Page 1

SERVICE &

INSTALLATION

MANUAL

Chest

Freezers

51-1371-04

02/03

CARRIER COMMERCIAL REFRIGERATION, INC.

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

Page 2

If additional information is necessary, call the factory.

Our toll free number is 1-800-684-1199.Technical assis-

tance engineers are willing to assist you in any way possible. Office hours are from 7:30 a.m. to 5:30 p.m.,

Eastern Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

All data and information in this manual is subject to change without notice.

MODEL DESIGNATION INFORMATION

115V, 60HZ

PAR T N O. MODELS

52-1904-21 2SF-13

52-1904-22 4SF-13

52-1904-23 4DF-13

52-1904-24 6DF-13

52-1904-25 8DF-13

52-1904-33 8FR-13

52-1904-26 10DF-13

52-1904-27 14DF-13

52-2034-01 DI4-2

EXPORT 220V, 50HZ

PAR T N O. MODELS

52-1904-34 E2SF-13

52-1904-35 E4SF-13

52-1904-36 E4DF-13

52-1904-37 E6DF-13

52-1904-38 E8DF-13

52-1904-39 E8FR-13

Page 3

SECTION I

General

Maintenance

& Repair

Ice Cream Cabinets

Except for routine cleaning, these chest freezers

require little maintenance. In the unusual event

that repair should be necessary , this manual presents information that is helpful in maintaining,

diagnosing, and repairing these cabinets.

Page 4

Table of Contents

GENERAL MAINTENANCE & REPAIR

Installation/Operation .......................................................... 3

Grounding Instructions ...................................................... 4

Cleaning Instructions .......................................................... 5

Defrosting Instructions ...................................................... 6

2SF / 4DF / 4SF / DI4 Specs. & Drawings .......................... 7

6DF / 8DF / 10DF / 14DF Specs. & Drawings .................... 8

8FR Specs. & Drawings ...................................................... 9

General Operations Information ........................................ 10

Cabinet Construction ........................................................ 10

Cooling Tank Assembly .................................................... 10

Chamber Guards .............................................................. 10

Replacing Chamber Guards .............................................. 11

Lids .................................................................................. 11

Replacing Stainless Steel Top Cap .................................... 11

Refrigerating Systems ...................................................... 11

Condenser ........................................................................ 11

Filter Drier ........................................................................ 12

Capillary Tube .................................................................. 12

Heat Exchanger ................................................................ 12

Replacing Heat Exchanger ................................................ 12

Refrigerant Cycle - Condenser & Evaporator .................. 13

Electrical Service .............................................................. 14

Thermostat ...................................................................... 14

Condensate Heater ............................................................ 15

Motor & Relay .................................................................. 16

Checking For Electrical Trouble ........................................ 17

Refrigeration Service: Compressor Installation ................ 17

Refrigerant Service .......................................................... 17

Cleaning System After Burnout ........................................ 19

Wiring Diagram: Chest Models ........................................ 20

ELECTRICAL & REFRIGERATION

SPECIFICATIONS

2SF-13 & 4SF-13 (R-404A) .............................................. 21

4DF-13 & 6DF-13 (R-404A) .............................................. 22

8DF-13 / 8FR-13 & 10DF-13 (R-404A) ............................ 23

14DF-13 & DI4-1 (R-404A) .............................................. 24

PAR TS LISTS

Cabinet Parts Illustration (R-404A) .................................. 26

Cabinet Parts Listing (R-404A) ........................................ 27

Cabinet Parts Listing (R-404A) Export................................28

Condensing Unit Comp. Listing (R404A) Export ................29

Condensing Unit Compartment Illustration (R404A) ..........30

Condensing Unit Compartment Listing (R404A) ................31

Condensing Unit Compartment Illustration & Listing

Model DI4-1........................................................................32

8FR Parts Listing (R-404) & Accessory Mounting .......... 33

Cleaning Chocolate & Syrup Pumps ................................ 33

Accessory Mounting Limitations ...................................... 34

Caster Assembly Installation ............................................ 35

2TABLE OF CONTENTS

Page 5

Installation & Operation Instructions

These instructions include information which is intended

to assure the operator of correct installation, operation,

and service. Before attempting installation, adjustment

or maintenance, be certain of the following:

1.That you have read and fully understand the instructions.

2.That you have all the tools required and are trained to

use them.

3.That you have met all installation and usage restrictions and are familiar with the functions and operation

of the unit.

4.That you follow all instructions exactly as given.

All fittings, measurements, procedures and recommendations are significant. Substitutions and approximation

must be avoided. Improper handling, maintenance,

installation and adjustment or service attempted by anyone other than a qualified technician, may void the

future warranty claims and cause damage to the unit

and/or result in injury to the operator and/or bystanders.

Record for Service

Model No. __________________________________

Serial No. ____________________________________

Installation Date ______________________________

Invoice Date__________________________________

Start-up Date ________________________________

Telephone for Service __________________________

INSTALLATION INSTRUCTIONS

Thermostat will maintain approximately zero degrees on

the original factory setting. Turn the adjusting screw

clockwise for colder and counterclockwise for warmer.

IMPORTANT: Turning control counterclockwise to the

stop shuts cabinet "OFF".

For storage of package ice cream, turn thermostat to

coldest position. Limit top layer of package to a height

consistent with cabinet usage and turn over of product.

LOCATION

Select a location for the cabinet which will be most convenient for the customer and which will allow adequate

air circulation.Restricted air flow will result in higher condensing pressures and operating costs.

Provide at least a 1-inch space around the exterior of

the cabinet. The outside shell is the condenser and

depends on the natural convection of room air for dissipation of its heat. Stainless or formica facing sheets

applied to the cabinet exterior should be in tight contact

with the cabinet's outer walls to improve the heat flow.

When a cabinet is built into a counter or back-bar and

space is allowed between the counter and the cabinet

walls, provide holes or louvers along the top edge f or hot

air to escape.Holes should be screened to keep insects

and rodents out.

IMPORTANT: Before building any piece of equipment

in, run it to be sure the operation is satisfactory.

BE SAFE. SEE ILLUSTRATION ABOVE.

When a cabinet is installed in a moving vehicle, use the

original crate mounting angles or equivalent to securely

bolt the cabinet to the vehicle floor so it won't move

going around corners or during sudden starts and stops.

INSTALLATION & OPERATION 3

Important information is contained in

these instructions which should be

retained in a convenient location for

future reference.

Page 6

Grounding Instructions

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazards.The

appliance should be plugged directly into a properly

grounded three-prong receptacle.

Where a two-prong wall receptacle is encountered, it

must be replaced with a properly grounded three-prong

receptacle in accordance with the National Electrical

Code and local codes and ordinances. The work must

be done by a licensed electrician.

IMPORTANT

Do not, under any circumstances cut or remove the

round grounding prong from the appliance plug.

WARNING

Consult a licensed electrician if you have any

doubt about the grounding of your wall

receptacle. Only a licensed electrician can

determine the polarization of your wall

receptacle. Only a properly installed threeprong wall receptacle assures the proper

polarization with the appliance plug.

4 GROUNDING INSTRUCTIONS

20 Amp

15 Amp

15 Amp

20 Amp

Page 7

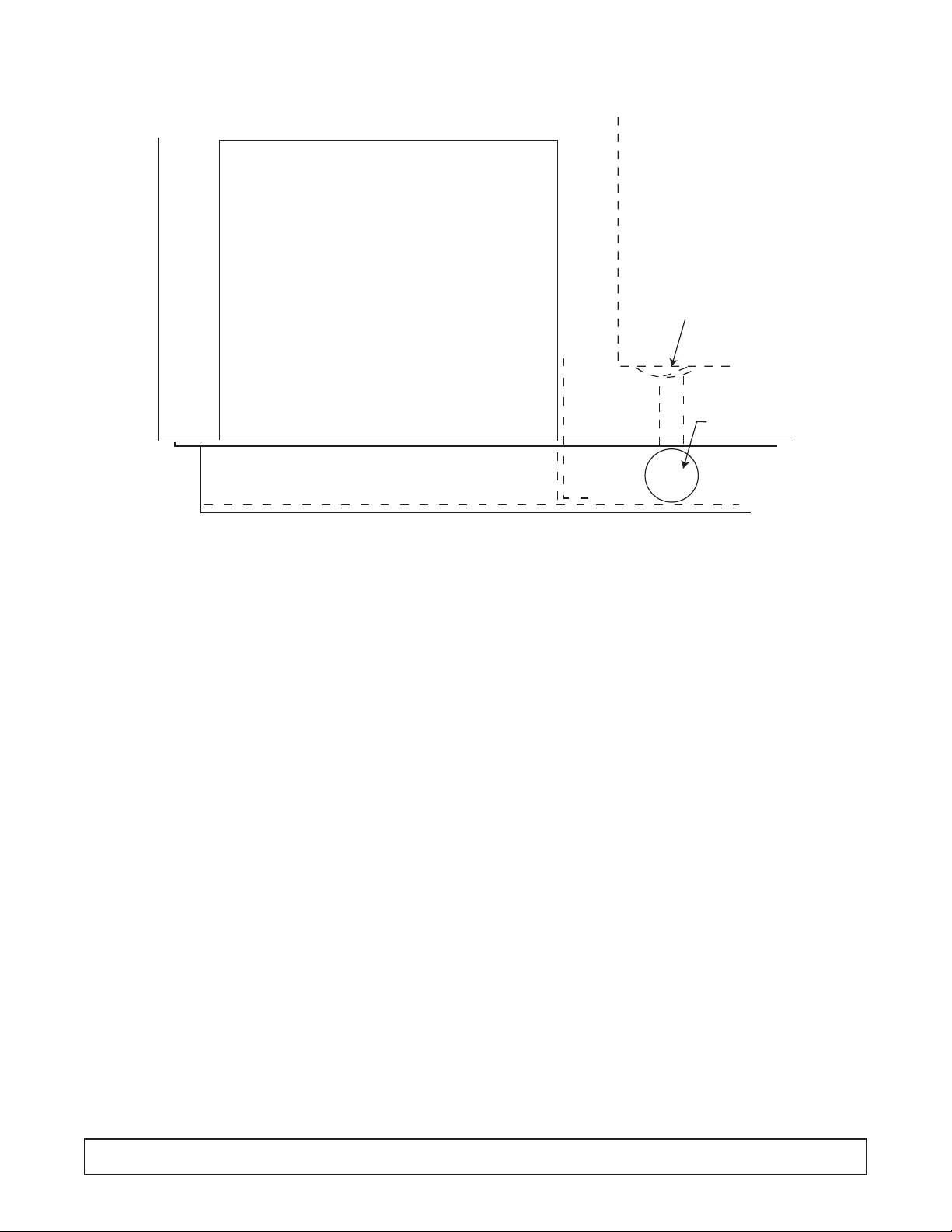

FIG. 2

Cleaning Instructions

DIRECTIONS FOR PROPER CARE &

CLEANING

1.Wipe up spilled foods promptly.

2. Use lukewarm detergent solution for cleaning the

cabinet interior, exterior, and lids.Follow with a clean,

damp cloth and then wipe dry.

3. Protect the exterior enamel finish and plastic lid frame

with automotive type cleaner and wax.

4. Protect all stainless steel surfaces with a commercial

silicone emulsion type cleaner.This cleaner is excellent for all stainless steel surfaces. It leaves a protecting film that prevents fingermarking and the adherence of food particles.

5. CAUTION:

a. Never use naptha or solvent type cleaner on plas-

tic parts or lid frames.

b. Never u se harsh abrasive polishes on plastic parts

or plastic lid frames.

c. Do not blow steam or dash excessively hot water

against plastic materials when cleaning the tank or

defrosting, as damage to plastic parts may occur.

6.When the cabinet is taken out of service for more than

a short period:

a. Remove lids. (DO NOT replace them on the cabi-

net until the cabinet is again refrigerated.)

b. Defrost cabinet and remove any spilled ice cream

from the chamber guards.

c.Wash and dry chamber guards and cabinet interi-

or.(See Item 2 above.)

INSTRUCTIONS FOR SEALING

CABINET TO FLOOR

The National Sanitation Foundation recommends these

cabinets be sealed to the floor to prevent w ater, dirt and

vermin, etc. from getting under the cabinet. The instructions below meet their requirements.

1. Position and level the cabinet.

2. Draw outline of the base on the floor.

3. Raise and block the front side of the cabinet as illustrated in FIG. 1.

4. Apply a bead of mastic (See approved list below) to

the floor one half inch inside the outline drawn. (See

FIG. 2.) Bead must be heavy enough to compress at

all points when the cabinet is set down.

5. Raise and block the rear of the cabinet as illustrated

in FIG. 1.

6. Apply mastic on the floor as outlined in step 4 on the

other three sides.

7. Examine to see that cabinet is sealed to floor around

entire perimeter.

NOTE. Asphalt floors are very susceptible to chemical

attack. A layer of tape on the floor prior to applying the

mastic will protect the floor.

APPROVED MASTICS

3M #EC800 ............................................................Caulk

3M #EC2185 ..........................................................Caulk

3M #EC1055 ..........................................................Bead

3M #EC1202 ..........................................................Bead

Armstrong Cork ........................................Rubber Caulk

Products Research Co.#5000..................Rubber Caulk

G.E. Silicone Sealer

CLEANING INSTRUCTIONS 5

FIG. 1

Page 8

Defrosting Instructions

A drain fitting is located in the bottom of the storage

tank.To drain the defrost water:

1. Remove and store products in another freezer.

2. Loosen and remove any items such as ice cream,

nuts, berries, paper labels, etc., which could plug the

bottom drain.

3. Remove the cap from the drain hose fitting.

4. Connect a hose to the fitting and run it to a floor drain,

a shallow (2" high maximum) pan, or to a “Filordrain”

at the sink.

5. Disconnect the cabinet by pulling the plug or turning

the thermostat off to melt down the frost.You can hasten the defrost by using the “Filordrain” or a hose to

spray warm water on the cabinet walls. (Detailed

instructions for using the “Filordrain” for spraying the

frost and removing the accumulated water are available from your dealer.)

6. Recap hose fitting after defrosting is complete.

6 GROUNDING INSTRUCTIONS

COMPRESSOR COMPARTMENT

DRAIN IN LINER

DRAIN CAP

Page 9

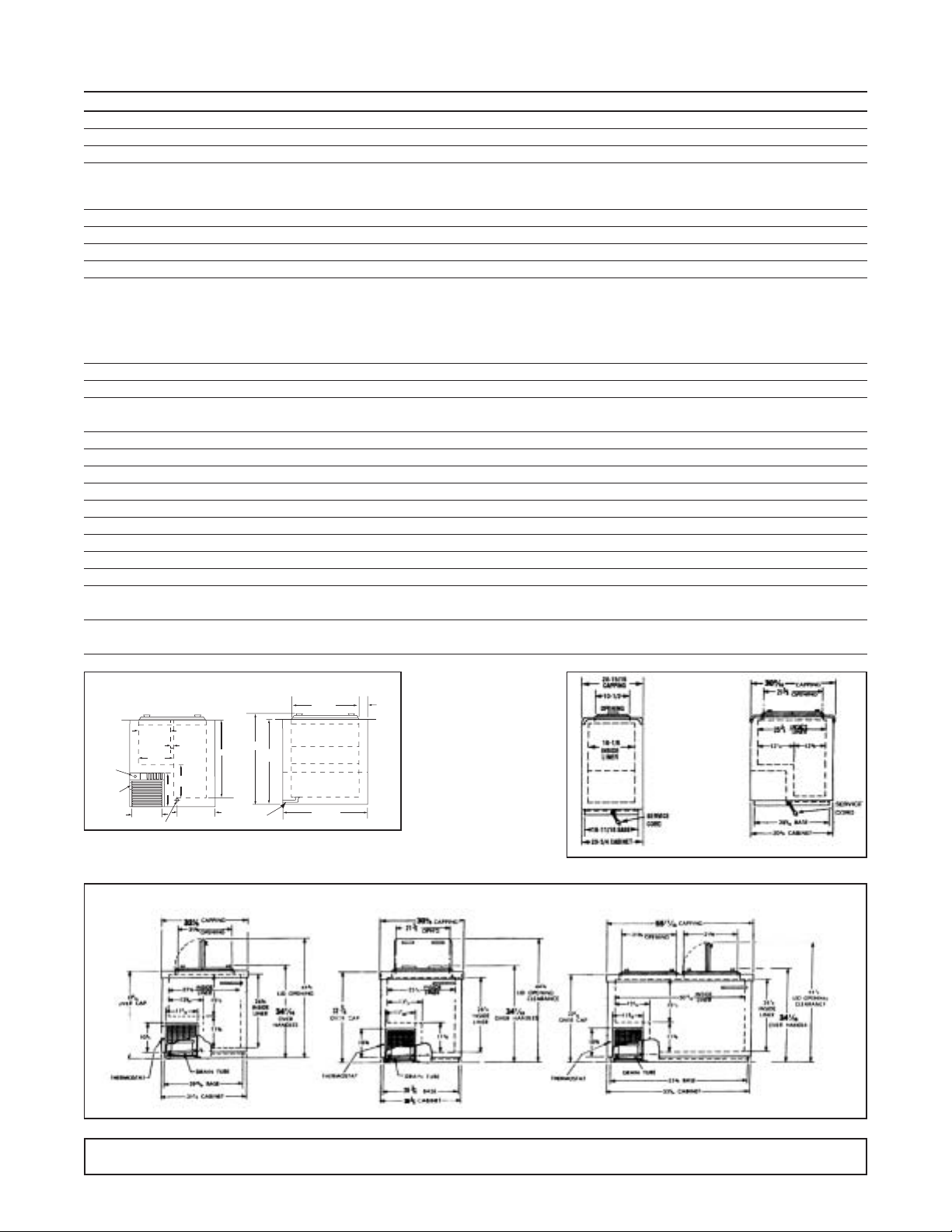

Specifications - Specifications Subject to Change without Notice.

DI4 2SF 4DF 4SF

Compressor Mount Front Front Front Front

Temperature Range 0° to -20°F (-18° to -29°C) 0° to -25° 0° to -25° 0° to -20°

Number of Lids 2 2 2 4

Lid Construction Stainless Steel, High Density, High Density, Foamed-in-Place High Density, Foamed-in-Place High Density, Foamed-in-Place

Foamed-In-Place Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets

Insulation w/ Vinyl Gaskets

Hinge Type Continuous Composition Continuous Composition Continuous Composition Continuous Composition

Insulation Polyurethane Foam Polyurethane Foam Polyurethane Foam Polyurethane Foam

Wall Thickness 2-1/4" 2-5/16" 2-5/16" 2-5/16"

Capacity 4.9 cu. ft. 5.4 cu. ft. 9.1 cu. ft. 11.3 cu. ft.

Capacity

3 gal. (9-

1

⁄2" I.D.) cans 6 4 9 10

2-

1

⁄2 gal. (9" I.D.) cans 6 5 10 13

2-

1

⁄2 gal.(9-1⁄4" I.D.) cans 6 5 12 15

1

⁄2 gal. packages — 63 116 136

Shipping Weight 210 lbs. 212 lbs. 247 lbs. 294 lbs.

Compressor Size 1/5 HP 1/5 HP 1/5 HP 1/5 HP

Condenser Type Forced Convection No-clog, Wrap-around No-clog, Wrap-around No-clog, Wrap-around

Radiant Shell Radiant Shell Radiant Shell

Evaporator Type Cold Wall Cold Wall Cold Wall Cold Wall

Refrigerant Type R404A R-404A R-404A R-404A

Refrigerant Control Capillary Capillary Capillary Capillary

Defrost System Manual Manual Manual Manual

Amp Draw 2.0 2.0 2.0 2.0

Electrical Specs. (V/Hz/Ph) 115/60/1 115/60/1 115/60/1 115/60/1

NSF-7 (Ice Cream Storage) Yes Yes Yes Yes

UL & CUL Listed Yes Yes Yes Yes

Interior Finish Baked Enamel on Galvanized Steel Baked Enamel Baked Enamel Baked Enamel

Exterior Finish Unpainted Galvannealed Steel Baked Enamel Baked Enamel Baked Enamel

w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap

Electrical Information Conduit Connected, Max. Fuse 15 Amp Service Cord 15 Amp Service Cord 15 Amp Service Cord

Size: 15 Amp, Circuit Ampacity: 15A NEMA 5-15P Plug NEMA 5-15P Plug NEMA 5-15P Plug

DI4 / 2SF / 4DF / 4SF SPECIFICATIONS 7

SF

Side View

DF

Side View

DI4 Front View

DI4 Side View

Model 2SF

Model 4DF Model 4SF

Thermostat

on Side

Handy

Box

10 7/8"

TYP.

1/2"

11 1/8"

13"

13"

Drain

12 1/8"

10 1/8"

25 1/2"

29 3/8"

Connector for

Drain Hose

27 3/4"

22 1/4"

SQ.

21 5/8"

Reach In Opening

2 1/4"

TYP.

Page 10

8 6DF / 8DF / 10DF / 14DF SPECIFICATIONS

Specifications - Specifications Subject to Change without Notice.

6DF 8DF 10DF 14DF

Compressor Mount Front Front Front Front

Temperature Range 0° to -20°F 0° to -20° 0° to -20° 0° to -25°

Number of Lids 4 4 6 8

Lid Construction High Density, Foamed-In-Place High Density, Foamed-in-Place High Density, Foamed-in-Place High Density, Foamed-in-Place

Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets Insulation w/ Vinyl Gaskets

Hinge Type Continuous Composition Continuous Composition Continuous Composition Continuous Composition

Insulation Polyurethane Foam Polyurethane Foam Polyurethane Foam Polyurethane Foam

Wall Thickness 2-5/16" 2-5/16" 2-5/16" 2-5/16"

Capacity 14.1 cu. ft. 18.6 cu. ft. 23.6 cu. ft. 31.5 cu. ft.

Capacity

3 gal. (9-

1

⁄2" I.D.) cans 16 21 29 40

2-

1

⁄2 gal. (9" I.D.) cans 19 25 33 47

2-

1

⁄2 gal.(9-1⁄4" I.D.) cans 21 30 40 56

1

⁄2 gal. packages 173 234 298 103

Shipping Weight 304 lbs. 353 lbs. 396 lbs. 598 lbs.

Compressor Size 1/3 HP 1/3 HP 1/3 HP (2) 1/3 HP

Condenser Type No-clog, Wrap-around No-clog, Wrap-around No-clog, Wrap-around No-clog, Wrap-around

Radiant Shell Radiant Shell Radiant Shell Radiant Shell

Evaporator Type Cold Wall Cold Wall Cold Wall Cold Wall

Refrigerant Type R-404A R-404A R-404A R-404A

Refrigerant Control Capillary Capillary Capillary Capillary

Defrost System Manual Manual Manual Manual

Amp Draw 3.0 3.0 5.5 6.0

Electrical Specs. (V/Hz/Ph) 115/60/1 115/60/1 115/60/1 115/60/1

NSF-7 (Ice Cream Storage) Yes Yes Yes Yes

UL & CUL Listed Yes Yes Yes Yes

Interior Finish Baked Enamel on Galvanized Steel Baked Enamel Baked Enamel Baked Enamel

Exterior Finish Unpainted Galvannealed Steel Baked Enamel Baked Enamel Baked Enamel

w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap w/ Stainless Steel Cap

Electrical Information 15 Amp Service Cord 15 Amp Service Cord 15 Amp Service Cord 15 Amp Service Cord

NEMA 5-15P Plug NEMA 5-15P Plug NEMA 5-15P Plug NEMA 5-15P Plug

Model 6DF

Model 8DF

Model 10DF

Model 14DF

Page 11

8FR SPECIFICATIONS 9

Specifications - Specifications Subject to Change without Notice.

8FR

Compressor Mount Front

Temperature Range 0° to -20°F

Number of Lids 2

Lid Construction High Density, Foamed-In-Place

Insulation w/ Vinyl Gaskets

Hinge Type Continuous Composition

Insulation Polyurethane Foam

Wall Thickness 2-5/16"

Capacity 14.1 cu. ft.

Capacity

3 gal. (9-

1

⁄2" I.D.) cans 21 - 12 top / 9 bottom

2-

1

⁄2 gal. (9" I.D.) cans 25

2-

1

⁄2 gal.(9-1⁄4" I.D.) cans 30

1

⁄2 gal. packages 234

Shipping Weight (Approx.) 353 lbs.

Compressor Size 1/3 HP

Condenser Type No-clog, Wrap-around

Radiant Shell

Evaporator Type Cold Wall Shell

Refrigerant Type R404A

Refrigerant Control Capillary

Defrost System Manual

Amp Draw 3.0

Electrical Specs. (V/Hz/Ph) 115/60/1

NSF-7 (Ice Cream Storage) Yes

UL & CUL Listed Yes

Interior Finish Baked Enamel on Galvanized Steel

Exterior Finish Baked Enamel

w/ Stainless Steel Cap

Electrical Information 15Amp Service Cord

NEMA 5-15P Plug

8FR

Page 12

Operation - General

All the chest freezer models are of the same basic

design consisting of a hot wall condenser cap tube fed

tank wrap evaporator. Ice formation on the walls over a

period of time is normal.This frost should be scraped off

periodically in order to maintain peak performance.

These cabinets are thermostatically controlled for various temperature requirements. The thermostat is

located post adjacent to the unit compartment and can

be accessed for adjustment by the user with a screwdriver or a dime. Thermostat position #1 being the

warmest and position #7 being the coldest.

These cabinets are manual defrost and a drain is provided for periodic cleaning. A garden hose can be

attached to the drain plug for draining any water that

may accumulate.This drain attachment is located in the

front base rail of the cabinet.

NOTE: The power supply cord must be disconnected

when cleaning or servicing these cabinets.

On initial cabinet pulldown, the hot wall condenser may

become warm to the touch until the normal operating

temperatures are achieved.

Refer top model serial data tag for cabinet amperage,

refrigerant charges and type.

CABINET CONSTRUCTION

The low side tank is lowered into the outer shell and

anchored to the sub top by a plastic extrusion and foam.

The space between the outer wrapper and the inner

tank is then filled with urethane foam insulation (2-1⁄4"

thick) forming a three-ply wall of single unit construction.

The low side tank then is not removab le and no repair of

the low side can be made.

The stainless steel top capping is of drawn one piece

construction. It is put in place after the inner tank is

assembled to the wrapper and is secured to the sides of

the cabinet with 1⁄8" pop rivets.

COOLING TANK ASSEMBLY

The low side assemblies are designed so that the sides

and the ends of the tank are refrigerated.

The evaporator coil assembly on the tank is different to

that on previous models. It is now a serpentine coil

arrangement.The new evaporator starts at the top of the

inner tank and spirals downward to the condensing unit.

The thermostat bulb well is located near the front of the

machine compartment in all models.

CHAMBER GUARDS

The one-piece vinyl chamber guard extends from the

top of the lid opening down into the inner tank.

Galvanized steel chamber guard retainers mounted in

the top of the tank frame hold the vinyl chamber guard

against the top stainless steel capping.A special sealing

compound laid on the inside angle of the retainers seals

the vinyl to the stainless steel capping. One-piece

retainer brackets along the low er edge of the tank frame

retain the lower edge of the vinyl chamber guard.

To remove the vinyl chamber guard, merely unhook

from lower edge of the brackets and the top edge of the

chamber guard retainers. (See below)

10 GENERAL OPERATIONS

Page 13

REPLACING THE CHAMBER GUARD

To install the New Vinyl Guards, Proceed as Follows:

1. Clear off the old mastic from around the top chamber

guard retainer.

2. Mastic is to be used between the stainless s te el t op

and the top chamber guard retainer. Hold the

tapered edge of the spout at an angle, then press

on tube and force mastic out.Pull along the retainer at an even pace.

3. Hook the four corners of the chamber guard in place

and work the top edge along the top retainers hooking

the top edge in place. (B). Then stretch the chamber

guard downward, and hook in place over the bottom

retainer (C). If there is any excess mastic from around

top, Hexane, light naptha, will remove the mastic.

LIDS

The cabinet lids of the Flip-Flop design are made in two

widths: single width and double width.The double width

lids are for the double row cabinets and co v er the square

area so the lids may be placed to lift from side to side of

from end to end as desired. Stainless steel lid assemblies are made in two widths.

To replace the hinges, proceed as follows:

1. Remove the lid from the cabinet.

2. Remove the screws securing the hinge plate to the lid.

3. Remove the defective hinge.

4. Align the new gasket and hinge plate in insert screws.

REPLACING STAINLESS STEEL TOP CAP

Should it become necessary to remove or replace the

top capping, the rivets can easily be removed by drilling

out with a small electric drill using a No.30 drill to insure

not increasing the size of the hole in either the cap or the

wrapper. In reassembling, install 1/8" aluminum pop

rivets, Number 576860, in the holes throughout the stainless steel cap and the cabinet wrapper.

REFRIGERATING SYSTEMS

All compressors have fusite mounted terminals and a

plug-on starting relay. The overload protector plugs on

the common fusite terminal.

The compressor and motor are built as one unit and

spring mounted inside a steel shell.Welded construction

makes the unit hermetically sealed. The compressor

embodies a reciprocating type pump, directly

connected to the motor.

An oil pump supplies oil to every moving part and literally floods every bearing surface with oil to minimize

friction and insure quiet operation. The compressor

dome is four-point base mounted.

CONDENSER

The condenser tubing is held to the inside of the cabinet

wrapper or shell along the front, the back, by saddle

clamps which are spot welded to the outer shell.

Efficient heat transfer is obtained from the tube to the

entire shell which is the condenser surface. By the natural convection of the room air due to the absorption of

the heat from the wrapper, an efficient cooling action is

obtained and sufficient heat is removed from the hot

compressor refrigerant vapor to result in the liquidation

of the refrigerant. During the initial pull down of a hot

GENERAL OPERATIONS 11

Page 14

12 GENERAL OPERATIONS

cabinet in a warm room the wrapper will be warm to

the touch. This is a nor mal condition with this type of

condenser.

The wrapper type condenser is free of many of the faults

common to the conventional type system. Because of

the design there are no fans to fail; no fins to clog with

grease, lint or dust causing high condensing temperatures. The condensing temperatures compare very

favorably with other types and the system has the added

advantage that condenser efficiency is constant

throughout the life of the cabinet.

FILTER DRIER

A filter drier’s purpose is to filter and trap minute particles of foreign materials and absorb any moisture which

may be in the system.

The drier is located in the liquid line ahead of the capillary tube. A fine mesh screen filters out foreign particles

and the desiccant absorbs the moisture.

REPLACING THE FILTER DRIER

1. Disconnect the cabinet from its power source.

2. Install a tap line service valve to both the high and low

side process tubes.

3. Attach a compound gauge manifold to system.

4. Hook up refrigerant reclaimer to system and remove

all refrigerant from cabinet.

5. Remove drier from system.

6. Replace with same part number. Changing drier

size will effect the system charge.

7. Evacuate system to 500 microns.

8. Refer to cabinet data plate for proper charge and type

of refrigerant used.

CAPILLARY TUBE

A capillary tube is used to regulate the flow of liquid

refrigerant into the low side of the system.Its resistance

or pressure drop due to the length of tube and smaller

diameter, meters the flow of the refrigerant.

HEAT EXCHANGER

The liquid and suction lines are soldered together to

form an efficient heat exchanger .The warm liquid refrigerant is sub-cooled by the cold suction vapor prior to

entering the low side.The heat exchanger is located in

the area above the compressor

REPLACING THE HEAT EXCHANGER

1. Disconnect the cabinet from the power source.

2. Install service tops to process tube on high and low

sides of system.

3. Attach a manifold gauge set.

4. Reclaim all refrigerant in cabinet.

5. Remove cork impregnated tape from refrigerant

lines at bottom of cabinet.

6. Disconnect heat exchanger suction line from low

side outlet line.

7. Disconnect the capillary line from the low side inlet

line.

8. Place replacement heat exchanger in position and

connect the lines.

9. Replace the filter drier.

10. Evacuate system below 500 microns.

11. Refer to cabinet data plate for charge and type of

refrigerant.After charging, pinch off service taps and

braze tube closed.

Page 15

REFRIGERANT CYCLE Condenser & Evaporator

Liquid refrigerant is evaporated in the low side coil by

heat absorbed from the tank walls. The refrigerant

passes as a vapor from the accumulator through the

suction line to the compressor. It enters the interior of

the shell which is at suction pressure. From the top of

the shell, vapor passes down through a tube into the

compressor cylinder. The pressure (and temperature)

of the vapor is raised in the cylinder by the compression

and the vapor is then forced through the discharge

valve and into the discharge line leading to the

condenser on where the vapor is cooled and some

condensation to a liquid takes place.

GENERAL OPERATIONS 13

Page 16

ELECTRICAL SERVICE

THERMOSTAT

The thermostat is mounted in the machine compartment

at top or left side of front opening and the thermal element is extended into the thermostat well. See Figure

10.The well is a cylindrical tube fastened to the exterior

of the inside tank, It is located near left front corner of

the machine compartment (left rear on single row).

NOTE: Caution must be exercised when replacing a

thermostat from thermal element tube so it does not

touch any of the refrigeration lines in the machinery

compartment. Because it senses the coldest temperature before attempting to change the range or the cutout point, make sure the thermostat thermal

element is properly inserted into the well to the red

mark.The correct distance from the end of the element

to the red mark on the element should be 22". Always

remember a poor contact will naturally affect the operating range and cabinet temperature.See table below.

The range and the cut-out point of differential can be

adjusted to settings other than those given in the table.

If a higher or lower range than is obtainable by the slotted shaft is desired, change the adjustment screw

located between the two space connector behind the

control.Turn the adjustment screw clockwise to raise the

temperature, and counterclockwise to lower the range.

THERMOSTAT - Adjusting Screw

The differential adjusting screw is covered with a liquid

sealer which must be removed before any adjustment

can be made. Turn the differential screw clockwise to

lower the cut-in temperature and narrow the differential.

Turn the screw counterclockwise to raise the cut-in

temperature and widen the differential.Adjust the screw

only if has been proven that the thermostat differential is

too narrow — less than 9.5°F, or too wide, 14.5°F.

THERMOSTAT- Temp Adjustment

Thermostat dial is labeled #1 thru #7. #1 being warmest

and #7 being coldest. To lower cabinet temperature,

insert a dime or screwdriver in the slot provided and turn

clockwise.

GENERAL OPERATIONS 14

THERMOSTAT SPECIFICATIONS

Differential at Mid-Position 9-1/2 to 14-1/2°F

TEMPERATURE SETTINGS AT CONTROL BULB - °F.

WARM POSITION MID-POSITION COLD POSITION

THERMOSTAT #1 CUT-IN OUT CUT-IN OUT #7 CUT-OUT

762938 or +20° 0 -1° -16° -30°

23-5117

2

1

3

4

7

5

6

Page 17

Condensate Heater

TO REPLACE HEATER WIRE

1. Unhook the bottom edge of the chamber guard and

remove.

2. Pull out screw nails and lift out chamber guard

retainer.

3. Unplug and pull out original heater, carefully checking

for any damaged areas. Carefully check recess for

heater where damaged heater wire was installed.

4. Plug in one end of the replacement heater (see FIGURE 14),and carefully insert heater in recess aroud

top opening.Tuck any excess lenght in space jprovided after plugging in the opposite end of the heater

wire. Reconnect the heater wiring. Replace in slots

provided and reseal cavity with clear silicone.

5. Check that heater operates before replacing retainer

and chamber guard.

GENERAL MAINTENANCE & REPAIR 15

Page 18

MOTOR & RELAY

Split phase motors are used in all compressors.Models

6-DF, 8-DF, and 10-DF have 2-pole, 3450 RPM motors.

The use of low starting torque motors is made possible

by unloading the compressor prior to the start, thus

reducing the required starting torque.

The starting relays on the “A” line compressors is the

push on type that mounts on the Start (S) and Run (R)

terminals of the compressor, as shown in Figure 15

below.The starting relay is a magnetic switch with starting contacts. Its magnetic coil is in series with the run

winding of the motor. The relay coil carries the main

winding current. The relay armature holds the starting

winding contacts in open position except during the

starting period. At the moment of starting, when the

thermostat closes the electrical circuit, a surge of electrical current passes through the main motor winding

and through the relay coil.

This energizes the relay coil and pulls up the rela y armature, allowing the starting winding contacts to close.The

current through the start windings introduces a second

out of phase, magnetic field in the starter and starts the

value motor. As the motor speed increases, the main

winding current is reduced. At a predeter mined condition, the main winding current, which is also the current

through the relay coil, drops to a value below that necessary to hold in the relay armature.The armature drops

and opens the starting winding contacts and takes the

starting winding out of the circuit.

Refrigerant 404A compressors utilize a Positive

Temperature Coefficient resistor (P.T.C.) The PTC resistor is connected in parallel with the run capacitor and in

series with the start winding. The PTC has a low resistance when it is cold. When the motor starts the low

resistance causes a large current to flow through the

resistor. Current drawn by the resistor is out of phase

with the current drawn by the motor windings. As the

resistor draws current it begins to heat and resistance

builds to a point where it cannot flow to the start windings, thus switching current to the run windings.

In series with the motor windings is a separate bi-metal

overload protector held in place on the compressor by a

spring clip.The short wire lead on the overload protector

connects to the common (C) terminal on the compressor.

Should the current in the motor windings increase to a

dangerous point, the heat developed by passage of the

current through the bi-metal disc will cause it to deflect

and open the contacts.This act breaks the circuit to the

motor windings and stops the motor before any damage

can occur.

The overload protector provides added protection f or the

compressor motor because in addition to protecting

against excessive current it also protects against excessive temperature rises.

After an overload or a temperature rise has caused the

overload protector to break the circuit, the bimetal disc

cools and returns the contact to the closed position.The

time required for the ov erload s witch to reset varies with

room temperature and compressor dome temperatures.

The overload protector is specifically designed with the

proper electrical characteristics for the compressor

motor and this ice cream cabinet application. Any

replacement must be made with the exact replacement

“NEVER SUBSTITUTE AN OVERLOAD

PROTECTOR WITH ANOTHER OF AN

UNAUTHORIZED PART NUMBER.”

The wrong protector can result in a burnt out motor. If

either the overload protector or the relay is found inoperative, both the rela y and protector should be replaced.

When the thermostat cuts off after normal cycle or when

the service cord is pulled from the wall during a running

cycle, about eight (8) minutes time is required for

unloading (longer if it occurs during pull down), which is

the reduction of the pressure differential between the

high side and the low side of the system. During this

unloading period, the overload will trip if the service cord

is plugged into the electrical outlet.

If the compressor does not start, look for other trouble

(low line voltage—less than 100 volts at the compressor

terminals during the star ting interval, inoperative relay,

inoperative compressor).

Since the relay is current operated and is designed f or a

specific compressor and motor current value, the current size relay represented by the part number is an

absolute must.

“NEVER SUBSTITUTE AN OVERLOAD

PROTECTOR WITH ANOTHER OF

AN UNAUTHORIZED PART NUMBER.”

These relays cannot be adjusted or properly repaired in

the field. If the compressor repeatedly star ts and runs

for a few seconds, and then cycles on the overload protector, the starting relay contacts may be stuck closed

and the excessive current is tripping the overload.

16 GENERAL OPERATIONS

Page 19

CHECKING FOR ELECTRICAL TROUBLE

When checking for electrical trouble, always be sure

there is a “live”electrical circuit to the cabinet and that the

thermostat dial is not in the “OFF” position. When the

sealed unit will not start and the cabinet temperature is

warm, the trouble may be in the relay, in the ther mostat,

in the wiring, or it may be in the compressor motor itself.

If the compressor will not run, make a test across the

power lead terminals (one at the relay, the other at the

overload protector). See Figure 15, page 18. The test

should show a live circuit if the thermostat knob is in the

normal operating position and not in the “OFF” position.

If this check does not show positive, the thermostat and

wiring should be checked for an open circuit.

If the compressor motor does not start, check the line

voltage, to see that there is not more than 10% variation

from the normal 115 volts. If the voltage is correct, relay

and overload check out, and the compressor will not start

and run, change the compressor.Even though the cause

of the electrical trouble is determined, check the complete electrical circuit. Look for broken wire, wires with

frayed ends, and loose terminals.

REFRIGERATION SERVICE

OPERATING CHARACTERISTIC

On the initial startup of a warm cabinet, the suction pressure drops rapidly to about 0 to 5 pounds.This will vary

some with the temperature of the cabinet and the ambient temperatures.After 15 to 20 minutes of operation, the

suction pressure begins to rise again and will rise to

about 20 to 30 pounds.

The head pressure also rises and they both “peak” or

stop rising about 30 to 60 minutes of operation.

Abnormally warm cabinets and high ambient temperatures will affect both the pressure and the time interval

involved by raising the pressures and lengthening the

intervals.

After this “peak” has been reached, the discharge and

suction pressures begin to drop slowly.

After some 30 minutes of operation, the system starts to

lower the air temperature inside the cabinet. The discharge pressure will gradually lower as the cabinet temperature drops until a point is reached consistent with the

ambient temperature. The suction pressure will drop as

the cabinet temperature drops until the compressor is

shut off by the thermostat.T able 3 on page 15 giv es av erage suction and discharge pressures for the different

sized cabinets for a thermostat setting of 5 1/2 on the

temperature selector dial.Discharge pressures are given

for both 70°, 80° and 90° ambient temperatures. To

check operating pressure, install service taps and service gauges.The capillary tube allows the high pressure

refrigerant to pass into the low side when the unit is on

the “OFF” cycle. The discharge pressure is therefore

lowered and the motor starting load is greatly reduced.

The time required for unloading is about 8 minutes when

the cabinet is down to operating temperatures as the

majority of the refrigerant is in the low side. However,

when a warm cabinet is just started and during the initial

pull down, the unloading is considerably longer.

CHANGING THE COMPRESSORS

Carefully study the section “Refrigeration Service”

before changing the sealed compressor and definitely

determine that this is necessary before proceeding.

TO INSTALL A REPLACEMENT

COMPRESSOR:

1. Disconnect power to the cabinet.

2. Disconnect wire leads from the compressor.

3. Attach a manifold gauge set to both high and low service taps of system.

4. Reclaim all refrigerant in system.

5. Unbraze secondary tube connections from the cabinet to a compressor assembly.

6. Install primary tubes on new compressor ; oil cooler;

discharge, etc.

7. Install the new compressor in the cabinet and

rebraze secondary tube connections.

8. Install a new filter drier.

9. Evacuate below 500 microns and valve off to check

for leaks.

10. Check serial rating plate for refrigerant type and

charge. Weigh in refrigerant and check for leaks

before turning cabinet on.

11. Refer ELECTRICAL & REFRIGERATION INFOR-

MATION pages for the proper refrigerant charge.

Weigh in the proper charge or use a charging cylinder to measure in the proper charge.

12. Check high side of system for leaks with compressor

running.Stop compressor and allow pressure to b uild

up on the low side, then check the low side for leaks.

13. Start compressor. Replace machinery compar tment

grill.

REFRIGERANT SERVICE

LEAK TESTING

The serviceman making a leak test on any cabinet that

has urethane foam insulation must first understand the

characteristics of the insulation and what some of its

chemicals are.Number one is that the urethane foam is

charged with Freon R-22 as a blowing agent.

The refrigerant is sealed in the cells of the urethane

foam and when a cell opens, it will release a small

GENERAL OPERATIONS 17

Page 20

amount of refrigerant which will show up as a leak. Do

not be quick to condemn the cabinet as a leaker.Let the

cabinet air out for a few minutes, then make another

leak test being careful not to pull on the tubing entering

the insulated area as other cells may be opened.

Proceed in a normal manner for leak testing a system.

To check a cabinet with a suspected internal leak:

1. Install service taps on both high and low side of system.

2. Reclaim all refrigerant in system.

3. Refer to page 14 to isolate evaporator from condenser, compressor, etc.

4. Pressurize each section with 250 pounds of dry nitrogen and install gauges.

5. Let the cabinet sit overnight to see which section

loses pressure.In most cases, any leaks f ound will be

in unit compartment area.

UNDERCHARGE OF REFRIGERANT

An undercharge of refrigerant caused by a refrigerant

leak or by improper installation of a replacement

compressor will result in a lower than normal suction

pressure, excessive or continuous operation of the

compressor or higher than normal cabinet temperature.

When a system has a normal refrigerant charge the

operating suction pressure will be shown on pages 29-

35.Also the suction line entering the compressor will be

slightly cooler than room temperature.

ADDING REFRIGERANT

CAUTION

Always introduce refrigerant in a vapor state into

the system.

When a system shows by its operating characteristics to

be short of refrigerant, it must be assumed that there is

a leak somewhere in the system. Proceed to check the

system with a leak detector.When the leak is located, it

should be repaired if it is a repairable leak. Any

repairable leak will occur as a broken tube, or possib ly a

loose flare fitting in the machinery compar tment.

Unless the system has lost most of its refrigerant

charge, the leak test can be made without the addition

of extra refrigerant. If the system is completely void of

gas, then a sufficient refrigerant charge must be added

to make a leak test, and the system must be completely evacuated and recharged.

COMPLETE RECHARGE

OF REFRIGERANT

Give the system a complete recharge of refrigerant in

case of a major refrigerant leak; one that is repairable,

such as a broken tube or a cracked flare connection

occurring in the machine compartment.

If such a leak should occur, the unit will run, but with partial or no refrigerant and the operating pressures are

usually low enough and below atmospheric pressure so

that with a leak on the low side, air and moisture are

drawn into the system.

If there is any reason to believe the system contains

moisture, the low side and high side should be evacuated and a new filter drier installed. Charge should be

weighed in.

OVERCHARGE OF REFRIGERANT

When the cabinet is pulled down to temperature, an indication of an overcharge is that the suction line will be

cooler than normal and may frost up.The normal temperature of the suction will be a few deg rees cooler than

room temperature.If its temperature is much lower than

room temperature, the unit will run longer because the

liquid is pulled beyond the accumulator into the heat

exchanger.When the overcharge is excessive, the suction line will sweat or frost.Purge any excess refrigerant

into a reclaimer.Purge carefully so that system does not

become undercharged.

COMPRESSOR MOTOR BURNED OUT

There are four major causes of motor burn out:

1. LOW LINE VOLTAGE

2. LOSS OF REFRIGERANT

3. HIGH HEAD PRESSURE

4. MOISTURE

1. LOW LINE VOLTAGE

When the motor winding in a compressor gets too hot

the insulation melts and the winding short circuits. A

blackened, burned out run or start winding is the result.

Low line voltage causes the winding to get very hot

because it is forced to carry the current at the same

compressor load. When this current gets too high or is

carried for too many hours, the motor run windings fail.

A burn out caused by low voltage is generally a slow

burn out, and contaminates the system.

2. LOSS OF REFRIGERANT

A second cause of motor burn out is loss of refrigerant.

In a hermetically sealed compressor the refrigerant

vapor passes down around the motor winding.The cool

refrigerant vapor keeps the motor operating at the proper temperature.If there is a refrigerant leak and there is

little or no cooling of the motor, the windings become too

hot and a burn out will result. The overload protector

may not always protect against this type of burn out,

since it requires the transfer of high heat from the motor

through the refrigerant vapor to the compressor dome.

18 GENERAL OPERATIONS

Page 21

3. HIGH HEAD PRESSURE

High head pressure is a third cause of motor burn out.

With high head pressure the motor load is increased

and the increased current causes the windings to overheat and eventually fail. Poor circulation of air over the

high side condenser can cause motor failure for this

reason. Another cause of excessive head pressure may

be caused by air in the system.

4. MOISTURE

The fourth major cause of motor burn out is moisture. It

takes very little moisture to cause trouble. In the compressor dome refrigerant is mixed with lubricating oil

and heat from the motor windings and compressor operation.If there is any air present, the o xygen can combine

chemically with hydrogen in the refrigerant oil to form

water. Just one drop of water no matter how it gets into

the system can cause trouble.

When the water comes in contact with the refrigerant oil,

in the presence of heat, hydrochloric or hydrofluoric acid

is formed. These acids destroy the insulation on the

motor windings. When the winding short circuits, a

momentary temperature of over 3000° F. is created.

Acids combine chemically with the insulation and oil in

the compressor dome to create sludge, which quickly

contaminates the refrigeration system.

Sludge collects in various places throughout the system

and is very hard to dislodge. A purge of the refrigerant

vapor through the system will not clean the system.

If any of these cases have occurred, an acid test kit

should be used to determine the true condition of the oil.

REFRIGERANT FLOW STOPPED

This condition may result in continuous running of the

compressor or it may cycle on overload depending on

the refrigerant charge and load conditions. High tank

temperatures result.This condition may be caused by a

restricted capillary tube due to moisture freezing at the

outlet end of the tube or foreign matter plugging the line.

The major part of the refrigerant charge will be pumped

into the high side resulting in very low suction pressure.

Moisture on a properly serviced system is a remote

possibility. However, if moisture does enter the system

with air drawn in on the suction side of the system or

during service operation, it will eventually freeze and

restrict or completely stop the flow of refrigerant into the

low side.

If this condition should occur, pull the service cord and

allow the cabinet to warm up to a temperature above

32°F. or room temperature.This warm up can be accelerated by the use of heat lamps inside the cabinet. 100

watt lamps can also be used to accelerate the warm up

period.

After the cabinet has warmed up sufficiently to melt the

ice and relieve the restriction in the capillary line, reclaim

refrigerant charge down to zero pounds gauge pressure. Blow out the low side and high side with nitrogen.

Follow the instructions given under “COMPLETE

RECHARGE OR REFRIGERANT” including replacement of the filter drier.

If the capillary line is plugged with foreign matter or dirt,

exert a pressure backwards through the line to free it.

Proceed as follows:

1. Install a compound gauge on the suction line to determine whether or not the low side is under a vacuum

or a pressure.If the low side is under a vacuum, hook

manifold gauge to a cylinder of dry nitrogen and

pressurize system to 0 pounds.

2. Disconnect the capillary line from the low side inlet

and remove the filter drier. Exert a vapor pressure in

the reverse direction through the capillary by “cracking” the drum valve.Allow the pressure to build up to

about 75 pounds if necessary to clear out any foreign

matter.

CLEANING SYSTEM AFTER BURN OUT

1. Install the service taps and reclaim all refr igerant in

cabinet.

2. Remove the inoperative compressor and filter drier.

3. Obtain a sample of oil and check the condition with an

acid test kit.

4. Connect the oil cooler lines together.

5. Most reclaimers have the ability to push liquid refrigerant through the system and back to the reclaimer

for cleaning.

Once this has been accomplished:

6. Install new compressor and filter drier.

7. Evacuate system below 500 microns.

8. Check serial rating plate for charge and weigh in correct amount.

GENERAL OPERATIONS 19

Page 22

20 WIRING DIAGRAM

Wiring Diagram - Chest Models

26-0959-00

POWER

ALARM ASSEMBLY

HC5 AND STD. UC744 ONLY

SWITCH

SONALERT

BK

BK

SEE ELECTRICAL RATING

PLATE FOR SUPPLY VOLTAGE

AND FREQUENCY.

ALARM TEST

SWITCH

BK

USE COPPER CONDUCTORS ONLY.

NOTE:

CABINET MUST BE GROUNDED.

THERMOSTAT (ALL MODELS EXCEPT

HC5 AND UC744. USED ON UC744

BLOOD BANK MODELS)

(CLOSE ON RISE)

BE

-

+

(2) 9 V BATTERIES

-

BK

RD

+

+

RD

-

BK

BK

BK

RUN CAP.

SUPPLY CORD FOR

ALARM RECORDER ASSY

BLOOD BANK MODELS ONLY

BK

BK

BK

START CAP.

BK

TERMINAL BOX

THERMOSTAT

(PTCR)

COMPRESSOR

3

4

2

1

*FOR 220-50 AND 220-60

EXPORT-CONNECT THE BLUE

IN PLACE OF WHITE AND BROWN IN

PLACE OF BLACK.

26-0959-00 REV. E

SERVICE

CORD

BK

BK*

WE*

GN

YW BK

BK

YW

FAN MOTOR

TOP HEATER

BE

14DF, HC5, UC744, AND UC744BB.

FAN USED ON MODELS 10DF,

Page 23

ELECTRICAL/REFRIGERATION SPECIFICATIONS 21

2SF-13 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP 110-1-3083

Recommended Operating Temp. Range +10°F to -20°F

Cabinet V olts 115

Expansion Device 7' x .031

Charge Refrig.Type / Oz. / Grams Refer to serial data plate located in unit compar tment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 1 1 1

Suction Pressure (PSIG) 13 14 17

Discharge Pressure (PSIG) 259 290 331

Compressor Amps 1.5 1.6 1.6

100% Run -30 -23 -16

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

4SF-13 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP 117-1-3085

Recommended Operating Temp. Range +10°F to -20°F

Cabinet V olts 115

Expansion Device 7' x .031

Charge Refrig.Type / Oz. / Grams Refer to serial data plate located in unit compar tment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) -1 0 1

Suction Pressure (PSIG) 10.6 13 15

Discharge Pressure (PSIG) 244 277 316

Compressor Amps 2.3 2.5 2.5

Total Refrigeration Amps 2.5 2.7 2.7

100% Run —— -18°F / -28°C ——

Page 24

22 ELECTRICAL/REFRIGERATION SPECIFICATIONS

4DF-13 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP 110-1-3083

Recommended Operating Temp. Range +10°F to -10°F

Cabinet V olts 115

Expansion Device 7' x .031

Charge Refrig.Type / Oz. / Grams Refer to serial data plate located in unit compar tment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) 0 -1 -2

Suction Pressure (PSIG) 15 16 18

Discharge Pressure (PSIG) 256 289 323

Compressor Amps 1.5 1.5 1.6

Total Refrigeration Amps 1.6 1.7 1.7

100% Run -25 -19 -11

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

6DF-13 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP 117-1-3085

Recommended Operating Temp. Range +10°F to -10°F

Cabinet V olts 115

Expansion Device 8' x .036

Charge Refrig.Type / Oz. / Grams Refer to serial data plate located in unit compar tment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) -2 -2 -4

Suction Pressure (PSIG) 10 11 13

Discharge Pressure (PSIG) 246 279 314

Compressor Amps 2.3 2.3 2.4

Total Refrigeration Amps 2.6 2.6 2.7

100% Run -29 -20 -14

Page 25

ELECTRICAL/REFRIGERATION SPECIFICATIONS 23

8DF-13 & 8FR-13 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP 121-1-3087

Recommended Operating Temp. Range +10°F to -15°F

Cabinet V olts 115

Expansion Device 8' x .036

Charge Refrig.Type / Oz. / Grams Refer to serial data plate located in unit compar tment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) -4 -2 -1

Suction Pressure (PSIG) 7 8 11

Discharge Pressure (PSIG) 242 277 314

Compressor Amps 3.1 3.1 3.3

Total Refrigeration Amps 3.2 3.3 3.5

100% Run -27 -21 -14

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

10DF-13 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP 127-1-3615

Recommended Operating Temp. Range +10°F to -13°F

Cabinet V olts 115

Expansion Device 7' x .042

Charge Refrig.Type / Oz. / Grams Refer to serial data plate located in unit compar tment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) -3 0 0

Suction Pressure (PSIG) 10 12 14

Discharge Pressure (PSIG) 238 274 318

Compressor Amps 4.0 4.2 4.4

Total Refrigeration Amps 4.4 4.5 4.6

100% Run -27 -21 -14

Page 26

24 ELECTRICAL/REFRIGERATION SPECIFICATIONS

14DF-13 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP 127-1-3515

Recommended Operating Temp. Range +10°F to -15°F

Cabinet V olts 115

Expansion Device 7' x .042

Charge Refrig.Type / Oz. Refer to serial data plate located in unit compartment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) +2 +3 +2

Suction Pressure (PSIG) 12 14 15

Discharge Pressure (PSIG) 236 269 304

Compressor Amps 4 4 4.5

Total Refrigeration Amps 4.8 5.0 5.1

100% Run —— 14°F / -10°C ——

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

NOTE: REFER TO SERIAL DATA PLATE FOR REFRIGERANT TYPE & CHARGE.

DI4-1 ELECTRICAL/REFRIGERATION SPECS

SYSTEM COMPONENTS - R-404A

SYSTEM PERFORMANCE -

(THERMOSTAT SET AT #4 POSITION)

Compressor Americold

Compressor Horsepower HP-110-1-3083

Recommended Operating Temp. Range +10°F to -15°F

Cabinet V olts 115

Expansion Device 7' x .031

Charge Refrig.Type / Oz. / Grams Refer to serial data plate located in unit compar tment.

AMBIENT 70°F / 21.1°C 80°F / 27°C 90°F / 32.5°C

Cavity Temp. (F/C) -7 -7 19

Suction Pressure (PSIG) 9 8 22

Discharge Pressure (PSIG) 221 240 332

Compressor Amps 1.3 1.3 1.7

Total Refrigeration Amps 1.9 1.9 2.2

Kwh / 24 hours 2.8 3.3 3.1

100% Run —— -19°F / -28.5°C ——

Stat Position #1

Page 27

Parts List

When ordering parts, order by part number and description, including, if at all

possible, the complete cabinet model

and serial number.

Page 28

Cabinet Parts Illustration

Models: 2SF, 4SF, 4DF, 6DF, 8DF, 8FR, 10DF, 14DF, DI4-2

26 CABINET PARTS ILLUSTRATION

Page 29

CABINET PARTS LIST – DOMESTIC 27

Cabinet Parts List – Domestic

Models: 2SF, 4SF, 4DF, 6DF, 8DF, 8FR, 10DF, 14DF, DI4-2

PARTS LIST - Cabinet Parts, Domestic

Hinge Plate, Small 320037 320037 320037 320037 320037

Hinge Plate, Large 320036 320037 320038 320039 320040 320041 320041

Hinge, Small 43-0238 43-0238 43-0238 43-0238 43-0238

Hinge, Large 43-0239 43-0239 43-0239 43-0239 43-0239 43-0239 43-0239

1Lid Ass'y, Small 28903 28903 28903 28903 28903

2Lid Ass'y, Large 29103 29103 29103 29103 29103 29103 29103

3Chamberguard, Large 10-1077-02 10-1077-02 10-1077-02 10-1077-02 10-1077-02 10-1077-02 10-1077-02

4Chamberguard, Small 10-1077-01 10-1077-01 10-1077-01 10-1077-01 10-1077-01

5Chamberguard Ret, Large 320A0006 320A0006 320A0006 320A0006 320A0006 320A0006 320A0006

6Chamberguard Ret, Small 318A0007 318A0007 320A0005 320A0005 320A0005

7 Heater, Top Large 21-0356 21-0356 21-0356 21-0356 21-0356 21-0356

8 Heater, Top Small 21-0357 21-0357 21-0357 21-0357 21-0357

11 Name plate 50-3221-01 50-3221-01 50-3221-01 50-3221-01 50-3221-01 50-3221-01 50-3221-01 50-3221-01

12 Grill, Unit Compartment 50-3527-00 50-3527-00 50-3527-00 50-3527-00 50-3527-00 50-3527-00 50-3527-00 50-3527-00

13 Service Cord 20-3117-03 20-3117-03 20-3117-03 20-3117-03 20-3117-03 20-3117-03 20-3117-03 20-3117-03

Item Description 2SF 4SF 4DF 6DF 8DF 8FR 10DF 14DF DI4-2

14 Drain Cap 10-0306-00 10-0306-00 10-0306-00 10-0306-00 10-0306-00 10-0306-00 10-0306-00 10-0306-00 10-0306-00

17

18

20 Handle Retainer 318D0001 318D0001 318D0001 318D0001 318D0001 318D0001 318D0001 318D0001 318D0001

21 Handle, rubber 43-0171 43-0171 43-0171 43-0171 43-0171 43-0171 43-0171 43-0171 43-0171

Page 30

Cabinet Parts List – Export

Models: E2SF, E4SF, E4DF, E6DF, E8DF, 8FR

28 CABINET PARTS LIST – EXPORT

PARTS LIST - Cabinet Parts, Export

Item Description E2SF E4SF E4DF E6DF E8DF 8FR

1Lid Ass'y, Small 28903 28903 28903

2Lid Ass'y, Large 29103 29103 29103 29103

3Chamberguard, Large 10-1077-02 10-1077-02 10-1077-02 10-1077-02

4Chamberguard, Small 10-1077-01 10-1077-01 10-1077-01

5Chamberguard Ret, Large 320A0006 320A0006 320A0006 320A0006

6Chamberguard Ret, Small 318A0007 318A0007 320A0005

7 Heater, Top Large 21-0561 21-0561 21-0561 21-0561

8 Heater, Top Small 21-0560 21-0560 21-0560

11 Name plate 50-3221-01 50-3221-01 50-3221-01 50-3221-01 50-3221-01 50-3221-01

12 Grill, Unit Compartment 50-3527-00 50-3527-00 50-3527-00 50-3527-00 50-3527-00 50-3527-00

13 Service Cord 19-1349-00 19-1349-00 19-1349-00 19-1349-00 19-1349-00 19-1349-00

14 Drain Cap 10-0306-00 10-0306-00 10-0306-00 10-0306-00 10-0306-00 10-0306-00

Hinge Plate, Small 320037 320037 320037

17

Hinge Plate, Large 320036 320037 320038 320039

Hinge, Small 43-0238 43-0238 43-0238

18

Hinge, Large 43-0239 43-0239 43-0239 43-0239

20 Handle Retainer 318D0001 318D0001 318D0001 318D0001 318D0001 318D0001

21 Handle, rubber 43-0171 43-0171 43-0171 43-0171 43-0171 43-0171

Page 31

COND. UNIT COMPARTMENT PARTS LIST – EXPORT 29

Condensing Unit Compartment Parts List – Export

Models: E2SF, E4SF, E4DF, E6DF, E8DF, E8FR

PARTS LIST - Condensing Unit Parts, Export

Item Description E2SF E4SF E4DF E6DF E8DF E8FR

1Thermostat 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117

2Compressor 16-0311-00 16-0311-00 16-0311-00 16-0312-00 16-0312-00 16-0312-00

3Drier / Filter 12-3024 12-3024 12-3024 12-3024 12-3024 12-3024

4 Start Relay 17-0300-00 17-0300-00 17-0300-00 17-0300-00 17-0300-00 17-0300-00

Start Capacitor 17-0301-00 17-0301-00 17-0301-00 17-0301-00 17-0301-00 17-0301-00

Run Capacitor 17-0302-00 17-0302-00 17-0302-00 17-0302-00 17-0302-00 17-0302-00

5Motor Protector 17-0317-00 17-0317-00 17-0317-00 17-0290-00 17-0290-00 17-0290-00

8Heat Exchanger 50-1099-01 50-1099-01 50-1099-01 50-1099-02 50-1099-02 50-1099-02

Page 32

30 COND. UNIT COMPARTMENT PARTS ILLUSTRATION

Condensing Unit Compartment Illustration

Models: 2SF, 4SF, 4DF, 6DF, 8DF, 8FR, 10DF, 14DF

Page 33

COND. UNIT COMPARTMENT PARTS LIST – Domestic 31

Condensing Unit Compartment Parts List – Domestic

Models: 2SF, 4SF, 4DF, 6DF, 8DF, 8FR, 10DF, 14DF

PARTS LIST - Condensing Unit Parts, Domestic

Item Description 2SF 4SF 4DF 6DF 8DF 8FR 10DF 14DF

1Thermostat 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117 23-5117

2Compressor 16-0308-00 16-0309-00 16-0308-00 16-0309-00 16-0309-00 16-0309-00 16-0313-00 16-0313-00

3Drier / Filter 12-3024 12-3024 12-3024 12-3024 12-3024 12-3024 12-3024 12-3024

4 Start Relay 17-0286-00 17-0286-00 17-0286-00 17-0286-00 17-0286-00 17-0286-00 17-0300-00 17-0300-00

Start Capacitor 17-0291-00 17-0291-00 17-0291-00 17-0291-00 17-0291-00 17-0291-00 17-0319-00 17-0319-00

Run Capacitor 17-0288-00 17-0288-00 17-0288-00 17-0288-00 17-0288-00 17-0288-00 17-0320-00 17-0320-00

5Motor Protector 17-0314-00 17-0315-00 17-0314-00 17-0315-00 17-0315-00 17-0315-00 17-0316-00 17-0316-00

8Heat Exchanger 50-1099-01 50-1099-01 50-1099-01 50-1099-02 50-1099-02 50-1099-02 50-1099-03 50-1099-03

9Condenser Fan 19-1699-00 19-1699-00

Page 34

32 COND. UNIT COMPARTMENT – DI4-1

Condensing Unit Compartment Illustration & Parts List

Model: DI4-1

Item Description Part Number

1Thermostat 23-5117

2Fan Motor 24-0396

3Fan Blade 24-0260

5Fan Bracket 24-0020

6Condenser Assembly 50-4124-00

7Drier / Filter 12-3024

8Start Relay 17-0286-00

9Motor Protector 17-0314-00

10 Compressor 16-0308-00

Start Capacitor 17-0291-00

Run Capacitor 17-0288-00

13 Heat Exchanger 50-4125-00

Page 35

8FR – PARTS & MOUNTING 33

8FR Accessories

DESCRIPTION PART NO.

Dipperwell Accessory 7300000

Stainless Steel Syrup Rail Kit 76-3745

S.S. Housing Cap Ass’y 76-3733P

Short Jar 33-0448

Pump Syrup 33-0449

Chocolate Pump 33-0450

Lid with Ladle 33-0544-01

Hinged Lid 33-0544

Cover with Ladle Attached 33-0545

Divider & Jar 33-0452

ACCESSORY MOUNTING

NOTE: There are provisions for either righthand or left

hand dipperwell position.

TO INSTALL DIPPER WELL:

1. Remove (2) 1/4 - 20 x 1/2 machine screws securing

the mounting plate to the cabinet. (Save the screws.)

If the dipper well is mounted on the opposite end,

remove the two plug buttons covering the mounting

holes. (Save the plug buttons.)

2. Mounting plate (supplied with the cabinet) must be

under the flange of the stainless steel cap.

3. Slide the flange of the dipper well under the mounting

place and line up the holes in the dipper well and

mounting plate to the holes provided in the cabinet.

4. Secure the dipper well and mounting plate to the cabinet with (2) 1/4 - 20 x 1/2 machine screws which were

removed in instruction #1.

5. Replace plug buttons (removed in instruction #1) in

the holes not being used.

CLEANING PROCEDURES FOR

CHOCOLATE & SYRUP PUMPS

In order to keep pumps in good working condition, all

pumps should be cleaned daily.

When the pumps are cleaned, it will be necessary to

remove the pump cups from the pumps. This can be

done by pushing up on the cup and turning. Before the

cup is removed, set the pump in a large container of

warm water and mild detergent, the pump several times

until flushed clean.After the pumping operation, remove

the cup and let it soak in the cleaning solution until all

syrups or chocolate have been removed. Once clean,

replace the pump cup on the pump. Final flushing

should be done with hot water only. The assembly is

now ready for the next day's operation.

It is recommended that you do not put pump parts in the

dishwasher.

Page 36

To install a dipper well, remove two aluminum pop rivets

in the area the dipper well is to be mounted.Remov e the

rivets using a NO.30 high speed drill. Use care to avoid

enlarging the holes in either the cap or the cabinet.The

drill should not penetrate more than 1/4 inch.

Slip the dipper well flange under the cap as illustrated

and slip a pin, drill or revet through the mounting hole.

Level the well and mark the location of the second hole

on the flange of the dipperwell.Remov e the well and drill

a hole the same size as the other two holes at the

marked location. Press in a small dab of sealer in each

hole before installing the dipper well using (2) No. 6

screws.

NOTE: If a smaller dipper well is used, one fastening

may be adequate.

DRAIN TROUGH

Remove jars and reach through opening to remove

(4) thumbscrews securing the drain trough to support gussets to permit dropping drain trough down

into product zone.

Accessory Mounting Limitations

34 8FR ACCESSORY MOUNTING LIMITATIONS

Page 37

Caster Installation Instructions– SF/DF Models

Caster Kit #

52-2777-01 SF Models

52-2777-02 DF Models

CASTER INSTALLATION 35

1. Attach the casters to the channels with 5/16 x 1/2"

bolts and hex nuts.The two casters with locks may

be placed at any position desired.

2. Lift one end of the cabinet and place the caster and

channel assembly under the cabinet base with the

channel flanges against the cabinet base.

3. Attach the caster mounting channels to the base of

the cabinet by screwing through the flanges of the

caster channel into the side of the cabinet base with

seven (7) of the #10 self-drilling sheetmetal screws

supplied with the kit.

4. Repeat steps 2 and 3 on the other end of the cabinet.

Loading...

Loading...