Big Dipper W-200-IS Installation Manual

Installation & Operation Instructions

For Big Dipper 51k Series

Internal Strainer (IS) Units

Models W-200-IS, W-250-IS, W-350-IS and W-500-IS

(Including 230 VAC Units)

® |

Complies with C22.2 |

*Please consult Thermaco, Inc. for specific models tested, certified and/or listed by these organizations.

Copyright ©2017 Big Dipper® Thermaco, Incorporated • P.O. Box 2548 • Asheboro, NC 27204

Toll Free: (800) 633-4204 • V: (336) 629-4651 • F: (336) 626-5739 info@thermaco.com • www.big-dipper.com

AFJ |

Part# MNL-ISPS51000 |

51K Series |

Table of Contents |

Table of Contents

IS System Overview |

3 |

IS System Maintenance |

4 |

IS Digital Control Operation |

5 |

IS System Troubleshooting |

6 |

How To Reverse IS System Operation |

7 |

Plumbing Installation |

8 |

Vented Flow Control Installation |

11 |

Electrical Installation |

12 |

IS System Wiring Diagram |

13 |

IS Component Identification |

14 |

IS Replacement Parts |

17 |

Limited Warranty |

18 |

©2019 Thermaco, Incorporated All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 |

MNL-ISPS51000 2 |

51K Series |

Big Dipper® Internal Strainer (IS) |

System Overview |

Big Dipper Internal Strainer System Overview

The Thermaco, Inc. Big Dipper® Automatic Grease and Oils

Removal System removes free-floating grease & oils from kitchen drain water flows. As most food service facility managers already know, grease buildup within a building’s plumbing

drainage system is a major cause of problems due to drain line blockages. These problems jeopardize normal operations as well as create health and safety hazards within the facility itself.

The proper installation of a Big Dipper System can reduce or eliminate grease problems. Use of the Big Dipper assures minimization and/or elimination of costly sewer surcharges and

fines through efficient separation and removal of free-floating grease & oils. In addition, the Big Dipper also helps reduce or

eliminate pumping and disposal costs associated with conventional grease separators or interceptors. The recovered grease & oils are substantially water-free and are suitable for recycling by local rendering and/or biodiesel companies.

The Big Dipper system is an automatic, self-cleaning device. As greasy kitchen effluent drains from kitchen fixtures, the unit contains the grease & oils. These separate from the effluent and rise to the surface of the separator tank. The unit automatically skims the contained grease & oils and transfers the grease & oils to a collection container. A digital control maintains the self cleaning operation, activating the skimming wheel periodically based on the setting chosen. Only the “cleaned” water exits the unit and flows into the facility drain lines. The Big Dipper IS automatic systems operate most efficiently when servicing single fixtures such as a 1 to 3-compartment sink or a pre-rinse station.

The Big Dipper system’s compact footprint allows installation directly at the source where grease problems originate. The system design also allows easy maintenance and operation requiring only a minimal amount of daily and weekly maintenance to maintain peak operating performance.

The Big Dipper system design allows for maximum installation flexibility. Reversing the system operation is a simple as rotating the cover assembly of the unit.

Hydromechanical grease interceptors (formerly referred to as grease traps), grease separators, automatic recovery units, grease removal devices and other similar plumbing devices receiving kitchen flows from sinks, floor drains, woks and other food bearing sources may generate odors. The 51k Series Big Dipper has been designed to seal in odors and prevent them from leaking into the kitchen through the tank lids. It does not prevent odors related to the rest of the plumbing system including but not limited to: open floor drains, air gaps, external solids straining devices, improper venting, and odors generated elsewhere in the plumbing system. These odors are usually prevented by good area ventilation, frequent fluid inputs, good product maintenance practices and proper product installation. Additional pretreatment steps not performed by the Big Dipper automatic grease interceptor, including aeration, chlorination, improved area ventilation and additional maintenance control, may be needed at some sites.

©2019 Thermaco, Incorporated All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 |

MNL-ISPS51000 3 |

51K Series |

Big Dipper® Internal Strainer (IS) |

System Maintenance |

Big Dipper® Internal Strainer (IS) System Maintenance

Daily Maintenance:

(A)Empty the clear plastic grease/oils collection container (located beside the unit) prior to its becoming full once each day. The Big Dipper recovers grease and oil virtually water-free so that they can be recycled. The collector container should be washed periodically so as to maintain the easy viewing translucent characteristic of the collector. Contents may be disposed of in rendering barrel with permission of rendering company or as solid food waste. To dispose in this manner, empty grease into plastic bucket lined with trash bag and allow contents to solidify at room temperature or in cooler before throwing into garbage.

(B)The internal strainer basket should be removed and emptied into a garbage container by shaking briskly. Wash the inside and outside surfaces of the strainer after emptying.

Weekly Maintenance:

(A)Check the collection trough and the wiper blades for any solids build-up. Wipe off any accumulated deposits and assure that the wiper blade assembly is re-placed properly.

(B)Press the Skim Start/Stop button (on the bottom-right of the user interface) to ensure that the motor and skimming wheel are still operating correctly. Press again to stop test. This will not affect the normal run-time of the unit.

(C)Check the thickness of the grease layer at the top of the unit. There should be no appreciable amount of grease or oil left in the tank immediately after the daily automatic skimming cycle. If there is more than a 1/2” (13 mm) thick layer of grease after the skimming cycle, this indicates a need to increase the skimming time. Increase the digital control settings accordingly until a clean unit appearance is obtained after the automatic skimming cycle. A simple guide is to change to the next higher setting and run for a period of time until enough grease is being skimmed from the tank.

Quarterly Maintenance:

(A) The internal strainer basket in the unit is designed to remove incidental solids from kitchen drain flows. Over a period of time, sediment consisting of very fine particles may begin to accumulate on the bottom of the unit. If this build-up is allowed to continue, it may eventually block the outlet baffle. To prevent this from occurring, remove the lid and stir the bottom of the unit with a long handled spatula while water is flowing to flush out the sediment. Occasionally drain and clean the unit thoroughly. Properly used, a wet-vac may be appropriate for this purpose.

*CAUTION! DISCONNECT POWER TO UNIT BEFORE CLEANING to prevent damage to the unit and personal injury

*NOTE: Before energizing unit after cleaning, fill tank with water to protect wipers and heater from damage

©2019 Thermaco, Incorporated All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 |

MNL-ISPS51000 4 |

51K Series |

Big Dipper® IS System |

Digital Control Operation |

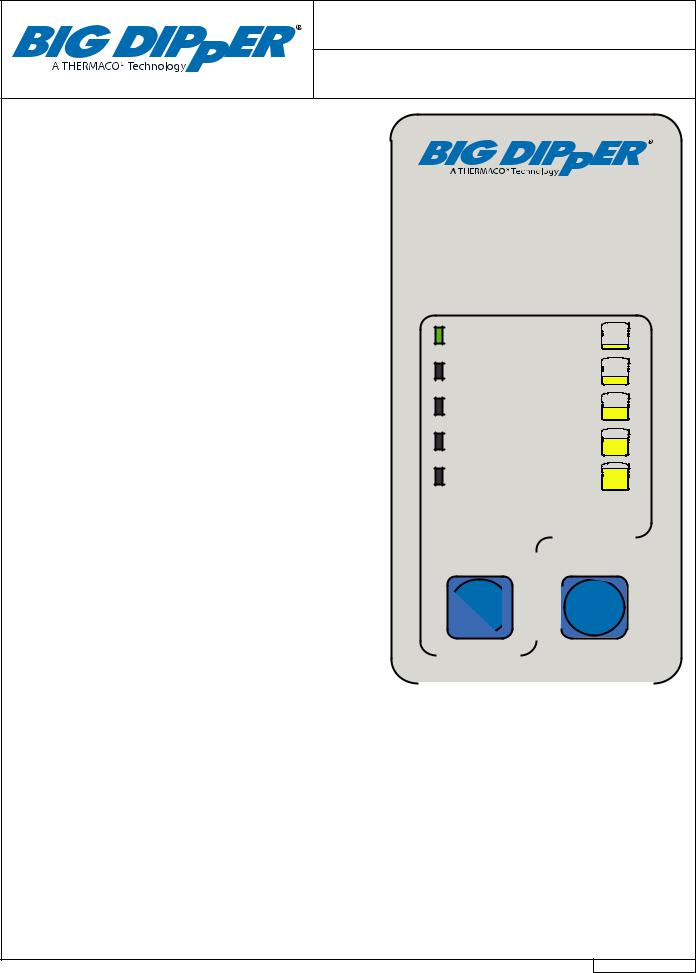

Timed Skimming Default

Using the “User Interface” five levels of skimming may be selected in the “default” mode using the ‘Select Skim Mode’ button. By selecting one of the skim settings – 1, 2, 3, 4, or 5 - the skimming time per day (indicated to the right of the light) is activated. The LED associated with the selected button is illuminated continuously as an indicator of the selected skim cycle and as a “power on” indicator. If the skimming level is changedduringanactiveskimmingcycle,thenextactiveskim cycle will be at the new setting (The LED associated with the newly selected level will change immediately). If the skimming cycle is changed between active skimming cycles the next skim cycle will be at the new level.

The skim cycle will occur at the same time each day. This is determined by the time at which power is applied to the unit. In the case of setting 5, the unit will skim for 60 minutes every 12 hours. To choose a new skim time, disengage power to the unit and reapply power at the time when skim cycle is desired.

All skim cycles will last no more than 60 minutes at one time. In the case of setting 5 in default mode or settings in extreme mode,theelectricalassemblywillrunmorethanone60minute cycle per day.

Motor Exercising

Forallselectedskimminglevelswithsystemdelaysgreaterthan 12 hours the skimmer motor will be energized for 5 seconds every 12 hours. Only the motor will be energized (no heater operation) at these exercising times.

Skim Start/Stop Button Operation

Any time the start button is depressed operation begins for the selected skim level. Pressing this button does not effect the normal timing of the unit. Pressing this button again will stop the current skim.

Automatic Operation:

Skimming wheel operates every day for the time indicated by setting below (may include more than one skim during the day). Use Select Skim Mode to toggle between skim settings. Skim Start/Stop button begins/stops skim cycle.

For help with operation, visit big-dipper.com/operation or call 800-633-4204.

I - Skim 15 min. per day

2 - Skim 30 min. per day

3 - Skim 45 min. per day

4 - Skim 60 min. per day

5 - Skim 120 min. per day

Information regarding additional settings and LED functionality available in product manual.

|

SELECT |

|

|

SKIM |

|

|

|

SKIM MODE |

|

|

START/STOP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heater Operation

By default, the heater activates 60 minutes prior to a scheduled skim cycle. The heater will operate under thermistor control with settings of 130°F heater off point, 120°F heater on point for the duration of the preheat and skim cycle..

Extreme Modes

Two (2) additional run-times are accessible which allow the unit to operate more frequently.

•2+5 - When lights 2 and 5 are both illuminated, the unit will skim for 60 minutes every 6 hours

•3+5 - When lights 3 and 5 are both illuminated, the unit will skim for 60 minutes every 4 hours

Selecting Default or Extreme skimming

To toggle between the two skimming levels remove power from the Big Dipper® either by unplugging the unit or lifting the center module to open the interlock switch. Reapply power while holding the Select Skim Mode button depressed. The number of LEDs illuminated will be the skim level indicator – 1 LED for the default modes and two for the extreme modes. When toggled from extreme to default mode, level 3 will be initially selected.

©2019 Thermaco, Incorporated All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 |

MNL-ISPS51000 5 |

51K Series |

Big Dipper® IS System |

Troubleshooting |

Big Dipper unit overflows

(1)Check to see that the outlet pipe is not reduced to a smaller size, the outlet piping is vented, has as few 90 degree outlet turns as possible, and that no “P” trap is installed on the outlet. Re-plumb the piping, if necessary. Check outlet piping for clogs. Have a plumber clean the line, if necessary.

(2)Make sure that the solids strainer is in place and emptied daily.

(3)Check the bottom of the grease chamber for excessive solids and silt buildup which may be blocking the outlet baffle. Disconnect the power and use a long handled spatula or similar instrument to stir the bottom while water flows through the unit. If necessary, drain andcleanthesedimentfromtheunit. Topreventrecurrence, schedule this cleaning to be done on a regular basis (properly used, a wet vac may be appropriate for cleaning sediment from the bottom of the unit).

(4)Make sure the flow rate to the unit does not exceed themaximumflowrate,whichisshownonthenameplate. If necessary, have a plumber install an approved flow control to restrict the inlet flow to the specified level or install a properly sized Big Dipper for the application.

Excessive water observed in the grease collection container

(1) Check Digital Control for excessive run time. Unit will pick up incidental water after all grease is removed. If necessary, reduce the digital control setting (i.e. 3 to 2) until no water is observed in the grease collection container.

No grease is collected in the container

(1)Check to be sure the power is on and the correct setting is chosen. One of the setting buttons should be illuminated. Ifnoneofthesettingbuttonsareilluminated, the unit is not powered.

(2)Lift the sump cover and clean away any buildup that may be present on the wiper blades or collection trough. Make sure the wiper blade(s) are properly in place on the skimmer wheels. Replace wiper blades when worn or warped.

(3)Press the Skim Start/Stop Button on the bottom of the user interface to ensure that the skimming wheel turns. CAUTION: Keep your hands away from moving parts to avoid possible injury. If the skimmer motor does not comeon,themotorassemblymayneedtobereplaced.

(4)Check for congealed grease in the unit. If the Big Dipper’s heating element is not warming the unit, the heating element may need to be replaced.

(5)Some sites do not generate enough grease to be capturedbytheskimmingprocess. SetControlformini- mumoperation-Setting1forLightSkimmingOperation.

Objectionable odor

(1)Clean the solids strainer and grease collection container more frequently.

(2)Make sure grease/oil is being skimmed properly from the unit.

(3)Check Digital Control for excessive run time. Unit will pick up incidental water after all grease is removed. If necessary, reduce the skim setting (i.e. 3 to 2) until no water is observed in the grease collection container.

(4)If excessive sediment has collected on the bottom of the unit, clean the unit as described in item 3 in “Big Dipper unit overflows.”

(5)Hydromechanicalgreaseinterceptors,greasetraps, automatic recovery units, grease removal devices and other similar plumbing devices receiving kitchen flows from sinks, floor drains, woks and other food bearing sourcesmaygenerateodors. WhiletheAdvancedOdor Protection features of your Big Dipper are designed to keep odors from escaping the lid, there may be other factors influencing odor evolution and dissemination. These include room ventilation, kitchen menu, ambient temperatures,warewashingpractices,grease/oilinput, dailyinputfluidvolume,sanitizers,installationplumbing design and product maintenance/upkeep. Odors are usually prevented by good area ventilation, frequent fluid inputs, good product maintenance practices and proper product installation. Additional pretreatment stepsnotperformedbytheBigDipperautomaticgrease interceptor, including aeration, chlorination, improved area ventilation and additional maintenance control, may be needed at some sites.

©2019 Thermaco, Incorporated All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

646 Greensboro St. • Asheboro, N. C. 27204-2548 • Phone (336) 629-4651 |

MNL-ISPS51000 6 |

Loading...

Loading...