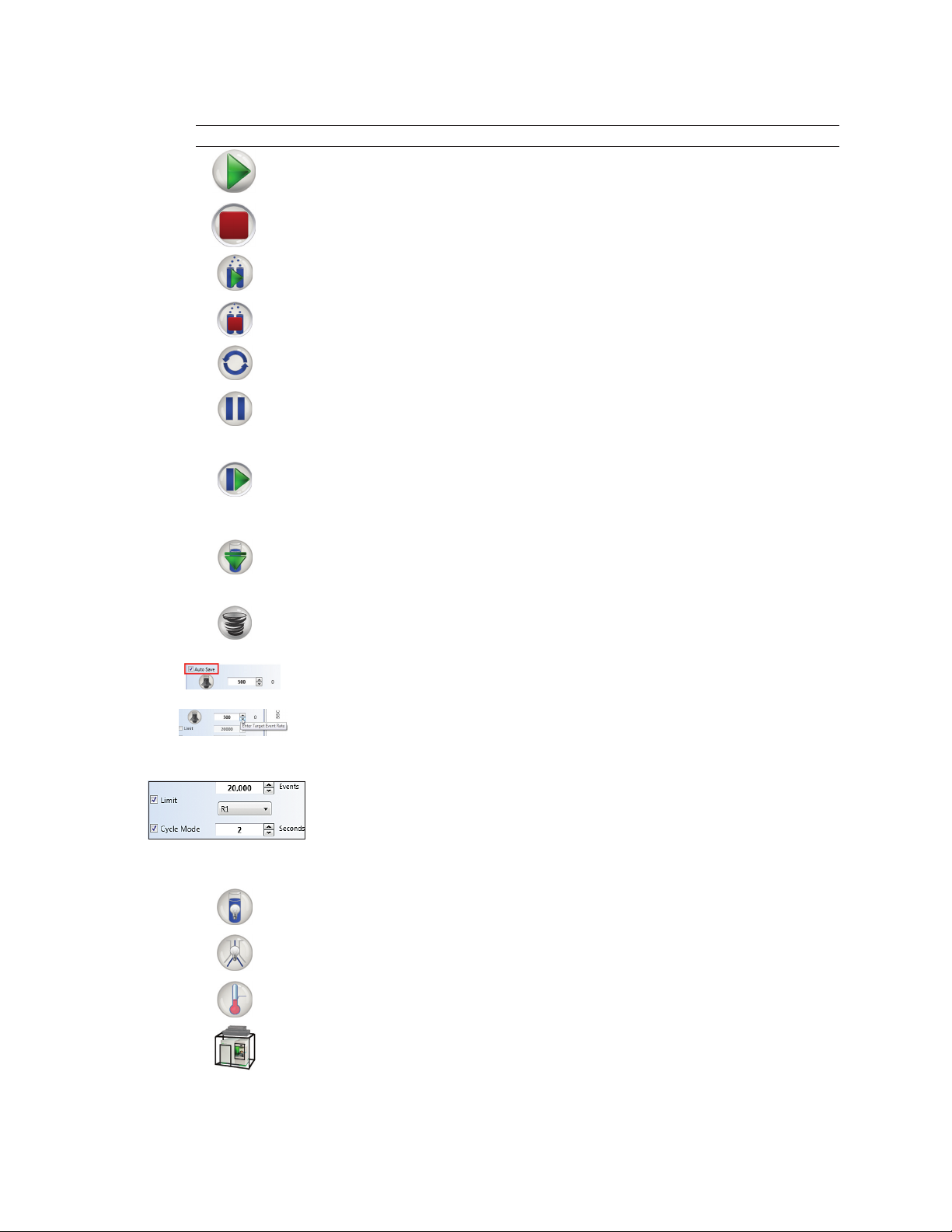

Table 20. Instrument controls and their functions.

Button Name Function

Start Sample Starts sample acquisition. If a data file is loaded and it has been saved,

Acquisition the data will clear and acquisition will start

Stop Sample Stops acquisition and sample flow. Regions, gates, and annotations may

Acquisition be modified before saving the FCS file

Start Sorting Starts sorting. If a data file is loaded and it has been saved, the data will

clear and sorting will start

Stop Sorting Stops sorting and sample flow. Regions, gates, and annotations may be

modified before saving the FCS file

Clear Acquired Data Clears acquired data. All plots and statistics will be refreshed.

Pause Sample Pauses sample acquisition and sample flow. The data at this point may be

appended (by the Resume function) or saved as is. Saving after pausing will

disable the Resume function. To remove sample tube, unlock the touchscreen

locking system located above the loading stage after pausing acquisition

Resume Sample Resumes acquisition when a sample has been paused. Resuming will

append the paused FCS file and the time paused can be seen on a time

histogram. If you have removed the sample tube it must be returned and

relocked before acquisition can be resumed

Eject Sample Tube Depressurizes and unlocks the sample. The loading stage can be moved

into wash position to access sample. The touchscreen locking system can

also be used to unlock the sample

Adjust Sample Starts or stops agitation of the sample. There are three levels of agitation:

Agitation low, high, and off. Click this button once to set to low, twice to set to high,

and three times to turn off agitation

Auto Save When checked, automatically prompted to save a data file after

acquisition stops.

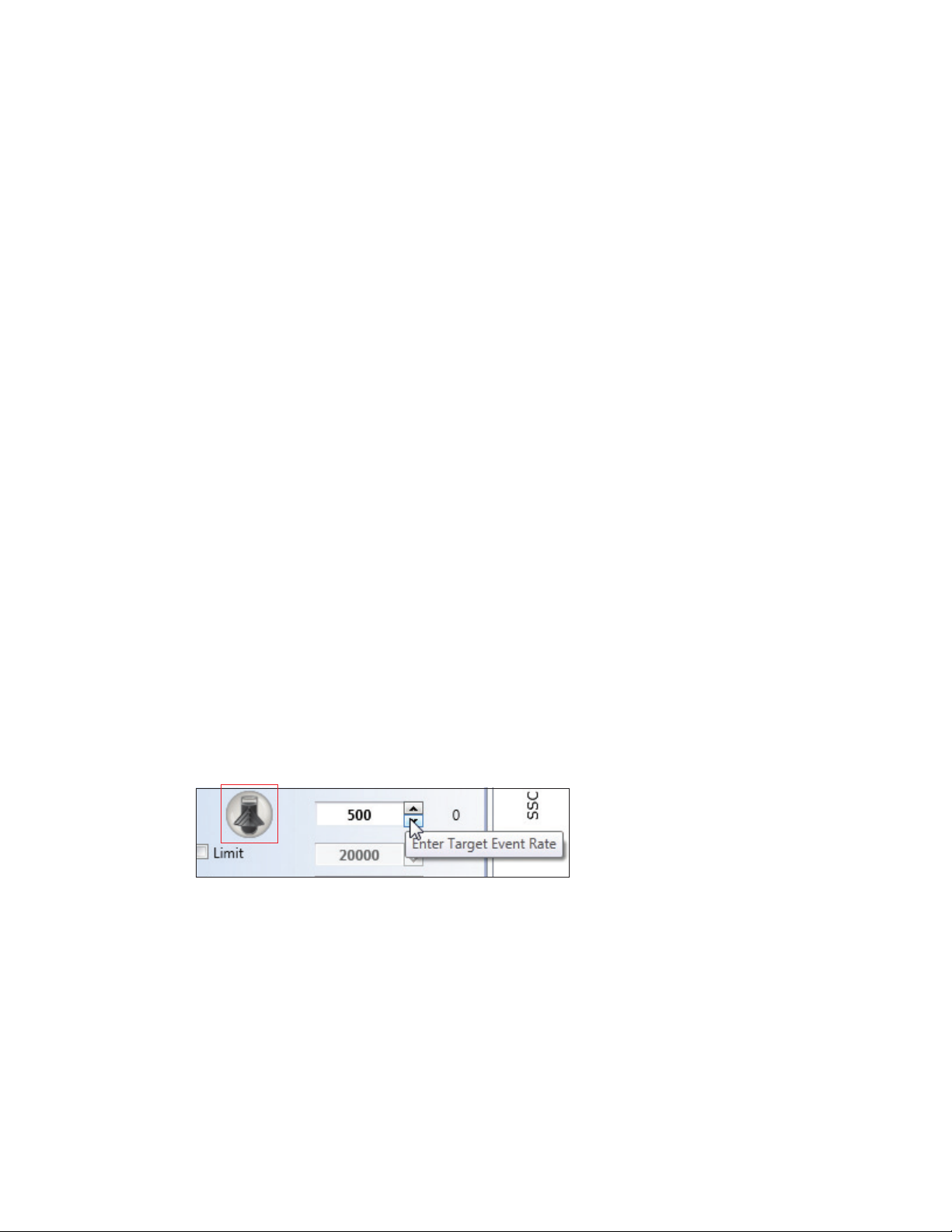

Target Event Rate Allows selection of target event rate for sample acquisition or use of preset

sample rates low/med/high based on sample concentration

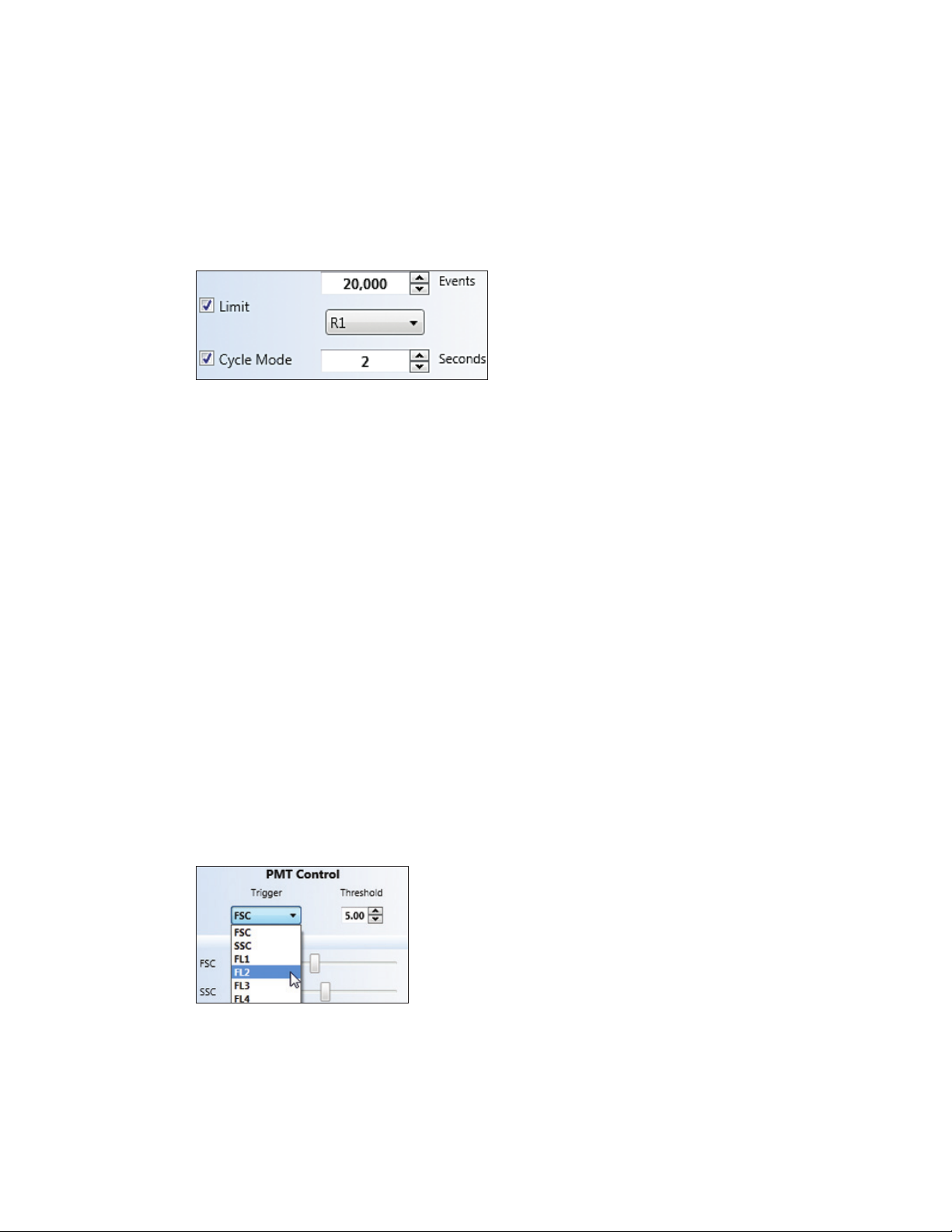

Limit When checked, stops data acquisition after the number of events entered

has been reached

Gate Limit When checked, data acquisition stops after the number of events entered

has been reached within the selected gate

Cycle Mode When checked, automatically refreshes the data displayed according to

the entered time. The acquired data set continues to accumulate in the file

Sample Chamber Turns the sample chamber light on and off

Light

Enable/Disable Sort Illuminates entire sort collection chamber for easy viewing of deflection

Chamber Light plates, sort stream, and collection vessels

Enable/Disable Enables or disables temperature control of the sample station and sort

Temperature Control collection vessel

Biosafet y Indicates the status of the biosafety system and gives information on filter life.

System Status If the biosafety system loses connection, cannot connect, or if the filter life is

at 0% an error will occur and not allow the user to sort or acquire.

continues

Instruction Manual | 21

Page 32

ProSort Software

Table 20. Instrument controls and their functions (continued).

Button Name Function

Fluidics System Indicates the status of the fluidics system and run time information. When

Status the fluidics system is down to an hour of run time, the fluidics status

window will automatically open to show which container needs attention.

If the run time reaches 5 min, the fluidics will automatically shut down

Toggle 488 nm Controls the 488 nm laser shutter. The shutter is interlocked for safety. When

Laser Shutter this button is grayed out, either the laser is off or the interlock is open

Toggle 561 or 640 nm Controls the 561 or 640 nm laser shutter. The shutter is interlocked for safety.

Laser Shutter When this button is grayed out, either the laser is off or the interlock is open

Adjust Laser The dropdown arrows next to each laser adjust the laser power. Actual

mWatt Power power is shown by hovering over the 488 nm, 561 nm, and 640 nm labels

Table 21. PMT controls and their functions.

Button Name Function

Editable The name for each parameter is editable and will be saved with the

parameter acquired FCS data. The edited parameter name will be applied to all

name plot axes, compensation controls, and filter configurations

PMT Voltage Adjusts the PMT voltage for the given detector

Select trigger The trigger parameter is used to alert the system to the presence of

parameter an event over the threshold. The default for this is Forward Scatter

Adjust threshold Threshold is a percentage of the trigger signal. The default value is 1.0%

setting

3.3 Administrator Tab Toolbar

The administrator tab is available only for administrator users. To change a user’s privileges,

refer to Section 3.3.5, Managing Users.

The toolbar for the administrator tab (Figure 17) consists of:

n

System and User Control — edit system controls and manage users

Table 22 describes the buttons in this section.

IMPORTANT! Adjusting any of these settings will impact the overall performance of

the system. Only knowledgeable users should make any changes to these settings.

All changes made here will apply globally to the system.

Fig. 17. Administrator tab toolbar.

22 | S3 and S3e Cell Sorters

Page 33

3.3 Administrator Tab Toolbar

Table 22. Administrator tab toolbar buttons and their functions.

Button Name Function

Edit QC Criteria View and edit the CV and PMT voltage criteria for the quality control

procedure. This may be done as a result of a bead lot change

Edit Droplets Edit the settings for droplet creation. These settings include drop drive amplitude,

drop drive frequency, charge phase, defanning, and drop delay. These settings are

automatically adjusted as part of the QC procedure and will result in sort changes.

These settings are grayed out while the system is maintaining

Edit Streams View sort streams and edit the settings for stream creation. These settings

Settings include deflection, charge plate voltage, defanning, phase, and test pattern

adjustment

Print User Report View usage reports including times, dates, and duration of system use for

all users

Manage Users Create new users, reset passwords for existing users, set rights, and

delete users

Decontaminate Run a decontamination wizard that will walk user through a complete fluidic

system decontamination. This will take approximately 2–3 hr

Calibrate Sample Reset the differential offset sample pressures, which returns the preset

Pressure Offset buttons (low, med, high) to their correct ranges

Global preferences Change global instrument options for sheath concentration used, idle

3.3.1 Editing QC Criteria

An administrator can edit the QC criteria used to pass or fail the instrument during the daily QC.

This should be performed only by an experienced user who has verified system performance.

The rewind arrow on the middle bottom of Edit QC Criteria window will reset the QC criteria to

the factory defaults for the system (Figure 18).

When receiving a new lot of ProLine calibration beads:

1. Download the bead lot file from the S3 or S3e Cell Sorter website,

www.bio-rad.com/cellsorter.

2. Click the green plus button (Figure 18).

3. Navigate to the new bead lot file.

4. Select the file and click Open.

The software will automatically update the QC criteria for the new lot of calibration beads.

Values in red indicate values that are not used for pass/fail criteria for QC. If you plan to enter

the bead lot information manually:

shutdown time limit, and boost adjustment, plot default options and file save

default location

1. Verify the acceptance criteria on the certificate of analysis.

2. Compare the old lot to the new lot.

3. Enter the new lot information into the Edit QC Criteria window.

IMPORTANT! Changes to these criteria will apply globally to the system.

Instruction Manual | 23

Page 34

ProSort Software

Fig. 18. Edit QC Criteria window with green plus

button and rewind arrow highlighted.

3.3.2 Edit Droplets

Droplet controls are available to the administrator for troubleshooting purposes. While the

system is maintaining, the drop delay, drop drive amplitude, and drop drive frequency cannot

be adjusted (Figure 19). If any of these settings is adjusted, use ProLine calibration beads to

recalculate the drop delay before running samples. The verify drop delay button at the bottom

of this screen will sort three puddles onto a slide which can be examined under a microscope

to confirm drop delay. These puddles will sort 100 events at the current drop delay – 1, the

current drop delay, and the current drop delay + 1.

CAUTION! Optimal settings are calculated automatically after performing a quality

control procedure. Adjusting any of these values will change the settings and will

affect the drop delay, including the break-off point.

3.3.3 Edit Streams

Streams controls are available to the administrator for troubleshooting purposes. While the

system is maintaining, these settings can be adjusted. Side streams can also be turned on or

off by checking the Enable Test Pattern box (Figure 20).

CAUTION! Optimal side stream settings are calculated automatically after performing

a quality control procedure. Adjusting any of these values will change the settings

and will affect the side streams and sort.

24 | S3 and S3e Cell Sorters

Page 35

Calibrate droplets

Recalculate drop delay

Verify drop delay

Close window

3.3 Administrator Tab Toolbar

Fig. 19. Droplet Controls window with drop settings highlighted.

Fig. 20. Streams Control window with Enable

Test Pattern highlighted.

Instruction Manual | 25

Page 36

ProSort Software

To check for stream defanning:

1. Locate the center stream. The stream is visualized as a small bright spot that is illuminated

by the stream laser.

2. Check the Enable Test Pattern check box the system will charge the side streams to

simulate a sort.

Fanning of the streams can be seen more easily with the center stream than the two side

streams. The test pattern will make the center stream slightly broader.

3. Determine if the center stream is one solid stream.

If the center stream spreads into several streams, the fanning should be adjusted.

4. Use the defanning slider until the center stream is as focused as possible (Figure 21).

5. Click the checkmark when completed to save the settings.

A

B

Fig. 21. Examples of a good center stream, A and a defanned center stream, B.

3.3.4 User Reports

User reports can be viewed, saved,

printed, and exported for analysis of

system usage and for billing purposes.

To display a user’s usage information,

select the date range of interest and

click Update (Figure 22).

26 | S3 and S3e Cell Sorters

Fig. 22. User Report window with date range highlighted.

Page 37

3.3.5 Managing Users

The Manage Users button opens the Manage Users window. This window allows an

administrator to add, delete, or edit users (Figure 23). Passwords can be reset and users can be

notified to reset their passwords from this window.

3.3 Administrator Tab Toolbar

Fig. 23. Manage Users window.

To edit a user’s information:

1. Click the pencil icon next to the

user’s name.

2. Modify user information in the Edit User

window (Figure 24).

3. Click Save.

Note: In the event that all administrator

passwords are lost or forgotten, call your

local technical support team to receive a

temporary password.

Fig. 24. Edit User window.

Instruction Manual | 27

Page 38

ProSort Software

3.3.6 Decontaminate

An administrator can run the decontaminate procedure if the system shows signs of heavy

background, noticeable debris when running water, or contamination. The complete

internal fluidic system will be decontaminated. Follow the wizard procedure located in

Section 10.7, Decontamination.

3.3.7 Calibrate Sample Pressure Offset

If the system shows an event rate of 0 when running calibration beads in the low setting, or if

it shows 500+ events, the offset will need to be reset. Using this tool will reset the differential

offset sample pressure, which will return the preset sample flow rates (low/med/high) back to

their correct ranges.

1. Load calibration beads into the sample station and move loading stage to the run position.

2. Click Calibrate Sample Pressure Offset.

A warning window will appear asking if the user wants to continue (Figure 25). ProLine

calibration beads must be running for this calibration process.

The system will automatically begin the calibration process (Figure 26). Once complete the

system offset pressure has been calibrated.

Fig. 25. Sample Calibration Warning dialog box.

Fig. 26. Calibration Sample Offset window.

28 | S3 and S3e Cell Sorters

Page 39

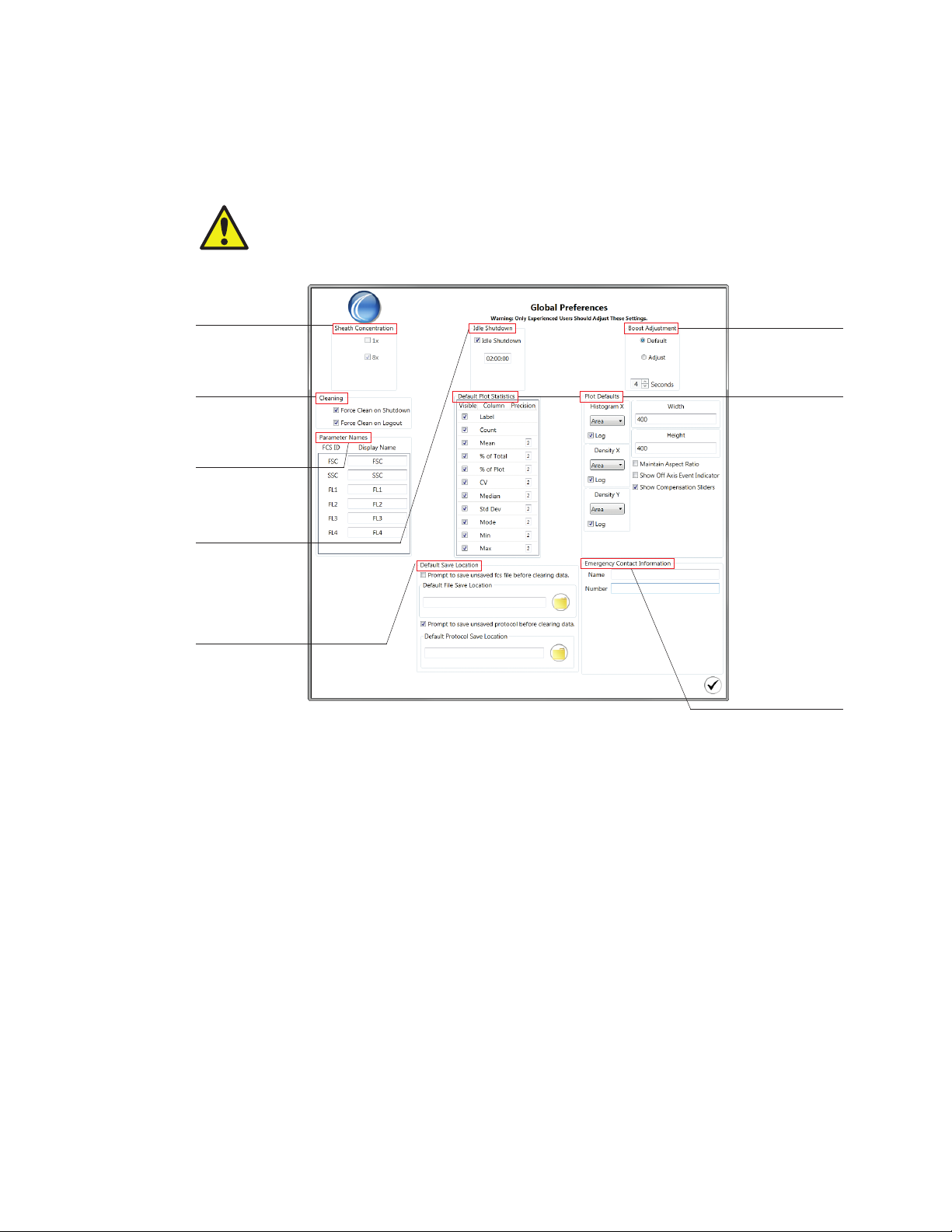

3.3.8 Global Preferences

Users with administrator privileges have the ability to change global settings for the instrument.

Changes to global preferences will become effective upon accepting the changes. Preferences

specific to plots will be displayed when new plots are created.

CAUTION! These settings are global and may influence other users’ experiments.

Adjusting any of these values will change the optimal settings for the instrument.

3.3 Administrator Tab Toolbar

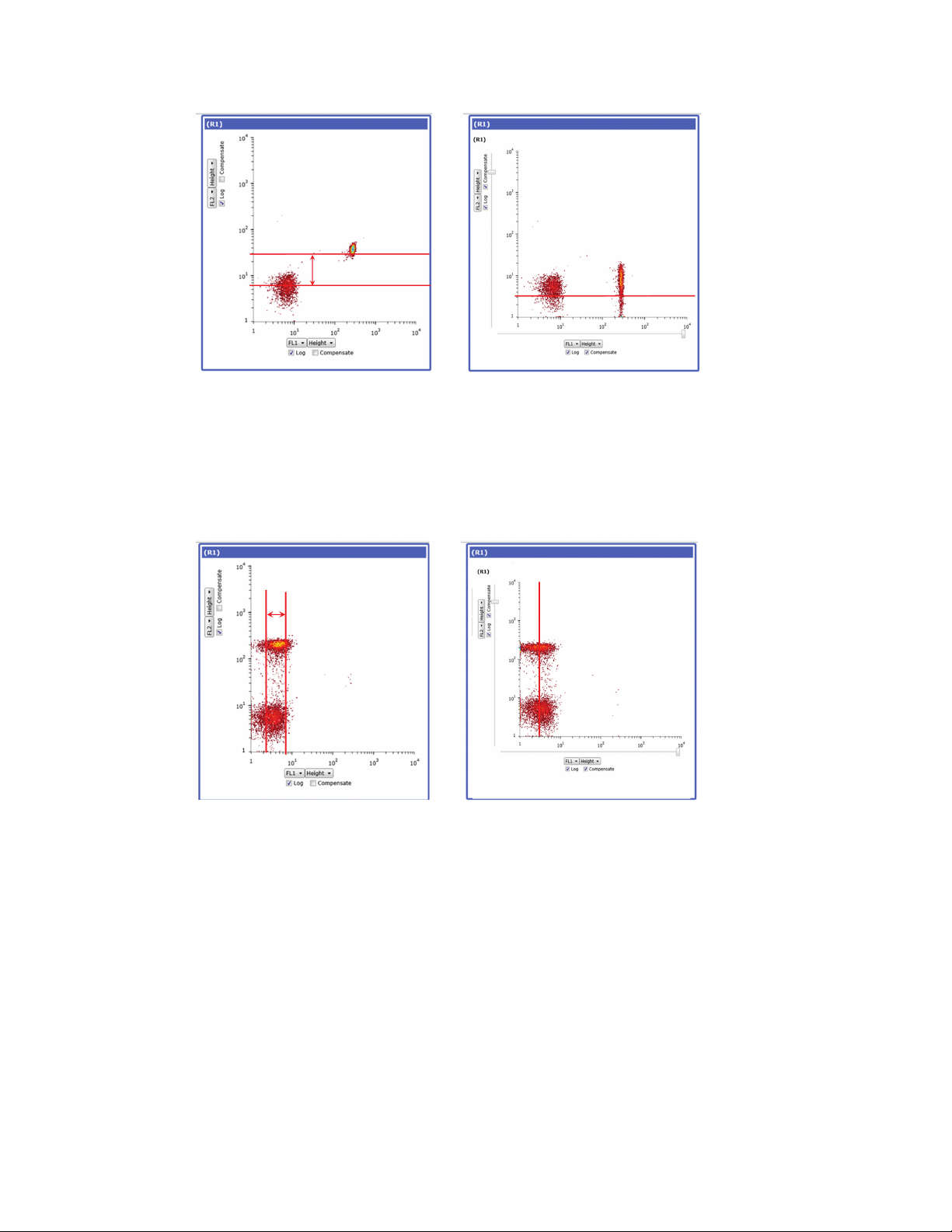

Sheath can be

used at 8x or at 1x

concentration

Option to enable

mandatory cleaning

upon shutdown

or logout

Parameter names

can be preset to

have user-defined

names displayed

Define idle

shutdown option

and countdown time

n

Choose to prompt

user to save

unsaved FCS and

protocols

n

Define default

save file locations

Fig. 27. Global Preferences window.

Boost duration

can be increased

or decreased

Plot default options:

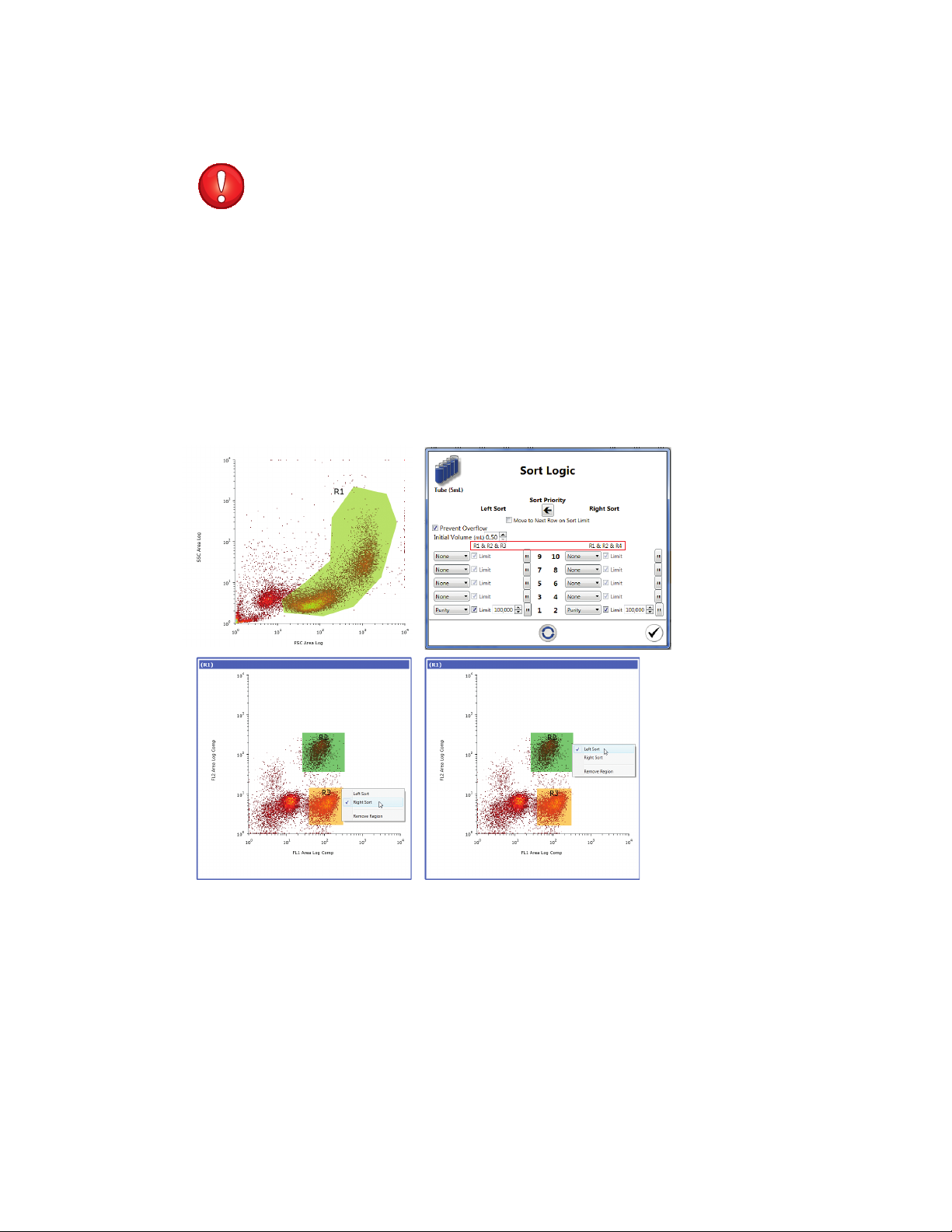

n

Define which plot

statistics to be

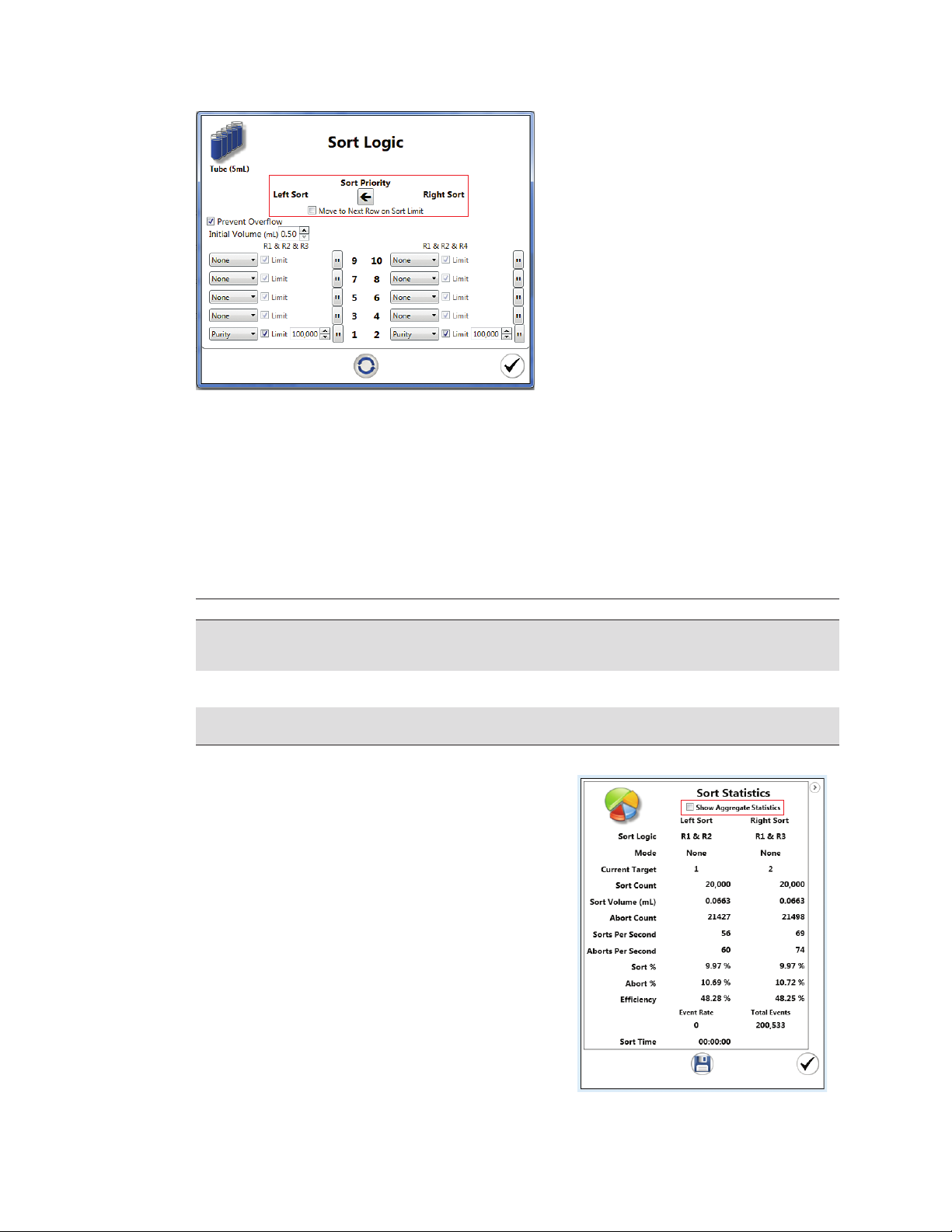

displayed and

number of digits

after the decimal

n

Choose which

axis parameter

will be displayed

and log verses

linear axis values

n

Define plot

display size,

maintain aspect

ratio of plots

n

Display and

highlight events

that are off axis

n

Display

compensation

sliders on plots

Define emergency

contact information

Sheath Fluid Options

The system can use 8x or 1x sheath solution. The default concentration is 8x. The 8x sheath

fluid will mix automatically with DI water prior to running through the system. One container of

8x sheath fluid will provide up to 50 hours of run time compared to 9 hours of run time for one

container of 1x sheath solution.

If a 1x sheath solution will be used, select 1x in the sheath concentration section prior to running

the system to avoid diluting the solution.

Idle Shutdown Time

The system has the ability to shut down automatically and start the shutdown procedure after

sitting idle for a designated time period. The system has a default setting of 2 hours.

This option helps to preserve laser lifetime and prevent the system from running overnight.

Instruction Manual | 29

Page 40

ProSort Software

Boost Adjustment

The default boost duration is optimized to bring the sample into position for interrogation by

the laser once acquisition is started. Default values can be restored by selecting Default. If this

value is adjusted, test the boost duration with a known sample to optimize the duration before

running the unknown samples.

Force Cleaning

There are two methods to end a user session in the software — log out or shut down. For both

methods, a Force Cleaning option is available to promote cleaning and maintenance of the

system. Force cleaning can help to avoid unnecessary clogs that can happen when the system

is not cleaned regularly or left overnight with sample in the lines.

Default Plot Statistics

Each plot can be displayed with statistics for all events or regions drawn on the plot. Each

statistic can be displayed or can be hidden by setting the preference. In addition, the number

of significant figures for each statistic can be defined. Once this parameter is changed the

subsequent new plots will reflect the new statistics defaults.

Plot Defaults

In this section there are several options that can be chosen.

n

Histogram and Density Plot axis parameters can be defined and set in the global

preferences. The user can choose the default axis parameter type: Area, Height, or Width. In

addition, the axis can be displayed in log or linear scales. Log can be selected as the default

by checking the box. Once these parameters are changed, subsequent new plots will reflect

the new parameter defaults

n

The width and height of the plot can be defined specifically. The default number of pixels

is 400 x 400. In addition, the aspect ratio can be maintained if the box is checked for this

option. This option applies to both histograms and density plots. Once this parameter is

changed, subsequent new plots will reflect the new size default

n

Events may fall off scale and be displayed on or below the axis. A preference can be chosen

to show an arrow indicator when events are off scale. This will help to raise awareness that

some settings may need to be adjusted

n

Auto compensation is the recommended method to compensate samples properly and in a

statistically correct method. Compensation sliders can be selected to be displayed or hidden

on the density plot axes when the compensate box is checked. Compensation bars can also

be used to make compensation adjustments, however proper gating and match medians

must be used to compensate correctly

30 | S3 and S3e Cell Sorters

Page 41

3.3 Administrator Tab Toolbar

Parameter Names

Each parameter is defaulted to its channel name (FSC, SSC, FL1, FL2, FL3, and FL4). The

default parameter name can be entered by the user. This will be the parameter name for all new

protocols created once the preferences have been changed.

Note: Parameter names can also be changed on the instrument panel but they will revert to

default names when a new protocol is opened. Refer to Section 5.1.6, PMT Voltages, to see

how to change names on the instrument panel.

Default Save Location

The software can autosave after each file has finished acquiring. Files can be saved to a default

destination folder on the computer. This can be set for both protocols and for FCS files. In

addition, there is an option to require a prompt prior to clearing data.

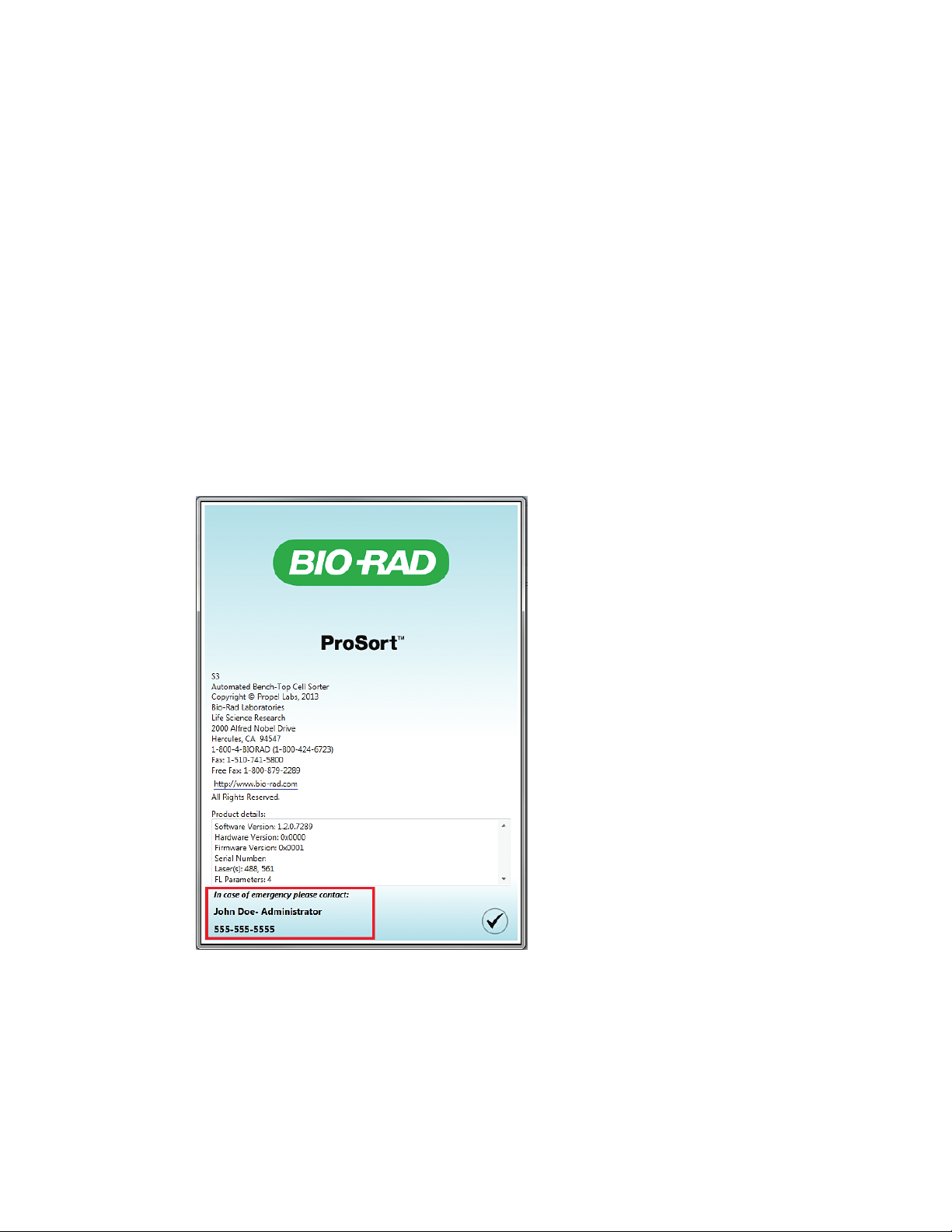

Emergency Contact Information

An emergency contact name and phone number can be entered into these fields. The

information will be displayed in the File > About window. This will let all users of the

instrument know what person within the lab or institution to contact for any emergency help

with the S3 or S3e System.

Fig. 28. About window displaying emergency contact information.

Instruction Manual | 31

Page 42

32 | S3 and S3e Cell Sorters

Page 43

4

Getting Started

After system installation by a Bio-Rad certified service engineer, the S3™ or S3e™ System should

not be turned off via the main power switch. The system is safe in standby mode after performing

a software shutdown of the system. This will help facilitate quick or automated startup.

If the system is shut off via the main power switch, always power the instrument on before

starting the ProSort

running in order to communicate with the software.

IMPORTANT! Powering the system on or off incorrectly can cause the instrument to

not run properly.

™

Software. The internal computer system of the instrument must be

4.1 Checking Bulk Fluidics

Prior to starting the ProSort Software, open the bulk fluidics door and check the volume

of each container. Ensure that the waste container is empty, and the sheath fluid and DI

containers are full.

Note: To change the bulk fluidics after starting the software or during a run, refer to Section 5.3,

Checking or Swapping Fluidics.

To refill or change a container (Figure 29):

1. Detach the quick disconnect from the cap assembly by pushing in the metal button and

lifting up the quick disconnect until it engages the magnetic holder.

2. Slightly lift and pull out the container.

3. Remove the cap assembly from the container.

4. Refill or change the container.

5. Carefully place the cap assembly onto the container and tighten the cap.

6. Place the container into position.

7. Attach the quick disconnect to the cap assembly. An audible click should be heard.

Instruction Manual | 33

Page 44

Getting Started

Sheath fluid cap assembly

Fig. 29. Bulk fluidics with sheath fluid components noted.

Sheath fluid container

Quick disconnect

IMPORTANT!

n

When handling sheath fluid and DI water containers, minimize air exposure to help

avoid contamination

n

While transferring cap assemblies to a new container, avoid touching the

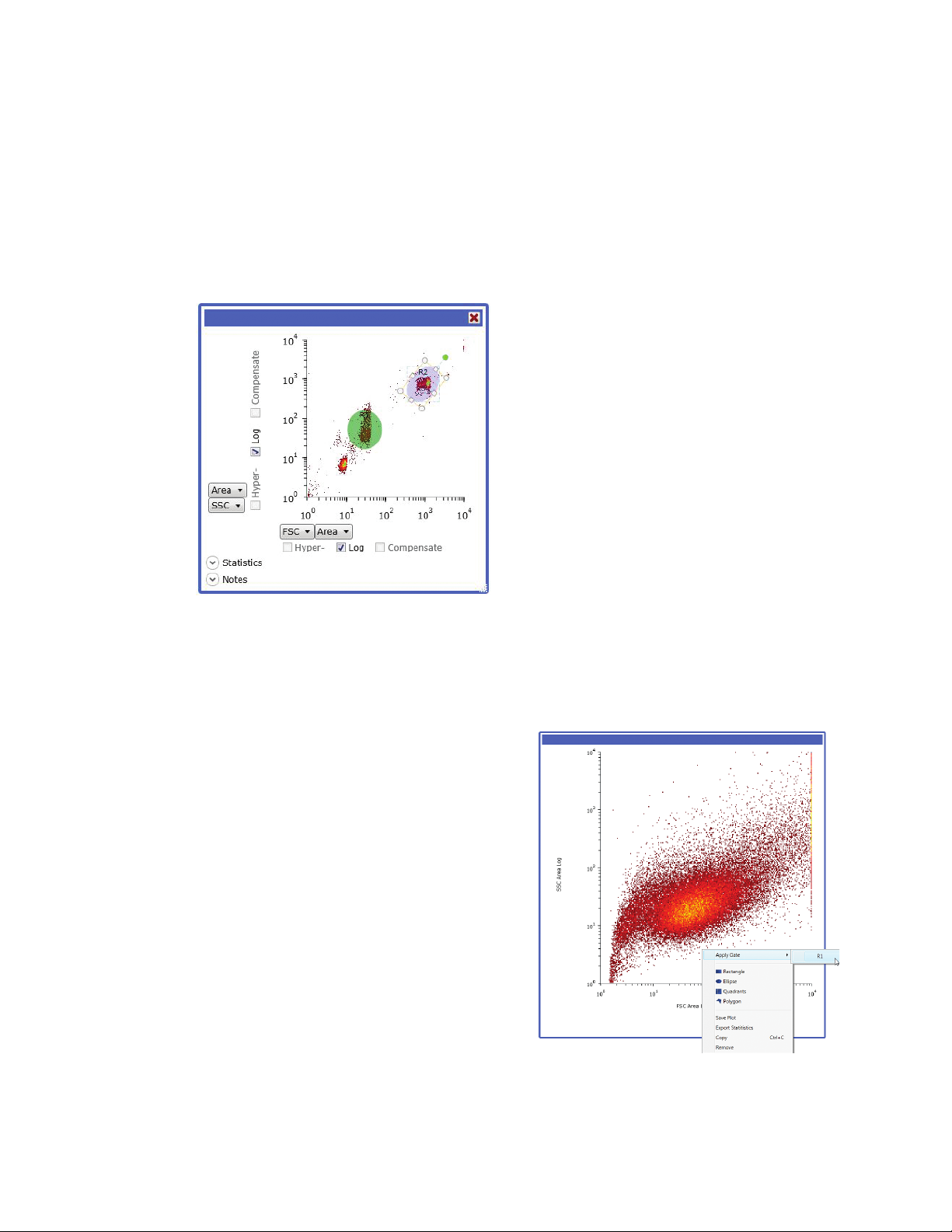

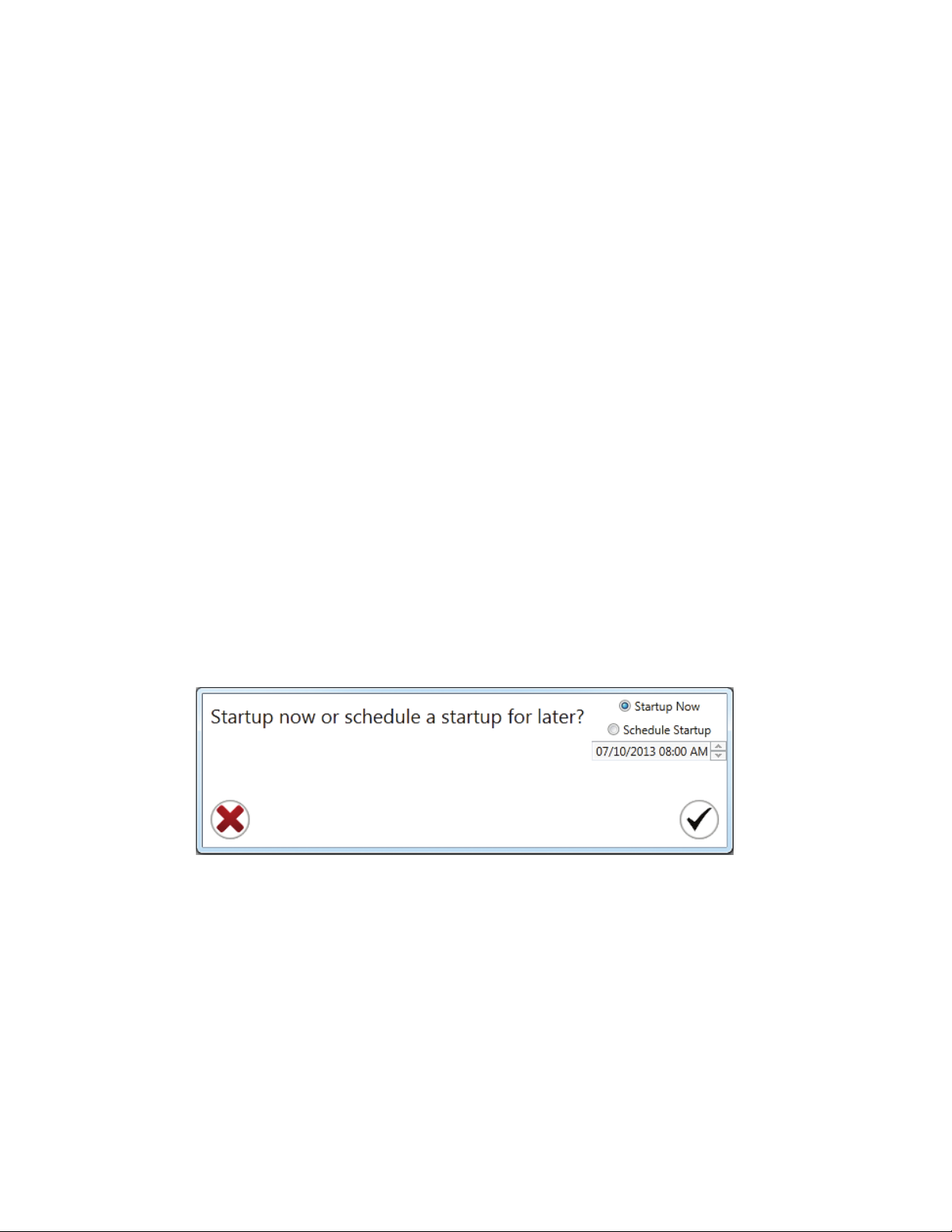

assembly to the outside surfaces of the containers. If it is necessary to place the