!

!

Innovative Foodservice Equipment

Custom Designed for Performance, Service and Value.

INSTALLATION AND OPERATING

INSTRUCTIONS

Hot Holding Cabinet

Model: CS82-CH8 & CS36-CH3

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this

equipment.

!

!

WARNING

Initial heating of unit may generate smoke or fumes and must be done in a

!

This equipment has been engineered to provide you with dependable service when used according to the

instructions in this manual and standard commercial kitchen practices.

Phone: +1

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

well-ventilated area. Overexposure to smoke or fumes may cause nausea or

dizziness.

ANSI/NSF4

(214) 421-7366

BevLes Company, Inc.

729 Third Avenue

Dallas, TX 75226

1

!

Form #780088 11/04

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is receiveddamaged, either apparent or

concealed, a claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freightbill at the time of delivery. It must then be signed by

the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier should

supply the necessary forms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection

must be made to the carrier within 15 days. The carrier should arrange an inspection.

BE CERTAIN TO HOLD ALL CONTENTS AND PACKAGING MATERIAL.

Installation and start-up should be performed bya qualified installer who thoroughly reads, understands and

follows these instructions.

BevLes Company takes pride in the design and quality of our products. When used as intended and with

proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensure best results, it is important that you read andfollow the instructions in this manual carefully.

Installation and start-up should be performed by a qualified installer who thoroughly reads, understands

and follows these instructions.

If you have questions concerning the installation, operation, maintenance or service of this product, write

Technical Service Department BevLes Company, Inc., 729 ThirdAvenue, Dallas, TX 75226.

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation is fully trained and

aware of all precautions. Accidents and problems can result by a failure to follow fundamental rules and

precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnel or the equipment. The words are defined as follows:

DANGER:

!

WARNING:

!

seriousinjuryor death.

CAUTION:

moderateinjuryorproductor property damage.

!

NOTICE:

eventhoughnot dangerous.

!

Thissymbolwarnsof imminent hazard which will result in serious injury or death.

This symbol refers to a potential hazard or unsafe practice, which could result in

Thissymbol refers to a potential hazardor unsafe practice,which may result in minor or

This symbol refers to information that needs special attention or must be fully understood

!

!

!

!

GENERAL INFORMATION

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

CAUTION:

positioned so the general public can use the equipment make sure that cautions, warnings, and

!

operating instructions are clearly posted near each unit so that anyone using the equipment will

useit correctly and not injurethemselvesorharm the equipment.

WARNING:

!

andfrequencylistedon the data plate. Connect only to1 or 3 phase as listed on the data plate.

WARNING:

!

nationalelectricalcodeand/orotherlocal electrical codes.

These models are designed, built, and sold for commercial use. If these models are

Checkthe data plate on this unit before installation.Connecttheunit only to the voltage

Electrical and grounding connections must comply with the applicable portions of the

2

!

!

!

WARNING:

!

powerplug,indicatingthat you are working on the circuit.

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

!

WARNING:

strongly recommend having a competent professional install the equipment.A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

!

be used when connecting these units to electrical power. In the absence of local codes, use the

latestversionof the National Electrical Code.

WARNING:

codes, or in the absence of local codes, with the National Electrical code, ANSI/NFPA 70, Latest

Edition to protect the user from electrical shock. It requires a grounded system and a dedicated

!

circuit, protected by a fuse or circuit breaker of proper size and rating. Canadian installation must

complywiththe Canadian ElectricalCode, CSAC22.2,asapplicable.

CAUTION:

!

unlessthereis at least 2- 4 breathingspacebehindunit.(Appliesto the CS36-CH3 Only)

WARNING:

!

maintenanceorrepair,contacttheBevLesCompany.

WARNING:

!

surface.

Installper the spacing requirementslisted in the installationsection of this manual. We

This device should be safely and adequately grounded in accordance with local

Do not set the unit with its back flat against the wall. It will not operate properly

Afactoryauthorizedagentshouldhandle all maintenance and repair. Before doing any

Never clean any electrical unit by immersing it in water. Turn off before cleaning

!

!

!

!

!

WARNING:

installationandfromthereto an independent earth connection.

!

NOTICE:

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition.

!

Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General

Requirements-CanadianElectrical Code PartII, 109-M1981-CommercialCookingAppliances.

WARNING: -

!

equipment.

NOTICE:

!

NOTICE:

Fire Protection Association, Inc. states in its NFPA96 latest edition that local codes are Authority

Having Jurisdiction when it comes to requirement for installation of equipment. Therefore,

!

installationshouldcomplywithalllocal codes.

CAUTION:

!

provided.

An earthing cable must connect the appliance to all other units in the complete

The unit when installed, must be electrically grounded and comply with local codes, or in

SHOCK HAZARD

Thisproductis intended for commercial use only.Notforhouseholduse.

Local codes regarding installation vary greatly from one area to another. The National

Suitable for installation on combustible floor when installed with legs or casters

De-energize all power to equipment before cleaning the

!

!

!

!

!

!

WARNING: -

!

SHOCK HAZARD

Donot open any panels that require theuse of tools.

3

!

TABLE OF CONTENTS

SECTION ITEM PAGE

Safety Precautions 2

General Information 2

1. Introduction 5

2. Operational Procedures 5

3. 6

4. 7

5. Troubleshooting Guide 8

6. Preventative Maintenance 9

7. Wiring Diagrams 10

8. Parts List & Exploded Views 13

9. Warranty 16

Cleaning

Specifications

A. Taco Bell Top Module 10

B. Taco Bell Control Panel 11

C. Taco Bell Front Panel Enclosure 12

A. Main Cabinet (Exploded View) 13

B. Top Module

C. Door Assembly

D. Parts List 15

(Exploded View) 14

(Exploded View) 14

IMPORTANT FOR FUTURE REFERENCE

Notes:

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

4

1. INTRODUCTION

BevLes Hot Holding Cabinets are designed and engineered to hold prepared foods within a precise

temperature range. Built from the finest materials available, BevLes Hot Holding Cabinets are custom

designed for performance, service and value.

All personnel responsible for the operation and maintenance of BevLes Hot Holding Cabinets

should become familiar with thismanual prior to operating the equipment.

Notes

All models are U.L., C.U.L., and U.L. Sanitation listed.

BevLes Hot Holding Cabinets are furnished with a 10-foot power cord with a 20 amp molded plug.A

NEMA5-20R receptacle is required.

Each cabinet is equipped with self-closing door hinges designed to open to a maximum of 180°.

Do not flex doors beyond 180°. Excessive stress on the hinge may lead to metal fatigue and

possible breakage.

Hot Holding Cabinets require a minimum of 4” between each Hot Holding Cabinet and other

equipment or surfaces for proper aircirculation to and from fan motor air vents; full size models (over

50” tall) also require 4” between the and other surfaces.

Do not place any objects over motor air vents located on right side of cabinet top mounted

heating unit.

top of the cabinet

2. OPERATIONAL PROCEDURES

Step 1.

Step 2.

Step 3.

If your Hot Holding Cabinet is equipped with stationary legs, it is important to level your cabinet for

proper operation. To level, simply turn the adjustable hex foot as needed on each leg.

Care should be exercised when adjusting to avoid loosening or removing the leg from the

cabinet base. Hold the leg firmly and adjust the hex foot. NOTE: Model CS82-CH8 must

remain equipped with factory authorized legs, and can never be mounted on casters of any

type.

Plug the cabinet into the power source. Use a separate electrical line (120V-20A), protected by a

circuit breaker of the proper rating. (NEMA 5-20R receptacle is required).

WARNING: Before plugging in cabinet, ensure compatibility with your electrical source by

referring to the serial number label located on the top side of the Hot Holding Cabinet. For

any necessary assistance, please contact the BevLes factory.

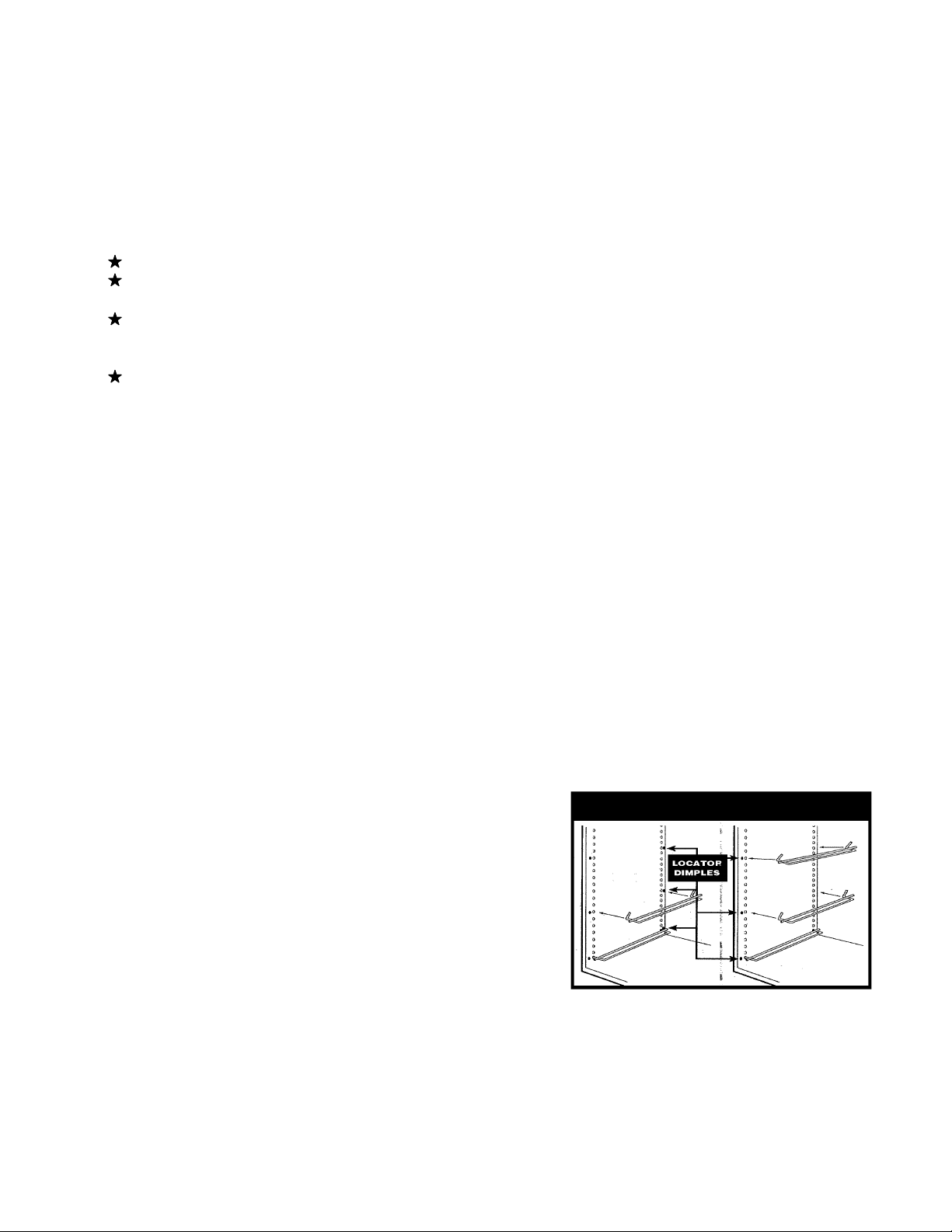

Make certain that the wire shelf supports have been

properly installed. Improperly spaced shelves may

affect air flow circulation within the cabinet interior

leading to “hot” or “cold” spots. As shown in Figure 1,

supports attach to the airflow (side) panels beginning

with the bottom holes in each airflow panel (left and right

side of cabinet). Small indentations (dimples) on the

airflow panels indicate the correct placement holes for

each wire shelf support.

equipped with other types of shelf supports; please

contact the BevLes factory with any questions on

shelf support installation.

NOTE: Some models may be

Figure 1

WARNING:

Step 4.

Step 5.

Push power switch to “ON” position. The digital display will light and show the current cabinet

temperature. A red LED light (located in the upper left corner of the display) will be displayed anytime

the cabinet temperature falls below the set temperature.

After five minutes, check the digital display and the air flow inside the cabinet to be sure that it is

heating properly. As a point of reference, most “empty” full size cabinets will reach their set

temperatures within approximately 30 minutes.

5

Your BevLes Hot Holding Cabinet features a 24-hour mechanical Timer to allow for automatic operation.

The Timer and a Timer ON-OFF switch are located behind the 3¾” x 6” door at the right of the black power

switch near the top of thecabinet. To open the door, turn the black knob counterclockwise untilyou can slide

the door up about ½ inch and then lift the door out and upward.

TO SET TIMER (See Figure 2)

Step 1.

Step 2.

Step 3.

Step 4.

Access the timer behind the sliding door next to the main power

switch near the top of the BevLes cabinet.

Activate the automatic ON/OFF Timer by toggling the switch to

the “ON” position. (NOTE: the switch is not shown in diagram - it

is located to the left of the Timer.)

Determine when you want the BevLes cabinet to automatically

turn on and turn off. Remove the RED TAB and replace it in the

slot when you want the BevLes cabinet to be turned . Press

down to attach the TAB to the Timer. Remove the BLACK TAB

and replace it in the slot when you want the BevLes cabinet to be

turned . Press down to attach the TAB to the Timer.

Turn the dial clockwise until the TIME ARROW (B) (the black

arrow located in the center of the Timer) is pointing at the correct

time of day.

Be sure that the main heated cabinet power switch (black) remains in the “ON” position.Step 5.

OFF

ON

Figure 2

Note: For unscheduled ON/OFF operation of the cabinet the Manual Knob may be used to

override the timer’s ON/OFF mode settings.

IN CASE OF POWER LOSS, RESET TIMER AS DESCRIBED IN STEP 4.

3. CLEANING

Step 1.

Step 2. WARNING: Always unplug the cabinet before

Step 3. CAUTION: At least two people should do the

Step 4.

Step 5.

Step 6.

Step 7.

IF YOU HAVE ANY QUESTIONS REGARDING THE INSTALLATION OR OPERATION OF YOUR

BEVLES HOT HOLDING CABINET, REVIEW THIS MANUAL AND THEN CALL THE BEVLES FACTORY

CUSTOMER SERVICE SUPPORT HOTLINE:

Push power switch to OFF position.

Unplug power cord from power source.

dismantling or cleaning.

If needed, remove the top mounted heating unit.

lifting to avoid possibleinjury.

Open door(s) to 90° position.

Remove the wire shelf supports.

Remove the airflow (side) panels by carefully lifting each panel and tilting the bottom toward the

center of the cabinet.

damage or bending may makere-installation difficult.

Clean all parts thoroughly with soapy water and soft cloths or sponges. Never use steel wool or

caustic cleaning compounds.

WARNING: Avoid splashing water or any other liquid into the top mounted heating unit to

prevent possible damage to electricalcomponents.

CAUTION: Use care when handling the airflow (side) panels. Any

BEVLES 800/441-1601

6

32.344

4. SPECIFICATIONS

22.507

39.314

4.977

82.221

72.882

7

5. TROUBLESHOOTING GUIDE

SYMPTOM MOST LIKELY CAUSE SOLUTION

Digital Controller displays 2 dots

at bottom of display (Open

Sensor Indicator Lights, See

Diagram).

Digital Controller Displays Temp.

Between 165-180 ºF.

VERIFY: 1)Actual cabinet temp. is

low, 2)There IS NO air movement

from left side air duct.

Digital Controller Displays a

Temp. Between 200-240 ºF.

VERIFY: 1)Actual cabinet temp. is

between 200-240 ºF, 2)Heater

Indictor Light is OFF, 3)There IS

air movement from left side air

duct.

IS

Temperature Sensor has

failed or the connector is

loose or not plugged in.

Main Blower (fan) has

failed.

The Relay has failed in

the Closed position (will

not turn the heater off).

Call the BevLes Technical Service

Department to verify symptoms and

for a possible solution involving

removing the Control Module (If

further repairs are required under

warranty obtain your Authorization

Number for repairs).

Call the BevLes Technical Service

Department to verify symptoms and if

under warranty to obtain your

Authorization Number for repairs.

Call the BevLes Technical Service

Department to verify symptoms and if

under warranty to obtain your

Authorization Number for repairs.

Digital Controller Displays a

Temp. Less Than 100 ºF.

VERIFY: 1)Actual cabinet temp. is

between 70-100 ºF, 2)Heater

Indicator Light is ON, 3)There IS

movement from left side air duct.

Digital Controller is Blank

VERIFY: 1)Power switch is on,

2)Unit is plugged in appropriate

outlet, 3)There is air movement

from left side air duct.

Digital Controller is Blank

VERIFY: 1)Power switch is on,

2)Unit is plugged in appropriate

outlet, 3)There IS NO air

movement from left side air duct.

Air

The Relay has failed in

the Open position (will not

turn the heater on).

The Transformer and/or

Temperature Controller

has failed.

1)Power Cord not

plugged in, 2)Circuit

Breaker may have

tripped, 3)Outlet may be

damaged, 4)Power cord

plug could be damaged,

5)Timer is being used

(Timer Bypass switch in

ON Position) but the time

or trippers are indicating

the wrong time, 6)Power

switch may have failed.

Call the BevLes Technical Service

Department to verify symptoms and if

under warranty to obtain your

Authorization Number for repairs.

Call the BevLes Technical Service

Department to verify symptoms and if

under warranty to obtain your

Authorization Number for repairs.

1)Verify Power Cord is plugged in

appropriate outlet, 2)Verify Circuit

Breaker is not tripped, 3)Verify Outlet

is functioning properly (unplug BevLes

unit, plug a known working appliance

into outlet with same voltage and turn

on, plug BevLes unit back into outlet),

4)Verify Plug is not damaged, 5)Set

the correct time and manually trip

timer to on position if necessary,

6)Call the BevLes Technical Service

Department to verify symptoms and if

under warranty to obtain your

Authorization Number for repairs.

Heat Indicator Light

Open Sensor Indicator Lights

DIGITAL

CONTROLLER

DISPLAY

8

6. Preventive Maintenance (

A minimum clearance of 4” should be maintained at the sides, back and top of all CS82-CH8 models. This

will allow for proper operation of all fan blowers and cooling fans. No objects should be placed on top of the

cabinet. The cabinet shouldbe level with all hex feet of the 6” legs firmly adjusted. The CS36 model should

have a minimum of 2” to 4” clearance at the sides and back.

The following should be performed at least once every three to six months:

POWER CORD SHOULD ALWAYS BE DISCONNECTED FROM POWER SOURCE BEFORE

PERFORMING ANY PREVENTIVE MAINTENANCE ON THE TOP MOUNTED HEATING UNIT.

All models have louver openings at the left front side corner of the Top Mounted Heating Unit.

These openings must remain open so that ambient air can circulate past the control module (cooling

the electrical components inside the Front Panel). On the CS82 model there are additional louver

openings located on the top of the Top Mounted Heating Unit that must also remain open to

prevent the main internal fan blower (motor) assembly from over heating. The CS36 model has

additional louver openings located in the rear panel (back) of the Top Mounted Heating Unit that

must also remain open to prevent it’s main internal fan blower (motor) assembly from over heating.

Use a slotted screwdriver to remove the four screws from the corners of the front Panel of the Control

Module. Carefully lift out the Control Module (you do not have to disconnect any wires at the rear of

the Control Module) and place it on top of the cabinet. Inspect the axial cooling fan located in the left

front corner of the Top Mounted Heating Unit, and make certain that it is clean and free of any dirt

or grease build-up. Next, inspect the left end of the Control Module (where the cooling fan blows) for

any dirt or grease build-up. You can use a damp cloth and mild cleanser to clean this surface

NOT get any liquid in the area behind the Control Module (where the 12 connector terminal

block is mounted).

Unit and secure with the four slotted screws. On CS36 model there a second axial cooling fan

located inside the rear panel (back) of the Top Mounted Heating Unit. It is extremely important that

this cooling fan also remain clean and free of any dirt or grease build-up.

After cleaning, place the Control Module back into the Top Mounted Heating

For Taco Bell Hot Holding Cabinet Models: CS82-CH8, CS36-CH3)

DO

Visually inspect the magnetic door gaskets for any damage (dirt or grease, tears, exposed magnet,

etc.). Clean or replace if needed.

Visually inspect power cord and 20Amp molded plug for any excessive wear ordamage.

On CS82 model, check 6” legs to be certain that all hex feet are properly adjusted and making firm

contact with the floor. (Check to see that cabinet is level). On CS36 model check to see that the

casters are free of any dirt or debris, and the brakes are in locked position when cabinet is in use.

Visually inspect the door latch and hinges to verify that they are securely attached to the door and

cabinet. Check attachment screws for snugness. If any screws are loose or missing they must be

placed back to correct position. Use a permanent “high strength threadlocker” to re-install screws,

or order replacement screws (with a threadlock patch) from .

Inspect to see that airflow side panels are properly mounted on the inner side walls of the cabinet.

Check to see that the Top Mounted Heating Unit is properly seated on the cabinet. This can be

easily verified by removing the left and right “top” airflow side panels and visually inspecting the fit of

the Top Mounted Heating Unit into the cabinet frame. Also, make certain that the wire shelf

supports (8 sets) are located in the proper positions for uniform airflow and temperature distribution.

Small indentations (dimples) on the airflow side panels indicate the correct placementholes for each

wire shelf support. The first wire shelf support should be located inthe bottom hole of the airflow side

panel (next to the base of the cabinet). The second is located 7 ½” above the first, and this continues

up the side of the cabinet.

BevLes (800)

733-2203

9

10

SENSOR

PROBE

TIMER BOX

P2

28 29 30

WHT

GRN

BLK

31

32

CONTROL

32

1

BLK

31

2

WHT

33

34

WHT WHT

35 38

WHT

ENCL

P3

P4

1

4

2

5

36

3

4

BRN

BRN

BLK

37

7. WIRING DIAGRAMS (1 of 3)

TACO BELL TOP MODULE

BLOWER

41

36

M

WHT

BLK

WHT

39

40

GRN

WHT

BLK

41

30

28

34

BRN

37

WHT

40

BLK

39

GRN

29

TB2

1

2

3

4

5

6

120V

AC INPUT

48 47 46

45

GRN

WHT

HEATING

ELEMENT

44

BLK

FAN

WHT

WHT

33

47

BLK

BRN

38

46

BLK

WHT

WHT

BLK

43

42

BLK

FAN POWER

CORD

45

44

42

BLK BLK

36 35

BLK

43

11

TIMER BOX

J1

S2

321

P1

WIRING DIAGRAMS (2 of 3)

TACO BELL CONTROL PANEL

WHT

WHT

6

7

5

2

1

24

25 23

BRN

WHT

XFORMER

WHT

7

6

LT

BRN

BRN

22

27

RELAY

1

423

89

WHT

WHT

WHT

WHT

5

4

J2

YEL

BLU

10

LT

13

12

10

11

BRN

BRN

1

BLK

12

GRN

BLK

WHT

GRN

123

3

WHT

15

16

14

J3

1

2365

4

WHT

WHT

WHT

BLK

BRN

4

18

17

BLK

BRN

TB1

15

18

17

1

2

3

4

14

5

19

6

16

BRN

LT

21

BRN

20

13

11

LT

WHT

5

876

BRN

43

27

BRN

26

WHT

WHT

22

2

BRN

ENCLOSURE BOX

BRN

FRONT

PANEL

S1

1

BRN

2

BLU

YEL

CONTROLLER

3

4

WHT

8

WHT

9

DIGITAL

WIRING DIAGRAMS (3 of 3)

TACO BELL FRONT PANEL ENCLOSURE

12

120V

INPUT

HEATING

ELEMENT

WHT

47

BLK

46

GRN

48

COOLING

FAN

FAN POWER CORD

M

WHT

BLK

47

BLK

BLK

44

BRN

BRN

WHT

GRN

33

34

35

36

37

38

BLK

2834

30

P4 J3

11

22

33

44

55

66

P2

11

22

33

16

15

19

18

17

J1

P1

TB1

1

15

18

17

1414

19

16

2,22,23,24

11,20

1

2

3

S1 S2

2

1

2

1

21

2

27

3

4

5

6

13

2

WHT

BLOWER

MOTOR

BLK

39

M

40

GRN

GRN

WHT

BLK

41

TB2

GND

1

2

3

4

5

6

GND

WHT

45

33

38

BLK

41

WHT

BRN

46

WHT

45

BLK

44

42

43

35

36

WHT

WHT

30

BLK

28

WHT

BRN

37

WHT

40

BLK

39

GRN

29 29

WHT

WHT

BLK

DIGITAL CONTROL

SENSOR

PROBE

WHT

BLK

32

P3 J2

4

11

31

3

22

33

897 6

5

3 4

20,21,25,26

20

252626 7

23

24

11

2

22

22

2

1

12

3

13

7654321

XFORMER

15

2

6

3

7

6

5

4

8

SS RELAY

12

27

4

9 8

3

23

25

24

22

44

13

MAIN CABINET

3

3

2

35

35

1

37

37

49

131

131

2

34

34

1

48

8. PARTS LIST & EXPLODED VIEW

6

6

24

1

1

1

1

5

5

1

14

14

4

23

23

1

24

4

48

48

66

47

47

16

4

4

10

10

4

8

8

1

12

12

2

27

27

2

48

66

26

26

8

25

25

4

1

11

11

4

9

9

1

20

20

19

16

18

18

1

19

34

40

40

1

42

42

4

21

49

49

2

21

16

28

28

1

29

29

17

17

1

1

22

22

1

36

36

39

39

1

43

43

4

31

31

1

38

33

33

29

32

32

38

1

1

1

44

44

4

45

45

4

30

41

41

16

30

20

46

46

2

16

16

1

15

100

13

13

15

4

7

7

1

2

2

1

PARTS LIST & EXPLODED VIEW (Continued)

14

Top Module

100

87

69

104

1

104

85

85

8

103

103

1

105

105

2

106

106

1

93

1

112

1

112

114

114

113

1

1

113

86

110

110

86

1

1

111

111

97

152

152

1

95

96

95

2

Door

53

53

2

57

Assembly

130

37

55

65

51

65

1

119

119

78

129

129

4

128

50

15

15

100

72

72

1

63

63

1

60

60

2

59

59

2

19

34

19

1

107

107

3

132

132

1

133

133

1

78

120

1

120

5

54

91

94

58

147

123

123

33

33

29

1

140

140

1

122

136

136

1

81

81

9

80

80

1

89

83

1

1

139

82

84

84

2

88

88

1

102

99

99

109

1

109

1

139

1

98

1

98

126

126

127

127

79

79

9

66

66

73

4

1

1

64

64

67

67

1

1

107

107

11

61

61

1

68

2

68

74

62

62

1

85

85

8

120

71

70

1

70

74

1

75

75

1

77

77

4

115

115

1

116

4

116

71

5

120

1

117

117

1

118

1

118

90

90

1

96

2

135

83

92

2

92

108

124

101

101

134

81

9

81

76

10

76

121

1

121

125

125

1

Item P/N Description Quan

747668

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

747669

784820

747670

784772

784776

747685

747686

747663

760030

760516

760512

760518

742040

8353600

747664

747665

747662

8353100

740565

770169

747666

747681

8353200

85196-00

8205500

760031

747661

747682

8211100

747695

747687

8175900

742128

747678

747676

770628

747677

747680

784780

8507900

784696

8507600

85082-00

8425200

742104

745747

770084

742172

784692

747691

BACK, OUTER

SIDE, OUTER, RIGHT

GASKET, MAGNETIC 32-2/5 X 28-1/8

SIDE, OUTER, LEFT

DUCT WRAP, 48 X 70 X 1.5 - CAB

DUCT WRAP, 21 X 70 X 1.5 - CAB

HINGE, RIGHT SUPPORT

HINGE, LEFT SUPPORT WELDMENT

INNER SIDE, LEFT

SHIM, SIDE, INNER

STRIP,BACKING .50 X .875 X 16.25

STRIP,BACKING .50 X .875 X 30.75

STRIP,BACKING .50 X .875 X 30.00

SUPPORT, BUTTON

RIVET, POP 3/16 FLUSH BREAK

INNER SIDE, RIGHT

BACK, INNER

BASE, INNER

RIVNUT, 10-32 THIN HEAD

BRACKET, HOOK, AIR DUCT

SCREW, SHT METAL, #10 X 1/2, Z

HEADER BAR, CENTER

COVER, HEADER BAR, CENTER

RIVNUT, 1/4-20 THIN HEAD

WASHER .75 X .281

SCREW, 1/4-20 X 1/2 TR HD

SHIM, CENTER INNER SIDE

HEADER BAR, TOP

COVER, HEADER BAR, TOP

SCREW, MACH 1/4-20 X 3/4

WELDMENT, GASKET RETAINER

GASKET RETAINER, OUTER, BOTTOM

SCREW, 10-32 X 1/2 TR HD,SS

GASKET RETAINER, OUTER, CENTER

GASKET RETAINER, OUTER, TOP

GASKET RETAINER, RIGHT, OUTER

12-24 X 1/2 TR HD PH W/PATCH

GASKET RETAINER, LEFT, OUTER

BASE, OUTER

DUCT WRAP, 18 X 29 1.5 - BASE

WASHER, LOCK, INT, 1/4, Z

LEG, ADJUSTABLE

WASHER, FLAT 1/4"

WASHER, LOCK, 1/4, ASME B18.21.1

NUT, HEX, 1/4-20 SS

AIR DUCT, BOTTOM

BRACKET,AIR DUCT

RIVET, SOFT, 5/16, 566PC/LB

AIR DUCT, TOP

HINGE - CAM RISE CHROME

DOOR, OUTER, TOP (TYPE B)

Item P/N Description Quan

1

1

2

1

1

1

1

1

1

4

4

2

4

4

100

1

1

1

34

16

16

1

1

4

4

8

2

1

1

20

1

1

29

1

1

1

49

1

1

1

16

4

4

4

4

2

16

66

2

4

1

52*

53

54

55

56*

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

720277

784768

8353000

784711

747693

720275

741984

741948

742076

742084

760484

742080

784832

742180

742260

741952

782144

8400100

742248

788005

741956

8967200

742000

782208

8105800

784724

742004

770344

742168

770536

742012

784680

770709

8408300

742164

747684

747683

784700

782149

782151

784548

784700

81108-00

8500700

8402900

89784-00

742024

742244

81778-00

742028

760488

DOOR, WELDM'T - TB BOTTOM/INNER

DUCT WRAP 29.75 X 33 X 1.50

POP RIVET

LATCH, MAGNETIC

DOOR, BOTTOM, OUTER

DOOR, WELDM'T - TB TOP/INNER

SKIN, OUTER TOP

CHANNEL, SIDE, TOP

SIDE, INNER, TOP

FRONT, INNER TOP

INSULATOR, HEATER TERMINAL

INNER, REAR TOP

URETHANE, 15.44 X 32 X 2

DEFLECTOR, AIR

COVER, INSULATION

CHANNEL, FRONT

TERMINAL BLOCK

NUT, HEX KEPS, #6-32

CLAMP,TIMER WIRE

BUSHING, SNAP 1/4 " BLACK NYLON

CHANNEL, REAR

BUSHING, SNAP .5 HOLE NYLON

WELDMENT, SLIDE, WATER PAN

THERMOSTAT

SCREW, PH, 6-32x3/8, S/S

CERAMIC INSULATOR

COVER, MOTOR

NUT,TINNERMAN CLIP

PANEL, REAR

TR HD PH SMS 10 X 1/2 SS

MOUNTING, COOLING FAN

FAN, AXIAL

SCREW, RD HD SL #8-32 X 2 ZN

#8-32 HEX NUT, KEPS, NI

CONTROL PANEL

ENCLOSURE, ELECTRICAL

ENCLOSURE, TIMER

BLACK CONNECTOR

PLUG, 4 PIN

CLAMP, "C"

MOUNTING ADAPTER CONN- RED

WIRE SET, TBCM

M/S TR HD PH 6-32x1"

LOCK WASHER EXT #6

NUT, HEX, 6-32 SS

BUSHING, 7/8 SNAP, HEYCO

TIMER, BRACKET

CLAMP,TIMER CORD

M/S, TR HD PH, 10-32 X 3/4 S/S

BRACKET, BRACKET

INSULATOR, TIMER, SWITCH TERMINALS

Item P/N Description Quan

1

2

48

2

1

1

1

2

2

1

1

1

1

1

4

1

2

11

1

1

1

4

1

1

10

4

1

9

1

9

1

1

2

8

1

1

1

1

1

2

2

1

2

2

2

2

1

1

7

1

1

*NOT SHOWN

16

9. BEVLES COMPANY LIMITED WARRANTY

729 Third Avenue * Dallas, TX 75226

Phone: +1 (214) 421-7366 Fax: +1 (214) 565-0976

1. Bevles warrants to the original purchaser that on the date the equipment is shipped (sold), it will be

free of defects in materials or workmanship. Bevles will, at its discretion, repair or replace, during

the warranty period printed below, any part that has a defect in material or workmanship that was

present when the product shipped from Bevles, and which manifests itself during the warranty

periodunder nomal use and service.

!

Parts:Two*years from dateof originalshipmentfrom the Bevles factory.

!

Labor:One** year

* Air Circulation BlowerAssemblies(motors) and Power Switchesshall be one year from date of

originalshipment.

CalrodAir Heating Elementsshallbethreeyearsfromdateoforiginalshipment.

fromdate of originalshipment from the Bevlesfactory.

** All electrical components120days

2. Bevles must be contacted, and pre-approval must be issued by the Bevles factory prior to any type

of service being performed. Bevles assumes no responsibility for any charges that were not expressly

authorizedby the Bevles factory,or for any chargesthatexceed,in Bevlessolejudgement, normal and

customaryamounts.

3. Bevles will payUPS Ground charges for any part that has a defectin material or workmanship that was

present when the product shipped from Bevles, and which manifests itself during the of the

warrantyperiod under normal use and service.All warranty replacement parts will ship F.O.B.Bevles

factory,Chino,CA91710.

4. This warranty shall be void in its entirety if any abuse of, misuse of, alteration/modification of or

improper maintenance of original product occurs. If, at any time a claim is reported to Bevles, the

purchaseris delinquent in paymentfortheproduct,warrantywill not apply.

5. BuyersRemedies-If a Bevles product fails due to a defect in material or workmanship in conformity

withthewarrantiesin paragraph one, buyer shall notify Bevlesof such failurewithinareasonabletime,

but in no event beyond fifteen (15) days of such discovery of defect in material or workmanship.

Bevlesshallprovide, in its sole discretion,either the repair or replacementof any defective or any non-

conforming part. Bevles specifically disavows any other representation, warranty or liability relating

tothecontinueduse of the product.

6 Exclusion of consequential and incidental damages-In no event shall Bevles be liable for any

incidental, special, indirect, or consequential damages, whether resulting from non-delivery or from

the use, misuse, or inability to use the product, or from defects in the product, or from

Bevlesown negligence or other tort. This exclusion applies regardless of whether such damages are

soughtfor breach of warranty,breach of contract, negligence,orstrictliabilityintortorunderanyother

legaltheory.

fromdate of originalshipment.

first year

7. Disclaimer of warranties-The warranties contained in paragraph one above are the exclusive

warranties given by Bevles and supersede any prior, contrary, or additional representations,

whether oral or written. Bevles hereby disclaims and excludes all other warranties-whether

expressed, implied, or statutory-including any warranty of merchantability, any warranty of

fitness for a particular purpose, and any implied warranties otherwise arising from course of

dealingor usage of trade.

4/02

16

Loading...

Loading...