Page 1

TDT50/TDT150

TDT100/TDT300

Transformer Installation Instructions

Th e s e i n s T r u c T i o n s c o v e r T h e i n s T a l l a T i o n o f T h e

f o l l o w i n g o u T p u T T r a n s f o r m e r s f o r 25/70/100 v o l T

s p e a k e r s y s T e m s

• TDT50

50watts Output Transformer for MCA8050 (Single Channel)

• TDT100

100watts Output Transformer for MCA8050 (Bridge Channels)

• TDT150

150watts Output Transformer for MCA8150 (Single Channel)

• TDT300

300watts Output Transformer for MCA8150 (Bridge Channels)

CAUTION – These servicing instructions are for use by

qualied personnel only. To reduce the risk of electronic shock,

do not perform any servicing other than that contained in the

operating instructions unless you are qualied to do so.

NOTE – To avoid fault conditions, High Pass Filters (HPF) must be

assigned on those channels having transformers installed.

KIT CONTENTS:

• (1) Transformer

• (1) Holding nut

• (2) rubber washers

• (1) Metal dome washer

• (1) stickers

• (1) Instructions

RECOMMENDED TOOLS:

• Phillips screwdriver

• Adjustable wrench

• Pliers

Page 2

TDT50 & TDT150 INSTALLATION INSTRUCTIONS

1. Disconnect AC power from the amplier.

2. Remove the amplier top panel by removing 17 screws

(6 on each side, 3 on back and 2 on front).

Please note that front screws are longer.

3. If the mounting bolts have two nuts, remove one and

save. These nuts will be used to hold the transformers

in place. If the mounting bolts have only one nut, do

not remove. Transformer will be held in place with

supplied nut.

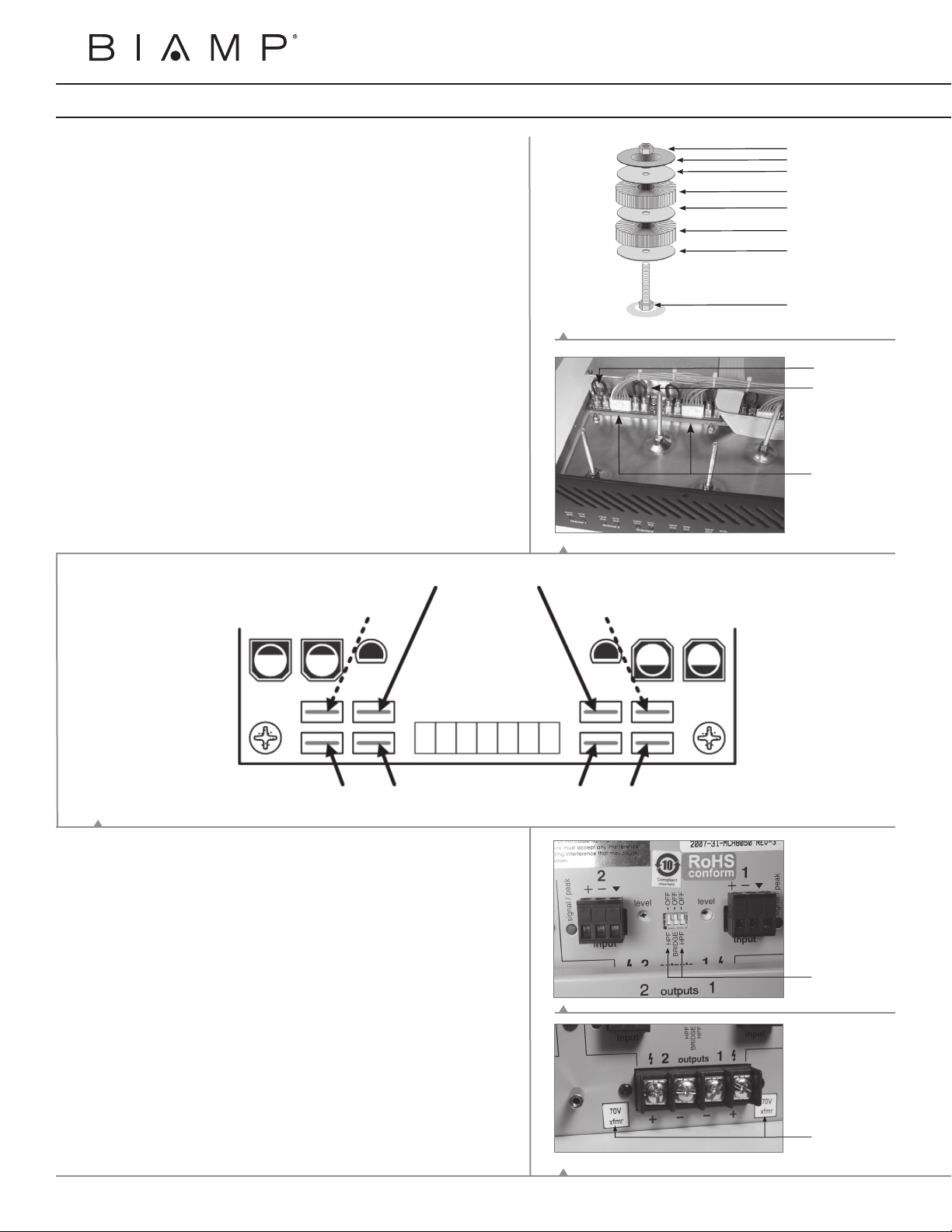

4. Install transformers as shown in gure 1.

5. Locate the amplier circuit boards and jumpers.

Each amplier card represents two individual output

channels; one odd and one even (refer to gure 2 for

reference).

6. Using a pair of pliers, remove the black and red jumper

from the associated amplier channel.

7. Following the diagram below (gure 3), connect the

wires as indicated.

Please note that wires on odd channel are

mirrored from wires on even channel.

Brown wire = 25V

Orange wire = 70V

Yellow wire = 100V

Blue wire Blue wire

Nut

Metal Dome Washer

Rubber Washer

Transformer

Rubber Washer

Transformer

Rubber Washer

Bolt

FIGURE 1

Odd channel

jumpers (Ch 1)

Even channel

jumpers (Ch2)

Amplier

Cards

FIGURE 2

Brown wire = 25V

Orange wire = 70V

Yellow wire = 100V

Odd

Channels

(1, 3, 5, & 7)

Green wire Green wireBlack wire Black wire

FIGURE 3

8. Replace amplier top panel (longer screws go on the

front).

9. Assign channel HPF (High Pass Filter) by ipping the

appropriate channel rear panel dip switch. (gure 4)

10. Apply appropriate rear panel “xfmr” voltage sticker.

(gure 5)

Even

Channels

(2, 4, 6, & 8)

High Pass Filter

(HPF)

dip switches

FIGURE 4

FIGURE 5

Afx transformer

stickers

Page 3

TDT100 & TDT300 INSTALLATION INSTRUCTIONS

1. Disconnect AC power from the amplier.

2. Remove the amplier top panel by removing 17 screws

(6 on each side, 3 on back and 2 on front).

Please note that front screws are longer.

3. If the mounting bolts have two nuts, remove one and

save. These nuts will be used to hold the transformers

in place. If the mounting bolts have only one nut, do

not remove. Transformer will be held in place with

supplied nut.

4. Install transformers as shown in gure 6.

FIGURE 6

5. Locate the amplier circuit boards and jumpers.

Each amplier card represents two individual output

channels; one odd and one even (refer to gure 7 for

reference).

6. Using a pair of pliers, remove the red jumper from

both amplier channels.

7. Following the diagram below (gure 8), connect the

wires as indicated.

FIGURE 7

Nut

Metal Dome Washer

Rubber Washer

Transformer

Rubber Washer

Bolt

Odd channel

jumpers (Ch 1)

Even channel

jumpers (Ch2)

Amplier

Cards

Orange wire = 70V

Blue wire Green wire

Yellow wire = 100V

Odd

Channels

(1, 3, 5, & 7)

FIGURE 8

8. Replace amplier top panel (longer screws go on the

front).

9. Assign channel HPF (High Pass Filter) by ipping the

appropriate channel rear panel dip switch. (gure 9)

10. Assign bridge mode by ipping the rear panel bridge dip

switch (gure 9)

11. Apply appropriate rear panel “xfmr” voltage sticker.

(gure 10)

Black wireBrown wire = 25V

Even

Channels

(2, 4, 6, & 8)

Bridge

dip switch

High Pass Filter

(HPF)

dip switches

FIGURE 9

FIGURE 10

Afx transformer

stickers

Page 4

DoC MCA201003

EC Declaration of Conformity

Biamp Systems Corporation, as manufacturer having sole responsibility, hereby

declares that the following described product complies with the applicable provisions of

the DIRECTIVES below except as noted herein. Any alterations to the product not

agreed upon and directed by Biamp Systems Corporation will invalidate this declaration.

Product Models: MCA 8050 with optional Output Transformers TDT50 or TDT100

MCA 8150 with optional Output Transformers TDT150 or TDT300

Product Description

Applicable EC Directives

LVD Directive (2006/95/EC) Safety EN 60065:2002

EMC Directive (2004/108/EC) Emissions EN 55103-1:1996, Environment E2

Immunity EN 55103-2:1996

Special Considerations for Product Environment or Compliance:

Shielded cabling must be used for system connections.

Technical Documentation File, Location and Contact:

Biamp Systems, Inc. phone: (503) 641.7287

9300 S.W. Gemini Drive fax: (503) 626.0281

Beaverton, OR USA 97008 e-mail: biamp@biamp.com

: Audio Amplifiers and Distribution Transformers

: Applicable Harmonized Standards:

Authorized Representative: Larry Copley, Compliance Engineer

Authorized Signature:

Issued: March, 2010

Page 5

Biamp Systems | 9300 S.W. Gemini Drive | Beaverton, OR | 97008 | USA | +1.503.641.7287 | www.biamp.com

Loading...

Loading...