Page 1

SERVICE &

INSTALLATION

MANUAL

Modular

Merchandiser

51-0195-01

1/2003

CARRIER COMMERCIAL REFRIGERATION, INC.

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

Page 2

If additional information is necessary, call the factory.

Our toll free number is 1-800-684-1199.Technical assis-

tance engineers are willing to assist you in any way possible. Office hours are from 8:00 a.m. to 5:30 p.m., Eastern

Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

Information in this manual is subject to change without notice.

MODEL DESIGNATION INFORMATION

115V, 60HZ

PART # MODEL # DATA PLATE STYLE

52-1029-01 CRPD3 CRPD3 MEDIUM TEMP, CURVED

52-1029-02 CRPD4 CRPD4 MEDIUM TEMP, CURVED

52-1029-05 CRPD6 CRPD6 MEDIUM TEMP, CURVED

52-1030-01 RPD3 RPD3 MEDIUM TEM, STRAIGHT

52-1030-02 RPD4 RPD4 MEDIUM TEMP, STRAIGHT

52-1030-04 RPD4PT RPD4 MEDIUM TEMP, STRAIGHT

52-1030-05 RPD6 RPD6 MEDIUM TEMP, STRAIGHT

52-1031-01 CDPD3 CDPD3 DRY, NON REF, CURVED

52-1031-02 CDPD4 CDPD4 DRY, NON REF, CURVED

52-1031-05 CDPD6 CDPD6 DRY, NON REF, CURVED

52-1032-01 DPD3 DPD3 DRY, NON REF, STRAIGHT

52-1032-02 DPD4 DPD4 DRY, NON REF, STRAIGHT

52-1032-05 DPD6 DPD6 DRY, NON REF, STRAIGHT

52-1033-01 CFPD3 CFPD3 LOW TEMP, CUR VED

52-1033-02 CFPD4 CFPD4 LOW TEMP, CUR VED

52-1034-01 FPD3 FPD3 LOW TEMP, STRAIGHT

52-1034-02 FPD4 FPD4 LOW TEMP, STRAIGHT

52-1035-01 COHM3 COHM3 MEDIUM, OPEN, CURVED

52-1035-02 COHM4 COHM4 MEDIUM, OPEN, CURVED

52-1035-03 COHM6 COHM6 MEDIUM, OPEN, CURVED

52-1036-01 OHM3 OHM3 MEDIUM, OPEN, STRAIGHT

52-1036-02 OHM4 OHM4 MEDIUM, OPEN, STRAIGHT

52-1036-03 OHM6 OHM6 MEDIUM, OPEN, STRAIGHT

52-1036-04 OHM3 BLACK OHM3 MEDIUM, OPEN, STRAIGHT

52-1047-02 BRD52 BRD52 LOW TEMP, STRAIGHT

EXPORT 220V, 50HZ

PART # MODEL # DATA PLATE STYLE

52-1033-05 ECFPD4 ECFPD4 LOW TEMP, CUR VED

52-1034-05 EFPD4 EFPD4 LOW TEMP, STRAIGHT

52-1047-06 EBRD52 EBRD52 LOW TEMP, SRAIGHT

EXPORT 220V, 60HZ

PART # MODEL # DATA PLATE STYLE

52-1033-03 KCFPD4 KCFPD4 LOW TEMP, CUR VED

52-1033-04 KCFPD4C KCFPD4 LOW TEMP, CUR VED

52-1034-03 KFPD4 KFPD4 LOW TEMP, STRAIGHT

52-1034-04 KFPD4C KFPD4 LOW TEMP, STRAIGHT

52-1047-04 KBRD52 KBRD52 LOW TEMP, STRAIGHT

Manual effective for models produced January,2003.

Starting serial number 6701822.

Page 3

MED TEMP LOW TEMP

Temperature Range 32°F to 60°F 0°F to -15°F

Insulation 23⁄16" Foam in Place 2 5⁄16" Foam in Place

Compressor Size 1/2 H.P. 1 H.P.

Condenser Type Fin & Tube Fin & Tube

Evaporator T ype Fin & Tube Slow Moving Air Fin & Tube Slow Moving Air

Refrigerant Type 404A 404A

Defrost System On Demand On Demand

Electrical Specs. 115/60/1 115/60/1

NSF NSF 1 NSF 1

Shelves

Shelves, Epoxy Coated, Bracket Supported Shelves, Epoxy Coated, Bracket Supported

UL & CSA Listing Yes Yes

MODULAR MERCHANDISER 1

SPECIFICATIONS - DISPLAY CABINETS

DIMENSION DRAWINGS - COHM & OHM

DIMENSION DRAWINGS - FPD, CFPD, RPD & CRPD

Page 4

An Important Message for Installers

and Operators

These instructions include information which is intended to assure the operator of correct installation, operation and service. Before attempting installation, adjustment or maintenance be certain of the following:

1.That you have read and fully understand

the instructions.

2. That you have all tools required and are trained to

use them.

3.That you have met all installation and usage restric-

tions and are familiar with the functions and operation of the unit.

4.That you follow all instructions exactly as given.

All fittings, measurements, procedures and recommendations are significant. Substitutions and approximations must be avoided.Improper handling, maintenance,

installation and adjustment, or service attempted by

anyone other than a qualified technician, may void the

future warranty claims and cause damage to the unit

and/or result in injury to the operator and/or bystanders.

Important Information Is contained In these

instructions which should be retained in a

convenient location for future reference .

Record for Service

Model No.

Serial No.

Invoice Date

Start-up Date

Telephone for Service

BE SURE TO INSPECT CABINET FOR SHIPPING

DAMAGE BEFORE AND AFTER UNCRATING IT.

HANDLING & INSTALLATION

Inspecting for Damage

NOTE: The transportation company or other parties

involv ed in the shipment are responsible f or loss and/or

damage.When direct delivery was made by the trans-

portation company, follow the procedure as outlined in

the following steps:Always make an Inspection before

and after uncrating.Inspect the uncrated unit(s) before

locating (preferably at the point of unloading by the

transportation company.) You may leave the skid on

the unit for ease of locating it later.

a. Damaged cartons or containers - If these are damaged in any way, open them and inspect the contents

in the driver’s presence.

b. Have the driver note the nature and extent of the

damage on the freight bill.

c. Notify the transportation company’s office to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

d. Always use care when removing shipping tape,

blocks, pads, hardware, or other materials. Retain all

crate and packaging material until you are satisfied

that the unit is completely operational.

e. Contact factory if technical assistance is required.

f. If damage is noticed (whether before or after uncrat-

ing the unit) the following claim procedure must be

completed.

Inspecting for Shortages

NOTE: Refer to the “Inspecting for Damage” instructions and follow the procedure described.

a. Check the number of cartons and/or containers

delivered with the quantity shown on your receipt.

b. If the quantities are not the same, have the driver

note the shortage and file your claim accordingly.

Filing Claims

a. File a claim for loss or damage at once with the

transportation company for:

1) A cash adjustment

2) Repairs

3) Replacement

b.When filing y our claim, retain all pac kaging materials

and receipts.

Handling the Cabinet

The refrigeration system of the cabinet is designed to

operate with the cabinet located on a flat surface.

Avoid tilting the cabinet more than 30° to any side. If

the cabinet must be tilted on an angle for handling or

moving purposes, allow it to sit in an upright position

20 to 30 minutes prior to plugging it in and starting the

cooling of the storage compartment.

GENERAL INFORMATION

2 MODULAR MERCHANDISER

Page 5

Removing the Skid

Remove the four (4) bolts securing the cabinet to four

(4) angle brackets attached to the skid. Remove the

skid bolts and angle brackets.Carefully slide the cabinet off the skid onto the floor.

Locating the Cabinet

This model is a display cabinet and should be positioned to expose the illuminated displays to customers

in the store and provide a clear space behind for the

person serving.

Select a location where you are sure that the cabinet

won’t be exposed to heat sources such as sun through

a window, store heating or cooling ducts, exhausts

from other cabinets, etc. Make sure there is adequate

space on the serving side for loading cabinet and serving efficiently.

DO NOT DRILL HOLES IN THE CABINET WALLS.

THIS WILL VOID THE W ARRANTY

a.The cabinet must be installed on a sturdy and solid,

level floor.

b. The cabinet should be installed in a protected, dr y,

and well-ventilated area, away from any heat source.

Leveling the Cabinet

Level the cabinet using a spirit level on top. Level front

to back and side to side to assure a quiet operation

and satisfactory door and drain operation. Doors are

self-closing (sliding door models only) when cabinet is

level. Shim under the cabinet base as necessary to

assure a level cabinet. To meet NSF requirements,

these cabinets must be sealed to the floor with an NSF

listed or FDA approved sealant.

Setting up the Cabinet

Cabinets are shipped with the adjustable shelf mounting brackets in place. Shelving is also supplied with

the cabinet.

Shipping material (cardboard, paper, plastic, ties,

etc.) should be removed from shelving and the

product area.

CAUTION: Make sure that the shelf light plugs or

receptacle covers are completely inserted into the light

socket receptacles.This prev ents electrical arcing and/

or possible equipment damage.

MODULAR MERCHANDISER 3

Grounding Instructions

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazards.The appliance should be plugged directly into a proper ly grounded three prong receptacle.

Where a two-prong wall receptacle is encountered, it must be replaced with a properly grounded threeprong receptacle in accordance with the National Electrical Code and local codes and ordinances.The

work must be done by a licensed electrician (cabinet should be on a dedicated circuit unto itself.Refer

to serial data for correct circuit ampacity).

20 Amp

15 Amp

15 Amp

20 Amp

GENERAL INFORMATION-cont.

Page 6

Power Supply Switch

NOTE:When ser vicing or cleaning supply power must

be turned off.The power supply switch is located at the

rear of each cabinet behind the lower rear grill. The

switch is incorporated into the electrical box assembly.

Light Switch-Auxiliary Outlet

The light switch is located at the rear of each cabinet

(when applicable) just above the unit compartment

opening on the right hand side.

The auxiliary outlet is provided to power an external

sign scale (when applicable).

These cabinets utilize a microprocessor control to

manage both cavity temperature and defrost functions.

Cabinet OperationRefrigeration Mode

Upon setting the cabinet in it’s final location, turn

power supply on. The cabinet display should be indicating the cabinet temperature.There is a three minute

time delay sequence built in each time the supply

power is lost (compressor circuit). Evaporator fan

starts and lights come on (medium temp models).

Three minutes later the compressor starts. On low

temp models the evaporator fan delays until the evaporator coil reaches 28°F.

The display located on the lower front panel has several functions,

Display cabinet temperature

Change cavity set point temperature

NOTE: ON MED TEMP CABINETS DO

NOT SET BELOW 33°F.

Display service interface. Only qualified service personnel should activate this function.

Defrost Mode

This is on a demand basis as needed on both medium

and low temperature models.Defrost can be manually

activated through the display if needed.See below.

High Temp Thermodisc Open 140°F

Close 90°F

Notable points

1. This system utilizes a 3 minute off cycle timer to pre-

vent short cycles.

2. When the system initiates a defrost, the setpoint will

flash on and off until the defrost is terminated and the

cavity reaches the setpoint. At this time the cavity tem-

perature will be displayed as normal.

Changing Setpoint

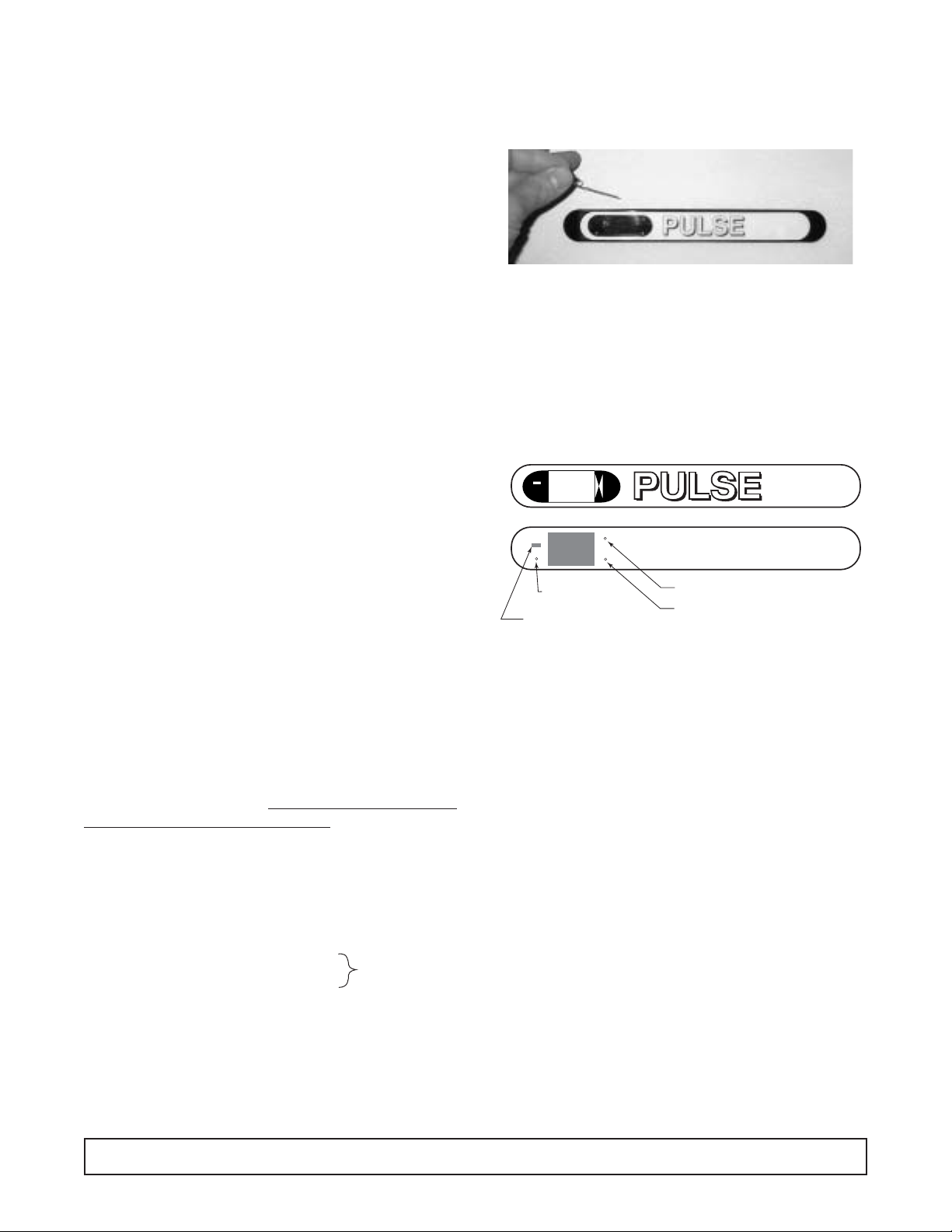

Note: Use a paper clip to access the

function keys.

1. Pressing the top right button(i.e. up key) on the display unit will raise the set point one degree

Fahrenheit. Holding the button down will scroll the

adjustment.

2. Pressing the lower right button(i.e.down key) on the

display unit will lower the set point one degree

Fahrenheit.

The Service Interface and

the Service Menu

(Refer to Pulse Service Manual 51-2484-00 for complete

service information.)

The service menu offers the service technician direct

control of the components of the system. This allows the

technician to force the system into a defrost state or the

refrigeration state. This feature also allows the technician to toggle the state in order to analyze separate components of the system (e.g., start kit, compressor,

heaters, etc.).

1. To access the service menu, press and hold the

service key for 2 seconds. The system will enter the

service menu and c0 will alternately flash with evaporator temperature. Code versions 1.5 and earlier do not

display evaporator temperature. This is the top of the

service menu. To exit the service menu, press the service key again at any time.

2. The service menu offers five functions:

Refrigeration state, Defrost state, code revision level

indication, the option to blank the display (code version

1.6 and later), and Celsius or Fahrenheit operation

(code version 1.6 and later).While in the service menu,

4 MODULAR MERCHANDISER

GENERAL INFORMATION-cont.

Low temp

models only

Service

Interface

Indicates T emp .

below 0°F

Setpoint up

Setpoint down

Page 7

the down key serves to scroll the menu and the up key

serves as a toggle to activate and deactivate the function state.

A. To access the functions simply press the down key

to scroll through the menu until the desired function

is reached.The Refr igeration state is the first function and is denoted by an alternating display of c0

and the evaporator temperature. The Defrost state

is the second function and is denoted by a display

of d0.The third function is a passive state and only

indicates which version of code is running. This

function alternately flashes cc and the code version

01 - 99. The fourth function allows the user the

option to blank the display and is denoted by S0.

The fifth and last option allows the user to select

between Fahrenheit and Celsius operation and is

denoted by a C or a F. Continuing to scroll will bring

the user to the top of the menu again where c0 will

be displayed.

B.To activate a function state, simply press the down

key to scroll the menu until the desired function is

reached. Now press the up key. At this point the

chosen function state is toggled from inactive to

active.

C. To force a defrost: First press and hold the

service button to enter the service menu. Then

press the down key until d0 is displayed. Next

press the up key. The heater is now energized

and d1 is displayed.

D. To activate the refrigeration state: (i.e., this turns on

the compressor, condenser fans, and evaporator

fans) First enter the service menu. Press the top

right button.c0 will change to c1.Use this function to

check refrigerant charge and pressures, evaporator

fans, compressor and start components and etc.

E. To deactivate the function state, press the up key

again (i.e., this button toggles the state from active

to inactive and vice versa).

NOTES:a. When an attempt is made to scroll the

menu while a function state is active, the

active function state will automatically

deactivate.This is to prevent the service

technician from simultaneously activating

the Refrigeration state and the Defrost

state. Only one function may be active at

any given time.

b. If no operation is performed within 45

minutes while in the service menu, the

system will automatically exit the service

menu and return to normal refrigeration.

c. If the Defrost state is activated and left

unattended, the service menu will terminate the defrost as normal on evaporator

temperature; otherwise, the defrost will

terminate in 45 minutes. Upon defrost

termination the system will automatically

exit the service menu.

d. When the system exits the service menu,

the compressor will not start for

3 minutes.

e. The off cycle timer is not incorporated in

the service menu so the service technician has direct control of components.

MODULAR MERCHANDISER 5

GENERAL INFORMATION-cont.

Page 8

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 39° 35° 30° 39° 35° 30° 39° 34° 30°

Suction Pressure (PSIG) 47 41 36 47 42 37 48 43 39

Discharge Pressure (PSIG) 255 245 233 286 276 262 320 309 297

Compressor Amps 5.9 5.6 5.3 6.0 5.7 5.5 6.2 5.9 5.7

Total Refrigeration Amps 7.9 7.5 7.3 8.0 7.7 7.5 8.2 7.8 7.6

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - RPD4 & CRPD4

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36° TO 42°

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 /24 / 680.4 grams

6 ELECTRICAL/REFRIGERATION SPECIFICATIONS

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - RPD3,CRPD3,RPD6,CRPD6

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36°F to 42°F

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 / 16 / 453.6 grams

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 42° 37° 3° 42° 37° 32° 43° 38° 32°

Suction Pressure (PSIG) 47 39 34 47 41 36 51 43 39

Discharge Pressure (PSIG) 249 231 223 281 268 256 317 303 242

Compressor Amps (Each Compressor) 6.1 5.7 5.6 6.3 6.0 5.7 6.5 6.2 6.0

TotalRefrigerationAmps (RPD3, CRPD3) 8.3 7 7 8.5 8.2 7.8 8.6 8.4 8.1

Total Refrigeration Amps (RPD6, CRPD6) 17.0 16.3 15.6 16.6 15.9 15.2 17.5 16.2 15.5

Page 9

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 43° 37° 34° 43° 40° 35° 44° 41° 39°

Suction Pressure (PSIG) 50 45 41 49 46 43 49 47 40

Discharge Pressure (PSIG) 269 254 247 295 283 283 326 323 304

Compressor Amps 6.2 6.0 5.7 6.3 6.2 6.1 6.5 6.5 5.9

Total Refrigeration Amps 9.0 8.5 8.3 9.1 8.7 8.6 9.3 9.0 8.7

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - OHM4 & COHM4

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36° TO 42°

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 /25 / 708.7 grams

ELECTRICAL/REFRIGERATION SPECIFICATIONS 7

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - OHM3,COHM3,OHM6,COHM6

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36°F to 42°F

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 / 18 / 510.3 grams

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 41° 37° 33° 42° 38° 34° 44° 41° 37°

Suction Pressure (PSIG) 45 43 37 46 44 40 47 46 40

Discharge Pressure (PSIG) 251 245 233 280 271 267 310 307 293

Compressor Amps (Each Compressor) 7.0 6.8 6.5 7.1 7.0 6.8 7.3 7.2 6.9

TotalRefrigerationAmps (OHM3, COHM3) 7.9 7.8 7.4 8.1 7.9 7.7 8.2 8.2 7.8

Total Refrigeration Amps (OHM6, COHM6) 11.6 11.4 11.2 11.7 11.1 11.4 11.6 11.2 11.3

Page 10

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

FPD4 EFPD4 KFPD4

CFPD4 ECFPD4 KCFPD4

BRD52 EBRD52 KBRD52

Compressor Copeland Copeland Copeland

Compressor Model RS80C1ECAA RS80C2ECAZ-250 RS80C2ECAV

Cabinet Volts 115V 60Hz 220V 50Hz 220V 60Hz

Recommended Operating Temp. Range 36° TO 42°

Expansion Device 7' x .049 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 /16/ 453.6 grams

AMBIENT 70°F 80°F 90°F

Display setting +5° -5° -15° +5° -5° -15° +5° -5° -15°

Cavity Temp.(F) 6.0° -2° -11° 6.0° -2° -11° 1.0° -2° -12°

Suction Pressure (PSIG) (115V) 10 8 6 12 10 7 14 12 9

Discharge Pressure (PSIG) (115V) 230 228 213 270 263 245 303 291 280

Compressor Amps (115V) 8.4 8.7 8.5 8.8 8.9 8.2 9.1 9.1 8.8

Total Refrigeration Amps (115V) 12.9 13.1 12.8 13.3 13.3 12.5 13.6 13.6 13.1

Suction Pressure (PSIG) (220V) 7.7 7.2 5.7 10.2 9.2 7.1 12.7 11.1 8.7

Discharge Pressure (PSIG) (220V) 211.1 209.0 203.5 245.3 239.6 232.3 281.2 272.5 263.6

Compressor Amps (220V) 5.0 5.0 4.7 5.0 5.2 4.8 5.6 5.4 4.9

Total Refrigeration Amps (220V) 6.1 6.0 5.9 6.3 6.2 5.9 6.5 6.3 6.1

8 ELECTRICAL/REFRIGERATION SPECIFICATIONS

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - FPD3 & CFPD3

SYSTEM PERFORMANCE -(READINGS AT CUT-OUT)

Compressor Copeland

Compressor Model RS80CIECAA

Recommended Operating Temp. Range 36°F to 42°F

Cabinet V olts 115

Expansion Device 7' x .049 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 / 14 / 396.9 grams

AMBIENT 70°F 80°F 90°F

Display setting +5° -5° -15° +5° -5° -15° +5° -5° -15°

Cavity Temp.(F) +5° -3° -13° +5° -3° -13° 6.1° -3° -12°

Suction Pressure (PSIG) 11.2 8.1 5.2 13 10 7.2 15 12 10

Discharge Pressure (PSIG) 262 244 216 296 272 246 334 311 289

Compressor Amps 9.0 8.3 7.7 9.2 8.6 7.8 9.3 8.7 8.3

Total Refrigeration Amps 12.0 11.3 10.7 12.3 11.6 10.9 12.3 11.8 11.3

Page 11

WIRING DIAGRAM 9

WIRING DIAGRAM – COHM3, COHM 4, OHM3, OHM4

HEATER, WATER DISSIPATION

LIGHT

SWITCH

BLACK

BALLAST BOX HARNESS

115 VAC. 60 Hz.-1Ø

15-AMP POWER SUPPLY

N

(L2)

L1

(BLUE)

(BROWN)

WHITE

BLACK

SUPPLY

SWITCH

GREEN

BLACK

BLACK

BLUE (BLACK ON 20W)

BLACK

3

5

4

6

BLACK

BLACK

WHITE

WHITE

WHITE

BLUE

WHITE

BLACK

1

2

BLACK

BLACK

BALLAST

BLACK

WHITE

BLACK

WHITE

WHITE

ORANGE

FUSE

WH

BLACK

PURPLE

RELAY #1

654

123

YELLOW

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

(FOR MODELS WITH LAMP)

BLUE

YELLOW

RELAY #2

BLACK

LED

BLACK

WHITE

PURPLE

ORANGE

BLACK

ORANGE

BLUE

BROWN

RELAY #4RELAY #3

1 2 3 4 5 6 7 8

O

BROWN

WHITE

RED

BLACK

BROWN

BLUE

UPPER LAMP HARNESS

WHITE

BROWN

N

1

2

3

BLUE

MAIN LAMP

S

3

2

1

4

3

2

1

5

4

98

6

7

DISPLAY

DISPLAY HARNESS

PROCESSOR HARNESS

GREEN

BLUE

GRAY

RED

BLACK

GREEN

RED

BLACK

BLACK

WHITE

RUN CAP.

12

3

4

5

6

7

8

9

EVAPORATOR HARNESS

BLACK

BLACK

YELLOW

RED

BLACK

START CAP.

ORANGE

BROWN

BLUE

RED

GRAY

WHITE

EVAPORATOR HARNESS

GREEN

BLACK

BLACK

CONDENSER

FAN MOTOR

YELLOW

COMPRESSOR

HARNESS

BLUE

2

3

1

4

COMPRESSOR

TERMINAL BOX

MOTOR

PROTECTOR

(PTCR)

BLACK

HEATER, ANTI-SWEAT

THERMOSTAT

BLACK

EVAPORATOR

FAN MOTOR

BROWN

DUMMY

PLUG

1

TEMP. SENSOR

EVAPORATOR

2

TEMP. SENSOR

WHITE

RETURN AIR

WIRING DIAGRAM-OPEN, MED-TEMP.

00-0219-00

Page 12

10 WIRING DIAGRAM

WIRING DIAGRAM – CFPD3, CFPD4, FPD3, FPD4, BRD52

LIGHT

SWITCH

BLACK

BALLAST BOX HARNESS

115 VAC. 60 Hz.-1Ø

20-AMP POWER SUPPLY

N

(L2)

L1

(BLUE)

(BROWN)

WHITE

BLACK

SUPPLY

SWITCH

RETURN AIR

1

TEMP. SENSOR

EVAPORATOR

2

TEMP. SENSOR

BROWN

WHITE

EVAPORATOR

FAN MOTOR

BLACK

BLUE

DISPLAY

S

LAMP

LAMP

LAMP

HEATER-GLASS

HEATER-GLASS

PERIMETER

HEATER-LAMP

CHANNEL

C

2

3

R

BLUE

PROTECTOR

COMPRESSOR

TERMINAL BOX

1

S

BLUE

RED

RED

MOTOR

BLUE

HEATER-DOOR

OPENNING

HEATER-DOOR

OPENNING

BLACK

UPPER LAMP HARNESS

BLACK

BLACK

BALLAST

BLACK

3

5

6

1

WHITE

4

2

WHITE

WHITE

BALLAST

WHITE

WHITE

BLACK

BLACK

WHITE

BROWN

GREEN

RED

BLACK

GREEN

RED

BLACK

BLUE

GRAY

BROWN

WHITE

WHITE

BLACK

BLACK

WHITE

WHITE

BLACK

ORANGE

FUSE

WH

BLACK

DUMMY

PLUG

PURPLE

RELAY #1

654

WHITE

RELAY #2

BLACK

LED

BLACK

WHITE

123

YELLOW

ORANGE

PURPLE

ORANGE

YELLOW BROWN

BLUE

12

3

4

5

6

7

8

9

EVAPORATOR HARNESS

WHITE

BLACK

RED

START CAP.

BLUE

RELAY #4RELAY #3

1 2 3 4 5 6 7 8

N

O

BROWN

BROWN

WHITE

BLACK

BLUE

YELLOW

RED

ORANGE

BROWN

BLACK

EVAPORATOR HARNESS

GREEN

BLACK

1

BROWN

2

3

BLUE

3

2

1

4

3

2

1

5

4

6

7

RED

GRAY

WHITE

BLACK

YELLOW

21

98

5

POTENTIAL RELAY

BLACK

RED

RED

SHELF LAMP HARNESS

YELLOW

YELLOW

YELLOW

YELLOW

DISPLAY HARNESS

PROCESSOR HARNESS

BLACK

BLUE

COMPRESSOR

HARNESS

WHITE

CONDENSER

FAN MOTOR

C

R

RUN CAP.

HEATER-DEFROST

WIRING DIAGRAM-DISPLAY, LOW TEMP.

00-0216-00

Page 13

WIRING DIAGRAM 11

WIRING DIAGRAM – CRPD3, CRPD4, RPD3, RPD4

BLACK

2-AMP.

CIRCUIT

BREAKER

BALLAST BOX HARNESS

115 VAC. 60 Hz.-1Ø

15-AMP POWER SUPPLY

EVAPORATOR

FAN MOTOR

LIGHT

SWITCH

N

(L2)

(BLUE)

WHITE

BLACK

1

2

BROWN

WHITE

WHITE

2-AMPS

MAXIMUM

L1

(BROWN)

SUPPLY

SWITCH

RETURN AIR

TEMP. SENSOR

EVAPORATOR

TEMP. SENSOR

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLACK

5

4

6

BLACK

WHITE

GREEN

RED

BLACK

GREEN

RED

BLACK

BLUE

GRAY

DUMMY

PLUG

3

BLACK

WHITE

WHITE

BLACK

BLUE

BLUE

BLUE

WHITE

BLACK

BLACK

BALLAST

BALLAST

BALLAST

BLACK

BLACK

BLACK

1

2

BLACK

WHITE

BLACK

RUN CAP.

WHITE

WHITE

WHITE

WHITE

ORANGE

FUSE

WH

BLACK

PURPLE

RELAY #1

321

456

RELAY #2

BLACK

LED

BLACK

WHITE

YELLOW

PURPLE

ORANGE

YELLOW

ORANGE

BLUE

1

2

3

4

5

6

7

8

9

EVAPORATOR HARNESS

BLACK

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

BLUE

BROWN

RELAY #3

RELAY #4

1 2 3 4 5 6 7 8

N

O

BLACK

BROWN

WHITE

BROWN

RED

BLACK

BROWN

BLUE

1

2

RED

ORANGE

BROWN

BLUE

BLACK

EVAPORATOR HARNESS

GREEN

BLACK

3

YELLOW

BLACK

START CAP.

UPPER LAMP HARNESS

MAIN LAMP

WHITE

SHELF LAMP HARNESS

WHITE

WHITE

4

S

SHELF LAMP

S

SHELF LAMP

S

3

2

1

4

3

2

1

5

9

8

6

7

RED

GRAY

WHITE

BLACK

BLUE

BLUE

BLUE

CONDENSER

FAN MOTOR

YELLOW

COMPRESSOR

HARNESS

DISPLAY

DISPLAY HARNESS

PROCESSOR HARNESS

BLUE

3

4

COMPRESSOR

TERMINAL BOX

MOTOR

PROTECTOR

(PTCR)

2

1

WIRING DIAGRAM-DISPLAY, MED-TEMP.

00-0217-00

Page 14

12 WIRING DIAGRAM

WIRING DIAGRAM – CDPD3, CDPD4, DPD3, DPD4

2-AMP.

CIRCUIT

BREAKER

LIGHT

SWITCH

BLACK

BLUE (BLACK ON 20W)

WHITE

2-AMPS

MAXIMUM

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLACK

5

6

3

4

BLACK

WHITE

BLUE

BLUE

BLUE

BLACK

BLACK

1

2

BALLAST

BALLAST

BALLAST

BLACK

WHITE

WHITE

WHITE

WHITE

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

UPPER LAMP HARNESS

MAIN LAMP

WHITE

SHELF LAMP HARNESS

WHITE

WHITE

S

SHELF LAMP

S

SHELF LAMP

S

BLUE

BLUE

BLUE

115 VAC. 60 Hz.-1Ø

POWER SUPPLY

N

(L2)

L1

(BLUE)

(BROWN)

WHITE

BLACK

SUPPLY

SWITCH

BLACK

WHITE

WIRING DIAGRAM-DISPLAY, HI-TEMP.

00-0218-00B

Page 15

WIRING DIAGRAM 13

WIRING DIAGRAM – COHM6, OHM6

WIRING DIAGRAM, 6-FT OPEN, MED-TEMP.

00-0226-00

CONDENSER

FAN MOTOR

TIME DELAY RELAY

3

54

1 2

WHITE

BLACK

WHITE

ORANGE

BLACK

BLACK

MOTOR

PROTECTOR

WHITE

WHITE

WHITE

WHITE

(PTCR)

1

2

4

3

TERMINAL BOX

COMPRESSOR

COMPRESSOR

HARNESS

BLUE

BLACK

GREEN

YELLOW

BLACK

REDBLUE

YELLOW ORANGE BROWN

BLACK

WHITE

BLACK

BLACK

BLACK

BLACK

GREEN

BLACK

BLACK

BLACK

BLACK

START CAP.

RUN CAP.

EVAPORATOR

FAN MOTOR

THERMOSTAT

BALLAST

BLUE

LIGHT

SWITCH

BLUE

MAIN LAMP

UPPER LAMP HARNESS

BLACK

BLUE

S

WHITE

(FOR MODELS WITH LAMP)

THIS BLACK WIRE NOT USED

ON THIS MODEL.

WHITE

WHITE

WHITE

BLACK

1

2

3

4

5

6

WHITE

BLACK

HEATER, ANTI-SWEAT

SECOND CABINET HARNESS

GREEN

DISPLAY

DISPLAY HARNESS

PROCESSOR HARNESS

RED

1

2

3

BROWN

BLUE

RED

BLACK

BLACK

PURPLE

WHITE

BLACK

ORANGE

BALLAST BOX HARNESS

LED

RELAY #1 RELAY #2 RELAY #3 RELAY #4

FUSE

20-AMP POWER SUPPLY

230 VAC. 60 Hz.-1Ø

123

4

N

O

1 2 3 4 5 6 7 8

WHITE

BLACK

WH

L2

L1

N

GRD

WHITE

RED

BROWN

RED

ORANGE

BLUE

PURPLE

YELLOW

YELLOW ORANGE

123

RED

BLACK

WHITE

GREEN

BLACK

654

BLACK

SUPPLY

SWITCH

WHITE

BLACK

WHITE

WHITE

WHITE

BLACK

WHITE

RED

GREEN

WHITE

BLACK

ORANGE

BLACK

BLACK

BLACK

BLACK

BROWN

BLACK

HEATER, WATER DISSIPATION

CONDENSER

FAN MOTOR

98

7

6

5

4

3

2

1

BROWN

ORANGE

RED

YELLOW

BLUE

3

4

12

RED

RED

BLACK

BLACK

GREEN

GREEN

RETURN AIR

EVAPORATOR

TEMP. SENSOR

TEMP. SENSOR

2

1

BROWN

THERMOSTAT

BLUE

5

BLUE

MOTOR

PROTECTOR

GRAY

RED

6

GRAY

7

WHITE

8

WHITE

(PTCR)

BLACK

9

2

3

BLUE

YELLOW

GREEN

EVAPORATOR HARNESS

BLACK

EVAPORATOR HARNESS

WHITE

DUMMY

PLUG

1

4

COMPRESSOR

BLACK

TERMINAL BOX

COMPRESSOR

HARNESS

BLACK

BLACK

BLACK

BLACK

EVAPORATOR

FAN MOTOR

START CAP.

RUN CAP.

HEATER, ANTI-SWEAT

HEATER, WATER DISSIPATION

Page 16

14 WIRING DIAGRAM

WIRING DIAGRAM – CRPD6, RPD6

WIRING DIAGRAM, 6-FT DISPLAY, MED-TEMP.

00-0225-00

BLACK

1 2 3 4 5 6 7 8

O

N

4

DISPLAY HARNESS

(L2) N

L1

1

DISPLAY

LED

2

20-AMP. POWER SUPPLY

FUSE

BLACK

3

RUN CAP.

START CAP.

FAN MOTOR

EVAPORATOR

BLACK

BLACK

BLACK

BLACK

HARNESS

YELLOW

COMPRESSOR

COMPRESSOR

TERMINAL BOX

4

1

DUMMY

PLUG

WHITE

EVAPORATOR HARNESS

BLACK

EVAPORATOR HARNESS

GREEN

BLUE

3

2

9

(PTCR)

BLACK

WHITE

8

WHITE

GRAY

6

7

RED

GRAY

PROTECTOR

MOTOR

BLUE

5

BLUE

BROWN

2

TEMP. SENSOR

EVAPORATOR

BLACK

RED

4

3

ORANGE

BROWN

FAN MOTOR

CONDENSER

1

TEMP. SENSOR

RETURN AIR

GREEN

BLACK

RED

12

YELLOW

ORANGE

GREEN

BLACK

BLUE

1

2

3

4

5

6

7

98

BLACK

BLACK

BROWN

BLACK

BLACK

BLUE

RED

WHITE

BLACK

WHITE

YELLOW

YELLOW ORANGE

PURPLE

ORANGE

BROWN

BROWN

WHITE

WHITE

ORANGE

PROCESSOR HARNESS

GREEN

SECOND CABINET HARNESS

WHITE

BLACK

SWITCH

BLACK

SUPPLY

654

WHITE

(BLUE)

BLACK

(BROWN)

WH

123

BLACK

WHITE

123

115 VAC. 60 Hz.-1Ø

RELAY #1 RELAY #2 RELAY #3 RELAY #4

BALLAST BOX HARNESS

BLACK

WHITE

ORANGE

PURPLE

BLUE

BROWN

BALLAST BOX HARNESS

WHITE

BLACK

6

5

4

3

BLUE

2

BLACK

1

BLACK

BLACK

WHITE

WHITE

WHITE

WHITE

SHELF LAMP HARNESS

WHITE

SHELF LAMP

S

SHELF LAMP

S

BLUE

BLACK

LIGHT

SWITCH

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLACK

BLUE

BLUE

BALLAST

BALLAST

BALLAST

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

WHITE

BLUE

UPPER LAMP HARNESS

MAIN LAMP

S

BLUE

LIGHT

SWITCH

FAN MOTOR

EVAPORATOR

RUN CAP.

START CAP.

HARNESS

BLACK

BLACK

BLACK

BLACK

COMPRESSOR

TERMINAL BOX

WHITE

WHITE

BLACK

YELLOW

COMPRESSOR

4

1

6

5

4

BLACK

WHITE

WHITE

BLACK

BLACK

GREEN

BLACK

BLUE

3

2

(PTCR)

BLACK

YELLOW ORANGE BROWN

REDBLUE

BLACK

WHITE

PROTECTOR

MOTOR

WHITE

BLACK

BLACK

321

ORANGE

WHITE

54

TIME DELAY RELAY

FAN MOTOR

CONDENSER

WHITE

3

BLUE

2

WHITE

WHITE

SHELF LAMP

S

BLUE

BLACK

1

BLACK

WHITE

SHELF LAMP HARNESS

WHITE

SHELF LAMP

S

BLUE

BLUE

BLUE (BLACK ON 20W)

BLACK

BALLAST

BLUE (BLACK ON 20W)

BALLAST

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

Page 17

WIRING DIAGRAM 15

WIRING DIAGRAM – CDPD6, DPD6

WIRING DIAGRAM, 6-FT DISPLAY, DRY (NON-REFG.)

00-0224-00

BLUE

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

BALLAST

BALLAST

BLACK

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

LIGHT

SWITCH

SHELF LAMP

SHELF LAMP HARNESS

BLACK

BLACK

BLUE

BLUE

S

WHITE

WHITE

1

3

5

BLACK

S

SHELF LAMP

WHITE

WHITE

WHITE

2

BLUE

4

6

WHITE

BLACK

ORANGE

BLUE

MAIN LAMP

UPPER LAMP HARNESS

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

BALLAST

BALLAST

BALLAST

BLACK

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

LIGHT

SWITCH

BLUE

S

WHITE

SHELF LAMP HARNESS

BLACK

BLUE

BLUE

BLACK

SHELF LAMP

BLACK

S

BLACK

ORANGE

1

3

5

WHITE

WHITE

BLACK

BLUE

WHITE

2

4

6

-AMP.

WHITE

IRCUIT

SHELF LAMP

WHITE

WHITE

BREAKER

BLUE

SECOND CABINET HARNESS

S

WHITE

BLACK

WHITE

WHITE

BLACK

LEFT HALF RIGHT HALF

L1

(L2)

N

115 VAC. 60 Hz.-1Ø

POWER SUPPLY

(BROWN)

BLACK

(BLUE)

WHITE

SWITCH

SUPPLY

BLACK

WHITE

ORANGE

2-AMPS

MAXIMUM

Page 18

16 WIRING DIAGRAM–EXPORT MODELS

WIRING DIAGRAM – DISPLAY, EXPOR T LOW TEMP

WIRING DIAGRAM, DISPLAY, LOW TEMP.

IL-2908B

YEL

BALLAST

RED

RED

WHT

BLK

504-114A

6 EA

WIRING DIAGRAM–DISPLAY, LOW TEMP.

IL-2098B

Page 19

In the event a display is to be replaced DISCONNECT

THE PO WER SUPPL Y T O THE CABINET.

Insert a small screwdriver at one end of the bezel.

Carefully pry out while working from one end to the

other.The display can now be removed from the holder.

MODULAR MERCHANDISER 17

DIGITAL DISPLAY REMOVAL

Page 20

ELECTRICAL BOX LAYOUT

The electrical box is located at the rear of the cabinet

on the left-hand side.

It houses the compressor run components and the

electronic control board.

A power switch is pro vided to shut the supply pow er off

to the cabinet in the event service or cleaning is needed. The electrical box can be removed as an entire

assembly by removing the two mounting screws in the

lower base assembly if needed.

18 MODULAR MERCHANDISER

CONTROL BOARD LAYOUT

1. 3 pin connector - Input cable from the display board.

2. 4 pin connector - Input cable from the cavity and

evaporator coil inlet sensor.

3. Microchip (DO NOT REMOVE).

4. Dip switch selector (DO NOT CHANGE FROM

FACTORY SETTING).

5. 9 pin connector - Power supply to the board.

6. Green LED light - Light blinking when power sup-

ply is turned on (indicates program running).

7. Relay #1 compressor.

8. Relay #2 not used.

9. Relay #3 Defrost Relay (low temp.models).

10. Relay #4 evap fan relay (low temp models).

55

55

66

66

77

77

88

88

99

99

111100

00

44

44

33

33

11

11

22

22

Page 21

1. Cavity sensor lead

(closed case low & med temp shown)

2. Evaporator fan motor

3. Evaporator air inlet

4. Evaporator air outlet

5. Captube outlet

6. Evaporator inlet sensor #2

- med. & low temp models

7. High limit thermodisc (low temp)

8. Cavity sensor (medium open top models)

MODULAR MERCHANDISER 19

EVAPORATOR AREA LAYOUT - Deck pan removed

(low temp shown)

11

11

11

11

22

22

33

33

44

44

55

55

22

22

77

77

66

66

88

88

Page 22

EVAPORATOR COIL/DEFROST HEATER REMOVAL

Disconnect power supply to cabinet when servicing.

The evaporator coil and or defrost heater can be

removed by:

-Remove all shelving from cabinet

-Remove deck pan from cabinet

-Remove the evaporator fan shroud

-Locate and remove the coil air baffles (each end of

coil)

-Remove the f our coil housing cover screws located on

each end of the coil.

This will allow the evaporator coil to be raised up and

tilted forward for the removal of the coil or defrost

heater. The defrost heater is held in place by spring

retaining clips.A block of wood can be used to hold the

coil up for the heater removal.

20 MODULAR MERCHANDISER

Page 23

The wiring for these models are basically the same.

Power supplied to the electrical box. It then branches

in three separate circuits. Compressor har ness, evaporator haness and lighting harness. The evaporator

harness (fig 1) is not foamed in and can be replaced

if necessary. It is routed from the electrical box up

through a hole that enters just behind the evaporator

coil (left-hand side).This bundle consists of two sensor

leads and power supply to the defrost heater and ev aporator fan motor (when applicable).

The lighting harness originates from the secondary

terminal board located just above the rear unit comparment.This comparment houses the lighting ballast,

auxilliary outlet with the circuit breaker and light switch.

The lighting harness supplies power in two ways:

#1 circuit to shelf lights and rear perimeter heaters’

#2 citcuit to upper cavity light, front glass, front glass

perimeter and upper lighting channel heater.

CAUTION: Make sure that the shelf light plugs or

receptacle covers are completely inserted into the light

socket receptacles.This prevents electrical arcing and

or possible equipment damage.

#3. Shelf light receptacles

#4. Rear perimeter heater raceway

Circuit #3

This circuit enters the foamed-in area behind the shelf

lighting. The receptacle travels up to the upper light-

ing receptacle #5 and power supply to glass and

perimeter heater #6 and #7.

Access these connections by removing the top from

the cabinet. Then pr y up the galvanized subtop cover

and lift out insulation. This will expose the wiring bundle (view shown with insulation removed).

MODULAR MERCHANDISER 21

WIRING & COMPONENT LOCATION

11

11

11

11

22

22

33

33

44

44

55

55

66

66

77

77

Page 24

PERIMETER HEATER (Rear)

There is a separate perimeter heater for each door

opening.The heater can be checked prior to changing

by removing the rear ballast cover located just above

the unit compartment.The perimeter heater harness is

wired to this terminal board (double set of black and

white wires) perimeter heaters are parallel at this point

(fig 1).

The perimeter heater can be individually checked by

removing the perimeter harness cover located just

below the inside door opening (View shown with cover

removed).

The open view models have only one anti-sweat

heater located just above the discharge air opening.

To replace this heater simply remove the discharge

air grill retaining bracket (upper s/s).Then lift the

plastic grill up and out of the way. Fig 1.

The foil back heater is attached to a V shaped hat

section as shown in Fig. 2. Reattach new heater and

the galvanized hat section.Resecure the stainless

steel grill retainer bracket.

22 MODULAR MERCHANDISER

11

11

DISCHARGE AIR OPENING

(anti-sweat heater)

Medium Temperature

Open Models

Fig. 1.

Fig. 2.

LLLLaaaammmmpppp CCCCoooovvvveeeerr

rr

LAMP COVER – FPD4, EFPD4, KFPD4, BRD52,

EBRD52, KBRD62

To remove the lamp cover, loosen the thumbscrews,

and slide the cover forward.

Page 25

MODULAR MERCHANDISER 23

FPD CABINET SEALING

For improved performance and sealing under cabinet

operating conditions, the corners of the cabinet are

sealed with DOW 733. Side brackets with foam backing are attached to each end with nine (9) #8 stainless

steel sheet metal screws to improve sealing of end

panels to cabinet structure.

Left and Right Side Brackets

PN 54044-135D-01

with foam backing

Page 26

24 MODULAR MERCHANDISER

CONDENSING UNIT LAYOUT

RPD Models 3' & 4'

FPD Models 3' & 4'

OHM Models 3' & 4'

NOTE: CRO valve setting 50#.

Page 27

PERIMETER HEATER REMOVAL

1. Disconnect power to cabinet.

2. Allow trim to war m up.

3. Inser t the edge of the putty knife 1/16" under the

outer flange of the trim breaker.

4. Rotate handle down to approximately 45°.

5. Bump the putty knife handle until breaker trim

releases (see figure 1).

6. Remove all trim in the same manner.

7. Locate per imeter heater exit points.

8. Pull defective heater from grove provided.

9. The perimeter heater is plugged into a wire harness located just inside the cabinet behind the

harness raceway.

10. Install new heater and reseal wire exit points.

11. Replace tr im and seal with a silastic compound.

MODULAR MERCHANDISER 25

Page 28

Aligning Doors

Proper alignment of the cabinet doors will elminate hinge

binding and provide correct gasket seal.

1. Check cabinet level and door alignment by firmly

closing each door. Observe the movement of the

other doors.They should open slightly, then close and

seal.

2.The hinge has slotted mounting holes for adjustment.

3. Additional adjustment can be made by adding shims

between the hinge wing and either the door or the

cabinet face.

Removing Doors:

1. Remove the hitch pin from the upper hinge pin.

2. Loosen lower hex nut (Nut “A”) and release tension

on the torsion rod.

3. Hold the door steady and unscrew the pin at top

of the door.The door can now be lifted out of the

lower hinge bracket.

Door Gasket Removal:

Allow door to warm up to room temperature. At one

corner simply pull the gasket out of the plastic grove

provided. Replace new gasket by firmly pressing the

rear dart of gasket into the plastic groove all the way

around the door.

26 MODULAR MERCHANDISER

DOOR REMOVAL(Rear)

WASHER

HINGE PIN

HITCH

PIN

Page 29

MODULAR MERCHANDISER 27

GENERAL MAINTENANCE INFORMATION

Cleaning & Maintenance

WARNING:

To avoid the possibility of an electrical shock,

turn OFF Master Supply Switch and unplug

the electric cord of the cabinet before cleaning

or touching electrical connections or parts.

Cleaning the Cabinet Exterior

Wipe the exterior with a cloth dampened in mild detergent water; rinse and wipe dry with a soft, dry cloth.Do

not use abrasive or caustic cleaners or scouring pads.

Cleaning the Condenser

Periodic cleaning of the condenser can be easily

accomplished by brushing the coils with a soft brush

and/or using a vacuum cleaner with a brush attachment.

Be sure that dirt, dust and collection of other debris

does not build up to a point air circulation through the

condenser is restricted.

Cleaning the Storage Compartment

Remove the product and store it in another suitable

cabinet, if possible. Be sure to prevent spoilage of the

product which may occur if it is left a room temperature.

Turn OFF the Master Supply Switch and unplug the

cabinet.

Remove the shelving.

Wash the inside surface of the doors and the entire

interior storage area with warm water and baking soda

solution per quart of water.Rinse thoroughly with clean

water and wipe dry. This procedure can also be used

for cleaning the door gaskets.

IMPORTANT:

Do not use any objects or cleaners which may

leave residues, odors, or par ticles. Avoid the

use of strong chemicals or abrasive cleaners

which may damage the interior surfaces and

contaminate produce within the storage area.

Wash, rinse and dry the shelving while it is outside of

the cabinet, using the same procedure as described

for the storage area.

Be sure to correctly reinstall the shelving, plug in the

cabinet, turn ON the Master Supply Switch, set the

Temperature Display, and allow time for the cooling of

the storage area before storing product.

NOTE: If a spill occurs within the storage cabinet and

any time the storage compartment is cleaned, removal

and cleaning of the cabinet storage compartment components is possible as follows:

1. Shelving lifts off the shelf brackets as well as storage compartment bottom. Price tag moldings will

slip off ends of shelves.

2. Shelf brackets will lift out of shelf standard slots

when needed.

3. The shelf standards are attached to left, right, and

center pillars in rear of storage compartment.

The shelves for the product area are shipped in place

and lift out for cleaning.

Clean the cabinet exterior, interior, and shelving. Refer

to “Cleaning the Cabinet Exterior” instructions in the

Cleaning & Maintenance Section.

Plug the cabinet into the electrical outlet following the

information in “Locating the Cabinet” instructions.

Electrical Supply– Cord Connected Cabinets

IMPORTANT

Wiring and connection in power supply system

must meet all applicable (local and national)

electrical codes.Consult these codes for entire

lengths and sizes prior to cabinet installation.

The wiring diagram should be consulted

before attempting any electrical service. Be

sure to turn OFF power supply to cabinet by

turning OFF the Master Power Supply Switch

and/or disconnecting power cord before performing electrical service.

Shelf

Bracket

Shelf

Bracket

Pillar

Page 30

GENERAL MAINTENANCE INFORMATION-cont.

WARNING

Failure to perform the installation and ser vice

procedures of the electrical system as

described in the following instructions may

result in a hazard to equipment operators and

bystanders. Covers, guards, and connections

of electrical components are designed for use

safety and must always be reinstalled or

returned to original manufactured condition

after installation or service.

IMPORTANT

If refrigeration system has trouble starting,

maintaining correct temperature, or the cabinet lights dim, have the supply voltage

checked by a licensed electrician: a.)with the

cabinet disconnected; b.) under starting conditions, and c.) under load. Low line voltage is

often the cause of a cabinet malfunction.

Electrical supply requirements (see specifications label) should be consulted before installation and any time the cabinet is serviced.

Maximum Fuse Size & Over-Current Protection:

Separately fused (or circuit breaker). Refer to serial

data plate for correct circuit ampacity.

Cabinet Power Supply Cord & Receptacle:

Grounded 3-Prong Plug, NEMA approved (National

Electrical Manufacturers Association).

NOTE: Do not use an adapter or an extension cord

with the power supply.

Voltage Check: Voltage at the compressor terminals

must be within 10% (plus or minus) of rated voltage as

compressor is starting up.If the voltage is not within this

specified range, power supply (including wiring length

and size) should be checked by a licensed electrician.

Sliding Door Models

The cabinet doors are the sliding type. Each is spring

loaded and will close automatically when opened and

released. The spring assembly for each door runs

through a channel in the top raceway.This assembly is

attached to each respective door by a spring follower.

IMPORTANT:Keep bottom tracks clean for good

door operation.

Removing the Doors

To remove the right hand door, slide it a few inches to

the left. Grasp the door firmly at the sides with both

hands. Lift up slowly, and pull out at the bottom from

the bottom raceway.Ease the door to the right to allow

the nylon follower to rest at its stop. Do not let the

spring snap.

To remove the left hand door, the right hand door must

be taken out first. Move left door a few inches to the

right and proceed by lifting up, pulling out at bottom,

and easing to the left– allowing the spring follower to

come to rest at its stop.

NOTE:To reinstall doors, use reverse procedure.

28 MODULAR MERCHANDISER

Page 31

TROUBLESHOOTING–COMPRESSOR 29

COMPRESSOR – TROUBLESHOOTING CHARTS

WON’T START. Open line circuit. Check wiring, fuses, receptacle.

NO HUM..

Protector open. Wait for reset—check current.

Control contacts open. Check control, check pressures.

WON’T START. HUMS Improperly wired. Check wiring against diagram.

INTERMITTENTLY.

(cycling on protector)

Low line voltage. Check main line voltage, determine location

of voltage drop.

Open starting capacitor. Replace starting capacitor.

Relay contacts not closing. Check by operating manually. Replace relay

if defective.

Open circuit in start winding. Check stator leads.If leads are all right,

replace compressor.

Stator winding grounded (normally Check stator leads.If leads are all right

will blow fuse.) replace compressor.

High discharge pressure. Eliminate cause of excessive pressure.

Make sure discharge shut-off and receiver.

valves are open if applicable.

Tight compressor. Check oil level—correct binding condition, if

possible.If not, replace compressor.

Weak starting capacitor or one weak Replace.

capacitor of a set.

COMPRESSOR STARTS - Low line voltage. Bring up voltage.

MOTOR WON’T GET OFF

STARTING WINDING.

Improperly wired. Check wiring against diagram.

Defective relay. Check operation—replace relay if defective.

Running capacitor shorted. Check resistances.Replace capacitor if

defective.

Starting and running windings shorted. Check capacitance - replace if defective.

Starting capacitor weak or one of a set open. Check capacitance.Replace if defective.

High discharge pressure. Check discharge shutoff valves.

Check pressure.

Tight compressor. Check oil level. Check binding.Replace

compressor if necessary.

Page 32

COMPRESSOR – TROUBLESHOOTING CHARTS

COMPRESSOR STARTS Low line voltage. Bring up voltage.

& RUNS BUT CYCLES

ON PROTECTOR.

Additional current passing through Check for added fan motors and pumps

protector. connected to wrong side of protector.

Suction pressure too high. Check compressor for proper application.

Discharge pressure too high. Check ventilation, restrictions and over-

charge.

Protector weak. Check current - replace protector if

defective.

Running capacitor defective. Check capacitance. Replace if defective.

Stator partially shor ted or grounded. Check resistances; check for ground.

Replace if defective.

Inadequate motor cooling. Correct cooling system.

Compressor tight. Check oil level.Check for binding condition.

Unbalanced line (three-phase). Check voltage of each phase. If not equal,

correct condition of unbalance.

Discharge valve leaking or broken. Replace valve plate.

STARTING CAPACITORS Short cycling. Reduce number of starts to 20 or less per

BURNT OUT. hour.

Prolonged operation on starting Reduce starting load (install crankcase

winding. pressure limit valve), increase voltage if

low—replace relay if defective.

Relay contacts sticking. Clean contacts or replace relay.

Improper relay or incorrect relay setting. Replace relay.

Improper capacitor. Check parts list for proper capacitor rating:

mfd. and voltage.

RUNNING CAPACITORS Excessive line voltage. Reduce line voltage to not over 10% above

BURNT OUT. rating of motor.

High line voltage and light load. Reduce voltage if over 10% excessive.

RELAYS BURNT OUT. Low line voltage. Increase voltage to not less than 10% above

motor rating.

Excessive line voltage. Reduce voltage to not more than 10%

above motor rating.

Incorrect running capacitor. Replace with correct capacitor.

Short cycling. Reduce number of starts per hour.

Relay vibrating. Mount relay rigidly.

Incorrect relay. Use relay recommended for specific motor

compressor.

30 TROUBLESHOOTING–COMPRESSOR

Page 33

TROUBLESHOOTING–FLUORESCENT LAMP 31

FLUORESCENT LAMP TROUBLESHOOTING

NORMAL END OF LIFE. Normal failure. Active material on Replace lamp promptly.

Lamp won’t operate. Flashes cathodes exhausted.

momentarily and goes out or

blinks on and off.

Ends probably blackened.

SHORT LIFE. Wrong lamp type used. Replace with lamp type marked in owner’s

manual.

Wrong type of starter. Replace with correct starter.

Ballast not supplying the specified Replace with correct ballast for rating for

electrical values. lamp size.

Wrong type of ballast used. Replace ballast with proper type.

Too low or too high voltage. Check primary voltage with range

specified on ballast name plate.

Poor circuit contact.(likely at lamp- Lampholders should be rigidly mounted

holders.) and lamp securely seated.

Ballast improperly or incompletely Study ballast label wiring diagram and

connected. check connections.

Too many lamp starts. Average life for most lamps is dependent on

number of starts and hours of operation.

END BLACKENING. Normal end of life. Replace lamp promptly.

Dense blackening at one end or

both, extending 2"-3" from base. Mercury deposit - generally within Should evaporate as lamp is operated.

1" of lamp end.

Poor circuit contact likely at the Lampholders should be rigidly mounted

lampholder. and lamp securely seated.

Ballast improperly or incompletely Study ballast wiring instructions and check

connected. connections.

Wrong type lamp used. Replace with correct lamp type.

Wrong type of starter or defective Replace with proper starter.

starter causing on/off blinking or

prolonged flashing at each start.

Ballast installed not supplying the Replace with ballast of correct rating for

specified electrical values. lamp size.

Line voltage too low or too high. Check line voltage with range specified on

ballast plate.

Ballast improperly or incompletely Study ballast label wiring instructions and

connected. check connections.

The manufacturer uses standard fluorescent lamps in ail of its applications. Standard one- and two-lamp ballast

circuits are used.

Replacement lamps should be purchased over the counter from a local electrical wholesaler.

The table below indicates general problems that may be encountered with fluorescent lighting applications,

possible causes, and corrective maintenance suggestions.

Page 34

FLUORSCENT LAMP TROUBLESHOOTING

32 TROUBLESHOOTING–FLUORESCENT LAMP

NORMAL END OF LIFE. Normal failure. Active material on Replace lamp promptly.

NO STARTING EFFORT Open lamp cathode circuit due to If open, circuit is shown by continuity test or

OR SLOW STARTING. broken cathode, air leak, or by viewing end of bulb against a pinhole

open weld. of light. Replace lamp.

Wrong lamp type used. Replace with lamp type indicated in owner’s

manual.

Starter at end of life. Replace starter.

Starter sluggish. Replace starter.

Ballast installed not supplying the Replace with correct ballast of correct

specified electrical values. rating for lamp size.

Temperature cold air contact to Correct installation of lamp protection

bulb. tubes, or shields to prevent cold air effects.

Circuit voltage. Check voltage and correct if possible.

DECREASED LIGHT Temperature operation, cold air Properly install jacketed lamps where

OUTPUT. Full illumination of affects lamp performance. applicable.

bulbs requires correct assembly

of all components of lighting system. Circuit voltage. Check voltage and correct if possible.

Ballast improperly or incompletely Study ballast label wiring instructions and

connected. check connections.

Dust or dirt on lamp or fixture. Clean.

BLINKING ON/OFF: Normal failure. Active material on Replace lamp promptly.

Accompanied by shimmering cathodes exhausted.

effect during “lighted”period.

Possible lamp fault in some lampholders. Replace lamp. Investigate further if

successive lamps blink or flicker during

“lighted” period.

Wrong type of starter or defective starter. Replace with proper starter.

Ballast installed not supplying the specified Replace with correct ballast with correct

electrical circuit. rating for lamp size.

Circuit voltage. Check voltage and correct if possible.

Loose circuit contact. Lampholders should be rigidly mounted and

lamp securely seated.

OVERHEATED BALLAST. Wrong lamp type used. Replace with correct lamp number located in

owner’s manual.

Wrong ballast used.Wrong voltage Replace ballast.

rating.

Circuit voltage. Check voltage and correct to design

specifications.

Ballast improperly or incompletely Study ballast label. Correct if installed

connected. wrong.

Page 35

COMPONENT IDENTIFICATION

-Condensing Unit

COMPONENT IDENTIFICATION 33

1

23

4

5

7

1

COMPRESSOR

2

MOTOR PROTECTOR

3

MOTOR STARTER

MOTOR

4

BLADE5

DRIER

6

CONDENSER COIL

7

P

SS

D

6

FLOW

Page 36

34 COMPONENT IDENTIFICATION

COMPONENT IDENTIFICATION

-Electrical Box Assembly

APPLY A THIN COATING OF THE

OF THE ENCLOSED THERMAL JOINT

COMPOUND, TO THE ENTIRE METAL

2

3

2

7

12

SURFACE OF THE RELAY, PRIOR TO

3

1

MOUNTING.

15

TO DISPLAY

MODULE

TO BALLAST

BOX

TO SECOND

CABINET

(6-FT CABINET)

14

ALTERNATE CAPACITOR MOUNTING (FPD)

1

BOX, ELECT

2

RUN CAPACITOR

3

START CAPACITOR

TOGGLE SWITCH

4

5

ON/OFF INDICATOR PLATE

6

POWER CORD

7

HARNESS, ELECT BOX

8

BOARD, MAIN TERMINAL

9

COMPRESSOR HARNESS

10

CIRCUIT BOARD

HARNESS, EVAP FAN

11

12

HARNESS, DISPLAY

13

RELAY

14

HARNESS, SECOND CABINET

15

RELAY

16

FUSEHOLDER

17

FUSE

18

ELB ASSY

31-2025-00 REV AR

1 2 3 4 5 6 7 8

O

N

6

9

8

10

15

18

16

54

TO WATER DISSIPATION HEATER (OHM)

17

TO COMPRESSOR

Page 37

COMPONENT IDENTIFICATION

-Evaporator Area

COMPONENT IDENTIFICATION 35

1

2

3

4

5

6

7

8

HEATER, DEFROST, LOW TEMP

WIRE TIE, NYLON

RETAINER, HEATER, LOW TEMP

THERMOSTAT, DEFROST LIMIT, LOW TEMP

SUCTION LINE

EVAPORATOR

ADAPTOR

INLET LINE

NOTE; THE SENSOR IS ATTACHED AFTER THE EVAPORATOR ASSY. IS INSTALLED IN THE CABINET.

3-EA. ON THE INSULATION.

2-EA. ON THE SENSOR,

5

THE WIRING HARNESS)

SENSOR (PART OF

WIRE TIE, 5-EACH

1

APPROX.

2

COPPER WIRE

6

3

4

NOTE LOCATION OF SENSOR

STARTING AT THE CENTER

LINE OF THE RETURN BEND.

TUBE INSULATION

8

2

45∞

SENSOR IS LOCATED 45∞ BELOW

THE HORIZONTAL CENTER LINE OF

THE INLET LINE.

7

Page 38

36 REPLACEMENT PARTS

REPLACEMENT PARTS LIST

REPLACEMENT PARTS

3FT Modular Merchandizers

PART NUMBER

16-0202-00 Compressor EA

16-0313-00 Compressor EA

17-0316-00 Protector EA

17-0300-00 Start Relay EA

17-0321-00 Start Relay EA

19-0933-00 Condenser Fan Motor EA

19-0101-00 Condenser Fan Blade EA

12-3024 Drier EA

18-1211-01 Condenser Coil EA

50-2170-* Accordian Coil EA

18-0385-00 CRO Valve EA 1-1-

17-0320-00 Run Capacitor EA

19-3024-00 Run Capacitor EA

17-0319-00 Start Capacitor EA

17-0325-00 Start Capacitor EA

19-0103-00 Supply Switch EA

19-0620-00 Service Cord EA

19-0967-00 Service Cord EA

19-1704-02 Circuit Board EA

18-0713-00 Evaporator Coil EA

18-0720-01 Evaporator Coil EA

19-0952-01 Evaporator Heater EA

19-1706-00 Defrost Limit EA

19-1156-01 Evaporator Fan Motor EA

19-1156-02 Evaporator Fan Blade EA

10-1450-01 Lower Front Panel EA

10-1451-01 Lower Front Panel EA

10-1452-01 Lower Front Panel EA

10-1441-01 Lower Front Panel EA

19-1705-01 Display Board EA

02-0291-01 Condensate Pan EA

19-1709-01 Condensate Pan Heater EA 1-1-

10-1408-01 Rear Grill EA

51-1527-* Sliding Doors w/Frame EA

51-2480-00 Rear Door EA

10-0234-00 Door Gasket EA

20-0084-01 Front Glass EA

20-0085-01 Front Glass EA

20-0086-01 Front Glass EA

20-0087-01 Front Glass EA

20-0088-01 Front Glass EA

20-0089-01 Front Glass EA

19-0957-01 Lamp Holder, Plunger EA

19-0957-02 Lamp Holder, Stationary EA

19-1975-00 Lamp Holder EA

19-0088-00 Lamp Holder w/St Socket EA

19-0144-00 Lamp Starter EA

19-0146-00 Ballast EA

19-1650-00 Ballast EA

19-0149-00 Lamp EA

19-3049-00 Lamp EA

10-0551-00 Safety Shield & End Cap EA

10-1446-00 Safety Shield & End Cap EA

19-0659-00 Light Switch EA

19-1047-00 Circuit Breaker EA

19-1319-01 Perimeter Heater, Front EA

19-1082-04 Perimeter Heater, Rear EA

19-1238-* Anti-Sweat Heater EA

03-1231-03 Hinge, Upper Door, LH EA

03-1231-04 Hinge, Upper Door, RH EA

25-0413-00 Hinge Pin EA

05-0238-01 Shelf Panel, Top EA

05-0238-02 Shelf Panel, Middle EA

05-0259-01 Deck Pan, Bottom EA

05-0234-01 Deck Pan, Bottom EA 1-1-

10-1422-01 Panel, Clear Front EA 1-1-

10-1421-00 Panel, Clear Side EA 2-

10-1423-00 Panel, Clear Side EA 2-

50-0172-01 Step Weld Assembly EA 1-1-

DESCRIPTION U/M QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.#

MODEL NO. MODEL NO. MODEL NO. MODEL NO. MODEL NO. MODEL NO. MODEL NO. MODEL NO.

COHM3 OHM3CDPD3 DPD3 CFPD3 FPD3CRPD3 RPD3

1-1-

1-1-

1-1-

1-1-

1-1-

1-1- 1-1-

1-1- 1-1-

1-1- 1-1-

1-1- 1-1-

1 -02 1 -02 1 -01 1 -01

1-1-

1-1-

1-1-

1-1-

1-1-1-1-1-1-

1-1-1-1-

1-1-

1-1- 1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-031-03

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1- 1-1-

1-1-

1-1- 1-1-

1- 1-1-

1-1-

1-1-

1-1-

1-

1-

1-1- 1-1-

1-

1-1- 1-1-

1-1-1-1-1-1-

1-1-

1-1-

1-1-

1 -01 1 -01 1 -03 1 -03

1-1-

1-1-

1-

1-

1-

1-

1-

1-

3-1-

3-1-

4-1-4-1-

414-1-

4-1-1-1-

3-1-3-1-

2-1-

4-1-4-1-

3-1-

4-1-4-1-

3-1-

1-1-1-1-1-1-

1-1-1-1-

1-1-

1-1-

1-05 1-05

1 -01 1 -01

1-1-

1-1-

1-1-

1-1-1-1-1-1-

1-1-1-1-1-1-

2-2-2-2-2-2-

Page 39

REPLACEMENT PARTS 37

REPLACEMENT PARTS LIST

REPLACEMENT PARTS

4FT Modular Merchandizers

PART NUMBER

16-0202-00 Compressor EA

16-0313-00 Compressor EA

17-0316-00 Protector EA

17-0300-00 Start Relay EA

17-0321-00 Start Relay EA

19-0933-00 Condenser Fan Motor EA

19-0101-00 Condenser Fan Blade EA

12-3024 Drier EA

18-1211-01 Condenser Coil EA

50-2170-* Accordian Coil EA

18-0385-00 CRO Valve EA 1-1-

17-0320-00 Run Capacitor EA

19-3024-00 Run Capacitor EA

17-0319-00 Start Capacitor EA

17-0325-00 Start Capacitor EA

19-0103-00 Supply Switch EA

19-0620-00 Service Cord EA

19-0967-00 Service Cord EA

19-1704-02 Circuit Board EA

18-0714-01 Evaporator Coil EA

18-0720-02 Evaporator Coil EA

19-0952-03 Evaporator Heater EA

19-1706-00 Defrost Limit EA

19-1156-01 Evaporator Fan Motor EA

19-1156-02 Evaporator Fan Blade EA

10-1453-* Lower Front Panel EA

10-1454-01 Lower Front Panel EA

10-1455-01 Lower Front Panel EA

10-1442-01 Lower Front Panel EA

19-1705-01 Display Board EA

02-0291-02 Condensate Pan EA

19-1709-01 Condensate Pan Heater EA 1-1-

10-1408-02 Rear Grill EA

51-1527-* Sliding Doors w/Frame EA

51-1528-02 Sliding Door Frame, PT EA

51-2480-00 Rear Door EA

10-0234-00 Door Gasket EA

20-0084-02 Front Glass EA

20-0085-02 Front Glass EA

20-0086-02 Front Glass EA

20-0087-02 Front Glass EA

20-0088-02 Front Glass EA

20-0089-02 Front Glass EA

19-0957-01 Lamp Holder, Plunger EA

19-0957-02 Lamp Holder, Stationary EA

19-1975-00 Lamp Holder EA

19-0088-00 Lamp Holder w/St Socket EA

19-0145-00 Lamp Starter EA

19-0458-00 Ballast EA

19-1725-00 Ballast EA

502-246B-01 Ballast EA

19-0150-00 Lamp EA

19-3049-00 Lamp EA

503-249B Lamp EA

10-0308-00 Safety Shield & End Cap EA

713-062C-05 Safety Shield & End Cap EA

10-1446-00 Safety Shield & End Cap EA

707-011D Lamp Cover EA 1

19-0659-00 Light Switch EA

19-1047-00 Circuit Breaker EA

19-1319-02 Perimeter Heater, Front EA

19-1082-04 Perimeter Heater, Rear EA

19-1238-* Anti-Sweat Heater EA

03-1231-03 Hinge, Upper Door, LH EA

03-1231-04 Hinge, Upper Door, RH EA

25-0413-00 Hinge Pin EA

05-0238-03 Shelf Panel, Top EA

05-0238-04 Shelf Panel, Middle EA

51-1543-05 Glass Shelf Ass'y, Top EA

51-1543-06 Glass Shelf Ass'y, Middle EA

05-0259-02 Deck Pan, Bottom EA

01-0250-02 Deck Pan, Bottom EA

05-0234-02 Deck Pan, Bottom EA 1-1-

10-1422-02 Panel, Clear Front EA 1-1-

10-1421-00 Panel, Clear Side EA 2-

10-1423-00 Panel, Clear Side EA 2-

50-0172-02 Step Weld Assembly EA 1-1-

DESCRIPTION U/M QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.#

RPD4 BRD52

1-1-1-

1-1-1-

1-1-1-

1-1-1- 1-1-1-

1-1-1- 1-1-1-

1-1-1- 1-1-1-

1-1-1- 1-1-1-

1 -02 1 -02 1 -02 1 -01 1 -01 1 -01

1-1-1-

1-1-1-

1-1-1-1-1-1-1-1-

1-1- 1-1-

1-1-1- 1-1-1-

1-1-1-

1-1-1- 1-1-1-

1-1-1- 1-1-1-

1 -01 1 -01 1 -01 1 -01 1 -06

1-

1-1-1- 1-1-1-

1-1-1- 1-1-1-

1-1-1-1-1-1-1-1-

1 -02 1 -02 2 -02 1 -04 1 -04

1-

1-

1-1-

1-

4-1-1-4-1-

4-1-1-4-1-

1-1-1-1-1-

4-4-4-4-4-

1-

4-1-1-4-1-

4-1-1-4-1-

1-1-1-1-1-1-1-1-

1-1-1-1-1-

1-1-1-1-1-1-1-

1-1-1-1-1-1-1-

2-2-2-2-2-2-2-

1-1-1-

1-1-1-

1-1-1-

1-1-1-

1-1-1-

1-1-1-

1-1-1-

1-1-1-

1-

2-2-2-

2-2-2-

1-

1-

3-1-1-

3-1-1-

3-

3-

3-

1-1-1-

1-1-1-

1 -06 1 -06 1 -06

2-2-2-

2-2-2-

2-2-2-

1-1-

1-1-

1-1-

1-1-

1-

-

2-

2-

2-

COHM4CRPD4 RPD4PT OHM4CDPD4 DPD4 CFPD4 FPD4

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1 -03 1 -03

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1-1-

1 -01 1 -01

1-1-

1-1-

1-1-

1 -02 1 -02

MODEL NO.MODEL NO.MODEL NO. MODEL NO. MODEL NO. MODEL NO.MODEL NO. MODEL NO. MODEL NO. MODEL NO.

Page 40

38 REPLACEMENT PARTS

REPLACEMENT PARTS LIST

REPLACEMENT PARTS

6FT Modular Merchandizers

PART NUMBER

16-0313-00

17-0316-00

17-0300-00

19-0933-00

19-0101-00

12-3024

18-1211-01

50-2170-*

17-0320-00

17-0319-00

19-1343-00 Relay, Time Delay EA

19-1345-00 Resistor, 47k, Time Delay EA

19-0103-00

19-0620-00

19-0967-00

19-1704-02

18-0713-00

18-0720-01

19-1156-01

19-1156-02

10-1450-01

10-1451-01

10-1452-01

10-1441-01

19-1705-01

02-0291-01

19-1709-01

10-1408-01

20-0084-03

20-0085-03

20-0087-03

20-0088-03

19-1975-00

19-0088-00

19-0144-00

19-0145-00

19-0146-00

19-0458-00

19-0149-00

19-0151-00

10-0551-00

10-0445-00

19-0659-00

19-1238-01

05-0238-01

05-0238-02

05-0259-01

05-0234-01

10-1422-03

10-1421-00

10-1422-00

50-0172-01

DESCRIPTION U/M QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.# QTY GR.#

Compressor EA

Protector EA

Start Relay EA

Condenser Fan Motor EA

Condenser Fan Blade EA

Drier EA

Condenser Coil EA

Accordian Coil EA

Run Capacitor EA

Start Capacitor EA

Supply Switch EA

Service Cord EA

Service Cord EA

Circuit Board EA

Evaporator Coil EA 2 - 2 -

Evaporator Coil EA

Evaporator Fan Motor EA

Evaporator Fan Blade EA

Lower Front Panel EA

Lower Front Panel EA

Lower Front Panel EA

Lower Front Panel EA

Display Board EA

Condensate Pan EA

Condensate Pan Heater EA 2 - 2 -

Rear Grill EA

Front Glass EA

Front Glass EA

Front Glass EA

Front Glass EA

Lamp Holder EA

Lamp Holder w/St Socket EA

Lamp Starter EA

Lamp Starter EA

Ballast EA

Ballast EA

Lamp EA

Lamp EA

Safety Shield & End Cap EA

Safety Shield & End Cap EA

Light Switch EA

Anti-Sweat Heater EA 2 - 2 -

Shelf Panel, Top EA

Shelf Panel, Middle EA

Deck Pan, Bottom EA

Deck Pan, Bottom EA 2 - 2 -

Panel, Clear Front EA 1 - 1 -

Panel, Clear Side EA 2 -

Panel, Clear Side EA 2 -

Step Weld Assembly EA 2 - 2 -

MODEL NO.

OHM6

2-2-

2-2-

2-2-

2-2-

2-2-

2-2-

2-2-

2-022-02

2-2-

2-2-

MODEL NO.MODEL NO. MODEL NO. MODEL NO. MODEL NO.

COHM6CDPD6 DPD6CRPD6 RPD6

2-2-

2-2-

2-2-

2-2-

2-2-

2-2-

2-2-

2-032-03