Page 1

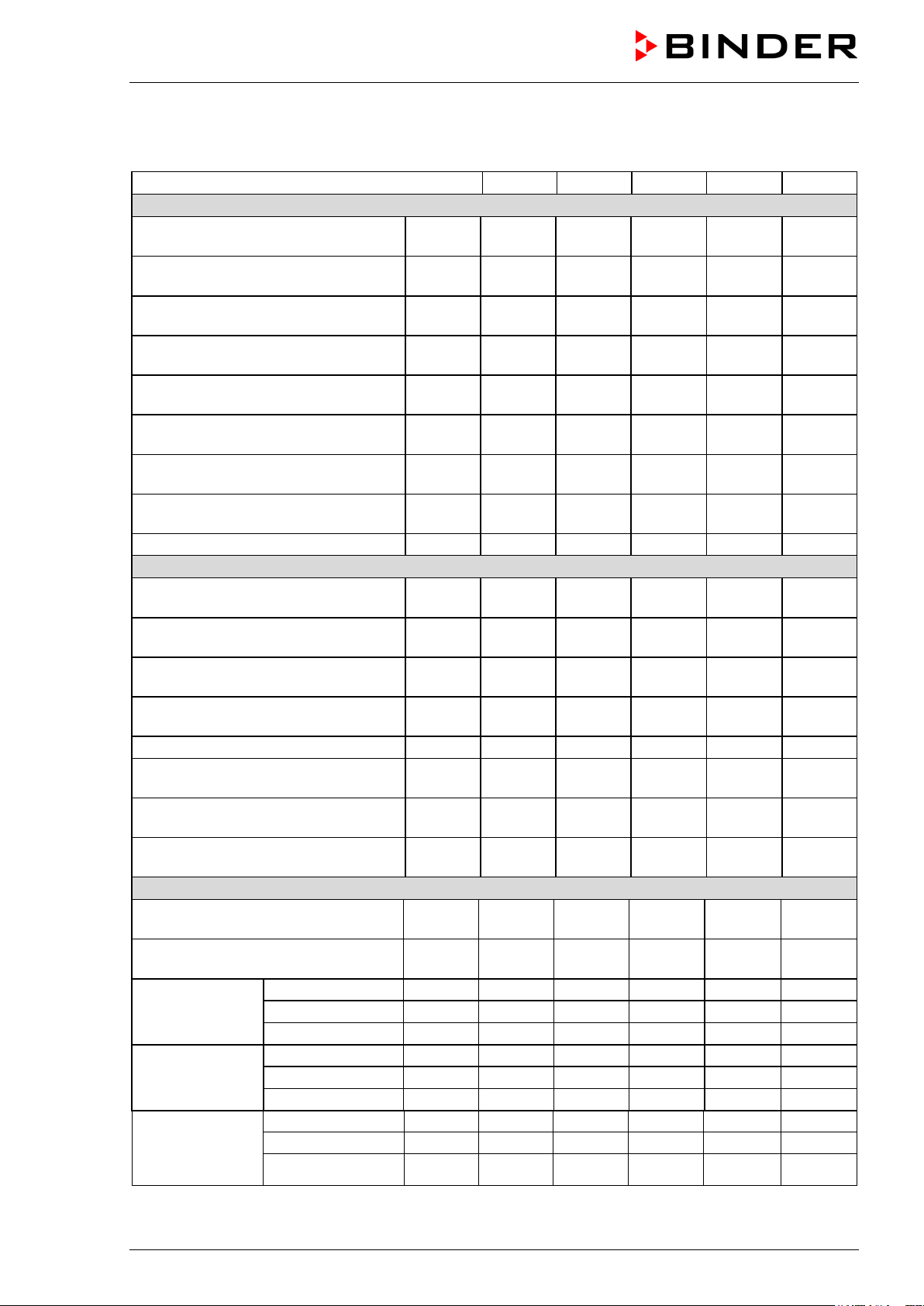

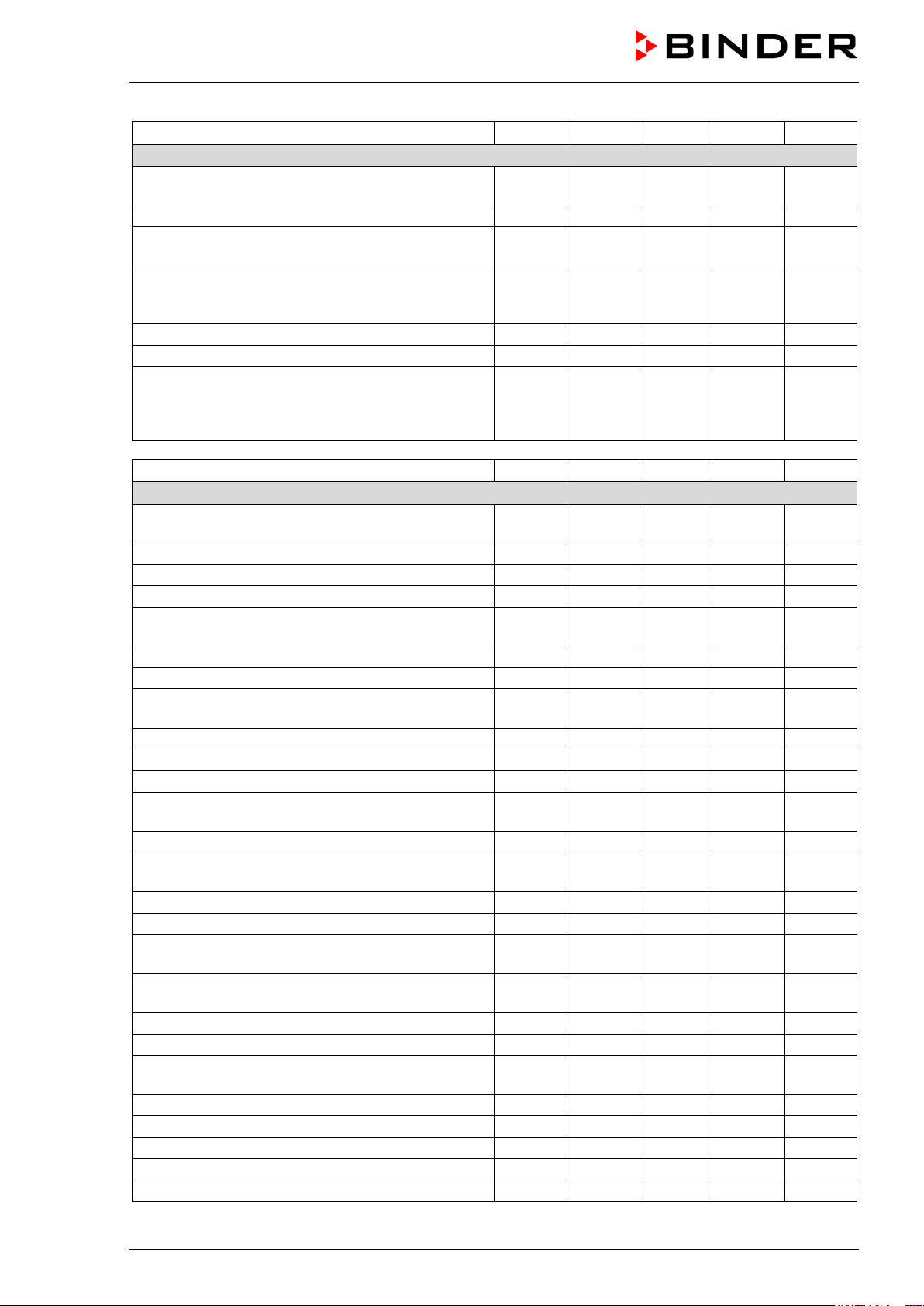

Model

Art. No.

FED 53 (E2)

9010-0210, 9110-0210

FED 53-UL (E2)

9010-0211, 9110-0211

FED 115 (E2)

9010-0212, 9110-0212

FED 115-UL (E2)

9010-0213, 9110-0213

FED 240 (E2)

9010-0214, 9110-0214

FED 240-UL (E2)

9010-0215, 9110-0215

FED 400 (E2)

9010-0216, 9110-0216

FED 400-UL (E2)

9010-0217, 9110-0217

FED 720 (E2)

9010-0218, 9110-0218

FED 720-UL (E2)

9010-0219, 9110-0219

Operating Manual

APT.line™ FED (E2)

Drying and heating ovens

with forced convection and enhanced timer

functions

with microprocessor temperature controller

BINDER GmbH

Address Post office box 102

D-78502 Tuttlingen

Tel. +49 7462 2005 0

Fax +49 7462 2005 100

Internet http://www.binder-world.com

E-mail info@binder-world.com

Service Hotline +49 7462 2005 555

Service Fax +49 7462 2005 93 555

Service E-Mail service@binder-world.com

Service Hotline USA +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacific +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS +7 495 98815 16

Issue 02/2015 Art. No. 7001-0070

Page 2

EG – KONFORMITÄTSERKLÄRUNG

EC – declaration of conformity

EC - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

Anbieter / Supplier / Fournisseur:

Anschrift / Address / Adresse:

Produkt / Product / Produit:

Typenbezeichnung / Type / Type:

Die oben beschriebenen Produkte sind konform mit folgenden EG-Richtlinien:

The products described above are in conformity with the following EC guidelines:

Les produits décrits ci-dessus sont conformes aux directives CE suivantes:

Niederspannungsrichtlinie

2006/95/EG

Low voltage directive

2006/95/EC

Directive basse tension

2006/95/CE

BINDER GmbH

Im Mittleren Ösch 5, D-78532 Tuttlingen

Trocken- und Wärmeschränke mit Umluft und erweiterten

Zeitfunktionen

Drying and heating ovens with forced convection and enhanced

timer functions

Étuves de chauffage et de séchage à convection forcée avec des

fonctions de minuterie avancées

FED 53, FED 115, FED 240, FED 400, FED 720

Richtlinie 2006/95/EG des Europäischen Parlaments und des

Rates vom 12. Dezember 2006 zur Angleichung der

Rechtsvorschriften der Mitgliedstaaten betreffend elektrische

Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen

Council Directive 2006/95/EC of 12 December 2006 on the

harmonization of the laws of Member States relating to electrical

equipment designed for use within certain voltage limits

Directive 2006/95/CE du Parlement Européen et du Conseil du 12

décembre 2006 concernant le rapprochement des législations des

États membres relatives au matériel électrique destiné à être

employé dans certaines limites de tension

EMV-Richtlinie

2004/108/EG

EMC Directive

2004/108/EC

Directive CEM

2004/108/CE

Die oben beschriebenen Produkte tragen entsprechend die Kennzeichnung CE.

The products described above, corresponding to this, bear the CE-mark.

Les produits décrits ci-dessus, en correspondance, portent l’indication CE.

Richtlinie 2004/108/EG des Europäischen Parlaments und des

Rates vom 15. Dezember 2004 zur Angleichung der

Rechtsvorschriften der Mitgliedstaaten über die

elektromagnetische Verträglichkeit und zur Aufhebung der

Richtlinie 89/336/EWG.

Directive 2004/108/EC of the European Parliament and of the

Council of 15 December 2004 on the approximation of the laws of

the Member States relating to electromagnetic compatibility and

repealing Directive 98/336/EEC.

Directive 2004/108/CE du Parlement Européen et du Conseil du

15 décembre 2004 relative au rapprochement des législations des

États membres concernant la compatibilité électromagnétique et

abrogeant le directive 98/336/CEE.

1 / 2

FED (E2) 02/2015 page 2/55

Page 3

Die oben beschriebenen Produkte sind konform mit folgenden harmonisierten Normen:

The products described above are in conformity with the following harmonized standards:

Les produits décrits ci-dessus sont conformes aux normes harmonisées suivantes:

Sicherheit / safety / sécurité:

EN 61010-1:2010 Sicherheitsbestimmungen für elektrische Mess-, Steuer-, Regel- und

Laborgeräte – Teil 1: Allgemeine Anforderungen (DIN EN 61010-1:2011,

VDE 411-1:2011)

Safety requirements for electrical equipment for measurement, control,

and laboratory use – Part 1: General requirements (IEC 61010-1:2010,

BS EN 61010-1:2010)

Règles de sécurité pour appareils électriques de mesurage, de

régulation et de laboratoire – Partie 1: Prescriptions générales (CEI

61010-1:2010, NF EN 61010:2011)

EN 61010-2-010:2003 Sicherheitsbestimmungen für elektrische Meß-, Steuer-, Regel- und

Laborgeräte – Teil 2-010: Besondere Anforderungen an Laborgeräte für

das Erhitzen von Stoffen (DIN EN 61010-2-010:2004)

Safety requirements for electrical equipment for measurement, control,

and laboratory use – Part 2-010: Particular requirements for laboratory

equipment for the heating of materials (IEC 61010-2-10:2005, BS EN

61010-2-10:2003)

Règles de sécurité pour appareils électriques de mesurage, de

régulation et de laboratoire – Partie 2-010 : Prescriptions particulières

pour appareils de laboratoire utilisés pour l’échauffement des matières

(CEI 61010-2-10:2003, NF EN 61010-2-10:2005)

EMV / EMC / CEM:

EN 61326-1:2013 Elektrische Mess-, Steuer-, Regel- und Laborgeräte - EMV-

Anforderungen - Teil 1: Allgemeine Anforderungen (DIN EN 613261:2013, VDE 0813-20-1:2013)

Electrical equipment for measurement, control and laboratory use EMC requirements - Part 1: General requirements (IEC 61326-1:2012,

BS EN 61326-1:2013)

Matériel électrique de mesure, de commande et de laboratoire Exigences relatives à la CEM - Partie 1: Exigences générales (CEI

61326-1:2012, NF EN 61326-1:2013.)

D-78532 Tuttlingen, 02.06.2014

BINDER GmbH

P. M. Binder

Geschäftsführender Gesellschafter

Managing Director

Directeur général

J. Bollaender

Leiter F & E

Director R & D

Chef de service R&D

2 / 2

FED (E2) 02/2015 page 3/55

Page 4

Product registration

FED (E2) 02/2015 page 4/55

Page 5

Content

EC – declaration of conformity ...................................................................................................................... 2

Product registration ....................................................................................................................................... 4

1. SAFETY .................................................................................................................. 7

1.1 Legal considerations ........................................................................................................................... 7

1.2 Structure of the safety instructions ...................................................................................................... 7

1.2.1 Signal word panel ........................................................................................................................... 7

1.2.2 Safety alert symbol ......................................................................................................................... 8

1.2.3 Pictograms ..................................................................................................................................... 8

1.2.4 Word message panel structure ...................................................................................................... 9

1.3 Localization / position of safety labels on the unit ............................................................................... 9

1.4 Type plate .......................................................................................................................................... 10

1.5 General safety instructions on installing and operating the drying and heating ovens FED.............. 11

1.6 Intended use ...................................................................................................................................... 12

2. UNIT DESCRIPTION ............................................................................................ 13

2.1 Equipment overview FED .................................................................................................................. 14

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION .................................................................................................... 14

3.1 Unpacking, and checking equipment and completeness of delivery................................................. 14

3.2 Guidelines for safe lifting and transportation ..................................................................................... 15

3.3 Storage .............................................................................................................................................. 15

3.4 Location of installation and ambient conditions ................................................................................. 16

4. INSTALLATION .................................................................................................... 17

4.1 Electrical connection ......................................................................................................................... 17

4.2 Connection to a suction plant (optional) ............................................................................................ 17

5. START UP ............................................................................................................ 18

5.1 Turning on the unit ............................................................................................................................ 18

5.2 Heating operation display .................................................................................................................. 18

5.3 Air change ......................................................................................................................................... 19

6. CONTROLLER SETTING .................................................................................... 19

6.1 Display / entry of temperature and ventilation set-points (without ramp function) ............................. 19

6.2 Display / entry of temperature and ventilation set-points (with selected temperature ramp) ............ 20

6.3 Time functions: Continuous operation and Timer operation ............................................................. 21

6.3.1 Switching between Continuous operation and Timer operation ................................................... 22

6.3.2 Continuous operation ................................................................................................................... 22

6.3.3 Setting the timer values ................................................................................................................ 23

6.4 User level settings ............................................................................................................................. 24

6.4.1 Temperature unit change between degrees Celsius °C and degrees Fahrenheit °F .................. 25

6.4.2 Enter a temperature ramp ............................................................................................................ 25

6.4.3 Chamber addressing .................................................................................................................... 26

6.4.4 Selecting the timer function .......................................................................................................... 27

6.4.5 Setting the interface mode and, if appropriate, the printer interval .............................................. 28

6.5 Temperature programming example ................................................................................................. 29

6.6 General notes .................................................................................................................................... 29

7. TEMPERATURE SAFETY DEVICES ................................................................... 30

7.1 Temperature safety device class 2 (DIN 12880) ............................................................................... 30

7.2 Temperature safety device class 3.1 (DIN 12880) (option) ............................................................... 31

7.3 Disconnectable audible over-temperature alarm (option) ................................................................. 32

FED (E2) 02/2015 page 5/55

Page 6

8. OPTIONS .............................................................................................................. 33

8.1 Communication software APT-COM™ 3 DataControlSystem (option) ............................................. 33

8.2 Data logger kit ................................................................................................................................... 33

8.3 HEPA fresh air filter (option).............................................................................................................. 33

8.4 Mostly gas-tight version (option for FED 53 and FED 115) ............................................................... 34

8.5 Inert gas connection with mostly gas-tight version (option for FED 53 and FED 115) ...................... 34

8.6 Analog output for temperature (option) ............................................................................................. 36

9. MAINTENANCE, CLEANING, AND SERVICE ..................................................... 36

9.1 Maintenance intervals, service .......................................................................................................... 36

9.2 Cleaning and decontamination .......................................................................................................... 37

9.2.1 Cleaning ....................................................................................................................................... 37

9.2.2 Decontamination .......................................................................................................................... 39

9.3 Sending the unit back to BINDER GmbH .......................................................................................... 40

10. DISPOSAL ............................................................................................................ 40

10.1 Disposal of the transport packing ...................................................................................................... 40

10.2 Decommissioning .............................................................................................................................. 41

10.3 Disposal of the unit in the Federal Republic of Germany .................................................................. 41

10.4 Disposal of the unit in the member states of the EC except for the Federal Republic of Germany .. 42

10.5 Disposal of the unit in non-member states of the EC ........................................................................ 43

11. TROUBLESHOOTING ......................................................................................... 44

12. TECHNICAL DESCRIPTION ................................................................................ 45

12.1 Factory calibration and adjustment ................................................................................................... 45

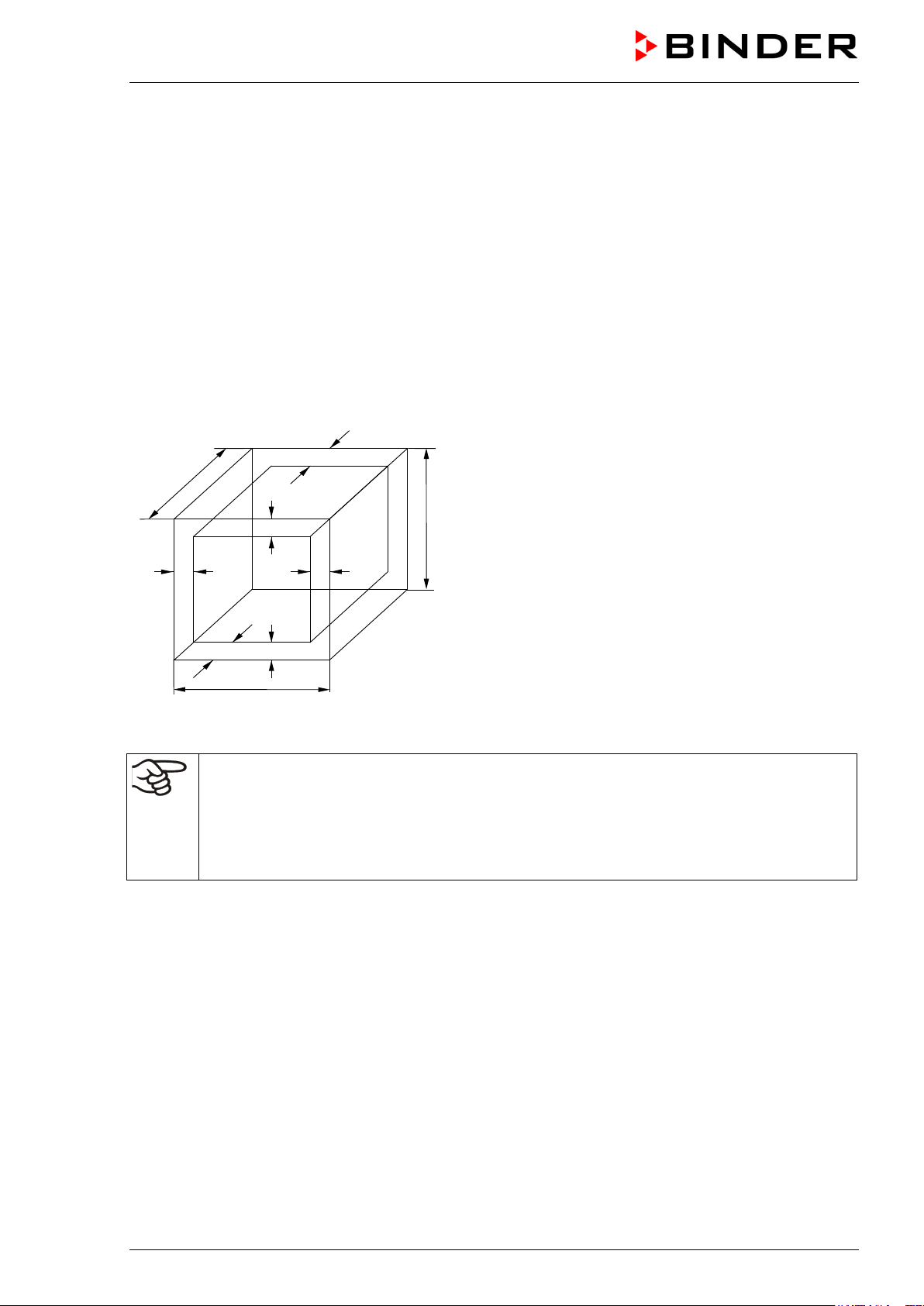

12.2 Definition of usable volume ............................................................................................................... 45

12.3 Over current protection...................................................................................................................... 45

12.4 FED technical data ............................................................................................................................ 46

12.5 Equipment and Options ..................................................................................................................... 47

12.6 Accessories and spare parts ............................................................................................................. 49

13. CONTAMINATION CLEARANCE CERTIFICATE ................................................ 50

13.1 For units located outside North America and Central America ......................................................... 50

13.2 For units in North America and Central America ............................................................................... 53

FED (E2) 02/2015 page 6/55

Page 7

Dear customer,

For the correct operation of the drying and heating ovens with forced convection FED, it is important that

you read this operating manual completely and carefully and observe all instructions as indicated. Failure

to read, understand and follow the instructions may result in personal injury. It can also lead to damage to

the unit and/or poor equipment performance.

1. Safety

This operating manual is part of the components of delivery. Always keep it handy for reference. The

device should only be operated by laboratory personnel especially trained for this purpose and familiar

with all precautionary measures required for working in a laboratory. Observe the national regulations on

minimum age of laboratory personnel. To avoid injuries and damage observe the safety instructions of the

operating manual.

WARNING

Failure to observe the safety instructions.

Serious injuries and unit damage.

Observe the safety instructions in this operating manual.

Carefully read the complete operating instructions of the drying and heating ovens

FED.

1.1 Legal considerations

This operating manual is for informational purposes only. It contains information for installing, start-up,

operation and maintenance of the product. Note: the contents and the product described are subject to

change without notice.

Understanding and observing the instructions in this operating manual are prerequisites for hazard-free

use and safety during operation and maintenance. In no event shall BINDER be held liable for any

damages, direct or incidental arising out of or related to the use of this manual.

This operating manual cannot cover all conceivable applications. If you would like additional information,

or if special problems arise that are not sufficiently addressed in this manual, please ask your dealer or

contact us directly by phone at the number located on page one of this manual

Furthermore, we emphasize that the contents of this operating manual are not part of an earlier or existing

agreement, description, or legal relationship, nor do they modify such a relationship. All obligations on the

part of BINDER derive from the respective purchase contract, which also contains the entire and

exclusively valid statement of warranty administration. The statements in this manual neither augment nor

restrict the contractual warranty provisions.

1.2 Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations

following the harmonization of ISO 3864-2 and ANSI Z535.6.

1.2.1 Signal word panel

Depending on the probability of serious consequences, potential dangers are identified with a signal word,

the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious (irreversible)

injury.

FED (E2) 02/2015 page 7/55

Page 8

Warning signs

Electrical hazard

Hot surface

or chemical burns

Biohazard

Mandatory action signs

plug

assistance

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

(irreversible) injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

(reversible) injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in damage to the product

and/or its functions or of a property in its proximity.

1.2.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury.

Observe all measures that are marked with the safety alert symbol in order to avoid death or

injury.

1.2.3 Pictograms

Lifting hazard

Suffocation hazard

Pollution Hazard

Explosive atmosphere

Harmful substances

Stability hazard

Risk of corrosion and /

Mandatory regulation

Lift with mechanical

FED (E2) 02/2015 page 8/55

Read operating

instructions

Environment protection

Disconnect the power

Wear protective gloves

Lift with several persons

Wear safety goggles

Page 9

Prohibition signs

water

Pictograms (Warning signs)

Service label

Do NOT touch

Do NOT spray with

Information to be observed in order to ensure optimum function of the product.

1.2.4 Word message panel structure

Type / cause of hazard.

Possible consequences.

∅ Instruction how to avoid the hazard: prohibition

Instruction how to avoid the hazard: mandatory action

Observe all other notes and information not necessarily emphasized in the same way, in order to avoid

disruptions that could result in direct or indirect injury or property damage.

1.3 Localization / position of safety labels on the unit

The following labels are located on the unit:

Hot surface

• Outer unit door

• On unit rear next to the exhaust

duct

Read operating manual

• UL units: on outer unit door

FED (E2) 02/2015 page 9/55

Figure 1: Position of labels on the unit front

Page 10

Indications of the type plate (example)

Information

BINDER

Manufacturer: BINDER GmbH

FED 115

Model designation

Drying and heating oven

Device name

Serial No.

00-00000

Serial no. of the unit

Built

2014

Year of construction

300 °C

572°F

Enclosure protection

IP 20

IP type of protection acc. to EN 60529

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN 12880

Class

2.0

Class of temperature safety device

Art. No.

9010-0212

Art. no. of the unit

Project No.

---

Optional: Special application acc. to project no.

1,60 kW

Nominal power

230 V 1 N ~

Nominal voltage ± 10%, phase indication

7,0 A

Nominal current

50/60 Hz

Power frequency

Nominal temperature

300 °C

1,60 kW

572°F

230 V 1 N ~

Temp. safety device

IP 20

DIN 12880

50/60 Hz

Class

2.0

Art. No.

9010-0212

US PATS 4585923 / 5222612 / 5309981

Built

2014

Drying and heating oven

D 78532 Tuttlingen / Germany

Internet: www.binder-world.com

Made in Germany

Keep safety labels complete and legible.

Replace safety labels that are no longer legible. Contact BINDER Service for these replacements.

1.4 Type plate

Enclosure protection

Project No.

Nominal temperature

Figure 2: Position of type plate

7,0 A

5405194 / 5601143 / 5773287 / 6079403

Tel. + 49 (0) 7462/ 2005-0

FED 115 Serial No. 00-00000

Figure 3: Type plate (example: FED 115 regular unit)

Nominal temperature

FED (E2) 02/2015 page 10/55

Page 11

Symbol on the type plate

Information

CE conformity marking

Electrical and electronic equipment manufactured / placed on the

market in the EC after 13 August 2005 and to be disposed of in a

separate collection according to directive 2002/96/EC on waste

electrical and electronic equipment (WEEE).

VDE-GS certification mark

or

(FED-UL only)

The equipment is certified in the GOST R certification system of

GOSTSTANDARD Russia.

The equipment is certified according to Customs Union Technical

Regulation (CU TR) for Russia, Belarus and Kazakhstan.

The equipment is certified by Underwriters Laboratories Inc.®

according to standards UL 61010A-1, UL 61010A-2-10, CSA C22.2

No. 1010.1-92, and CSA C22.2 No. 1010.2.010-94.

1.5 General safety instructions on installing and operating the drying and

heating ovens FED

With regard to operating the drying and heating ovens FED and to the installation location, please observe

the guideline BGI/GUV-I 850-0 on safe working in laboratories (formerly BGR/GUV-R 120 or ZH 1/119

laboratory guidelines issued by the employers’ liability insurance association) (for Germany).

BINDER GmbH is only responsible for the safety features of the unit provided skilled electricians or

qualified personnel authorized by BINDER perform all maintenance and repair, and if components relating

to chamber safety are replaced in the event of failure with original spare parts.

To operate the unit, use only original BINDER accessories or accessories from third-party suppliers

authorized by BINDER. The user is responsible for any risk caused by using unauthorized accessories.

CAUTION

Danger of overheating.

Damage to the unit.

∅ Do NOT install the unit in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Do not operate the drying and heating ovens FED in hazardous locations.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT operate the unit in potentially explosive areas.

KEEP explosive dust or air-solvent mixtures AWAY from the unit.

FED (E2) 02/2015 page 11/55

Page 12

The drying and heating ovens FED do not dispose of any measures of explosion protection.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT introduce any substance into the heating oven which is combustible or

explosive at working temperature.

∅ NO explosive dust or air-solvent mixture in the inner chamber.

Any solvent contained in the charging material must not be explosive or inflammable. I.e., irrespective of

the solvent concentration in the steam room, NO explosive mixture with air must form. The temperature

inside the chamber must lie below the flash point or below the sublimation point of the charging material.

Familiarize yourself with the physical and chemical properties of the charging material, as well as the

contained moisture constituent and its behavior with the addition of heat energy.

Familiarize yourself with any potential health risks caused by the charging material, the contained moisture

constituent or by reaction products that may arise during the temperature process. Take adequate

measures to exclude such risks prior to putting the drying and heating ovens into operation.

DANGER

Electrical hazard.

Danger of death.

∅ The unit must NOT become wet during operation or maintenance.

The drying and heating ovens were produced in accordance with the VDE regulations and were routinely

tested in accordance to VDE 0411-1 (IEC 61010-1).

During and shortly after operation, the temperature of the inner surfaces almost equals the set-point.

CAUTION

The inner chamber, the exhaust duct, the door window (option), the door gaskets,

and the access ports will become hot during operation.

Danger of burning.

∅ Do NOT touch the inner surfaces, the exhaust duct, the door window, the access ports,

the door gaskets, or the charging material during operation.

1.6 Intended use

The drying and heating ovens FED are suitable for drying and heat treatment of solid or pulverized

charging material, as well as bulk material, using the supply of heat. The solvent content must not be

explosive or flammable. A mixture of any component of the charging material with air must NOT be

explosive. The operating temperature must lie below the flash point or below the sublimation point of the

charging material. The drying and heating ovens FED can be used to dry e.g. glassware.

Other applications are not approved.

The drying and heating ovens FED are not classified as medical devices as defined by the Medical

Device Directive 93/42/EEC.

Do NOT use the unit for drying processes when large quantities of vapor would form and result in

condensation.

FED (E2) 02/2015 page 12/55

Page 13

Due to the special demands of the Medical Device Directive (MDD), these ovens are not

qualified for sterilization of medical devices as defined by the directive 93/42/EWG.

Following the instructions in this operating manual and conducting regular maintenance work

(chap. 9) are part of the intended use.

The charging material shall not contain any corrosive ingredients that may damage the

machine components. Such ingredients include in particular acids and halides. Any corrosive

damage caused by such ingredients is excluded from liability by BINDER GmbH.

2. Unit description

BINDER drying and heating ovens FED are equipped with an electronic PID-controller with digital display.

The temperature is indicated with an accuracy of one degree.

BINDER drying and heating ovens with forced convection FED are heated electrically and are ventilated

by fan-assisted, forced-air circulation. They FED are equipped with a temperature safety device according

to DIN12880 (chap. 7).

The APT.line™ preheating chamber system guarantees high level of spatial and time-based temperature

precision, thanks to the direct and distributed air circulation into the interior. The fan supports exact

attainment and maintenance of the desired temperature accuracy.

The inner chamber, the pre-heating chamber and the inside of the doors are all made of stainless steel

V2A (German material no. 1.4301, US equivalent AISI 304). When operating the unit at temperatures

above 150 °C, the impact of the oxygen in the air may cause discoloration of the metallic surfaces

(yellowish-brown or blue) by natural oxidation processes. These colorations are harmless and will in no

way impair the function or quality of the unit. The housing is RAL 7035 powder-coated. All corners and

edges are also completely coated.

All unit functions are easy and comfortable to use thanks to their clear arrangement. Major features are

easy cleaning of all unit parts and avoidance of undesired contamination.

BINDER drying and heating ovens FED are equipped with a serial interface RS 422 for computer

communication, e.g. via the communication software APT-COM™ 3 DataControlSystem (option, chap.

8.1). For further options, see chap. 12.5.

The model FED 720 is equipped with

four castors. Both front castors can be locked by brakes.

The unit can be operated in a temperature range of 5 °C / 9 °F above room temperature up to 300 °C /

572 °F.

FED (E2) 02/2015 page 13/55

Page 14

(6)

(9)

(7)

(8)

(10)

(1)

2.1 Equipment overview FED

(1) Display

(2) Set-point value key

(3) Selector keys

(4) Time management key

(5) Switch ON/OFF

(6) Lever for ventilation slide

(2)

(3)

(4)

(5)

(7) Safety device

(8) Door handle

(9) Switch for interior lighting (with

option interior lighting) or

Buzzer switch (with option

audible over-temperature alarm)

(10) Main power switch for sizes 400

and 720

Figure 4: FED drying and heating oven

3. Completeness of delivery, transportation, storage, and

installation

3.1 Unpacking, and checking equipment and completeness of delivery

After unpacking, please check the unit and its optional accessories, if any, based on the delivery receipt

for completeness and for transportation damage. Inform the carrier immediately if transportation damage

has occurred.

The final tests of the manufacturer may have caused traces of the racks on the inner surfaces. This has

no impact on the function and performance of the unit.

Please remove any transportation protection devices and adhesives in/on the unit and on the doors and

take out the operating manuals and accessory equipment.

CAUTION

Sliding or tilting the unit.

Damage to the unit.

Risk of injury by lifting heavy loads.

∅ Do NOT lift or transport the unit using the door handle or the door.

∅ Do NOT lift units size 400 and 720 by hand

Lift the unit size 53 and 115 from the pallet at its four lower corners with

the aid of 2 people, unit size 240 with the aid of 4 people.

Lift units size 400 and 720 from the pallet using technical devices (fork

lifter). Set the fork lifter only from the rear in the middle of the unit. Make

sure to place all the lateral supports of the unit on the forks.

FED (E2) 02/2015 page 14/55

Page 15

If you need to return the unit, please use the original packing and observe the guidelines for safe lifting

and transportation (chap. 3.2).

For disposal of the transport packing, see chap. 10.1.

Note on second-hand units (Ex-Demo-Units):

Second-hand units are units that have been used for a short time for tests or exhibitions. They are

thoroughly tested before resale. BINDER ensures that the chamber is technically sound and will work

flawlessly.

Second-hand units are marked with a sticker on the unit door. Please remove the sticker before

commissioning the unit.

3.2 Guidelines for safe lifting and transportation

The front castors of units size 720 can be blocked by brakes. Please move the units with castors only

when empty and on an even surface, otherwise the castors may be damaged. After operation please

observe the guidelines for temporarily decommissioning the unit (chap. 10.2).

CAUTION

Sliding or tilting the unit.

Damage to the unit.

Risk of injury by lifting heavy loads.

Transport the unit only in its original packaging.

Secure the unit with transport straps for transport.

∅ Do NOT lift or transport the unit using the door handle or the door.

∅ Do NOT lift units size 400 and 720 by hand.

Lift unit size 53 and 115 at its four lower corners with the aid of 2 people, unit size 240

with the aid of 4 people, and place it on a transport pallet with wheels. Push the pallet

to the desired site and then lift the unit from the pallet at its four lower corners.

Place units size 400 and 720 using technical devices (fork lifter) on the transport pallet.

Set the fork lifter only from the rear in the middle of the unit. Make sure to place all the

lateral supports of the unit on the forks.

Transport units size 400 and 720 ONLY with the original transport pallet. Set the fork

lifter only to the pallet. Without the pallet the unit is in imminent danger of overturning!!

• Permissible ambient temperature range during transport: -10 °C to +60 °C.

You can order transport packing and pallets for transportation purposes from BINDER Service.

3.3 Storage

Intermediate storage of the unit is possible in a closed and dry room. Observe the guidelines for

temporary decommissioning (chap. 10.2).

• Permissible ambient temperature range during storage: -10 °C to +60 °C.

• Permissible ambient humidity: max. 70 % r.H., non-condensing

When after storage in a cold location you transfer the unit to its warmer installation site, condensation may

form. Before start-up, wait at least one hour until the oven has attained ambient temperature and is

completely dry.

FED (E2) 02/2015 page 15/55

Page 16

3.4 Location of installation and ambient conditions

Set up the drying and heating oven FED on an even and non-flammable surface, free from vibration and

in a well-ventilated, dry location and align it using a spirit level. The site of installation must be capable of

supporting the unit’s weight (see technical data, chap. 12.4). The chambers are designed for setting up

inside a building (indoor use).

CAUTION

Danger of overheating.

Damage to the unit.

∅ Do NOT set up units in non-ventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

• Permissible ambient temperature range during operation: +18 °C up to +40 °C. At elevated ambient

temperature values, fluctuations in temperature can occur.

The ambient temperature should not be substantially higher than the indicated ambient

temperature of +25 °C to which the specified technical data relate. For other ambient

conditions, deviations from the indicated data are possible.

• Permissible ambient humidity: 70 % r.H. max., non-condensing.

• Installation height: max. 3000 m / 9842 ft. above sea level.

When placing several units of the same size side by side, maintain a minimum distance of 250 mm

between each unit. Wall distances: rear 100 mm, sides 160 mm. Spacing above the unit of at least 100

mm must also be accounted for.

Two devices up to size 115l can be piled on top of each other. For this purpose, place rubber pads under

all four feet of the upper unit to prevent the device from slipping.

CAUTION

Sliding or tilting of the upper unit.

Damage to the units.

When stacking, place rubber pads under all four feet of the upper unit.

To completely separate the unit from the power supply, you must disconnect the power plug. Install the

unit in a way that the power plug is easily accessible and can be easily pulled in case of danger.

Do not install or operate the drying and heating oven FED in potentially explosive areas.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT operate the unit in potentially explosive areas.

KEEP explosive dust or air-solvent mixtures AWAY from the vicinity of the unit..

FED (E2) 02/2015 page 16/55

Page 17

4. Installation

4.1 Electrical connection

The drying and heating ovens FED are supplied ready for connection. The socket must also provide a

protective conductor.

• FED 53, FED 115, FED 240:

Shockproof plug, power supply voltage 230 V (1N~) +/- 10 %, 50/60 Hz

Fixed power connection cable of 1800 mm in length

• FED 400, FED 720:

CEE plug 5 poles, power supply voltage 400 V (3N~) +/- 10 %, 50/60 Hz

Fixed power connection cable of 2700 mm in length

• FED 53-UL, FED 115-UL:

NEMA plug 5-20P, power supply voltage 115 V (1N~) +/- 10 %, 60 Hz

Fixed power connection cable of 1800 mm in length

• FED 240-UL, FED 400-UL, FED 720-UL:

NEMA plug L21-20P, power supply voltage 208 V (3N~) +/- 10 %, 60 Hz

Fixed power connection cable of 2700 mm in length

• Prior to connection and start-up, check the power supply voltage. Compare the values to the specified

data located on the unit’s type plate (unit front behind the door, bottom left-hand, chap. 1.4).

• When connecting, please observe the regulations specified by the local electricity supply company and

as well as the VDE directives (for Germany). We recommend the use of a residual current circuit

breaker.

• Pollution degree (acc. to IEC 61010-1): 2

• Over-voltage category (acc. to IEC 61010-1): II

CAUTION

Danger of incorrect power supply voltage.

Damage to the equipment.

Check the power supply voltage before connection and start-up.

Compare the power supply voltage with the data indicated on the type plate.

See also electrical data (chap.12.4).

To completely separate the unit from the power supply, you must disconnect the power plug.

Install the unit in a way that the power plug is easily accessible and can be easily pulled in case

of danger.

4.2 Connection to a suction plant (optional)

When directly connecting a suction plant the spatial temperature exactitude, the heating-up and the

recovering times and the maximum temperature will be negatively influenced. So no suction plant should

be directly connected to the exhaust duct.

Active suction from the oven must only be performed together with extraneous air. Perforate

the connecting piece to the suction device or place an exhaust funnel at some distance to the

exhaust duct.

FED (E2) 02/2015 page 17/55

Page 18

The green “Standby“ LED illuminates.

If the oven is operating (time functions “Continuous operation”, or “Timer

The heating is active as soon as the red heating control light in the

CAUTION

The exhaust duct will become hot during operation.

Danger of burning.

∅ Do NOT touch the exhaust duct during operation.

5. Start up

5.1 Turning on the unit

Warming chambers may release odors in the first few days after commissioning. This is not a

quality defect. To reduce odors quickly we recommend heating up the chamber to its nominal

temperature for one day and in a well-ventilated location.

1. Insert the power plug into a suitable socket (chap. 4.1).

2. Turn on units of sizes 400 and 720 at the main power switch (10)

3. Press

The controller is now in normal display (actual value display).

operation” with the set time just running down chap. 6.3), the actual

temperature value (example: 22 °C) is displayed

If the oven is in time function “Timer operation” with no time programmed or the set time run-off (chap.

6.3), the unit is inactive (no heating). The display alternately shows the actual temperature value

(example: 22 °C) and “tOff”:

until the display lights up.

Adjust the temperature safety device following any changes of the set-point (chap. 7).

5.2 Heating operation display

bottom right corner of the display slowly begins to flash depending on the

heat requirement (example: 70 °C):

FED (E2) 02/2015 page 18/55

Page 19

The unit is operating, the controller is in normal display (actual value

5.3 Air change

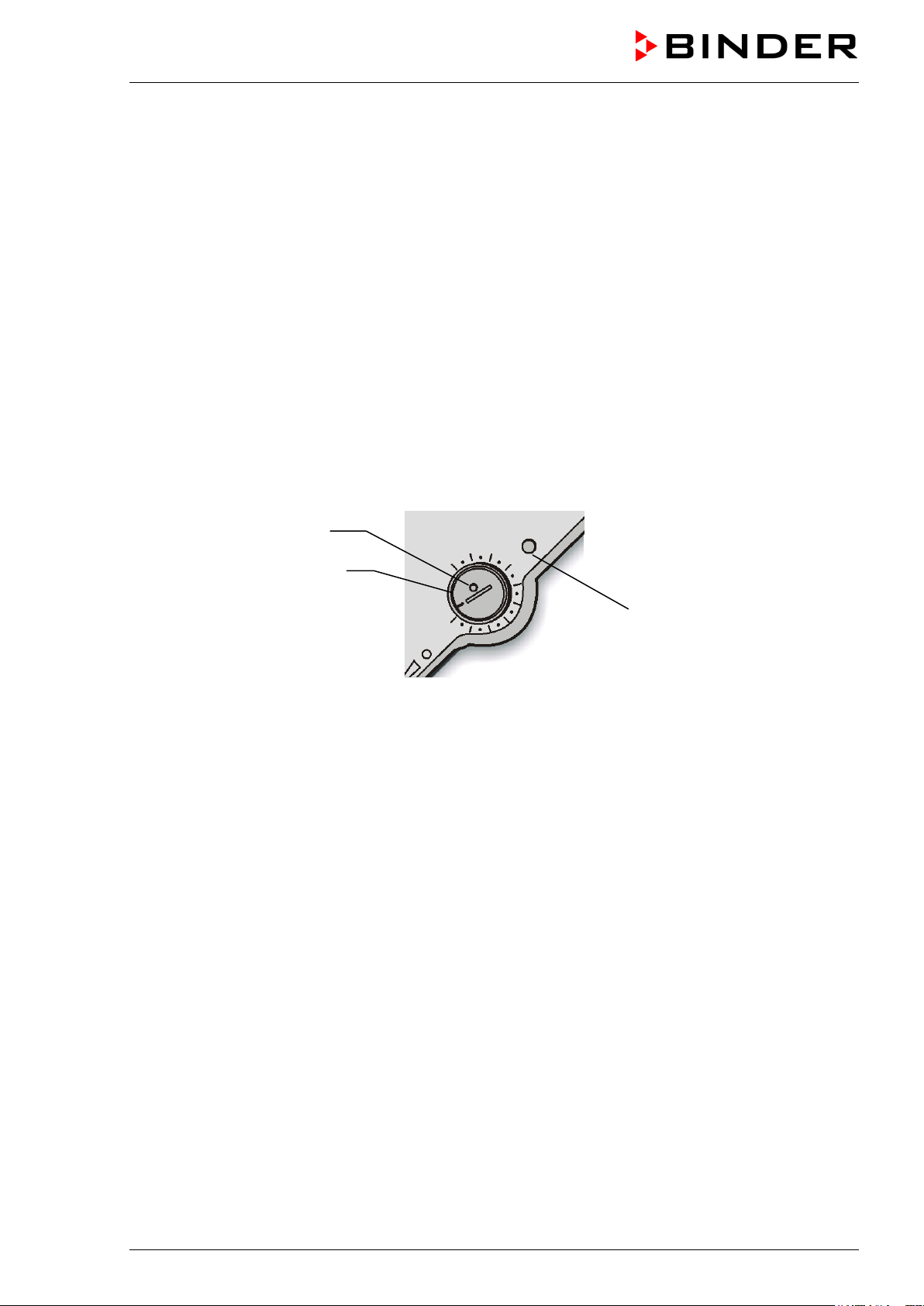

Opening the air flap in the exhaust duct serves to adjust the

air change.

Without connecting a suction plant:

• If the air flap is open and the fan is operating, fresh air

comes in via aeration gaps.

• If the air flap is completely open, the spatial temperature

accuracy can be negatively influenced.

Figure 5: Adjusting the air flap

6. Controller setting

6.1 Display / entry of temperature and ventilation set-points (without ramp

function)

display). The actual temperature value (example: 22 °C) is displayed:

1. Press

The display shows alternately “SP” and the previous temperature set-point (example: 60 °C):

2. With the

Wait 2 seconds until the entered temperature value is taken over (display flashing once).

3. Press

button

buttons enter a set-point value between 0 and 300.

The desired temperature set-point can be selected in a temperature range from 5 °C

above room temperature up to 300 °C.

button to proceed to the fan speed entry.

The display shows alternately “n” and the previous fan speed set-point (example: 100%):

4. Set the desired fan speed with the

buttons.

The fan speed can be set to a value between 0% and 100%.

Wait 2 seconds until the entered value is taken over (display flashing once).

FED (E2) 02/2015 page 19/55

Page 20

The oven is operating, the controller is in normal display (actual value

5. Press

button to return to normal display (actual value display) (automatically after approx. 30

seconds).

Adjust the temperature safety device following any changes of the set-point (chap. 7).

6.2 Display / entry of temperature and ventilation set-points (with selected

temperature ramp)

If previously a temperature ramp value has been selected (chap. 6.4.2):

Press button

actual temperature ramp mset-point changing according to the selected gradient in addition to the entered

final set-points for temperature and fan speed.

display). The actual temperature value (example: 22 °C) is displayed:

1. Press

The display shows alternately “SPr” and the actual temperature ramp set-point changing according

to the selected gradient (example: 42 °C):

in normal display / actual value display during ramp operation to have displayed the

button

This ramp set-point is only displayed, not adjustable.

2. Press

button

The display shows alternately “SP” and the previous temperature set-point (example: 60 °C):

3. With the

buttons enter a set-point value between 0 and 300.

The desired temperature set-point can be selected in a temperature range from 5 °C

above room temperature up to 300 °C.

Wait 2 seconds until the entered temperature value is taken over (display flashing once).

4. Press

button to proceed to the fan speed entry.

The display shows alternately “n” and the previous fan speed set-point (example: 100%):

FED (E2) 02/2015 page 20/55

Page 21

Timer running

Heating activity depending on the entered time value and

5. Set the desired fan speed with the

buttons

The fan speed can be set to a value between 0% and 100%.

Wait 2 seconds until the entered value is taken over (display flashing once).

6. Press

button to return to normal display / actual value display (automatically after approx. 30

seconds).

Adjust the temperature safety device following any changes of the set-point (chap. 7).

6.3 Time functions: Continuous operation and Timer operation

Press the time management button .

The timer indicates its current time function. There are two possible time functions:

Continuous operation

The display shows alternately “t1” (time function) and the time function “Continuous operation” “t inf”:

The heating is permanently active, independent of the timer setting.

Timer operation

The display shows alternately “t1” (time function) and the running-down time or “tOff”:

or

Remaining time (example: 28 Min.) –

down

the timer function selected in the user menu (chap.6.4.4)

Timer not programmed or run-down “t off”

Press

seconds).

button to return to normal display (actual value display) (automatically after approx. 30

FED (E2) 02/2015 page 21/55

If the timer has run-down, the unit’s behavior depends on

the pre-selected timer function (chap. 6.4.4).

Page 22

The actual temperature value (example: 22 °C) is displayed:

6.3.1 Switching between Continuous operation and Timer operation

Press the time management button .

The controller displays the actual time function. In time function “Continuous operation”, “t1” and “t inf” are

displayed alternately. In time function “Timer operation”, “t1” is displayed alternately with the running-down

time or “tOff”.

If in time function “Timer operation” the Timer is just running off (“t1”displayed alternately with the runningdown time) the timer must at first be set to Zero (chap. 6.3.3). Now “t1” is displayed alternately with “tOff”,

and the controller can be changed to time function “Continuous operation”.

Continuous operation

2 seconds

Press

2 seconds

Timer operation

button to return to normal display / actual value display (automatically after approx. 30 sec).

Timer not programmed or run-down

6.3.2 Continuous operation

1. Press the time management button .The timer indicates its current time function.

2. If necessary, switch to Continuous operation by button .

The display shows alternately “t1” and the time function “Continuous operation” “t inf”:

3. Press

button to return to normal display (actual value display) (automatically after approx. 30

seconds).

Now the controller operates with the entered set-points (chap. 6.1) in continuous operation. The heating is

permanently active, independent of the timer setting.

To cancel Continuous operation, proceed accordingly:

1. Press the time management button

2. Switch to Timer operation by pressing down button for 2 seconds (chap. 6.3.1).

FED (E2) 02/2015 page 22/55

.

Page 23

The actual temperature value is displayed (example: 22 °C):

6.3.3 Setting the timer values

1. Press the time management button . The controller indicates its current time function.

2. If necessary, switch to timer operation by button .

The display alternately shows”t1” and the running-down time or “tOff”:

or

Remaining time (example: 28 minutes) – Timer

running down

Timer not programmed or run-off “t off”

3. Set the desired time [hh.mm] with the arrow buttons

.

The set value is automatically adopted after 2 seconds.

The display alternately shows “t1” and the set time now running down.

The time directly begins to run off after taking-over of the entered value. The use of this time depends

on the timer function selected in the user menu (chap. 6.4.4).

4. Press button

to return to normal display (actual value display) (automatically after approx. 30

seconds).

The controller operates with the entered set-points (chap. 6.1) until run-down of the set time. Heating

activity depending on the entered time value and the timer function selected in the user menu (chap.6.4.4)

To know the remaining timer time or, if appropriate, to modify it, press the time management button

in normal display (actual value display).

The display alternately shows “t1” and running-down time:

After the set time has run down the display alternately shows the actual temperature value (example: 22

°C) and “tOff”:

Now the heating is inactive. The fan continues operating.

FED (E2) 02/2015 page 23/55

Page 24

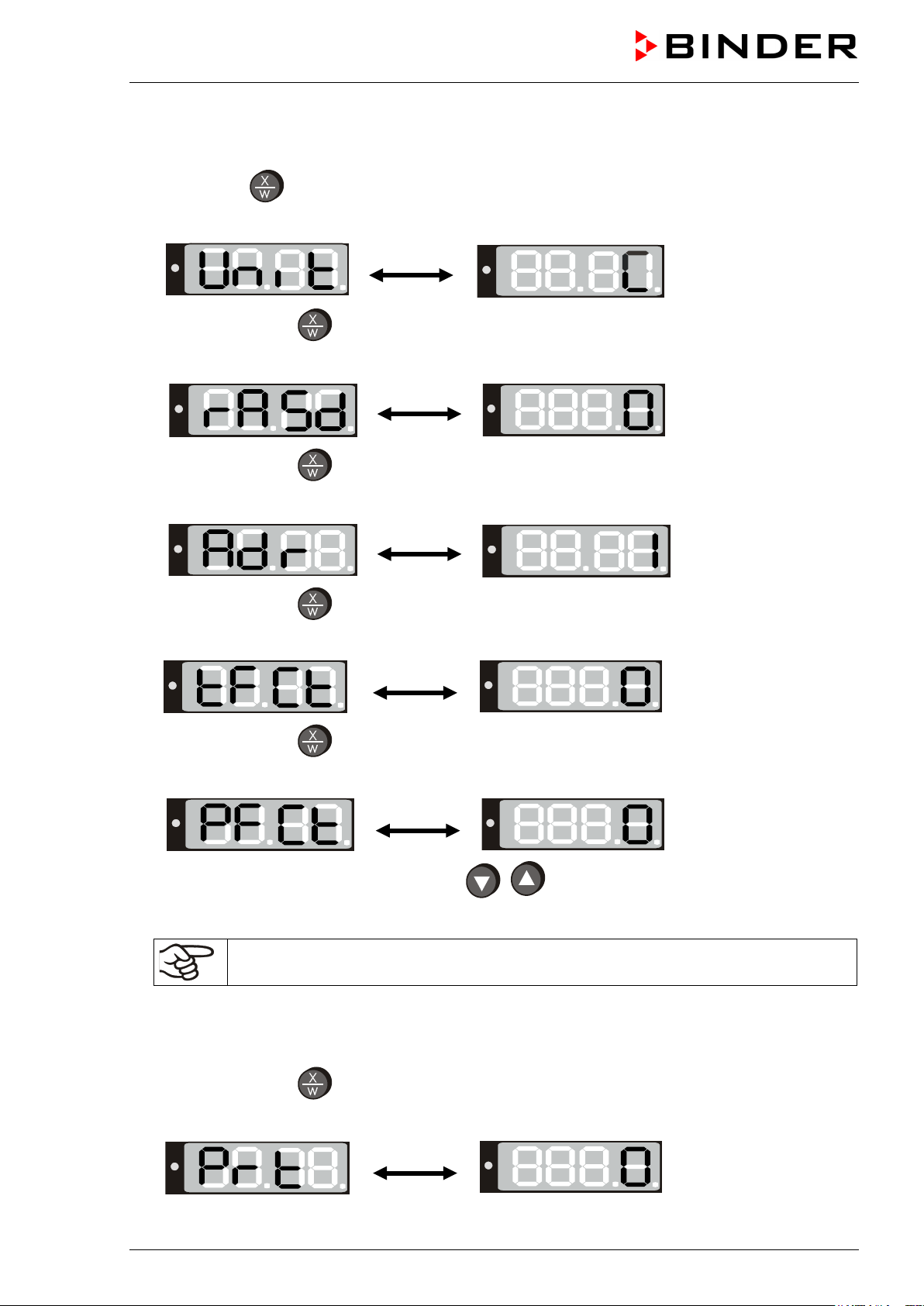

User level overview:

button for approx. 5

6.4 User level settings

By pressing down button in normal display (actual value display) for 5 sec, you enter the user menu.

Settings in this menu affect controller operation.

Press down button

for approx. 5 seconds

Select the temperature unit (chap. 6.4.1)

Press

button

Ramp function (chap. 6.4.2)

Figure 6: Press down

seconds

Press

button

Setting the unit address (chap. 6.4.3)

Press

button

Timer function (chap. 6.4.4)

Press

button

Setting the interface mode and, if appropriate,

the printer interval (chap. 6.4.5)

Press button to return to normal display with display of the temperature set-point. Or:

After approx. 30 seconds the controller automatically returns to normal display / actual value display.

All settings can be carried out independently (as described in the individual sections) or one after the other

during one single process.

The defined parameters are not deleted when the main power switch is turned off or in case

of power failure.

FED (E2) 02/2015 page 24/55

Page 25

6.4.1 Temperature unit change between degrees Celsius °C and degrees Fahrenheit °F

If required, the temperature display can be changed as follows:

1. Press down

button for approx. 5 seconds.

The display alternately shows “unit” and the actual setting of the temperature unit:

2. Use the

buttons to set the required unit.

3. The set unit is automatically adopted after 2 seconds.

C = degrees Celsius

F= degrees Fahrenheit

0 °C = 31°F

100 °C = 212°F

Conversion:

[Value in °F] = [Value in °C] ∗ 1,8 + 32

When specifying the set point ramp (see chap. 6.4.2) this setting is accordingly taken as the basis.

If the unit is changed, the temperature set-point and limits are converted accordingly.

6.4.2 Enter a temperature ramp

Temperature ramps can be programmed in order to extend heating up times. This may be necessary in

some cases, in order to prevent temperature stresses in the material during the heating up phase.

Temperature ramps should only be used if required. The use of temperature ramps may result in the

heating up times being considerably slowed down.

The entry in °C/min or in °F/min meaning the nominal value gradient and limits the maximum temperature

increase to this value. Due to the heat and evaporation energy assumed by the drying material, smaller

temperature gradients may also result.

A temperature ramp proceeds from the previously entered to a new set-point. The temperature must have

adjusted to the start set-point. Enter settings in 3 steps:

1. Enter set-point of ramp start temperature. Let temperature adjust to this set-point temperature.

2. Set the ramp to the desired gradient in °C/min or in °F/min.

You can enter a gradient value from 0 up to 10.

Setting the gradient to 0 means ramp function off = maximum heating power.

Setting the gradient to another value, e.g., 3, means the unit will try to heat up with a speed of 3

°C/min.

A heat-up rate of 4 °C/minute can be regarded as a realistic maximum.

3. Enter set-point (final ramp temperature).

The ramp should only be set if required. The setting “0” means ramp function switched off. The unit is

being heated at maximum heat output.

FED (E2) 02/2015 page 25/55

Page 26

1. Press down

button for approx. 5 seconds.

The display alternately shows “unit” and the temperature unit:

2. Press again button

.

The display alternately shows “rASd” and the actual setting of the set-point gradient:

3. Set the desired ramp gradient with buttons

(set-point gradient in °F or °C acc. to setting

in chap. 6.4.1).

The set value is automatically adopted after 2 seconds.

During ramp operation the actual set-point (SPr) continually rises in accordance to the entered gradient

from the previously entered set-point to the new one (SP). The actual value follows the set-point value.

About set-point display during ramp operation see chap. 6.2.

6.4.3 Chamber addressing

If several drying and heating ovens FED are networked with a PC via the APT-COM™ communication

software (option, chap. 8.1), each unit must be allocated a unique address. Addressing takes place on the

chamber controller as follows:

1. Press down

The display alternately shows “unit” and the temperature unit:

2. Press again button

The display alternately shows “rASd” and the set-point gradient:

3. Press again button

The display alternately shows “Adr” and the actual setting of the unit address:

button for approx. 5 seconds.

.

.

FED (E2) 02/2015 page 26/55

Page 27

4. Set the required address with buttons

.

You can enter address values between 1 and 30.

The set value is automatically adopted after 2 seconds.

6.4.4 Selecting the timer function

The unit provides three different timer functions:

• Delayed off (setting “0”)

After the defined time has elapsed, the heating is turned off.

• Temperature-controlled delayed off (setting “1”)

The defined time only begins to run when the current value is by 1 °C below the set point. After the

defined time has expired, the heating is turned off.

• Delayed on (setting “2”)

After the time set has passed, the heating is turned on and remain in continuous operation.

1. Press down

button for approx. 5 seconds.

The display alternately shows “unit” and the temperature unit:

2. Press again button

.

The display alternately shows “rASd” and the set-point gradient:

3. Press again button

.

The display alternately shows “Adr” and the unit address:

4. Press again button

The display alternately shows “tFCt” and the actual setting of the timer function:

5. Set the desired timer function 0, 1 or 2 with buttons

.

The set value is automatically adopted after 2 seconds.

FED (E2) 02/2015 page 27/55

Page 28

6.4.5 Setting the interface mode and, if appropriate, the printer interval

1. Press down button for approx. 5 seconds.

The display alternately shows “unit” and the temperature unit:

2. Press again button

.

The display alternately shows “rASd” and the set-point gradient:

3. Press again button

.

The display alternately shows “Adr” and the unit address:

4. Press again button

The display alternately shows “tFCt” and the timer function:

5. Press again button

The display alternately shows “PFCt” and the actual setting of the interface mode:

6. Set the desired interface mode with buttons

.

Settings: Modbus = “0” printer = “1”

In case of temperature data acquisition by the communication software APT-COM™

(option, chap. 8.1) interface mode ”0” (Modbus) must be selected.

The setting is automatically adopted after 2 seconds.

If interface mode “1” (printer) has been selected, the printer interval for the automatic output can be set in

an additional menu step:

7. Press again button

The display alternately shows “Prt” and in the entry level the actual setting of the printer interval:

FED (E2) 02/2015 page 28/55

Page 29

8. Set the desired value from 0 to 255 with buttons

.

The printer intervals via the RS 422 interface can be set between 1 and 255 min. Setting “0”

signifies the printer interval set to off.

A protocol printer records the temperature data in the set interval.

The set value is automatically adopted after 2 seconds.

6.5 Temperature programming example

The unit shall heat up to a temperature of 50 °C, maintain this temperature for three hours and then turn

off.

1. In normal display press down button

• Select timer function “1” = “temperature-dependent delayed off“ (chap. 6.4.4)

2. In normal display press button

• Enter the set point “50” (chap. 6.1)

3. In

normal display press the time management button . The controller displays the actual time

function.

for 5 sec and then several times until “tFCt” is displayed

.

• If necessary select the time function “Timer operation” (chap. 6.3.1)

• In the entry level enter the desired time “3.00” (chap. 6.3.3)

6.6 General notes

Approx. 30 sec. after the last entry the controller returns to normal display (actual value

display).

The functions set-point entry (chap. 6.1), time functions (chap. 6.3), and calling up the user

menu (chap. 6.4) can only be selected from normal display (actual value display).

When selecting the functions set-point entry and time functions, and when selecting the user

menu functions, the respective button

Shorter pressing will be ignored by the controller.

After a power failure, the timer returns to the previous status. A remaining time, if any, will

continue running down.

Adjust the temperature safety device following any changes of the set-point (chap. 7).

or must be pressed down for a about 1 sec.

FED (E2) 02/2015 page 29/55

Page 30

(7)

(7a)

(7b)

7. Temperature safety devices

7.1 Temperature safety device class 2 (DIN 12880)

The temperature safety device class 2 protects the chamber, its environment and the charging material

from exceeding the maximum permissible temperature.

Please observe the guideline BGI/GUV-I 850-0 on safe working in laboratories (formerly BGR/GUV-R 120

or ZH 1/119 laboratory guidelines issued by the employers’ liability insurance association) (for Germany).

In the event of a fault in the temperature controller, the safety device (7) permanently turns off the

chamber. This status is reported visually by the indicator lamp (7a) and, in case of the option audible

alarm with activated buzzer (chap. 7.3), by the buzzer sounding.

Check the operation of the safety device (7) by moving it slowly counter-clockwise until the chamber turns

off. The safety device cut-off is reported visually by the indicator lamp (7a) and, in case of the option

audible alarm with activated buzzer (chap. 7.3), by the buzzer sounding.

Then release again the safety device by pressing the reset button (7b) and turn on the chamber as

described.

Figure 7: Temperature safety device class 2

Function:

The safety device class 2 is functionally and electrically independent of the temperature control device and

turns off the chamber permanently.

If you turn the control knob (7) to its end-stop (position 10), the safety device protects the appliance. If you

set it to a temperature a little above the controller’s set-point temperature, it protects the charging material.

If the safety device has turned off the chamber, identifiable by the red alarm lamp (7a) lighting up and, in

case of the option audible alarm with activated buzzer (chap. 7.3), by the buzzer sounding, proceed as

follows:

• Disconnect the chamber from the power supply.

• Have an expert examine and rectify the cause of the fault.

• Release the safety device by pressing the reset button (7b).

• Restart the chamber as described in chap. 5.

Setting:

To check the response temperature of the safety device, turn on the chamber and set the desired setpoint at the temperature controller.

The scale division from 1 to 10 corresponds to the temperature range from 30 °C / 86 °F up to 320 °C /

608 °F and serves as a setting aid.

FED (E2) 02/2015 page 30/55

Page 31

1. Turn the control knob (7) of the safety device using a coin to its

2. When the set point is reached, turn back the control knob (7) until

3. The trip point is identifiable by the red alarm lamp (7a) lighting up;

(7)

(7a)

end-stop (position 10) (chamber protection).

its trip point (turn it counter-clockwise).

the reset button (7b) pops out.

With the option audible alarm and the buzzer activated (chap.

7.3), the buzzer sounds as an additional signal. You can turn it off

with switch (11).

4. The optimum setting of the safety device is obtained by turning

the control knob clockwise by approx. one graduation mark on the

scale.

5. Push the reset button (7b) in again.

The chamber is only active with the reset button (7b) pushed in.

When the safety device class 2 responds, the red alarm lamp (7a) lights up, the reset button (7b) pops

out, and the chamber turns off permanently.

Check the setting regularly and adjust it following any changes of the set-point.

Function check:

Check the temperature safety device class 2 at appropriate intervals for its functionality. It is

recommended that the authorized operating personnel should perform such a check, e.g., before starting

a longer work procedure.

7.2 Temperature safety device class 3.1 (DIN 12880) (option)

The temperature safety device class 3.1 serves to protect the oven, its environment, and the charging

material from exceeding the maximum permissible temperature.

Please observe the guideline BGI/GUV-I 850-0 on safe working in laboratories (formerly BGR/GUV-R 120

or ZH 1/119 laboratory guidelines issued by the employers’ liability insurance association) (for Germany).

Figure 8: Temperature safety device class 3.1

Function:

The temperature safety device is functionally and electrically independent of the temperature control

system and if an error occurs it performs a regulatory function. If you turn the control knob (7) to its endstop (position 10), the safety device class 3.1 protects the chamber. If you set it to a temperature a little

above the controller’s set-point temperature, it protects the charging material.

FED (E2) 02/2015 page 31/55

Page 32

1. Turn the control knob (7) of the safety device with a coin to its

2. When the set point is reached, turn back the control knob (7)

3. The trip point is identifiable by the red alarm lamp (7a) lighting

4. The optimum setting of the safety device is obtained by turning

If the safety device has taken over control (identifiable by the red alarm lamp (7a) lighting up and, in case

of the option audible alarm with activated buzzer (chap. 7.3), by the buzzer sounding), proceed as follows:

• Disconnect the unit from the power supply.

• Have an expert examine and rectify the cause of the fault.

• Restart the unit (see chap. 5).

Adjustment:

In order to check at which temperature the safety device class 3.1 responds, turn on the chamber and set

the desired set-point on the temperature controller

The sections of the scale from 1 to 10 correspond to the temperature range from 63 °C / 145.4 °F to

350 °C / 662 °F and serve as a setting aid.

end-stop (chamber protection).

until its trip point (turn it counter-clockwise)

up.

With the option audible alarm and the buzzer activated (chap.

7.3), the buzzer sounds as an additional signal. You can turn it

off with switch (11).

the control knob clockwise by approximately one scale division,

which leads to extinguish the red alarm lamp (7a).

Check the setting regularly and adjust it following any changes of the set-point.

Function check:

Check the temperature safety device class 3.1 at appropriate intervals for its functionality. It is

recommended that the authorized operating personnel should perform such a check, e.g., before starting

a longer work procedure.

7.3 Disconnectable audible over-temperature alarm (option)

This option permits activating an audible signal with the buzzer switch (11):

Position 0 = buzzer off

Position 1 = buzzer active

If the buzzer is activated, an audible signal sounds when the limit temperature set at the temperature

safety device class 2 (chap. 7.1) or class 3.1 (chap. 7.2) is exceeded, this happens in addition to the red

alarm pilot lamp (7a) lighting up. The buzzer can be turned off using the buzzer switch (11).

Turning off the audible alarm does not influence the safety device’s regulatory or turning-off

function. Proceed as described in chap. 7.1 / 7.2.

FED (E2) 02/2015 page 32/55

Page 33

Pin allocation of the RS 422 interface:

pin 2: RxD (+)

pin 7: Ground

8. Options

8.1 Communication software APT-COM™ 3 DataControlSystem (option)

The oven is regularly equipped with a serial interface RS 422 that can connect the BINDER

communication software APT-COM™ 3 DataControlSystem. The connection to a computer is established

using the FED interface via an interface converter RS 422 / RS 232.

Make sure that the interface mode is correctly set to “0” = “Modbus” in the user level (chap.

6.4.5).

The actual temperature, and fan speed values are given at adjustable intervals. Programming can be

performed graphically via PC. Up to 30 chambers with RS 422 interface can be cross linked. For further

information, refer to the operating manual of the BINDER communication software APT-COM™.

pin 3: TxD (+)

pin 4: RxD (-)

pin 5: TxD (-)

If several drying and heating ovens FED are to be recorded via a PC, each one must be

allocated a unique address. Addressing is performed via the chamber controller (see chap.

6.4.3).

8.2 Data logger kit

BINDER Data Logger Kits offer an independent long-term measuring system for temperature. They are

equipped with a keyboard and a large LCD display, alarm functions and a real-time function.

Measurement data are recorded in the Data Logger and can be read out after the measurement via the

RS232 interface of the Data Logger. It offers a programmable measuring interval and permits storing up to

64000 measuring values. Reading out is done with the Data Logger evaluation software. You can give out

a combined alarm and status protocol directly to a serial printer.

Data Logger Kit T 350: Temperature range 0 °C / 32 °F up to +350 °C / 662 °F

For detailed information on installation and operation of the BINDER Data Logger, please

refer to the mounting instructions Art. No. 7001-0204 and to the original user manual of the

manufacturer, supplied with the data logger.

8.3 HEPA fresh air filter (option)

With this option, the introduced fresh air is cleaned by means of a high efficiency submicron particulate air

filter type HEPA class H 14 (acc. to DIN EN 1822). Replace the filter insert, if necessary, by removing the

metal cover of the filter at the left side of the unit (Art. No. 6014-0003).

FED (E2) 02/2015 page 33/55

Page 34

8.4 Mostly gas-tight version (option for FED 53 and FED 115)

With this option the oven is additionally sealed, so the loss when introducing gases is decreased. The unit

is not completely gas-tight, so it is impossible to establish overpressure. The sealing diminishes the

release of vapors via the housing that may be set free from the charging material when heated. Carryingoff via the regular evacuation duct, e.g. into a waste air installation, is likely to further reduce emissions.

The unit is not completely gas-tight. Gases from inside the oven can escape into the

surrounding atmosphere.

Observe the occupational exposure limit OEL for the released substance set by the national

authorities (formerly maximum permitted workplace concentration). Respect the relevant

regulations.

Any harmful gas that might escape has to be led out via good room ventilation or a suitable

exhaust system. Place the unit, if necessary, below a gas vent.

The air flap does not close the exhaust duct completely. The delivered plug serves to avoid emerging of

vapors or loss of introduced inert gas, if any, via the exhaust duct. Due to special demands of heat

resistance, use the delivered plug only.

CAUTION

Use of inappropriate plug.

Danger of inflammation.

To close the exhaust duct use the delivered plug only.

For drying purpose, please remove the plug in order to permit dissipation of the generated vapor, which

would lead to condensation in the inner chamber.

8.5 Inert gas connection with mostly gas-tight version (option for FED 53 and

FED 115)

With this option the oven is additionally sealed, so the loss when introducing inert gases is decreased. For

details on the mostly gas-tight version please refer to chap. 8.4.

The oven is equipped with two ports for inert gas (nitrogen or noble gases).

The ports are located on the top panel in the middle and on the right side at the bottom right. Each

of these ports can be used as inlet or outlet, depending on the nature of the inert gas:

• lighter gas (nitrogen, helium): lower port as inlet

• heavy gas (e.g. argon): upper port as inlet

Connection

Observe the legal requirements and relevant standards and regulations for the safe handling of gas

cylinders and inert gases.

FED (E2) 02/2015 page 34/55

Page 35

cap when not in

General information for safe handling of gas cylinders:

• Store and use gas cylinders only in well ventilated areas.

• Open the gas cylinder valve slowly to avoid pressure surges

• Secure gas cylinders during storage and use against falling (chaining).

• Transport gas cylinders with a cylinder cart, do not carry, roll, or throw them

• Always close the valve even with apparently empty cylinders; screw on the

use. Return gas cylinders with the valve closed

• Do not open gas cylinders by force. Mark them when damaged

• Observe relevant regulations for dealing with gas cylinders.

Connect a flexible gas tube to the gas hose connection adapter (diameter 10mm), which is used for gas

inlet, and secure it with hose clamps (hose and hose clamps are not enclosed). There is a constant gas

flow after establishing the connection.

After connecting the gas cylinder, check all gas connections for leaks (e.g. with leak spray or

diluted soap solution).

Use a pressure reducer and make sure to avoid any excessive outlet pressure when connecting the gas

hose to the oven.

The unit is not entirely gas-tight. Inert gases from inside the drying and heating oven can

escape into the surrounding atmosphere.

Inert gases in high concentrations is hazardous to health. They are colorless and almost odorless and

therefore practically imperceptible. Inhalation of inert gases can cause drowsiness up to respiratory arrest.

When the O

content of the air decreases below 18%, there is risk of death from lack of oxygen. Any gas

2

that might escape has to be led out via good room ventilation or a suitable exhaust system.

WARNING

High concentration of inert gas.

Risk of death by suffocation.

∅ Do NOT set up units in non-ventilated recesses.

Ensure technical ventilation measures.

Respect the relevant regulations for handling these gases.

Inert gases, which are heavier than air, may accumulate in low-lying areas of the installation

site.

The “Mostly gas-tight version” reduces the loss of gas.

Setting (sample values):

If you want to flush the unit with an air exchange rate of 1 per hour, set the flow rate on the pressure

reducer according to the interior volume.

FED 53 with 53 l internal volume: The flow rate corresponding to 53 l / h is 0.9 l / min.

FED 115 with 115 l internal volume: The flow rate corresponding to 115 l / h is 1.9 l / min.

The air flap does not close the exhaust duct completely. The delivered plug serves to avoid loss of

introduced inert gas via the exhaust duct. Due to special demands of heat resistance, use the delivered

plug only.

FED (E2) 02/2015 page 35/55

Page 36

ANALOG OUTPUT 4-20 mA DC

A suitable DIN plug is enclosed.

CAUTION

Use of inappropriate plug.

Danger of inflammation.

To close the exhaust duct use the delivered plug only.

For drying purpose, please remove the plug in order to permit dissipation of the generated vapor, which

would lead to condensation in the inner chamber.

8.6 Analog output for temperature (option)

With this option the chamber is equipped with an analog output 4-20 mA for temperature. This output

permits transmitting data to external data registration systems or devices.

The connection is carried out as a DIN socket at the rear of the chamber as follows:

PIN 1: temperature –

PIN 2: temperature +

Temperature range:

0 °C to +300 °C

Figure 9: Pin allocation of DIN socket for option analogue outputs

9. Maintenance, cleaning, and service

9.1 Maintenance intervals, service

DANGER

Electrical hazard.

Danger of death.

∅ The unit must NOT become wet during operation or maintenance work.

∅ Do NOT remove the rear panel of the unit.

Before conducting maintenance work, turn off the unit at the main power switch and

disconnect the power plug.

Ensure all maintenance work is conducted by licensed electricians or experts authorized

by BINDER.

Ensure regular maintenance work is performed at least once a year.

The warranty becomes void if maintenance work is conducted by non-authorized personnel.

Replace the door gasket only when cold. Otherwise, the door gasket may become damaged.

FED (E2) 02/2015 page 36/55

Page 37

We recommend taking out a maintenance agreement. Please consult BINDER Service.

BINDER telephone hotline: +49 (0) 7462 2005 555

BINDER fax hotline: +49 (0) 7462 2005 93555

BINDER e-mail hotline: service@binder-world.com

BINDER service hotline USA: +1 866 885 9794 or +1 631 224 4340 x3 (toll-free in the USA)

BINDER service hotline Asia Pacific: +852 390 705 04 or +852 390 705 03

BINDER service hotline Russia and CIS +7 495 988 15 16

BINDER Internet website http://www.binder-world.com

BINDER address BINDER GmbH, post office box 102, D-78502 Tuttlingen

International customers, please contact your local BINDER distributor.

9.2 Cleaning and decontamination

Clean the unit after each use to avoid potential corrosion damage by ingredients of the test material.

DANGER

Electrical hazard.

Danger of death.

∅ Do NOT spill water or cleaning agents over the inner and outer surfaces.