Beverage Air MT27 Installation Manual

IMPORTANT

INFORMATION

FOR

MM / MT / FC / Rl

SERIES

This cooler has passed the

QUALITY CONTROL INSPECTION

And meets the high standards at Beverage-Air

This inspection includes complete refrigeration

System, cabinet construction & finish.

IMPORTANT

PLEASE RETAIN FOR YOUR RECORDS

SALES OFFICE: P.O. BOX 5932 SPARTANBURG, S.C. 29304-5932

PHONE: (864) 582-8111 TOLL FREE 1-800-845-9800

TECHNICAL SERVICE: 1-800*684-1199, PARTS ORDER FAX: 1-800-262-9381

PLANTS: SPARTANBURG, S.C. BROOKVILLE, PA. HONEA PATH, S.C.

809-005A

Rev. E

1. Installation

BEVERAGE-AIR®

INSTALLATION AND OPERATING INSTRUCTIONS

Models: MT/RI/FC

ILA-0931

SHEET 1 OF 3

REV. B

a. Receiving Inspection

Upon receipt, check all packages and accessories or optional components including legs, casters,

and shelves.

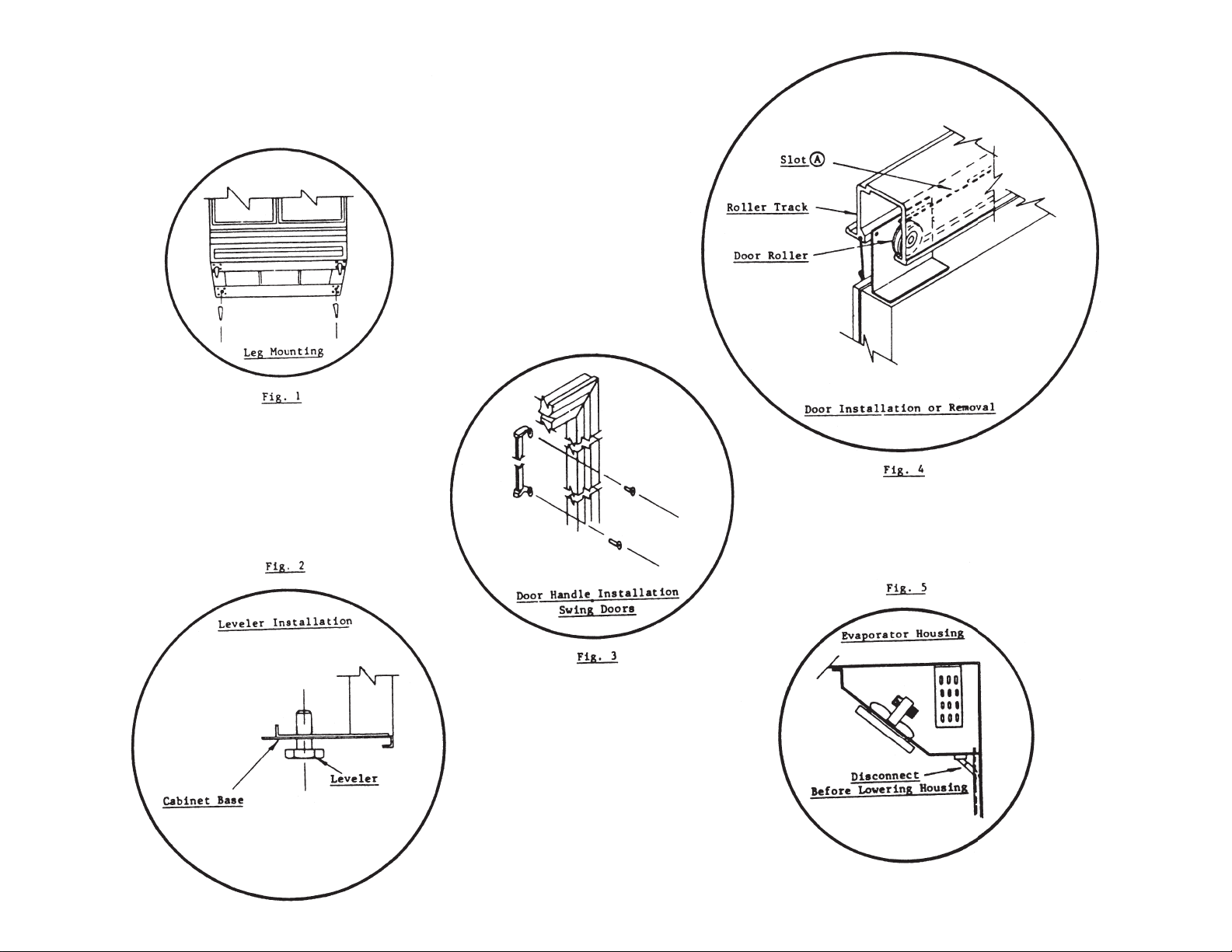

b. Legs & Casters

Legs screw directly into the base. Caster are plate-mounted. To install casters, tip or raise the

cabinet one side at a time and remove the four hex head screws in each corner of the bottom.

Use these same screws to attach the mounting plate. Screw-on type legs simply screw into the

adapter nut provided in each corner of the bottom.

c. Leveling

To provide adequate condensate drainage and proper door alignment and operation. It is

necessary that the cabinet be level. Level cabinet from front to rear and from side to side with

leveling bolts, or leg inserts. This should be done after cabinet has been set in its final operating

position. The leveling bolts are the same bolts used to attach the wood base to the cabinet. BE

SURE THAT DRAIN HOSE IS ATTACHED AND DRAINING PROPERLY INTO EXTERIOR

CONDENSATE PAN LOCATED BEHIND BOTTOM GRILLE ASS’Y. THE HOSE COULD

POSSIBLE BE KNOCKED LOOSE IN TRANSIT.

d. Door Handles

Door handles with mounting screws are packed inside each cooler.

To mount handle, lift door gasket behind two holes in front and insert screws through the holes.

Attach handle, with offset away from cabinet corner, and tighten screws. (NOTE: It may be

necessary to adjust position of handle end mounts on handle bar to match hole spacing in door

frame.)

: (See Fig. 2)

: (optional) (See Fig. 1)

: (See Fig 3.)

:

e. Shelves

Shipped inside each cabinet are shelves packed in plastic and a bag of shelf supports. Shelf

spacing is adjustable to suit requirements. See Instruction Sheet ILA-0904 for installing.

f. Door Removal and

(1) Slide Doors

Proper

a. Locate Door Rollers under slot A

Adjust spring by moving hook to next hole or by shortening.

If door gaskets do not seal properly follow step 1 and 2.

Step 1: Check to see if cabinet base is level.

Step 2: Adjust the Location

(2) Swing Doors

“Swing Back

instructions see enclosed instruction sheet ILA-0859.

g. Locating Cooler

Provide at least three inches of space

end and rear of cabinet.

* For FC model, factory setting of temperature control is at No. 4 position (normal) which will

:

- Each door has its own Closing Spring located at the top and is positioned for

Tension. However if adjustment is required remove doors as follows:

bottom of door out.

” of doors, and does not require field adjustment. For replacement parts and

:

maintain the flower at about 42°F.

Adjustment:

show in fig. 4, and lift door off track while tilting

፨

of door Rollers in the Roller Brackets.

- Spring tension in the bottom hinges is Factory Adjusted for adequate

between cabinet and any adjacent wall or fixture, at left

2. Operation

a. Electrical Supply and Connections:

Plug all standard models into 115 volts A.C. 60 cycle outlet. Low line voltage is often the cause

of service complaints. Check to see that the line voltage is 110 volts or more with the unit

running. Other motors or heavy appliances should not be used on the same circuit with the

cooler. When working on the inside of the cooler disconnect from electrical circuit for safety

reasons. CAUTION: If an extension cord is necessary, use only a three wire grounding type of

wire size 16 AWG or larger; do not exceed 20 ft. in length. The use of ungrounded cords or

overloaded circuits voids compressor warranty.

b. Initial Start-Up:

Turn Power on and check to verify that the condenser fan is running. On all Models, except

RI18, the defog fan and light switches are located on the blower housing front inside the

cabinet, the Defog Switch in “ON” position permits the Condenser Fan to run continuously for

maximum Door Defoging in high humidity locations.

c. Temperature Control:

Factory setting of temperature control is at No. 5 position (normal) which will maintain the

product at about 36°F.* For colder temperatures, turn knob clockwise one number at a time.

Excessive tampering with temperature control could lead to service difficulties. For operation

about 3000 ft. altitude, have thermostat adjusted by a qualified serviceman.

BEVERAGE-AIR®

ILA-0931

SHEET 2 OF 3

REV. B

d. Condensate Disposal:

The evaporator blower housing serves as a pan to collect and direct the condensate to the

evaporator pan located behind the front grille. Air flow over the pan hastens condensate

evaporation so that external drain plumbing is not required.

3. Maintenance

a. Cleaning Cabinet Exterior:

Cabinets should be cleaned with a solution of mild soap and water. Do not use caustic soap or

abrasive cleaners, since these might damage the cabinet finish. If stainless steel surface becomes

discolored, scrub by rubbing only in the direction of the finish grain. Do not use steel wool.

b. Cleaning Interior Surfaces:

The inside of the cabinet is coated with baked-on vinyl (except stainless steel cooler). To clean,

use mild soapy water and cloth or sponge.

c. Condenser:

For efficient operation, it is recommended that the condenser coil and fans be cleaned every

3 to 6 months. Remove front grille for access. Vacuum clean front surface of coil thoroughly or

direct forced air through condenser fins. Failure to clean condenser can cause compressor

malfunction and will void warranty.

d. Evaporator Fan:

Evaporator pan should be cleaned periodically to prevent odors and maintain evaporating

efficiency. The pan contains wicks to assist evaporation and should be replaced periodically.

e. Evaporator Housing:

If internal parts (e.g. fans, control) are to be serviced, lower housing as shown in (Fig 5). Make

certain to remove drain tube before lowering housing.

REV. B

SHEET 3 OF 3

ILA-0931

Loading...

Loading...