Billi 915000LPL, 914000LBG, 914000LGM, 914000LPL, 915000LBG Installation Guide

...

Installation guide

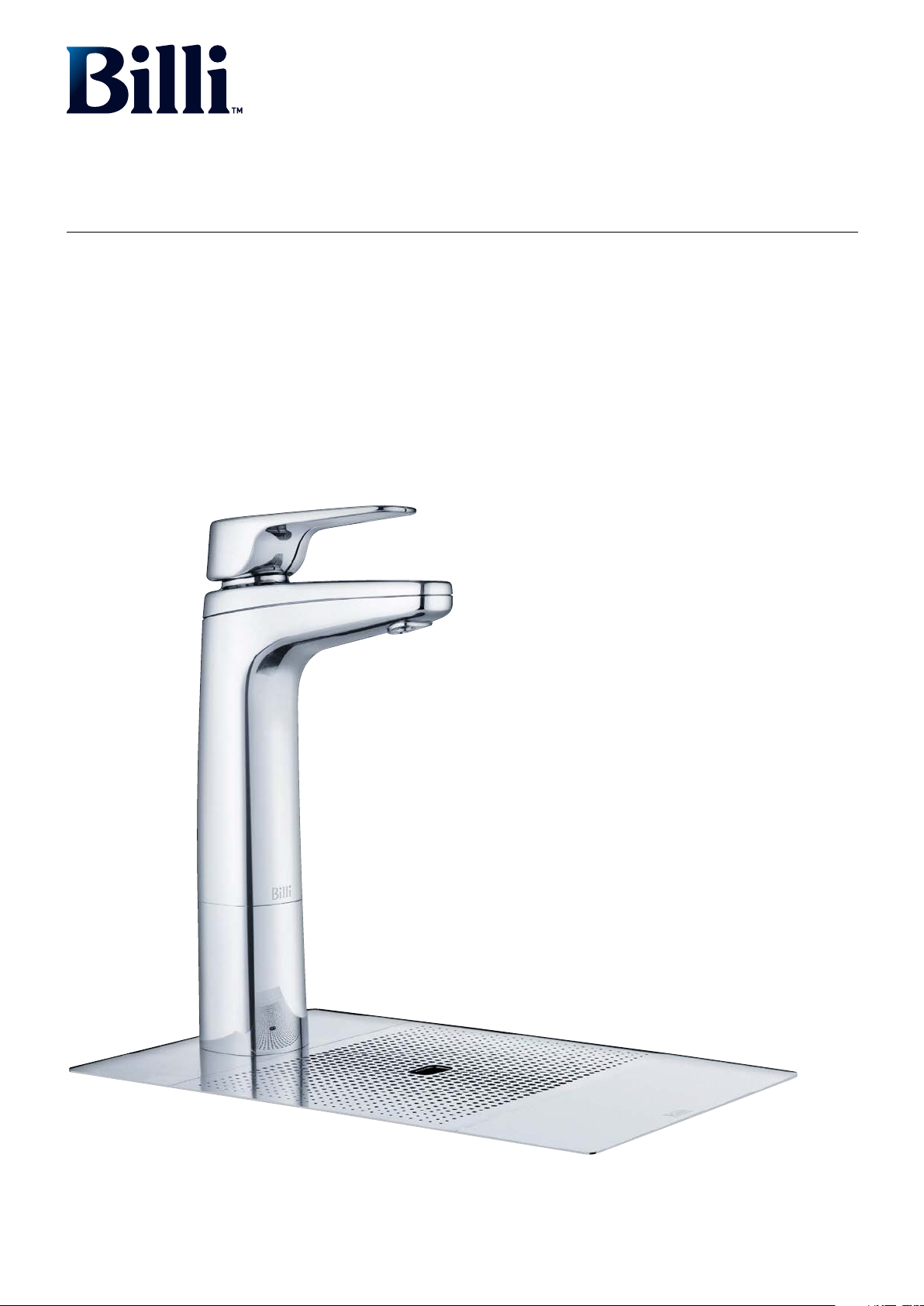

XI Font – Proud & Flush Mount

Installation requirements.

Proud & Flush Mount

Components included

Before commencing installation, ensure

you have identified the following pieces:

1. Spill tray

2. Font cover plate set 1 set (3 piece)

3. Mount riser – chrome

4 M4 studs – 3 x 74mm

5. M4 flange nuts x 3

6. M5 x 40mm screw x 1

7. Drain adapter

8. O-ring

9. 90° elbow 3/4”

10. 3/4” – 11/2” bush

11. Tap riser kit

12. M6 x 45mm Hex bolts x 4

13. M6 Flange nuts x 4

Determine unit location

Plan the installation. Dispenser tube lengths,

benchtop and cupboard restraints and drainage

requirements must be considered when

determining location. Use template enclosed

for drilling and cut-out details. Refer also to

appliance installation requirements supplied

with Drinking Water System.

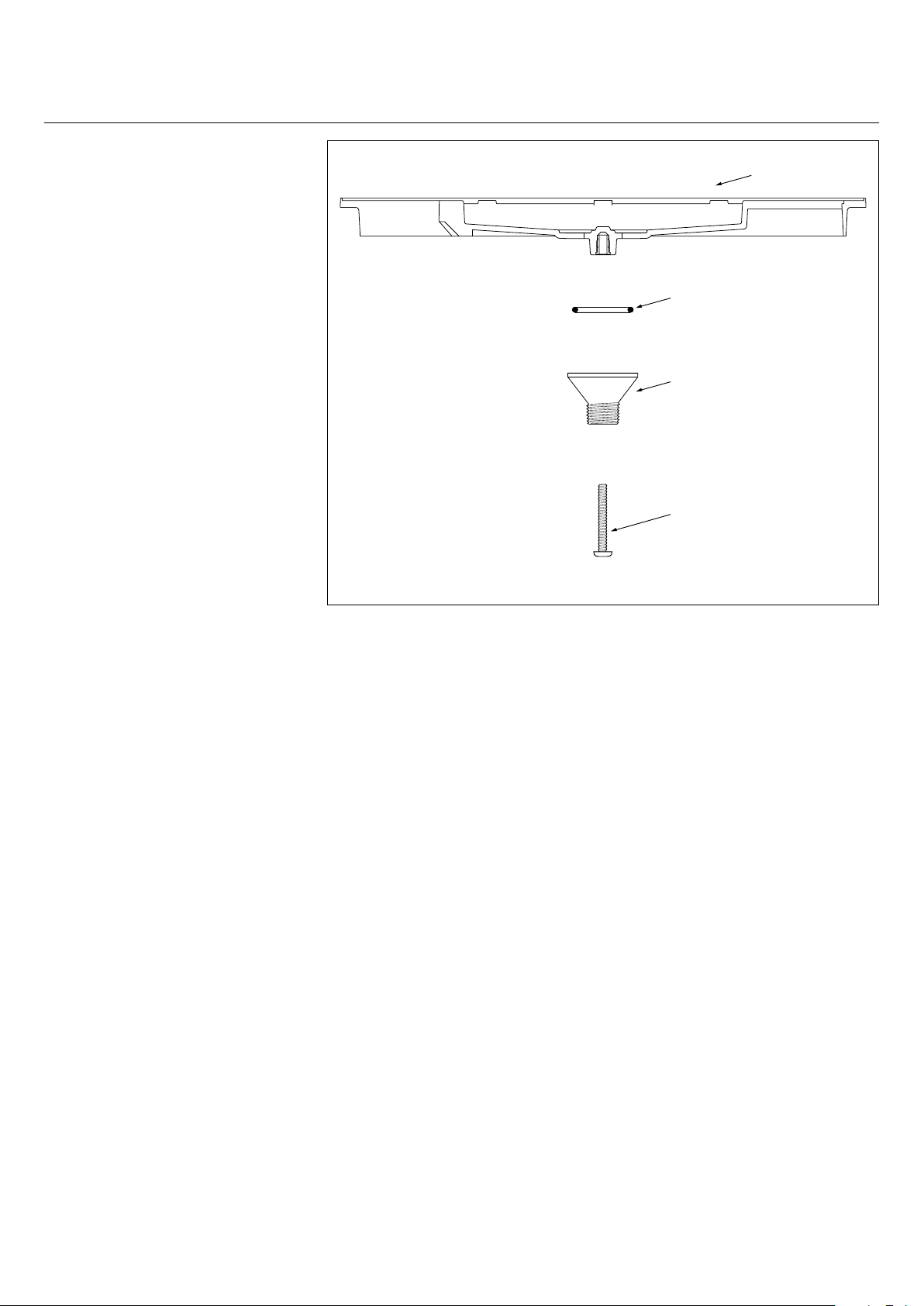

Font tray

O-ring

Drain adapter

M5 x 45 screw

Drainage location

Careful design and installation is essential

to provide satisfactory drainage performance

and to prevent later blockages. The Billi Font

is designed to be able to be connected to

a dishwasher nipple using either flexile or

rigid tubing or copper tubing. Where a

horizontal run is needed, we recommend

20mm or 25mm copper tubing be used.

An adapter bush is supplied for use where

a standard 40mm trap and drain is installed.

IMPORTANT

If drain is to be connected to a dishwasher

nipple, ensure hole through nipple is drilled

to at least ø12.7mm (1/2”) and de-burred,

to allow adequate flow.

Drain must be installed with a continual

fall along the entire length of the tube.

The Billi Fixture is to be installed by

a licensed tradesperson in accordance

with as 3500.4 Or AS/NZ 3500.4.2

And in compliance with applicable

state regulatory requirements.

Diagram 1

2

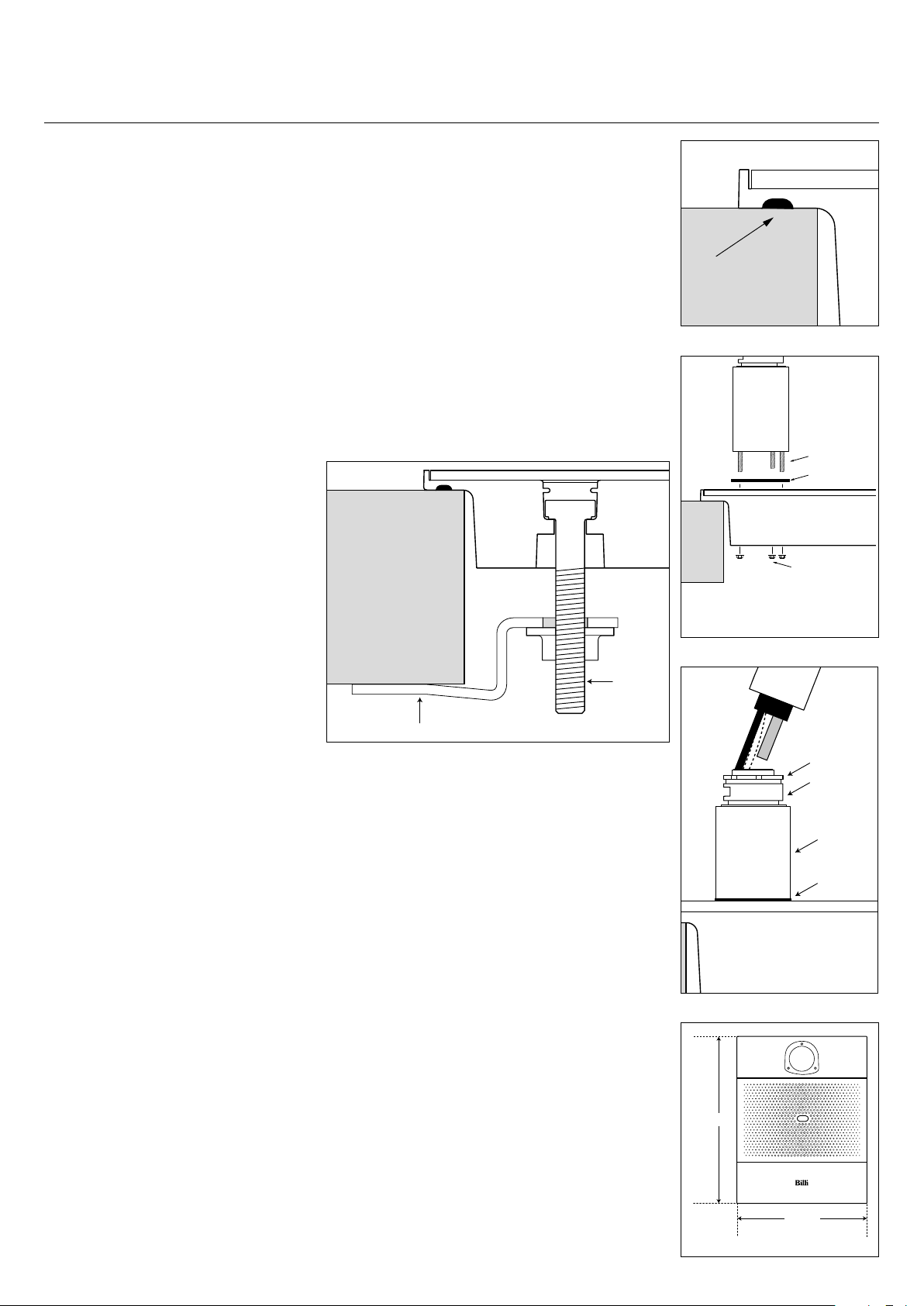

Installation procedure.

Proud Mount

1. Marking and Drilling Holes

a. Cut the template out and place template

in appropriate position. Check underneath

benchtop for possible obstructions such

as dividers, existing plumbing, etc. Trace

round the template and drill a pilot hole

for the jigsaw, using the jigsaw follow the

line in which was traced onto the bench

– see diagram 7 on next page.

2. Fitting Drain Adapter

a. Fit O-ring to Drain adapter.

b. Fit Drain adapter to tray. Tighten M5

screw, Note: Do NOT over-tighten

the screw.

c. Drain tube and elbow fitting are to

face dispenser mount hole – refer to

diagram 1 on previous page.

3. Fitting Billi Font to Benchtop

a. Ensure silicone bead is installed around

the edge of the cut out – ref to diagram 2.

b. Lower the Font tray into the cut out and

insert 4 x M6 bolts, one in each corner.

c. Fit the clips and M6 Flange nuts to all 4

bolts – refer to Diagram 3.

e. Tighten nuts until rim sits flat on

benchtop. Do NOT over-tighten nuts.

straight ahead position. Fit M4 x 10mm

retaining screw rear threaded hole and

tighten with

Allen Key supplied.

7. Connect Tubing to Underbench Module

a. Connect dispenser tubing to underbench

module as per installation instructions

supplied with your unit.

8. Connect Drainage

a. Connect drainage tubing with reference

to Drainage Requirement instructions

on previous page. Drainage tube must

be installed with a continual fall along

the entire length of the tube and must be

adequately clipped and supported.

Bench Font tray

Bench Font tray

Seal between

Font and Benchtop

Diagram 2

Riser

3 x M4 studs

Gasket

Font trayBench

3 x M4 nuts

4. Fit front and rear cover plates

a. Remove protective film from cover

plate set.

b. Remove gasket cover and insert cover

into font tray.

c. Ensure holes in rear cover plate align with

the holes in the font tray.

d. Apply pressure around edge of plate(s)

to ensure proper gasket seal.

5. Fitting Dispenser Riser – refer to diagram 4.

a. Screw 3 x M4 studs into the rear

of the riser.

b. Fit the Gasket over the studs.

c. Place the riser through the cover plate

and into position on the font.

d. Fit and tighten 3 x M4 Flange nuts

to the underside of the Font tray.

6. Fitting Dispenser Head Assembly

(refer to diagram 5)

a. Feed dispenser tubing and loom

through centre hole in riser

in the following order:

i. Dispenser power cord

ii. Grey vent silicone tube. Feed tube until

reducing join passes through Mount

riser assembly – see diagram 5.

iii. Red and blue silicone tubing. Check

tubing is not kinked or twisted.

b. Turn dispenser head to 60° from the

straight ahead position of mount base.

Slide head assembly onto base assembly

whilst gently pulling tubing downwards

from underneath. Dispenser mounting

lugs will pass over and slide down the 3

grooves on the swivel bearing.

c. Once fully down, turn dispenser head to

Clip

M6

Bolt

Diagram 3

291mm

Diagram 4

Nut

Swivel

bearing

Mount riser

Gasket

Font tray

Diagram 5

191mm

Diagram 6

3

Loading...

Loading...