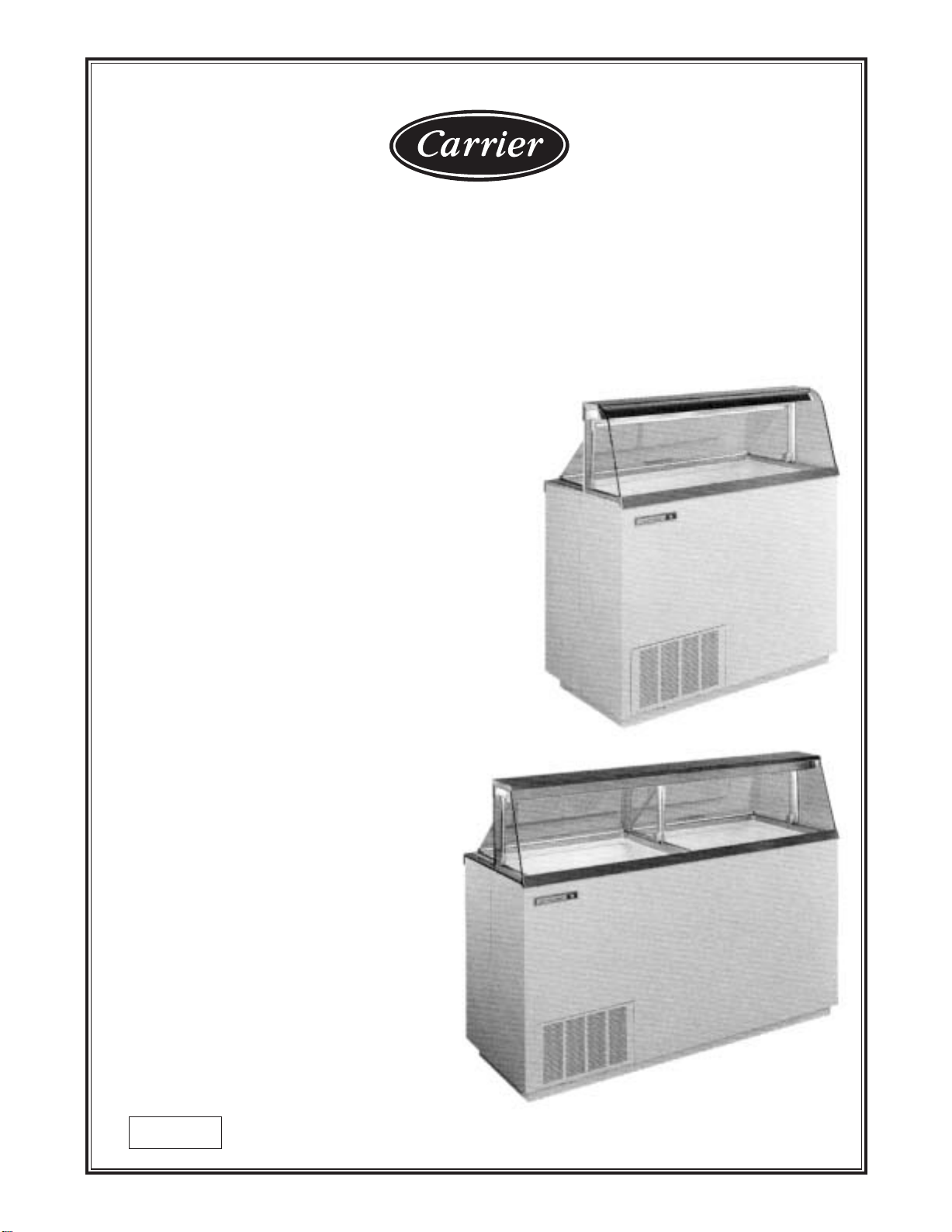

Beverage Air 8HR Service Manual

CARRIER COMMERCIAL REFRIGERATION, INC.

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

SERVICE &

INSTALLATION

MANUAL

DIPPING

CABINETS

R-404A Refrigerant

1 / 2003

51-1298-02

If additional information is necessary, call Carrier Refrigeraiton

Operations headquarters.

Our toll free number is 1-800-684-1199.Technical assistance engineers are

willing to assist you in any way possible. Office hours are from 8:00 a.m. to

5:30 p.m., Eastern Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

Information in this manual is subject to change without notice.

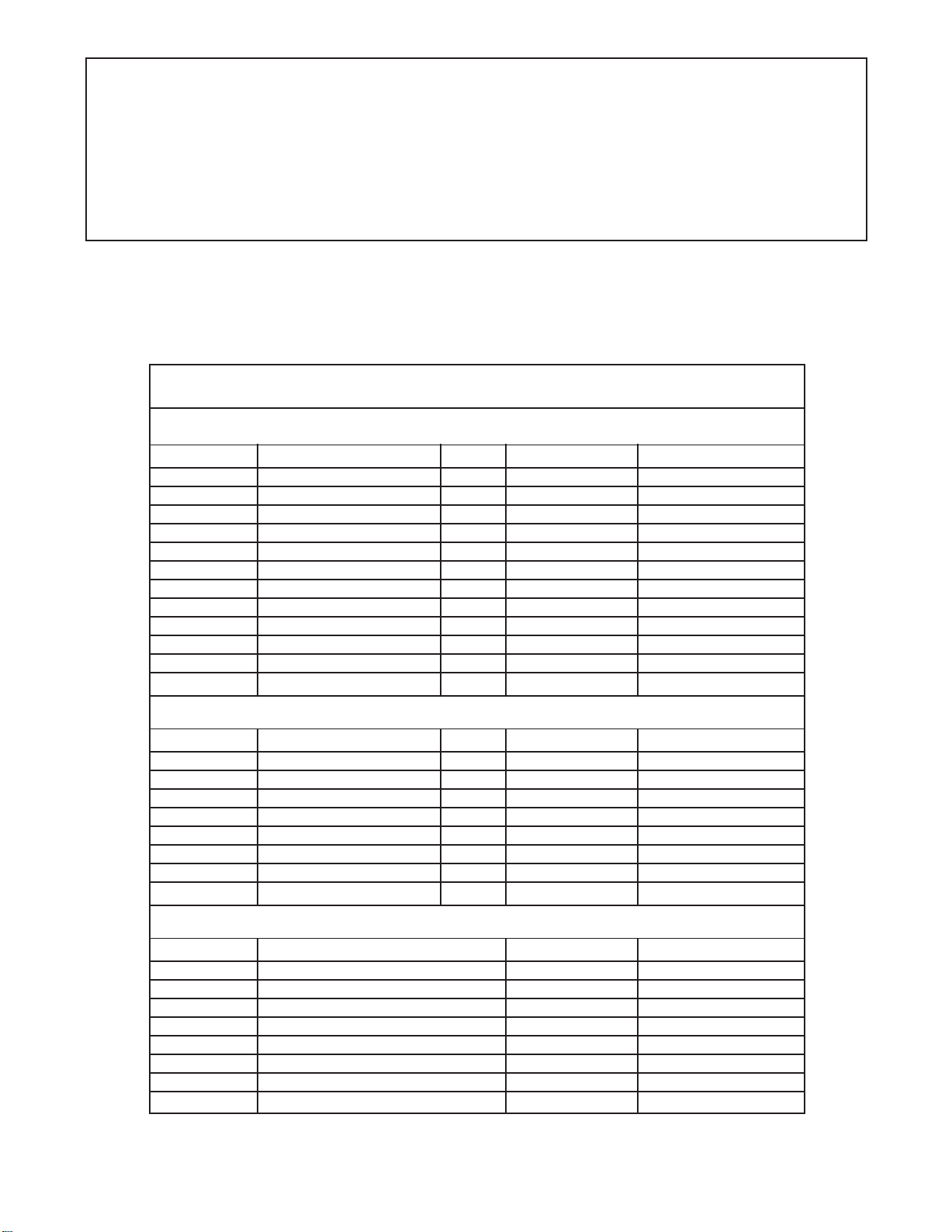

MODEL DESIGNATION INFORMATION

115V, 60HZ

PAR T # MODEL # DATA PLATE STYLE

52-1802-31 CKDC27 4HC CURVED

52-1802-32 CKDC47 8HC CURVED

52-1953-31 CKDC47 3500K LIGHTS 8HC CURVED

52-1802-33 CKDC67 12HC CURVED

52-1953-33 CKDC67 3500K LIGHTS 12HC CURVED

52-1802-34 CKDC87 16HC CURVED

52-1953-32 CKDC87 3500K LIGHTS 16HC CURVED

52-1802-35 KDC27 DL4C 4HR/4HJ STRAIGHT

52-1802-36 KDC47 DL8C 8HR/8HJ STRAIGHT

52-1963-31 KDC47F SS NO LIGHTS 8HF STRAIGHT

52-1802-37 KDC67 DL12C 12HR STRAIGHT

52-1802-38 KDC87 DL16C 16HR STRAIGHT

EXPORT 220V, 50HZ

PAR T # MODEL # DATA PLATE STYLE

52-1901-35 ECKDC27 E4HC CURVED

52-1901-36 ECKDC47 E8HC CURVED

52-1901-31 ECKDC67 ECKDC-67 CURVED

52-1901-32 ECKDC87 ECKDC-87 CURVED

52-1901-37 EKDC27 EDL4C E4HR STRAIGHT

52-1901-38 EKDC47 EDL8C E8HR STRAIGHT

52-1901-33 EKDC67 EDL12C EKDC-67 STRAIGHT

52-1901-34 EKDC87 EDL16C EKDC-87 STRAIGHT

EXPORT 220V, 60HZ

PAR T # MODEL # DATA PLATE STYLE

52-1944-35 KCKDC27 E4HC2 CURVED

52-1944-36 KCKDC47 E8HC2 CURVED

52-1944-31 KCKDC67 E12HC2 CURVED

52-1944-32 KCKDC87 E16HC2 CURVED

52-1944-37 KKDC27 E4HR2 STRAIGHT

52-1944-38 KKDC47 E8HR2 STRAIGHT

52-1944-33 KKDC67 E12HR2 STRAIGHT

52-1944-34 KKDC87 E16HR2 STRAIGHT

Manual effective for models produced January, 2003. Starting serial number 6527372.

Introduction

Dipping Cabinet Introduction

These Dipping Cabinets are designed to merchandise ice cream or yogurt type

products. Dipping cabinets are produced in four sizes: 4, 8, 12, and 16 facings

of ice cream containers. The cabinet systems contain R-404A refrigerant,

metered into the system by a capillary tube. The evaporator is a cold wall which

has the refrigerant lines strapped to the inner liner of the cabinet. The condenser

is a bare tube mounted on a pullout machinery compartment tray for ease of

servicing. All electrical controls are easily accessible for repair. The temperature

within the cavity is controlled thermostatically, allowing for maintenance of

correct dipping temperatures.

Mechanical equipment may require repair at times. This manual presents

information that is helpful in maintaining, diagnosing, and repairing these

cabinets.

The high level of quality built into these units will allow for many years of

trouble free operation.

2 INTRODUCTION

TABLE OF CONTENTS

INTRODUCTION

Introduction ........................................................................ 2

Table of Contents ................................................................3

CABINET SPECIFICATIONS/DIMENSIONAL DRAWINGS

4HR & 4 HC & EXPORT .................................................. 4

8HR & 8HC & EXPORT .................................................. 5

12HR & 12HC & EXPORT .............................................. 6

16HR & 16HC & EXPORT .............................................. 7

Handling & Installation ...................................................... 8

Product Load Line Location .............................................. 10

PRINCIPLES OF OPERATION

General Operations Information ........................................ 13

4HR & 4HC Electrical & Refrigeration Specs .................... 14

8HR & 8HC Electrical & Refrigeration Specs .................... 15

12HR & 12HC Electrical & Refrigeration Specs ................ 16

16HR & 16HC Electrical & Refrigeration Specs ................ 17

E4HR & E4HC Electrical & Refrigeration Specs. .............. 18

(220V / 60 Hz)

E8HR & E8HC Electrical & Refrigeration Specs. .............. 19

(220V / 60 Hz)

E12HR & E12HC Electrical & Refrigeration Specs. .......... 20

(220V / 60 Hz)

E16HR & E16HC Electrical & Refrigeration Specs. .......... 21

(220V / 60 Hz)

4HR, 4HC / 8HR, 8HC / E4HR, E4HC / E8HR, E8HC

Wiring Diagram ................................................................ 22

12HR, 12HC / 16HR, 16HC Wiring Diagram .................... 23

Condenser Fan Motor Replacement .................................. 44

Ballast Replacement ........................................................ 45

Metering Device / Heat Exchanger Replacement .............. 46

Cabinet Troubleshooting Guide ........................................ 47

Compressor Troubleshooting Guide ................................ 49

Fluorescent Lamp Troubleshooting Guide ........................ 50

Measurements - Starting Lamp Voltage .......................... 52

ILLUSTRATIONS & PARTS

Cabinet Parts - Exploded View .......................................... 54

Cabinet Parts List ............................................................ 55

Canopy Parts - Exploded View .......................................... 56

Canopy Parts List ............................................................ 57

Condensing Unit - Exploded View .................................... 58

Condensing Unit Parts List .............................................. 59

Electrical Components - Exploded View .......................... 60

Electrical Components Parts List ...................................... 61

Lid - Exploded View .......................................................... 62

Lid Parts List .................................................................... 63

ACCESSORIES

Can Skirt Accessory Parts List ........................................ 67

Can Skirt Installation ........................................................ 68

Dipperwell Installation ...................................................... 70

Sanitary Base Leg Installation .......................................... 71

Caster Installation ............................................................ 72

Lid Lock Kit Installation .................................................... 73

Can Clamp Installation ...................................................... 74

Round Can Clamp Installation .......................................... 75

Half-way Shelf Bottom Support Kit Installation ................ 76

ECKDC67, EKDC67 / ECKDC87, EKDC87

E12HC2, E12HR2 / E16HC2, E16HR2

WIRING DIAGRAM..............................................................24

8HC, 12HC, 16HC (3500K LIGHTS)

WIRING DIAGRAM..............................................................25

MAINTENANCE & REPAIR

Pre-Service Check List ...................................................... 29

General Maintenance Information .................................... 30

Compressor Installation / Diagnostics .............................. 32

Cleaning & Maintenance .................................................. 34

Cleaning the Lid & Touch-up Painting .............................. 35

Lid Seal Replacement ...................................................... 36

Lid Gasket Replacement .................................................. 37

Lid Pivot Bushing Assembly Replacement ...................... 38

Center & End Pivot Rod Replacement .............................. 39

Fluorescent Lamp Holder/Light Starter Socket Replac. .... 40

Fluorescent Bulb & Starter Replacement .......................... 41

Thermostat Replacement .................................................. 42

Master Power Supply Switch / Light Switch Removal ...... 43

Specifications are subject to change without notice.

TABLE OF CONTENTS 3

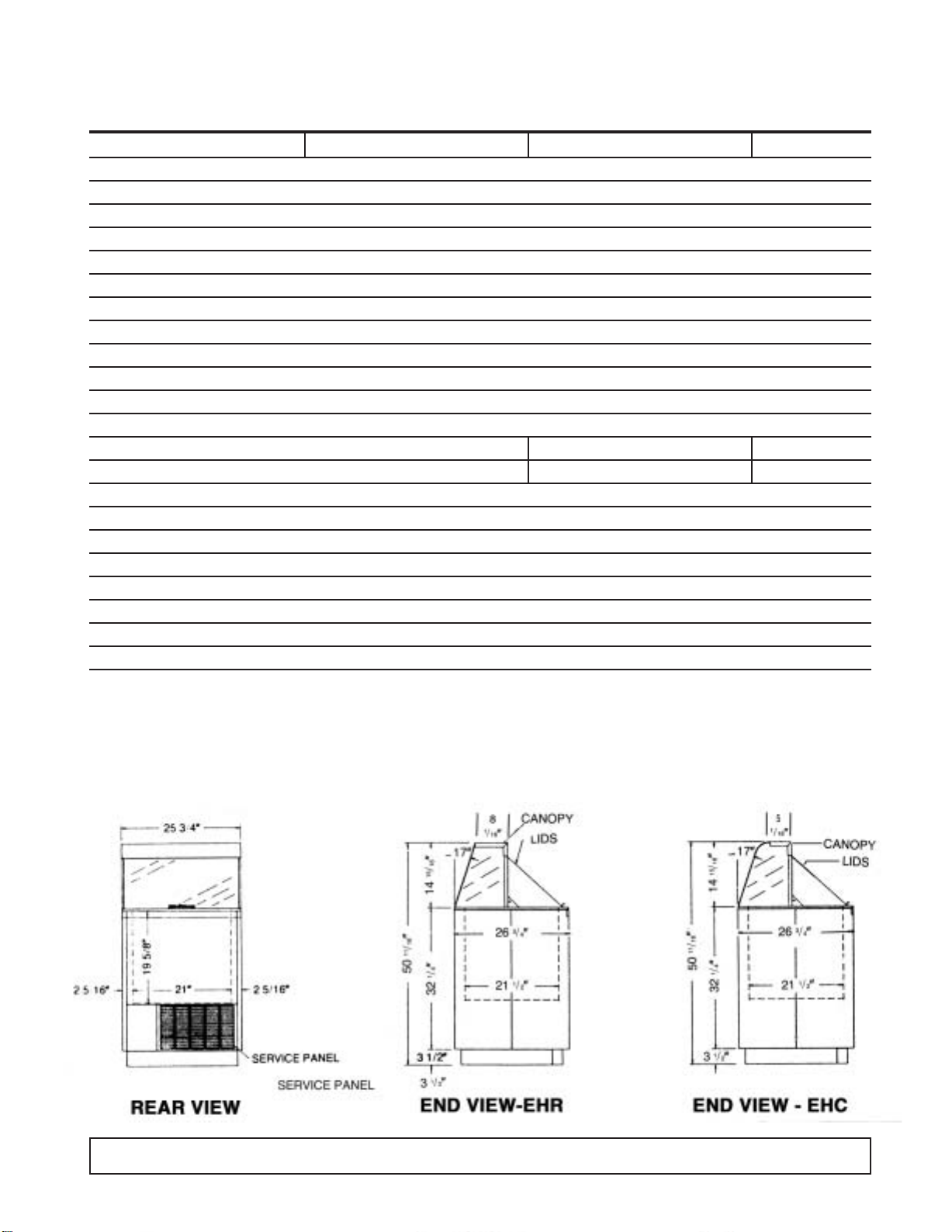

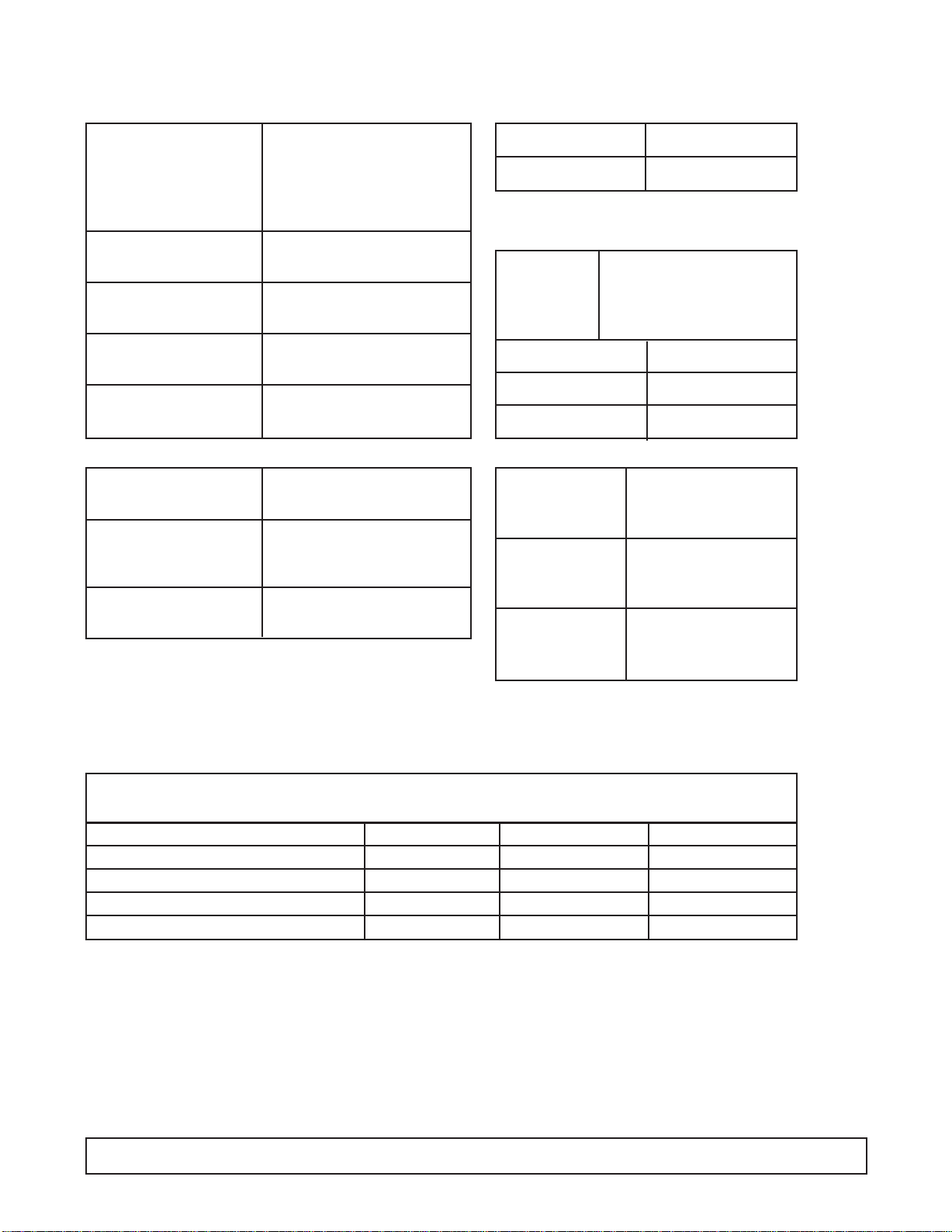

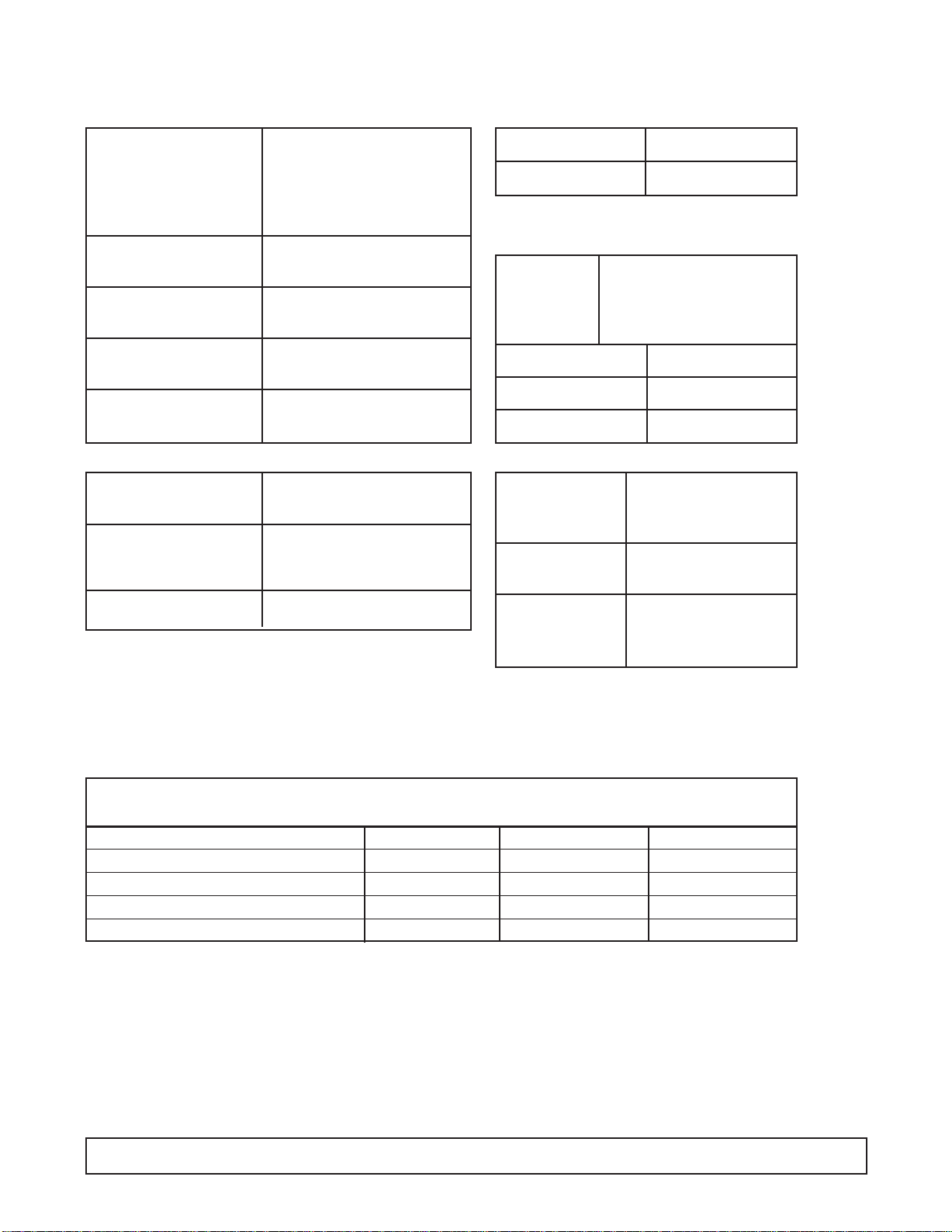

CABINET SPECIFICATIONS

4HC & 4HR/4HJ E4HC & E4HR E4HC2 & E4HR2

Temp. Range +10°F to -8°F

Capacity 4.6 Cu. Ft.

Capacity (3 Gal. Tubs) 4

Facings (3 Gal. Tubs) 4

Storage (3 Gal. Tubs) 0

Compressor Size 1/4 Hp.

Shipping Weight (App.) 235 lbs.

Condenser Type Bare Tube

Evaporator Type Cold Wall

Refrigerant R-404A

Refrigerant Control Capillary Tube

Defrost System Manual

Rated Amps 3.0 1.7 1.7

Electrical Specs. 115V, 60 Hz., 1 Ph. 220V, 50 Hz., 1Ph 220V, 60 Hz., 1 Ph.

Power Cord No. 16AWG

NSF Listing NSF7

Canopy Construction S.S. Top with Glass ends Straight or Curved Front Glass

Lids (Plexiglass) 1 Lid

Interior Finish White Baked Enamel on Galvanized Steel

Exterior Finish White Baked Enamel

Lighting One 20 Watt Bulb

Accessories Can Skirt Kit, Lid Locks, Dipperwell, Night Covers, Casters, Legs

DIMENSIONAL DATA

4 INTRODUCTION

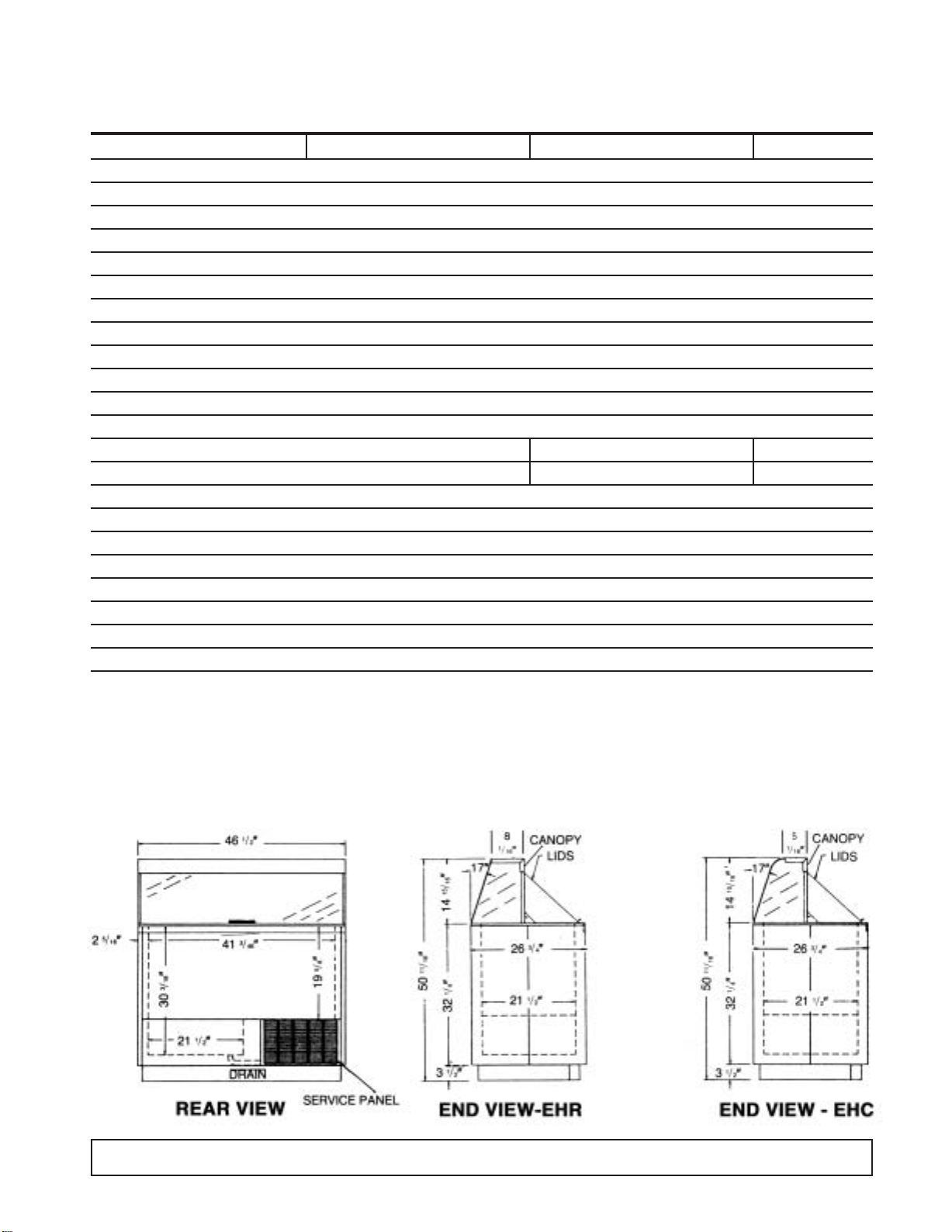

CABINET SPECIFICATIONS

8HC & 8HR/8HJ & 8HF E8HC & E8HR E8HC2 & E8HR2

Temp. Range +10°F to -8°F

Capacity 12.0 Cu. Ft.

Capacity (3 Gal. Tubs) 12

Facings (3 Gal. Tubs) 8

Storage (3 Gal. Tubs) 4

Compressor Size 1/3 Hp.

Shipping Weight (App.) 365 lbs.

Condenser Type Bare Tube

Evaporator Type Cold Wall

Refrigerant R-404A

Refrigerant Control Capillary Tube

Defrost System Manual

Rated Amps 4.0 2.1 2.1

Electrical Specs. 115V, 60 Hz., 1 Ph. 220V, 50 Hz., 1 Ph. 220V, 60 Hz., 1Ph.

Power Cord No. 16AWG

NSF Listing NSF7

Canopy Construction S.S. Top with Glass ends Straight or Curved Front Glass

Lids (Plexiglass) 1 Lid

Interior Finish White Baked Enamel on Galvanized Steel

Exterior Finish White Baked Enamel

Lighting Two 20 Watt Bulbs Standard (17 Watt Bulbs on Special Cabinets with 3500 K Lighting)

Accessories Can Skirt Kit, Lid Locks, Dipperwell, Night Covers, Casters, Legs

DIMENSIONAL DATA

INTRODUCTION 5

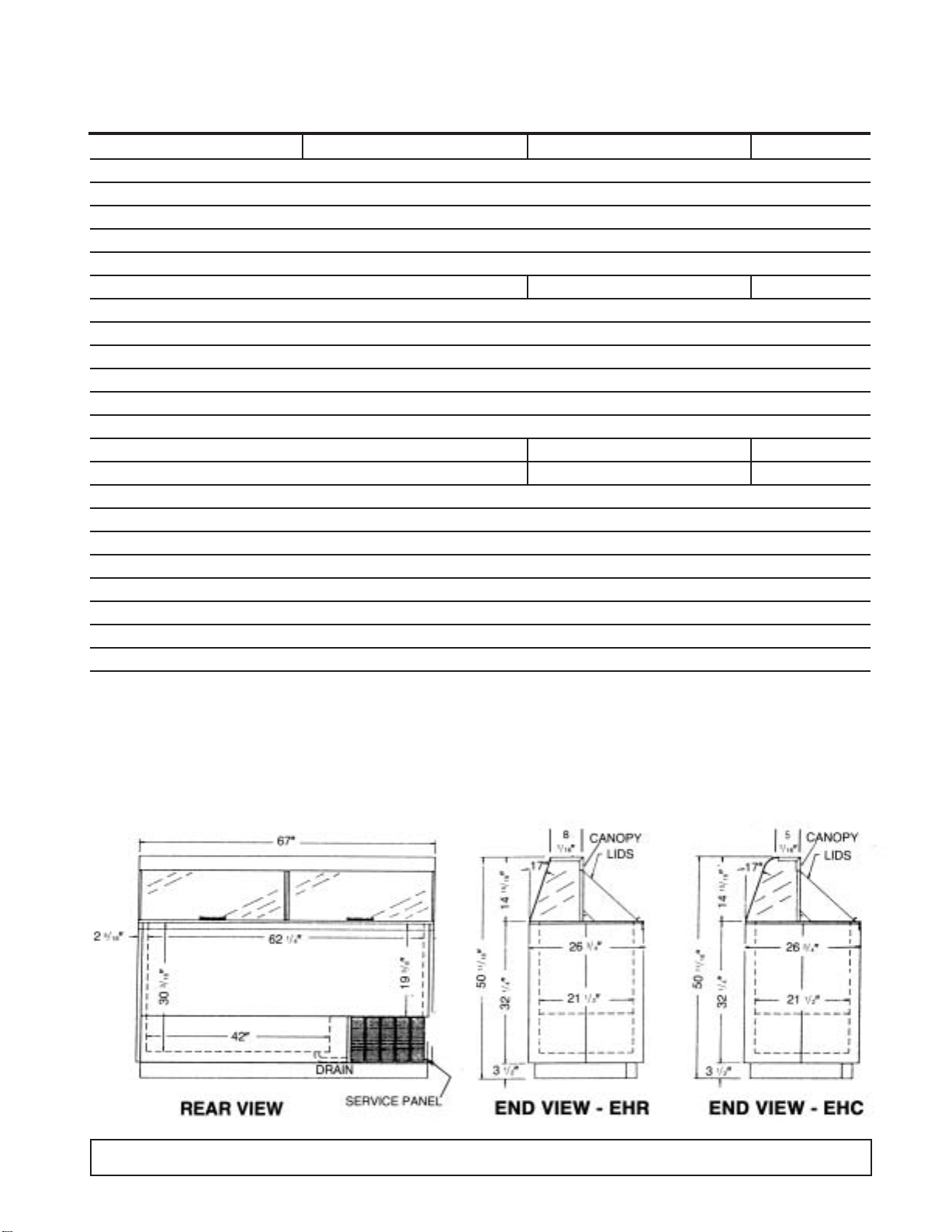

CABINET SPECIFICATIONS

12HC & 12HR ECKDC-67 & EKDC-67 E12HC2 & E12HR2

Temp. Range +10°F to -8°F

Capacity 19.1 Cu. Ft.

Capacity (3 Gal. Tubs) 20

Facings (3 Gal. Tubs) 12

Storage (3 Gal. Tubs) 8

Compressor Size 1/3 Hp. 3/4 Hp. 3/4 Hp.

Shipping Weight (App.) 525 lbs.

Condenser Type Bare Tube

Evaporator Type Cold Wall

Refrigerant R-404A

Refrigerant Control Capillary Tube

Defrost System Manual

Rated Amps 8.0 4.1 4.1

Electrical Specs. 115V., 60 Hz, 1 Ph. 220V, 50 Hz, 1 Ph. 220V, 60 Hz, 1 Ph.

Power Cord Yes

NSF Listing NSF7

Canopy Construction S.S. Top with Glass ends Straight or Curved Front Glass

Lids (Plexiglass) 2 Lid

Interior Finish White Baked Enamel on Galvanized Steel

Exterior Finish White Baked Enamel

Lighting Two 30 Watt Bulbs Standard (32 Watt Bulbs on Special Cabinets with 3500 K Lighting)

Accessories Can Skirt Kit, Lid Locks, Dipperwell, Night Covers, Casters, Legs

DIMENSIONAL DATA

6 INTRODUCTION

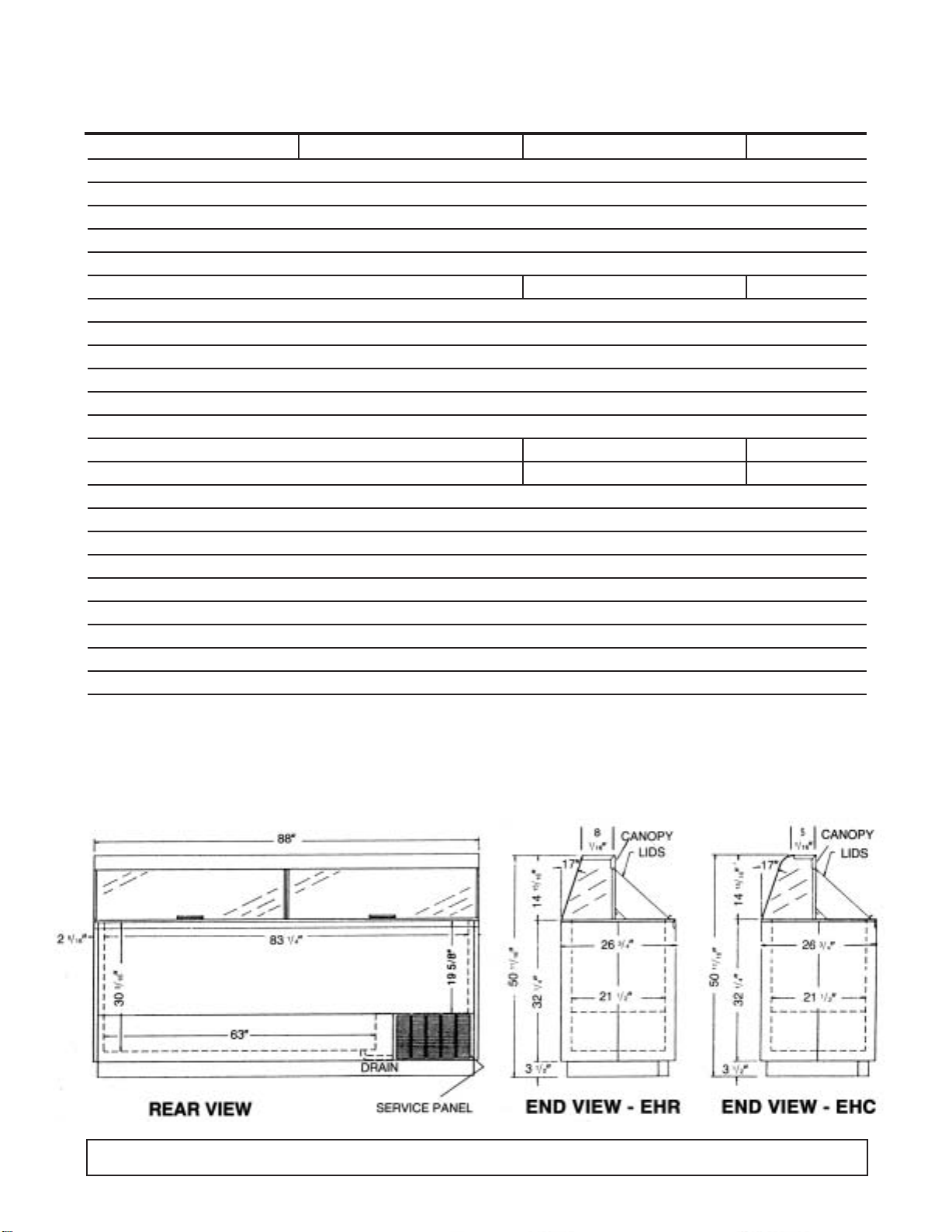

CABINET SPECIFICATIONS

16HC & 16HR ECKDC-87 & EKDC-87 E16HC2 & E16HR2

Temp. Range +10°F to -8°F

Capacity 19.1 Cu. Ft.

Capacity (3 Gal. Tubs) 20

Facings (3 Gal. Tubs) 12

Storage (3 Gal. Tubs) 8

Compressor Size 1/3 Hp. 3/4 Hp. 3/4 Hp.

Shipping Weight (App.) 525 lbs.

Condenser Type Bare Tube

Evaporator Type Cold Wall

Refrigerant R-404A

Refrigerant Control Capillary Tube

Defrost System Manual

Rated Amps 8.0 4.1 4.1

Electrical Specs. 115V, 60 Hz., 1 Ph. 220V, 50 Hz, 1 Ph. 220V, 60 Hz, 1 Ph.

Power Cord Yes

NSF Listing NSF7

Canopy Construction S.S. Top with Glass ends Straight or Curved Front Glass

Lids (Plexiglass) 2 Lid

Interior Finish White Baked Enamel on Galvanized Steel

Exterior Finish White Baked Enamel

Lighting Two 40 Watt Bulbs Standard (32 Watt Bulbs on Special Cabinets with 3500 K Lighting)

Accessories Can Skirt Kit, Lid Locks, Dipperwell, Night Covers, Casters, Legs

DIMENSIONAL DATA

INTRODUCTION 7

HANDLING & INSTALLATION-Illuminated Dipping Cabinets

FREIGHT DAMAGES AND SHORTAGES

IMPORTANT

The cabinet was inspected and packaged at the

factory, and should have arrived in excellent

condition. The transportation company or other

parties involved in the shipment are responsible for

loss and/or “damage.” Always make an inspection

before and after uncrating, pref erab ly at the point of

unloading by the transportation company.

INSPECTING FOR DAMAGES

Note:

Always use care when removing shipping tape,

blocks, pads, hardware or other material. Contact

your dealer or distributor if technical assistance

is required.

Check the cartons or containers. If these are damaged

in any way, open them and inspect the contents in the

driver’s presence. If damage is detected, do the

following:

1. Have the driver note the nature and extent of the

damage on the freight bill.

2. Notify the transpor tation company’s office to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

3. If damage is noticed, file a claim with the

transportation company.

FILING A CLAIM

File a claim for loss at once with the transportation

company for:

A. A cash adjustment B. Repairs C. Replacement

When filing your claim, retain all packaging materials

and receipts.

HANDLING THE CABINET

Note:

The refrigeration system of the cabinet is designed

to operate with the cabinet located on a flat surface.

Do not tilt the cabinet more than 30° to any side. If

the cabinet must be tilted on an angle for handling or

moving purposes, allow it to sit in an upright position

20 to 30 minutes prior to operating.

CHOOSE A LOCATION

This model cabinet should be situated to allow proper air

circulation. The cabinet must be installed on sturdy, level

floor and positioned so that it can be plugged into a

properly grounded three-prong electrical wall outlet. The

electrical outlet should not be controlled by a wall switch

which might be turned off accidentally.

UNCRATING THE CABINET

The cabinet should be moved as close as possible to

the operating location before removing the skid. Be

sure to follow the steps in the “INSPECTING FOR

DAMAGES” instructions.

INSTALLING THE CABINET

Whenever possible leave the crate skid on the cabinet

until it is moved close to the final position. When it is

necessary to move the cabinet through a doorway, it

may be necessary to remove the crate skid.

Run the cabinet down to storage temperature before

adding product.

CAUTION

A. Do not locate cabinet where sunlight or drafts from

fans, air conditioners or open doors can affect product

temperature.

B. Run cabinet before building in or attaching panels or

accessories.

C. Employee side access panel must be kept clear for

adjustments and service.

D. Cabinet must be installed on the finished floor to

assure rear raceway cover and condensing unit

(employee side) can be pulled or removed for service.

DO NOT seal in with cover molding or caulking in the

area where condensing unit pulls out.

E. Do not use extension cords to power this equipment.

Run any necessary electrical, water supply and drain

lines before setting the cabinet in position. Shim under

the cabinet as necessary to level it. N.S.F. approval

requires sealing the cabinet to the floor. This can be

done by applying a bead of mastic sealer between the

cabinet bottom flange and the floor.

Should several cabinets be set up in a row, space is

provided in the rear toe space for routing electrical and

plumbing lines.Access to this space requires removing

screws and the metal cover which runs the length of the

cabinet.

Rivnuts are provided on the operator's side for

mounting dipperwell and other accessories.

CABINET START-UP

Once the cabinet has been located in its permanent

location and the proper power and grounding have

been provided, the following items must be checked or

completed:

A. Cut and remove the compressor hold-down band (if

applicable) so the compressor “floats” freely.

8 INTRODUCTION

B. Check for traces of oil on the compressor pan which

could mean a broken or leaking refrigeration line.

UNDER NO CIRCUMSTANCE SHOULD THE

COMPRESSOR BE STARTED WHEN OIL IS

PRESENT UNTIL INSPECTED BY A SERVICE

TECHNICIAN.

C. INSPECT THE FACTORY WIRING FOR

TERMINALS THAT MIGHT HAVE VIBRATED

LOOSE IN SHIPPING. TIGHTEN ALL SCREW

TYPE TERMINALS.

D. Check the refrigeration lines to see that they are

“free” and no damage was done during shipping.

E. Check fan blade for free operation.

F. Turn on the main power switch.Once the compressor

starts, the voltage should be checked at the

compressor terminals to determine if there is proper

voltage to the compressor. The voltage should not

exceed the 10% above or below the rated

compressor voltage.

EXAMPLE: If the voltage reads 220 volts with no load

and it drops below 210 volts when the compressor

starts, it may indicate that the supply wiring is too small

or that the wire run is too long.

G. Listen for any unusual noise such as lines vibrating,

etc. Correct the problem by tightening screws,

slightly bending tubing, etc.

H.The temperature control thermostat which is located

in the rear post is factory set for average conditions.

A customer adjustment requires a coin or

screwdriver to turn the slotted shaft.A numbered dial

makes it easy to keep track of adjustments. #1 is

warmest setting and #7 is coldest setting. An “OFF”

position is provided for your convenience in

defrosting the cabinet.

I. Allow the cabinet to pull down and cycle prior to

loading with product (Approx. 24 hours).

GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong

(grounding) plug for your protection against shock

hazards.The appliance should be plugged directly into

a properly grounded three-prong receptacle.

Where a two-prong wall receptacle is encountered, it

must be replaced with a properly grounded three-prong

receptacle in accordance with the National Electrical

Code and local codes and ordinances. The work must

be done by a licensed electrician.

IMPORTANT

Do not, under any circumstance, cut or remove the

round grounding plug from the appliance plug.

WARNING

Consult a licensed electrician if you have any doubt

about the grounding of your wall receptacle. Only a

licensed electrician can determine the polarization of

your wall receptacle. Only a properly installed threepronged wall receptacle assures the proper

polarization with the appliance plug.

IMPORTANT USAGE INSTRUCTIONS

Dipping Cabinet

The cabinet must be located in an area free from air

drafts created by open doors, air conditioning ducts,

and fans. The cabinet should not be located in the

direct sunlight.

The rear grill must be clear of any obstructions so the

intake and exhausting of air f or the condensing unit can

move freely.

Dipping cabinets are designed for use in an air

conditioned store. This cabinet is designed for

merchandising, not hardening of the product.

High humidity can cause fogging of the lid and front glass.

High temperatures, installation of warm product and

heavy usage can cause the product to soften. This

condition will be more noticeable at the top of the cans.

The corners of the cabinets are the coldest areas.

These areas should be used for product that is more

difficult to keep firm.

Frost and ice act as insulators. The need for defrosting

will depend on usage and product firmness.

If the frost is scraped daily with a plastic scraper,

intervals between complete defrosting may be

extended.

Thermostat adjustments should be made one

increment warmer or colder allowing 24 hours between

adjustments to allow the product to stabilize.

INTRODUCTION 9

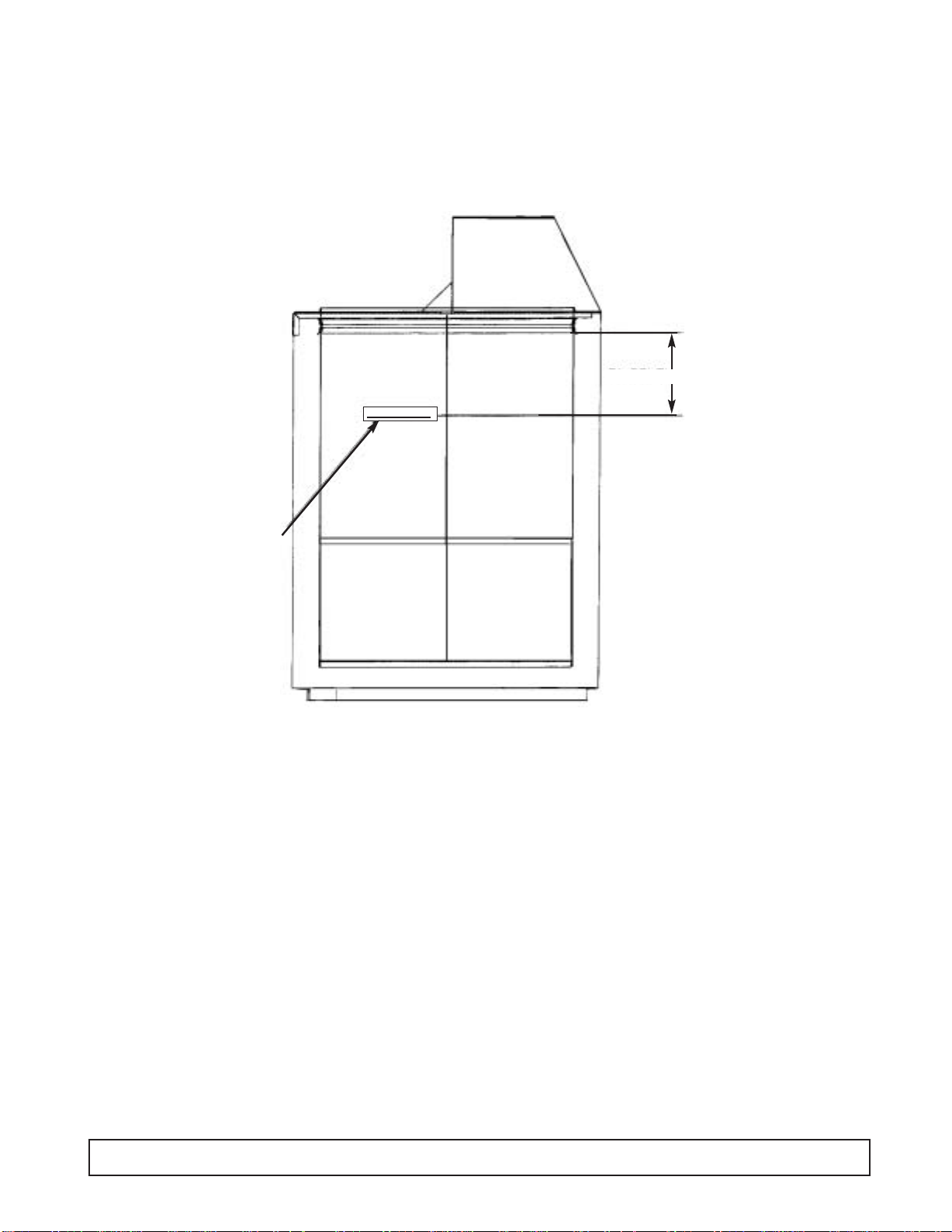

PRODUCT LOAD LINE LOCATION

KEEP PRODUCT BELOW RED LINE

7" BELOW BREAKER

NOTE:

KEEP PRODUCT

BELOW THIS LINE.

10 INTRODUCTION

SECTION II

Principles of

Operation

blank

GENERAL OPERATIONS

All the dipping cabinet models are of the same basic

design, consisting of a bare tube condenser and a cap

tube fed tank wrap evaporator.

Ice formation on the walls over a period of time is

normal. This frost should be scraped off periodically in

order to maintain peak performance. These cabinets

are thermostatically controlled for various temperature

requirements.The thermostat is located post adjacent

to the unit compartment and can be accessed for

adjustment by the user with a screwdriver or a dime.

Thermostat position #1 being the warmest and

position #7 the coldest.

These cabinets are manual defrost and a drain is

provided for periodic cleaning. A garden hose can be

attached to the drain plug for draining away any water

that might have accumulated.This drain attachment is

located in the front base rail of the cabinet.NOTE:The

power supply cord must be disconnected when

cleaning or servicing these cabinets.

NOTE: On initial cabinet pull down the bare tube

condenser may become warm to the touch until

the normal operating temperatures are achieved.

Compressors being used in these cabinets utilize

refrigerant 404A and polyol ester oil. Because of the

hygroscopic nature of this oil, extreme care must be

taken when any component is changed within the

system. In the case of compressor replacement, work

should be completed before the caps are removed

from the compressor.

Agitation of the oil should be kept to a minimum.

Compressors should not be open to the atmosphere

for more than 15 minutes max. Should contamination

occur the oil can be removed and recharged (following

compressor manufacturer's guidelines when

performing this procedure). Because of the porous

nature of plastic, polyol ester oil should be stored in a

metal container. Moisture contained within the oil

cannot be removed even under high vacuum

conditions and must be replaced.

Refer to model serial data tag for cabinet amperage,

refrigerant charge & type.

PRINCIPLES OF OPERATION 13

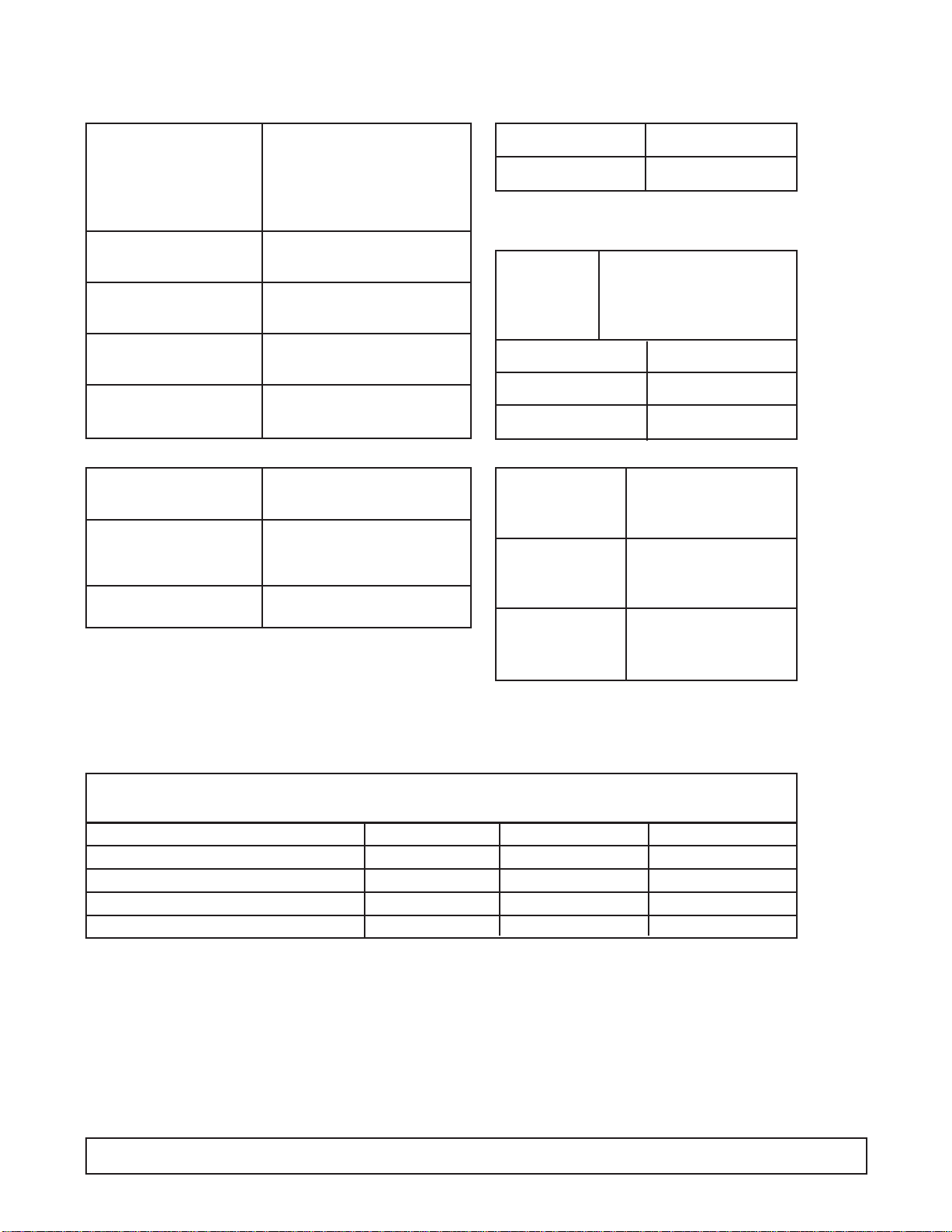

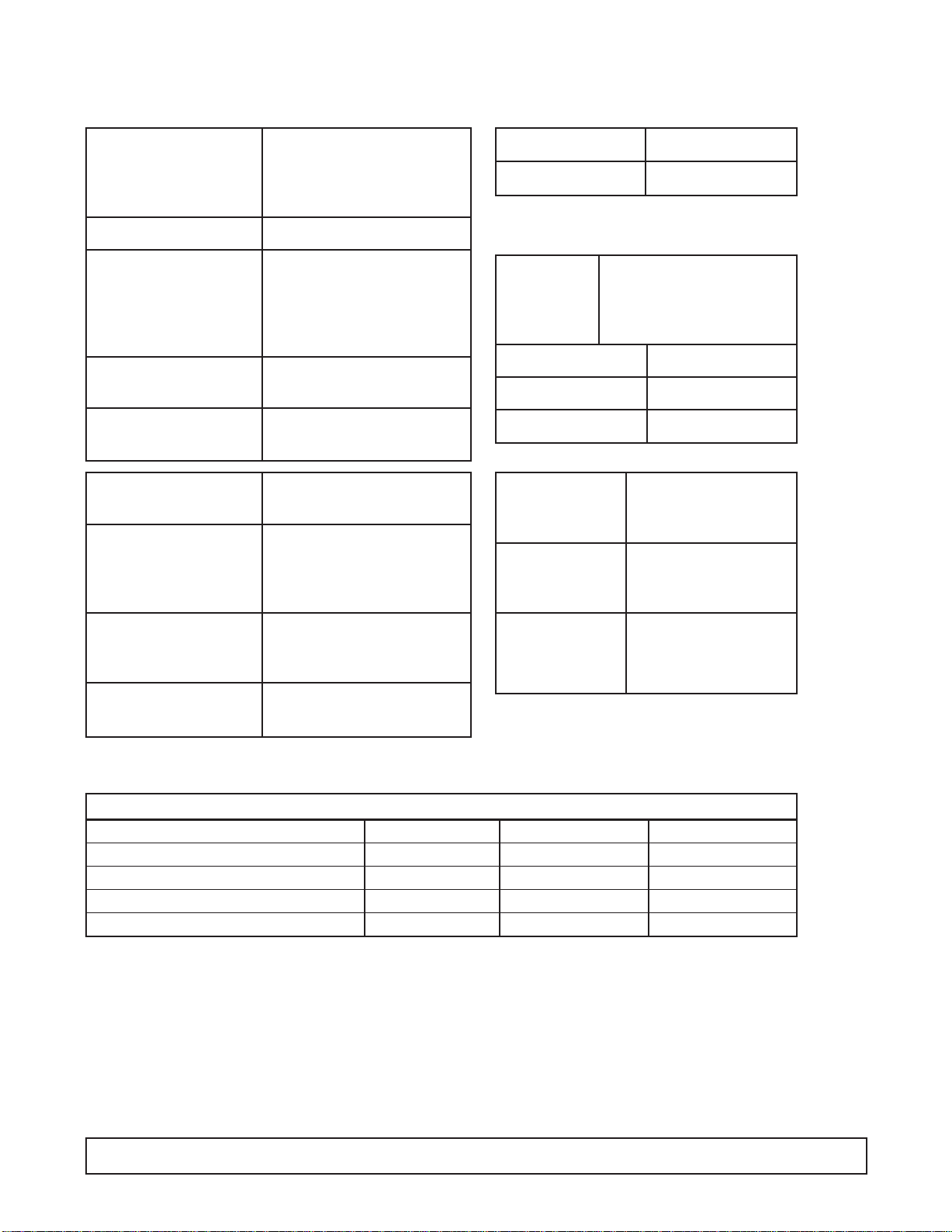

SYSTEM INFORMATION - 4HR & 4HC

ELECTRICAL

Compressor Manufacturer: Americold

Model: HP-110-3083

V.: 115/100 R.L.A.: 2.0

L.R.A.: 10 Phase 1

Overload Protector Americold #1456-3453

Start Relay T.I.: Americold #1456-3372

Start Capacitor V.A.C.: 165 M.F.: 88-108

Run Capacitor V.A.C.: 180 M.F.: 15

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:5KSM51GG-37845

Evaporator Cold Wall

Capillary Tube 7' of .031

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/240 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 14

A.: 15 @ 125V

Light Ballast Manufacturer: G.E.

Model: 89G457

Condenser Diameter: 8" # of Blades: 3

Fan Blade Width of Blades:1 7/8"

REFRIGERATION -

Refrig. Charge: R-404A / 11.5 oz. / 326.02 grams / No.4 Stat Position

Fluorescent Manufacturer: G.E.

Lamp F20T12 CW

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CONTROL SETTINGS #4 C.S. #4 C.S. #4 C.S.

Suction Pressure - C.O. PSIG/Kpa 13 / 13 / 14 /

Discharge Pressure - C.O. PSIG/Kpa 196 / 224 / 246 /

Compressor Amps 1.8 1.8 1.8

Total Cabinet Amps 2.3 2.0 2.0

Cavity Temperature C.L. 0°F / -17°C 2°F / -16°C 3°F / -16°C

14 PRINCIPLES OF OPERATION

SYSTEM INFORMATION - 8HR & 8 HC

ELECTRICAL

Compressor Manufacturer: Americold

Model: HP-117-1

V.: 115/100 R.L.A.: 3.0

L.R.A.: 21.4 Ph.: 1 HP:

Overload Protector Americold #1456-3454

Start Relay T.I.: 8EA1206K1A

Start Capacitor V.A.C.: 165 M.F.: 88-108

Run Capacitor V.A.C.: 200 M.F.: 15

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: Morrill

Fan Motor Model:SPB9S1

Condenser Diameter: 8" # of Blades: 3

Fan Blade Width of Blades:2 3/4"

1

⁄3

Evaporator Cold Wall

Capillary Tube 8' of .036

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/240 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 14

A.: 15 V.: 125

Light Ballast Manufacturer: G.E.

Model: 89G457(STD)

B232I120RH (3500K)

Fluorescent Manufacturer: G.E.

Lamp F20T12 CW (STD)

F17T8 / SP35 (3500K)

REFRIGERATION -

Refrig. Charge: R-404A / 17 oz. / 481.95 grams / No.4 Stat Position

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CONTROL SETTINGS #4 C.S. #4 C.S. #4 C.S.

Suction Pressure - C.O. PSIG/Kpa 9 / 12 / 13 /

Discharge Pressure - C.O. PSIG/Kpa 187 / 228 / 251 /

Compressor Amps 2.9 2.9 2.9

Total Cabinet Amps 3.5 3.5 3.5

Cavity Temperature C.L. 5°F / -15°C 7°F / -13°C 8°F / -13°C

PRINCIPLES OF OPERATION 15

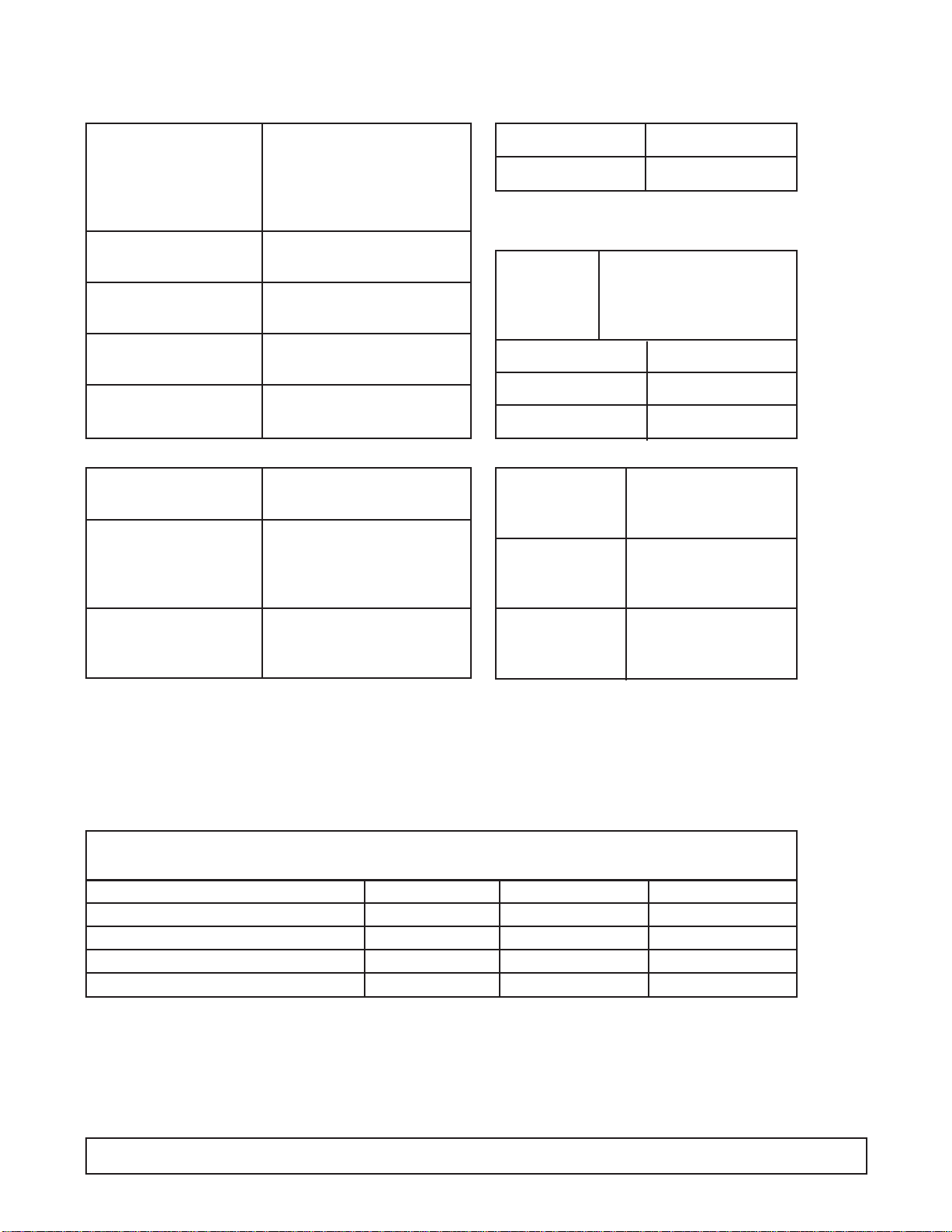

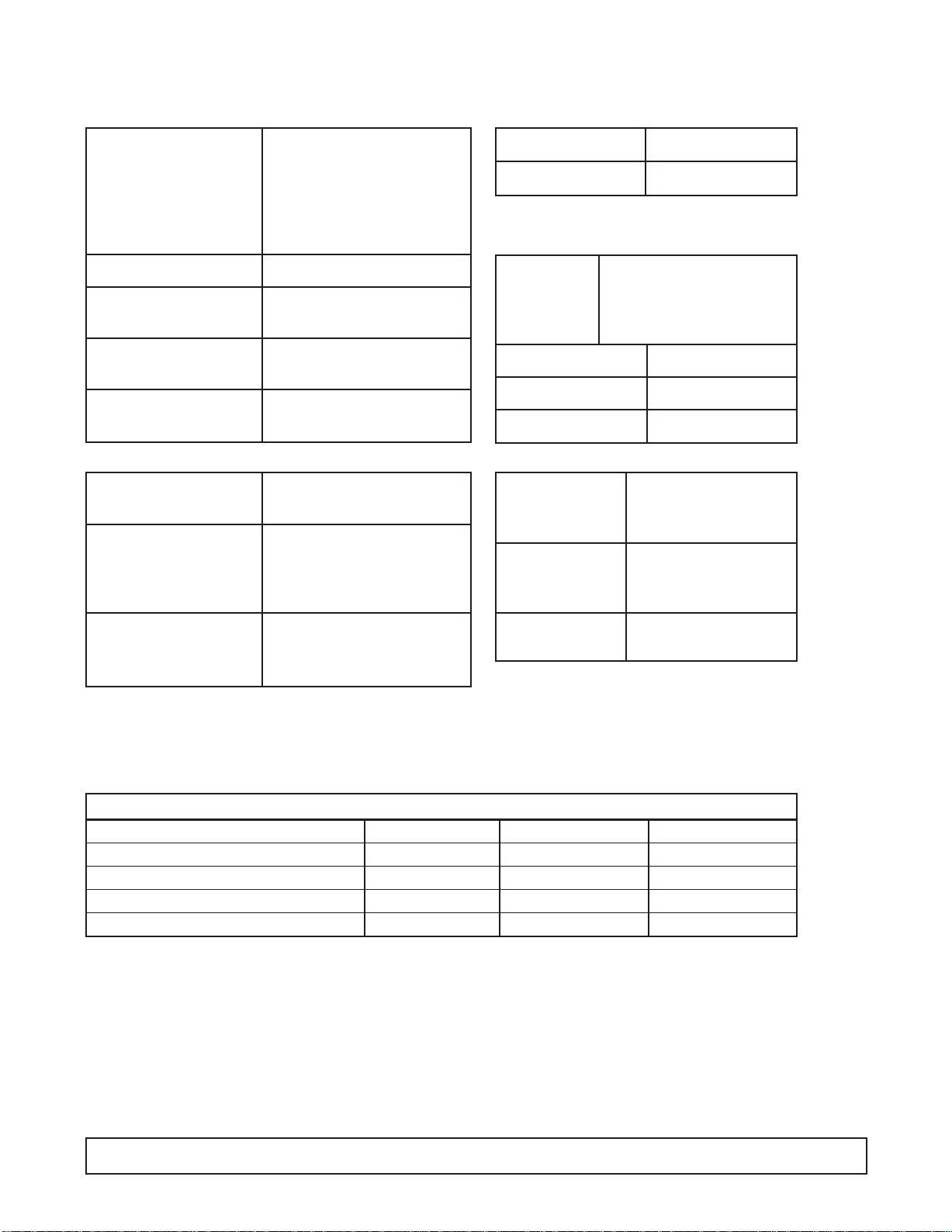

SYSTEM INFORMATION - 12HR & 12HC

ELECTRICAL

Compressor Manufacturer: Americold

Model: HP-127-1

Ph.: 1 Hz.: 60

Volts: 115 Amps: 4.2

Overload Protector Manufacturer: Amer icold

Start Relay Manufacturer: Americold

Start Capacitor V.:125 M.F.: 189-227

Run Capacitor VAC: 370 M.F.: 20

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:5KSM51GG3784

Condenser Diameter: 9.5" # Blades: 3

Fan Blade Width of Blades:1 29/32"

Evaporator Cold Wall

Capillary Tube 7' of .042

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/250 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 16

A.: 15 V.: 125

Light Ballast Manufacturer: G.E.

Model: 89G457(STD)

B232I120RH(3500K)

Fluorescent Manufacturer: G.E.

Lamp F40T12CW (STD)

F32T8/SP35 (3500K)

REFRIGERATION -

Refrig. Charge: R-404A / 25 oz. / 708.75 grams / No.4 Stat Position

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CONTROL SETTINGS #4 C.S. #4 C.S. #4 C.S.

Suction Pressure - C.O. PSIG/Kpa 9 / 10 / 11 /

Discharge Pressure - C.O. PSIG/Kpa 198 / 230 / 268 /

Compressor Amps 4.2 4.2 4.3

Total Cabinet Amps 6.1 6.1 6.2

Cavity Temperature 0°F / -17°C 1°F / -17°C 2°F / -16°C

16 PRINCIPLES OF OPERATION

SYSTEM INFORMATION - 16HR & 16HC

ELECTRICAL

Compressor Manufacturer: Americold

Model: HP-127-1

Volts: 115 R.L.A.: 4.2

L.R.A.: — Ph.: 1 Hz.: 60

Overload Protector Americold #1456-3321

Start Relay Americold #1456-3374

Start Capacitor V.:125 M.F.: 189-227

Run Capacitor V.: 370 M.F.: 20

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:5KSM51GG3784

V.: 115 Hz.: 60 Ph.: 1

Evaporator Cold Wall

Capillary Tube 7' of .042

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/240 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 16

A.: 15 V.: 125

Light Ballast Manufacturer: G.E.

Model: 8G3706 (STD)

B232I120RH (3500K)

Condenser Diameter: 9.5" # Blades: 3

Fan Blade Width of Blades:1 29/32"

REFRIGERATION -

Refrig. Charge: R-404A / 27 oz. / 765.45 grams / No.4 Stat Position

Fluorescent Manufacturer: G.E.

Lamp F40T12CW (STD)

F32T8/SP35 (3500K)

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CONTROL SETTINGS #4 C.S. #4 C.S. #4 C.S.

Suction Pressure - C.O. PSIG/Kpa 9 / 10 / 12 /

Discharge Pressure - C.O. PSIG/Kpa 207 / 234 / 262 /

Compressor Amps 3.8 3.8 3.9

Total Cabinet Amps 6.3 6.3 6.3

Cavity Temperature C.L. -.5°F / -18°C -.3°F / -17.9°C -1.2°F / -18.4°C

PRINCIPLES OF OPERATION 17

SYSTEM INFORMATION - E4HR & E4HC (220V / 50 Hz)

ELECTRICAL E4HR2 & E4HC2 (220V / 60 Hz)

Compressor Manufacturer: Americold

Model: HP-110-12-3084

V.: 220 R.L.A.: 2.0

L.R.A.: 12.6 Phase: 1/50Hz.

Overload Protector T.I.: Americold #1456-3444

Start Relay T.I.: Americold #1456-3374

Start Capacitor V.A.C.: 250 M.F.: 108-130

Run Capacitor V.A.C.: 370 M.F.: 7.5

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:5KSM51ECG3905

Evaporator Cold Wall

Capillary Tube 7' of .031

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/240 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 14

A.: 15 @ 125V

Light Ballast Robertson #02025 (50Hz)

Robertson #02026 (60Hz)

Condenser Diameter: 8" # of Blades: 3

Fan Blade Width of Blades:1 7/8"

REFRIGERATION -

Refrig. Charge: R-404A / 11.5 oz. / 326.02 grams / No.4 Stat Position

Fluorescent Manufacturer: G.E.

Lamp F20T12/CW

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CONTROL SETTINGS #4 C.S. #4 C.S. #4 C.S.

Cavity Temperature C.L. 0°F / -17°C 2°F / -16°C 3°F / -16°C

Suction Pressure - C.O. PSIG/Kpa 12 / 82 13 / 89 14 / 96

Discharge Pressure - C.O. PSIG/Kpa 206 / 1420 214 / 1475 239 / 1647

Compressor Amps 2.0 2.0 2.0

Total Cabinet Amps 2.3 2.3 2.3

18 PRINCIPLES OF OPERATION

SYSTEM INFORMATION - E8HR & E8HC (220V / 50 Hz)

ELECTRICAL E8HR2 & E8HC2 (220V / 60 Hz)

Compressor Manufacturer: Americold

Model: HP-118-12

V.: 220 R.L.A.: 3.0

L.R.A.: 12.6 Phase: 1/50Hz.

Overload Protector Americold #1456-3321

Start Relay T.I.: 8EA14

Start Capacitor V.A.C.: 250 M.F.: 108-130

Run Capacitor V.A.C.: 370 M.F.: 7.5

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:5KSM51ECG3905

Evaporator Cold Wall

Capillary Tube 8' of .036

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 120/240 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 14

A.: 15 @ 125V

Light Ballast Robertson #02026

Condenser Diameter: 8" # of Blades: 3

Fan Blade Width of Blades:1 7/8"

REFRIGERATION -

Refrig. Charge: R-404A / 17 oz. / 481.95 grams / No.4 Stat Position

Fluorescent Manufacturer: G.E.

Lamp F20T12/CW

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CONTROL SETTINGS #4 C.S. #4 C.S. #4 C.S.

Cavity Temperature Range 5°F / -15°C 7°F / -13°C 8°F / -13°C

Suction Pressure - C.O. PSIG/Kpa 13 / 89 15 / 103 16 / 110

Discharge Pressure - C.O. PSIG/Kpa 213 / 1468 250 / 1723 292 / 2013

Compressor Amps 2.9 3.0 3.1

Total Cabinet Amps 3.5 3.7 3.7

PRINCIPLES OF OPERATION 19

SYSTEM INFORMATION -

EKDC-67 & ECKDC-67

ELECTRICAL E12HR2 & E12HC2 (220V / 60 Hz)

Compressor Mft: Copeland (3/4 HP)

Model: KAMB-007E-CAV

Phase: 1 Hz.:50

Overload Protector Model No.: 071-0092-29

Start Relay G.E. 3ARR3CT3E5

Pick up: 340-360

Drop out: 45-115

Model No.: 040-0001-03

Start Capacitor V: 220 M.F.: 145-174

Run Capacitor 10UF - 370V

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:KSM51GG3705

Evaporator Cold Wall

Capillary Tube 9' of .049

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 125/250 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 16

Amp: 15

Light Ballast VOSSLOH SCHWABE

Model: L36.291 (50Hz)

Robertson: 1-4026 (60 Hz)

Condenser Diameter: 9-1⁄2"# Blades: 3

Fan Blade Width of Blades:1-29⁄32"

Pressure Switch C.O.: 350# C.I.: 250#

REFRIGERATION -

Refrig. Charge: R-404A / 25 oz. / 708.75 grams / No.4 Stat Position

Fluorescent Manufacturer: G.E.

Lamp F40T12CW

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CAVITY TEMPERATURE 2°F / -17°C 4°F / -16°C 6°F / -14°C

Suction Pressure - C.O. PSIG/Kpa 8 / 55 10 / 69 12 / 82

Discharge Pressure - C.O. PSIG/Kpa 188 / 1246 225 / 1551 253 / 1744

Compressor Amps 7.2 7.1 7.1

Total Cabinet Amps 9.5 9.3 9.4

20 PRINCIPLES OF OPERATION

SYSTEM INFORMATION -

EKDC-87 & ECKDC-87 (220V / 50 Hz)

ELECTRICAL E16HR2 & E16HC2 (220V / 60 Hz)

Compressor Mft: Copeland (3/4 HP)

Model: KAMB-007E-CAV

R.L.A.: 5.6 L.R.A.: 36.0

Phase: 208/230V 60 Hz.

200/220V 50 Hz.

Overload Protector Model No.: 071-0092-29

Start Relay G.E. 3ARR3CT3E5

Start Capacitor V: 220 M.F.: 145-174

Run Capacitor V.: 370 M.F.:10

Condenser Manufacturer: Heatcraft

Condenser Manufacturer: G.E.

Fan Motor Model:KSM51GG3705

Evaporator Cold Wall

Capillary Tube 9' of .049

Thermostat Manufacturer: Ranco

F.L.A.: 25

V.: 125/250 L.R.A.: 100

Warm C ut-in 11° Warm Cut-out —

Mid Cut-in -12° Mid Cut-out -24°

Cold Cut-in — Cold Cut-out -34°

Pow er Cord A.W.G.: 16

Amp: 15

Light Ballast VOSSLOH SCHWABE

Model: L36.291 (50Hz)

Robertson: 1-4025 (60 Hz)

Condenser Diameter: 9-1⁄2"# Blades: 3

Fan Blade Width of Blades:1-29⁄32"

REFRIGERATION -

Refrig. Charge: R-404A / 27 oz. / 765.45 grams / No.4 Stat Position

Fluorescent Manufacturer: G.E.

Lamp F40T12CW

AMBIENT TEMPERATURE 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

CAVITY TEMPERATURE 2°F / -17°C 4°F / -16°C 6°F / -14°C

Suction Pressure - C.O. PSIG/Kpa 8 / 55 10 / 69 12 / 82

Discharge Pressure - C.O. PSIG/Kpa 228 / 1572 257 / 1772 284 / 1958

Compressor Amps 7.4 7.5 8

Total Cabinet Amps 9.5 9.3 10

PRINCIPLES OF OPERATION 21

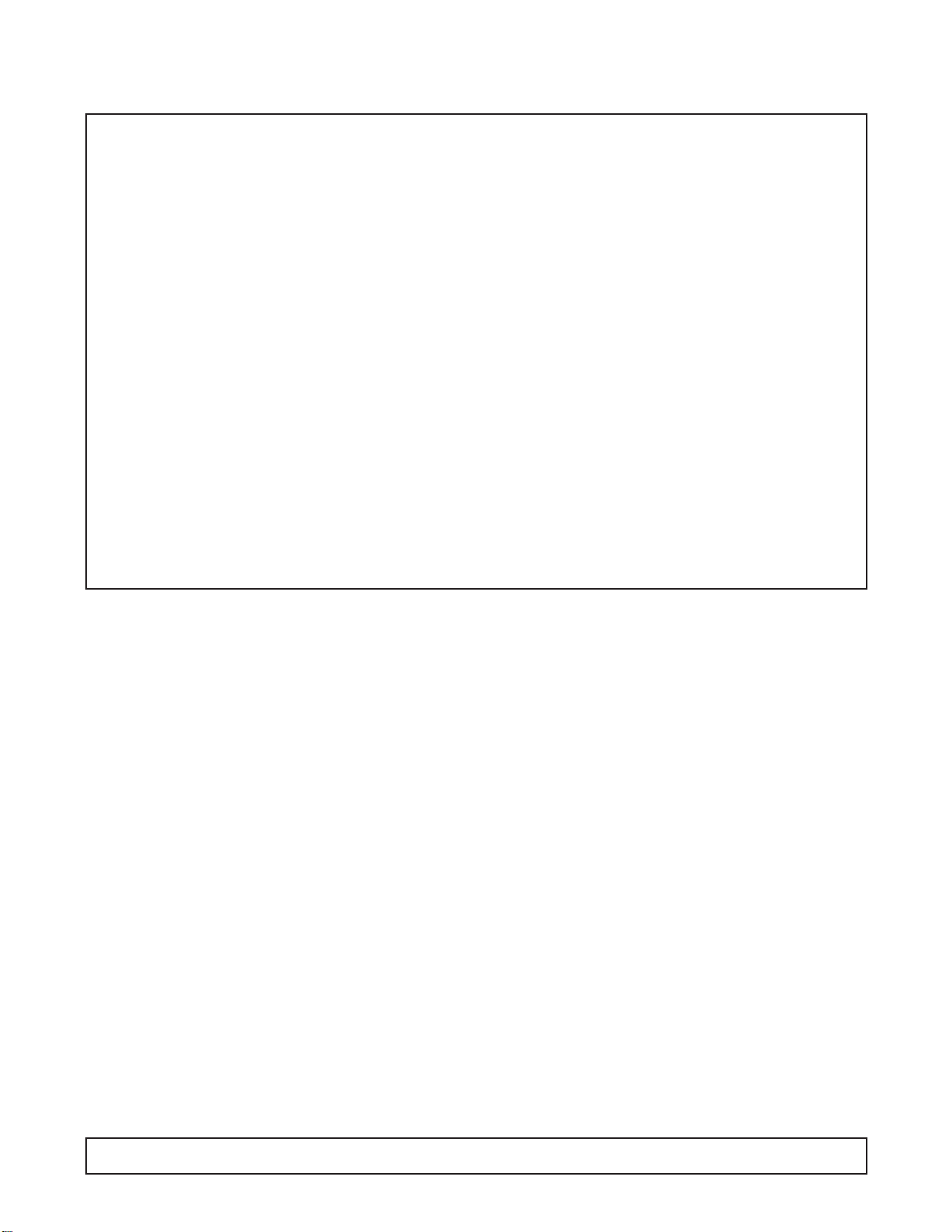

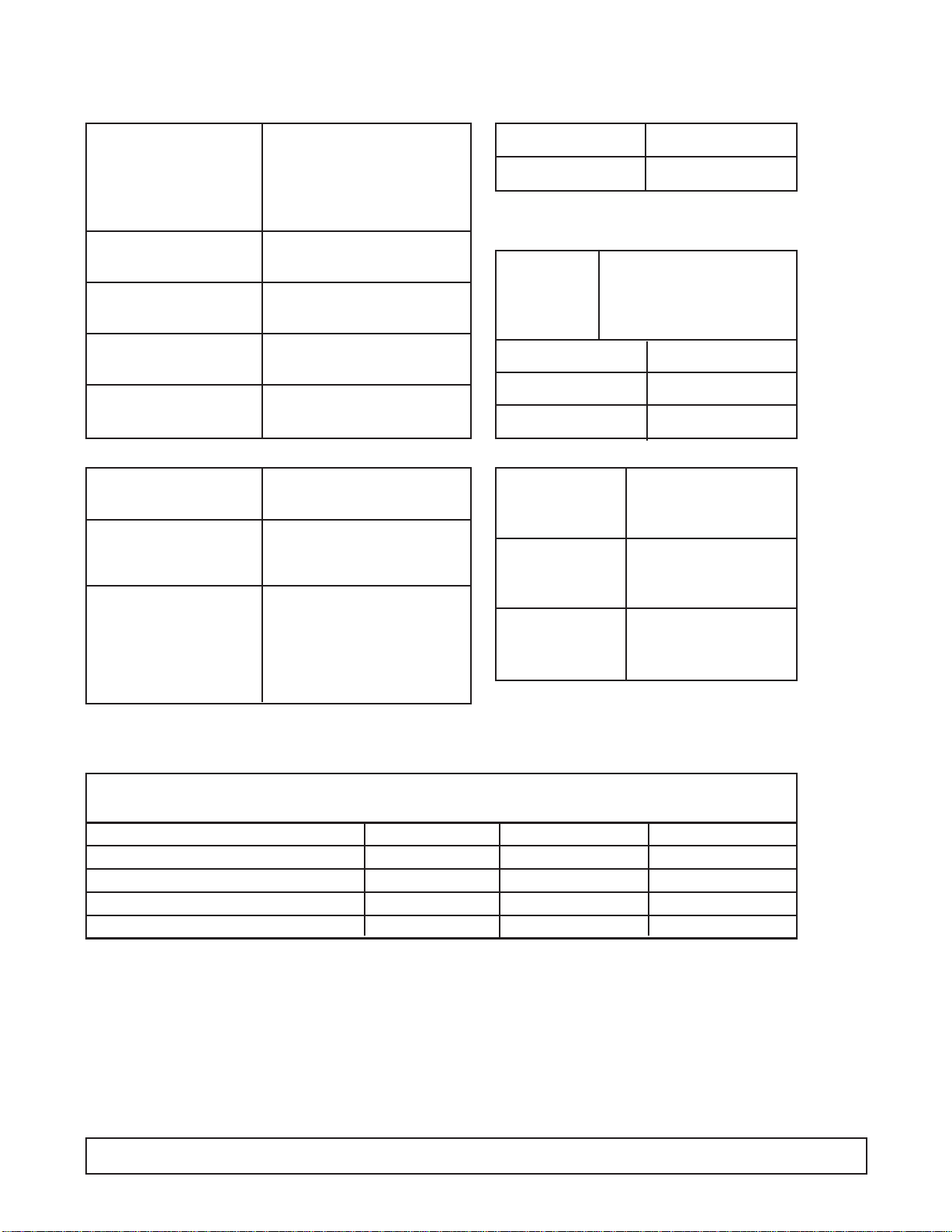

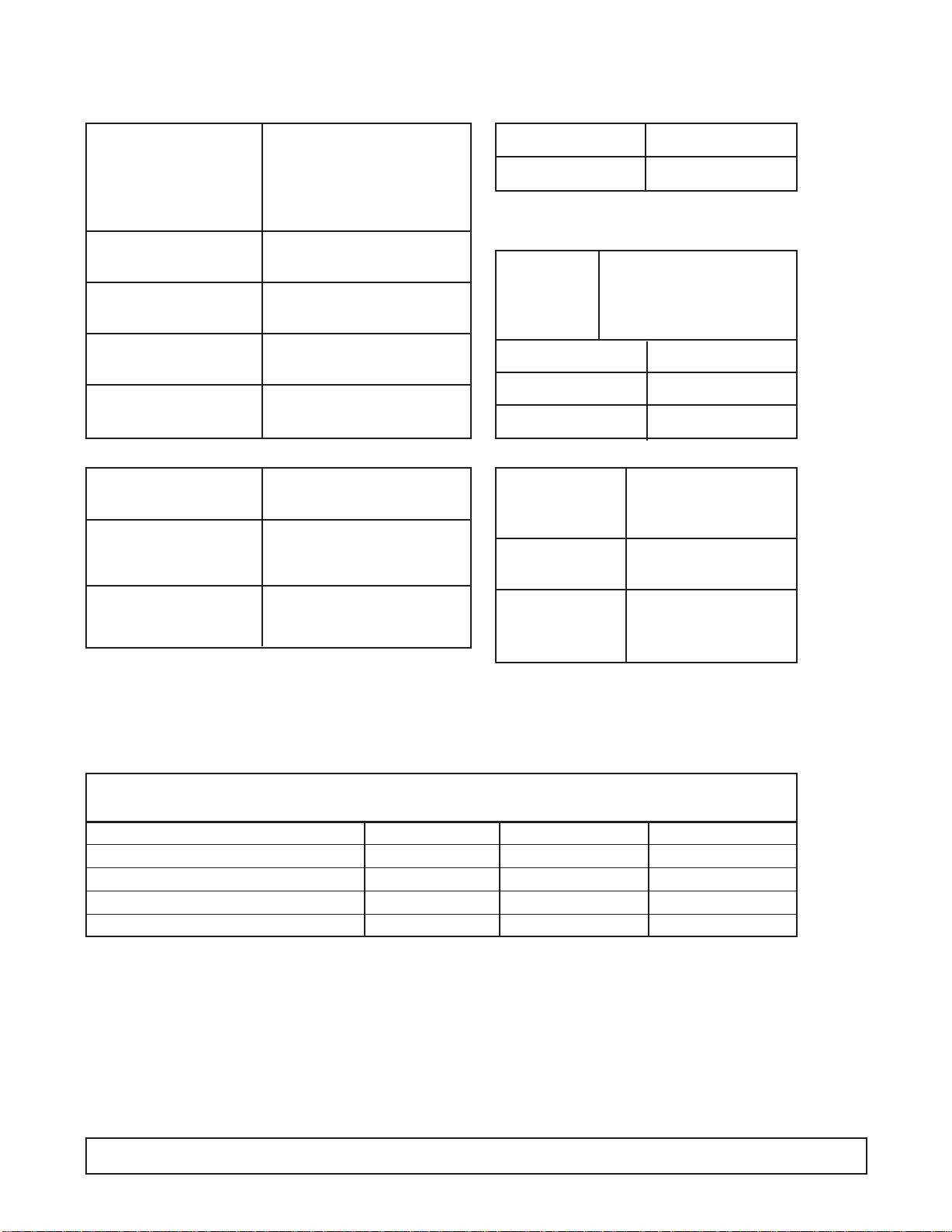

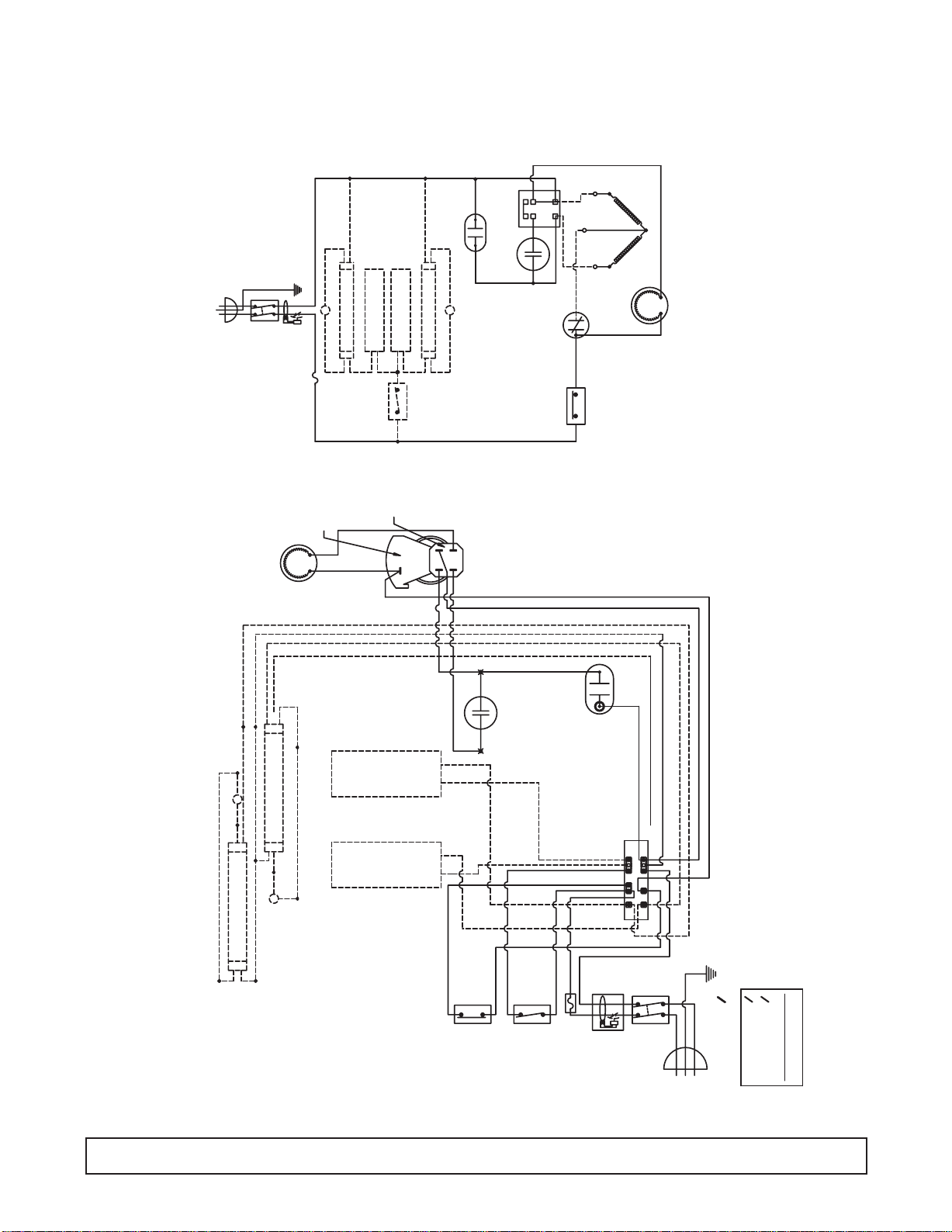

WIRING DIAGRAM - 4HR, 4HC / 8HR, 8HC

E4HR, E4HC / E8HR, E8HC

E4HR2, E4HC2 / E8HR2, E8HC2

SWITCH

SUPPLY

FAN MOTOR

S

GFCI

FUSE

BLACK WHITE

MOTOR PROTECTOR

LAMP

BALLAST

SWITCH

LIGHT

(PTCR)

BALLAST

LAMP

R

C

S

COMPRESSOR

RUN CAP.

(PTCR)

START CAP.

1

2

3

4

S

PROTECTOR

MOTOR

CONTROL

TEMP.

1

2

4

3

TERMINAL BOX

COMPRESSOR

FAN MOTOR

-THE 8HF/4HJ/8HJ HAVE NO LIGHTS.

WIRE DIAGRAM

00-C-2030-00 F

NOTES: -RED WIRE IS AN EXTRA WIRE.

-THE 4HR AND 4HC HAS ONLY ONE LIGHT.

BLUE

S

LAMP

WHITE

BLUE

LAMP

S

BALLAST

BALLAST

BLUE

BLACK

YELLOW

BLACK

BLACK

TEMP.

BLK.BLK.

BLACK

CONTROL

BLACK

BLACK

START CAP.

BLACK

BLACK

LIGHT

SWITCH

( SEE NOTES)

BLACK

BLACK

FUSE

RUN CAP.

WHITE

(SOME MODELS)

TERMINAL

ELB

(SOME MODELS)

BOARD

1

3

5

BLACK

RED (EXTRA)

2

4

6

SWITCH

SUPPLY

WHITE

BLUE

BLACK

L1

(BROWN)

BLUE

WHITE

WHITE

(L2) N

BLACK

(BLUE)

OR

220 VAC. 60 Hz.-10

POWER SUPPLY

115 VAC. 60 Hz.-10

115 VAC. 60 Hz.-10

POWER SUPPLY

220 VAC. 50 Hz.-10

POWER SUPPLY FOR

EXPORT MODELS ONLY

ELECTRICAL INFORMATION.

SEE SERIAL PLATE FOR

22 PRINCIPLES OF OPERATION

Loading...

Loading...