Page 1

MODEL PIK33D

SUITABLE FOR USE IN DAMP LOCATIONS WHEN INSTALLED IN A GFCI PROTECTED BRANCH-CIRCUIT.

INTENDED FOR OUTDOOR COVERED PATIO OR LANAI AREA.

INTENDED FOR DOMESTIC COOKING ONLY

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION ON PAGES 11 AND 12.

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800-558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.com 866-737-7770

To register your product online or for additional information visit: www.BestRangeHoods.com

SV06322 Rev. 10

HB0034

INSTALLATION INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

!

!

Page 2

WARNING WARNING

- 2 -

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number

listed in the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service disconnecting means to

prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by

qualified personnel in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guidelines and

safety standards such as those published by the

National Fire Protection Association (NFPA) and the

American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE) and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any other solid-state speed

control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded and protected by a GFCI.

10. Suitable for use in damp locations only when installed

in a GFCI PROTECTED branch-circuit.

11. When applicable local regulations comprise more

restrictive installation and/or certification requirements,

the aforementioned requirements prevail on those of

this document and the installer agrees to conform to

these at his own expenses.

TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

a) Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or

medium settings.

b) Always turn hood ON when cooking at high heat or

when flambeing food (i.e.: Crêpes Suzette, Cherries

Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should

not be allowed to accumulate on fan, filters or in

exhaust ducts.

d) Use proper pan size. Always use cookware

appropriate for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS

IN THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid cookie

sheet or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. IF THE FLAMES

DO NOT GO OUT IMMEDIATELY, EVACUATE AND

CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN—You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels—This could cause a violent steam explosion.

4. Use an extinguisher ONLY if

A. You own a Class ABC extinguisher and you know

how to operate it.

B. The fire is small and contained in the area where it

started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

*Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

3. Your insert motor has a thermal overload which will

automatically shut off the motor if it becomes

overheated. The motor will restart when it cools down.

If the motor continues to shut off and restart, have the

insert serviced.

4. The minimum hood distance above cooktop must not

be less than 36”. A maximum of 42” above cooktop is

highly recommended for best capture of cooking impurities.

5. Two installers are recommended because of the large

size and weight of this unit.

6. To reduce the risk of fire and to properly exhaust air, be

sure to duct air outside—Do not exhaust air into

spaces within walls or ceiling or into attics, crawl space

or garage.

7. This product is equipped with a thermostat which may

start blower automatically. To reduce the risk of injury

and to prevent power from being switched on

accidentally, switch power off at service panel and lock

or tag service panel.

8. To reduce the risk of fire and electric shock, the Best

model PIK33D must be installed only with interior

blower model P8D, exterior blower model EB12 or

EB15, or in-line blower model ILB11 (sold separately).

Other blowers cannot be substituted.

9. When used as demonstrator: use with approved

cord-connection kit only.

10. Please read specification label on product for further

information and requirements.

!

!

Page 3

- 3 -

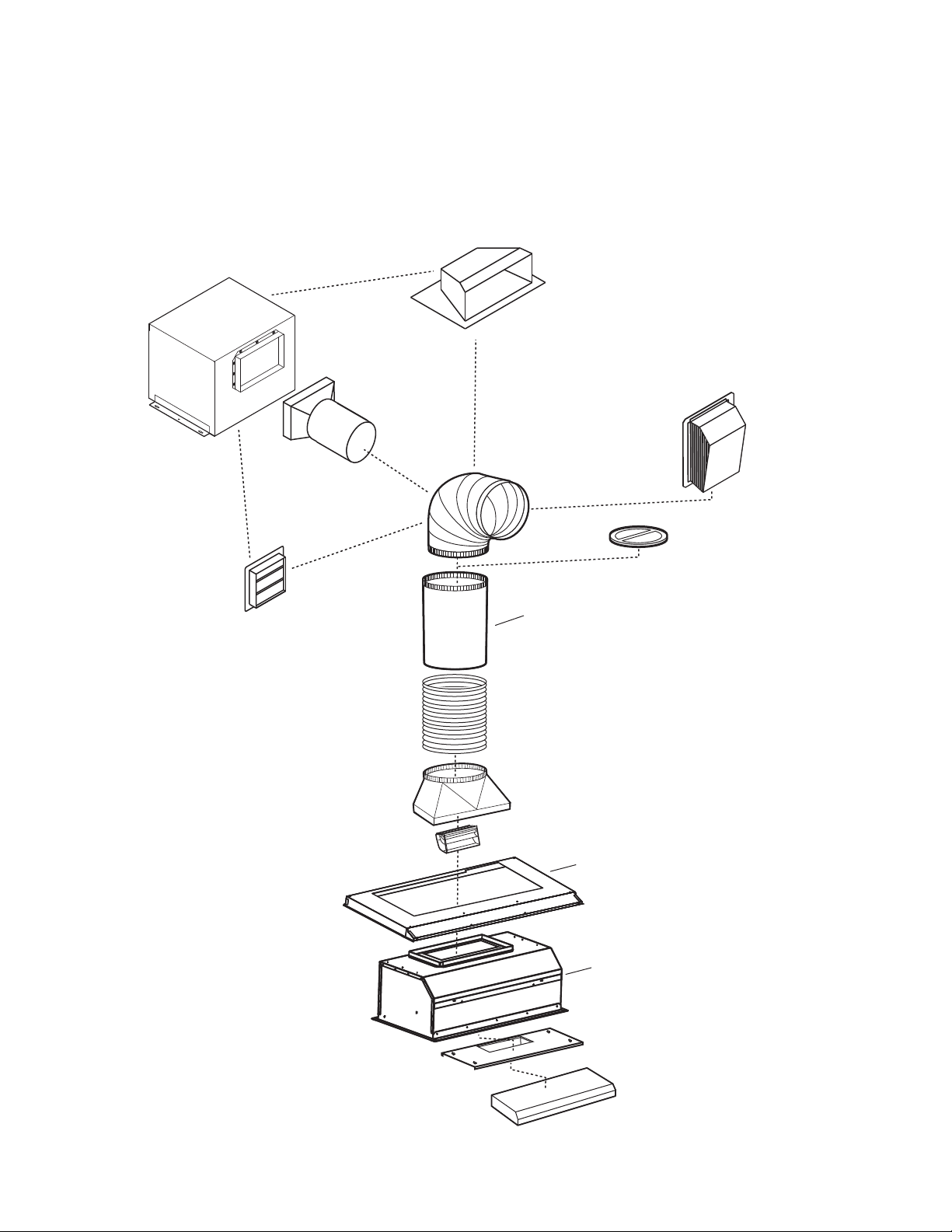

Dual-blower P8D

(sold separately)

Model 410

(10” Round duct

2 ft. sections)

Model 418

(10” round adjustable

elbow, optional)

Model 441

(10” round

wall cap)

Model 421

(10” round vert. in-line damper)

(Recommended for use with

exterior blowers)

PIK33D INSERT

- PIK33D -

INSERT SYSTEM

Model ILB11 (1100 cfm)

In-line blower (includes two 8” x 12”

to 10’’ round transitions)

Model 437

(High capacity roof cap)

Model EB12

(1200 cfm) or

EB15 (1500 cfm)

Exterior blower

L3336D or L3348D

Custom Hood Liner (optional)

Rough-in plate

(supplied with interior blower P8D)

10” round metal

flexible duct

(optional)

Model SV03428

Transition (9” x 18” to 10” round) (included)

Flow deviator

(supplied with interior blower P8D)

HL0080

Page 4

- 4 -

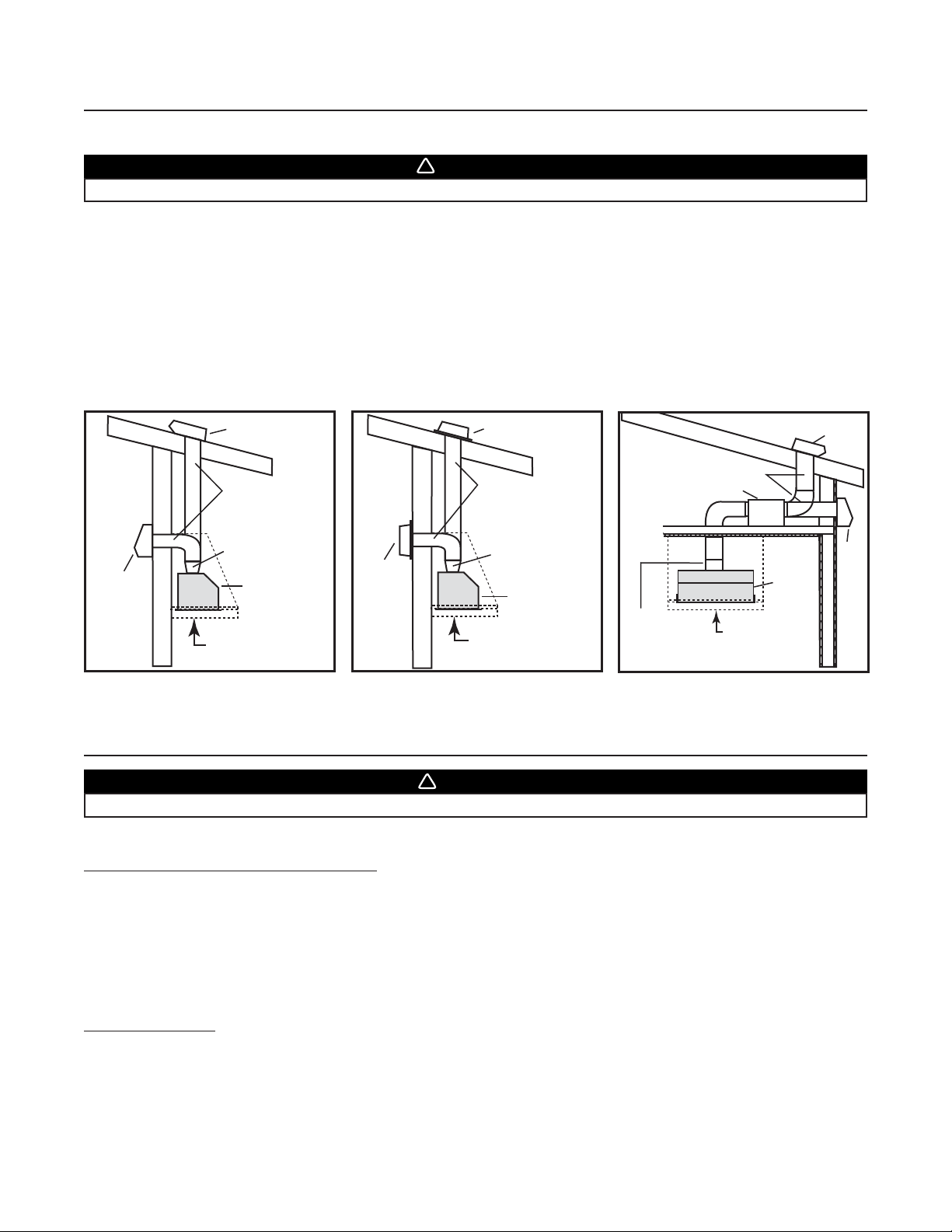

1. SELECT BLOWER OPTION AND INSTALL DUCTWORK

This insert is designed for use with gas or electric outdoor cooking appliances when operated in an outdoor covered patio or

lanai area. As with all electrical appliances, this unit must be protected from the effects of weather.

The insert model PIK33D must be installed with the interior blower P8D, or with the exterior blower model EB12 or EB15 or with

the in-line blower ILB11 only (sold separately). Other blowers cannot be substituted.

If installing in-line blower, refer to instructions packed with in-line blower and follow steps 1 up to 6, 10 up to 13, 15

and up of this manual.

Plan where and how the ductwork will be installed. Access to the top of the insertd is preferred for connection of ductwork. As

an alternative, flexible metal ductwork may be used.

Install 10” steel ductwork, elbows and roof or wall cap for the type of blower you are installing. Use round ductwork, with a short

section (about 4’ expanded) of flexible metal duct (optional) for attachment to the transition. Use screws to attach flexible metal

duct to the rigid duct. Use 2” metal foil duct tape to seal duct joints.

The minimum hood distance above cooktop must not be less than 36”. A maximum of 42” above cooktop is highly

recommended for best capture of cooking impurities.

Distances over 42” are at the installer and users discretion.

MODEL P8D

INTERIOR BLOWER

TYPICAL DUCTWORK

MODEL EB12, EB15

EXTERIOR BLOWER

TYPICAL DUCTWORK

MODEL ILB11

IN-LINE BLOWER

TYPICAL DUCTWORK

In-line blower

10” round duct

HH0067A

36” minimum

above

cooking surface

10” round

metal flex. duct

(optional)

Roof cap

Wall

cap

Insert

2. PREPARE THE INSTALLATION

NOTE: Before proceeding to the installation, check the contents of the box. If items are missing or damaged, contact the

manufacturer.

Make sure that the following items are included

:

- Insert

- Accessories:

• Transition (9” x 18” to 10” round)

• 3 Baffle filters

• 2 Shielded halogen bulbs (120 V, 50 W, type GU10)

• Bag of parts including: 3 waterproof wire connectors, 6 no. 10 x 2" hex head screws, 2 wire clamps LP16-AP,

8 no. 8 x 3/8" stainless steel screws.

Included in parts bag, but not to be used (please discard): 2 no. 8 x 5/8" screws, 4 no. 10 x 2" flat head screws,

2 wall anchors, 6 washers 3/16" ID x 3/4" OD, 4 stainless steel 10-32 locknuts, 2 no. 8 x 3/8" zinc-plated screws.

Parts sold separately

:

- Interior blower P8D with rough-in plate and flow deviator

- Exterior blower assembly EB12 or EB15 (do not use rough-in plate included with exterior blower)

- In-line blower assembly ILB11 (includes rough-in plate and 2 transitions, do not use the rough-in plate)

- Custom hood liner Model L3336D or L3348D (optional)

- Ductwork (rigid and flexible), elbows, dampers, wall and roof caps. Refer to page 3 for a complete list of venting options and

model numbers.

NOTE: During installation, protect countertop and/or cooktop.

WARNING

When performing installation, servicing or cleaning the unit, it is recommended to wear safety glasses and gloves.

WARNING

This unit is not designed for use with a charcoal grill.

!

!

Roof cap

Exterior

blower

Wall cap

HH0005A

10” round ducts

with 10” round

metal flex. duct

(optional)

9” x 18” to 10”

round transition

Insert with

interior

blower

36” minimum

above

cooking surface

Exterior

blower

HH0042A

10” round duct

with 10” round

metal flex. duct

(optional)

9” x 18” to 10”

round transition

Insert

36” minimum

above

cooking surface

Page 5

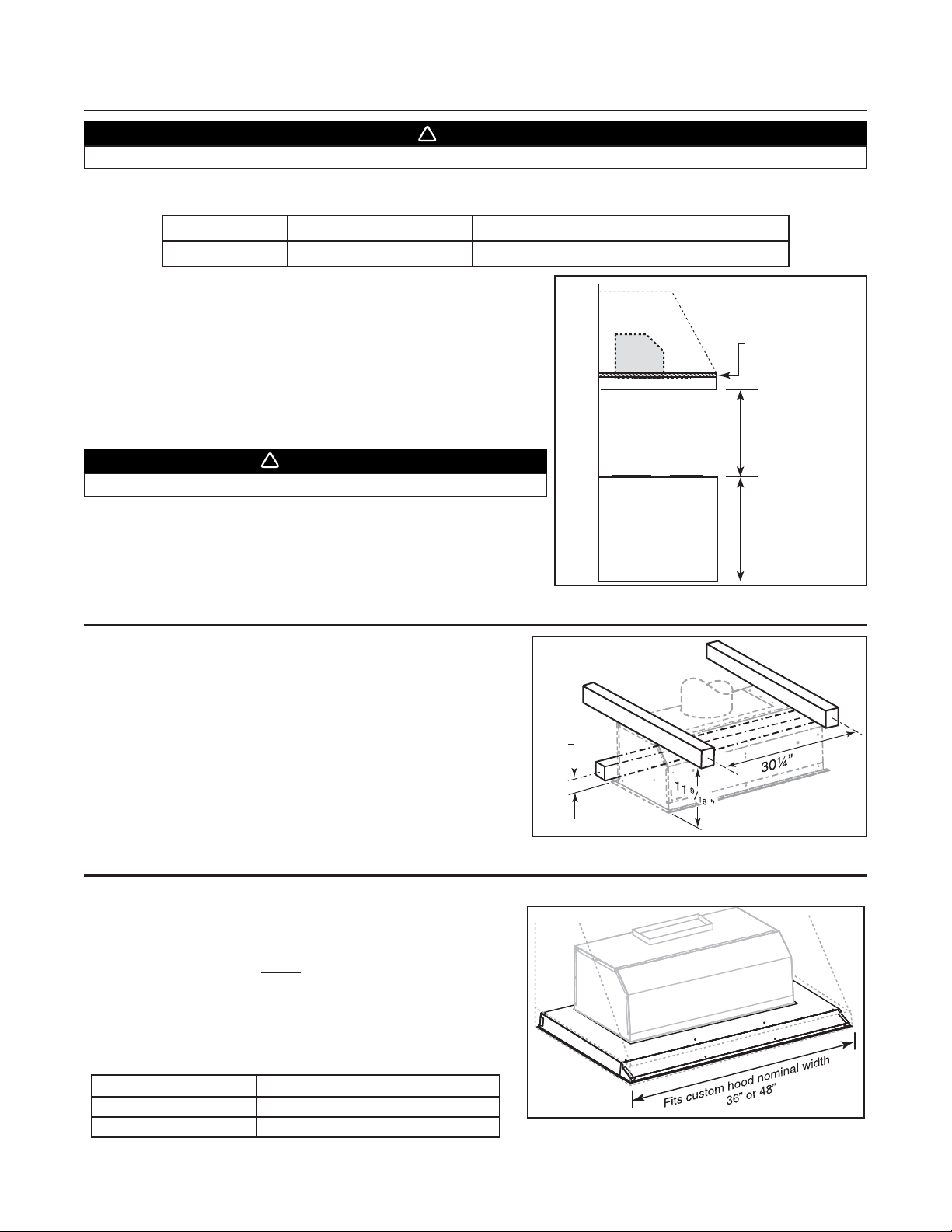

Start with the custom hood base, because its position will determine the

height of the insert. We recommend the base of the custom hood should be

3/4 inch thick plywood.

If an optional custom hood liner will be installed, we recommend the sides

and front of the custom hood to be 3/4 inch thick, assuming standard

cabinet widths. If the optional custom hood liner will not be installed, the

custom hood side and front thickness is at the installer’s discretion.

Run power cable to installation location.

Stub out a 4 foot length of electrical cable below the custom hood.

- 5 -

WARNING

The power cable must be a GFCI protected branch circuit.

!

4. SUGGESTED CUSTOM HOOD INTERNAL FRAMEWORK

The mounting holes for both top stud supports are located at 119⁄16” up

from the insert base. The on center distance between both studs is 30¼”.

The mounting holes for the rear stud support are located at 1½” up from

the insert base. See illustration at right.

Once the custom hood base and frame are done, finalize the custom

hood.

3. CUSTOM HOOD PREPARATION

The custom hood frame must be sized to the shape and total weight of the insert assembly. Refer to the table below for total

weight of the insert, according to the type of blower chosen.

WARNING

When building a custom hood, always follow all applicable construction codes and standards.

!

INSERT MODEL WITH INTERIOR BLOWER WITH EXTERIOR BLOWER OR IN-LINE BLOWER

PIK33D 49 LB. 27 LB.

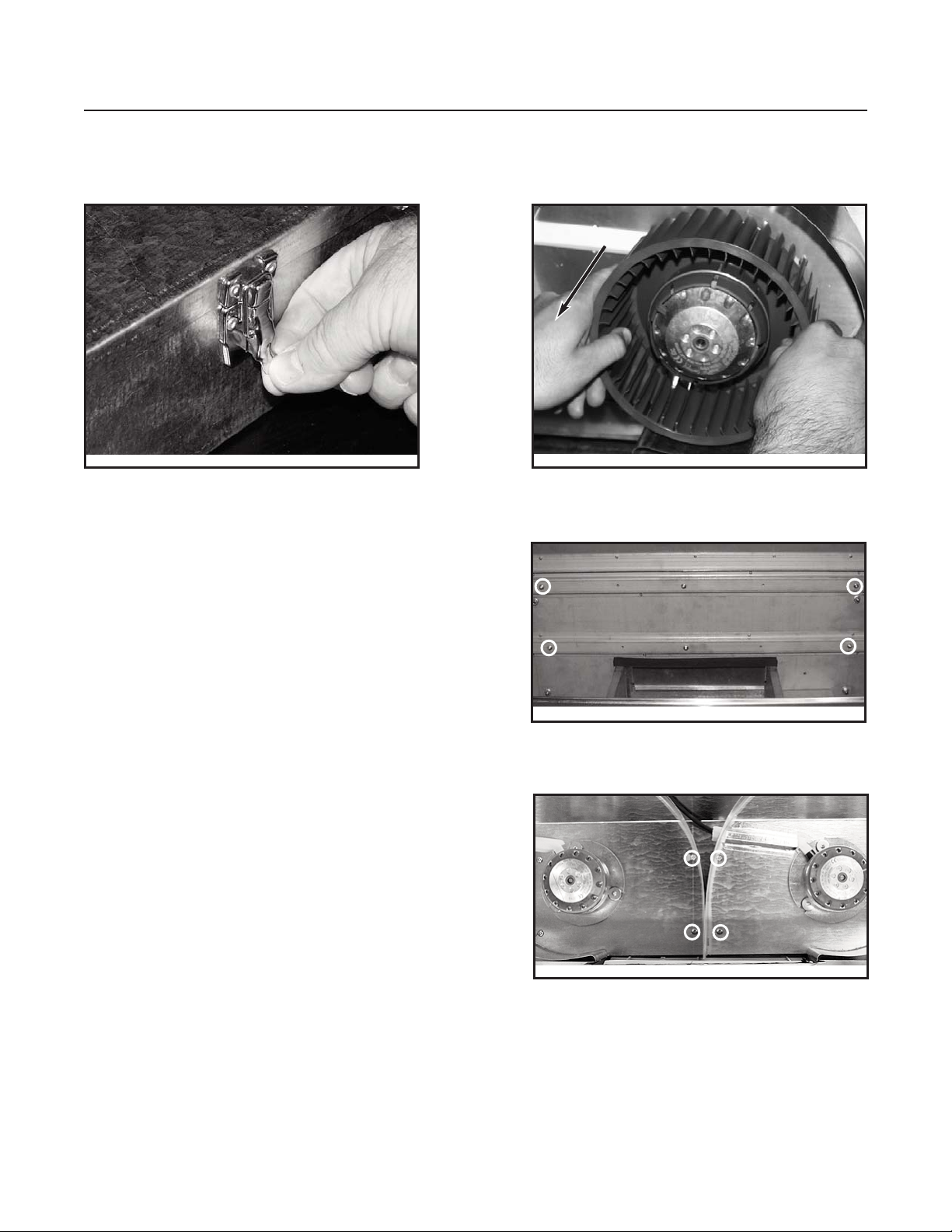

5. INSTALL CUSTOM HOOD LINER (OPTIONAL)

The liners are specially designed to protect the exterior base of the

custom hood. Both models are adjustable for depth from 23½” to 26½”

(front to back, without backboard).

The liner must be installed before

the insert. To order, refer to table

below to find the right liner model number for the custom hood width.

To view specific model information, including depths for each liner

model, visit www.BestRangeHoods.com

or contact Technical support

(phone number listed on page 14, in warranty text).

To install, see instructions packed with the custom hood liner.

HA0039A

INSERT MODEL CUSTOM HOOD NOMINAL WIDTH

L3336D 36”

L3348D 48”

Plywood base

thickness: 3/4”

36” to 42” above

cooking surface

HH0044A

1½”

HH0043A

Standard 36” h.

cooktop

Page 6

- 6 -

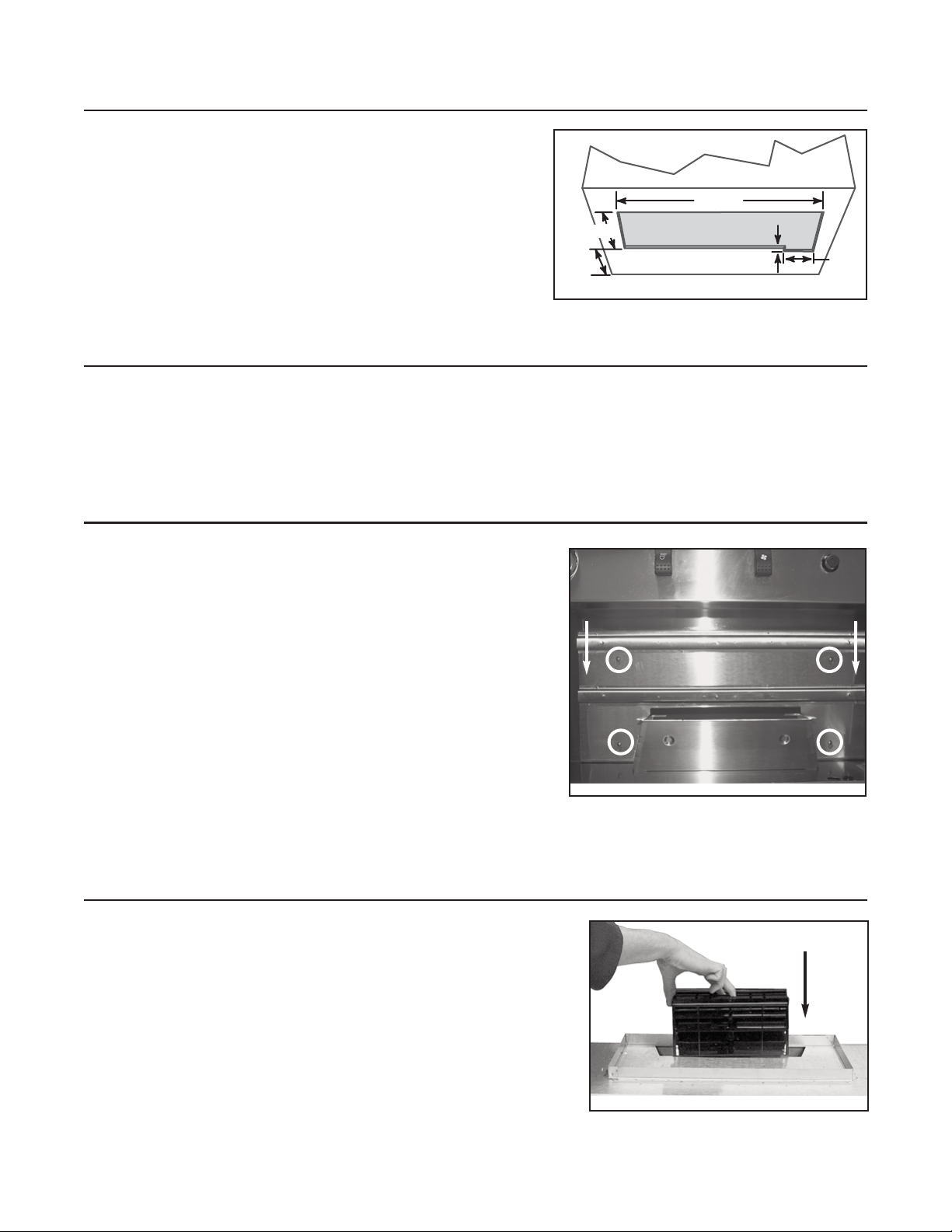

6. CUT THE HOLE IN CUSTOM HOOD BASE

If it is not done yet, cut a hole in the bottom of the cabinet, using the

dimensions shown at right.

NOTES: 1. The recommended distance from the back to the rearmost

cutout edge is 2¼” minimum.

2. When cutting the 10¾’’ notch for the wiring, also notch out the

rear stud or provide clearance for the wiring.

7. INSTALL THE EXTERNAL BLOWER (EB12, EB15 OR ILB11 MODELS ONLY)

Refer to instructions packed with EB12, EB15 or ILB11 external blowers and follow steps 10, 11, 12, 13, 15 and up of this

manual.

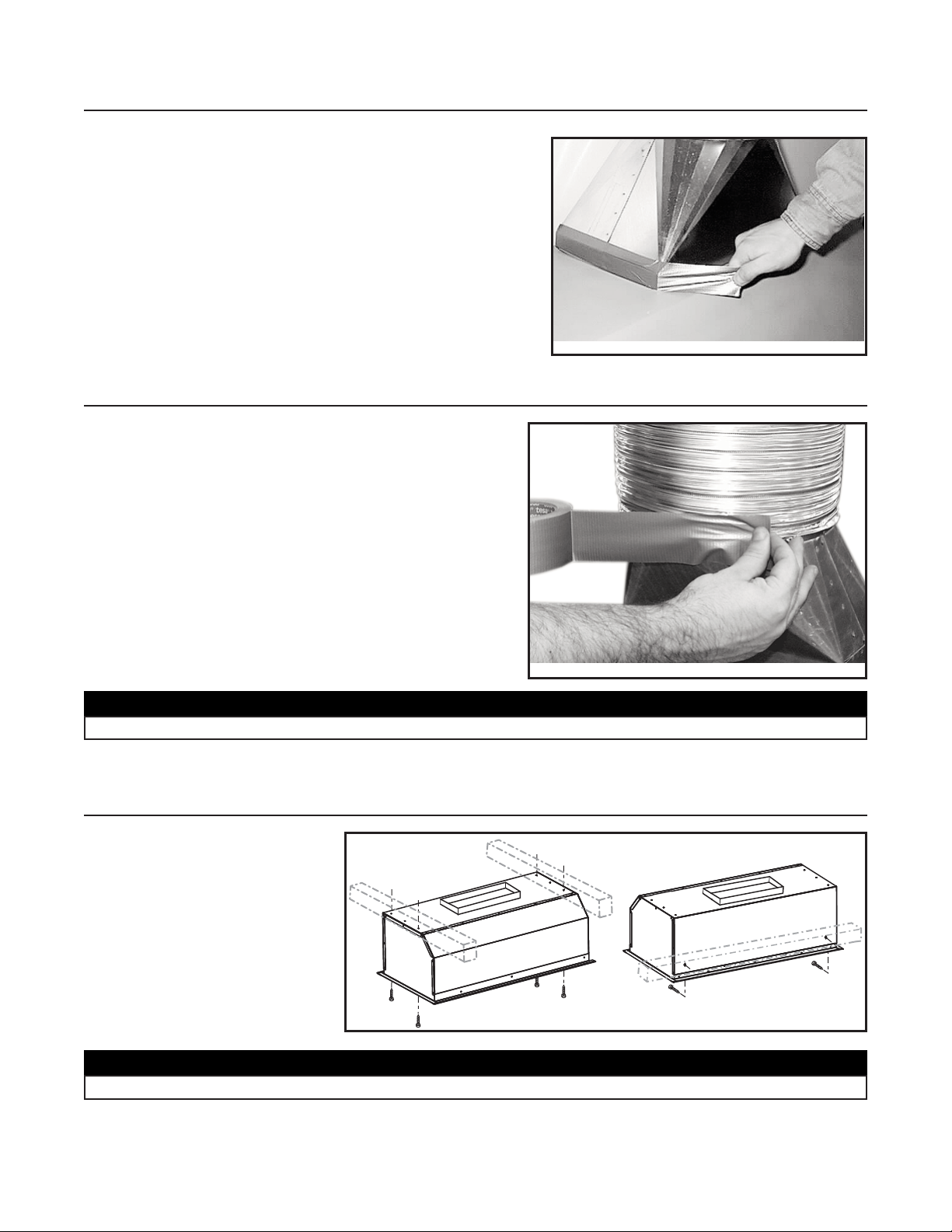

8. INSTALL THE ROUGH-IN PLATE

(USE WITH INTERIOR BLOWER P8D MODEL ONLY)

Hang the rough-in plate onto the insert inner top (screws through the large

part of the keyhole). Slide the rough-in plate toward the rear of insert (screws

in the smaller part of the keyhole). Tighten the (4) screws.

9. INSTALL THE DEVIATOR

(USE WITH INTERIOR BLOWER P8D MODEL ONLY)

Slide the deviator inside the insert as shown.

NOTE: If installed correctly, the deviator will protrude about 1/8” above the insert.

HO0022

HO0023

16½”

2¼”

min.

HD0101A

32½”

11/16”

10¾”

Page 7

Connect wires as follow: BLACK to ORANGE (G), WHITE to 2 other WHITE wires (H), and

GREEN under ground screw (I). DO NOT FORGET TO CONNECT THE GROUND.

Reinstall the wiring box cover.

Connect wires as follow: BLACK to BLACK (C) and GREEN or BARE wire under ground screw (D). DO NOT FORGET TO

CONNECT THE GROUND. Do not reinstall the wiring box cover yet.

- 7 -

10. CONNECT WIRING

ALL INSTALLATIONS:

Punch out the knock-out hole(s) located on back side of the insert.

NOTE: Punch (1) hole for interior blower installation or (2) holes for exterior blower or in-line blower installation.

Remove the insert wiring box cover. Remove both flexible wire sleeves from the wiring box and keep for further use. Install one

wire clamp (A) on the back side of the insert and the other in the knock-out hole of the wiring box. Position insert below the

installed custom hood. Slide the power cable into one of the wire sleeves (B) provided. Pass power cable with sleeve through

the wire clamp on the back side of the insert and through the wire clamp in the wiring box. Tighten both wire clamps completely

to secure the cable. The wire sleeve ends must be secured by the wire clamps. Connect cable into wiring box using provided

waterproof wire connectors.

WARNING

Risk of electric shock. Electrical wiring must be done by qualified personnel in accordance with all applicable codes and standards. Before connecting wires, switch power off at service panel and lock

service disconnecting means to prevent power from being switched on accidentally.

!

HE0034

WATERPROOF WIRE CONNECTORS INSTRUCTIONS:

1 Strip wires 3/8”.

2. Align frayed strands or conductors.

3. Do not pre-twist. Place stripped wires together with ends even, but lead smaller

stranded wires slightly ahead of larger solid or stranded wire.

4. Twist connector onto wires pushing firmly until hand-tight. DO NOT over torque.

5. When inserting wires into connectors, some sealant may leak out. Wipe off excess

sealant in and around conductors. DO NOT REUSE.

CAUTION

Do not connect the WHITE wires yet.

B

C

D

A

A

EXTERIOR OR IN-LINE BLOWER INSTALLATION ONLY:

Install a wire clamp (not provided) in the knock-out hole beside the wire clamp on the back of

the insert. Slide the power cable into the other wire sleeve (E) (provided). Pass the exterior blower

cable with sleeve through the wire clamp and tighten to secure the blower cable. The wire sleeve

end must be tightened by the wire clamp.

Pass the blower cable (with its sleeve) through the plastic clamp (F) in the wiring box.

Completely tighten the plastic clamp. See figure at right.

Connect blower cable into wiring box using provided waterproof wire connectors.

NOTE: Refer to the W

ATERPROOF WIRE CONNECTORS INSTRUCTIONS box (earlier in this page) to

perform proper connectors installation.

VO0084

Not completely

tightened

Completely

tightened

F

E

F

G

H

HE0033

I

Page 8

Attach the transition to insert top. Use metal foil duct tape to make all joints

secure and airtight.

- 8 -

11. INSTALL THE TRANSITION

A. When there is access to the top of the hood, connect ductwork and

seal connections with duct tape after Step 13 Install the insert.

B. When there is no access to the top of the hood, carefully pull down

the metal duct through the custom hood base hole. Slide this duct

over the transition. Seal the connection with metal foil duct tape.

HD0092

13. INSTALL THE INSERT

Install the insert inside the custom hood

and secure to the frame by using the

6 no. 10 x 2" hex head screws (included).

Position insert rearward so 3½" notch

from step 6 is covered. Start with 2 front

screws on top, then 2 rear screws on top,

and finish with 2 on rear side.

(See figure at right for mounting screw

specific locations.)

TOP

REAR

CAUTION

Take care not to kink ducting when installing insert (step 13).

CAUTION

Take care not to kink ducting or pinch electrical cable when installing insert.

HD0057

12. DUCTING CONNECTION

HD0102

Page 9

- 9 -

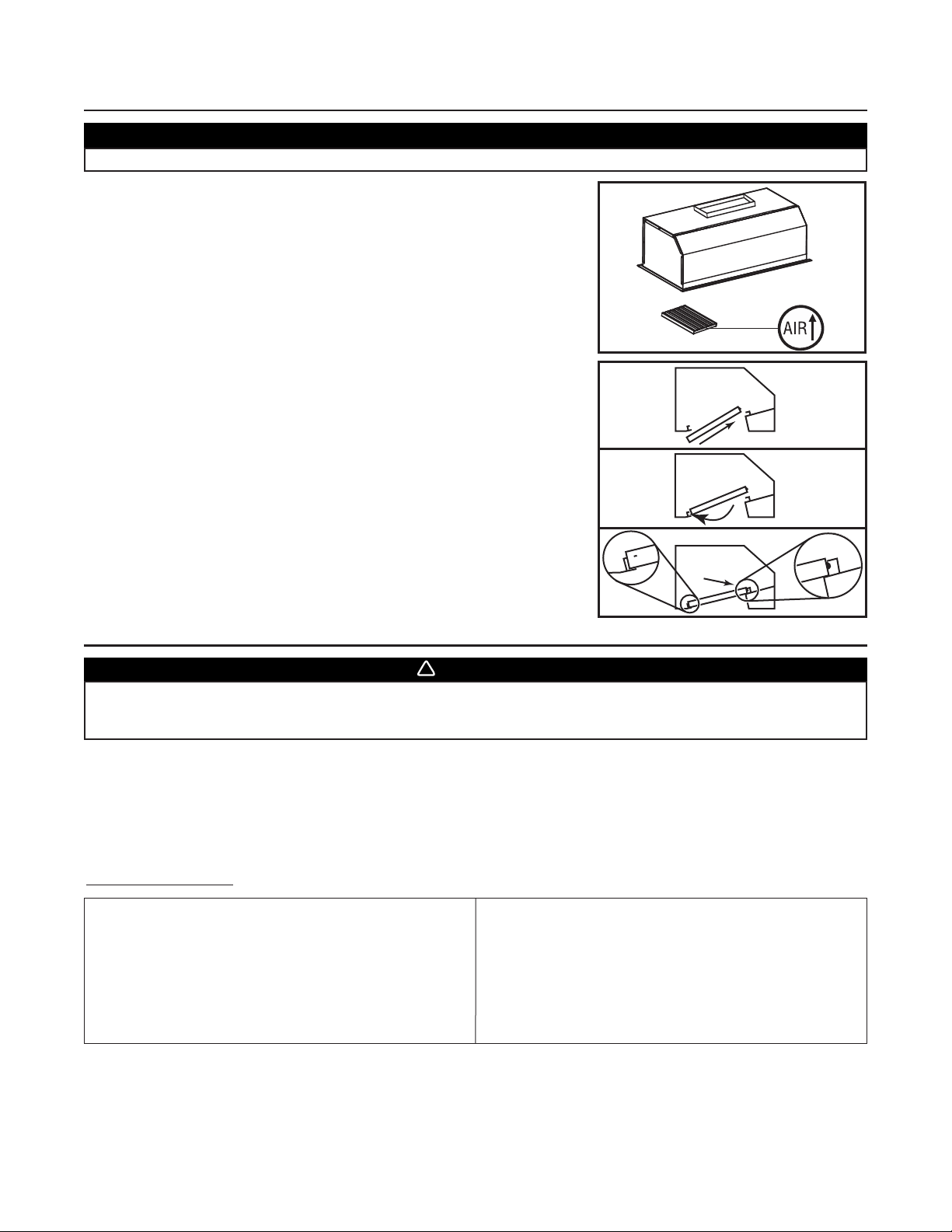

14. INSTALL THE INTERIOR BLOWER (P8D BLOWER MODEL ONLY)

The blower must be installed to the insert using 8 no. 8 x 3/8” screws. Remove the cover from the blower assembly. Remove the

impellers by pulling them out gently (see pictures below).

HD0021

HD0022

Install 4 no. 8 x 3/8” screws into the location as shown in the picture at

right. Do not tighten screws down fully, leave a 1/8” gap. Hang blower

unit onto insert inner top (screws through the large part of the keyhole).

Slide the blower to its position (screws in the small part of the keyhole).

Tighten the 4 screws.

Secure the blower by installing 4 more no. 8 x 3/8” screws into the

locations shown in the picture at right. Reinstall impellers and cover.

HD0081

HD0045

Page 10

Connect wires as follow: ORANGE to ORANGE (B), WHITE to 2 other WHITE wires (C)

from step 10, and GREEN under ground screw (D). DO NOT FORGET TO CONNECT

THE GROUND. Reinstall the wiring box cover.

15. LIGHT BULBS

Both impellers are different in the dual blower, one rotates

clockwise and the other counterclockwise. Each wheel and

motor have an arrow and a number on them, you have to

match them correctly (see drawing at right).

FRONT

HD0023

1

2

14. INSTALL THE INTERIOR BLOWER (P8D BLOWER MODEL ONLY) (CONT’D)

Pass the blower cable through the plastic clamp (A) in the wiring box. Completely tighten the

plastic clamp. See figure at right.

Connect blower cable into wiring box using provided waterproof wire connectors.

VO0084

Not completely

tightened

Completely

tightened

A

A

B

C

HE0033

WATERPROOF WIRE CONNECTORS INSTRUCTIONS:

1 Strip wires 3/8”.

2. Align frayed strands or conductors.

3. Do not pre-twist. Place stripped wires together with ends even, but lead smaller

stranded wires slightly ahead of larger solid or stranded wire.

4. Twist connector onto wires pushing firmly until hand-tight. DO NOT over torque.

5. When inserting wires into connectors, some sealant may leak out. Wipe off excess

sealant in and around conductors. DO NOT REUSE.

D

CAUTION

Make sure the impellers are correctly installed, the insert will not work properly if reversed.

This insert requires shielded halogen lamps (120 V, 50 W, MR16 or PAR16 with GU10 base), included.

1. Install the lamps by placing the bulb leads into their grooves in the socket.

2. Gently push upwards and turn clockwise until secure.

To remove lamps, gently push upwards and turn counterclockwise to disengage bulb

leads from their grooves.

NOTE: To ease removal of the bulbs, use a rubber dishwashing glove or use suction

cup tool available from Best. Contact Best Customer Service at 1-800-558-1711

to order suction cup tool, part no. 99526707.

12

HO0090

WARNING

Do not touch lamps during or soon after operation. Burns may occur. In order to prevent the risk of

personal injury, only install shielded halogen lamps. Also, never install a cool beam, a dichroic lamp, a

lamp not suitable for use in recessed luminaires or identified for use in enclosed fixtures.

!

- 10 -

HD0023

21

Page 11

BAFFLE FILTERS AND IMPELLER(S).

The baffle filters, impeller(s) and grease rail should be cleaned frequently. Use a warm detergent solution. Baffle filters and

impeller(s) are dishwasher safe.

Remove baffle filters by pushing them towards the back of hood and rotating downward.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of the filter may occur if using

phosphate detergent or as a result of local water conditions—but this will not affect filter performance. This discoloration is not

covered by the warranty.

Stainless steel cleaning

: How to maintain its “BRIGHT LOOK” and help prevent corrosion.

17. USE AND CARE

Avoid when choosing a detergent:

• Any cleaners that contain bleach will attack stainless steel.

• Any products containing : chloride, fluoride, iodide, bromide will deteriorate surfaces rapidly.

•Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc., are highly explosive and

should never be used close to a range.

It is recommended to install side filters first and finish with center one.

A vertical arrow with the word AIR can be found on the filters border. Make sure to

install the baffle filters with the arrow pointing towards the inside of the hood insert.

See figure at right.

1. Insert upper end of baffle filter into the insert.

2. Raise lower end of baffle filter to position inside of unit and push to insert the

rear clip inside its slot in baffle back side.

3. While pushing the baffle filter, slide it under the inner retaining piece.

Make sure the baffle filters are positioned as shown at right in order to allow the

grease to reach the grease rail easily.

Remove protective plastic film covering the baffle filters before installing them.

3

2

1

16. INSTALL BAFFLE FILTERS

WARNING

Before servicing or cleaning the unit, switch power off at service panel and lock service panel to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

!

- 11 -

CAUTION

Do:

• Regularly wash with clean cloth or rag soaked with warm

water and mild soap or liquid dish detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after cleaning.

Wipe dry completely.

• You may also use a specialized household stainless steel

cleaner.

Do not:

• Use any steel or stainless steel wool or any other scrapers

to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach

the hood. During construction/renovation, cover the hood to

make sure no dust sticks to stainless steel surface.

HO0021

HD0090

Page 12

- 12 -

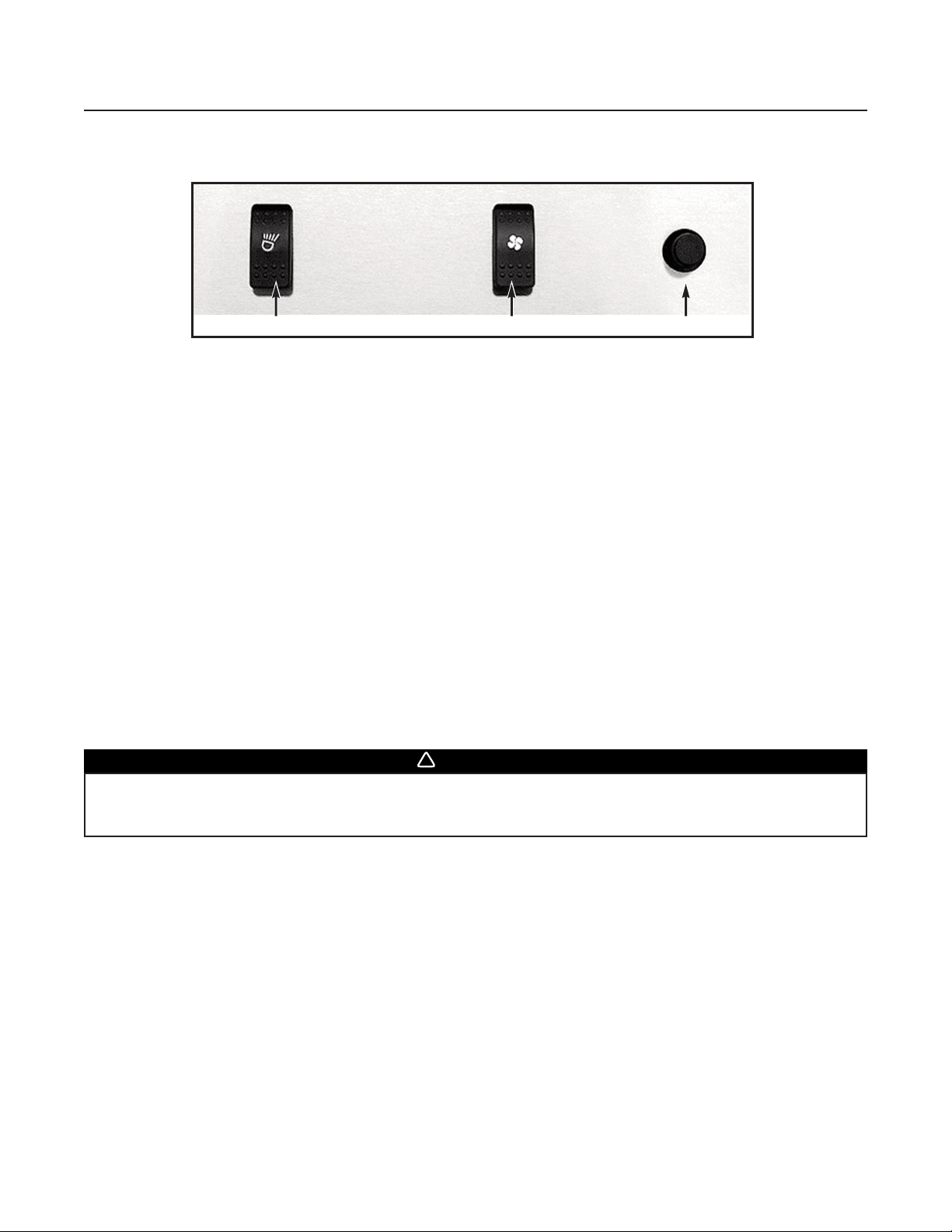

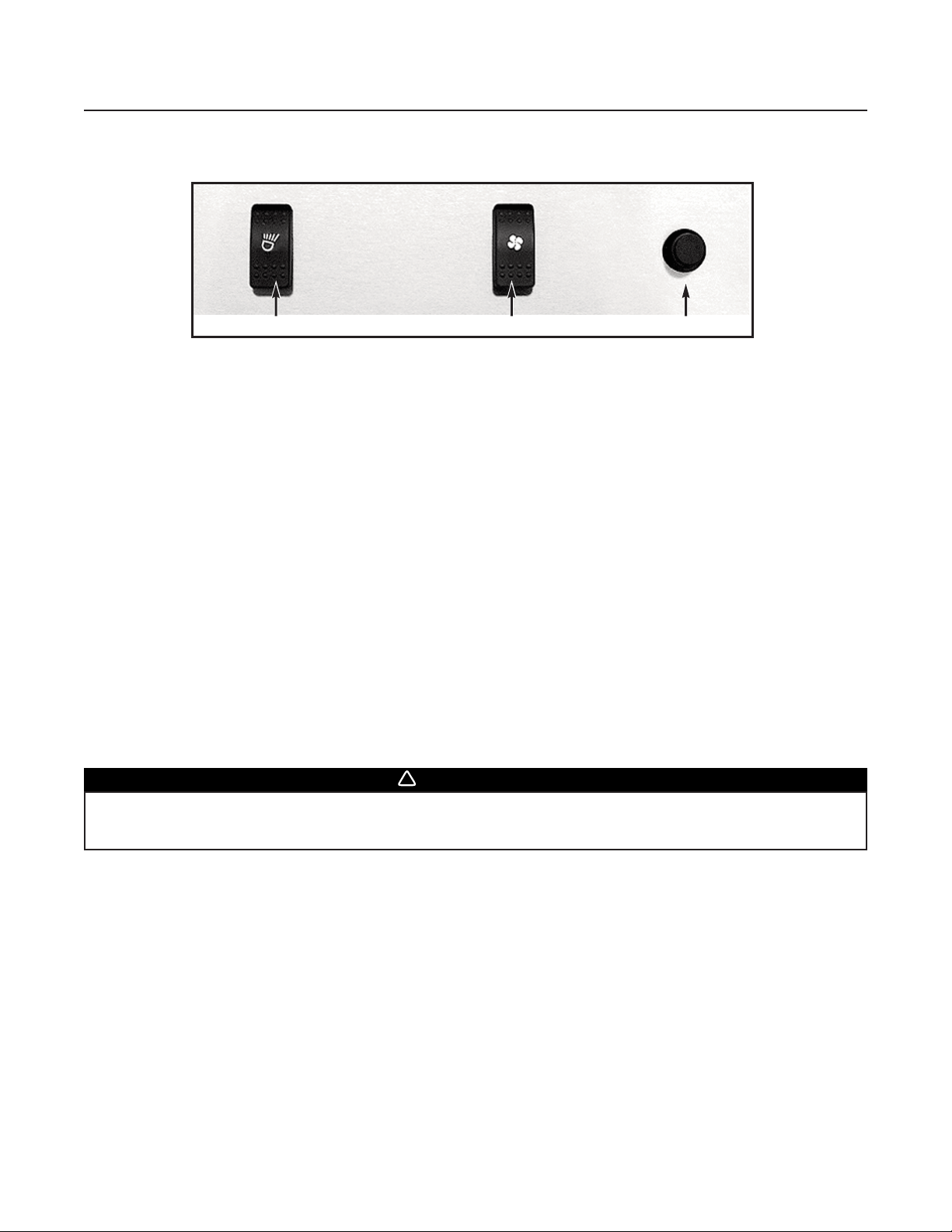

18. OPERATION

1) Light switch 2) Blower ON/OFF switch 3) Blower speed control

1 2

3

HC0014

The insert is operated using the (3) controls located beneath the front edge of the insert.

COOKTOP LIGHTING (HALOGEN)

The light switch turns the halogen lights ON and OFF.

Use shielded halogen bulbs (120 V, 50 W, type GU10), included.

BLOWER

The blower is operated using two (2) controls.

The blower ON/OFF switch turns the blower ON to the speed preset by the speed control. The blower must be turned ON and

OFF using this switch.

Turn the blower speed control counterclockwise to increase blower speed—clockwise to decrease speed.

HEAT SENTRY™

This unit is equipped with a Heat Sentry thermostat. This thermostat is a device that will turn on or speed up the blower if it

senses excessive heat above the cooking surface.

1) If blower is OFF—it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting—it turns the blower up to HIGH speed.

When the temperature level drops to normal, the blower will return to its original setting.

Test all insert switches.

WARNING

The Heat Sentry can start the blower during a range top fire or other excessive heat situations even if the

hood is turned off. If this situation occurs, it is impossible to turn the blower OFF with blower switch. If

you must stop the blower, do it from the main electrical panel.

!

Page 13

- 13 -

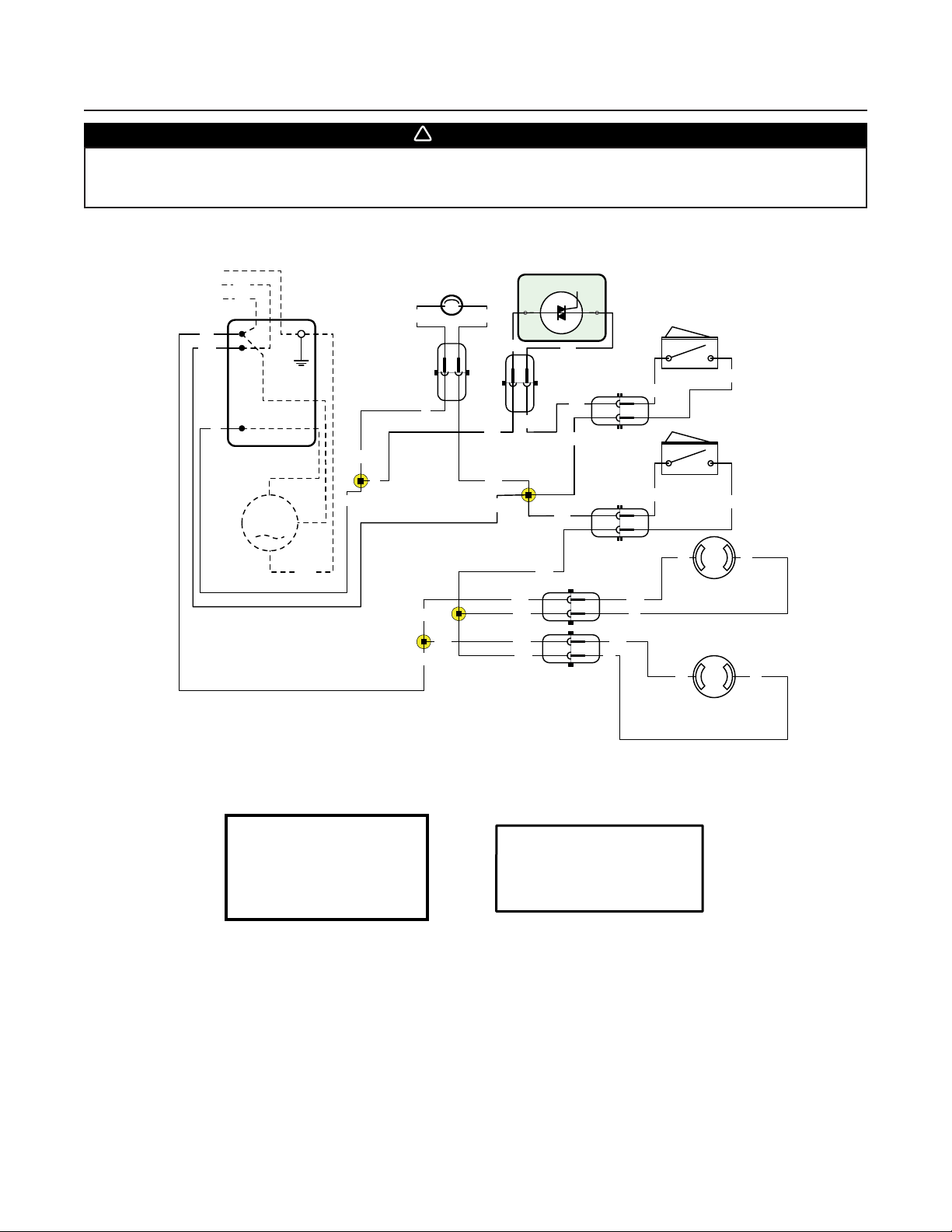

19. WIRING DIAGRAM

WARNING

Risk of electric shock. Electrical wiring must be done by qualified personnel in accordance with all applicable

codes and standards. Before connecting wires, switch power off at service panel and lock

service disconnecting means to prevent power from being switched on accidentally.

!

120 VAC

Ground

Neutral

Supply

W

BK

Line

BK

W

O

BLOWER

Neutral

BLOWER

Line

FIELD WIRING

BOX

O

O

O

HS

THERMOSTAT

O

M

G

W

W

W

BNBN

O

BK

BK

SPEED CONTROL

BK

R

Y

W

Y

W

Y

BK

FAN SWITCH

R

BK

BK

BK

LIGHTS

BK

SWITCH

W

W

W

W

W

BK

BK

W

LIGHT SOCKET

LIGHT SOCKET

W

W

1. If any of the original wire, as

NOTES

supplied, must be replaced, use the

same equivalent wire.

2. Field wiring must comply with

applicable codes, ordinances and

regulations.

HE0035A

WIRING COLOR CODE

BK BLACK

BN BROWN

G GREEN

O ORANGE

R RED

W WHITE

Y YELLOW

Page 14

- 14 -

WARRANTY

ONE-YEAR LIMITED WARRANTY FOR BEST PRODUCTS

Broan-NuTone LLC (Broan-NuTone) warrants to the original consumer purchaser of Best products that such

products will be free from defects in materials or workmanship for a period of one year from the date of original

purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or

part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND

INCANDESCENT BULBS, FUSES, FILTERS, DUCTS, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES

FOR DUCTING. This warranty does not cover (a) normal maintenance and service or (b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by

Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty.

Some states or provinces do not allow limitation on how long an implied warranty lasts, so the above

limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE

THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE

SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT

OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states or provinces do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state

or province to another. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number stated

below, (b) give the model number and part identification and (c) describe the nature of any defect in the product

or part. At the time of requesting warranty service, you must present evidence of the original purchase date.

In USA - Best

®

, 926 W. State Street, Hartford, WI 53027 (800-558-1711)

In Canada - Best®, 550 Lemire Blvd., Drummondville, QC, Canada, J2C 7W9 (866-737-7770)

www.BestRangeHoods.com

Page 15

- 15 -

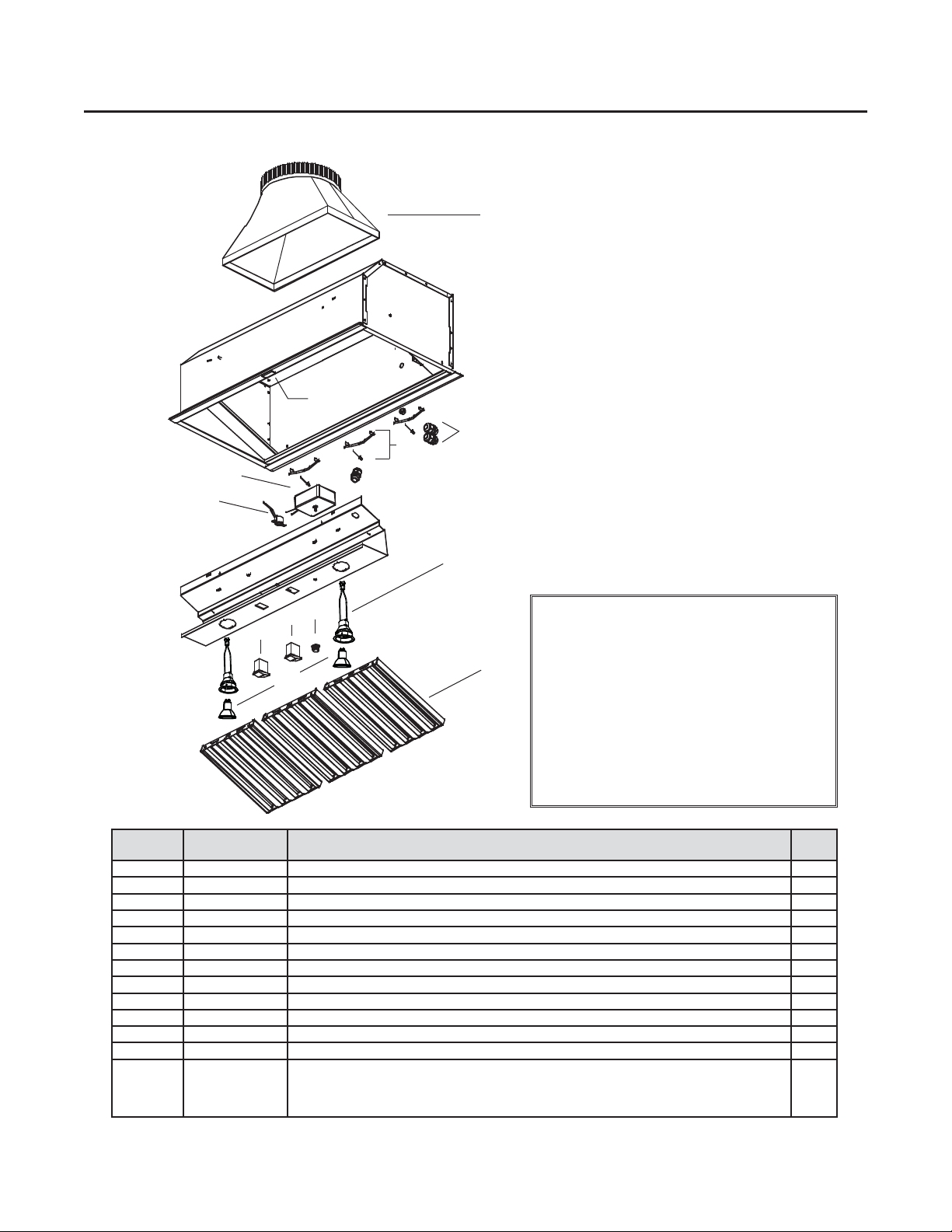

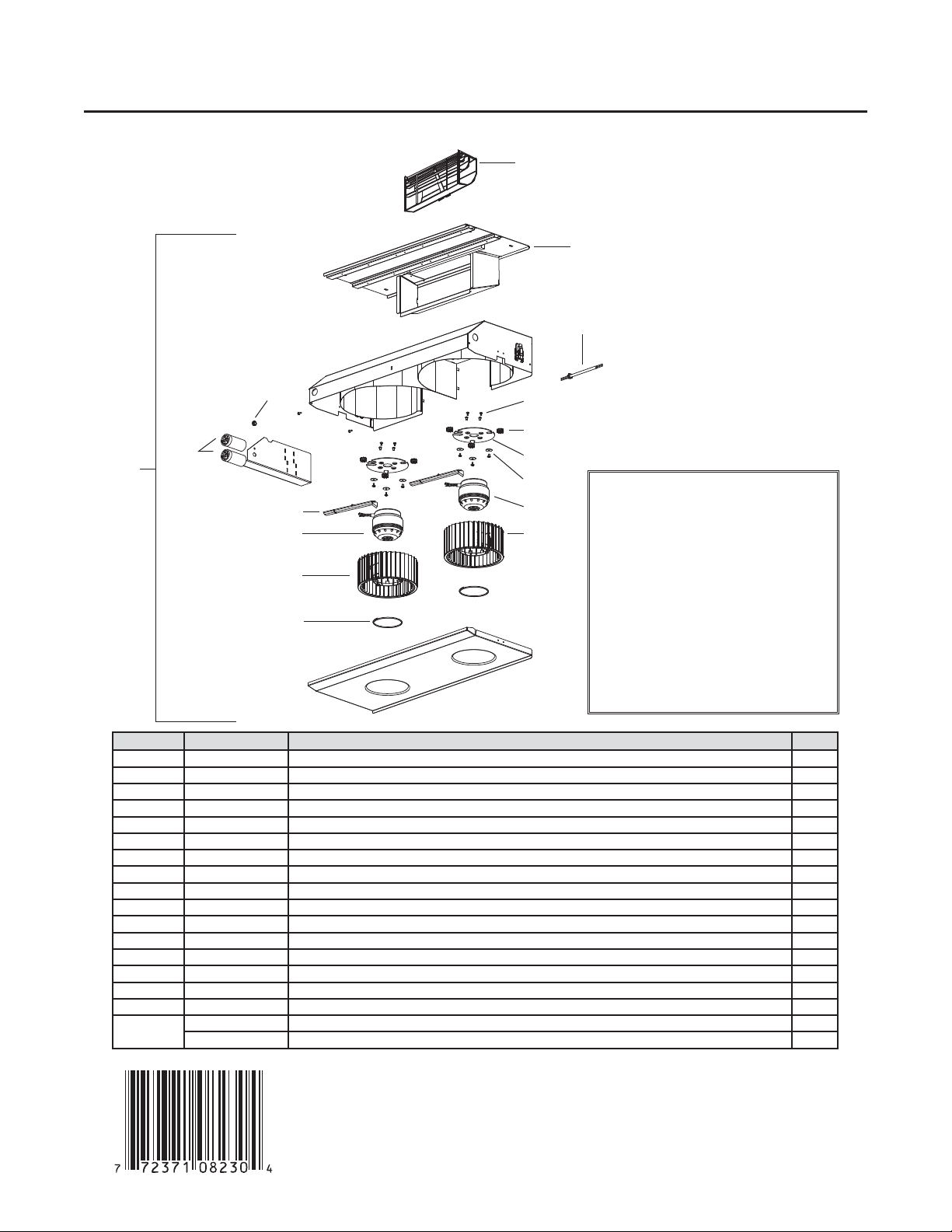

REPLACEMENT PARTS

REF. NO. PART NUMBER DESCRIPTION

QTY.

1 SV03428 TRANSITION 9” x 18” TO 10” ROUND 1

2 SV05869 BEST LOGO 1

3 SV06508 NYLON CONNECTOR KIT 2

4 SV15432 FILTER CLIP KIT 3

5 SV06364 POTENTIOMETER 1

6 SV06497 THERMOSTAT 1

7 SV16765 LAMP SHELL, SOCKET & TRIM ASSEMBLY (OUTDOOR) 2

8 SV03504 BLOWER SPEED CONTROL KNOB 1

9 SV06496 BLOWER SWITCH 1

10 SV06495 LIGHT SWITCH 1

11 SV05921 SHIELDED HALOGEN BULBS 120 V, 50 W, GU10 2

12 SV15422 BEST BAFFLE FILTERS 9.25’’ x 12.5’’ 3

SV04216

PARTS BAG INCLUDING: 3 WATERPROOF WIRE CONNECTORS, 6 NO. 10 X 2" HEX HEAD SCREWS,

2 WIRE CLAMPS LP16-AP, 8 NO. 8 X 3/8" STAINLESS STEEL SCREWS. 2 NO. 8 X 5/8" SCREWS,

4 NO. 10 X 2" FLAT HEAD SCREWS, 2 WALL ANCHORS, 6 WASHERS 3/16" ID X 3/4" OD,

4 STAINLESS STEEL 10-32 LOCKNUTS, 2 NO. 8 X 3/8" ZINC-PLATED SCREWS.

1

2

3

1

6

5

12

7

10

9

4

PIK33D MODEL

8

11

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working

condition, you must use Broan-NuTone genuine

replacement parts only. Broan-NuTone genuine

replacement parts are specially designed for each

unit and are manufactured to comply with all the

applicable certification standards and maintain a high

standard of safety. Any third party replacement part

used may cause serious damage and drastically

reduce the performance level of your unit, which will

result in premature failing. Broan-NuTone recommends

to contact a certified service depot for all replacement

parts and repairs.

HL0123

Page 16

2

3

1

16

15

13

6

9

10

11

12

14

4

5

- 16 -

REPLACEMENT PARTS

DUAL BLOWER P8D

7

8

REF. NO. PART NUMBER DESCRIPTION

QTY.

1 P8D DUAL BLOWER ASSEMBLY 1

2 SV02160 CAPACITOR 15 µF 2

3

*

LOCK NUT NO. 6-32 1

4 SV01857 WIRE COVER 2

5 SV06338 MOTOR 165W CW 1

6 SV03400 BLOWER IMPELLER, HOOD 7.094” X 3.375” CW 1

7 SV01810 IMPELLER RING 2

8 SV03399 BLOWER IMPELLER, HOOD 7.094” X 3.375” CCW 1

9 SV06339 MOTOR 165 W CCW 1

10

*

WASHER 3/16” ID X 3/4” OD 6

11 SV11705 MOTOR MOUNT 2

12 SV02001 MOTOR GROMMET G-431-1 6

13 SV01927 METRIC SCREW M4 X 6 MM PAN QDRX 8

14 SV06369 BLOWER POWER CORD 1

15 SV15443 P8D ROUGH-IN PLATE 1

16 SV03500 AIR DEFLECTOR 1

*

8” TIE WRAP 2

SV11614 WIRE NO. 18 TEW BROWN X 10” 2

* STANDARD HARDWARE - MAY BE PURCHASED LOCALLY.

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good

working condition, you must use

Broan-NuTone genuine replacement parts

only. Broan-NuTone genuine replacement

parts are specially designed for each unit

and are manufactured to comply with all the

applicable certification standards and

maintain a high standard of safety. Any third

party replacement part used may cause

serious damage and drastically reduce the

performance level of your unit, which will

result in premature failing. Broan-NuTone

recommends to contact a certified service

depot for all replacement parts and repairs.

Page 17

GUIDE D’INSTALLATION

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800 558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.com 866 737-7770

Pour enregistrer votre produit en ligne ou pour plus d’information, consultez notre site

www.BestRangeHoods.com

SV06322 Rév. 10

CONÇU POUR LA CUISSON DOMESTIQUE SEULEMENT

INSTALLATEUR : LAISSER CE GUIDE AU PROPRIÉTAIRE.

PROPRIÉTAIRE : DIRECTIVES D’UTILISATION ET D’ENTRETIEN EN PAGES 27 ET 28.

LIRE ET CONSERVER CES DIRECTIVES

!

!

HB0034

MODÈLE PIK33D

CONVIENT À UNE UTILISATION DANS DES LIEUX HUMIDES LORSQUE RACCORDÉ À UN

DISJONCTEUR DE FUITE À LA TERRE (DDFT).

C

ONÇU POUR FONCTIONNER SUR UN PATIO COUVERT OU DANS UNE VÉRANDA.

Page 18

- 18 -

AVERTISSEMENT

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE,

D’ÉLECTROCUTION OU DE BLESSURES CORPORELLES,

SUIVEZ LES DIRECTIVES SUIVANTES :

1. N’utilisez cet appareil que de la façon prévue par le

manufacturier. Si vous avez des questions, contactez

le manufacturier à l’adresse et au numéro de

téléphone indiqués dans la garantie.

2. Avant de réparer ou de nettoyer l’appareil, couper

l’alimentation électrique en verrouillant le panneau de

distribution afin d’éviter sa remise en marche accidentelle.

Si le panneau de distribution ne peut être verrouillé, y

fixer un avertissement en évidence, telle qu’une

étiquette de couleur vive.

3. Les travaux d’installation et de raccordement électrique

doivent être effectués par une personne qualifiée,

conformément aux codes et aux standards de

construction, incluant ceux concernant la protection

contre les incendies.

4. Une quantité d’air adéquate est requise afin d’assurer

une bonne combustion et l’évacuation des gaz par la

cheminée dans le cas des équipements alimentés au

gaz afin de prévenir les retours de cheminée.

Conformez-vous aux instructions et aux standards de

sécurité des manufacturiers d’équipement de

chauffage, tel qu’ils sont publiés par la

National Fire

Protection Association

(NFPA) et l’

American Society

for Heating, Refrigeration and Air Conditioning

Engineers

(ASHRAE) ainsi que les responsables des

codes locaux.

5. Lorsque vous coupez ou perforez un mur ou un

plafond, prenez garde de ne pas endommager les fils

électriques ou autre installation qui pourraient y

être dissimulés.

6. Les ventilateurs avec conduits doivent toujours évacuer

l’air à l’extérieur.

7. Ne pas utiliser cet appareil avec une commande de

vitesse à semi-conducteur additionnelle.

8. Afin de réduire les risques d’incendie, n’utilisez que

des conduits en métal.

9. Cet appareil doit être mis à la terre et protégé par un

DDFT (disjoncteur de fuite à la terre).

10. Convient à une utilisation dans des lieux humides

seulement lorsqu’elle est raccordée à un

DISJONCTEUR DE FUITE À LA TERRE (DDFT).

11. Lorsqu’une réglementation est en vigueur localement

et qu’elle comporte des exigences d’installation et/ou

de certification plus restrictives, lesdites exigences

prévalent sur celles de ce document et l’installateur

entend s’y conformer à ses frais.

AFIN DE RÉDUIRE LES RISQUES DE FEU

DE CUISINIÈRE :

a) Ne jamais laisser les appareils de cuisson sans

surveillance lorsqu’ils sont réglés à feu vif. Les

débordements engendrent de la fumée et des

déversements graisseux pouvant s’enflammer.

Chauffez l’huile lentement, à feu doux ou moyen.

b) Toujours mettre la hotte en marche lorsque vous

cuisinez à feu vif ou que vous cuisinez des mets

flambés (par ex. : crêpes Suzette, cerises jubilé, steaks

au poivre flambés).

c) Nettoyez régulièrement la (les) roue(s) du ventilateur.

Ne laissez pas la graisse s’accumuler sur le ventilateur,

les filtres ou les conduits d’évacuation.

d) Utilisez le bon format de casserole. Servez-vous

toujours de casseroles et d’ustensiles appropriés à la

dimension de la surface chauffante.

AFIN D’ÉVITER TOUT RISQUE DE BLESSURES LORS

D’UN FEU DE CUISINIÈRE, SUIVEZ CES DIRECTIVES* :

1. Étouffez les flammes avec un couvercle hermétique,

une tôle à biscuits ou un plateau métallique et ensuite,

éteindre le brûleur. PRENEZ SOIN D’ÉVITER LES

BRÛLURES. SI LES FLAMMES NE S’ÉTEIGNENT

PAS IMMÉDIATEMENT, ÉVACUEZ LES LIEUX ET

APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS UNE CASSEROLE EN

FLAMMES DANS VOS MAINS, vous pourriez subir

des brûlures.

3. N’UTILISEZ PAS D’EAU, incluant un linge à vaisselle

ou une serviette mouillée, cela pourrait occasionner

une violente explosion de vapeur.

4. N’utilisez un extincteur QUE DANS LE CAS OÙ :

A. Vous savez qu’il s’agit d’un extincteur de classe

ABC et que vous en connaissez le fonctionnement.

B. L’incendie est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en ayant accès à

une sortie de secours.

*Tirées du

Kitchen Fire Safety Tips

publié par la NFPA.

ATTENTION

1. Pour usage domestique seulement. Ne pas utiliser

pour évacuer des vapeurs ou des matières

dangereuses ou explosives.

2. Afin d’éviter tout dommage au moteur et de

débalancer ou de rendre bruyante la roue du moteur,

garder votre appareil à l’abri des poussières de gypse

et de construction/rénovation, etc.

3. Le moteur de votre module de hotte encastrable

possède une protection thermique qui éteindra

automatiquement le moteur s’il devient surchauffé. Le

moteur repartira automatiquement une fois refroidi. Si

le moteur continue à arrêter et à repartir, faites-le vérifier.

4. La distance minimale entre le bas de votre hotte et la

surface de cuisson ne doit pas être inférieure à 36 po.

Un maximum de 42 po au-dessus de la surface de

cuisson est fortement recommandé pour une meilleure

évacuation des odeurs de cuisson.

5. Vu la grande dimension et le poids de cette hotte, il est

recommandé de confier son installation à 2 personnes.

6. Afin de réduire les risques d’incendie, assurez-vous

d’évacuer l’air à l’extérieur. Ne pas évacuer l’air dans

des espaces restreints comme l’intérieur des murs ou

plafond ou dans le grenier, faux plafond ou garage.

7. Cet appareil est équipé d’un thermostat pouvant faire

démarrer le ventilateur automatiquement. Afin de

réduire les risques de blessures, couper le courant à

partir du panneau de distribution et verrouiller ou

apposer un avertissement sur le panneau afin de

prévenir que la hotte soit mise en marche automatiquement.

8. Afin de réduire les risques d’incendie et d’électrocution,

le modèle PIK33D doit être installé uniquement avec

l’un des ventilateurs interne P8D ou avec le ventilateur

externe EB12 ou EB15 ou le ventilateur en ligne ILB11

(vendu séparément). Aucun autre ventilateur ne doit

être utilisé.

9. Lorsqu’il est utilisé comme appareil de démonstration,

ce module de hotte encastrable ne doit être utilisé

qu’avec un ensemble de cordon d’alimentation approuvé.

10. Veuillez consulter l’autocollant apposé à l’intérieur du

produit pour plus d’information ou autres exigences.

!

!

Page 19

- 19 -

Transition modèle SV03428

(9 po x 18 po à 10 po ronde) (incluse)

Plaque ventilateur incluse avec

le ventilateur intérieur P8D

MODULE DE HOTTE

ENCASTRABLE PIK33D

- MODÈLE PIK33D -

SYSTÈME DE MODULE DE HOTTE ENCASTRABLE

Déviateur d’air

(inclus avec ventilateur intérieur P8D)

Revêtement d’armoire (optionnel)

L3336D ou L3348D

Ventilateur en ligne

ILB11 (1100 PCM)

(incluant deux transitions rondes

de 8 po x 12 po à 10 po)

Modèle 441

(Capuchon de mur

de 10 po rond)

Modèle 437

(Capuchon de toit à haut rendement)

Ventilateur extérieur

Modèle EB12

(1200 PCM)

ou EB15 (1500 PCM)

(vendus séparément)

Conduit de métal flexible de

10 po rond (optionnel)

Ventilateur double P8D

(vendu séparément)

Modèle 421

(Volet intérieur

10 po, rond vert.)

(Recommandé

pour utilisation

avec ventilateurs

extérieurs)

Modèle 410

(Conduit de 10 po rond

standard, sections de 2 pi)

Modèle 418

(Coude ajustable de 10 po,

optionnel)

HL0080

Page 20

- 20 -

1. SÉLECTIONNER L’OPTION VENTILATEUR ET INSTALLER LES CONDUITS

Le module de hotte encastrable PIK33D doit être installé uniquement avec le ventilateur intérieur P8D, le ventilateur extérieur

EB12 ou EB15 ou le ventilateur en ligne ILB11 (vendus séparément). Aucun autre ventilateur ne peut être utilisé.

Si un ventilateur en ligne est installé, se reporter aux directives incluses avec celui-ci et suivre les étapes 1 à 6, 10 à 13, 15 et plus de ce guide.

Déterminer à quel endroit et de quelle façon les conduits seront installés. Il est préférable de garder un accès au-dessus du

module pour le raccordement des conduits. Sinon, des conduits de métal flexibles peuvent être utilisés. Installer des conduits

de 10 po en métal, coude(s) et capuchon de mur ou de toit selon le type de ventilateur. Utiliser des conduits circulaires avec

une petite section de conduit de métal flexible (environ 4 pi étiré) (optionnel) pour le raccordement à la transition. Utiliser des

vis pour fixer le conduit de métal flexible au conduit rigide. Utiliser du ruban adhésif de métal pour assurer l’étanchéité des joints.

La distance minimale entre le bas de votre hotte et la surface de cuisson ne doit pas être inférieure à 36 po. Un maximum

de 42 po au-dessus de la surface de cuisson est fortement recommandé pour une meilleure évacuation des odeurs de cuisson.

Une distance de plus de 42 po demeure à la discrétion de l’installateur et de l’utilisateur.

2. PRÉPARER L’INSTALLATION

NOTE : Avant de commencer l'installation, vérifier le contenu de la boîte. Si des pièces sont manquantes ou endommagées,

contacter le manufacturier.

S’assurer que les articles suivants soient inclus

:

- Module de hotte encastrable

- Accessoires :

• Transition (9 po x 18 po à 10 po ronde)

• 3 filtres à chicane

• 2 ampoules halogènes avec écran (120 V, 50 W, Type GU10)

• Sac de pièces incluant :3 capuchons de connexion étanches, 6 vis à tête hexagonale n° 10 x 2 po, 2 serre-fils LP16-AP,

8 vis en acier inoxydable n° 8 x 3/8 po.

Inclus dans le sac de pièces, mais à ne pas utiliser (svp jeter) : 2 vis n° 8 x 5/8 po, 4 vis à tête fraisée n° 10 x 2 po,

2 douilles à expansion, 6 rondelles de 3/16 po DI x 3/4 po DE, 4 contre-écrous 10-32 en acier inoxydable,

2 vis n° 8 x 3/8 po plaquées zinc.

Pièces vendues séparément

:

- Ventilateur intérieur, modèle P8D avec plaque ventilateur et déviateur d’air

- Ensemble ventilateur extérieur, modèle EB12 ou EB15 (ne pas utiliser la plaque ventilateur incluse avec le ventilateur extérieur)

- Ensemble ventilateur en ligne, modèle ILB11 (incluant la plaque ventilateur et 2 transitions, ne pas utiliser la plaque ventilateur)

- Revêtement d’armoire, modèle L3336D ou L3348D (optionnel)

- Conduits (rigides et flexibles), coudes, volets, capuchons de mur ou de toit. Consulter la page 19 pour la liste complète des

accessoires de ventilation et des numéros de modèle.

NOTE : Lors de l’installation, protéger le plan de cuisson et/ou le comptoir de cuisine.

INSTALLATION TYPIQUE

VENTILATEUR INTÉRIEUR

MODÈLE

P8D

I

NSTALLATION TYPIQUE

VENTILATEUR EXTÉRIEUR

MODÈLES

EB12 OU EB15

INSTALLATION TYPIQUE

VENTILATEUR EN LIGNE

MODÈLE

ILB11

AVERTISSEMENT

Il est recommandé de porter des lunettes et des gants de sécurité lors de l’installation, de l’entretien ou

de la réparation de cet appareil.

Ce module de hotte encastrable a été conçu pour fonctionner avec une cuisinière extérieure électrique ou au gaz, lorsqu’elle est utilisée

sur un patio couvert ou une véranda. Comme tous les électroménagers, cet appareil doit être à l’abri des intempéries.

AVERTISSEMENT

Cet appareil n’est pas conçu pour être utilisé avec un barbecue au charbon de bois.

!

!

Ventilateur

extérieur

Conduit rond de

10 po avec conduit

de métal flexible de

10 po rond (opt.)

Transition de

9 po x 18 po à

10 po

Module

Minimum de 36 po

au-dessus de la

surface de cuisson

Conduit rond

de 10 po

Ventilateur en ligne

Conduit métal flex.

de10 po

rond (opt.)

Minimum de 36 po

au-dessus de la

HH0067F

surface de cuisson

Capuchon de toit

Module

Capuchon

de mur

Capuchon

de mur

HH0005F

Capuchon

de toit

Conduit rond de

10 po avec conduit

de métal flexible

de 10 po rond (opt.)

Transition ronde

de 9 po x 18 po

à 10 po

Module avec

ventilateur

intérieur

Minimum de 36 po

au-dessus de la

surface de cuisson

HH0042F

Page 21

- 21 -

3. PRÉPARATION DE L’ARMOIRE POUR HOTTE

AVERTISSEMENT

Toujours suivre les codes et standards en vigueur lors de la contruction de l’armoire pour hotte.

!

Construire la charpente de l’armoire en fonction du format et du poids total du module de hotte encastrable.

Le tableau ci-dessous indique les poids des modules selon le type de ventilateur choisi.

Commencer avec la base de l’armoire, car sa position déterminera la

hauteur du module de hotte encastrable. Nous recommandons qu’elle

soit faite de contreplaqué de 3/4 po d’épaisseur.

Si un revêtement d’armoire optionnel sera installé, nous recommandons

que les côtés et l’avant de l’armoire soient de 3/4 po d’épaisseur, selon

que l’armoire soit de largeur standard. Si le revêtement d’armoire

optionnel n’est pas installé, l’épaisseur des côtés et de l’avant de l’armoire

est à la discrétion de l’installateur.

Passer l’alimentation électrique jusqu’à l’emplacement de l’installation.

Laisser dépasser une longueur de 4 pi de câble électrique sous l’armoire.

4. CHARPENTE DE L’ARMOIRE SUGGÉRÉE

Les trous d’assemblage du dessus du module sont à 119⁄16 po de la base

de celui-ci. La distance centre à centre entre les 2 supports est de

30¼ po.

Les trous d’assemblage du support arrière sont à 1½ po à partir de la

base du module. Voir l’illustration ci-contre.

Une fois la base et la charpente de l’armoire terminées, finaliser l’armoire.

AVERTISSEMENT

Le fil d’alimentation doit être raccordé à un disjoncteur de

fuite à la terre (DDFT).

!

HOTTE ENCASTRABLE AVEC VENTILATEUR INTÉRIEUR AVEC VENTILATEUR EXTÉRIEUR OU EN LIGNE

PIK33D 49 LB 27 LB

5. INSTALLER LE REVÊTEMENT D’ARMOIRE (OPTIONNEL)

Les revêtements d’armoire ont été conçus spécialement pour protéger

la base de l’armoire. La profondeur de ces deux modèles s’ajuste de

23½ po à 26½ po (de l’avant vers l’arrière, sans panneau arrière).

Le revêtement d’armoire s’installe avant

le module. Pour commander,

consulter le tableau ci-dessous afin de trouver le modèle de revêtement

correspondant à la largeur de l’armoire.

Visiter le site www.BestRangeHoods.com

ou joindre le service technique

(le numéro de téléphone se trouve dans le texte de garantie, en page

30) afin de connaître leurs caractéristiques spécifiques, incluant les

profondeurs de chacun des modèles. Pour l’installation, voir la feuille

d’instruction du revêtement d’armoire.

REVÊTEMENT LARGEUR NOMINALE DE L’ARMOIRE

L3336D 36 PO

L3348D 48 PO

HH0044F

Épaisseur de la

base de

contreplaqué : 3/4 po

De 36 po à 42 po

au-dessus de la

table de cuisson

Table de cuisson

standard de

36 po de hauteur

1½ po

HH0043F

HA0039F

Page 22

- 22 -

6. DÉCOUPER LE TROU DANS LA BASE DE L’ARMOIRE

Si ce n’est pas déjà fait, découper le trou dans la base de l’armoire

selon les dimensions indiquées ci-contre.

NOTES : 1. La distance minimale recommandée entre l’arrière de l’armoire

et le rebord arrière de la découpe est de 2¼ po.

2. Lors de la découpe de l’encoche pour le câblage de

10¾ po, faire aussi l’encoche dans la poutre arrière ou

prévoir un dégagement pour le câblage.

7. INSTALLER LE VENTILATEUR EXTÉRIEUR (MODÈLE EB12 OU EB15 SEULEMENT)

OU LE VENTILATEUR EN LIGNE ILB11)

Voir les instructions fournies avec le ventilateur extérieur EB12 ou EB15 ou le ventilateur en ligne ILB11 et suivre les étapes 10,

11, 12, 13, 15 et suivantes de ce guide.

8. INSTALLER LA PLAQUE VENTILATEUR

(AVEC LE VENTILATEUR INTÉRIEUR MODÈLE P8D SEULEMENT)

Installer la plaque ventilateur au dessus intérieur du module (les vis à travers

la plus grande partie des trous en forme de poire). Glisser la plaque ventilateur

vers l’arrière du module (les vis dans la plus petite partie des trous en forme

de poire). Serrer les quatre (4) vis.

HO0023

9. INSTALLER LE DÉVIATEUR

(AVEC LE VENTILATEUR INTÉRIEUR MODÈLE P8D SEULEMENT)

Installer le déviateur tel qu’il est illustré.

NOTE : S’il est bien installé, le déviateur dépasse d’environ 1/8 po au-dessus du

module de hotte encastrable.

HO0022

16½ po

2¼ po

min.

HD0101F

32½ po

11/16 po

10¾ po

Page 23

Connecter le fil NOIR au fil ORANGE (G), le BLANC au deux autres BLANCS (H) et le

VERT à la vis de mise à la terre (I). NE PAS OUBLIER DE CONNECTER LA MISE À LA

TERRE. Refermer le boîtier électrique.

Connecter le fil NOIR au NOIR (C) et le VERT ou le fil dénudé à la vis de mise à la terre (D). NE PAS OUBLIER DE

CONNECTER LA MISE À LA TERRE. Ne pas refermer tout de suite le boîtier électrique.

10. BRANCHEMENTS ÉLECTRIQUES

TOUTES LES INSTALLATIONS :

Perforer l’ouverture préamorcée située à l’arrière du module.

NOTE : Perforer (1) ouverture pour une installation avec ventilateur intérieur et (2) ouvertures pour une installation avec un

ventilateur extérieur ou en ligne.

Enlever le couvercle du boîtier électrique et y retirer les (2) gaines pour fils. Les conserver pour usage ultérieur. Installer un

serre-fils (A) dans une ouverture préamorcée de la paroi arrière du module et l’autre dans le boîtier électrique. Placer le module

sous son armoire. Passer le fil d’alimentation électrique dans une des gaines (B) fournies. Puis, le passer avec sa gaine au travers

du passe-fils de la paroi arrière du module ainsi que celui du boîtier électrique. Serrer les vis des deux serre-fils pour le maintenir

en place. Les deux bouts de la gaine doivent être serrés dans les serre-fils. Connecter les fils à la boîte électrique en utilisant

les capuchons de connexion étanches fournis.

AVERTISSEMENT

Risque de chocs électriques. Le raccordement électrique doit être effectué par du personnel qualifié

conformément aux codes et aux standards. Avant d’effectuer le branchement, coupez l’alimentation

électrique au panneau de distribution et verrouillez-le pour éviter une mise en marche accidentelle.

!

HE0034

MARCHE À SUIVRE POUR L’UTILISATION DES CAPUCHONS DE CONNEXION ÉTANCHES :

1. Dégainer les fils d’une longueur de 3/8 po.

2. Égaliser les brins ou les conducteurs.

3. Ne pas les tordre. Rapprocher les fils et mettre leurs bouts égaux, sauf pour les fils à

brins plus petits, lesquels doivent dépasser légèrement des fils plus gros.

4. Insérer les fils dans le capuchon de connexion en poussant fermement et tordre.

NE PAS trop tordre.

5. Un peu de scellant pourrait s’échapper lors de l’insertion des fils dans un capuchon de

connexion. Essuyer l’excès de scellant autour des conducteurs. NE PAS RÉUTILISER.

ATTENTION

Ne pas connecter tout de suite les fils BLANCS.

B

C

D

A

A

VENTILATEUR EXTÉRIEUR OU EN LIGNE SEULEMENT :

Installer un serre-fils (non-inclus) dans l’ouverture située à l’arrière du module, à côté de l’autre

serre-fils. Passer le fil du ventilateur extérieur ou en ligne dans l’autre gaine (E) (fournie), puis

à travers le serre-fils et serrer. Le bout de la gaine doit être serré dans le serre-fils.

Passer le câble du ventilateur (et sa gaine) dans le serre-fils de plastique (F) du boîtier électrique.

Serrer complètement le serre-fils de plastique. Voir la figure ci-contre.

Connecter les fils à la boîte électrique en utilisant les capuchons de connexion étanches fournis.

NOTE : Afin d’effectuer adéquatement les connexions, voir la M

ARCHE À SUIVRE POUR L’UTILISATION

DES CAPUCHONS DE CONNEXION ÉTANCHES

(texte encadré plus haut).

Pas

entièrement

serré

Entièrement

serré

F

E

F

G

H

HE0033

- 23 -

I

VO0084

Page 24

- 24 -

Glisser la transition par-dessus l’adaptateur. Sceller la transition à

l’adaptateur en utilisant du ruban adhésif de métal.

11. INSTALLER LA TRANSITION

A. Si l’accès au-dessus de l’armoire demeure ouvert, aller au point 13.

Installer le module, puis raccorder les conduits et sceller les joints

à l’aide de ruban adhésif de métal.

B. Lorsque l’accès au-dessus de l’armoire est fermé, tirer doucement

le conduit de métal à travers le trou de la base de l’armoire. Glisser

ce conduit par-dessus la transition. Sceller le raccordement à l’aide

de ruban adhésif de métal.

13. INSTALLER LE MODULE

IInstaller le module à l’intérieur de

l’armoire et le fixer à sa charpente en

utilisant les 6 vis à tête hexagonale

n° 10 x 2 po (incluses). Positionner le

module vers l’arrière pour couvrir

l’encoche de 3½ po de l’étape 6.

Commencer par les 2 vis avant du

dessus, puis les 2 vis arrière du dessus,

et terminer par les 2 vis arrière. (Voir la

figure ci-contre pour l’emplacement

exact des vis de montage.)

DESSUS

ARRIÈRE

ATTENTION

Prendre soin de ne pas plier les conduits en installant le module (point 13).

ATTENTION

Prendre soin de ne pas plier les conduits ou de pincer le fil d’alimentation électrique en installant le module.

12. RACCORDER LES CONDUITS

HD0092

HD0057

HD0102

Page 25

- 25 -

14. INSTALLER LE VENTILATEUR INTÉRIEUR (MODÈLE P8D SEULEMENT)

Le ventilateur doit être installé à la plaque ventilateur en utilisant huit vis n° 8 x 3/8 po. Enlever le couvercle du ventilateur. Retirer

les roues du ventilateur en tirant délicatement (voir photos ci-dessous).

Installer quatre 4 vis n° 8 x 3/8 po aux endroits indiqués sur la photo

ci-contre en laissant un espace d’environ 1/8 po. Accrocher ensuite le

ventilateur à l’intérieur du module de hotte encastrable (passer les têtes

de vis à travers la grande partie des trous). Glisser ensuite le ventilateur

en position (les têtes de vis dans la petite partie des trous). Serrer

complètement les quatre 4 vis.

Terminer la fixation du ventilateur à l’aide de quatre autres vis n° 8 x 3/8 po

aux endroits indiqués sur la photo ci-contre. Remettre en place les

roues de ventilateur et le couvercle.

HD0021

HD0022

HD0081

HD0045

Page 26

- 26 -

Connecter le fil ORANGE au fil ORANGE (B), le BLANC au deux autres fils BLANCS (C) de

l’étape 10 et le VERT à la vis de mise à la terre (D). NE PAS OUBLIER DE

CONNECTER LA MISE À LA TERRE. Refermer le boîtier électrique.

Dans le cas d’un ventilateur double, les deux roues de

ventilateur sont différentes; une doit tourner dans le sens

des aiguilles d’une montre et l’autre dans le sens contraire

des aiguilles d’une montre. Chaque roue et moteur comportent

une flèche et un numéro, vous devez les associer correctement.

(Voir dessin ci-contre.)

AVANT

HD0023

1

2

14. INSTALLER LE VENTILATEUR INTÉRIEUR (MODÈLE P8D SEULEMENT) (SUITE)

Passer le câble du ventilateur dans le serre-fils de plastique (A) du boîtier électrique. Serrer

entièrement le serre-fils de plastique. Voir la figure ci-contre.

A

A

B

C

HE0033

D

ATTENTION

S’assurer que les roues soient bien replacées; le module ne fonctionnera pas normalement si inversées.

MARCHE À SUIVRE POUR L’UTILISATION DES CAPUCHONS DE CONNEXION ÉTANCHES :

1. Dégainer les fils d’une longueur de 3/8 po.

2. Égaliser les brins ou les conducteurs.

3. Ne pas les tordre. Rapprocher les fils et mettre leurs bouts égaux, sauf pour les fils à

brins plus petits, lesquels doivent dépasser légèrement des plus gros fils.

4. Insérer les fils dans le capuchon de connexion en poussant fermement et tordre.

NE PAS trop tordre.

5. Un peu de scellant pourrait s’échapper lors de l’insertion des fils dans un capuchon de

connexion. Essuyer l’excès de scellant autour des conducteurs. NE PAS RÉUTILISER.

Pas

entièrement

serré

Entièrement

serré

15. AMPOULES HALOGÈNES

L’éclairage de ce module est produit par des ampoules halogènes avec écran (120 V, 50 W, MR16 ou PAR16 avec culot GU10), fournies.

1. Installer les ampoules en glissant leurs conducteurs dans les rainures, à l’intérieur

des douilles.

2. Pousser doucement vers le haut et tourner dans le sens des aiguilles d’une

montre jusqu’à ce que les ampoules soient bien en place.

Pour retirer les ampoules, pousser doucement vers le haut et tourner dans le sens contraire

des aiguilles d’une montre pour dégager les conducteurs hors de leurs rainures.

NOTE : Pour obtenir une meilleure prise de l’ampoule lors de son retrait, utiliser un gant

à vaisselle ou la ventouse de Best. Contacter le service à la clientèle de Best au

1 800 558-1711 pour commander la ventouse, numéro de pièce 99526707.

AVERTISSEMENT

Ne pas toucher aux lampes durant ou peu après leur utilisation. Peuvent causer des brûlures. Afin de

réduire le risque de blessures corporelles, n’installer que des ampoules halogènes avec écran. Aussi, ne

jamais installer une ampoule à faisceau froid, dichroïque, non conçue pour des luminaires encastrés ou

conçue uniquement pour des luminaires fermés.

!

VO0084

21

HD0023

12

HO0090

Page 27

- 27 -

Il est recommandé d’installer d’abord les filtres situés aux extrémités et de terminer

par le filtre du centre.

Une flèche verticale accompagnée du mot « AIR » apparaît sur le rebord des filtres.

S’assurer d’installer les filtres de façon à ce que la flèche pointe vers l’intérieur du

module. Voir figure ci-contre.

1. Insérer la partie supérieure du filtre à chicanes dans le module.

2. Faire pivoter la partie inférieure vers l’intérieur et pousser pour insérer l’attache

arrière dans sa fente à l’arrière du module.

3. Tout en poussant sur le filtre, le glisser sous sa pièce de retenue intérieure.

S’assurer que les filtres à chicanes soient positionnés tel qu’il est illustré ci-contre

afin que la graisse puisse se rendre facilement à la gouttière.

ATTENTION

Avant d’installer les filtres à chicane, retirer le plastique protecteur de ceux-ci.

Acier inoxydable : Comment maintenir son apparence étincelante et aider à prévenir la corrosion.

3

2

1

16. INSTALLER LES FILTRES À CHICANE

FILTRES À CHICANE ET ROUES DE VENTILATEUR.

Les filtres à chicane, la gouttière et les roues de ventilateur doivent être nettoyés une fois par mois. Utiliser de l’eau chaude

additionnée de détergent. Les filtres à chicanes et les roues peuvent être nettoyés au lave-vaisselle.

Pousser les filtres à chicanes vers l’intérieur du module et les désengager de la gouttière pour ensuite les retirer.

Nettoyer les filtres fabriqués entièrement de métal au lave-vaisselle à l’aide d’un détergent sans phosphate. L’utilisation d’un

détergent avec phosphates ainsi que les conditions locales de l’eau peuvent entraîner une décoloration des filtres, sans

toutefois affecter leur performance. Cette décoloration n’est pas couverte par la garantie.

17. ENTRETIEN

À éviter lors du choix d’un détergent :

• Tous produits nettoyants qui contiennent des agents de blanchiment; ils attaqueront l’acier inoxydable.

• Tous produits contenant du chlorure, de l’iode ou du bromure; ils détérioreront rapidement les surfaces.

• Tous produits combustibles utilisés pour le nettoyage : acétone, alcool, éther, benzène, etc.; ils sont hautement explosifs

et ne devraient jamais être utilisés près d’une cuisinière.

AVERTISSEMENT

Avant de réparer ou de nettoyer l’appareil, couper l’alimentation électrique en verrouillant le panneau de

distribution afin d’éviter sa remise en marche accidentelle. Si le panneau de distribution ne peut être

verrouillé, y fixer un avertissement en évidence telle qu’une étiquette de couleur vive.

!

À faire :

• Laver régulièrement les surfaces à l’aide d’un chiffon ou

linge propre imbibé d’eau tiède et de savon doux ou

détergent liquide à vaisselle.

• Toujours nettoyer dans le sens du polissage.

• Toujours bien rincer avec de l’eau claire (2 à 3 fois) et

essuyer complètement.

• Un nettoyant domestique conçu spécialement pour l’acier

inoxydable peut aussi être utilisé.

À ne pas faire :

• Utiliser une laine d’acier ou d’acier inoxydable ou tout autre

grattoir pour enlever la saleté tenace.

• Utiliser une poudre nettoyante abrasive ou rugueuse.

• Laisser la saleté s’accumuler.

• Laisser la poussière de plâtre ou tout autre résidu de

construction atteindre la hotte. Couvrir la hotte pour la durée

des travaux afin de s’assurer qu’aucune poussière

n’atteigne la hotte.

HO0014

HD0090

Page 28

- 28 -

18. FONCTIONNEMENT

1) Commande d’éclairage

2) Commande MARCHE/ARRÊT du ventilateur

3) Commande de réglage de vitesse du ventilateur

1 2

3

HC0014

Le module fonctionne à l’aide des (3) commandes situées sous son rebord inférieur avant.

ÉCLAIRAGE

Cette commande contrôle les lampes halogènes.

Utiliser des ampoules halogènes de 120 V, 50 W, type GU10 (fournies).

VENTILATEUR

Le ventilateur fonctionne à l’aide de deux commandes.

La commande MARCHE/ARRÊT actionne le ventilateur à la vitesse présélectionnée par la commande de vitesse. Le ventilateur

doit être mis en marche et arrêté par cette commande.

Pour augmenter la vitesse, tourner le bouton de commande de vitesse dans le sens contraire des aiguilles d’une montre.

Pour ralentir la vitesse, tourner dans le sens des aiguilles d’une montre.

HEAT SENTRY

MC

Cet appareil est équipé d’un détecteur de chaleur Heat Sentry. Ce détecteur mettra en marche automatiquement le ventilateur ou

augmentera sa vitesse s’il détecte de la chaleur excessive au-dessus de la surface de cuisson.

1) Si le ventilateur n’est pas en marche, il le met en marche à haute vitesse.

2) Si le ventilateur est en marche à une vitesse inférieure, il le règle à la vitesse maximale.

Lorsque la température revient à la normale, la vitesse du ventilateur retourne à sa position originale.

Tester toutes les commandes du module.

AVERTISSEMENT

Lors d’un feu de cuisson ou d’une chaleur excessive, le Heat Sentry peut mettre le ventilateur en marche

même s’il est arrêté. Si tel est le cas, il est impossible d’arrêter le ventilateur à l’aide de son interrupteur.

Si vous devez arrêter le fonctionnement du ventilateur, faites-le depuis le panneau de distribution principal.

!

Page 29

19. SCHÉMA ÉLECTRIQUE

AVERTISSEMENT

Risque de chocs électriques. Le raccordement électrique doit être effectué par du personnel qualifié

conformément aux codes et aux standards. Avant d’effectuer le branchement, coupez l’alimentation

électrique au panneau de distribution et verrouillez-le pour éviter une mise en marche accidentelle.

!

- 29 -

Mise à

la terre

Ligne

Neutre

120 V c.a.

Alimentation

B

N

O

N

B

VENTILATEUR

Neutre

VENTILATEUR

Ligne

M

BOÎTE DE CÂBLAGE

O

O

V

O

THERMOSTAT HS

O

B

B

B

COMMANDE

DE VITESSE

BRBR

N

O

N

N

N

R

R

N

N

J

B

J

B

J

INTERRUPTEUR

DU VENTILATEUR

N

INTERRUPTEUR D’ÉCLAIRAGE

N

B

DOUILLE D’AMPOULE

B

B

B

B

B

DOUILLE D’AMPOULE

N

N

B

B

1. Lors d’un remplacement de fil,

NOTES

utiliser le même type ou l’équivalent.

2. Les fils installés sur place doivent

respecter les codes et règlements

en vigueur.

HE0035F

CODE DE COULEUR DES FILS

B BLANC

BR BRUN

J JAUNE

O ORANGE

R ROUGE

V VERT

N NOIR

Page 30

- 30 -

GARANTIE

GARANTIE LIMITÉE DE UN AN DES PRODUITS BEST

Broan-NuTone LLC (Broan-NuTone) garantit à l’acheteur consommateur initial de produits Best qu’ils sont

exempts de tout défaut dans les matières premières ou la main-d’œuvre, pour une période de un an à compter

de la date d’achat par le consommateur initial. IL N’Y A PAS D’AUTRES GARANTIES, EXPRIMÉES OU

IMPLICITES, INCLUANT, MAIS NON LIMITÉES AUX GARANTIES IMPLICITES POUR FIN DE

COMMERCIALISATION ET DE CONVENANCE DANS UN BUT PARTICULIER.

Durant cette période de un an, Broan-NuTone, à sa discrétion, réparera ou remplacera gratuitement, tout produit

ou pièce qui s’avère défectueux et ayant été utilisé normalement et d'une manière non abusive.

CETTE GARANTIE NE COUVRE PAS LES STARTERS DE TUBES FLUORESCENTS, LES FLUORESCENTS,

LES AMPOULES HALOGÈNES ET À INCANDESCENCE, LES FUSIBLES, LES FILTRES, LES CONDUITS,

LES CAPUCHONS DE TOIT, LES CAPUCHONS DE MUR ET LES AUTRES ACCESSOIRES DE CONDUITS.

Cette garantie ne couvre pas (a) l’entretien et le service normal ou (b) tout produit ou pièce endommagé à la

suite de mauvais usage, de négligence, d’accident, d’entretien inapproprié ou de réparation (autre que par

Broan-NuTone), d’une installation inadéquate ou non conforme au mode d’installation recommandé.

La durée de toute garantie implicite est limitée à une période de un an telle qu’elle est spécifiée pour la

garantie exprimée. Certains États ou provinces ne permettent pas de limite de temps sur les garanties

implicites. Si tel est le cas, veuillez ne pas tenir compte de la dernière limite décrite ci-dessus.

L’ENGAGEMENT DE BROAN-NUTONE DE RÉPARER OU DE REMPLACER, AU CHOIX DE

BROAN-NUTONE, SERA LA SEULE OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE.

BROAN-NUTONE NE SERA PAS TENUE RESPONSABLE DES DOMMAGES DIRECTS, INDIRECTS OU

SPÉCIAUX SURVENANT À CAUSE DE OU EN RAPPORT À L’UTILISATION OU À LA PERFORMANCE

DE SES PRODUITS. Certains États ou provinces ne permettent pas l’exclusion ou la limite relative aux

dommages directs, indirects ou spéciaux. Si tel est le cas, veuillez ne pas tenir compte de l’exclusion

ou de la limite ci-dessus.

Cette garantie vous donne des droits légaux spécifiques et il se peut que vous ayez d’autres droits qui

varient d’un État ou d’une province à l’autre. Cette garantie annule toutes les autres garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou au numéro de téléphone

mentionnés ci-dessous, (b) donner le numéro du modèle et l’identification de la pièce et (c) décrire la nature

de tout défaut dans le produit ou la pièce. Au moment de la demande de service sous garantie, vous devez

présenter une preuve de la date d’achat initial dudit produit.

Aux États-Unis - Best

®

, 926 W. State Street, Hartford, WI 53027 (800 558-1711)

Au Canada - Best

®

, 550, boul. Lemire, Drummondville (Québec), Canada J2C 7W9 (866 737-7770)

www.BestRangeHoods.com

Page 31

- 31 -

PIÈCES DE REMPLACEMENT

MODÈLE PIK33D

N°

DE RÉF.

N°

DE PIÈCE

DESCRIPTION QTÉ

1 SV03428 TRANSITION RONDE 9 po x 18 po à 10 po 1

2 SV05869 LOGO BEST 1

3 SV06508 ENSEMBLE DE CONNECTEURS DE NYLON 2

4 SV15432 ENSEMBLE ATTACHE FILTRE 3

5 SV06364 POTENTIOMÈTRE 1

6 SV06497 THERMOSTAT 1

7 SV16765 ENSEMBLE DE DOUILLE ET GARNITURE DE LAMPE (EXTÉRIEUR) 2

8 SV03504 COMMANDE DE RÉGLAGE DE LA VITESSE DU VENTILATEUR 1

9 SV06496 COMMANDE DU VENTILATEUR 1

10 SV06495 COMMANDE D’ÉCLAIRAGE 1

11 SV05921 AMPOULES HALOGÈNES AVEC ÉCRAN 120 V, 50 W, DE TYPE GU10 2

12 SV15422 FILTRES À CHICANE BEST 9,25 po x 12,5 po 3

SV04216

SAC DE PIÈCES : 3 CAPUCHONS DE CONNEXION ÉTANCHES, 6 VIS À TÊTE HEXAGONALE N° 10 X 2 PO,

2 SERRE-FILS LP16-AP, 8 VIS EN ACIER INOXYDABLE N° 8 X 3/8 PO. 2 VIS N° 8 X 5/8 PO,

4 VIS À TÊTE FRAISÉE N° 10 X 2 PO, 2 DOUILLES À EXPANSION, 6 RONDELLES DE 3/16 PO DI X 3/4 PO DE,

4 CONTRE-ÉCROUS 10-32 EN ACIER INOXYDABLE, 2 VIS N° 8 X 3/8 PO PLAQUÉES ZINC.

1

2

3

1

6

5

12

7

10

9

4

8

11

PIÈCES DE REMPLACEMENT ET SERVICE

Pour assurer le bon fonctionnement de votre appareil,

vous devez toujours utiliser des pièces d'origine

provenant de Broan-NuTone. Les pièces d'origine de

Broan-NuTone sont spécialement conçues pour

satisfaire toutes les normes de certification de

sécurité applicables. Leur remplacement par des

pièces ne provenant pas de Broan-NuTone pourrait

ne pas assurer la sécurité de l'appareil, entraîner une

réduction sévère des performances ainsi qu'un risque

de défaillance prématurée. Broan-NuTone recommande

également de toujours vous référer à une entreprise

de services compétente et reconnue par

Broan-NuTone pour vos pièces de remplacement et

appels de service.

HL0123

Page 32

- 32 -

PIÈCES DE REMPLACEMENT

VENTILATEUR DOUBLE P8D

N°

DE RÉF.

N°

DE PIÈCE

DESCRIPTION

QTÉ

1 P8D VENTILATEUR DOUBLE ASSEMBLÉ 1

2 SV02160 CONDENSATEUR 15 µF 2

3

*

ÉCROU DENTELÉ N° 6-32 1

4 SV01857 CACHE-FILS 2

5 SV06338 MOTEUR DE 165 W CW 1

6 SV03400 ROUE HOTTE 7,094 PO X 3,375 PO CW 1

7 SV01810 ANNEAU DE ROUE 2

8 SV03399 ROUE HOTTE 7,094 PO X 3,375 PO CCW 1

9 SV06339 MOTEUR DE 165 W CCW 1

10

*

RONDELLE DE 3/16 PO DI X 3/4 PO DE 6

11 SV11705 SUPPORT DE MOTEUR 2

12 SV02001 OEILLET MOTEUR G-431-1 6

13 SV01927 VIS MÉTRIQUE M4 X 6 MM PAN QDRX 8

14 SV06369 CORDON D’ALIMENTATION DU VENTILATEUR 1

15 SV15443 PLAQUE VENTILATEUR P8D 1

16 SV03500 DÉFLECTEUR D’AIR 1

*

COLLIER DE SERRAGE 8 PO 2

SV11614 FIL N° 18 TEW BRUN X 10 PO 2

2

3

1

16

15

13

6

9

10

11

12

4

5

7

8

14

*QUINCAILLERIE STANDARD, PEUT ÊTRE ACHETÉE LOCALEMENT.

PIÈCES DE REMPLACEMENT ET SERVICE

Pour assurer le bon fonctionnement de

votre appareil, vous devez toujours utiliser

des pièces d'origine provenant de

Broan-NuTone. Les pièces d'origine de

Broan-NuTone sont spécialement conçues

pour satisfaire toutes les normes de

certification de sécurité applicables. Leur

remplacement par des pièces ne provenant

pas de Broan-NuTone pourrait ne pas

assurer la sécurité de l'appareil, entraîner

une réduction sévère des performances

ainsi qu'un risque de défaillance

prématurée. Broan-NuTone recommande

également de toujours vous référer à une

entreprise de services compétente et

reconnue par Broan-NuTone pour vos

pièces de remplacement et appels de service.

HL0051

Page 33

MANUAL DE INSTALACIÓN

CONCEBIDO SÓLO PARA USO DOMÉSTICO

INSTALADOR: DEJAR ESTE MANUAL AL PROPIETARIO.

PROPIETARIO: INFORMACIÓN SOBRE LIMPIEZA Y FUNCIONAMIENTO EN LAS

PÁGINAS 43 Y 44.

BEST; Hartford, Wisconsin www.BestRangeHoods.com 800-558-1711

BEST; Drummondville, QC, Canada www.BestRangeHoods.com 866-737-7770

Para registrar su producto en línea o para obtener más información, visitar nuestro sitio

www.BestRangeHoods.com

SV06322 Rev. 10

LEER Y CONSERVAR ESTAS INSTRUCCIONES

MODELO PIK33D

HB0034

!

!

ADECUADA PARA LUGARES HÚMEDOS CUANDO SE INSTALA EN UN CIRCUITO

DE DERIVACIÓN PROTEGIDO CON UN DISYUNTOR.

PREVISTA PARA PATIOS O TERRAZAS CUBIERTAS.

Page 34

- 34 -

ADVERTENCIA ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO,

DESCARGA ELÉCTRICA, O LESIONES A

PERSONAS, CUMPLA LOS SIGUIENTES PUNTOS:

1. Solamente use esta unidad de la manera propuesta

por el fabricante. Si tiene alguna pregunta,

comuniquese con el fabricante en la dirección o

teléfono anotados en la garantía.

2. Antes de limpiar o poner en servicio la unidad, apague

el interruptor en el panel de servicio, y asegure el

panel de servicio para evitar que se encienda

accidentalmente. Cuando el dispositivo para

desconectar el servicio eléctrico no puede ser cerrado

con algún tipo de traba, sujete fuertemente al panel de

servicio, una etiqueta de advertencia prominente.

3. El trabajo de instalación y el alambrado eléctrico

deben llevarse a cabo por personal calificado de

acuerdo con todos los códigos y las normas

aplicables, incluyendo los códigos y normas de

construcción contra incendios.

4. Se requiere una cantidad de aire suficiente para la

combustión y escape de gases por la chimenea del

equipo de quemado de combustible para evitar salirse

de las especificaciones y estándares de seguridad del

fabricante, tales como los publicados por la Asociación

nacional de protección contra incendios (NFPA por sus

siglas en Inglés), y la Sociedad americana de

ingenieros de calefacción, refrigeración y aire