Best K3490CMSS Installation Manual

Model K34

ENGLISH............................................2

FRANÇAIS.......................................12

ESPAÑOL.........................................22

BEST BY BROAN P.O. Box 140 Hartford, WI 53027

READ AND SAVE THESE INSTRUCTIONS

!

INTENDED FOR DOMESTIC COOKING ONLY

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock service

panel to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction codes

and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes

Suzette, Cherries Jubilee, Peppercorn Beef Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or

filter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface

element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam explosion will

result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know how to operate

it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

- 2 -

!

CAUTION

1. To reduce risk of fire and to properly exhaust air, be sure to duct air outside. Do not vent

exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

2. Take care when using cleaning agents or detergents.

3. Avoid using food products that produce flames under the Range Hood.

4. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

5. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

6. Your hood motor has a thermal overload which will automatically shut off the motor if it

becomes overheated. The motor will restart when it cools down. If the motor continues

to shut off and restart, have the hood serviced.

7. For best capture of cooking impurities, the bottom of the hood should be a minimum of

24" and a maximum of 30" above the cooking surface.

8. Two installers are recommended because of the large size and weight of this hood.

9. This product is equipped with a thermostat which may start blower automatically. To

reduce the risk of injury and to prevent power from being switched on accidentally,

switch power off at service panel and lock or tag service panel.

10. Use with approved cord-connection kit only.

11. Please read specification label on product for further information and requirements.

- 3 -

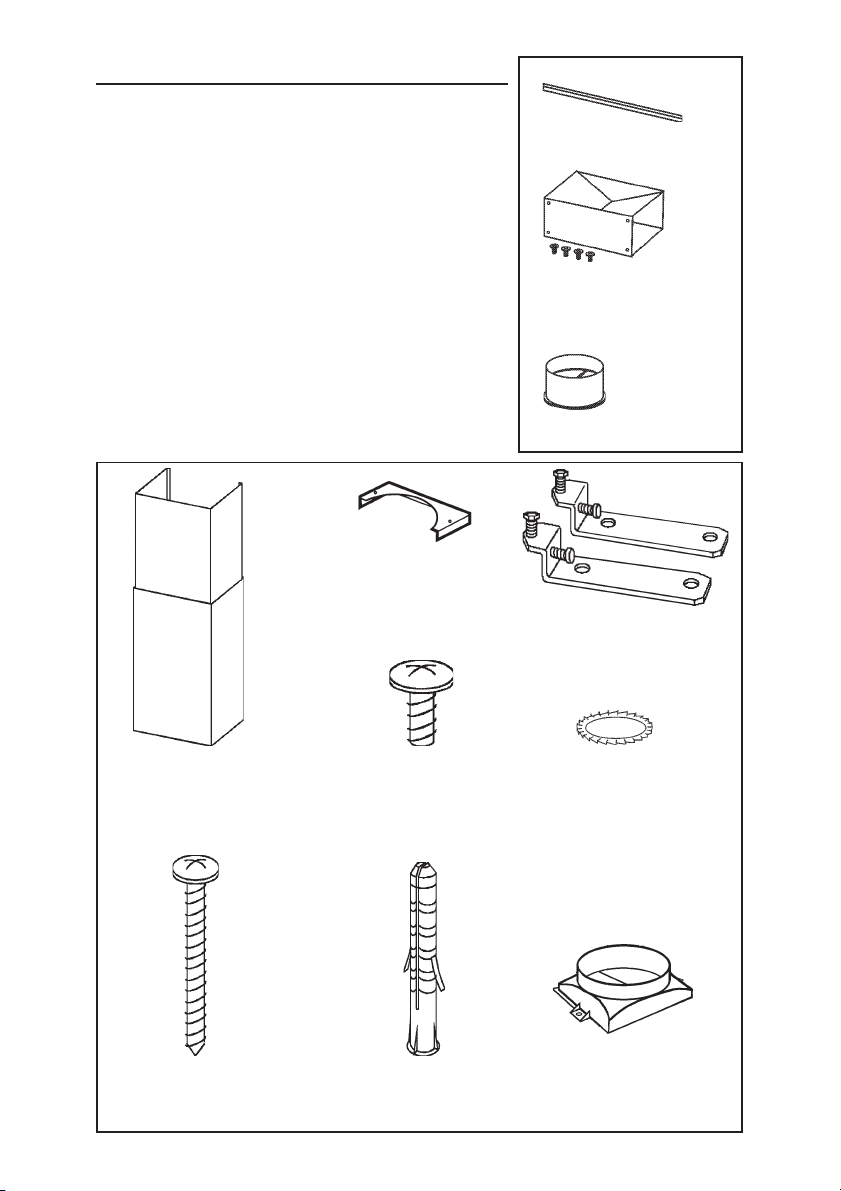

PREPARE THE HOOD

Unpack hood and check contents.

You should receive:

1 - Hood

1 - Decorative Flue Assembly

1 - Parts Bag (B080810533) containing:

1 - Duct Connector

1 - Flue Mounting Bracket

2 - Mounting Brackets

8 - Mounting Screws (4,8 x 38mm Pan Head)

11 - Mounting Screws (3,9 x 9,5mm Pan Head)

2 - Washers (ø4.3mm)

8 - Drywall Anchors

1 - Ductfree Plenum

1 - Duct Connector of the Ductfree Plenum

1 - Support Rods

1 - Installation Instructions

1 - Warranty Card

FLUE MOUNTING

BRACKET

SUPPORT RODS

DUCTFREE PLENUM

DUCT

CONNECTOR

OF THE

DUCTFREE

PLENUM

MOUNTING

BRACKETS

DECORATIVE

FLUE

8 MOUNTING SCREWS

(4,8 x 38mm Pan

Head)

11 MOUNTING

SCREWS (3,9x9,5mm

Pan Head)

8 DRYWALL

ANCHORS

- 4 -

2 WASHERS

Ø 4.3mm

DUCT

CONNECTOR

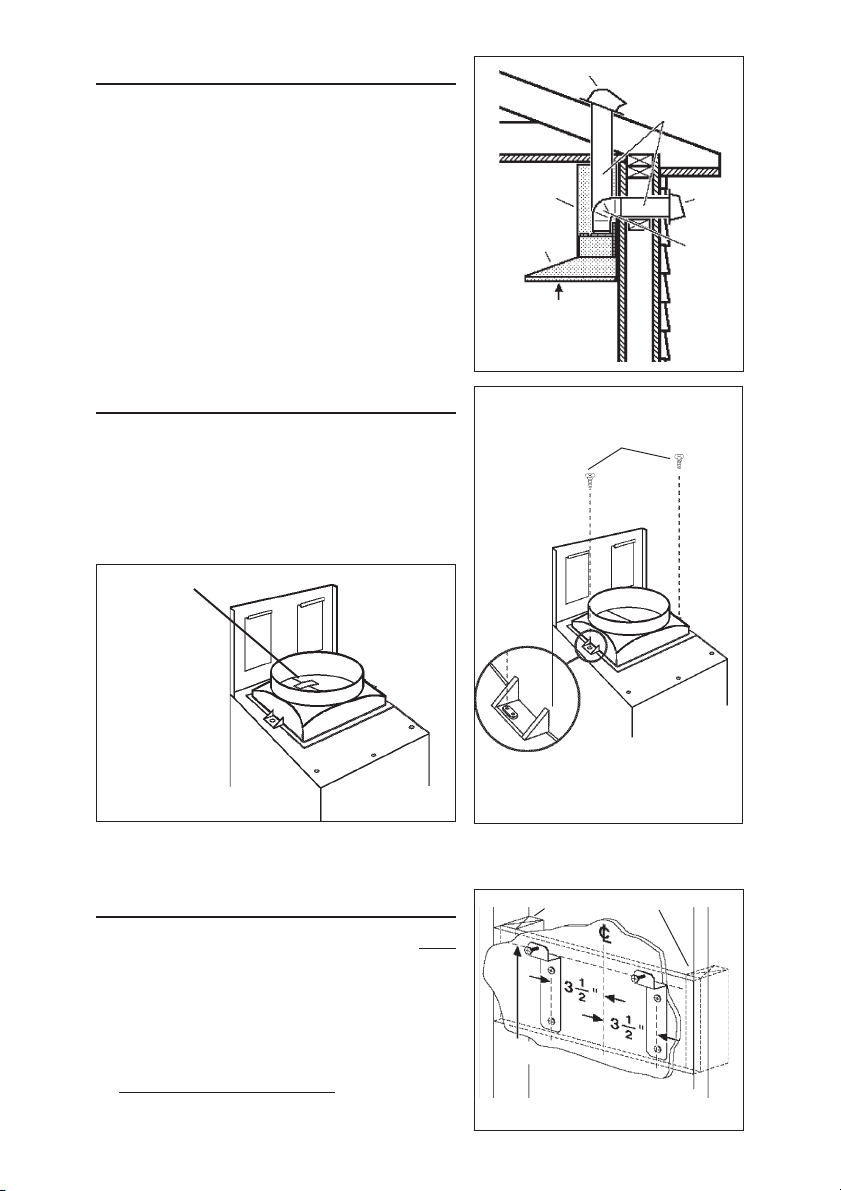

INSTALL THE DUCTWORK

ROOF CAP

NOTE: To reduce the risk of fire, use only

metal ductwork.

1. Decide where the ductwork will run between

the hood and the outside.

2. A straight, short duct run will allow the hood

to perform most efficiently.

3. Long duct runs, elbows, and transitions will

reduce the performance of the hood. Use as

few of them as possible.

4. Install a roof or wall cap. Connect 6" round

metal ductwork to cap and work back towards hood location. Use duct tape to seal

the joints between ductwork sections.

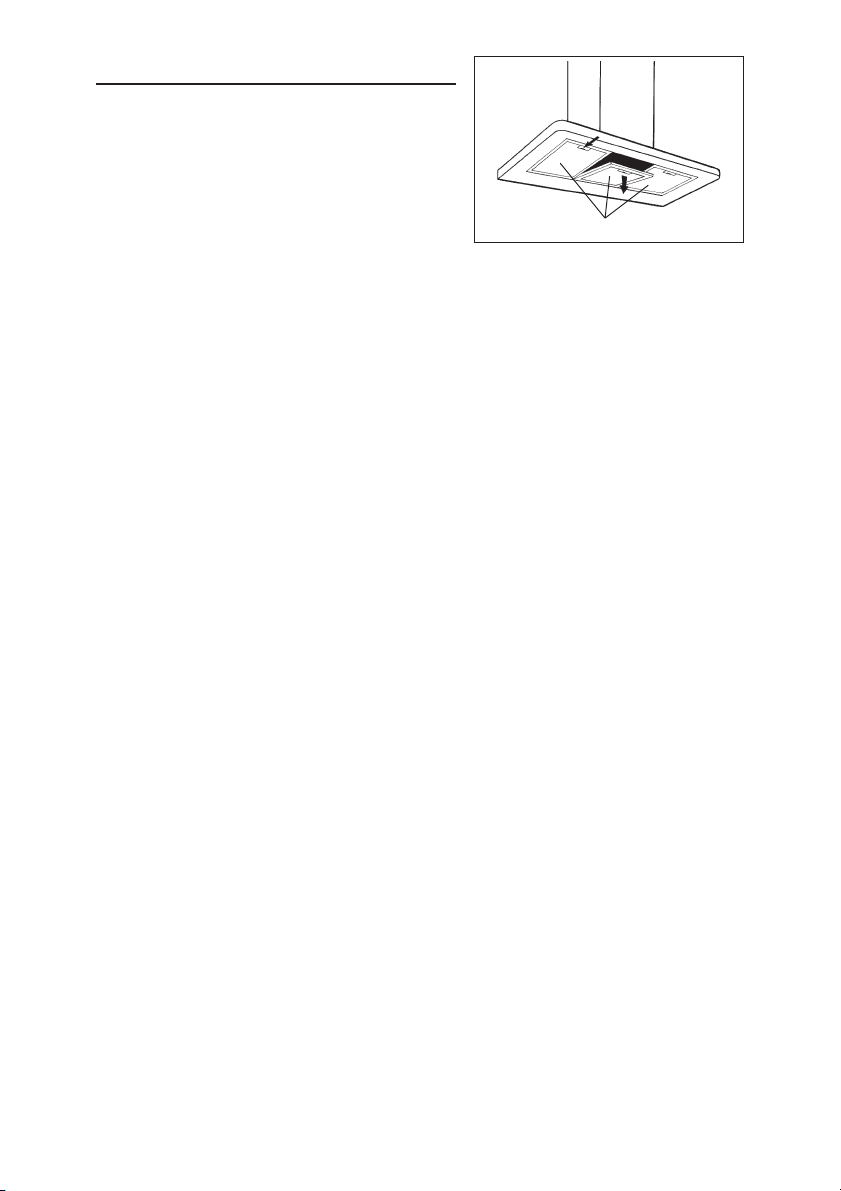

INSTALL DUCT CONNECTOR

1. Fix the duct connector onto the hood; it must

be fixed either by means of mounting screws

(3.9x9.5mm).

Be careful to the position of the duct

connector (see figure).

2. Remove the tape located on the damper.

REMOVE THE TAPE

DECORATIVE

FLUE

HOOD

24” TO 30” ABOVE

COOKING SURFACE

MOUNTING SCREWS

(3.9x9.5mm)

6” ROUND DUCT

WALL

CAP

6” ROUND

ELBOW

INSTALL MOUNTING

BRACKETS

1. Construct wood wall framing that is flush

with interior surface of wall studs.Make sure:

a) the framing is centered over installation

location.

b) the height of the framing will allow the

mounting brackets to be secured to the

framing within the dimensions shown.

After wall surface is finished, secure mount-

2.

ing brackets to framing using dimensions

shown.

- 5 -

FRAMING BEHIND DRYWALL

38-7/8” to 44-7/8”

above cooktop

38-7/8"= bottom of hood 24" above cooktop

44-7/8"= bottom of hood 30" above cooktop

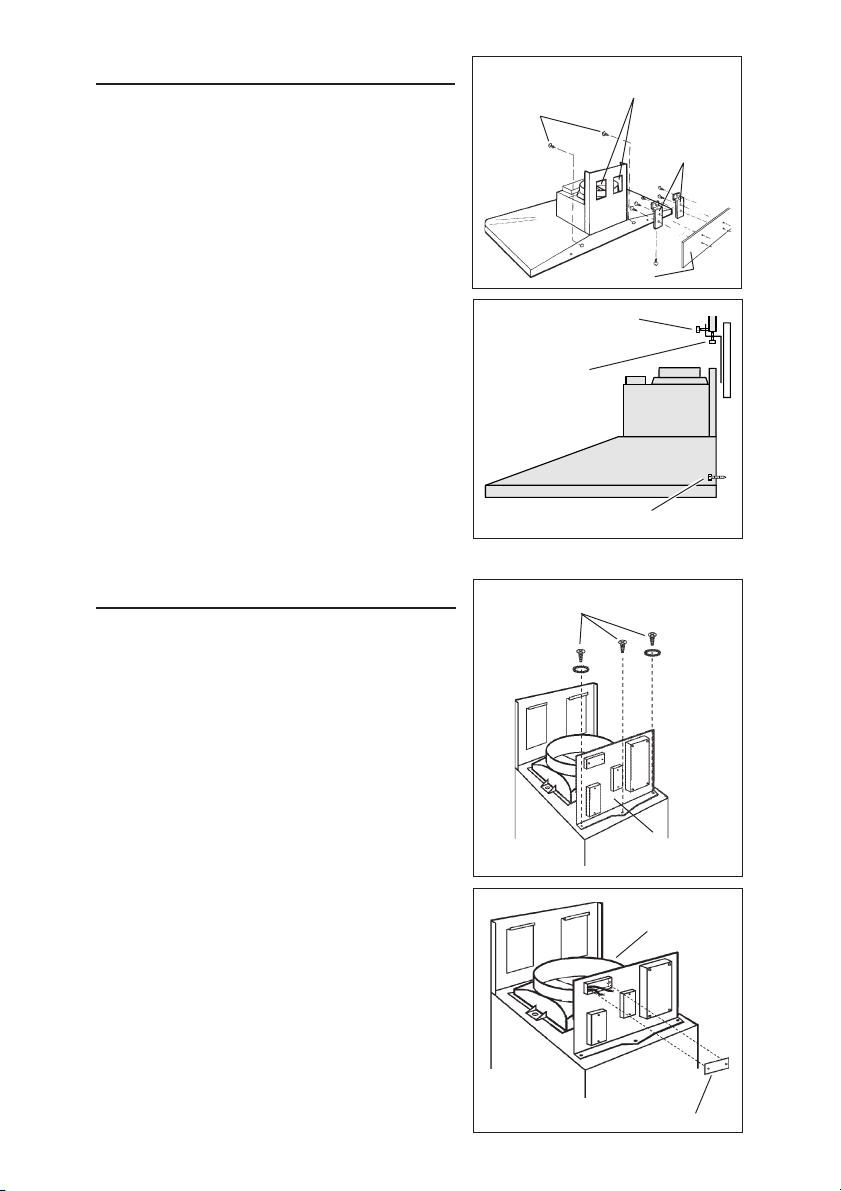

INSTALL THE HOOD

1. Hang the hood from the brackets through

the rectangular cut-outs on the back of the

hood. Cut-outs are larger than the brackets

to allow for horizontal adjustment.

The bottom of the hood should be 24" to 30"

above the cooking surface.

2. Height adjustment screws provide vertical

adjustment.

3. Depth adjustment screws provide horizontal adjustment.

4. Secure the hood with mounting screws

(4.8x38mm). Use drywall anchors,

provided, if wall studs or framing are not

available.

MOUNTING

SCREWS

(4.8x38mm)

WALL

FRAMING

DEPTH ADJUSTMENT

SCREWS

HEIGHT

ADJUSTMENT

SCREWS

MOUNTING SCREWS

(4.8x38mm)

RECTANGULAR

CUTOUTS

MOUNTING

BRACKETS

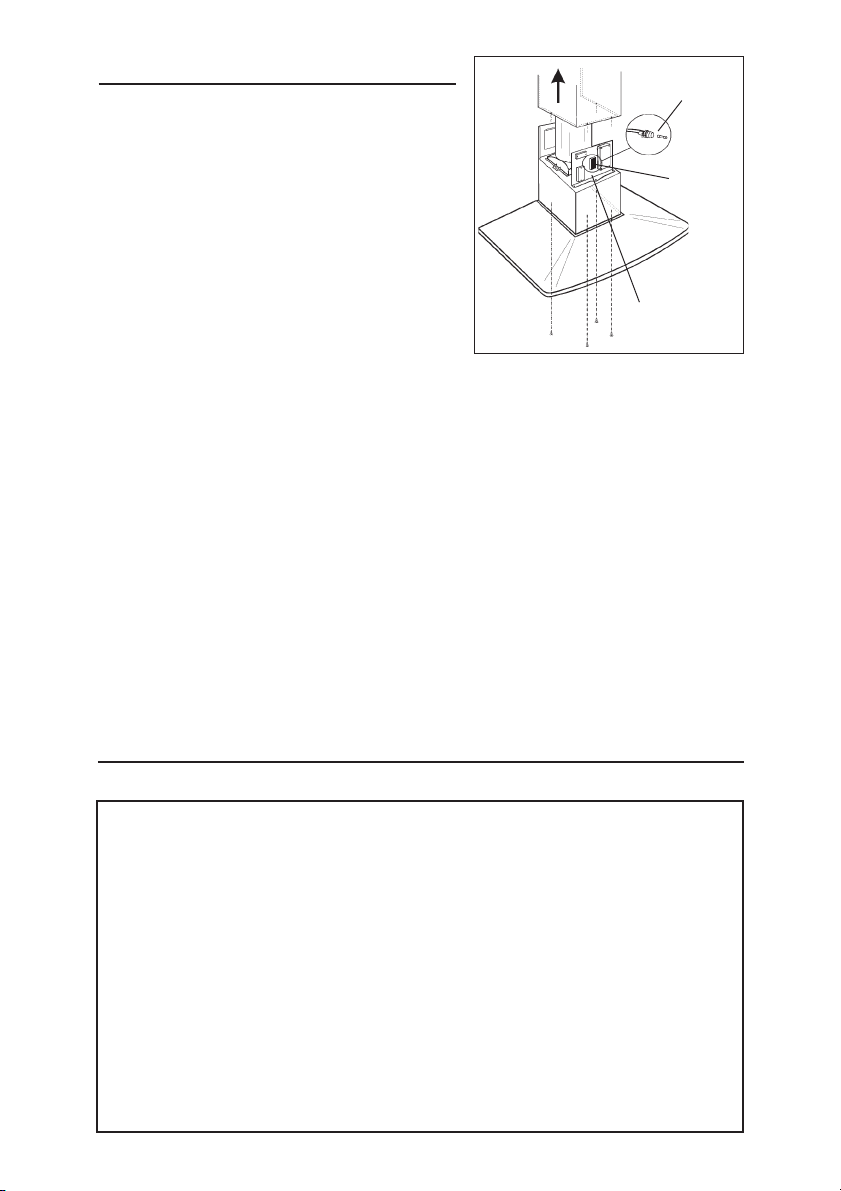

WIRING

Note: This range hood must be properly

grounded. The unit should be installed by a

qualified electrician in accordance with all

applicable national and local electrical codes.

1. Secure electrical box support with three (3)

screw provided (3.9x9.5mm) and two (2)

washers.

2. Remove the wiring box cover. Remove a

knockout from the wiring box.

3. Secure the conduit to the wiring box

through a conduit connector.

4. Make electrical connections. Connect white

to white, black to black and green to green.

5. Replace wiring box cover and screws. Make

sure that wires are not pinched between

cover and box.

- 6 -

SCREWS (3.9x9.5mm)

AND WASHERS

ELECTRICAL

BOX SUPPORT

DUCT

CONNECTOR

WIRING BOX COVER

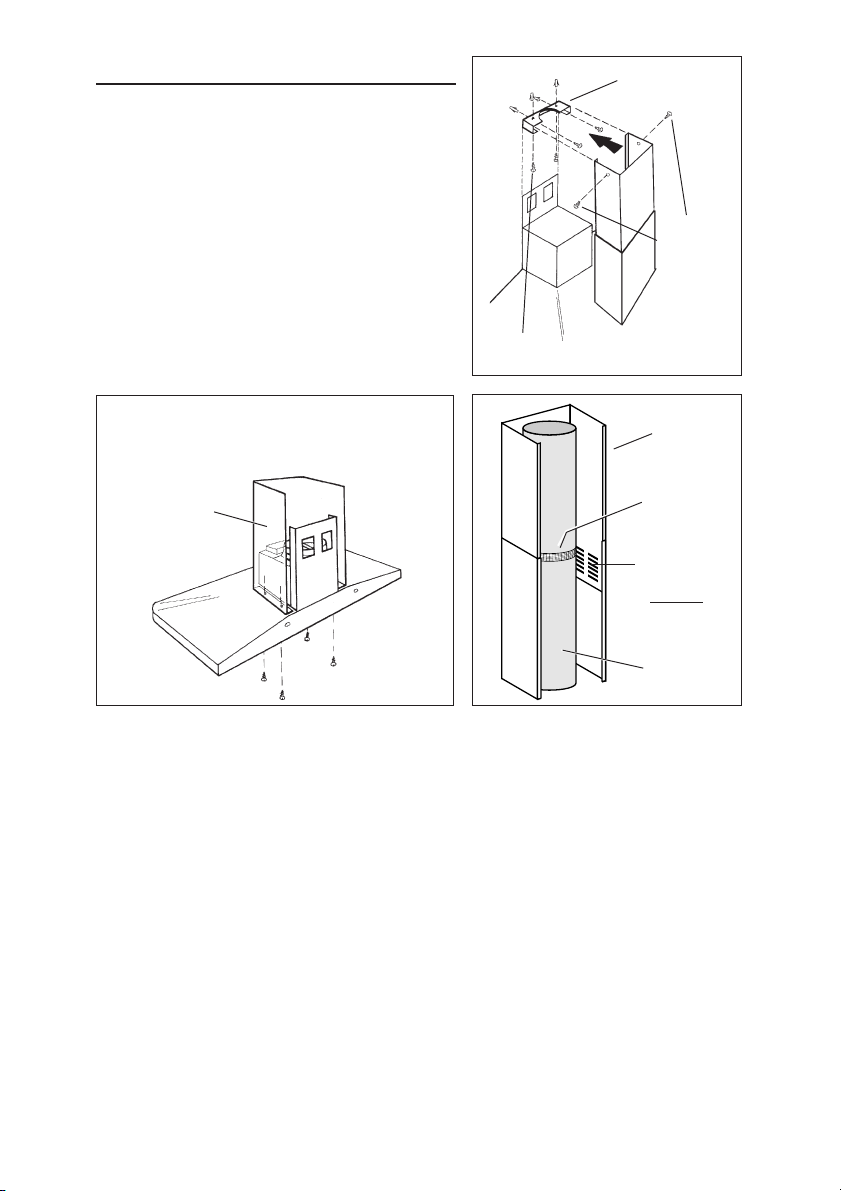

CONNECT DUCTWORK

Ducted Configuration

1. Use screws (4.8x38mm) and wall anchors

(supplied) to secure flue mounting bracket

to the ceiling or wall as shown.

2. Use 6" round metal duct to connect the duct

collar on the hood to the ductwork above.

3. Use duct tape to make all joints secure and

air tight.

4. Connect the decorative flue to the bracket

with 2 screws provided (3.9x9.5mm).

5. Slide the lower flue downward, until it fits

properly around hood.

6. Secure decorative flue to hood with 4 screws

provided (3.9x9.5mm).

FASTEN

FLUE TO

HOOD

WITH

SCREWS

(3.9x9.5mm)

MOUNTING SCREWS

(4.8x38mm)

FLUE MOUNTING

BRACKET

FASTEN

FLUE TO

BRACKET

WITH

SCREWS

(3.9x9.5mm)

DECORATIVE

FLUE

DUCT TAPE

AIR VENT

POSITION FOR

DUCTED

CONFIGURATION

- 7 -

6" ROUND

METAL DUCT

CONNECT DUCTWORK

Ductfree Configuration

1. Use screws and wall anchors

(supplied) to secure the flue

mounting bracket to wall or ceiling

as shown.

2. Turn upper flue section upside

down so air vents are at the top.

Slide upper flue section into lower

flue section.

3. Snap the duct connector of the

ductfree plenum into the hole in

the bottom of the ductfree plenum.

Connect the ductfree plenum to the

upper flue section with (4) flat-head

UPPER

FLUE SECTION

DUCTFREE

PLENUM

DUCT

CONNECTOR

OF THE

DUCTFREE

PLENUM

LOWER

FLUE SECTION

6" ROUND

METAL DUCT

DUCT

CONNECTOR

(in upper flue section)

DUCT

SEAM

AIR

VENTS

FLUE MOUNTING

BRACKET

MEASURE

screws (supplied).

4. Measure the distance from the top

of the duct connector to the ceiling. Cut a length of 6" round metal duct 6"

shorter than this dimension.

5. Fit duct section over the duct connector of the ductfree plenum. For best fit,

make sure duct seam is toward the front.

6. Set duct/flue assembly on hood with top tilted away from wall. Reach around

flue to engage bottom of duct with duct connector on hood. Tilt flue up against

wall. Duct seam can be cut to length if necessary.

7. Raise upper flue section and screw it to flue mounting bracket with (2) screws

(3.9x9.5mm). Screw lower flue section to hood with screws (3.9x9.5mm).

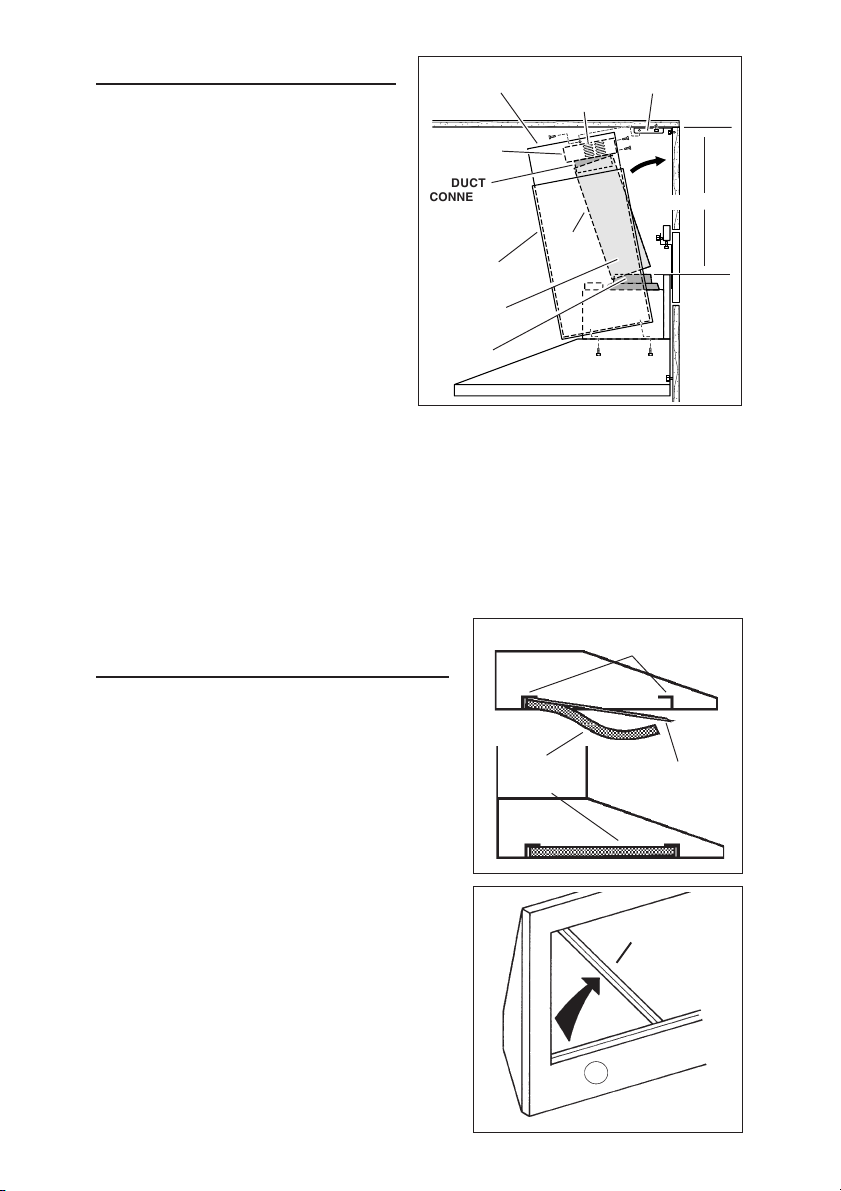

DUCTFREE FILTER

INSTALLATION

DuctfreeConfiguration Only

1. Purchase a ductfree filter kit (model no.

FILTERK3490CM or FILTERK3448”) from

your dealer.

2. Remove the grease filters : at the handle,

push the stop inwards and pull the filters

downwards.

3. Holding the ductfree filter on its side,

insert one of the support rods, into the

upper groove in back that runs parallel

with the front of the hood, in order to avoid

that the filter might be sucked onto the

motor.

4. Fold the filter and insert it into the front,

upper groove.

5. Install the other support rods beneath

filters.

6. Replace the grease filters.

- 8 -

DUCTFREE

FILTER

GROOVES

SUPPORT

ROD

SUPPORT

ROD

MAINTENANCE

Proper maintenance of the Range Hood will

assure proper performance of the unit.

Grease Filters

The grease filters should be cleaned fre-

quently. Use a warm detergent solution. Grease

filters are dishwasher safe.

To take off the grease filters: at the handle, push

the stop inwards and pull the filters downwards.

Ductfree Filter

The ductfree filter should be changed every 6 months. To remove the filter refer to the

section “DUCTFREE FILTER INSTALLATION”, and reverse the steps.

Hood Cleaning

Stainless steel is one of the easiest materials to keep clean. Occasional care will

help preserve its fine appearance.

Cleaning tips:

● Hot water with soap or detergent is all that is usually needed.

● Follow all cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth to

avoid water marks.

● For discolorations or deposits that persist, use a non-scratching household cleanser

or stainless steel polishing powder with a little water and a soft cloth.

● For stubborn cases, use a plastic scouring pad or soft bristle brush together with

cleaser and water. Rub lightly in direction of polishing lines or "grain" of the

stainless finish. Avoid using too much pressure which may mar the surface.

● DO NOT allow deposits to remain for long periods of time.

● DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere

to the surface causing rust.

● DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to

remain in contact with stainless steel for extended periods. Many of these compounds contain chemicals which may be harmful. Rinse with water after exposure and wipe dry with a clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

GREASE FILTERS

- 9 -

0

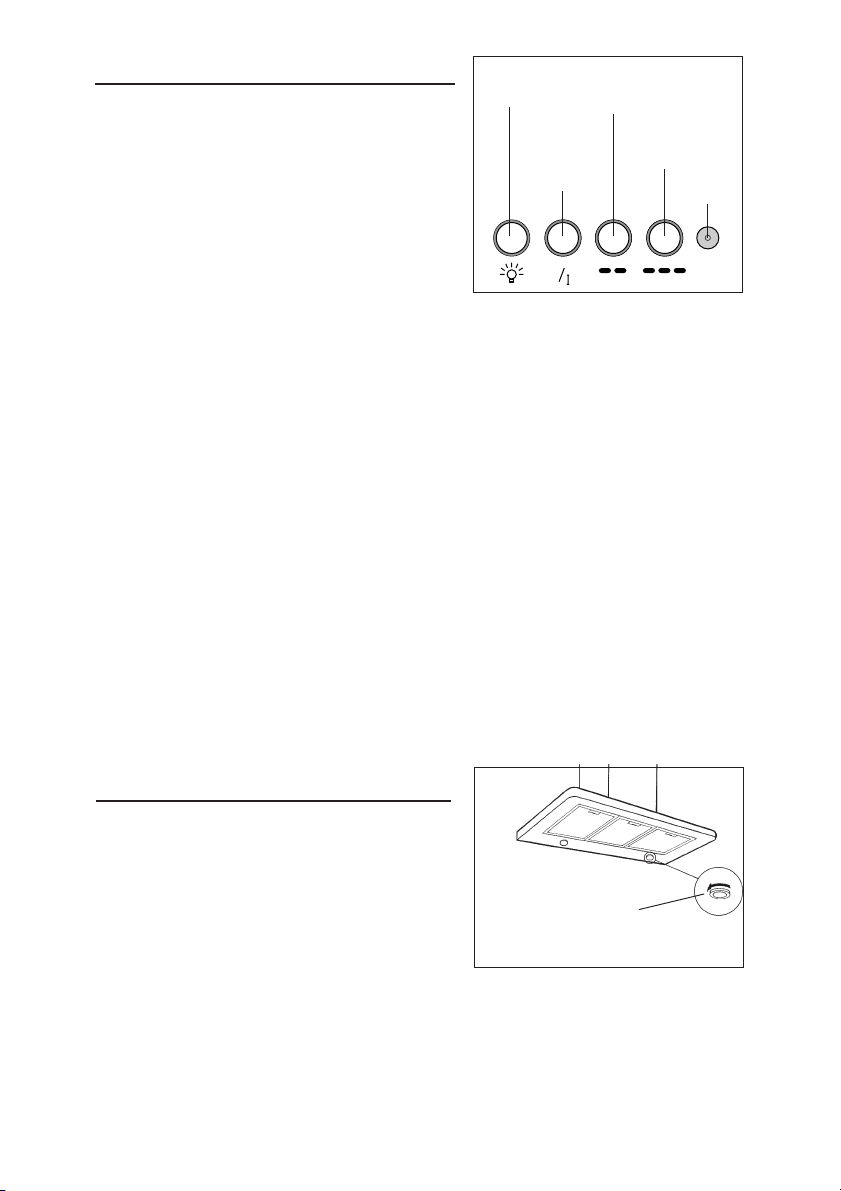

OPERATION

Controls

The hood is operated using the (4) push-buttons located at eye-level, on the front edge of

the hood.

The light switch turns the halogen lights on

LIGHT

SWITCH

BLOWER

ON-LOW /

OFF

SWITCH

BLOWER

MEDIUM

SPEED

BLOWER

HIGH

SPEED

PILOT

LAMP

and off.

The blower on-low / off switch turns the blower

on to its lowest running speed. The blower must

be turned on using this switch. Turn the blower

off by pressing this switch a second time.

The blower medium speed switch changes the blower speed to medium. This

switch works only if the blower is already running at low or high speed.

The blower high speed switch changes the blower speed to high. This switch works

only if the blower is already running at low or medium speed.

The pilot lamp lights up whenever the blower is on.

HEAT SENTRY™

Your hood is equipped with a HEAT SENTRY™ thermostat. This thermostat is a

device that will turn on or speed up the blower if it senses excessive heat above

the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up to HIGH speed.

When the temperature level drops to normal, the blower will return to its original

setting.

WARNING

The HEAT SENTRY thermostat can start the blower even if the hood is turned

OFF. When this occurs, it is impossible to turn the blower OFF with its switch.

If you must stop the blower, do it from the main electrical panel.

HALOGEN BULBS

This range hood requires 2 (or 4) halogen

bulbs (Type JC, 12Volt, 20 Watt Max, G-4

Base).

ALWAYS SWITCH OFF THE ELECTRICITY

SUPPLY BEFORE CARRYING OUT ANY

OPERATIONS ON THE APPLIANCE.

To change bulbs:

1. Loosen the ring nut by turning it

counterclockwise.

2. Remove the bulb by pulling sideward - DO NOT ROTATE. CAUTION: BULB

MAY BE HOT!

3. Replace with Type JC, 12Volt, 20 Watt Max, G-4 Base halogen bulb. Do not

touch replacement bulb with bare hands!

- 10 -

RING NUT

FUSE REPLACEMENT

SWITCH OFF THE ELECTRICITY SUPPLY.

Remove the grease filters.

Remove the decorative flue bottom to the

hood with four (4) screws.

Remove the fuse box screws.

Open the fuse box.

Replace with the same type of fuse (5x20mm,

4A, 125V).

FUSE

FUSE

BOX

ELECTRICAL

BOX

SUPPORT

WARRANTY

Broan warrants to the original consumer purchaser of its products that such products will be free from defects in materials or

workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OR MERCHANT ABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

During this one-year period, Broan will, at its option, repair or replace, without charge, any product or part which is found to

be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES, HALOGEN AND

INCANDESCENDT BULBS. This warranty does not cover (a) normal maintenance and service or (b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by Broan), faulty

installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not

allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN’S OPTION, SHALL BE THE PURCHASER’S SOLE AND

EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty

supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan at the address stated below or telephone: 1-800-637-1453, (b) give

the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting

warranty service, you must present evidence of the original purchase date.

BEST BY BROAN, P.O. Box 140 Hartford, Wisconsin 53027

BROAN ONE YEAR LIMITED WARRANTY

- 11 -

Loading...

Loading...