Page 1

S1000™ Thermal Cycler

Instruction Manual

Catalog # 184-2000

# 185-2096

# 185-2048

# 185-2384

Page 2

Copyright ©2009 Bio-Rad Laboratories, Inc. Reproduction in any form, either print or

electronic, is prohibited without written permission of Bio-Rad Laboratories, Inc.

Windows XP and Windows Vista are trademarks of Microsoft Corporation.

LICENSE NOTICE TO PURCHASER

Purchase of this instrument conveys a limited non-transferable immunity from suit for the

purchaser’s own internal research and development and for use in applied fields under one or

more of U.S. Patents Nos. 5,656,493, 5,333,675, 5,475,610 (claims 1, 44, 158, 160-163 and

167 only), and 6,703,236 (claims 1-7 only), or corresponding claims in their non-U.S.

counterparts, owned by Applera Corporation. No right is conveyed expressly, by implication or

by estoppel under any other patent claim, such as claims to apparatus, reagents, kits, or

methods such as 5’ nuclease methods. Further information on purchasing licenses may be

obtained by contacting the Director of Licensing, Applied Biosystems, 850 Lincoln Centre

Drive, Foster City, California 94404, USA.

Bio-Rad’s thermal cyclers and real-time thermal cyclers are covered by one or more of the

following U.S. patents or their foreign counterparts owned by Eppendorf AG: U.S. Patent Nos.

6,767,512 and 7,074,367.

Hard-Shell PCR plates are covered by one or more of the following U.S. patents or their

foreign counterparts owned by Eppendorf AG: U.S. Patent Nos. 7,347,977, 6,340,589,

6,528,302.

i

Page 3

ii

Page 4

Bio-Rad Laboratories Resources

Table 1 lists Bio-Rad resources and how to locate what you need.

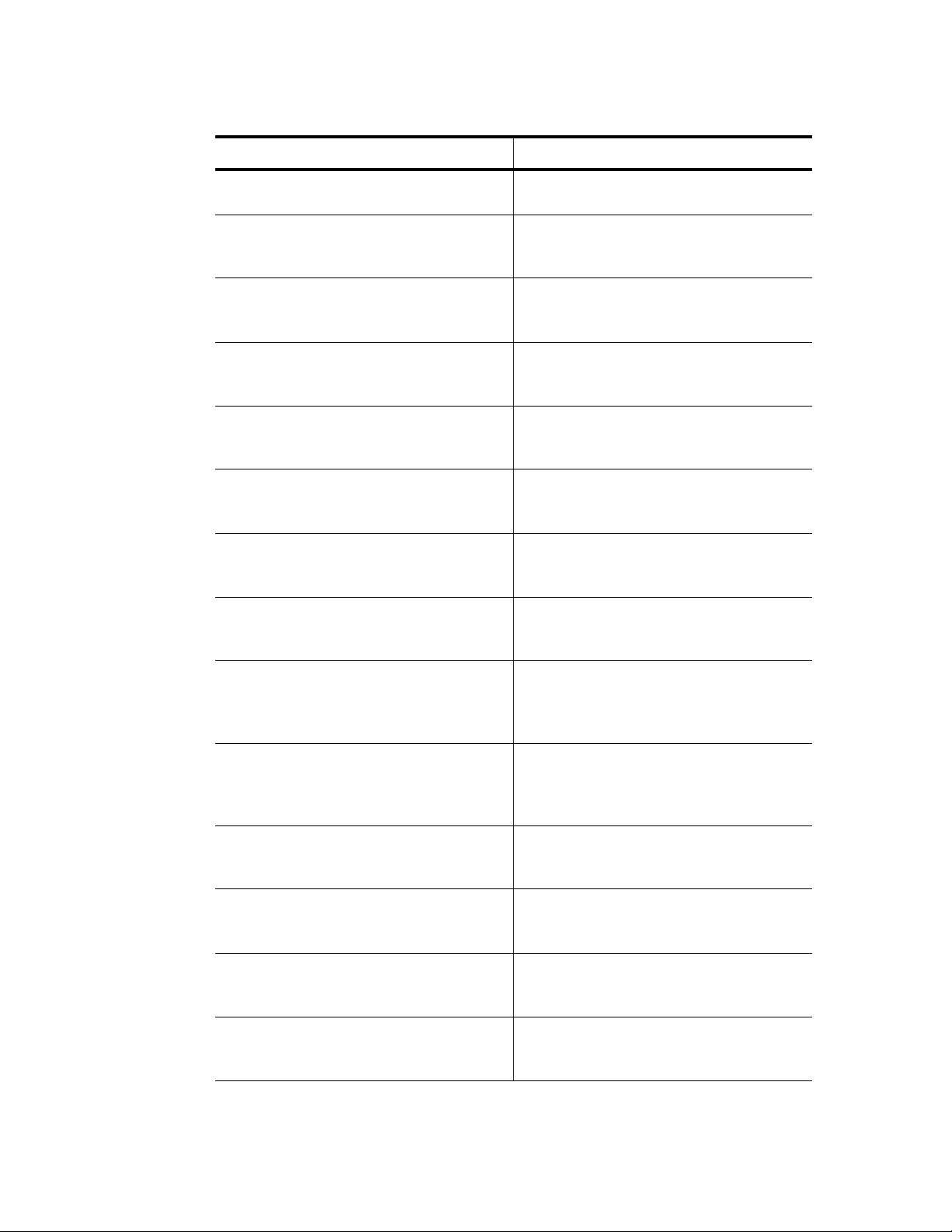

Table 1. Bio-Rad resources

Resource How to Contact

Local Bio-Rad Laboratories

representatives

Technical notes and literature Go to the Bio-Rad Laboratories web site (www.bio-

Technical specialists Bio-Rad Laboratories provides quality technical support.

Find local information and contacts on the Bio-Rad

Laboratories web site by selecting your country on the

home page (www.bio-rad.com). Find the nearest

international office listed on the back of this manual

rad.com). Type a term in the Search box and select

Literature to find links to technical notes, manuals, and

other literature

We staff our Technical Support department with

experienced scientists to provide our customers with

practical and expert solutions

To find local technical support on the phone, contact your

nearest Bio-Rad Laboratories office. For technical support

in the United States and Canada, call 1-800-424-6723

(toll-free phone), and select the technical support option

S1000 Thermal Cycler Manual

Warranty

The S1000 thermal cycler and associated accessories are covered by a standard Bio-Rad

warranty. Contact your local Bio-Rad Laboratories office for the details of the warranty.

Writing Conventions Used In This Manual

This manual provides instructions on how to safely set up and operate the S1000 thermal

cycler and uses the writing conventions shown in Table 2 to quickly provide relevant

information.

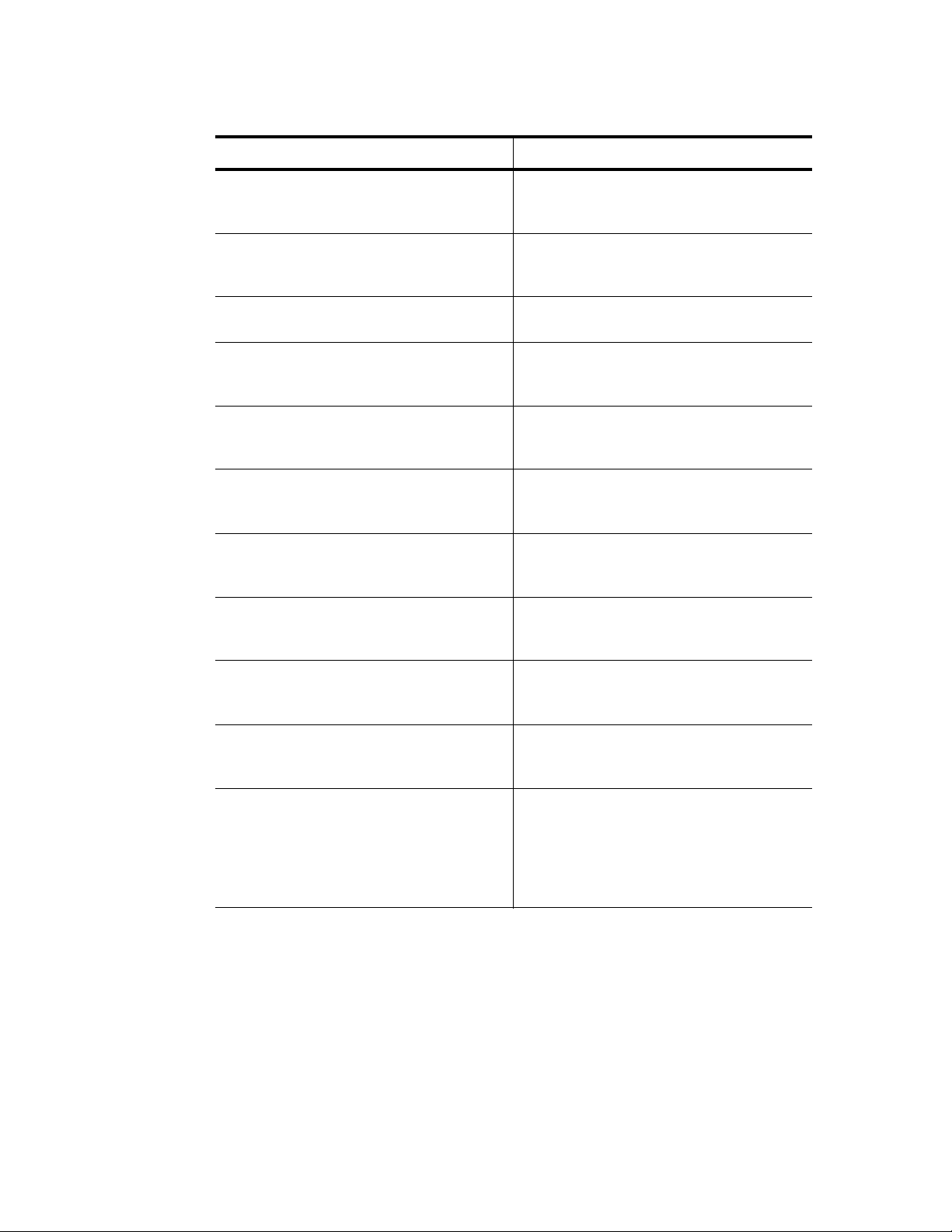

Table 2. Manual conventions

Convention Meaning

TIP: Provides helpful instructions, including information explained in

further detail elsewhere in this manual

NOTE: Provides important information, including information explained in

further detail elsewhere in this manual

WARNING! Explains crucial information about a topic that may lead to injury

to the user, instrument damage, or data loss

Screen message Indicates the one or more words on the screen the user should

select

iii

Page 5

Safety and Regulatory Compliance

Table 2. Manual conventions (continued)

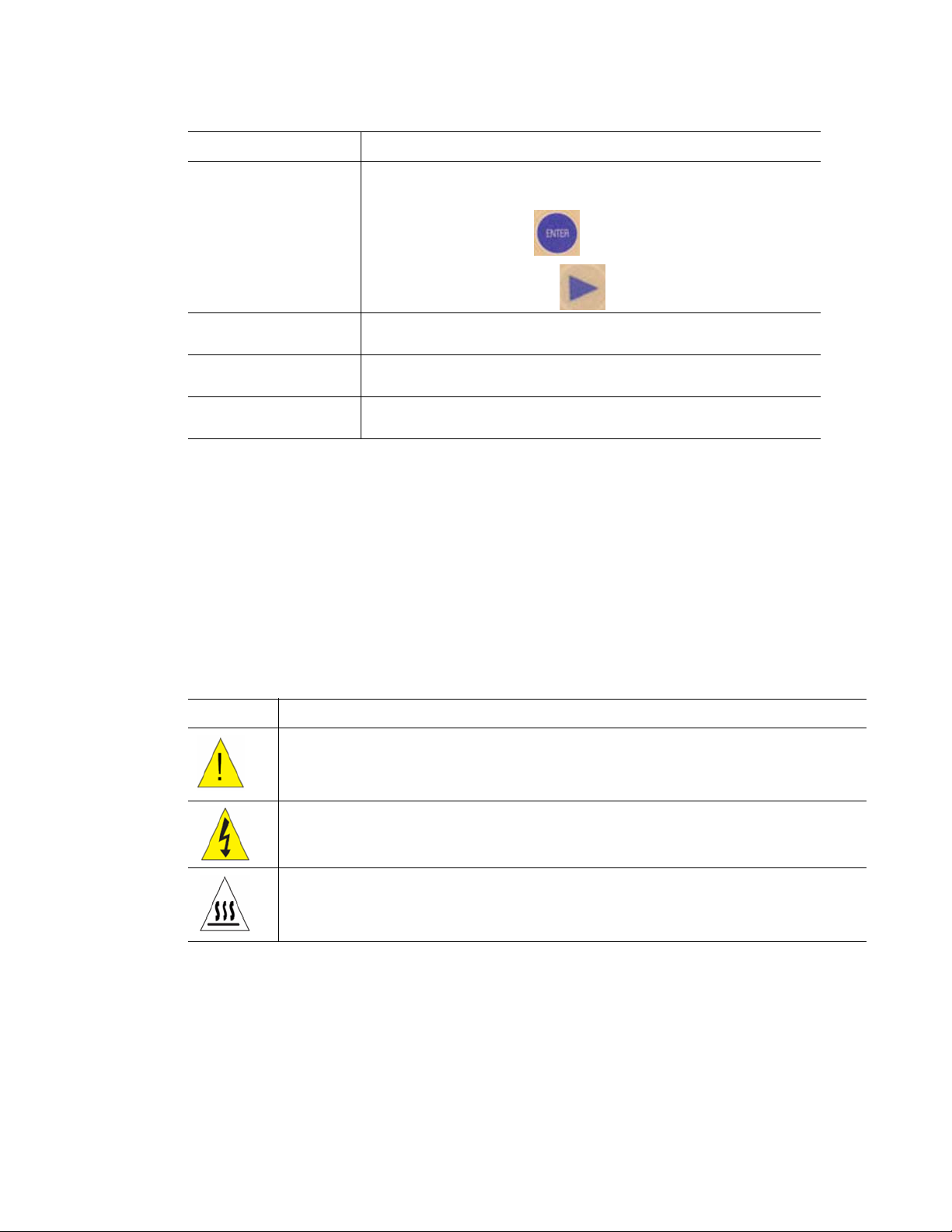

Convention Meaning

NAME of control panel

key

Select X Select X using the arrow keys. For example, select NEW means

Select X > Y From menu X, select Y. For example, select MAIN

Press X Press the X key on the control panel. For example, press ENTER

Indicates a key on the thermal cycler control panel. For example,

these keys have the following names:

•The ENTER key is

•The right arrow key is

use the arrow keys to select the NEW option on the screen

means select the RUN option in the MAIN menu

means press the ENTER key on the control panel

Safety and Regulatory Compliance

>

RUN

The S1000 thermal cycler heats and cools very quickly during operation. We strongly

recommend that you follow the safety specifications listed in this section and throughout this

manual.

Safety Warning Labels

Warning labels posted on the instrument and in this manual warn you about sources of injury

or harm. Refer to Table 3 to review the meaning of each safety warning label.

Table 3. Instrument safety warning labels

Icon Meaning

CAUTION: Risk of danger! This symbol identifies components that pose a risk of

personal injury or damage to the instrument if improperly handled. Wherever this

symbol appears, consult the manual for further information before proceeding

CAUTION: Risk of electrical shock! This symbol identifies components that pose a

risk of electrical shock if improperly handled

CAUTION: Hot surface! This symbol identifies components that pose a risk of

personal injury due to excessive heat if improperly handled

iv

Page 6

S1000 Thermal Cycler Manual

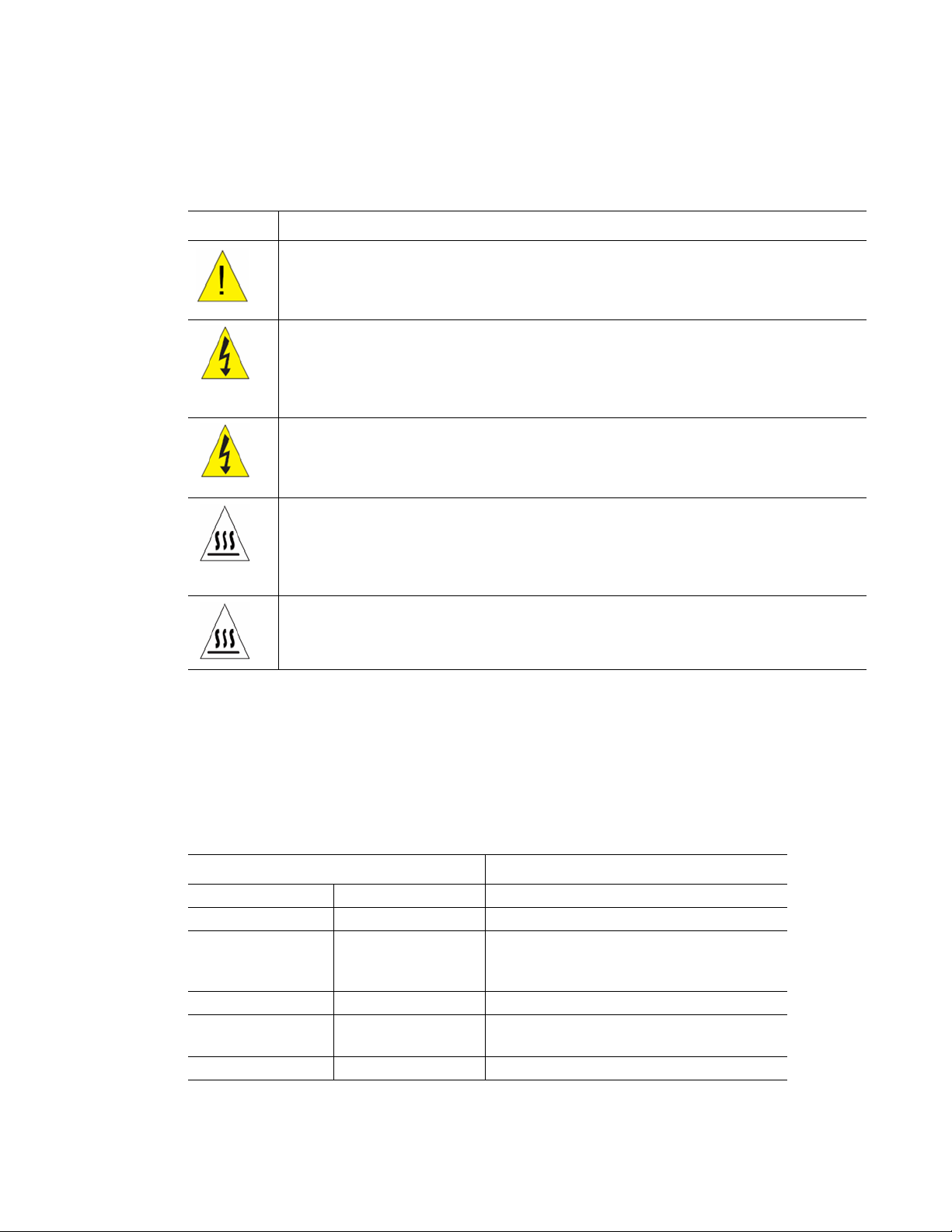

Instrument Safety Warnings

The following warning labels display on the instrument, and refer directly to the safe use of this

S1000 thermal cycler (Table 4).

Table 4. Instrument safety warning labels

Icon Meaning

Warning about risk of harm to body or equipment.

Operating the S1000 thermal cycler before reading this manual can constitute a

personal injury hazard. Only qualified laboratory personnel should operate this

instrument

Warning about risk of harm to body or equipment from electrical shock.

Do not attempt to repair or remove the outer case of this thermal cycler base, power

supply, heat pump, or other accessories. If you open these instruments, you put

yourself at risk for electrical shock and void your warranty. All repairs must be done

by an authorized repair service

Never remove the outer case of a thermal cycler base. This may cause you to

receive an electrical shock.

This thermal cycler uses neutral fusing, which means that live power could still be

exposed inside the instrument even when the fuse is blown or removed

Warning about risk of burning.

A thermal cycler generates enough heat to cause serious burns. Wear safety

goggles or other eye protection at all times during operation. Always allow the

sample block to return to idle temperature before opening the lid and removing

samples. Always allow maximum clearance to avoid accidental skin burns

Warning about risk of explosion.

The sample blocks can become hot enough during the course of normal operation

to cause liquids to boil and explode

Safety and Regulatory Compliance

This instrument has been tested and found to be in compliance with all applicable

requirements of the following safety and electromagnetic standards (Table 5).

Table 5. Safe use specifications

Safe User Requirements Specifications

Input power Rated 100–240 Vac, 50–60 Hz

Fuses 250 V, 10 A

Temperature Indoor use Ambient temperature of 15–31°C. Relative

humidity maximum of 80%

(noncondensing)

Altitude Up to 2,000 meters above sea level

Overvoltage

Categories

Pollution degree 2

II

v

Page 7

Safety and Regulatory Compliance

SAFETY COMPLIANCE

This instrument has been tested and found to be in compliance with all applicable

requirements of the following safety and electromagnetic standards:

• UL Std No. 61010A-1 Electrical Equipment for Measurement, Control, and

Laboratory Use, Part 1: General Requirements

• UL Std No. 61010A-2-010 Electrical Equipment for Measurement, Control, and

Laboratory Use, Part 1: General Requirements

• CAN/CSA C22.2 No. 1010.1-92 - Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use, Part 1: General Requirements

(includes Amendment 1)

• CAN/CSA C22.2 No. 1010.1B-97 - Amendment 2 CAN/CSA C22.2 No. 1010.1-92

- Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use, Part 1: General Requirements

• CAN/CSA C22.2 No. 1010.2.010A-97 - Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use, Part 2-010: Particular

Requirements for Laboratory Equipment for the Heating of Materials, Amendment

No. 1

• IEC 61010-1 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements

• IEC 61010-1 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory use, Part 2: Particular Requirements for Laboratory

Equipment for the Heating of Materials

ELECTROMAGNETIC COMPATIBILITY (EMC)

• FCC Title 47 Part 15B as a Class A digital device

• EN61326 Class A Electrical Equipment for measurement, control, and laboratory use

- EMC Requirements

FCC WARNINGS AND NOTES

•Warning. Changes or modifications to this unit, not expressly approved by the party

responsible for compliance, could void the user’s authority to operate the equipment

•Note. This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference, at his own expense

• Note regarding FCC compliance. Although this design of instrument has been tested

and found to comply with Part 15, Subpart B of the FCC Rules for a Class A digital

device, please note that this compliance is voluntary, for the instrument qualifies as an

“exempted device” under 47 CFR 15.103(c), in regard to the cited FCC regulations in

effect at the time of manufacture

• Note regarding Canadian EMC compliance: Le present appareil numerique n’emet

pas de bruits radioelectrique depassant les limites applicables aux appareils numeriques

de class A prescrites dans le reglement sur le brouillage radioelectrique edicte par le

Ministere des Communications du Canada

•Cables. Shielded cables must be used with this unit to ensure compliance with the Class

A FCC limits

• Use only Bio-Rad USB cable (catalog #184-8000) when using any 1000-series cycler

vi

Page 8

Table of Contents

Bio-Rad Laboratories Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Writing Conventions Used In This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety and Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

S1000 Thermal Cycler Manual

Chapter 1. Introduction to the S1000™ Thermal Cycler . . . . . . . . . . . . . . . 1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Reaction Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setting Up the S1000 Thermal Cycler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating the Reaction Module Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2. Creating and Editing Protocols . . . . . . . . . . . . . . . . . . . . . . . . 11

Protocol Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Creating a New Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parameters for Temperature or Gradient Steps . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Editing an Existing Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Sample Volume and Lid Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3. Running Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preparing to Run a Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Monitoring the Protocol Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pausing and Resuming a Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Skipping a Step During the Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Canceling a Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Incubating Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 4. Managing Protocol Files and Folders . . . . . . . . . . . . . . . . . . . 39

Managing Protocol Files and Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

vii

Page 9

Chapter 5. Optimizing PCR on the S1000 Thermal Cycler . . . . . . . . . . . . 47

Optimizing a Protocol for Faster PCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Optimizing Annealing Temperature Steps with a Gradient . . . . . . . . . . . . . . . . . . 49

Optimizing PCR With Small Sample Volumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Transferring Protocols from Another Thermal Cycler . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting PCR Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Selecting Compatible Reaction Vessels and Sealing Options . . . . . . . . . . . . . . . 51

Chapter 6. Advanced Tools and Functions . . . . . . . . . . . . . . . . . . . . . . . . 53

TOOLS Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Controlling S1000 Thermal Cyclers with a C1000 Thermal Cycler . . . . . . . . . . . . 61

Chapter 7. Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . 63

Cleaning and Maintaining the S1000 Thermal Cycler . . . . . . . . . . . . . . . . . . . . . . 63

Maintaining Sufficient Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Troubleshooting Error Messages on the S1000 Cycler . . . . . . . . . . . . . . . . . . . . . 66

Appendix A: Preinstalled Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Standard Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Touchdown Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Optimized Protocol Using iTaq™ Polymerase . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Optimized Protocols Using iProof™ Polymerase . . . . . . . . . . . . . . . . . . . . . . . . . 73

Optimized Protocol Using the iScript™ Reverse Transcriptase . . . . . . . . . . . . . . 74

Nested Primer Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendix B: Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Components of Bio-Rad’s 1000-Series Thermal Cyclers . . . . . . . . . . . . . . . . . . . 77

Accessories for the 1000-Series Thermal Cyclers. . . . . . . . . . . . . . . . . . . . . . . . . 78

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

viii

Page 10

S1000 Thermal Cycler Manual

1 Introduction to the S1000™

Thermal Cycler

Read this chapter for information on setting up the S1000 thermal cycler.

• System overview (below)

• Reaction modules (page 3)

• Setting up the S1000 thermal cycler (page 5)

• Operating the reaction module lid (page 7)

System Overview

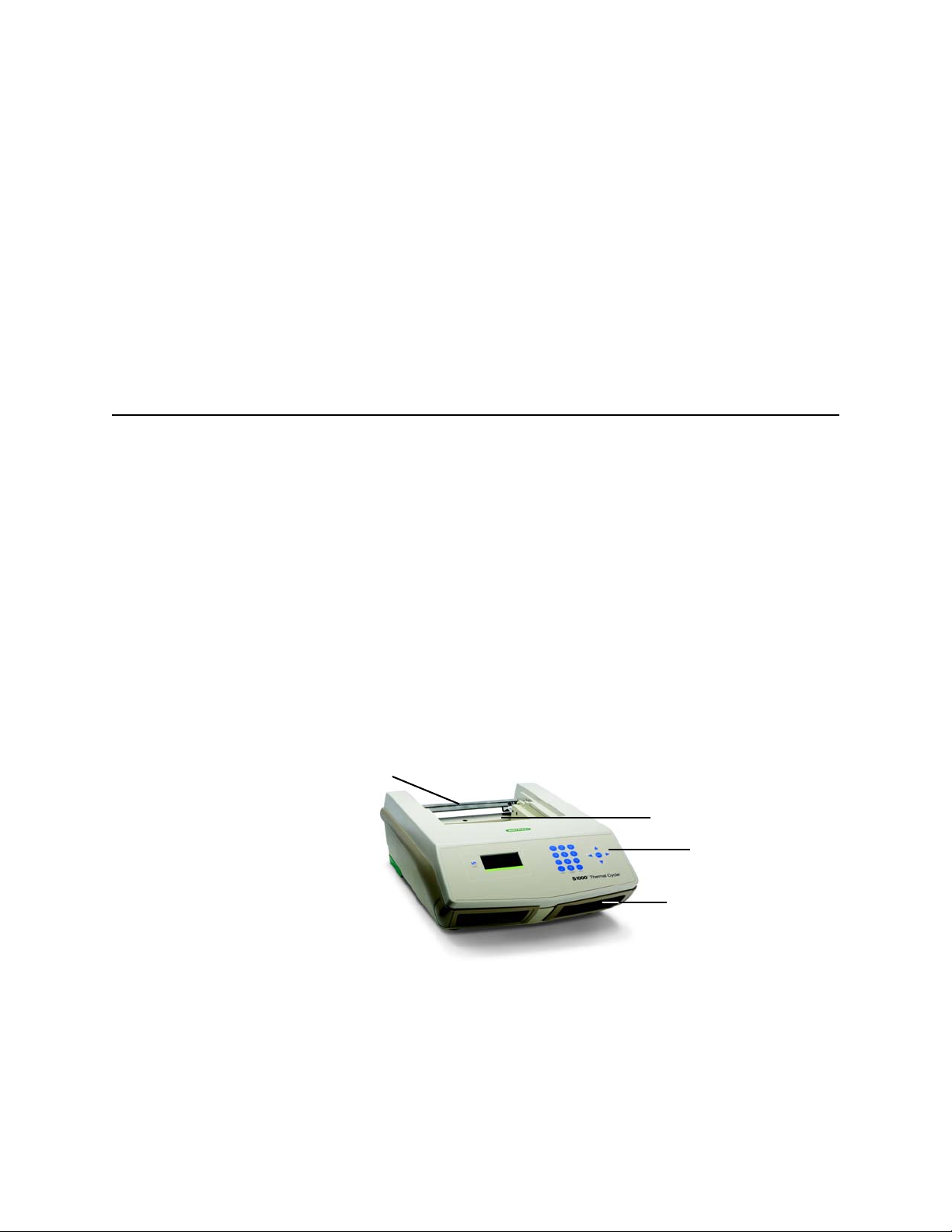

The S1000 thermal cycler base (Figure 1) includes:

• Reaction module bay – holds the inserted reaction module

• Reaction module locking bar – locks the inserted module in place

• Control panel – provides access to all the functions needed to create and run PCR

protocols

• Air vents – allow the thermal cycler to heat and cool quickly

Module locking bar

The back panel of the S1000 thermal cycler includes data ports (Figure 2).

• USB B port — connects the S1000 thermal cycler to a C1000™ thermal cycler

• USB A ports — currently inactive

Reaction module bay

Control panel

Air vents

Figure 1. Frontal view of the S1000 thermal cycler.

1

Page 11

System Overview

• Test port — for service testing only

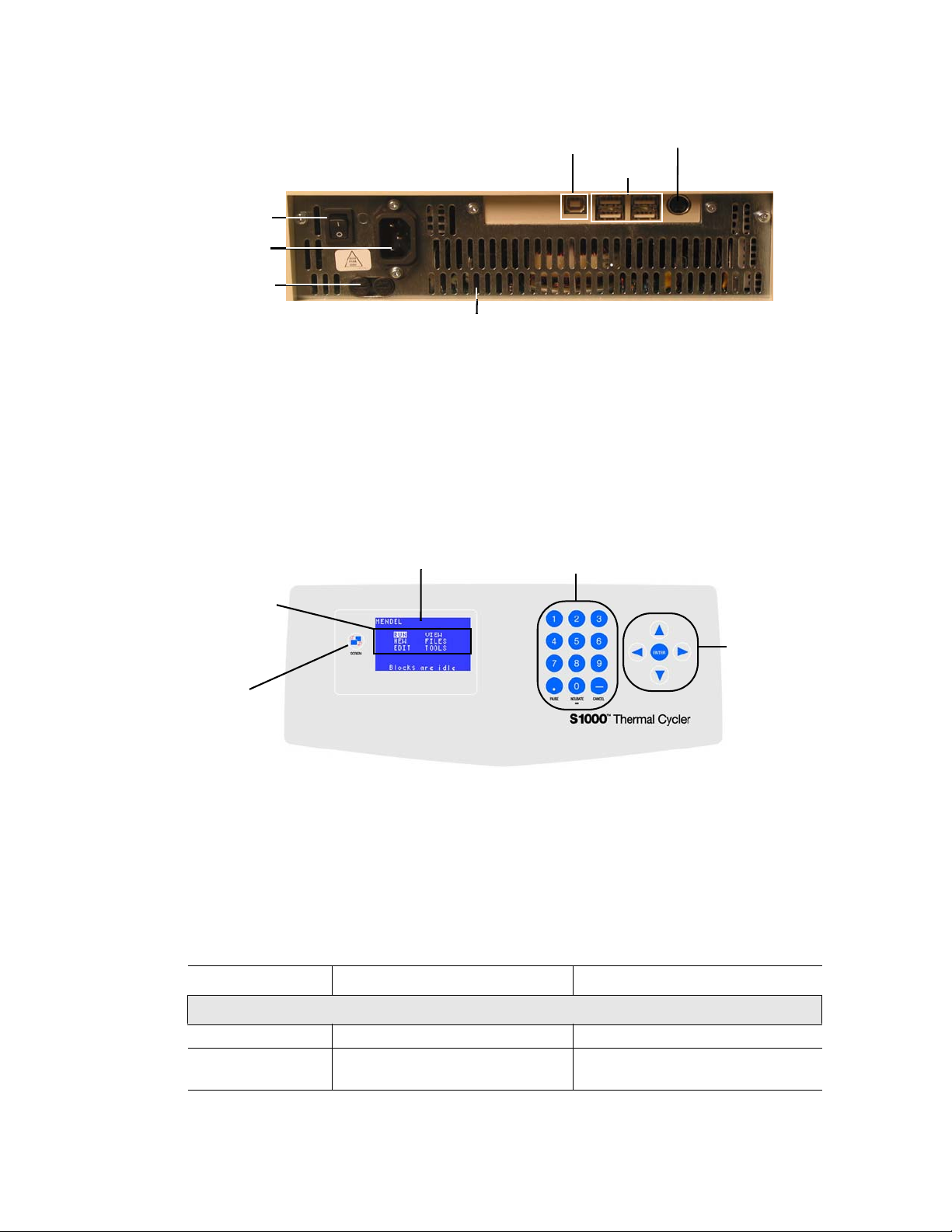

The control panel on the S1000 thermal cycler provides access to all the functions needed to

run the thermal cycler and includes the following components:

• Liquid crystal display (LCD) — displays the main menu and other screens

• Command, numeric, and navigation keys — use these keys to enter commands,

The main screen is displayed after booting is complete. Figure 3 shows the components of the

control panel.

USB B port

Power

switch

Power

input

Fuses

Cooling vents

Figure 2. Back panel of the S1000 thermal cycler.

numbers, or letters, and navigate various screens

Numeric and

LCD

command keys

Test port

USB A ports

Main menu

options

Navigation

keys

Screen

key

Figure 3. Components of the control panel on the S1000 thermal cycler.

Function of the Control Panel Keys

The control panel of the S1000 thermal cycler contains five sets of keys with the functions

listed in Table 6.

Table 6. Function of keys on control panel

Key Function Additional Notes

Numeric and Command Keys

1 through 9 Enter numbers

0, INCUBATE Inserts a zero or infinity, or starts

instant incubation

2

Page 12

S1000 Thermal Cycler Manual

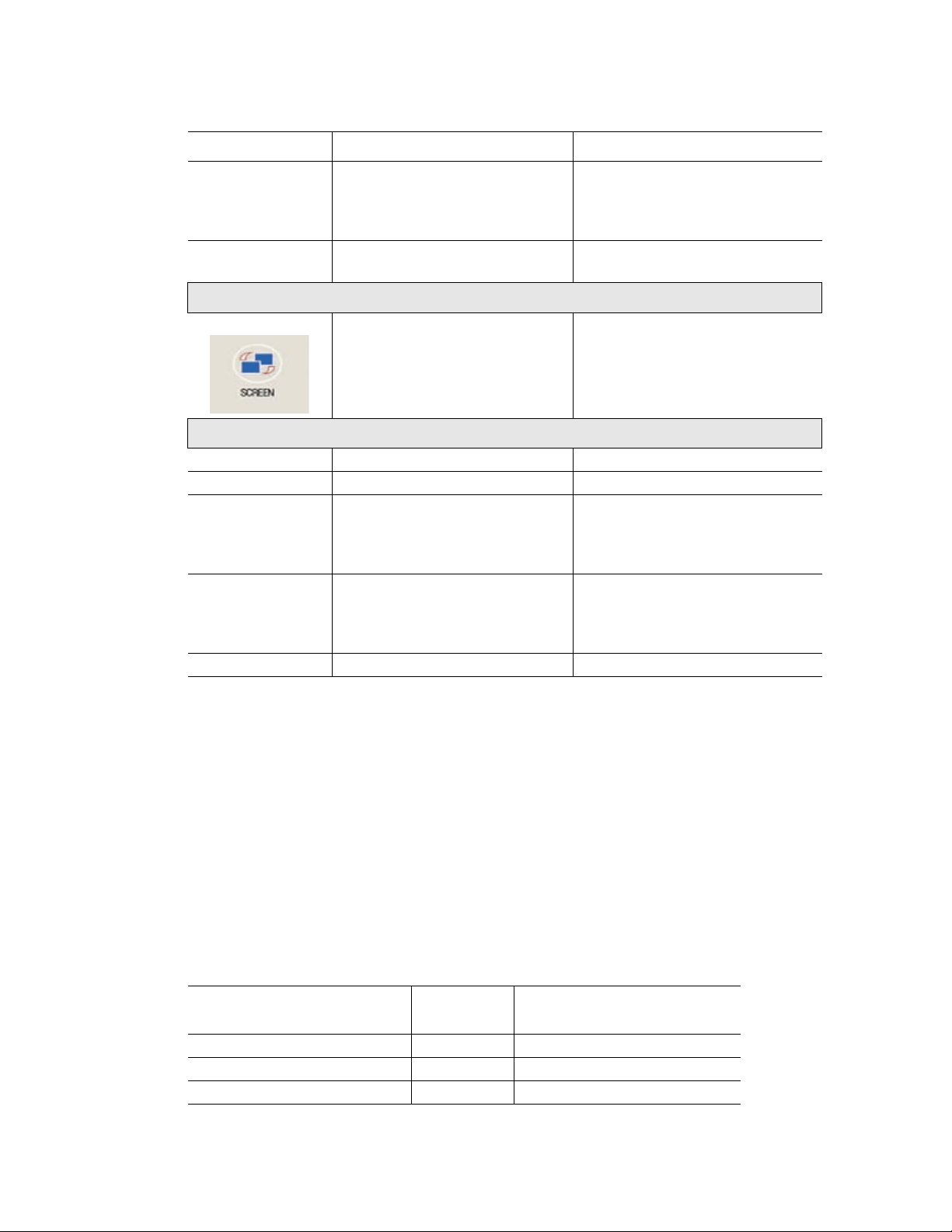

Table 6. Function of keys on control panel (continued)

Key Function Additional Notes

CANCEL (–) Enters a minus sign or cancels a

function

PAUSE (

SCREEN key

Navigation Keys

Right arrow Moves the cursor to the right

Left arrow Moves the cursor to the left

Up arrow Moves the cursor up Press the up arrow key to scroll

Down arrow Moves the cursor down Press the down arrow key to scroll

ENTER Confirms a selection

.

) Enters a decimal point or pauses

a protocol

Toggles between screens for

alternative views

Press this key to delete an entry,

cancel a function, stop a protocol,

end an incubation, or delete text

on the screen

Press this key to view the status of

a run

from A to Z on the screen. For

example, press the up key three

times to select the letter C

from Z to A on the screen. For

example, press the down key eight

times to select the letter S

Reaction Modules

The S1000 thermal cycler is compatible with any 1000-series reaction module. The reaction

modules come in three block sizes: the 96-, dual 48-, or 384-well block. Each block in the

reaction module includes a fully adjustable heated lid that is capable of running reliably with a

broad range of reaction vessels.

Recommended Sample Volume

When using the S1000 thermal cycler, the maximum sample volume is determined by the type

of reaction module used. -well reaction module is used. Table 7 lists the recommended

sample volume, as well as the maximum sample volume to be used with different reaction

modules.

Table 7. Size and volume limit for the 1000-series reaction modules

Number of Wells

Dual 48/48 2 10–50 µl (50 µl limit)

96 1 10–50 µl (50 µl limit)

384 1 3–30 µl (30 µl limit)

Number of

Blocks

Recommended Sample

Volume (Upper Limit)

3

Page 13

Reaction Modules

Specifications of Reaction Modules

Specifications for each 1000-series reaction module are listed in Table 8.

Table 8. Reaction module specifications

Feature 96-Well Fast Dual 48/48 Fast 384-Well

Sample capacity 96 x 0.2 ml tubes 2 x 48 x 0.2 ml tubes 1 x 384-well PCR

Gradient direction Back (upper

Gradient temperature

range

Gradient temperature

differential

Gradient accuracy ±0.2°C of

Gradient (end row)

uniformity

Gradient calculator

accuracy

Heated lid temperature 0–110°C 0–110°C 0–110°C

Average ramp rate 3.3°C/sec 3.0°C/sec 2.0°C/sec

Maximum ramp rate 5.0°C 4.0°C 2.5°C

Temperature range 0–100°C 0–100°C 0–100°C

Temperature accuracy ±0.2°C of

Temperature uniformity ±0.4°C well-to-well

microplate

Back (upper

temperature) to front

(lower temperature)

of block

30–100°C 30–100°C 30–100°C

1–24°C 1–24°C 1–24°C

programmed

temperature at end

rows

±0.4°C well-to-well

(within row) within 10

sec of arrival at

target temperature

±0.4°C of the actual

well temperature

programmed target

at 90°C

within 10 sec of

arrival at 90°C

temperature) to front

(lower temperature)

of block

±0.2°C of

programmed

temperature at end

rows

±0.4°C well-to-well

(within row) within 10

sec of arrival at

target temperature

±0.4°C of the actual

well temperature

±0.2°C of

programmed target

at 90°C

±0.4°C well-to-well

within 10 sec of

arrival at 90°C

Back (upper

temperature) to front

(lower temperature)

of block

±0.2°C of

programmed

temperature at end

rows

±0.4°C well-to-well

(within row) within 10

sec of arrival at

target temperature

±0.4°C of the actual

well temperature

±0.2°C of

programmed target

at 90°C

±0.4°C well-to-well

within 10 sec of

arrival at 90°C

Each reaction module contains cooling fins for fast heating and cooling and a fully adjustable,

heated lid. Figure 4 shows the lid and cooling fins for the 96-well reaction module.

• Heated inner lid — adjusts the lid temperature to prevent condensation and

evaporation

• Sample/reaction block — holds reaction vessels, including tubes and microplates

4

Page 14

S1000 Thermal Cycler Manual

Lid

Cooling fins

Figure 4. The lid and cooling fins of a 96-well reaction module.

The top of a reaction module lid includes a lid lever, lid force knob, and status LED (Figure 5).

• Lid lever — opens and closes the lid

• Lid force knob — sets lid force and seals the reaction

• Status LED — turns on to indicate that the block is selected or running

Lid force knob

Lid lever

Figure 5. A top view of a reaction module.

Setting Up the S1000 Thermal Cycler

The S1000 thermal cycler package includes:

• S1000 thermal cycler base

• Power cord

• Consumables selection guide

• Instruction manual

• Quick guide for system installation

Reaction modules for use with the S1000 thermal cycler are shipped in separate packaging.

Remove all packaging materials and store them for future use. If any item is missing or

damaged, contact your local Bio-Rad office.

Place the S1000 thermal cycler base on a flat, dry surface with sufficient cool airflow to run

properly. The instrument can run in two modes: stand-alone or software-controlled. When

running the system under software-controlled mode, make sure there is sufficient space for a

computer during setup.

Status

LED

5

Page 15

Setting Up the S1000 Thermal Cycler

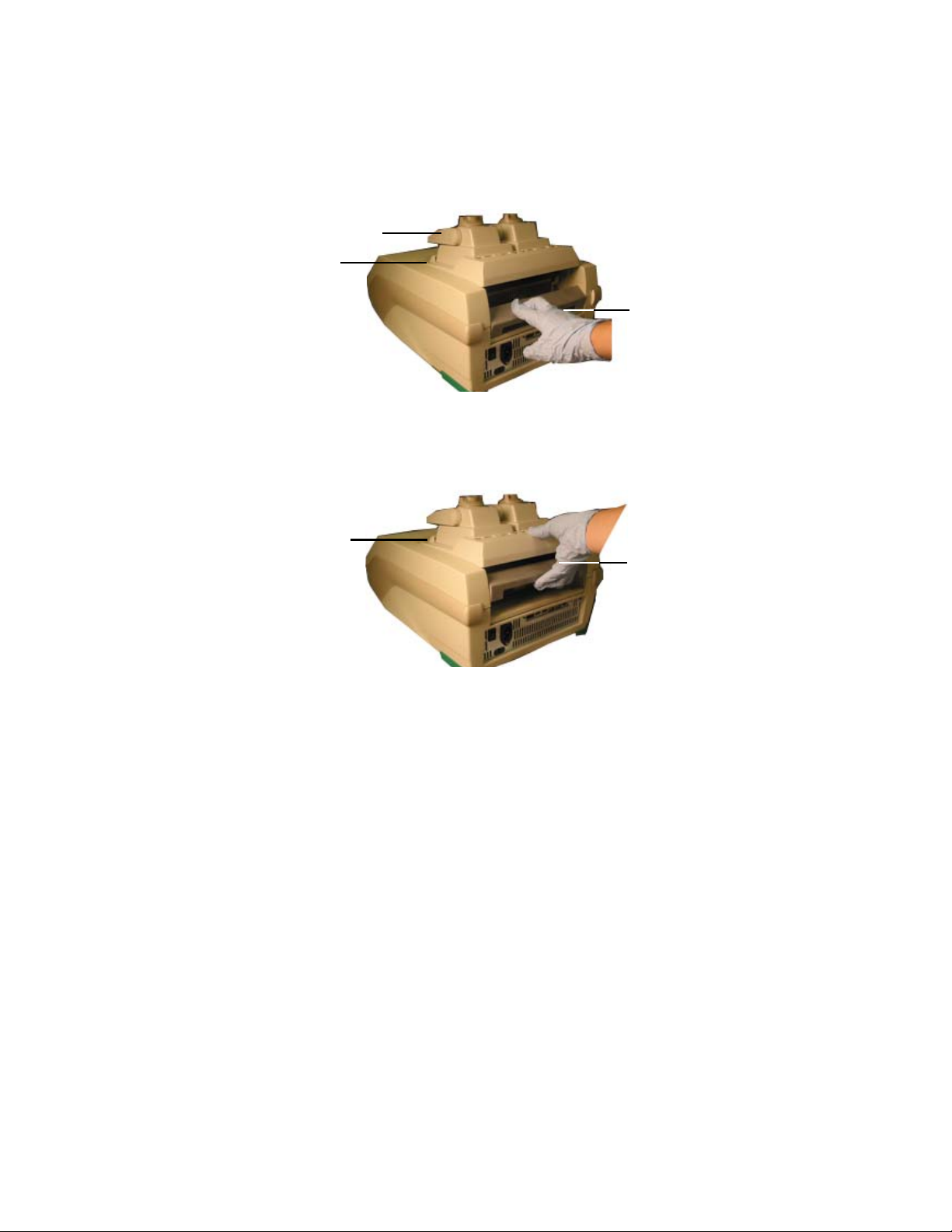

To insert either a 96-, dual 48-, or 384-well reaction module into the reaction module bay

of the thermal cycler base, follow these instructions:

1. With the locking bar in the down position and the lid lever of the reaction module

pointing to the front, lift the reaction module into the reaction module bay (Figure 6).

Leave about 1–2 cm of space in front of the module.

Lid lever (front)

Leave space here

Figure 6. Inserting the reaction module into the bay.

2. Pull the locking bar up to lock the reaction module in place (Figure 7). There is no space

at the front of the module when it is locked into the S1000 thermal cycler base.

TIP: Store the reaction module in the base when it is not in use.

Locking bar

(down position

when unlocked)

No space here

(in the locked position)

Figure 7. Locking the reaction module in place.

3. Plug the supplied power cord into the appropriate electrical outlet.

4. Turn on the thermal cycler using the power switch on the back panel of the thermal

cycler base.

NOTE: Before operating the thermal cycler, be sure to read the safety

specifications (“Safety and Regulatory Compliance” on page iv) and operating

requirements.

5. When the S1000 thermal cycler starts up, it goes through two screens: the black booting

and the self-test screens. Once the self-test is run to verify proper functions, the main

menu is displayed. Use the main menu to begin operating the thermal cycler.

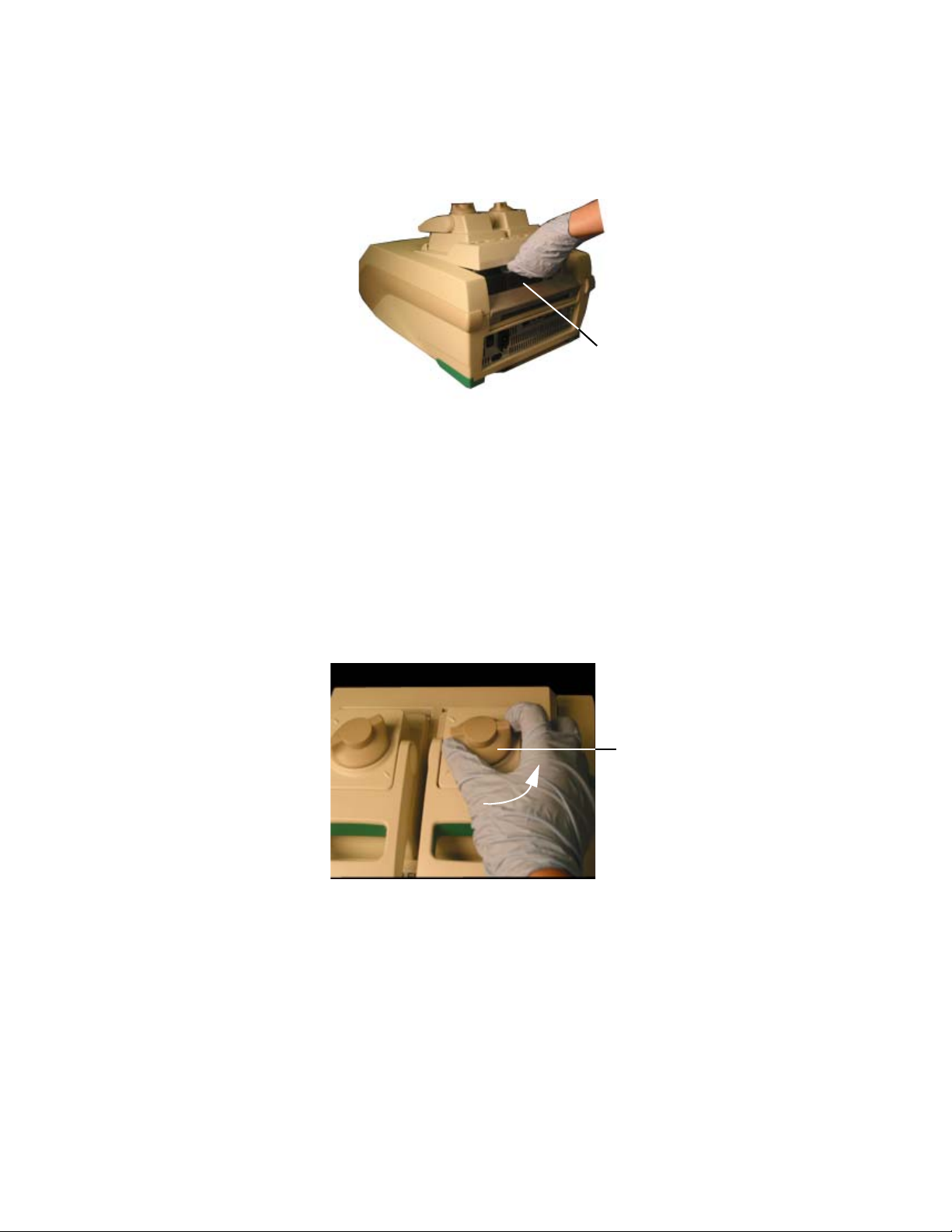

To remove the reaction module from the thermal cycler base, follow these instructions:

1. Turn off the thermal cycler.

2. Unlock and release the reaction module by pushing the locking bar down.

Locking bar

(up position

when locked)

3. Carefully lift the reaction module out of the bay (Figure 8).

WARNING! Cooling fins may be hot immediately after running a protocol or

incubation. Before lifting the reaction module, make sure that the cooling fins are

not hot.

6

Page 16

4. After removing the reaction module from the S1000 thermal cycler, store it on a clean,

flat surface where it cannot get bumped, scraped, or dropped.

Scraping the cooling fins of the reaction module or dropping the module on the fins

could compromise the ability of the module to heat and cool correctly.

Figure 8. Lifting the reaction module out of the bay.

Operating the Reaction Module Lid

S1000 Thermal Cycler Manual

Cooling fins

The inner lid of the reaction module applies heat and force to the reaction vessel lids (caps or

tape) to produce consistent and successful reactions. Heating the inner lid prevents

condensation, while applying force seals the reaction to prevent evaporation.

WARNING! After a run, the heated inner lid can remain hot. Use caution when

opening and closing the lid.

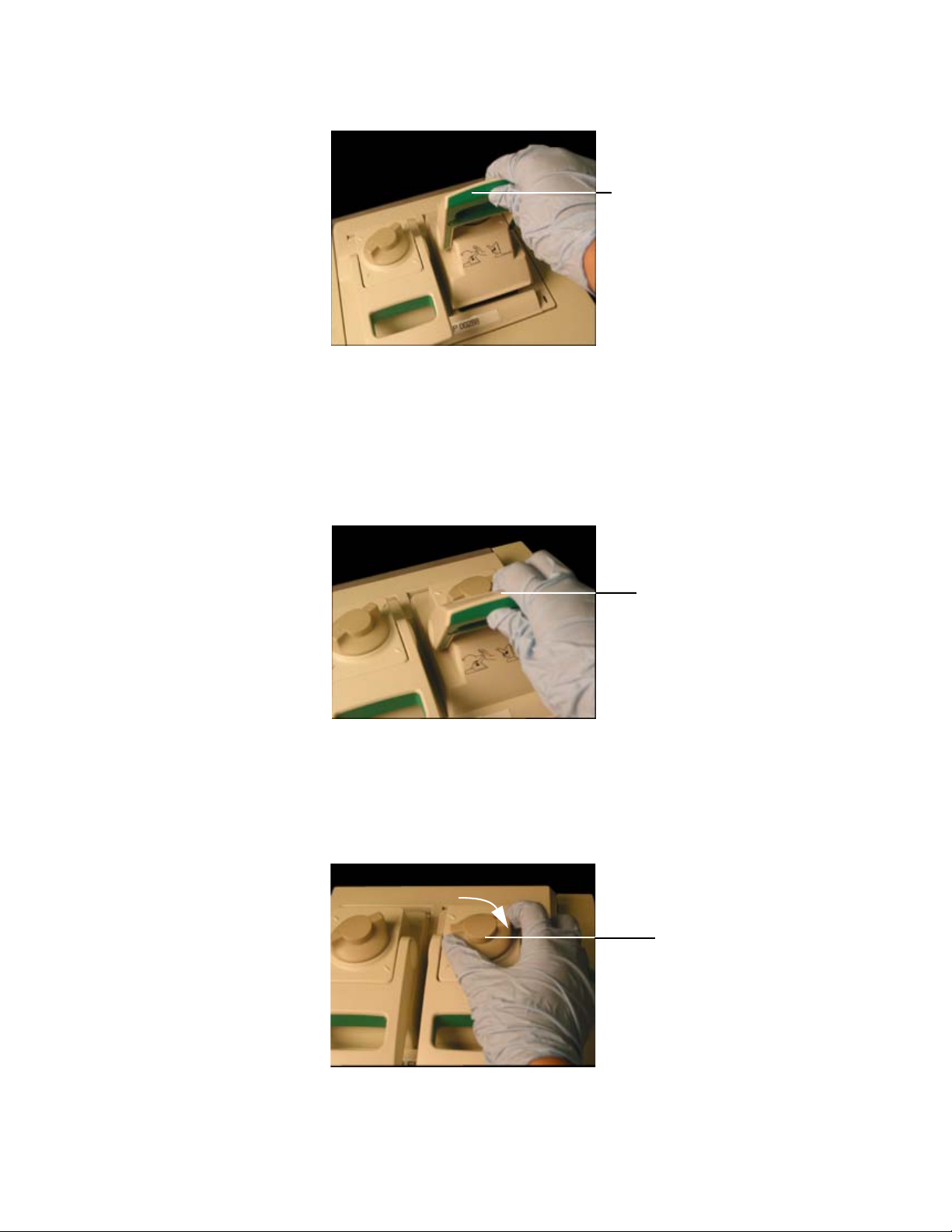

To open the lid, use the following steps:

1. Turn the lid force knob counterclockwise to release the inner lid (Figure 9).

Lid force knob

(Turn counterclockwise

to release the lid)

Figure 9. Turn the lid force knob counterclockwise to release the inner lid.

7

Page 17

Operating the Reaction Module Lid

2. To open the lid, push the lid lever back and then lift it up (Figure 10).

3. Lift the lid lever completely until the reaction module stays open without assistance.

To close the lid, use the following steps:

1. Push the lid lever down (Figure 11), making sure that the front of the lid is secured

beneath the housing, and then lock it in place.

Lid lever

Figure 10. Lift the lid lever up to open the lid.

Lid lever

Figure 11. Push the lid lever down.

2. Adjust the lid force by turning the lid force knob (Figure 12).

• Turn the knob 1/4 clockwise (to the right) to increase the lid force

• Turn the knob 1/4 counterclockwise (to the left) to decrease the lid force

Adjust the lid force to a similar setting each time by turning it to the same position.

NOTE: The position marks on the lid indicate 1/4 turns.

Lid force knob

(Turn clockwise to

secure the lid)

Figure 12. Adjust the lid force by turning the lid lever.

8

Page 18

S1000 Thermal Cycler Manual

Loading Sample Vessels into the Reaction Block

To ensure uniform heating and cooling of samples, vessels must be in complete contact with

the reaction block. Adequate contact is achieved by:

• Confirming that the block is clean before loading samples

• Firmly pressing the individual tubes or the microplate into the block wells

TIP: When using one or a few tubes, make sure to place them in the center of the

block to ensure uniform thermal cycling of all samples. Use the tube frame (catalog

#184-9000), or load at least one empty tube in each corner of the block to ensure

that the lid exerts even pressure on individual tubes.

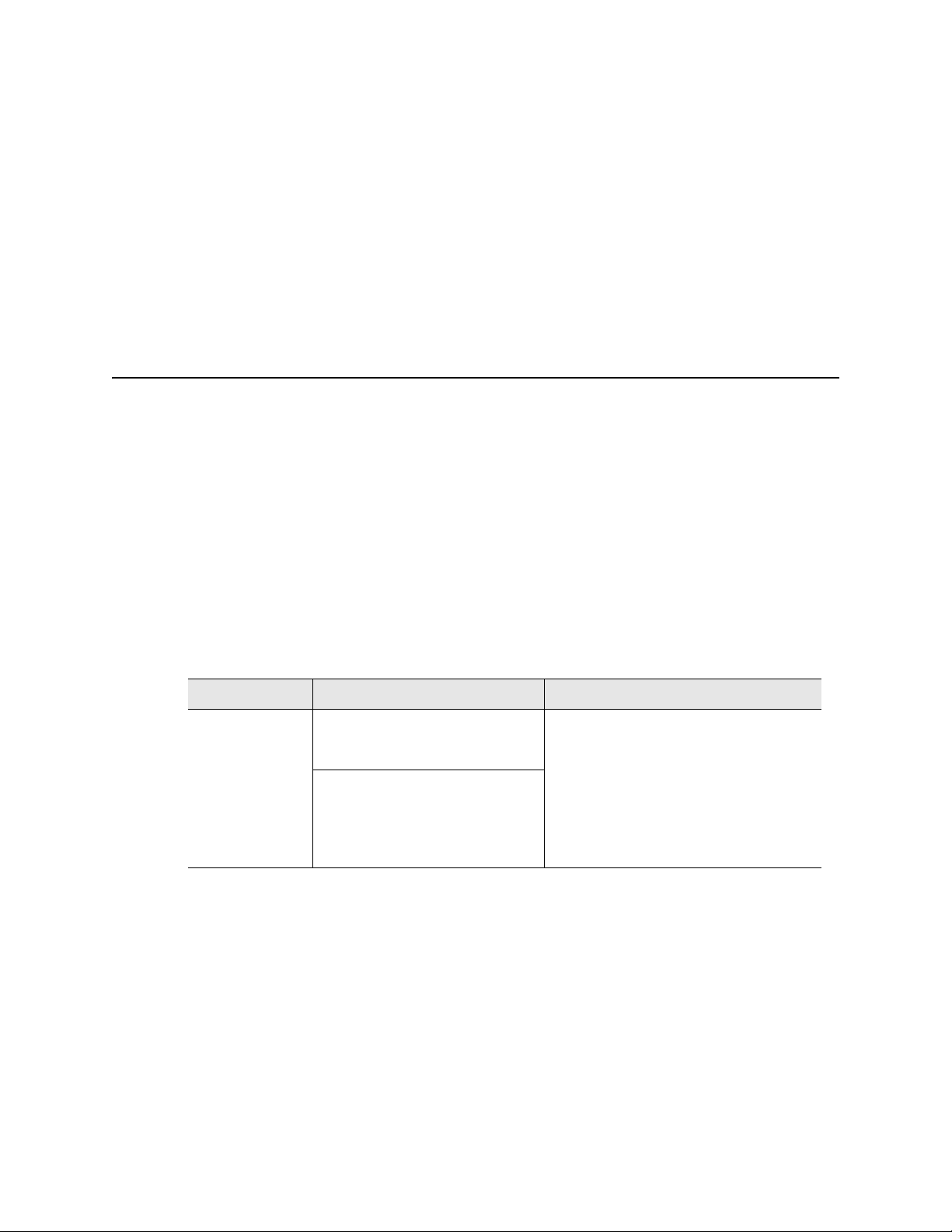

Main Menu

The main menu (Figure 13) provides access to all thermal cycler operations and displays the

status of the reaction module and the name of the thermal cycler.

Name of

thermal cycler

Options

Status message

Figure 13. The main window of the S1000 thermal cycler.

Select the options in the main menu to start these instrument functions:

• RUN

• NEW

• EDIT — to modify stored protocol files

• FILES

• VIEW

• TOOLS

— to run an existing protocol file

— to create a new protocol file

— to copy, move, rename, delete, or secure protocol files and/or folders

— to review an existing protocol file

— to change thermal cycler settings or to view the last protocol that was run

The File Tree

All protocol files are stored in the file tree. The file tree displays when you need to select a

protocol to run, edit, or view.

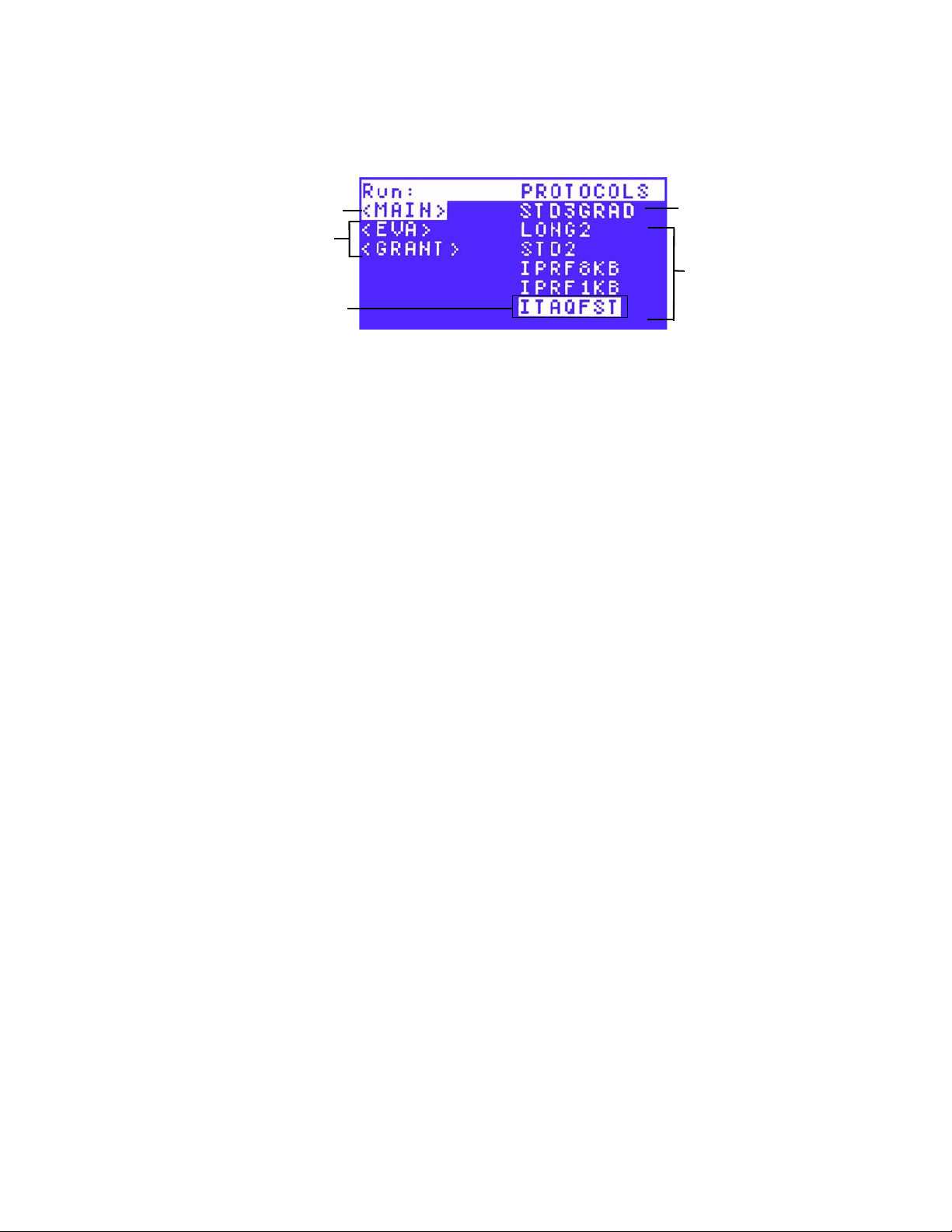

The file tree (Figure 14) includes these folders:

• MAIN folder — stores the preinstalled protocols and cannot be deleted or renamed.

The preinstalled files can be run or copied by any user. Do not store user-created

protocols in the MAIN folder

9

Page 19

Operating the Reaction Module Lid

• User folders — contain user-created protocol files. User folders and associated files

can be secured with a password. The files cannot be edited or deleted without using

the password

Selected folder

User folders

Selected file

Figure 14. The file tree of the S1000 thermal cycler.

NOTE: If a folder contains more than six protocols, use the arrow keys to scroll

down to see all the protocols. All folder names are displayed with angle brackets (<

and >) surrounding the name.

User-created

protocol file

Preinstalled

protocols

10

Page 20

S1000 Thermal Cycler Manual

2 Creating and Editing Protocols

Read this chapter for information on creating and editing protocols.

• Protocol steps (below)

• Creating a new protocol (page 12)

• Parameters for temperature or gradient steps (page 19)

• Editing an existing protocol (page 22)

• Sample volume and lid temperature (page 27)

Protocol Steps

Table 9 includes a list of steps in a protocol. The table also includes the limits and range of the

parameters.

Table 9. Protocol steps and parameters of the S1000 thermal cycler

Step Name Parameters and Ranges Description

TEMP

(Temperature)

Temperature in °C: The target

temperature between 0.0 and

100.0°C in tenths of a degree

Hold time: The hold time

between 1 sec and 18 hr in the

format of hr:min:sec. To enter an

infinite hold, press the ∝ (infinite,

0) key

Instructs the thermal cycler to ramp to

the target temperature, and hold that

temperature for the specified amount

of time

11

Page 21

Creating a New Protocol

Table 9. Protocol steps and parameters of the S1000 thermal cycler (continued)

Step Name Parameters and Ranges Description

GRAD

(Gradient

range)

GOTO GOTO step: The step number of

END (No parameters) A protocol step that instructs the

Lower: The lower temperature

in the gradient. Enter a number

between 30.0 and 99.0°C in

tenths of a degree

Upper: The upper temperature

in the gradient. The maximum

temperature is 100°C. Enter a

temperature within 24.0°C of the

lower temperature

Time:The hold time between 1

sec and 18 hr in the format of

hr:min:sec. To enter an infinite

hold, press the ∝ key (infinite, 0)

key

the first step in the repeat.

ADDTNL REPEATS: The

number of additional times that

the steps repeat.

Instructs the thermal cycler to ramp to

the target temperature gradient across

the block, and hold that temperature

gradient for the specified amount of

time

A protocol step that instructs the

thermal cycler to repeat a set of steps

for the specified number of times.

NOTE: The total number of cycles in

the protocol is the number of GOTO

repeats, plus the first cycle.

thermal cycler to finish the protocol

Creating a New Protocol

NOTE: The internal memory of the S1000 thermal cycler can hold up to 400, 2-step

protocols.

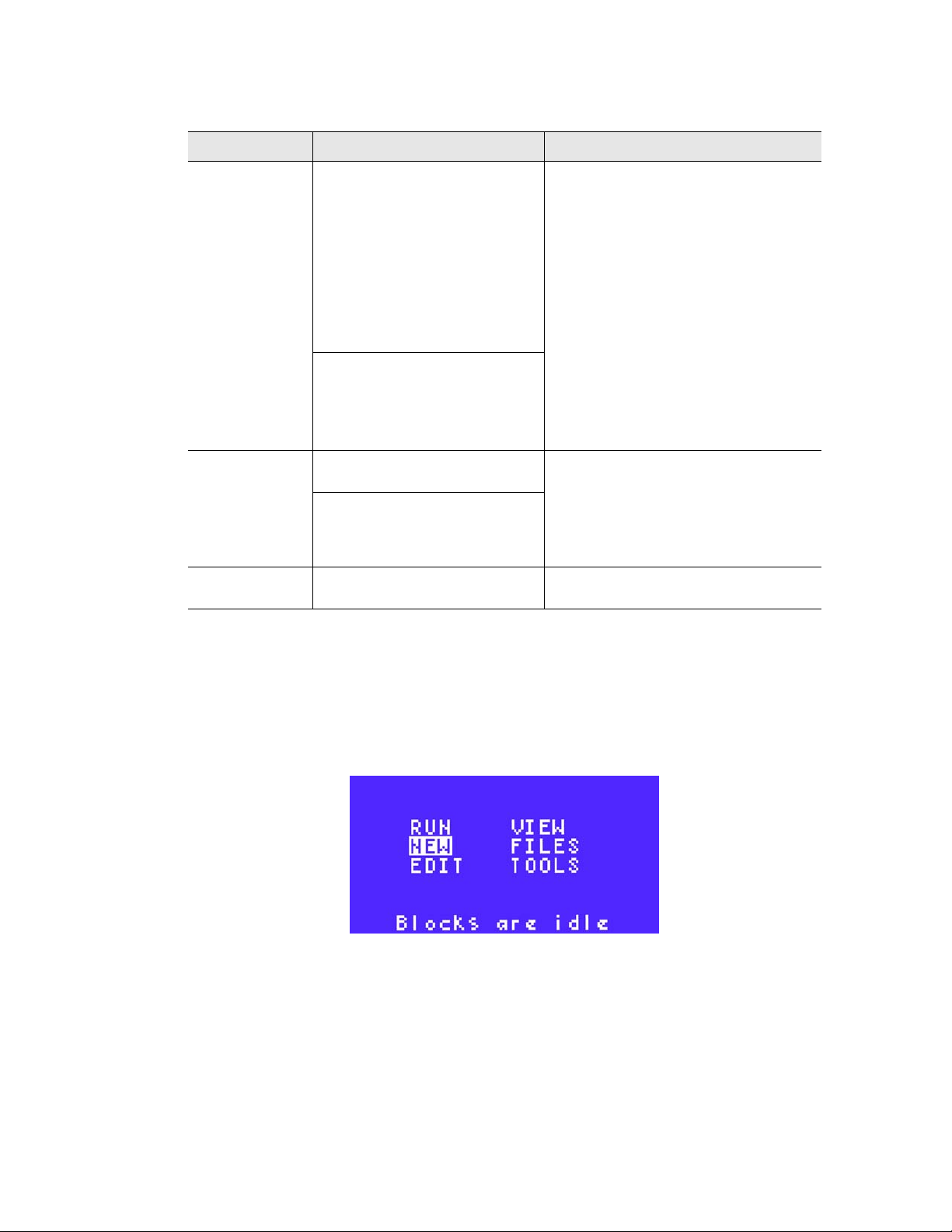

To create a protocol:

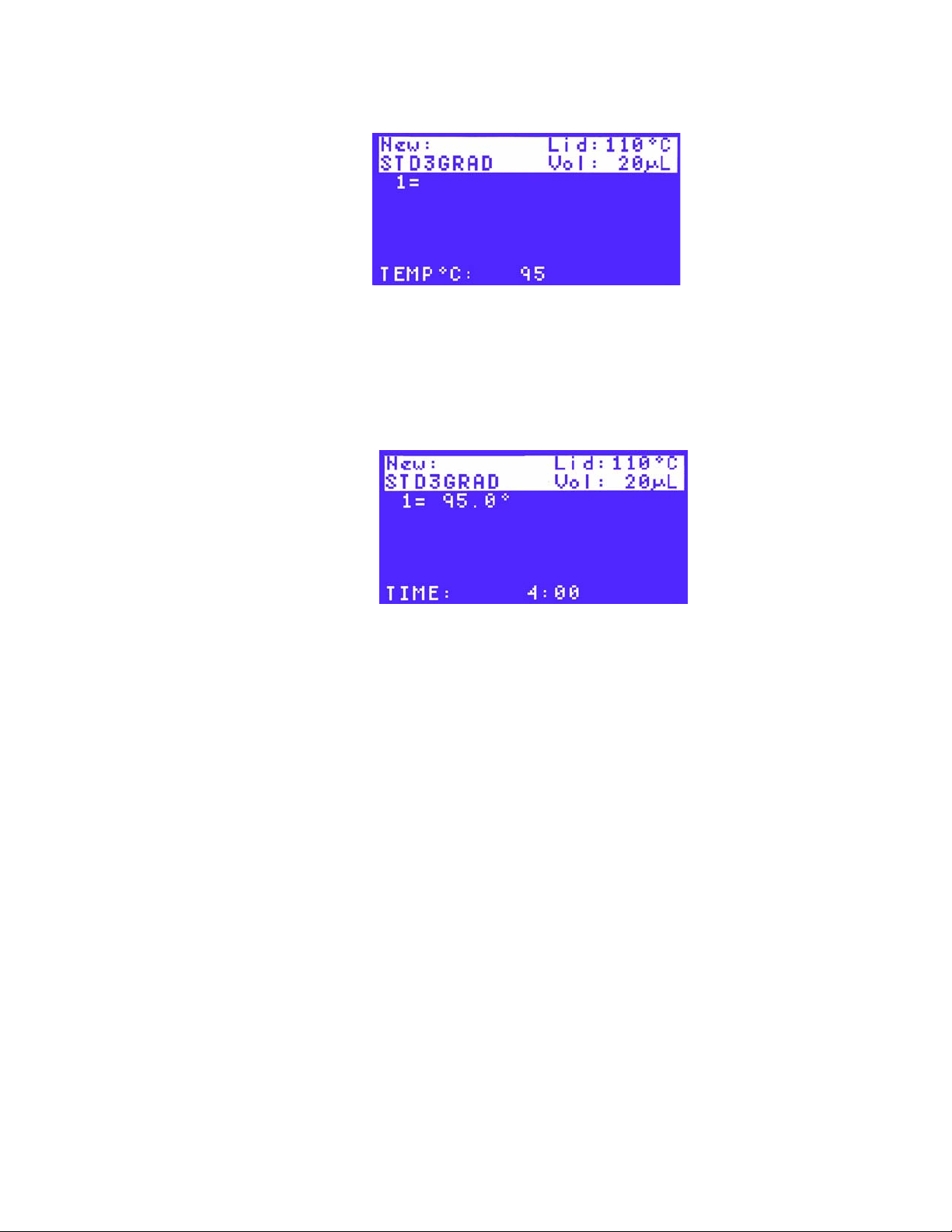

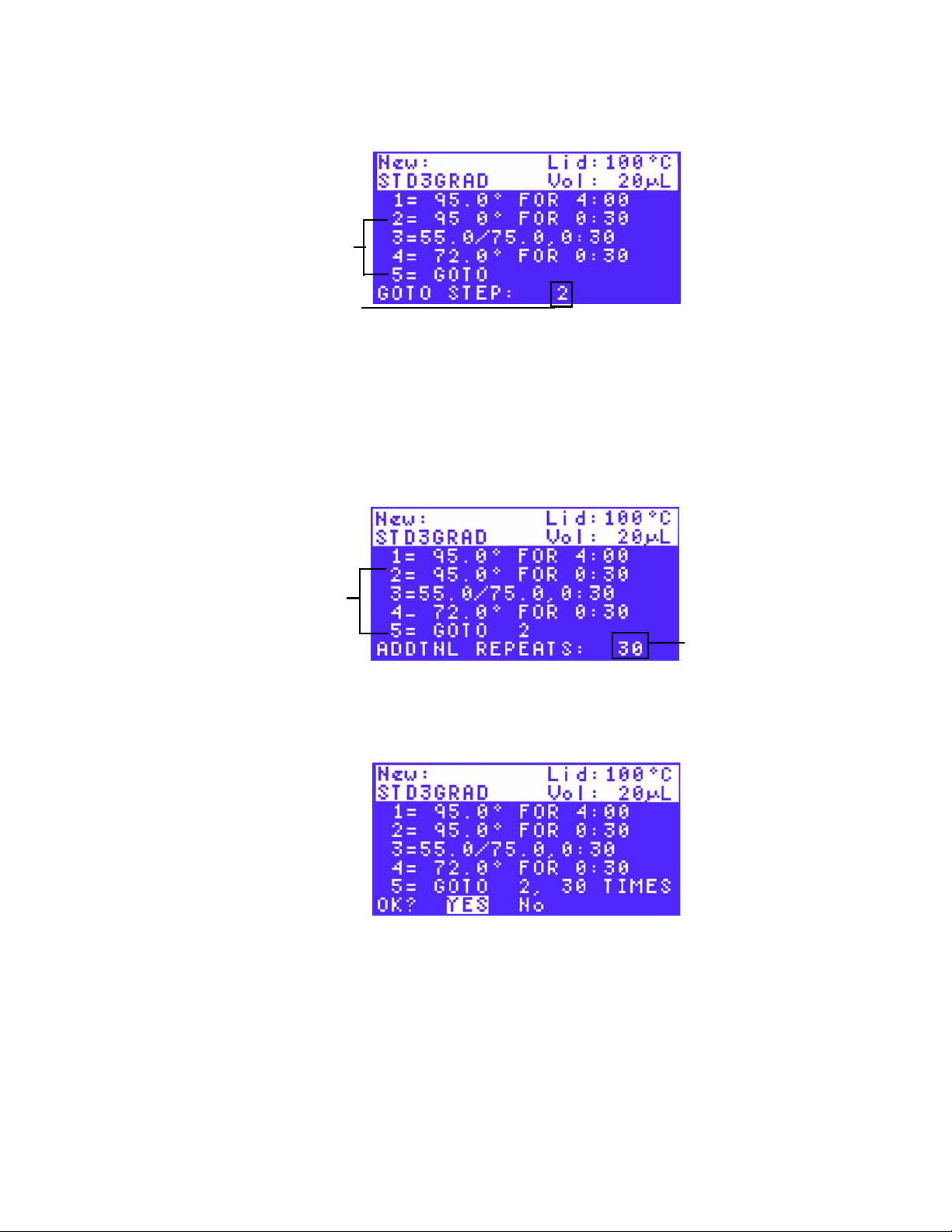

1. Select NEW from the main menu (Figure 15). Press ENTER to confirm the selection.

Figure 15. Select NEW from the main menu.

2. Use the numeric keys to enter the name of the new protocol file. Enter a letter by

pressing the up or down arrow key and a number by pressing the numbered key. For

example, to select the letter C, press the up key 3 times. To select the letter S, press the

12

Page 22

S1000 Thermal Cycler Manual

down key eight times. Press ENTER to continue to the next space. Press ENTER to

continue to the next screen.

NOTE: A protocol file name can contain 1–8 characters and must be unique to the

folder. To delete or change a letter, press CANCEL and select a new letter. To

delete the entire name, press CANCEL multiple times.

In Figure 16, the characters STD3 are entered, and the cursor is highlighting the next

space.

Figure 16. STD3 is entered as the protocol name.

3. (Optional) Enter a new lid temperature, and press ENTER to continue to the next screen.

NOTE: The lid temperature can range from 0 to 110°C. When the block is running

an infinite hold at a temperature below the Turn off below parameter, the lid heater

maintains 31.0°C. To change the default Turn off below parameter, select TOOLS

> DEFAULTS.

4. (Optional) Enter the sample volume in microliters (µl), and press ENTER to continue to

the next screen.

NOTE: Entering a sample volume between 1 and 50 selects Calculated

Temperature control mode, which is the standard mode. Entering zero (0) in the

volume field selects Block mode. Calculated mode is the recommended mode

because it most accurately represents the actual sample temperature. For more

information about Temperature control modes, see page 27.

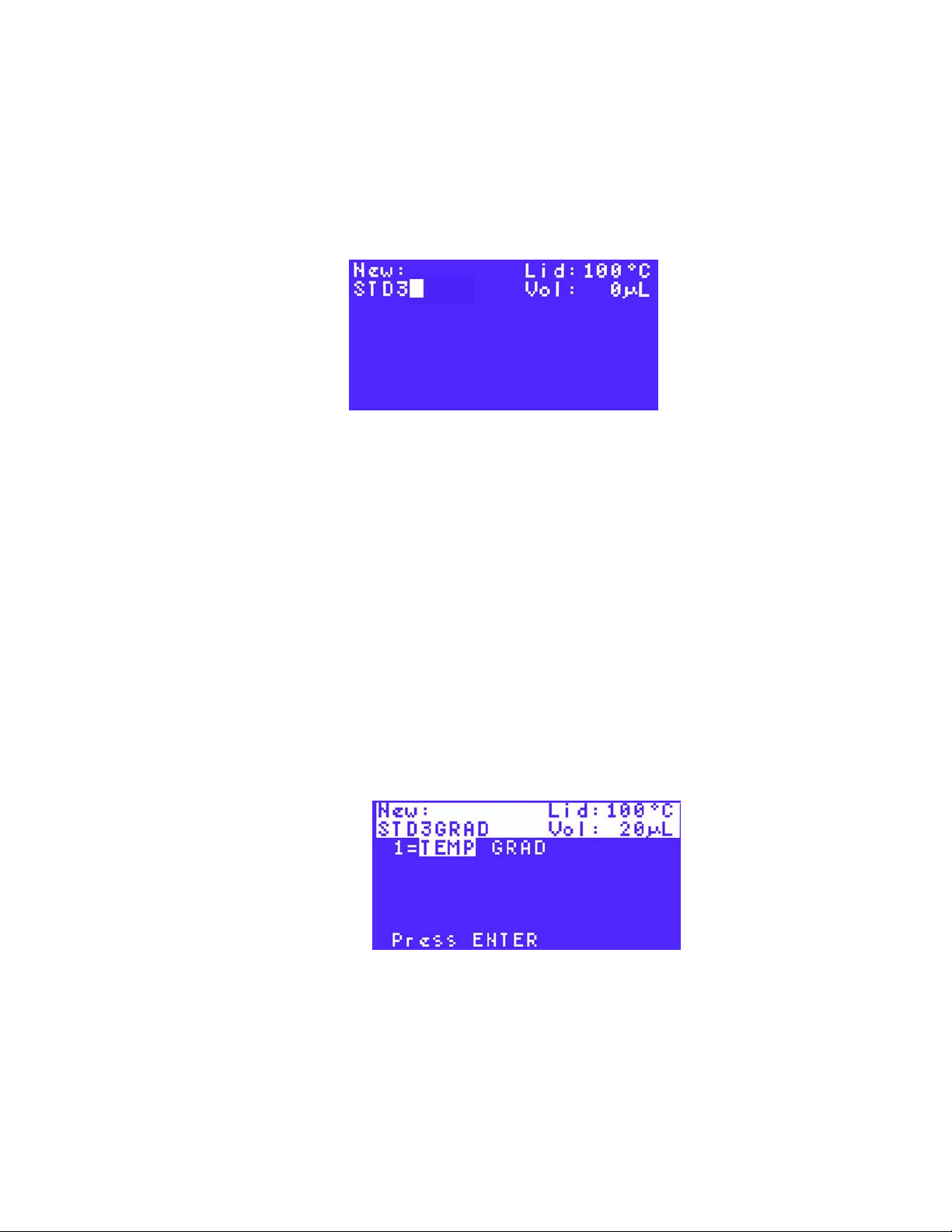

5. Using the arrow keys, select TEMP to enter a temperature step or GRAD to enter a

gradient temperature step in the protocol file. Press ENTER to continue to the next

screen.

In Figure 17, TEMP is selected as the temperature step.

Figure 17. TEMP is selected as the temperature step in this protocol file.

NOTE: The first step in a protocol must be either a TEMP or GRAD step.

6. Enter the target temperature between 0 (zero) and 100.0°C for the temperature step.

Press ENTER to continue to enter the next item in the protocol.

13

Page 23

Creating a New Protocol

In Figure 18, the target temperature is 95°C.

7. Enter the hold time (TIME) in minutes and seconds using the numeric keys. The hold

time (TIME) ranges between 0:01 (one second) and 18:00:00 (18 hours). Entering 0 (zero)

adds an infinite hold and holds this step FOREVER. Press ENTER to continue to the

next field.

For example, to enter 4 minutes (4:00), type 400. To enter 30 seconds, type 30. In

Figure 19, the hold time is four minutes.

Figure 18. Target temperature of 95°C is used in this protocol.

Figure 19. The hold time is 4 minutes in this protocol.

8. Select YES, No, or Option by pressing the right and left arrow keys. Press ENTER to

continue to the next screen.

• YES — to confirm the current parameters for this protocol step

• No — to change a parameter in this protocol step

• Option — to add more parameters to this protocol step. For more information

about entering options, see “Adding an Increment to a Temperature Step”

(page 19)

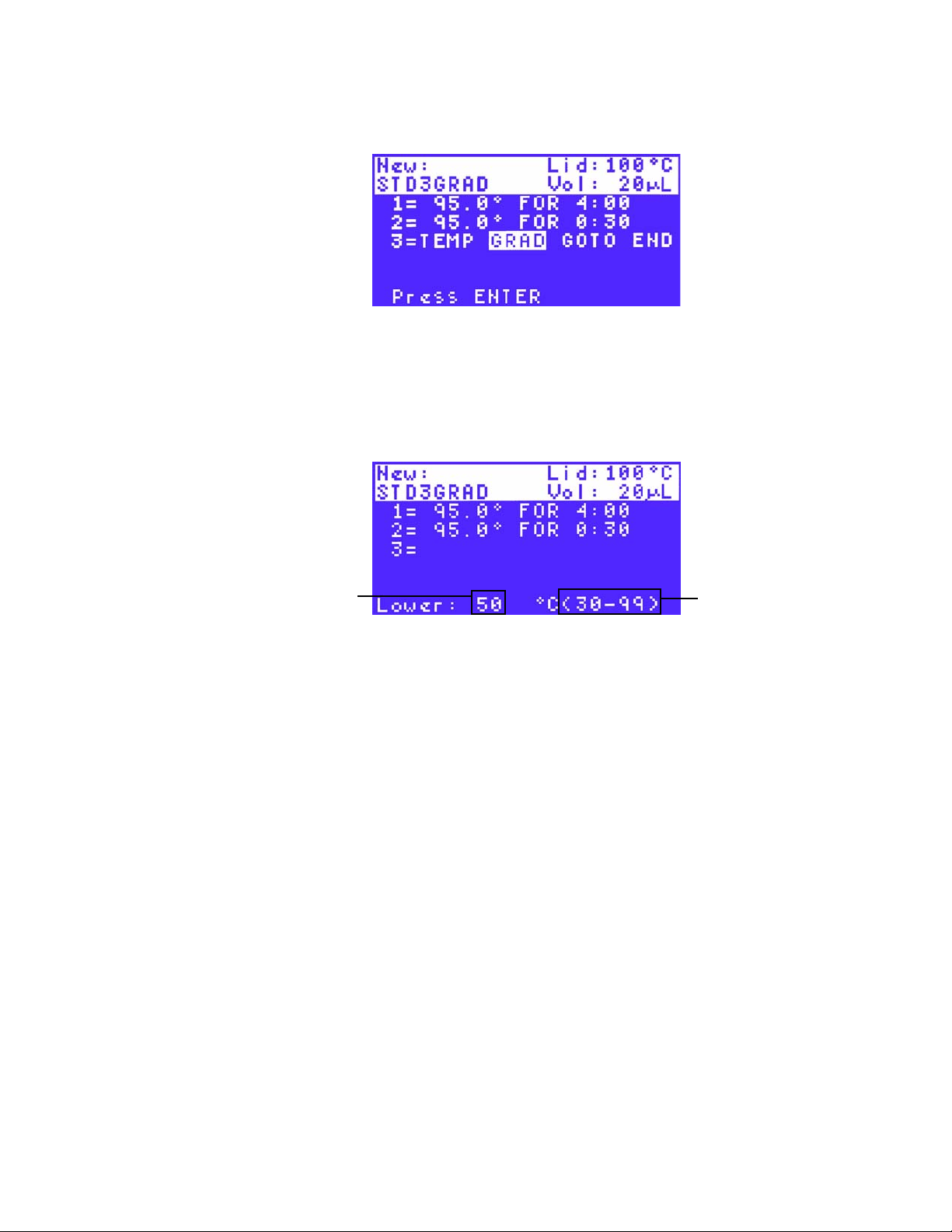

9. (Optional) Enter a gradient temperature step by pressing the right arrow key to select

GRAD (Figure 20). Press ENTER to continue to the next screen.

NOTE: A temperature gradient is limited to a 24°C spread. The lowest possible

“lower” temperature in the gradient is 30°C and the highest “upper” temperature is

14

Page 24

S1000 Thermal Cycler Manual

100°C. Therefore the lowest gradient is 30–54°C, and the highest possible gradient

is 76–100°C.

Figure 20. GRAD is selected in the gradient temperature step.

TIP: Check the temperature in each row of the block in a gradient by selecting the

gradient calculator tool (TOOLS > GRADCALC on page 58).

10.Enter the lower temperature in the gradient. The lower temperature is at the front (row H)

of the block.

In Figure 21, the lower temperature is 50°C.

Lower

temperature

(back row)

Figure 21. The lower temperature is 50°C in this protocol.

11.Enter the upper temperature in the gradient. The upper temperature is at the back (row

A) of the block.

NOTE: The range of temperature is limited by the widest available range for

gradient, which is 24°C. The highest value that can be entered for the upper

temperature is 100°C.

12.Enter a hold time between 0:01 (one second) and 18:00:00 (18 hours).

13.Select YES, No, or Option by pressing the right and left arrow keys, then press ENTER

to continue to the next screen:

• YES — to confirm the current parameters for this protocol step

• No — to change a parameter in this protocol step

• Option — to preview the temperature gradient. If Option is selected, select VIEW

on the next screen to view the gradient or EXT to add a hold time extension. Press

ENTER again to return to the previous screen

Range of

temperatures to

be chosen

15

Page 25

Creating a New Protocol

In Figure 22, the gradient is formed on a 96-well block with a range from 55–75°C. This

screen displays the approximate temperature of each row of the block, and labels the

front and back rows.

14.Repeat the instructions in steps 6–9 to continue entering additional temperature steps. In

Figure 23, four steps are entered.

Entered steps

Figure 22. The approximate temperature of each row of the block.

Choose new

step type

Figure 23. Enter all the temperature steps.

NOTE: A protocol can contain up to 99 protocol steps. The first step must be a

temperature (TEMP) step, while the last step must be an END step.

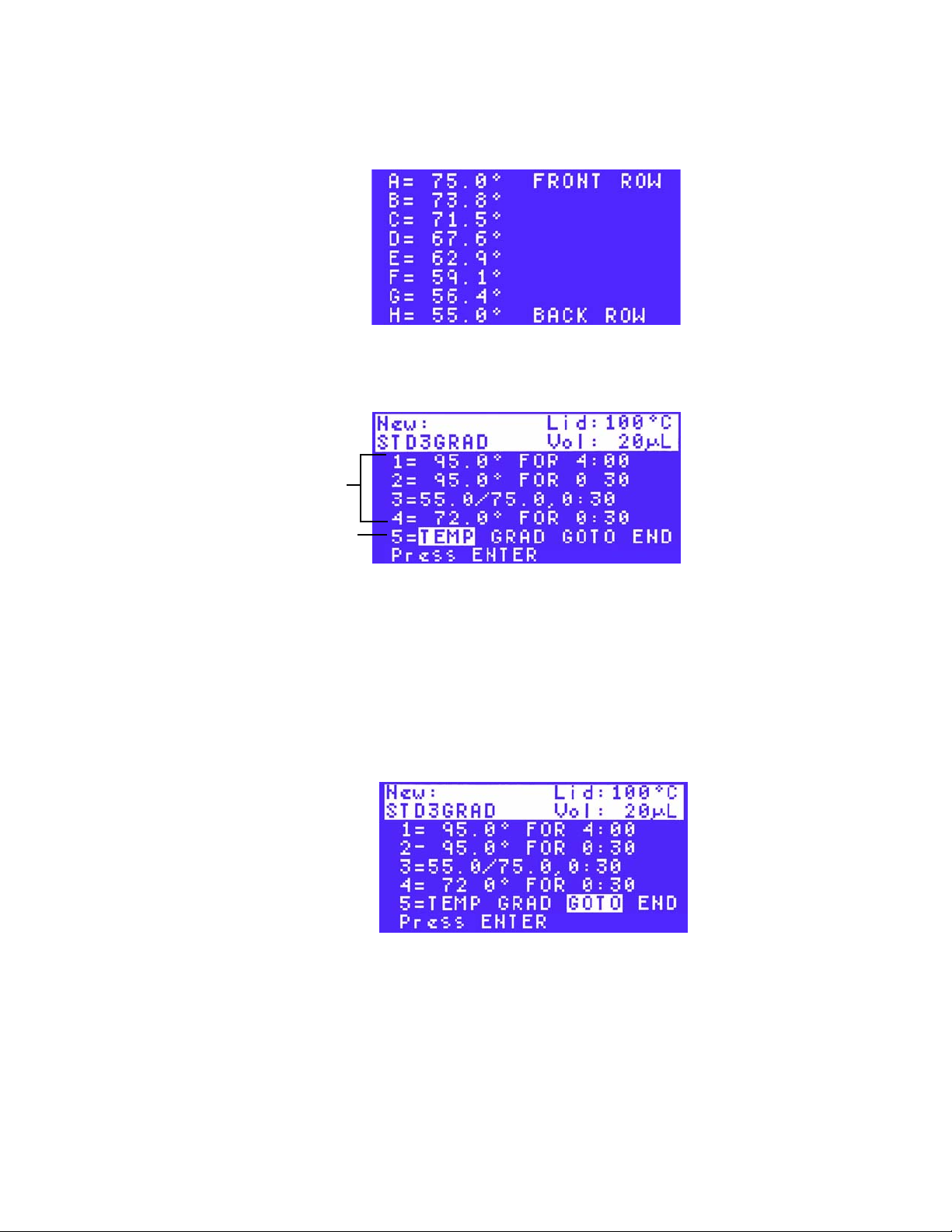

15.(Optional) To enter a GOTO step immediately after the set of steps to be repeated in a

cycle, use the arrow keys and select GOTO. Press ENTER to continue to the next

screen.

For more information about how the GOTO step creates a cycle, see “Protocol Steps”

(page 11).

In Figure 24, step 5 is a GOTO step.

Figure 24. A GOTO step is selected.

NOTE: The GOTO step cannot be the first or the last step in the protocol.

16

16.Enter the step number for the first step in the GOTO repeats using the numeric keys.

Press ENTER to continue to the next screen.

Page 26

S1000 Thermal Cycler Manual

In Figure 25, the first step is 2. The GOTO step instructs the thermal cycler to return to

step 2 and repeat all the steps between steps 2 and 5.

Steps that

repeat during

GOTO step

First step in

GOTO repeats

Figure 25. Enter the first step in the GOTO repeats.

17.Enter the number between 1 and 9999 for the additional repeats (ADDTNL REPEATS) in

the GOTO step. Then press ENTER to continue to the next screen.

NOTE: The GOTO step adds additional cycles to the PCR protocol. The first cycle

is not included in the GOTO step. For example, to run a PCR protocol with 31

cycles, enter 30 repeats in the GOTO step.

In Figure 26, the number of repeats is 30, and the total number of cycles is 31.

Steps that

repeat in the

GOTO step

Figure 26. Enter the number of repeats in a GOTO step.

18.Select YES to accept the GOTO step parameters (Figure 27), or select No to return to

the beginning of this step and change the GOTO step parameters. Then press ENTER to

continue to the next screen.

Figure 27. Confirm a GOTO step by selecting YES.

19.Enter the remaining steps by choosing the step type and adding parameters. Then press

ENTER to continue to the next screen.

TIP: To instruct the thermal cycler to emit a sound at the end of the protocol,

include a BEEP option in the final temperature step (page 21).

Number of

additional repeats

in a GOTO step

17

Page 27

Creating a New Protocol

20.Select END using the arrow keys to instruct the thermal cycler to finish the protocol file.

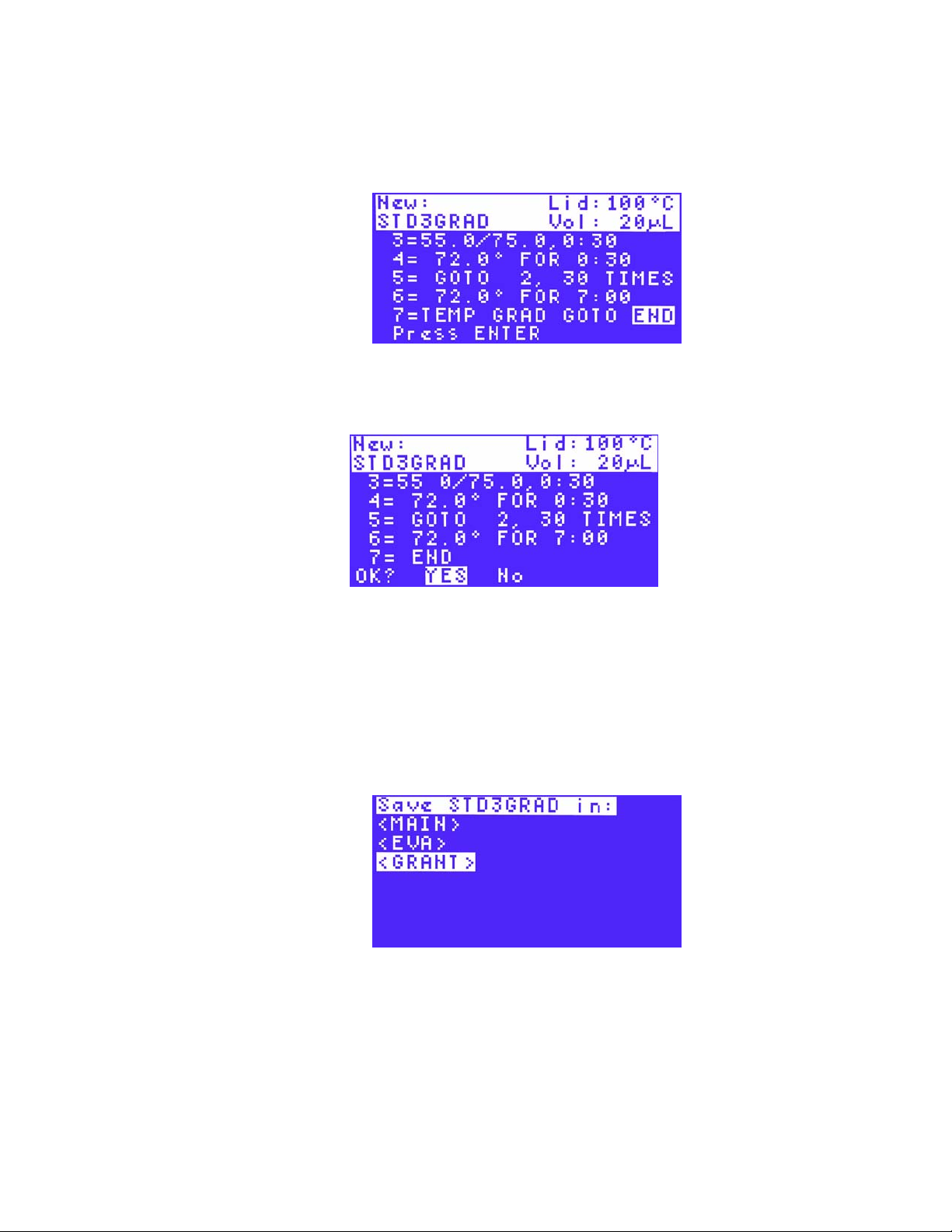

Press ENTER to continue to the next screen. In Figure 28, the END step is selected.

NOTE: The END step must be the last step of a protocol; a protocol can only

contain one END step.

21.Select YES (Figure 29) to accept the protocol step parameters or No to return to the

beginning and select a different protocol step.

Figure 28. The END step in a protocol.

Figure 29. Select YES to accept the protocol parameters.

22.Use the arrow keys to select the folder where you want the new protocol file to be saved,

and press ENTER to save the protocol file.

NOTE: The file tree folder screen does not appear if there are no user-created

folders (i.e. the MAIN folder is the only folder on the list). Saving the protocol in the

MAIN folder is not recommended. If the protocol is saved in the MAIN folder, we

recommend moving it to a user-created folder. (See “Moving a Protocol File” on

page 41 for more information.)

In Figure 30, the STD3GRAD file is saved in the GRANT

Figure 30. The STD3GRAD file is to be saved in the GRANT folder.

To run a protocol, follow the instructions in “Preparing to Run a Protocol” on page 29.

folder.

18

Page 28

S1000 Thermal Cycler Manual

Parameters for Temperature or Gradient Steps

Table 10 includes a list of options for temperature and gradient steps for the S1000 thermal

cycler. The table also includes the limits and range of the parameters.

Table 10. Options and parameters for protocols on the S1000 thermal cycler

Step Name Parameters and Ranges Description

INC

(Increment)

EXT

(Extend)

RATE

(Ramp rate)

Beep (No parameters) Applies only to a temperature step (see

A temperature from –10.0 to

10.0°C per cycle in tenths of a

degree

A time from –60 to 60 sec per

cycle

A number from 0.1 to 5°C per

sec

Applies only to a temperature step (see

“Adding an Increment to a

Temperature Step” on page 19).

Instructs the thermal cycler to

increment (change) the target

temperature of a step with each cycle,

where a positive number increases the

temperature and a negative number

decreases the temperature

Applies to both temperature and

gradient steps (see “Extending the

Hold Time in a Temperature Step” on

page 20). Instructs the thermal cycler

to extend the hold time with each

cycle. A positive number increases the

hold time and a negative number

decreases the hold time

Applies only to a temperature step (see

“Changing the Ramp Rate in a

Temperature Step” on page 21).

Instructs the thermal cycler to ramp to

the target temperature at the specified

ramp rate in that step

“Adding a Beep to a Temperature

Step” on page 21). Instructs the

thermal cycler to beep to signal that

the thermal cycler has reached the

target temperature for that step

Adding an Increment to a Temperature Step

The increment (INC) parameter changes the target temperature of a protocol step. The

increment can increase or decrease the target temperature with each cycle in the protocol.

To add an increment:

1. Select OPTION using the arrow keys. Press ENTER to continue to the next screen.

19

Page 29

Parameters for Temperature or Gradient Steps

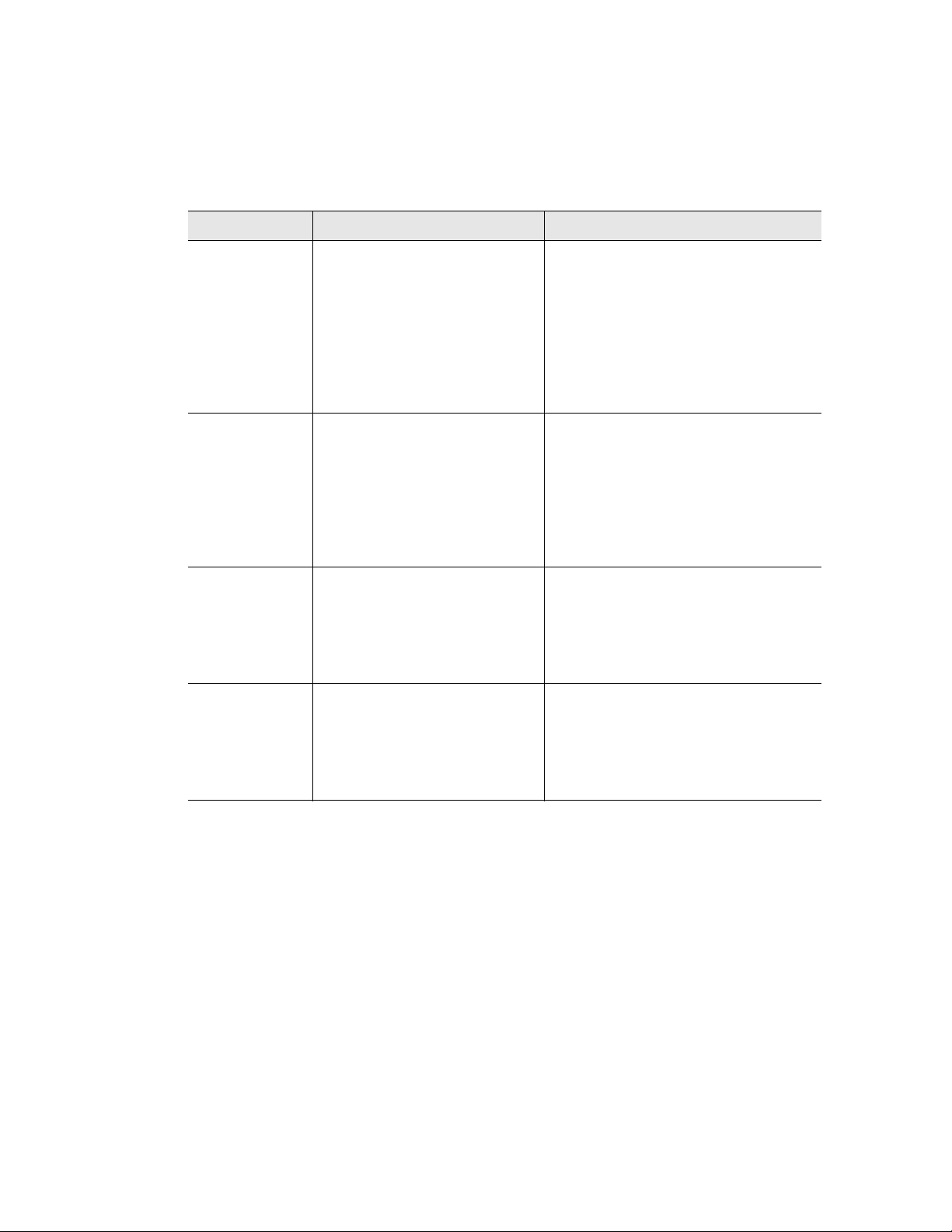

In Figure 31, OPTION is selected to add an increment to a temperature step.

Figure 31. Select OPTION to add an increment to a temperature step.

NOTE: The INC parameter must be added to a step within the GOTO repeats in

order to increment with each cycle of the reaction.

2. Select INC using the arrow keys (Figure 32) to add an increment to the protocol step in

each cycle. Press ENTER to continue to the next screen.

Figure 32. Select INC to add an increment.

3. Enter the increment temperature using the numeric keys. To decrease the temperature

each cycle, enter a negative number by pressing the CANCEL (–) key. Press the PAUSE

(

.

) key to enter a decimal point. Then press ENTER to continue to the next screen.

NOTE: Enter an increment from –10.0 to 10.0°C per cycle in tenths of a degree,

and within the limits of a temperature step (0–100°C).

In Figure 33, the increment is +0.5°C. The target temperature for step 3 will increase by

0.5°C each cycle.

Figure 33. Enter the increment temperature.

4. To confirm the parameters of the protocol step, select YES and then press ENTER. To

change the parameters, select No and then press ENTER.

Extending the Hold Time in a Temperature Step

20

The EXT parameter changes the hold time for a temperature or gradient temperature step. The

extension increases or decreases the hold time with every cycle.

Page 30

S1000 Thermal Cycler Manual

To add an extension:

1. Select OPTION using the arrow keys. Press ENTER to continue to the next screen.

2. Select EXT using the arrow keys to add an increment to the protocol step in each cycle.

Press ENTER to continue to the next screen.

NOTE: The EXT option must be added to a step within a GOTO repeat in order to

extend with each cycle of the reaction.

3. Enter the extension time in seconds using the numeric keys. To decrease the hold time in

each cycle, enter a negative number by pressing CANCEL (–). Then press ENTER to

continue to the next screen.

NOTE: Enter an extension time from –60 to 60 seconds per cycle in whole

numbers. The time entered must be between tenths of a degree. This value should

also be within the limits of a temperature step, which is 1 second to 18 hours.

4. To confirm the parameters of the protocol step, select YES and then press ENTER. To

change the parameters, select No and then press ENTER.

Changing the Ramp Rate in a Temperature Step

The RATE parameter changes the ramp rate of a temperature step. The ramp rate is the rate at

which the thermal cycler heats or cools to the target temperature of a step.

To change the rate, follow these instructions:

1. Select OPTION after entering the initial temperature step parameters, and then press

ENTER to continue to the next screen.

2. Select RATE to change the ramp rate (Figure 34). Press ENTER to continue to the next

screen.

Figure 34. Select RATE to change the ramp rate.

3. Enter a ramp rate (in °C/sec) using the numeric keys. Press PAUSE (

point.

NOTE: Enter a ramp rate between 0.1 and 5°C/sec in tenths of a degree.

4. To confirm the parameters of the protocol step, select YES and then press ENTER. To

change the parameters, select No and then press ENTER.

.

) to enter a decimal

Adding a Beep to a Temperature Step

The BEEP parameter instructs the thermal cycler to emit a sound when the temperature

reaches its target. A

TIP: Add the beep step to a temperature step, such as an infinite (FOREVER) hold,

to have the thermal cycler give a signal when it initiates the step.

BEEP can be added to any temperature step.

21

Page 31

Editing an Existing Protocol

To add a beep:

1. Select OPTION after entering the initial temperature step parameters, and then press

ENTER to continue to the next screen.

2. Select BEEP to signal the end of the protocol step. Press ENTER to continue to the next

screen.

NOTE: The BEEP parameter can only be added to a temperature step.

3. To confirm the parameters of the protocol step, select YES and then press ENTER. To

change the parameters, select No and then press ENTER.

Editing an Existing Protocol

NOTE: A protocol that is already running cannot be edited. Changes made in a

protocol that is running apply to the next time the protocol runs. To stop editing a

protocol, press CANCEL several times.

Editing the Lid Temperature and Sample Volume

To edit an existing protocol:

1. Select EDIT from the main menu (Figure 35). Press ENTER to confirm the selection.

Figure 35. Select EDIT from the main menu.

2. Using the arrow keys, select the folder that contains the protocol file to be edited. Press

ENTER to continue to the next screen.

In Figure 36, the file named STD3 is selected in the folder named EVA.

Figure 36. THE STD3 file in the EVA folder is selected.

3. Enter the new lid temperature (optional) or use the default lid temperature. Press ENTER

to accept the lid temperature and continue to the next screen.

NOTE: The lid temperature can range from 0 to 110°C. When the block is running

an infinite hold at a temperature below the Turn off below parameter, the lid heater

maintains 31.0°C. To change the default Turn off below parameter, select TOOLS

> DEFAULTS.

22

Page 32

S1000 Thermal Cycler Manual

4. Enter a new sample volume (optional) or use the default volume. Press ENTER to

continue to the next screen.

NOTE: Entering a sample volume between 1 and 50 selects Calculated

Temperature control mode, which is the standard mode. Entering zero (0) in the

volume field selects Block mode. Calculated mode is the recommended mode

because it most accurately represents the actual sample temperature. For more

information about temperature control modes, see page 27.

Inserting a Protocol Step

1. Select EDIT from the main menu (Figure 37). Press ENTER to confirm the selection.

Figure 37. Select EDIT from the main menu.

2. Using the arrow keys, select the folder that contains the protocol file to be edited. Press

ENTER to continue to the next screen.

3. Select a protocol step to edit using the arrow keys. Press ENTER to continue editing the

step.

In Figure 38, step 4 is selected for editing.

Figure 38. Select the protocol step to be edited.

4. Select INS to insert a step above the selected protocol step. In Figure 39, INS is selected

to insert a step above step 4.

Selected step

Choose a method

Figure 39. INS is selected to insert a step above step 4.

5. Select TEMP, GRAD, or GOTO as the type of protocol step to be inserted. Press ENTER

to continue to the next screen.

23

Page 33

Editing an Existing Protocol

In Figure 40, a temperature step (TEMP) is selected.

Figure 40. TEMP is selected as the type of protocol step to be inserted.

6. Enter the step parameters, then press ENTER to confirm each parameter.

In Figure 41, the target temperature of 72°C is entered.

Figure 41. The temperature of the inserted step is entered.

7. (Optional) Enter more step parameters by selecting OPTION. For example, add an

increment or extension to this temperature step. For more instructions about entering

additional parameters to a step, see “Parameters for Temperature or Gradient Steps” on

page 19.

In Figure 42, OPTION is selected to add parameters to step 4.

Figure 42. Select OPTION to add additional parameters.

8. Enter the parameters of the new step. Then press ENTER to confirm each parameter.

Deleting a Protocol Step

1. Select EDIT from the main menu. Press ENTER to confirm the selection.

2. Using the arrow keys, select the folder that contains the protocol file to be edited. Press

ENTER to continue to the next screen.

24

3. Select a protocol step to delete using the arrow keys. Press ENTER to continue editing

the step.

4. Select DEL to delete the selected protocol step. In Figure 43, step 4 is selected to

delete. Press ENTER to continue to the next screen.

Page 34

S1000 Thermal Cycler Manual

In Figure 43, step 4 is selected to be deleted.

Figure 43. Select DEL to delete a protocol step.

ENTER

5. Delete the selected step. Press

screen. Notice that the deleted step parameters are replaced with the parameters of the

next step.

6. Confirm the deletion. When prompted with Save changes?, select YES and press

ENTER to delete the step. Alternatively, select No and press ENTER to return to the

beginning of this step.

In Figure 44, YES is selected.

to delete the step and continue to the next

Figure 44. Select YES to delete the selected step.

Editing a Protocol Step

To change the parameters in the existing protocol steps, use the following instructions:

1. Select EDIT from the main menu. Press ENTER to confirm the selection.

2. Using the arrow keys, select the folder that contains the protocol file to be edited. Press

ENTER to continue to the next screen.

3. Select a protocol step to delete using the arrow keys. Press ENTER to continue editing

the step.

4. Select EDIT to delete the selected protocol step. Press ENTER to continue to the next

screen.

TIP: When you first select EDIT

protocol step. To edit the parameters in a different protocol step, press the arrow

keys to go to that step.

,

you can edit the parameters in the selected

25

Page 35

Editing an Existing Protocol

In Figure 45, step 4 is selected to be deleted. Notice the original parameter for

temperature is 55°C.

Choose EDIT

5. Change the first parameter in the step by pressing the keys on the control panel to enter

the temperature. Then press ENTER to continue to the next parameter.

In Figure 46, the temperature is changed from 55 to 65°C.

Original

parameters

Figure 45. Select EDIT to delete a protocol step.

Figure 46. Enter a new temperature.

6. Change the second parameter in the step by pressing the numeric keys to type a new

parameter. Then press

In Figure 47, the hold time is changed to 35 seconds.

7. Continue editing the existing parameters in each step (optional). Press the up and down

arrow keys to choose an earlier or later step in the protocol.

ENTER

to continue to continue to the next step.

Figure 47. Enter a new hold time.

Enter a new

parameter

26

Page 36

In Figure 48, the temperature parameter is changed to 70.0°C in step 4.

Enter new

parameter

in next step

Figure 48. The temperature parameter is changed from 72.0°C to 70.0°C.

8. Press ENTER to finish changing parameters in the step and to continue editing the

protocol.

Sample Volume and Lid Temperature

The sample volume and lid temperature influence the outcome of a PCR protocol.

• Sample volume — determines the temperature control mode, which influences the

amount of time the samples are held at the target temperature

• Lid temperature settings — determine the temperature of the heated lid and when it

cuts off. If the temperature is too high, the sample temperature might rise above the

target temperature

S1000 Thermal Cycler Manual

The S1000 thermal cycler provides various ways of managing and entering sample volume

and lid temperature settings:

• Change the setting when creating a protocol (page 12)

• Change the settings when editing the protocol (page 22)

• Change the settings when preparing to run a protocol (page 29)

Temperature Control Modes

The S1000 thermal cycler uses one of two temperature control modes to determine when the

sample reaches the target temperature:

• Calculated mode — the thermal cycler calculates the sample temperature based on

the sample volume when a sample volume between 1 and 50 µl is entered for 96- or

dual 48-well reaction modules or a volume between 1 and 30 µl is entered for the

384-well reaction module. The calculated mode is recommended, because it most

accurately represents the actual sample temperature

• Block mode — when a sample volume of zero (0) µl is entered, the thermal cycler

assumes that the sample temperature is the same as the measured block

temperature

Choosing the Appropriate Lid Temperature

The adjustable heated lid of the reaction module allows the user to control the lid temperature

and force. Heating the lid prevents condensation from forming inside the tubes and plates.

When the S1000 thermal cycler is running, the heated lid maintains the temperature specified

for the protocol being run. Without a heated lid, water can be lost from the reagents to

condensation, concentrating the reactants in the tube or plate.

27

Page 37

Sample Volume and Lid Temperature

The default lid temperature of the S1000 thermal cycler is 105°C for 96- or dual 48-well

reaction blocks and 95°C for 384-well blocks.

NOTE: When the block is running an infinite hold at a temperature below the Turn

off below parameter, the lid heater maintains 31.0°C. The default Turn off below

setting is 30.0°C. To change the default Turn off below, select Tools > Defaults.

28

Page 38

S1000 Thermal Cycler Manual

3 Running Protocols

Read this chapter for information on setting up the S1000 thermal cycler.

• Preparing to run a protocol (below)

• Monitoring the protocol run (page 32)

• Pausing and resuming a run (page 33)

• Skipping a step during a run (page 34)

• Canceling a run (page 34)

• Incubating samples (page 35)

Preparing to Run a Protocol

NOTE: You can run a protocol in a secure folder without entering the password

first. See “Securing Files in a Folder” on page 43 for more information about files in

secure folders.

To run a protocol:

1. Load the samples in the block. Close the lid and set the lid force using instructions on

page 8.

2. Select RUN from the main menu. Press ENTER to confirm the selection and continue to

the next screen.

NOTE: The main menu status should show Block is idle (Figure 49). With a dual

48/48 reaction module, the status message is Block are idle when the blocks are

both available to run a protocol.

Figure 49. Select RUN from the main menu.

29

Page 39

Preparing to Run a Protocol

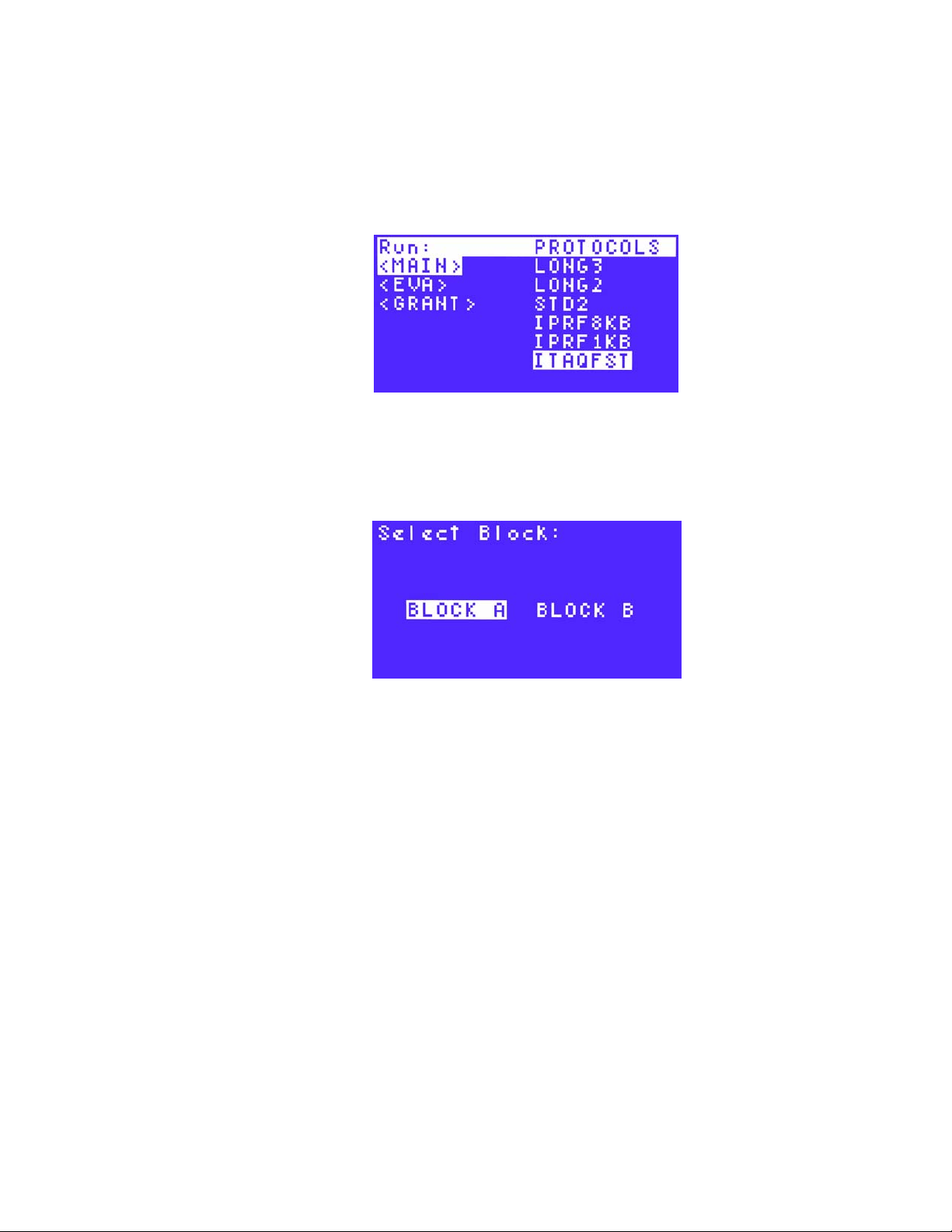

3. Select a folder that contains the protocol file of interest, and then press the right arrow

key to select the file. Press ENTER to confirm the selection and continue to the next

screen.

NOTE: Select a protocol from the preinstalled protocols from the MAIN folder or

any user folder in the file tree.

In Figure 50, the preinstalled protocol ITAQFAST is selected in the MAIN folder.

4. Select BLOCK A or BLOCK B using the right and left arrow keys. Press ENTER to

continue to the next screen. In Figure 51, BLOCK A is selected

NOTE: When a block is selected, the LED on the reaction module lights up. In a

dual 48/48 reaction module, BLOCK A appears on the left side.

Figure 50. Select the folder and protocol file.

Figure 51. Block A is selected.

5. Enter the sample volume. To use the Calculated mode (standard), enter a value between

1 and 50 µl. To use Block mode, enter 0 (zero).

NOTE: Calculated mode is the recommended temperature control mode because

it most accurately represents the actual sample temperature. See “Temperature

Control Modes” on page 27.

6. Press the numeric keys to enter a new sample volume, then press ENTER to continue to

the next screen.

30

Page 40

S1000 Thermal Cycler Manual

In Figure 52, the sample volume is 25 µl.

Figure 52. Enter a new sample volume.

NOTE: When running a dual block, the message is RUN ITAQFST on A, where

ITAQFST is the protocol and A is the block.

7. (Optional) Select VIEW to review the protocol before starting the run (Figure 53), and

press ENTER to confirm the selection.

Figure 53. Select VIEW to review the protocol.

NOTE: While reviewing the protocol, press ENTER to scroll down through the

steps in the protocol. When you reach the last step in the protocol, press ENTER

again to exit. In Figure 54, the screen shows the steps in the ITAQFST protocol.

Figure 54. View the steps of the protocol.

8. Select RUN using the arrow keys (Figure 55), and press ENTER to start running the

protocol.

Figure 55. Select RUN to start running the protocol

31

Page 41

Monitoring the Protocol Run

Monitoring the Protocol Run

Once the run begins, the progress of the run can be monitored with any one of the following

screens:

• Running screen – displays the current step parameters, temperature, hold time,

and cycle (Figure 56)

• Graphical screen – displays a graph that approximates the relationship of the

target temperatures in each step in the protocol. Each step is listed by

temperature only (Figure 57)

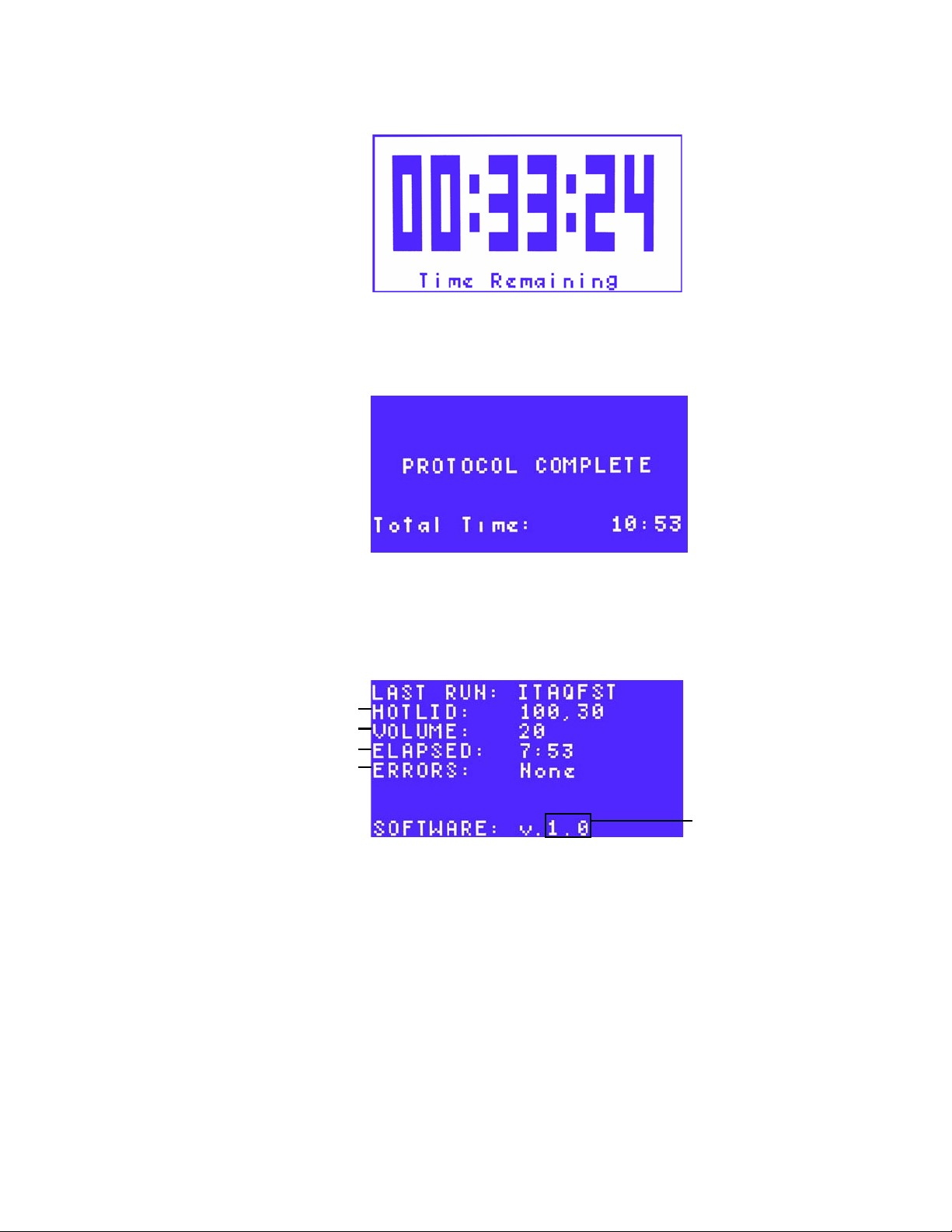

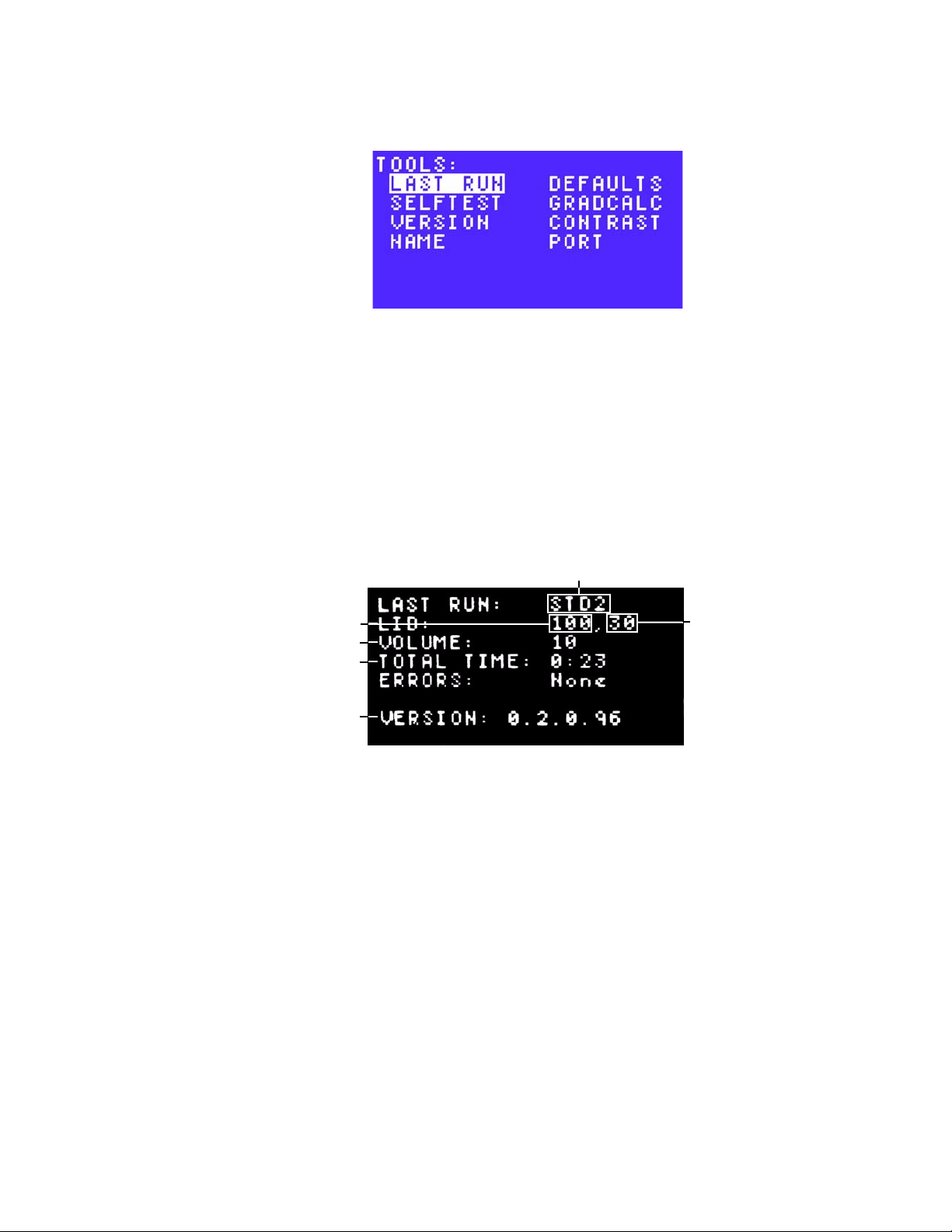

• Time Remaining screen – shows the amount of time remaining until the end of

the protocol (Figure 58)

To monitor the run:

1. Press SCREEN on the control panel.

The Running screen appears as a default (Figure 56). If SCREEN is pressed again, the

instrument shows graphical screen (Figure 57). Press SCREEN again to see the Time

Remaining screen (Figure 58).

NOTE: For the dual 48/48 reaction module, the thermal cycler displays these

screens for Block A and then for Block A. Pressing SCREEN toggles the display

through each screen and both blocks.

.

Protocol steps

(by temperature)

Target temperature

for the current step

Figure 56. The Running screen is displayed.

Hold time for current step (counts up)

Figure 57. The graphical screen is displayed.

Current hold time

Current

temperature

Flashing thick

bar shows

current step

32

Page 42

S1000 Thermal Cycler Manual

Figure 58. The Time Remaining screen.

2. When the S1000 thermal cycler completes running the protocol, the PROTOCOL

COMPLETE screen is displayed (Figure 59). After viewing this screen, press ENTER to

return to the main menu.

Figure 59. PROTOCOL COMPLETE screen is displayed with the run is completed.

3. (Optional) Press SCREEN to see a synopsis of the last protocol that was run. The

protocol summary is displayed on the LAST RUN screen (Figure 60).

NOTE: For dual 48/48 blocks, press SCREEN again to view the LAST RUN screen

for each block.

Lid temperature

Sample volume

Total run time

Errors that occurred

during the run

Figure 60. Summary of the last protocol is listed on the LAST RUN screen.

TIP: The LAST RUN screen is also available in the TOOLS option (page 53).

4. Press SCREEN

again to return to the main menu

Pausing and Resuming a Run

A running protocol may be temporarily paused. During a pause, the thermal cycler maintains

the block temperature at the current target temperature. If the block temperature has not

reached the target temperature, then the thermal cycler continues to heat or cool until it

reaches that target temperature.

Firmware used

during run

33

Page 43

Skipping a Step During the Run

WARNING! Pausing a protocol can alter the results of your PCR experiment. When

a protocol is paused during a temperature step, a longer hold time is created for

that step.

To pause and then resume a running protocol:

1. Press PAUSE on the control panel (Figure 61).

Figure 61. The protocol is paused.

2. To resume the protocol, press PAUSE again.

Skipping a Step During the Run

Protocol

paused

To skip a step while the protocol is running:

1. Press ENTER when the step to be skipped is running.

The thermal cycler skips to the next step in the protocol.

TIP: The S1000 thermal cycler cannot skip a GOTO repeat, unless the instrument is

controlled by a C1000 thermal cycler.

2. Press the right and left arrow key to select YES or No.

3. Press ENTER again to confirm the selection.

Canceling a Run

A protocol may be cancelled while it is running. When a protocol is cancelled, the block

immediately stops changing the temperature.

To cancel a running protocol:

1. Press CANCEL, then press the arrow key to select YES or No.

34

Page 44

S1000 Thermal Cycler Manual

2. Press ENTER to confirm the selection, and continue to the next screen. In Figure 62,

YES is selected.

Figure 62. Select YES to cancel a running protocol.

TIP: To cancel a protocol that is running on a dual 48/48 reaction module, press

CANCEL and then select the block that you want to cancel the run on. Press

ENTER to confirm the protocol cancellation.

The PROTOCOL CANCELLED screen appears. This screen displays the total time that

the protocol ran before being cancelled. In Figure 63, the protocol has run 2 minutes and

57 seconds.

Figure 63. The PROTOCOL CANCELLED screen.

3. Press ENTER again to return to the main menu

Incubating Samples

Samples may be kept at a constant temperature for any amount of time. The incubation

continues indefinitely unless cancelled.

WARNING! Incubating samples for an extended period of time at 4–10°C,

particularly in areas of high humidity, can cause excessive moisture condensation

around the block.

To start incubating samples:

1. Load your samples into the thermal cycler block and press INCUBATE.

NOTE: For the dual 48 reaction module, the block that contains the samples must

first be selected before continuing to the next screen.

35

Page 45

Incubating Samples

2. Select YES to use the heated lid during the incubation or No to turn off the lid during

incubation. Press ENTER to confirm. In Figure 64, YES is selected.

3. If using the heated lid, enter the lid temperature. Press ENTER to accept the default lid

temperature, or use the numeric keys to type a new lid temperature.

NOTE: Press PAUSE (

CANCEL.

In Figure 65, the lid temperature is 100°C.

Figure 64. Select YES to use the heated lid during the incubation.

.

) key to enter a decimal point. To delete a number, press

Figure 65. Enter the lid temperature.

4. Enter the incubation temperature. Press ENTER to accept the default incubation

temperature of 75°C, or use the numeric keys to type a new incubation temperature

between 0 and 100°C.

NOTE: Press PAUSE (

CANCEL.

In Figure 66, the incubation temperature is 95°C.

.

) to enter a decimal point. To delete a number, press

Figure 66. Enter the incubation temperature.

36

Page 46

S1000 Thermal Cycler Manual

5. Press ENTER to start the incubation. In Figure 67, the block is incubating at 95.0°C.

Incubation

temperature

Figure 67. The incubation temperature is 95.0°C.

TIP: During incubation, use any options in the main menu except RUN. You cannot

start a run on a block that is running an incubation.

6. To stop an incubation, press CANCEL.

7. Select YES to stop the incubation or No to continue the incubation. Press ENTER to

confirm the selection and return to the main menu. In Figure 68, YES is selected.

Figure 68. Select YES to cancel a protocol.

8. Press SCREEN three times to view the incubation parameters summarized in the LAST

RUN screen (Figure 69).

Figure 69. The incubation parameters are summarized in the LAST RUN screen.

37

Page 47

Incubating Samples

38

Page 48

S1000 Thermal Cycler Manual

4 Managing Protocol Files and

Folders

Read this chapter for information on managing protocol files and folders.

Managing Protocol Files and Folders

To manage protocol files and folders, select FILES from the main menu to open the file library

Figure 70). The menu of functions in the file library provides options for managing files and

(

folders and changes based on what is selected in the file library.

Folder

functions

Figure 70. Options for managing protocol files and folders.

Table 11 lists all the functions in the FILES option. Protocol and folder names can have a

maximum of 8 characters.

Table 11. List of functions in the FILES option

Function Description

PROTOCOLS

COPY

MOVE

DELETE

RENAME

Copies an existing protocol file and saves it with a new name

Moves a protocol file to another folder

Deletes a protocol file

Renames a protocol file

Protocol file

functions

FOLDERS

NEW

Creates a new folder

39

Page 49

Managing Protocol Files and Folders

Table 11. List of functions in the FILES option (continued)

Function Description

SECURE

DELETE

RENAME

Copying a Protocol File

To copy a protocol file:

1. Select FILES from the main menu.

2. Select COPY using the arrow keys (Figure 71), then press ENTER to confirm the

selection.

NOTE: The COPY function makes a copy of the existing file and requires a new file

name for the copied file. You can copy and move secured or preinstalled protocols

to your folder.

Protected files can be deleted and edited once the password

protecting them is entered

Deletes an empty folder.

NOTE: A folder cannot be deleted if it contains protocol files.

Renames an existing folder

Figure 71. Select COPY using the arrow keys.

3. Using the arrow keys, select the folder that contains the protocol file to be copied, then

press the right arrow key to select the appropriate file. Press ENTER to continue to the

next screen.

In Figure 72, the STD2 protocol file is selected in the MAIN folder.

Figure 72. The STD2 protocol file is selected for copying.

40

Page 50

S1000 Thermal Cycler Manual

4. Using the arrow keys, select the destination folder. In Figure 73, the copied file is placed

into the GRANT folder. Press ENTER to confirm that the protocol was successfully

copied.

Figure 73. Select the destination folder.

5. Type a new name for the protocol copied file by pressing the up and down arrows to

select letters and the numeric keys to type numbers (Figure 74). Press ENTER to accept

the selection.

NOTE: A protocol file name can contain 1–8 characters. The characters are

numbers or capital letters. Each protocol name must be unique.

Figure 74. The protocol was successfully copied.

TIP: After copying the protocol file, make changes to the file by selecting EDIT in

the main menu (page 22).

Moving a Protocol File

NOTE: If the folder is secure, then you must enter a password to move the file.

However, the protocols in a secure folder can be copied to another folder.

To move a protocol file to another folder:

1. Select Files from the main menu.

2. Select MOVE using the arrow keys (Figure 75), then press ENTER to confirm the

selection.

Figure 75. Select MOVE using the arrow keys.

41

Page 51

Managing Protocol Files and Folders

3. Using the arrow keys, select the folder that contains the protocol file to be moved, then

press the right arrow key to select the appropriate file. Press ENTER to continue to the

next screen.

4. Using the arrow keys, select the destination folder. Press ENTER to confirm the move.

Deleting a Protocol File

NOTE: If the folder is secure, then you must enter a password to delete the file.

To delete a protocol file:

1. Select FILES from the main menu.

2. Select DELETE using the arrow keys (Figure 76), then press ENTER to confirm the

selection.

.

Figure 76. Select DELETE to delete a protocol file.

3. Using the arrow keys, select the folder that contains the protocol file to be deleted, then

press the right arrow key to select the appropriate file. Press ENTER to continue to the

next screen.

4. To delete the file, select YES and then press ENTER to return to the main menu. Select

No to cancel the deletion.

Renaming a Protocol File

To rename a protocol file:

1. Select FILES from the main menu.

2. Select RENAME using the arrow keys (Figure 77), then press ENTER to confirm the

selection.

42

Figure 77. Select RENAME to enter a new protocol name.

Page 52

S1000 Thermal Cycler Manual

3. Using the arrow keys, select the folder that contains the protocol file to be renamed, then

press the right arrow key to select the appropriate file. Press ENTER to continue to the

next screen.

4. Enter a new protocol file name using the up and down arrows to select letters and the

numeric keys to type numbers. Then press ENTER to accept the new name and return to

the main menu.

NOTE: A protocol file name can contain 1–8 characters. The characters are

numbers or capital letters. Each protocol name must be unique to all folders on the

S1000 thermal cycler.

Creating a New Folder

The S1000 thermal cycler can contain 11 folders in addition to the MAIN folder. Protocol files

are stored in the MAIN folder by default; however, it is highly recommended that files be

stored in user-created folders for easy access and ability to password-protect the files.

To create a new folder:

1. Select FILES from the main menu.

2. Select NEW from the menu using the arrow keys (Figure 78). Press ENTER to confirm the

selection.

Figure 78. Select NEW to create a new folder.

3. Enter the folder name using the up and down arrows to select letters and the numeric

keys to type numbers. Then press ENTER to accept the new name and return to the

main menu.

NOTE: A folder name can contain 1–8 characters. The characters are numbers or

capital letters. Each protocol name must be unique to the thermal cycler.

Securing Files in a Folder

Securing folders with a password prevents other users from editing, deleting, or moving your

files from the S1000 thermal cycler.

NOTE: To edit, move, or delete files stored in a secure folder, a password must be

entered. However, a password is not required for viewing, copying, or running

protocol files that are located in a secure folder.

To secure a folder with a password or to change an existing password:

1. Select FILES from the main menu.

43

Page 53