Page 1

Model KER222

ENGLISH......................................3

FRANÇAIS.................................12

ESPAÑOL...................................21

BEST BY BROAN P.O. Box 140 Hartford, WI 53027

- 1 -

Page 2

- 2 -

Page 3

READ AND SAVE THESE INSTRUCTIONS

!

INTENDED FOR DOMESTIC COOKING ONLY

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock service

panel to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction codes

and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes

Suzette, Cherries Jubilee, Peppercorn Beef Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or

filter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface

element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam explosion will

result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know how to operate

it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

- 3 -

Page 4

!

CAUTION

1. To reduce risk of fire and to properly exhaust air, be sure to duct air outside. Do not vent

exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

2. Take care when using cleaning agents or detergents.

3. Avoid using food products that produce flames under the Range Hood.

4. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

5. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

6. Your hood motor has a thermal overload which will automatically shut off the motor if it

becomes overheated. The motor will restart when it cools down. If the motor continues

to shut off and restart, have the hood serviced.

7. For best capture of cooking impurities, the bottom of the hood should be a minimum of

24" and a maximum of 30" above the cooking surface.

8. Two installers are recommended because of the large size and weight of this hood.

9. This product is equipped with a thermostat which may start blower automatically. To

reduce the risk of injury and to prevent power from being switched on accidentally,

switch power off at service panel and lock or tag service panel.

10. Use with approved cord-connection kit only.

11. Please read specification label on product for further information and requirements.

- 4 -

Page 5

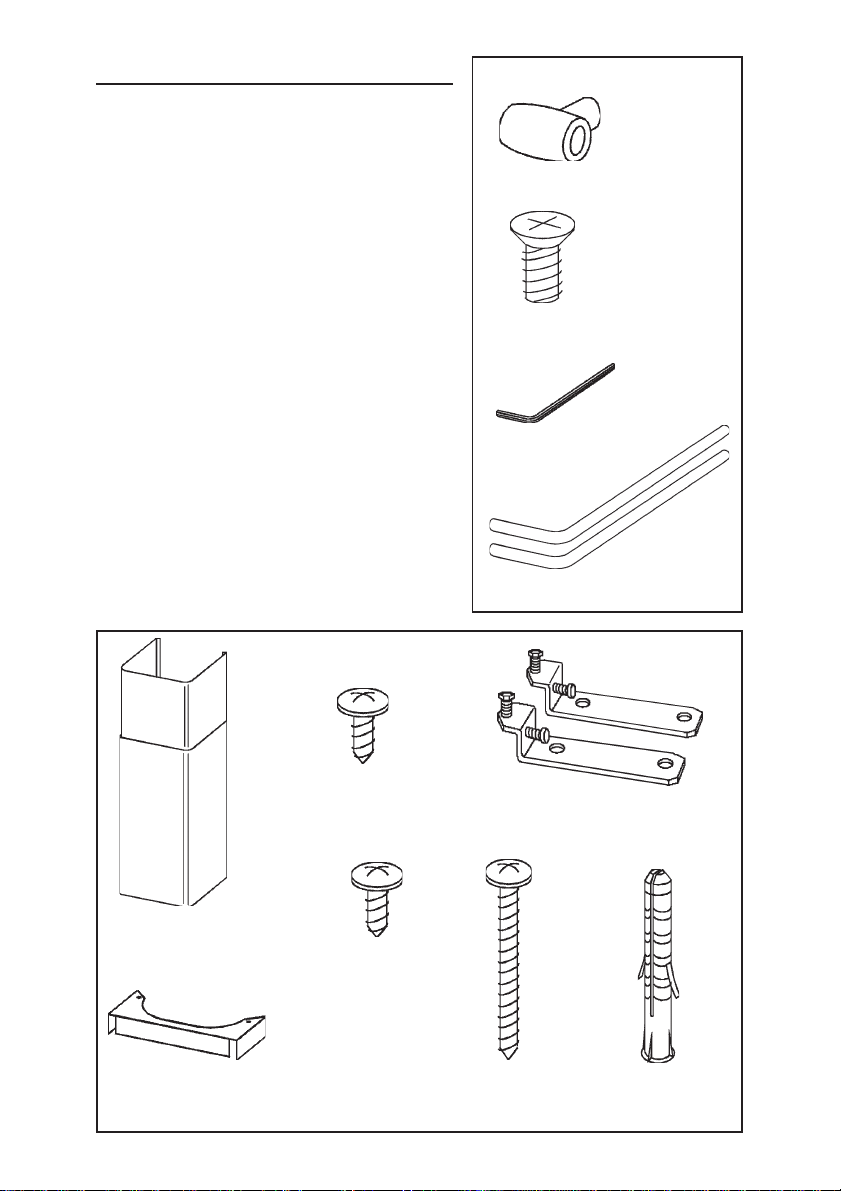

PREPARE THE HOOD

Unpack hood and check contents.

You should receive:

1 - Hood

1 - Decorative Flue Assembly

1 - Flue Mounting Bracket

1 - Parts Bag (B080810601) containing:

2 - Mounting Brackets

8 - Mounting Screws (4,8x38mm Pan

Head)

4 - Mounting Screws (3,9x9,5mm Pan

Head)

4 - Mounting Screws (3,9x9,5mm Pan

Head Black)

8 - Drywall Anchors

1 - Parts Bag (B080810321) containing:

2 - Side Ladle-Bars

2 - End Bits of the Ladle-Bars

2 - Mounting Screws (M8 x 14mm)

1 - Key

1 - Installation Instructions

1 - Warranty Card

END BITS OF

THE LADLEBARS

2 MOUNTING

SCREWS

(M8x14mm)

KEY

SIDE LADLEBARS

DECORATIVE

FLUE

FLUE MOUNTING

BRACKET

4 MOUNTING

SCREWS (3,9 x 9,5mm

Pan Head)

4 MOUNTING

SCREWS (3,9 x 9,5mm

Pan Head - Black)

8 MOUNTING

SCREWS (4,8 x

38mm Pan Head)

- 5 -

MOUNTING

BRACKETS

8 DRYWALL

ANCHORS

Page 6

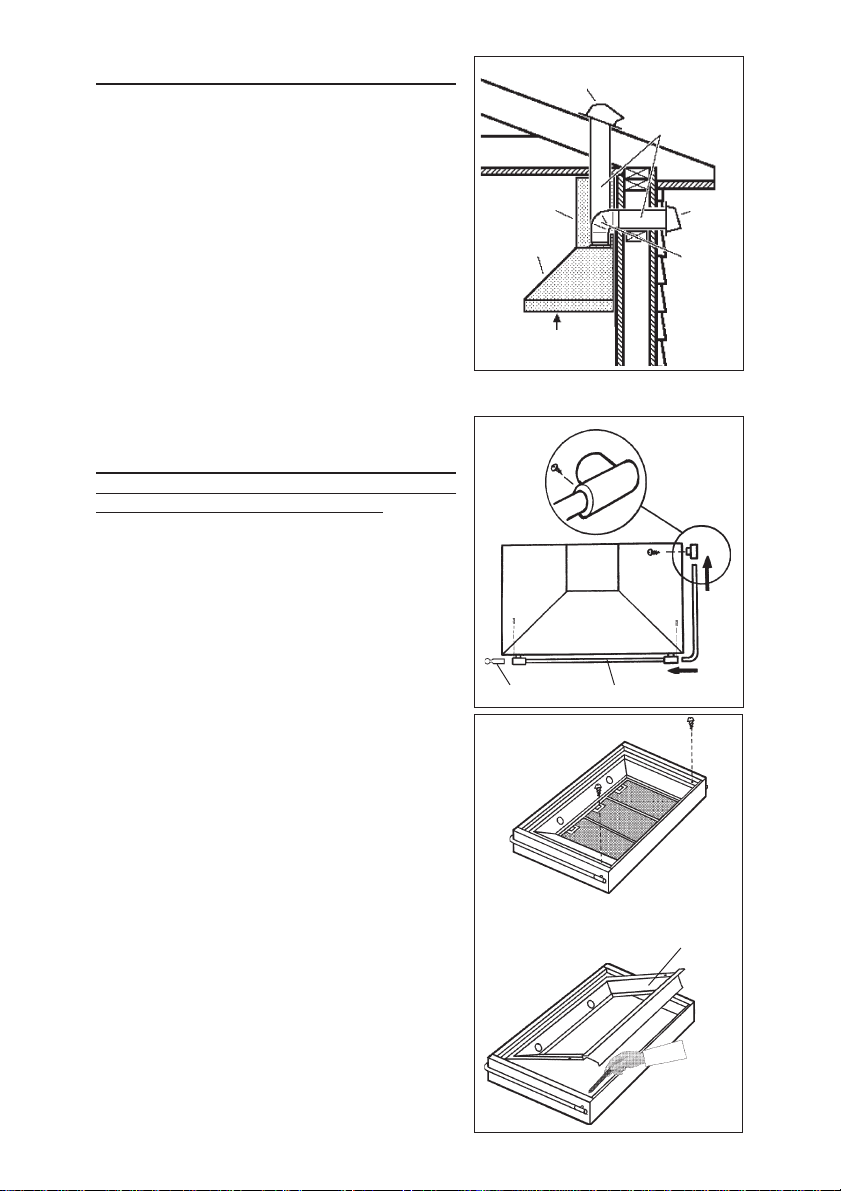

INSTALL THE DUCTWORK

NOTE: To reduce the risk of fire, use only

metal ductwork.

1. Decide where the ductwork will run between

the hood and the outside.

2. A straight, short duct run will allow the hood

to perform most efficiently.

3. Long duct runs, elbows, and transitions will

reduce the performance of the hood. Use as

few of them as possible.

4. Install a roof or wall cap. Connect 8" round

metal ductwork to cap and work back towards hood location. Use duct tape to seal

the joints between ductwork sections.

HOW TO ASSEMBLE THE

LADLE BAR

The side ladle bars must be assembled before

installing the hood against the wall.

To assemble the side ladle -bars follow the

instructions below:

1. Take off the two end bits of the ladle bar

slackening screws B. Insert the side ladle

bars where the end bits were and fix them

by means of screws B.

2. Insert the fixing element M into the side ladle

bar and fix it tightening screw C.

3. To fix definitively the M element onto the

hood, it is necessary to have access from

the inside of the hood:

- remove the grease filters: at the handle,

push the stop inwards and pull the filters

downwards.

- take off the lower part of the hood

unscrewing the two screws A. The lower part

of the hood must not be completely taken

off, but it must be bent slightly until the

screwdriver can have access. Fix element

M to the hood from the inside.

4. Reassemble the lower part of the hood.

ROOF CAP

DECORATIVE

FLUE

HOOD

24” TO 30” ABOVE

COOKING SURFACE

C

B

END BITS

8” ROUND DUCT

M

LADLE BAR

A

LOWER PART OF

THE HOOD

8” ROUND

ELBOW

B

WALL

CAP

A

- 6 -

Page 7

INSTALL MOUNTING

BRACKETS

1. Construct wood wall framing that is flush

with interior surface of wall studs.

Make sure:

a) the framing is centered over installation

location.

b) the height of the framing will allow the

mounting brackets to be secured to the

framing within the dimensions shown.

After wall surface is finished, secure

2.

mounting brackets to framing using

dimensions shown.

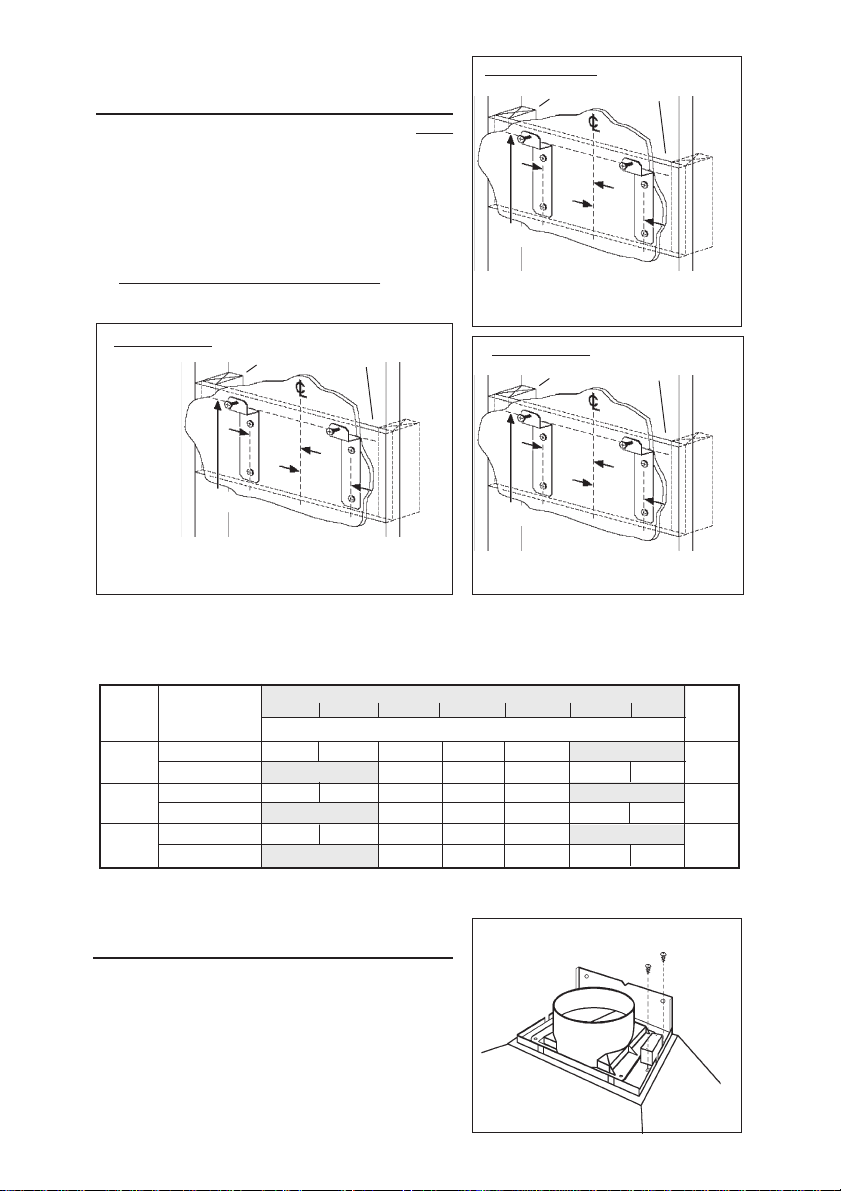

VERSION 42”

FRAMING BEHIND DRYWALL

VERSION 90cm

FRAMING BEHIND DRYWALL

9-5/8”

9-5/8”

32-11/16” to 38-5/8” above

cooktop

32-11/16”= bottom of hood 24" above cooktop

38-5/8"= bottom of hood 30" above cooktop

VERSION 48”

FRAMING BEHIND DRYWALL

9-15/16”

9-15/16”

33-15/16” to 39-15/16” above

cooktop

33-15/16”

= bottom of hood 24" above cooktop

39-15/16"= bottom of hood 30" above cooktop

Note: minimun hood distance above cook top must not be less than 24”. A maximum

of 30” above cook top is highly recommended for best capture of cooking impurities.

cooktop

34-7/16”

40-7/16”

8-7/8”

8-7/8”

34-7/16” to 40-7/16” above

= bottom of hood 24" above cooktop

= bottom of hood 30" above cooktop

Distances over 30” are at the installer and users discretion; and if ceiling height and

flue length permit.

HOOD

WIDTH

90CM

42”

48”

CEILING

HEIGHT

8 FEET

9 FEET

8 FEET

9 FEET

8 FEET

9 FEET

29-13/16”

31-1/16”

31-9/16”

INSTALL THE HOOD

HOOD DISTANCE ABOVE 36” HIGH COOK TOP

24” 25” 26” 27” 28” 29” 30”

BRACKET LOCATION ABOVE 36” COOK TOP

30-13/16” 31-13/16”

N / A

32-1/16”

N / A

32-9/16”

N / A

31-13/16”

33-1/16”

33-1/16”

33-9/16”

33-9/16”

32-13/16”

32-13/16”

34-1/16”

34-1/16”

34-9/16”

34-9/16”

33-13/16”

33-13/16”

35-1/16”

35-1/16”

35-9/16”

35-9/16” 36-9/16”

REMOVE THE ELECTRICAL BOX

34-13/16”

36-1/16”

N / A

35-13/16”

N / A

37-1/16”

N / A

37-9/16”

DIM.

“A”

9-5/8”

9-15/16”

8-7/8”

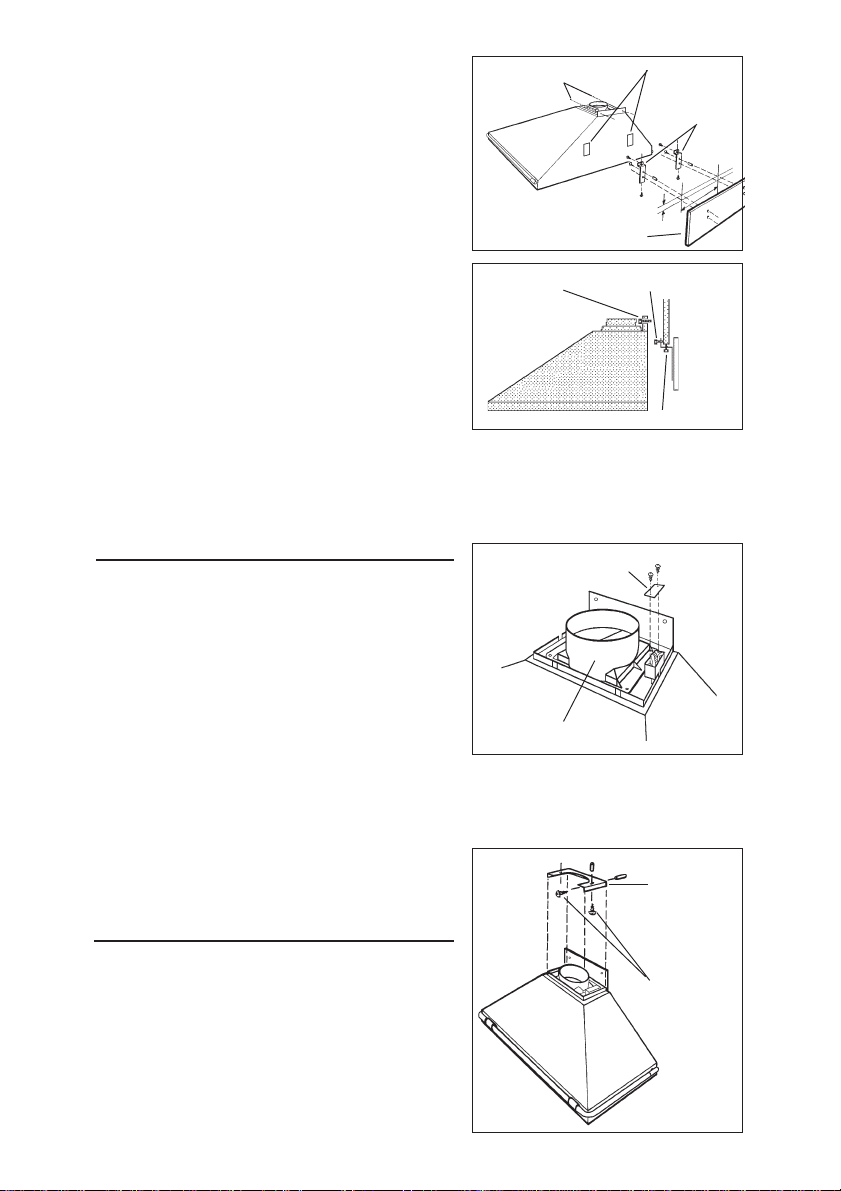

1. Before mount hood remove the electrical box.

2. Hang the hood from the brackets through

the rectangular cut-outs on the back of the

hood. Cut-outs are larger than the brackets

to allow for horizontal adjustment.

The bottom of the hood should be 24" to 30"

above the cooking surface.

3. Height adjustment screws provide vertical

adjustment.

- 7 -

Page 8

4. Depth adjustment screws provide

horizontal adjustment.

5. Secure the hood with mounting screws

(4,8x38mm). Use drywall anchors,

provided, if wall studs or framing are not

available.

6. Replace electrical box.

MOUNTING

SCREWS

(4,8x38mm)

WALL

FRAMING

RECTANGULAR

CUTOUTS

MOUNTING

BRACKETS

MOUNTING

SCREWS

(4,8x38mm)

DEPTH ADJUSTMENT

SCREWS

HEIGHT ADJUSTMENT SCREWS

WIRING

Note: This range hood must be properly

grounded. The unit should be installed by a

qualified electrician in accordance with all

applicable national and local electrical

codes.

1. Remove the wiring box cover. Remove a

knockout from the wiring box.

2. Secure the conduit to the wiring box through

a conduit connector.

3. Make electrical connections. Connect white

to white, black to black and green to green or bare wire.

4. Replace wiring box cover and screws. Make sure that wires are not pinched

between cover and box.

WIRING BOX COVER

DUCT

COLLAR

CONNECT DUCTWORK

1. Use mounting screws (4,8x38mm) and wall

anchors to secure flue mounting bracket

to the ceiling or wall as shown.

2. Use 8" round metal duct to connect the duct

collar on the hood to the ductwork above.

3. Use duct tape to make all joints secure and

air tight.

4. Adjust the decorative flue to the desired

lenght and tighten screw.

- 8 -

FLUE

MOUNTING

BRACKET

MOUNTING

SCREWS

(4,8x38mm)

Page 9

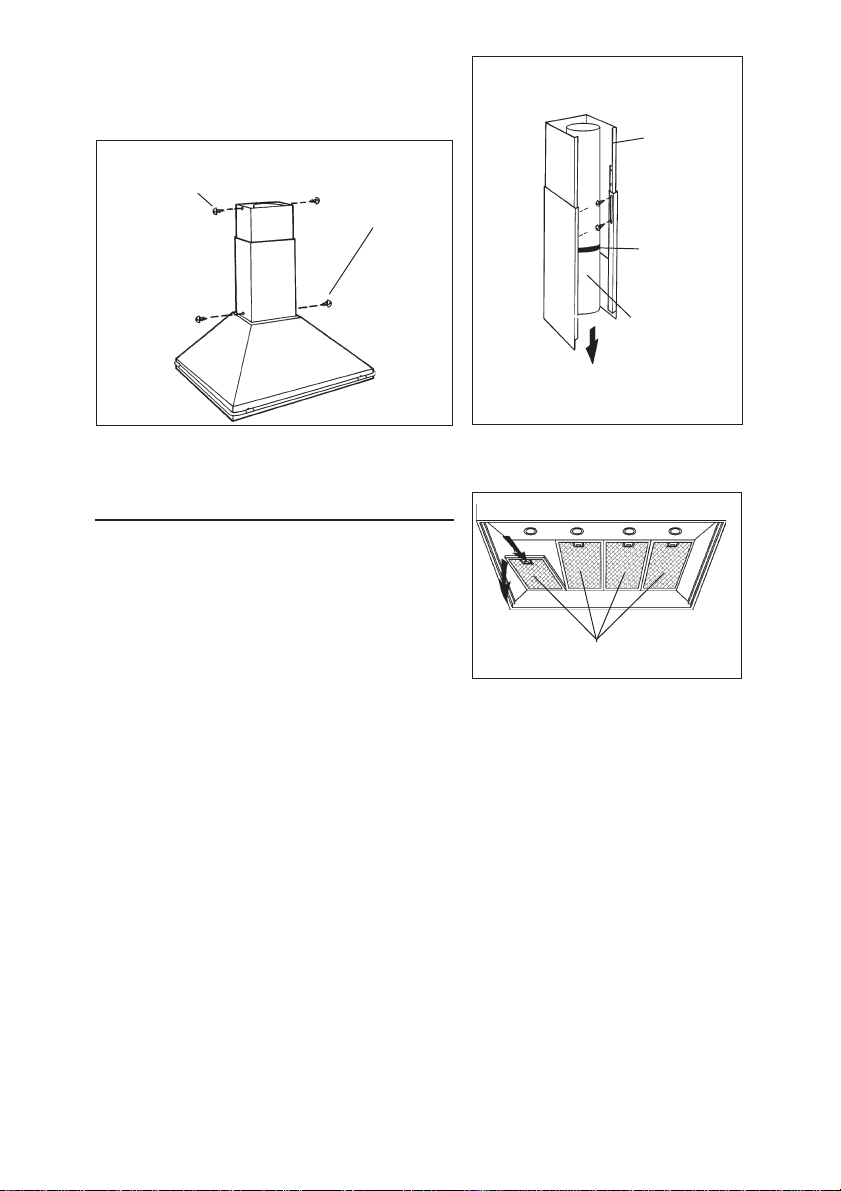

5. Secure the decorative flue to the mounting

bracket, and to the hood by tightening

locking mounting screws (3,9x9,5mm) as

shown.

FASTEN FLUE TO

BRACKET WITH

MOUNTING SCREWS

(3,9x9,5mm)

FASTEN FLUE

TO HOOD

WITH MOUNTING

SCREWS

(3,9x9,5mm)

DECORATIVE

FLUE

DUCT TAPE

8" ROUND

METAL DUCT

MAINTENANCE

Proper maintenance of the Range Hood will

assure proper performance of the unit.

Grease Filters

The grease filters should be cleaned frequently. Use a warm detergent solution. Grease

filters are dishwasher safe.

To take off the grease filters: at the handle, push

the stop inwards and pull the filters downwards.

Hood Cleaning

Stainless steel is one of the easiest materials to keep clean. Occasional care will

help preserve its fine appearance.

Cleaning tips:

● Hot water with soap or detergent is all that is usually needed.

● Follow all cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth to

avoid water marks.

● For discolorations or deposits that persist, use a non-scratching household cleanser

or stainless steel polishing powder with a little water and a soft cloth.

● For stubborn cases, use a plastic scouring pad or soft bristle brush together with

cleaser and water. Rub lightly in direction of polishing lines or "grain" of the

stainless finish. Avoid using too much pressure which may mar the surface.

● DO NOT allow deposits to remain for long periods of time.

● DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere

to the surface causing rust.

● DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to

remain in contact with stainless steel for extended periods. Many of these compounds contain chemicals which may be harmful. Rinse with water after exposure and wipe dry with a clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

GREASE FILTERS

- 9 -

Page 10

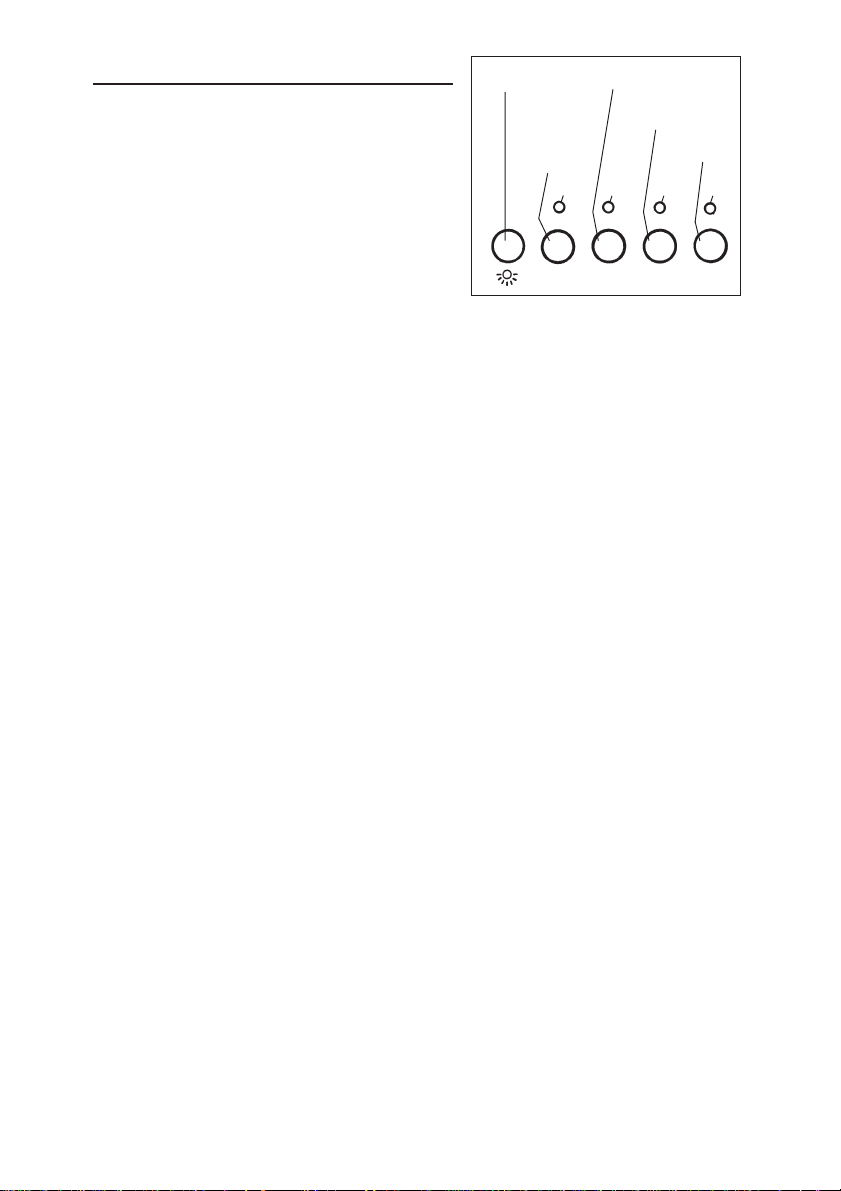

BLOWER

ON-OFF /

SPEED 1

LED LED

BLOWER

SPEED 2

BLOWER

SPEED 3

BLOWER

SPEED 4

LED

LED

OPERATION

Controls

The hood is operated using the (5) pushbuttons located at eye-level, on the front edge

of the hood.

The light switch turns the halogen lights on

LIGHT

SWITCH

and off. The blower on-off / speed 1 switch

turns the blower on to its lowest running

speed. Turn the blower off by pressing this

switch a second time. The blower speed 2

switch turns the blower on to medium-low

running speed. Pressing this switch a second

time sets a timer which keeps the blower operating at this speed for 10 minutes.

0-1

234

The LED will blink during this time and the blower will shut off automatically.

The blower speed 3 and blower speed 4 switches operate the same as blower

speed 2 switch except: Blower speed 3 is medium-high and blower speed 4 is

high.

At the end of each working time of 30 hours, all the leds blink at the same time; this

indicates that the grease filter need to be cleaned.

Once the clean grease filters are on, push the “blower speed 2 switch” twice (or

else the “blower speed 3 switch” or the “blower speed 4 switch”) during the blink of

the LED, to make the count down start again.

HEA T SENTRY™

Your hood is equipped with a HEAT SENTRY™ thermostat. This thermostat is a

device that will turn on or speed up the blower if it senses excessive heat above

the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up to HIGH speed.

When the temperature level drops to normal, the blower will return to its original

setting.

WARNING

The HEAT SENTR Y thermost at can start the blower even if the hood is turned

OFF . When this occurs, it is impossible to turn the blower OFF with its switch.

If you must stop the blower, do it from the main electrical panel.

- 10 -

Page 11

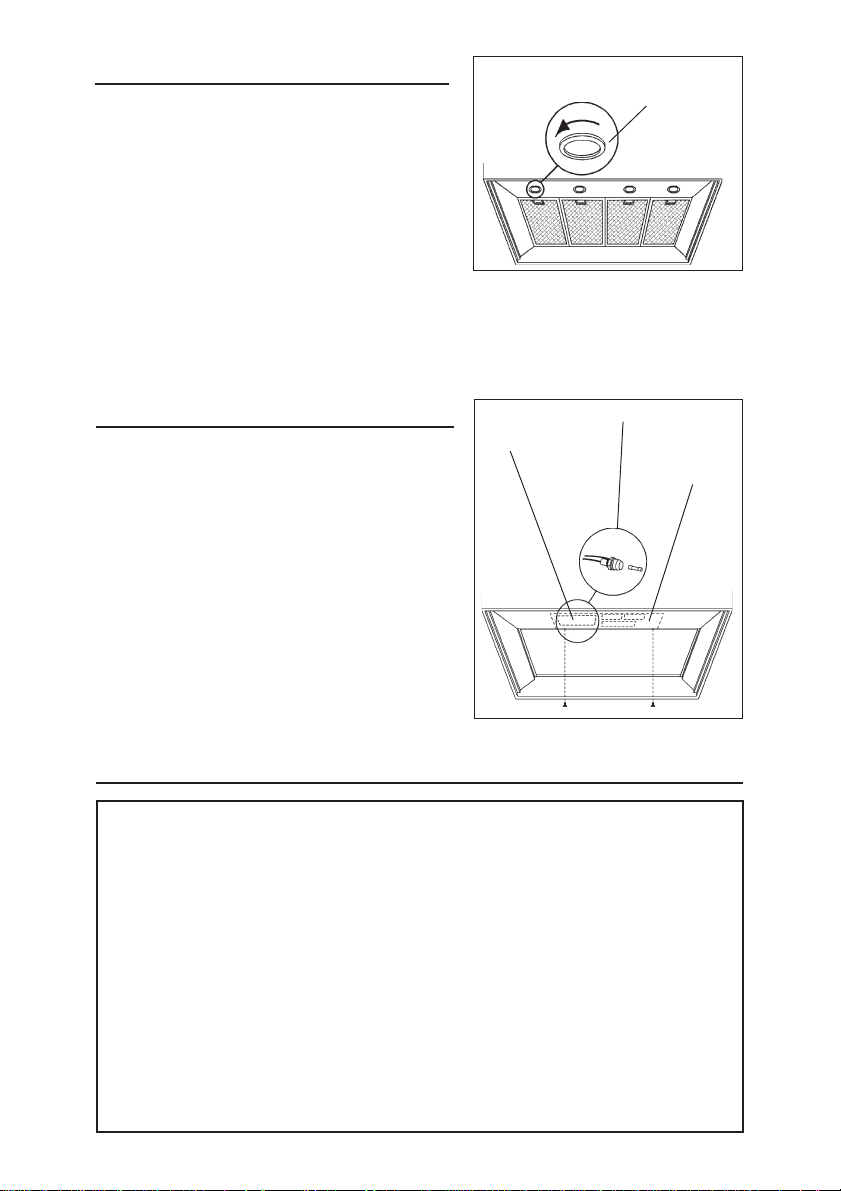

HALOGEN BULBS

This range hood requires two (2) or four (4)

halogen bulbs (Type JC, 12V, 20W Max, G4 Base).

ALWAYS SWITCH OFF THE ELECTRICITY

SUPPLY BEFORE CARRYING OUT ANY

OPERATIONS ON THE APPLIANCE.

To change bulbs:

1. Loosen the ring nut by turning it

counterclockwise.

2. Remove the bulb by pulling sideward (Do

not rotate). CAUTION: BULB MA Y BE HOT!

3. Replace with Type JC, 12 V, 20W Max G-4 Base halogen bulb.

Do not touch replacement bulb with bare hands!

RING NUT

FUSE REPLACEMENT

SWITCH OFF THE ELECTRICITY SUPPL Y .

Remove the grease filters.

ELECTRICAL

BOX

FUSE

ELECTRICAL

BOX

SUPPORT

Remove the electrical box support and open

the electrical box.

Replace with the same type of fuse (5x20mm,

4A, 125V).

WARRANTY

Broan warrants to the original consumer purchaser of its products that such products will be free from defects in materials

or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING , BUT NOT LIMITED TO, IMPLIED W ARRANTIES OR MERCHANT ABILITY OR

FITNESS FOR A P ARTICULAR PURPOSE.

During this one-year period, Broan will, at its option, repair or replace, without charge, any product or part which is found to

be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND

INCANDESCENDT BULBS. This warranty does not cover (a) normal maintenance and service or (b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by Broan), faulty

installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do

not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN’S OBLIGATION T O REP AIR OR REPLACE, A T BROAN’S OPTION, SHALL BE THE PURCHASER’S SOLE AND

EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN SHALL NOT BE LIABLE FOR INCIDENT AL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty

supersedes all prior warranties.

T o qualify for warranty service, you must (a) notify Broan at the address stated below or telephone: 1-800-637-1453, (b) give

the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting

warranty service, you must present evidence of the original purchase date.

BEST BY BROAN, P .O. Box 140 Hartford, Wisconsin 53027

BROAN ONE YEAR LIMITED WARRANTY

- 11 -

Page 12

LISEZ ET CONSERVEZ CES INSTRUCTIONS

!

SEULEMENT POUR UTILISATION DOMESTIQUE

!

AVERTISSEMENTS

POUR REDUIRE LES RISQUES D’INCENDIE, DE DECHARGES ELECTRIQUES OU

DE DOMMAGES AUX PERSONNES, OBSERVEZ LES INSTRUCTIONS SUIV ANTES:

1. N’utilisez cet appareil que comme cela est indiqué par le constructeur. Si vous avez des

problèmes, contactez le fabriquant à l’adresse ou au numéro de téléphone indiqués dans

la garantie.

2. Avant de pourvoir à l’entretien ou au nettoyage de votre appareil, éteignez-le au tableau

des commandes ou bloquez le tableau des commandes afin d’éviter de le mettre en marche

accidentellement. Si vous ne pouvez pas bloquer le système permettant d’éteindre votre

appareil, appliquez un avertissement extérieur d’une façon sure, comme par exemple un

panneau, sur le tableau des commandes.

3. L’assemblage et la connexion électrique doivent être faits par des personnes qualifiées

en respectant les normes et règlements en vigueur, y compris les normes et règlements

concernant les possibilités d’incendie.

4. Il est indispensable qu’il y ait suffisamment d’air pour que la combustion et l’évacuation des

gaz à travers le tuyau du brûleur du combustible ait lieu sans retour de flamme. Suivez

les indications données par le fabricant du brûleur ainsi que les normes de sécurité comme

celles qui sont publiées par l’Association Nationale pour la Protection contre les Incendies

National Fire Protection Association (NFPA) et la American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), et les autorités locales en matière de normes.

5. Quand vous coupez ou percez des trous dans le mur ou le plafond, n’abîmez pas les fils

électriques ou autres.

6. Le ventilateur canalisé doit toujours évacuer l’air vers l’extérieur.

7. N’utilisez pas cet appareil avec un appareil contrôlant la vitesse à état solide.

8. Afin de diminuer tout risque d’incendie n’utilisez que des conduits en métal.

9. Votre appareil doit être relié à la terre.

ATTENTION - POUR REDUIRE LES RISQUES D’INCENDIE DES MATIERES GRASSES

QUI SONT EN TRAIN DE CUIRE:

A. Ne laissez jamais ni vos éléments chauffants, ni vos casseroles ou poêles sur le feu

sans les contrôler si vous réglez l’apport de chaleur sur une position élevée. Si vos

casseroles ou poêles débordent cela provoque de la vapeur et des éclaboussures de

graisse qui peuvent prendre feu. Chauffez les huiles lentement à feu bas ou moyen.

B. Faites toujours fonctionner votre hotte quand vous cuisez à des températures élevées

ou quand vous cuisinez des plats flambés. (par ex. crêpes Suzette, Cerises “Jubilé”,

Steack au poivre flambé).

C. Nettoyez régulièrement les ailes de vos ventilateurs. Ne permettez pas que la graisse

s’accumule sur le ventilateur ou sur le filtre.

D. Utilisez des casseroles de taille appropriée. Utilisez toujours des ustensiles de cuisson

dont la taille est appropriée à la surface de votre élément de cuisson.

AVERTISSEMENTS

POUR REDUIRE LES RISQUES DE DOMMAGES AUX PERSONNES AU CAS OÙ VOTRE

CUISINIERE PRENDRAIT FEU, OBSERVEZ LES INSTRUCTIONS SUIVANTES:*

1. ETEINDRE LES FLAMMES à l’aide d’un couvercle le plus hermétique possible, une

plaque à gâteaux, ou un plateau en métal, puis éteindre le brûleur. ATTENTION à NE

PAS VOUS BRÛLER. Si les flammes ne s’éteignent pas immédiatement, SORTEZ ET

APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS EN MAIN UNE POÊLE OU UNE CASSEROLE QUI A PRIS FEU

- Vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, ni torchons ou serviettes mouillés - vous provoqueriez une

violente explosion de vapeur.

- 12 -

Page 13

4. Utilisez un extincteur SEULEMENT si:

A. Vous savez que vous avez un extincteur Classe ABC, et vous en connaissez déjà le

mode d’emploi.

B. Ce n’est pas un très gros incendie et qu’il se limite à l’endroi où il a explosé.

C. Vous êtes en train d’avertir les pompiers.

D. Vous avez la possibilité d’essayer d’éteindre l’incendie en ayant le dos tourné vers

une issue.

* D’après les “Suggestions concernant la Sécurité contre les incendies des cuisines”

publiées par NFPA.

!

ATTENTION

1. Pour réduire tout risque d’incendie et pour évacuer correctement l’air, assurez-vous de

prévoir un conduit de ventilation extérieur. Ne videz pas l’air dans les espaces limités

par des murs ou des plafonds, les combles, les passages étroits ou les garages.

2. Faites très attention quand vous utilisez des produits de nettoyage ou des détergents.

3. Évitez d’utiliser des aliments pouvant s’enflammer sous la Range Hood.

4. N’utilisez cet appareil que pour une ventilation générale. Ne l’utilisez pas pour évacuer

des matières ou des vapeurs dangereuses ou qui peuvent exploser.

5. Pour éviter de causer des dommages au moteur et de rendre les rotors bruyants et/ou

non équilibrés, évitez que les sprays pour murs secs, la poussière de construction

entrent en contact avec la partie électrique.

6. Le moteur de votre hotte a un thermostat qui éteindra automatiquement le moteur s’il est

surchauffé. Le moteur se remettra en marche lorsqu’il se sera refroidi. Si le moteur

continue à s’éteindre et à se remettre en marche, faites vérifier votre hotte.

7. Pour mieux capturer les impuretés de cuisine, le bas de votre hotte devrait être à une

distance minimum de 24” et à une distance maximum de 30” au-dessus du plan de

cuisson.

8. Vu que cette hotte est grande et lourde, il est recommandé de confier l’installation de

cette hotte à deux personnes.

9. Ce produit est doté d’un thermostat qui active automatiquement le moteur. Pour

réduire le risque de dommages et éviter l’activation accidentelle, positionner l’interrupteur

du panneau de service sur la position OFF et bloquer le panneau de service ou mettre

un avertissement externe, par exemple une plaquette.

10. Utiliser uniquement avec un kit de connexion pour alimentation homologué.

11. Nous vous recommandons de lire l’étiquette indiquant les caractéristiques de votre

hotte pour de plus amples informations et exigences.

- 13 -

Page 14

PREPAREZ LA HOTTE

Enlever la hotte dans l’emballage et

controller le contenu.

Vous devez recevoir :

1 - Hotte

1 - Conduit décoratif

1 - Étrier de support

1 - Sachet (B080810601) avec:

2 - Étriers d’assemblage

8 - Vis d’assemblage (4,8x38mm Tête

ronde)

4 - Vis d’assemblage (3,9x9,5mm Tête

ronde)

4 - Vis d’assemblage (3,9x9,5mm Tête

ronde Noir)

8 - Chevilles

1 - Sachet (B080810321) avec:

2 - Porte-outils latéraux

2 - Fermoirs des porte-outils latéraux

2 - Vis d’assemblage (M8 x 14mm)

1 - Clé

1 - Instructions pour l’installation

1 - Garantie

FERMOIRS

DES PORTEOUTILS

LATERAUX

2 VIS

D’ASSEMBLAGE

(M8x14mm)

CLE

PORTEOUTILS

LATERAUX

CONDUIT

DECORATIF

ETRIER DE SUPPORT

4 VIS D’ASSEMBLAGE

(3,9 x 9,5mm Tête

ronde)

4 VIS D’ASSEMBLAGE

(3,9 x 9,5mm Tête

ronde - Noir)

8 VIS D’ASSEMBLAGE

(4,8 x 38mm Tête ronde)

- 14 -

ETRIERS

D’ASSEMBLAGE

8 CHEVILLES

Page 15

INSTALLATION DU SYSTEME

D’EVACUATION

REMARQUE: Pour réduire les risques

d’incendie, n’utilisez que des tuyaux en métal.

1. Décidez où le tuyau doit être installé, entre

votre hotte et l’extérieur.

2. Un tuyau droit et court permettra à votre hotte

de fonctionner d’une façon plus efficace.

3. Un tuyau long avec des coudes et des

transitions réduira le bon fonctionnement de

votre hotte. En utiliser le moins possible.

4. Installez un couvercle sur le toit ou au mur.

Reliez un tuyau en métal rond de 8” au

couvercle et faites-le aller jusqu’à

l’emplacement de votre hotte. Rendez les

jonctions du tuyau hermétiques au moyen

d’un ruban pour tuyaux.

INSTALLATION DE LA

TRINGLE PORTE-OUTILS

Les tringles latérales doivent être

assemblées avant de fixer votre hotte contre

le mur.

suivez les indications suivantes:

1. Enlevez les extrémités du porte-outils en

2. Enfilez le fermoir M dans le porte-outils

3. Pour fixer définitivement l’élément M à votre

4. Remontez le bas de votre hotte.

Pour assembler les porte-outils latéraux

désserrant les vis B. Insérez, à la place des

extrémités le porte-outils latéral en le fixant

toujours à l’aide des vis B.

latéral et fixez-le en serrant la vis C.

hotte, vous devez pouvoir avoir accès de

l’intérieur de celle-ci:

- enlever les filtres anti-graisse: à l'aide de

la poignée, pousser l’arrêt vers l’intérieur

et tirer le filtre vers le bas.

- démontez le bas de votre hotte en dévissant

les deux vis A. La partie du bas de votre hotte

ne doit pas être enlevée complètement, elle

doit être seulement inclinée afin de permettre

au tourne-vis de passer. Fixez l’élément M à

votre hotte de l’intérieur.

COUVERCLE DU TOIT

CONDUIT

DÉCORATIF

HOTTE

DE 24” À 30”

AU-DESSUS DU PLAN DE

CUISSON

C

B

EXTREMITE

PORTE-OUTILS

TUYAU ROND

M

A

BAS DE VOTRE

HOTTE

DE 8”

COUVERCLE

DU MUR

COUDE ROND

DE 8”

B

A

- 15 -

Page 16

INSTALLATION DES ETRIERS

D’ASSEMBLAGE

1. Construisez un cadre en bois pour le mur

dont les vis-pivot ne dépassent pas.

Assurez-vous:

a) que le cadre est centré au-dessus de

l’emplacement de l’installation.

b) la hauteur du cadre permettra que les

étriers d’assemblage soient fixés au cadre

en respectant les dimensions indiquées.

2. Après avoir terminé la surface du mur, fixez

les étriers d’assemblage au cadre en

respectant les dimensions qui sont indiquées.

VERSION 42”

CADRE POUR LE MUR

9-15/16”

(25.2cm)

9-15/16”

de 33-15/16” à 39-15/16” au-

dessus du plan de cuisson

(25.2cm)

VERSION 90cm

CADRE POUR LE MUR

9-5/8”

(24.5cm)

9-5/8”

de 32-11/16” à 38-5/8” au-dessus

du plan de cuisson

32-11/16” (83cm) = si la distance entre la hotte

et le plan de cuisson c’est de 24”(61cm)

38-5/8" (98.1cm) = si la distance entre la hotte

et le plan de cuisson c’est de 30” (72cm)

(24.5cm)

VERSION 48”

CADRE POUR LE MUR

8-7/8”

(22.5cm)

8-7/8”

de 34-7/16” à 40-7/16” au-dessus

du plan de cuisson

(22.5cm)

33-15/16”(86.2cm) = si la distance entre la hotte et le plan

de cuisson c’est de 24” (61cm)

39-15/16" (101.4cm) = si la distance entre la hotte et le plan

de cuisson c’est de 30” (72cm)

Remarque : la distance minimum au-dessus du plan de cuisson doit être supérieure à

24". Pour que la hotte puisse mieux aspirer les impuretés, il est recommandé de prévoir

34-7/16”(87.5cm) = si la distance entre la hotte

et le plan de cuisson c’est de 24” (61cm)

40-7/16”(102.7cm) = si la distance entre la hotte

et le plan de cuisson c’est de 30” (72cm)

une distance maximum de 30" au-dessus du plan de cuisson. L’installateur et l’utilisateur

peuvent décider d’installer la hotte à une distance supérieure à 30", si la hauteur du

plafond et la longueur du conduit le permettent.

LARGEUR

DE LA

HOTTE

90CM

42”

48”

HAUTEUR DU

PLAFOND

8’

9’

8’

9’

8’

9’

INSTALLATION DE VOTRE HOTTE

1. Avant l’assemblage de votre hotte enlever

ESPACEMENT ENTRE LA HOTTE ET LE PLAN DE CUISSON DE 36” DE HAUT

24” 25” 26” 27” 28” 29” 30”

EMPLACEMENT DU SUPPORT DE FIXATION AU-DESSUS DU PLAN DE CUISSON DE 36” DE HAUT

29-13/16”

N / A

31-1/16”

N / A

31-9/16”

N / A

30-13/16” 31-13/16”

31-13/16”

32-1/16”

32-9/16”

33-1/16”

33-1/16”

33-9/16”

33-9/16”

32-13/16”

32-13/16”

33-13/16”

33-13/16”

34-1/16”

34-1/16”

34-9/16”

34-9/16”

35-1/16”

35-1/16”

35-9/16”

35-9/16” 36-9/16”

ENLEVER LA BOÎTE DE CONNEXION

N / A

34-13/16”

N / A

36-1/16” 37-1/16”

N / A

ELECTRIQUE

35-13/16”

37-9/16”

DIM. “A”

9-5/8”

9-15/16”

8-7/8”

la boîte de connexion électrique.

2. Accrochez votre hotte aux étriers par les

trous rectangulaires qui se trouvent

derrière votre hotte. Les trous sont plus

grands que les étriers afin de vous permettre

d’ajuster le tout horizontalement. Le fond

de votre hotte devrait être à entre 24” et 30”

au-dessus de la surface de cuisson.

- 16 -

Page 17

3. Les vis de réglage en hauteur permettent

de régler verticalement.

4. Les vis de réglage en profondeur

permettent de régler horizontalement

5. Fixez votre hotte avec des vis

d’assemblage (4,8x38mm). Utilisez des

chevilles pour mur à sec, qui vous sont

fournies, si vous ne trouvez pas les vis-pivot

ou le cadre.

6. Remettez a boîte de connexion électrique.

VIS D’ASSEMBLAGE

(4,8x38mm)

PLANCHE DE BOIS

POUR L'ADAPTATION

TROUS RECTAN-

GULAIRES

ETRIERS

INSTALLATION ELECTRIQUE

Remarque: Ce modèle de hotte doit être

relié à la terre correctement. Cet article

devrait être installé par un électricien

qualifié selon les lois nationales et locales

en matière d’électricité.

1. Enlevez le couvercle de la boîte de

connexion électrique. Ouvrez un trou de

la boîte de connexion électrique.

2. Fixer le “conduit” au boîtier de connexion

à l’aide d’un connecteur approprié pour

ce “conduit”.

3. Faites le raccordement électrique. Reliez le blanc

au blanc, le noir au noir et le vert au vert.

4. Remettez le couvercle de la boîte de

connexion et les vis. Assurez-vous que les

fils se sont pas coincés entre le couvercle

et la boîte.

VIS

D’ASSEMBLAGE

(4,8x38mm)

VIS DE REGLAGE EN HAUTEUR

COUVERCLE DE LA BOÎTE

DE CONNEXION

COLLIER DU TUYAU

VIS DE REGLAGE EN

PROFONDEUR

CONNEXION DU SYSTEME D’EVACUATION

1. Fixez l’étrier de support au plafond ou au

mur au moyen des vis d’assemblage

(4,8x38mm) et des chevilles comme cela

est indiqué.

2. Reliez le collier du tuyau qui se trouve sur

votre hotte au système de conduction qui

se trouve au-dessus au moyen d’un tuyau

rond en métal de 8” (200mm).

3. Utilisez un ruban pour tuyauterie afin de

rendre toutes les jonctions sures et

étanches.

4. Réglez la hauteur du conduit décoratif et

fixez les vis respectives.

- 17 -

ETRIER DE

SUPPORT

VIS

D’ASSEMBLAGE

(4,8x38mm)

Page 18

5. Fixez le conduit décoratif à l’étrier du support et à la hotte, au moyen des vis

d’assemblage (3,9x9,5mm) comme cela est

indiqué.

FIXEZ LE CONDUIT

DECORATIF À LA

FIXEZ LE CONDUIT

DECORATIF À

L’ÉTRIER DU

SUPPORT AU

MOYEN DES VIS

D’ASSEMBLAGE

(3,9x9,5mm)

HOTTE AU

MOYEN DES VIS

D’ASSEMBLAGE

(3,9x9,5mm)

CONDUIT

DÉCORATIF

RUBAN POUR

TUYAUTERIE

TUYAU ROND EN

METAL

DE 8” (200MM)

ENTRETIEN

Un bon entretien de votre hotte garantira

une excellente performance.

Filtres anti-graisse

Les filtres anti-graisse doivent être nettoyés

fréquemment. Utilisez une solution contenant

un détergent tiède. Les filtres anti-graisse

peuvent être lavés au lave-vaisselle.

Pour enlever les filtres anti-graisse: à l’aide de

la poignée, pousser l’arrêt vers l’intérieur et tirer le filtre vers le bas.

Nettoyage de votre hotte

L’acier inoxydable est une des matières les plus faciles à nettoyer. Un entretien de

temps en temps permettra de le conserver en parfait état. Conseils pour le nettoyage:

● Eau chaude et savon ou détergent est tout ce qui est normalement nécessaire.

● Après chaque nettoyage, rincez bien à l’eau claire. Essuyez avec un chiffon

propre et doux afin d’éviter les taches d’eau.

● Si des décolorations ou des dépôts persistent, utilisez un nettoyant domestique non

abrasif ou de la poudre pour l’acier inoxydable et un peu d’eau et un chiffon doux.

● Dans les cas difficiles, utilisez une éponge en plastique ou une brosse douce avec du

nettoyant et de l’eau. Frottez légèrement en suivant la direction du polissage ou du

“grain” de l’acier inoxydable. Evitez de frotter trop fort afin de ne pas abîmer la surface.

● NE LAISSEZ PAS les taches trop longtemps.

● N’UTILISEZ PAS de laines d’acier ordinaires ou des brosses en acier. Des débris

d’acier pourraient adhérer à la surface et causer de la rouille.

● NE PERMETTEZ PAS que des solutions salées, des désinfectants, des

blanchissants ou des produits nettoyants restent en contact avec l’acier pendant

longtemps. Beaucoup de ces produits contiennent des produits chimiques qui

pourraient causer des dommages. Rincez à l’eau immédiatement s’ils entrent en

contact et essuyez avec un chiffon humide.

Les surfaces peintes doivent être nettoyées avec de l’eau tiède additionnée d’un

détergent doux seulement.

FILTRES ANTI-GRAISSE

- 18 -

Page 19

FONCTIONNEMENT

Commandes

Votre hotte fonctionne grâce aux (5) boutons sur

lesquels vous devez appuyer et qui se trouvent à

la hauteur de vos yeux, sur le devant de votre

hotte. Le bouton de la lumière allume et éteint les

BOUTON

DE LA

LUMIERE

VENTILATEUR

VITESSE 2

VENTILATEUR

ON/OFF

VITESSE 1

LED

VENTILATEUR

VITESSE 3

VENTILATEUR

VITESSE 4

LED

LED LED

lampes halogènes. Le bouton ON/OFF vitesse 1

du ventilateur fait fonctionner le ventilateur à la

vitesse la plus basse. Vous éteignez le ventilateur

en appuyant sur le bouton une deuxième fois. Le

bouton deuxième vitesse fait fonctionner le

0-1

2

4

3

ventilateur à une vitesse moyennement basse.

En appuyant une deuxième fois sur ce bouton vous faites fonctionner un timer qui fera

fonctionner le ventilateur à cette vitesse pendant 10 minutes. Le voyant lumineux clignotera

pendant tout ce temps et le ventilateur s’arrêtera automatiquement. Les boutons du

ventilateur 3ème et 4ème vitesse font fonctionner ce dernier comme le bouton deuxième

vitesse avec la différence que le bouton 3ème vitesse est une vitesse moyennement

élevée et le bouton 4ème vitesse est une vitesse élevée.

Au bout d'environ 30 heures de fonctionnement, tous les voyants lumineux se mettent à

clognoter en même temps; cela indique que la grille métallique doive être nettoyée. Après

avoir remonté la grille propres, appuyer 2 fois sur le “bouton deuxième vitesse” (ou

également sur les boutons du ventilateur 3ème et 4ème vitesse) au même temps les

voyants lumineux clignotons, afin de remettre le comptage en marche.

HEA T SENTRY

MC

Votre hotte est munie d’un thermostat HEAT SENTRYMC. Ce thermostat est un

dispositif qui actionnera ou augmentera la vitesse du ventilateur s’il détecte une

chaleur excessive au-dessus de la surface de cuisson.

1) Si le ventilateur n’est pas en marche - il actionnera le ventilateur en haute

vitesse.

2) Si le ventilateur fonctionne en basse vitesse - le ventilateur tournera en haute

vitesse.

Lorsque la température revient à la normale, le ventilateur retourne à sa vitesse

d’origine.

AVERTISSEMENT

Le thermostat HEAT SENTRY

MC

peu actionner la hotte même si la hotte est

arrêtée. Si tel est le cas, il est impossible de l’arrêter avec l’interrupteur. Si

vous devez arrêter le ventilateur, faites-le à partir du panneau électrique

principal.

- 19 -

Page 20

AMPOULES HALOGENES

BAGUE

Ce modèle de hotte veut deux (2) ou quatre

(4) ampoules halogènes (

AVANT DE PROCÉDER À QUELCONQUE

OPÉRATION, DÉBRANCHEZ L ’APP AREIL.

Pour changer les ampoules:

1. Dévissez la bague dans le sens contraire

aux aiguilles d’une montre.

2. Enlevez l’ampoule en tirant sur le côté (Ne

la faites pas tourner).

A TTENTION: L’AMPOULE PEUT ETRE CHAUDE!

3. Remplacer par une ampoule ayant les mêmes caractéristiques (Type JC, 12V,

20W Max, G-4 Base). Ne touchez pas l’ampoule neuve de vos mains nues!

Type JC, 12V, 20W,G-4Base

).

REMPLACEMENT FUSIBLE

DÉBRANCHEZ L’APPAREIL.

Enlevez les filtres anti-graisse.

BOÎTER

INSTALLA TION

ELECTRIQUE

FUSIBLE

SUPPORT

BOÎTER

INSTALLA TION

ELECTRIQUE

Démontez le support boîtier installation

électrique et ouvrir le boîtier installation

électrique.

Remplacez par un fusible du même type

(5x20mm, 4A, 125V).

GARANTIE

Broan garantit au consommateur-acheteur de ses produits que ces produits seront sans défauts concernant les matières

employées et concernant la fabrication pendant une période d’un an à partir de la date d’achat. IL N’Y A AUCUNE AUTRE

GARANTIE, EXPLICITE OU IMPLICITE, Y COMPRIS, MAIS NON P AS LIMITEE A, LES GARANTIES IMPLICITES OU

CONCERNANT LA CAP ACITE COMMERCIALE OU LA CONVENANCE POUR TOUT BUT P ARTICULIER. Pendant cette

période d’un an, Broan réparera ou remplacera, s’il le jugera nécessaire, gratuitement, tout article ou toute pièce qui résulteront

défectueux à condition qu’ils aient été utilisée et entretenu correctement.

CETTE GARANTIE NE S’ETEND PAS AUX INTERRUPTEURS DES NEON, NEON, LAMPES HALOGENES, AMPOULES

d”ILLUMINATION. Cette garantie ne couvre pas (a) l’entretien normal ni (b) tout article ou toute pièce qui aient subi une

utilisation erronée, une négligence, un accident, un entretien erroné ou une réparation (autre que de la part de Broan), une

installation défectueuse ou bien une installation ne respectant pas les instructions d’installation recommandées.

La durée de toute garantie implicite est limitée à un an comme cela est spécifié dans la garantie explicite. Quelques états ne

permettent pas de limites quant à la durée d’une garantie implicite, par conséquent la limitation indiquée ci-dessus peut ne pas

vous concerner.

L’OBLIGA TION DE REPARER OU DE REMPLACER DE LA P ART DE BROAN SERA LE SEUL ET EXCLUSIF REMEDE

DE L’ACHETEUR COUVERT PAR CETTE GARANTIE. BROAN NE SERA PAS RESPONSABLE DES DOMMAGES

ACCIDENTELS, CONSEQUENTIELS OU SPECIAUX DUS A L’UTILISA TION DU PRODUIT OU A SA PERFORMANCE

OU EN ETANT LA CONSEQUENCE. Quelques états ne permettent pas l’exclusion ou la limit ation des dommages accidentels

ou conséquentiels, par conséquent la limitation indiquée ci-dessus peut ne pas vous concerner. Cette garantie vous donne des

droits légaux spécifiques, et vous pouvez aussi avoir d’autres droits, qui varient d’Etat à Etat. Cette garantie dépasse toute

garantie précédente. Pour avoir droit à la garantie, vous devez (a) avertir la Maison Broan à l’adresse indiquée ci-dessous ou

téléphoner : 1-800-637-1453, (b) donner le numéro du modèle et l’identification de la pièce défectueuse et (c) décrire la nature

de tout défaut de l’article ou de la pièce. Au moment où vous demandez le service de garantie, vous devez présenter la preuve

d’achat avec la date.

BEST BY BROAN, P .O. Box 140 Hartford, Wisconsin 53027

GARANTIE BROAN LIMITÉE À UN AN

- 20 -

Page 21

LEA Y CONSERVE ESTAS INSTRUCCIONES

!

INDICADO P ARA EL USO EN COCINAS DOMESTICAS

!

ADVERTENCIA

PARA EVITAR EL RIESGO DE INCENDIO, CORTOCIRCUITO O DAÑO PARA LAS

PERSONAS, OBSERVE A TENT AMENTE LAS SIGUIENTES NORMAS:

1. Use esta unidad solamente de la manera indicada por el fabricante; si tiene dudas,

póngase en contacto con éste a la dirección o teléfono indicados en la garantía.

2. Antes de hacer una revisión o de limpiar la unidad, desconéctela de la red para evitar

que se encienda de manera accidental. En el caso de que éste no pueda ser desactivado, se indicará nel panel de servicio.

3. El montaje y la instalación eléctrica debe hacerlos un técnico especializado siguiendo

las normas estándar e incluyendo aquellas de construcción anti incendio.

4. Necesita aire suficiente para una apropiada combustión y escape de gases a través del

tubo del depósito de quema de combustible. Para evitar que el humo aspirado vuelva a

la cocina, siga las directivas del fabricante y las normas estándar de siguridad así como

las normas publicadas por la Asociación de prevención de incendios (NFPA) y la Sociedad americana de especialistas en cale-facción, refrigeración y aire acondicionado y

además las normas de las autoridades locales.

5. Hacer un corte o un taladro en la pared o en el techo no debe dañar la instalación

eléctrica u otras instalaciones ocultas en la pared.

6. Los conductos ventiladores deben siempre desalojar al exterior.

7. No use esta unidad con dispositivo de control de la velocidad a estado sólido.

8. Para evitar el riesgo de incendio, use solamente conductos de metal.

9. Esta unidad tiene que ser conectada a tierra.

PARA EVITAR EL RIESGO DE FUEGO POR ALTO NIVEL DE GRASA:

A. Nunca abandone los quemadores con el fuego alto. La cocción causa humo y restos

de grasa que pueden arder. Caliente el aceite a fuego medio o bajo.

B. Encienda siempre la campana cuando cocine a fuego alto o cuando cocine alimentos

fácilmente inflamables. (por ejemplo Crepes Suzette, Cerezas Jubilee, Ternera

flambeada con granos de pimienta).

C. Limpie con frecuencia los ventiladores. No se debe acumular grasa en el ventilador o

en el filtro.

D. Usa el tamañp de cazuela apropiado. Use siempre utensilios de cocina de tamaño y

material adecuados.

ADVERTENCIA

PARA EVITAR EL RIESGO DE DAÑOS A PERSONAS EN CASO DE FUEGO POR ALTO

NÍVEL DE GRASA, TENGA EN CUENTA LO SIGUIENTE:*

1. SOFOQUE LA LLAMA con una tapadera apropiada, una bandeja metálica ó un utensilio

de cocína que pueda cubrirla, despues, apague el quemador. ACTÚE CON

PRECAUCÍON PARA EVITAR QUEMADURAS. Si la llama no se extingue inmediatamente, SALGA Y LLAME A LOS BOMBEROS.

2. NUNCA COJA UNA SARTEN EN LLAMAS, porque corre el riesgo de quemarse.

3. NO USE AGUA ni paños o toallas húmidas porque puede provocarse una violenta

humareda.

4. Use un extintor SOLAMENTE si:

A. Posee un extintor de clase ABC y sabe perfectamente cómo usarlo.

B. El fuego es pequeño y está controlado en el mismo sitio en que empezó.

C. Ha llamado con anterioridad a los bomberos.

D. Puede combatir el fuego retrocedíendo hacia la salida.

* Basado en “Seguridad antifuego en la cocína” publicado por NFPA.

- 21 -

Page 22

!

ADVERTENCIA

1. Para reducir el riesgo de incendios y para evacuar correctamente los humos, asegurarse

de haber realizado una conducción del aire hasta el exterior. No expulsar los humos en

espacios cerrados por paredes o techos, áticos, espacios angostos o garajes.

2. Prestar la máxima atención al utilizar productos de limpieza o detergentes.

3. Evitar el uso de productos alimentarios que puedan inflamarse bajo la campana.

4. Sólo para ventilación total. No use gases de escape peligrosos o materiales y vapores

explosivos.

5. Para evitar daños en el funcionamiento del motor e impulsores ruidosos y/o desequilibrados, mantenga alejados de la unidad de encendido pulverizadores en seco o polvo.

6. El motor tiene un nivel de sobrecarga térmica que apaga automáticamente el motor

cuando se ha recalentado excesivamente. El motor se pone de nuevo en fincionamento

cuando la temperatura baja. Si el motor comienza a encenderse y a apagarse, deberá

hacer una revisión de éste.

7. Para limpiar mejor las impurezas al cocinar, la distancia entre la parte inferior de la

campana y la zona de cocción debe ser mínimo 24” - maximo 30”.

8. Debido a su gran tamaño y peso, se recomienda su montaje por parte de dos técnicos

esperializados.

9. Este producto está dotado de un termostato que pone en marcha automáticamente el

motor. Para reducir el riesgo de daños y evitar que se encienda accidentalmente,

colocar el interruptor del panel de servicio en la posición OFF y bloquear el panel de

servizio o colocar una advertencia externa como por ejemplo un letrero o una chapita.

10.Use solamente con juego de conexión para alimentación aprobado.

11. Se recomienda leer la placa de caracteristicas del producto para ulterior información.

- 22 -

Page 23

PREPARE LA CAMPANA

Sacar la campana de l’embalaje y controlar

el contenido.

Recivireis:

1 - Campana

1 - Tubo decorativo

1 - Soporte para el montaje del tubo

1 - Bolsita (B080810601) con:

2 - Soportes de montaje

8 - Tornillos de montaje (4,8x38mm

cabeza redonda)

4 - Tornillos de montaje (3,9x9,5mm

cabeza redonda)

4 - Tornillos de montaje (3,9x9,5mm

cabeza redonda - negra)

8 - Escarpias

1 - Bolsita (B080810321) con:

2 - Barras laterales portautensilios

2 - Partes laterales del portautensilios

2 - Tornillos de montaje (M8 x 14mm)

1 - Llave

1 - Instrucciones para instalación

1 - Garantia

PARTES

LATERALES

DEL

PORTAUTENSILIOS

2 TORNILLOS

DE MONTAJE

(M8x14mm)

LLAVE

BARRAS

LATERALES

PORTAUTENSILIOS

TUBO

DECORATIVO

SOPORTE PARA EL

MONTAJE DEL TUBO

4 TORNILLOS DE

MONTAJE

(3,9 x 9,5mm cabeza

redonda)

4 TORNILLOS DE

MONTAJE

(3,9 x 9,5mm cabeza

redonda - negra)

8 TORNILLOS DE

MONTAJE (4,8 x 38mm

cabeza redonda)

- 23 -

SOPORTES

DE MONTAJE

8 ESCARPIAS

Page 24

INSTALACION DEL TUBO DE

EXTRACCION

NOTA: p ara evitar el riesgo de incendio, use

solamente material de metal.

1. Decida donde va a colocar el tubo de extracción

entre la campana y la parte exterior.

2. Un recorrido de tubo corto y recto permitirá a

la campana funcionar de manera más eficaz.

3. Los recorridos largos de tubo, codos y

manguitos impiden el buen funcionamiento

de la campana. Use el menor número de

ellos posible.

4. Instale una cubierta ó una tapa. Una el tubo

de metal de 8” de diámetro a la cubierta y

retroceda hasta la posición de la campa-

na. Use une cinta para precintar las juntas

entre las partes del entubado.

INSTALACION DEL

PORTAUTENSILIOS

Las barras laterales portautensilios ser

instaladas antes de sujetar la campana a la

pared.

Para montar el portautensilios lateral, siga las

siguientes instrucciones:

1. Extraiga las dos partes laterales del

portautensilios aflojando los tornillos B. En

lugar de las partes laterales, introduzca el

portautensilios lateral, sujetándolo siempre

con los tornillos B.

2. Introduzca el taco M en el portautensilios

lateral e inmobilícelo apretando el tornillo C.

3. Para sujetar definitivamente el elemento

M a la campana, se tiene que acceder al

interior de ésta:

- extraer los filtros antigrasa: empuje de las

manillas hacia dentro y tire de los filtros

hacia abajo.

- desmonte la parte inferior de la campana,

desatornillando los dos tornillos A. La parte

inferior no se tiene que quitar completamente,

simplemente se inclina hacia un lado de

manera que permita introducir el

destornillador. Sujete el elemento M a la

campana desde el interior de ésta.

4. Cologue de nuevo la parte inferior de la

campana.

CUBIERTA DEL TEJADO

TUBO

DECORATIVO

CAMPANA

24” A 30” POR ENCIMA

DE LA ZONA DE COCCIÓN

C

B

PARTES

FINALES

PORTAUTENSILIOS

A

TUBO DE 8” DE

DIÁMETRO

TAPA

PARED

MANGUITO

DE 8” DE

DIÁMETRO

M

B

PARTE INFERIOR

DE LA CAMPANA

A

- 24 -

Page 25

INSTALACION DE LOS

SOPORTES PARA EL MONTAJE

1. Construya una estructura de madera en

la pared que quedará nivelada con la parte

interior de los tacos en la pared. Asegúrese

de que:

a) La estructura se encuentra centrada

por encima de la instalación del tubo.

b) La altura de la estructura permite fijar

los soportes para el montaje en esta

estructura siguiendo las dimensiones

indicadas.

Una vez que la superficie de la pared esté

2.

aca-bada, sujete los soportes para el

montaje siguiendo las dimensiones

indicadas.

VERSION 42”

ESTRUCTURA DE MADERA EN LA PARED

VERSION 90cm

ESTRUCTURA DE MADERA EN LA PARED

9-5/8”

(24.5cm)

9-5/8”

de 32-11/16” a 38-5/8” por

encima de la zona de

cocción

32-11/16” (83cm) = si la distancia entre la

campana y la zona de cocción es de 24” (61cm)

38-5/8" (98.1cm) = si la distancia entre la

campana y la zona de cocción es de 30” (72cm)

(24.5cm)

VERSION 48”

ESTRUCTURA DE MADERA EN LA PARED

8-7/8”

(22.5cm)

8-7/8”

de 34-7/16” a 40-7/16” por

encima de la zona de

35-1/16”

35-1/16” 36-1/16”

35-9/16”

35-9/16” 36-9/16”

(22.5cm)

si la distancia entre la

si la distancia entre la

N / A

34-13/16”

35-13/16”

N / A

37-1/16”

N / A

37-9/16”

(61cm)

(72cm)

DIM. “A”

9-5/8”

9-15/16”

8-7/8”

cocción

33-15/16”(86.2cm) =

de cocción es de 24”

39-15/16" (101.4cm) =

de cocción es de 30”

LARG.

DE LA

CAMPA-

NA

90CM

42”

48”

(61cm)

(72cm)

ALTURA DEL

TECHO

8’

9’

8’

9’

8’

9’

9-15/16”

(25.2cm)

9-15/16”

de 33-15/16” a 39-15/16” por

encima de la zona de

si la distancia entre la campana y la zona

si la distancia entre la campana y la zona

29-13/16”

(25.2cm)

cocción

34-7/16”(87.5cm) =

campana y la zona de cocción es de 24”

40-7/16”(102.7cm) =

campana y la zona de cocción es de 30”

DISTANCIA DE LA CAMPANA POR ENCIMA DE 36" SOBRE LA SUPERFICIE DE LA COCINA

24” 25” 26” 27” 28” 29” 30”

UBICACIÓN DEL SOPORTE DE MONTAJE POR ENCIMA DE 36"SOBRE LA SUPERFICIE DE LA COCINA

N / A

31-1/16”

N / A

31-9/16”

N / A

30-13/16” 31-13/16”

31-13/16”

32-1/16”

32-9/16”

33-1/16”

33-1/16”

33-9/16”

33-9/16”

32-13/16”

32-13/16”

34-1/16”

34-1/16”

34-9/16”

34-9/16”

33-13/16”

33-13/16”

Nota: la distancia mínima entre la campana y la parte superior de la cocina no debe ser menor

que 24". Es muy recomendable utilizar un máximo de 30" sobre la parte superior de la cocina

para obtener una mejor captura de las impurezas procedentes de la cocción. Las distancias

mayores que 30" son a discreción del usuario y del instalador, y siempre que la altura del

techo y la longitud de la salida de humos lo permitan.

INSTALACION DE LA CAMPANA

CAJA DE CONEXIÓN ELÉCTRICA

1. Antes de instalar la campana quitar la caja

de conexión eléctrica.

2. Cuelgue la campana de los soportes por

los agujeros rectangulares situados detrás

de la campana. Los agujeros son más

grandes que los soportes para permitir el

ajuste en horizontal. La parte inferior de la

- 25 -

Page 26

campana debe estar a una distancia de 24”

ó 30” por encima de la zona de cocción.

3. Los tornillos para la regulación de la altura

permiten un ajuste en vertical.

4. Los tornillos para la regulación de la

profundidad permiten un ajuste en

horizontal.

5. Sujete la campana con tornillos para el

montaje (4,8x38mm). Use escarpias si no

dispone de tacos o de la estructura de

soporte en madera.

6. Reponer la caja de conexión electrica.

TORNILLOS PARA

EL MONTAJE

(4,8x38mm)

ESTRUCTURA DE

MADERA EN LA PARED

TORNILLOS PARA

EL MONTAJE

(4,8x38mm)

REGULACIÓN DE LA ALTURA

AGUJEROS

RECTANGULARES

SOPORTES DE

MONTAJE

TORNILLOS PARA LA

REGULACIÓN DE LA

PROFUNDIDAD

TORNILLOS PARA LA

INSTALACION ELECTRICA

Nota: Este tipo de campana tiene que ser

conectada a tierra cuidadosamente. La

unidad debe instalarla un técnico electricista siguiendo las normas nacionales y

locales.

1. Quite la tapa de la caja de conexión eléctrica

y saque un cable.

2. Fije el “conduit” a la caja de conexión por medio

de un conector idóneo para el “conduit”.

3. Haga las conexiones eléctricas, una blanco

con blanco, negro con negro y verde con

verde.

4. Vuelva a conectar la tapa de la caja de

conexión. Compruebe que los cables no

queden pillados.

ENTUBADO DE CANALIZACION

1. Use tornillos para el montaje (4,8x38mm) y

escarpias para fijar al techo o a la pared el

soporte para el montaje del tubo como se

indica.

2. Use un tubo de metal de 8” (200mm) de

diámetro para unir el casquillo que se

encuentra encima de la campana al tubo

de extracción situado arriba.

3. Use cinta para ajustar todas las junturas y

que quede hermético.

4. Ajuste el tubo decorativo a la largura

deseada y sujételo por medio de tornillos.

- 26 -

TAPA DE CONEXIÓN

ELÉCTRICA

CASQUILLO DE

UNIÓN AL TUBO

SOPORTE

PARA EL

MONTAJE DEL

TUBO

TORNILLOS

PARA

MONTAJE

(4,8x38mm)

Page 27

5. Asegure el tubo decorativo al soporte de

montaje y a la campana inmobilizandolo

con los tornillos para el montaje

(3,9x9,5mm) como muestra la figura.

SUJETE EL TUBO

AL SOPORTE

POR MEDIO DE

TORNILLOS

PARA EL

MONTAJE

(3,9x9,5mm)

SUJETE EL TUBO

A LA CAMPANA

POR MEDIO DE

TORNILLOS

PARA EL

MONTAJE

(3,9x9,5mm)

TUBO

DECORATIVO

CINTA

TUBO DE

METAL DE 8”

(200MM) DE

DIÁMETRO

MANTENIMIENTO

Un mantenimiento adecuado de la campana

asegura el funcionamiento correcto del

aparato.

Filtros antigrasa

Los filtros antigrasa deben limpiarse a

menudo. Use un detergente que no sea fuerte.

Los filtros antigrasa se pueden meter en el

lavavajillas.

Para extraer los filtros antigrasa, empuje de las manillas hacia dentro y tire de los

filtros hacia abajo.

Limpieza de la campana

El acero inoxidable es uno de los meteriales más fáciles de limpiar, pero sería

aconsejable un especial cuidado en su uso para mantenerla en buen estado.

La campana se puede limpiar de las siguientes maneras:

● Agua caliente con jabón o detergente es la mejor manera para limpiarla.

● Aclárela con agua corriente, séquela con un paño suave y limpio para evitar las

huellas que deja el agua.

● Para las manchas o restos de grasa que persistan, use un producto químico

doméstico que no raye ó un limpiador para acero inoxidable con poca agua y un

paño suave.

● Si las manchas persisten, use un estropajo y un cepillo de cerdas suaves con un

producto limpiador y agua. Frote suavemente en el sentido del pulido o de las “vetas”

del remate del inoxidable. No apriete demasiado porque podría dañar la superficie.

● No deje que las manchas se acumulen durante mucho tiempo.

● No use utensilios o cepillos de acero. Pequeñas particulas de acero pueden

adherirse y oxidarse.

● No use soluciones salinas, desinfectantes, lejías, o productos de limpieza que

permanezcan en contacto con el acero inoxidable durante largos periodos de

tiempo. Muchos de estos productos contienen componentes químicos que podrían

resultar nocivos. Aclare con agua y seque con un paño limpio.

Las superficies lacadas deben limpiarse solamente con agua tibia y detergente no

muy fuerte.

FILTROS ANTIGRASA

- 27 -

Page 28

FUNCIONAMIENTO

Mandos

La campana se pone en funcionamiento

usando los mandos situados a la altura de los

ojos a un lado de la parte frontal de la campana.

El interruptor luz enciende y apaga las

INTERRUPTOR

LUZ

MANDO DE

ENCENDIDO/

APAGADO Y

VELOCIDAD 1

MANDO DE

VELOCIDAD 2

MANDO DE

VELOCIDAD 3

MANDO DE

VELOCIDAD 4

DIODODIODODIODODIODO

lámparas halógenas. El mando de encendidoapagado y velocidad 1 del aspirador pone en

funcionamiento el aspirador a una velocidad

mínima. Accionando este mando otra vez, se

apaga el aspirador. El mando de velocidad 2

0-1

234

pone el aspirador a una velocidad media- baja.

Si acciona este mando otra vez se pone en funcionamiento un timer que mantiene

el aspirador funcionando a dicha velocidad durante diez minutos. El diodo se mantiene

encendido durante ese tiempo y el aspirador se apaga automáticamente. El mando

de velocidad 3 y el de velocidad 4 funcionan como el de velocidad 2 pero el de

velocidad 3 funciona a una velocidad medio- alta y el de velocidad 4 lo hace a una

velocidad alta.

Después de unas 30 horas de funcionamiento, todas las espias relampaguean

contemporáneamente indicando que hay que limpiar los filtros metálicos. Una vez

vueltos a colocar los filtros antigrasa limpios, pulsar dos veces el “mando de velocidad

2” (o bien los mandos de velocidad 3 o 4) mientras que la pantalla o dígitos (espias)

parpadean a fin de activar nuevamente el contador.

HEA T SENTRYMR

Su campana esta equipada con termostato HEAT SENTRYMR. Este termostato

tiene un mecanismo que se encenderáo aceleratáel ventilador si se detecta un

calor excesivo encima de la cocina.

1) Si el ventilador esta apagando - el se prenderá a una velocidad máxima.

2) Si el ventilador esta encendido a una velocidad minima - el se prenderá a una

velocidad máxima.

Cuando la temperatura disminuye a un nivel normal, el ventilador vuelve a la

función de origen.

AVERTENCIA

El HEAT SENTRYmr termostato puede comenzar a funcionar al igual si la

campana esta parada. En este caso, es imposible parar el ventilador con los

interruptores. Si usted para la campana, halago a partir del panel eléctrico

principal.

- 28 -

Page 29

LAMPARAS HALOGENAS

ABRAZADERA

Este tipo de campana necesita dos (2) ó cuatro

(4) lámparas halógenas (

ANTES DE PROCEDER A CUALQUIER

OPERACIÓN, ES NECESARIO

DESCONECTAR EL APARATO.

Para cambiar las lámparas:

1. Destornillar la abrazadera en sentido

antihorario.

2. Extraiga la lámpara oblicuamente (no la

gire)- ATENCIÓN: LAS LÁMPARAS

PUEDEN ESTAR CALIENTES.

3. Sustituir con lámparas del mismo tipo (JC, 12V, 20Watt Max, G-4 Base).

No toque la lámpara de repuesto con las manos desnudas.

Tipo JC, 12V, 20W,G-4Base

).

SUSTITUCION FUSIBLE

DESCONECTAR EL APARATO.

Remover los filtros antigrasa.

PLACA

INSTALACION

ELECTRICA

FUSIBLE

CAJA DE LA

INSTALACION

ELECTRICA

Desmontar la placa de la instalación eléctrica

y abrir la caja de la instalación eléctrica.

Sustituir por un fusible del mismo tipo

(5x20mm, 4A, 125V).

GARANTIA

Broan garantiza al consumidor-comprador de sus productos que dichos productos no tendrán defectos en los materiales

o fabricación, durante un periodo de un año a partir de la fecha de la compra. NO HAY OTRO TIPO DE GARANTIAS QUE

INCLUYAN O SE LIMITEN EXCLUSIV AMENTE A GARANTIAS IMPLICIT AS O DE CAP ACIDAD COMERCIAL O CONVENIENCIA P ARA UN PROPOSITO ESPECIFICO.

Durante el periodo de un año, Broan, si lo estima conveniente, reparará o reemplazará sin gastos para el usuario cualquier

producto o parte de éste que sea defectuosos habiéndose usado correctamente. EST A GARANTIA NO CUBRE: EST ARTER

DE NEON, NEON, LÁMPARAS HALÒGENAS, LÁMP ARAS DE ILUMINACIÓN. Tampoco cubre el mantenimiento ni los

productos o partes de éstos que hayan sido usados de forma incorrecta, con negligencia, rotos accidentalmente o por una

incorrecta manutención ó reparación (distinta da la realizada por Broan), montaje incorrecto ó instalación que no se ajuste

a las instrucciones de montaje indicadas. Le duración de la garantía se limita al periodo de un año como está especificado

en la garantía explicita. Algunos paises no permiten un limite en la duración de la garantía implicita; si es asi en su caso,

esta limitación arriba indicada podría no aplicarse.

LA PRESENTE GARANTIA CUBRIRA EXCLUSIVAMENTE AL COMPRADOR LOS SERVICIOS DESCRITOS

ANTERIORMENTE. BROAN NO SE HACE RESPONSABLE DE DANOS PRODUCIDOS DE MANERA ACCIDENT AL

O RELACIONADOS CON EL USO INCORRECTO DEL PRODUCTO O SU FUNCIONAMIENTO.

Algunos paises no permiten la exclusión o limitación de los daños producidos de manera accidental, si es así en su caso,

esta limitación arriba indicada podría no aplicarse. Esta garantía le da derechos legales específicos y podría también

disponer de otros derechos que varian de país a país. Esta garantía supera otras garantías dadas con anterioridad. Para

disfrutar de la garantía usted deberá a) Avisar a la dirección abajo indicada ó bien llamar por teléfono al número 1-800-6371453 b) Dar el número de serie del modelo correspondiente o bien una descripción de la parte averiada, c) Descripción del

defecto en el producto o bien en una de sus partes. Para requerir un servicio en garantía debe presentar el justificante con

la fecha de la compra.

BEST BY BROAN, P .O. Box 140 Hartford, Wisconsin 53027

GARANTIA BROAN POR UN AÑO

- 29 -

Page 30

SERVICE PARTS

MODEL KER222 - Parts for stainless steel models shown. For service parts for

black, white, polished brass, or brushed copper models, call Broan Customer Service.

KEY NO. PART NO. DESCRIPTION

9 B08087135 Grease Filter (90cm/42” models)

9 B08087136 Grease Filter (48” models)

14 B02300233 Motor Capacitor

16 BE3345767 Electrical Box Support (90cm/42” models)

16 BE3345786 Electrical Box Support (48” models)

19 B03295005 Capacitor Protection

26 B02300891 Halogen Lamp Bulb

37 B02300787 Heat Sentry

38 B03292357 Electrical Box

38 BW0000027 Controls Cover

39 B03294033 Electrical Box Cover

42 B03295001 Ductfree Filter Bracket

48 B02310201 Motor

49 B03295071 Blower Wheel

53 B03202007 Rubber Washer

56 B03292465 Duct Connector

57 B02011004 Damper Flap

63 BE3403611 Upper Bracket

64 BE3243021 Bottom Bracket

68 B02011064 Right Blower Housing

69 B02011063 Left Blower Housing

113 B08091852 Nameplate

115 BE3495228 Wiring Box

116 BE3334252 Wiring Box Cover

118 BE3341301 Decorative Flue Bottom

119 BE3338411 Decorative Flue Top

120 BE3300517 Flue Mounting Bracket

133 B02009290 Utensil Rail (48" models)

133 B02009293 Utensil Rail (90cm models)

133 B02009292 Utensil Rail (42” models)

136 B02009291 Side Utensil Rail

136 B02009126 Side Utensil Rail

141 B02009187 End bits

144 B03292287 Wire Clamp

147 BR2300135 Junction Clamp

156 B02009186 Coupling Sleeve

165 B03295008 Wiring Box

166 B08086662 Circuit Board

208 B02300783 Transformer (90cm models)

208 B02300792 Transformer (42”/48” models)

223 B03202296 Switch Button

274 B03295035 Fuse Box

474 B02300790 Halogen Lamp Housing

477 B03295006 Closing

998 B080810601 Hardware Package

* B06002007 Blower Assembly

* B06107579 Switch Box Assembly (Includes Key

- B02300782 Fuse

- B02300674 Fuse Holder

(Includes Key Nos. 42, 48, 49, 53, 68, 69)

Nos. 107, 223, 230, 234, 38, 67)

* Not shown assembled.

- 30 -

Page 31

LISTE PIECES DE RECHANGE

MODELE KER222 -

recharge des modèles de couleurs noir, blanc, laiton jaune poli, cuivre brossé, contacter Broan Customer

Service.

N. PART N. DESCRIPTION

9 B08087135 Filtre anti-graisse (modèles 90cm/42”)

9 B08087136 Filtre anti-graisse (modèles 48")

14 B02300233 Condensateur

16 BE3345767

16 BE3345786

19 B03295005 Protection condensateur

26 B02300891 Lampe

37 B02300787 Capteur de température

38 B03292357 Boîte installation electrique

38 BW0000027 Couvercle commandes

39 B03294033 Couvercle boîte installation electrique

42 B03295001 Support filtre

48 B02310201 Moteur

49 B03295071 Turbine du moteur

53 B03202007 Pare chocs

56 B03292465 Bride de raccordement

57 B02011004 Clapet anti-retour

63 BE3403611 Etrièr supérieur

64 BE3243021 Etrièr inférieur

68 B02011064 Cocue moteur droite

69 B02011063 Cocue moteur gauche

113 B08091852 Plaquette logo

115 BE3495228 Boîte de alimentation

116 BE3334252 Couvercle Boîte de alimentation

118 BE3341301 Tube inférieur

119 BE3338411 Tube supérieur

120 BE3300517 Etrier montage tube

133 B02009290 Porte-outils de cuisine (modèles 48")

133 B02009293 Porte-outils de cuisine (modèles 90cm)

133 B02009292 Porte-outils de cuisine (modèles 42”)

136 B02009291 Porte-outils de cuisine lateral

136 B02009126 Porte-outils de cuisine lateral

141 B02009187 Extrémités porte-outils

144 B03292287 Serre cable

147 BR2300135 Borne

156 B02009186 Manchon

165 B03295008 Boîte installation electrique

166 B08086662 Circuit imprimé installation electrique

208 B02300783 Trasformateur (modèles 90cm)

208 B02300792 Trasformateur (modèles 42”/48”)

223 B03202296 Bouton

274 B03295035 Boîte Fusible

474 B02300790 Boîte lampe halogène

477 B03295006 Fermeture

998 B080810601 Accessoires de fixation

* B06002007 Ensemble moteur (Comprenant n. 42, 48,

* B06107579 Ensemble commandes (Comprenant n.

- B02300782 Fusible

- B02300674 Porte-fusible

* Illustrées separement.

Ci-dessous liste pièces de rechange pour hottes en inox. Pour les pièces de

Support boîte installation electrique (modèles 90cm/42”)

Support boîte installation electrique (modèles 48”)

49, 53, 68, 69)

107, 223, 230, 234, 38, 67)

- 31 -

Page 32

LISTA DE PIEZAS DE RECAMBIO

MODELO KER222 - Aquí aparecen solamente las piezas de recambio para

campanas de acero inoxidable, si desean las piezas de recambio de los modelos

en blanco, negro, latón lustrado ó cobre acepillado, pónganse en contacto con el

servicio al cliente de Broan.

CÓD. N. PIEZA N. DESCRIPCIÓN

9 B08087135 Filtro antigrasa (modelos 90cm/42”)

9 B08087136 Filtro antigrasa (modelos 48")

14 B02300233 Condensador

16 BE3345767

16 BE3345786

19 B03295005 Protección Condensador

26 B02300891 Lámpara halógena

37 B02300787 Sensor de temperatura

38 B03292357 Caja base de instalación eléctrica

38 BW0000027 Tapa mandos

39 B03294033 Tapa de la caja base de instalación eléctrica

42 B03295001 Soporte filtro

48 B02310201 Motor

49 B03295071 Manilla del motor

53 B03202007 Almohadilla antivibraziones

56 B03292465 Conector del tubo

57 B02011004 Válvula de no ritorno

63 BE3403611 Soporte superior

64 BE3243021 Soporte inferior

68 B02011064 Lado derecho del motoe

69 B02011063 Lado isquierdo del motoe

113 B08091852 Placa marca

115 BE3495228 Caja de alimentación eléctrica

116 BE3334252 Tapa de la caja de alimentación eléctrica

118 BE3341301 Tubo decorativo inferior

119 BE3338411 Tubo decorativo superior

120 BE3300517 Soporte de montaje del tubo

133 B02009290 Porta utensilios de cocina (modelos 48")

133 B02009293 Porta utensilios de cocina (modelos 90cm)

133 B02009292 Porta utensilios de cocina (modelos 42”)

136 B02009291 Porta utensilios de cocina lateral

136 B02009126 Porta utensilios de cocina lateral

141 B02009187 Partes finales del porta utensilios

144 B03292287 Sujeta cabos

147 BR2300135 Terminal

156 B02009186 Manguito

165 B03295008 Caja base de connección eléctrica

166 B08086662 Base para instalación eléctrica

208 B02300783 Trasformador (modelos 90cm)

208 B02300792 Trasformador (modelos 42”/48”)

223 B03202296 Mando

274 B03295035 Caja fusible

474 B02300790 Caja de la lámpara halógena

477 B03295006 Cierre

998 B080810601 Accessorios para el montaje

* B06002007 Conjunto motor (Incluye los N. 42, 48, 49,

* B06107579 Conjunto caja mandos (Incluye los N. 107,

- B02300782 Fusible

- B02300674 Portafusible

* Se encuentran por separado.

Soporte de la caja de instalación eléctrica (modelos 90cm/42”)

Soporte de la caja de instalación eléctrica (modelos 48”)

53, 68, 69)

223, 230, 234, 38, 67)

- 32 -

Page 33

SERVICE PARTS - LISTE PIECES DE RECHANGE -

LISTA DE PIEZAS DE RECAMBIO

MODEL KER222

- 33 -

Page 34

Page 35

Page 36

04306955/4 - KER222 HS

Loading...

Loading...